FEBRUARY 2016

WHY A STEEL PLANT’S MAINTENANCE PROGRAM STEALS THE WIN

AWARD-WINNING PULP AND PAPER MILL IMPROVES INCIDENT RECORD

RELIABLE AND QUICK ACCESS TO SPARE PARTS INVENTORIES

BENEFITS OF OUTSOURCING THE MOTOR MANAGEMENT PROGRAM

FEBRUARY 2016

WHY A STEEL PLANT’S MAINTENANCE PROGRAM STEALS THE WIN

AWARD-WINNING PULP AND PAPER MILL IMPROVES INCIDENT RECORD

RELIABLE AND QUICK ACCESS TO SPARE PARTS INVENTORIES

BENEFITS OF OUTSOURCING THE MOTOR MANAGEMENT PROGRAM

If you could only invest in one condition monitoring technology, which one would it be?

WHAT’S NEW BEARINGS DRIVES HARSH ENVIRONMENTS WHAT’S NEW MOTORS & CONTROLS DRIVE SYSTEMS PUMPING SYSTEMS

Whether you pump it, compress it, blow it or convey it, Baldor Large AC GPM motors are the perfect choice for your application. Available in low voltage or medium voltage configurations, Baldor Large AC GPM motors are inverter ready and in stock for fast delivery.

And, if you need a general purpose motor modified with optional features to fit your exact specifications, you can count on Baldor Large AC GPM motors to set the new standard in performance with the fastest turnaround in the industry.

baldor.com 479-646-4711

• Low & Medium Voltage

• Modifications Available

• In Stock & Ready to Ship

• Designed for Safe Operation

Welcome to your first edition of Machinery and Equipment MRO in its new format.

The decision to reinvent a publication is difficult when its performance is strong. From a publishing standpoint, it’s tempting to want to stay the course unless there is evidence to prove that change is needed.

On the flip side, old metrics can prove deceptive if you’re measuring against an evolving audience.

The maintenance organization as we know it has reached an inflection point. While basic knowledge of mechanics, electricity, automation and an overall business view of the impact that maintenance has on operations is still key to success, our technology-enabled, just-in-time, zero-downtime industrial manufacturing plants can no longer afford to ignore the interconnectedness of machines, components and products. And we know that the fundamentals of predictive maintenance are steadily gaining ground as a driver of value in a successful maintenance, repair and overhaul program.

The timing of our refreshed publication is as much a function of the change in the maintenance landscape as it is an opportunity to flex our editorial muscle. For me, any chance to reimagine a publication to suit the needs of its readership is both a privilege and an obligation. As a trade publication, we are mandated to develop relevant content and share practical information for maintenance, reliability and asset management professionals. In essence, we’re discovering what it takes to ensure a plant’s financial and functional needs are fulfilled, and what their frustrations are in the process of doing the job.

Whether you’re a devoted reader looking for your regular column, or a newcomer discovering the world of maintenance, I invite you to flip through the issue with a critical eye.

This issue contains all of our usual features, profiles and product news in a more contemporary design. You will find Maintenance 101 on page 34, and the popular, longstanding tips by Mr. O, The Practical Problem Solver on page 50.

We’re also introducing a few new elements. In our new Counterpoint column (page 30), two industry heavyweights debate the merits of everyday practices. This issue pits oil analysis against vibration analysis. (Who’s side are you on?) And in What’s up Doug? (page 40), we debut the practical insights of Douglas Martin, a heavy-duty mechanic based in Vancouver, who finds a solution to a problem he encounters on the job.

I am very excited about this year’s editorial lineup and I hope the new format meets your satisfaction, too. I welcome your feedback and ideas for stories you would like to read. Please email me at rbegg@annexweb.com.

Rehana Begg Editor

FEBRUARY 2016

Volume 32, No. 1

Established 1985 www.mromagazine.com www.twitter.com/mromagazine

EDITORIAL

Rehana Begg, Editor 416-510-6851 rbegg@annexweb.com

Mark Ryan, Art Director Contributing Editors Carroll McCormick, Peter Phillips

BUSINESS

Jim Petsis, Publisher 416-510-6842 jpetsis@mromagazine.com

Jay Armstrong, Sales Manager 416-510-6803 jarmstrong@mromagazine.com

Tracey Hanson, Account Coordinator 416-510-6762

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbizmedia.com

Tim Dimopoulos, Vice-President Annex Business Media tdimopoulos@canadianmanufacturing.com

Mike Fredericks, President & CEO Annex Business Media

Machinery & Equipment MRO is published by Annex Business Media Inc., 80 Valleybrook Dr., Toronto, ON Canada M3B 2S9; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Subscription rates. Canada: 1 year $58.95, 2 years $94.95. United States: 1 year $85.95. Elsewhere: 1 year $87.95. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates. On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact us via one of the following methods – phone: 1-800-668-2374, e-mail: privacyofficer@businessinformationgroup.ca, fax:

Canada’s energy sector will need to think about more than just low oil prices in 2016. There are numerous structural issues facing the sector that will need to be overcome, according to a new report from the C.D. Howe Institute. In “The Future of Canadian Energy Policy,” the second edition of the Institute’s National Priorities 2016 series, author Benjamin Dachis contends that getting elements of energy policy right should be made a national priority.

“Few in the Canadian energy sector – as well as the many Canadians who depend on it – are sad to see 2015 move into the history books. In 2016, the energy sector will be nervously watching government policies,” states Dachis.

The report classifies the policy issues facing Canada’s energy sector into four main themes, as follows.

Global competitiveness of Canada’s energy industry: Top of mind for most stakeholders in the Canadian energy industry in 2016 will be the global competitiveness of its oil and gas and electricity sectors. With Alberta’s resource royalty review about to conclude in early 2016, it should recommend that the province adopt the international best practice of cash-flow tax design. As for competitiveness in electricity, Ontario should consider the implementation of a capacity market, where generators would compete to offer supply at a lower price than they do now.

Social acceptance to enable market access for Canadian energy: Getting Canadian energy to world markets will remain a key priority in 2016. Having a robust regulatory approval system is critical for governments – and the energy sector –

Nexen reported on its ongoing response to the accident that occurred at its Long Lake oil sands facility south of Fort McMurray on January 15. The explosion resulted in the death of one employee, while another employee sustained serious injuries after they were changing out valves on a compressor.

Immediately following the accident, the facility’s hydrocracker unit was shut down, and the site has been stabilized. Nexen has also shut down its upgrader and reduced its steam-assisted gravity drainage (SAGD) facility to minimum rates.

Nexen’s leadership team in Long Lake, Calgary and Beijing were activated and are supporting the response to this crisis. Nexen notified the regulator immediately and is also conducting its own investigation.

The incident comes after the Alberta Energy Regulator (AER) issued a Suspension Order to Nexen Energy ULC, due to noncompliant activities at Long Lake oilsands operations pertaining to pipeline maintenance and monitoring.

For more information, visit www.nexencnoocltd.com.

The Ontario Superior Court of Justice ordered Emmanuel de Guzman and Falcon Group International Inc. to cease holding themselves out as being qualified to practise professional engineering contrary to the Professional Engineers Act. The Honourable David G. Stinson made the order on January 11, 2016. Emmanuel De Guzman, Falcon Group’s principal, has never been licensed as a professional engineer.

An investigation was opened after Professional Engineers

to ensure that Canada’s energy products get to world markets safely and in environmentally friendly, socially accepted ways. When it comes to the pipeline review process, however, the federal government should focus on minor changes, not major reforms, and should be especially wary of changing the review process for pipelines already underway. But social acceptance entails more than the regulatory process, and requires governments to take the lead in areas outside the remit of regulators.

Collaborative governance: Carbon pricing will likely be the key collaborative governance issue in 2016, and the new federal government will need to tackle a provincial policy patchwork on climate issues. Energy producers and transportation companies will also need to look at their own practices to improve their chances of getting project support. Both federal and provincial regulators will need to examine how their securities and competition policies will affect potential mergers in the energy sector.

Innovation: Rather than focus innovation and diversification policies on what is physically produced in Canada and its provinces, governments should focus on how to enable Canadian companies to become global leaders in the specific technologies they are best at applying.

“In 2016, governments across Canada should act to provide a competitive resource tax and fiscal regime, competitive electricity prices, a robust but prompt regulatory review system, collaborative carbon policies, and an economy that encourages an innovative energy sector,” says Dachis.

A Call for Abstracts is now open for this year’s MainTrain conference, slated for September 19 – 22 at the Sheraton Toronto Airport Hotel & Conference Centre, Toronto.

This is the 18th conference planned by the Plant Engineering & Maintenance Association of Canada (PEMAC). The focus of this year’s event is on “Sustainable, Effective and Evolving” solutions for organizations.

The association is searching for the best workshops, experience-based presentations, case studies and poster sessions that will provide takeaway strategies for participants. Abstracts should include a brief outline of the presentation and should be either designed for a 45-minute presentation, or a halfor full-day skill-building workshop. Submissions must be received by Monday, March 14, 2016.

For more information, visit www.maintrain.ca.

Ontario (PEO) received reports that De Guzman had held himself out as a professional engineer and applied a professional engineer’s seal bearing his own name. Witnesses attested that their employers contracted Falcon Group to provide engineering services while under the belief that De Guzman was a duly licensed professional engineer.

PEO granted a Certificate of Authorization to Falcon Group in March, 2011. This certificate allows individuals or firms in

Ontario to offer or provide engineering services directly to the public. PEO revoked Falcon Group’s Certificate of Authorization in December, 2014. However, Falcon Group continued to represent itself as a professional engineering firm.

The court ordered De Guzman to refrain from using the titles, “professional engineer,” “P.Eng.” and “engineer,” and not to use a professional engineer’s seal. Falcon Group was further ordered to refrain from using the words “engineer,” “engineering,” or any other term, title or description that will lead to the belief that it may provide professional engineering services to the public. PEO was awarded $6,600 for its costs of applying to the court for the order. Nick Hambleton, associate counsel, regulatory compliance, represented PEO on the application.

Through the Professional Engineers Act, PEO governs over 85,000 licence and certificate holders and regulates professional engineering in Ontario to serve and protect the public. Professional engineering safeguards life, health, property, economic interests, the public welfare and the environment. Professional engineers can be identified by the P.Eng. after their names. Holders of limited licences can be identified by LEL after their names.

To check whether an individual is licensed or a firm holds a Certificate of Authorization (C of A), search the directories of practitioners (licence and C of A holders) at www.peo.on.ca.

SOURCE: Professional Engineers Ontario

QVLA® proportional output signal works with a proportional air valve becoming a servo...

iNSiGHT® Series air cylinders are the next generation smart cylinder. Our fast QVLA® sensor ~ NON-CONTACT,NOMAGNETS, NOGUNDRILLING,NOSIZEINCREASE! Works well in high vibration environments and weld fields. Onboard voltage regulator for 12-36 VDC supply. Proportional VDC output signal from an IP67 M8 connector. Available bores from 1½” to 6,” strokes to 48”, NFPA and non–NFPA sizes. Patented and patent pending. Ask us about Wireless and predictive failure analysis.

Women in Reliability & Asset Management (WIRAM) is an association that empowers women around the world to understand the importance of asset management and reliability.

The WIRAM group operates under the Association for Asset Management Professionals (AMP), says Maura Abad, global relationship manager for Reliabilityweb.com.

Abad has been instrumental in creating a website and social media accounts for the group, and with the support of her employer, has been approaching women in the industry to prepare 20-minute webinar presentations.

By December 2015, Abad had corralled at least seven webinars on topics ranging from Understanding the Urgency and Importance of Attracting Women to The Fields of Reliability & Asset Management, Criticality Analysis and The Internet of Things, to Leadership and Communication, Operational Excellence and Operator Driven Reliability.

The first couple of webinars drew a large number of people from around the globe, including from Scotland, Ireland and Middle East, and attendees were not restricted to women. “We also started including men in live calls and we started exceeding expectations,” says Abad.

On December 8, 2015, WIRAM held its first face-to-face meeting at the International Maintenance Conference (IMC 2015) in Bonita Springs, Florida. The event attracted about 60 women and six sponsors. During the keynote presentation, “Understanding the Urgency and Importance of Attracting Women to The Fields of Reliability & Asset Management,” presenters Marie Getsug, M&R Services, and Cathy Wilson, Sunair Co., unpacked national studies behind the statistics and reasons for women’s under-representation in science, technology, engineering and mathematics (STEM).

The number of female attendees at IMC 2015 has increased by 65% year-over-year. If these numbers are a show of ambition, then the group hopes to some day have a full-blown global conference with women presenters, Abad says.

Abad forecasts a bright future for the WIRAM group: “First, we have more women who are messengers. Then, men are messengers as well – the men tell the women. For every male connection, I receive 10 contacts.”

Furthermore, the group has been approached by universities that have shown interest in collaborating on future events, says Abad.

WIRAM’s goals for 2016 are to translate English webinars into Spanish; develop a podcast show inviting panels of women to discuss industry topics; and invite active participation of young engineers by having them present on topics at conferences and webinars.

Abad says her team is also planning a dedicated track for women in reliability and asset management at The Reliability Conference in Las Vegas, Nevada (April 11-15, 2016).

Access WIRAM webinars at maintenance.org.

Industry Newswatch is written and edited by Rehana Begg. Visit our website for the latest news and more detailed versions of the items covered here.

News and views about companies, people, product lines and more.

• Fairfield, Conn. – GE has selected Boston for its corporate headquarters location. The content of GE’s headquarters will also change, with more emphasis on innovation. In Boston, GE will have roughly 800 people; 200 from corporate staff and 600 digital industrial product managers, designers and developers split between GE Digital, Current, robotics and Life Sciences. A GE Digital Foundry will be created for co-creation, incubation and product development with customers, startups and partners. The headquarters will be located in the Seaport District of Boston.

• Montreal – SNC-Lavalin has been awarded a contract by BWXT Canada Ltd. for the primary side cleaning of the steam generator tubes at Cernavodă Unit 1, for the Societatea Nationala Nuclearelectrica S.A. (SNN) in Romania. BWXT Canada is the original manufacturer of the steam generators at Cernavodă Unit 1 and the lead contractor on this project as part of a 10-year comprehensive agreement for steam generator services with SNN, dating back to 2011.

• Calgary – TriWest Capital Partners completed the acquisition of ATCO Emissions Management from ATCO Structures & Logistics Ltd., on December 31, 2015. ATCO, which will operate initially as AEM Emissions Management Ltd., has delivered guaranteed performance and com-

pliance on more than 3,500 projects globally since 1977. Senior management at ATCO predict the purchase of the industry-leading company from ATCO, by a leading Ca-

nadian private equity firm, TriWest Capital Partners, will create a bright future and outstanding opportunity for sustainable, profitable growth.

• Chicago, Ill. – The Power Transmission Distributors Association (PTDA), the leading association for the industrial power transmission/ motion control (PT/MC) distribution channel, recently welcomed six new member

companies. The list of members include distributor member MJ May Material Specialists Inc., South Holland, Ill.; and manufacturer members Auburn Bearing & Manufacturing (Macedon, N.Y.); Helical Products Company – A Location of MW Industries, Inc., Rosemont, Ill.; iwis Drive Systems, LLC, Indianapolis, Ind.; Rosta USA Corporation, South Haven, Mich.; and Wittenstein, Inc., Bartlett, Ill.

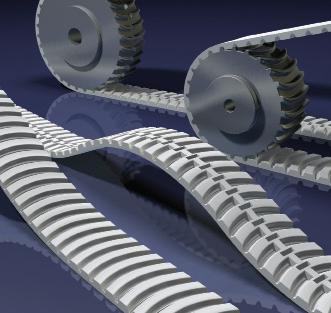

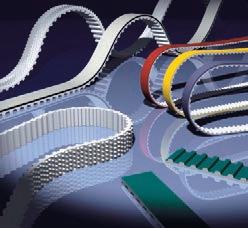

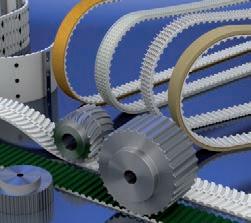

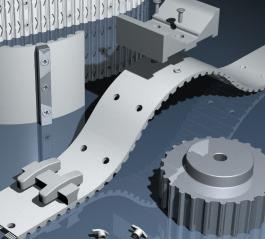

BRECOflex CO., L.L.C. is the pioneer and world leader in the polyurethane timing belt industry. We offer our customers a wide range of timing belts, drive components, metal pulleys and accessories designed and manufactured with the highest priority given to quality and precision.

Whether you are looking for a standard product from our inventory or a custom design tailored to your requirements, your application can benefit from our perfectly matched timing belt and pulleys. Without fast response and quick delivery even the best drive solutions are ineffective. We take pride in our rapid customer response time and industry-leading product delivery.

For additional information regarding our products and technical support services, visit our website at: www.brecoflex.com or call 732-460-9500.

• Chicago, Ill. – Castell has improved service to customers in the southeast by appointing Mayer Electric Supply as a distributor for its complete line of trapped key interlocking and Salvo dock safety products. Castell’s trapped key interlocks ensure that personnel follow a predefined sequence of actions to assure safe access to machinery and adhere to safe operating procedures. Interlocking systems

are unique to each application, often requiring product customization to suit customer needs. Mayer now offers Castell customers a local contact for expert technical consultation on product selection, system design, installation, and service. The company will sell all of Castell’s trapped key interlocks, including its switchgear, machine guarding, and Salvo drive-away prevention products.

• Birmingham, Ala. – Motion Industries, a leading distributor of industrial maintenance, repair, and operation replacement parts, announced several key changes as part of the company’s organizational structure alignment, according to Motion Industries’ President and CEO, Tim Breen. Randy Breaux assumed the position of Senior Vice President of Marketing, Distribution and

Krytox® lubricants will:

• Ensure bearings run quieter and wear less

• Reduce rusting as well as extend bearing and component life

• Protect bearings under high loads

• Protect metal-to-metal contact and thereby reduce wear

They are chemically inert; safe for use with acids, bases or other harsh chemicals and reactive gases, Nontoxic, nonflammble, oxygen compatible, thermally stable, operates at temperatures up to 800˚F, low vapor pressure, low outgassing. Offers extreme pressure, anticorrosion and antiwear properties.

Purchasing. In this new role, Breaux will retain current responsibility for Marketing and Strategic Planning, but gain overall responsibility for the additional areas as above. Tony Cefalu was named Senior Vice President of Hose & Rubber, Shops and Service Centers. In this new position, Cefalu will continue to lead Motion’s efforts for hose, rubber, and gaskets, and now has the added responsibility for Shops and Service Centers including Automation, Fluid Power, Pumps and Repair. Kevin Storer was named Senior Vice President of U.S. Operations, President of Mi Mexico. Storer’s new role will include all U.S. branch and field sales operations. He will continue to have complete responsibility for Motion’s Mexico operations.

• Calgary – TransCanada Corporation has filed a Notice of Intent to initiate a claim under Chapter 11 of the North American Free Trade Agreement (NAFTA) in response to the U.S. Administration’s decision to deny a Presidential Permit for the Keystone XL Pipeline on the basis that the denial was arbitrary and unjustified. TransCanada also filed a lawsuit in the U.S. Federal Court in Houston, Texas, asserting that the President’s decision to deny construction of Keystone XL exceeded his power under the U.S. Constitution. TransCanada’s legal actions challenge the foundation of the U.S. Administration’s decision to deny a Presidential border-crossing permit for the project. In its decision, the U.S. State Department acknowledged the denial was not based on the merits of the project. The State Department concluded Keystone XL would not significantly increase GHG emissions and that, in fact, alternative methods of oil transportation were more GHG intensive.

• Greene, N.Y. – The Raymond Corporation received the

President’s Award from Toyota Industries Corporation (TICO) in recognition of Raymond’s exceptional achievements and contribution to Global Quality Improvement Activity for Raymond’s paint improvement project at its headquarters and manufacturing plant in Greene, New York. The activity was championed by Toyota Material Handling Group (TMHG) to ensure the four direct influencers of efficient manufacturing are optimized – man, material, machine and methods. After implementation, Raymond showed significant improvement in its paint process quality.

• Vadnais Heights, Minn.

– Nexen Group, Inc., announced a new partnership with Industri/Motion, Inc. Industri/Motion now provides expert coverage of all Nexen products in Chicago and northern Illinois. Nexen Group, Inc. manufactures precision motion control solutions including linear drive systems, precision rotary indexers, and linear locking components.

• Atlanta, Ga. – Dematic, a global supplier of integrated automated technology, software and services for the supply chain, is considering plans to close its manufacturing plant in Grand Rapids, Mich. This action is part of its proactive focus on operating scaled production facilities across the globe in order to remain cost competitive for its customers. If implemented, most production activities will be transferred to its facility in Monterrey, Mexico over an approximate six to nine month period, likely beginning in early 2016 and concluding in September, 2016.

• Helsinki, Fin. – FocalSpec, Ltd., the leading developer and manufacturer of Line Confocal Imaging (LCI) sensors and LCI-based 3D Automated Optical Inspection (AOI) and Automated Optical Measurement (AOM) systems

announced the launch of FocalSpec, Inc., a wholly-owned U.S. subsidiary based in Cumming, Ga. By forming the new company, FocalSpec will provide sales, technical and application support throughout North America.

• Washington, D.C. – The National Association of Manufacturers (NAM) announced that Heidi Brock, president and CEO of the Aluminum Association, has been elected

chair of the NAM’s Council of Manufacturing Associations (CMA) to serve a one-year term. The CMA, made up of nearly 260 industry-specific manufacturing associations in the United States, is a vital component of the NAM, providing resources and networks to members. William Carteaux, president and CEO of SPI: The Plastics Industry Trade Association, was elected vice chair, and Chris Jahn,

president of The Fertilizer Institute, was elected second vice chair.

• Suzhou, PRC – GGB Bearing Technology, formerly Glacier Garlock Bearings, has launched a Chinese version of its new website (www.ggbearings.cn). Designed to provide visitors a better online experience, it features a fresh, new look with regular updates on news, trade shows and career opportunities. MRO

The only cloud-enabled touchscreen laser shaft alignmentsystem with a range of built-in connectivity features.

The industry-leading precision that you’ve come to expect from PRUFTECHNIK can now be integrated with your workflows, for a more mobile, more connected way of managing your assets.

Find out more: pruftechnik.com/ca

PRUFTECHNIK Inc. 4406, Louis-B.-Mayer Laval, QC H7P 0G1 Tlf.: (514) 738 6565 info@pruftechnik.ca

BY CARROLL MCCORMICK

How hard can it be to be a parts supplier? Draw up spares lists with customers, order a year’s worth at a time, ship some to be stocked on site and hold onto the rest to be doled out as needed. The reality, however, is not so neat and tidy.

“What we are trying to do is sit with a customer and see what they have been through in terms of wear parts. We usually try to get an annual purchase order from them. With customers who don’t want everything in one shipment, we keep the stock and ship to them,” says Guillaume Paquet, vice-president, operations with Manuquip, a distributor for

crushing, screening, washing, conveying, demolition and recycling equipment for the aggregate industry.

The company has a branch in Candiac, just south of Montreal, and another in Quebec City. It sells and supplies parts for around 50 brands of equipment, including bruisers like crusher plants, jaw crushers, blademills, cyclones and bucket wheels made by manufacturers such as KPI-JCI-AMS and KPI-JCI-Astec.

There are many ponderables when deciding what spares to order and where best to keep them. Manuquip considers what it calls critical, maintenance and emergency parts, some customers’ de -

sire to have as little paid-for inventory as possible, where they are working, the cost to fly heavy parts to remote areas, Arctic shipping schedules …

“Pretty much wherever there has been mining activity in Quebec, our equipment is there,” says Richard Paquette, CEO and majority owner, Manuquip. Many locations are hundreds of kilometres from even the nearest rabbit trail.

Manuquip has made a study of what is faster, sometimes cheaper, but which delivers the parts as quickly as possible. “We have everything covered,” Paquette says. Its transportation bag of tricks includes its own half-tonne truck mobile

units, transport trucks, couriers, ships and even a military C-17, used once to fly jaw crushers to Meadowbank, Manitoba. In theory, the more serious the consequences of a part failure, the more reason to keep spares on site. At one end of the panic spectrum are wear parts and maintenance parts. A wear part could be extremely worn, but still be working. An oil filter could be dirty, but the equipment still run. At the other end are critical and emergency parts. They include everything that could stop the machinery from operating and interrupt production.

That said, wear parts are more likely to

be stored at the work site, precisely because it is a certainty that they will need replacing. “That is what we are targeting, the wear parts, and a few obvious failure parts, like springs and bearings,” Paquet says.

Manuquip works with its customers to set min/max quantities, which depends on the customer’s history and the number of units in the field. Reordering is triggered manually, on an on-demand basis, or by the calendar.

“Historically, we can set min/max … the customer knows that every 10,000 tonnes an impactor will need replacing. But we never take chances on wear parts. Customers keep some and we keep some. I can’t think of a time we have had to fly in wear parts,” Paquette says. Paquet adds, “Spares quantities depend on the working conditions. It is a mix of our experience, and [that of the] the customers and suppliers.”

This sounds straightforward, but a customer with a new piece of equipment may have no experience with the number of spares he should buy. And

some occasionally have unrealistic expectations of the tonnage of production they can expect with a set of wear parts. Throw in the fact that customers sometimes worry that the supplier will sell them too many spares. Add in things like cost, weight, transportation options, and the possibility of catastrophic failures, and making the right decision requires experience and good judgment. Take blow hammers for impact crushers. They can weigh 900 pounds apiece and cost $10,000 for a set of four. Two thousand-kilogram jaw dies may run $8,000 to $9,000 a set. A mantle and liner for a cone may weigh 5,000 pounds for a set, depending on the model, and cost $15,000 a pop. Moving them by truck is no problem, but what if the only transportation option is by ship?

Ordering these big parts is usually done in the fall, Paquette says. “We do a phone blitz, come up with the number of spares. We know which parts might be required. We also contact people with competitors’ equipment and offer them parts. We identify this potential and try

to come up with good pricing for customers.”

To do this well takes advanced planning, especially for Arctic shipments, where northern waters may only be ice-free for three or four months a year. Customers that delay too long in placing their parts orders, and some do wait till the last minute, can literally miss the boat.

“It may take 10-12 weeks to get an order, and when we finally get the goahead, the [time available for delivery may be] shorter than the manufacturing time. Even experienced customers don’t always get it when we tell them ‘if you don’t place the order now, you won’t get it in time.’ They think it is a sales gimmick,” Paquette says. The delivery time from a supplier can also slip, which is all the more reason to order early.

As for trying to discourage customers from waiting till the last minute to order, Paquette smiles, “We haven’t won that battle yet.”

Manuquip evens out the bumps in the supply chain by keeping lots of spares in

its warehouses, particularly those from its suppliers in the far corners of the continent. Manuquip uses a customs agent to smooth the passage of parts across the border.

As for payment options, Paquette says, “In some cases we keep inventory and the customer pays when he gets the stock. But if the customer does not pay for it [to be stored] he runs the risk of it being sold to someone else. If he pays, the part is reserved for him.”

As nice at it would be for Manuquip to stock everything, it simply isn’t possible, for all machines, for all model years. Manuquip might sell a part once every five years, or sell three of them in one month. A customer might hit something with a backhoe. “It is always a balance, what to keep or not keep in stock,” Paquette comments.

If a customer suffers a catastrophic part failure, Manuquip will bend over backward to get in a replacement. “I remember one, for a competitor’s machine,” Paquet recalls. “A customer was

having trouble getting parts from his supplier. He called us. I was 500 kilometres from the office. There were 20 parts in the order. By ten that night I was able to get the parts supply confirmed with my supplier, who was not normally in. We booked a plane in Oregon, it left Saturday night and [the shipment] was in Quebec City at my door on Monday morning.”

Planes are an expensive shipping option, but they can be a customer’s salvation. “It is not so much the weight, but if [a part] is small enough to go through the doors. Sometimes they can go to 500-600 pounds, even 1,000 pounds,” Paquet says.

Advance planning and expert counsel is the key, but when things do go sideways, Paquette says, “The customer calls us and we usually will have the part to the customer’s door within 24 hours.”

MRO

Montreal-based Carroll McCormick is the award-winning senior contributing editor for Machinery & Equipment MRO.

A maintenance manager with a winning mindset delivers on his game plan.

BY REHANA BEGG

Philip Lawlor made a plucky move when he applied for the 2015 PEM Maintenance Award. As relatively new hire at Canam Group Inc.’s Mississauga, Ont. plant, the maintenance manager and his team would be up against any number of Canadian plants vying for national recognition for excellence in maintenance best practices. Past winners – including such multinationals as OPG Pickering Nuclear, ArcelorMittal Dofasco, Glencore Sudbury Integrated Nickel Operations and Cameco – have demonstrated high levels of maturity across their maintenance departments.

The odds could have been stacked against Lawlor, an Irish native who had moved to Canada in 2014. He was about eight months into implementing a maintenance program at Canam Group’s Mississauga plant when he submitted an application for the award. When Lawlor was hired, Canam Mississauga had no measurement systems in place to gauge the impact of the plant’s physical assets or the level of maturity of asset management practices.

But the panel of jurors had compelling reasons for naming Canam Group as the year’s winner in the Best Maintenance –Large Plant/Facility category. Canam Mississauga showed evidence that the maintenance program was approached with a level of sophistication and demonstrated that the company

had benefited from its maintenance initiative within a short period of time. “The strength of Canam Group’s program was the diligence they showed,” says Braam Meij, VP, Customer Services, Siemens, who served as a juror in the category. “They looked at how they could improve the organization and they did it in record time. They looked at three aspects: people, process and technology.”

The Canam Mississauga plant employs 170 people and the maintenance team is made up of six craftsmen, a stores man, a supervisor and a manager. The plant produces joists, girders and deck products, operates on 214,700 sq. ft. (19,945 m2) and has a capacity for 60,000 tons – about 15,000 tons of deck a year and 35,000 tons of joists a year.

The Mississauga operation is one of 22 plants. The parent company, founded in St. Gédéon-de-Beauce, Quebec in 1961, specializes in the design and fabrication of customized construction products and solutions and is today the largest fabricator of steel components in North America. The group averages 10,000 construction projects every year. The Company operates in three groups of products and services: building construction, structural steel construction and bridge con-

struction. Iconic projects include Rogers Place in Edmonton, BMO Field in Toronto, Maison symphonique in Montreal, and the Honda of Canada (Plant 2) in Alliston, Ont.

Performance improvement

Lawlor confirmed his competence and leadership right out of the gate. When he joined Canam Group, he conducted an assessment of the team’s maintenance planning activities in order to grow the maturity of the plant. Based on these results, one of his first tasks was to create systems whereby production could

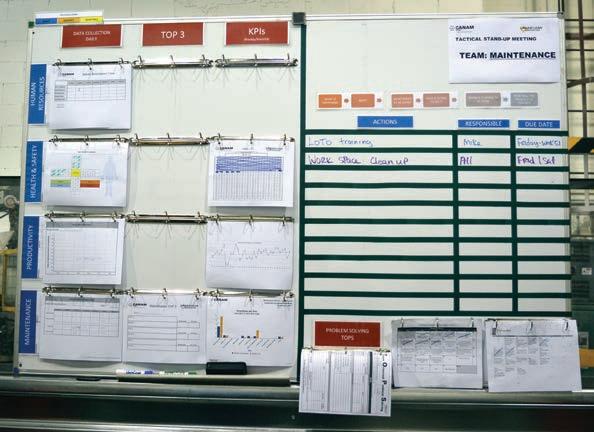

request maintenance time for both proactive and reactive job types and so that maintenance could schedule priority work at least one week in advance. Within six months the Mississauga plant was transformed from doing mostly reactive work to one that enforced a maintenance program drawing from tried-andtested best practices, such as maintenance planning and total productive maintenance. The Canam crew is currently in the throes of aligning key performance indicators (KPIs) as a way to forge a strategic approach across the plant.

A newly installed maintenance program would need to be

NSKHPS Series Bearings deliver a high performance standard for load capacities, limiting speeds and operating life across an expanded range of sizes. These bearings provide dramatically improved reliability and maintenance cost-efficiency across a vast array of industrial applications. Maximize operating life and minimize downtime - NSKHPS Series Bearings are designed to outperform and outlast in the toughest conditions.

1.877.994.6675 www.nskamericas.com

in keeping with the multinational parent company’s values of high-efficiency production. That is why Lawlor drew from experience and looked to a South African asset management company, Pragma, for inspiration. He adapted their maturity-modelling concept and developed his own agile performance improvement framework for manufacturers as part of his masters degree thesis back in 2011. The model measures current performance levels through assessment and matches maturity levels and KPI targets in accordance with five maturity levels, namely, firefighting, stabilizing, preventing, optimizing and excellence.

An assessment-based survey completed by 13 employees in key positions of operations in April 2015 showed Lawlor precisely which areas to focus on and which high-level factors needed improvement, says Lawlor. A follow-up assessment in October 2015 showed improved results with two of the 30 good practices scoring 100% on the assessment, while the remainder having scores ranging from 60% to 85%. “Initially we scored 9% overall, six months later we scored 77%. Through consensus, it showed

me that we were improving based on the implemented systems, business processes and training,” says Lawlor. These assessments tie in with the maturity model because Lawlor is able to create a KPI target. “We scored 77%, which put us in the optimizing phase. Obviously, the target now is to be excellent and to select a new KPI target based on the assessment information.”

Lawlor created first and second-line roles as a way to redirect the crew’s focus from breakdown work and to improve overall communication amongst departments. “The first-line role is the person spearheading the responsibility for reactive work and the second line is given planned work so we can break out of the reactive cycle many plants find themselves in,” says Lawlor, who explains that two craftsmen respond to breakdowns through the first line roles, while the remaining four focus on planned work and this improves the reliability of the equipment by reducing interruptions to planned work.

With a full line of power transmission drive systems, Continental ContiTech strives for industry-leading innovations to provide you with the most advanced solutions available.

Work is managed daily through a paper-based (carboncopy) work order management system and line-side planning board. During weekly asset-care meetings the operations and maintenance team jointly assess the work to be done for the upcoming week. The purpose of the meeting is to ensure the right skills, spares and machinery is available for prioritized work, says Lawlor.

Waiting on information and instructions, travelling to and from jobs, finding tools and materials, and waiting on other people are examples of waste. Lawlor conscientiously documents these types of activities in order to isolate bottlenecks and increase wrench time. “It’s not making them work harder, but it is creating that environment to be productive and removing the things that stop employees from doing that,” he says.

Expediting communications

While the work order system is paper-based, Lawlor does not yet see the need for a complete electronic system. Although completed preventive maintenance and requests are logged in an EAM system, the process will remain paper based on the request and scheduling side for now. “At the moment we are really focused on getting good at following business processes, and using paper really helps us with that,” says Lawlor. “Technology, as you know, only has one purpose: to reduce the duration of the time it takes for us to complete activities. It makes it easier for us to report, retrieve and capture data. Having a fully electronic system is not going to add any value to the maintenance team at the moment. I am not seeing that need yet, but I think it will naturally go in that direction.”

The plant invested in mobile phones to facilitate better communication between the production and maintenance teams and to help with an escalation procedure. Being connected allowed faster reaction time when there was a breakdown. The maintenance team previously used a two-way radio system, which restricted communication between departments, says Lawlor.

Every day the team analyzes work order feedback in order to identify the assets that have top losses. “For instance, just this week we looked at a failure on a splicing line. We had a pneumatic valve failure because it wasn’t being lubricated,” says Lawlor. “It’s such a simple thing, but we lost three hours diagnosing it and then repairing it. But now we know what caused it and we’ve rectified the root cause. We have a 6' x 4' problem-solving whiteboard dedicated to root cause analysis in the workshop to help us make sense of why breakdowns happen.”

Weekly comparisons of planned work are charted and six-monthly health-check reports are furnished to management. Important measures include planned completion rates, amount of minutes spent doing breakdowns, and work planning and control. “If I was to focus on one thing, then work planning and control is the heart of it,” says Lawlor. The metrics also provide a sense of what and where the least reliable assets are. By isolating the least reliable assets, Lawlor is able to consider whether preventative maintenance is needed on an asset, or what types of failures are prevalent, and then perform root cause analysis to prevent recurring failures.

Lawlor also scrutinizes job types to find out where the crew is actually spending time. Work requests rank the highest, followed by breakdowns, safety, unplanned requests, work request follow-up, breakdown follow-up, and preventive maintenance follow-up. Lawlor also introduced a preventive maintenance follow-up job type in order to evaluate the value of completed maintenance PMs. And closing the asset management loop, an asset register and criticality rankings help make decisions easier when it comes to work prioritization and preventive maintenance.

A key improvement project was to apply a total productive maintenance (TPM) model to manage the overall effectiveness of the plant’s most important production line, the flash welder (“considered the heart of the factory”). Lawlor adapted a model used by a former U.K. colleague, Peter Willmott. The program essentially enables employees to take ownership of their equipment and workspaces on the main production

line. To this end, an electronic schedule is set up so operators can update the results of machine inspections and cleaning schedules. Operators were also given lubrication training and a photographic manual of instructions so operators could follow standards.

With the maintenance workspace redesigned through 5S, finding tools and conducting inspections is a cinch. “We designed our workshop around some of the routine work that we do. If you think of a welding plant – preparing guns and preparing welding machines – these are repetitive tasks. So we developed stations where all of that work can be done easily, and we have reduced some of the time spent on these repairs.”

The walls were painted white to increase light levels and new standardized workbenches were purchased. The total workspace was divided into separate areas with a dedicated service area, personal work area and machine shop for such tasks as cutting, drilling, grinding, welding and parts repair. PPE was organized along one wall so the crew could store and inspect their safety equipment, harnesses and work wear.

Significant strides have been made since the new maintenance program was implemented, says Lawlor, who credits the manufacturing teams and the general manager, Warren Fournier,

for providing ongoing support. “We have increased costs a little in the short term – more lubrication, new tools, workshop organization… but on the flip side, we have increased the team’s efficiency and effectiveness, so we do more of the right work in the same available time. We’ve cleared all the small backlog jobs and spend more time now on projects and continuous improvement, which adds more value.”

If gaining recognition for a job well done was a motivation, Lawlor and maintenance team have met their mark. The process has cleared a path for a new vision for maintenance at Canam Group Mississauga, but Lawlor says the process gives back much more. “There are still improvements we can make, and I know we’re heading in the right direction.” MRO

Lovejoy Hydraulics is a leading supplier of products tailored for hydraulic applications including a complete line of flexible shaft couplings, rigid and noise dampening pump / motor mounts for NEMA and IEC motors, aluminum tanks, reservoir accessories and water-oil coolers for fluid power applications.

Quality products, engineering expertise, and over 100 years of industry experience – Lovejoy Hydraulics delivers optimum solutions for hydraulic applications.

• Aluminum Tanks / Reservoirs

• Pump / Motor Mounts

• Water-Oil Coolers

• Hydraulic Couplings

• Accessories

Domtar’s award-winning Windsor mill examines the sources of error

BY CARROLL MCCORMICK

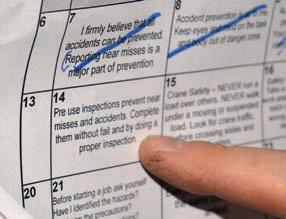

Aworker is tasked to cut some failed bolts on a pressure vessel door. In the process, he cuts his finger and takes five stiches. An investigation determines that this accident was just waiting to happen. In a new approach to understanding the cause of incidents like this, Domtar’s pulp and paper mill in Windsor, Que. is

improving its safety programs by adopting a more correct way of understanding the nature of errors.

Adapting an approach developed to reduce the number of incidents in the nuclear power industry, called Human Performance Improvement (HPI), the Windsor mill is focusing less on how an incident happens, and more on why. Be -

hind this tactic lies the dawning awareness that individual errors contribute far less to incidents than do organizational weaknesses.

Examine an event, incident, or unwanted outcome – whatever name you prefer. A traditional belief, now considered false, is that human errors arise only at the level of the individual. The

truth is more like this: 20% of events are due to equipment failures and 80% are due to human error. But only 30% of that 80% are due to individual mistakes. The other 70% are due to organizational weaknesses.

So how did that worker cut himself? “In the old days we asked the worker why he screwed up. But when we analyzed this one, we found a lot of organizational weaknesses,” says Eric Ashby, general manager, Domtar Windsor Mill.

First, the bolts had been improperly torqued. Second, the inside door was bigger than the outside door. The worker had to wrestle with it to remove it. Third, his supervisor warned, “don’t drop the bolts in the tank.” The only way to do all this and remove the bolts was to grind with one hand. He lost control of the grinder and cut himself.

The worker just happened to be the last one to show up at someone else’s party.

Additionally, although there were protocols in place for the task, there wasn’t one for what to do if the job could only be done with one hand. Among the lessons learned during the post-event in-

vestigation, Ashby says, “As part of the corrective action, what do you do if you have to use one hand? Stop.”

This example reveals several bold changes in the approach to safety at the Windsor mill. One, it is an example of what is called a just culture. Simply put, in a just culture workers are not punished for actions that are in line with their training and experience. “You separate individual and organizational culpability. We have a just culture decision tree that tells us if it is an individual or organization that is culpable,” Ashby says.

Two, rather than simply blaming the worker, look to management for the cause of events. For example, says Ashby, “If a lockout system is too complex, there is a higher probability that an employee will make an error. This is an organizational weakness.” Or, a tricky startup sequence may be begging for an event to happen.

Three, moving away from what is called the circle of despair: an incident, panic, fixing it, and then waiting for the next incident. “Part of HPI is how to move from reactive to proactive. Can we do better analyses of existing incidents and put in SMART+ER (Specific, Mea-

surable, Actionable, Realistic, Timely + Effective Reviews) corrective actions?

The issue we see now is that when we analyzed our investigations in the past, we were very good at identifying what happened, but not why it happened,” Ashby explains.

He continues. “The big shift is moving away from Root Cause Analysis. In [HPI], we don’t focus on identifying the root cause. We believe we have causal factors. You want to eliminate all causal factors you can identify. Every contributing factor is a weakness in your barriers.”

The barriers Ashby refers to are ways set up to reduce the consequences of errors, while granting that people will always make them. Ashby lists four types: Cultural: norms that a group of people generally agree on. For example, people in one region might interpret a yellow traffic light as a cue to speed up, while those in another understand it as a cue to slow down; Administrative: Examples include lockout sheets, checklists or procedures; Engineering: guards on equipment and seatbelts are examples; Management/ oversight: A radar and a sign displaying your speed is an oversight barrier designed to get you to slow down.

Barriers are imperfect. Each has weaknesses, or holes, which is why Ashby refers to the “Swiss cheese model.” The more holes that line up, the greater the likelihood of a significant event linked to an error. “Our job is to identify all the holes. You have to figure out a way that there are the best barriers possible. If you are only protected by one barrier, there probability of an incident is 100%,” Ashby says. “Seventy per cent of our work is to identify latent organizational weaknesses and put better controls in place.”

Ashby cites a formula that captures this process: “RE + MC --> zero significant events.” Written out, it reads, “reducing the probability of making a human error, plus instituting the proper management control in the plant, leads to zero significant events.”

The Windsor mill has replaced the term “incident” with “significant event.” “The flaw of Occupational Health and Safety Act (OHSA) incident rate is that it does not show its severity. One fatality equals one cut on the OHSA scale. We have four levels of significant event: Level 4: near misses, or minimum first aid; Level 3: Minor recordable (requires diagnosis and treatment); Level 2: hospitalization of more than one person; Level 1: permanent impairment; for example, amputation or long lost time,”

Ashby says. This extra detail lets Domtar distinguish between, say, three cuts with two stitches, and losing a leg.

There are many moving parts to this version of HPI that Domtar has adapted to the Windsor mill, all designed to give a face to errors, quantify them and reduce the number of events. “We are pushing for zero significant events. We

know that the company that survives is [the one that is] controlling significant events,” Ashby says.

For example, he says, “We have defined 14 tools to lower the probability of human error. For example, there is the concurrent verification tool, where one person does a lockout and someone else verifies it. This decreases the probability of error.” Then there are the 32 error precursors Domtar had already identified, such as frustration, fatigue, rushing and complacency, which are expanded in HPI. For example, a dirty area will increase the probability of making an error.

Domtar is also capitalizing on the concept of the three performance modes that every human supposedly has, and their associated error types and rates: Skill-based, rule-based and knowledge-based. The main error mode for skill-based performance is inattention, at a rate of one error per 10,000 actions. For rule-based behaviour it is misinterpretation. “The person doesn’t know what to do, but follows step-by-step processes, following a set of instructions. When you work in rule mode, your error rate is 1/1,000,” Ashby says. The main error

mode for knowledge-based behaviour is an inaccurate mental model of, say, a system or process. The error rate here is 50%. Ashby illustrates what can be done with this information. “Imagine two rule-based workers doing concurrent verification. The probability becomes

1,000 times 1,000, or one chance in one million of an error.”

Domtar uses 14 HPI human intervention tools to minimize the probability of errors. “The supervisor will work with his workers, have the proper tools; e.g., risk assessment, circle of danger, etc. This is the RE,” Ashby says.

For now, HPI at the Windsor mill is being driven at the leadership level, where 70% of human errors reside. It begins with the mill manager, then managers, superintendents and then supervisors. As the plant evolves its version of HPI it will get more involvement from employees.

Initially, HPI was applied after there was an error. But doing audits is taking it beyond reaction to proaction. There are also continuous improvement mandates; e.g., improve an area as a result of several near misses, or the perception of a risk. Here, employees get a lot of involvement in audits.

Ultimately, Domtar wants to bring its Windsor mill employees to a team mindset, or, for those familiar with the Dupont Bradley Curve of a maturing safety culture, an interdependent stage where zero injuries is believed to be an attain-

Domtar’s Windsor pulp and paper mill has long sought to drive down its incident rate. Between 2008 and 2012 it was 1 to 1.2 per 200,000 hours. With the addition of techniques such as reporting and analyzing near misses in 2012, Domtar was awarded the 2012 Paper Week Canada Safety Leadership Award, with just five recordable incidents in the course of 1,483,056 hours worked. Combined with tools such as the safety sphere – an imaginary, three-metre diameter bubble which workers constantly analyze for danger, a notebook called “J’analyselatâche” (I am analyzing the task) with a checklist of possible risks and room for noting problems, and risk assessments that, for example, led to a plant-wide ban on utility knives, the mill pushed the incident rate below one: 0.8 in 2013.

“The question was if we could do better: 0.5,” says Eric Ashby, general manager, Domtar Windsor Mill. In what would signal a move from individual responsibility to a team approach, a just culture and improving its understanding of the source of errors, Domtar began to modify an approach to safety from the nuclear power industry called Human Performance Improvement. “Can we catch the errors, human or organizational, before we get a consequence?” Ashby asks. Domtar’s efforts have paid off: the Windsor mill had its best ever safety performance in 2014, and 2015 was the third best year for safety performance.

The mill’s safety approach has gone through a major evolution. “[It has] brought us to a level which has a lot of differences from 2013,” Ashby says. “We are very proud to have moved in that direction.”

able goal. Ashby says, “The key way to approach a just culture is how to approach human error. It is a shift, a continuous evolution. We are very proud that our mill and community have moved in that direction.” MRO

Editor’s note: Domtar Windsor Mill, Quebec, is the winner of the 2015 PEM Maintenance Award – Best Safety Program.

Montreal-based Carroll McCormick is the award-winning senior contributing editor for Machinery & Equipment MRO.

The PEM Maintenance Awards program was first introduced in 1999 and gives maintenance and facilities managers the opportunity to tell their own success stories. The award acknowledges and recognizes maintenance excellence and best practices in physical asset management.

Thank you to our 2015 PEM Maintenance Awards sponsors.

Best Maintenance – Large Plant/Facility

Canam Group Inc. Mississauga

Sponsored by: Siemens Canada

Best Safety Program

Domtar Windsor Mill, Quebec

Sponsored by: Toromont Cat

The program will rebrand as the MRO Maintenance Awards in 2016.

WORK SA FE R AND M OR E EFFI C IE NTLY with the ne w FLIR ® C M174 cl am p mete r wi th bu il t- in the r ma l i mag i ng camera. Featuring Infrared Guided Measurement (IGM) te chno logy, the CM174 visua lly points you to the pre cise location of potential electrical issues. You’ll find problems faste r, get mo re done, an d boost you r cre dibility .

TO SEE IGM I N ACTI ON G O TO WW W.FLIR.CA/C M1 74

BY MARK BARNES AND JEFF SMITH

Over the past 10 - 15 years, predictive maintenance has evolved from something that only the most progressive organizations do, to something that most companies have at least explored. But with a variety of choices out there, one of the key questions is: which technology provides the greatest benefit? To gain some insight, we asked two industry experts: “If you could only invest in one condition monitoring technology, which one would it be?”

The answer depends on the type of asset and the most common failure modes, but for rotating or reciprocating equipment, my choice would have to be oil analysis. Numerous studies have shown that when it comes to rotating equipment, 50 - 70% of all failures can be directly traced to a lubrication-related failure, most of which can be found with oil analysis. What most people don’t really appreciate about oil analysis is that it’s about much more than determining if the oil is still “good”; it can actually help diagnose other leading causes of machine failure beyond the oil simply not being fit for continued use.

A simple analogy I often share with people is to think about oil analysis in the same light as a blood test. While a blood

test can be used to highlight problems directly related to the health of our blood such as a low iron count, it can also infer other health problems such as the presence of contaminants, such as high cholesterol, or identify certain pathogens indicating other diseases. Just like a blood test, where the presence or absence of certain things can be used by a trained physician to determine the root cause of an illness so they can prescribe the appropriate corrective action, a trained oil analyst can use the data from an oil sample to determine the onset of machine failure, detect the presence of unwanted contaminants such as particles or moisture or detect “poor oil health,” such as low additive content or the onset of oil oxidation.

Where most people go wrong with oil analysis is with sampling. Unlike a blood test where the results are homogenous, meaning the analysis should be the same no matter where the blood sample is collected from, many oil analysis parameters are very sensitive to where and how the sample is taken. A good example would be particle counting. Sampling from a large sump or immediately downstream from a filter will provide very little indication of particle ingression. Converse -

ly, sampling immediately after a component that’s wearing or immediately downstream from a source ingression, such as bearing housing or hydraulic actuator, is an excellent way of finding a problem early. The keys to oil analysis are to sample from the right location at the right frequency, make sure the lab is doing the correct series of tests based on the known or anticipated failure modes and to understand how to interpret the results so that the right corrective action can be taken.

Jeff Smith refers to condition monitoring and “predictive maintenance” in his introduction. Below by definition, predictive maintenance means using a technology like oil analysis or vibration analysis to predict when a machine is starting to fail. But with oil analysis, recognizing that the oil is contaminated or that the base oil or additives have degraded allows us to take a more proactive approach to condition-based maintenance; which is why, dollar-for-dollar, my vote would have to be with oil analysis.

Jeff Smith Acuren

As a firm believer in integrated condition monitoring this question is not as simple as it first appears – all types of condition-based maintenance (CBM) have strengths and weaknesses. To make this choice one must consider the purpose and value add. CBM adds value to an organization by enabling early enough detection of faults to align intervention within the constraints of the operational campaign. With this in mind I would select vibration analysis.

Vibration analysis will give early detection of numerous faults in rotating equipment. The ability to detect the onset of bearing failures, gear issues, looseness, misalignment, imbalance, belt issues, broken rotor bars as well as electrical faults gives vibration analysis a wide range of use as a CBM technology.

A good vibration program will also cover inspection aspects of CBM as the analyst collecting the data will physically be at the asset taking the readings; this enables a visual inspection to be conducted with no additional effort. Another advantage of vibration is that once a failure is detected the data collection frequency can be altered to manage the progression of the failure, thereby managing the degradation of the asset. With the addition of a current clamp to a vibration data collector, electrical faults can be managed. This enables motor current analysis and the detection of power quality issues.

Vibration can be utilized for both rotating and static assets, using operational deflection shapes to solve complex problems. This technology also enables management of critical frequencies (both linear and torsional) within assets to ensure they are operated outside of damaging speeds. The onset of VFD (variable frequency drives) only increased the importance of managing critical frequencies.

My reasoning for not selecting other technologies lies in evaluating what is controllable and what is not. If I only had a vibration program I would ensure that my lubrication practices were very advanced – the better you are at managing your ingresses, the less issues you will find with oil analysis. As for the degradation of lubricants, consider your car’s oil change indicator light. It works on an algorithm that considers your driving (operational loading) and evaluates the likelihood of degradation and lights accordingly. With this logic, change intervals can be optimized (I do acknowledge it would be a lot easier with oil analysis history). Therefore, if I control my ingresses and schedule my changes, the last key point of oil analysis is the detection of equipment failures. Vibration analysis is a superior technology and applicable over a much wider range of assets.

>> Continued on p32

Jeff, I think you and I are in alignment that, when it comes to condition-based maintenance, the value of an integrated approach using all available technologies is far greater than the sum of the parts. This is really a case where 1+ 1 = 3! Whether you use oil analysis, vibration analysis or for that matter any other CBM technology, the secret is to focus on the proactive aspects of the technology – degraded lubricant or contaminated oil in the case of oil analysis or imbalance, misalignment or soft foot in the case of vibration so that corrective action can be taken before the downstream effects of machine wear and failure occur. In some cases where the decision to shut down a production line, or to effect an expensive repair needs to be made, it’s nice to have several technologies pointing to the same conclusion so that an informed decision can be made. Ultimately, one needs to have a good understanding of the possible or likely ways any asset might fail, then selecting the technology or technologies that are best able to identify the causative factors will always provide the best return on investment when it comes to CBM.

I concur Mark; the base value of CBM is prediction of failures. The advanced value of integrated CBM is developing a clear

understanding of the causes and effects that created the failure in the first place. In reality we don’t want to detect failures, we want to eliminate them, or strategically manage them – as in run-to-failure options. Oil and vibration are two great sources of information that when combined with process data, can lead to true prognostics.

All applicable CBM is capable of detecting certain failures, but this information is only an input to drive decision support. What you do with the information is ultimately what drives your organization to success.

The reality is that to add value a lot of things have to go right, and they have to happen in series. To be effective you have to do the right work (RCM, FMEA, PMO) and you have to plan it properly. To be efficient you have to schedule well and execute properly. To continuously improve you need to manage the failures, not just react to them. There is a lot of information in oil lab results, and the vibration spectrum, but correlating this to the operational loading and life cycle with a FRACAS program will enable continuous improvement. MRO

Mark Barnes, PhD, CMRP, is vice president of Reliability Services at Des-Case Corporation. Barnes has published more than 100 articles and several book chapters on lubrication and oil analysis. His PhD is in Analytical Chemistry. Reach him at mark.barnes@descase.com.

Jeff Smith is the reliability subject matter expert for Acuren. Smith has served as senior advisor for the Association for Maintenance Professionals (AMP) and served on the U.S. tag for ISO 55000. Reach him at jsmith@acuren.com.

Peter Phillips’ ongoing analysis of a current project at an Ontario food plant will continue in the April issue of MRO

BY PETER PHILLIPS

The first issue of the year is an opportunity to set some goals that will get your maintenance team focusing on small achievable goals that will boost equipment reliability.

We’ve spent approximately 1,600 hours in manufacturing facilities around North America this past year. A very common theme from plant to plant is the focus on preventive and reactive maintenance (repairs and breakdowns). PM completion rates, PM versus downtime, and other maintenance performance indicators are graphed and displayed for all to see. In some cases, PM completion rates are set by corporate headquarters and plants must report their results every month.

Both PM and reactive maintenance are very important components of keeping equipment available for production but there is one ingredient missing that will further improve equipment reliability, namely predictive maintenance (PdM).

PdM includes some maintenance activities that are considered a notch above our PM efforts. They include activities that can forecast or discover

maintenance-related issues before they become equipment or process failures.

In the month of December, I spent a week in a gypsum sheetrock plant in North Carolina. They have a well defined PM program and they generate around 200 work orders every week. The maintenance planner diligently plans and distributes the work orders to the maintenance staff. Work requests from supervisors and engineers are also planned and executed on their weekly 10-hour down day. Work orders are promptly closed in their maintenance software after the work is completed. They do a great job on these two elements of their maintenance strategy.

However, they do not create work orders for equipment breakdowns and this information is therefore not recorded in their maintenance software. Although their software has the facility to do breakdown analysis, it is not used because the breakdown data is not available.

They also take infrared temperature readings on critical motors and gearboxes. While the information is gathered, it is not monitored to determine whether the temperatures are reaching values

where corrective measures need to be taken. Certainly, taking these readings is the beginning of a PdM program. And if you are using sophisticated tools to measure temperature and vibration values, then it is important to use those readings to predict equipment failures.

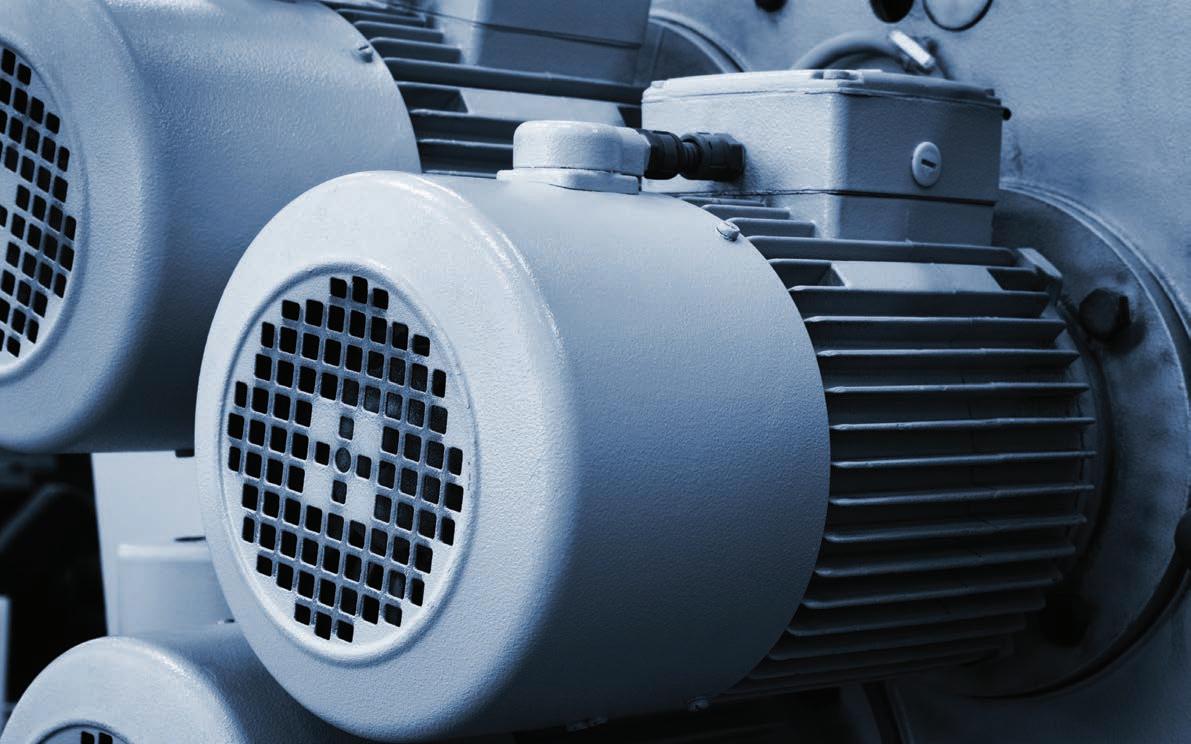

Thirty years ago, before these tools were readily available, the maintenance department I worked in devised a simple method to forecast motor failure. We checked three things:

• We felt the motor with our hand to see if it was running hot.

• We used a screwdriver or wooden dowel to listen to the bearings to see if they were noisy.

• We checked the amperage of each phase feeding the motor to see if they were within their range and the amperages were balanced across each phase.

If the motor failed any two of the three checks, then the motor was replaced. Our PdM method solved a problem with motor failures on a group of 30 conveyors. One program this plant excels at is their tagging program. Operators fill out red

tags and attach them to the equipment where there is a problem. The carbon copy of the tag is delivered to the maintenance department where the planner promptly schedules the repair. This tag program is simple and easy for operators to report equipment and process issues. Anyone who has ever worked at a manufacturing facility would have to admit that no one knows the equipment better than an experienced operator.

Many years ago I quickly learned this valuable lesson as a young apprentice millwright at Michelin Tire. I was given a couple days of training on a group of equipment and was immediately assigned to a shift by myself. I was responsible for the maintenance on a group of wire drawing machines. If it wasn’t for the experienced operators pointing out equipment problems and many times how to fix them, I would never have survived my early days of shift work.

Operators can immediately hear, smell, feel and see any adverse changes to their equipment. Addressing operator concerns is one of the cheapest components of a PdM program. It needs no tooling or special systems and costs zero dollars. I learned to become a good listener as a young millwright. Experienced operators were my best resource to find and fix equipment problems. My supervisor at the time was George McRae, a seasoned maintenance manager from Ireland. He was my mentor and told me to take the time to get to know equipment operators because as friends they would share with me their years of experience operating the equipment. He was right. Although he passed away 25 years ago, his lessons are still applicable.

The lessons here are simple. PdM does not need to be sophisticated. They don’t always need high-tech equipment or knowledge.

Let’s review some key ingredients to a PdM program – four goals for the year:

• Continue with your Preventive Maintenance program. Make sure it is up to date and has specific details of what you want checked during the PM.

• Record your breakdown work orders so they can be used to spot repetitive failures. Implement corrective actions to address the root causes.

• Start a motor and gearbox monitoring program. Critical motor and drive unit failures can be reduced and even eliminated if simple measurements are taken. Use vibration analysis, take temperature readings or practise the 2 out of 3 rule (feel, listen and amperage checks); today we have readily available instruments that provide accurate, repeatable and safe measurement.

• Implement a program where an operator’s equipment and process concerns are captured and addressed. A tag program works extremely well.

Set these four goals for the year. Find the time to do predictive maintenance activities. Facilities that have imple mented these simple strategies have seen remarkable results in equipment and process reliability. MRO

Peter Phillips of Trailwalk Holdings, a Nova Scotia-based maintenance consulting and training company, can be reached at 902-7983601 or by email at peter@trailwalk.ca.

because they have a passion for doing things the right way or doing things in an optimal way,” says Smith.

For 11 years CPR benefited from Smith’s proclivity to learn. The railway promoted him seven times, each time offering a new challenge to master equipment for heavy haul systems and optimize processes and logistics.

When a restructuring caused a swath of layoffs at CPR, Smith could have taken a demotion in order to stay on, but he opted for a cash buyout instead and started his own consulting company –Accu-Track Machinery. Ironically, Smith contracted his skills back to CPR. With just two mechanics and a small shop, his outfit repaired electronic components for the railway until his client roster grew to include banks that required him to apply reliability engineering to equipment in their appraisals. “It was quite a going little business,” says Smith.

From stints in open pit mines and pulp mills, to synfuels and breweries, one mechanic set a course for mastering the entire reliability universe.

BY REHANA BEGG

Jeff Smith was working on track maintenance gangs for Canadian Pacific Railway when a machine in his line of sight blew a hydraulic hose. As he watched mechanics spring into action to install a new hose, he noticed the dirty fittings and thought: “Well, that could be done better. We could have

done it another way and we could have done it faster and we could have done it so that it wouldn’t happen again.”

Smith recalls the moment as the first time he engaged in reliability. “Mean time to repair, mean time between failure… I didn’t even know these terms existed back then.”

It was 1982 and not a lot of people did. Yet Smith, who is

currently a reliability subject matter expert with Acuren, Corporate, made it his mission to continuously improve and to run diagnostics on systems and equipment so that they “run cooler and better.”

If the railway incident was the trigger, Smith set a course for his career as a perpetual student of reliability. “Certain people are drawn to reliability

Then, a life-altering incident forced Smith to close up shop. His estranged father had cancer. Smith moved to Chetwynd, B.C. to be with him and during this time reverted to his trade ticket. “Because of all my upper management experience, Bullmoose Mine gave me a job as a lead hand on a shovel and drill crew in a mining operation,” says Smith.

But when a position for a predictive maintenance specialist opened at a pulp mill, Smith scooped up the role. He set to work by dividing the crews of millwrights into two groups – a proactive maintenance group and a reactive maintenance group. One project involved introducing the mill’s first set of handheld computers (“the old green screen DOS boxes”). The software provider, Design Maintenance Systems Inc., took note of his talent and poached him to implement condition-based maintenance programs, including vibration and thermography, for clients. “With

Design Maintenance Systems I learned CBM – and I am considered fairly good at it – but I learned after four years of doing it that I had saturated what I could learn there.”

DMSI didn’t do much in the way of structured work, such as reliability centered maintenance and task analysis, and Smith wanted to fill these gaps in his knowledge. An opportunity at Ivara Corp. (now owned by Bentley Systems) offered this prospect before making Molson’s Vancouver brewery his next pit stop.

Molson allowed Smith to apply task analysis and to design their CBM program. The brewery ran about 1,600 cans per minute at the time Smith joined the plant. Within two years Smith’s reliability implementation helped the brewery increase efficiency to 2,200 cans per minute, and shrinkage was down to 0.07 per cent from 2.75 per cent. “That alone is worth millions. We reduced customer complaints by 66 per cent. Terry Carrie, the brew master thought I was a hero!” After two years the line was running at 75 hectolitres per man-hour, which is two-times world class.

Smith says that he started placing constraints on how much time he would spend with an organization so he could be challenged to achieve a goal of learning and then applying his knowledge. He told Molson that he would work for them for two years. “I thought: In two years I am either going to be very successful or not. Reliability engineering is a change job – if you do it right, you actually have a finish point. Not that you’re ever done optimizing things, but you have continuous improvement loops so that the system is self-sustained.”

Not big on routine, Smith moved on to start up his own company, Reliability Laboratory, in 2007, which allowed him to subcontract until Teck Coal Ltd. later lured him into

a full-time role as a reliability lead. During his tenure, Teck won Uptime’s Best Emerging Maintenance Reliability Program Award and Smith was nominated for corporate leadership and innovation awards.

An unintended consequence from Smith’s ongoing learning is that he has made an indelible mark by sharing his knowledge; his expertise has landed him on commit-