Navigating the world of respiratory protection

10 | Legal View

Keith breaks down a recent case involving a supervisor convicted of criminal negligence

TODD HUMBER

BY GAIL COHEN

Navigating the world of respiratory protection

10 | Legal View

Keith breaks down a recent case involving a supervisor convicted of criminal negligence

TODD HUMBER

BY GAIL COHEN

By Todd Humber, Senior Editor

When I first saw the issue of workplace violence

on the agenda at a major OHS conference, I viewed it as a curiosity more than anything else. It was a U.S.-based event, after all, and my smug Canadian self wandered in, found my seat, and marvelled at the red, white, and blue experiences of mass shooter drills and the installation of metal detectors at entrances.

But some of the stories and examples were universal and gave me pause. For example, Lev Pobirsky, the Philadelphia-based senior director of safety and security at Pepsi, talked about how — because of the labour shortage — companies were lowering standards and "begging" people to join their ranks who, in the past, they wouldn't have hired.

Canada, of course, does not exist in a bubble. While workplace-related shootings and violent assaults are less common here, they happen — and we have to prepare for them. As we were going to press, a man walked into Edmonton's City Hall on Jan. 23, lobbed a Molotov cocktail bomb and opened fire with a long gun.

Glass was shattered in the building but there were, astonishingly, no injuries.

Police Chief Dan McFee told reporters that the man was heavily armed and he credited the actions of an unarmed security guard for preventing a worse tragedy.

I marvelled at the red, white, and blue experiences of mass shooter drills and the installation of metal detectors.

"His actions were above and beyond and for that we are grateful," he said. "Active shooter events like this have lasting effects on our community."

On the other end of the country, we recently reported the story of Kelly Gomes. The 60-year-old works as a constituency assistant for an MLA in Nova Scotia. On Dec. 14, 2023, she was attacked by a man in the constituency office. If not for the help of a teenager, on a work term, things "could have ended very badly."

The attacker held her by the throat and threw an air purifier, knocked over a Christmas tree, smashed pictures, and upended a desk before finally leaving. She's calling on the province to ensure at least two

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Cindy Moser: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

people are in constituency offices at all times as a result.

Of course, there have been far worse incidents that resulted in serious injury and death, including the 1999 shooting at an OC Transpo garage in Ottawa. Former worker Pierre Lebrun shot six workers, killing four, before turning the gun on himself.

In 2022, a man shot and killed Toronto cop Andrew Hong in an ambush attack before driving to his workplace — an auto body shop in Milton, Ont., where he shot three more people, killing the owner.

I've folded up and packed my Canadian smugness when it comes to the risks posed by workplace violence. It is most definitely not a uniquely American phenomenon.

It's a problem for us all to tackle — and not just on the shoulders of OHS professionals. Background screening helps, but so too does fostering supportive environments where people feel safe to report threats and cultures that stamp out bullying and harassment.

We can't be complacent. The reality is that workplace violence requires immediate and sustained attention to prevent tragedies and build safer working environments.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

READER SERVICE

Print and digital subscription inquiries or changes, please contact

Angelita Potal

Tel: 416-510-5113

Fax: 416-510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SENIOR EDITOR Todd Humber 289-264-4883 thumber@annexbusinessmedia.com

MEDIA DESIGNER Graham Jeffrey

ACCOUNT CO-ORDINATOR

Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Serina Dingeldein 416-510-5124 sdingeldein@annexbusinessmedia.com

BRAND SALES MANAGER Silvana Maiolo smaiolo@annexbusinessmedia.com

SENIOR PUBLISHER Paul Burton pburton@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

PRESIDENT/COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published four times per year –Winter, Spring. Summer, Fall Canada $70/yr plus tax USA $98/yr Foreign $162/yr CDN —$120 USD Single copy $19 CDN

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2024 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Jeff Gooch, a construction site foreman, has been acquitted of criminal negligence causing the death of one of his workers by the Supreme Court of Nova Scotia.

Brandon Alcorn was killed on the job on March 13, 2018, while installing “blueskin” on the walls of the entrance tower of a new Kent Building Supply store that was under construction in Dartmouth, N.S. He was part of a three-person crew working that day.

As the three were working on the right-hand side of the tower, Alcorn fell off of the far right edge of the canopy plunging 18 feet to the ground below. This occurred about 10 minutes after Alcorn arrived for work at around 10 a.m. Alcorn was late to start his shift that morning, with Gooch stating he told him he had “slept in.”

Gooch was charged with a single count under the Criminal Code for criminal negligence in causing the death of Alcorn.

The court thoroughly reviewed the evidence and testimony from a number of witnesses and experts. It noted the statements indicated that Alcorn was not in the “proper work area” when he fell.

A toxicologist also testified that Alcorn had both Delta-Carboxy THC and Delta-9 THC in blood samples taken about five-and-a-half hours after his fall. The court said Gooch’s guilt was not proven beyond a reasonable doubt.

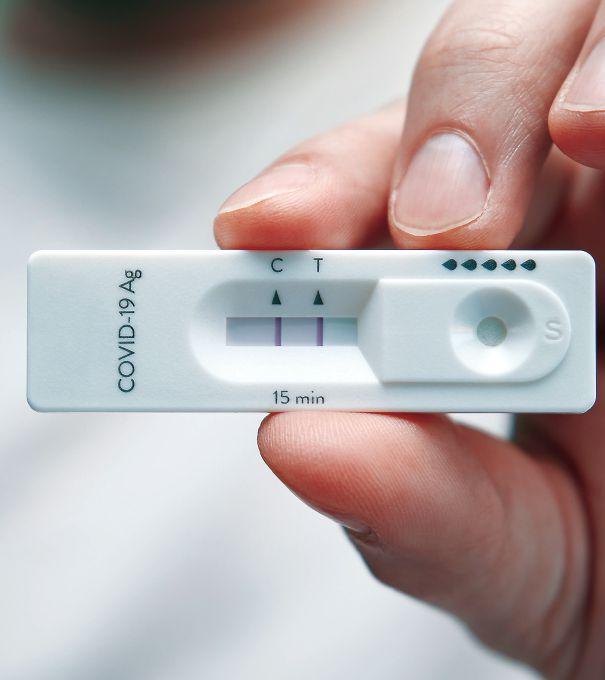

Number of camps operated by Horizon North Camp & Catering. Only one, Sanataa Lodge, experienced a COVID-19 outbreak during the pandemic, a fact that was attributed to its communal living arrangements.

A camp operator that provides lodging and meals for industrial staff has been fined more than $200,000 by WorkSafeBC after one of its workers contracted COVID-19 and was later found dead in 2021.

The COVID-19 outbreak at Sanataa Lodge in Dawson Creek, operated by Horizon North Camp & Catering and Dexterra Group, not only resulted in a worker’s death but also exposed serious deficiencies in the implementation of health and safety protocols, according to redacted reports prepared by WorkSafeBC and obtained by OHS Canada.

The victim, known as Worker 1, displayed symptoms of COVID-19 shortly after his arrival at the camp on Nov. 30, 2021 — but he was not isolated promptly. On Dec. 7, 2021, he was overheard telling a supervisor he was unwell and was told to

lie down. On Dec. 8 and Dec. 9, Worker 1 signed into daily health and safety meetings, suggesting he was present and not isolating in his room.

On Dec. 11, Worker 1 was moved into a bedroom with its own washroom in the isolation wing of the main camp. An appointment was made for him to undergo COVID testing at a clinic on Dec. 12 in Fort St. John, B.C. Worker 1 was taken to the appointment by a Horizon North Shuttle and returned back to the camp at 4 p.m. on Dec. 12.

That was the last time he was seen alive. “Living conditions at the camp, including shared washrooms and communal spaces, were a likely factor in the spread of the illness,” the report said. “Additionally, lack of spacing during staff meals was likely a factor.”

The requirements, as of Jan. 1, 2024, will support a “more effective and fair workers’ compensation system in the province and help restore workers to their previous employment status after suffering an injury on the job,” the province said in a press release.

All employers and injured workers in B.C. will have a new legal duty to co-operate with each other and with WorkSafeBC to ensure workers can return to their previous jobs or other suitable work, it said. The duty to co-operate requires employers and workers maintain communication, identify suitable work for the worker and provide WorkSafeBC with required information to support return-to-work efforts.

Any employer with 20 or more workers who has employed someone for at least one year before an injury will have an obligation to maintain that worker’s employment. They must make any necessary changes to the work or workplace to accommodate the injured person, unless the changes create an undue hardship.

The requirements will help WorkSafeBC oversee the return-to-work process by laying out clear expectations. WorkSafeBC has the authority to reduce or suspend benefits of workers and apply penalties to employers who fail to comply, it said.

A Nova Scotia constituency assistant who faced a violent attack at work is calling on the government to approve funding for a second employee at legislators’ offices as a safety measure.

Number of infrastructure strikes involving Chohan Freight Forwarders in B.C. in the last two years. The company was suspended by the province's Commercial Vehicle Safety and Enforcement.

Kelly Gomes said a man whom she had assisted over the past four years entered her constituency office and held her by the throat against a hallway wall. She says things “could have ended very badly” if it hadn’t been for the presence of a teenage student who

was doing a work term at the office of Brendan Maguire, the Liberal member of the legislature for Halifax Atlantic. Gomes says the man released his grip after the student threatened to call police, but he then threw an air purifier, knocked over a Christmas tree, smashed pictures and upended a desk before departing.

The 60-year-old says neither door locks nor panic buttons can protect constituency assistants in many situations.

British Columbia’s transport minister has written to his federal counterpart asking for the closure of road safety gaps he says allow some trucking companies to avoid consequences while operating unsafely across Canada.

Rob Fleming’s letter on Monday to Pablo Rodriguez comes after a series of incidents involving commercial trucks or their cargo slamming into highway overpasses.

A company involved in an overpass crash on Highway 99 last month had its B.C. fleet taken off the road, but because it’s part of a group that also has a fleet in Alberta, those trucks are still allowed to work in B.C.

Fleming says in the letter that suspension or cancellation of a carrier’s safety certificate in one jurisdiction doesn’t affect their operations based in another.

He says safety certificates are issued by the jurisdiction where a vehicle is plated, and no single authority is responsible for oversight of a carrier’s entire operations if they have certificates in multiple jurisdictions.

The Transportation Safety Board of Canada says a distracted maintenance worker who drove onto an active runway required an Air Canada plane to scrap an initial landing attempt to avoid a collision at Toronto’s Pearson airport last year.

A new report from the board says the driver of the maintenance vehicle was distracted by “the planning of the upcoming tasks that he would be supervising” at the time of the incident, which took place shortly after midnight on Oct. 15, 2022.

The TSB says that as a result, the driver was paying less attention to hazards on his route and drove onto the runway even though he had received and read back instructions not to do so.

According to the report, the air traffic controller saw what happened and told the plane to stop its approach and go back around before trying again.

The report says the plane was able to land “uneventfully” on its second try.

The board says the incident shows “how a lapse in attention by even an experienced airport maintenance vehicle driver can result in a runway incursion.”

Purolator’s

Purolator’s decision to extend its COVID vaccine mandate beyond June 2022 has been roundly criticized by an arbitrator who deemed it to be a “poor decision.”

“Some of the considerations listed as favourable to the continuance of the mandate had nothing to do with enhanced workplace safety but addressed concerns such as possible employee resentment and possibly being seen to acknowledge they were wrong to impose a mandate in the first place,” said arbitrator Nicholas Glass in the ruling after reviewing a draft memo from management and following a 24-day hearing.

It stemmed from a series of grievances filed by Teamsters Local Union No. 31 on behalf of some unvaccinated workers in British Columbia.

Hourly employees and group grievance members were awarded compensation for lost wages and benefits from July 1, 2022, until their return to work post-May 1, 2023.

Owner operators are eligible for compensation due to revenue losses from the inability to use vaccinated relief drivers, with specific details pending.

23_011328_OHS_CN_WNTR_CN Mod: January 4, 2024 2:35 PM Print: 01/10/24 page 1 v2.5 ORDER BY 6 PM FOR SAME DAY SHIPPING

Pedigree Poultry has been fined a total of $46,000 after it pleaded guilty to violating Saskatchewan’s Occupational Health and Safety Regulations.

On July 10, 2021, a worker suffered serious injury after their foot became entangled within a horizontal auger system at a worksite near Regina Beach.

As a result of these charges, the court imposed a fine of $32,857.14, with a surcharge of $13,142.86.

Pedigree was fined for contravening clause 3-1 (a) of the regulations (being an employer, fail to provide and maintain plant, systems of work and working environments that ensure, as far as is reasonably practicable, the health, safety and welfare at work of the employer's workers, resulting in a serious injury to a worker).

Agrow Canada has been fined a total of $46,000 after one of its workers was injured on the job near Waldron, Sask.

The charges stemmed from an incident that occurred on Sept. 30, 2021, when the worker suffered a serious injury after stepping onto an energized auger.

The company pleaded guilty in Melville Provincial Court to one violation of The Occupational Health and Safety Regulations, 2020.

The company was fined for contravening subsection 10-4 (2) of the regulations (being an employer, fail to ensure that a safeguard required by section 10-4 (1) remains in place at all times, resulting in a serious injury to a worker.)

As a result of these charges, the company was fined $32,857.14 along with a $13,142.86 surcharge.

Two companies have been fined a total of $400,000 after two workers were killed and four others critically injured when a section of a building under construction in London, Ont., collapsed.

Number of companies fined in the London, Ont., construction collapse that killed 2 workers. iSpan Systems was fined $260,000 and East Elgin Concrete Forming was fined $140,000.

The incident happened on Dec. 11, 2020, when it collapsed to the ground floor during a fourth-floor roof level concrete pour.

iSpan Systems LP fabricated the building’s structural steel frame, including the frames necessary to support the concrete forms. East Elgin Concrete Forming Ltd. was responsible for the concrete pour, retaining supervisory duties while subcontracting the roof pour to another company.

A Ministry of Labour, Immigration, Training and Skills Development (MLITSD) investigation identified deficiencies in iSpan’s fabrication and methodological

errors in East Elgin’s procedures that contributed to the collapse. East Elgin employed a laser level and directed the subcontractor to pour to the height of the laser level. The laser level on its own failed to account for the deflection of the steel frame that occurred from the weight of the concrete. The use of a dipstick would have remedied this problem by providing a true reading. As a result, workers were left with the incorrect assumption that the concrete depth was insufficient at certain locations in the pour. Consequently, more concrete was applied than had been specified.

An engineering analysis carried out by MLITSD engineers determined that the concrete placed exceeded the design values by considerable amounts. The weight of the applied concrete contributed to the collapse and/or its severity.

A Saskatchewan man has been fined $2,800 after a worker suffered serious injuries after being pinched between a water truck and a payloader on Jan. 21, 2022, near Griffin, Sask. Robert W. Jones pleaded guilty to one violation of the Occupational Health and Safety Regulations, 2020, specifically under subsection 11-13 (3) around the movement of equipment. As a result, the court imposed a fine of $2,000 with a surcharge of $800, for a total amount of $2,800. One other charge was withdrawn.

A cold storage company in Brampton, Ont., has been fined $65,000 after a worker was injured by an automatic rolldown door while driving a forklift.

The incident happened on Nov. 24, 2022, at Nova Cold Logistics, operating as Americold. On that day, a worker at the facility was instructed to move pallets of product from a loading dock to a freezer room with an electric lift truck.

After the pallets were moved into the room the worker drove toward the exit. A co-worker was standing in front of the exit door, known as the H-Door.

The H-Door is a large (8-foot wide, 12-foot high), high-speed, roll-down door operated by pull cords. Once a cord is pulled the door ascends quickly and remains open for seven seconds, after which it descends quickly unless the cord is pulled again.

As the co-worker saw the worker on the lift truck approach, the co-worker pulled the cord to open the H-Door.

The worker standing on the lift truck throttled it forward towards the door while looking backward and speaking to the co-worker. By this time, the door had started to descend and came in contact with the worker causing a critical injury. The door did not reverse when it struck the worker.

The H-Door was equipped with a sensor in its bottom leading edge. When it functions properly, the sensor causes the door to reverse if it meets resistance. The sensor was not functioning at the time. There is no other means of closing or stopping the descending door in the event something is under it. There was no means of warning or alerting a worker that the door was descending and that it would not reverse.

Manitoba has fined an employer just over $7,000 after a worker sustained “significant” injuries in an explosion. On June 23, 2020, a worker employed by Prairieview Custom Basements Inc. was working in an excavated area at a residential property, applying Rub-R-Wall foundation coating to a foundation that had been recently torch-treated to remove moisture.

After spraying the coating for several minutes, the vapour ignited and caused an explosion, injuring the worker. Workplace Safety and Health officials conducted an investigation and laid charges under the Workplace Safety and Health Act.

Prairieview Custom Basements Inc. pleaded guilty to section 4(1)(a) of the act for failing to ensure, so far as practicable, the safety, health and/or welfare of workers at work. Specifically, the employer had not ensured the work area had been adequately ventilated during the application of the Rub-R-Wall foundation coating so as to prevent fire or explosions. A fine and court cost fee of $7,070 was imposed upon Prairieview Custom Basements Inc. by the court.

By Norm Keith

Arecent trial decision of the New Brunswick Court of King’s Bench resulted in another prosecution of a supervisor under the Westray Bill amendments to the Criminal Code, effectively establishing a new crime of occupational health and safety criminal negligence.

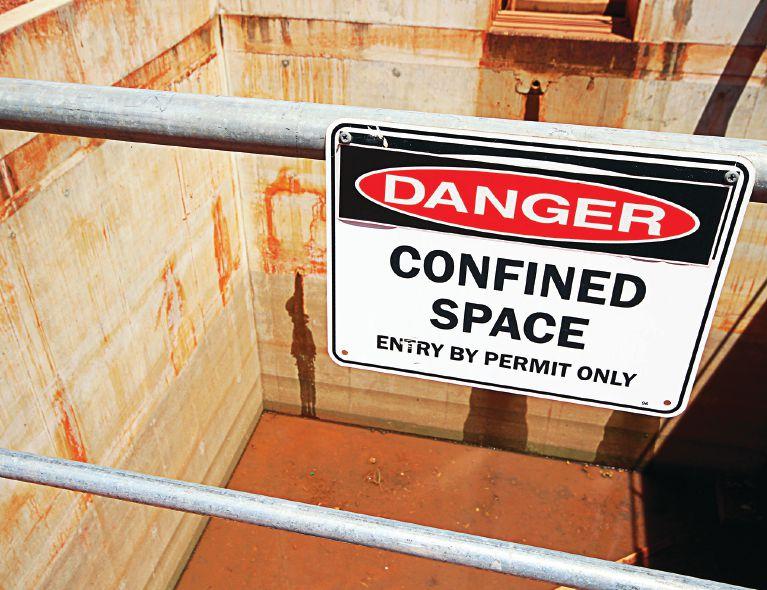

T he case arose from confined space work that went wrong at a municipal wastewater treatment and pumping plant. The supervisor was charged when a worker under his direction was subject to an inrush of water into the confined space that trapped the worker. He could not be rescued in time to save his life.

This important case addressed a number of legal issues and at least three critical questions that apply to all Canadian employers. These questions are also important for the information and guidance to OHS professionals.

First, can OHS regulatory standards be used to form the basis of an OHS criminal negligence charge? Second, is there a legal obligation to conduct a formal “hazard assessment” when conducting potentially dangerous work? Third, what is the personal responsibility of a supervisor to understand and follow OHS regulatory standards not provided formal training by his employer?

On Aug. 16, 2018, Michael Henderson died at a construction site in Fredericton. He was employed on the site by Springhill Construction Ltd. and worked under the supervision of the accused, Mr. King. The

The plug released into the hole with an onrsuh of water, pinning the worker in his confined space work area.

charge on the Indictment reads as follows: “On or about August 16, 2018 at Fredericton, New Brunswick did, by criminal negligence cause the death of Michael Henderson, contrary to s. 220(b) of the Criminal Code of Canada and amendments thereto”.

The facts leading up to the incident were as interesting as they were tragic. The owner of the municipal wastewater treatment and pumping contracted out the construction of a secondary clarifier.

The project would enhance the plant 's treatment of liquid waste before it went into the Saint John River. The deceased was working in an eight feet deep hole in the middle of the new clarifier. He was protected from the surrounding water by a large pneumatic rubber plug.

The plug unexpectedly released into the hole with an onrush of

water, pinning the worker in his confined space work area that quickly filled with water. The worker drowned before the emergency response effort could rescue and recover him.

The evidence at trial was that the supervisor of the worker was not specifically trained in the provincial confined spaced safety regulations and he had not read the instructional manual relating to the use of the industrial plug. The trial judge summarized the failures of the accused as follows:

159 Mr. King had no viable safety plan in place. He knew Michael Henderson was in the hole, after lunch finishing the clean-up, yet he kept putting water into the manhole increasing the pressure on the plug. Mr. King did not do a hazard assessment before directing that anyone work

within a clearly identifiable confined space. He did not place any barrier around the hole during the test to ensure no one went near it. He put water into the system knowing a person was working on the other side of a plug installed in a manner inconsistent with the manufacturer's clear direction. He ignored the Springhill site specific directions for work in a confined space. He did not comply with the legislative provisions that he was required to uphold.

160 At 12:51, under the pressure of the water that Mr. King had begun to introduce into the manhole approximately an hour earlier, the plug let go. It trapped Mr. Henderson and, despite the best efforts of those on scene, including his brother Eric, Michael could not be removed from the hole. Approximately one minute after the plug released and trapped Mr. Henderson, Mr. King turned off the hydrant stopping the flow of water into the hole. But the force of the plug on Mr. Henderson's chest, and the water that was rushing into the hole, could not be overcome. By the time Michael Henderson was removed from the hole, efforts to revive him were futile.”

The central legal development of the Westray Bill is the new legal duty under section 217.1 of the Criminal Code , which if contravened may lead to a charge of OHS criminal negligence. It reads as follows: That legal duty reads as follows: “Everyone who undertakes, or has the authority, to direct how another person does work or performs a task is under a legal duty to take reasonable steps to prevent bodily harm to that person, or any other person, arising from the work or task.” [emphasis added]

This raises the first question mentioned above — can OHS regulatory standards be used to form the basis of an OHS criminal negligence charge? This has critical implications for all workplace stakeholders, not just supervisors. The trial judge conducts the following analysis and provides the answer to that question in the affirmative:

167 As noted above, I am satisfied that the duties set out in the Act and Regulations impose legal duties on Mr. King and fall within the intent and meaning of s. 219 of the Code when it speaks of duties that arise by the imposition of law. I will not therefore,

opine on the application of the Crown's alternative argument as it relates to s. 217 [sic] of the Code.

The second question of the courts review was the accused supervisor’s failure to conduct a hazard assessment of the construction work. The supervisor had neither been asked by his contractor employer, nor the owner the facility to conduct a hazard assessment. The accused argued that this duty did not apply to the supervisor and, alternatively, the workplace was not a "confined space."

Both arguments were rejected and the failure of the accused supervisor to conduct a hazard assessment of the work at the construction project was a critical failure of a legal duty of the accused supervisor. The second question was also answered in the affirmative.

Third, since the supervisor did not have confined space training from his employer, the trial judge had to determine what degree of responsibility did the supervisor have to conduct hazard assessment, understand the precautions to be taken when using the plug, and how to be prepared to rescue the worker if something went wrong.

The standard of proof of all elements of an OHS criminal negligence charge, and any criminal offence, is proof beyond a reasonable doubt. However, the rank tragedy of the worker’s preventable death appears to have moved the court towards strict application of the OHS regulatory standards to the accused under the Westray Bill. The court says,

172 In my view, the standard expected of a reasonable site supervisor on a construction site of this type must include, at a minimum, that the supervisor had familiarized themselves with the legislated duties that were binding upon them as set out in the Act and the Regulations. Construction sites, by their nature, contain hazards and can be dangerous (as this incident so tragically proves) and the legislative scheme is meant to reduce and, if followed, hopefully eliminate, that risk. In addition, one should expect that the reason-

able supervisor would have familiarized themselves with any site-specific safety plan. Furthermore, the reasonable site supervisor would have familiarized themselves with the basic manufacturer's instructions regarding the safe use of equipment used on the site. These are the basic, fundamental elements of what I find to be the minimally acceptable standard of conduct for a supervisor in the circumstances of Mr. King. I use the phrase 'basic fundamental elements' because, in my view, any failure to meet those basic fundamental elements would, by its very nature, represent a marked and substantial departure from this acceptable minimum standard.

The net result of this assessment of the accused to take “basic fundamental elements” of workplace safety, even though that is not part of the criminal law, was a criminal conviction. There appeared to be little sympathy towards the accused supervisor’s plea that he was not given proper safety training by his employer.

The judge says the following: “I accept Mr. King's evidence that he was not given any training by Springhill. There was no evidence to the contrary. But whatever the reason, Mr. King did not take the steps one would expect of a "reasonably prudent person" to protect Mr. Henderson, having directed him to work in a confined space in the circumstances existing. With that said, it must be established that his acts or omissions give rise to criminal liability as set out on the Indictment.” (para. 174)

On balance, the accused supervisor was convicted in a trial where he was remarkably the only accused. This case and the reasons for judgement reinforce the importance for supervisor, and their employers of hazard assessment, OHS law compliance, and informed decision making before hazard work is performed. It is also stark reminder that the consequences of failing to take those steps may result in criminal charges under the Westray Bill that retrospectively place blame on all those who may have been able to prevent a workplace tragedy.

The views and opinions expressed herein are those of the author and do not necessarily represent the views and opinions of KPMG LLP.

By Lisa McGuire

“ The future of safety training is changing fast, and leaders will need to keep up, especially if they want to connect with a younger workforce on a deeper level. Gamification, virtual reality, augmented reality, the metaverse, and artificial intelligence are fuelling a training revolution."

Propelled by innovative technologies that promise to enhance efficiency and knowledge transfer, workplace health and safety training is undergoing a transformation. Manufacturers are looking to immersive technologies such as virtual reality (VR) and augmented reality (AR) tools to equip their teams with consistent and effective health and safety training.

Hands-on safety training significantly improves understanding and retention of training information. In the past, this was only achievable through costly on-site training. Today, AR and VR training immerses workers in simulations of real-world situations where they can practice and apply the most complex safety procedures from anywhere. This results in efficiencies and cost reductions for some employers—with stunning improvements in results compared to traditional methods.

Immersive training can also engage learners through gamification elements such as points, rewards, and competition. For leaders, this new technology creates opportunities to make training more enjoyable and interactive. Engaged employees support a strong and healthy safety culture. And workers are more likely to stay focused, complete training modules, and retain

crucial safety knowledge through short, directed, and hands-on virtual learning.

and convenient way to ensure that all their technicians receive the same standardized training.

“Immersive training can also engage learners through gamification elements such as points.”

S ince October 2023, two independent systemic literature reviews have been published through Safety Science on the use of immersive technologies for occupational health and safety training and education. These reviews concluded that indicators strongly suggest immersive solutions are more effective than traditional training methods.

Anecdotally, workers young and old at Husky Technologies, an Ontario-based global injection molding packaging systems manufacturer, have come to perceive the use of immersive technologies as the future of training. Trainees shared that their immersive learning platform has added value to their learning experience of how to work safely on client sites. And for the company, it provides a streamlined

A s businesses adopt immersive technology, there are broader implications for workplace culture and risk management as well. Business leaders are beginning to recognize that investments in advanced training technology can take them beyond regulatory compliance in a strategic move toward creating a safer, healthier, and more productive work environment.

As leaders consider the benefits of a shift from a compliance-driven approach to training to a proactive, data-driven, and employee-centric model, they are seeing long-term benefits to their training technology investment. Sustainable gains in efficiency and performance support the collective skills and competency of learners and underscore the value of their people.

By Todd Humber

The former health, safety and training manager for a building supply company in Ontario has lost a wrongful dismissal lawsuit she filed after being fired for cause in the wake of a workplace injury she allegedly suffered.

Shari Lagala had been in her role at Patene Building Supplies for more than 13 years. She was let go in the wake of her management and non-reporting of a workers’ compensation claim she made on her own behalf to the Workplace Safety and Insurance Board (WSIB). Lagala allegedly fell in the parking lot of the company’s Brantford, Ont., location on March 28, 2019 because of ice — though the employer presented evidence about the weather on that date which showed ice was unlikely.

Despite her role and expertise in health and safety, Lagala failed to report the incident to her supervisors until months later, a delay that went against the grain of standard workplace safety protocols — and those of her employer. In the interim, she initiated and managed her own WSIB claim and received benefits for physiotherapy.

In October 2019, the WSIB asked Lagala to have her supervisor sign off on the employer’s claim form. She sought that signoff at the end of October, about one month after she included the accident on a monthly report of health and safety incidents she provided to management. That led to an internal investigation that involved Patene’s president, Patrick George.

T he investigation raised significant concerns regarding Lagala’s management of the incident, particularly her delayed reporting and the potential manipulation

of evidence related to the accident. These actions were found to be in direct violation of Patene’s established safety policies and procedures, which Lagala herself was responsible for enforcing.

G eorge, having lost trust in Lagala, made the decision to terminate her employment for cause on Dec. 18, 2019. She was 53 at the time with an annual salary of $72,500 along with benefits including health and dental benefits, a company cellphone, a company car and an annual bonus. Subsequently, Lagala sued for wrongful dismissal.

Justice Lemay of the Ontario Superior Court of Justice emphasized the discrepancies in Lagala’s accounts and her failure to adhere to the very policies she was entrusted to uphold. He highlighted the integral role of health and safety managers in setting an example and maintaining the integrity of safety protocols.

The court noted that Lagala said she was too embarrassed to report the injury to her supervisors. She testified that, at the time the incident happened, that she contacted Dale Cormier, the traffic manager at the Brantford branch, to complain about the incident and express “my frustration that the potholes are not getting filled.”

But Cormier testified he never had any such discussion with Lagala, and the first time he heard about any accident was in October 2019 when she called him and asked him to write an email about it. “The plaintiff dictated what she wanted the email to say,” the court said.

Counsel for the plaintiff suggested that Cormier was lying about the incident to protect his job, but the court rejected that suggestion. It found Lagala to be untruthful with both George and the court about reporting the incident to Cormier in March 2019 and that she attempted to use her relationship with Cormier — they were childhood friends — to conceal this lie.

“ This is very significant misconduct that might, on its own, be sufficient to support (Patene’s) decision to terminate (her) employment for cause,” the court said.

It also pointed out that her decision not to report that accident, in any way, until after the WSIB had allowed her claim was a “breach of the employer’s policies on accident reporting.”

The court also noted Lagala went to the emergency department in August 2019 to seek medical treatment that was, at least arguably, related to the accident.

Continued on page 19

By Todd Humber

You betcha. What’s going on down in Ontario?"

S heldon Kennedy’s voice crackles through his Bluetooth connection as he pilots his truck down the highway on the onehour drive from Saskatoon to his farm. It’s his answer to the standard opening salvo in an interview: “Is now still a good time to chat?”

His early morning drive across the Canadian prairie is a million miles from Detroit’s old Joe Louis Arena, where he laced up his skates for the Red Wings for five years, including the 1992-93 season that saw him rack up 19 goals and 11 assists — his best offensive performance in the NHL.

But he’s not interested in reliving

the glory days of donning the jerseys of the Red Wings, Calgary Flames or Boston Bruins. He has a new passion that can be summed up with one word: Respect. And he’s taking that message beyond the locker room and deep into corporate board rooms.

“Our workplace program really came from an extension of our sport program,” he said. In 2004, he teamed up with Wayne McNeil to create the Respect Group. One of its offerings is Respect in the Workplace, which is a 90-minute online interactive training program to prevent BAHD (bullying, abuse, harassment, and discrimination) behaviours.

“ We started in sport to try and educate all coaches across this country on the issues of bullying, abuse, harassment, discrimination and neglect in all forms,” he said.

"We started in sport to try and educate all coaches across this country on the issues of bullying, abuse, harassment, discrimination and neglect."

The message resonated with the volunteer coaches, who saw the value and started asking about bringing it to their workplaces, said Kennedy.

Kennedy sees a lot of parallels between locker rooms and workplaces, and he’s hard pressed to think of anything more important than mental health.

“Both of them need to be a psychologically safe space, or we’re never

“When people don't feel safe... they will never perform at their best.”

Sheldon Kennedy

going to get the best out of the team,” he said. “When people don’t feel safe, whether they’re on a team or as an employee, they will never perform at their best. They need to feel welcomed and respected.”

There has been a lot of lip service paid to the fact that performance is 75 per cent mental, he said, but many organizations are failing to build supportive cultures — or not even trying.

“Right now, we build culture on a hope and a prayer,” said Kennedy. “We don’t have a strategic approach.”

To stamp out the BAHD cancers, organizations need to empower their workers — the 98 per cent of them that are good people — with the tools to build the confidence to step up and step in when issues arise, he said.

“ When we have a strong, healthy and respectful culture, these issues don’t happen. And if they do happen, they’re dealt with right away,” he said, adding that in those scenarios the perpetrators won’t feel welcome. Organizations need to move be -

yond having “posters, buttons, and policies,” he said.

“ This is about leadership. Our role as leaders is to create a strong team,” said Kennedy. “What we know today is that psychological safety is the main factor behind why many young people choose which team they’re going to play on.”

Kennedy has seen some common traits among people who have successfully built psychologically safe environments. It starts with leaders

Leadership is not about sitting in the corner office. It's connecting with teammates – often and genuinely.

who can truly communicate with their teams on their level.

“You need to be able to walk the hallways, communicate and walk the walk,” he said. Too often, policies are pushed out without the true support of leaders and managers, and that is very transparent to employees.

“ If the executives are not fully bought in, the team will never buy

in,” said Kennedy.

H is advice is to keep it simple, and break change down into achievable chunks. “What’s one thing we can do for the first half of this year? Walk that walk as a leader and talk to people and ask them how it’s going.”

Leadership is not about sitting in the corner office, he said. It’s connecting with teammates — often

and genuinely.

“ That’s huge. When they see it, and you start speaking about it, it resonates through the group,” he said. Coaches that have had the most success and have gained the most respect from players, from parents and those people around them, it’s those that communicate well, engage the team, ask questions, and learn from them.”

In the C-suite, there’s so much focus on revenue and profitability, he said, but not a lot of awareness around the massive impact culture can have on flow of red versus black ink.

“ The ultimate goal of the com-

"If numbers is our goal, we have to prioritize our culture."

pany is to get better results on the numbers side, right? For the investors, or whoever that is, our best way to achieve that is to prioritize people’s well-being,” he said. “If numbers is our goal, we have to prioritize our culture.”

Chaos and trauma: 'A very different hockey career'

Kennedy’s path on his ascent from minor hockey to the NHL isn’t the most pleasant to discuss. Fans of the game likely know his story. When asked who the best coach or leader he ever had as a player, he paused.

“ Well, I had a very different hockey career than probably 90 per cent of people,” he said. "It’s a very difficult question for me to answer. I’ve had some very strong managers in business, and I’ve had some very strong leaders in my world that have helped me find a way out of my own personal chaos and trauma from the abuse I suffered.”

He learned a lot from coaches about who he doesn’t want to be and had his eyes opened about just how much of an impact a bad leader can have on individuals, teams and organizations.

He was abused by his coach in junior hockey, a man who was honoured as Man of the Year by Hockey News magazine in 1989. That title was later revoked by the publication when the story came to light.

The ripple effect

Kennedy talked about the ripple effect of that behaviour which he discovered goes far beyond the ac-

tual victim.

“It’s not just the one being bullied that will leave or suffer,” he said. “It’s people that have witnessed that bullying happen in a workplace what are more apt to leave that company or that workplace.”

He made his own wellness and health his number one priority, and that has made a huge difference in his life.

“I learned how to become a good human being and how to treat myself well,” said Kennedy. “I think this is important. I can’t go out and tell people how to do it and how to be it if I can’t do it myself. If I’m not in a good position emotionally, physically, and spiritually, I can’t be leader I want to be.”

T he numbers are massive: The Respect Group has trained nearly 2.4 million Canadians to date, and that number is still growing.

One of the biggest learnings for participants is where the line is drawn when it comes to bullying and harassment. They’re asked, before the program, if they ever engaged in poor behaviour — and posed that question again at the end.

“ The number who said they have doubles, coming out of self-admittance that people didn’t know where the line was drawn,” said Kennedy.

“I've had some very strong leaders in my world that have helped me find a way out of my own personal chaos and trauma."

A leader who does that, and shows up every day for their teams, and makes 99.9 per cent of their decisions with culture in mind is going to be successful, he said.

Kennedy said there’s “no doubt” leadership styles have improved from the 1980s and 1990s.

“I told my story in 1996 and there was nothing in this space,” he said, adding he spent a lot of time just trying to convince people that these issues are real.

“Now, when you look at the leading companies in our country and around the world, the majority have already prioritized wellness and mental health and psychological safety in their workplaces,” he said. “That is one of their pillars of success. That’s huge.”

Over the last few decades, workplace culture has gone from being an esoteric concept to one that is embraced and understood.

“Culture, really, is about prioritizing and practicing and communication,” he said. “If we can have those things — and practice good, healthy communication to connect with someone else — that’s going to go a long way.”

“ We get people over the hump of being overridden with fear and anxiety when it comes to this type of training and this type of knowledge,” he said. “They’re engaging and embracing and, to me, when we get to that point is when we’re going to see change.”

Kennedy wants to ensure that what happened to him never happens to anyone else.

“I set out on a journey, and I didn’t realize how many people it has impacted. I thought I was the only one that his had ever happened to,” he said. “Most of the time, when people are in a horrible situation — whether it’s in the workplace or as a kid — they feel they’re alone. I realized quickly when I told my story that I wasn’t alone.”

It’s an unfortunate reality that people coming into the workforce likely have experienced some level of trauma in their lives.

“ If we are not paying attention to that, that’s going to eliminate a lot of people from our work and our ability to find workers — because most people have had some kind of impact in their lives,” said Kennedy. “We shouldn’t have to try to convince people, at some point, that this is important. That’s my goal.”

The biggest compliance issue in workplaces involves hard hats –which are often worn incorrectly

By Gail J. Cohen

Driving along Richmond Street in downtown Toronto the other day, two men were out on the street acting as flag people to allow a concrete mixer to safely exit a highrise construction site.

It was a cold day and both men had their hard hats precariously balanced atop toques and the pulled-up hoods of their sweatshirts.

Those hard hats were unlikely to provide much protection if something were to fall on their heads. Hats that don’t fit tightly enough — so they’re harder to put on and off than a baseball cap — won’t provide protection if they just come off on impact or if a worker falls, said Remi Badra, product manager of head protection at manufacturer PIP Canada.

Anything worn under a hard hat should also be approved by the manufacturer, said Badra, and needs to be relatively thin and tight.

“If the manufacturer approves them, it is because they have tested the fit and have ensured that the hat will continue to pass the CSA requirements,” he said.

No matter what the safety rules or requirements are, if a hard hat doesn’t fit well or isn’t comfortable for the worker, they’re less likely to wear one, says Mike Russo, owner of health and safety consultancy WorkBright. To spur on compliance, some

companies now have workers test out different hard hat options to get feedback before making a purchasing decision on what works best for them in their particular circumstance.

“The supervisor is an extremely important pivotal role, but they also need support from the owner.”

Mike Russo

Hard hats today are being designed for a secure and comfortable fit, with multiple adjustment points including ratchet suspensions and straps, said Leslie Molin, personal safety market segment manager at equipment distributor Levitt Safety.

Russo said he analyzed 80,000 client orders from Ontario government health inspectors in 2022 and the No. 1 compliance issue in workplaces involved hard hats.

Of course, the biggest problem, he said, was workers not wearing hard hats at all. Workers, first of all, have to be advised that wearing head protection is a company policy but it’s almost more important for the company to monitor the use of that protection. Supervisors are pivotal to observate, remind, and enforce those policies.

“ The supervisor is an extremely important pivotal role, but they also need support from the owner of the company, [especially] if it is a small company, to ensure that the expectations are set for the types of PPE that are required,” said Russo. Workers also need to know what to watch out for. Orientation in their workplaces is key to understanding the hazards their heads may face, such as protruding objects, electrical, or materials falling from above, said Russo.

Wearing too much under a hard hat in winter is a common mistake workers make, but there are many user errors that detract from the effectiveness of wearing a hard hat. One of the biggest: not storing a hard hat properly. They’re often left in cars or on dashboards, which results in damaging UV exposure, said Badra. They should be stored in a clean location away from extreme temperatures and direct sunlight, said Molin.

While it may be fun and look cool, covering a hard hat in stickers can be problematic. Chemicals in the adhesive can degrade the hat’s plastic but they will also cover up any cracks or damage to the hat, said Russo. Many workplaces don’t permit stickers on their hard hats for this reason.

Molin noted that daily inspections for wear and tear often aren’t done. Every day workers should check their hard hats for brittleness, cracks, dents, frayed straps, or damage to the wheel or slip ratchet mechanism, she said.

In addition to the issues with winter gear, Russo said, baseball hats should never be worn under a hard hat because they’ll also affect the suspension.

Mix-and-match add-on accessories like visors or hearing protection that aren’t approved for that manufacturer’s gear can also compromise safety, said Molin.

Some workers even try to store safety glasses or other small items inside their hard hats between the suspension and the shell, said Russo.

Continued from page 13

Under the Workplace Safety and Insurance Act (WSIA) that triggered the notification requirement and the accident had to be reported by the employer within three days. By not reporting it until weeks later, she “put her employer at risk of being found in violation of section 21 of the WSIA,” the court said. The sanctions that could have flowed from her failure to report the alleged accident in a timely way are “significant,” it said.

It was also part of her job to protect her employer from these penalties by ensuring accidents were reported promptly, it noted.

“These concerns also illustrate the fact that (Lagala’s) decision to report her own accident on behalf of the employer put her in a conflict of interest,” it said.

“She would be interested in obtaining benefits from the claim, while the Defendant would want a full investigation into the claim, particularly given the inconsistencies in the Plaintiff’s reporting. This is a classic conflict of interest that any manager

“If there is impact, the gap between the suspension and the hardhat is so important because that'll slow down the impact and if there are materials in that gap, it kind of defeats the purpose,” he said.

A mistake that companies often make, that can lead to individuals compounding safety challenges, is not assessing use requirements before providing hard hats. Welders are a perfect example, said Russo. They often wear their hard hat backwards, which is fine if the manufacturer has tested and approved it for that purpose, but is a problem if it hasn’t.

Molin noted that hats approved to be worn backwards will have a “reverse donning arrow” symbol inside.

When it comes to choosing hard hats, workers and companies must conform to the classes approved by the CSA and in each jurisdiction. Ontario, for instance, requires Class E hard hats that provide head protection against high-voltage conductors. But there’s also the option for Type 1 (crown only) or Type 2 (crown,

sides, and back).

Everyone’s familiar with the standard hard hat style, with the small visor in the front, but there are a few new developments in technology and design.

MSA Safety, for example, has developed the V-Gard C1, said Molin. It features a full brim and uses thermal barrier technology to keep the inside of the hard hat 11°C cooler in sunny weather, making it the coolest hard hat on the market.

So-called “safety helmets” are also becoming more widespread, said Russo. They look more like climbing helmets and are made of lightweight materials and have a chin strap, which helps keep the helmets in place in case of trips and falls, especially from heights.

These newer styles though are costlier than traditional hard hats.

“Some workplaces have said, ‘Before we make a decision, we want to see objective data to substantiate the need for a safety helmet over a traditional hardhat,’” said Russo.

who works in the human resources field should have been able to see,” it said.

The fact she was prepared to put herself into this conflict, while denying it was a conflict, is a “significant” reason why Patene Building Supplies was “correct” to have lost confidence in her, the court said.

But perhaps the most damning words from the court came in relation to a meeting between Lagala and management once her WSIB claim came to his attention.

During an interview conducted on Nov. 1, 2019, where George was also present, Lagala failed to provide the complete WSIB file, notably omitting a decision letter from the WSIB which she had received. This omission was perceived by the court as an attempt by Lagala to conceal information from her employer.

Justice Lemay highlighted that Lagala’s

conduct during this incident was part of a pattern rather than a singular lapse in judgment.

“All of this misconduct must be considered in light of the fact that (she) was directly responsible for the administration of the Defendant’s Health and Safety policies,” it said. “Put simply, an employer cannot be expected to employ a Health and Safety manager who does not comply with health and safety policies when those policies affect her, and then is dishonest with her employer about what happened after the fact.”

The court dismissed her claim and asked the parties to agree on legal costs, but said it was available to review submissions if they could not come to agreement. Typically, winning parties in court cases are entitled to recover at least costs from the losing parties.

For more information, see Lagala v. Patene Building Supplies Ltd, 2024 ONSC 253 (CanLII).

99 Crompton Dr. Barrie ON L4M 6P1

Tel: 647-699-7702

Web: www.aed.ca

AED.ca is Canada’s AED Company. We are automated external defibrillator (AED) specialists. We sell and service AEDs and offer AED inspections and training. Do you have questions on which AED is best for your location? We offer expert advise and can help create an AED program for your location(s). We truly care and are here to help you protect the people at your location. AED.ca

528 5e rue de la Pointe Shawinigan QC G9N 1E8

Tel: 877-746-5653

Web: safecontractor.com

Alcumus SafeContractor takes the pain out of compliance for organizations, helping them protect their people, their operations, and the planet. We support our network of hiring clients, suppliers, and contractors by keeping them compliant with the standards that matter most, from health and safety and sustainability to ethical behaviour. We deliver an end-to-end contractor management solution that will streamline your internal processes, save you time and resources, and provide your business with unrivalled expert guidance and support.

Key features:

• An easy-to-use digital tool to gain visibility and control of your contractor and worker management

• Access to real-time data about the risk status of your entire business, across sites and departments

• Guidance and support from a team of trained safety assessors

• Collaborate exclusively with reliable and safe contractors who have been approved to a standard of excellence. safecontractor.com

2637 S 158th Plz Suite 110 Omaha NE 68130

Tel: 402-562-7878

Web: www.appruv.com

Appruv is a powerful global prequalification platform that helps clients streamline the process of screening and hiring contractors. By using our platform, you can easily ensure that your contractors meet your specific safety, insurance, financial, and performance standards before they start working, thus reducing the risk of safety hazards, legal liabilities, and other issues that can arise. Our platform is designed to streamline the prequalification process and make it more efficient and cost-effective compared to manual screening. With Appruv, you’ll be able to prequalify contractors quickly and easily, while also improving contractor performance and accountability. Additionally, our platform offers online orientation training for contractors, which helps ensure that they are prepared and informed before they start working on a job site.

Calgary Place II, 355 4 Ave SW

Calgary AB T2P 0J1

Tel: 587-287-1125

Web: avetta.com

Avetta leads the world in connecting leading global organizations across several industries including oil/gas, telecom, construction materials, facilities management and many others, with qualified and audited suppliers, contractors and vendors. The company brings unmatched access and visibility to its client’s supply chain risk management process through its innovative and configurable technology, coupled with highly experienced human knowledge and insight. We contribute to the advancement of our clients’ sustainable growth by protecting supply chains from a wide range of potential risks through trusted contractor prequalification, safety training and monitoring, regulatory compliance, insurance/financial stability, and other

areas of risk. Avetta currently serves more than 450 enterprise companies and 125,000+ suppliers across 120+ countries. Visit www.avetta.com for more information.

6700 Century Ave Suite 100 Mississauga ON L5N 6A4

Tel: 905-567-7198

Web: www.bcrsp.ca

The mission of the Board of Canadian Registered Safety Professionals (BCRSP) is to act in the public interest in granting certification and upholding it as a recognized standard of excellence for competent and ethical safety practitioners. A federally incorporated not-for-profit organization, BCRSP establishes and enforces education, examination, experience, and ethics requirements for CRSP and CRST certified professionals.

710 COCHRANE DRIVE MARKHAM ON L3R 5N7

Tel: 416-433-9786

Web: www.BradyCanada.ca

Brady is a manufacturer of complete solutions that identify and protect people, products and places. Brady’s products help customers increase safety, security, productivity and performance and include highperformance labels, signs, safety devices, printing systems and software!

604 Industrial Road 3 Cranbrook BC V1C 4V2

Tel: 250-426-3400

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the

only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

10121 Barlow Trail NE Calgary AB T0M 0E0

Tel: 403-248-0018

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

BRANDT

10630 176 St NW Edmonton AB T5S 1M2

Tel: 780-484-6613

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt

Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

360 MacKenzie Blvd #5 Fort McMurray AB T9H 4C4

Tel: 780-791-6635

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

1521 33 St N Lethbridge AB S7L 0X2

Tel: 403-330-8859

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

101 Burnt Park Dr Red Deer AB T0M 0E0

Tel: 403-343-7557

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of

material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

Highway #1 East Regina SK S4P 3R8

Tel: 306-791-7777

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

BRANDT TRACTORSASKATOON

800 60 St W Saskatoon SK S7K 3N2

Tel: 306-664-4141

Web: brandt.ca/Material-Handling

Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our

certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

3700 McGillivray Blvd Winnipeg MB R3Y 1X2

Tel: 204-231-2333

Web: brandt.ca/Material-Handling Brandt training programs provide students with the basic principles of material handling and construction equipment operation, load handling, maintenance, and safety, and is the only training that provides students with a practical operator assessment required by Occupational Health & Safety (OH&S) and Canadian Standards Association (CSA). After successful completion of the theory test and a final practical assessment, an Operator Equipment Safety Certification is provided to students. Enhance your safety, productivity, efficiency and confidence on the job with Brandt Equipment Safety Training. Our certification meets and exceeds safety standards across Canada with OH&S and CSA compliance.

2425 Skymark Ave., Unit 1 Mississauga ON L4W 4Y6

Tel: 905-212-6600

Fax: 905-212-6602

Web: www.draeger.com

Draeger was established in 1889 as a manufacturer of gas detection and respiratory protection and serves customers worldwide. The current portfolio includes stationary and personal gas detection systems, respiratory protection equipment, fire training systems, thermal imaging cameras and alcohol and drug detection units. “Technology for Life” is the guiding philosophy. Whether in clinical applications, industrial safety applications, oil & gas, mining or fire and emergency services, Dräger products protect, support and save lives. www.draeger.com

10700 Secant St. Montreal

QC H1J 1S5

Tel: 514-354-2511

Fax: 514-354-6948

Web: www.geneq.com

GENEQ inc. is a Canadian Supplier of Scientific Instruments for the Environment and Occupational Health and Safety since 1972.

1831 North Park Avenue Burlington NC 27217

Tel: 336-227-6211

Web: glenguard.com

GlenGuard is the ultimate inherent fabric for arc-rated, flame-resistant workwear – delivering the perfect blend of comfort, durability, and versatility. GlenGuard is lightweight and breathable to keep workers comfortable, and its protective properties are engineered to overcome even the harshest conditions. With the industry’s best weight-to-protection ratio, GlenGuard helps workers reach their peak performance and stay in compliance. Specify GlenGuard and enable your workers to be more compliant with their AR/FR work wear. For more information, visit www.glenguard.com.

305 Bend Hill Rd Fredonia PA 16124

Tel: 724-962-9231

Fax: 724-962-3611

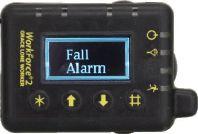

Web: www.graceloneworker.com

Do You Have People Working Alone?

Use an employee check-in system and a lot can happen between employee “check-in’s”. You need an Immediate Notification System

Grace Lone Worker Systems:

• DO NOT - use cellular networks

• DO NOT - Require internet connections

• INTEGRATE with SCADA/Fire/ Weather Alarms

• BEST OF ALL - NO Subscription Fees

Do You Have People Working at Heights?

Fall Detection and Suspension Trauma Prevention that exceeds traditional standards for Fall Safety Self-Rescue. When a worker is unable to self-rescue, you need a WorkForce® Immediate Notification System

Grace WorkForce® Systems:

• PREVENTs SUSPENSION TRAUMA with an Immediate Notification of a worker in distress – when selfrescue is not possible WorkForce® is there to automatically make a distress call

• USED ALSO IN LONE WORKER APPLICATIONS

10665 Jasper Avenue NW 14th Floor Edmonton AB T5J 3S9

Tel: 866-337-4734

Web: www.hseigroup.com

HSE International can provide a diverse range of practical, custom-tailored services and solutions to help you address your most pressing health and safety risks and challenges, and help meet your due diligence and compliance needs and goals. We provide a diverse range of complementary services including audit and assurance, management consulting, risk advisory and training to our clients throughout Canada and abroad. Our consultants and advisors are recognised as leading practitioners in occupational health, safety, environmental, contractor management, and personnel learning and development strategies. Our approach is geared for sustainability – both financial and cultural. We are passionate about keeping people safe at work and we help organizations to improve and change the way safety is perceived and handled across their business. We are a certified educational institution, a certified diverse supplier, and have a better business bureau (BBB) A+ rating.

70 Floral Parkway Toronto ON M6L 2B9

Tel: 416-248-5625

Fax: 416-248-9945

Web: idn-inc.ca

IDN Canada has 10 locations across Canada:

• 1228 Old Innes Road Unit

317 Ottawa, ON K1B 3V3 phone: 613.749.2172

• 2010 30th Avenue NE Unit 15 Calgary, AB T2E 7K9 phone: 403.291.4844

• 9681 45th Avenue Edmonton, AB T6E 5Z8 phone: 780.944.0014

• 8052 Winston Street Burnaby, BC V5A 2H5

phone: 604.253.0017

• 39 Mosher Drive Dartmouth, NS B3B 1E5

phone: 902.468.1373

• 1600 rue Beaulac Saint-Laurent, QC H4R 1W8

phone: 514.956.0248

• 1800 Appleby Line Unit 5 Burlington, ON L7L 6A1 phone: 905.319.7400

• 37 Mosher Drive Dartmouth, NS B3B 1E5 – phone: 902.468.0772

• 445 Milner Avenue Unit 5 Scarborough, ON M1B 2K4 phone: 416.295.5625

40 Dussek Street PO Box 524

Belleville ON K8N 5B2

Tel: 613-966-0062

Web: impacto.ca

With over 35 years in the industry, IMPACTO® is a leader in personal protective equipment manufacturing. We provide our customers with innovative ergonomic solutions and safety products that enhance safety and productivity in the workplace without compromising comfort. IMPACTO® products are distributed around the world and are used in many applications including manufacturing, warehousing, assembly lines, industrial applications, construction, mining, forestry, office settings and many more.

We pride ourselves on our attention to detail, superior product quality and customer service. We are committed to customer satisfaction, the continual improvement of our products and expanding our markets by developing personal protective equipment in compliance with the latest safety standards. Let us help you navigate the many ergonomic and safety products we offer and ensure that you are comfortably working safe.

1661 Finfar Court Mississauga ON L5J 4K1

Tel: 905-823-6150

Fax: 905-823-7608

Web: www.latoplast.com

Discover the Forcefield Women’s High Visibility Safety Apparel Collection, designed to keep you safe on the job. Our Essentials line offers all the core items you will need through the year, combining functionality with high-quality materials and a “madefor-women” fit. Be seen, be protected, and take charge of your workplace safety. Explore our collection in the OHS Buyers Guide now!

2872 Bristol Circle Oakville ON L6H 5T5

Tel: 905-829-3299

Web: levitt-safety.com

We are a 100% safety-focused company. We don’t just sell safety supplies or service equipment. We find the best solutions from manufacturers who’ve been in the business for decades. We train our technicians to service the equipment to keep your business running. We can also train your team on equipment or concepts like confined space or working at heights, so they are confident in every job they do. So what does all of this mean? It doesn’t matter what you do or where you work, your job puts you at risk. We have the equipment, technical skills and know-how to keep you safe so you can live life to the fullest. Take a look through our website, it’s divided

into shoppable products, specialty products, services and training, and if you have a question contact us – we’re here to help. We partner with our customers to solve their fire, safety and environmental challenges. Our motivated, knowledgeable people deliver value through high-quality solutions, products and services.

2115 South Service Road West Box #3 Oakville ON L6L-5W2

Tel: 289-351-2920

Fax: 833-905-6532

Web: www.OLFA.com

Sharp since 1956. Yoshio Okada, the founder of OLFA, developed the first snap-off blade knife in 1956. He envisioned an economical tool that remains sharp. By snapping used segments, this knife revolutionized cutting. The durable and reliable design improved efficiency. The angle and length of OLFA snap blades set the industry standard, now used around the world. Using high-quality steel, OLFA forges blades with technologies that stem from traditional swordmaking. Expert honing sharpens each blade for extended life. Precision craftsmanship in every blade delivers superior performance. OLFA durable handles house these ultra-sharp blades for unmatched performance. Vigorous manufacturing standards ensure every OLFA handle provides user reliability. OLFA remains committed to making tools that improve how people cut by creating professional-grade tools for construction, warehouse operations, and office work. OLFA also specializes in tools used in papercrafts, quilting, and more.

2477 Michelin St. Laval QC H7L 5B9

Tel: 514-409-2859

Web: www.pipcanada.ca

Our relentless focus on customer satisfaction is at the center of everything we do. We seek to develop, train, and provide all customers

with innovative safety products that help keep all workers safer, more comfortable, and more productive. And with approximately 7 million women employed in the Canadian workforce, we recognize women as being important contributors on job sites all across Canada. It is essential that women have access to PPE that is designed specifically to fit and protect them properly, providing peace of mind as they work. Oversized PPE in traditionally male-dominated industries can get in the way, reducing productivity and potentially leading to injury. Learn more about how PIP Canada is fast becoming a leader in providing women’s PPE options that have been researched and designed to be comfortable, flattering for diverse body shapes, and most importantly to provide optimal protection.

View our Women’s PPE guide here: https://tinyurl.com/vtn982jf

70 Planchet Rd. Concord ON L4L 6E1

Tel: 905-660-6700

Fax: 905-660-6903

Web: www.roncosafety.com

RONCO Safety is a world-class manufacturer of Personal Protective Equipment (PPE) for head, hand, and body. Our trusted distribution network delivers products to endusers striving to comply with safety standards for both their employees and work processes. RONCO PPE are designed to minimize risk for workers and maintain a safe and healthy occupational environment in a variety of industries. Commitment to social and environmental sustainability has always been a top priority at RONCO, and this can be seen through the RONCO Earth product line of environmentally friendly products. Headquartered in the Toronto area, RONCO is supported by sales operations across Canada as well as international offices in Romania, China, Bangladesh and Malaysia. RONCO’s first domestic PPE manufacturing plant in Ontario went operational in 2021. RONCO is dedicated to a culture of growth and innovation to meet the needs of customers and their target industries.

Box 22, Site 1, RR4 Olds AB T4H 1T8

Tel: 403-350-4007

Web: safetycheckconsulting.com

Safety Check Consulting provides on-site health and safety management along with program development and monitoring. We are able to manage health and safety using your established programs, or, in the case of new / startup projects, we can provide full safety management using Our JobSight SMS system.

JobSight SMS, is a full Occupational Health and Safety management program that offers: