MAY/JUNE 2012

MAY/JUNE 2012

Award-winning pork producers

6

Top hog operations

Four exceptional farms are honored as the Pork Checkoff 2011 Pork Industry Environmental Stewards.

12

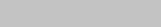

Wisconsin’s Dane County moves ahead with second AD facility

Dane County is moving forward with plans for a second cow power facility, selecting a site for the project, and entering into a new partnership for the project.

14

Manure digester helping large hog farm bring home the bacon

Ideal Family Farms LLC of Pennsylvania has taken its manure management costs – a major drag on the farm’s bottom line – and changed them for the better by investing in an anaerobic digestion system.

20

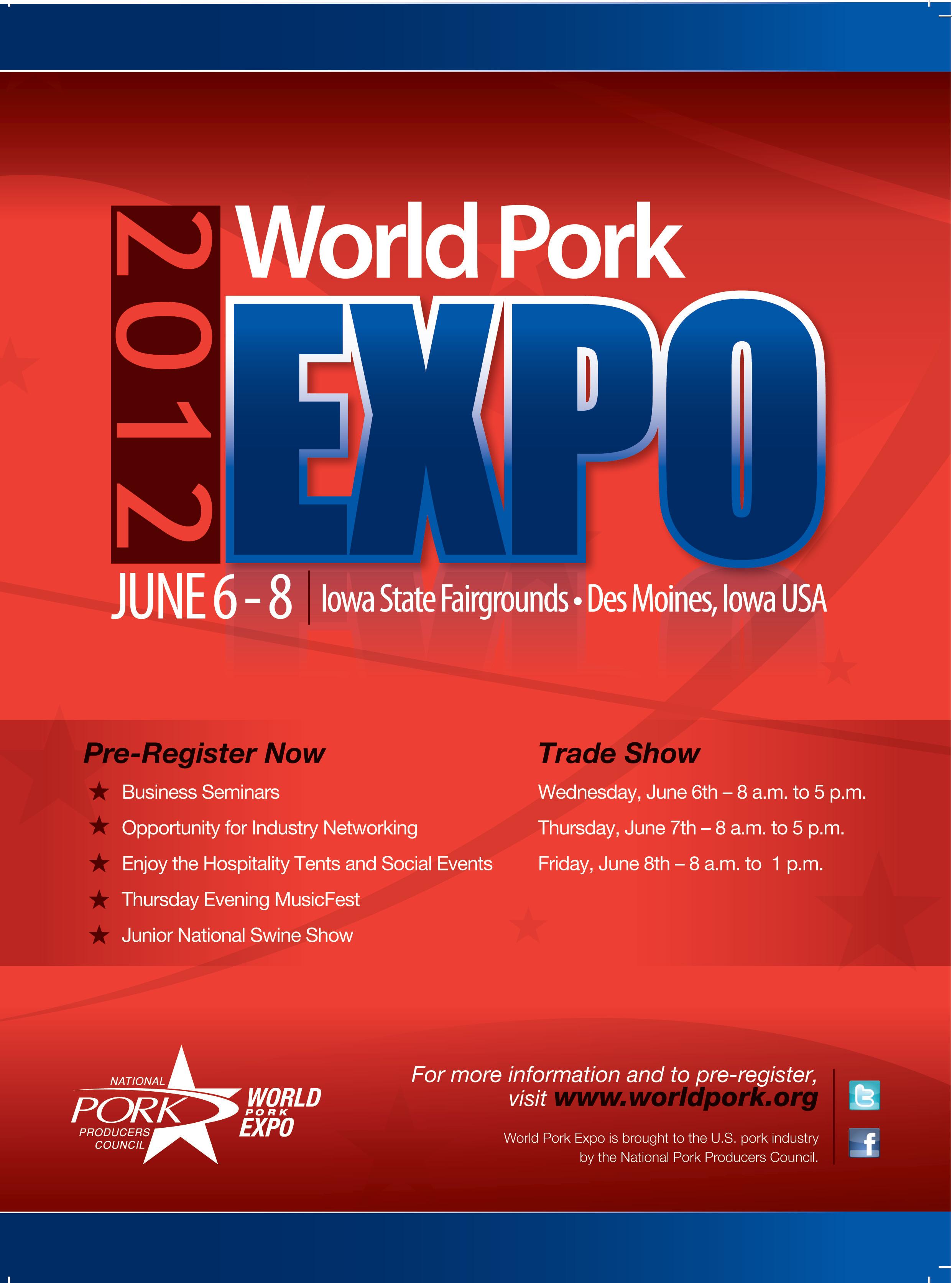

World’s largest pork-specific trade show is back, June 6 to 8

Seeing the pork industry’s newest technologies, participating in business seminars and showing outstanding breeding stock are just a few of the opportunities that draw nearly 20,000 people to the 2012 World Pork Expo.

22

B.C. Agriculture Council launches Cowpower!

More than 100 B.C. poultry and livestock producers attended the second-annual Pacific Agri-Energy Forum hoping the experts would tell them that income is just around the corner through the use of anaerobic digesters.

MI field day features farm drainage from installation to nutrient

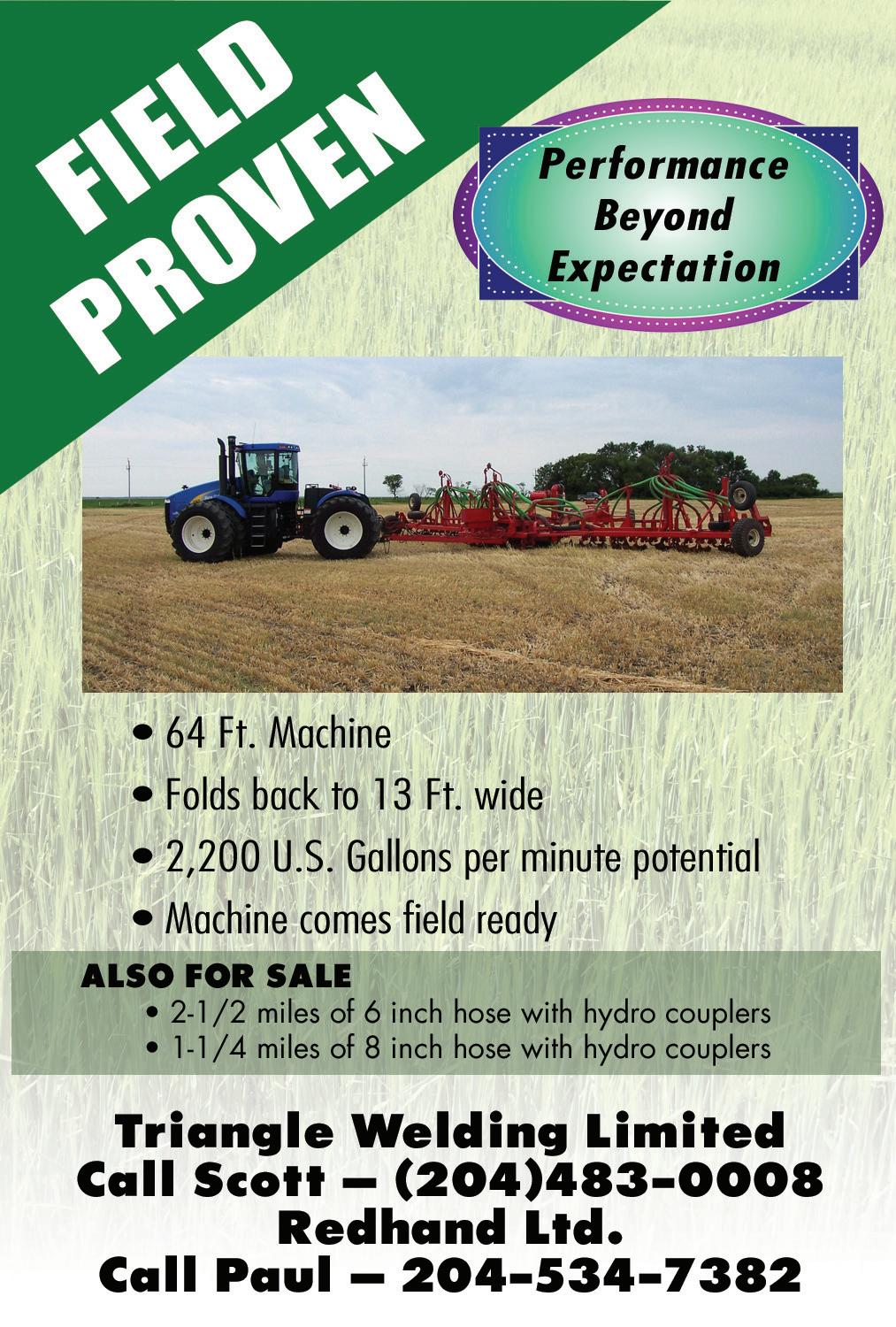

Cover: Jeff and Alan Wuebker’s Ohio farrow-to-wean hog operation was one of four farms honored as the National Pork Board's Pork Checkoff 2011 Pork Industry Environmental Stewards. Contributed photo

May/June 2012

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

mland@annexweb.com

Contributing Editors

Marcia Endres, Tony Kryzanowski, Diane Mettler, David Schmidt

Advertising Manager

skauk@annexweb.com

Sales Assistant

mburnie@annexweb.com

Media Designer Emily Sun

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com

Printed in Canada

Circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

$47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

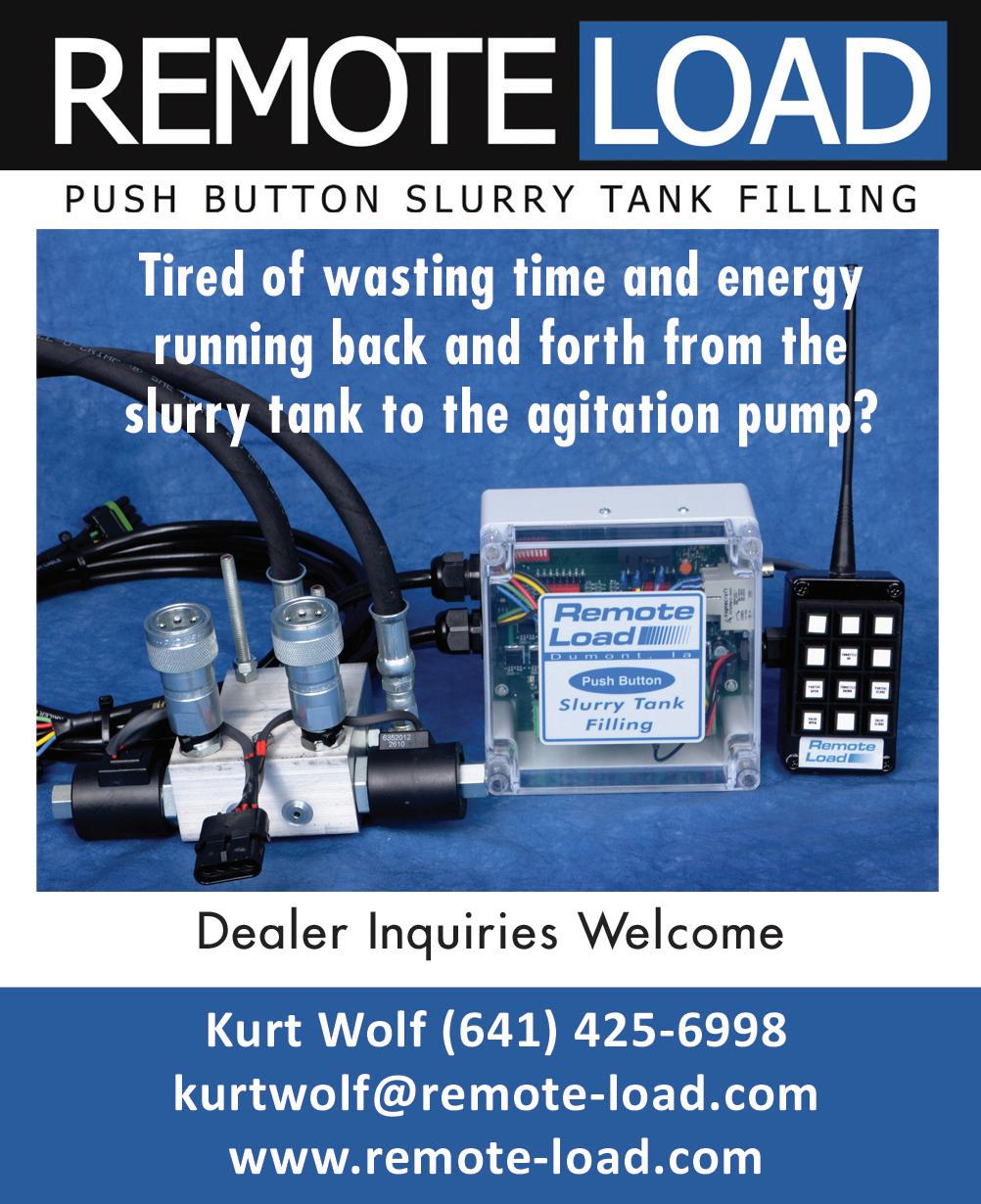

By Margaret Land

It would appear those researchers Down Under have found an economical and helpful way to deal with Down Under hog manure. According to a recent report from Australia’s Cooperative Research Centre (CRC) for Contamination Assessment and Remediation of the Environment (CARE), the centre has developed new digester technology, with the help of Chinese researchers and the technology firm HLM Asia Ltd. The technology was developed specifically to deal with the 1.4 million tonnes of manure and seven million tonnes of urine produced annually by China’s 700 million hogs.

CRC CARE’s managing director, Dr. Ravi Naidu, says the new technology can produce biogas and fertilizer using a two-step anaerobic bioreactor, located underground. Research to date has established a loading rate and retention time, and, using a set combination of treatments, the researchers have been able to recover nutrients from the waste while also producing clean biogas.

“The technology has been demonstrated in the field and is now being scaled up to treat large volumes of waste from a number of (pig) farms,” says Dr. Naidu. The main scientific and technical challenges solved by the technology include the high nitrogen and phosphorus loads in pig waste compared to sewage, the small size of current biogas reactors, the slow rate of digestion, the limiting influence of temperature and the presence of heavy metal contaminants. According to Dr. Naidu, the new technology has overcome each of these issues.

He is hopeful the knowledge gained through the research will also be of assistance to Australia’s livestock and food industries.

I’m hopeful it might provide some assistance to my heating bill.

My family and I live in what famous Canadians Bob and Doug McKenzie lovingly referred to as the Great White North. Winter here involves freezing temperatures and white stuff falling from the sky. In other words, it’s cold.

We live in a 100-year-old (probably older) farmhouse on our own little 10 acres of chaos. Unfortunately our location does not have access to natural gas lines and we’ve been heating with furnace oil and, for the past five years, a homemade wood boiler – created by my engineering-type husband – that involved the addition of a car radiator to our furnace duct work (a long story for another day). This past winter – a mild one in our neck of the woods – my husband decided his back had experienced enough caber tossing for one lifetime and we shifted back to furnace oil and a set back thermostat. I shivered through the evenings, wrapped in multiple blankets.

This spring, he announced his next great house-heating venture – an air source heat pump. My first question to him was would it be able to heat the house to a reasonable temperature. There was some answer about efficiencies to -8 C and the need for a backup heat source powered by electricity or propane. I’m still not 100 percent won over by this idea. According to Dr. Naidu, maybe what our acreage needs are some pigs and an underground anaerobic bioreactor that can supply nutrients to our hay field and pasture plus clean biogas to heat our house. We have the barn, we have the technological know-how (my husband), we have the feed source (my cash cropping neighbor), we even have the labor (our children).

It’s nice to dream about a cozy warm house. Here’s hoping the air source heat pump works (we may need more blankets) and that the new digester technology will benefit hog producers everywhere.

Now, more than ever, pork producers recognize the impact their operations can have on the world around them. Proactive eco-management with MicroSource S can help reduce environmental burdens. By feeding MicroSource S, producers benefit from: relationships out more manure the pig’s lifecycle, MicroSource S can help you better balance the challenges of efficient pork production with environmental stewardship.

To learn more, contact your feed supplier, go to www.unlimitednutrition-na.dsm.com, or call 1 800 526 0189.

By Diane Mettler

Each year the National Pork Board honors farm families that demonstrate a firm commitment to safeguarding the environment and their local communities.

Judges representing pork producers and environmental organizations choose the winners based on applications provided by the producers. Their operations are evaluated on their manure management systems, water and soil conservation practices, odor-control strategies, farm aesthetics and neighbor relations, wildlife habitat promotion, innovative ideas used to protect the environment and an essay on the meaning of environmental stewardship.

“These four families, in addition to being committed stewards of the land, are great representatives of the thousands of pork producers who work every day to protect our environment and to be good neighbors in their communities,” says Everett Forkner, president of the National Pork Board.

Let’s meet the 2011 winners:

Golden Circle Pork

Rod and Missy Bice own Golden Circle Pork, a 3,300-head wean-to-finish farm near Woodward, Ia. For nearly three decades they’ve been practicing sustainable farming.

Even though the Bices have been constantly looking for ways to improve the farm since building their three barns in 1996, they were a little surprised by the award.

“It just seems like most of the stuff we do is just common sense,” says Rod.

The farm has shallow pits under the barns that are scraped daily, and the manure is gravity fed to the 1.2-million-gallon manure tank. The manure is agitated and spread on their farmland in the spring and the fall.

Rod uses flow meters on the tanks and rate controllers in the cab.

“We also use auto steer equipment,” he says.

He injects the manure eight to 10 inches deep to eliminate run-off potential. And the auto-steer technology on his tractor allows even more precise manure application.

When injecting, Rod uses DMI injectors on the back of his manure tanks, but sometimes, depending on how dry or how wet the field is, he leaves the trench open. Therefore, “we added disk covers to throw the dirt back into the trench.

To help ensure they are not over applying, Rod says they also do a fall stock test.

“We gather up some of the stocks

that were left in the field and test to see if there’s any nitrogen left in them. The results give us a better idea if we are under or over applying.”

Of the Bices’ approximately 1,300 acres, manure is applied to about 300 acres annually. “We’re a 50/50 corn/soybean rotation, so usually around 650 to 700 acres of corn a year and probably about half of that gets manure applied to it.”

The Bices have also taken on other environmental projects, like planting rows of trees around the manure storage tank as a wind buffer, and ensuring they don’t spread anywhere near ditches or creek fronts.

“We also planted grass buffers about 100 feet out from each side of the creek and ditches,” says Rod.

It hasn’t always gone smoothly. When the Bices built their barns, people as far as 20 miles away signed a petition. But soon people saw there wasn’t a threat.

“The nearest neighbors moved in just shortly before we built and they thought it was just going to completely ruin their lives. About three years later, we got a letter from them apologizing for any inconvenience they have caused us,” says Rod.

He points out that USDA incentive programs have helped. Although one of the reasons they applied was that the eight practices that made a farmer eligible were things they were already doing.

“Everybody asks, what did you do to

win, and all I can say is that little things make a big difference,” says Missy. “It’s just what you do when that’s your livelihood. You want to protect the environment where you work and raise your family.”

Joel and Sarah Knoebel are the new generation of farmer. At only 28 and 27, respectively, and having only been farming for four years, they’ve already had a big impact in their community of Elysburg, Pa.

At the time of the award the couple had 4,400 head. Since then they have purchased another farm and feed mill and have acquired 6,600 head and doubled their acreage.

Joel feels the reason their farm stands out is his and his wife’s strong community relations and involvement.

“I’m a 4H leader for the countywide livestock club and oversee the 4H market program. We also host our local high school’s junior/senior ecology class,” says Joel. “The class comes out to our farm every year and we explain what we do and how it fits into our farming program.”

The couple has also created their own scholarship, which is offered to any student with an interest in a postsecondary education in an ag-related field. It’s a simple process.

“They submit their applications and my wife and I go over them and then we choose,” says Joel.

The Knoebels presently have two large barns — a large 4,400-head barn with four rooms, and a two-room 2,200head barn. Each barn has a six-foot-deep pit, which they pump in the spring and fall to a tanker and apply onto their fields.

“We topographically apply everything,” says Joel. “And sometimes, we will incorporate with the disk.”

Manure is spread as far as 3.5 miles.

“We have a tank we haul behind our tractor and I also utilize custom haulers, which have trucks with low-compaction tires,” says Joel.

Knoebel’s crops are a rotation of corn and soybean crops, and Joel says they also utilize cover crops as much as possible.

Even in the rural farming area of Elysburg, some neighbors have complained about odors. Joel says their best line of defense is communication.

“We try to keep good neighbor relations to alleviate the two or three days a year when it smells to some people,” says Joel.

For example, when individuals near their new farm got a little upset last spring, Joel wasted no time stepping up.

“We try to talk to them directly. Answer their questions on why we do

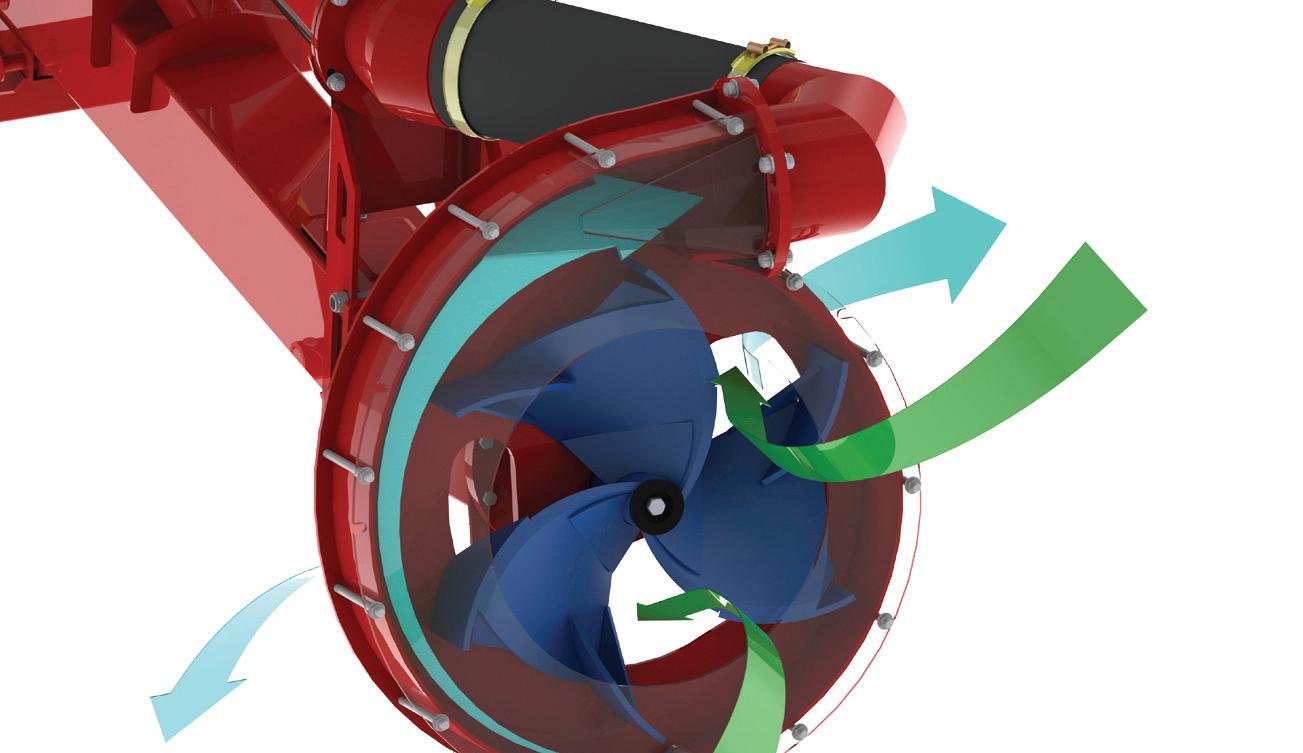

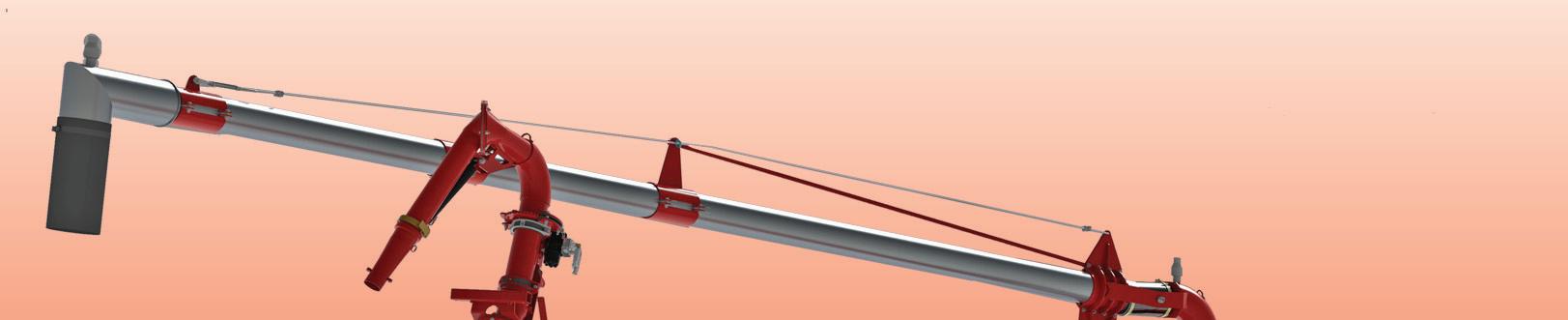

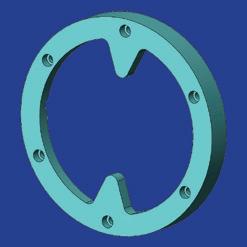

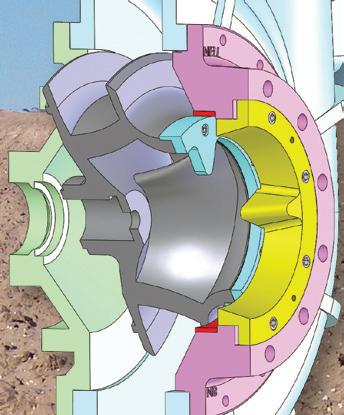

The PUMPELLER Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

what we do. That doesn’t seem to appease everyone, but it helps alleviate about 80 percent of the concern.”

Joel, who runs the farm with his brother, dad and father-inlaw, says they take pride in how they do business with people. They also like that they’ve had an impact on the farmersto-be. “We give back thousands of dollars each year through 4H and through the scholarships,” says Joel. “We’re proud that we give back when we can and keep trying to give back to the area that raised us.”

As for the future, it looks bright for the young couple.

“We’re going to continue to diversify and do what’s sustainable for our family and our business plan.”

At the 205-acre Langdon Farm, located in North Carolina, you’ll find crops, a 5,000-head feeder-to finish-operation and a cattle operation.

This Pork Industry Environmental Steward award isn’t the first time John and Eileen Langdon have been recognized. They were honored by the Cattlemen’s Association several years ago and were a Conservation Farm Family two years ago.

“We’ve put in a lot of best management practices,” says John. “We try to conserve fresh water and we also try to recycle the nutrients from the hog farm through an anaerobic lagoon, which treats those nutrients. We irrigate the effluent from the lagoon onto our fields and crops, which grow hay and pasture grass and grain.”

The Langdons also installed automatic, frost-free waterers in the fields so the cattle don’t drink from the creek, fenced the creeks, and maintain grass or trees as a filter strip along the banks.

“We will do a little bit each year, as we can afford to do so,” John says.

As for the hog houses, John has four anaerobic lagoons, built between 1977 and 1996. Waste is flushed into the lagoons and the anaerobic process digests most of the nutrients in the lagoon before the Langdons pump the top 18 inches onto their crops.

“The anaerobic bacteria digests the majority of the manure,” explains John. “The lagoons reduce the nutrient load and thereby reduce our land requirements to utilize that material.”

When it’s time to pump, the Landgons use a six-cylinder diesel Cummins engine with a Cornell pump.

“We have six-inch underground PVC trunk lines that run out along our fields with hydrants at 360-foot spacings. We hook three-inch hard hose traveling reels to those hydrants and use a one-inch taper bore nozzle to apply the effluent,” says John. “We

Left: John and Eileen Langdon operate Langdon Farm, a 205-acre farming operation located in North Carolina with a 5,000-head feeder-to-finish operation, cash crops and a cattle operation. Contributed photos

Below: The Langdons have put in a lot of best management practices, including different ways of conserving fresh water on the farm.

also have some solid set irrigation, which is on 80-foot spacings and has small sprinklers where the fields are odd shaped or the topography is such you don’t need high volumes.”

This efficient system allows them to utilize almost all their fields.

With cities crawling ever outward, odor has become a concern. The Langdons try to maintain a good relationship with their neighbors. And, ironically, in some cases the neighbors are hopeful a pig farm will keep more people from building nearby.

“For the most part I think we live in harmony relatively well,” says John.

He says he’s proud that he’s continued on the family farm. His father and grandfather raised crops and they’ve added livestock.

“I’m also proud that my wife, a veterinarian, has encouraged us to step it up a notch,” says John. “It helps us strive for excellence so far as the animal health and welfare goes. Not that we wouldn’t without her, but it’s a benefit.

“Our children are watching us and we feel a moral obligation to do the right things, not just talk about it, but actually practice it,” adds John. “And hopefully they will look at what we do and will pass it on to the next generation and help sustain agriculture in our country.”

Farms LLC

In 1999, when Jeff and Alan Wuebker’s father passed away suddenly from a heart attack, the two brothers instantly became partners in the family’s hog operation. It was a lot to handle at the time, but today Jeff says they feel blessed to have such a tightly knit family.

Today, the brothers have 1,800 sows in a farrow-to-wean operation and produce pigs on contract for another Ohio family. The Wuebkers also raise some feeder steers and farm approximately 1,200 acres of corn, soybean, wheat and a little alfalfa, grown primarily to export manure off the farm.

Each year the farm applies close to four million gallons of manure. Jeff says the slurry isn’t terribly strong because the water used for washing dilutes it and the sows in gestation are on a maintenance (versus growing) diet.

“We’ve used the same custom applicator for 20 years and he understands that because we’re a breeder operation, biosecurity is very important to us.”

Over the decades, the Wuebkers have been making improvements to the farm. The most recent addition to the farm was an enclosed wash bay with wastewater storage built in 2009.

“It’s located away from the hogs and allows for more thorough cleaning and drying of transport trailers, especially during the winter months,” explains Jeff. “We feel this will reduce the chance of disease transmission compared to washing them outside on a concrete apron and not being able to thoroughly dry them.”

One of their most unique barns was built in 2006 — an 80-foot by 309-foot barn with a full eight-foot-deep pit underneath. What makes this barn unique is the trough running the two short lengths of the barn. It’s four feet wide and two feet deep, and was built at the request of the custom applicator.

“Many barns have a small area where manure pools when pumping out, but our applicator wanted something bigger because we’re pumping 1,100 to 1,300 gallons a minute through our drag line system, because our manure isn’t very thick,” says Jeff. “With the trough, when we’re pumping down to that last eight inches, the manure is just rushing all the way across the floor and into the trough — causing a flushing effect like a dairy barn.”

The trough was a little more expensive because it required a couple more concrete pours, but it’s been worth it.

“Every time we pump it we’re right down to three to four inches of sludge at the bottom.

The Wuebker family has always been up for trying what’s new. Jeff and Alan’s dad was very involved early on with the local water district when they built their twomillion-gallon holding pond. And today, the brothers are experimenting with cover crops.

To date their efforts have been met with some obstacles, including a radish crop that produced radishes the size of a two-liter pop bottle. This year, however, they are expecting their hard earned knowledge to pay off.

When asked what he thinks makes their farm stand out, Jeff says, “Everyone on the farm is focused on doing a good job. We don’t cut corners.”

Wisconsin’s Dane County is moving forward with plans for a second cow power facility, selecting a site for the project, and entering into a new partnership for the project with healthcare provider Gundersen Health System, Dane County executive Joe Parisi announced recently.

Construction of the manure digester is anticipated to begin in late 2012.

Dane County and Gundersen Health System plan to join with three farm families in the town of Springfield, just outside of the city of Middleton – the Ziegler Dairy Farm, Blue Star Dairy (owned by the Meinholz family) and the Hensen Brothers Farm. US BioGas will also join the partnership as project developer.

More than a year ago, Dane County was the first county in Wisconsin to construct a cow-powered community manure digester, located near Waunakee.

Madison Gas and Electric will purchase 11 million kilowatthours of electricity annually from the Springfield facility, enough to power approximately 1,600 homes. The electricity will be added to the local electric grid to help serve all customers.

The county’s digester facilities will help farmers with the storage and management of manure. Dane County has 400 dairy farms, which equates to approximately 50,000 dairy cows.

“Converting manure into electricity not only provides a 24/7 source of renewable energy, but also helps keep algae-causing

phosphorus out of our lakes,” said Greg Ziegler, a Springfield dairy farmer participating in the project.

Agreements for the community manure digester project will move forward pending approval by the Dane County board. In addition to county board approval, the project will also need approval from the Town of Springfield and air and water permits from the state Department of Natural Resources.

By Tony Kryzanowski

When Dennis Brubaker and his business partner, Gerald Stauffer, established Ideal Family Farms LLC, one of Pennsylvania’s largest hog producers, in 2007, they soon discovered that their manure management costs were a major drag on their bottom line and that their energy costs were making it difficult to bring home the bacon.

However, both of those scenarios have changed for the better since they invested in an anaerobic digestion system to process the seven million gallons of liquid hog manure the farm generates annually. Also, about 90 percent of the manure odor has disappeared.

Ideal Family Farms is located in Snyder County, about 50 miles north of Harrisburg, Pa., an area dominated by hog and dairy producers. It raises approximately 30,000 nursery and finishing hogs annually under contract for Country View Family Farms. The farm consists of three 3,300-head finishing barns and one 4,400head nursery that were originally built in the mid-1990s.

In 2007, power and heating costs made up about a quarter of the farm’s

Main: The 700,000-gallon anaerobic digester, situated between two hog barns, looks like just another part of the overall hog farm operation at Ideal Family Farms. Contributed photos

Above: The 180-kilovolt power generator on the Ideal Family Farms hog operation burns biogas and supplies four times more power than the farm needs. The surplus is sold to a Pennsylvania state utility.

expenses, with the challenges being both energy cost and price volatility. Furthermore, electricity costs were projected to increase by 30 percent in that part of Pennsylvania. So Ideal Family Farms began investigating various alternative energy options including solar, wind and biogas. They eventually invested in an anaerobic digester to process their

hog manure, which generates biogas to produce power for their entire farm as well as heat for their nursery barn. They chose this option because it was the best fit for the farm operation and gave them direct control over both those expenses. It also produced an income to help balance the cost of paying to custom apply their liquid hog manure. The farm sits

on only 55 acres and depends on other local farms to dispose of its liquid byproduct, which is now more easily absorbed because the raw manure undergoes a nutrient transformation in the anaerobic digester. While disposing of the manure is not a problem, which is in demand among local farmers, it will still cost Ideal Family Farms $40,000 to $50,000 annually to contract the work.

“For us, the manure was nothing but a liability because we were paying to haul it away,” says Brubaker. “We started looking at how we could turn this liability into an asset and the first phase of that decision was to extract any benefit while it was on the farm.”

A feasibility study commissioned by Ideal Family Farms in the spring of 2008 determined that an anaerobic digestion system for the hog operation was highly feasible because the hog operation was of sufficient size to support a profitable system.

The digester began to produce biogas in July 2011 and since that time, has produced more than 500,000 kilowatts of power for use on the farm and for sale under contract to Pennsylvania Power and Light Company (PPLC).

“It has probably exceeded our expectations to this point,” says Brubaker of the anaerobic digestion system. “I’m very happy with the performance.”

Prior to the digester becoming operational, Ideal Family Farms was spending about $35,000 annually for power and about $27,000 for propane. Now, the farm has no power bill, and because the 180-kilowatt (kW) power generator produces about four times more power than the farm needs, that extra power is being sold to PPLC and distributed on the state power grid.

While the primary goal initially was to use the biogas generated through anaerobic digestion of the hog manure for power generation, as the project came together, Ideal Family Farms soon discovered that the anaerobic digestion system offered other savings and potential income streams. For example, heat recovered from the engine that burns the biogas through its liquid cooling system is used to boil water that provides heat to the farm’s nursery barn. Because of that project, Brubaker says that they expect to cut their propane bill in half. The nursery barn is a major consumer of energy, as it needs to be heated almost year round.

He estimates that the digester could pay for itself in five years. That is based on all the grant money that has helped to build the project, savings in farm power costs, the income from power sales, reduced propane consumption as well

as a few unconventional income sources. This includes income from tipping fees charged for accepting and processing food waste produced elsewhere in the digester as well as the sale of carbon and renewable energy credits.

So far, the farm has one food waste client and continues to work hard to expand its client base.

Before the digester was installed, the hog farm generated about 3,400 metric tonnes of greenhouse gases annually. Processing hog manure through the digester has reduced those emissions considerably, and by metering the biogas

produced, the farm is able to sell the carbon credits it is now generating through the California Air Resources Board. This is generating between $12,000 and $15,000 annually for the farm under a four-year sales contract, as well as $7,000 annually in renewable energy credits sold to a utilities commission in North Carolina. The farm’s digester system provider and installer, RCM International, headquartered in Berkeley, Calif., helped Ideal Family Farms learn how to participate in these carbon credit and renewable energy trading markets.

“It actually requires quite a lot of

Workers prepare the concrete floor for the nine-foot-deep, 700,000-gallon anaerobic digester tank at Ideal Family Farms in Pennsylvania. Contributed photos

Berkeley, Calif.-based, RCM International, provided the anaerobic digester technology and acted as the project general contractor on the Ideal Family Farms project.

of that heated water is piped to the nursery barn. It consists of seven rooms and seven circulator pumps that channel the heated water through heat exchangers that hang in each room.

The size of the farm operation is a major contributor to the economic viability of an anaerobic digester system, Brubaker says, and because most other hog operations in that area are about one-quarter the size of Ideal Family Farms, it is unlikely that a similar system would make sense for operations of that size. He hopes that will change.

“I would like to see more of it being done just simply from the benefits that our farm has seen from it,” says Brubaker, “and for continuing to do what it takes to advance the technology to where the application can be feasible for smaller farms.”

By Marcia Endres

Stall bedding materials for cows are becoming increasingly expensive and difficult to find, prompting some dairy producers to search for alternatives, such as sand and recycled manure solids.

Although sand can be considered the ideal bedding source for dairy cows, not all producers are willing and able to convert to sand bedding because it presents some manure-management challenges. So, what about recycled manure solids? Is anyone making it work in the Midwest?

Adam Husfeldt, a University of Minnesota graduate student, and Marcia Endres, with University of Minnesota Extension, conducted an observational study on 38 dairy farms using solids for bedding freestalls in Wisconsin, Minnesota, South Dakota and Iowa. They wanted to find out what management practices and bedding characteristics were associated with bulk tank somatic cell count (SCC) and evaluate animal welfare in these operations.

The pair documented various aspects of herd management, including how solids were obtained and managed, their bedding practices, etc. Bedding, milk and feed samples were collected. Cows were scored for hygiene, hock lesions and locomotion, and milking prep procedures were recorded.

Their goal was to collect as much information as possible during the farm visits and from records throughout the year. In the end, 23 variables were used for analysis of their association with bulk tank SCC.

Endres and Husfeldt concluded that excellent cow preparation at milking time, sanitation of milking equipment, cow hygiene, adequate dry cow housing and bedding/stall management appear to be critical in maintaining a low SCC while successfully using manure solids for bedding. The type of manure solids used – digested, raw or composted –had no association with SCC.

Moisture is one of several factors necessary for bacterial growth in bedding materials. Therefore, it is important to keep stall bedding as dry as possible to minimize exposure to environmental mastitis pathogens. Additional methods to help dry stall bedding (use of a blower, good barn ventilation, adding equipment to remove moisture after separation) could help reduce bedding moisture.

They also learned that lameness prevalence was similar, hock lesion prevalence was slightly higher and cow hygiene was better than in herds using sand for bedding.

More of the teams results and observations are available on the University of Minnesota Extension dairy website at www.extension.umn.edu/go/1092.

For more educational information and resources for dairy producers, visit www.extension.umn.edu/dairy.

Marcia Endres is an animal scientist with University of Minnesota Extension.

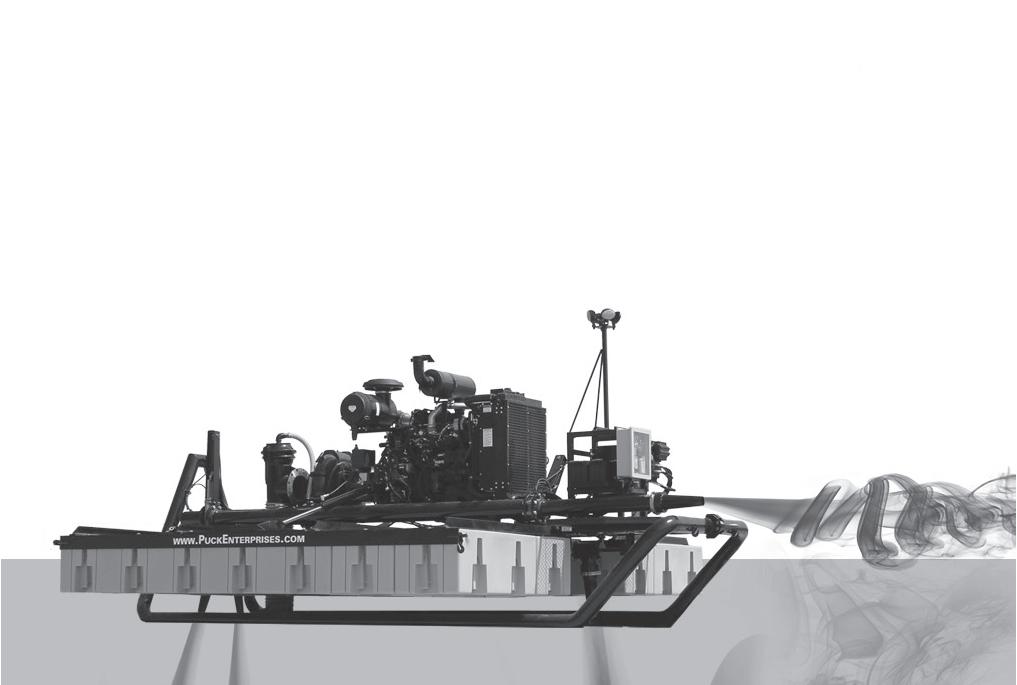

Right: This three-day National Pork Producers Council (NPPC) event also features PORK Academy and business seminars where producers can learn the latest about important issues affecting the pork industry.

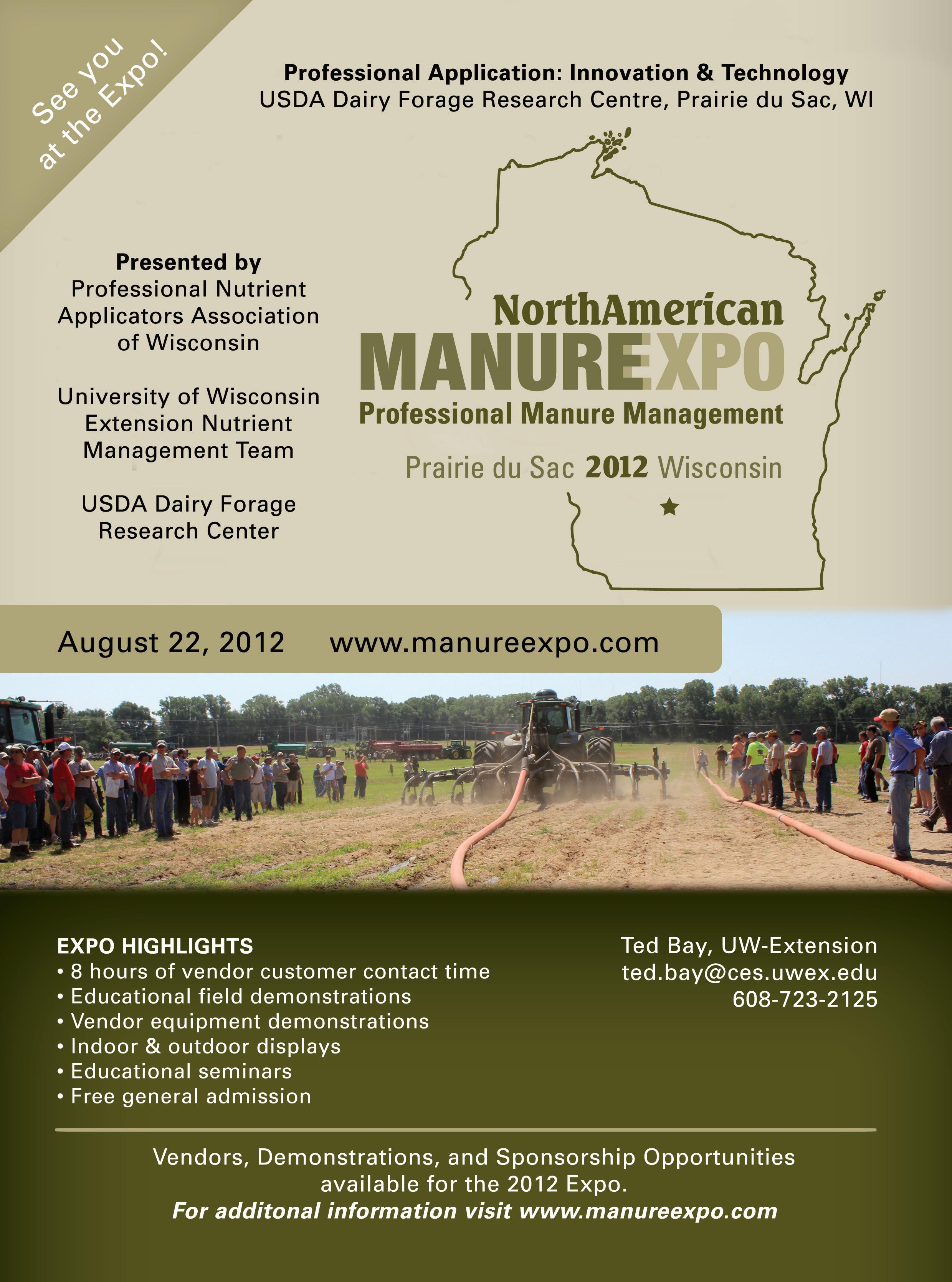

Seeing the pork industry’s newest technologies, participating in business seminars and showing outstanding breeding stock are just a few of the opportunities that draw nearly 20,000 people to the 2012 World Pork Expo.

Producers, agribusiness representatives and porkindustry enthusiasts are making plans to come to the Iowa State Fairgrounds in Des Moines, June 6 to 8, to participate in Expo — the world’s largest pork-specific trade show. This three-day National Pork Producers Council (NPPC) event also features business seminars and PORK Academy, the Junior National swine show, breeding stock shows and sales, live entertainment, and delicious food.

“From the debut of new equipment that improves pig welfare and performance, to well-known entertainers performing at MusicFest, everything is world class at World Pork Expo,” says R.C. Hunt, NPPC president from Wilson, N.C. “Before and after continuing your education at business seminars, you’ll see the very latest technology on display. Add in great food and hospitality, and you’ll have a first-rate experience along with outstanding ideas to take back home.”

More than 450 commercial exhibitors will display the industry’s best at the Expo’s trade show. It will be open 8 a.m. to 5 p.m. on Wednesday and Thursday, as well as 8 a.m. to 1 p.m. on Friday. Don’t miss this opportunity to learn about new products and services that can improve profitability while helping produce quality pork. When in the Varied Industries Building, cast your ballot for your favorite new technology in World Pork Expo’s New Product Tour.

On Wednesday and Thursday, the Varied Industries Building will be home to a variety of educational presentations from leading experts.

Expo-goers can choose from business seminars focusing on new technologies and management techniques, PORK Academy

presentations about feed ingredient availability, doing what’s right versus looking for the camera, export issues and managing PRRS.

Top genetics on display

In the Fairgrounds’ Swine Barn, attendees will see one of the top youth shows — the World Pork Expo Junior National. Exhibitors from across the country will show crossbred barrows on Wednesday and purebred gilts on Thursday.

On Friday, Expo-goers can view open-show exhibitions including both purebred and crossbred classes. The breeding stock sales are on Saturday, from 8 a.m. until they’re completed at approximately noon.

Grammy-caliber entertainment at MusicFest

Once again, MusicFest will be the Expo’s social highlight. From 4:30 p.m. to 8 p.m. on Thursday, attendees can enjoy free roasted pork and refreshments while watching live performances.

Grammy Award winner David Ball, a country music singer and songwriter, will open MusicFest. His chart-topping hits include “Riding With Private Malone,” which made him one of the first artists to take an indie single to the Country Top 5, and“Thinkin’ Problem.”

Called America’s No. 1 Tribute Band, The Blooze Brothers will bring its signature high-powered, choreographed, 12-pieceband show to the MusicFest stage. They have mastered the music and crazy antics that John Belushi and Dan Aykroyd made famous on Saturday Night Live.

Even before Expo begins, attendees can experience Midwest agriculture at its finest on three pre-Expo tours, June 4 and 5.

The two-day tour will take participants to see the locks-and-dam system that enables agricultural products to traverse the Mississippi River, and the John Deere Pavilion museum. They also will visit Cinnamon Ridge Farms, which features 4,000 acres of corn and soybeans, wean-to-finish swine facilities and a beef operation.

For those with limited schedules, two one-day tours are available. The Monday Iowa Agriculture Tour will feature a Christensen Farms feed mill, and the newly remodeled Iowa State University College of Veterinary Medicine. The Tuesday-only Iowa Agribusiness tour features stops at Swine Genetics International’s boar-reproduction facility and Pioneer Hi-Bred.

This year World Pork Expo is debuting an app to help attendees make the most of their Expo visit by downloading up-todate schedules, finding exhibitor booths, locating special events and more. The WPX2012 app will be available from Apple and Android stores in late May.

“The best advice I can share regarding World Pork Expo is to carve out more than just one day to take it in,” says Hunt. “There’s so much to see – your family and employees will thoroughly enjoy every minute as they mingle with top pork producers

from throughout the world.”

Those who pre-register at www. worldpork.org by Saturday, June 2, will receive $10 off the regular admission price of $15 that provides entry on all three days. More information is available at www.worldpork.org.

World Pork Expo, the world’s largest pork-specific trade show, is brought to you by NPPC. On behalf of its members, NPPC develops and defends export markets, fights for reasonable legislation and regulation, and informs and educates legislators. For more information, visit www.nppc.org.

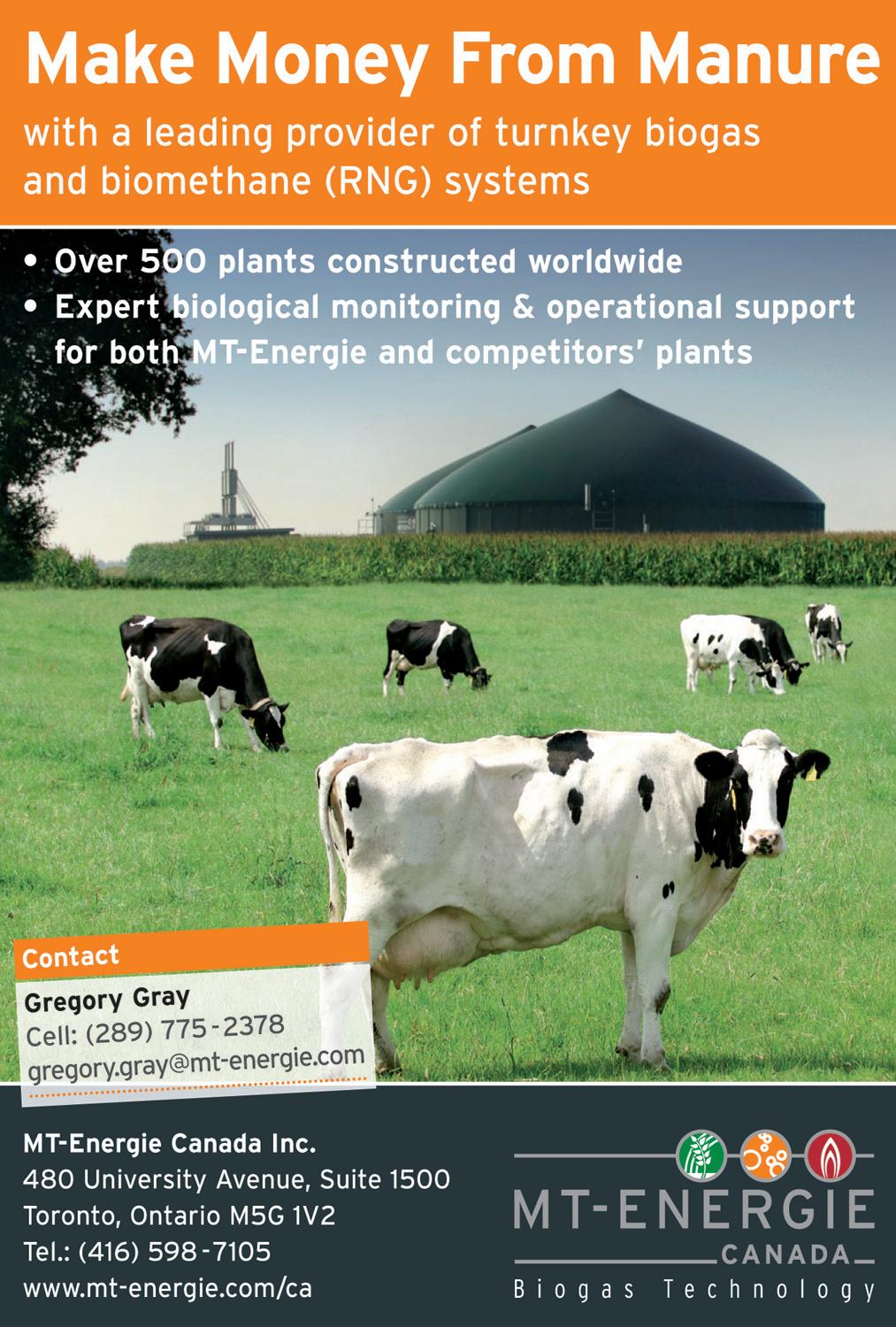

By David Schmidt

Half of what a poultry farmer produces is waste. The percentage is perhaps a little smaller but just as significant for livestock producers.

“It would be great if that waste became a second income stream,” says B.C. Agriculture Council (BCAC) chair Garnet Etsell, an Abbotsford, B.C., turkey grower.

Over 100 B.C. poultry and livestock producers attended the second-annual Pacific Agri-Energy Forum at the end of January, hoping the experts would tell them that income is just around the corner through the use of anaerobic digesters.

The potential exists but it is still far from being a reality for most farmers. Etsell notes that there need to be regulatory changes, a service infrastructure and increased returns to make anaerobic digesters viable in B.C.

“We’re still struggling with economics since we live in an area with the cheapest energy costs in North America,” he says.

The BCAC has taken the first step in that direction by using the forum to launch Cowpower!

The Cowpower! program is intended to help B.C. farmers build economically viable anaerobic digesters, says BCAC renewable agri-energy initiative co-ordinator Matt Dickson.

At present, there are two digesters in the province, both in the Abbotsford area where B.C.’s poultry and dairy industry is centered: Catalyst Power is a large plant producing biomethane and Bakerview Eco-Dairy is a small demonstration project generating electricity.

The province’s natural gas utility, Fortis BC, has demonstrated its interest in anaerobic digesters by providing

financial and logistical support for Catalyst. It paid for an upgrader to scrub Catalyst’s biomethane so it can be injected directly into the natural gas line that runs right by the property.

“The idea is to extend the concept of what we do,” says Fortis BC business development manager Scott Gramm.

To pay for the additional cost of the Catalyst biogas, and similar projects in future, Fortis BC has started a program where consumers can choose to “stop waste from going to waste” by agreeing to pay extra for renewable natural gas.

“For about five dollars more per month for the average home, you can designate 10 percent of the gas you use as renewable natural gas,” the Fortis website states.

The program is currently available only to residential gas customers but Fortis will soon offer a program for commercial users, which will also make them eligible for a 10 percent credit on B.C.’s carbon tax.

“We’re happy with where the [residential] program is at,” Gramm says, noting it is already about one-third subscribed.

While experts believe using anaerobic digesters to produce biogas is viable, the cost of the upgrader and availability of a nearby natural gas line severely limits the number of farms able to take advantage of biogas. Most B.C. dairy and poultry farms are therefore restricted to using their digesters to generate electricity. There are two programs they can use to supply electricity to B.C. Hydro. The first is the Net Metering Program, aimed at small projects generating 50 kW or less.

“The Net Metering Program is intended for producers who are generating power to offset their own needs,” explains

Laura Creech, BCH energy planning and economic development manager. “You generate power to offset your needs and we buy any excess. At the end of the year, the power you provide and the power you draw are reconciled and we pay you for the difference.”

Unfortunately, the program’s rate is only 8.16 cents/kWh, although it is expected to increase to 9.99 cents/kWh.

That would bring it closer to the BCH Standing Offer Program rate. Designed for 50 kW to 15 MW generators, the SOP offers 20- to 40-year contracts at rates ranging from 9.486 cents/kWh in the Peace region to 10.369 cents/ kWh in the Fraser Valley. However, the program also requires special permits and interconnection costs not charged under Net Metering.

Even B.C. Hydro admits that is not enough to make anaerobic digesters viable.

“Projects producing under a megawatt of electricity [which would be the case with most on-farm digesters] tend to struggle,” Creech says.

That’s where Cowpower! enters the picture, a program similar to the Fortis BC program but designed for electricity rather than biogas production.

Under the program, consumers voluntarily sign up to pay an additional 4 cents/kWh for 25, 50 or 100 percent of the electricity they consume. Residential consumers may sign up for as short a period as a month although commercial customers must sign a three-year contract.

The additional fee is for the anaerobic digesters’ “environmental attributes,” such as the additional benefits that result from the production of that electricity. These include reduced greenhouse gas emissions and odor from waste systems, increased water and food safety, environmental protection, nutrient recovery, and support of local farms.

Producers who put in an anaerobic digester will receive the additional Cowpower! funding for five years, meaning they will receive a total of 13 to 13.5 cents/ kWh for their electricity. Ethan Warner of CH4 Biogas believes this should make some projects move forward. He says farmers need a ready supply of on-farm manure and at least 25 percent nonmanure waste to make a digester viable.

If the electricity generated through anaerobic digesters does not meet the demand for the Cowpower! program, excess funds will be used to provide additional incentives.

“With Cowpower!, we’re providing electricity users with an affordable and effective way to directly support local, sustainable agriculture while also improving their own environmental sustainability. It’s truly a win-win situation,” says Matt Dickson.

His goal is to find “0.5 percent of B.C. Hydro customers” who would support at least 500 AD projects.

Warner doesn’t believe that number is likely unless the rate increases even more. He believes the rate needs to go to 16 to 19 cents/kWh before there will be wholesale adoption of anaerobic digesters.

John de Jonge, a partner in Avatar Canada, the company that built the Bakerview anaerobic digester, says the aim of the demonstration digester is to “show farmers the technology first-hand,” and determine the value of other benefits of an on-farm anaerobic digester.

The Bakerview anaerobic digester, which uses the manure from 50 cows plus 11 percent milk fat, generates about 20 kWH. While this is not commercially viable, deJonge notes the Avatar system is scalable and may not need a much larger farm than Bakerview to be viable.

“We are trying to determine how many different things we can produce with the system,” he says.

In addition to heat energy and electricity, the anaerobic digester’s solid residue is used to produce bedding for the cows while excess nutrients are recovered from the liquid effluent by a trickle filter.

“If we can show the additional benefits the anaerobic digester provides, it will make the system more attractive to farmers,” de Jonge states.

Even before it was officially launched, Dickson says the Cowpower! program has started to gain traction. The Pacific Agriculture Show was “Cowpowered” and he expects other local green-conscious businesses to follow suit.

Eric Powell of Washington State University, who is involved in a digester project at Vanderhaak Dairy in Whatcom County, across the border from Abbotsford, notes there are now seven anaerobic digesters in Washington state, all producing electricity.

He agrees that digesters need to do more than just produce electricity for farmers to adopt them. Like the Bakerview digester, the patented Vanderhaak system includes a fiber separator to produce bedding and a treatment system to remove phosphorus from the effluent, which then becomes liquid fertilizer.

During the 2012 world meeting of GEA Farm Technologies held February in Buenos Aires, Argentina, the subsidiary GEA Farm Technologies Inc. Canada/Division GEA Houle was awarded the prize for the best performing subsidiary in 2011.

This award is presented annually to the subsidiary that has distinguished itself the most in terms of profitability, productivity and improvements at the production and management levels of the company.

“A mention such as this is very rewarding and I am very proud,” said Alain Courtemanche, president and CEO of GEA Farm Technologies Canada Inc. “This success is entirely due to the excellent work of all employees of the Division GEA Houle. Our team went through the torments of the recession and pressure from many implementations. Being honored by our peers is an appreciation that encourages us for the years to come.”

Despite the persistent shadow of recession in some countries during 2011, GEA Houle recorded nearly a 25 percent increase in production and maintained it into 2012.

New equipment was installed in the plant to increase productivity. Employees are currently receiving training as a robotics team who will become, in the short and long term, a resource to help anticipate future needs and adapt production for the company. The implementation of environmental systems for ISO 14001 certification is also ongoing with systems applicable to all areas of the company and internal management

Accepting the award on behalf of GEA Houle is (from left to right): Vern Foster, COO GEA Farm Technologies; Randy Gorter, International Support Specialist GEA FT Canada Inc./Division GEA Houle; Alain Courtemanche, CEO GEA FT Canada Inc.; Cyrille Morvan, VP Operation Management GEA FT Canada Inc./Division GEA Houle, and Dr. Ulrich Hullmann, CEO GEA Farm Technologies. Contributed photo

processes are being revised to improve customer service.

GEA Farm Technologies Inc. Canada/Division GEA Houle, formerly known as J. Houle & Fils Inc., is a manufacturer of farm equipment dedicated to manure management. It is located in Drummondville, Que., and employs nearly 350 employees. It develops and manufactures all of its equipment, which is distributed around the world and largely in North America..

The Ontario Sustainable Energy Association (OSEA) is hosting a renewable energy tour to Germany June 30 to July 8, 2012.

The tour will feature stops at various energy generation sites, including a biogas facility in Village Malstedt. There will also be opportunities to site-see at various locations across the country.

For more details about the tour, contact Nicole at nicole@ ontario-sea.org or call 416-977-4441, ext. 3.

Space on the tour is limited and people are asked to register soon.

The Agrienergy Producers’ Association of Ontario (APAO) recently changed its name to the Biogas Association. The Biogas Association is a member organization that represents the collective voice of Ontario’s growing biogas industry. It works to promote the development of biogas to its full potential as a clean, green energy source in Ontario by developing biogas opportunities on farms and municipalities, helping shape biogas policy, creating networks, and offering guidance and assistance to members. The Biogas Association is also a member of the American Biogas Council.

GSE Lining Technology, LLC, a manufacturer and provider of geosynthetic lining products and services, recently announced the launch of its rebranded identity as GSE Environmental. This rebrand reflects the company’s transition from a multi-regional company to a global organization.

The rebranding process began in June 2011 as GSE engaged BrandExtract to collaborate with employees, clients and partners in the brand research and development process. The feedback gained throughout the initiative surfaced six key brand attributes that reflect GSE’s new global brand: sustainability, leadership, consistency, collaboration, flexibility and innovation.

GSE’s new brand identity, including the name change, logo and tagline – Durability runs deep – were direct results of the research and rebranding process. Additionally, the corporate website has been completely redesigned to better represent GSE’s extensive worldwide capabilities, products and expertise.

Originally founded in 1972, GSE has evolved to a global provider of geosynthetic lining products and services.

www.gseworld.com

A new water discharge permit for Concentrated Animal Feeding Operations (CAFOs) was recently unveiled in Idaho.

The new Environmental Protection Agency (EPA) General Permit regulates discharges to surface waters from most Idaho CAFOs, including those on tribal lands. The permit covers a wide array of Idaho livestock operations, including beef cattle, dairy cows, horses, sheep, pigs and poultry.

According to Mike Bussell, director of EPA’s office of water and watersheds in Seattle, the agency is reaching out to help CAFO owners or operators understand why they need to apply for the permit.

“This permit will give producers the certainty they’ve been seeking,” said Bussell, “Our message is clear: If you operate a CAFO and there’s runoff from pens, feed and manure storage areas, or areas where manure is spread, you need a permit.”

Operations covered by the new general permit include: any animal feeding operation that either meets the EPA definition of a CAFO, or designated a CAFO by EPA; and any CAFO that discharges to surface water from where animals are confined or manure and wastewater is spread.

In addition to the standard permit application, CAFO owners and operators must submit a nutrient management plan for EPA’s initial review. The EPA reviews these documents and will make them available for public comment before granting permit coverage.

CAFOs that have had permits in the past and wish to have continued coverage under the new permit, or CAFOs that discharge, will have 90 days after May 9, 2012 to apply for their permit, submit their plan for review and obtain coverage under the new permit.

For more information visit www. epa.gov/region10/water/npdes/ generalpermits.html.

For the latest news and information affecting manure handling and management, visit www.manuremanager.com.

The new 259B3 is a new addition to the Cat Compact Track Loader (CTL) range. By combining a small-frame CTL platform with the Cat C3.4T DIT engine, Caterpillar designed the 259B3 as a machine capable of taking on jobs in confined spaces. With features such as an independent, fully suspended steel undercarriage, steel embedded rubber tracks, and hydraulics, the 259B3 completes the CTL line by providing a machine that works in poor soils and harsh environments.

At 35 percent tipping load, rated operating capacity for the 259B3 is 2,065 pounds (937 kg), and 2,950 pounds (1,338 kg) at 50 percent tipping load, increasing to 3,000 pounds (1,360 kg) with the optional counterweight. Vertical-lift loader linkage gives the new CTL 120 inches (3,046 mm) of lift height for easy truck loading and precise material placement.

Rated at 71 net horsepower (53 KW) the 259B3 is powered by the C3.4T DIT engine, which complies with U.S. EPA Tier-4 Interim and E.U. Stage-3A emissions regulations. This engine delivers speed and torque in difficult applications and, combined with the Cat anti-stall system, the 259B3 can operate at part-throttle.

The 259B3 features a standard, independent, fully suspended undercarriage. Designed and manufactured by Caterpillar, the undercarriage uses four heavy-duty torsion axles, which move independently to isolate the machine chassis from the undercarriage and absorb much of the shock from rough-terrain operation.

Hydraulic pumps for the 259B3’s implement system (boom and bucket) and auxiliary system (for powering work tools) are driven directly from the engine, eliminating intermediate drive belts. The auxiliary system supplies oil flow up to 22 gpm (83 L/min) at pressures to 3,335 psi (23,000 kPa) – generating a calculated hydraulichorsepower rating of 42.8 (31.9 kW).

The 259B3 is equipped with Cat ToughGuard XT™ hydraulic hoses, for additional abrasion resistance, and auxiliary lines (with heavy-duty, flat-face quick

couplers) are attached to the lift arm. A universal work-tool coupler is standard equipment, and an optional hydraulically actuated coupler is available.

Designed for comfort, convenience and safety, the 259B3’s operator compartment features pilot-control joysticks – the right controlling lift and tilt functions, and the left, direction and speed. The joysticks provide proportional control of auxiliary-hydraulic functions, and optional deluxe joysticks expand the 259B3’s capability with control over work-took electrical functions.

www.cat.com/requestCatinfo

SFP recently introduced More Than Manure Nutrient Manager, referred to as MTM, a product that protects both phosphorus (P) from lock-up and nitrogen (N) from leaching, denitrification and volatilization in applied manure.

MTM maximizes P and N in all manures and litters – both dry and liquid. Increasing availability of these valuable nutrients can lead to yield increases and better overall crop performance.

“Improving yield potential and grower return on investment is always our ultimate goal,” says Larry Sanders, Ph.D., SFP president and CEO. “MTM overcomes nutrient management challenges for growers using any manure as fertilizer –optimizing phosphorus and nitrogen use.”

Of the 15.8 million U.S. cropland acres fertilized with manure, varied percentage of N and P can be lost during handling and storage as well as after application, leaving both nutrients unavailable for crops.

MTM has proven to successfully increase P and N availability when added to confinement lagoons or pits, or in transportation and application equipment (liquid), or when sprayed over-the-top of dry-applied litter or manure. Additionally, when added to an in-ground lagoon or pit, MTM can reduce solids and ammonia levels in livestock-confinement operations.

Independent, third-party research shows increased plant growth, root development and yield by adding MTM to manure fertilizer applications. Test plot

results, including corn, forage and wheat, throughout the United States prove MTM benefits.

“As everybody knows the cost of liquid N seems to continue to increase, increase, increase,” says Jonathan McClain, a Mt. Airy, Ga. grower who’s adopted MTM on his farm. “Using MTM in conjunction with broiler house litter that we used, we saw better results and darker foliage, and it was more equally dispersed.”

No special equipment is required to apply MTM through pivots, application equipment for variable rate applications or pretreatment in pits or lagoons, and the product offers crop-rotation flexibility (i.e. soybeans or other crops can be planted after MTM-treated manure application). Additionally, research is showing reduction in ammonia levels in barns with MTM pretreated pits.

“The ammonia levels were immediate, you could walk in a barn and really couldn’t tell you were in a hog barn anymore. Your eyes weren’t burning and the odor was more or less gone instantly as soon as you dumped it in,” says Sam McKnight, a producer and custom applicator in Afton, Ia.

www.morethanmanure.com

New Zealand’s Skellerup Industries recently announced its full line of Quatro Footwear is now available to farming and agricultural applications in the U.S.

The flagship model of Skellerup footwear, the Quatro Waterproof Farm Boot is hand-built using natural rubber formulations developed to meet quality standards, plus comfort and durability.

Built for the demanding environments of agribusiness, each Quatro boot features uppers made of UV resistant natural rubber that is treated to resist acid found in manure and urine. The Quatro Comfort system consists of cushioned rubber midsoles, arch support systems, and outsoles designed to cushion and distribute the weight of the wearer. Antimicrobial, antibacterial moisture-wicking linings keep feet dry. The Quatro safety system includes anti-skid zones at the forefoot

and easily handles corrosive loads. Compare our inexpensive maintenance, ease of cleaning, fast reliable unloading and the industry’s highest resale values and you can see why other Call 1-800-235-6577 for all the details.

ThermoEnergy’s Thermo ARP™ high-efficiency ammonia recovery system is an unbeatable option for operators of anaerobic digesters who want to both comply with nitrogen regulations and recover ammonia as a valuable product. Thermo ARP recycles the ammonia in digester wastewater into ammonium sulfate or ammonium nitrate for the production of valuable fertilizers and industrial products. Thermo ARP is energy efficient, extremely robust, and compact – suitable for even rugged field conditions.

For more information email info@thermoenergy.com or visit our website at www.thermoenergy.com . Just the mention of chicken manure is enough to make most trailers lay an egg. Not us. Eagle Bridge™ Stainless Steel Trailers are the perfect manure hauling machines. Stainless steel construction and our unique “Bridge” design is not only lighter, it’s more

and heel of the foot for slip resistance, hardened rubber caps for foot protection, raised ribbing for forefoot protection, and an internal fiberglass shank for standing on ladders or fence posts. An optional safety toe is also available, meeting ASTM 2413-05 protection rating.

Quatro boots are available in 13-inch calf-height and 16-inch knee height for all applications. Both lengths are available with and without 4mm neoprene foam insulation that has a thermal insulation rating of –58 F. www.QuatroFootwear.com

JCB has added the 550-80 Agri Plus Loadall to its agricultural telescopic handler line.

The 550-80 features:

An 11,000lb lift capacity with a lift height with of 26ft 7in

A 130hp (97 kW) JCB Dieselmax engine

37 gpm variable flow hydraulics and Hi-flow pipe work for faster loader cycle times and auxiliary service performance

Heavy-duty boom design to provide 14,600 lb of breakout force

The 550-80 is JCB’s highest capacity Loadall, and is designed for heavy-duty farm applications. These applications include digging manure or silage and loading the manure spreader or feed wagon. The 550-80 Agri Plus is powered by a 130hp (97 kW) JCB Dieselmax engine. The machine has a powershift transmission,

37 gpm variable flow hydraulics and high flow pipe work for rapid cycle times and auxiliary service flow.

The 26ft 7in lift height, 11,000lb maximum lift capacity machine has been developed in direct response to customer demand for a machine with greater loader performance. With servo controls supplied standard, operators benefit from low joystick lever efforts. In addition, JCB’s Smooth Ride System (boom suspension) offers improved load retention and increased operator comfort.

The inner boom of the 550-80 has been designed and engineered for strength and reliability, in heavy duty digging applications, it incorporates a Z-bar bucket linkage. This system provides 14,600 lbs of break out force – an increase of more than 50 percent on the current 541 Agri Plus.

www.jcb.com

OtterBox iProtection provides fortification for Apple devices; and recently released the OtterBox Defender Series iProtection for the latest Apple device, the new iPad®.

The Defender Series for the new iPad provides protection while allowing mobility and functionality. Memory foam pads cradle the device within a polycarbonate shell. A silicone skin wraps around the shell to absorb shock and protect ports from dust and dirt. A built-in screen protector keeps the display free from scratches, and any smudges or fingerprints can easily be cleaned.

The case includes a polycarbonate stand that supports viewing in portrait or landscape mode and functions as a screen shield when the iPad is not in use. The stand also incorporates two magnets to initiate device sleep mode when placed over the screen and awaken the device when removed.

www.otterbox.com/new-ipad

New Holland’s T9 Series 4WD tractors meet the needs of row crop and broad acre producers with a standard or wide frame, hydraulics, a large cab and a cab suspension system.

The T9 Series is also available with the new SmartTrax™ tracks option, providing producers with a larger footprint and less soil compaction.

“SmartTrax tracks boost the productivity and pulling efficiency of our T9 Series tractors,” says Sean Dorosz, New Holland’s high horsepower tractor marketing manager. “Producers using this track option will increase traction and reduce soil compaction and slippage, which translates into less surface damage and a smoother ride.”

SmartTrax, available for New Holland’s wide frame T9.615 and T9.670 tractor models, have long belt life and provide uniform load to the ground. They are available in standard and high idler modules. The high idler configuration has a sled-shaped leading edge that drags crop residue and topsoil under the footprint for better traction and flotation. It makes it easier to drive in and out of ditches and climb over rough terrain and obstacles without undue stress on the operator or the machine.

SmartTrax tracks are versatile. They can be used on a tractor for spring planting and then installed on a combine for fall harvest. When it’s time to replace a tractor or combine, they can be easily removed to install on the next machine. Installation is as easy as changing tires. The tracks bolt to the hubs without adapters, allowing conversion from wheels to tracks. www.newholland.com

Kyte Centrifuge supplies reconditioned or new centrifuges for manure dewatering and fine particle separation. Benefits include: uses no screens / filters, separates particles to less than 50 microns in size, and reduces phosphorus, nitrogen and potassium in wastewater.

The 2012 Farm Drainage and Nutrient Management Field Day will feature onsite subsurface drain designs and installations.

The 2012 Farm Drainage and Nutrient Management Field Day sponsored by the Michigan Land Improvement Contractors Association and Michigan State University Extension will be held Aug. 1 and 2, 2012, in south-central Michigan.

The events will feature various onsite sub-subsurface drain designs and installations, GPS surveying, water control devices and bioreactors. Complementing these demonstrations will be a focus on manure land application management systems that recycle both fertilizer and manure nutrients.

“Everyone knows that drainage increases yields,” states Natalie Rector, Michigan State University Extension educator. “It also decreases ponding and runoff, and in doing so reduces surface erosion that carries sediment and nutrients offsite. We want to take advantage of this benefit without consequently losing nutrients through the soil profile and through the drains.”

Taking a two-pronged approach to manure, this event will demonstrate first how to customize management systems on your farm to avoid manure and/or nutrients reaching subsurface drain tiles and second, in the event that it does happen, what systems could be put in place to keep it from doing environmental harm.

Subsurface tile drainage occurs in

conjunction with very unique and uncontrollable forces – soil types and precipitation – that interact and create a new set of circumstances every day. Only the farmer in charge of manure hauling can adjust on the go to these conditions.

“Farmers have told me that dropping a field cultivator across the field to disrupt macro pores, surface applying liquid manure and then shallow incorporation to control odor is a system to avoid manure reaching tile lines, along with monitoring manure application rates,” states Rector. This is especially important as manure has becomes more liquid.

“This event is to help farmers, custom applicators, consultants, and anyone else, learn more about the dynamic system but most importantly, to find ideas that will work on their farm, under their system.”

Blaine Baker, a dairy farmer, and Tom VanWagner from NRCS, will discuss a unique system that Baker has been operating for more than seven years during the educational sessions. Baker’s goal was to find a way to deal with milk house wash water and runoff by maximizing its use during the driest part of the growing season. Liquid waste from the dairy operation goes to a two-celled constructed wetland for initial treatment and then is sent through a subirrigation system covering about 20 acres of farmland. The system has resulted in increased crop yields while

effectively treating dairy wastewater. This system is not right for all soil types or farming systems, but for Baker, it has been a win-win solution and has allowed him to continue his no-till cropping system.

Dr. Larry Brown from Ohio State University, and Dr. Richard Cooke, University of Illinois, will discuss their specialties of water control devices and infield bioreactors. Frank Gibbs from Ohio will show a unique way to look at soil pore space with a smoking tile line demonstration and Tim Harrigan from Michigan State University will demonstrate seeding cover crops in the manure applicator.

Various vertical tillage and other types of tillage will run over wheat stubble to show soil disruption and crop residue management.

The exhibitors will be on hand from 9 a.m. to 4 p.m. both days. Tile drainage installation demos and exhibits will run continuously and educational sessions will be repeated each day at 10:30 a.m. and 1:15 p.m.

The 2012 Farm Drainage and Nutrient Management Field Day will be held at 5211 W. Chicago Road, Jonesville, MI 49250. The field day is free and will repeat events over the course of both days. More detailed times and events can be found at www.michiganlica.org. For more information, contact Natalie Rector, rector@msu.edu or 269-967-6608.