MAY/JUNE 2011

MAY/JUNE 2011

Pembroke Oaks Farm sow unit designed for pigs and the environment

Sticking with a system that works

Pembroke Oaks Farm’s sow unit was designed to be healthy for the pigs and environmentally friendly. The system helped the farm receive the National Pork Board’s 2010 Pork Industry Environmental Steward Award.

Brothers Burning manure unfolding as potential disposal option

removal of phosphorus from manure

Switch to sand, new manure management system ‘best thing’ for B.C. dairy

World Pork Expo World’s largest pork-specific trade show June 6-8 in Des Moines, Iowa

Cover: When you find something that works, stick with it. That’s the philosophy of Pembroke Oaks Farm, in Wheatfield, Ind. Despite the interior complexities of the operation, from the outside, the barn design is simple – a breeding/gestation barn and a farrowing barn. Contributed photo

May/June 2011

Volume 9 • No. 3

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Tony Kryzanowski, Diane Mettler, David Schmidt, Stephanie Schupska, S. Ram Shrivastava

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Artist Kelli Kramer

VP Production/group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

subscription rates Canadian subscriptions $35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2011 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

ABy Margaret Land

s I write this editorial (on May 5, 2011), the sun is shining outside my window. A slight breeze from the northwest is rustling the maple leaves bursting on the tree shading the front lawn. And my two horses are slugging through hock-deep mud, muck and mire in their pasture.

My farmyard is a mucky, muddy, soggy mess and I know it won’t be improving anytime soon. According to my local weather forecast, I can expect rain tomorrow, and the next day, and the next day, and the next day, and the – well, you get the picture. All of this extra moisture comes after almost three weeks of continual rain with a nasty windstorm thrown in for extra drama. Sections of my hay field are under water, my neighbor’s fall wheat is looking more than a bit yellowed, not one seed of corn or soybeans has been planted in the area and it’s basically impossible to mow the lawn, which is getting to first cut hay stage.

I know I’m not alone in my weather conundrum. According to a local crop advisor in my area, this is the worst year for working and planting farm fields he’s seen in 27 years.

I also recently received a nice e-mail from a reader and farmer in northern Iowa who was hopeful for some warm weather to dry up the fields in his neck of the woods.

“Our temperatures in this area have been 10 to 15 degrees below normal and it has been very wet,” he wrote. “This makes it very difficult to apply manure to the fields.”

He’s not alone. Tractors are sitting idle on many New York state farms where some are forecasting yield losses in the range of millions of dollars. Vermont dairy farmers are unable to apply manure and prepare their fields for planting. And in Wisconsin, manure pits are beginning to creep to the brim as wet fields prevent proper application.

Meanwhile, farmers in southwestern Kansas are experiencing severe drought conditions that have led to wildfires destroying 9,600 acres in two counties. Western Texas, the Oklahoma Panhandle and southeastern New Mexico are also experiencing severe drought conditions, having received only 10 percent of normal precipitation over the past six months.

Well, I know exactly where those states’ normal precipitation has gone – it’s fallen on my small, 10-acre farm. And they’re free to come and pick it up anytime they’d like. Just bring a big sponge and a very large water tanker. We could also probably jury-rig our basement sump pump, which hasn’t stopped working in the past three weeks (except when the electricity went off in the big windstorm and when it had to be replaced because the motor burned out), to pump directly into water jugs.

In all seriousness, this monsoon needs to end soon before I’m picking mushrooms off my horses’ backs and planting rice in my hay field.

Now, more than ever, pork producers recognize the impact their operations can have on the world around them. Proactive eco-management with MicroSource S can help reduce environmental burdens. By feeding MicroSource S, producers benefit from:

• Reduction in noxious manure gases, like ammonia and VFAs, for less odor – resulting in better community relationships

• Increased nitrogen retention in manure - resulting in improved N:P Ratio

• Lower manure viscosity - resulting in less power required for pump outs and the ability to pump out more manure

• Decreased stickiness of manure resulting in reduced labor requirements due to easier/less cleaning MicroSource S contains selected microbes that digest the solids in hog manure. It begins to work even before the manure hits the floor and continues to act on manure during handling and storage. Fed throughout the pig’s lifecycle, MicroSource S can help you better balance the challenges of efficient pork production with environmental stewardship.

To learn more, contact your feed supplier, go to www.unlimitednutrition-na.dsm.com, or call 1 800 526 0189.

Pembroke Oaks Farm’s sow unit was designed to be healthy for the pigs and environmentally friendly. The system helped the farm receive the National Pork Board’s 2010 Pork Industry Environmental Steward Award.

By Diane Mettler

When you find something that works, stick with it. That’s how Malcolm DeKryger, vice-president of Belstra Milling, feels about the two-barn sow unit at Pembroke Oaks Farm, in Wheatfield, Ind. The successful design is something they’ve used at four of their locations.

Pembroke is affiliated with Belstra Milling, a family and employee-owned corporation, and is one of 10 compounds throughout Northwest Indiana and Northeast Illinois that Belstra designed and built from scratch.

The 20-acre Pembroke Oaks Farm location was chosen in part because of the sparse population of both pigs and people, as well as nearby grain farming operations, which would find use for the farm’s manure.

The small acreage is also strategic.

“We don’t try to own everything,” says DeKryger “We work very hard to establish relationships with neighbors before we ever get started.”

For example, early on Belstra worked with the family-owned Harper Brothers Farm. “They were contiguous to where we wanted to do our work and, before the barns were built, we had agreements on over 500 acres of corn and soybean ground that we could work with for our nutrient management program when our permits and our facilities were put together,” says DeKryger.

When Belstra decided to build at Pembroke, they worked with engineering specialist, Dr. Mike Veenhuizen of Livestock Engineering Services in Greenwood, Ind.

“He’s a former professor of Ag Engineering at Ohio State [University] and his specialty is designing manure containment and doing the permitting on facilities – pigs, dairy and poultry,” says DeKryger.

Dr. Veenhuizen drew up all of the concrete and design criteria. His design

included, among other things:

• Seepage control. Controlled cracks with rubber gaskets inside to avoid any chance of leakage through the concrete cracks or seams. “If you set a wall on a floor, you’ve got a seam, and we’ve got that all sealed off with what they call barbell seals and it’s a rubber seal that goes in the wall and in the floor so that it’s all very, very safe,” says DeKryger.

• Exterior pressure prevention. When it rains hard, the ground water can come up and push against the side of your building, causing damage. Tiles were placed around the bottom of the building so water could be picked up by the tiles and taken to a nearby ditch.

“In addition, we have a vertical test culvert in ground to the tile, with a valve on it,” explains DeKryger. “With it we can

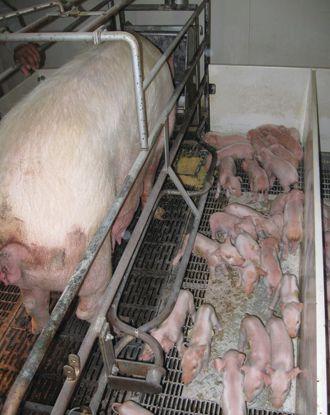

Although the design of Pembroke Oaks Farm’s barns may appear simple, the complexities are on the inside and helped Pembroke Oaks Farm win the National Pork Board’s 2010 Pork Industry Environmental Steward Award. Contributed photos

The proof of the success of

Oaks Farm is in the pigs. The operation recently had a sow give birth to 26 live piglets.

The way the barns at Pembroke are designed, the air blowing out is relatively odor-free. Large fans draw fresh air in at the end of the barn and pull it through quickly. This pulls heat off the animals for comfort, but doesn’t pick up much odor.

test the water to see if any manure water is coming out of the building. If it is, we can shut that off and stop the water from getting out to a ditch, until we can dig it up and find out where the problem is.”

Dr. Veenhuizen also provided a booklet that illustrated all the pieces of dedicated land for the future nutrient management. It demonstrated that all the manure could be contained within Harper Brothers ground, “although over time other people in the area have asked for manure and we’ve worked with them,” says DeKryger.

Despite the complexities, from the outside, the design is simple – a breeding/gestation barn and a farrowing barn.

“We’ve got between 2,450 and

2,480 sows on site at all times and produce about 70,000 baby pigs a year,” says DeKryger.

The farrowing barn has a shallow pit with a sloping floor underneath. The depth is about eight to 15 inches and the plugs are pulled about every three weeks to drain it into the pig gestation/ breeding barn.

The 400-foot by 120-foot breeding/ gestation barn has a much larger eightfoot pit, capable of storing up to 2.87 million gallons.

Although DeKryger says they could store up to eight or nine months, it’s emptied every six months – in the spring and then in the fall. “We plant a corn crop in April. And in October/November we go back and distribute manure because beyond that it freezes,” he says.

A unique aspect of Pembroke Oaks Farm is its adjacent neighbor — an 8,000-acre wilderness known as the Jasper-Pulaski State Fish and Wildlife Area, maintained by the Department of Natural Resources (DNR).

Hiring out the pumping

When it comes time for pumping

Pembroke Oaks hires Heartland Farm Services, a company that specializes in dragline manure injection and nutrient placement.

“We have the fields and the roads set up so that we can drag line hoses as far as two miles away,” says DeKryger. “Heartland puts manure on at an agronomic rate to balance what the crop needs are for the Harper Brothers. And Kurt Nagel is the nutrient compliance person for Belstra Milling that works with Harpers to balance the nutrients.”

In addition to Heartland, Pembroke has a couple other farmers pump from the barn into tanks. Afterwards they take it up to four or five miles away to distribute it on their crops.

Malcolm DeKryger (left), vice-president of Belstra Milling, with Kurt Nagel, nutrient compliance official for Belstra Milling. Pembroke Oaks Farm is affiliated with Belstra Milling, a family and employee-owned corporation, and is one of 10 compounds throughout Northwest Indiana and Northeast Illinois that Belstra designed and built from scratch.

Although Pembroke doesn’t make any money on the manure, they are happy to break even.

“It’s a good deal for my neighbors,” says DeKryger. “And when my neighbors have a good deal, then I have a license to continue to just keep on doing what I’m doing.”

A unique aspect of Pembroke Oaks Farm is its adjacent neighbor — an 8,000-acre wilderness known as the Jasper-Pulaski State Fish and Wildlife Area, maintained by the Department of Natural Resources (DNR). The land butts up to one of the barns and there was initially serious concern in the community that the farm would have a negative impact on the bird sanctuary. People need not have worried.

“This past winter when I went to the DNR to get what I call my report card, to see how we’re doing, they said, ‘You’re doing fine,’” says DeKryger. “Then they said, ‘Hey, we’ve got a question for you. Who are a couple of different people that handle your manure because we want to get a bid to have them apply it to our ground at the DNR?”

The DNR raises sunflowers and corn to feed wild animals, including the 30 to 40,000 Eastern Sandhill Cranes that come through in the spring and fall. The manure would fertilize the crops needed to feed the birds.

The future neighbors were so worried about the future farm in 2005 that they filed a lawsuit through Indiana’s Department of

Environmental Management to stop the building.

“We worked through that and the people are today surprised at how little impact the farm has,” says DeKryger. “I had one of the people involved come to the door the other day and say, ‘You know, I have to tell you the truth. I haven’t smelled you for a year-and-a-half now.’ So that’s been pretty huge for us.”

Pembroke has also done its part to improve neighbor relationships by helping out in a time of need. During a recent winter storm when the electricity went out, DeKryger let his neighbors know the farm had a generator and heat, and folks could come over if they needed to.

“It’s hard some days,” says DeKryger. “Nobody likes to have people confront them. But my neighbors aren’t afraid to find me if there is a question and I will try to move heaven and earth to try to make them happy if there is anything we can do to make a difference for them.”

One of the ways Pembroke keeps the odor down for its neighbors is by venting toward the DNR hunting grounds. It doesn’t bother the deer and the thick woods would serve as a giant filter.

“It doesn’t do any damage to the wildlife or the trees,” explains DeKryger. It’s 70 feet away, so there’s some blending of air that goes on and it’s not like it’s caustic air or anything like that.”

Also, the way the barns are designed,

the air blowing out is relatively odor-free. Large fans draw fresh air in at the end of the barn and pull it through quickly. This pulls heat off the animals for comfort, but doesn’t pick up much odor.

There are smaller fans in the pit. “It doesn’t take a lot to ventilate the area where the manure is,” says DeKryger. “So there’s not a lot of air going across the manure and it therefore doesn’t push a lot of smell out.”

This particular design isn’t new to Belstra. “What we did here pretty much mimics the farm that we did about three years before it.”

It worked so well that Belstra used the same design on the following two projects after Pembroke Oaks. “It’s a system that we like a lot,” says DeKryger.

It also helped Pembroke Oaks Farm win the National Pork Board’s 2010 Pork Industry Environmental Steward Award.

DeKryger believes one thing that sets the farm apart is the number of professional groups and companies that oversee this farm and have done their jobs professionally from the start.

“We’ve got the right people doing the job,” he says. “Everyone from Dr. Veenhuizen, to the construction crew, and others like Kurt Nagel, Heartland Farm Services and Harper Brothers, who do a great job of farming the ground.”

DeKryger says the proof is in the pigs. Pembroke recently had a sow give birth to 26 live piglets. “A great farm means healthy pigs.”

Installation of a manure combustion system will allow Wiese Brothers dairy to double its milk cow herd from 2,000 to 4,000 head. Contributed photos

By Tony Kryzanowski

manure unfolding as potential disposal option

Is burning your manure a better option than land applying or investing in anaerobic digestion? The technology now exists to combust manure to generate power. The prototype has proven the concept and is being upgraded to handle the manure resulting from a twofold expansion of a Wisconsin dairy farm.

Two breakthroughs advanced the Elimanure technology developed by EcoCombustion Energy Systems compared to attempts to burn manure in the past. These were learning to handle the high percentage of noncombustibles in manure and techniques to manage air emissions to satisfy Environmental Protection Agency (EPA) requirements. Adapted from the pulp and paper industry, the technology is the

brainchild of company cofounder, Paul Schneider, who with the assistance of a federal agency called Farm Pilot Project Coordination Inc. (FPPC), established a 600-kilowatt installation on the Wiese Brothers dairy farm in Brown County, Wis., in 2005.

Although Schneider made his living in the pulp and paper industry, he never forgot his strong farming roots, realizing that the problem for large farms wasn’t the fiber in the manure, but the nutrientrich liquid that was running off into watercourses. He adds that hauling the liquid manure also represents a huge expense for farmers.

“If you stretch your imagination, what we do in the paper industry is very similar to problems that you have with manure,” says Schneider. “In the paper industry, we separate the fiber from the liquid and then we need to manage the liquid as well. My concept is to evaporate the moisture in the manure, burn it, and then create energy.”

The company has finalized its patented combustor design and secured a combustor manufacturer that has

given a 100 percent guarantee on the system’s energy output. Developing a strategic alliance with the manufacturer means that the company no longer needs to build its own units, but can have them manufactured commercially by a company that builds as many as 3,500 combustors a year. The manufacturer can also build them cheaper and more robust. EcoCombustion Energy has designed three sizes.

Finding a combustor manufacturer willing to work with the company was a challenge because of issues associated with the manure’s ash content. Burning sawdust produces about two percent ash while manure produces about 15 percent.

“With the help of FPPC, we got a grant to study how to burn the manure at high temperatures,” says Schneider. “So we designed a combustor and we have the expertise for operating the combustor to burn that high ash content. Once we learned that and were able to prove it, then the combustor manufacturers had confidence to work with us.” Farms will need to dispose of the ash, but it is considered a soil amendment and it can

The combustor is connected to a cyclone for cleaning particulate from the air stream.

be land applied. It is a lot less expensive to transport ash than liquid manure. The ash is a 0-8-10 chemical compound, so farmers will still be limited in how much can be applied per acre in many areas because of its phosphorus content. Where it shines is as a seed starter soil amendment.

The Wiese dairy installation is certified as a renewable energy facility. Schneider says it does not put any more carbon into the atmosphere than would have occurred naturally through land spreading. The system initially had issues with controlling air emissions, but the installation of pollution control equipment has been a game changer, and has resolved the problem.

The Wieses are doubling the size of their farm from 2,000 to 4,000 milk cows and are expanding the Elimanure system to support the expansion. The first phase will be focused on doubling the farm’s capacity to dry and burn the manure using the same turbine to generate 600 kilowatts of power. The second phase in about a year will add a second turbine, which will result in doubling its electrical

output to about 1.2 megawatts. There will be a total of 9,000 cows on the farm, which includes their heifers and young stock. The construction project will feature a total redesign and rebuilding of the manure drying and combustion system based on what EcoCombustion Energy has learned from operating the prototype. The system is quite efficient, as the heat generated from combustion is used to evaporate moisture from the manure. Once completed this October, the dairy

will be disposing of 45 million gallons of manure annually either by incineration or by recycling into bedding.

The net benefits of installing the Elimanure system to farms are elimination of greenhouse gas emissions such as methane into the environment, the potential to generate their own power, simplification of manure handling, production of their own cow bedding material, and sale of power to a utility. The power generated is also available 24/7,

JUNE 8-10, 2011

Iowa State Fairgrounds

Des Moines, Iowa USA

For

Pre-Register Now

• Business SeminarIs

• Opportunity for IndIustry Networking

• Enjoy the HospitalIity Tents and SociaIl Events

• Thursday Evening MusIicFest

• Junior National SwiIne Show Trade Show

Wednesday, June 8thI – 8 a.m. to 5 p.mI.

Thursday, June 9th I– 8 a.m. to 5 p.m.I Friday, June 10th –I 8 a.m. to 1 p.m.I

and to pre-register, visit

which makes it more attractive as an alternative energy investment for power utilities than solar or wind.

“In Brown County, the requirement is to have three acres of land per cow to spread manure,” says Schneider. “Because the Wieses won’t be putting the manure on the land, their need to have additional land to expand is no longer necessary.”

Schneider says he doesn’t view anaerobic digestion, which is another manure disposal route taken or being considered by some dairy owners, as competition. Nor should promoters of that technology view Elimanure as competition. He believes anaerobic digestion has its place when farm operations are producing very wet manure.

“We work best in systems where the manure is somewhat thicker and drier,” says Schneider. He understands why many dairy farmers adopted anaerobic digestion because it was the only manure processing technology available, although it does not eliminate the need for land spreading. Farmers needed to take action to maintain their permits. Schneider adds that both Elimanure and anaerobic digestion reduce the carbon footprint from agriculture and an additional benefit of Elimanure is that it can help overcome land spreading issues.

The farming community has shown considerable interest in what EcoCombustion Energy is developing at the Wiese dairy. Schneider says he expects that sales will take off once the commercial version proves itself at that location. The success and value of this installation in the eyes of the farming community is extremely important to the company, as developing the process has been costly, with government grant support provided only for the initial prototype. The company must also overcome some of the skepticism that farmers have developed concerning alternatives to traditional methods of land spreading manure that haven’t succeeded.

“Because of some of the problems that have been experienced from anaerobic digesters, farmers are very, very nervous about new processes,” says Schneider. “Farmers would like to see it work first. We have to complete the Wieses’ project and have it running, and then sales will go.”

Large farms are operating more and more like industries such as the pulp and paper industry, Schneider says,

The turbine and generator on the Wiese Brothers’ farm is where incinerated manure ultimately produces electricity.

which has created a trend for more engineered processes making their way to large farms.

“I think the time has come when we are going to see an awful lot of new technologies, new innovations, and new ways of doing things on the farm,” says Schneider. As farms get bigger, farmers are starting to see the value of engineered processes and are becoming more industrialized. Industrial technology like Elimanure is just one example of that trend. As time progresses, EcoCombustion Energy intends to develop additional

manure handling and alternative energy solutions.

The minimum entry point at which an Elimanure system would make financial sense is a farm milking about 1,500 cows with a total herd of 3,700 cows or larger. That’s because of the cost of power turbines and the amount that utilities are prepared to pay at present for renewable energy. EcoCombustion Energy is hopeful that the situation will change in future so that renewable energy prices are higher and the price for turbines comes down.

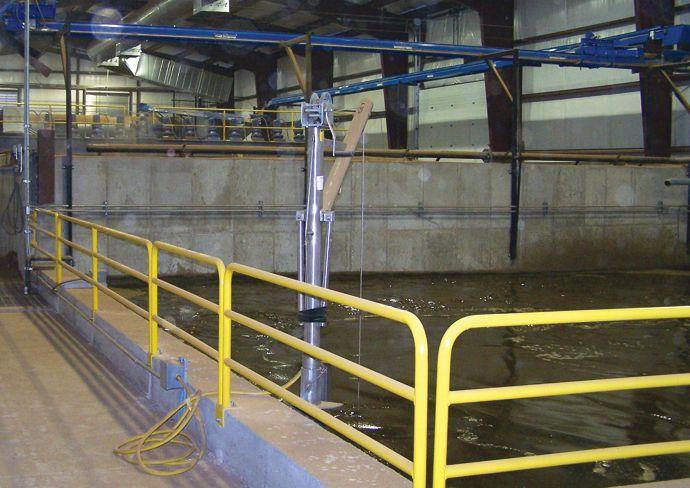

• Reduces surface & bottom solids

• Provides a consistent manure slurry from �irst load to last

• Enhances manure fertilizer value

• Signi�icantly reduces manure mixing at time of draw down

• Reduces barn odor, and odor on land applications

• Reduces pests via odor suppression

• Enhance manure value on application

• Stimulates root growth

• Fixes nitrogen

• Improves crop yield

• Controls nutrient run off

By David Schmidt

Since nutrients are brought onto a dairy farm in the form of feed and fertilizer, an equivalent amount of nutrients needs to be removed from the farm to make it sustainable. Milk, the main product leaving a farm, does not take enough of those nutrients to balance the equation. That is particularly true in British Columbia’s Fraser Valley, where farms as large as 3,000 cows are packed onto small acreages and fed a diet rich in imported hay and grain. The manure is then spread onto the limited farmland, increasing, even overloading, nutrients in the fields and leading to a vicious cycle. Homegrown corn and other forages become increasingly rich in phosphorus, leading to cow health issues. Excess phosphorus also leaches out of the field, causing eutrophication of nearby watercourses. At the same time, the world is running out of raw phosphorus, an essential ingredient in fertilizer.

The answer seems all too obvious – remove phosphorus before the manure is applied to the land and use it to create fertilizer for areas not rich in cow manure, such as the fields that originally supplied the imported hay and grain.

That, in a nutshell, is the premise behind some leading research and development being conducted at the University of British Columbia (UBC). After several years of testing in the UBC engineering labs, UBC civil engineering professors Victor Lo and Don Mavinic and their associates are about to build a pilotscale recovery system at the UBC Dairy Education and Research

Centre in Agassiz, B.C. The system would remove phosphorus from the manure and convert it into struvite (ammonium magnesium phosphate) crystals.

Lo, Mavinic and DERC director Jim Thompson call their system a “logical, integrated approach” to manure management that would prevent pollution and include efficient solids destruction. The latter would produce both salable nutrients and bioenergy.

“Our dream is to have a system on the farm which removes some of the energy and nutrients,” says DERC director Jim Thompson.

Mavinic says they are already using the patented system to produce struvite from sewage waste at a plant in Edmonton and are building plants at seven plants in the U.S. and one in England.

“Now we intend to produce it from dairy and hog manure,” he says, noting there is far more potential to produce struvite from animal waste than from human waste.

Lo notes a herd of only 50 cows produces 2.75 tonnes of manure per day at 15 percent total solids. Given its nutrient content, that’s an annual total of 5.3 tonnes of nitrogen, 1.1 tonnes of potash, 3.4 tonnes of phosphorus plus lesser amounts of calcium and other minerals.

“Humans excrete three to four grams of phosphorus/day but cows and pigs excrete 50 to 100 grams/day. The herd at DERC (about 300 milking cows plus young stock and replacements) excretes as much phosphorus as all the people in Whistler,” Mavinic states, pointing out that while there are six to seven billion people in the world, there are 10 times as many cows.

Under the UBC system, manure first goes through a liquid/ solids separator. The liquid goes through an anaerobic digester to create bioenergy, then through an advanced oxidation process in a type of microwave oven to stabilize the nutrients and organic particles. Finally, those particles go through a crystallization process to produce struvite.

Using this process, Lo projects the waste from 50 cows would generate over $12,000 a year – $6,400 from the methane/ biogas and $6,000 from the struvite.

He claims the treated effluent will meet standard discharge criteria, whereas the solids can be composted to generate additional revenue.

“Our pilot plant will be a first in the world,” Mavinic says. Both NSERC (Natural Sciences and Research Council of Canada) and Agriculture and Agri-Food Canada (AAFC) have provided funding support for the project. Mavinic has also received an NSERC Synergy Award for Innovation for his groundbreaking research.

•

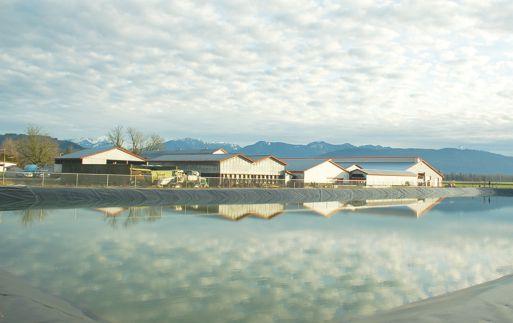

•

Baarsview’s lagoon has a polyethylene seam-welded liner. The Baarses intend to spread the liquid on their land using a dragline to minimize odor.

Gerard and Harm Baars of Baarsview Farms, shown here standing in front of their farm’s new One-Shot sand separator, decided to switch to sand bedding from sawdust after building a new barn to house their 130-cow milking herd.

Flush

By David Schmidt

One thing leads to another.

Necessity is the mother of invention.

Those old adages are certainly true at Baarsview Farms in Deroche, B.C.

When Gerard and Harm Baars decided to build a new barn to house their 130-cow milking herd, their vet recommended they switch to sand instead of sawdust bedding for the health benefits it would provide.

Enter the adage, “one thing leads to another,” as that decision ultimately led to installation of Canada’s first DariTech Biolynk system with a One-Shot sand separator. Developed just across the border by DariTech Inc. of Lynden, Wash., the sand separator and Biolynk system are the result of the second adage – necessity is the mother of invention.

After agreeing to use sand, the Baars brothers decided to use a flush system instead of alley scrapers to clean out the barn.

“The sand would cause too much wear and tear on mechanical scrapers,” Gerard explains.

However, flush systems have two drawbacks: a need to filter the sand out of the waste stream and increased odor from the recycled liquid. The Biolynk system and sand separator are intended to resolve both those issues.

The One-Shot Sand Separator is a new product, the Baarsview installation being only the second in North America. It eliminates the large settling ponds that most farms using sand bedding put in to remove sand from the manure.

It also has more horsepower than the only other mechanical sand separator made in North America, says DariTech’s outside sales manager Steve Peerce. The separator uses two screens, not only enabling it to handle both fine and coarse sand, but also allowing it to remove more of the sand in the initial separation process.

From the separator, the effluent – now minus most of its sand – is pumped into the first (sand sedimentation tank) of the three tanks that make up the Biolynk system.

As per its name, the tank is intended to allow the remaining sand to settle to the bottom of the 28-foot-high tank from which it is regularly “burped” out. Meanwhile the top six feet of liquid is pumped across into the second “process” tank, the largest of the three tanks. The top six feet of water from the process tank, which by now has been cleared of virtually all of its solids, is then reused as flush water.

“For every 100 gallons which go into the process tank, about 85 gallons go back into the flush system,” Peerce explains.

The remaining 15 gallons of “concentrated effluent” are pumped under high pressure into a third “buffer” tank, then across a second separator to remove the remaining solids and fine grains of sand before being pumped into a storage lagoon.

Baarsview’s lagoon has a polyethylene seam-welded liner, Gerard calling it “better and more reasonable than concrete.”

The Baars intend to reuse the sand as bedding and spread the liquid on their land using a dragline to minimize odor. They also hope to either sell the solids or spread them on their own fields. However, the Biolynk system has been designed so the solids can be used in a Bedding Master (another of the company’s products, which produces bedding from the solids) or an anaerobic digester.

“The buffer tank produces a more concentrated effluent, which results in

From the separator, the effluent – now minus most of its sand – is pumped into the first of the three tanks that make up the Biolynk system.

more effective separation. Combining the output of the process and buffer tanks also results in an ideal feedstock for an anaerobic digester,” Peerce says. The system reduces the amount of storage capacity a farm requires as just 15 percent of the water ends up in the lagoon. Because none of the water in the lagoon is used for flushing, it can be fully emptied at any time. However, the best payback cannot be measured

in dollars. That is the reduced odor of the flushwater.

“You can’t put a number on that,” Peerce states. “It’s up to the dairyman as to how much it’s worth.”

For the Baarses, the answer is a lot.

“Switching to sand and installing the separator and Biolynk system are the best thing we did,” Gerard states emphatically.

Thousands of people are making plans to travel to the 2011 World Pork Expo. The U.S. pork industry’s newest technologies and educational seminars are just a few reasons to attend this exposition, scheduled for June 8 to 10 at the Iowa State Fairgrounds in Des Moines, Iowa.

Once on site, Expo-goers will find trade-show exhibits featuring the very latest. They will have access to industry experts presenting business seminars on profitability and current issues. They can watch junior showmen and swine breeders exhibit some of the best market hogs and breeding animals available. And throughout the event, they will feast on great food and enjoy family entertainment.

A trade show that’s second to none

Each year, nearly 20,000 producers and industry professionals attend Expo, the world’s largest pork-specific trade show. They can see the newest products, services and technologies offered by more than 450 commercial exhibitors that cater to the pork industry.

The trade show will be open from 8 a.m. to 5 p.m. on June 8 and June 9, as well as from 8 a.m. to 1 p.m. on June 10. It is a prime opportunity to learn about new products and services that can improve profitability while helping produce quality pork.

30th anniversary of the New Product Tour

World Pork Expo’s New Product Tour, sponsored by National Hog Farmer magazine, allows producers to examine products and

Once again, attendees will fill the Main Concourse of the Iowa State Fairgrounds for World Pork Expo, June 8-10, 2011, in Des Moines, Iowa. Photo courtesy of National Pork Producers Council

services introduced to the pork industry during the last 12 months. These products will be on display during the trade show, where people can vote for their favorite new technology to determine the Producers Choice Award.

Seminars with the latest insights

On June 8 and 9, the fairgrounds’ Varied Industries Building will

Wednesday, June 8

8 a.m. – 5 p.m. Trade Show

(Cattle barn, Varied Industries Building, outdoor space and hospitality tents)

Other activities

• New Product Tour sponsored by National Hog Farmer

• National Swine Registry –America’s Best Genetics Alley

• World Pork Expo merchandise shop

• Pork Academy

• Youth PQA Plus® training

• Business seminars sponsored by Intervet/Schering-Plough Animal Health and Techmix Inc.

• The Big Grill

• World Pork Expo Junior National barrow shows

• PQA Plus® and TQA® training

Thursday, June 9

8 a.m. – 5 p.m. Trade Show

(Cattle barn, Varied Industries Building, outdoor space and hospitality tents)

Other activities

• New Product Tour sponsored by National Hog Farmer

• World Pork Expo Junior National showmanship

• World Pork Open Clay Target Championship (Waukee, Iowa)

• National Swine Registry –America’s Best Genetics Alley

• World Pork Expo merchandise shop

• Pork Academy

• Business seminars sponsored by Eastern Research Group Inc. & the U.S. Environmental Protection Agency, and Cargill

• The Big Grill

• World Pork Expo Junior National purebred gilt show

• MusicFest performances continue until 8 p.m. (Grand Avenue)

Friday, June 10

8 a.m. – 1 p.m. Trade Show

(Cattle barn, Varied Industries Building, outdoor space and hospitality tents)

Other activities

• World Pork Expo breed show

• New Product Tour sponsored by National Hog Farmer

• National Swine Registry –America’s Best Genetics Alley

• World Pork Expo merchandise shop

• The Big Grill

• World Pork Open Golf Outing (Legacy Golf Course, Norwalk, Iowa)

• World Pork Expo Junior National judging contest

• World Pork Expo Junior National novice judging contest

• World Pork Expo Junior National sweepstakes ceremony

Mark your calendar

This is a tentative schedule. All seminars and events are subject to change without notice. For the most up-to-date program information, visit www.worldpork.org.

be home to a variety of educational presentations from leading experts. Expo-goers can choose from business seminars focusing on new technologies and management techniques, as well as PORK Academy presentations that cover carbon footprint, euthanasia, feed costs and nutrition labeling.

Top genetics on display

In the fairgrounds’ Swine Barn, attendees will see one of the top youth shows – the World Pork Expo Junior National. Exhibitors from throughout the country will show crossbred barrows on June 8 and purebred gilts on June 9. Starting the morning of June 10, Expo-goers can view open-show exhibitions including both purebred and crossbred classes. The breeding stock sales will take place on June 11, from 8 a.m. until they’re completed (at approximately noon).

Grammy-caliber entertainment at MusicFest

Once again, MusicFest will be the social highlight of World Pork Expo from 3:30 p.m. to 8 p.m. on June 9.

Attendees can enjoy roasted pork and refreshments while watching a performance by Grammy® Awards nominee Highway 101, which has been named Vocal Group of the Year twice by both the Academy of Country Music and the Country Music Association.

Another Grammy nominee, Papa Doo Run Run, has delighted audiences with its surfer sound as Disneyland’s celebrity house band for 15 years, while on tour with Jan & Dean, and now at World Pork Expo. Back for an encore performance, Tony Valdez & the Retro Rockets specialize in classic rock ‘n’ roll.

Easy to register, stay in touch

Those who pre-register at www.worldpork. org by June 4, will receive a $10 discount off the normal at-the-door-admission price of $15 (admission is good for all three days). You also can use vouchers when you register online. Registering early means you’ll start receiving free Expo alerts via email so that you’ll always have the most current information.

The website also has the latest details about room availability at the official Expo hotels in its “Producer” section. Additional information is available when you connect with World Pork Expo on Facebook and follow World Pork Expo on Twitter (use #NPPCWPX).

When you have a job to get done, you can count on Gorman-Rupp pumps to work just as hard as you. Whether it’s transferring waste from lagoons, irrigating the fields, refueling machinery, fertilizing the crops or any other task around the farm, Gorman-Rupp has the pump to meet your needs.

Contact your local Gorman-Rupp distributor for all of your self-priming centrifugal, drum or portable enginedriven pump needs.

According to a University of Georgia (UGA) poultry specialist, if chickens eat a bit of charcoal it helps lower the amount of ammonia in their manure, which can lead to happier, healthier and more environmentally friendly chickens.

Casey Ritz, a UGA Cooperative Extension poultry scientist, has been researching charcoal as an additive to poultry bedding to control ammonia levels in chicken houses for the past four years. It was working, but he thought charcoal might be able to do more from inside the chicken.

“Our question was: if we feed it to chickens, could we stop ammonia production before it hits the ground?” he said.

High levels of ammonia in litter can affect a chicken’s growth and performance.

One group of chickens was given feed with charcoal added. Another group received normal feed without charcoal. Ritz and his colleagues then took the chicken manure and incubated it. They found a significant drop in the amount of ammonia in the manure of the chickens fed the charcoal compared to the chickens who ate regular feed, he said.

The researchers were initially worried that the chickens might not eat feed with charcoal in it. Chicken feed is usually light brown. The charcoal turns it black. Fortunately, the color didn’t bother the chickens. And, thanks to the charcoal’s effect on manure color, the researchers knew without a doubt which chickens had charcoal in their diets.

Charcoal is very porous, making it an excellent natural filter. It has no nutritional value for chickens, so it would only be filler in their feed. The scientists now want to see how much charcoal needs to be added to a chicken’s diet in order to be effective.

“We want to have the biggest bang for the buck with added char,” Ritz said. Right now, he thinks that number is between one percent and two percent of poultry feed. He’ll conduct experiments in the next few months to figure final formulation.

Chickens produce ammonia through their manure, also called litter. The nitrogen in the feed they eat is converted into uric acid in their intestines. When charcoal is used in the feed, the bacteria in the manure convert the uric acid into ammonium, not ammonia. This makes the litter less odorous or harmful, and can make it a better nitrogen fertilizer for crops, too.

“Chicken litter is a great fertilizer,” Ritz said. “But if we can enhance it a little bit, we’d make it even better. Chicken litter, from a volume standpoint, is only about three percent nitrogen. If we could enhance it a couple of percentage points, it would be a big deal.”

Ammonia dissipates quickly into the air. The human nose detects ammonia between five and 50 parts per million.

“We can’t even get five parts per million very far outside of a chicken house,” he said. In other words, unless someone is standing inside a poultry house, it isn’t the ammonia that stinks; it’s other odors.

Ammonia is not on the list of the Environmental Protection

By Stephanie Schupska

University of Georgia researcher Casey Ritz is experimenting with the use of charcoal as a feed additive for chickens. When charcoal is added to poultry diets, Ritz has found it reduces ammonia levels in poultry manure. Photo by April Sorrow, UGA

Agency’s six top air pollutants. But lowering it can help overall air quality.

“When it really comes down to it, we need to stop ammonia before it’s made instead of trying to mitigate it after it is emitted,” Ritz said. “I think this is one of the strategies that has a good chance of success.”

Next, Ritz and his colleagues want to make the charcoal feed additive affordable for poultry producers and find companies that will produce and sell it as a poultry additive. The U.S. Food and Drug Administration and the U.S. Department of Agriculture must approve the use of charcoal as a commercial poultry feed additive. The charcoal is already approved for human consumption, he said.

Stephanie Schupska is a news editor with the University of Georgia College of Agricultural and Environmental Sciences.

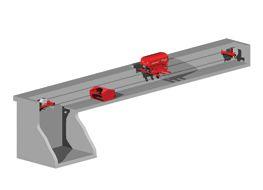

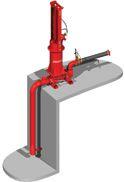

Jamesway Farm Equipment recently introduced a new family of PTO Vertical Pumps.

The new trailer mounting provides easy entry of the pump through the small access areas commonly found in covered manure storages. The full-length trailer and two-stage PTO shaft make set-up or takedown fast and easy. Both the six-inch and eight-inch discharge models are available with manual controls, hydraulic controls or the unique “under-floor” controls kit designed for precise control in slatted floor barns.

Much of the manure handled in today’s operations contains calcium, sand or other forms of grit so the Jamesway Verti-Pump features a new lower seal assembly specifically designed to work in these conditions. Operations handling grit-laden manure will also benefit from the Hardox-450™ Abrasion Resistant Impeller option.

The Jamesway Verti-Pump is available for pit depths from six to 14 feet. www.jameswayfarmeq.com

With the growing season approaching quickly, soil nutrient programs will soon be put to the test. These programs should be carefully developed with input from an agronomist or fertilizer dealer because fertility is responsible for as much as 40 percent of crop yield. As growers see their investments pay off and yields increase, it’s important to remember that high-yielding crops remove proportionally more nutrients such as phosphorus (P) and potassium (K) from the soil. Nutrient application must

keep pace with crop removal.

Progressive growers monitor soil fertility using soil tests, but also closely manage fertility programs by predicting future crop nutrient needs. This is especially important in years when ideal growing conditions result in yields that go beyond yield goals and the corresponding nutrition program designed to reach that yield goal.

One way to get an idea of future fertility needs is to calculate the difference in crop removal rate between the yield goal and actual yield harvested.

For example, if a soil fertility program is designed to produce a 180-bushel-peracre corn yield, the crop P removal rate will be 63. (180 yield bu. x .35 [P2O5/bu. removal constant] = 63 removal rate). If growing conditions are positive and crop yield increases to 220 bushels per acre, the crop P removal rate increases to 77 (220 yield bu. x .35 = 77). This difference of 14 is taken from the soil by the crop, reducing soil test phosphorus and potentially creating a negative balance for soil phosphorus levels.

For more information about crop nutrient removal, soil test trends and managing soil fertility to maximize crop yields, visit http://www.mosaicco.com/ resources.htm, an agronomy resource The Mosaic Company offers to growers. For more production information, visit Back-to-Basics.net.

Woodchips, sawdust and sand are major expenses for dairy farmers, who depend on a steady supply of quality, affordable bedding material for their cows. To save money and ensure a fresh supply, farmers are turning to technology from the Bauer

Group affiliate FAN Separator, called the Bedding Recovery Unit (BRU). The BRU processes cow manure into clean, dry bedding – and provides other benefits.

The Bedding Recovery Unit lets dairy farmers reclaim 25 to 30 cubic yards per day or more of high-quality bedding material from the undigested fibers in cattle manure. The machine separates, dries and treats the fibers in an aerobic process, resulting in a self-contained cycle that reduces manure management costs, improves cow comfort and boosts milk output.

According to the company, farmers find the BRU easy to use, requiring minimal maintenance such as changing oil, greasing and cleaning screens once a month. The BRU works by pumping the raw manure from the collection pit into the press screw separator, technology from Bauer’s affiliate company FAN. There, undigested fibers are separated from the liquid. The separated solids are then fed into a 30-foot-long rotating drum by way of a patented conveyor system.

It takes the material about 12 to 18 hours to pass through the drum, where micro-organisms act on the material. The temperature inside the drum rises to about 150 F, hot enough to kill pathogens that cause mastitis and other costly diseases.

The dry bedding material is then moved by an auger or conveyor to an intermediate storage area.

www.bauer-at.com

JOZ, barn-cleaning specialists for cattle farms, recently introduced a fully automated and integrated claw cleaning and disinfection system. The Claw Clean System (CCS) was developed in

collaboration with the Dutch engineering firm Heemskerk. The system is animalfriendly and suitable for all barn types. It consists of a central control unit and one or two spray units. The easy-to-operate system works preventively and replaces the process of foot bathing that is both timeconsuming and unpleasant for cattle.

Until now, foot baths have become rapidly soiled by manure introduced on the animals’ hooves, as a result of which the disinfectant has only a short effective life and can indeed even have negative consequences. Cleaning was a timeconsuming and difficult process. On larger farms, it often had to be undertaken during milking. This clearly led to considerable stress for the animals and the milker.

CCS cleans and disinfects the claws hygienically and fully automatically. The spray causes no discomfort to the cattle. CCS is a continuous, preventive approach. As a result, claw problems remain under control, savings are achieved in both time and money, and the cows maintain production levels and live longer.

The central unit is connected to the main water and electricity supply. A dosing unit guarantees the correct mix of disinfectant and water. A high-pressure pump carries the solution to the spray nozzles.

Following assembly, it is simply a question of placing a section of hose in a container of disinfectant, and activating the system by turning a knob. From that time on, CCS will treat the claws of every cow detected by the sensor. The spray units are positioned in the return alley of the milking parlor or at the exit of the milking robot. www.jozgroep.nl

Trimble recently announced the release of its new DCM-300™ modem.

The multi-use modem provides access to VRS™ Real-Time Kinematic (RTK) corrections and handles wireless data transfer to deliver information to and from the field or track assets.

The new modem can be used to access Trimble® VRS Now™ Ag RTK correction service and to enable Connected Farm™ wireless field data transfer. The DCM-300 modem is also compatible with the new Farm Works® Dispatch™ asset tracking software, an expansion of the Connected Farm solution. Dispatch software uses wireless communications and Global Positioning System (GPS) to manage vehicle

movement and productivity.

The DCM-300 modem is available in two models for use on Global System for Mobile Communications (GSM) cellular networks, such as AT&T, or Code Division Multiple Access (CDMA) cellular networks, such as Verizon. The modem is available with a single data plan subscription, which will be provided by Trimble, offering farmers a cost-saving solution to consolidate data plans under one subscription.

The DCM-300 offers efficient access to both Connected Farm and VRS Now RTK sub-inch accurate correction service. Job orders, coverage maps and A-B lines may be transferred wirelessly to multiple vehicles in different locations for followup operations, or within the same field for accurate overlap protection. Farmers can save time without the need to hand-deliver electronic data cards or jump drives from the farm office.

www.trimble.com/agriculture

gorman-rupp receives isO certification

Officials with the Gorman-Rupp Company, a manufacturer of pumps and pumping-related equipment, recently announced the company’s Mansfield Division in Mansfield, Ohio, has achieved certification to ISO 14001:2004 for its environmental management system.

Certification to the internationally recognized standard demonstrates the company’s commitment to minimizing the impact of the company’s activities on the environment through use of best management practices, technological advances, promotion of environmental awareness and continual improvement.

The Gorman-Rupp Company, established in 1933, is a manufacturer of pumps and pumping systems for the municipal, water, wastewater, sewage, industrial, construction, and original equipment manufacturing markets. www.GRpumps.com

The American Society of Agricultural and Biological Engineers (ASABE) has completed a revision to the front-end loader safety standard. The revised standard, ANSI/ASAE S355.4, Safety Practices for Agricultural Front-End Loaders, was revised to clarify normal operation and travel of the loader, loader arm position during transport, and travel locks. References for the document were also revised.

A copy of the document can be ordered by contacting ASABE headquarters directly at: martin@asabe.org. ASABE members and those with site-license privileges to the ASABE online Technical Library – available at www.asabe.org – can view an electronic copy of the standard.

Conformance to ASABE standards is voluntary, except where required by state, provincial, or other governmental requirements, and the documents are developed by consensus in accordance with procedures approved by the American National Standards Institute.

Mailed six times per year. Subscriptions are free to farm owners, partners and managers of large livestock or poultry operations in Canada and the USA. free subscriptions must be renewed annually. Great rates are available to other interested readers.

For best service, subscribe or renew online at www.manuremanager.com. If you are renewing, please quote the seven digit customer number found on your mailing label.

Telephone 866-790-6070 • fax 877-624-1940 e-mail mweiler@annexweb.com www.manuremanager.com

By S. Ram Shrivastava

America faces a serious challenge due to its dependence on oil- and petroleum-based energy sources. Billions of dollars go out of the country and the economy suffers as energy costs keep going up and there is no end in sight. Fortunately, communities with large animal farm-based businesses have an enormous untapped resource to help solve the energy problem in a collective manner.

New York is one of the top three states in the country with very large dairy and animal farms. Some counties, such as Wyoming and St. Lawrence, have more than 40,000 cows. Historically, the neighbors have complained about odors and other environmental problems resulting from these large farm businesses, some having 2,000 to 3,000 cows on one farm. The main cause is reported to be undigested manure that is collected and spread in the dry season on the farm land.

A risk associated with capital investments has prevented most farmers from making an investment in anaerobic digester technologies. With renewed interest and grant funding for renewable green energy production at federal and state levels, now is the time to take action and extract the gold within manure waste. In this case the word “gold” refers to biogas energy that can be recovered using efficient digester

technology, and complemented by gas processing to make bio-fuel for transportation needs.

A great example of this approach is Whatcom County in Washington state, which has made a county-wide effort to help the farmers realize this value and deal with the high cost of transportation fuel needs in the community. The chart below clearly shows that significant economic value can be realized by generating power for use on the farm and using excess biogas to clean and produce fuel for the vehicles as compressed natural gas or hydrogen.

Imagine a county with 40,000 cows able to make auto fuel of 20,000 gallons per day with current value of $80,000 per day.

The electricity from manure digestion can make the farm energy-independent. Excess biogas can provide revenue via the sale of auto fuel, digested or composted solids sold as organic fertilizer, and treated effluent applied back on the farm with no odors and complaints. It is a win-win solution.

Most of the farm communities also have dairy processing plants with organic waste produced. The farms with digesters can increase their revenues and higher biogas production by treating this hauled-in waste. The central digester concept has been very profitable for farmers and makes them part of an energy generation center. Since excess power transmission is not permitted across property lines, it makes sense to broaden the approach and install gas cleaning and hydrogen generation units for best value in the form of energy that can be shipped to fueling stations serving municipal or private cars.

The political leaders need to capture this opportunity and help their farms become catalysts of growth and partners in seeking energy independence. Such an initiative will create new jobs, strengthen farm businesses and result in a better environment.

The country is seeking to produce green power to replace oil. Many financial incentives are going to be offered to farmers. Start planning the countywide initiatives and solve these energy problems. If the community is lucky enough to have a large animal base, treat it like an oil well with an unlimited source of clean energy in various forms.

What are we waiting for?

S. Ram Shrivastava is a professional engineer, LEED-AP, and president of Larsen Engineers, based in Rochester, N.Y.

GUTTER-CAT

FLUSH-FLUME SYSTEM

B-15/16 CROSS CLEANER

B-15/16 CHAIN SCRAPER

DURA-CHAIN SCRAPER

SEMI-TRANS PISTON PUMP

SOLID-TRANS PISTON PUMP

VERTICAL PUMPS

LIQUI-TRANS PISTON PUMP ELECTRIC PROP AGITATOR

MECHANICAL PISTON PUMP

XD-SERIES CABLE SCRAPERS

4, 6 or 8

JAMESWAY FARM EQUIPMENT, INC.

FACTORY: St. Francois-Xavier (Quebec) USA WAREHOUSE: Tomah, WI PHONE: 819-845-7824

ULTRA-PUMP 3PH PUMPS & PROPS

PTO-DRIVEN PUMPS

PTO PUMPS ULTRA-PUMP TRAILER LAGOON

PUMP

MOUNTED