ESSENTIAL PRODUCTS for

HAND & SURFACE HYGIENE

Discover our dedicated range of effective and trusted products. Extensively tested and liked by the people who use them.

HAND SOAP, HAND SANITIZER, SURFACE CLEANING & DISINFECTION PRODUCTS

Use our Essential Products in conjunction with our Impactful Education materials to implement effective hygiene measures in your facility following the new 8 Moments for Targeted Hygiene guidance.* The Targeted Hygiene Program can work as part of a comprehensive plan, in combination with social distancing, facial coverings and other hygiene measures applicable to your facility, to help reduce the spread of infection from person to person or through surface contact.

MEAGAN GILLMORE

ALEXANDRA SKINNER

From the Editor

By Todd Humber, Publisher

Steel-toed shoes, distracted workers and a safety lesson

The first, and thankfully only, time I’ve witnessed a workplace safety incident it was hot.

Not in the sort of uncomfortable hot-for-Canada way, but in that sticky and steamy can’tescape-it-no-matter-how-hardyou-try kind of way.

A heat wave had settled in around Windsor, Ont., in July 1991. The thermometer was pushing 35C, and the newscasters said the humidity made it feel more like 45C.

It was day one on the job for me, the ultimate summer gig on the line at Chrysler’s Windsor Assembly Plant building Dodge Caravans and Plymouth Voyageurs. We had just come out of orientation, and a good part of that time was spent on safety.

E quipped with steel-toed shoes, gloves and goggles we wandered on to the factory floor to get our first assignment. My job was pinning the fuel line, running from the gas tank to the engine, to the undercarriage of the van.

My thoughts were focused on two things: That first paycheque and making sure I did a good job. My father, after all, worked for Chrysler and any mistake I made would un -

EDITORIAL ADVISORY BOARD

doubtedly get back to him and become fodder for uncomfortable dinner conversation.

About a dozen vans into my shift, I heard a horn and a yell. I turned just in time to watch a forklift loaded with engines run over the foot of one of the other summer students. An alarm sounded, and the line went down.

We all rushed over to check on her. Thankfully, she was fine – her steel toe somewhat dented but the foot underneath unscathed. The PPE had done its job, no small feat given the size of the machinery that rolled over it.

Hours later, I found her at the lunch table and settled in next to her. “You OK?”

“Yes,” she responded. “That was lucky. I was so distracted I didn’t see him.”

Turns out her grandmother had passed away that morning, just hours before her shift started. She didn’t want to miss her first day. But it also meant her grieving mind was wandering as she crossed the aisle.

That story always reminds me of everything we bring to work with us on a daily basis. You can’t check your feelings and emotions at the door. What happens at home spills into work, and vice-versa.

When it comes to safety, it only takes a second for things to head south. That’s why, increasingly, mental health is such an important part of the conversation when it comes to workplace safety.

Distracted workers are unsafe workers. That’s a big part of the reason OHS Canada has teamed up with our sister media brand, TalentCanada, to launch the Psychologically Safe Workplace Awards.

If you have two minutes, go to www.PsychologicallySafe Workplace.com and watch the explainer video. This isn’t a vanity awards program, but a credible and independent evaluation.

It’s powered by the Mental Fitness Index (MFI), an assessment your teams take that gives them individual data. The video explains it far better than I can in this space.

The program is a small, but important, step that can help leaders make intelligent and evidence-based decisions. It also shows your employees you care about their health, and are dedicated to improving the culture at your organization.

It all culminates with a celebration on Sept. 15 in Toronto at the Globe and Mail Centre. We hope to see you there.

Paula Campkin: chief safety officer at Energy Safety Canada in Calgary, Alta.

Marty Dol: health and safety leader with Sleegers Engineered Products in London, Ont.

Cindy Moser: director of communications for the Institute of Work & Health in Toronto

Natalie Oree: prevention consultant with SAFE Work Manitoba in Winnipeg

David Powers: director of HSE with Oxford Frozen Foods in Oxford, N.S.

Richard Quenneville: senior director of corporate services with T. Harris Environmental Management in Toronto

Maureen Shaw: lecturer and presenter in Victoria

Dylan Short: managing director of The Redlands Group in Oakville, Ont.

Spring 2022 Vol. 38, No.2 ohscanada.com

READER SERVICE

Print and digital subscription inquiries or changes, please contact Serina Dingeldein, Audience Development Manager Tel: 416-510-5124

Fax: 416-510-6875

Email: sdingeldein@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Todd Humber (Acting)

MEDIA DESIGNER

Graham Jeffrey

ACCOUNT CO-ORDINATOR

Cheryl Fisher 416-510-5194 cfisher@annexbusinessmedia.com

BRAND SALES MANAGER

Silvana Maiolo smaiolo@annexbusinessmedia.com

GROUP PUBLISHER

Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

ISSN 0827-4576 (Print) ISSN 1923-4279 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published five times per year – Winter, Spring, Summer, Fall, Buyer’s Guide Canada $100/yr plus tax USA $130/yr (100 USD) Foreign $214/yr ($164.50 USD)

Occasionally, OHS Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Business Media Privacy Office privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

In the News

B.C. plans to license asbestos contractors, require mandatory training and certification for workers

British Columbia has introduced legislation designed to help keep workers safe from asbestos.

Bill 5 – 2022: Workers Compensation Amendment Act proposes a new of new protections. It would require asbestos abatement contractors to be licensed to operate in B.C.

In addition, any workers and employers who perform this work must complete mandatory safety training and certification, according to a press release from WorkSafe BC. The bill is currently being considered by the Legislative Assembly. Upon passage of the bill, WorkSafeBC will implement the new requirements, which would include:

• Developing the standards that asbestos safety training and certification programs must comply with

• Developing a licensing scheme for abatement contractors

• Amending the Occupational Health and Safety Regulation to align with the changes to the Workers Compensation Act, and support the certification and licensing schemes

• Identifying who will act as the training and certifying bodies for asbestos abatement workers

“We will share details of our implementation plan as it progresses,” WorkSafe BC said in its press release. “Active participation from workers, employers, and other stakeholders will play a key role in shaping the province’s asbestos abatement safety training and certification program, so consultation and opportunities to provide input will be key elements of our plan.”

60

km/h

Alberta has introduced legislation requiring motorists to slow down when passing a stopped roadside worker vehicle with its light flashing. The maximum speed when passing such a vehicle is 60 kilometres per hour, it said.

Workplace injury insurance for Nova Scotia firefighters and their families will soon cover more types of cancer and heart attacks, the province said. Presumptive coverage is being increased from six types of cancer to 19, and also includes heart attacks that occur within 24 hours of an emergency call.

“Firefighters put their health at risk and their lives on the line every day,” said Premier Tim Houston.

“Those who protect us should, in turn, be protected by their government and have access to the workplace injury coverage they need when they need it.”

The additional coverage will be in amendments to the Firefighters Compensation Regulations under the Workers’ Compensation Act. The 13 types of cancer being added are:

• esophageal

Nova Scotia expands firefighters’ presumptive coverage for cancer, heart attack Visit us online

• lung • testicular

• ureter

• breast

• multiple myeloma

• prostate

• skin

• ovarian

• cervical

• penile

• thyroid

• pancreatic.

There is existing coverage for bladder, brain, colorectal and kidney cancer, leukemia and non-Hodgkin’s lymphoma. The province will cover the total liability cost of $80.6 million for four fiscal years. Municipalities will not incur additional liability costs until 2025-26.

There are more than 6,000 volunteer firefighters and 600 paid firefighters in Nova Scotia.

Find the latest workplace health and safety-related news, columns and analysis from across Canada on our website! ohscanada.com

Sister confirms death of man who spent 5 hours in the water

HALIFAX (CP) - A fisherman who was lifted by helicopter after spending five hours in frigid ocean waters off eastern Nova Scotia has died. Alana Lewis said her brother, 35-year-old Jeremy Hart of Windsor Junction, N.S., died on March 13 after being found by a rescue team.

“When they found him he was unresponsive, but at that point they still had hope that they could save him,” Lewis said. “But they were unable to get his core temperature back up, and he passed away.”

She said an autopsy was being conducted, adding that Hart had only joined the crew of the halibut fishing vessel Mucktown Girl a week prior.

A Canadian Coast Guard spokeswoman said earlier a man wearing an immersion suit, which is designed to keep the wearer afloat and protect against hypothermia, had spent close to five hours in the water before a helicopter rescue at around 11:30 a.m. Sunday.

The coast guard has said he ended up in the water during the transfer of the fishing boat’s crew from a life-raft to a coast guard vessel at around 6:30 a.m. Sunday. The four other crew members were rescued.

“They lost him during the transfer,” Lewis said. “He got away from the (rescue) boat very quickly and they spent hours searching for him.”

Coast guard spokeswoman Alexandra McNab said a second coast guard vessel, Spindrift, was also on scene at the time of the transfer, as were a Cormorant helicopter and two airplanes.

“The crew of the Canadian Coast Guard Vessel Jean Goodwill attempted rescue of the five crew members by manoeuvring alongside the life-raft. At this time, seas were estimated to be eight to 10 metres, with winds of 83 to 92 kilometres per hour,” said the email. McNab said the rescuers were unable to reach Hart, “due to the sea conditions.”

On-the-job murder in Ontario leads to $170,000 fine

$2 per litre

As gas prices soared in March, some groups called for provinces to enact pay-before-youpump legislation to protect gas station workers who might be inclined to put themselves in harm’s way to stop a gas theft. British Columbia and Alberta already have that legislation in place.

An Ontario company has been fined nearly $170,000 after one of its workers was murdered on the job.

On July 24, 2020, an employee at a home in Kemptville, Ont. – operated by Pathways to Independence – was injured and killed as a result of workplace violence.

Pathways to Independence is a community based, not-for-profit agency providing assisted community living services and supports to people with an acquired brain injury (ABI) or a developmental disability who may also have complex needs based on their unique goals, abilities, and choices, according to its website.

A worker employed by Pathways arrived for their overnight shift, working alone, at one of the assisted living group homes operated by Pathways, which is headquartered in Belleville, Ont.

Shortly after, a co-worker received a call indicating the

worker on the overnight shift had been fatally injured. The co-worker returned to the workplace to find the worker on the floor unresponsive, and immediately called 911.

The worker was transported to a nearby hospital and was pronounced dead.

An investigation by the Ministry of Labour, Training and Skills Development determined that Pathways failed to reassess the risk of workplace violence as required.

Following a guilty plea in provincial offences court in Brockville, Ont., Pathways to Independence was fined $135,000 by Justice Richard Knott.

The court also imposed a 25-per-cent victim fine surcharge as required by the Provincial Offences Act, bringing the total fine to $168,750. The surcharge is credited to a special provincial government fund to assist victims of crime.

Find the latest workplace health and safety-related news, columns and analysis from across Canada on our website! ohscanada.com

Saskatoon company fined $70K after worker injured

A Saskatchewan court has fined a contracting company $70,000 after a worker was injured while loading concrete forms.

On March 9, Ryderz Contracting Inc. pleaded guilty in Saskatoon Provincial Court to one violation of occupational health and safety regulations.

The company pleaded guilty to contravening subsection 129(a) of The Occupational Health and Safety Regulation s, 1996 (being an employer, contractor or owner, fail to ensure that no material or equipment is placed, stacked or stored so as to constitute a hazard to workers, resulting in the serious injury of a worker).

The charge stemmed from a workplace

WSPS announces cancellation of PIP conference and tradeshow

The annual Partners in Prevention conference and tradeshow has been cancelled.

Workplace Safety and Prevention Services (WSPS) made the announcement in an email to exhibitors, attendees and on its website. The event was scheduled to run May 3-4 at the International Centre in Mississauga, Ont. There will be no virtual component either, it said.

“We understand this news is disappointing and wish the situation was more favourable,” it said.

“A survey of potential sponsors, exhibitors, and attendees was conducted late last year that indicated people were very excited about getting back to face-to-face events,” the email said.

“Unfortunately, circumstances have changed, and the feedback we’ve since received has shown the appetite to resume in-person activities for this type of event is not yet back to anticipated levels.”

incident that occurred on April 21, 2020, at a worksite in Saskatoon. While loading concrete forms, the form cage tipped over and injured the worker.

As a result of this violation, the Court imposed a fine of $50,000, along with a surcharge of $20,000, for a total amount of $70,000.

Tough and Flexible

Reflex Polymer Safety Barriers

Protect people and equipment from accidental impact of moving vehicles.

Industry leading polymer safety barriers flex upon impact and return to their original state. This energy absorbing ability significantly reduces maintenance costs and help prevent expensive floor repairs.

Our patented, proprietary, REFLEX polymer is scratch resistant, safe in food processing environments and is fire resistant.

The modular design can accommodate virtually any application.

Used in over 85 countries REFLEX polymer safety barriers are the most cost effective logical choice for modern day facility and asset protection.

Ontario Bollards, 53 Armstrong Ave., Unit 1, Georgetown ON L7G 4S1 844-891-8559 info@ontariobollards.com www.ontariobollards.com

Safety Leadership

By Lisa McGuire

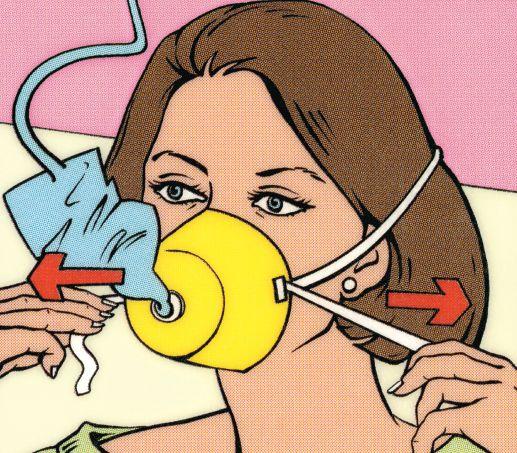

In case of an emergency, put on your oxygen mask first

We all know the drill – we’ve heard it every time we’ve boarded an airplane. “In the event of an emergency, put on your oxygen mask first before helping others.”

T he reasoning behind this is obvious: It’s impossible to care for others when you are incapacitated. Then, why is it that so many leaders struggle to care for themselves so that they can take good care of their people?

The challenges facing manufacturing over the last two years have taken a toll on workers, and it’s also impacted those in leadership positions. Unfortunately, leaders often choose to take care of themselves last.

Usually the first in, and the last home, they work through lunches and weekends, don’t make time to recharge and adequately fuel their bodies, and often defer taking a vacation.

The pandemic, coupled with a series of natural disasters in British Columbia, has blurred the lines between work and home more than ever. Leaders find it increasingly difficult to separate themselves from work and spend quality downtime. The stress of taking care of their people and business during the pandemic and other emergencies bombarding our communities often has leaders turning a blind eye to their health.

Here are some things to consider to keep yourself physically and mentally fit to make the complex decisions needed for your business and people.

Self-care is NOT selfish

Taking care of yourself is an essential lifestyle practice for good health. It’s both a preventative and proactive part of a healthy lifestyle. It’s critical to take care of both your physical and mental health so you can be at your best as a leader.

Take breaks throughout the day. Microbreaks (five minutes or less) can be an effective way to reset. Get up for a stretch, have a quick chat with a colleague, or make a cup of tea. Studies show microbreaks can improve your concentration and reduce workplace stress.

Get enough sleep. Workplace fatigue leads to many undesirable consequences. It increases accident risk, impairs decision-making, and reduces productivity. There has been a trend amongst leaders to deprioritize sleep – even brag about only needing “four hours of sleep a night.” Research suggests a strong link between effective leadership and adequate sleep. With the increasing demands of leaders, you cannot afford to be operating at less than optimum performance.

Set boundaries. Ask yourself, “Do I need to take every opportunity,

especially when my plate is already overflowing? “ Or, “what would happen if I let someone else take care of this?” Learn to delegate tasks that don’t require your attention. Often, leaders choose not to delegate because they fear the work won’t meet their standards. Developing your team is an essential leadership responsibility –knowing that mistakes are part of learning. Leaders can’t lead when they are doing all the work themselves.

Look after your physical and mental health. You know what a model lifestyle is – eat a healthy diet, exercise, practice mindfulness. Find enjoyment outside of work that allows you to disconnect from the stress of the office. These activities could include connecting with friends and family, enjoying a hobby, joining a team, or volunteering. These activities allow you to recover and bring new and innovative solutions to work when practiced regularly.

Practice grace. The crises of the last two years have shown us all that there are some things we have little or no control over. It’s essential to recognize that you won’t have all the answers for leading through events like the pandemic, fires and floods, and the rise of war. Be honest to yourself and your team on the situation at hand and your limitations, knowing that you cannot be all things to everyone. When faced with an uncertain and rapidly changing situation – focus on being adaptable instead of controlling.

Taking time for self-care will make you a stronger, more effective leader. Chronic stress can negatively impact your ability to make good decisions. Self-care will help you build resilience and achieve higher performance levels. When you model self-care, you permit your team to take care of themselves, too.

Lisa McGuire is the CEO of the Manufacturing Safety Alliance in Chilliwack, B.C.

Legal View

By David Reiter

Reopening offices? Check these things

Here we go again. Spring is here, COVID case numbers are declining, and most of us are feeling hopeful. That has especially been the case given recent government announcements that COVID restrictions are being lifted. Fingers crossed — hopefully life is starting to return to normal.

Against that backdrop, many employers have started, or are poised to start, bringing employees back to offices and other workplaces. From an OHS perspective, employers would be well advised though to remain mindful of the risks that COVID may still pose, along with other risks connected to returning to the workplace.

Understanding that, a good starting place for employers always has been the risk assessment. This time, though, it may be appropriate also to include in their assessments the indirect occupational health and safety risks that stem from the pandemic.

For example, if workers have been out of the office for a good part of the last two years, employers may need to conduct a thorough inspection of the workplace for any hazards that may have developed over the course of the pandemic. Mold or bacterial build up may have occurred in certain parts of the workplace, such as in the vents or in communal kitchens where cleaning may not have been as consistent without workers in the office.

Fire safety equipment should also be tested if it hasn’t been done recently, as should other equipment or tools or equipment which may have suffered from neglect or lack of use. Simply put, proper and comprehensive inspections of the workplace are always going to be useful.

Other precautions employers may want to look at could include the added stresses workers may face after having been away for so long. Anxiety about COVID and the return to in person working may be a consideration. So too, the stresses associated with exposing vulnerable family members to COVID, or just gener-

al re-adjustment to being away from family and home all day, may be considerations. While employers may be within their rights to require workers to come back to the office, they must also take reasonable steps to protect workers from harm, and accommodate disabilities.

Appreciating that, strategies employers may want to consider to mitigate these concerns could include providing employees with significant notice about return to office plans, implementing phased-in approaches to the return, encouraging the use of, and making available, personal protective equipment, and the avoidance of large, in person meetings — at least during the early stages of the return.

Of course, many employers may also choose to continue taking measures aimed directly at COVID, such as requiring masks and social distancing. In many situations, such measures may be appropriate or even required. However, employers may also benefit from other methods to improve occupational health and safety that offer less intrusive approaches. For example, improving ventilation in the workplace through increasing air flow and filtration may be warranted. It may be that this can be done through the installation of HEPA filters, cleaning and improving HVAC filtration, or even just keeping windows open as the weather permits. Changes like that

can improve workplace health and safety without employees feeling restricted, or even noticing the changes.

Having noted that, given that we’re still in the early stages of what hopefully will be the beginning of the end of the pandemic, employers may be wise - for the foreseeable future at least - to maintain a written COVID safety plan, remembering that in some jurisdictions they may continue to be required. These plans should be re-evaluated and updated as appropriate as the pandemic continues to evolve. Finally, employers may also do well to remember that the situation can be fluid, and restrictions could come back. Additionally, some local health units and municipalities could impose more stringent measures on workplaces. For instance, many local health units have workplace vaccination policy requirements. Appreciating that some municipalities may remove these policies faster than others, employers should also be considering their messaging, recommendations, and requirements from their local public health authorities, and any local restrictions that affect their workplaces.

This article offers general comments on legal developments of concern to business organizations and individuals, and is not intended to provide legal advice. Readers should seek professional legal advice on the particular issues that concern them.

David Reiter is a partner with Aird & Berlis in Toronto.

‘

My new co-worker is shiny

’

Pandemic has accelerated the pace of adoption for robots, and the technology might be one of the key safety solutions for the evolving workplace

By Jack Burton

As new workplace health and safety needs surface due to the pandemic, these emerging demands require fresh, dynamic solutions. Among the potential tools to help employers adapt is robotics — a field whose focus on innovation has positioned its technology to be a perfect fit for occupational safety.

For robotics, pandemic was its time to shine

The intersection between advancements in workplace robotics and the pandemic’s heightened need for new occupational safety tools has lead organizations to not only explore these new technologies, but

re-evaluate and recast robotics’ role as an appropriate workplace safety solution, according to Rob Vomiero, Workplace Safety & Prevention Services’ specialized services lead in machine and robotics safety.

Vomiero explained that, in the years before the pandemic, “from a user-based or organizational standpoint, I think the perception used to be that robotics were expensive or overcomplicated, or the return on investment or learning curve might not be ideal.”

However, the increased safety demands of COVID-19 left organizations more open to any solutions that could help, and Vomiero believes robotics have succeeded at using this opportunity to showcase

“Its just really opened the eyes of some organizations.”

– Rob Vomiero, WSPS

the potential operational impact they can have.

“With some of the needs that robots have been able to fill during the pandemic,” Vomiero said that, “overall, its just really opened the eyes of some organizations to the fact that robotics can really benefit operations, and they don’t really involve the level of complexity that they once did.”

Pandemic or not, Vomiero does not see robotics’ expanded role as temporary.

“ With the introduction of some of these new technologies, what the pandemic has really set industries

“What the pandemic has really set industries up for is more out of the box thinking on the different uses for robots.”

up for is more out of the box thinking on the different uses for robots,” he said.

Two types of robots

Vomiero highlighted two types of robot that, in recent years, have become primary drivers of growth in workplace robotics’ potential safety applications, these being the collaborative application robot and the industrial mobile robot.

The impact of these technologies comes from groundbreaking safety features that allow them to openly assist

and operate alongside employees onsite. Specifically, this allows collaborative application robots to safely aid employees with otherwise risky job tasks, while built-in GPS and mapping software allows industrial mobile robots to navigate the work area in a secure and autonomous way.

“Really, what these robots become is a co-worker to the human being,” said Vomiero. By moving this technology toward a more direct, collaborative role, these innovations mark a significant and more impactful development away from workplace robots’ previous methods of implementation.

“ This ability to work side by side, between human and robot, increases efficiency and safety when compared to your traditional robots. Those didn’t have some of these safety capabilities and functionalities built into them, and this required complete separation between the human and the robot,” Vomiero explained.

Real innovation through real-world design philosophies

Accelerating the growing impact and adoption of these new technologies is a needsbased, worker-first approach that modern safety robotics has made the focus of its research and development process, according to Alex Mihailidis, a professor at the University of Toronto’s Department of Occupational Science and Occupational Therapy, and the Barbara G. Stymiest Research Chair in Rehab Technology.

“ Typically in terms of research and development in robotics, we really try to go

after real world problems that are trying to be solved,” said Mihailidis. “It really becomes a matter of working towards specific problems that truly exist out there, as opposed to just having a technology-first approach.”

Designing robots aimed at making a tangible impact on workplaces depends on a number of variables, with developers looking not just at the tasks this technology aims to optimize, but also the needs of the workplace and worker as well.

“Obviously, in terms of us who develop these robotic systems, we always keep key things in mind, such as

improving the safety, efficiency, and effectiveness of the work team and staff members,” Mihailidis said. “We also then try and understand where new processes can be introduced, such as where a robot may be able to complete tasks with a higher degree of precision and efficiency as needed.”

This design focus has lead to solutions that build a system that compliments the needs of both the workplace and those within it, Mihailidis said. “One thing we always also look at and try to understand in our research is the interaction of the worker and the robot itself. We look at how robotics can

22_0535_CN_OHnS_MAR_APR_CN Mod: February 16, 2022 4:21 PM Print: 03/09/22 1:37:21 PM page 1 v7

increase the safety of each particular worker.”

Robotics aim to empower, not replace Mihailidis emphasized that organizations adopting robotics to perform otherwise unsafe or stressful workplace tasks is not about replacing employees who would traditionally be performing them, but rather providing an overall enrichment of safety in these environments.

For Mihailidis, whose research has focused on the use of safety robots in healthcare settings, “the whole idea there is not to replace nurses or care staff, but to really free up their time so that they can be focusing on the more important parts of their care duties, as opposed to spending time doing the repetitive tasks that robots excel at doing.”

While concerns of job displacement can be associated with automation and robotic solutions, Mihailidis clarified that the ultimate aim of most developers is collaboration, not replacement, when it comes to the relationship between worker and robot.

“In many activities, it’s hard to do a complete replacement of a human worker as opposed to them working together with the robots as a system. That’s really what we aim for,” he said. “It’s about a combination of human workers and robots working together to create an overall better environment for everyone to be working in.”

Artificial intelligence ’s path to the future

O ne of the main technologies bridging human effort with robotic assistance is artificial intelligence.

“ What I’m seeing in the field is that a lot of companies are thinking about how artificial intelligence can enhance existing technologies that are being utilized for health and safety practices,” said Arif

Jetha, a scientist at the Institute for Work & Health.

The promise of artificial intelligence has far-reaching implications in helping employees and robotics collaborate toward a safer workplace, Jetha believes, specifically by allowing machines and humans not just to work together, but grow together.

“ The ability for a machine to take different types of data and information and evaluate it, and then learn and make predictions: that type of technology has great promise to advance a lot of the different types of functions that exist within a workplace, to enable machines to be smarter, and to work alongside humans more effectively,” he said.

Two concerns that Jetha highlighted, however, was a relative lack of studies and academic literature on the impact of workplace artificial intelligence due to the newness of this field, along with this technology’s

“It’s about a combination of human workers and robots working together to create an overall better environment.”

potential for algorithmic biases.

“ This is an important lesson that health and safety professionals can think about as they’re evaluating what types of artificial intelligence tools they want to bring into their workplace and how they want to integrate it,” Jetha said. For him, “properly navigating these biases means ensuring that the technology serves and favours the needs of the employee.”

“ I think this idea of equitable artificial intelligence that is emerging is something that people should be paying attention to, as there’s this growing realization that if an artificial intelligence tool isn’t built equitably and with the perspectives of the worker in mind, there’s a potential that the worker could be disadvantaged by that tool,” Jetha said.

Jack Burton is a Toronto-based freelance writer who regularly contributes to OHS Canada.

Leo worked for moments like this… you work so your employees can have more moments like this.

Leo was a big strong man with a booming voice, but he didn’t hesitate to push his daughter’s stroller through the park or get on the floor to play cars with his son. To provide for his family, he worked for a paving company.

Learn more about Leo’s family at threadsoflife.ca/erin/

We care as much about health and safety as you do. We support families like Leo’s after the worst happens: an on-the-job fatality, serious injury or occupational disease.

You can help turn workplace tragedy into hope:

Spread the word Build Threads of Life into your emergency response and EAP programs. Let those who need help know where to find it: www.threadsoflife.ca.

Get involved Our members share their stories to help prevent future tragedy. Book a Threads of Life speaker for your health and safety day: www.threadsoflife.ca/speakers.

Designate and donate – Make Threads of Life your company’s Charity of Choice. Your company’s contributions will directly support Canadian families affected by workplace fatalities, life-altering injuries and occupational disease – visit www.threadsoflife.ca/donate

® The family lost its cornerstone the day Leo didn’t come home from work.

Helping you prevent workplace tragedy. Helping victims of tragedy heal.

Legionnaires Disease

There could be something very bad lurking in your water

Employers must implement controls and monitor systems to prevent bacteria growth

By Alexandra Skinner

As many businesses across Canada shut down due to the pandemic, the main objective in reopening was to reduce the risk of COVID-19 transmission in the workplace. Unfortunately, idle water systems created another risk: Legionnaire’s disease.

“Throughout the pandemic, and even currently — with many office workers still working from home — we see some commercial buildings operating at reduced or low capacity, meaning their water systems may not have been maintained,” explains WorkSafeBC Occupational Hygiene Officer, Kimiko Banati.

“Legionella bacteria can thrive in stagnant water systems if the water is not hot enough, or not properly maintained—and many industries are not aware of the associated risks.”

Legionnaire’s Disease

Legionella bacteria can be found in water systems such as swimming pools, hot tubs, water tanks, condensers, and cooling towers used in residential or commercial buildings. Many of water systems have a component that allows the water and contaminants to become airborne.

Spray and evaporation of contaminated water can be inhaled and cause a

potentially deadly pneumonia-like illness called Legionnaire’s Disease.

The disease was first discovered in the 1970s, after an outbreak at a Legion Convention in the United States caused many delegates to fall ill with severe respiratory symptoms. The cause was exposure to bacterial contamination that occurred in the hotel ventilation system’s cooling tower.

Legionnaire’s Disease can often go misdiagnosed as a general pneumonia infection. This results in the source of infection not being identified—leaving the door open for further infections to both workers and the public.

Legionella can also be found throughout the soil and natural environment, as well as a variety of industrial/commercial water systems, making it difficult to pinpoint the source of the bacteria. This was the case in the summer of 2021 in Moncton, N.B., when seven people fell ill with Legionnaire’s Disease, and one person died. Despite an investigation by public

health, the source of the outbreak was never confirmed.

Legionella bacteria can travel in the air up to six kilometres

Cases of Legionnaires have been increasing across the country and around the world. Anyone can be exposed to the bacteria in both indoor and outdoor spaces and in a variety of settings—from big box and grocery stores to hotels and hospitals.

Like other respiratory diseases, those most at risk include seniors, those who are immunocompromised, and people with underlying health issues. Bacterial growth can develop quickly—if a water source has the right environment, nutrients, and temperature for the bacteria to grow, it only needs to become airborne to pose a risk to workers and others.

Manufacturing industry also at risk

WorkSafeBC’s Risk Analysis Unit investigated Legionella risks associated with water systems (due to COVID-19 temporary closures and reduced capacity) in the summer of 2021. The industries inspected focused on hotels, municipalities, and food manufacturing.

Inspections revealed that while hotels and municipalities had good awareness of Legionella and had controls in place to monitor and prevent bacteria growth, the food manufacturing industry had lower awareness about the risk to workers, and how to prevent exposures.

A variety of controls must be used to prevent bacteria buildup

Qualified personnel—either in-house

staff or third-party contractors—must monitor the water systems to ensure the controls they are using are effective. This includes monitoring the water system’s parameters for bacteria, Legionella, water chemistry, disinfectants, and any visual indications that a problem may exist.

“The key is to maintain a balanced system,” says Banati, adding that a variety of controls should be implemented to prevent Legionella growth and to monitor the controls to ensure they are effective.

Some of these controls include:

• Maintaining a clean and balanced system so bacteria and sludge do not develop.

• Adding disinfectant to kill any bacteria that develops.

• Recirculating water so it does not become stagnant.

• Modifying water temperature to inhib -

Board of Canadian Registered Safety Professionals

it bacteria growth.

• Regular flushing of the water system and any parts that are closed at one end or areas which water cannot flow.

• Reducing or preventing aerosolization of the water.

Employers who have staff or thirdparty contractors who manage water systems need to develop and implement a Legionella exposure control plan

Workers who monitor and maintain water systems should have the appropriate training and personal protective equipment. To mitigate health risks associated with Legionella, some municipalities (such as the City of Vancouver) have also implemented water testing reporting requirements to secure a water system operating permit.

“It’s important for all employers to be aware of the risks associated with water

Conseil Canadien Des Professionnels En Sécurité Agréés

systems in various worksites,” says Banati. “Employers are responsible for protecting their workers, and workers have the right to know how employers are ensuring water systems comply with health and safety requirements.”

For more information on Legionella bacteria in water systems, see WorkSafeBC’s risk advisories at worksafebc.com.

• worksafebc.com/legionnaires-idle-systems

• worksafebc.com/legionnaires-water-vapour

In addition, there are many resources available to employers through the Centre for Disease Control (CDC), including how to develop and implement a Legionella exposure control plan.

The BCRSP is a self-regulating, self-governing organization certified by BSI Management Systems to ISO 9001. The CRSP certification is accredited by the Standards Council of Canada to ISO/IEC 17024. www.bcrsp.ca

The following individuals have been granted certification as a Canadian Registered Safety Professional (CRSP)®/Professionnel en sécurité agréé du Canada (PSAC)®

Anas Sobhi AlMahmoud CRSP

Samuel Ofoe Atichogbe CRSP

Andrew Brown CRSP

Joseph Murray Burrows CRSP

Roberto Camba Baldomar CRSP

Stephanie Chauvette-Courtemanche CRSP

Dennis Wayne Cheng CRSP

Anthony James Coldwell CRSP

Elsie Cooper CRSP

Monday Allyn Cryne CRSP

Tara Dakin CRSP

Colin de Raaf CRSP

Yetunde Khifayat Zainab Emmanuel CRSP

Obinna Chinedu Eronini CRSP

Chelsey Foster CRSP

Travis Gallup CRSP

Emily Meganne Hogan CRSP

Abdullah Javaid CRSP

Peter Joseph CRSP

Steve Kallies CRSP

Maxat Kikbayev CRSP

Vsevolod Kuzmenko CRSP

Shelby Langridge CRSP

Benjamin Levannier CRSP

Nadine Daisy Livingston CRSP

Elisha Malette CRSP

James Marles CRSP

Jody Mathers CRSP

Ashley Elizabeth McCallum CRSP

Akeem Mustapha CRSP

Justice Nkrumah CRSP

Vinoy Thomas Rajan CRSP

Adam Ranger CRSP

Kevin Joseph Robinson CRSP

Sohely Shafique CRSP

Martin Mateen Sheridan CRSP

Avinash Singh CRSP

Carolyn Single CRSP

Kessie Jo Stevens CRSP

Nathan Thompson CRSP

Nolan VanDenHeede CRSP

Lisa Tonette Wells CRSP

Courtney Wolfe CRSP

Simon Wong CRSP

Alexandra Skinner is the manager, government and media relations, at WorkSafeBC.

Commercial fishing deaths in Canada hit 20-year high

Lifejackets have improved, but TSB says crews need adequate information about vessel stability

By Meagan Gillmore

Despite improvements in safety training and awareness, commercial fishing remains one of the most dangerous professions in Canada.

The Transportation Safety Board of Canada reports that 45 workers died between 2018 and 2020, the highest three-year total in 20 years. And fishing safety has been on the board’s watchlist of important safety matters since 2010.

But fishing fatalities are preventable. The Transportation Safety Board also reports that 29 workers died between 2015 and 2021 after their boats capsized or sank without personal floatation devices or distress-alerting devices.

“You’ve got to be prepared for the worst-case scenario, and that’s where we see that they’re not prepared,” said Glenn Budden, a former fisherman and now a senior marine investigator in Vancouver with the transportation safety board.

More styles of equipment increase safety options

Proper equipment, including personal flotation devices, life boats, ladders and emergency position-indicating radiator beams (EPIRBs) is crucial. While federal regulations require there to be enough life jackets for everyone on board, and say that all vessels need to have some combination of flashlights and emergency signalling devices, safety professionals are still concerned about ensuring that everyone obeys the rules.

Equipment like personal floatation devices comes in many different styles, so fishermen can find the product that’s best for them, said. Matthew Duffy, the executive director of Fish Safe NS, an organization in Halifax that promotes safety within the commercial fishing industry.

He knows captains that keep several styles of life jackets in-stock so that workers can find one that suits them best.

“I think at this point, we’re at the stage where there isn’t as much excuse not to wear (the life jacket), because there is quite a bit of variety to find one that will fit and is workable,” he said, noting how workers often stop wearing them because they’re uncomfortable, or they get in the way of their work. “I think it is much more attainable now more than it has been in the past.”

Fish Safe NS will cover half of the purchasing cost for life jackets for its members and will deliver them directly to the members. The goal is to encourage captains to keep their stock up-to-date and in good working condition, Duffy said.

For Budden, the need to invest in proper safety equipment is obvious. “It’s a pretty simple solution that can save hundreds of lives over time,” he said.

Maintaining boat stability is key

But the best defense against drowning is making sure that workers stay on-board their vessels, said Pat Olsen, a manager in prevention field services for WorkSafeBC in Courtenay, B.C. “PFDs are a huge safety component,” he said. “But if you’re in the water, it’s going to give you a few more minutes of meaningful time to hopefully get rescued. What causes drowning is workers are ending up in the water,” he said.

“They’re not on the boat.”

The Transportation Safety Board has been raising concerns about the need for crews to have adequate information about a vessel’s stability for years.

Crews should have access to reports by naval architects about the vessels where they work, said Budden. Stability assessments aren’t “an exact science,” he said, “but it does give them at least some sort of a measuring stick.” Under

“What causes drowning is workers are ending up in the water. They’re not on the boat.”

- Pat Olsen, WorkSafeBC

federal regulations, stability reports are mandatory for all new vessels that are longer than 9 metres and for herring and capelin boats that weigh more than 15 gross tonnes.

But having reports isn’t sufficient; crews need to be able to understand interpret the report so they know how much weight their vessel can bear, said Olsen. Fishermen need to keep the boat as light as possible, including managing the free service so heavy liquids or fish aren’t sloshing around or keeping hatches and doorways closed whenever possible during fishing so the boat doesn’t take on extra water. Loading needs to be done properly as well.

Even so, it can be difficult for crew members to detect all the risks to a vessel’s stability. “It can be invisible,” Olsen said. “You can look at a vessel and not recognize that it’s right on that knife’s edge of being stable or unstable.”

That’s one of the reasons why crews need to be trained every time they are assigned to a new vessel. Even crews with decades of experience can have accidents if they haven’t been properly trained on

the specific vessel where they’re working. Transport Canada certification is important, but “crews need to be orientated to whatever vessel they’re going to be running,” said Olsen.

Asking

for help reduces common injuries

But injuries can also happen onboard during fishing and processing. Moving, wet surfaces make tripping, slipping and falling key hazards for fishermen. In Nova Scotia, Fish Safe NS stresses the importance of preventing musculoskeletal injuries. This means reminding workers to work in pairs to lift heavy items, or use forklifts if they need to.

It can be difficult to change the culture and show people the need for proper safety training and equipment, said Duffy. “Some folks at the fishery, still like to do things the old-fashioned way,” he said, noting how some workers are reluctant to ask for help when moving heavy objects. “And that’s how some of these injuries happen at times.”

However, he hasn’t experienced

much resistance to the need for lifeboats, ladders or other equipment to help fallen fishermen get back on the boat. “The door’s wide open (for conversation),” he said, describing how fishermen often call Fish Safe NS with questions. “The conversations are happening.”

Safety involves everyone

Conway Hutt, an off-shore captain with Clearwater Seafoods, has seen an increase in safety training and awareness throughout his career.

“It’s been slowly evolving over the last few decades to the point that now it’s one of the top concerns when we go to work every day,” he said from his home in Shelburne, N.S. Hutt, who became a captain n 2015, says that workers feel more comfortable raising safety concerns.

All of his workers need to take a WHIMS course just to get on the boat; they come to work wearing hard hats and safety boots. Hutt, his mate and his safety representative inspect their boat before leaving the wharf, and those inspections are compared to inspections that the last crew did when the boat came into the wharf.

There are regular safety meetings during a voyage, and all the information from the meetings is shared with every boat in a fleet. Involving more people in inspections means more problems can get noticed, and fixed, he said.

Hutt makes sure to involve new crew members in safety training, and that each member is trained on all the different roles for safety drills. Because while getting enough fish is important, there’s something more valuable on every boat.

“Every decision I make, that’s in the back of my head: the 25 guys that follow me,” he said.

Meagan Gillmore is a freelance writer in Ottawa.

Quarterly Check-In

CSA Group

CSA Group is a global organization dedicated to safety, social good and sustainability. It is a leader in standards development and in testing, inspection and certification around the world, including Canada, the U.S.A., Europe and Asia. CSA Group’s mandate is to hold the future to a higher standard.

Q&A: Addressing psychological health and safety in the workplace

CSA Group director of HSSE walks through the key trends she expects in 2022

When COVID-19 shook the world in early 2020, CSA Group immediately sprang into action to develop standards, research and certification programs designed to help protect Canadians and strengthen Canada’s PPE ecosystem. On the home front, like other organiz-

ations, CSA Group was quickly adapting its own policies and processes to help ensure the safety of its over 2,000 global employees, which included evaluation of its mental health and wellness programs.

Manisha Mistry, senior director of health, safety, security and the environment (HSSE) speaks to OHS about how CSA Group’s safety-first mission has addressed psychological health and safety and some of the trends she expects in 2022.

Can you tell us about your role at CSA Group?

I joined CSA Group more than 20 years ago in the organization’s first-ever dedicated health and safety role. Given the nature of CSA Group’s work as both as a standards development organization and a testing, inspection and certification provider, safety has always been at the core of our mission and vision.

Over the past few years, we’ve signifi-

cantly invested in and grown our internal health and safety program and policies. Today, I oversee CSA Group’s global health, safety, security and environment (HSSE) programs, supported by a team of exceptional health and safety professionals.

Together, we are responsible for promoting and stewarding HSSE programs at CSA Group, which includes the organization’s psychological health and safety. I also oversee the organization’s diversity, equity and inclusion (DEI) efforts.

How did COVID-19 impact the mental health of CSA Group employees during COVID-19?

The impact of COVID-19 as a health and safety hazard for CSA Group, like employers around the world, was multi-dimensional. Very quickly, we had to address the physical risks of COVID-19 and the need for infection prevention and controls measures like providing appropriate PPE

for our essential, on-site laboratory teams.

W hat differentiated COVID-19 from other hazards our team had managed in the past was the psychosocial impact it had on many of our employees who were experiencing increased levels of stress and anxiety driven by fear, uncertainty and isolation.

What are some of the steps CSA Group is taking to create a psychologically healthy and safe workplace?

COVID-19 was a very unique hazard, but fortunately we already had a solid foundation in place including global, multi-site registration to ISO 45001 and ISO 14001, and implementation of the Psychological Health and Safety in the Workplace standard (CAN/CSA-Z1003-13).

Over the past two years, our HSSE team worked closely with our Total Rewards team to reinforce and communicate the existing benefits as well as to use the opportunity to add new benefits such as a virtual health solution for substance use disorder for eligible employees in Canada.

B eyond strengthening these benefits and expanding resources and training, something we realized very quickly was the connection that many of our employees had to the organization and their need for a sense of belonging.

We tackled this by ramping up our employee communications making them more frequent, clear, and informative, and by normalizing the conversation about mental health. Our executive team, including our president and CEO, played a significant role in doing this, sending out regular emails, videos and participating in virtual events.

Can you share some of your key learnings for implementing a standard like Z1003?

P rior to implementing CAN/ CSA-Z1003-13 in 2019, CSA Group already had numerous resources and offerings for employees focused on mental health and wellbeing.

Implementing a standard is not a means to an end, but a way to look at things more

systematically to streamline implementation of programs and policies, identify gaps and measure success.

How does DEI factor into how CSA Group is addressing psychological health and safety?

Prioritizing diversity, equity and inclusion in all facets of our organization is fundamental to creating a culture where employees feel comfortable and able to bring their whole selves to work every day.

Feeling a sense of belonging and fostering a culture where employees have colleagues who “look like them” or who have similar life circumstances, contributes to a positive work experience.

How has CSA Group solicited feedback from employees to inform its approach to psychological health and safety?

Gathering regular feedback and input from our employees is crucial. In addition to regular engagement surveys which includes questions about mental health and wellbeing, we have deployed regular check-in surveys to understand how employees are feeling and what they need.

For OHS professionals in the early days of developing programs and policies focused on employee mental health and wellbeing, do you have any learnings to share?

Creating a strong mental health and wellness program is a fluid process as the challenges and needs of employees are constantly changing. It’s important to regularly step back, evaluate progress and tweak as needed.

It’s also important that employers avoid building policies and programs in a silo, without consulting employees. Remember to ask employees for their suggestions and feedback, as consultation with employees can be a positive input.

What are some of the trends that you believe will influence how employers address psychological health and safety in 2022?

2022 is shaping up to be an unprecedented year for health and safety professionals. One of the top trends facing employers will be managing the physical and psychological safety of employees in a hybrid workplace, from technology to encouraging a new type of life-work integration.

Employers will also be looking at how they can level the playing field to be sure that employees, whether they are working from home or at the office, are provided with the same opportunities for advancement and visibility. Finally, it’ll be interesting to see how employers begin to plan and execute on-site activities for larger groups of employees.

CCOHS Corner

Canadian Centre for Occupational Health and Safety

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness.

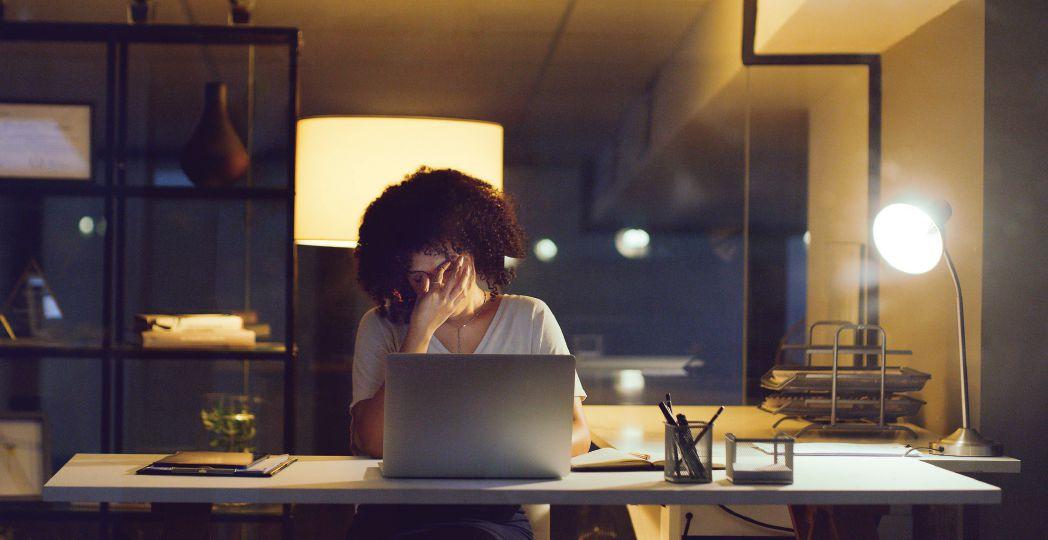

Always on: Supporting employees’ need (or right) to disconnect from work

AAfter six months at her new job, Amira’s office went completely remote. At first, she welcomed being able to work from home and reclaim the personal time she used to spend commuting. The flexibility, however, seemed to come at a price.

To show her supervisors she’s just as productive at home, Amira makes sure she’s always available to answer calls and responds quickly to messages and emails – even if they come in well outside her working hours. With no clear separation between her work life and home life, Amira struggles to be present with friends and family. She’s always a little fatigued, which makes it impossible to get through her task list before her workday ends.

To avoid the stress, fatigue, and burnout that come with the pressure of being “always on,” workers need support from their employers to fully disconnect from work.

What prevents disconnecting?

According to a Privy Council Office Survey from August 2020, 43 percent of workers in Canada check their work email outside of standard working hours. One in three answer work emails, calls or texts, and 28 percent perform other work-related duties. Many cite being available to supervisors and stakeholders as an expectation that comes with their job. Others send texts and emails in their personal time to manage a heavy workload, or due to irregular working hours.

Not being able to disconnect for a sustained period of time can lead to burnout, depression, and anxiety. There is also a concern that employers could reward workers who don’t disconnect

The need to disconnect

Disconnecting from work means having the ability to stop working and not feel obligated to respond to work issues outside of defined working hours. Having uninter-

rupted personal time and space away from work stressors allows your body and mind the opportunity to relax and recover.

Depending on the nature of the work, it can be easy or difficult to disconnect. Workers who are unable to work when outside the workplace (e.g., manufacturing or construction) may have an easier time. Workers that can easily continue working (e.g., sales, finance, consultants, technical specialists) may find it harder.

What the law says

Last year, Ontario became the first province to pass laws to help employees disconnect. Effective June 2022, the new act requires workplaces with 25 or more people to have a written policy.

Moreover, provincial, territorial, and federal governments have laws that require employers to provide time off from work, unless the occupation is exempt (e.g., police officer) or there are extenuating circumstances. Some employment standard laws include protections for workers to have time off work on a per day and per week basis unless other arrangements have been made Some jurisdictions specifically state that “on-call” or “stand-by” workers are not considered to be working. However, if the worker is called in, they are considered to be working and must be compensated.

Create a supportive culture

To get started, develop a policy on disconnecting that defines the boundaries between work and non-work time. It should set expectations for response times to non-essential emails sent after established hours and how working across different time zones will be addressed. Consider how disconnecting impacts emergencies and other safety-related issues and include how labour or employment standards protections will be respected.

Organizations can also implement ‘quiet hours’ to reduce and discourage emails or meetings outside of established hours. If an

email is sent after hours, make it clear a response is not expected outside of established hours. If a worker is regularly working outside of the established hours, have a conversation and offer support.

Managers and supervisors can lead by example by signing off when their working hours are over and sharing how they transition from work time to personal time. This also shows that disconnecting isn’t a barrier to advancement.

Help workers disconnect

• Lead by example.

• Promote disconnecting at the end of the day as part of your corporate culture.

• Provide awareness of work-life balance skills as part of workplace health and wellness programs.

• Do not send, and instruct workers not to respond to, work communications during their time off.

• Avoid rewarding workers who continue to work outside of their established hours.

Employers and employees can support this initiative by not routinely calling or emailing outside the established working hours and by indicating when a communication doesn’t need immediate attention.

Disconnecting can start with something as simple as an end-of-workday ritual, like heading out for a walk immediately after shutting down your computer. If you have enough space at home, create a separate working room or area, and ignore it when the workday is over.

The rise of mobile technology and alternate work arrangements have opened the doors to unlimited access to work, and pressure to continue working outside of required hours.

Like Amira, the boundaries between being at work and not at work have become increasingly blurred for many workers. Promoting the right to disconnect can help everyone work toward a safer, healthier and more productive workplace.

Freedom 100

RICHMOND, Calif. (AP) — The oldest active park ranger in the United States is hanging up her Smokey hat at the age of 100.

Betty Reid Soskin retired Thursday after more than 15 years at the Rosie the Riveter/ WWII Home Front National Historical Park in Richmond, California, the National Park Service announced.

Soskin “spent her last day providing an interpretive program to the public and visiting with coworkers,” a Park Service statement said.

She led tours at the park and museum honoring the women who worked in factories during wartime and shared her own experience as a Black woman during the conflict. She worked for the U.S. Air Force in 1942 but quit after learning that “she was employed only because her superiors believed she was white,” according to a Park Service biography.

German man gets 90 COVID shots

BERLIN (AP) — A 60-year-old man allegedly had himself vaccinated against COVID-19 dozens of times in Germany in order to sell forged vaccination cards with real vaccine batch numbers to people not wanting to get vaccinated themselves.

Bizarre beach trash

LONG BEACH, N.J. (AP) — Volunteers picked up a record amount of trash from New Jersey’s beaches last year, with plastic items dominating the haul, and bizarre castoffs including male enhancement pills, a set of braces, a glow-in-the-dark condom and a Turkish Airlines hygiene kit found on the sand as well.

And some of it was just head-scratching, if not stomach-turning.

A hunk of human hair; a full set of dentures (“I TOLD you not to take your teeth to the beach!”); a thong; a used narcan kit (used to revive drug overdose victims); several marijuana bags (empty, of course); a bullet casing, and a fake eyeball were among items picked up.

There also was a parking ticket; a lottery ticket; a glue stick; a mini-refrigerator; a toilet brush; a TV remote control; a Mason jar filled with (we hope) liquor; a plastic monkey, and a set of rosary beads, possibly from someone praying for the cast of characters that left all this behind.

All told, 513,605 items were collected last year, the most ever since the beach sweeps began in 1985.

Presented

The BD Veritor™ At-Home COVID-19* Test enables reliable, self-administered COVID-19 testing with digitally displayed, shareable results in just 15 minutes.