Use any device: PC, laptop, mobile, handheld computer

Work anywhere: access Tofino with or without internet

The importance of routine checks.

Use any device: PC, laptop, mobile, handheld computer

Work anywhere: access Tofino with or without internet

The importance of routine checks.

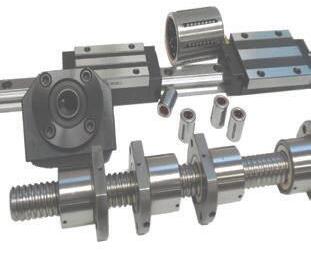

SKF’s world class bearing technology combined with superior sealing technology from CR Seals means long lasting protection against contamination and lost production.

• Ideal for heavy industries like aggregate, metals, pulp and paper

• Excellent resistance to wear and high temperatures for long service life

• Multiple sealing lips exclude the harshest contamination

• Designed for relubrication

• Fully interchangeable

• Proven to withstand 600+ hours in mud slurry testing with zero contamination ingress

SKF’s Mounted tapered roller bearings are backed by over a century of SKF expertise PLUS an SKF Performance Warranty.

SKF performed over 10x the competition in seal testing

Find out more:

WORKING SAFELY WITH HEAVY EQUIPMENT

Safe and healthy workers are at the heart of any operation, investing in their well-being and safety will always provide a strong return.

COMPLIANCE OR INTENT

Being ISO 9000 certified should be an indicator of doing good businesses and standardizing performance; however, for the longest time – it wasn’t.

IMPORTANCE OF ROUTINE CHECKS FOR MECHANICAL REPAIRS

Mechanical components in a factory require the most attention from a maintenance perspective, as they have a high propensity to fail, making it a high priority for maintenance teams.

A CERTIFICATION PROGRAM THAT WILL CHANGE MAINTENANCE

The new alignment certification will document exactly what an alignment specialist is certified to perform in the way of alignment tasks according to the latest internationally accepted standards.

IMPORTANCE OF AIR QUALITY

MRO sat down with Kevin Lisso at EnerSavings to speak about air quality. 18 20 22 24 26

Back in 2018, a simpler time before the world was introduced to the COVID-19 pandemic, I took over as editor of Machinery and Equipment MRO magazine. At the time I was new to the industry and had to acclimatize myself rather quickly. Luckily, the former editor of MRO was still a part of Annex Business Media and was very helpful in getting me up to speed.

Although the content was everything that our readers expected, MRO had not had a design update for a while. Since then, and I’ll quote a former publisher of mine, “we have been taking small bites of the elephant, with minor changes.” We did update our logo in 2020, but everything else has remained the same. Until now!

The September 2022 issue of MRO has had a complete revamp. Welcome to MRO Canada’s Maintenance Voice. For many we have always been and always will be simply MRO, and that is great.

Everything from the logo, tagline, and layout, has changed in our print issues, while the web site, e-news, and social media channels will be updated to take on the new look.

One thing that will not change, is the content that is provided within the pages of MRO. Long running columns, the MRO Quiz, Maintenance 101, What’s Up Doug, will all remain. Articles from our regular contributors will also continue to be featured.

A noticeable change of the rebrand is our Mr. O feature. While our unofficial mascot has always had a role, it is now time to move forward with a more professional look. Therefore, we introduce MRO Pro Tips, which will feature the same great tips from industry experts, but with a more professional focus. In turn, our In Conversation with Mr. O podcast will now be, In Conversation with MRO. Over the coming months we plan to offer new episodes of the podcast, covering a deep dive on a variety of topics that our listeners want to learn more about.

Going forward, we do not plan on

standing still, we will introduce new offerings under the MRO umbrella if they improve the information that our readers, listeners, and watchers want. One example is a renewed focus on our video content, as our YouTube channel continues to grow, we plan on offering more videos on our web site and channel.

Another example is being the pulse of the industry in terms of attending and reporting on events. We plan to return at a pre-pandemic level, as more trade shows, conferences, and company events are scheduled or planned. Plan to see a lot more of the MRO team over the coming months.

Don’t hesitate to offer us feedback on the new MRO brand, including any suggestions on what you would like us to feature within any of our offerings (print, web, podcast, and others).

Enjoy the new MRO.

Thank you,

MARIO CYWINSKI Editor mcywinskiw@mro.ca

ESTABLISHED 1985

SEPTEMBER 2022

Volume 38, Number 4

READER SERVICE

Print and digital subscription inquiries or changes, please contact Customer Service

Angelita Potal, Customer Service Administrator Tel: 416-510-5113 email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR Mario Cywinski 226-931-4194 mcywinski@annexbusinessmedia.com

SENIOR PUBLISHER Paul Burton 416-510-6756 pburton@annexbusinessmedia.com

ASSOCIATE EDITOR Monica Ferguson 416-510-5206 mferguson@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER Ilana Fawcett 416-829-1221 ifawcett@annexbusinessmedia.com

BRAND SALES MANAGER Chander Verma 437-218-0941

CVerma@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

MEDIA DESIGNER Brooke Shaw

ACCOUNT CO-ORDINATOR Catherine Giles 416-510-5232 cgiles@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

Subscription rates. Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer Privacy@annexbusinessmedia.com 1-800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

De Havilland Aircraft of Canada Limited is increasing its Component Solutions Program with agreements signed by Air Niugini Limited and flybe Limited. Under the agreements, De Havilland Canada will manage component maintenance, repair, and overhaul services for the airlines’ Dash 8-400 aircraft. The DCS Program will provide access to De Havilland Canada’s strategically located exchange pool.

Air Niugini, Papua New Guinea’s national airline, signed a five-year DCS agreement to support up to five Dash 8-400 aircraft. Established in April 2021, flybe Limited will operate throughout the United Kingdom and European Union. The airline’s fiveyear DCS agreement will support a fleet of up to 32 Dash 8-400 aircraft.

The Electrical Apparatus Service Association (EASA) announces international officers for the 20222023 administrative year.

The new roles include Sid Seymour of Seymour-Smith Electric Motor and Pump Service in Burlington, Ontario, Canada as Chairman of the Board, Sean McNamara of Komatsu in Rutherford, New South Wales, Australia as Vice-Chairman, and Paul Rossiter of Energy Management in Salt Lake City, Utah as Secretary and Treasurer.

Seymour has 36 years of experience in the electrical apparatus industry. He has been active in EASA’s Ontario Chapter and was director of EASA Region Eight that includes all Canadian provinces. He has served several on EASA international committees.

Innio Waukesha Gas Engines and Detechtion Technologies announced a technology collaboration that will expand asset connectivity, drive a digital ecosystem and transition to decarbonization.

The technology partnership will combine Innio’s Waukesha engine analytics with Detechtion’s compression monitoring and optimization technology into a solution for both new and existing compressor skids. The solution will remotely manage assets securely and in real-time. The system anticipates unexpected events, determines if assistance is required, improves energy production, and reduces plant downtime.

Wencor and Alp Aviation signed a multi-year purchase agreement

Wencor and Alp Aviation signed a multi-year purchase agreement. Wencor will provide consumable and expendable parts to support Alp Aviation’s production requirements.

The parties held a signature ceremony during the Farnborough Airshow in Hampshire, England.

Alp Aviation and Wencor have been in partnership for over 20 years. The new contract will extend this relationship through 2027.

Ontario Power Generation (OPG) and X-energy signed a framework agreement to pursue deploying Xe-100 small modular reactors for industrial applications in Canada. Under the agreement, deployment would occur in Ontario at industrial sites and identify further potential end users and sites throughout Canada.

The Xe-100 high-temperature gas-cooled reactor optimizes technology to enable decarbonization of industrial end use applications. Combining high-temperature steam and power production, the Xe-100 can support oil sands operations, mining applications, and industrial processes.

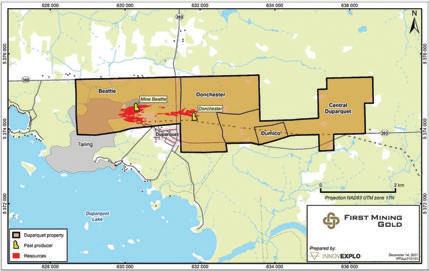

First Mining Gold made an offer to acquire all issued and outstanding

shares of Beattie Gold Mines located in Quebec.

First Mining, directly and through its wholly owned subsidiary, Clifton Star Resources already owns approximately 25.3 per cent of the issued and outstanding shares of Beattie Gold. The total consideration of the Beattie Offer is $4.43641 cash per Beattie Gold share and 35 First Mining Shares per Beattie Gold share for a total cash consideration of $6,227,176 and the issuance of 49,127,820 First Mining common shares.

Portugal-based ESI has developed a system with Festo for packaging corks that reduces volume by 30 per cent.

ESI’s patented solution consists of an autonomous cell and palletizing system, with an articulated robot and pneumatic components from Festo. Festo’s DSNU round cylinders can work in dusty environments, and

while compressing the corks as they are sucked in by the vacuum cups and placed in the carton. The 20 cylinders are controlled by a VTUG valve terminal.

Classic Fire + Life Safety celebrates 10 years of business in Winnipeg. Founded in 2012 under the FCFP banner, the company rebranded in late 2021. Its name was changed to Classic Fire + Life Safety, a reflection of its merger with Classic Fire Protection. In 2020, the team was composed of four employees. Today, it has grown to 10 – and looking to add more. Its largest project has been a contract for a women’s hospital, delivering essential fire sprinkler protection systems to this mission and community-critical facility.

Classic Fire + Life safety has over nine branches across Canada, servicing industries, including the areas of fire sprinkler, fire alarm and security systems.

Electromate was named the winner of the Innovation and Technology Award at the 2022 Business Achievement Awards presented by the Vaughan Chamber of Commerce. Electromate been operating in Vaughan for over 20 years and is a member of the Chamber of Commerce.

appointed Bob Bush as Chief Financial Officer.

Bush has over 33 years of broad finance experience. He began his career at Momentive in 2013 and has held several finance leadership roles in FP&A, global operations, business finance, and most recently served as vice-president and treasurer.

Motion Industries named Lisa Solomon as Senior Vice-President – Corporate Accounts.

Solomon joined the Company in 2015 as a business development manager focused on an automotive industry account, before transitioning the same year into an automotive specialist role concentrating on a different automotive account. In 2016, she expanded her role to a corporate accounts manager overseeing the entire automotive segment. In 2021, Solomon was promoted to area VP – Corporate Accounts, leading a team of 16 sales professionals in the Central Group.

In her new role, she will lead all of Motion’s corporate accounts in North America and corporate accounts support group, corporate accounts development, P2MRO, onsite solutions, energy services and international sales.

Beaumont Machine was recently repurchased, after the owners sold the business in early 2013.

“We had a great relationship with the new owner, but we believed the company needed a revitalization to benefit our customers, employees and the evolving EDM industry. In addition to repurchasing Beaumont Machine, we have reassumed the dayto-day operation of the company. In addition, we have moved the operation into a larger location to increase production and expand our service capabilities,” said co-owner, Ed Beaumont.

The new plant is located just outside of Cincinnati at 2010 Glenn Parkway in Batavia, Ohio.

Metallurgical Sensors (Metsen), opened a new office in Mississauga at 1495 Bonhill Rd.

“After many years of operating virtually, we are excited to have a dedicated space to gather and collaborate with employees and customers,” said Shiva Bissoon, general manager and director of sales and business development, Metsen. “But I think the most exciting thing about this move is what drives it — steady growth. Despite the economic disruptions of a pandemic, we require facilities to meet expanded customer service, product assembly, order fulfillment, testing, and shipping needs. This is quite outstanding.”

The 2,000 square feet location offers space for staff, product testing, and future research and development facilities.

The Canadian Institute of Steel Construction names Greg Miazga as the Director of Engineering.

Miazga has over 35 years in the construction industry, holding roles

as chief engineer and vice-president of engineering for a major Alberta structural steel fabricator and erector, and most recently as COO for an Edmonton based energy solutions company.

Christopher Kidd was appointed as Simard Suspensions regional sales manager for the Ontario and Maritimes markets.

Kidd has 10 years in the heavy vehicle and transport industry. He joined Simard Suspensions in 2018 for the business development of the DRAMIS division. For the past three years, Kidd has acted as a parts and aftermarket sales support specialist.

The 2022 AD Industrial & Safety Canada Supplier Summit was hosted in Vancouver with nearly 400 participants in attendance.

The event saw the re-launch of AD Canada’s Gender Equity Network (previously known as the Women in Industry Network). The objective is to promote healthy workplaces

where everyone feels included and empowered, with overall awareness, and change as it relates to gender inequities being a primary focus of the group.

The division returned 101 per cent of rebates to members, while growing remittances by 20 per cent and increased rebate redistribution by 24.4 per cent.

Bioveld Canada and HOPA Ports have signed an industrial switch agreement with Canadian rail services provider, GIO Railways Corporation, to enable the use of existing CN Rail infrastructure at the Thorold Multimodal Hub to transload cargo.

A switching agreement allows a short line operator (GIO Rail) to use the track owned by CN to provide first- and last-mile delivery and transload services.

The Thorold Multimodal Hub is a 200+ acre multimodal industrial complex in Niagara, adjacent to the Welland Canal. It features marine, rail and highway access, and over 500,000 square feet of indoor warehouse and outdoor storage space.

BY MONICA FERGUSON

FABTECH Canada, which is billed as the country’s largest metal forming, fabricating, welding, and finishing event, returned for the first time in four years recently to the Toronto Congress Centre, in Toronto, Ontario.

The three-day event had attendees connect with suppliers, see the latest industry products and developments, and discover the newest manufacturing solutions.

Over 50 conference sessions and workshops were available covering solution-based, transformative content to address today’s challenges, improve productivity and increase profits. The lineup of keynote speakers, panel discussions and educational programs, were held in a special presentation area within the trade show floor.

“The feedback has been overwhelmingly positive,” said John Catalano, SME senior director, FABTECH. “The show remains to be the best place for attendees to explore the latest technology advancements, connect with peers, network, and gain a competitive business edge. Exhibitors were enthusiastic about the high-quality of leads they collected, and the sales inquiries generated during the show.”

A highlight of the show were two leadership exchange

panels, one on The Digital Transformation and Canada’s Economic Strength (pitched top left) featuring Jayson Myers, CEO, NGen; Mark Kirby, industry training and outreach coordinator, University of Waterloo; Martin Cloake, CEO, Raven AI; and Ian Howcroft, CEO, Skills Ontario. While the other was Changing the Gear Ratio —Women in the Automotive Industry (pitched top right) featuring Taylor Dittrich, wire products research engineer, Lincoln Electric Company; Stephanie Hoffman, owner, Underground Metal Works; Nikki Noble, coordinator and professor of welding, Lambton College; and Leanne Jefferies, vice-president, Assured Performance Network/Certified Collision Care.

FABTECH Canada’s 80,000 square foot show floor had over 200 exhibitors, showcasing the latest innovations covering 40 technology focus areas, including, cutting, lasers, press brakes, robotics, and welding machines.

As part of the show, Annex Business Media, and its manufacturing brands, were on hand to answer any questions attendees had, when visiting Annex’s table. Annex brands on hand included: Plant magazine, MRO, Manufacturing Automation, Canadian Manufacturing, and Design Engineering.

The informal group Quebec Bearing and Power Transmission (QBPT) hosted it’s 60th annual Québec Bearings Golf Tournament at the Royal Bromont golf club.

In all 119 golfers took part in the tournament, which raised over $6,000 for the Opération Enfant Soleil charity. The gala dinner portion saw 178 attendees, with 65 distributor attendees, 41 manufacturer attendees, 30 agent attendees,

and 42 others.

“There have been a few years when the event could not take place, so it has been around longer than 60 years, an amazing feat, I think you will be hard pressed to find an industry that can match this,” said Lars Ruuth, SKF. “Competitors and partners in manufacturing and distribution got together to celebrate the camaraderie of the bearing and power transmission industry over a day on the golf course and a gala dinner.”

CO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price)

The International Fluid Power Exposition (IFPE) is the place where engineers meet to:

Spark new ideas with in-depth technical conversations with other engineers.

Discover solutions current suppliers can offer to your unique challenges.

Find new partners among suppliers pushing the envelope on what fluid power can do.

Including Bosch Rexroth , Danfoss Power Solutions , Parker Hannifin , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more!

Join your peers from these OEMs:

∙ Caterpillar Inc

∙ Volvo Construction Equipment

∙ Liebherr

∙ CASE Construction Equipment

∙ Komatsu

∙ John Deere Construction

∙ Doosan Bobcat

∙ KOBELCO Construction Machinery USA

∙ LBX Company

“ There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

KEN ROSENBECKER SALES MANAGER NORTH AMERICA | WIPRO INFRASTRUCTURE ENGINEERING

Grease acts as both a lubricant and a key component of seals used in split pillow block housings.

BY DOUGLAS MARTIN

In greased bearing applications, grease serves two purposes, to provide lubrication and to provide a barrier preventing and carrying away contamination. It provides lubrication by forming reservoirs on the bearing cage, and in the un-swept areas adjacent to the rolling elements within the bearing itself. From these reservoirs, oil is bled into the rolling contact zone to lubricate.

As a sealing element, the grease barrier slows or stops contamination from moving between the external seal and the bearing. Keep in mind, external labyrinth seals on their own are not perfect seals, there is no contact between the rotating shaft (or flinger) and the stationary part of the seal itself (stator). The gap is large enough to allow for angular misalignment within the bearing. The gap is also wide enough to allow thermal expansion of the shaft between the bearings.

Therefore, any labyrinth seal requires that there be grease in the seal to close the gaps. When there is lots of contamination, there is lots of pressure, pushing the contamination through the labyrinth seal, and unless balanced or overridden by an equal grease pressure in the grease inside the housing, it can enter the housing cavity. Once inside the bearing cavity, the external pressure now by be relieved, but within that cavity is the shaft which is rotating and in contact with the grease packed in the housing. The rotation of the shaft shearing with the grease acts like a mixer and the contamination is transported along the shaft from the dirty seal end to the clean bearing end. This is if there is no grease pressure to counteract this transport of contamination.

Therefore, when using labyrinth seals, there must be regular grease flow creating the internal pressure that pushes the contamination out of the housing and out of the seal. Rather, the grease pressure needs to be there to prevent the entrance of grease into the seal to begin with.

Referring to a labyrinth seal, could be as simple as a ‘triple lab’ or LOR/ LER seal, which is the standard seal for most split pillow blocks. A ‘taconite’ seal is also a type of labyrinth seal, but taconite seals tend to be more complex than standard triple lab seals and may include, both radial and face labyrinths and lip contact seals. However, there is no standard on the design of a taconite seal. The most significant defining feature is taconite seals have built-in grease inlets such that the seal itself gets its own feed of grease, which prevents the entrance of and purges away contamination.

Where should the grease be put into the assembly? This depends on the housing arrangement: both ends open (BEO – having two seals) or one end closed (OEC – have a seal and end cover); and the type of housing seal (triple lab or taconite), whether it is an open or sealed bearing.

In this case, grease should be supplied to the centre of the bearing housing to feed grease into the W33 groove of the bearing. The grease should then flow out from the bearing in the direction of the seals. The grease should be added frequently enough that over time, there appears to be a steady (slow) flow of clean grease from the seals. There is a situation in which there may be a fear of ‘over greasing’. Since

the bearing is open, and the labyrinth seals are open, there is ample room for grease flow out of the bearing and housing. To keep the grease flowing though the bearing, one should increase the frequency of applying grease to the bearing as opposed to increasing the amount of grease at the time of applying the grease. Therefore, grease the bearing two times per month instead of once a month, but put in the same dose which should be calculated based on the bearing dimensions.

The dose of grease for manual re-lubrication through the W33 groove is:

G (grams) = D (OD in mm) x B (width in mm) x 0.002

The factor 0.002 is adjusted for grease from the side of the bearing and for different units of measure for the grease dose.

In the case of an OEC arrangement, do not suggest add a grease nipple to the end cover, and then used as the single grease inlet to the assembly. I have a specific case in which the contamination

‘won the battle’ at the inboard labyrinth. The grease had to travel across the full width of the housing, through the moving bearing to fight its ingress. The contamination essentially plugged up the inboard labyrinth, caused a dam and no grease flowed. The end cover plate that was made of steel became dished from the pressure generated by the grease gun trying to push grease into the plugged housing.

When an application has taconite seals installed, it is recognized that this is a highly contaminated application. The focus should be on ensuring the taconite seals are fed with grease (and worry less about the bearing).

Although there are formulas from the individual bearing companies on how much grease to apply to the taconite seal, the values derived are guidelines to use as a starting point. Fresh grease should be seen slowly purging from the seal, which would indicate that the seal/ grease system is working correctly.

When a sealed bearing is used, the frequency of re-greasing the bearing can be significantly extended. When doing the calculation for the required frequency of re-greasing, it would be safe to assume that the cleanliness level is good to excellent. This may mean that the bearing itself will only need to be regreased every three months (depending on bearing size and the speed of the pulley). If using a taconite seal, then it should still be greased as normal, such that there is fresh grease apparent at the gap.

If using a triple lab seal, then consideration should be given to either pack the bearing cavity, on either side of the sealed bearing, to 90 to 100 per cent and choose to either not replenish it or put a grease inlet either side of the bearing (many housings have a predrilled inlet to the side of the bearing or they have a dimple indicating where the grease inlet hole should be drilled).

If the arrangement is OEC, then feed

grease into the inboard side between the sealed bearing and housing seal. Do not feed grease to the side that has the end cover. If the arrangement is BEO, then feed grease into the cavities either side of the sealed bearing.

To determine the amount/frequency of grease addition to the housing cavities, it could be treated like a taconite seal, in that, there should be enough to cause some fresh grease to purge from the housing seal.

To achieve a flow of grease through the sealing system (taconite or triple labyrinth), it essentially means regular visits by a lubrication technician or some form of automated lubrication system. These can be as simple as a single point lubricator on each seal or a more complicated multipoint automated lubrication system that feeds several bearings and seals. Automated systems still need attention at least in terms of monitoring them to ensure that they are still running, they have not been knocked off by rough handing, the lines cut or damaged, the lines being forgotten to be re-attached, and the reservoir becoming empty.

The best time for manual greasing is when the machine is running. This allows for the newly added grease to be pushed out of the swept area of the bearing and to freshen up the reservoirs adjacent to the rolling surfaces. It is understood that this is not always possible, so greasing when the machine is at a standstill is still better than not greasing at all.

In summary, grease acts as both a lubricant and a key component of seals used in split pillow block housings. When determining re-lubrication practices of split pillow blocks, getting grease to and through the seal is of prime importance. This is achieved by both appropriate placement of the grease inlets and the appropriate timing of the delivery of grease.

A sealed spherical roller bearing can provide a third barrier to contamination given that the external seal and housing grease pack is not fully effective.

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him at mro. whats.up.doug@gmail.com.

Any plant has the potential to have a successful maintenance department, the payoff is an engaged maintenance team providing focused equipment care and customer service to the production department with a result of sustainable equipment reliability.

BY PETER PHILLIPS

Over the past few MRO issues, I’ve written about the role and responsibilities of each member of the maintenance team. This installment focuses on the maintenance manager and how they influence the success of the maintenance department, their improvement goals, and the performance of maintenance staff.

The maintenance manager has many responsibilities; however, they have two primary responsibilities to their maintenance team:

• Lead their team to achieve and sustain maintenance initiatives that will improve equipment reliability.

• High quality service to the production department.

A major problem many maintenance managers face is explaining the added value of maintenance activities

to upper management. According to conducted research, more than 60 per cent of top managers still look at maintenance strictly as a cost centre and necessary evil.

This is a problem since it is the direct cause of why many maintenance managers work with a tight budget and compromise on the overall quality of the work their department can deliver. A strong maintenance management team that doesn’t have to compromise can bring competitive advantages to the company by ensuring high asset uptime and utilization, keeping a good brand image, and preventing and eliminating technical difficulties that can have a negative impact on the productivity of their facility.

When looking at equipment uptime and reliability, many factors play a role for the maintenance manager to

consider including basic maintenance fundamentals and new technical advances for the maintenance team and equipment.

Many maintenance departments lack the basic maintenance fundamentals that are the core of maintaining equipment. Without these fundamentals, maintenance technicians will struggle to complete their maintenance activities successfully and with a high degree of quality.

There are two elements that make up the basic maintenance fundamentals; the quality of maintenance being performed, and the experience and knowledge of the maintenance staff.

To address these two elements the maintenance manager needs to evaluate the maintenance activities their team performs and assess the skills, knowledge, and attitudes (SK&A) of the team members. Very often these two factors need to be improved, which will help the team deliver better maintenance and build the confidence of the technician.

The maintenance team delivers an array of services. One of the key deliverables of the basic fundamentals is the preventive maintenance (PM) program. Very often the PM program has not been reviewed and evaluated on a regular basis and PM routines are outdated, and maintenance documents are poorly written and inaccurate.

The structure of preventive maintenance has changed over the past few years, now the historical time-based PM program has been split into other categories. Time based inspections, time-based replacement (TBR), condition-based monitoring (CBM) and run-to-failure have replaced traditional maintenance programs. To implement these new systems, it may be necessary for the maintenance manager to get an internal or external specialist to help setup the new categories and train maintenance planners how the build a new PM program. Secondly, when it comes to the technician’s knowledge and experience, the maintenance manager needs to assess everyone’s SK&A and provide them with a roadmap to improve their performance. Providing training and hands-on experience builds the skills of each team member and their overall contribution to the team. It is the responsibility of the maintenance manager to help assess each member and to build a training plan for them. The manager may find it beneficial to seek external services, so assessments

are fair and unbiased. Even the most seasoned maintenance person can benefit from training, especially with new technology and advanced methods of inspection and repair.

The maintenance manager also needs to look at the new technical advances for the maintenance program, such as TBR and CBM.

TBR of equipment parts sounds somewhat simple, “change out the part at a set time before it fails.” However, determining when the part was changed last and why it failed can be difficult. Often historical equipment records are not available, therefore the normal procedure to start this TBR program is to refurbish the equipment and restore it to as close to new condition as possible. Then maintenance teams need to determine when the part will fail and calculate when it needs to be replaced to prevent a failure. Lastly, a schedule for replacement needs to be setup in the maintenance program (CMMS).

Along with TBR, the equipment will also need new schedules for time-based inspection and intermittent CBM. Depending on the size of the facility and number of pieces of equipment it will take a significant investment of time to setup the new PM program. The cost of equipment refurbishment will be substantial, and the maintenance manager will need to include the added cost in their maintenance budget.

CBM has been in use since the 1930s. Advancements in technology now provide continuous monitoring with real-time feedback and analysis of equipment health. The price of CBM components and software have fallen

sharply the last few years, making the cost more palatable to the maintenance budget. Statistics indicate that continuous equipment monitoring that provides advanced warning of equipment component failure out weights the cost of sensor hardware, implementation, and yearly service contracts. Yet another activity the manager needs to facilitate and budget.

On top of their other responsibilities, maintenance staff expect to see the manager in the maintenance shop and out on the production floor during maintenance. They want the maintenance managers guiding leadership and helping when navigating through occasional rough waters. They want regular updates on the team’s performance, and want the manager to set team goals and keep them focused.

Any plant has the potential to have a successful maintenance department. Leadership and maintenance commitment from the top down provides the direction the maintenance staff expect. Maintenance managers and every person on the team needs to be held accountable to their roles and responsibilities. The payoff is an engaged maintenance team providing focused equipment care and customer service to the production department with a result of sustainable equipment reliability.

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotiabased maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@trailwalk.ca.

Gas turbine efficiency can be determined by concentrating on troubleshooting four important areas: gas path analysis, fuel control systems, vibration, and lubrication.

BY L. (TEX) LEUGNER

The gas path consists of the compressor, combustor, and turbine, all of which are susceptible to damage by contamination, fouling, erosion, corrosion, sulphidation, nitration, oxidation, water emulsions, plugged or damaged fuel or turbine nozzles, and broken blades or vanes.

Q | Does the maintenance group fully understand the gas path parameters necessary to correct combustion problems?

LOGIC: Compressor fouling occurs due to foreign deposits on the blades, plugged or damaged fuel nozzles and damaged combustor liners. Normal operation depends on fuel flow, exhaust gas temperature and compressor discharge pressure. The turbines cycle signature is related to power output, corrected turbine inlet temperature, rotor speed and performance factors including pressure, temperature, speed, fuel flow and BHP.

Q | Does the maintenance group understand how to monitor and manage fuel and governor controls?

LOGIC: Problems such as ‘hot’ starts are usually caused by a too rich fuel schedule, while ‘hung’ starts may be the result of a too lean fuel schedule. Running problems such as an inability to accelerate, or a too rapid acceleration, are usually caused by a governor problem. Both pneumatic and hydraulic governor controls are susceptible to leaks, contamination, and wear. Pneumatic systems can also be erratic if moisture is in the air lines. The trouble-shooter must know how the control systems work,

how to recognize malfunctions and verify corrosion, erosion, and foreign damage with a borescope inspection.

Q | Does the turbine maintenance group have a well-designed vibration monitoring schedule?

LOGIC: Vibration analysis is an essential element of condition monitoring of gas turbines. Gas turbine bearing problems are related to lubricant quality, contaminants, wear, temperature and vibration. Rotational speeds of aero-derivative turbines may run at speeds ranging from 9,000 to 20,000 RPM, while heavy industrials operate at speeds in the 3,000 to 12,000 RPM range. All new aero-derivatives and most industrials now use rolling element bearings to support rotors and shafts more effectively.

The vibration frequencies related to anti-friction bearings are fundamental train frequency, ball pass frequencies of the inner and outer raceways, and the ball spin frequency. These frequencies depend upon rotor speed and bearing geometry. Troubleshooters should know the name and part numbers of gas turbine rolling element bearings to obtain the manufacturers bearing geometry data and thus know the frequencies of the bearings. The bearing geometry data required to accurately calculate vibration fault frequencies are ball or roller diameter, pitch diameter, number of rolling elements and contact angle. If the bearing frequencies are not known, or cannot be obtained from manufacturers, the following calculations can be used to obtain the approximate frequencies of the bearings inner and outer raceways.

Inner Race Frequency

# of Rolling Elements X Shaft RPM

X 65 per cent

Outer Race Frequency

# of Rolling Elements X Shaft RPM

X 45 per cent

Resonant frequencies are found in every piece of equipment and turbines are no exception. Resonant frequencies that may affect turbine operation can be found in rotors, base plates, mounting pads, piping, and bearing or bearing supports. Other sources of vibration include rotor imbalance, looseness, and misalignment.To obtain as much vibration data as possible, it is wise to measure displacement, velocity, and acceleration. Proximity transducers are recommended to measure displacement at radial bearings. Accelerometers are used to measure high frequencies of turbine blade vibration, while the most uniform measurement of vibration

Symptoms of nitrogen oxides and oxidation include an increase in viscosity, acid number and oil discolouration, all of which indicate serious degradation.

data is velocity to detect a wide range of vibration data occurring at low, mid, and high frequencies. Vibration data should be collected in the vertical, horizontal, and axial positions.

Q | Is the maintenance group fully aware that proper turbine lubrication is critical?

LOGIC: High operating temperatures and catalysts like water and air cause oxidation and thermal degradation of the oil that generate varnish and sludge. Oxidation is a chemical reaction when oil is mixed with oxygen. Thermal degradation occurs in the combustor at temperatures around 205ºC (400ºF) or higher, or when trapped air bubbles travel from low to high-pressure areas. The hot air bubbles implode, and the high concentration of heat raises the oil temperature dramatically.

Symptoms of nitrogen oxides and oxidation include an increase in viscosity, acid number and oil discolouration, all of which

glycol mixtures in coolers, and it is recommended that the oil side operating pressure of the cooler be higher than the water side operating pressure.

Q | Does the maintenance group use the best techniques available for turbine lubricant analyses?

LOGIC: A typical 250-hour turbine oil analysis report should reflect the following results.

Membrane Patch Colorimetry: measures varnish potential; a varnish potential of 35 or less is normal, 50 and higher is considered severe.

Remaining Useful Life Evaluation

Routine (RULER): measures the antioxidant additives (amines and phenols), in turbine oil by ASTM D6810-02 or D6971. RULER result of 50 per cent provides a warning, any result of 20-25 per cent indicates immediate action required.

Ultracentrifuge (UC) : determines the level of insoluble contaminants that indicate varnishing, zero reflects new oil, four is considered marginal and a UC value exceeding six is critical.

Total Acid Number (AN): is an indication of the remaining useful life of a lubricant by ASTM D664 or D974. New turbine oil has an AN of about 0.03 and in service turbine oil must not exceed 0.2.

indicate serious degradation that results in tar-like deposits on mechanical seals, varnishing on inlet vane valves or bearings, thick deposits trapped in oil filters and premature plugging of oil coolers.

Electrostatic discharge occurs in lubricants due to internal molecular friction and differences in electrical potential between the fluid and component surfaces and contributes to varnish and sludge formation. Static electrical discharge occurs at servo valve surfaces, in filters and reservoirs and spark discharges can reach temperatures of 20,000ºC, promoting thermal degradation instantly.

Static discharge can be heard if one is close enough to the reservoir of an operating turbine where this is occurring. As little as 500 PPM of water can promote foaming, emulsions, and bacterial growth. Oil sight glasses may show these conditions. Contaminants will cause scoring and wear on bearings and control valves in governor systems. Other contaminants include water/

Water by Karl Fischer: by ASTM D6304, determines the amount of water. Acceptable water levels are less than 500 ppm, unacceptable levels are 1000 ppm.

ISO Particle Count 4406: measures the number of particles in lubricants in size ranges of four, six and 14 microns by optical particle counter. New turbine oil cleanliness standards are 16/14/12 or as specified by the turbine manufacturer. In service turbine lubricant cleanliness levels should never exceed 18/15/13. When any combination of these results indicate unacceptable contamination levels, increased varnish potential, or a buildup of insoluble materials, immediate action is recommended.

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

Safe and healthy workers are at the heart of any operation, investing in their well-being and safety will always provide a strong return.

BY CANADIAN CENTRE FOR OCCUPATIONAL HEALTH AND SAFETY (CCOHS)

Heavy equipment allows manufacturers to achieve incredible results, from building vehicles and prefab housing to keeping communities supplied with the necessities of life. However, operating heavy equipment, or working near it, comes with an increased risk of injury and even death. Workers in facilities with heavy equipment must receive thorough training on the proper operation of the equipment, and steps to take to ensure the safety of those close to it.

Identify hazards and assess risks

Hazards associated with working with or near heavy equipment will vary

depending on the exact equipment used. Struck-by injuries may occur if the operator’s sight is obstructed or poor, either due to carrying a load or equipment or plant design. Workers can also get caught between the equipment and a wall or crushed if equipment is overturned. Exposure to moving parts, hazardous energy (gravitational, electrical, electromagnetic, magnetic), hot or cold, noise, and vibration should also be considered. Wherever gas or liquids are under pressure, there is a risk of injuries from injection from these pneumatic or hydraulic systems. With the increased risk of serious injury comes psychological hazards such as stress and other mental health risk factors.

Since there are many different types of machines and processes, a risk assessment should be conducted, and control measures implemented for each machine or situation before it’s used. It may be necessary to involve people with specialized or technical expertise such as an engineer, safety professional, or the equipment manufacturer. Pre-operational checks and an assessment of the workplace prior to using any machinery is critical. Workers should be trained on procedures for mounting and dismounting machinery, the capacity or payload of each machine, its swing radius, and how much of a buffer zone or ‘working circle’ is required that other workers must stay clear of.

When hazards have been identified, and risks assessed and controlled, workers preparing to use heavy machinery should start with a thorough visual assessment of the equipment. Check tires for signs of wear or loose parts and verify fluid levels. Are any parts cracked or damaged? Test that its lights, horns, and backup alarms are working properly. Is any of the equipment’s normal movement or extension impeded in any way? Never operate a machine that isn’t working exactly as the manufacturer intended, and do not substitute a machine designed for a different task.

Required safety equipment for workers may include roll-over protection, seatbelts, guard rails, and personal protective equipment such as hard hats, gloves, hi-vis clothing, and steel-toed work boots. Ensure that all workers in the general vicinity understand the hazards and where the working circle is, how to stay clear of it, and how to signal if something is wrong.

Never operate a machine that isn’t working exactly as the manufacturer intended, and do not substitute a machine designed for a different task.

Equipment size and noise may prevent equipment operators from being able to see or hear if a co-worker is nearby, so it is important that everyone in the workplace understands

the proper means of communication if access to the area is required. Consider using two-way radios or have a spotter nearby to warn nearby workers of danger and signal to the operator to stop. In the event an injury occurs, workers should be trained on who to alert and how to dispatch emergency services swiftly.

An integral part of maintaining a safe workplace with heavy equipment is ensuring workers feel encouraged and supported to come forward with any health and safety concerns, including psychological safety. They should know that they can flag any perceived safety issues to their supervisor and not fear repercussions.

There are several ways employers can encourage psychological safety: through workload management, clear leadership, civility and respect, and protection of physical safety, to name a few. In addition, ensuring there are adequate breaks for workers throughout the day, implementing fatigue

management programs, and educating workers about substance use and how it can affect fitness for work.

Supervisors can encourage psychological safety by checking in with workers regularly to make sure they’re maintaining work-life balance and not experiencing burnout or other symptoms of decreasing mental health.

Heavy equipment and machinery have been a boon to the manufacturing sector, helping to increase outputs and achieve targets while improving safety outcomes for workers. However, let’s not forget that safe and healthy workers are at the heart of any operation. Investing in their well-being and safety will always provide a strong return.

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well-being — physical, psychosocial, and mental health — of workers in Canada by providing information, advice, education, and management systems and solutions that support the prevention of injury and illness. Visit www.ccohs.ca for more safety tips.

Understand the equipment and how to use it safely.

1. Identify all tasks performed by and associated with the equipment. What hazards may occur from use and misuse? What moving parts and corresponding safeguards are currently in place?

2. Identify who will be using the equipment, and how often.

3. Determine how the equipment will be used.

4. Estimate the risk of each hazard by considering the severity of possible injuries and or incidents, and the likelihood of occurrence.

5. Eliminate hazards where possible.

6. Use protective measures to control the risk of each hazard, considering the design, safeguarding, administrative controls, including training, and other measures such as personal protective equipment.

7. Re-assess to estimate the new risk level.

8. Repeat the process if the risk level has not been eliminated or effectively controlled.

22_001959_MRO_SEP_CN Mod: July 29, 2022 11:51 AM Print: 08/09/22 page 1 v2.5

Being ISO 9000 certified should be an indicator of doing good businesses and standardizing performance; however, for the longest time – it wasn’t.

BY CLIFF WILLIAMS

A few years ago, speaking with the team that had helped develop the ISO 55000 Asset Management Systems Standard Suite, it was asked who they thought would be interested in certifying to the standard.

Surprisingly, one of them said that they really weren’t concerned about it. During the discussion, he explained that he was involved with many organizations that certified to various ISO standards and found himself very disappointed with their performance and approach. It seemed to him that the goal of certifying was being able to ‘fly the flag’ proudly on their buildings, not actually using the standards to help drive improvements.

This took me back to my experience with the early days of ISO 9000 and the mad scramble to become certified. At that time, being ISO 9000 certified was becoming the price of admission for doing business, if you wanted to be

a preferred or qualified suppler, you had to be 9000 certified. This should of been a good indicator of businesses improving and standardizing their performance; however, for the longest time – it wasn’t.

Organizations took the standard to mean that they should document what they intended to do and then prove that they were doing it – even if what they were doing was making an inferior product. The point that the standard was supposed to give the organization a consistent basis on which to build and improve their performance was missed, as the question that organizations were really interested in answering was “Are you ISO 9000 certified?”

ISO 9000 developed over the years, but by that time many organizations no longer saw the value in being certified, and didn’t do more than what was required by the audit to continue certification. Compliance to the

standard’s requirements had missed on the intent of the standard.

Today, we see different uptake in the ISO 55000 suite around the world. In Canada there has been more activity, with Ontario producing O.Reg. 588/17 Asset Management Planning for Municipal Infrastructure.

This regulation was enacted with the intent that municipalities would take a structured approach to managing their assets and making best use of the grants, taxes, and other funding. While also providing value to their stakeholders by ensuring their processes and procedures were the most effective and efficient they could be.

It seemed to him that the goal of certifying was being able to ‘fly the flag’ proudly on their buildings, not actually using the standards to help drive improvements.

The submission date for the initial core asset plans has passed and if you visit most municipality web sites you will find a link to their asset management plan (AMP). While everything seems to be in place, at least to meet the requirement of the regulation; however, when digging deeper, it becomes apparent that the AMPs are not quite what they appear.

What has happened in most municipalities is that to comply with the regulation they have taken a snapshot in time and considered that as the basis for the plan. This might seem the obvious way to go but much like the

early days of ISO 9000, there is no evaluation as to whether what you are doing today or the results you are getting today. are the right ones.

Having seen instances where there is not sufficient data to support what is reported, other than an opinion, or instances where one or two people have produced these AMPs with scant involvement from asset owners, or instances where asset owners very quickly abdicate any responsibility for providing meaningful data or developing meaningful processes.

When we look at how this situation can exist, we often find that those close to the top of the organization feel the same way, and when asked about their role in driving sustainable asset management they openly admit that they tend to defer to the asset management department for understanding.

O.Reg. 588/17 missed out on what were the most important points of ISO 55000 suite, and that was the influence of leadership and culture on the success of any sustainable, holistic asset management endeavours. What happened is that municipalities continue to behave the way they have always behaved, do the things the way they always did them, live with the culture they have always had, which ended up with the results that prompted the introduction of O.Reg. 588/17 to correct this.

There has been good work done by good people to produce these AMPs, but once again we have fallen into the trap of the

goal being to meet compliance at the expense of intent.

The interesting sidebar to this is many of those municipalities who are not covered by the O.Reg. have recognized the need for leadership and culture influence and have worked on those as the basis for building their AMPs.

Therefore, it seems when organizations must comply , they tend to see nothing else other than the certification. They

must comply but not viewing it from the perspective of intent does not lead where the compliance is meant to. This can permeate through organizations where people do the same thing at department level, take the favourite maintenance KPI of PM compliance and achieve certification. However, equipment is still breaking down because they are the wrong PMs or are being done incorrectly.

Cliff Williams is author of the bestselling maintenance novel People – A Reliability Success Story. He is a maintenance and asset management educator, and a keynote speaker at conferences worldwide, who believes success is achieved through people. Currently, he shares his knowledge and experience as an advisor on maintenance and reliability for people and processes, and asset management with TMS asset management and is a facilitator for PEMAC’s Asset Management Program.

Mechanical components in a factory require the most attention from a maintenance perspective, as they have a high propensity to fail, making it a high priority for maintenance teams. In turn, it is always better to prevent failures than resort to reactive maintenance.

BY BRYAN CHRISTIANSEN

It is important to note that routine checks help in preventing mechanical troubles in the factory. Let’s look at some of the most prevalent mechanical failures experienced by machines in a factory. While also considering how routine checks have the potential to be an antidote to mechanical failures.

Different forces act on mechanical components while they are in operation. They work in an environment where interaction with other components and people in the factory is necessary. Such factors cause mechanical failures.

Wear and tear: The most common mechanical problem experienced in any machine is the wear and tear of components. When machines are in operation, there are frictional forces acting between components. This friction causes material degradation of components.

Materials degrade to an extent where they can no longer perform their functions. Another risk is the sudden failure of the component while it is in operation. Components experiencing wear and tear need to be replaced before they evolve into a larger failure.

Overheating: Mechanical components in operation generally produce heat. This is due to friction when two surfaces slide against each other. Machines are designed to factor in this heat due to frictional forces.

Overheating is an indication of some fault in the machine. The root cause could be improper installation, lack of lubrication, or leakage of coolant. You need to perform root-cause analysis to identify the underlying cause that is manifested as overheating and rectify it.

Mistakes from operators: Machine operators can perform their tasks erroneously, causing mechanical problems. This could be due to a lack of training or experience of the operator. The operations teams might not have standard operating procedures (SOP) in place, leading to errors from operators, damaging mechanical components.

Establishing SOPs and enforcing them with checklists reduces the mistakes performed by operators. Increased automation is another way of eliminating the potential for operator mistakes.

Improper maintenance: Machines and machine components each have a limited life, which depends on regular maintenance and upkeep performed.

Scheduled maintenance activities must be done to make sure machines and their components are utilized to their full potential. Regular maintenance and replacement of worn-out components is required to prevent mechanical failures and extend machine life.

Routine checks are performed to inspect machines and their components for any sign that could indicate a future failure. Routine checks are performed

as a preventive measure.

Trained maintenance professionals and operators inspect machines in operation and in an idle state. They are looking for signs of material degradation. You also need to check for any anomalies such as odd sounds, bangs, sparks, and unexpected output.

The anomalies identified must be investigated to find their cause. Rectifying them avoids mechanical failures and the costs that damage could cause.

Routine checks help to identify smaller faults that have not manifested to a noticeable scale. Rectifying such faults in a timely manner ensures potential large failures do not happen.

Positive impacts of routine checks include:

Routine checks help to identify small faults before they grow large enough to cause machine failure. When such faults are identified, maintenance can be scheduled in such a manner that it does not affect factory operations. Rectifying the problems eliminates

the chance of unscheduled downtime. This will ensure that maintenance activities can be performed to cause minimal disruption to factory operations.

Routine checks force the maintenance team to identify the root cause of any small faults that occur.When the faults are minor, they will be observed closer to the root cause. In operations where routine checks are not done, you will get to know of faults only when a large failure occurs.

The root cause of problems becomes difficult to identify. Reactive maintenance in most cases will be able to patch up problems at the surface level. The root cause will be the origin of more failures that will require regular maintenance and machine downtime. Routine checks will help to catch mistakes in the start, reducing the maintenance needs of machines.

Mechanical faults cause wastage in many forms. Increased energy consumption for operations is a common

effect of mechanical trouble. The consumed energy could be electrical energy or heat from the combustion of fossil fuels.

Similarly, mechanical faults can cause an increased consumption of raw materials, lubricants, and coolants. Wastage can be avoided with routine checks and rectifying even minor mechanical faults that are observed. This ensures sustainable plant operations and an increased utilization ratio of resources.

Machine life depends on many factors in its operations. Minor faults are unavoidable in any machine operation. Sustaining the faults without any rectification damages the machine. Larger catastrophic failures could also happen due to the compounding of smaller faults. These factors adversely affect the life of the machine.

Routine checks help to catch smaller anomalies and defects before they become a larger failure. Routine checks help in performing preventive maintenance, making the machine more

robust compared to its counterparts that undergo reactive maintenance.

Routine checks are indispensable for proper operations and the maintenance of machines in a factory. They come with many benefits that save a lot of time, energy, and money.

You need to incorporate routine checks as part of regular machine operations. Create a checklist of tasks that must be performed on a daily, weekly, and monthly basis to inspect the health of machines. Making these checklists accessible to all maintenance and operations teams is a wise idea.

This helps anyone interested in following and performing routine checks. A cloud-based computerized maintenance management system (CMMS) is ideal for maintaining the checklist for routine checks.

Bryan Christiansen is the Founder and CEO at Limble CMMS (a mobile CMMS software company). He can be reached at bryan@ limblecmms.com.

The new alignment certification will document exactly what an alignment specialist is certified to perform in the way of alignment tasks according to the latest internationally accepted standards.

BY JOHN LAMBERT

Let’s face it, even in high school we wanted to stand out (for the right reasons) and in today’s business world we call this a differentiator. Being different, standing out from the crowd, being unique.

The new certification program offered by the Canadian Machinery Vibration Association (CMVA) will allow maintenance professionals the opportunity to stand out. However, the big winner will be asset machinery reliability.

In brief, it is a certificate in machinery installation and shaft alignment targeted for mechanics, millwrights, technologists and engineers, while it will allow the individual to show their level of expertise or skill level. For the maintenance manager, they can see who does and doesn’t hold this valuable skill set. For the contractor, they can show the quality and value of their staff and the company this staff represents.

What is the CMVA and why do we need it?

The CMVA, in collaboration with industry, is working to continually improve machine asset reliability. This is mainly achieved through knowledge-sharing.

CMVA is an International Standards Organization (ISO) 17024 compliant

certification body as accredited by the Standards Council of Canada. It validates the knowledge of hundreds of machine vibration analysts, many of whom are also certified mechanics, millwrights, technologist and engineers, through a certification process, based on ISO 18436 series of standards.

Certification is available in four levels (categories I, II, III and IV) for the vibration analyst, being an individual who is certified in vibration analysis at a certain level and is competent in specific tasks to that specific level. The ISO created ISO 18436-2, which specifically defines all these tasks. CMVA certifies that the individual who has trained to this standard is competent, proficient, and skilled to their level.

This is important, as for example, If you go into a doctor’s office, you normally see their credentials on the wall. This gives you confidence in their ability (competence, proficiency, and skills) to diagnose and treat you. If you fell afoul of the law, you would want to know that your lawyer was also qualified.

It is the same in our industry, as it wouldn’t make sense to invest in a vibration analyzing instrument, and not

have a certified operator to use it. If you contracted this service out, would you get a company that was certified, or would you hire someone who says they are competent?Yes, they may have been doing it for many years, but are they skilled and proficient at it? How would they know? How would you know?

For a vibration analyst, it’s about interpreting what they see, including amplitude, frequency, and spectra, which may point to a problem such as misalignment or imbalance. It can be the same for millwrights and maintenance mechanics who must interpret and analyze different scenarios on a regular basis, including visual inspections of the base and machine setup, which can similarly point to problems.

Years ago, when I started my business, I went to a plant requiring an alignment done on their machine (motor to compressor). At the time, laser alignment work was still very new and upon arrival, a group of maintenance employees wanted to see it in action. One individual had a big straightedge and declared to all those on that site that the machine had to come up.

I quickly setup and took some readings. My conclusion was that there had to be an amount of shim to be removed from the machine; in fact, lowering it. This did not go over well with the one individual, and he told me again, in no uncertain terms, that the machine had to come up.

If you look at the basic sketch (above), the straightedge (the line) shows a gap between the edge and the top of the coupling hub. Yes, if we are moving the machine on the right, it needs to come up, but to do that you have to lower the backend of the machine. This is due to the large amount of angular misalignment. In fact, you must lower both bearing supports to achieve shaft to shaft alignment as you can see (below) on the same graphic.

This will not be the first or last time this mistake is made. However, we must be competent and skilled, and we must interpret and analyze what we see. Using a straightedge to align two shafts takes skill, and many received this training at trade school. Some only got ‘on the job’ training, and in my experience,

the correct use of a straightedge is not shown ‘on the job’. The reason is that nobody wants to be taught what is perceived to be such a simple measurement process, therefore, the individual learns it by themselves. Basically, using trial and error.

Present day maintenance mechanic and millwright programs differ on what they teach. For example, the colleges that I am involved with in Ontario, mainly teach rough-in alignment (using straightedges) and the rim and face dial alignment method, and basic laser alignment. In Western Canada, they cover more, including rim and face, reverse dial and cross dial alignment method, basic laser alignment and advanced alignment work, and bore alignment, which is basic geometric measurement (straightness).

What this all means is that we do not have a level playing field in this important and fundamental skill.

Change coming as CMVA will offer alignment certification program

This certification will validate the knowledge of many millwrights and maintenance mechanics. It is based on the American National Standard (ANSI) Shaft Alignment Methodology, Part one. It will also include many methods that are a requirement of the Canadian Millwright Red Seal program.

There will be two levels; level one will cover the removal of static strain, distorted bases, softfoot, pipe strain, as well as rim and face and basic laser alignment. Level two will cover all of level one, plus the removal of dynamic strain (thermal growth), cross dial or reverse dial including the graphical and mathematical corrective calculations and advanced laser alignment work.

This is big news

Why? What the CMVA did for vibration analysts (tradespeople, engineers) by bringing accountability to prove their proficiency – they can now do the same for millwright and maintenance mechanics, and others involved in machinery installation and alignment.

To understand the scope of this, at present there may be two certified vibration analysts per plant, whereas this same plant would have at least 10 skilled tradespeople

involved with machinery installation and shaft alignment. By pursuing this standard, it allows a tradesperson to become specialized, accredited, and certified. When companies look to hire, they look for a differentiator, something that make them unique to stand out. It makes that individual more valuable, which is a benefit to both employee and employer.

Companies who invest in training want to know if their investment has paid off and they will know if the certification is earned. Contractors who provide this service, will be able to prove their proficiency and value.

The new alignment certification will document

exactly what an alignment specialist is certified to perform in the way of alignment tasks (including analysis), according to the latest internationally accepted standards. It will assure the plant owner a minimum level of quality maintenance that their assets are receiving.

It is a win-win situation, but it will not happen overnight, there will be some adjustment along the way. Level one will be offered as a two-day course at this year’s CMVA Annual Technical Conference in October.

John Lambert is the President of BENCHMARK PDM. He can be reached at john@ benchmarkpdm.com.

speak about air quality.

BY MONICA FERGUSON

Air quality in workplaces is not as simple as it may seem. How do you go about ensuring your businesses’ HVAC system is enhancing air quality by dealing with the pesky microbes you might not see but are certainly there. We look at what aspects need to be looked at with Kevin Lisso.

Q | Can you provide an overview on the current air quality in workplaces and the impact COVID-19 had?

LISSO : Three years ago and today, it’s a night and day difference. Air quality has not been a forefront concern, until the pandemic struck, as it was below average before the pandemic. It has become much

more important in workplace environments, health care facilities, hospitals, gymnasiums, almost everywhere. Businesses would have a service contract with their HVAC company, which would come out once a month or every quarter and change the filtration system. Essentially clean the unit, oil, and lubricate any motors, make sure the tension was correct on the belts, and top up Freon levels. There was a maintenance focus, and the filtration was an add-on or afterthought. Typically, the older filters in rooftop units and in each HVAC system are like the ones in homes. A mesh filter that captures the larger particles of dust is designed to protect the equipment, but not the air quality in the business.

Since COVID-19 started, companies are looking at this much differently. They are thinking, “what can we do to decrease or eliminate the number of microbes in the air, which

weren’t important to us before but are certainly out there.”

Inexpensive products exist, one is an ignitor system, and one is the UV light system. Both systems will eliminate 99 per cent of harmful particles, COVID-19 related particles and others. There is no maintenance work required with these systems, as it all comes down to a UV light on the inside of the ductwork. As the particles go by, they’re killed on contact with the UV light. These systems eliminate larger and smaller dust particles, which is important for the operating machinery and operating equipment. They are eliminating smaller particles that would be recirculated through the air.

Q | How sustainable is this system in comparison with previous HVAC systems?

LISSO: These systems use very little electricity, which allows for operations to run a lot smoother. It is much cleaner in comparison

to the previous systems that would generate a dirt buildup which would restrict air flow and be tiresome on the motors. Now, there is less maintenance required and less breakdowns. From a sustainability standpoint, it saves money on operating costs since the system is running more efficiently.

Q | Which particles are being eliminated in this process?

LISSO: There are thousands of different dust particles, dust mites and microbials. The filtration

systems prior to COVID-19 were expensive and the main objective was capturing larger particles to protect equipment, leaving 90 per cent of smaller particles in the air. Using UV light, a reactionary process happens, which burns and eliminates 99 per cent of any airborne particles dangerous to our health. It is a vast improvement from before. The microbes that are harmful to our health and operation are reflective, which the UV light can detect and instantly eliminate. The microbes that are ‘good’ for our health are not reflective, thus

the UV light would not interfere.

Q | What steps can a company take to increase their air quality?

LISSO : Speak to a HVAC company to conduct an assessment. Companies will come in with devices to show you what PPM is passing through your system. Assessments shows the type of air quality you have currently, what type of air filtration system you have in place, and give recommendations. They will evaluate the assets, put together a proposal, and eliminate air particles that need to be eliminated.

Q | What should manufactures be weary of when upgrading their HVAC?

LISSO: There’s a lot of scammers that are preaching that their product does various things, which are not true. My advice is to be very careful when choosing the right type of air

quality control systems, and do your homework. Ensure the product has been vetted and has the proper accreditations. Always ask for referrals. We’ve seen a lot of products that make bold claims, and are just not true. The government has a web site that lists approved products.

Q | Is there any government assistance regarding businesses’ upgrading their HVAC?

LISSO: Yes, business owners should reach out to municipal, provincial, and federal levels. Ask what’s available to better air quality and ask what kind of assistance is available. There are some great programs offered by the Ontario provincial government, which can subsidize air filtration system costs.

Monica Ferguson is an associate editor for MRO magazine, Plant magazine and Food and Beverage magazine at Annex Business Media.

Endress+Hauser has developed Micropilot FWR30, a wireless 80GHz IIoT sensor. Its recorded measurement data can be accessed remotely via the sensor’s cloud connection.

FWR30 enables real-time monitoring of often remotely stored inventories of substances like liquid additives in plastic or metal tanks, cleaning agents in food and beverage production, or for solids like building materials at construction sites. Its setup covers level measurement in plastic and open tanks. An optional process connection enables measurement of media in metal tanks like animal feed in agriculture or storage of wood pellets for heating systems. FWR30 can be installed without special tools in under three minutes. The unit’s integrated battery means no external power supply is needed. The free space radar sensor covers measuring ranges up to 15 metres and temperatures between -20°C and 60°C. www.endress.com

Nippon Pulse announced the second generation of box-level motion controllers, the Commander box (CMD-4EX).

The biggest improvement to the new CMD box controller is the switch in USB interface from a custom API to a Windows HID API, which allows users to get the device up and running without installing additional software. The second-generation controller features helical interpolation on the X-Y-Z axes and allows for circular and arc interpolation between any two axes, not just X and Y. CMD-4EX has a

built-in four-axis driver with a TBD option, a pulser and an extra axis of buffer compared to the PMX. www.nipponpulse.com

JW Winco expands its indexing plungers’ range with GN 817.7, which is pneumatically actuated and can be integrated into automated processes. The new indexing plunger detects both end positions with a single sensor. It can be used in hard-toreach locations and integrates into automated processes. The high signals upon reaching the respective end positions are transmitted directly over the four-pin M8 cable plug to the control unit of the system.

The indexing plunger operates with pressures between four and six bar, while the IP 67-compliant sensor emits DC signals between 12 and 30 volts.

www.jwwinco.com

Festo UR+ certified multi-axis solution for universal robotics cobots adds up to four axis of motion beyond the UR cobot six axes.

The multi-axis system requires no programming during the set up and no additional PLC is required. Multi-axis are configured through the UR HMI. End users set position,

speed, and acceleration on the HMI or using the URCap toolbar, move the axis in manual mode to configure motion.