At Gas Clip Technologies, we believe that quality and budget-friendly should go hand-in-hand, which is why we create top-of-the-line gas detection solutions that have a low cost of ownership. Each detector is compliance-based and designed to withstand the roughest treatment in the harshest environments.

All of our products are available through distributors worldwide.

Scan QR code to visit our website!

10 | Legal View

Workplace safety improvements through DPAs 13 | Safety Leadership

Defining the OHS profession for tomorrow

30 | Time Out

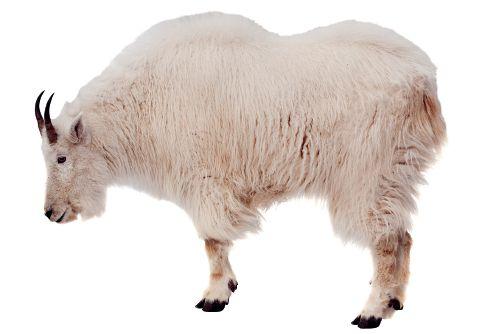

A centenarian's crispy secret to longevity and the tale of Chug, the stuck mountain goat

and killed

AND ALONE Sharing Ian's story on the 25th anniversary of his death

CHRISTINE O'DONNELL

| From the Editor

long, and thanks for all the fish

| CCOHS Corner

and safety in the age of artificial intelligence

| Quarterly Check-in

CSA group standard tackles equity, diversity, inclusion

RESPONDERS

psychosocial factors shield first responders from mental harm

By Todd Humber, Senior Editor

Health and safety is one of the best beats in B2B journalism. If you knew me about 15 years ago, when I was the managing editor of Canadian HR Reporter and its family of workplace publications, that statement would have shocked you.

Thomson Reuters, the media company I worked for at the time, had purchased a health and safety magazine and I found the stories to be a little technical and dry. There was lots of ink spilled talking about N95s, confined space rules, and arguments over what type of FR fabric was the best.

But I can admit when I’m wrong. And, boy, was I wrong. It didn’t take long to figure out what a gem of a profession workplace safety is — and it was the people doing the work that convinced me. Search as long as you want, but you’ll never find a group of people more passionate about their careers. I hate spewing cliches, mostly, but you can’t talk about OHS without stating the obvious: In the workplace, there is no more important job than ensuring everyone goes home safe at the end of the day.

While I still love writing about HR, there is a veil that can be tough to be pierce in

that profession. Not everyone is willing to share their trade secrets, to open up about what is and isn’t working at their company, for fear of either losing a competitive edge or landing in hot legal water.

This

is my last issue as editor of OHS

Canada. It's been a fun ride, and I'm inspired by the work of safety pros.

But safety? The minute somebody figures out a way to keep people safer, they start talking about it as loudly and as often as they can. As a journalist, that’s a godsend. There are no state secrets in the world of safety, just a community of caring and dedicated professionals who want to keep raising the bar.

This is my last issue as editor of OHS Canada. It’s been a fun ride working with the team at Annex. That starts at the top with the leadership of CEO Scott Jamieson, who trusted me to join the management team as a group publisher in 2019, and didn’t bat too many eyes when I decided to return to my writing roots.

It extends to senior publisher Paul Burton, who has become a good friend. He’s always pointing the ship in the right direction, and if you’re looking

Paula Campkin: chief safety officer, Energy Safety Canada

Marty Dol: president and founder, HASCO Health & Safety Canada

Cindy Moser: director of communications, Institute of Work & Health

Natalie Oree: prevention consultant, SAFE Work Manitoba

David Powers: EHS director (Atlantic), Sysco Canada

for someone to sit beside for a post-conference pint, he’s tough to beat.

Silvana Maiolo, the national brand sales manager, always has a smile on her face — despite my constant sarcastic barbs. She has a great sense of humour, and a terrible sense of direction. If you ask her to meet you at a taco stand in San Diego 10 minutes from her hotel, get comfortable. It’s gonna be a while.

It’s always dangerous to start naming names, but a special nod to Graham Jeffrey, the designer behind the look and feel of the print issues. And account co-ordinator Cheryl Fisher, the magic behind-the-scenes person that makes everything hum.

The headline of this column may have confused you. I stole it from John Hobel, former publisher of Canadian HR Reporter. He was a massive fan of the Hitchhiker’s Guide to the Galaxy. I had never read it, and was flummoxed by the headline when he handed in his last column for editing.

Uttered by the dolphins on their departure from Earth as it was being demolished to make way for an intergalactic bypass, it remains a favourite way to say goodbye.

So long, and thanks for all the fish.

Richard Quenneville: senior director of corporate services, T. Harris Environmental Management

Maureen Shaw: lecturer and presenter

Dylan Short: managing director, The Redlands Group

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal

Tel: 416-510-5113

Fax: 416-510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SENIOR EDITOR

Todd Humber

289-264-4883 thumber@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey

ACCOUNT CO-ORDINATOR

Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER

Serina Dingeldein 416-510-5124 sdingeldein@annexbusinessmedia.com

BRAND SALES MANAGER Silvana Maiolo smaiolo@annexbusinessmedia.com

SENIOR PUBLISHER Paul Burton pburton@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital) PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published four times per year –Winter, Spring. Summer, Fall Canada $70/yr plus tax USA $98/yr Foreign $162/yr CDN —$120 USD Single copy $19 CDN

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2024 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

The number of workplace fatalities in Nova Scotia decreased last year, according to the latest data from the Workers’ Compensation Board of Nova Scotia.

Eighteen Nova Scotians died at work or because of their work in 2023, down from 24 fatalities in 2022 “but still a sobering reminder of the human impact of workplace tragedy, and a reminder that one workplace death is too many,” the agency said.

Already in 2024, four Nova Scotians have died either at work or because of their work, including two acute fatalities in the same week in February.

There are three classifications of workplace fatalities: Acute, where an incident on the job, like a fall, drowning, or a motor vehicle accident, leads to a fatality; chronic (occupational disease), like mesothelioma or other work-related illnesses; and chronic (health), where a person dies while at work, but for health reasons which may or may not be related to their work.

Among the 2023 fatalities, seven resulted from acute traumatic injuries on the job, a decrease from nine in 2022. These acute deaths spanned various industries, including two in both construction and manufacturing.

There were 11 fatalities classified as chronic in 2023, compared to 15 in 2022. This includes nine deaths related to occupational diseases stemming from past exposures, as well as two caused by health-related issues like heart attacks. It’s important to note that while these deaths occurred at work, they may not necessarily have been caused by work, it said. 18

Number of workers killed in Nova Scotia in 2023, an improvement from the previous year but an indication that more work is needed.

New commercial truck drivers who have not received adequate training are putting the safety of Canada’s roads and highways in jeopardy, according to a report from the Insurance Bureau of Canada (IBC).

IBC worked with MNP, a professional services firm, to identify the key factors impacting the cost of insurance for commercial truck operators. It found drivers with less training and experience are more likely to be involved in collisions and make costly claims than drivers with more training and experience. Insurance claims related to commercial trucking accidents have been increasing rapidly in recent years, it said.

Key findings in the report include the following:

• Truck drivers with less than three years of experience have a greater likelihood of being

involved in a collision.

• Collisions involving heavy loads or dangerous goods tend to be more severe and have potential for greater damage. As a result, the level of required liability coverage increases when these goods are transported, affecting premiums.

• Premiums for vehicles travelling outside of Canada are impacted by exposure to excessive jury verdicts in the United States – court verdicts where juries award plaintiffs exceptionally high amounts.

• The enforcement of commercial truck regulations violations is inadequate.

• Mandatory Entry-Level Training (MELT) has yet to be implemented across Canada.

• Training quality varies by school; there needs to be oversight, and standards need to be enforced.

Specially trained and better equipped security staff are now working at Manitoba’s largest hospital the Health Sciences Centre in a bid to reduce violence against health-care workers. More institutional safety officers, armed with pepper gel and greater powers than regular security guards, are to be posted later in other health-care settings.

“All health-care workers deserve to be safe and feel safe at their places of work, as do patients,” Health Minister Uzoma Asagwara said Wednesday.

The officers were initially promised by the former Progressive Conservative government in 2021, and legislation was passed to outline their duties and authority.

Health workers have long complained about escalating violence from people under the influence of drugs or having mental health issues. The Manitoba Nurses Union filed a grievance last year, alleging its members at the Health Sciences Centre were not in a safe workplace.

An arbitrator agreed with the union in a decision, citing an assault on a nurse who was accessing a staff-only entrance.

“It is my opinion that the current situation on campus, which includes minimal outside security patrols either by vehicle or on foot, does not meet the requirements for providing a safe workplace,” the arbitrator wrote.

Quebec’s workplace safety board says a lack of training and equipment contributed to the deaths of two firefighters during a flood northeast of Quebec City last May.

The volunteer firefighters were using an amphibious vehicle equipped with tracks and an outboard motor in an attempt to reach residents of a house that was surrounded by floodwaters in the small community of St-Urbain, Que.

Number of locomotives that derailed, along with 16 cars, after a CN Rail train accident in Ontario.

The board says the current of the swollen Gouffre River swept the

vehicle off course and into a tree, throwing the men into the river. In its report, the board says that it was inappropriate to use the vehicle in a flooded field.

It also found that the operation lacked planning and that the firefighters didn’t have the appropriate skills, knowledge or equipment to attempt the rescue.

The victims were identified last year as 23-year-old Christopher Lavoie and 55-year-old Regis Lavoie, who were not related.

The Transportation Safety Board says alcohol consumption played a role in a 2021 head-on crash between two freight trains that left several crew members injured and destroyed hundreds of feet of track in Prescott, Ontario.

The crash saw four locomotives and 16 cars derail after a CN train heading west to Toronto crashed into another CN train on a side track near Edward Street in the town of Prescott.

The safety board’s report says a manually operated switch connecting the side track to the mainline had been routed incorrectly and cites alcohol consumption by the rail traffic controller as a contributing factor in the crash.

Unlike aviation regulations in Canada, neither the Railway Safety Act nor its associated regulations currently prescribe a time period prohibiting the consumption of alcohol by employees before they assume their duties.

Employers in Prince Edward Island continue to report high levels of overall satisfaction with the province’s Workers Compensation Board, according to new survey data.

The WCB said the number matches the previous record from four years ago. It surveys its two major stakeholder groups – injured workers and employers – on a biannual basis. For employers, service satisfaction with the overall WCB experience matches the highest level recorded with 85 per cent attesting that they are completely or mostly satisfied with their experience. In addition, the performance index, a composite measure of employers’ overall experience with the WCB, now stands at 84.2, an increase of 10.8 points since 2003. Overall, 91 per cent of employers expressed that the WCB is fair and 88 per cent are satisfied with available online services.

“We are very pleased to see that employers continue to report high levels of satisfaction with the service provided by WCB team members,” said Dan Campbell, CEO of the Workers Compensation Board. “Our team members are the very foundation of this continued trend of excellence. Our people are the key to the work that we do, and these results highlight their client-centered focus.”

The total injury rate in Saskatchewan for 2023 was 3.95 per 100 workers an almost nine per cent drop from 2022 and the lowest rate in the province’s history, according to the Saskatchewan Workers’ Compensation Board (WCB).

From 2009 to 2023, the WCB’s total injury rate has decreased by 57.6 per cent, it said.

“Through the WorkSafe Saskatchewan partnership with the Ministry of Labour Relations and Workplace Safety, as a province, we are on the right track as we see our Total and Time Loss injury rates continue to come down,” said Gord Dobrowolsky, chair of the WCB.

For the fourth year in a row, 90 per cent of Saskatchewan workplaces had zero fatalities and zero injuries last year. In addition to the Total injury rate decrease in 2023, the Time Loss injury rate also dropped to 1.78 per 100 workers, it said.

This represents a decrease of 12.7 per cent from the 2022 rate of 2.04 per 100 workers. “An almost 13 per cent decrease in the Time Loss injury rate is certainly significant for 2023,” said WCB CEO Phillip Germain. “While we are moving in a positive direction, we all need to continue prioritizing workplace safety to drive our rates even lower.”

Saskatchewan’s Time Loss injury rate is fourth among Canadian provinces, it said.

24_002897_OHS_CN_SPR_CN Mod: April 8, 2024 8:22 AM Print: 04/17/24 page 1 v2.5

Syncrude Canada has been fined $390,000 after one of its workers was killed near Fort McKay, Alta., in 2021.

A worker was operating an excavator to build a berm when the bank the excavator was on slumped into the water. The excavator cab became submerged and the worker drowned. Under a creative sentence, the company will pay $390,000 to the David and Joan Lynch School of Engineering Safety and Risk Management, the UAlberta Geotechnical Centre and the Alberta Municipal Health and Safety Association.

The funds will be used to develop an employer best-practice guide and field-ready mobile app for trenching, excavation and adjacent work. These will provide real-time training, work planning and decision support to enhance safe work practices.

The OHS Act provides a creative sentence option in which funds that would otherwise be paid as fines are directed to an organization or project, to improve or promote workplace health and safety.

Alberta’s OHS laws set basic health and safety rules for the province’s workplaces. They provide guidance for employers to help them ensure their workplaces are as healthy and safe as possible while providing rights and protections for workers. Charges under OHS laws may be laid when failing to follow the rules results in a workplace fatality or serious injury.

$680,000 fine handed down in devastating explosion that killed 6 workers in

Number of organizations in Alberta that will receive funds from Syncrude following the court's decision to impose a "creative sentence" in a fatal workplace accident.

An Ontario company and its director have been fined a total of $680,000 after an explosion killed six workers and seriously injured another in January 2022.

The incident happened at Eastway Tank, Pump, and Meter Limited’s facility in Nepean, Ont., just outside of Ottawa.

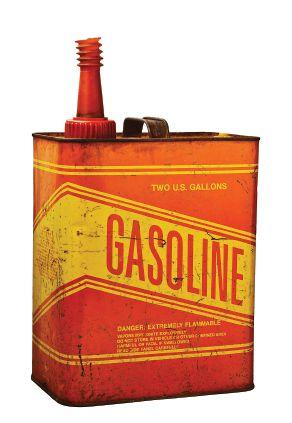

On Jan. 13, 2022, workers inside the company’s fabrication shop performed a wet test on a newly built tank truck to check for leakage. This entailed running diesel test fuel through different compartments of the tank and other truck components.

This was a routine operation at the workplace. Workers knew never to use gasoline and the company had a standard operating procedure that prohibited gasoline, or any tanker truck containing gasoline, from entering the fabrication shop. The diesel test fuel was stored in a tank outdoors.

The day before, another worker had used the diesel test fuel to wet test a different newly built tank truck outdoors. They left the diesel test fuel in the truck to calibrate the diesel meter. At some point, more fuel was added to the truck.

On Jan. 13, a worker pumped the diesel test fuel from the truck

outside into the truck in the fabrication shop. That afternoon, flammable liquid vapours in the vicinity of the truck in the shop ignited, causing one explosion followed by a second larger explosion. Seven workers were injured, six fatally and one critically, as a result.

Following the explosions and fire, several fuel storage tanks at the workplace were tested for contamination. Gasoline was identified as a contaminant in several tanks of diesel, and diesel was identified as a contaminant in a tank of gasoline.

An Ontario Fire Marshall investigation found that the gasoline involved in the explosion was the result of contaminated diesel test fuel being used in the wet test. The diesel test fuel from the outdoor storage tank was contaminated with gasoline, and it was increasingly contaminated by gasoline when it was transferred to the outdoor tank truck. These two sources of gasoline cross-contaminated sufficiently to cause the explosions.

Following a guilty plea in the Ontario Court of Justice in Ottawa, Eastway Tank, Pump and Meter Limited was fined $600,000, and director Neil Greene was fined $80,000.

TMI Contracting and Equipment

Rental has been fined $120,000 after a worker was fatally struck by a dump truck at a landfill site.

The company was subcontracted to provide equipment and workers for the grading of soil being brought into a landfill site.

On Dec. 9, 2021, a TMI worker was acting as a signaller for dump trucks unloading soil. The job entailed guiding trucks to the tipping face of the landfill. That afternoon, a truck arrived to dump its load. Contrary to safety procedures, the signaller did not give verbal direction to the driver. Instead, they left their vehicle, walked up the hill towards the dump location and attempted to guide the driver to the proper location. At this point, the driver reversed up the hill and fatally struck the signaller. TMI Contracting and Equipment Rental Ltd. failed to ensure that the signaller communicated with the truck driver by means of a telecommunication system or, where visual signals were clearly visible to the driver, by means of prearranged visual signals, contrary to subsection 106(3) of Regulation 213/91, violating s. 25(1) (c) of the Occupational Health and Safety Act.

Waste Management of Canada Corporation – the owner of the landfill site – earlier pled guilty and was fined for the same offense.

Boucher Bros. Lumber has pled guilty to charges under Alberta’s Occupational Health and Safety (OHS) Act after a worker was injured by a wood planer.

The charges stem from an incident at a Nampa lumber and building supplies business on Sept. 28, 2022. The worker was injured when their hand contacted the blades of a wood planer.

Under the creative sentence, the company will pay $102,000 to the Alberta Forest Products Association for a mill safety education campaign that includes developing a series of safety education videos aimed at the lumber industry. The OHS Act provides a creative sentence option in which funds that would otherwise be paid as fines are directed to an organization or project to improve or promote workplace health and safety.

The Crown withdrew 11 other charges under OHS legislation. Victim fine surcharges are added to fines payable to the Crown. Surcharges are not applied to other entities under creative sentences.

By Norm Keith

Canadian occupational health and safety regulators have legal authority and moral responsibility to set, communicate and enforce workplace safety standards across Canada.

The important question is what the best regulatory model to protect workers on the job and ensure the highest standards of workplace safety. Many Canadian regulators enforce OHS laws by prosecuting employers, and other workplace stakeholders, when there are incidents, injuries and fatalities in the workplace.

O HS penal prosecutions may take the form of either quasi-criminal charges under health and safety laws or criminal charges under the

Many compliance models exist, and are worthy of consideration.

Westray Bill. In either case, a conviction may result in high fines, jail terms, and debarment from future public and private business opportunities, that adds to the punishment and costs of the corporate employer.

The recent decision of the Supreme Court in City of Greater Sudbury has increased the use of pre-qualification and debarment of convicted employers by governments at all levels.

Also, private sector owners and developers of construction projects are excluding contractors with prior OHS records of conviction. The theory behind this risk management strategy is that an employer with a record of conviction of an OHS offence has a suboptimal commitment and execution of their OHS program

and an increased risk of a compliant, incident or injuries to workers that will result in OHS regulatory enforcement.

The use of penal prosecutions by governments to enforce OHS standards under the criminal sanctions model is only one of many means available of OHS accountability and enforcement. Many other models of regulatory compliance exist and are worthy of consideration to improve workplace safety.

For example, in the United States, the use of citations with Administrative Monetary Penalties (AMPs) are frequently used as a model of OHS enforcement. British Columbia is the only Canadian jurisdiction that most frequently uses AMPs and

much more than penal prosecutions to enforce OHS laws.

O ther countries, such as the United Kingdom, use proactive inspections, constructive collaboration and mandatory compliance orders more often than prosecutions to achieve OHS law compliance. In fact, the United Kingdom, with a considerably larger population has far fewer OHS prosecutions annually than Canada.

Another enforcement tool in the OHS regulators tool box are Deferred Prosecution Agreements (DPAs). The regulatory mechanism of DPAs gives the option of resolving OHS non-compliance allegations constructively rather than by means of the criminal sanctions model.

A trial with OHS charges results in defendants spending a lot of time distracted with legal proceedings, asserting all available rights under the Charter of Rights and Freedoms, raising every possible legal defence available, and spending a great deal of money in non-recoverable legal fees.

D PAs avoid the very expensive and uncertain outcome of penal prosecution process for all parties and the taxpayer funded judicial system. DPAs are now the preferred resolution mechanism in the United States, the United Kingdom, and France. In fact many jurisdictions around the world have considered the benefits of using DPAs as a better way to encourage compliance and ensure enforcement by organizations rather than the blunt and expensive criminal sanctions model.

A DPA is essentially a diversion program for corporate accused in a regulatory or criminal law enforcement context. Canadian criminal law has used diversion programs for young offenders, indigenous offend-

The United Kingdom, with a considerably larger population, has far fewer OHS prosecutions annually than Canada. It uses proactive inspections, collaboration and mandatory compliance orders.

ers, and special need offenders for decades. A diversion program deals with individual accused who have been either arrested or charged with a criminal offence.

A diversion program requires the accuse to acknowledge their legal contravention and non-compliance, accept responsibility of the consequences of their actions, commit to address the non-compliant conduct, and then commit to a corrective rehabilitative program. The person who have been accused of violating the legal standards agrees to all of this in open court and is subject to judicial supervision.

For example, long before the legalization of cannabis by the federal government in 2018, young offenders arrested for the possession or consumption of cannabis were usually offered the option of entering into a diversion program rather than facing a criminal trial, a conviction, a criminal penalty of a fine or jail, and a criminal record.

Youth diversion programs usually required the young offender to publicly acknowledge that they and broken the law, attend a drug education program to learn the adverse effects of cannabis use, and publicly commit to a stop the criminal behaviour.

Corporate diversion program also exist in Canada. The Competition Bureau uses the co-called ‘Immunity Program’ with good effect in resolving price fixing and other of-

fences under the Competition Act. The federal government has also used Environmental Protection Alternative Measures (EPMA) agreements pursuant to the Canadian Environmental Protection Act, to effect resolution of environmental offences that result in environmental radiation but do not result in corporate convictions.

Finally, the penultimate DPA in Canada is under the Criminal Code, that permits corporate criminal offenders to admit to the fraud, corruption or other white collar crimes in a manner that results in rehabilitation of the offender without getting a criminal records and therefore automatic debarment from government and may other business opportunities.

Corporate DPAs provide a potential ‘win-win’ result for both the regulator and the societal interest that they represent and the legitimate business interests of the corporate offender, without harming their investors, their employees, and other corporate stakeholders. Therefore, DPAs may be an effective option to striking that balance in OHS legal compliance without the expense of a trial, the damage to innocent stakeholders, and the risk to the state that the charges will be dismissed.

A comprehensive review of the advantages and disadvantages of DPAs for corporate offenders have been addressed by the author elsewhere. A brief summary of the benefits of DPAs for OHS legal enforcement may include the following:

1 The lengthy, costly, and uncertain outcomes of an enforcement by OHS charges that result in a quasi-criminal or criminal trial;

2. The consequences that a public trial and conviction have on the employer’s business reputation and debarment from future business opportunities;

3 The adverse effects on innocent stakeholders, including investors, employees, customers, and suppliers who did not cause the incident.

Although the goal of OHS laws and their enforcement is the improvement of workplace safety, the use of penal prosecutions had become so prevalent in Canada there has been little reflection of the efficacy of the criminal sanctions enforcement model.

There is no meaningful empirical study in Canada that reliably confirms a positive correlation between increased OHS prosecutions and increased penalties and a reduction in workplace incidents, injuries and fatalities. The absence of such evidence is shocking given the continuing trend of Canadian OHS regulators to increase both the penalties and frequency of OHS prosecutions. Rather than double down on a failed policy model, there must be a better way to improve workplace safety.

The actual process of how a DPA could work to achieve OHS enforce -

Rather than double down on a failed policy model, there must be a better way.

ment without the lengthy, costly, adversarial process of a penal prosecution may look like this:

1 There is a workplace incident, injury or fatality; the OHS regulator investigates and determines there has been an OHS legal contraventions;

2 The terms and conditions of the DPA is voluntarily negotiated between the OHS regulator and the corporate employer and their respective legal counsel;

3 The DPA will include requirements for acknowledgement of a legal contravention of a legal OHS violation by the corporate employer;

4 The DPA will require the payment of a significant monetary penalty for not complying with the OHS legal standard in question;

5. The DPA will include requirements to add or improve current OHS policies, procedures, training, accountability and other workplace safety measures.

6. The DPA will be reviewed in a public judicial proceeding by a justice that records the full details

of the commitment to the improved OHS compliance program;

7 When the above 3 criteria are completed, the pending or actual OHS penal charges will be stayed by a judge at the request of the prosecutor.

The use of DPAs will not be always used by OHS regulators, especially in cases involving fatalities and repeat offenders. The role of quasi-criminal and criminal OHS prosecutions will be preserved. However, the tremendous time, costs, and talent that are tied up in penal prosecutions can be better put into constructive resolution discussions to improve workplace safety. If governments and OHS regulators are truly committed to reducing workplace incidents, injuries, and fatalities, and improving workplace safety, there is no reason to not have OHS DPAs available in every jurisdiction in Canada.

This brief review of the concept of DPAs as an effective and efficient means of holding corporate employers accountable for OHS legal contraventions. It may not necessarily reduce the monetary penalties the employers face, but it will not cripple them from future business activity that punishes employers, investors, supplies, customers, and other workplace stakeholders inadvertently.

DPAs also prevent a record of conviction from debarring an otherwise capable and competitive business from offering its good and services to both the public and private sector. DPAs have been widely used in many other free and democratic countries with resounding success. While DPAs are not a panacea to improving workplace safety in Canada, they may go a long way to supporting legal enforcement of offenders and preventing hardship to non-offenders and avoiding the existential threat of corporate capital punishment by OHS prosecutions, convictions and debarment.

By Lisa McGuire

Every day, people are injured on the job in Canadian workplaces. In 2022, more than 7,000 British Columbians were seriously injured on the job, and provincially, employers lost 3.99 million workdays to work-related injury or illness.

B usinesses face increasing risk of fire and flood, and psychological injury claims. Employers can also expect to encounter new hazards as they introduce automation and bring on an influx of new workers to replace retiring workers with decades of experience.

All these factors have employers grappling with increased risk and liability. Business leaders need qualified OHS advice more than ever.

Most practitioners enter the safety profession indirectly as a mid-career transition, either driven by personal experience with the impact of workplace injury or inheriting safety responsibilities in their existing positions. They are put into the position of learning on-thejob or seeking certification and education for these crucial new responsibilities.

A sector market labour study underway since 2017 has generated important insights in addressing the challenge of standardizing competencies and skills for OHS practitioners in the manufacturing sector. With the input of stakeholders from government, industry, labour, OHS experts, educational institutions, and

other areas, the study identified that people working in health and safety roles too often lack an understanding of business operations and people-centric skills, psychological components in health and safety, and industry-specific operations and risks.

At the same time, research has shown that many employers do not clearly understand what qualifications to look for when hiring a safety professional.

In an era of rapid change fueled by technology adoption, climate change impacts, and fast-tracked new OHS regulation and growing recognition of psychological risk, Canadian businesses are experiencing a greater need for qualified OHS practitioners than ever before.

With more than 20 health and safety designations in Canada — where educational paths can range from a few months to six years or more — the route to proficiency is also unclear. Compounding the problem, more than half the people responsible for health and safety in the manufacturing sector in

British Columbia have no formal certifications at all.

Here in B.C., through the development of a comprehensive OHS competency framework and capabilities profile with national and international experts, a comparison found a 30 percent gap between the competencies businesses need and the skills taught in OHS post-secondary programs.

Most professions have governance structures in place to ensure consistency of education, aligned to the required competencies, and with practical application of skills in a mentorship/internship oversight structure. This structure is, unfortunately, absent in the health and safety profession.

We are working to change this — to position OHS practitioners and businesses in the manufacturing sector for success. We see this in Germany’s experience, for instance. In comparison with Germany, where the OHS profession is regulated, the workplace fatality rate in Canada is three times higher.

As leaders and mentors, it is crucial that we build workplace environments that position

future leaders for success. By ensuring that OHS professionals have the knowledge and skills to advise businesses effectively in building dynamic safe work environments, we make our organizations more resilient and adaptable.

Canadian employers need access to qualified health and safety advice and support. Likewise, current and future health and safety professionals need a clear path to competence to support their growth and the growth of the industry. This path to proficiency needs to also include practical experience with qualified oversight and mentorship that incorporates mandatory professional development.

The ability to protect workers and their expertise is one of the key focus areas for the upcoming Expo 2025 in Japan as well, where health and safety is being highlighted for the first time at a world exposition.

R eflecting trends from around the world, the theme is “Designing future society for our lives,” where sustainability, climate change, and increasing technological advancements will be woven into themes focusing on safety, health, and wellness, exploring ways to protect our populations, our workers, and to expand and extend our lifespans.

Here in Canada, as we set the path forward on these critical questions, many questions remain — but the cost of inaction is too high. The time to act is here.

By Todd Humber

There is no sure-fire way to spot someone who is at risk of an opioid poisoning or substance abuse, but there are some red flags to watch out for, according to Vicky Waldron, Vancouver-based executive director of the Construction Industry Rehabilitation Plan.

“What you’re looking for is someone that’s behaving out of the norm,” she said, noting the warning signs can vary not just by individual but also by gender.

Such deviations might include increased irritability, argumentativeness, and risk-taking behaviors, particularly in men who may express stress through outward anger and aggression.

“It usually starts with kicking of tools or throwing things around,” said Waldron. “And this is something

that’s going on for a while that might be getting progressively worse.”

For women, the signs might manifest as withdrawal, becoming more tearful, or neglecting personal hygiene, she said..

Stats and research have shown that workers in construction are at higher risk of opioid poisonings, and there are a few things driving that, according to Waldron. First is the transient nature of the industry.

Layered on top of that is the toxicity of the drugs and a push to get injured workers back on the job quickly because of labour shortages, she said.

“There is a pressure to get back to work quickly,” said Waldron.

Warning signs by age

Julian Toy, a substance abuse professional and a former addict, said it’s

"A person can go from despondent to angry within seconds, with no noticeable explanation."

important to also consider the age of the worker. It’s not that unusual for a 19-year-old, for example, to think it’s cool to go out and get drunk and high on the weekends, he said.

“That’s normal, for people who are young, to experiment with substances,” said Toy.

But if you’re looking at a 40-yearold worker exhibiting the same behaviour, “that’s something I would take a closer look — at that employee’s attendance, performance, and behaviour simply because of the fact

that’s not age appropriate.”

He agreed with the warning signs raised by Waldron, and noted that there is often no transition period between “anger and happiness, despair and joy” among an addict.

“It will happen instantly, it’s not going to happen slowly,” said Toy. “A person can go from despondent to angry within seconds, with no noticeable explanation. If a person has substance abuse disorder, you’d probably be left confused at the wide swing of emotions.”

Ken Brodie, senior HSE specialist for Modern Niagara Vancouver, said construction sites are inherently dangerous workplaces — even for clear-minded individuals. An impaired worker, either through medication, alcohol, or drugs, can pose a significant risk.

If someone on his team suspects a worker is under the influence, they intervene, he said.

“We have a talk with that person,

and we take them somewhere private,” said Brodie. “And we have two people do this so it’s unbiased.”

The first question asked is: “What’s going on?”

“Hopefully, we can get them talking and they’ll probably self-disclose, because that’s what we found in the past,” said Brodie. “They’ll actually tell you what’s going on. Maybe it was a medical emergency — the medications were changed. Maybe there’s a family emergency, something happened — marital discord.”

Brodie said that, in order to be reactive to an opioid situation, a company has to be proactive in developing policies — and that includes training and communication.

“There’s no more helpless feeling than when a person is confronted with an emergency situation and they don’t know what to do to help,” he said. “Our employees are excellent at building… and making buildings work. But they’re not trained medical personnel.”

But giving staff basic information can give them a leg up when they’re confronted with an overdose, he said. That includes a policy that outlines guidelines and responsibilities, he said.

“ We constantly offer free Naloxone training courses,” he said, adding that they also pay the worker for the time they’re in the training.

He noted that, in the past, workers would have to use needles — but the new nasal sprays are handy and simple to use. “It’s not daunting at all… one spray up the nostril.”

O ne-quarter (25 per cent) of Modern Niagara Vancouver employees have been trained on using Naloxone, he said — from apprentices right up to the CEO.

The first thing to do in the event of an overdose is to call 911, said Waldron. Then it’s time to follow the rest of the “SAVE ME” steps, republished

here from the Government of British Columba’s website:

S – Stimulate. Check if the person is responsive, can you wake them up? If they are unresponsive, call 911. The sooner you call, the better the chance of recovery.

A – Airway. Make sure there is nothing in the mouth blocking the airway, or stopping the person from breathing. Remove anything that is blocking the airway.

V – Ventilate. Help them breathe. Plug the nose, tilt the head back and give one breath every 5 seconds.

E – Evaluate. Do you see any improvement? Are they breathing on their own? If not, prepare naloxone. M – Medication. Administer the Naloxone.

“It's a harsh, fast, and quick withdrawal. And so people bolt upright.”

Vicky Waldron

E – Evaluate and support. Is the person breathing? Naloxone usually takes effect in 3-5 minutes. If the person is not awake in 5 minutes, give one more dose.

The reason Naloxone isn’t administered immediately is that it puts people into “precipitated withdrawal,” said Waldron.

“It’s a harsh, fast, and quick withdrawal,” she said. “And so people bolt upright. It will put them into that withdrawal, and they may get up, run away, and they may go off and use again straight away, because it’s incredibly painful.”

If you haven’t called 911 by that point, there is a danger that they will take opioids again — and they won’t get the effect of them.

“Because they’ve got Naloxone in

their system as that dissipates,” she said, noting that it has a half life of about 90 minutes while opioids have a half life of between four and eight hours.

“What that means is that once the Naloxone has disappeared, all the opioids that were in the system are now going to reattach to the receptor sites, they go back into the brain — plus the new amount of opioids they’ve used,” she said. “That can really lead to an increased risk of fatalities.”

Brodie also offered another useful tip — which is to send someone to the entrance of the worksite to greet and guide the first responders.

“It’s daunting — construction sites — even for the workers, but for somebody new to the site? Send somebody out to find them,” he said.

Gina Vahlas, secretary, College for the Certification of Canadian Professional Ergonomists and product owner, Prevention Business Product Management, at WorkSafeBC, said it’s important to look at the personal factors that can lead people down the path to substance abuse.

“ There is a link between workplace factors and opioid abuse,” she said. It’s something she has witnessed first-hand when she worked in a physical therapy clinic.

It was not uncommon to observe a recurring cycle among patients with muscular injuries or disorders, said Vahlas. Initially, these individuals would seek treatment, make a recovery, and subsequently return to their professional environments. However, the relief was often temporary.

“ When they go back to full-time duties and hours, they would end up going off work again because of the pain,” she said. “Because the workplace factors that created the injury did not change.”

"Focusing solely on the use of opioids attacks the symptoms... and will not solve the crisis."

Physical factors are high on the list of things to consider, such as “high force, awkward postures — which are extreme body positions, like working with our arms over our head or bending forward,” she said. Other dangers include repetition, temperature, vibrations, and contact stress.

“There are other cognitive factors, such as perception and memory and psychosocial factors, such as low job control and getting rewarded or paid more for doing more — which incentivizes workers to go beyond what is healthy and safe,” said Vahlas.

She views the opioid crisis as more of a “pain crisis” than anything else. Programs that can ease pain, including ergonomics, can eliminate the need to take strong medication in the first place.

“Focusing solely on the use of opioids attacks the symptoms of the crisis and will not solve the problem,” she said.

M ike Russo, president of WorkBright, said naloxone kits are critical in treating an overdose. Ontario has mandated that naloxone kits be made available in certain high-risk workplaces — a move he called “significant and groundbreaking.”

But just making the kits available isn’t enough, he said. There are specific compliance requirements in the legislation that organizations need to take into account.

“ The act sets out specific responsibilities for the employer to assign a person in charge of the naloxone kit, and that that person be

trained,” he said. That includes recognizing the signs of an overdose and how to administer the product.

A nother key consideration is where the naloxone is physically stored, because it needs to be kept in a strategic location so it’s easily accessible, said Russo.

“Many workplaces have multiple sites, they have multiple shifts,” he said. There are also climate considerations, because the kits are temperature sensitive to both extreme cold and extreme heat.

“ I’ve spoken with workplaces that have handed out naloxone kits to their supervisors, and instructed them to lock them in the desk to avoid them from being misplaced or taken home,” said Russo. “You want to avoid that. It needs to be really accessible.”

Don't lock naloxone kits away. "You want to avoid that. It needs to be really accessible."

Mike Russo

Prevention and support Lilian Riad-Allen, senior director, workplace health, safety and wellness at the Liquor Control Board of Ontario (LCBO), said prevention can go a long way in preventing overdoses. One of the tactics it takes is to create a culture where people feel comfortable speaking up.

“How do we create safe spaces where people feel comfortable to come forward and identify risks,” she said. “It may be just noticing when someone may not be themselves… and creating an opportunity to have those check-ins to connect with someone, to look for those signs of impairment.”

The goal is to treat an opiate overdose or poisoning in the workplace the same way any other medical event is treated, she said, just like a cardiac event or any other situation that required medical intervention.

“Our approach is to always have the person’s best interests at heart,” she said.

How the person is welcomed back to the workplace following an

overdose is also critical, said RiadAllen. Two things happen upon preparing for that return, she said.

“ The first is a conversation with the affected individual, where we let them know in advance what the conversation with the team will look like — which is that we will always preserve people’s confidentiality and privacy related to any medical situation,” she said.

The second is what she called a “huddle” with the person’s manager to equip them and prepare them in advance.

“ We provide them with scripts of things they can say, and things they can’t say,” said Riad-Allen.

B ut she stressed that the best opportunity for organizations isn’t how to respond to an event, it’s to prevent it in the first place.

“ This goes back to that duty to inquire, but also created a safe psychological space for someone to come forward and share,” she said. “Whether it’s that they’re using opiates, or that they have any other kind of impairment that may affect them in the workplace.”

S he also recommends implementing a “robust system” to prevent reoccurrence. That could include working with the person’s family — with the person’s consent, of course.

“ We have had really good success working with collateral partners, whether that be family support partners but also bridging and creating those supports as part of a return to work plan,” she said.

The language Riad-Allen uses in these situations is always focused on safety, she said.

“ That’s the language we always use. Safety is the root and the anchor of everything we talk about,” she said. “People, intuitively, can appreciate that what we’re putting in place isn’t punitive. It is for their safety and the safety of their colleagues.”

By Todd Humber

An Alberta court has convicted a contracting company and one of its supervisors under the province’s Occupational Health and Safety Act after a worker was struck and fatally injured by a pick-up truck.

Habtom Abraha, who worked for Volker Stevin Contracting, was killed on Oct. 2, 2019, while he was conducting routine inspections of storm drain catch basins on a residential street in Airdrie, Alta.

He was run over by a pickup truck being driven by Michael O’Neill, a utilities foreman and supervisor at Volker Stevin.

The incident unfolded as Abraha and O'Neill, a two-person crew, were inspecting a catch basin next to a residential driveway.

O’Neill had parked the vehicle they were driving, a Ford F-550 company truck, in front of the private driveway — inadvertently

The argument of the defendants failed to consider the 'power imbalance' in the workplace.

blocking it. Abraha was working in front of the vehicle while the supervisor was on a phone call in the truck. As this was happening, the homeowner arrived and opened his garage door.

“O’Neill was so focused on this call that he did not even end the call when (the homeowner) arrived looking to enter his driveway,” the Court said in the ruling, adding that his distraction was compounded by the fact he didn’t want to inconvenience the homeowner who was trying to get his car into the garage.

As a result, O’Neill pulled forward about two metres, “moving the vehicle without concerning himself with safety generally, and Abraha’s safety in particular,” the Court said.

Abraha was run over by the truck, suffered catastrophic injuries, and was killed instantly.

Charges laid Volker Stevin along with O'Neill, faced multiple charges under the Occupational Health and Safety Act for failing to ensure the safety of their workers.

"The evidence of the primary inves-

tigator included photographs taken while sitting in the driver’s seat of the work vehicle. I accept her evidence that at the distance Abraha was from the truck, the driver of the vehicle would not be able to see Abraha in a ‘kneeling down’ position in front of the truck," the Court said.

It was particularly critical of Volker Stevin's vague and unenforced safety protocols.

"Creating a visual control zone with cones signifying an area into which the vehicle is not to drive, and ensuring when parking the vehicle that it is sufficiently behind the area within which work is to be completed so that the work is not being conducted within the blind spot of a driver," were cited as reasonably practicable steps that were neglected by the company.

The defense argued that the actions of Abraha, such as his placement

near the vehicle, were not reasonably foreseeable by the defendants and it was up to him to ensure his own safety. The Crown said that argument was akin to victim blaming, an opinion the Court agreed with.

“Workers, of course, have some responsibility for their physical, psychological and social well-being while working,” the Court said. “However, to suggest this responsibility is the first that should be considered after a workplace incident fails to recognize that there are many aspects of workers’ employment and its safe conduct that they cannot control but which are controlled by their employers.”

It said the argument of the defendants failed to consider the “power imbalance” between the employers and the worker or supervisor.

The Court pointed out that the work truck, on its own, did not create the hazard that resulted in the fatality. Instead, it was the utilization of the truck as a “shield” — pro-

tecting the worker from traffic — and leaving it running while in close proximity to workers that created the hazard.

It said a walkaround should have been required in these situations before moving the vehicle, rejecting an argument from the defense that it could “result in workers at worksites needing to do a walk around every time they get in a motorized vehicle, which is unreasonable given that in most circumstances doing so is neither necessary nor reasonable.”

Using the truck as a shield to protect workers meant that it had been “converted into a safety device,” the Court said, and Volker Stevin was obligated to put in place safety precautions as a result.

That could include creating a visual control zone with cones signifying an area into which the vehicle is not to drive and ensuring that, when the truck was parked, work was not being carried out in a blind spot. The Court accepted those steps as “appropriate safety precautions” that could have been taken in this case.

O’Neill was convicted on three counts, in part for his failure as a supervisor to protect the safety of his subordinate. His responsibilities included overseeing the safety and proper execution of tasks by less senior workers like Abraha.

The court found that "a ‘reasonably practicable step’ that a supervisor should take to fulfill their obligation to a worker in their two-man crew is to ensure the worker’s location is known before moving the vehicle."

O'Neill's failure to perform this fundamental safety check led directly to the tragic accident. Thus, the court convicted O'Neill of failing to take necessary precautions as a supervisor to protect Abraha, effectively holding him accountable for the oversight that led to Abraha's death.

“ The reasonable steps he may have taken to ensure Abraha was not exposed to danger prior to moving the powered mobile equipment include several commonsense steps such as ending his call, getting out of the truck to confirm where Abraha was working and ensuring that his focus was on his operation of the powered mobile equipment as opposed to the phone call,” it said.

Volker Stevin Contracting was convicted on four counts, including:

• Failing to ensure that Abraha was beyond the range of powered mobile equipment while working.

• Failing to sufficiently or adequately train employees in work around catch basins and powered mobile equipment. This count was conditionally stayed.

• Failure to ensure O'Neill was trained in the safe operation of equipment he was required to operate. This conviction was later stayed.

• Permitting a part of powered mobile equipment to create a danger to a worker, Abraha, allowing him to remain within the range of the equipment. At press time, the sentences for these convictions were unknown. For more information, see R v. Volker Stevin Contracting Ltd., 2024 ABCJ 85 (CanLII).

By: Raghu Chakkravarthy, Gilbane and Ian Lanpher, Superior Glove

Hand injuries are the #1 preventable industrial accident. But if they’re preventable, why are they still so common in construction?

At first glance, the facts make little sense. There are countless PPE choices on the market, hand protection technology continues to advance, and more workers are wearing safety gloves than ever before. Shouldn’t this be enough to avoid preventable hand injuries?

Gilbane and Superior Glove didn’t think so. When they looked at the prevalence of preventable hand injuries, they saw that the construction industry and its partners were viewing hand safety the same way they always have. Hand safety programs were PPE-centric and one-size-fits-all.

Gilbane’s Federal Division partnered with Superior Glove to challenge this status quo. They knew that construction was not like other industries such as manufacturing, where operations are similar day-to-day and third-party workers are few. Construction tasks and hazards vary as project phases and schedules shift by the day, week, or month. In addition, third party partners are an integral part of everyday work.

Safety standardization, culture, and communication are very complex in construction. Construction requires a replicable way to scale safety solutions across worksites and with trade partners, but one-size-fits-all does not work, nor does a PPE focus that doesn’t address foundational elements like safety culture and communication. Together, Gilbane and Superior

Glove developed a customized Hand Safety Program suited specifically to tackle these issues in the construction industry. The program was built on two key principles from the book REThinking Hand Safety, which was written by Superior Glove’s Vice President, Joe Geng. The first key principle is that an effective safety culture requires addressing the full hierarchy of safety controls and PPE should always be the last line of defense. The second key principle is that all stakeholders should be engaged in the development process to ensure all affected parties are empowered and share responsibility for safety.

Over a three-month period, Superior Glove’s hand safety specialists worked onsite with Gilbane safety professionals and stakeholders, including general contractors, trade partners, workers, and owners. Together they reviewed incident data, analyzed safety policies and procedures, observed employees, and collected feedback from worker interviews to identify any gaps or deficiencies in existing safety measures. The goal was to prevent accidents from occurring in the first place rather than solely relying on protective equipment. This approach not only reduced the dependence on gloves, but also instilled a proactive approach to safety within the workforce. Workers were observed and interviewed on site across trades and tasks to determine environment-specific and task-specific hazards and to determine how they could be addressed with the hierarchy controls to eliminate

or minimize hazards before PPE recommendations and trials commenced. This wholistic approach emphasized addressing non-PPE safety changes first, leaving fewer hazards for safety gloves to fight against.

Although PPE was being treated as the last line of defense in Gilbane’s hand safety program, providing appropriate safety gloves was still necessary. Trialing solutions were an integral part of finding the best hand protection for each worksite task. Each trade or application may have different types of primary or secondary hazards. Different tasks require disparate levels of dexterity, insulation, grip, and durability. By trying various gloves for each trade, Gilbane ensured that workers felt comfortable, protected, and uninhibited while working.

Unlike typical safety gloves trials, which are done in a single day, Superior Glove worked with Gilbane to conduct extended trials to accommodate multiple schedules, workers being moved weekly to different sites, and the multitude of tasks that changed as a result. Extended PPE trials were conducted over two-week periods across multiple locations. Workers received various gloves tailored to their specific tasks and used them onsite over multiple days, providing Gilbane and Superior Glove with direct feedback on comfort and performance.

What started with three months of intense assessment and support has continued as a long-term Hand Safety Program partnership that has reduced hand injuries by 95%

in Gilbane’s Federal Division. “This was not an overnight success. It took about three years for us to see the desired injury reduction within the division. It was worth the wait, and we couldn’t have done it without Superior Glove, our workers, our trade partners, and other stakeholders who were committed to this program’s long-term success,” says Raghu Chakravarthy, Safety Director at Gilbane Federal Division.

Ian Lanpher, Superior Glove’s Construction Specialist for North America, agrees and adds, “By working with Gilbane Federal we were able to develop a practical approach and tools to support that approach that are specific to the construction industry. Together we shifted safety culture with new ways to communicate effectively across stakeholders, guidance for hazard elimination and reduction, safety specification language, and glove selection tools that made safety standards clear before projects started. This allowed for a proactive approach that could be replicated across projects without being one-size-fits-all or PPE-centric. What we created with Gilbane made it possible for hand safety to be an everyday priority that all stakeholders want to participate in and that drives real injury reduction. To me, that’s a job well done.”

Gilbane and Superior Glove continue to work together to maintain and improve hand safety. They hope to inspire more industry leaders to change the way construction approaches hand safety with partnerships like theirs.

By Christine O’Donnell

Iwould like to share a story of a workplace injury that is close to my heart. He left the house like any other day to attend his job in the construction industry. He was untrained and not prepared for the task requested by his supervisor.

He was only 28 years old. He had a wife. He was a new dad and stepfather.

He was working with defective equipment.

He was working on the shores of a lake and the equipment he was using was from an electrical source.

He was electrocuted and his death was due to drowning.

He died alone.

He was not given a chance to say “goodbye.”

He was laid to rest the day before his parents’ 30th wedding anniversary.

His name was Ian.

He was my cousin.

This year is the 25th anniversary of Ian’s death and to this very day my uncle’s eyes fill with tears at the mention of his name. My aunt is still devastated over the loss of her first born.

They say the most stressful life altering moment in time is the loss of a loved one. The loss of one’s child, no matter the age, is inconceivable to most. Ian’s two brothers Steve and Paul and sister Nancy lost their big brother. Ian left behind a loving wife, a stepdaughter Samantha (then 8) and son Mark (then 5).

There is a photo of Ian and his children in a prominent place in my aunt and uncle's home. His face smiling in laughter at some joke long since forgotten, hugging his kids.

Many families like Ian’s have been tested and tried in ways too difficult to express with mere words. No family should feel such devastating loss.

Training, training, training ….is the phrase I have expressed in my job as a Health and Safety Inspector to many employers.

It is critical that everyone in the workplace has been trained to understand their role and responsibilities. To understand in a meaningful way that ensures compliance with the standards prescribed in Occupational Health and Safety.

The training must be equally delivered to the most senior man-

ager, as she or he will be the role model of overall safety in the company. The middle managers must be trained to ensure that health and safety is more important than operational demands. The supervisors must be trained to ensure that health and safety is a daily concern, every hour of the day.

A comprehensive Occupational Health and Safety Program results in a safer and more productive workplace.

The employees must be trained to not just know their rights and responsibilities, but to understand them and be empowered to act if or when required. Finally, is the “newly hired” employee. He or she must be trained to know all the hazards of the workplace before day one. There should be no such thing as “on the job training.” The newest employee should be protected with training, knowledge, and the ability to ensure their own safety at work before they take the first step of operating equipment or the workload.

When I first started my job as a Health and Safety Inspector, I reviewed many investigations. I still recall reading my first fatality file. There was a photo of a covered body at the scene. Extended from the cover was a hand. He was wearing a wedding band. I immediately thought of his wife and children. It may not have been my personal loss; however, it did leave an imprint.

In my role as an Inspector, I conduct hazardous occurrence investigations in the workplace. The purpose of such assignments is to determine the root cause of the incident. To determine if there were any violations of the Occupational Health and Safety legislation. To take action with the employer, to ensure that there will not be any further incidents.

It is with a focus of prevention.

Meaningful and fully understood training improves the overall knowledge of all parties in the workplace. The responsibility of health and safety is embraced by all. Workers are encouraged to look out for each other, with the empowerment to stop a short cut, or stop the operation, so to swiftly address a health and safety issue.

Not “get the ticky” training, not “on the job training”, not “read this when you get a chance” training.

Young workers are the most vulnerable at work. They are usually male, under 30 and with experience less than one year.

Ian was a male under 30 with less than a year of experience. He was untrained, only getting the “on the job” training. Yet clearly, he was more than a statistic. He was a cherished son of my aunt and uncle. He was a big brother. He was a husband and a dad of two young children. He was my cousin. His name was Ian.

Christine O’Donnell is an Occupational Health and Safety Inspector.

By James Careless

According to the Canadian Centre for Occupational Health and Safety (CCOHS), "Many workers are injured and killed each year while working in confined spaces. An estimated 60 per cent of the fatalities have been among the would-be rescuers."

The CCOHS defines a confined space as "a fully or partially enclosed space that is not primarily designed or intended for continuous human occupancy."

Whether manmade or natural, such spaces have limited/restricted entrances and exits, are difficult for rescuers to access easily, and can

pose health and safety risks to occupants due to their design, inadequate air availability/circulation, and possible toxic chemicals inside.

As a former firefighter, Access Rescue Canada instructor Mark Alderman has no problem citing examples of confined spaces that may require rescues. They include workers entering a railcar or road-trailer for the purpose of inspection and cleaning. Such workers may be exposed to toxic, corrosive, or flammable liquids and gases, he said.

" Unconsciousness results from atmospheric hazards, while Dry-Bulk Cargo Trailers may expose the worker to engulfment hazards, respiratory hazards, and potential for flashover." Similar engulfment risks exist for workers inside a grain elevator and being engulfed by its contents, and

"an individual working on a partial excavation of a residential home to repair a foundation leak and being engulfed by mud or water."

For companies and organizations whose work environments include confined spaces, the need to execute a confined space rescue safely is a possibility that should not be dismissed. Here is a brief look at the factors involved in preparing for such events — bearing in mind that the actual process and capabilities required are much more complicated and should be created with the help of certified confined space rescue professionals.

The first step in establishing a relevant rescue capability is to decide

what kind of confined space scenarios your company/organization may need to respond to. If your company inspects enclosed tanks/tankers, for instance, then your rescue equipment, techniques, and risk assessments should be focused on these environments.

Next, "you need to anticipate what hazards are possibly in the confined space," said Barry Nakahara, Senior Manager of Prevention Field Services with WorkSafe BC. "You also need to consider the means of access to the space. If it's a top-down vertical manhole entry, you need certain types of equipment like winching systems, and tripods to get a person out. Whereas if it's a horizontal entry at ground level, the equipment is different."

With the help of certified rescue professionals, you can determine which equipment to buy and have on hand. They can also help you select the right people for the job, which is just as important.

There are basically three kinds of confined space rescue teams, said Chris Irwin, Global Training Instructor Lead with MSA Safety.

"The first is a rescue team you contract with, which could include off duty firefighters who standby as a rescue team if needed," he said. "The second is a local first responder rescue team that comes after you've called 911 for help, and the third is your own onsite team of workers who have specific tasks and can be ready to go when an incident happens."

If you choose the "own team" option, you will be responsible for the training and all required certification of your rescue team, their equipment, support and ongoing retraining through regular rescue exercises. The benefit of this responsibility is that your own rescue team can be trained specifically to meet your own confined space rescue needs and be dedicated to these needs 365 days a

year. Finally, planned responses to possible confined space rescue scenarios should be codified in Incident Action Pans (IAPs). "These are general actions that should be considered and taken," Alderman said. "The steps may be altered, depending upon the size-up and rescue response capability or completed concurrently."

In a confined space, rust is a threat because there's no real means of efficient oxygen replacement.

Whether it is evaluating possible confined rescue scenarios or coming to extricate workers during an actual confined space incident, making thorough threat assessments before deploying rescuers is an absolute must. As the CCOHS pointed out, about 60 per cent of confined space fatalities occur among "the would-be rescuers "

According to Alderman, such assessments have to be done to comply with government regulations before any incidents ever take place. And yet again, such assessment must be thorough, because the range of life-endangering threats can be as varied as they are unexpected. For instance, a storage tank that is damp and rusty can be home to toxic

mold spores, requiring rescuers to wear breathing masks and possibly HAZMAT suits as well. But that's not the only risk: "One thing people don't realize or really take into account is that rust is the act of oxidation, which means the metal is absorbing the oxygen in that space," said Blake Underhill, President of Industrial Safety and Rescue. "Normally it's not a problem because there's oxygen replacement in open areas. But in a confined space, rust is a threat because there's no real means of efficient oxygen replacement while the act of rusting is actually absorbing oxygen from that space.”

In such oxygen-deficient spaces, rescuers need to wear self contained breathing apparatus (aka SCBA facemasks and air tanks). Because SCBA equipment is heavy and bulky, they will also need to train while wearing it, before actually attempting such confined space rescues. Meanwhile, attempts should be made to ventilate the confined space for the sake of the victims, and to dissipate any toxic/flammable gases.

This brings up another life-saving tip for confined space rescuers: "Stay within your role and level of training and competence," Alderman said. "Do not enter the confined space unless you are qualified to conduct an entry-level rescue and that all rescue procedures available are followed."

These are just some of the many considerations associated with safe confined space rescues, which is why professional guidance should be sought by anyone seeking such capabilities for their company/organization.

But don’t be discouraged: With the right planning, assessments, equipment, personnel, and training, confined space rescues can be executed with enhanced safety and reduced risk.

TThe Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips

Workers in Canada are in a new age: the Fourth Industrial Revolution. And just like revolutions passed, it’s critical for workers to know how to use the tools and resources, like Artificial Intelligence (AI), that are being made available to them. But before workplaces enter the world of AI, they must first realize the potential ergonomic, physical, and psychosocial risks and hazards it may pose, and how to overcome them.

There are two words that are making their way across Canada’s

AI isn't just a trend, but a tool. And like any other tool, it requires training on how to use it.

workplaces, filtering into boardrooms, factory floors, watercooler chats, and everywhere in between: Artificial Intelligence (AI).

AI is a major part of the Fourth Industrial Revolution. However, unlike years passed when revolutions transformed our economies by utilizing coal, gas, electricity, and information technology, this transformation is happening through embedded connectivity, changing the way humans live, connect, and work.

What does this mean for the future of work and the health and safety of workers?

B efore those questions can be

answered, it’s important to remember that AI isn’t just a trend, but a tool. And like any other tool, it requires the training of how to use it properly, and an understanding of the risks and hazards it can pose.

Since the 1950s, AI has grown into a specialty within computer science that aims to replicate human intelligence and problem-solving abilities through the collection and processing of data. In this respect, AI’s goal is to learn from the past and improve the future. Today, many workplaces use AI

to do just that. For example, there are AI-powered cameras that aid in noticing irregularities when monitoring camera video feeds and AI-powered virtual reality (VR) to help employees learn about potential hazards and how to respond in a simulated environment without the risk of actual injury. There’s also generative AI that can be used for writing and editing documents (such as ChatGPT) and coding tasks like debugging.

In these scenarios, AI can support the work environment by creating efficiencies and handling mundane or difficult tasks. And as AI works, it learns and evolves—which is why it’s imperative that workers and workplaces evolve their understanding of the tool, too.

A I can be helpful, but it doesn’t come without risks, including ethical, legal, and safety concerns.

Let’s take the scenario of Lee, the owner of a small landscaping business. Lee has hired a handful of new staff for the season, but instead of creating health and safety training tailored to his business, he uses ChatGPT to draft guidelines for workers to read. However, Lee is unaware of AI’s limitations, including its lack of human instinct and the fact that it’s not always a reliable source of information. This means that Lee is exposing his workers to potential risks. Are workers properly trained on all the tools they’ll be using? What if ChatGPT provided outdated information? What happens if workers have questions or don’t understand their roles?

This scenario is just one example of why AI cannot fully replace or be relied on for a role, especially the kind where human intervention and interaction is needed, like training.

Below are a few other risks that AI-powered technologies can pose if not used correctly.

Artificial intelligence and wearable sensor technologies that monitor and manage workers could result

in micromanagement,

competitiveness, social isolation, and decreased privacy and trust.

New ergonomic hazards: The automation of processes could introduce a new work pace or make work more repetitive and less diversified, increasing the potential for repetitive strain injuries.

New physical hazards: New assistive technologies could also lead workers to lift heavier loads, increasing the potential for musculoskeletal injuries. Machines that work closely with workers, like autonomous vehicles, could also be hazardous if they malfunction or break down.

New psychosocial hazards: AI and wearable sensor technologies that monitor and manage workers could result in micromanagement, performance pressure, competitiveness, social isolation, and decreased privacy and trust. Workers may also fear being replaced if they can’t keep up. Automation may also cause jobs to lose variety or become less satisfying. These experiences may increase anxiety, disengagement, stress, or job insecurity.

A lthough there are risks, when managed properly, AI has the potential to help workers do their jobs more efficiently and effectively. If implementing AI in your workplace, consider the following guidelines: