TREENA HEIN

BILL HOWATT

BRANDI COWEN

TREENA HEIN

BILL HOWATT

BRANDI COWEN

By Brandi Cowen, Editor

One in five women have personally experienced a situation where ill-fitting PPE caused an injury on the job, and 37 per cent have personally experienced a near miss where ill-fitting PPE was the cause, according to a new global report on women’s access to proper personal protection equipment (PPE) from The Safety Rack.

The non-profit, which is dedicated to closing the PPE equity gap for women across all industries, surveyed 505 women around the world, including in Canada and the United States. The results detail a startling reality where many women lack access to female-specific PPE (70 per cent), often (51 per cent) or sometimes (33 per cent) modify standard-issue PPE to better fit their bodies, and believe lack of properly fitting PPE hinders their ability to perform their jobs safely (66 per cent) and effectively (65 per cent).

If you recall CSA Group’s findings from its 2022 research on Canadian women’s experiences with PPE in the workplace, this may come as no surprise. The CSA Group’s survey of almost 3,000

Canadian women who use PPE in their daily job functions found 58 per cent of these women used the wrong size PPE at least some of the time, and 28 per cent didn’t wear all the required PPE because of issues with fit. Perhaps most troubling? Nearly 40 per cent reported experiencing an injury or incident that they perceived to be related to their PPE.

Nearly 40 per cent reported experiencing an injury or incident that they perceived to be related to their PPE.

So, both surveys show that the very gear meant to help protect women on the job is, at least some of the time, hurting them instead.

We’ve got a lot of work to do to close the PPE equity gap for women. Some of that work happened on March 19, when OHS Canada hosted our third annual ProtectHer summit.

During the 2.5-hour virtual event, delegates learned about innovations in women’s PPE, best practices to ensure proper fit, and strategies to advocate for PPE that’s inclusive and designed with women’s unique requirements in mind. (You

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Uyen Vu: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

can find coverage of the event starting on page 28, or view full recordings of the sessions on our website.)

It’s a start – and a good one, if I do say so myself. But just as important as the information shared were the connections forged during the event. In the days since, I’ve heard from delegates who have discovered new categories of PPE tailored for women, and others who have found local suppliers specializing in women’s PPE. This is how we move the needle on PPE equity for women.

T hat needle must move, because two in five women experiencing an injury or incident related to their PPE is an unacceptable statistic.

If you’d like to learn more about women’s PPE, but aren’t sure where to start, talk to your suppliers. You may be surprised by what they already offer. Organizations like The Safety Rack and the Alliance of Women’s Safety Apparel Manufacturers (AWSAM) also provide valuable resources to help locate suppliers offering PPE designed for women.

As an industry, we can, and must, do better to ensure every worker returns home healthy and safe at the end of every work day.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal

Tel: 416-510-5113

Fax: 416-510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Brandi Cowen 437-770-4370 bcowen@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey

ACCOUNT CO-ORDINATOR Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Barbara Adelt 416-510-5184 badelt@annexbusinessmedia.com

BRAND SALES MANAGER Silvana Maiolo smaiolo@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital) PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published four times per year –Winter, Spring, Summer, Fall Canada $70/yr plus tax USA $98/yr CDN Foreign $162/yr CDN Single copy $19 CDN

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2025 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

WorkSafeBC is launching an awareness campaign to inform newcomers to British Columbia that all workers have the right to a safe workplace from day one on the job and are covered by WorkSafeBC insurance regardless of their immigration status or term of work.

Recent research from WorkSafeBC revealed that workers who have been in Canada for five years or less are significantly less likely to speak up about workplace health and safety and are less aware of their right to file a claim if they’re injured on the job compared to those born in Canada.

The research also found that an average of 50 per cent of Chineselanguage-speaking workers felt they had to tolerate health and safety risks to keep their jobs, and 30 per cent feared that speaking up about unsafe conditions could harm their reputation.

“WorkSafeBC is reaching out to newcomers to reinforce a critical message: You have the right to a safe and healthy workplace,” said Howard Wu, occupational hygiene officer at WorkSafeBC. “And if your job task is unsafe, you have the legal right to refuse work, without fear of retaliation or job loss.”

In a media release, WorkSafeBC stressed that by law, employers are prohibited from penalizing workers for raising a health and safety issue. Workers and employers with workplace health and safety questions should visit worksafebc.com for resources or call WorkSafeBC’s Prevention Information Line anonymously at 1-888-621-7233.

report drawing on the expertise of more than 1,500 commercial drivers with nearly 15,000 years of combined driving experience to identify causes of distracted driving and practical solutions drivers need to stay safe.

50 per cent of Chineselanguage-speaking workers surveyed in B.C. felt they had to tolerate health and safety risks to keep their jobs

Staying focused on the road remains a challenge, with 76 per cent of drivers reporting often being distracted by their personal mobile devices. This finding is consistent across age levels and years of experience as a commercial driver. Reading and sending messages (32 per cent), making calls (29 per cent), and scrolling social media (29 per cent) were among the most common distractions identified.

However, it’s not all personal mobile use, as 74 per cent of respondents used their phones or other technology for workrelated tasks while driving. Drivers reported the top three ways employers can help them reduce work-related mobile use on the road include improved communication systems to limit work-related calls and messages (44 per cent), better in-cab routing and navigation (43 per cent), and implementing policies that prioritize safety over speed (42 per cent).

The report also showed drivers want to feel safe and valued. Ninety per cent of respondents

said they are more likely to stay with organizations that proactively address distracted driving through preventative strategies. Notably, global organizations in Canada and the United States are at the forefront of these efforts, where 97 per cent of drivers said they receive targeted coaching and training. Additionally, 82 per cent of drivers indicate that positive reinforcement, such as recognition and incentives, is a more effective deterrent to distracted driving than punitive measures. The impact of comprehensive training is evident, with 95 per cent of drivers reporting improved driving habits following such programs. Digital platforms have emerged as the preferred training method, favoured by 64 per cent of drivers.

Other key findings include:

• 54 per cent identified accurate, AI-powered detection and alerts as the most desired technology to combat distracted driving.

• 93 per cent acknowledged that reviewing dash camera footage of their driving increased their awareness of distracted behaviours.

• 49 per cent of drivers would support policies requiring in-vehicle safety features such as in-cab alerts.

To read “Behind the Wheel: Distracted Driving in Physical Operations”, visit www.samsara.com.

WCB Nova Scotia’s Protect More Strategic Plan aims to return the equivalent of 1,000 positions to the province’s workforce by 2030.

As part of its new strategic plan, WCB Nova Scotia implemented a new approach to address sprains and strains – the province’s most common workplace injuries – last fall. Data indicates the new model is making an impact with 90 per cent of workers returning to work within 30 days and 98 per cent returning within 60 days, plus treatments reduced from 30 sessions to just seven.

“While we are beginning to see progress, still, over one million days are lost every year due to workplace injuries,” said Karen Adams, CEO of WCB Nova Scotia. “These are workers who want to be, and should be, building roads and homes, caring for loved ones, and keeping our communities running. We need Nova Scotians back to work because that leads to better physical, psychological, and financial outcomes for injured workers, a stronger workforce, and more efficient use of valuable health services.”

A key component of the new model focuses on the first 30 days of a claim. By collaborating closely with health care providers, WCB Nova Scotia introduced measures to make sure injured workers receive the right support and effective treatment from the start.

This approach, guided by medical disability guidelines, has been shown to resolve 80 per cent of cases within the initial treatment phase.

98 per cent of injured workers in Nova Scotia return to the job within 60 days

J. J. Keller & Associate, Inc. and the International Safety Equipment Association (ISEA) recently conducted a comprehensive study on top challenges around managing PPE procurement and proper usage. The “2025 PPE Pain Points Study: Top Trends and Challenges” results were released in March. To qualify to complete the survey, respondents had to have responsibility for purchasing and/or managing PPE across a range of industries.

Key findings included:

• PPE management is generally strong: Of those responding to the survey, 95 per cent completely or somewhat have the time and resources needed to properly assess PPE needs, and 70 per cent talk with their employees regularly about PPE.

• Getting employees to always wear PPE continues to be a challenge: More than 75 per cent of respondents reported that at least some of the time, they have difficulty getting employees to wear PPE.

• Durability is the number one criteria when purchasing PPE: More than one-third of respondents prioritize durability, followed by comfort, emphasizing the need for PPE

that workers can and will consistently wear.

• Challenges lay in finding PPE in larger and smaller sizes: While 75 per cent of respondents have not experienced problems buying PPE in the sizes they need, those who have had issues find difficulty locating larger and smaller sizes.

• Weather is a consideration, but there’s more opportunity here: While 84 per cent of respondents factor weather conditions into PPE purchases, there is a growing need for education on selecting PPE optimized for extreme temperatures.

• Women’s sizing is increasingly considered: More companies are prioritizing PPE designed for women, though nearly one-third of respondents still face challenges finding properly fitting options.

• Training is a challenge: Nearly half of respondents struggle with training employees on critical PPE usage aspects, including when PPE is necessary, how to properly wear it, and its limitations.

The full report can be downloaded from www.jjkellersafegear.com; ISEA members can download it from www.safetyequipment.org.

As part of its commitment to help move the needle on workplace health and safety, Ontario’s Workplace Safety and Insurance Board (WSIB) has partnered with the Canadian Centre for Occupational Health and Safety (CCOHS) to provide all WSIB-registered businesses free access to CCOHS’ Business Safety Portal.

The portal is an online hub offering industry-specific and scalable resources, like templates, online courses and practical manuals businesses can use to help make their workplaces safer and meet their legal obligations.

“We created the Business Safety Portal to address the unique health and safety challenges faced by these owners and employers. We’re proud to partner with WSIB as they roll out free access to the portal for Ontario businesses. We all share the goal of providing easy access to credible tools and resources that can help keep workplaces and workers safe,” said Anne Tennier, president and CEO of the Canadian Centre for Occupational Health and Safety.

WSIB-registered businesses can save up to $1,700 annually on the Business Safety Portal’s subscription fee. Nearly 1,000 businesses have already signed up.

“Access to these resources is a value-add for every Ontario business and has the power to improve health and safety outcomes and reduce injury rates,” said Jeff Lang, WSIB president and CEO.

To access the portal, businesses can log in to their WSIB account at www.wsib.ca.

The Canadian Centre for Occupational Health and Safety (CCOHS) has released a free Workplace Mental Health Toolkit to help Canadian organizations create a supportive environment for mental health at work.

The online toolkit aims to empower business owners, managers, and supervisors to build a workplace culture where employees feel safe, respected, and valued. It includes informative videos, practical checklists, infographics, posters, and podcasts to help develop a strong mental health program, address hazards and risks, and hold meaningful conversations about mental health with colleagues. It also makes the connection between mental health and other human rights issues. Together, the resources in the toolkit can help organizations create a psychologically safe and healthy workplace for all employees.

“Creating an environment where employees feel supported and valued not only improves their well-being but also strengthens organizations. This toolkit can help employers start their journey toward a mental health program in the workplace,” said Anne Tennier, president and chief executive officer of CCOHS.

For more information and to access the Workplace Mental Health Toolkit, visit www.ccohs.ca/workplace-mental-health-toolkit.

25_003440_OHS_Canada_Spring_CN Mod: April 2, 2025 9:06 AM Print: 04/08/25 4:02:07 PM page 1 v7

Marvara Farms Ltd. has been fined $175,000 after a worker was critically injured falling into an operating cardboard bale hopper.

The agricultural business, which operates a recycling and reclaiming factory in Drayton, Ont., pleaded guilty to failing, as an employer, to ensure that the measures and procedures prescribed by section 76 (where the starting of a machine, transmission machinery, device or thing may endanger the safety of a worker, (a) control switches or other control mechanisms shall be locked out; and (b) other effective precautions necessary to prevent any starting shall be taken) of Ontario Regulation 851/90 at a workplace were enforced, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

On Jan. 10, 2023, workers were on an elevated platform separating recycling onto various conveyors. Cardboard packaging was getting caught on two pipes that went across one conveyor.

A worker moved from the elevated platform to a sloped chute that led to the cardboard conveyor and attempted to clear the jam using a stick but was unable to do so. The worker then climbed further up onto the equipment near the end of the conveyer for better access to clear the blockage and was standing with one foot on a cardboard conveyor gearbox with the other foot on a conveyor pulley guard.

As the worker was freeing the cardboard, they slipped and fell into a running 70-inch-deep baler hopper.

A Ministry of Labour, Immigration, Training and Skills Development investigation revealed the cause of the incident was that all hazardous motion was not prevented before attempting to unjam the cardboard above the baler hopper.

The court also imposed a 25 per cent victim fine surcharge, as required by the Provincial Offences Act

Siltech Corporation fined $90,000 an employer, containers were bonded and grounded as required by section 22(4) (b) of Ontario regulation 851, contrary to section 25(1)(c) of the Health and Safety Act.

2workers injured, one fatally, in an explosion at a manufacturing facility in Toronto

On Sept. 8, were transferring flammable liquid from a large container into two smaller metal pails at the company’s manufacturing facility on Wicksteed Avenue in Toronto. While they were filling the second pail, an explosion occurred, injuring one of the workers and fatally injuring the other.

Section 22(4)(b) of Ontario regulation 851 requires containers and dispensing equipment to be grounded when liquid is disThis prevents electricity that could ignite the vapours and cause an explosion.

A Ministry of Labour, Immigration, and Skills investigation workers had used to transfer the liquid. Plastic cannot be bonded or grounded. The investigation found that the metal pails were also not grounded or bonded to the other equipment in the setup.

Though it remains unproven that the cause of the explosion was static electricity, Siltech Corporation still failed, as an employer, to ensure the pails and pump were bonded and grounded as required

Canadian General–Tower Limited has been fined $175,000 after a worker became caught in the pinch point of a machine and was critically injured.

The company, which produces polymericcoated textile fabrics and vinyl films for automotive and industrial applications, pleaded guilty to failing to ensure the worker was protected from the pinch point, as required by section 25 of Ontario Regulation 851/90, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

On Dec. 1, 2022, workers at an emboss station, where layers of material are combined and embossed onto rolls, noticed a defect mark on the finished product and were trying to determine where the mark was coming from.

A worker entered the emboss station while the machine was running to examine the roller surfaces. While inside, the worker’s gloved hand was caught between two counter-rotating rollers. These created a pinch point that critically injured the worker.

In addition to the fine, the court imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

Three companies have been fined $1.2 million over a workplace death in northern Alberta.

Suncor Energy Services Inc., Joy Global Canada Ltd., and NCSG Crane & Heavy Haul Services Ltd. each pleaded guilty to a charge under Alberta’s occupational health and safety rules.

Several other counts were withdrawn.

The province says the worker died after being hit by a piece of equipment that fell from a crane near Fort McMurray in July 2022.

It says the collective fine is to go to the University of Calgary, Mount Royal University and the University of Alberta to research rigging and hoisting practices.

The funds are also to be used to develop industry tools, recommend safety standards and set up an occupation health and safety research institute for Alberta.

- The Canadian Press

New Horizon Development Group (Waterdown) Inc. and TKEM Electric Ltd., have been fined a total of $230,000 after a fatality at a commercial construction project in Hamilton, Ont.

An electrician was running wire to the roof of a two-storey commercial building under construction on Aug. 16, 2022. While on the roof, the worker suffered a fatal fall to the ground below.

The roof had a parapet wall along its perimeter with no temporary fencing or guarding at the roof’s edge. Access to this part of the roof was from a stairwell that was not locked. The stairwell and roof had no signs warning about the fall hazard.

New Horizon pleaded guilty to failing to ensure there were warning signs posted about the fall hazard, as required by section 23(1)(a) of the Occupational Health and Safety Act The company was fined $130,000 as a result.

TKEM Electric pleaded guilty to failing to provide information, instruction or supervision related to the fall hazard as required by section 25(2)(a) of the Act. It was fined $100,000.

The court also imposed a 25 per cent victim fine surcharge on each company, as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

Saturn Tool & Die (Windsor) Inc. has been fined $180,000 after a worker was fatally injured while troubleshooting a stamping press at its facility in Oldcastle, Ont.

The company pleaded guilty to failing to ensure that the motion of any part of the press that could endanger a worker was stopped and blocked during maintenance work, as required by section 75 of Ontario Regulation 851, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

The charge stemmed from an incident on March 28, 2022, when a maintenance worker was called to troubleshoot a quality control problem with an Eagle 2750-ton stamping press.

The worker entered the press through its light curtain, which caused the press to stop operating. The worker did not lock out the machine by putting its ram blocks into place and plugging in the electronic lockout plugs.

Unaware that the maintenance worker was inside, another worker returned to the press, reset the light curtains and cycled the press, fatally injuring the maintenance worker.

A Ministry of Labour, Immigration, Training and Skills Development investigation found that it was common practice at the time of the incident for workers on the production floor not to use ram blocks for troubleshooting or maintenance work of a short duration.

In addition to the fine, the court imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

fatality

Fourwinds Construction Inc. has been fined $130,000 after a worker was fatally injured at a road widening project in Vaughan, Ont.

On Aug. 31, 2023, three workers employed by the company were installing a headwall, a wall of concrete with a hole near the middle that frames the outlet of a drainage pipe or culvert. As they attempted to fit the headwall to the pipe, the workers determined the excavation site was not wide enough to align the headwall, requiring further digging.

To clear the area for digging, the excavator operator moved the headwall and placed it in an upright position. Workers removed the chain sling from the excavator boom and attached the digging bucket.

While excavating to fit the headwall, the excavator bucket contacted the headwall, causing it to tip and fatally injure a worker.

Fourwinds Construction pleaded guilty to failing, as an employer, to ensure a headwall was moved and stored in a manner that did not endanger a worker, as required by section 37(1) of Regulation 213/91, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

The court also imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act The surcharge is credited to a special provincial government fund to assist victims of crime.

company fined $250,000 after four workers injured, two fatally

Direct Underground Inc. has been fined $250,000 after four workers were injured, two of them fatally, during the installa tion of a new underground sewer system in Ajax, Ont.

On Aug. 8, 2024, six workers employed by Direct Underground were installing a new catch basin system as part of a storm sewer for a road widening project.

conditions leading to

The investigation also found that there was no engineering opinion on the stability of the excavation wall, and no support system installed for the weaker layer of soil.

workers were injured, two fatally, while installing a new underground sewer system in Ajax, Ont.

While four workers were in the excavation to install the system, the north wall of the excavation collapsed, resulting in fatal injuries to two of the workers and non-fatal injuries to the other two workers.

An investigation by the Ministry of Labour, Immigration, Training and Skills Development found that the excavation wall had a weaker layer of soil present, which was classified as Type 3 per Ontario Regulation 213/91. This required shoring or appropriate sloping of the walls to prevent unstable

Direct Underground Inc. pleaded guilty to failing to ensure that the walls of the excavation were supported by a shoring system or appropriate sloping of the walls that complied with sections 235, 236, 237, 238, 239 and 241 of Ontario Regulation 213/91, as required by section 234(1) of the regulation, contrary to section 25(1)(c) of the Occupational Health and Safety Act.

In addition to the fine, the court imposed a 25 per cent victim fine surcharge as required by the Provincial Offences Act. The surcharge is credited to a special provincial government fund to assist victims of crime.

$420,000

A Calgary-based machine shop has been ordered by Alberta’s top court to pay a six-figure fine after one of its workers died on the job in 2019.

Inland Machining Ltd. was found liable in October 2023 after an employee was fatally injured while operating a manual lathe and became entangled in a moving part.

The company appealed on the grounds the sentence was excessive, but the bid was dismissed in November by an appeal court judge.

The province says the 30-day period to file further appeals has now expired and the company is to pay $420,000.

Alberta officials say the counts relate to failing to ensure the health and safety of a worker and failing to provide safeguards to protect against contact with moving parts of equipment or machinery.

- The Canadian Press

By: Superior Glove, leading safety glove innovator

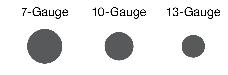

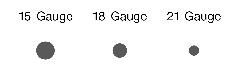

From cotton to nylon to aramids, string knit safety gloves offer various levels of hazard protection and are typically classified by their gauge, ranging from 7-gauge to 21-gauge. But what is glove gauge and how does it affect glove performance?

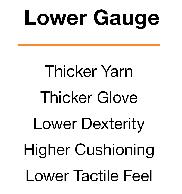

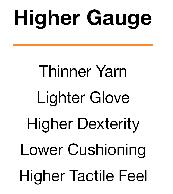

Gauge refers to the number of stitches per inch of knit material. As the number of stitches increases, so does the gauge. Simply put, glove gauge is a way to refer to glove thickness.

Traditionally, workers have relied on lower-gauge gloves for high-risk tasks as they provide a thicker barrier from penetrating the material. However, thicker gloves make precision work impractical as they lack dexterity and tactile feel. Thanks to technological advancements in manufacturing yarn, we can now integrate high levels of mechanical protection like extreme cut resistance into higher-gauge gloves.

Higher-gauge gloves (18-gauge to 21-gauge) are more dexterous because they are thinner and lighter, offering more flexibility and a higher tactile feel. This makes them ideal for tasks that require fine motor skill and precision work.

Medium-gauge gloves (13-gauge to 15-gauge) offer some more cushioning than higher-gauge gloves but more dexterity than lower-gauge gloves.

Lower-gauge gloves (7-gauge to 10-gauge) are less dexterous, because they’re thicker and less flexible and have a lower tactile feel. These make them a better option for heavy material handling that requires more cushioning but less dexterity.

Generally, lower-gauge gloves are more durable because they are thicker. This is why, lower-gauge gloves are often the preferred option for tasks that are rough or abrasive. Additives like palm coating can also significantly improve durability of high-gauge gloves.

Ready to find what you’re looking for? Visit superiorglove.com to explore the wide range of string knit safety gloves and other products—plus request free samples.

By Norm Keith

The world of work is changing in Canada. New technologies, an aging population, the upcoming great wealth transfer, immigration trends, new markets for goods and services, and ongoing geopolitical challenges will all affect the jobs of the future. As the Canadian labour market changes, so do the job hazards, risks of injury, and organizational and societal costs. This article, the first in a series of three, will address trends in the labour market and how they may affect workplace safety. Subsequent articles will address the costs and risks of neglecting workplace safety and the positive organizational opportunities associated with improving workplace safety.

Every year in Canada, hundreds of thousands of workers are injured on the job. The rate of injury and death in the workplace is higher than in the United States. Occupational injuries undermine the overall well-being of workers, their families, their co-workers, their employers, and their communities. Workplace injuries impact the cost of doing business and the legal risk of liability for employers, officers, and directors. This article investigates how the changing labour market may affect these important concerns for all workplace stakeholders.

Data relating to workplace injuries can assist in predicting future risks and opportunities for improvement. The most widely available Canadian injury statistics come from the Association of Workers’ Compensation Boards of Canada (AWCBC) and give us a dire picture. Also, the AWCBC underreports the total number of

worker injuries since it only reports injuries in workplaces governed by worker compensation legislation. Therefore, for a broader data set, we looked at the AWCBC data, as well as data from Statistics Canada and the U.S. Bureau of Labor Statistics.

Every year in Canada, hundreds of thousands of workers are injured on the job.

The first challenge in our review was to determine what types of jobs may increase, stay the same, or decrease in demand over the next decade. The most recent jobs report from the federal government provides a helpful snapshot of the current labour market. Statistics Canada data from 2024 shows that overall employment has increased by 2.1 per cent. Public sector job growth was 3.7 per cent and was more than double private sector job growth of 1.4 per cent. The highest job growth was in the following sectors: health care and social services; education services; transportation and warehousing; building support services;

technology development and support positions; and food services. Even amid 2024’s housing crisis, there was negative job growth in Canada’s construction sector.

Second, we obtained research from several sources examining predicted job growth in the Canadian labour market for the next 10 years, improving the quality of the information relied upon for this analysis. The federal government has predicted that the top five job growth categories for the next 10 years will be: (1) health care; (2) computer systems design and related services; (3) support activities for mining, oil, and gas extraction; (4) social assistance; and (5) legal, accounting, consulting, and other professional services.

Another list of the top five jobs of the future, this time from Fanshawe College, is as follows: (1) nursing aides, orderlies, and patient services; (2) registered nurses and registered

psychiatric nurses; (3) transportation and truck drivers; (4) information systems specialists; and (5) retail sales supervisors. Yet another source, Immigration.ca, lists the following top five jobs of the future: (1) computer software developer; (2) registered nurse; (3) construction project manager; (4) warehouse worker; and (5) welder. The online recruitment service Indeed.ca identifies the following “best future jobs” as follows: (1) physical therapist; (2) nurse practitioner; (3) registered nurse; (4) dental hygienist; and (5) optometrist.

In a report on the subject, the Brookings Institution, an American think tank, concluded: “… job growth will be driven by the health care and computer sectors.” This conclusion supports many of the above predictions about future job growth in Canada. The Canadian economy is more resource-based than the U.S., which will likely affect future job growth. Factors that may affect future labour market trends for Canadian workers may include the global demand for rare earth minerals for electric vehicle batteries and electronic devices (mining), building materials demand after recent wildfires in Jasper, Alta., California, and other locales (logging, lumber, and construction materials), and food security and local sourcing initiatives (agriculture).

Third, we assessed the risk of workplace injury to workers performing these “jobs of the future.” This analysis was based on data from the most recent workplace injury statistics and applied to the growth jobs of the future. According to the AWCBC, the total number of reported lost time injuries in Canada in 2022 was 348,747 and the total number of workplace fatalities in Canada was 993. For that same year in the United States, there were 1,483,400 injuries and 5,486 fatalities. Canada, with a population of

Canadian workers generally have a significantly higher risk of death and more than double the risk of workplace injury than American workers.

38,940,000 in 2022, had about oneninth of the population of the United States. Therefore, Canadian workers generally have a significantly higher risk of death and more than double the risk of workplace injury than American workers.

Looking more closely at the worker injury data for 2022, the highest incidence of lost time injuries in Canada is neither intuitive nor obvious. The occupations with the most injuries according to the AWCBC data are as follows: (1) health care and social assistance; (2) manufacturing; (3) construction; (4) retail trade; and (5) transportation and warehousing. This ranking is based on total and not per capita injury rates.

The fourth step in our review was to compare future labour market predictions with the current injury rates in those occupations. In other words, what risk of workplace injury do the jobs of the future have in Canada? In our view, the data suggests that most occupations with predicted high labour market demand in Canada fall into either a medium- or high-risk category. Some in-demand jobs of the future, such as computer software development, technology servicing, retail, and hospitality jobs, pose a lower risk of injury, according to the AWCBC data. Health-care and direct care workers, manufacturing, transportation, and warehousing, and (perhaps) the construction sector fall within both the high growth and medium to high risk of workplace injury category for the next 10 years. This is where the risks and costs associated with worker injuries and fatalities are the greatest.

The health-care worker category

has the highest incidence of workplace injuries, including workplace violence and worker compensation lost-time claims. Moreover, the global demand for rare earth minerals, which Canada has in abundance (mining), new home construction and renovations (construction), and the large number of imports from foreign jurisdictions (transportation and warehousing) all involve highrisk occupations. Therefore, we predict that many, but not all, of the high growth jobs in the next 10 years have a high risk of worker injury.

The future risk of worker injury, however, is not set in stone. The conclusions assume that current trends do not change. However, many employers and industries with high-risk jobs have demonstrated that safety improvement is possible. For example, after the Westray mine explosion, the Canadian mining sector changed its once disastrous safety record to become one of the safest industries in Canada. Our finding about jobs of the future having medium to high risk of worker injury is a story that is not yet written.

Now is the time to address the next two subjects of this series: What are the real costs of worker injuries to all workplace stakeholders, and how can Canada’s poor safety record be turned around?

In conclusion, as the Canadian labour market changes, so do the risks of workplace injuries. The data and analysis raise concerns for OHS regulators and all workplace stakeholders. Past trends of occupational injuries need not be repeated if their causes can be identified and proactively corrected. Constructive initiatives are required now to change this predictive trend. The next article in this series will address the costs and risks of doing nothing, while the final article will offer some recommendations to address these findings.

The Canadian Centre for

Scents have the power to delight or offend us.

Fragrances found in perfumes, soaps, lotions and other products, like a hint of vanilla or a whiff of lemon, are intended to be pleasurable and even stress-relieving. On the other hand, smells associated with industrial settings or workplace renovations – the smell of paint, carpet glue or industrial cleaning products – tend to be viewed as irritating. Regardless of the source, scents can be more than a matter of preference or a petty annoyance for workers who are sensitive. Exposure to scents can trigger migraines, allergic reactions and many other sometimes debilitating symptoms.

When employers take scent sensitivities seriously, they fulfill their legal duty to accommodate while demonstrating their consideration of everyone in the workplace. A great place to start is by gathering information on how scents are already affecting people in the workplace, then using that information to develop an appropriate policy. Clear communication, education, and ongoing collaboration will help ensure your scent-free policy is successful.

Fragrances can enter the body through inhalation, ingestion, or absorption through the skin. If a person is wearing a fragrance, they may experience irritation or an allergic reaction after using a perfume, cream or lotion.

It is important to remember that scents can affect not only the person wearing the product but also anyone else who may be exposed. In addition to personal hygiene products and

cosmetics, fragrances are also added to products such as laundry detergents, cleaners, air fresheners, soaps, and some types of garbage bags, to name just a few examples.

The affected person might experience a range of symptoms such as nausea, dizziness, headaches, itchy skin, hives, itchy eyes and nose, and a runny nose. They may also experience wheezing, coughing, difficulty breathing, a sore throat, asthma or asthma-like symptoms, and strange tastes in their mouth.

One of the best ways to prevent a reaction is to avoid exposure to products that have fragrances. This can be a challenge considering how many chemical fragrances are present in so many of the products we use every day. Reading and understanding product labels can

help. Look for “perfume-free” or “fragrance-free” products, which are the most likely to contain no fragrances.

Unscented vs. fragrance-free

B e aware that products labelled “unscented” are not necessarily fragrance-free. According to Health Canada’s labeling regulations, the terms “fragrance-free” or “unscented” mean that no fragrances have been added to the cosmetic product, or a masking agent has been included to hide the scents from the other ingredients in the product. Fragrances used in products are not always labelled as ingredients. Fragrance formulas, which can be a product’s trademark, are often well-guarded trade secrets, making

it challenging to link reactions to specific ingredients.

It’s an employer’s duty to protect workers with scent sensitivities by promoting air awareness. If your workplace doesn’t have a scent-free policy, here’s how to get started. Conduct an assessment or survey workers to understand the extent of the workplace needs. Collect opinions and suggestions to help inform and develop a policy that is appropriate to your workplace. Your survey questions should indicate if workers are or have ever been affected by scented products, if they support the organization becoming scent-free, and give them an opportunity to offer recommendations and solutions. Once your assessment is complete, you’ll need to designate a key person to oversee the policy’s development. You could also create a committee with representation from all groups, such as health and safety committee members or representatives, workers, unions, and management.

I nform and educate workers about health concerns related to scents and why the policy is needed. Include information on your organization’s intranet, screensavers, and internal newsletters. Everyone has a role to play to keep the air at work healthy, so make it clear the policy applies to everyone at the workplace, including visitors. Also be clear about what the next steps will be for the products used, brought in, or worn in the workplace.

In addition, workplaces should try to identify the specific source of the issue. If it’s building-related, reduce all emissions from building materials, cleaning products, and other sources. Keep indoor air quality high by ensuring that fresh air is regularly introduced and that scents are not recirculated throughout the building.

Everyone has a role to play to keep the air at work healthy, so make it clear the policy applies to everyone at the workplace, including visitors.

Review all safety data sheets for products that may be scented. When replacing these products, check the ingredients. Some products claim to be scent-free but use additional chemicals to mask smells instead of truly being unscented. If there will be construction, remodelling, or painting activities in the workplace, support workers with sensitivities by making alternate work arrangements or modifying their duties.

Request that workers not wear fragrances or use scented products. It may be helpful to post a list of unscented personal care products on a notice board for workers to easily source.

In some cases, approaching someone who continues to use or wear scents might be necessary. This request may come from human resources, the supervisor, management or the union according to terms of the policy and procedures as established by your organization. The person affected by the scent should not have to be the one to approach the individual responsible for the scents, nor do they need to be identified. Describe what actions will be taken. For example, they may be asked to wash or remove fragrances, change their clothes, or work in a separate room.

Finally, make sure the policy can be easily referenced by posting it on notice boards and in common areas, and by having workers acknowledge it as part of your business procedures.

It’s important that everyone in the workplace understands why the policy is being implemented and how they can contribute to making

the workplace a healthier space for all. Give presentations on the importance of being air aware. Let workers know the policy is being introduced because of health concerns, not because of anyone’s personal preference or a dislike of certain smells.

Communicate that better air quality benefits everyone. Reducing reliance on scented products and opting for fragrance-free alternatives can lead to fewer workplace irritants overall, improving general health and comfort.

Creating a scent-free workplace is about more than writing a policy – it’s about fostering a culture of respect and inclusion. Scent sensitivities can have serious health consequences, and for affected individuals, exposure to certain fragrances is not a minor inconvenience but a genuine barrier to their well-being. Taking proactive steps to eliminate unnecessary scents makes for a more accommodating working environment where everyone can perform their duties without the risk of discomfort or illness.

R emember : making reasonable accommodations for scent sensitivities is a human rights issue. Creating a workplace that is truly safe and healthy means considering scent- s ensitive workers and protecting them with an inclusive policy. Ultimately, ensuring a safe and accommodating workplace for those with scent sensitivities is a matter of equity and respect. By creating and maintaining a scent-free policy, employers send a strong message: every worker’s health matters. Through education, awareness, and thoughtful policy development, organizations can pave the way for a more inclusive, productive, and healthier work environment for everyone.

In an increasingly interconnected world, globalization is transforming occupational health and safety (OHS) in workplaces across Canada and beyond. As organizations expand across borders, so too do the challenges of maintaining consistent safety standards. However, this global shift also brings opportunities, allowing countries to collaborate, share leading practices, and improve workplace safety on an international scale. For more than 75 years, CSA Group has been at the forefront of OHS standards development, shaping policies that influence not only Canadian workplaces but also the North American and global OHS landscape.

C SA Group’s Candace Sellar explains how globalization is reshaping OHS, how CSA Group’s leadership is driving international and bi-national standardization, and how Canadian OHS professionals can engage in shaping the future of workplace safety.

How is globalization influencing OHS in workplaces?

Canada is home to many multijurisdictional and multinational enterprises (MNEs) spanning diverse sectors such as manufacturing, natural resources, and professional services. As these organizations operate across jurisdictions, they significantly influence OHS in the workplace. MNEs can adopt leading OHS practices and standards from one region and implement them globally, which may enhance workplace safety worldwide.

The workforces of MNEs are also becoming increasingly varied in terms of language, religion, cultural norms, and physical characteristics.

This shift compels organizations to define worker needs more precisely and understand workplace hazards in a broader context. It is crucial that OHS standards reflect the wide range of workers’ needs.

CSA Group is strategically developing standards with these factors in mind, as seen in CSA Z301:24, Equity, diversity, inclusion, and accessibility in apprenticeship programs. This standard applies to all aspects of apprenticeship systems, including classroom learning, mentorship, and on-the-job training, supporting an inclusive approach to worker safety and development.

How have CSA Group OHS standards demonstrated thought leadership and influenced standards development on a global scale?

Canada has a strong tradition of innovation and collaboration in workplace safety, and CSA Group has played a key role in shaping OHS standards both nationally and internationally.

One major example is CSA Z1000, Occupational health and safety management, which was an important foundational document considered for ISO 45001, Occupational health and safety management systems – Requirements with guidance for use. CSA Z1000 introduced key concepts, such as proactive risk management, systematic hazard identification, worker participation, and leadership commitment, which became core principles in ISO 45001. Similarly, Canada was a pioneer in addressing workplace mental health. CSA Z1003-13/BNQ 9700-803/2013 Psychological health and safety in the workplace – Prevention, promotion, and guidance to staged implementation

CSA Group is a global organization dedicated to safety, social good, and sustainability. It is a leader in standards development and testing, inspection, and certification around the world, including in Canada, the U.S., Europe and Asia. CSA Group’s mandate is to hold the future to a higher standard.

was a first-of-its-kind publication that later informed ISO 45003:2021, Occupational health and safety management – Psychological health and safety at work – Guidelines for managing psychosocial risks.

Another example is CSA B701:17, Carer-inclusive and accommodating organizations. This standard influenced the development of ISO 25551:2021, Ageing societies – Guidelines for carer-inclusive organizations – addressing an increasingly critical issue as global populations age. Through contributions like these, CSA Group continues to help shape OHS standards that improve workplace safety worldwide.

Given recent political pressures on trade, does it make sense to have multi-jurisdictional or binational standards?

Cohesive cross-border or international standards are as important as ever today. Organizations often extend beyond political boundaries with workplaces in more than one country or jurisdiction, and workers often move between jurisdictions as part of their jobs. To support consistency, CSA Group collaborates

with American standards development organizations to align safety standards wherever possible.

For instance, CSA Z462:24, Workplace electrical safety, is based on NFPA 70E, Standard for Electrical Safety for the Workplace. The CSA standard integrates key elements from NFPA 70E while aligning with the Canadian Electrical Code, supporting consistent electrical safety measures across North America.

Additionally, CSA Group adopts numerous American National Standards from the Outdoor Power Equipment Institute (OPEI), covering hand-held outdoor power equipment such as grass or hedge trimmers, and portable cut-off machines. This harmonization helps facilitate seamless use of equipment and safety protocols throughout the continent.

How do CSA Group OHS standards help to promote regulatory harmonization within Canada?

Regulatory harmonization efforts are coordinated and championed by the Canadian Association of Administrators of Labour Legislation –Occupational Safety and Health

(CAALL-OSH), which supports over 1.22 million employer businesses nationwide. To enhance consistency and efficiency, CAALL-OSH often references CSA Group standards in national policy development.

Harmonization of OHS regulations across all provinces, territories, and the federal government, including harmonized references to OHS standards, is beneficial to all Canadians. For employers, it simplifies compliance and may reduce administrative costs. For workers, it supports consistent safety training and awareness, while regulators benefit from improved enforcement and oversight. Furthermore, harmonization can support trade by helping products and services meet uniform safety standards.

Approximately 70 per cent of CSA Group’s OHS standards are directly referenced in regulations, with 13 standards nationally harmonized across all jurisdictions, including, but not limited to the following:

• CSA Z94.1:15, Industrial protective headwear – Performance, selection, care, and use

• CSA Z94.2:14, Hearing protection devices – Performance, selection, care, and use

• CSA Z94.3:15, Eye and face protectors

• CSA Z94.4.1:21, Performance of filtering respirators

• CSA Z195:14, Protective footwear

• CSA Z1210:17, First aid training for the workplace – Curriculum and quality management for training agencies

• CSA Z1220:17, First aid kits for the workplace

What international OHS standards is CSA Group currently monitoring and contributing to?

CSA Group staff and expert volunteer members are always monitoring and contributing to the work of the International Organization for

Standardization (ISO) Technical Committee (TC) 283 on Occupational Health and Safety Management Systems (OHSMS).

This includes contributing to the ongoing development and revision of key standards, such as ISO 45001, Occupational health and safety management systems – Requirements with guidance for use. Other emerging areas of focus include OHS risks related to climate change, remote work, and workplace considerations for menstruation and menopause.

Notably, Troy Winters, vice chair of CSA Group’s OHS Strategic Steering Committee and CUPE’s national health and safety co-ordinator, was appointed the role of convenor of the ISO Working Group to revise and update ISO 45001, further solidifying Canada’s leadership in OHS standardization.

How can Canadian OHS professionals engage with CSA Group on international standardization priorities for the benefit of Canadian workers, employers, and regulators?

Canadian OHS professionals can directly contribute to standards development by volunteering with CSA Group. CSA Group currently administers the Canadian OHS Mirror Committee for work being completed by ISO TC 283. The mirror committees are established, approved, and operated under the authority of the Standards Council of Canada (SCC). CSA Group works collaboratively with the SCC to help capture and articulate the knowledge and perspectives of leading Canadian experts, and to convey this critical input to the international community. By participating in CSA Group’s committees, professionals can help advance worker safety, drive regulatory alignment, and strengthen Canada’s leadership in global OHS standards.

By Era Poddar, PhD, CCPE

Era Poddar is the director and principal ergonomics consultant of Ergoera Services Inc., based in Langley, B.C.

Incorporating human factors and ergonomics (HFE) is an effective method to address occupational health and safety (OHS) challenges in industrial settings. The benefits of ergonomics extend well beyond merely preventing musculoskeletal injuries (MSIs) or carrying out an office assessment. For decades, HFE has been practiced as a system level subject with the aim of improving productivity and human performance and reducing system errors.

Despite this, in many countries, ergonomics is frequently linked solely to occupational health and safety legislation. As a result, companies often fail to integrate ergonomics into their strategic planning. However, practitioners have always recommended including HFE considerations at an early design stage. Numerous international studies support this, finding that incorporating ergonomics early in the strategy and design process reduces operational costs through injury reduction, and also significantly enhances productivity and ensures quality of the product. These benefits can only be achieved if HFE inclusion is considered at the strategy level.

The early inclusion of HFE is a wellestablished method within many industrial engineering projects. However, its application in industry, particularly within manufacturing, tends to be reactive rather than proactive. In sectors where manual handling interfaces with advanced automated systems, the complexity of situations increases. Ideally, continuous operations, automation, an aging workforce, and fluctuating production rates will necessitate ongoing consideration of HFE at the systemic level. However, incorporating HFE principles or involving HFE professionals typically occurs after reported incidents or regulatory mandates. This delay hampers risk management at the source, complicates the provision of

economically viable solutions, and leads to retrofitting efforts. Consequently, HFE is frequently viewed as an additional burden with associated costs for the company, which ultimately diminishes the efficacy of the discipline.

In practice, HFE professionals are often engaged following an incident. We submit a report containing recommendations, and what happens next is beyond our control. Companies with a substantial international presence, a well-developed safety culture, or larger budgets may integrate these recommendations into new design updates. Conversely, companies with limited awareness or a less developed safety culture may use these reports merely to meet regulatory requirements without necessarily implementing the suggested changes.

Consider the example of a meat processing company (Company A), which received an order from the regulatory authority due to high occurrences of musculoskeletal injuries (MSIs) and inadequate ergonomics controls. After multiple orders, an HFE consultant was engaged to conduct an MSI risk assessment. MSIs, particularly cumulative trauma disorders, are common in the meatpacking industry, and this case was no exception. Job functions such as meat preparation, meat cutting, packaging, and docking stations were identified as having high to very high musculoskeletal disorder (MSD) risk.

The primary postural risk factors observed included: repetitive motion of the hand, arm, and wrist; static body posture with twisting, forward bending, trunk flexion and rotation; reaching overhead (shoulder abduction and adduction); neck flexion; wrist flexion; extension; pinching; and gripping. Some of these postures were adopted while handling loads exceeding 120 pounds. These postural risk factors have been associated with back, shoulder, and wrist injuries. Various system and workstation design issues (such as poorly designed assembly

components, inefficient workstation arrangement, inadequate space allocation, and poor anthropometric considerations) were identified, which may have contributed to workers adopting poor postures.

The local regulatory authority had already classified this workplace as potentially high risk and indicated that Company A needed to develop an MSI control plan. Following a risk assessment, several recommendations were made, including engineering changes and administrative controls.

During the site visit, the HFE professional observed and reported that the employer had already invested in and procured machinery with a view to improving systems. However, these investment decisions were made without proper consideration of the current job processes or risk assessments. Neither the employees (including the safety manager) nor an HFE professional were involved or consulted in this process. It was frequently noted that management strategies tended to focus on a single factor at a time, such as enhancing productivity through automation or employee motivation. Nevertheless, more comprehensive approaches tend to be more successful than one-dimensional strategies.

The report and recommendation presented to Company A’s management indicated that incorporating HFE at an early stage of design would lead to cost savings and improved return on investment. This approach would also enhance productivity and improve system safety.

This real-world industry case demonstrates that responses to the control of MSD risks are frequently reactive. The field of human factors and ergonomics has much more to offer beyond risk assessment; it can address major business and societal challenges related to work and product/service systems. It is, therefore, practical for regulatory bodies, HFE practitioners, and industry stakeholders to collaborate and engage in ongoing discussions to achieve sustainable results by integrating human needs into business strategies and enhancing system safety.

Bulky gloves slow you down, especially on oily surfaces.

The new G-Tek® Paradox™ by PIP® changes everything: 21-gauge construction with A4-A7 cut resistance delivers a true second-skin feel. Lightweight yet durable, it preserves full dexterity without compromising protection. Safety shouldn’t mean sacrificing performance.

Systems are already being deployed and many more are on the horizon

By Treena Hein

It seems a safe bet that within a few short years, some degree of artificial intelligence (AI) will be found in just about every occupation, whether to improve efficiencies and enable better decision-making or better protect health and safety. Many occupational health and safety (OHS) applications for AI are already available, and use is growing. “As we’ve seen AI technologies mature, so have the benefits,” explains Dave Chalmers, product vice-president at SafetyCulture, a U.S. maker of workplace AI platforms. “These technologies boast not just speed and accuracy but also the ability to detect and predict, so organizations can take a proactive approach to risk management.”

The power of AI lies in its ability to monitor and analyze vast amounts of data. In workplace settings, this means it can monitor and analyze the entire health and safety picture – environmental, equipment and human behaviour data, from ambient gas composition and machine motor temperature to physical obstacles and signs of human fatigue. Then, as needed in real-time, the AI can alert workers to risks and even direct emergency response. When connected to cameras and sensors, AI can also analyze worker movements to detect things like improper equipment handling to prevent long-term strain injuries.

At the same time, AI oversight supports better compliance, notes Chalmers,

reducing the risk of fines, legal battles and compensation, and damage to an organization’s reputation. AI can also enhance safety training through using virtual reality and other types of interactive learning, all in an environment free of the risks associated with actually handling hazardous materials or working at heights, to name just two examples. Using drones and computer vision technology, advanced AI systems can eliminate the need for humans to be physically present in high-risk inspection scenarios. The applications really are endless.

Of course, the more data AI has, the more useful it is. In the big picture of workplace health and safety, AI can identify patterns, point out if one shift or location is having more safety incidents than another (and provide some insight into why), highlight areas for improvement and much more. All of this information enables leaders to make the best decisions about updating safety protocols, investing in new tech and more. (At the same time, of course, data needs to be protected and used ethically.)

Because AI is only as good as the data it’s provided, Chalmers says that the best results are seen when these systems have complete visibility across an organization’s entire operations. “Businesses are often using multiple systems for different aspects of their safety management, creating complexity and a data disconnect,” he explains.

“When safety management systems are integrated and speak to each other, that’s when organizations will unlock the most valuable insights and opportunities.”

In his view, leaders also need to execute AI rollout in tandem with people management, including education and training. “One approach we’ve seen work successfully, internally and with our customers, is identifying internal champions within teams that can support and advocate for the project from the outset,” Chalmers explains. “These champions … spot opportunities for technology to help workplaces run safer, smoother and better, connecting frontline workers and leaders, and rallying teams to drive change. They can work hand-in-hand with AI models to speed this up, but personal experience and expertise will always be critical to this process. Champions can make or break the success of a project, especially if there’s internal resistance to change, or a perceived ‘top-down’ rollout mandate.”

S ukhDev Mishra at India’s National Institute of Occupational Health can

provide more insight into what influences the integration of AI solutions in workplace health and safety. In his view, these are primarily the level of risk to which workers are exposed, the availability of reliable AI-driven solutions, and cost. He recently published an overview of AI implementation in workplace settings with his colleague, Immad Shah, in the Journal of Occupational Health.

These three factors are connected to specific industries. “Certain sectors such as agriculture, logistics and manufacturing are leading the way due to the relative ease of implementation and the availability of AI solutions tailored to their specific risks,” Mishra says. “While many companies express interest in adopting AI for hazard detection, predictive maintenance and behaviour monitoring, they are still evaluating their options to ensure minimal disruption to existing operations.”

Mishra also notes that, in general, the pace of AI development in occupational health and safety is relatively

slower compared to high-priority domains like healthcare, finance and autonomous systems. AI solutions fundamentally rely on well-structured, high-quality datasets, he says, “Yet OHS data is often fragmented, inconsistent or lacks the granularity needed to develop robust predictive models. Unlike healthcare and finance, where standardized data collection has been in place for years, workplace safety data is still evolving, making AI adoption more challenging.”

Another major limitation to AI adoption in OHS is stiff competition for AI talent and computational resources, with these tending to go to industries that directly drive business growth like e-commerce and the development of new technologies for widespread sales to the public. “Workplace safety, while critical, often remains a compliance-driven function rather than a core investment area, which slows down funding and innovation,” notes Mishra. However, he also says AI in

OHS is expected to gain momentum “as industries recognize its long-term benefits in cost reduction and efficiency improvements.”

Among the AI-enabled devices now available, Mishra and Shah point to “smart helmets” equipped with a sensor array – for example GPS, RFID, ultra-wideband sensors, an aroundview monitor and even air quality sensors. This means that instead of sensors being located in the worker environment, the worker’s wearable device can collectively monitor worker location, activities and even the surrounding environment for improved individual health and safety.

Battery-powered exoskeletons are one example of AI-enabled devices that can help protect the health and safety of workers. These wearable robotic suits enhance the function of muscles and joints, preventing injury while also boosting productivity.

Battery-powered exoskeletons are another example of AI-enabled OHS devices. These wearable robotic suits enhance the function of muscles and joints, preventing injury while also boosting productivity. Germanybased German Bionics is a global leader in exoskeleton development. “Over the past two to three years, and especially into late 2024 and early 2025, we’ve observed a significant increase in interest … across multiple sectors,” reports Thomas Leliveld, director of operations for North America. “The most active industries remain logistics and manufacturing, as these environments are characterized by physically demanding, repetitive tasks.”

He explains that the company’s exoskeleton provides appropriate external energy through actively learning and adapting to individual users’ movements. “Unlike passive or hybrid exoskeletons, which require users to expend energy to receive support, our system delays the onset of fatigue,” he says. “As a result, workers experience greater stamina and endurance, increasing their potential output while protecting their health and well-being. Handling tasks require less effort, making movements easier and often faster. Users benefit from up to 36 kg (80 lb) of support per lifting movement,

active walking assistance and counterforce capabilities for protecting the back when lowering loads or working in bent-over postures.”

ROI calculations for these types of devices encompass injury rates, productivity gains and many other factors, but because jobs are made easier with these devices, easier recruitment and retention should also be considered.

Leliveld is very positive about the future of AI-enabled devices like exoskeletons in health and safety, predicting that they will play an increasingly critical role in individualizing support. “As the technology continues to advance, motion control, power assistance and overall comfort will become even more precisely optimized to meet individual needs,” he says.

Looking at AI in OHS in general, Chalmers says that the effectiveness of AI in workplaces will be realized in how much it enhances decision-making and other human capabilities. And while in his view, “there remains a high level of skepticism about AI amongst [health and safety] professionals that needs to be addressed,” he also believes “the role of AI in safety management is only going to become more prominent, and organizations that fail to embrace it will ultimately fall behind.”

Mishra predicts that over the next five years, AI adoption in OHS is likely to progress at different rates in different areas, depending on industry, regulatory frameworks and tech readiness. “Predictive analytics, hazard detection and real-time monitoring are expected to see increased use, particularly in high-risk industries like

construction, mining and manufacturing, where AI solutions can offer measurable safety improvements,” he says. “However, adoption may be slower in sectors with lower perceived risk or constrained budgets, though advancements in cost-effective AI solutions and regulatory incentives could influence this trajectory.”

Over the next 10 years, he believes AIdriven automation, wearable technology and digital twinning could become more widely integrated into safety protocols, leveraging coming advancements in machine learning, the Internet of Things and robotics. “Industries that prioritize workforce safety as a key

Balance AI and human oversight.

AI can perpetuate biases within the data it’s trained on and present other hazards. Ensure human oversight is still present.

Ensure employee understanding.

Lack of training can result in misuse, misinterpretation or mistrust of AI systems.

Data security.

AI systems can analyze vast amounts of personal and operational data, from worker behaviour to health information. Anonymize or aggregate worker data to protect personal information, ensuring compliance with data privacy laws.

operational metric, such as logistics and hazardous environments, are likely to lead in adoption,” says Mishra. “Meanwhile, AI’s role in ergonomic assessments, mental health monitoring and adaptive safety systems could become more pronounced.”

Overall, he believes the rapid evolution of AI presents both opportunities and challenges in OHS. “The key to widespread adoption,” he says, “will be the development of scalable, reliable, and cost-effective solutions that can seamlessly integrate into existing safety protocols.”

Focus on real-time applications.

Being proactive beats the best reactive solution. Real-time monitoring applications such as hazard detection, predictive maintenance and behaviour analysis allow companies to prevent accidents before they occur.

Start small and scale gradually.

Integrating AI into safety management systems may disrupt existing processes if it’s adopted too quickly. Start with smaller, more manageable projects to test AI in controlled environments, then gradually adjust the approach based on feedback and lessons learned.

SOURCE: SAFETYCULTURE.

By Wayne Arondus

When we hear daily news about new tariff threats and trade posturing, our health and safety programs aren’t the first things that come to mind.

As tariffs and retaliatory measures continue, we are faced with many choices: where to shop, what to buy, how to support Canadian producers, and more. And at work, we face difficult decisions as we prepare for the business impacts.

B ut in our business decisions, often overlooked are the potential risks and impacts of our actions on the safety and psychological wellbeing of our teams.

Some manufacturers and processors are already anticipating the possibility of slowdowns, layoffs, and even potential plant closures. As these companies brace for an economic downturn, these shifts within the manufacturing environment will echo through the halls of manufacturing facilities and into the minds of workers.

It’s natural for workers to worry for their jobs, their finances, and how they will be able to keep their families afloat. The water cooler talk will be about what they think the impacts will be, who might lose their jobs, which departments might see cuts. Whether you are a worker, supervisor, manager, or business leader, there is no way for any of us to switch off these worries and pretend that these things don’t matter.

For some, these worries can spiral into crippling anxiety. For others, the distraction could cause a momentary lapse of attention or judgement that, in the best-case

scenario, is a near miss, and in the worst, could lead to a catastrophic injury or fatality.

Leaders need to recognize that no one likes surprises at work. Proactively addressing worker concerns and doubts can bring down anxiety levels and build trust.

A s parents, we often think that what our children don’t know won’t hurt them; and many apply this same strategy to their workplace teams. However, pretending that nothing is going to change and not addressing the elephant in the room breeds distrust. It can also undermine your team’s mental well-being and ability to respond and adapt. Leaders need to recognize that no one likes surprises at work. Proactively addressing worker concerns and doubts can bring down anxiety levels and build trust.

Instilling a culture of transparency is not easy, but frank and frequent communication is crucial to ensuring that workers are less distracted and more present. Let your teams know what’s coming next and what major impacts might be on the horizon – even if you aren’t sure what the impacts will be. This transparency will help workers focus better on doing what they do best while ensuring that you and your team are able to find alternatives and respond to new opportunities that may arise.

We need to be mindful as owners, managers, and supervisors of the psychological impact of uncertainty

on workers, not only in response to tariffs and a decline in trade, but also any time we face change or when new safety orders are issued.

Our workers have been pulled in many different directions over the last five years. Their psychological well-being has been profoundly impacted, and their ability to cope may be compromised. By being more present as supervisors, managers, and leaders, we show our people compassion and understanding, letting them know that we are there as much as possible. Talk to workers to learn about their concerns. Fix what’s fixable. Solve whatever safety issues you can immediately and demonstrate to your employees through your actions that their opinions matter.

By communicating clearly, listening to concerns, and taking action to resolve the things in your control, you can help reduce anxiety and build up your team.

Use any and every moment that you can to explain what is currently happening, while reminding your workers of existing supports for stress, depression, and anxiety in your benefits plan, your community, or through your health and safety association.

Use crew talks, employee updates, and training to reinforce vigilant health and safety practices.

T he way through this crisis is together. Focus on your people and build up your team. Make sure your people and your brand’s safety record do not fall victim to economic turmoil, and you will find your team members to be your strongest allies in the crisis and the loudest advocates for your brand in the years to come

By Brandi Cowen

Lithium-ion batteries power everything from the smartwatch on your wrist to the electric and plug-in hybrid electric vehicles in your parking lot. With these rechargeable batteries found in everything from vape pens and smartphones to hand tools and forklifts, it’s easy to underestimate how many lithium-ion powered products are in your workplace.

The technology is generally quite safe, however, lithium-ion batteries can pose health and safety risks when they are not used, stored, installed or disposed of properly.

“ When these batteries are defective, damaged or not operated

safely, overheating in the cells can occur, resulting in a chemical reaction,” says Mathew MacLeod, senior health and safety specialist at the Canadian Centre for Occupational Health and Safety (CCOHS).

M acLeod explains that this chemical reaction generates more heat than can be dispersed, fueling further chemical reactions and, in turn, creating additional heat in a phenomenon known as thermal runaway.

“ This results in the release of corrosive, flammable and toxic liquids and gases. These substances are harmful if they’re inhaled and can cause skin and eye burns and other adverse health effects. The extreme heat and inflammable substances that are also released

can lead to a fire or explosion,” MacLeod says.