2019

Vol. 35, No. 4

Established 1985 www.mromagazine.com

Twitter: @mro_maintenance Instagram: @mromagazine

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Contributors

Mark Edmunds, L. Tex Leugner, Douglas Martin, Doc Palmer, Peter Phillips, James Reyes-Picknell, and Brooke Smith

Michael King, Publisher 416-510-5107 mking@annexbusinessmedia.com

Mark Ryan, Media Designer

Barb Vowles, Account Co-ordinator 416-510-5103 bvowles@annexbusinessmedia.com

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbusinessmedia.com

Tim Dimopoulos, Vice-President tdimopoulos@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Mike Fredericks, President & CEO

Machinery and Equipment MRO is published by Annex

Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital) PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

E-mail: BLao@annexbusinessmedia.com

Tel: 416-442-5600 X3552 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription rates.

Canada: 1 year $65, 2 years $110; USA: 1 year $110 Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (USA), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com, 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

When I assumed the role of Editor at Machinery and Equipment MRO just over a year ago, I had a general understanding of the MRO world. Coming from the automotive world, I noticed that many similarities existed between the two. Over the past year, I’ve been learning something new every day.

The most exciting aspect is observing how the industry is changing and how, in many ways, I’m learning and adapting along with it.

Some of you may have noticed that we’ve updated our mascot, Mr. O, recently. The original Mr. O, who relatively remained unchanged for many years, had a wrench, hardhat, toolbox, and overalls. For many years, he was indicative of the way many maintenance managers and maintenance professionals perceived the MRO world. Most maintenance was done right on the shop or plant floor, with computerized maintenance monitoring and technology playing much smaller roles than they do today.

Our updated Mr. O still has a hardhat (for safety, of course), but his main tool is no longer a wrench. It’s now a tablet. The rise of digitization has updated the way predictive maintenance (PM) can be done. Maintenance managers now use technology to forecast PM. Technology is more efficient at minimizing breakdowns.

Sensors can now be connected to most equipment, and, in many cases, real-time data is sent from equipment to a computer, a tablet, or a smartphone. Maintenance professionals have the option of monitoring their assets—without actually having to see the equipment.

While some operations are further along the road to technological transformation than others, some are doing quite well with legacy machinery that has proven its worth over the years.

Either way, preventative and scheduled maintenance can’t be ignored. It’s still an important underpinning of a general maintenance program: making sure machines are lubricated properly (manually or automatically); equipment has been torqued properly (sensors can alert operators when the torque is off); and equipment is running properly (real-time vibration monitoring).

As more and more companies advance toward connectivity through predictive analytics and other advanced technological capabilities (Industry 4.0 and IIoT), the future of maintenance is following suit. And while these technologies are on the market, it’s up to the end user to embrace them.

MRO

Good day,

Predict machinery issues before operations are impacted. Simplified inspection, machine health data collection and analysis are now within everyone’s reach.

With SKF Pulse, anyone can monitor machine health without the need for training or diagnostic expertise.

Combining an easy-to-use sensor with a free mobile app, you can quickly and easily identify machine condition and share machine health data within your organization. In-app SKF Pulse Checks also provide access to expert analysis and advice from SKF.

It’s easy to get started, and with a cost-effective price point, there’s no need to make the case for capital expenditure.

Reliability

Maintenance Strategy / 14

How to develop and manage a maintenance strategy.

MRO Quiz / 20

Oil analysis: “basic wear” programs provide inadequate condition monitoring.

What’s Up Doug / 28

Maintenance 101 / 18 The importance of equipment ledgers.

Maintenance Scheduling / 24 How

BY MARIO CYWINSKI

Recently, SKF USA Inc. invited North American journalists to its Technical Press Day 2019 in Philadelphia, to learn about what the company is up to. SKF executives and product specialists outlined how SKF is adapting to the ever-changing digital environment.

The event kicked off with SKF USA Inc., President John Schmidt welcoming attendees and thanking them for attending.

Michael D’Argenio, Vice-President, Digital Transformation and Customer Experience, SKF Americas dove into Digital Disruption and Transformation as it relates to SKF. Special attention was paid to digital in the industrial sector; namely, IIoT and connectivity, with new possibilities on the horizon and how those will bring new challenges. The upcoming 5G connectivity was discussed and how it can help IIoT, including being used for pipe, cargo ship, freight train, and turbines. D’Argenio discussed SKF's strategic approach, which includes: a centralized digital platform, a unified data strategy, an ecosystem of connected products and apps, and a results-focused business model.

John Chioffe, Director of Business Intelligence, SKF USA, discussed The New Power of Data and how it is being used. Traditional use of data, which includes calculating costs, determining profitability, and reporting production, is changing into more innovative use of data with real-time output and productivity, predictive maintenance, and success probability.

Up next was Josh Flemming, Strategic Marketing Director, SKF USA, who spoke about Connected Devices: Insight Through

Technology. He explained how SKF is transforming what common challenges companies face (limited operational budgets, resistance to capital expenditures, plant infrastructure shortcomings, run-to-failure mindset, multiple machines from different OEMs, and more), and how connected devices are the entry into predictive maintenance. SKF Pulse, a vibration and temperature monitoring device; SKF Connected System 24, an automatic lubrication system; and SKF Connected Grease Gun, a manual connected lubrication gun; and how they can help customers, were outlined.

Lars Kahlman, Senior Application Expert and Technical Lead, SKF Group, presented New Bearing Technology–SKF Fiber Optic Sensing and how it works. He briefly outlined the history of fibre optic sensing at SKF: 2008 to 2012 was the development of the system from an idea, 2015 to 2018 was having long-term testing and proof of concept, and 2019 was the final product development. How can OEMs use this technology? To help with design verification, warranty, service/troubleshooting, and others. How does an end user benefit? By helping commissioning, efficiency and reliability, and more.

Other presentations focused on Lubrication Management, Digital Modeling and Simulations, and Rotating Equipment Performance. SKF USA experts led each.

The presentations were divided into two blocks; at the end of each, there was time for demonstrations of and discussions about SKF products. SKF product specialists were on hand to answer any and all questions attendees had.

While it was a lot of information to take in, attendees were left with a greater insight into what SKF is doing now and what it plans to do in the future. MRO

BY MARIO CYWINSKI

Harting Canada held its annual trade media lunch at Madrina Bar y Tapas in Toronto’s Distillery District. The event gave those in attendance a look at how the company is doing and what it's working on and its upcoming sales expansion.

Ashley Smith-Heine, Vice-President of Sales, Harting Americas; Carl Maalouf, Director of Sales; and Peter Hanna, Territory Sales Manager Greater Toronto Area, Harting Canada; were present to give information about Harting and answer any questions that were raised.

Harting Canada has recorded double-digit revenue growth regularly, including so far this year. As a result, the company is expanding its Canadian sales force in the coming months. Harting has been in Canada for over seven and a half years.

Smith-Heine said, “The sales force expansion is particularly attractive be -

cause of a number of stellar opportunities in the Canadian marketplace.”

Several topics were discussed at the lunch, including automation and digitalization, and market diversification.

“We see the uptake of IIoT accelerating in the Americas, with commensurate benefits in optimizing operational efficiency and business costs,” said Smith-Heine. “By 2023, the smart manufacturing market worldwide is expected to be worth US$299 billion, with a compound annual growth rate of 11 per cent.”

The Harting representatives discussed the company's share growth and how expanding its sales presence helps to build customer relationships.

“There is no substitute for boots on the ground; our customers have always appreciated that of Harting,” said Maalouf. “We’re not just there to sell products, but to help them select the most appropriate ones from both a technical and a business standpoint.”

Two new products were also highlighted: Han 1A and T1 Industrial. The Han 1A is a compact modular connector series with up to 12 contacts for transmitting date, power, or signal. The T1 Industrial is a single pair Ethernet connector that can carry power and data on one pair of wires. MRO

BY MARIO CYWINSKI

The Canadian Tooling & Machining Association's (CTMA) Toronto Chapter recently held a tour at one of its member companies, Samco Machinery. The tour included an overview of Samco’s operations by CEO Bob Repovs, and a tour of the facility, which included four bays housing equipment assembly, tool and die, CNC and machine shop capabilities, electrical assembly, and a rolling division.

“CTMA would like to thank our hosts, Bob Repovs, Jaswinder Bhatti, and the Samco team for opening their doors and showcasing their impressive 164,000 square-foot facility,” said Robert Cattle, Executive Director, CTMA. “CTMA has three chapters, Toronto, Southwestern Ontario, and Windsor, that organize plant tours in the spring and fall. If you missed this tour, we hope to see you at one of our fall tours.”

After the tour, participants got together for dinner and networking at The School Fine Dining.

Samco Machinery, founded in 1972 by Joe Repovs, has been in business for over 46 years. It is ISO 9001 certified and provides turnkey rollforming systems, including uncoilers, coil

BY MARIO CYWINSKI

Onward Manufacturing Company Ltd., maker of Broil King barbecues, along with the Canadian Tooling & Machining Association (CTMA), hosted a plant tour and barbecue, at its Waterloo, Ont., plant. Over 50 attendees were treated to a tour of the 200,000 square foot facility, which has assembly lines (three), paint lines (two), and a press shop (stamping, CNC, and tool and die capabilities).

“It was fantastic to see a great turnout of over 50 people show up for this event. We actually had to close down registration, for we couldn’t fit any more people in! President Ted Witzel’s passionate presentation of his company’s products and why it is so important to keep the manufacturing of these items here in Canada had 100 per cent attention and focus from all participants,” said Robert Cattle, Executive Director, CTMA.

cars, flatteners, rollform dies, rollformers, presses, and material handling solutions.

It has clients in 34 countries and manufacturing plants in Canada (Toronto) and in India, and offers solutions for automotive, metal building and construction, transportation, storage, energy, and consumer products. MRO

Upon arrival at the facility, attendees were greeted by a room full of Broil King barbecues and a presentation that preceded the plant tour. It included an overview of the products and market strategy for Broil King by Colin Kirvan, Vice President of Product Management, Onward Manufacturing, as well as an overview of global operations and trade challenges for Broil King from President, Ted Witzel.

“Attendees were divided into groups and toured the 200,000 square foot manufacturing facility, which showed us all the different steps and components that are needed to build these

high-quality products,” said Cattle. “To cap it off, Broil King’s executive chef had prepared a barbecue lunch that included slow-roasted brisket, pulled pork, and chicken, along with vegetables all prepared in their in-house kitchens! This will be hard to top.”

Onward has three facilities, Waterloo, Huntington, Ind.; and Dickson, Texas; which all produce Broil King products. The company is family owned and has been in business since 1906. The company designs, manufactures, markets, distributes, and services products for over 40 countries. MRO

Endress+Hauser Canada will build a new $28 million Customer Experience Centre in Burlington, Ont. The new 47,000 square foot building plans to achieve LEED Gold certification standard and function on a net zero carbon and energy basis.

“Our goal is to create an exceptional facility in all respects that will not only be sustainable on the day it opens, but will also still be considered as such decades from now,” said Anthony Varga, CEO and GM, Endress+Hauser Canada Ltd.

The new facility, to be opened in fall 2020, will be a full Customer Experience Centre, featuring the second Process Training Unit in Canada and a calibration laboratory, an expanded workshop, and a large training centre.

The building will effectively be off the hydro grid. It will use a reflective roof with double-sided solar panels to generate electricity during the day. At night, most electrically powered systems like video monitors will be turned off rather than drawing even standby power, and the building environment will be maintained by heat pumps supplemented by a geothermal system. The new headquarters will feature two cafes, a fully equipped health and fitness room, a wellness room, and a multifaith prayer room. There will be an atrium and an outdoor terrace. MRO

Fluke Corp. has acquired Ismaning, Germany-based Pruftechnik.

“Fluke’s acquisition of Pruftechnik reflects the growing importance our customers place on reliability systems to keep their equipment in optimum operating condition,” said Marc Tremblay, President, Fluke Corp. “This business will help us usher in the next generation of solutions for our industrial customers.”

Fluke is a leader in test and measurement instruments, while Pruftechnik is a leader in precision laser shaft alignment, condition monitoring, and non-destructive testing. MRO

News and views about companies, people, product lines and more.

• MANN+HUMMEL finalized the acquisition of Hardy Filtration, a Canada-based air filtration company.

Hardy Filtration expands MANN+HUMMEL’s offering in air filtration solutions. Hardy has been developing, manufacturing, and marketing a large variety of filtration products for various applications, such as air filters, paint booth filters, and dust collector bags, for over 25 years.

• Handling Specialty’s Russell Johnston has been awarded the George Burwash Langford Memorial award from the Council of the Ontario Association of Certified Engineering Technicians and Technologists.

Johnston, an Advanced Engineering Specialist, has been with the company for nearly 20 years, and has held several roles.

As an engineer, George Burwash Langford felt a strong sense of public responsibility that led him into many fields of interest, including starting the Great Lakes Institute and helping develop the Canadian mining industry.

• Gregstrom Corp. named Clark Boyce as Vice-President of Sales, taking over for Jim Leitz, who is retiring after 30 years of service.

Boyce has a deep knowledge of rotational moulding. He served as Regional Sales Manager for the Wheeler Boyce Company for eight years.

Boyce has been active in the Associ-

ation of Rotational Molders for over 20 years. Most recently he worked for Mold In Graphics, as an account manager, assistant director of sales, and branding specialist.

• Toyota Motor Manufacturing Canada Inc. (TMMC) won two J.D. Power 2019 Plant Quality awards, part of the U.S. Initial Quality Study.

TMMC’s North Plant won the platinum award for the Toyota Corolla, while the South Plant won bronze for the Lexus RX. Both plants are located in Cambridge, Ont. TMMC has won the platinum plant award on three occasions, and has won two awards in one year for the fourth time. In all, TMMC has won 18 plant awards.

The J.D. Power U.S. Initial Quality Study includes 2019 model year vehicles purchased or leased between November 2018 and February 2019. Customers own the vehicles for 90 days following their purchase and then complete the J.D. Power survey. Plant awards are based on the lowest number of customerreported defect/malfunction problems per vehicle.

• Andy Zosel has been appointed President and CEO of OMRON Microscan based in Renton, Wash.

Zosel has been with Microscan since 1997, holding several leadership positions in customer service, marketing, and engineering. Most recently, he was Senior Vice-President of Engineering and Commercial Operations for OMRON Microscan.

• Honda of Canada Mfg. and Honda Canada Foundation announced an over $1.8 million donation to Georgian College, part of a new partnership. The announcement took place during the Georgian College Auto Show on the Barrie Campus. On hand for the announcement were Tom Lake, Executive Vice-President, Honda of Canada Mfg., and Vice-Chair, Honda Canada Foundation; and MaryLynn West-Moynes, President and CEO, Georgian College.

The five-year agreement includes funding for equipment, research and develop-

ment, collaborative program support, and new scholarships for Georgian College students. Honda and Georgian College will also work to recruit students and provide additional co-op placement opportunities.

• Atlas Copco is celebrating its 70th anniversary in Canada in 2019. Throughout the year, the company is commemorating this milestone with employees, customers, distributors, and other stakeholders, while hosting several activities and events.

On May 9, 1949, Canadian Copco Ltd. was born and headquartered in Kirkland Lake. Canada was the first country in the Americas to open an Atlas Copco office and the eighth international office established.

• Nederman Canadian headquarters in Mississauga played host to the company’s 30th anniversary celebration of operating in Canada.

”We are proud to celebrate 30 years in Canada protecting people, planet and products from harmful effects of industrial processes,” said Michael Catalano, VP of Nederman Canada. ”We look forward to continued growth in products and systems to help Canadian manufacturers and workshops improve the safety, cleanliness and efficiency of their business.”

Nederman Holding AB, founded by Philip Nederman in 1944 is also celebrating, it is its 75th anniversary, it is headquarted in Helsinborg, Sweden.

Nederman has invested heavily over its history in strategic acquisitions to expand its product and service offerings. In 2010, Nederman acquired Dantherm Filtration and in 2013, EFT (Environmental Filtration Technologies), doubling the company in size. The most recent aquisitions occurred last year; Auburn FilterSense LLC and Luwa Air Engineering AG. MRO

• Parliamentary Secretary Paul Lefebvre, on behalf of the Honourable Amarjeet Sohi, Canada's Minister of Natural Resources, announced a $2.9-million investment in Bracebridge Generation Ltd.'s Smart Proactive Enabled Energy Distribution Intelligently Efficiently Responsive smart grid project.

This project enables Parry Sound, Ont., to eventually generate as much energy as it consumes, making it one of the first net zero communities in Canada.

This investment will increase electricity grid reliability, defer costly upgrades, make better use of existing assets, help speed-up the adoption of electric vehicles, and give residents greater control over how they use energy.

• Hydro-Québec has invested $85 million to grow TM4, now called Dana TM4, to ensure its leadership position in the electric powertrain sector.

The investment allows Hydro-Québec to maintain its 45 per cent interest in Dana TM4, and adds the following strategic relationships:

- Dana TM4 will hold 100 per cent of Chinese company Dana Electric Motor Co. Ltd., formerly called Prestolite E-Propulsion Systems, in which Dana TM4 previously held a 50 per cent interest. Dana Electric Motor Co. manufactures and markets electric powertrain systems, particularly for buses and trucks. This transaction will enable Dana TM4 to optimize its operations and ensure the development of its activities in China, the fastest growing market in terms of transportation electrification.

- Dana TM4 will also integrate the activities of electric motor company SME, an Italian company that has developed a range of electric motors and controls for a wide range of off-highway electric vehicle applications, including material handling, agriculture, construction, and automated-guided vehicles. SME low-voltage systems are a complement to the Dana TM4 high-voltage product

line. This investment puts Dana TM4 in a position to offer electric powertrain systems for all types of land vehicles, including light vehicles (cars and pickups), commercial vehicles (buses and trucks), and off-highway vehicles (construction, mining, and lift trucks).

• Total Lubrifiants announced it is acquiring Houghton International’s aluminum hot rolling oil), steel cold rolling oil, and tinplate rolling oil business in North America and Europe. The transaction includes associated technical support services.

“We believe this acquisition will create value both for Total and our customers from these industries. It will strengthen our position in the industrial lubricants market, which is an important part of our strategic vision for the future,” said Philippe Charleux, Senior Vice-President, Lubricants and Specialties, Marketing and Services Division, Total. “Geographically we are strengthening our strong presence in Europe and expanding our activities and market penetration in North America, especially in the U.S.A.”

• John Aldag, Member of Parliament for Cloverdale – Langley City, on behalf of the Honourable Navdeep Bains, Minister of Innovation, Science and Economic Development and Minister responsible for Western Economic Diversification Canada, announced funding for two British Columbia companies in the steel and aluminum sector.

Menzies Metal Products will receive over $660,000 in funding, which will be used to purchase two pieces of equipment, install a resource system, and adopt lean management practices.

Reliable Tube Inc. will receive $1 million and be able to upgrade its manufacturing capacity with a tube laser-cutting machine.

• The City of Airdrie and ENMAX announced the completion of Canada's

largest municipal rooftop solar installation. A 1.55 megawatt system is now providing renewable energy to Airdrie's Genesis Place Recreation Centre.

The solar array will reduce greenhouse gas emissions by over 1,000 tonnes per year and is expected to export approximately 140 kilowatts per hour back to the city grid during peak summer months. A second phase, due to be completed in September, will include 240 modules on a double-wing carport in the parking lot of Genesis Place.

• Adventus Zinc Corp. has announced that the TSX Venture Exchange approved the change of name of the company to Adventus Mining Corp

The name change became effective at market opening on June 12 and Adventus will continue to trade under the symbol "ADZN" on the TSX-V and "ADVZF" on the OTCQX.

• The Timken Company has recently acquired Diamond Chain Co., combining forces with Drives to help make an impact in markets around the world.

“This acquisition serves as a key component in Timken’s growth strategy and ability to make an impact in markets around the world,” said Tom Young, President, Diamond Chain and Drives. “With Diamond now part of the family, we’ve greatly increased Timken’s presence in the global roller chain market by adding a product line used in a multitude of applications. And, it gives us additional opportunities to deliver more value for customers in the industrial distribution, material handling, food and beverage, agriculture, and construction industries.”

• The Government of Canada is investing in CBN Nano Technologies (CBNNT) venture.

The Honourable Navdeep Bains, Minister of Innovation, Science and Economic Development, announced a $40-million investment in CBNNT, which is engaged in research into the commercialization of technology that allows atomically precise manufacturing.

CBNNT is a sister company of Canadian Bank Note Company, Ltd. (CBN) whose $220-million nanotechnology project will be the first in the world to undertake atomically precise manufacturing on a commercial scale.

This new technology will help establish Canada as the global leader in advanced manufacturing processes in a

variety of sectors. For example, it will also have potential applications in advanced health care treatments, reducing pollution, building high-performance computing capabilities, and producing super-efficient solar energy.

Thanks in part to this investment, CBNNT and CBN will create 469 new jobs, 364 of which will be highly skilled.

• Hammond Power Solutions (HPS) has appointed Markus Rocca as Director of Business Development, EMEA. Previously, he was Director of Sales with HPS in Europe from November 2017.

He will work on developing new business in EMEA for HPS related to products manufactured in North America and India. Rocca brings knowledge of building demand for HPS products and his previous skills to the HPS marketing team. He has the ability to facilitate longterm business relationships.

He has a BA in Business and Industrial Engineering from the Karlsruhe University of Applied Sciences.

• The Mining Association of Canada (MAC) announced that Gordon Stothart, Executive Vice-President and COO of IAMGOLD (for the past 11 years), has been elected Chair of MAC for the next two-year term.

Stothart has over 30 years of experience in the mining sector, and is familiar with MAC, having been a participant on multiple committees, including the Executive Committee, over the past several years.

Stothart replaces Anne Marie Toutant, Vice-President, Fort Hill Operation, Suncor Energy Inc., who served as Chair from June 2017 to June 2019.

Prior to joining IAMGOLD, Stothart worked for over 20 years in the Noranda/Falconbridge Ltd./Xstrata organizations in a number of operations, projects, and corporate roles in Canada, Peru, and Chile.

He graduated from the University of British Columbia in 1987 with a Double Major in Mining and Mineral Process Engineering.

• Clean Commodities Corp. has appointed Elias Shoufani as Vice-President Business Development. He will be responsible for supporting the company's business development activities.

Shoufani has an extensive international pharmaceutical and business background, with working experience throughout Israel and Canada.

He holds a B. Sc. (in Pharma) from The Hebrew University of Jerusalem and has completed additional studies in Clinical Pharmacotherapy at The Hebrew Uni-

versity Hadassah Medical School.

• Canada's Oil Sands Innovation Alliance (COSIA) named Wes Jickling as its next CEO, effective August 6.

Jickling comes to COSIA from his current role as CEO of Innovation Saskatchewan and Deputy Minister of Intergovernmental Affairs in Saskatchewan.

He has held senior roles in government, corporate, and international organizations, including with the United Nations in Brazil, Swaziland, Ukraine, and Sudan. MRO

How to develop and manage a maintenance strategy.

BY MARIO CYWINSKI

MRO recently had the opportunity to speak with Gilberto Rodriguez Ledezma, Maintenance Manager at Corpus Christi Polymers LLC, about how to develop and manage a maintenance strategy at a plant.

Ledezma presented a case study on the topic during the Reliable Plant 2019 Conference and Exhibition earlier this year. His presentation focused on how developing and managing a maintenance strategy worked at a chemical complex that will produce polyethylene terephthalate (PET) and purified terephthalic acid (PTA).

MRO: Can you summarize what you presented at Reliable Plant?

Ledezma: A short version of “maintenance reality” on a chemical plant, where there are resources restrictions (budget and personal), in addition with an easy (but effective) way to administrate the maintenance department. As well as a clear picture of how a maintenance strategy could be developed in order to reach company goals.

MRO: Can you outline the case study in your presentation?

Ledezma: The case of study was referred with the maintenance statistics in reference with the equipment type and failure modes, in addition with the case of study in order to define the critical equipment list.

MRO: What do you see as some of the main goals of a good CMMS?

Ledezma: The main goal of a good CMMS is the maintenance administration in terms of cost and performance.

MRO: What foundation must be laid for a good CMMS?

Ledezma: A good CMMS must have a definition of an equipment database, the equipment type, and a matrix for failure modes and the possible causes.

MRO: Can you speak to the importance of spares for maintenance?

Ledezma: Spares are important, as more than 35 per cent of maintenance issues are subjected to issues with spares.

MRO: What is the importance of maintenance security strategy?

Ledezma: It is important to remember that risk is always present.

MRO: What would you say are the most important processes in maintenance?

Ledezma:

• Planning and scheduling,

• Cost control,

• And personal development (training program).

MRO: Can you briefly describe Perception, Truth, and Reality?

Ledezma:

Perception: Maintenance is a necessary “evil.”

Truth: Maintenance is the department with the most important role in terms of cost and with high influence on the company goals.

Reality: Not everything on the market is useful or achievable (due to high cost). MRO

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada, and a judge for the Canadian Truck King Challenge. He has over 10 years of editorial experience and over 15 years of automobile industry experience, as well as small business industry experience.

Lubriplate’s complete line of premium-quality compressor fluids has been formulated to deliver unsurpassed performance in a wide range of compressors. They meet and exceed the performance specifications of most compressor manufacturers and interchange directly with most OEM fluids. Available products include...

• High-performance, 100% synthetic, polyalphaolefin (PAO)-based fluids.

• Provides extended drain intervals up to 8,000 hours in most compressors.

• Fully compatible OEM fluid replacement. ISO grades 22, 32, 46, 68 & 100.

• High-performance, 100% diester-based synthetic air compressor fluids.

• Formulated to eliminate varnish buildup in high temperature applications.

• Allows extended drain intervals up to 8,000 hours.

• NSF H1 Registered and NSF ISO 21469 Certified - Food Machinery Grade.

• 100% synthetic, ISO 46 grade, high-temperature polyglycolester-based fluid.

• ECO-friendly - readily biodegradable (Pw1).

• Fortified with Lubriplate’s proprietary anti-wear additive .

• NSF H1 registered and NSF ISO 21469 certified - food machinery grade.

• 100% synthetic, PAO-based fluids for food processing and bottling plants.

• Available in ISO viscosity grades 22, 32, 46 and 68.

• Fortified with Lubriplate’s proprietary anti-wear additive .

• High-performance, 100% synthetic polyolester (POE)-based, fluids.

• Provides extended fluid change intervals up to +10,000 hours.

• ECO-friendly - readily biodegradable (Pw1). ISO grades 32, 46 and 68.

• High-performance, 100% synthetic, polyglycolester-based fluid.

• ECO-friendly - readily biodegradable (Pw1).

• For high-temperature applications. ISO 32/46 grade.

• High-quality, petroleum-oil based, anti-wear fortified compressor fluids.

• Formulated to reduce carbon and varnish build-up.

• They effectively fight friction, wear, heat and foaming.

• Available in six ISO viscosity grades for a wide range of conditions.

• High-quality, zinc-free, petroleum-oil based fluid

• Formulated to meet the requirements of most centrifugal air compressors.

• Provides excellent oxidation resistance.

• ISO viscosity grade 32.

BY MARIO CYWINSKI

During the recent Reliable Plant 2019 Conference and Exhibition in Cleveland, MRO had the opportunity to sit in on learning sessions, which covered a broad range of topics in the maintenance field. One such session was Operational Reliability: What Is It and How You Can Achieve It by George Williams, Founder and CEO and Joseph Anderson, COO, of ReliabilityX.

Their presentation focused on how to bring a holistic approach to ensure reliable operations. They explained how operational reliability bridges the gap between organizational silos by including all aspects of the business to focus on delivering business value through reliability. They presented a framework, which provides a better understanding of how complex it is for an organization to deliver reliable performance. Framework structure was explained to show how organizational objectives are met through asset objectives and operations objectives, which are met through sound strategy and tactical delivery.

They explained how operational reliability seeks to ensure every ounce of performance is delivered by eliminating losses. Reliable operation is about minimizing losses, not just breakdowns. Operational reliability is a more proactive

approach to ensuring losses are seen as failures, or defects, and are, in turn, eliminated. MRO spoke to Williams and Anderson to get a more in-depth look at the holistic approach to reliable operations that they presented.

MRO: You spoke to a holistic approach to reliability, can you explain that?

Williams/Anderson: Reliability, much like safety, takes everyone to achieve. You can have a machine with zero breakdowns, but if procurement seeks to save a penny per container and the new container specs necessary to save that penny causes minor stops, not only will you never see the penny savings, you will also increase costs to produce due to the minor stops. Procurement, being in their silo, is claiming a cost savings and cheering themselves on while performance decreases and no one makes the connection. This happens across many groups, and while each individual silo believes it is doing the right thing, without a holistic approach, shared goals, and training, ultimately, the line's performance suffers.

MRO: What do you see as the main goals of operational reliability?

W/A: Delivering on not only business objectives, but to truly understand what

is possible and deliver on that. Ensuring each person understands his or her impact on reliability; as well as evolving, not changing, culture.

MRO: Can you speak about loss analysis and how it plays a role in MRO?

W/A: The loss analysis seeks to identify how performance is being impacted and buckets those into 25 loss categories. The loss categories tell us what types of losses are contributing to lower than possible performance. Operational reliability seeks to eliminate losses, and MRO management plays a significant role in the elimination of certain losses. Ensuring consumables for the production operation are available when needed and readily accessible is vital to overall line performance.

A filter for printer ink, which clogs but then is not available, can have a major impact to the production team. In addition, items necessary from a maintenance perspective, whether needed as PM wear component replacements or critical spares must be managed appropriately.

Practices that exist today causing losses driven by poor MRO management, include:

1. Simple MTTR efficiency associated

with searching undocumented satellite stores such as people's tool carts, shop areas, storage sheds, etc.

2. Not stocking the right level of spares due to:

a. Lack of math driving ROP analysis, and adjustments in stocking levels and;

b. Existence of satellite stores, which minimize turns and, cause storeroom, which uses math to lower stocking levels.

3. Not controlling the storeroom and all items. This causes the above issues. The list can go on and on but the point is, the MRO management piece aids in loss elimination for both operations and maintenance.

MRO: You mentioned how organizations are like football teams. Can you expand on that?

M/A: It is an analogy to compare the plant to a football team with the archrival being losses.

i. The plant manager is the coach;

ii. Maintenance manager is the quarterback;

iii. Maintenance department is the rest of the offence;

iv. Operations group is the defence;

v. Quality organization is the referees;

vi. Corporate is the front office;

vii. Safety/training departments are the athletic trainers; viii. Logistics is logistics.

ix. Losses are your archrival that keeps you from being world champions. They are out to get you and they are winning! Average plant is 33 per cent efficient. World-class plant is 70 to 85 per cent, depending upon product mix.

MRO: What is the importance of having operations be involved in maintenance?

W/A: Maintenance starts with operations. The front-line defence is operations. They know the pulse of the line. If we can invest in them to understand the manufacturing process mechanically and provide them with an opportunity to proactively find defects and sources of losses, they can play a signif-

icant role in ensuring reliable operation.

MRO: What would you say are the most important aspects of operational reliability?

W/A: People, people, people. Business understanding. Understanding how losses impact business goals and which losses your role contributes to.

Empowering your team to eliminate their own losses. Empowerment takes two major pieces. First, you must “give” empowerment. This is the easy part. Leadership gets everyone in a room and

says, “you’re empowered.” That alone, however, does not create empowerment. Second, people must “feel” empowered. This is where most efforts to “change” culture or empower people fail. MRO

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada, and a judge for the Canadian Truck King Challenge. He has over 10 years of editorial experience and over 15 years of automobile industry experience, as well as small business industry experience.

Connectivity in the automation of industrial automation.

Many challenges and lots of potential to become:

• Faster. With design and engineering tools from Festo

• Better. With the broadest product portfolio of pneumatic and electric components for maximum scalability and solutions at all levels

• Connected. Smooth and seamless automation thanks to mechanical, electrical and intelligent connectivity of hardware and software from Festo

Visit us at booth #1131

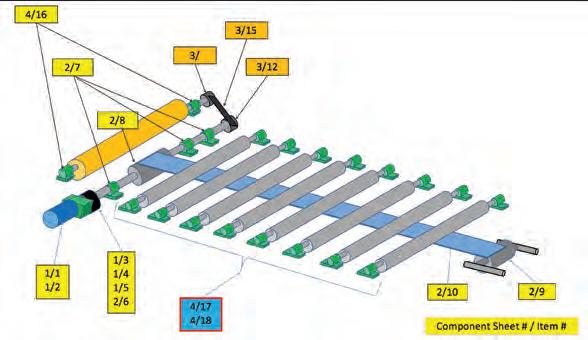

BY PETER PHILLIPS

In the June 2019 issue of MRO, the focus of my article was what equipment restoration means and how the driving force to sustain equipment reliability is to have a strong commitment to the restoration process.

This article will focus on the most time-consuming element of the restoration process: the equipment ledger. Be prepared to invest several months identifying every equipment wear component. Everything from bearings, belts, bushings, couplings, and cylinders, to gearboxes, motors, and rollers. Every component needs enough specifications and part information in order to be easily purchased from a vendor.

The ledger generally consists of two parts.

First is the assembly drawing that identifies the location of the equipment wear components, and second is the ledger document that lists the specifications of each component.

The assembly drawing can be the CAD drawing of the machine, or, in absence of that, a simple cartoon drawing. Whichever one you use, every component is shown and given a number that corresponds with the ledger.

A simple assembly drawing (left) and a detailed ledger; to-

gether, they include every aspect of the components in a clear and concise template.

The second important use of a completed ledger is to determine the maintenance strategy for each component. Some

will have time-based replacement frequencies or time-based inspection. Remember, the goal is to sustain a piece of equipment in like-new condition. With a complete ledger, maintenance staff can determine what type of preventive maintenance plan the machine requires to sustain long-term reliability.

For facilities that manufacture the same product, equipment ledgers and drawings may be shared plant to plant as the equipment is similar. To enhance this process of plant sharing, some companies have developed master component lists that list every mechanical or electrical component that is found on production lines. This approach requires a lot of upfront work by a team that knows and understands the equipment and processes.

In the past month, our team has completed a master component list. It took nearly 18 months and has hundreds of components. The payoff is that every one of the 14 manufacturing facilities can use this master component list to develop their ledgers, taking only a fraction of the time it would take for each plant to do it individually. Without the master component list a typical plant with approximately 500 to 600 pieces of equipment would take nine to 12 months to create a full ledger. It takes this long because of the availability of the equipment to remove guards and dismantle assemblies to document the wear components. This is especially true in older facilities, where drawings and equipment documentations are scarce.

On the other hand, newer plants normally have drawings and component lists from the equipment manufactures, which certainly speed up the ledger creation process. The newer the plant and equipment, the faster and more economical the ledger development will be. Documentation will be readily available, and there will be very few, if any, undocumented equipment modifications.

Some companies have opted to hire outside resources to develop the ledgers. These vendors will come on-site and gather the data for you. They will examine the available equipment drawings and documents and compile the information into a ledger document. Whatever is not available in documentation, they go into the field and remove guards to gather the component details. Again, this can be a time-consuming process based on equipment availability and the number of people used to gather the data. The average time for an outside vendor to complete 500 pieces of equipment in an older factory is approximately six to eight months at a cost of $200,000.

Whether we use in-house or external resources, the cost is significant. However, equipment ledgers are the key building blocks of the restoration process. They provide a complete understanding of the equipment and their components in order to develop a preventive maintenance strategy.

Now we start to comprehend the magnitude of a restoration. The more equipment in the facility, the more complex and time-consuming process. And, with that, the cost will escalate. Be prepared, the cost and timelines shared here are real. Be assured, though, that the cost is worth it, provided the rest of the restoration steps are followed and completed.

Most important, the process must be sustained; as new equipment is added or modified, the ledgers must be updated. Equipment ledgers are where restoration and reliable long-term equipment begin. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or by e-mail at peter@trailwalk.ca.

The goals for any maintenance operation: keep process machinery moving reliably. Control quality and costs. In that effort, NSK is the partner of choice.

NSK rolling bearings deliver stable, smooth, energyefficient operation in high heat, high speed, high load conditions for pumps and compressors of all types. To get the results you need: long lasting, maintenance free, high output performance.

With NSK, you stay in motion. You stay in control.

“Basic Wear” Programs Provide Inadequate Condition Monitoring

BY L. (TEX) LEUGNER

Many equipment reliability managers and engineers who maintain industrial equipment in mining, pulp and paper, oil and gas, and other heavy industries do not use oil analysis programs effectively. The primary reason is because the “basic wear” oil analysis programs marketed

by oil analysis laboratories provide insufficient information.

There is a perception among these users that the “basic wear” packages provide sufficient condition monitoring detail, because the programs cover component wear rates, additive levels, viscosity levels, and basic physical oil

condition. Unfortunately, these fundamental programs do not provide the detail necessary to indicate oil degradation conditions such as oxidation and nitration or types of contamination, depending on the equipment type.

The analyses that should be included are acid number analyses for natural

gas engines, turbines, and recirculating systems and base number analyses for diesel engines. In addition, ISO standard 4406, or membrane filtration (patch tests) should be included for all recirculating systems in order to monitor contamination levels that spectroscopic wear analyses are incapable of “seeing.” The inclusion of these analyses would provide “root cause failure detection,” making oil analyses truly proactive.

1. How do you monitor potential lubricant end-of-life conditions such as oxidation, compression heating, or thermal degradation, or a combination of these chemical reaction mechanisms?

Logic: The cause of high nitration and/ or oxidation is often combined with high levels of carboxylic acids and/or higher-than-normal viscosity levels. In order to monitor these lubricant conditions and determine the remaining life of the lubricant, it is recommended to include acid number analysis to natural gas engine and recirculating systems (hydraulic, gear drive, pump, and compressor) oil analyses packages.

The addition of base number analyses should be applied to diesel engine oil analyses packages to determine correct oil drain intervals. Without these additional tests, the generation of varnishing, sludge, carbon, and other causes of potential equipment failure may never be known until it’s too late.

2. How do you monitor recirculating lubrication system contamination levels?

Logic: Over 70 per cent of lubrication-related failures are caused by contaminated oil. This is particularly true in gear drives and pumps whose shafts are supported by rolling element bearings with critical clearances, screw-type compressors, and high-pressure hydraulic systems using piston pumps and motors. This contamination is dirt, dust, water, and other large particle contamination that cannot be “seen” with just the application of spectroscopic wear rate analyses. As a result, it is recommended that the addition of ISO 4406 fluid cleanliness analyses using optical par-

ticle counters is included in these oil analysis packages.

(The use of optical particle counters is recommended over pore blockage instruments because optical instruments will determine all contaminants, including varnish.)

Karl Fischer water analysis is essential wherever water is a potential concern, such as in screw compressors.

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant special¬ist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

The following are case histories where the full and complete use of the analyses tests described above would have provided early warning of a potential catastrophic failure.

“Regularly scheduled acid number analysis would have provided early warning of these conditions.”

“A regularly scheduled base number analysis would have indicated the remaining useful oil life, preventing a catastrophic failure.”

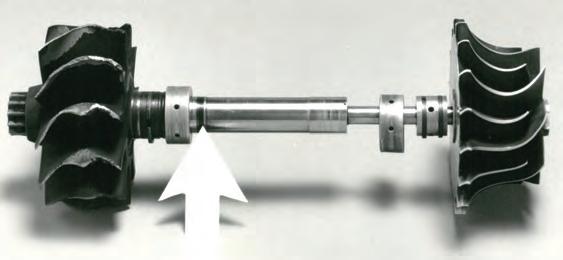

This diesel engine turbocharger failure was caused by carbon build-up.

“Photos confirm the damage that will occur when unmonitored/uncontrolled contamination is allowed to exist in any lubricated system. Contamination should be monitored on a regular basis using optical particle analysis based on the ISO 4406 contamination code.”

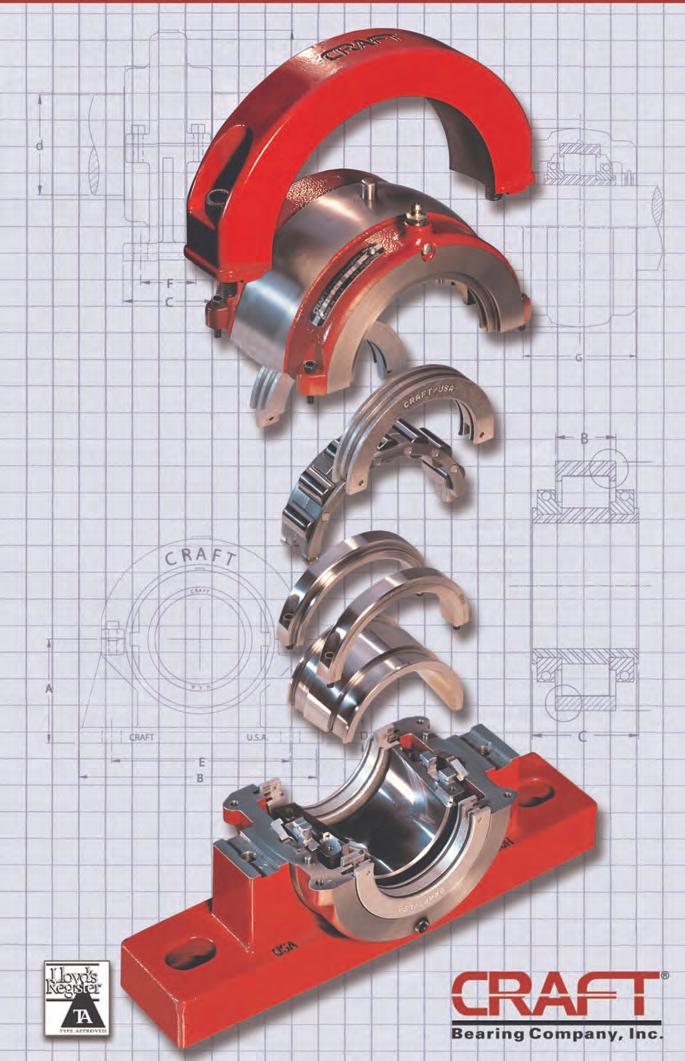

Global Bear Inc. is pleased to announce the opening of a branch in Langley, BC.

The 3000sq. ft. facility will be stocked with a broad range of all the products distributed by Global.

“The plan has always been to have coverage across Canada”. “That dream has now become a reality”, stated Harold Benz, founder and President of Global.

We look forward to servicing our Western Canadian customers from the new facility and welcome all inquiries for bearings, belts and power transmission products.

Our stock, featuring CRAFT and NKE bearings in Langley, will help distributors service the “end-user” markets in Alberta and British Columbia.

Please visit our web site(www.globalbear.ca) for all the products we offer and/or call us with your inquiries. Tel: 604-256-3553 • Toll free: 1-888-567-1399 • Fax: 604-371-0056

Email: rolandv@globalbear.ca or davida@globalbear.ca Global Bear Inc. striving to service the market through distribution.

pump failure caused by contamination.

Turbine rolling element bearing failure caused by contamination.

“The bearing failed as a result of corrosion, not spalling, which is often blamed.”

“The inclusion of a Karl Fischer water analysis is essential if water contamination is a concern.”

In our June 2019 issue of MRO, due to a technical issue, some degree symbols in the Quiz Lubricating Grease Selection and Application, were shown larger and looked like zeroes. The issue was corrected in the digital edition of the magazine (www.mromagazine.com/ digital-archives/may-june-2019/). We apologize for any inconvenience this may have caused.

BY DOC PALMER

How far in advance should you schedule maintenance? New things go into the backlog constantly, so, hopefully as early as possible; however, a plant can only schedule as much work as it can do.

There are multiple schedules in maintenance, each with its proper purpose. Different horizons include a daily schedule, weekly schedule, monthly schedule, yearly schedule, and schedules beyond the current year. A plant should utilize all of these schedules: daily, weekly, monthly, yearly, and beyond.

There is also the "run-to-fail strategy,” without any scheduling, where a plant just fixes something after it breaks. Some of these schedules are better understood than others, but using each schedule correctly enhances maintenance effectiveness.

First, “run to failure,” also described as “don’t touch it if it isn’t broken; fix it when it breaks.” However, maintenance effectiveness is the primary objective. Maintenance is “keeping something from breaking.” A plant wants to maintain that something’s performance. If that something breaks, the plant has not

done its job. The plant did not maintain it. No matter how fast the plant fixes it after it breaks, it’s better to keep it from breaking in the first place.

Real financial profit comes from keeping assets running. Downtime is expensive. Industry wisdom says the work done to keep assets from breaking is generally worth 10 times its value. In other words, every $100 worth of labour and parts the plant puts into an extra proactive maintenance task saves the plant $1,000 on the bottom line.

(Nevertheless, “run to failure” is a proper component of an RCM (reliability centered maintenance) strategy, but only going through a disciplined series of questions concerning how to keep something from breaking.)

The purpose of yearly maintenance schedules and multi-year maintenance schedules generally revolves around budgets, projects, and contractors. Projects include installing new assets or systems and modifying them, but also larger maintenance events such as specific planned major shutdowns and turnarounds. Schedules for a year generally show the exact dates of events,

whereas schedules spanning multiple years are a bit more concerned with figuring out the dates of the events. They also involve writing specifications, gathering funding and bidding work.

To co-ordinate their preparation work, engineers and project managers need to know when the major events are scheduled. Some plants could do better on a monthly basis, updating their yearly and beyond-outage schedules. The yearly schedules would have more exact dates and the 10-year schedule might just list the events, but not exact dates. Since issues with yearly and beyond schedules are important, most plants do them relatively well.

A closely associated schedule with the yearly schedule is a particular shutdown schedule. This schedule for a particular event would include everything from the specifications to the bidding to the execution to the start-up. For larger outages, preparation work may start a year and a half before the start of the execution. Taking a production unit offline impacts profits, so plants usually perform these events.

Plants also manage, in concept, what

Tip: The purpose of weekly schedules is to help focus supervisors who create daily schedules.

might be called a monthly maintenance schedule. The purpose of looking at maintenance monthly is keeping up with preventive maintenance (PM). PMs are calendar- or usage-based mainte -

nance tasks such as lubrication or human sensory inspections that plants perform on a regular basis. Plants want high PM compliance. The plant’s reliability function designs these PMs to

keep things from breaking. The CMMS should automatically issue PMs into the work order backlog in advance.

An associated practice is predictive maintenance (PdM), which uses technology such as vibration analysis, ultrasound, or infrared thermography to predict an impending failure based on an asset’s current condition. PdM technicians complete routes with their technology to find otherwise undetectable indications of developing problems. As with PM, plants want high compliance with completing PdM routes to find small problems they can address proactively before the plants suffer breakdowns. Most plants correctly use monthly schedules to look at PM compliance, but many could do better keeping up with PdM route compliance.

The purpose of the daily schedule is to assign specific work orders to specific individuals and co-ordinate lock out/tag out with operations for specific times. This schedule presumes the existence of maintenance first-line supervisors. It should not be the responsibility of craftspersons to decide which work orders they should do next. There is a lot of churn in daily maintenance, with jobs taking longer or shorter than expected and with a significant amount of new reactive work arising that cannot wait. The supervisor looks at how current jobs are progressing and what work is waiting and then matches the appropriate individuals to the appropriate jobs.

The supervisor also co-ordinates this information with operations personnel for clearance to work on equipment. This understanding of current progress and deployment to the next jobs merits a supervisor, often full-time for a crew of 10 to 15 craftspersons. Usually in the early afternoon each day, the supervisor creates the daily schedule for the next day, showing expected assets needing clearance and assignments for individuals. In the later afternoon, the supervisor discusses the schedule with operations to request clearance.

Finally, the weekly maintenance schedule is the most misunderstood device for helping maintenance. Because of this confusion, it might provide the greatest opportunity for achieving more effective maintenance. On the one hand, the weekly schedule is not simply sticking five daily schedules together in advance. There is too much churn in real life maintenance. Such a schedule would require a great amount of time every single day, moving everything around

for the rest of the week. On the other hand, the weekly schedule must exist.

Often plants will not have a weekly schedule at all. They reason that supervisors know about the work orders in the backlog, including PM and should keep everyone busy. The culture at plants with no weekly schedule is “we need to take care of operations and otherwise keep everyone busy.” The problem with this approach is the management question How much work should the workforce complete? The answer is not an indefinite “as much as it can with the supervisors keeping everyone busy.”

Industry experience has shown that plants that create a weekly schedule complete more work orders each week. The plant has a scheduler sort through the backlog, finding the best work for the crew the next week. The key is that rather than a complex assigning of individuals a week ahead of time, the weekly schedule is simply a batch of work that matches the whole crew capacity. The batch of work functions as goal setting to give a 10person crew 400 hours' worth of work orders for the next week.

The culture becomes “we need to complete this work, but it’s okay if we don’t do it all if operations suddenly needs us.” This definite subset of the backlog gives the supervisor a better focus on how much work to assign and surprisingly leads to as much as 50 per cent or more work completion–considering that most plants are already very good at handling all the reactive work from operations calls, that nearly all of the additional work completed through proper weekly scheduling is proactive work. Weekly scheduling of full labour capacity simply as a batch of work gives the plant a more effective maintenance program because the workforce starts to do more proactive work that soon heads off more breakdowns.

Rather than to address “how far ahead,” a single week seems to be better for the goal-setting aspect of productivity than going two or three weeks in advance. A plant might try to

create advance schedules beyond a week as skeleton schedules, but not yet fully load them. Things do change at plants from week to week, especially with PdM finding things that can wait, but not for long. Operations calls can also sometimes be put off, but not for long. Fully loading the labour capacity for a single week seems to balance putting enough work together for a goal and allowing for some break in reactive work.

Each of these schedules has its place and is equally important, but the daily and weekly schedules tend to be the

least understood. The daily schedule needs an active first-line supervisor. The weekly schedule needs to focus that supervisor on how much work. MRO

Doc Palmer, PE, MBA, CMRP, is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook . As Managing Partner of Richard Palmer and Associates, he helps companies worldwide with planning and scheduling success. For more information, including a schedule of current public workshops, visit www.palmerplanning.com, or e-mail Doc at docpalmer@palmerplanning.com.

BY DOUGLAS MARTIN

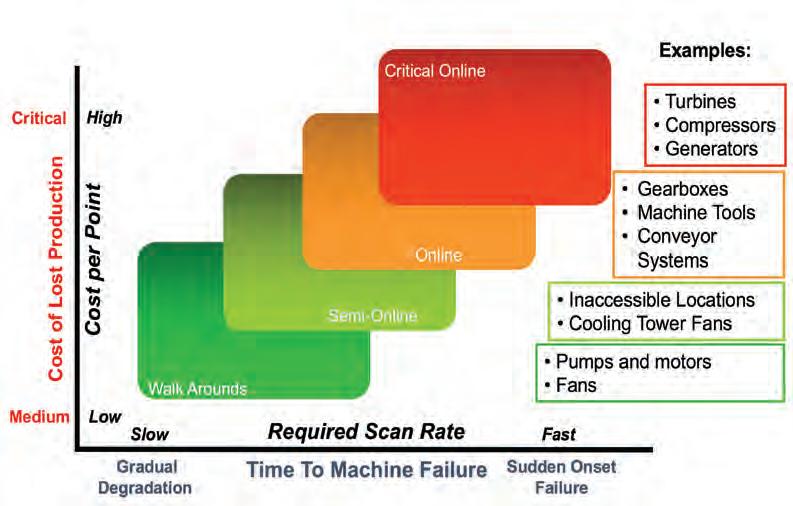

In this article, the monitoring of temperature and vibration (velocity and acceleration) will be discussed. Although there are other parameters that give a rotating asset’s condition, these are generally the most well known within the field of rotating assets.

Of note, for vibration, there are two parameters looked at: acceleration and velocity. The velocity reading typically focuses on vibrations in the range of one to four times the shaft speed and can provide information about mechanical issues such as out of balance or misalignment. Acceleration readings focus on higher frequency vibrations (higher multiples of shaft speed) and can give information about bearing damage or gear tooth damage.

Most Simple Question: If you are monitoring a bearing, what do you want the system to do?

A – Tell you the overall condition (vibration and/or temperature) is in alarm and you need to change it or at least further investigate the problem.

OR

B – Same as A, but also give you the ability to diagnose what is going wrong (for instance, is it the bearing, is the rotating assembly out of balance, etc.)

Thousands of engineers in fluid power, power transmission and motion control will come together at IFPE 2020 to exchange knowledge, solve technical problems and discover new solutions. Join them in Las Vegas in March 2020.

OR

C – Shut the machine down due to an excessive vibration or temperature.

If your choice is A, you must determine how you want to collect and display the information.

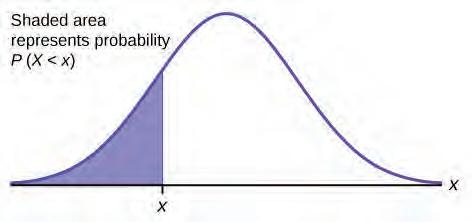

Manually/Route Based – There are many basic devices that can collect temperature and vibration. With these, the technician walks around with the instrument, takes the measurement, and manually documents it. That individual measurement can be compared to historical measurements and/or ISO standardized values and, from this, action steps can be taken. An example of such a table is below:

SEVERITY SHAFT DIAMETER SPEED

On Line – Permanent sensors can be mounted on assets and data sent to a data collection device. Often, this is the facility DCS/PLC that the operators monitor, and within the DCS/ PLC, the alarm levels would be programmed. In most cases, the standard “input” into a DCS is four to 20mA signal. Be -

tween the sensor and the DCS/PLC, there needs to be a “transmitter” to convert the sensor signal to the four to 20mA signal, which is a standard input for PLC/DCS systems.

Some “transmitters” have available lights that may glow red, yellow, or green so people walking past the asset can get an idea as to the current condition without needing to go to the operator’s booth or control room.

If your choice is B, you are essentially looking for “vibration analysis.”

Vibration analysis looks deeper into the specific vibration readings (acceleration and velocity) and tries to associate what the specific frequencies were generated by. Using vibration analysis can tell you which bearing is failing and what component (inner ring or outer ring) is failing of that bearing.

As noted, data can be collected either route based or online. Route-based vibration analysis is the one most people are familiar with. A technician walks a specified route with a data collector that provides a step-by-step (preprogrammed) route, in which either a magnetized sensor is placed in a specific position or the data collector is connected via cable to a mounted sensor. The data in the data collector will give the technician a current reading of the asset condition and show any alarms. When that data is later downloaded to the user’s PC, the reading can be compared to the previous readings, and trends in the vibration levels can be compared. In case of an alarm, the vibration analyst can make a decision to recommend one of the following: repair immediately, repair at the next planned shutdown, or continue monitoring and only take action if the condition worsens. Often a low alarm may result only in a recommendation to add grease and observe.

In some cases, with route based, the data collector is connected to the transmitter between the sensor and the DCS. The main difference being that the data collected by the data collector is detailed and can look at the vibration spectra to diagnose any issues, whereas the data going to the DCS is generally a single reading of the overall magnitude of the vibration reading.

The operator looking at their screen will only see that the acceleration reading has increased from one value to the next, say 20 per cent, but the vibration analyst should be able to say that the increase in the acceleration level is due to a spall that is developing on the inner race of the motor drive end bearing.

If your choice is C, then you are looking for machine protection.

Machine protection is typically used for high-speed applica-

tions like turbines, such that if anything goes wrong, the resultant damage can be catastrophic.

So which to choose?

There are several factors to consider when deciding on which approach to use for facility and for a specific asset. One must consider the criticality of the asset and the cost of an unplanned failure, and how that would affect overall production. There's also the frequency that maintenance can be done (i.e., weekly, monthly, annually), the available manpower to take the data, and who will be taking the data (operators? maintenance personnel? lubrication technicians?).

In terms of a strategy for a specific asset, by knowing which component is failing, it gives the opportunity to plan for the changing of that component. However, if the component is a “throwaway” (i.e., a small HP motor), then knowing that the inner race of the motor bearing has a spall may not be of great value, as the whole motor will have to be replaced.

Therefore, have in mind:

• What are my most critical assets?

• How will the data be collected (what resources will be needed)?

• Am I looking for just an alarm, do I want a diagnosis, or do I want the machine to shut down to protect it from further damage?

The diagram below outlines the suggestions. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by e-mail at mro.whats.up.doug@gmail.com.

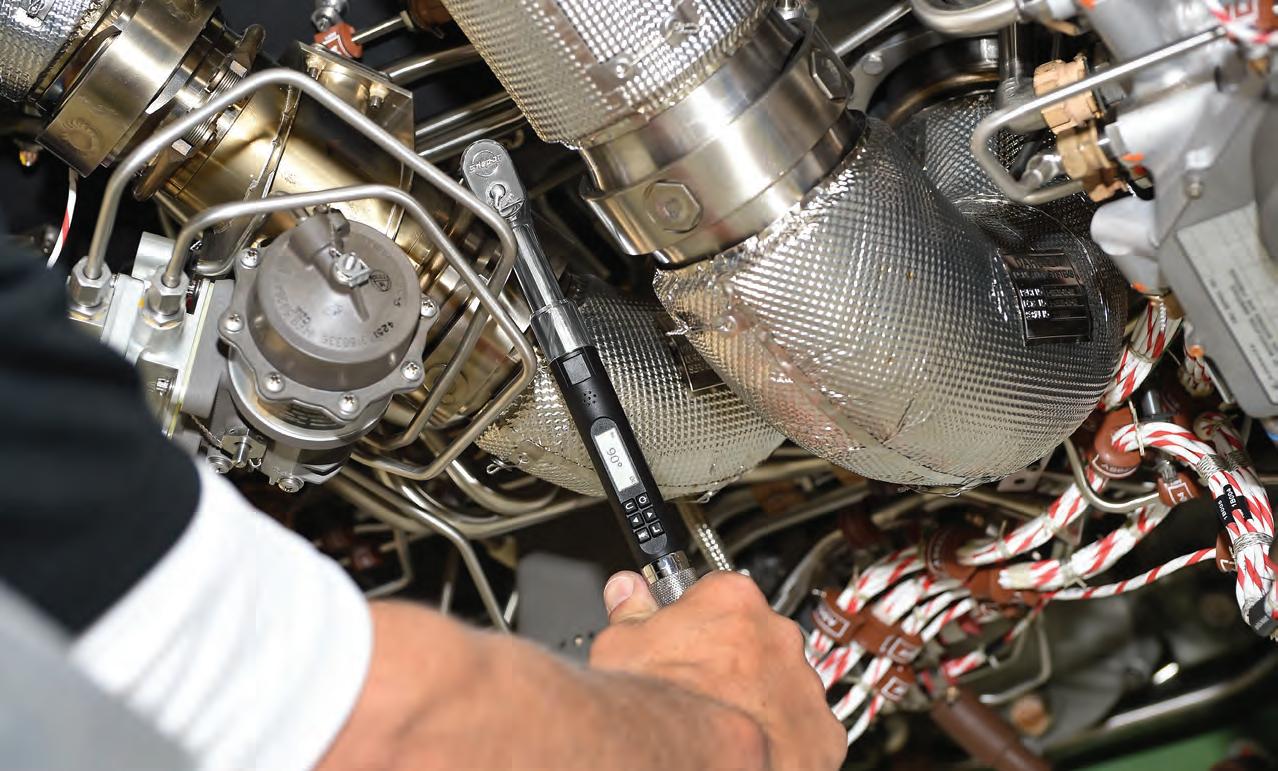

Understanding the principles of torque is much more involved than simply cranking down on a fastener until you hear the torque wrench click. There is a right way to safely and accurately apply torque. Recognizing the physics of torque, as well as the dos and don’ts when using a torque wrench, will make you a more efficient technician, while also ensuring the integrity of your work.

A good starting point for understanding torque is to appreciate what exactly occurs when torque is applied to a threaded fastener.

The physics of torque can be understood by first defining the term torque. Simply put, torque is rotational force. Torque is calculated (not measured directly) by multiplying applied force by the distance from the centre of rotation, or the pivot point. This is why the units of torque always have a distance component (inch, foot, metre) and a force component (pound, ounce, newton).

When torque is applied to a threaded fastener, that fastener is stretching ever so slightly. The fastener is being elastically pulled (or stretched) in one direction as the threads force the joint together. Tension in the fastener increases as torque is applied and friction holds the fastener in place.

As torque is being applied with a torque wrench, technicians can feel when the targeted torque setting is nearing due to the amount of effort needed to turn the wrench. It is at this point in the torque process where technicians can get into trouble by applying too much torque.

For example, if a technician keeps applying force to a torque wrench after the targeted torque setting is reached, the fas-

“Click!” That’s the magic sound many technicians wait to hear when using a torque wrench. When you hear it, the proper amount of torque is applied and you’re finished. But was it applied correctly? How do you know?

BY MARK EDMUNDS

tener can be plastically deformed (meaning, the fastener will not go back to its original shape) and elongated, i.e., stretched beyond its limits. This is called the yield phase. If a fastener yields, the clamp force will likely drop, and the joint will be compromised. Damage to the fastener’s threads, as well as crushing of the installation material, can also occur during over-torquing.

Over-torquing is common, especially when using mechanical torque wrenches. That’s because some technicians still apply force after they hear the click. Once they hear the click, a customary old-school practice is to give it one last little pull for good measure. That can result in the fastener being overtorqued.

Even if a technician stops when he or she hears the click, the time it takes to release pressure on the wrench can result in over torquing and the fastener being stretched beyond its limits.

Why does this occur? Often, it’s a speed issue. Technicians sometimes rush to get the job done faster, and, in doing so, they’re not applying the steady, methodical force of torque that they need. One way to reduce this occurrence is to slow things down and turn the torque wrench slowly, especially when the targeted torque setting is in range, so as not to overtorque the fastener.

It’s important to remember that an under-torqued fastener can also pose problems. Vibrations can occur when a fastener is under-torqued and there is not enough clamping force to hold the joint properly. The fastener could start to come loose over time, compromising the integrity of the joint. Vibrations resulting from an under-torqued joint can also cause cracks in the fastener, and those cracks will grow and could eventually lead to catastrophic failure of the fastener and assembly.

Mechanical torque wrenches are popular within many industries because they are relatively inexpensive, and it is the style many technicians grew up with. While mechanical wrenches represent an older technology, they perform well if the technician uses the tool correctly, stores it properly, and keeps it accurately calibrated.

Electronic torque wrenches tend to offer greater accuracy than mechanical models. The chance of over-torquing is reduced with electronic wrenches as illuminating LEDs provide operational guidance, signalling the user that he or she is approaching the targeted torque.

Data collection is another benefit of electronic torque wrenches. For each use, instant data on the exact torque applied is displayed and stored, which can be downloaded and analyzed for tracking and auditing purpos-

es. These wrenches come with built-in calibration factors for different head lengths and adaptors, and alert the user when the wrench is due for calibration based on pre-set date and cycle count reminders.

It is difficult to obtain accurate results from either a mechanical or an electronic model if the tool isn’t properly used. That’s why correct hand position on the wrench is critical.

Your hand should fit squarely on the steel or plastic-covered handle. Positioning your hand on any other part of the wrench, or even just off-centre on the handle, can lead to injury and result in a false torque reading. If two hands need to be used, place one hand on top of the other. The length of a torque wrench is designed and calibrated in such a way that your hand(s) needs to be properly positioned on the handle during use. Changing the loca-

tion of your hand negatively affects the tool’s performance.

Tips for safe torque wrench use include the following:

• Wearing safety glasses.

• Always pull rather than push the wrench when applying torque.

• Never use sockets that are worn or showing signs of cracking or fatigue.

• Ensure fasteners and bolts are well cleaned and dry (thread condition actually changes the amount of torque required to achieve proper fastener tension and clamping force).

• Avoid using accessories or handle extensions unless specifically allowed by the torque wrench manufacturer. Some tooling manufacturers offer torque training to tech-

nicians and students to become certified in all things torque. These training seminars cover understanding torque theory, learning the proper procedures for applying torque, identifying bolt hardness and metal grades/thread pitch, fastener lubrication, appropriate safety measures, and selecting the right tool for the job. Reputable manufacturers host these seminars on the job site, while many technical schools offer them as part of their training programs.

There is a perception that applying torque to a fastener is intuitive, that anyone can do it. Sometimes that is not the case. Ensuring torque is applied properly takes an in-depth understanding of the physics behind the action. Using the right type of torque wrench and following sound safety practices are a must when applying torque. Fortunately, there are resources available to help learn more about the fundamentals of torque, which will go a long way toward making technicians more resourceful in their jobs.

MRO

Mark Edmunds is a Product and Natural Resources Program Manager at Snap-on Industrial. He focuses on managing the torque and bolting solutions product lines and has helped develop and launch several products designed to solve issues in critical bolting applications. Mark has worked in the mining and the oil and gas industries in capacities ranging from drill rig labourer to engineering and product management. He can be reached at mark.w.edmunds@snapon.com.

Mark October 9, 2019 on your calendar Bingemans Centre, Kitchener, Ontario

Morning Keynote Speaker

Derek Kidnie

GM Manufacturing in Woodstock at Toyota Motor Manufacturing Canada discusses the future of automotive manufacturing in Ontario.

• MEET face-to face with suppliers & develop new business opportunities

• SEE new products and services

• ENJOY FREE PARKING on-site

ATTENDANCE IS FREE – REGISTER TODAY

See the latest products and services…

• Precision Maintenance

• Bearings and Power Transmission

• Lubricants, Adhesive and Sealants

• Motion Control

• Hydraulics & Pneumatics

• Instrumentation

• Safety Products

• Plant Automation

• Pumps and Fluid Handling

• Filtration …and more

Learn about best practices, the latest technologies and products face to face with industry experts!

Booth and Exhibiting inquiries contact: Mike King, Publisher • 416-510-5107

Model 300 Mist Collector filters the air on enclosed machinery to remove harmful oil mist and particulates from CNC machines, milling, and grinding processes. It offers a primary control solution by mounting to the machinery and filtering the mist at the source. Mist Collector can also be used for coolant and water-soluble mist. The filter chamber includes a pre-filter, carbon filter, and the main filter (HEPA or ULPA). No exterior ducting is required. www.sentryair.com

IQORON VP from MANN+HUMMEL offers a filtration concept in dusty environments. The two-stage air cleaners,

• Real-time data, signal, and control communication

• PVC, PUR, or TPE jackets resist abrasion, impact, extreme temperature, and torsion

• Tray rated, continuous flex, Halogen-free options

• Industry compliance: PROFIBUS, DeviceNet, CAN/CANopen, AS-Interface, INTERBUS

www.lappcanada.com

which make the most of installation space, complement conventional round air cleaners and have nominal flow rates from 14 to 33 cubic metres per minute. The core element of the compact air cleaner series is the filter element concept called VarioPleat. It provides high power density with filter systems with an axial air flow. www.mann-hummel.com

Model 300 RuggedAir Mobile Fume Extractor protects the operator’s breathing zone from harmful airborne fumes and particulates produced from industrial processes such as welding, metalworking, solvents use, powder handling, and working with chemicals. It features a cleanable particulate filter with the ability to clean the filter with compressed air without removing it from the unit. This unit offers a digital display with a magnehelic gauge and hour counter, allowing the operator to monitor filter saturation and maintain consistent PM schedules. The seven-foot heavyduty extractor arm features a power button and light. www.sentryair.com