FOCUS ON:

Creating an effective hearing conservation program. ALSO: CMMS – Cloud-based versus on-site installs.

Using testing techniques to troubleshooting equipment.

Creating an effective hearing conservation program. ALSO: CMMS – Cloud-based versus on-site installs.

Using testing techniques to troubleshooting equipment.

What will the future of maintenance entail?

12 20 24 27

CREATING AN EFFECTIVE HEARING CONSERVATION PROGRAM

Excessive noise in the workplace is a significant health concern, affecting millions of workers across Canada.

NEXT GENERATION MAINTENANCE

MRO spoke with maintenance and asset management experts to get their perspective on what they see happening for the next generation of maintenance.

OUTSOURCING MAINTENANCE – IS IT TIME YET?

If we ask finance and operational leaders about their desire for improved asset performance and lower costs, they are interested, but cautious about just how it can be achieved.

UNPLANNED DOWNTIME COSTS BUSINESSES NEARLY QUARTER MILLION DOLLARS PER HOUR

A survey from ABB has found that 68 per cent of industrial businesses in Canada experience unplanned outages at least once a month.

MRO has run a round table at the PEMAC Asset Management Association of Canada Maintrain conference since before I become editor of MRO in 2018. The 2023 conference was held in Winnipeg, and the round table was the biggest ever.

This year, the speakers included Paul Daoust, SCIO Asset Management Inc., who led a discussion about minimalist maintenance metr ics; Susan Lubell, Steppe Consulting Inc., discussed competenc y frameworks for asset management; and James Reyes-Picknell, Conscious Asset, looked at if it’s time to outsource maintenance, which is available as an article on page 24.

The final speaker was Erika Mazza, The Regional Municipality of Durham, who asked her group about green maintenance and if it is a trend or a responsibility.

I wanted to focus on Mazza’s discussion, as it is of utmost importance with our ever-changing climate. Her group talked about the need to start monitoring and understanding how we are impacting our environment. This is important, as you cannot improve anything if you don’t measure it fir st, meaning the need to measure and understand, and then start identifying strategies that can reduce this impact. Waste and how to manage it is a big part of that. She asked, “how are we managing the disposal of products and how can we replace assets when they are no longer active or useful, or to repair them.”

In this respect, Mazza mentioned that planning is essential to reducing waste, to make sure jobs are safe, and to conserve resources.

Also important is reducing the amount of mobilization of crews, which is a big part of the ecological footprint, as we are putting emissions into the environment just by mobilizing crew from one site to another.

Fur ther, if you are a company that works in remote locations and need

to mobilize machinery, think about using drones in that area, which reduces the impact on the environment.

Another big aspect mentioned of reducing waste was to make sure to design for repair or design to be ecological responsible. If we think from the design stage about how assets are going to live their life and how much they’re going to impact the environment during their useful life, we can reduce the amount of waste, and be more efficient.

On last item to think about is making sure to have a policy of asset life cycle inventory. Inventory, a lot of times, is a use it or lose it proposition. Therefore, when it has reached the end of it’s lifespan (shelf life), it is scrapped. In that respect, carry only what you need.

To learn more about the topics discussed, view MRO’s summary videos of the round table are available on our web site and YouTube channel. As the topics are different each year, you can also find videos from the 2022 version there as well.

Next year, the Maintrain conference makes its way to Saint John, New Brunswick, and MRO will once again be there running the round table. It will again have insightful discussions about the topics that are of utmost important to the maintenance community. Hope to see you there.

MARIO CYWINSKI Editor mcywinski@mro.ca

ESTABLISHED 1985

WINTER 2023

Volume 39, Number 4

READER SERVICE

Print and digital subscription inquiries or changes, please contact Customer Service Angelita Potal, Customer Service Administrator Tel: 416-510-5113 email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR Mario Cywinski 226-931-4194 mcywinski@annexbusinessmedia.com

SENIOR PUBLISHER Paul Burton 416-510-6756 pburton@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett 416-829-1221 ifawcett@annexbusinessmedia.com

BRAND SALES MANAGER Chander Verma 437-218-0941 cverma@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

MEDIA DESIGNER Graham Jeffrey

ACCOUNT CO-ORDINATOR Debbie Smith 416-510-5107 dsmith@annexbusinessmedia.com

GROUP PUBLISHER Anne Beswick abeswick@annexbusinessmedia.com

PRESIDENT/COO Scott Jamieson sjamieson@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates.

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

ANCA Inc., is expanding its footprint Canada by adding Brady Roarke as applications eng ineer and technical sales expert, based near Toronto, Ontario.

“I am honoured to be part of ANCA’s talented team and to contribute to the company’s ongoing success in the Canadian market,” said Brady. I look forward to collaborating with colleagues and clients alike to deliver exceptional grinding solutions.”

Brady brings nine years of experience as applications engineer. Five of those years were spent milling, and four grinding.

“We are thrilled to welcome Brady to our team,” said Russell Riddiford, president, ANCA Inc. “With his extensive experience and deep insights into the grinding industry, we are confident that Brady will be instrumental in driving ANCA’s growth and success in Canada.”

The Canadian Renewable Energy Association (CanREA) launch the Clean Energy Jobs Canada web site (cleanenergyjobs.ca). It aims to help accelerate recruitment of skilled workers into the renewables and energy storage industries.

The new web site allows job seekers to post their CVs, search for current openings across Canada, apply for jobs, and create personal job alerts. Employers can post job openings and search a database of qualified candidates.

“We know that the number of people interested in renewables is higher than it’s ever been, and we have heard from our member companies that there is a crying need for workers, so CanREA has built this website to try to connect those dots,” said Mathieu Côté, director of CanREA’s Operations Program.

“Clean Energy Jobs Canada aims to move people from ‘interested’ to ‘employed’ in this industry.”

CanREA member companies get complimentary job postings on the site in 2023 and discounted posts in 2024.

German Technology Day hosted 22 of Germany’s leading automation and advanced manufacturing equipment manuf acturers. The fifth iteration of the annual event, has the number of exhibitors and presenters steadily growing since its inception.

With the theme of transformation, the show showcased each company’s industry-leading, energy-efficient solutions, and a series of 30-minute presentations from each participant throughout the day.

Standout presentations included Weidmuller’s automation and network specialist, Visal Jhurry, presenting the company’s recently released u-OS, a Linux-based embedded OS designed for IIoT and automation applications, and Pilz’s product manager, Guillaume Lavoie, who explained how IO-Link Safety is

transforming the future of safety communication and diagnostics.

Other standouts included a WAGO case study on optimizing uptime with predictive maintenance, presented by Tyrone Visser; and Murr Elektronik, head of system solutions, Tom Jensen’s summary of IIoT infrastructure technologies.

Thomas Böck, has been appointed as head of the Management Board at Festo, succeeding Oliver Jung, effective Jan 1, 2024.

“I am very much looking forward to contributing my experience to Festo. Together with the Festo team, we will keep the value-oriented family-owned company on course for success and promote its further development,” said Böck.

Böck was most recently CEO and previously chief technology officer of CLAAS. Böck brings a wealth of experience in implementing an international growth strategy in a high-tech environment.

“I am very proud of what we have achieved to date at Festo together with our employees. I wish Mr. Böck all the best for the ongoing development of the company. Personally, I will continue to feel closely connected to the Festo family in the future,” said Jung.

BY MARIO CYWINSKI

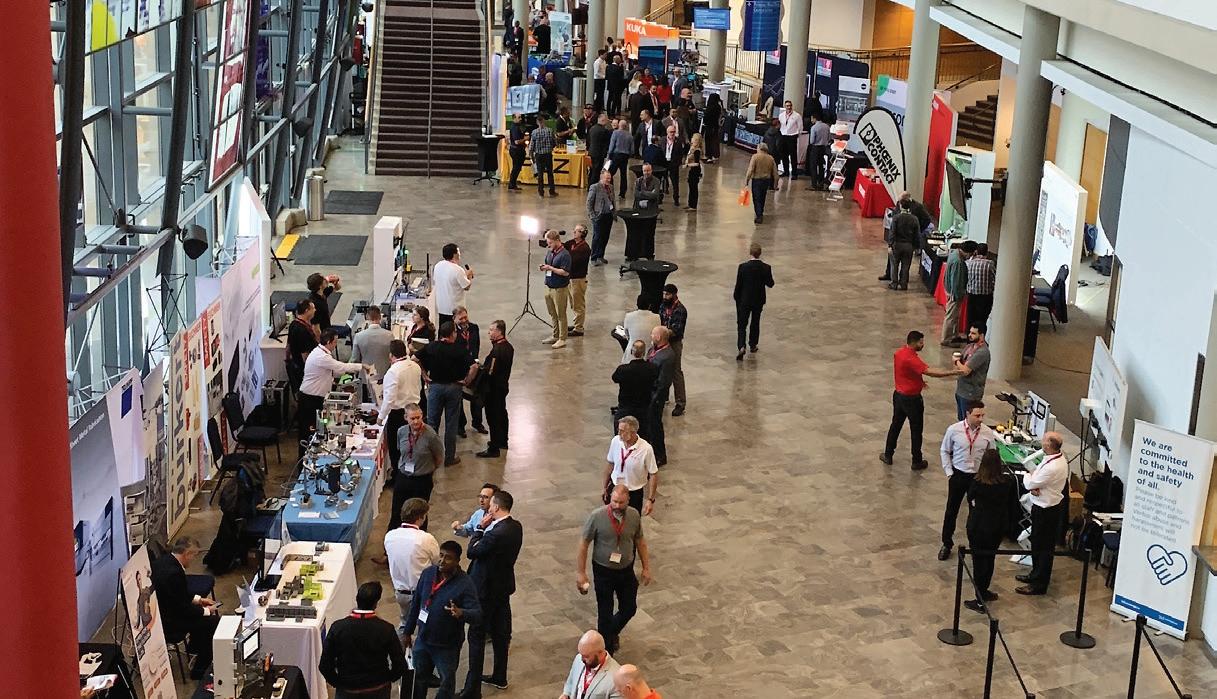

The 2023 edition of the Canadian Manufacturing Technology Show (CMTS) drew over 8,000 attendees to the Toronto Congress Centre near the airport. The show offered attendees over 50 knowledge sessions, over 200 new products to view, over 500 suppliers and original equipment manufacturers (OEMs) to network with, and over 250,000 sq. ft. of floor space to discover.

CMTS (which takes place every other year, alternating with IMTS in Chicago) focuses on the latest equipment and technology in automation, robotics, additive manufacturing, machine tools, metal forming, fabricating, and digital transformation. Those in attendance represent many industries, including automotive, aerospace, energy, government, commercial and industrial, and oil and gas.

This year, even Canadian Prime Minister Justin Trudeau made time to visit the show. Trudeau walked the show and spoke to members of the manufacturing community. He also had a fireside chat with Flavio Volpe, president of the Automotive Parts Manufacturers’ Association, which held its Annual Conference in conjunction with CMTS.

The transportation revolution Flavio Volpe, also provided a keynote about How Canada Can Drive the Next Transportation Revolution. He spoke about the Project Arrow, which was displayed on the CMTS trade show floor. The Arrow is an all-electric automotive concept vehicle which features materials and parts from 60 Canadian companies.

In what was the biggest CMTS since the start of the COVID-19 pandemic, over 500 suppliers and OEMs showed off over 200 of their new products.

Robotic machines were everywhere, as can be seen in the videos below. The show floor was busy for all four days of the show, as attendees and exhibitors networked.

The show floor also included a Canadian Tooling and Machining Association tooling pavilion, a CWB-EWI welding showcase, and an emerging innovators showcase. The Smart hub was where attendees could relax and network with fellow colleagues and grab a refreshment.

Other highlights included a smart theatre that presented a plethora of experts on the topic of smart manufacturing adoption and a bright minds student summit, which included 120 high school students.

CMTS opened with a keynote by Massimiliano Moruzzi, CEO, Xaba, who spoke about Shaping Tomorrow’s Industry: Canada’s Odyssey with Industrial AI

Another day one keynote was presented by Diane Reko, CEO, Reko Inter national Group Inc., who spoke about Charting the Future of Canadian Manufacturing. Sarah Syed, innovator, climate activist and poet, delivered another

keynote, focusing on the Impact: How to Transform Your Passions into a Medium for Change

Syed also participated in the Wonderous Women in Manufacturing panel, along with moderator Julie Pike, Lisa Block, chief revenue officer, Hybrid Manufacturing Technologies, and Mihaela Vlasea, mechanical and mechatronix engineering professor, University of Waterloo.

Other keynotes and panels included: Unleashing the Power of AI in Manufacturing by Chris Casey, industrial manuf acturing and automotive sector lead, PwC Canada, and Micheal Gardiner, manufacturing industry lead, Microsoft Canada; Staying Ahead of the Curve with Industry 5.0, ESG and Workforce Upskilling by Subo Chatterjee, digital operations and industry 5.0, PwC Canada, Nadia Malik, transformation head, Bombardier, and Micheal Gardiner; Making the CASE (Connected, Autonomous, Security, Electric) for Canada by John Heaton, partner, KPMG LLP, Alex Qi, CEO, Pontosense, and John Komar, executive director, ACE, Ontario Tech University; and Leading in the Transforming Manufacturing Industry by Greta Cutulenco, CEO, Acerta.

Maintenance, asset management, and reliability professionals came to Winnipeg, Manitoba for the PEMAC Asset Management Association of Canada Maintrain 2023 conference.

BY MARIO CYWINSKI

The PEMAC Maintrain conference takes place annually, in different locations each year. Last year, it took place in central Canada, in Toronto, Ontario, next year it will go to eastern Canada, and this year it was in western Canada.

Attendees participated in workshops, sessions, panel discussions, keynote speeches and an exhibition showcase. The hybrid model allowed those not attending in person to attend the conference. Also, pre-conference online only sessions were available before the conference started.

The conference was jam packed with information, in turn, to make it easier to cover, we’ve broken it down into sections.

MRO held its annual round table once again; this year’s edition was the

biggest yet, as around 100 attendees were on hand (live and online). The round table allowed delegates to discuss maintenance topics of utmost impor tance to their operations.

The speakers were Paul Daoust, founder, at SCIO Assset Management Inc., who spoke about minimalist maintenance metrics; Susan Lubell, principal consultant at Steppe Consulting Inc., who discussed competency frameworks for asset management; Erika Mazza, acting project manager, Systems Policies Process GroupWorks Department., The Regional Municipality of Durham, who asked green maintenance - a trend or a responsibility; and James Reyes-Picknell who is the principal consultant at Conscious Asset, looked at if It’s time to outsource maintenance?

The speaker summaries for the round table are available on MRO’s web site.

Each morning, a keynote started the day. This year the keynote speakers included: Chief Gordon BlueSky of the Brokenhead Ojibway Nation; John Hardwick, executive director - asset management, Transport for NSW Government who spoke about Creating an Asset Management Culture for Success; and Jim Pawluk, director of asset management, Manitoba Hydro, who discussed Asset Management - Engaging with the Enterprise.

A big highlight each year, are available facility tours that are part of the conference. This year attendees had the opportunity to visit WinPak Ltd., a manufacturer and distributor of packaging materials and machines, and MacDon Industries Ltd., a manufacturer of harvesting equipment, f acilities. The tour allowed attendees

to see how maintenance and asset management is done at these companies, and what they do to make sure they run efficiently.

Exhibitor showcase

A big part of the conference each year is the exhibitor showcase, which allowed attendees to network with fellow industry professionals and discover the latest products that are available on the market. Those exhibitors in attendance included Cameco, Cohesive, IPS, Northern Lakes College, Revisionz, STI, UE Systems, Wajax, and many others.

Each year PEMAC hosts its Awards Banquet during the MainTrain conference. Awards were given out to those who showed excellence in the maintenance and asset management sphere.

Each year PEMAC hosts its Awards Banquet during the MainTrain conference. This year, Alan Cox, chair of the PEMAC Awards Committee took on the hosting duties. A selection of awards was given out to those who show excellence in the maintenance and asset management sphere.

The winner of the MMP Capstone – Business Process award was Brian Sibley, maintenance

manager at the City of Saskatoon Water Treatment Plant, for work on the City of Saskatoon Maintenance Workflow Optimization project. MMP Capstone – Technical Focus award winner was Chris O’Rielly, maintenance supervisor at Halliburton for the project Halliburton Service Truck Replacement . AMP Capstone winner was Ashvin Koarga, manager of Asset and Order Management at Metrolinx - PRESTO, for his project, Metrolinx’s Station Fare Transaction Processor Asset Management Framework. Other award winners included: Susan Lubell who won the Asset Management Leadership award; Mike Crowell, won the Maintenance Management Leadership award; Maintenance Team of the Year for a large organization was the maintenance department of Simcoe Muskoka Catholic District School Board; Maintenance Team of theYear award for a small organization is Capital Power’s York Energy Centre; Asset Management Achievement award was given to the Nunavut division of Agnico Eagle Mining Limited; and the Sergio Guy Memorial award was given posthumously to Chris Murphy.

Workshops and Sessions

Workshops and sessions were presented by industry experts and allowed for attendees to learn from those who are experts on the topics they are discussing. Four sessions took place simultaneously in different rooms.

Other highlights PEMAC hosted members of the Global Forum on Maintenance and Asset Management (GFMAM) and the World Partners in Asset Management (WPiAM) international organizations, who also contributed to the conference prog ram.

After the conference, attendees networked at The Canadian

Museum for Human Rights. Maintrain will go east next year as the 2024 conference will be in Saint John, NB.

Mario Cywinski is the Editor of MRO, Plant, and Food and Beverage magazines, and a member of the Automobile Journalists Association of Canada. Contact him at mcywinski@mromagazine.com

Most CMMS applications fall under two categories: on-site and cloud-based.

Computerized maintenance management systems (CMMS) are a hot topic for many corporations and maintenance departments. Maintenance departments may be looking to purchase their first CMMS or upgrading their current maintenance software. Maintenance departments use different tools and resources to maintain equipment, one of the crucial ones is CMMS. Both on-site and cloud-based CMMS solutions are designed to provide an application that can plan and track equipment maintenance.

BY PETER PHILLIPS

Typically, when people think of software, the concept is, there’s an application, you install it on a computer, phone, or tablet, and use it. When a user installs software, it’s typically tied to the device. In the case of a traditional CMMS, it’s deployed onsite and is tied to the on-site hardware and is deployed on each computer across the organization.

Cloud-based solutions are entirely the opposite. The application is not tied to the company’s hardware and resources. With cloud-based systems users can access the application on any device that has an Internet

connection. With cloud-based systems, fewer IT resources are required as the cloud-based solutions don’t need maintenance – everything is done by the vendor through a support contract. Finally, cloud-based solutions are typically cheaper to implement and operate.

Users are not tied to the premise or the workshop, they can access the app from anywhere and whenever the work requires them to. In contrast, older CMMS requires them to be present on the site.

Apps can be accessed from smartphones and tabloids, users only need to log-in and have an Internet connection. The maintenance planner, super visor and technicians can use their mobile devices or workstations to keep track of the maintenance

tasks, assign new work orders, and provide feedback when necessary – something that’s not always possible with on-site solutions.

The solution is handled by the vendor. The IT team can show a user or provide a manual on how to access and use the CMMS cloud-based app on their devices. Maintenance team members can start using the app r ight away after logging in.

With on-site solutions, there can be issues, for example, maintenance, implementation, and operating system updates. All of these require servers, hardware, and more IT personnel, incurring costs in the process.

Major updates can be long, cumbersome, and disruptive. Cloud-based CMMS software, makes updates seamless, users are notified about updates and no other actions are required by IT or user s. With on-site solutions, even the smallest updates can be time-consuming, whereas, with cloud-based solutions, the under-the-hood improvements are occurring constantly.

Organizations need to ensure that required resources like the hardware and servers are available, and CMMS supporting resources and software loaded on the servers. While it might sound simple, getting management to sign off on machinery and software can be time-consuming.

Organizations just need to make the recurring application payment to the vendor, and they will provide accounts to use the solution. Users log onto their devices on a secure Internet connection to use it, making implementation faster. With appropriate training and demonstration, maintenance team members can start using it right away.

A dedicated IT person is not required. There are no additional servers or hardware required, the application is easy to implement, and can be used from any compatible device. As a result, organizations that use cloud-based solutions are saving up-front costs. The payment model is quite simple –organizations need to pay a certain amount based on the number of users.

Security and maintenance is taken care of by the vendor. This relieves the IT personnel from having to troubleshoot problems with on-site CMMS solutions. When a user identifies a problem with the cloud-based solution, they only need to report it to vendor support.

A unique benefit for dynamic organizations is scalability. For instance, if an organization has few maintenance team members now, it needs a solution that can match the lower workload. However, if the same organization aims to expand its maintenance team significantly, it needs a solution that must be able to match the increased workload and maintenance tasks.

The maintenance team is completely mobile with work orders on their tablets and access to parts inventory and equipment information through the app. The users just need to log-in to the authorized devices and they’re good to go, they get access to crucial information, such as spare parts availability, assets, vendors, and tasks. These modern maintenance management apps cut down response time to unexpected equipment breakdowns and prevent production disruptions.

Cloud-based CMMS applications ensure that asset, vendor, spare parts, and technician information are kept in a centralized location in an organized manner. Moreover, authorized users can monitor the progress of technicians, work orders, and repairs. While the maintenance supervisor can add further work details and schedule work, technicians can update the status of their assigned work orders using the app.

Regular workers including production supervisors and operators can also submit work requests. Robust maintenance management apps also allow them to add images

or videos to show the precise problems with the faulty equipment. Maintenance supervisors, upon verification of the work request, can assign technicians to work order for action or can add it to the maintenance backlog. All in all, a cloud-based CMMS helps improve collaboration between the production department and streamline maintenance efforts.

CMMS vendors list potential benefits of their software, they include:

• Reduce equipment downtime;

• Increase productivity;

• Lower maintenance costs;

• Improve inventory management;

• Schedule preventive maintenance;

• Increase life of equipment;

• Enhance work order management;

• Generate custom reports;

• Make data driven maintenance decisions; and,

• Meet compliance and safety standards.

The trick to choosing a CMMS for your company, is finding a system that fits the maintenance department’s needs and ease of use and provides reports and KPIs to guide the maintenance team to effectively maintain the equipment and spare part inventory, and to fit the maintenance department budget.

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@trailwalk.ca.

Excessive noise in the workplace is a significant health concern, affecting millions of workers across Canada.

BY THE CANADIAN CENTRE FOR OCCUPATIONAL HEALTH AND SAFETY (CCOHS)

It’s estimated that over 11 million Canadians aged 19 to 79 have worked in noisy environments, defined as the need to speak in a raised voice to communicate with co-workers at arm’s length. Of those workers, 56 per cent were classified as vulnerable to noise—they were not required to use hearing protection and only did so sometimes, rarely, or never.

Constant exposure to excessive noise is a hazard that, in the shortterm, can be disruptive and affect our ability to hear signals, speech, and machinery. In the long-term, it can lead to noise-induced hearing loss, permanently damaging workers’ hearing and affecting their quality of life. Hearing loss can also occur from a single traumatic event, such as a sudden burst of extremely loud noise near the ear.

In less extreme cases, excessive noise exposure can still cause damage. Workers can experience non-auditory effects such as increased stress, disruptions to cardiovascular function (changes to blood pressure and/or heart rate), sleep problems, and impacts to their mental health.

Hear ing conservation programs can help address noise hazards by emphasizing the early detection and control of excessive noise levels through appropriate measures to protect workers’ hearing.

Across Canada, each jurisdiction

outlines an occupational exposure limit of 85 dBA of continuous noise over an eight-hour period, except for federal workplaces, which have a limit of 87 dBA. When noise exceeds the jurisdiction’s exposure limit, controls must be implemented. Alberta, British Columbia, Manitoba, Newfoundland and Labrador, Northwest Territories, Nunavut, Prince Edward Island, Saskatchewan, and workplaces under the federal jurisdiction require a hearing conservation program when noise exceeds the exposure limit.

While not all jurisdictions have a requirement for a hearing conservation program, the elements of a program, such as training, noise assessments, and audiometric testing, also known as hearing testing, are necessary when workers are exposed to noise above the exposure limit.

The CSA Standard Z107.56, Measurement of noise exposure, recommends that the employer conduct a noise assessment if noise levels in the workplace exceed 80 dBA. This recommendation extends to any changes

in the workplace such as renovation or repair work, when new equipment is introduced, or a modification is made to a work process that may result in a significant change in a worker’s exposure to noise.

The first step in any hearing conservation program is to assess workplace noise levels. This step involves conducting noise monitoring to determine the magnitude of exposure in different areas and job roles. Using sound level meters and noise dosimeters help to ensure accurate measurements.

One of the primary objectives of workplace hearing conservation programs is to control noise at the source. Substituting equipment with quieter alternatives or implementing engineering measures, such as sound insulation, can help reduce noise levels and minimize employee exposure. Policies and procedures that limit workers’ exposure to excessive noise can also be introduced. This may include limiting the duration of tasks in noisy environments, implementing a job rotation schedule to reduce cumulative noise exposure, and designating rest breaks in quieter areas.

When noise levels cannot be adequately reduced, employers must provide suitable hearing protection, such as earplugs or earmuffs. Workers must be trained in the proper use, fit, maintenance, and care of personal protective equipment (PPE) to ensure their effectiveness in reducing noise.

Regular audiometric testing is a critical component of these programs. It involves baseline and periodic assessments of employees’ hearing abilities to detect any changes over time. By tracking changes in hearing thresholds, employers can monitor the effectiveness of controls, identify early signs of hearing loss, and take appropriate actions.

Make sure to provide education and training on the measures that are in place to reduce exposure and the elements of the hearing conservation program. Workers must be aware of the risks associated with elevated noise exposure and the long-term effects of noise-induced hearing loss.

Training should also include the safe use and limitations of hearing protection, covering all elements listed in CSA Z94.2, Hearing protection devices – Performance, selection, care, and use. Education and training should be provided at regular intervals, at least once every two years, or when conditions change. Hearing conservation programs can significantly reduce the incidences of noise-induced hearing loss by preserving workers’ auditor y health and preventing related

health issues like increased stress levels and tinnitus, which causes a ringing or buzzing in the ear. Through these programs, employers demonstrate their commitment to the health and safety of their workforce while fostering a sense of well-being and job satisfaction among employees.

By integrating noise monitoring, effective controls, and audiometric testing into an effective hearing conservation program, employers can protect employees by reducing the risk of noise-induced hearing loss, creating a safer and healthier work environment for everyone.

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

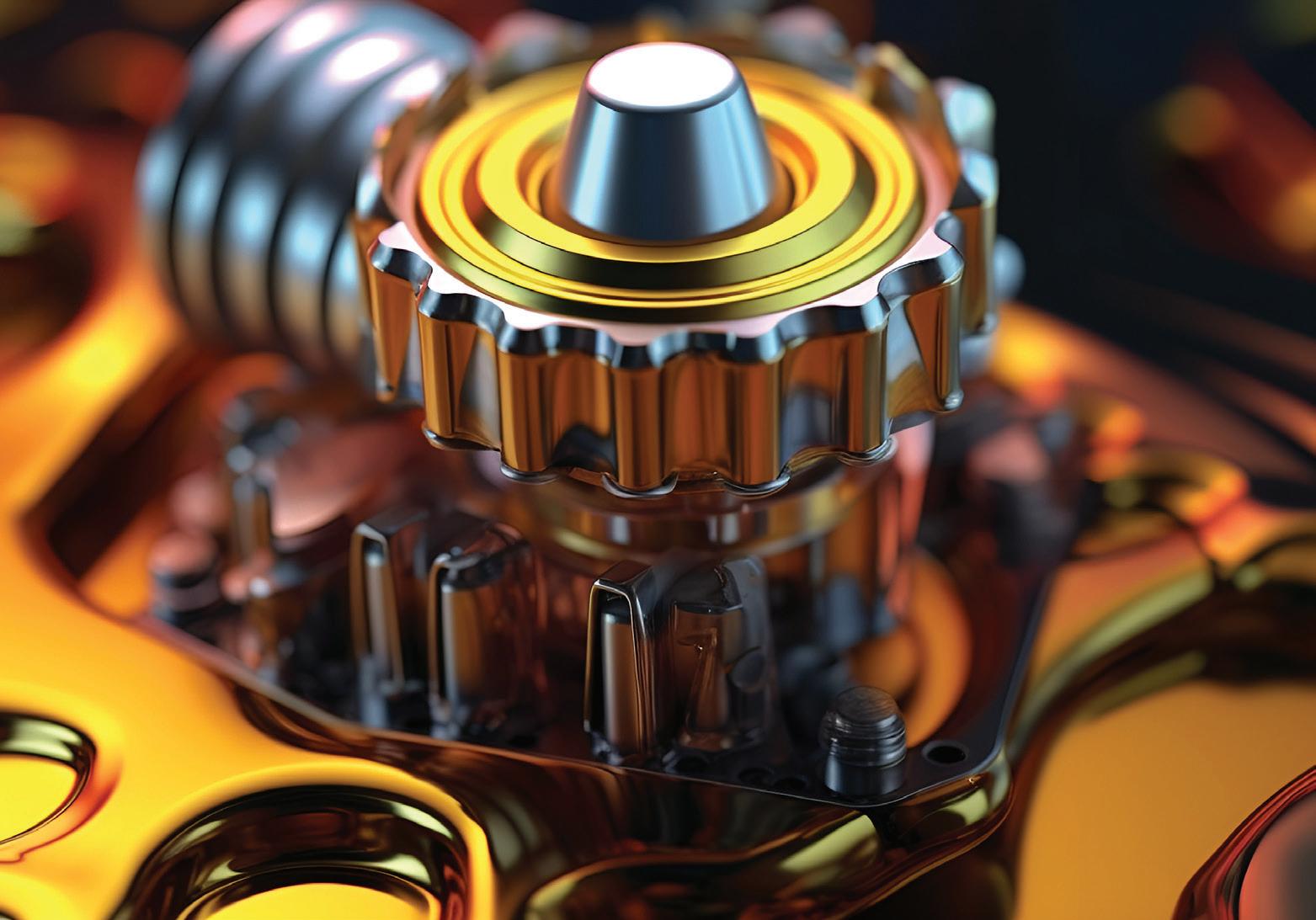

Monitoring equipment condition has been around since the creation of the wheel. The wheel squeaked, the wheel hub began to burn, and we learned to grease the wheel with tallow. As the application of the tallow became more precise, the time between wheel failure was extended.

In turn, the development of troubleshooting using the senses of sound, sight, touch, and smell. However sensory perceptions have the disadvantage of being subjective and imprecise, over the years, condition monitoring technologies have been developed for industrial equipment.

In his book, Reliability Centered Maintenance , John Moubray describes 96

techniques to monitor the operating condition of equipment. These range from sensor y techniques to the application of highly sophisticated technologies such as fast Fourier transform (FFT) analyser, to determine the causes of vibration frequencies in rotating equipment.

The use of testing techniques can only be justified if they demonstrate a clear economic benefit. Substantial evidence exists that the intelligent use of even simple testing techniques will provide huge benefits to industry including:

1 Elimination or reduction of catastrophic machine failures and secondary damage where a failure has occurred.

2. Reduction in maintenance costs by avoiding repairs.

3. Reduction in downtime by reducing the scope of repair.

4. Increase in production by scheduling repair when convenient to operations.

5. Reduction in downtime and costs by having advanced warning, permitting effective planning, and scheduling.

6. Reduction in r isk to equipment and personnel from a safety perspective.

7. Revised insurance costs.

8. Elimination of ineffective or unnecessary preventive maintenance tasks.

9. Extension of time-based intervals of necessary preventive maintenance tasks.

10.Improvement in reliability, productivity, and efficiency of machinery.

Operators often know more about the equipment they operate than do maintenance personnel and can be trained to monitor equipment condition. Effective testing

At least annually, a thermographic analysis should be carried out to locate hot spots in electric motors and mechanical devices such as drive couplings, bearings, and gear drives.

applied by operators must be gathered when equipment is at operating temperature and taken at the same point on the machine component when the data is collected.

The following testing techniques are common, easily applied, and only require that operations personnel have a sound knowledge of their equipment’s operation.

Q | Do the applicable equipment operators understand how contaminants enter a lubricated system?

LOGIC: Contamination of machine systems occurs in four ways, generated by the system itself (by nor mal wear, poor system or component design, surface fatigue and temperature related chemical reactions), implanted (by welding slag), induced (by careless maintenance practises), and escaped contamination (that enters a lubricated system through poor quality filters or poor filtration system design).

An operator’s simple contamination test is to obtain an oil sample in a glass jar allowed to sit overnight. When the jar is turned over, any contaminant will remain visible on the bottom surface of the jar. A decision can be made for further laboratory testing.

Q | Do the equipment operators know how to determine if water is a problem in a machine system?

LOGIC: Water contamination in a lubricated component can be determined by placing a few drops of oil on a hot plate. If the oil drops crackle or sizzle, there is excessive water present.

Q | Do operators know how to determine how effective oil filters are?

LOGIC: Every time an oil filter is replaced, it should be cut open, the filter media spread on a bench; and using a good quality magnifying glass or microscope, contaminants and wear metals will be obvious. A magnet passed under the filter media will move all ferrous materials. If any machine damage is suspected, or the level of contaminant or wear metals have increased since the last filter inspection, a ferrographic analysis of an oil sample should be carried out.

Q | Do operators know if a machine’s operating temperature has increased beyond normal?

LOGIC: Operating temperatures of industrial equipment are often unknown or

ignored until after a failure occurs. The first step is to ensure that operators know the operating temperatures of their equipment under normal conditions, record this standard in the operators log or maintenance files and train operators to monitor any change in that standard during the life of the equipment.

Operators should be aware of the following component systems and corresponding maximum acceptable operating temperatures.

a) Rolling element bear ings – 71ºC (160ºF). This is the temperature at which lubricating oil or grease begins to oxidize.

b) Hydraulic systems – Bulk oil temperature at the exterior of the reservoir should not exceed 60ºC (140ºF).

c) Gear drives – Operate best in a temperature range of 49ºC–60ºC (120ºF–140ºF). Remember that an operating temperature rise of 50ºC (90ºF), combined with an ambient temperature of 15.6ºC (60ºF) will result in a “total oil operating” temperature of about 66ºC (150ºF).

d) Worm gears – Operate best at oil temperatures of about 60–65ºC (140–150ºF). Higher temperatures may promote pitting of the phosphor bronze gear and the use of polyglycol synthetic oil can reduce temperatures by up to 10ºC, and reduce gear pitting.

e) V-belts – Should not operate at temperatures higher than 60ºC (140ºF) and should be covered with wire mesh shrouds to ensure air flow.

f) Gas turbines – Oil temperatures should be in the range of 54ºC–71ºC (130ºF–160ºF).

g) Electr ic motors – There are four classes of motor winding insulation, each with a corresponding maximum temperature rating.

Q | Are your operators willing and prepared to learn to effectively use these tools?

LOGIC: Operators can be easily taught to use common methods of testing temperature conditions that include the use of various temperature probes such as the digital temperature indicator.

When measuring the temperature of any component, remember it is the housing temperature that is being recorded. The internal components, (motor windings, rolling bearings, or the lubricant in a reservoir or gear housing), will be about 20ºC higher than the recorded temperature.

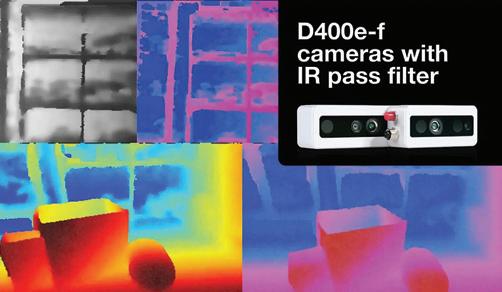

At least annually, a thermographic analysis should be carried out to locate hot spots in electr ic motors and mechanical devices such as drive couplings, bearings, and gear drives. There is almost no limit to the uses for which infrared thermography may be used for monitoring temperature related problems by operators, and handheld devices such as the thermocam are available.

Q | Do operators recognize machinery vibrations in your plant?

LOGIC: Technically defined, vibration is the oscillation of an object about its position of rest and these oscillations (or cycles) in a given length of time are referred to as the frequency of vibration measured in cycles per minute (CPM), or cycles per second hertz (HZ).

The amplitude of vibration is measured in displacement (distance or movement), velocity (speed) and/or acceleration (force), of the source of the frequency. Every piece of equipment contains moving parts, each of which will vibrate at certain frequencies. These frequencies are governed or generated by the vibration sources and will vary across a wide range referred to as a spectrum.

Common vibrations are unbalance, misalignment, defective bearings, or mechanical looseness. Once operators are f amiliar with these fundamentals, they can determine most common vibrations by placing a washer or coin on a smooth machine surface. The coin will display the vibration with its own. Good luck with these testing techniques.

The temperatures listed for electric motors include combined ambient temperature and temperature rise. For every 10ºC increase in temperature above the listed rating, the service life of the motor is reduced by about 50 per cent.

L. (Tex) Leugner, author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

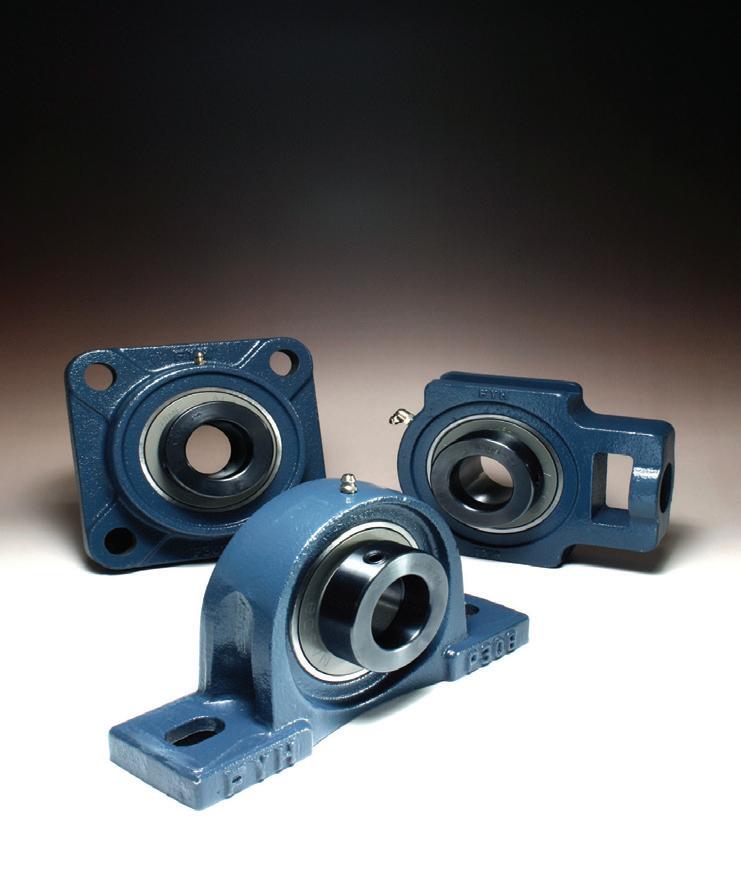

Ringball Corporation, the ultimate source for bearings, linear motion, and power transmission products, is proudly celebrating its 70th year in business. Since its establishment in 1953, Ringball has consistently delivered top-notch solutions, earning a reputation as a trusted industry leader. With commitment to innovation, quality, and customer satisfaction, Ringball has navigated the evolving industrial landscape and cemented its position as a cornerstone in the field. This milestone anniversary is a testament to the company’s unwavering dedication and pursuit of excellence.

A Legacy of Innovation and Expertise: Throughout its 70-year journey, Ringball Corporation has continually pushed the boundaries of innovation, striving to provide cutting-edge solutions to meet the ever-evolving needs of its customers. With a team of highly skilled engineers and technicians, Ringball has consistently developed and improved its extensive portfolio of bearings, linear motion components, and power transmission products.

Over the years, Ringball and it’s partners has introduced ground-breaking technologies that have revolutionized various industries, from automotive and aerospace to manufacturing and robotics. By staying at the forefront of industry advancements, the company has delivered products that enhance efficiency, reliability, and performance, driving progress across countless sectors.

Ringball’s unwavering commitment to quality has been a cornerstone of its success. The company adheres to rigorous quality control standards throughout every stage of the manufacturing process, ensuring that its

products meet and exceed industry specifications. By leveraging state-of-the-art facilities and advanced testing methodologies, Ringball guarantees that its customers receive products of unparalleled quality and durability.

Moreover, Ringball places great importance on building lasting relationships with its clients. The company prides itself on its customer-centric approach, which entails understanding each client’s unique requirements and providing personalized solutions. With a dedicated sales and support team, Ringball ensures that its customers receive expert guidance and assistance, fostering trust and long-term partnerships.

A Global Reach: Ringball Corporation has achieved an impressive global presence over the past 70 years. Through strategic partnerships and an extensive distribution network, the company has expanded its reach to serve customers around the world. From local businesses to multinational corporations, Ringball’s diverse client base relies on the company’s comprehensive product offerings and exceptional service.

“Ringball Corporation is fully committed to providing its customers with the best possible service. With global resources, expertise and over 400,000 square feet in five distribution centres we serve our North American customers with the highest of standards. We are proud to say that Ringball is an important player in Canadian economy servicing sectors from Agriculture, Farming and Forestry Industry all the way to Science and Technology with superior and reliable products,” said Gus Muho, General Manager for Ringball Corporation.

To learn more about Ringball Corporation and its comprehensive range of products and services, visit their website at

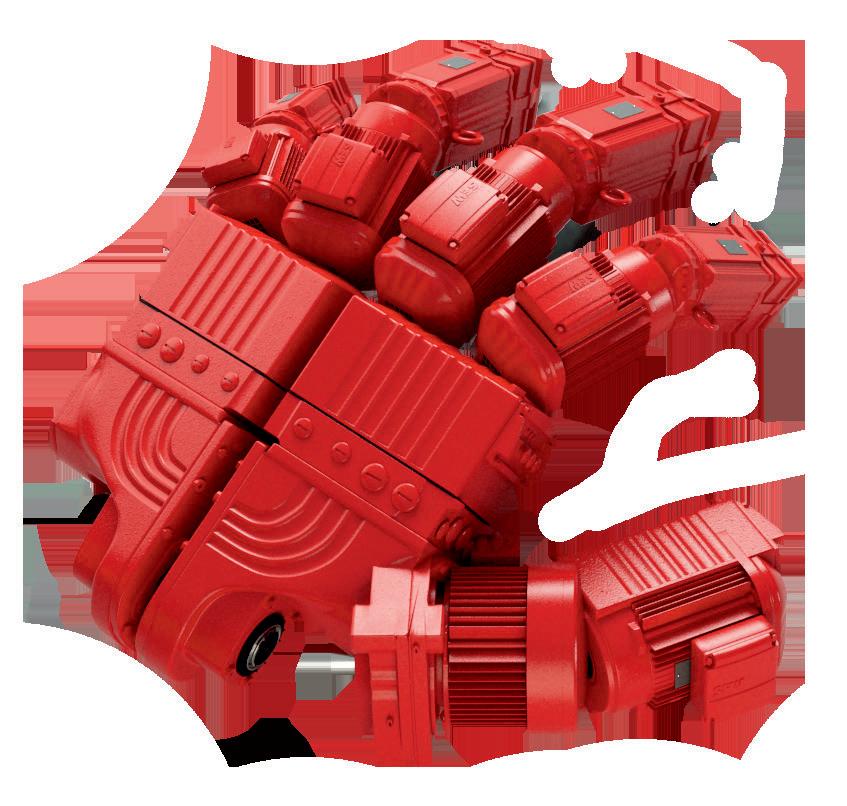

What we are seeing is a move towards a situation where the operating facility changes out a complete assembly or asset, rather than just the bearing.

BY DOUG MARTIN

Recently, I visited a large mine site in Northern Canada on a day that layoffs were announced, and one of the maintenance personnel I was to meet, was one of the casualties. Driving on the site with my hosts, a discussion began about how they will have to depend more on suppliers for technical assistance. This comment clearly defines what may be the future of maintenance. However, this story is not new, it has been hanging over the traditional

maintenance structure in Canada (or at least traditional heavy/primary industry) for the decades. That story is exemplified by the anecdotal evidence of new pulp mills built in South America in the late ‘80s early ‘90s. In these facilities, the maintenance department was a contractor. T he pulp company was an entity that “made pulp” and any support “departments” were contractors. What does this mean for large facilities like the mine site? For several years, instead of changing a single

bearing on a belt conveyor pulley, the whole pulley is removed. In turn, companies who changed out whole motors when there is a bearing problem had their own motor shops, but now they use an outside motor shop.

Today, we are seeing larger assets being changed out and rebuilt off-site by a contracted shop. Even the traditional bearing distributors have developed their own service centres, in which they rebuild these assemblies. It is the way they can continue to sell the bearings,

seals, and other components, they once sold as individual parts, to the large users.

What is the benefit to this transformation? It allows the mining company or pulp company to focus their attention on what they produce, and not trying to manage a maintenance department, or a rebuild department. It may also allow a higher level of quality control. They can write and enforce tighter quality controls over the rebuild than they were able to achieve within their own organization (especially in times when resources were strained). There are also some cases where recognized organizations or consultants will certify rebuild shops on behalf of users, in turn, giving a degree of confidence in quality of the job.

Last month, while at a pulp mill assisting with a critical fan installation. One portion of the job was to balance the rotating assembly prior to installation.This is a critical aspect of the job.The rotating assembly was sent out to a sub-contractor and returned within a day. I later asked why the fan was not balanced in house, knowing that they likely had the equipment to do so. The reply was they may have the equipment, but when their crew may only balance two or three assemblies a year, they lack the expertise to do the job quickly and with a degree of quality.

In terms of less expensive systems, there is a move towards surveillance systems as opposed to diagnosis systems. What a surveillance system can do is monitor basic parameters like overall vibration and temperature, and then with its AI, learn how that machine runs and warns the user there has been a change in the asset.

With the lack of resources industrial facilities, the management group needs to find ways of putting hands on wrenches, not on data collectors, as is typical of the most common method of data collection for vibration analysis. However, even with online systems that do not require a technician to spend days on prescribed routes, there still is a level of maintenance required to maintain these systems.

A number of mills have online systems that are not being used simply due to a lack of system maintenance that includes, re-connecting data cables after the asset has been

maintained, and replacing any wires that may have been damaged.

Another hurdle that condition monitoring/ vibration analysis systems face is the issue of security. Many of the latest technologies offered require an Internet connection to allow access to the software for the data analysis. The benefit of the online software is it removes the need for regular software release to be manually downloaded and installed (maintenance of system), and it allows collaboration within the organization. However, with recent data breaches and ransomware issues, IT departments have become very strict in who and what is allowed to be connected through the network.

There are other condition monitoring technology that may provide an alternate. There are online systems that can connect to the local cellular networks and allow communication/data transfer with the cloud, outside of the company’s internal network. The user can access the vibration data through a secure web site that does not endanger the security of the IT system.

In terms of less expensive systems, there is a move towards surveillance systems as opposed to diagnosis systems. What a surveillance system can do is monitor basic parameters like overall vibration and temperature, and then with its AI, learn how that machine r uns and warns the user there has been a change in the asset. This can lead to inspection and diagnosis of the problem with more complex tools (such as a route-based data collector). The benefit is shifting those in the vibration department from being data collectors to inspectors and troubleshooters of identified issues.

I have identified the change that we are in the process of, not made any bold predictions. That is production facilities becoming streamlined, focused on production of their product, and not large organizations with different departments dealing with all aspects of the operation. They will be supported by local vendors and shops that have become experts in their specialty and have the quality systems in place to provide a high level of service.

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him at mro.whats.up.doug@gmail.com.

MRO spoke with maintenance and asset management experts to get their perspective on what they see happening for the next generation of maintenance.

BY MARIO CYWINSKI

Greek philosopher Heraclitus is credited with saying “change is the only constant in life.” In his time, the issues we are facing today in maintenance were not around. However, all this time later, the saying still holds true, and in turn, those companies who do not adapt to ongoing change, will be left behind. Many of the technologies that we are seeing in the world today, were only seen in science fiction movies years ago.

Like the rest of the world, maintenance is constantly changing and evolving. Obviously, the core values remain, but how things are done, continues to change. We are seeing advancements in artificial intelligence (AI), use of data and diagnostics, moves to outsource maintenance, more focus on predictive maintenance, and focus on many other new technolog ies.

MRO reached out to experts come from across the maintenance and asset management sphere, to get a complete look at what the future holds for the world of maintenance. They include Hugh Alley, president, First Line Training Inc.; Richard Kunst, president and CEO, Kunst Solutions; Susan Lubell, principal consultant, Steppe Consulting Inc.; James Reyes-Picknell president and principal consultant, Conscious Asset; and Cliff Williams, author, and asset management exper t.

MRO: What do you see as the biggest advancement in maintenance in the next five years? Ten years?

Hugh Alley: Five years, there will be more retrofittable sensors that will provide diagnostic data about equipment condition that will connect wirelessly. Some equipment

manufacturers will start taking data security seriously, and more maintenance operations will be looking for secure connectivity; just being connected will no longer be enough.

In 10 years - equipment manufacturers and maintenance service organizations will increasingly provide uptime as a ser vice, as they leverage the data they gather.

Richard Kunst: Sensors are getting cheaper, faster and have broader capability. Add to that how the bandwidth and speed of data highways has become, and we will see a migration from preventive maintenance to predictive maintenance through the early detection of subliminal abnor malities for quicker, cheaper, and easier repair s. It is now very cost effective to build several layers of redundancy within an automated system, repairs can be made without incurring any actual processing downtime. The coolest aspect is that we will be aware of a potential problem before we even physically realize it.

Susan Lubell: In the next five years, we will continue to see step changes in the use of predictive maintenance for asset health monitoring. As sensors and condition monitoring becomes cheaper to install and can be placed in more hazardous environments, we will be gathering more asset health data on a real time 24/7/365 basis. This analysis will inform our decisions on run, repair, replace for physical assets, providing the information to decide when to maintain physical assets and what the scope of the repair will be.

With the advancements seen in the last few years, 10 years out is too far to predict what new data and information the future technologies will enable.

In the short term, competitive pressures are driving a push towards productivity and in all but new plant and equipment, they are struggling with reliability issues.This is causing an uptick in focus on reliability currently.Within the next five years, we will see a reset, going back to basics in both reliability (maintenance tactics) and in work management practices. Processes and systems are in place but are often used poorly and to little effect. The workforce has lost a lot of experience with the retirement of large numbers of people during and shortly after COVID-19. With relatively few baby boomers left, and in most cases, no attempts to capture their knowledge, companies are realizing just how much they depended on them. They are repeating old mistakes and realizing that they are not as systematic in their methods as they may have thought.

In the longer term (10 years) we will see a shift towards outsourcing of maintenance in small, medium and some larger industrial operations. Attempts to fix the problems above will not be entirely successful due to an unwillingness to invest enough in maintenance, and the continued drain

of experience. Realizing that they are not as good at maintenance as they want to be, and that they are seemingly incapable of managing changes, they will look to outside expertise - not in consulting, but to delegate the whole function. This will open the door to a big shift, particularly in North America, where outsourcing hasn’t been popular, from in-house management of maintenance and reliability to reliance on external specialists who treat it as a business, and not just a troublesome cost centre.

Cliff Williams: Obviously AI and machine learning will be the advancements – how effective they will be in mainstream maintenance and reliability is the question. Many lack the basics of good maintenance and reliability, don’t appreciate, or use the data they have –or should have, so there is skepticism around how they will take advantage of the advancements. At the Society for Maintenance & Reliability Professionals (SMRP) Conference, there were more AI technology vendors than any others – but what they were selling was the technology and not necessarily the solutions. These will depend on

the knowledge and understanding of what drives results in the maintenance and reliability organizations. It will also involve a lot of change in approaches, roles, responsibilities, and we’ve proven time and again to be lacking in change management.

MRO: How do you see AI affecting maintenance operations?

Alley: AI is about multi-dimensional pattern recognition. It demands very large datasets, which are only going to be available to organizations managing large quantities of equipment. This will create challenges for small organizations, which won’t have the analytical capacity, or the quantity of data needed. This will open opportunities for specialist maintenance services to aggregate data, through the better understanding provided by the data, they will be able to offer superior uptime to smaller operations. It will also open opportunities for manufacturers to provide monitoring services, and they will aggregate the performance data from the equipment they build, allowing them to tune where they make improvements and to provide better

guidance about maintenance needs. The manufacturers will therefore be able to develop ongoing revenue streams from sharing the results of a customer’s data with them.

Kunst: First, AI is going to be a big benefit to user manuals to insure people properly start and operate machines. In many cases we fail to optimize the capability of our equipment because we get used to using only cer tain functions. Second, AI will be critical to early detect and resolve potential issues. With AI we can be constantly running diagnostics in the background, while the machine is operating, stealthily detecting, and seeking abnormalities and quietly switching to a redundant process while alerting the organization what and where to perform maintenance.

Lubell: The vast quantities of data gathered are staggering. We will need AI techniques to build analytical models and frameworks to harness and analyze the data, turn it into information, and allow us to make business decisions. The maintenance operations space is no different. The

increased collection of asset health monitoring data needs to be analyzed to be useful for business decisions and this will require AI.

Reyes-Picknell: As companies shift more towards installed sensors and non-human data gathering the quality of data will improve. This will enable more reliable performance of predictive/prognostic tools that are presently hampered by poor quality maintenance data, that often lacks the granularity needed to be used for reliability analysis. Deterministic algorithms that are in use will become more valuable as the quality of data feeding them improves.

With more sensors and data, the door will open to data scientists who can apply more general analytic tools to finding relationships, correlations, and helping to identify where we may find causation of those correlations. We will still need to intervene in making those latter determinations as the analytics don’t “know” what’s going on aside from the numerics. This will all enable shifting towards greater reliance on condition monitoring and may reveal the correlation of excessive inspection work and overhauls to lower reliability to those who remain skeptical today. Reliability engineers will be increasingly needed, and in turn, they will need enhanced analytical/data science backgrounds.

MRO: Do you see any maintenance activities that will be eliminated in the future?

Alley: Routine monitoring activities will become less necessary as it becomes cheaper and easier to connect sensors wirelessly. Time-based preventative maintenance will be replaced by condition-based predictive maintenance.

Kunst: If we gauge our maintenance efforts in the form of frequency and severity, I envision that severity will significantly decline due to better early detection of potential problems, before they can create a catastrophic consequence such as a machine breakdown. However, it would be reasonable to expect more minor maintenance requests being performed.

The more data you feed AI the more effective your AI will assist you. Like CNC machining, where you can enter “tool wear parameter” so the machine will tell you when to replace

a specific tool. We need to take a fresh look and develop parameters that we do not actively monitor, temperatures, amp draw, and vibrations, we have the detection technology, but have not created upper and lower control limits.

Lubell: With the increased focus on predictive maintenance and asset health monitoring on a real time continuous basis, maintenance activities will shift to more analytics and interpretation of the data and information. The fundamental understanding and performance of maintenance activities won’t go away; however, the emphasis and time spent will shift to more analytic interpretation and deciding how to respond followed by more targeted repair strategies.

Reyes-Picknell: Already we see less inclination to perform repairs at the component and assembly level in favour of swapping out parts and assemblies. Some assemblies still get repaired, but less by in-house shops. That trend will continue with two possible outcomes. For those who invest in the ability and knowledge needed to do effective troubleshooting, repair times are likely to shrink and that could potentially contribute to a drop in workload overall.

For those who do not invest in those abilities and knowledge, it will lead to higher usage of parts and assemblies, as they are swapped out, not knowing if they need to be.

We already see that in the realm of electronics, where circuit cards and modules are swapped out to hasten repairs, without knowing if they are flawed. That will expand into the mechanical world, because of the loss of exper ience and expertise that is well in progress today. Sadly, what will be disappearing in many cases, is that ability to troubleshoot effectively.

Williams: No, I hope not, we still see organizations that don’t do what they should be doing, the hope is that we don’t eliminate any activities, but progress to using the right ones for the specific situation.

MRO: What can facilities do to make themselves more technology-ready in the short term? Long term?

Alley: It’s all about developing your people. Maintenance staff will always need the wrenching skills, but they will need to know how to tap into the insights from large quantities of data. Those skills are unlikely to be available “on the street.” Hiring the skills, you need was more possible 30 years ago, when controls for most machinery and equipment were mechanical. If you knew how hydraulics and mechanical systems worked, you could fix just about everything. In the coming years that won’t work; every company’s specific needs will be different because their specific mix of equipment and products will be

unique. Consequently, companies will need to be able to learn these skills as they apply to each of their specific machines. They’ll also need to be able to retain and teach what they’ve learned as staff change over time. Meaning maintenance leaders will need to become better instructors, and better at the skills of developing scientific thinking. These are skills companies can start developing now, and they will have almost immediate payback. For leaders with these capabilities, the new technologies will present lots of opportunity.

Kunst: Get your user manual into a digital footprint, make sure all corrective actions are logged digitally. Of course, building your data foundation still requires a manual input so conducting your physical daily total productive maintenance (TPM) checks and logging the abnormalities is the fodder for creating a more effective AI.

Lubell: One of the areas that is starting to get more attention is asset and maintenance information management. We need to think ahead to what questions we want to answer in three or five years and structure our data to allow us to do this. Ask yourself, how complete is your asset register? Do you know what assets you own? Do you know the value that that they bring to your organization? Consider cost, risk, and performance in terms of safety, health, environment, economics, regulatory obligations, social and governance. Infor mation is an asset by itself and needs to be managed as an asset, collecting data without a specific purpose quickly becomes overwhelming to manage and often ignored.

Reyes-Picknell: In terms of IT and OT knowledge and skills, most operations have this already. Many have already deployed technologies that are underutilized or not utilized at all. The technologies that are available, have in many cases, exceeded the ability to use them to much effect. In fact, these systems are often generating work just keeping themselves going. The danger we face is not in lack of technical capability, rather it is in jumping to technological solutions before they really know what they are doing to do with them.

I see a bit of “ready, shoot, aim” going on. There is need to do more “aim” and sooner, before deciding on technology and its rollout. It will be necessary to find and/or develop some expertise in production processes, equipment, and industrial systems (not just the IT), working together with maintainers, operators, and reliability engineers to help guide the need for and deployment of technology where it can do some good.

Williams: Plan replacements based on latest technology – get an understanding of what the technology can bring and how it fits in with their organization – identify the opportunities through baseline measures of where they are today and set goals to be achieved through technology. Educate and inform all who will be involved and manage the change.

MRO: Can you speak about the assets and those which need updating the most?

Kunst: As our appetite for data continues to expand and grow, we need to increase our wireless capability within our premises. For many companies it will likely require a review of their electronic policies, as smartphones continue to be an extension of the human capability, preventing them to accompany people into work environments will be limiting the effective use of AI and enhancing employee effectiveness.

Reyes-Picknell: There is a lot of aged infrastructure in our “basic industrial” capability (old plants and equipment). Investment in these more basic industries has largely been directed overseas, allowing our capacity to age and degrade. The impacts of COVID-19 on supply chain were a wake-up call about globalization, too much reliance on just-in-time and excessive lean. The world is far less stable that it was just a few years ago. To sustain our capabilities, so that we are less vulnerable to global calamity and disruptions, we need to sustain that basic industrial capability and some of its capacity.

W illiams: In true asset management style, it would be the systems we use, the

processes we employ, the measures we make, and the culture we build – it’s all about people. Updating equipment while employing the flawed practices won’t work, not having the right data or having a way of turning that data into knowledge and eventually into wisdom should be the starting point where we can then, with confidence, understand the asset that needs updating –and not before.

MRO: Anything to add?

Alley: Like many sectors, the world of maintenance is in the middle of losing large numbers of extremely capable technicians as baby boomers retire. A lot of knowledge is walking out the door. For many firms with limited maintenance management systems, this loss can be substantial. I have one client where the entire maintenance staff has turned over in two years and the new supervisor is having to rebuild the entire knowledge base of the facility.

Organizations that can capture that knowledge before it leaves will have a significant leg up on the competition.While new technology can help, the underlying discipline of developing standard work depends on leaders who are committed to the objective of delivering reliable uptime, and who are able to convince business leaders of the necessity of maintaining their assets well.

Lubell: We are seeing huge advances in the use of technologies, sensors, and data analytics to advance predictive maintenance and asset health monitoring. It’s important to make conscious decisions on what and how we will use the data collected, how we will analyze it, and the maintenance decisions that it enables. Otherwise, we will be drowning in data and starving for information, when we want to be in a position of gather ing maintenance and asset data and turning it into information that allows for business decisions.

Reyes-Picknell: History repeats itself because of organizations failing to learn the lessons of the past. Don’t under-estimate the impacts of demographics on your workforce, your in-house expertise, your capabilities, and your capacity. Waiting too long to capture what knowledge remains will prolong the pain of reduced capacity and increase the likelihood of repeated mistakes. The younger workforce is smart, tech-savvy, and eager to learn, but quickly losing the experienced guidance you may still have.

Mario Cywinski is the Editor of MRO, Plant, and Food and Beverage magazines, and a member of the Automobile Journalists Association of Canada. Contact him at mcywinski@mromagazine.com

If we

ask finance and operational leaders what they think about outsourcing

of maintenance, they will admit to being uninformed, therefore unable to give a fact-based answer. If we ask them about their desire for improved asset performance and lower costs, they are interested, but cautious about just how it can be achieved.

BY JAMES REYES-PICKNELL

Finance and operational leaders are aware of problems with maintenance are not going away. The availability of skilled workers is a massive problem globally. The loss of experience, as baby boomers have/are retiring, has resulted in a lot of guesswork and re-learning of old lessons. It has also left the workforce with less experienced middle management, who learned management from that older cohort. Those old school management techniques are not working well with the younger workforce, and the work ethic is different.

Management techniques and provisions to accommodate it, have not adapted par ticularly well. Maintainers are often unhappy that they are treated as low value expense items and unworthy of investment. They are unhappy with inexperienced leadership that doesn’t listen. They do feel a sense of ownership, but seldom get the feeling that everyone who manages them shares that feeling. They want to see things improve but lack confidence in their management ability to affect it.

If we ask maintainers and their leaders if they want to be outsourced, the answer is invariably no. Outsourcing has negative connotations that are not necessarily valid. For one, there is a perception that it isn’t core, meaning the function being outsourced is not

important to the business. Core business functions are those that generate revenues, and in that sense, maintenance isn’t. Maintenance is neither core to most businesses, nor is it truly unique, with relatively few specialty activities that might be unique to the business (e.g. industry or asset specific skills and knowledge).

Another connotation is it will result in lower pay, worse working conditions and it could result in the loss of employment.While this has happened when other functions such as IT, HR, accounting and marketing have been outsourced, that does not set a precedent for maintenance.

Firstly, it is important to understand that outsourcing is not the same as contracting out.With outsourcing, the service provider becomes a business partner with the owner. A well-constructed outsourcing agreement will lower costs through efficiencies, but it will also result in enhanced revenues through improved asset performance. Both the asset owner and the service provider can benefit if the owner’s revenues improve because of performance improvements.

To achieve that, it is imperative that the workforce be motivated to perform. That is not achieved through reductions in pay, working conditions, job losses, or any other disincentives. Unlike IT, HR and accounting, skilled maintainers are not available in big numbers at relatively low cost. They

are valuable, difficult to find and difficult to retain.

While the maintainers an owner already has would be valuable, it is fair to say that they may also require additional training, particularly in processes (such as work management) that would change. They may require skills upgrading to use technologies that they were not using before, and to enable them to participate in determining what are the best maintenance tactics to be used in the systems with which they are already familiar. One thing a smart service provider would want to do, is to capture the lessons learned and use them.

The sense of ownership over problems and performance could be enhanced as that would become the focus of the outsource service provider. A lot of the concerns about the cur rent state can be addressed and indeed removed in an organization that made reliability and maintenance its business.

If outsourcing were used, the service provider would need to have

control over the maintenance that is done, how it is done, and how it is supported. Successful proven practices in those areas would need to be brought to the table. Relying on the owner’s stores and purchasing could be a huge mistake, especially if it is not working well before outsourcing.

At PEMAC’s MainTrain conference earlier this year, MRO did a roundtable discussion of the subject to see if perceptions could be shifted and to find out what concerns might exist. We had some very interesting feedback.

We found that negative perceptions of risk were largely based on the perception that outsourcing would be like contracting out. In outsourcing, the contractual focus is on outcomes, not activities. In contracting, the scope is well defined, and often very prescriptive. Outsourcing should be based on a clear definition of the desired outcomes and leaving the “how to” to the creativity of the services provider. Imagine the potential if your service provider was specialized in delivering

highly reliable equipment, rather than merely fixing something that has broken. Concerns about work quality and control over what is being done should disappear as results begin to materialize. Invariably, if the business case for outsourcing is substantial, there are very likely some quick wins that can be used to dispel some of these concerns.

A concern was raised about the ability to meet collective bargaining agreement terms, which often include provisions for contracting. Without question, that will be a challenge to deal with, in most cases, but if the overall package, as experienced by the union member is an improvement, the hurdles become much easier to overcome.

We heard that communications between maintenance and operations/production departments are already difficult and sometimes almost non-existent. There’s legitimate concer n about whether a contractor could achieve better communications or worsen an already bad situation. Often this stems from unprofessional behaviors on the part of the operations

departments. There would be a need to have an enforceable contractual requirement and mechanism (based in good work management practices) to ensure the customer communicates. If problems arise, contractual remedies will need to be enforced. If that had to happen, the pressure from contracts on operations would likely be substantial and their ability to behave badly curtailed.

If maintenance, reliability, condition monitoring, engineering, stores, and other personnel, were moved from the “owner” to the “service provider”, there would be a substantial change management challenge. They’d need to learn new ways of working and new systems. Training and coaching would be needed, and all while continuing to deliver the work they were doing before the transition. Both those who are, and are not outsourced, may feel a sense of loss that will need to be dealt with. On the part of those leaving, the overall conditions must be seen to be improving. The owner may need help in dealing with the feelings and

motivations of those who are left behind and that should be built into the agreement.

Business processes that may require participation of both parties will require attention. For example, if stores are outsourced but purchasing are not, then how will communications work. Many companies unknowingly rely on informal relationships and methods that “make up for” the inadequacies of their business processes and systems. Those need to be identified and managed in more for mal ways if the full scope of what is needed to be done is not entirely outsourced.

If things go wrong, particularly with asset performance, there would be tendency for finger pointing and defensive behaviours. The agreement must make provisions for what happens when performance isn’t up to expectations, including defining what that performance should be. Failures are often caused by human error, both on the part of maintainers (outsource service provider) and operations (owners). Dealing with failures and their causes must be done with an open mind and willingness to accept that the causes could be on one or both sides. More importantly, actions to eliminate causes must be

mutually agreed and executed.

In the short-term, costs could rise. Where there is likely to be a substantial business case for outsourcing, under performance is probably a big problem. A lot will need to change in processes, practices, and training, to turn that around with the same personnel who have just moved from the owner to the service provider.That has a cost. It is likely to be lower than the cost of the owner obtaining help to fix it themselves and deal with all the change management issues that will arise. Most operating companies are bad at that and tend to go far too slowly. They are not consultants, trainers, and masters of managing change; they are not set up to deal with it. Making the changes to gain the business benefits will be slow, much slower than with a competent outsource service provider that can bring experience and those skills to the table from the outset.

Intellectual property could be a concern, in cases where production processes or formulations are secrets. Those would need to be dealt with in the agreement and through initiating controls.That said, it is worth pointing out that most maintenance skill and activity does not require knowledge of those secrets and that noting in terms of maintenance skills, knowledge and