There's an app for CRap

6

There’s an app for crap

A Midwest custom manure applicator is benefiting from mobile device technology.

11

Compost is not created equal

California’s Diestel Turkey Ranch is developing a high-value turkey compost using compost turner technology.

16

Dynamic duo

Partnership eases path to quality composting for large Minnesota dairy system.

20

New York’s largest biogas power project online

U.S. Sen. Charles Schumer (D-N.Y.) joined state and local officials recently at the grand opening of New York state’s largest on-farm, co-digestion biogas power project.

21

U.S. EPA launches waste to biogas mapping tool

The U.S. Environmental Protection Agency’s Pacific Southwest Region has launched an online “waste to biogas mapping tool” to support the use of organic waste for energy projects.

22

Decades of digester development

RCM is celebrating 30 years of business in 2012 and the company has taken its technology from a simple idea to being a leader in the industry. 28

Cover: Jeremy Puck using a Zoom mobile device to make adjustments to a pump. Custom manure operators are moving toward mobile device technology to help deal with rising labor costs and unexpected shutdowns. Submitted photo

July/August 2012

Volume 10 • No. 4

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors Tony Kryzanowski, Diane Mettler

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Media Designer Kelli Kramer

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@annexweb.com

Printed in Canada

Circulation

e-mail: subscribe@annexweb.com

Tel: 866-790-6070 ext. 211 Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2012 Annex Publishing and Printing Inc.. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

‘I always feel like somebody’s watching me’

It would appear that CAFO operators in Iowa and Nebraska have had a valid reason to be experiencing those creepy-crawly feelings; you know the sensation, where the hair on the back of your neck rises up and tingles and you feel like someone is watching you but you just can’t see them. That’s because someone has been watching these hardworking livestock producers – from the sky.

This past spring, the U.S. Environmental Protection Agency (EPA) came clean with the fact employees have been zipping around in the skies snapping photos of large U.S. livestock operations for more than 10 years, ensuring these licensed facilities have been complying with environmental laws. According to the EPA, surveillance flights most recently were conducted in Iowa during 2010 and Nebraska in 2011.

Not surprisingly, livestock operators haven’t been too keen on the idea of being spied upon, especially since their families live on the same properties the EPA is photographing.

“Big Brother sure as hell is watching me,” stated one Nebraska feedlot operator during a recent information meeting held by the EPA in Lexington, Neb. (as quoted by the Omaha World-Herald).

It’s a view also held by Kristen Hassebrook, director of natural resources and environmental affairs for the Nebraska Cattlemen.

“The practice by EPA Region 7 of flying over and photographing livestock operations is intrusive, unnecessary and a waste of taxpayer resources,” she stated in a press release from the association, adding that someone’s home, their children’s playground, the decks they have family parties on are right there, “smack dab” in the line of sight when the government takes photos of their property.

“There is no need to spy on citizens,” said Hassebrook.

Nebraska’s congressional delegation sent a letter to the administrator of the EPA in early June questioning the flyover practice. A proposal by a Republican Senator from the state seeking to halt the flights until the EPA answers more questions about the program was ultimately defeated in the U.S. Senate later in the month.

Besides the impression they are being spied upon, Nebraska feedlot operators are baffled as to why the EPA is “doubling up” on regulations already being handled by Nebraska’s Department of Environmental Quality, which has inspectors who are already working with CAFOs in the state and conducting on-site inspections.

“EPA inspectors have all the tools they need to monitor operations without flyovers,” said Hassebrook. “Access to a producer’s file is available to them and they can speak with the state-based regulators.”

Personally, I find the whole thing kind of creepy with government officials flying over properties snapping pictures of farm operations plus people sunbathing, swimming in backyard pools or jumping through the sprinkler. Whatever happened to privacy?

And I question the effectiveness of the practice. East Coast poultry producers are all too aware of how well flyover programs work for finding environmental infractions. Back in 2009, a volunteer service that flies over Delmarva Peninsula poultry operations snapped a photo of what members thought was a “suspect” litter pile on a poultry operation near Berlin, Md. It was actually a pile of legally obtained Class A, intensively treated biosolids received from a local wastewater treatment plant. Several lawsuits later, the finger pointing is still going on and the Hudson family is still waiting for their day in court, scheduled for later this fall.

There’s an app for Crap

By Tony Kryzanowski

Custom manure applicator benefiting from mobile device technology

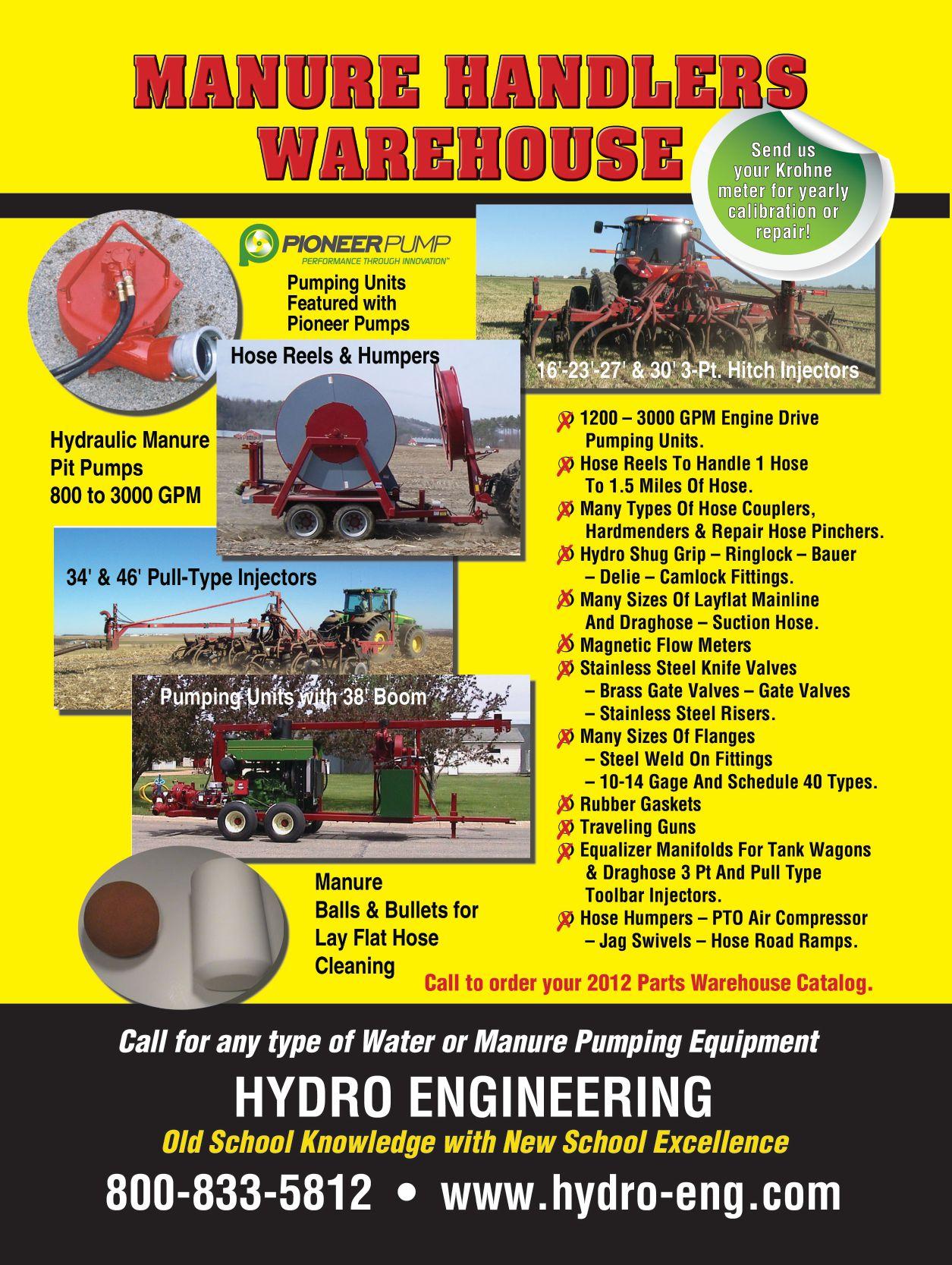

Concerned about the cost of operating and monitoring drag hose systems, the cost of unexpected pump shutdowns, and the cost of labor for each drag hose crew? There are now mobile apps to help deal with that as long as there is reliable cellphone coverage to support it.

Mobile communication technology is now available to custom manure applicators using drag hose systems to monitor and adjust the performance of pumps on each setup using either software operating on a tablet device, laptop computer or on a smartphone.

While the mobile app technology related to pumping operations is not cheap, the benefits are that they give company owners and managers the ability to monitor and adjust the performance of drag hose systems

without being present and from a great distance.

Wisconsin custom manure applicator Ernie Sundstrom says it cost him about $18,000 to install the communication hardware for each pump but, by using the technology, he needs fewer workers on each drag hose crew to get the job done. This saving in salary alone has easily paid for the installation. He began using his mobile communication system last fall and, at present, has three pumps equipped with the technology. He is working to equip a fourth.

Sundstrom and his brothers, Willie and Jordan, own Sundstrom’s Pit Pumping located in Colfax, Wisc., about 70 miles east of Minneapolis/St. Paul, Minn. They offer custom manure transport and application service using drag hose systems, tanker trucks, semi tankers and frac tanks. Their fleet consists of five, 4,600-gallon tanker trucks, three drag hose systems, a conventional dredge and two stirring

dredges. They also offer solid manure transport and disposal and have an industrial waste disposal service. The company has been in business since 1994. They have 30 employees and five crews.

Sundstrom worked with Ben Puck from PCE Manure Equipment in Iowa to provide him with his pump communication and control system. It is manufactured by a company called Mobile Star and Sundstrom Pit Pumping has subscribed to the online communication service provided by Mobile Star to stay in communication contact with their pumps. The system consists of a communication unit on a pump that is connected to the electronic control module (ECM) connection on the engine that powers the drag hose setup. Sundstrom described it as essentially a plug and play system where he plugs the pump communication unit into the ECM on the engine and he is ready to go to work. By simply connecting to the Mobile Star website using his tablet with

Investigating local cellphone coverage is important before custom manure applicators consider mobile app technology that uses a cellphone network. Submitted photo

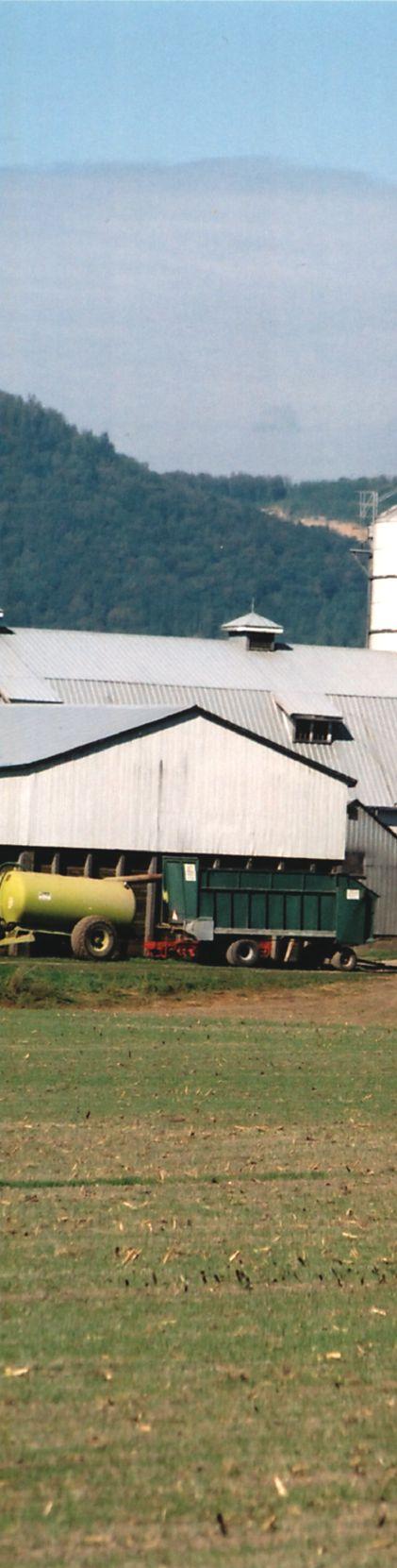

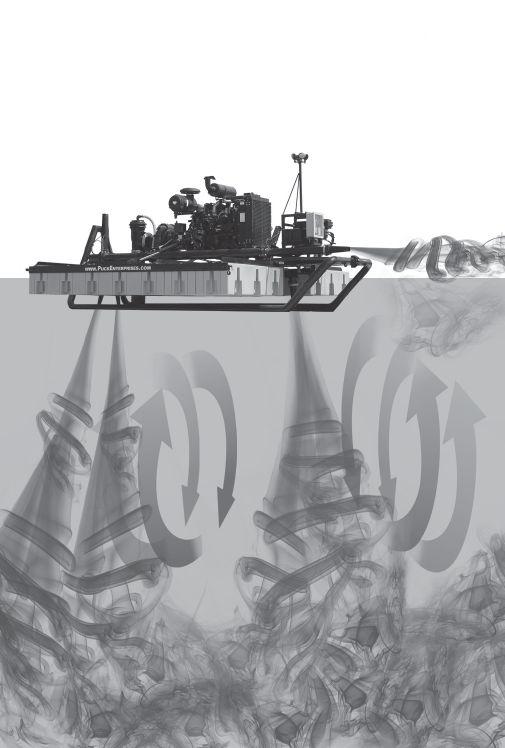

The PUMPELLER Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

his user name and password, he is able to receive data and send instructions as needed to each equipped pump. He is able to both monitor and make pump adjustments using his Zoom tablet provided by Verizon, but Sundstrom says he can only monitor the system using a smartphone.

“The ability to monitor what the system is doing faster than the human eye can was very appealing to us,” says Sundstrom. “Now, we can have one employee run three or four pumps instead of having four guys out there, and our reaction time is actually faster. The other nice thing is that I could be sitting on the beach in the Bahamas and by pulling up my laptop and logging in to the Mobile Star site, I could be looking at what my guys are doing in northern Wisconsin or northern Minnesota.”

With the relatively short manure application window each year, the ability to closely monitor and make adjustments in real time over long distances has the potential to deliver a significant efficiency dividend. It means less travel for owners and for onsite crew members responsible for monitoring pump performance. As he was being interviewed, Sundstrom was supervising one of his drag hose crews and monitoring the system’s pump performance on his tablet from the cab of his truck.

“I can see all three of my crews’ pumps on my tablet,” says Sundstrom. “I can see what they are running for rpms, gallons, pressures, everything. I can also adjust those pumps from my truck.”

PCE Manure Equipment owner Ben Puck says they use the mobile communication equipment themselves and have been offering it to other custom applicators for about two and a half years. They commissioned Mobile Star to build the system around PCE Manure Equipment’s specifications. They have equipped about 100 pumps with the system, and of the 15 pumps sold this spring, only one did not have the mobile communication equipment installed. The full capabilities of the communication system are the ability to read the inlet and outlet pump pressures, read the digital signal from the Krohne flow meter, start and turn off the engine, vary the engine rpm by 25 rpm increments, prime the pump, change up to three flow gates, and protect the line from spot pressure spikes. Other features include monitoring the engine oil pressure, fuel consumption and engine hours.

“The system will soon have the

Jeremy Puck uses a Zoom mobile device to make adjustments to a pump. Submitted photo

The hardware for the communication technology that plugs into the engine electronic control monitor costs Sundstrom’s Pit Pumping in the range of $18,000 per pump. Submitted photo

ability to dump the information onto an Excel spreadsheet to tell you how many hours the system ran, how many gallons of fuel were burned, and how many gallons were pumped on a particular job,” Puck says.

The ability to monitor and control manure pumps with either a tablet or smartphone device could revolutionize day-to-day operations for custom manure applicators.

“This really is a new phenomenon that has grabbed hold in the last six months,” says Kevin Erb, conservation professional training co-ordinator with the University of Wisconsin. Among his responsibilities is working with the forhire manure application industry across the American Upper Midwest.

“It wouldn’t surprise me if a year from now, use of this mobile app technology went from only five percent of the applicators in Wisconsin to more than 50 percent,” he adds. “I think the potential for growth is there. The only thing holding it back is that the industry isn’t aware that these types of applications are out there – from draglines to tracking tankers in the field.”

In states like Wisconsin, custom manure applicators land apply about six billion gallons of dairy manure alone per year. Companies range from applying a few hundred thousand gallons to as much as 500 million gallons per year. Some have as many as seven crews in the field working at different locations all at once.

“For a lot of our Wisconsin dairy operations that are in that 100- to 150-

cow range, a custom manure applicator could have crews working in three different counties on three different farms at the same time,” says Erb.

The ability to idle up or idle down pumps using radio-controlled devices has been available for over a decade and pumps are now typically outfitted with Murphy switches that automatically shut down the system in the event of a pressure change resulting from a blockage or leak. While this safety innovation works well, it can take a considerable amount of time to restart the system once a shutdown occurs. New mobile app technology can be set up so that it alerts the custom manure applicator of a potential problem at a distance, allowing him to react and make adjustments before the system automatically shuts down. Given this capability and the costs associated with unexpected downtime within a short production window, Erb adds, it’s little wonder that the custom manure applicator industry is quickly embracing this communication technology.

In terms of troubleshooting, Sundstrom had a recent experience where he had six pumps working in line with the last pump computer controlled and connected to his tablet. From 20 miles away, he noticed that the pressure was going up.

“I knew I had a problem and it turns out that the tractor operator had hit a lever in the tractor that had closed off one of the valves,” he says. Recognizing the problem before it turned critical, he was able to make a call, troubleshoot the

problem, and save a lot of time repairing what would likely have resulted in a blown hose.

The development and availability of purpose-built, mobile apps specifically for the custom manure application industry is very much an evolving landscape. Erb says it has really been fueled by the greater proliferation of mobile devices and smartphones. Software developers with an understanding of the communication power of these mobile devices have started creating applications aimed specifically at the custom manure application industry.

Spokesman for drag hose system provider Hydro Engineering, John Hochstein, says it is working with another company to explore the potential of making apps available for use on mobile devices with its system, but currently provides its customers with an FM radio communication system. It allows customers to start, stop, speed up and slow down pumps, as well as put the clutch in and out on the system engine. One challenge that the company has noted so far with an app system is the occasional unreliability of cell coverage in rural areas that customers would have to rely on with a mobile app type system, which is why the company is providing a more reliable FM radio communication system at the present time. Another concern is the potential cost of a mobile app control and communication system.

Puck acknowledges that his system is not perfect from the cellphone coverage standpoint, but the company has taken a few measures to minimize the problem. The system uses a five-watt antenna versus a quarter-watt antenna on a cellphone. Also, the system uses digital technology, which is the same technology to send text messages not voice messages. The company can also place 12-volt enhancers around the pump to improve the signal strength.

“It’s not perfect, but by the same token I haven’t seen anyone throw their cellphones away because they can’t get service all the time,” says Puck.

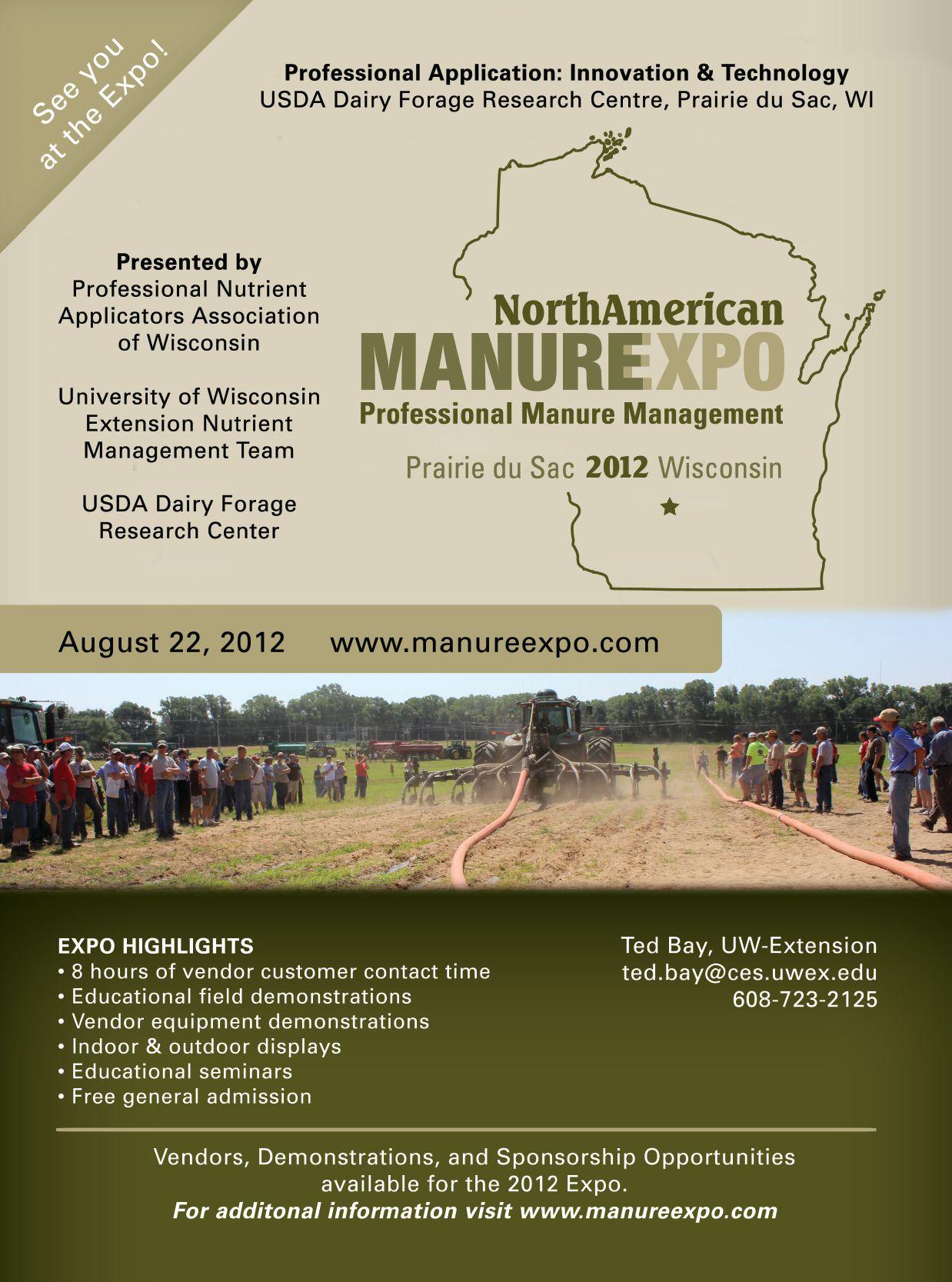

Attendees of this year’s North American Manur Expo, being held Aug. 22 in Prairie du Sac, Wis., will have an opportunity to learn more about the various options that are currently available to custom manure applicators. A presentation has been dedicated to this specific topic, featuring current users of the technology and their experiences with it. The planning team is considering live demonstrations of mobile apps.

A tractor operator can monitor information on the Zoom mobile device screen while he is driving and make adjustments as needed. Submitted photo

Compost is not created equal

By Diane Mettler

Diestel Turkey Ranch develops high-value turkey compost using turner technology

After five minutes with Jason Diestel, you quickly learn there is more to compost than meets the eye.

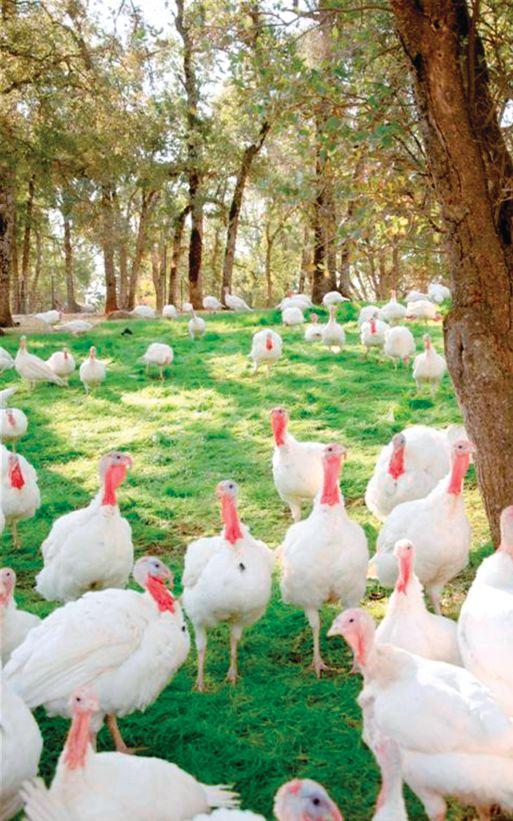

Jason is the director of sustainability for the Diestel Turkey Ranch, located near Sonora, Calif. His grandfather founded a 50-acre turkey farm in 1949. Customers back then (and now) lined up for the turkeys grown the old-fashioned way and thought they tasted better. The farm continued in that direction. In 1980, Jason’s dad took over and today the 200-plus-acre farm processes 200,000 organic turkeys a year – all grown in the old fashioned way – and sells them to stores throughout the West.

Quality is key for the Diestels, whether it’s turkeys or compost. “My great uncle Ernest taught my grandpa about the concept of quality – not rushing the process and allowing time to develop the highest quality possible,” says Jason.

Senior project and compost

When the Diestels started processing in the 1980, everything could be taken to a rendering plant, but today the State of California won’t take the feathers. With 200,000 turkeys, that’s

a lot of feathers. Jason says there’s also no market for them. “The only option in California is to take it to a landfill.”

By the time Jason was in college at Cal Poly in the 1990s, applying raw manure had also become more regulated. When it came time to choose a senior project, Jason wanted to find a way to turn their byproducts into something productive.

“I started looking for something that made sense to me,” says Jason. “I started going to U.S. Composting Council and BioCycle and other areas and I heard the same thing over and over: “Compost is great stuff. Put it in a pile, turn it a few times, it turns black. Compost is compost.”

This didn’t make sense to Jason. “We have successfully differentiated ourselves for [more than] 60 years in the turkey business and you’re telling me that all compost is created equal? There had to be more to it.”

Jason’s search led him to Midwest Bio Systems, a company out of Illinois that focused on creating compost from the plant’s perspective – on humus-based soil fertility, which is the practice of building long chain polymer carbons in a very efficient 10-week composting process.” And, Jason says, corn and soybean farmers who were paying $120 per ton for humus compost and outperforming other soil fertility

Diestel Turkey Ranch, located near Sonora, Calif., produces turkeys the old-fashioned way. It also produces compost from the manure and feathers. Contributed photo

practices with better yields and lower input costs.

“That really caught my eye, not only from a profitability standpoint, but also if they were selling a product of such high value, it has to work or they’d be out of business.” And it was this realization that led Jason to take a year away from the farm to work for MBS, to explore soil fertility, and learn what he needed to do at the farm to make the system work.

Breaking down feathers

Back at the Diestel Farm, the challenge was composting 12-inch turkey feathers, which refused to break down. “We tried doing it with a loader bucket and we weren’t able to keep the moisture,” says Jason. “The other problem was, we had no way of releasing carbon dioxide and weren’t getting the breakdown process needed.” The answer turned out to be an Aeromaster Compost Turner from Midwest Biosystems.

“The Aeromaster Compost Turner is extremely efficient,” says Jason. “It removes carbon dioxide and applies water at the same time and does a great job of aerating. The tines spin slow enough that it’s not pulverizing the product and that allows for the humus chains to be built. It also doesn’t

take a lot of horsepower to get through the rows. It flips the material backwards and allows CO2, which is heavier than air, to release from the bottom of the row.”

After the Diestels started using the turner, they were able to adjust their water application and keep it consistently at the necessary 45 to 50 percent. “If you can keep a consistent moisture throughout and not just the first few inches of the row, you can really break down some organic matter,” says Jason. “And after you break down the organic matter, you can start building up humus.”

High-quality compost

As with the turkeys, Jason and his family focus on quality compost. Their goal is to make the highest quality possible. To do so, they also use windrow covers. It’s a little more labor, but saves some water and a couple of turns by keeping the environment stable.

Jason says they also have the luxury of having extremely good quality control over what enters their compost.

With the addition of humus soil fertility technology, Jason feels there is a big opportunity to increase soil organic matter by percentage points in as few as three years, balance mineral ratios, increase nutrient availability and improve soil structure.

“All this can be done with fewer truckloads of compost over more acres of farm land,” says Jason. “Now that is sustainable when you consider that most of the cost of manure or compost is typically in the transportation.

“By changing, or optimizing, the soil structure, we’re optimizing the biological balance from a fertility perspective and that’s also allowing the nutrients to cycle more efficiently,” explains Jason. “You can’t sustain good biology in the soil unless you have a good soil structure. By utilizing the humus technology, we’re addressing all that.

Jason believes soon farmers will see that they are losing a lot of fertility value in manure by not converting it into something more stable like humus compost. And they can take care of odor issues at the same time.

“Typically, I want to see my nitrate be much higher in my finished compost than my NH4, which is ammonia. That tells

The organic turkey operation uses a 10-week process to produce compost. First, manure, feathers and ground wood chips are combined. During the next two weeks, the rows are turned every day, except Sunday. The following weeks the number of turns are reduced with a total of 20 to 30 turns expected during the life cycle of the row. Contributed photo

Two employees work full time on the compost business, which is in operation year round. Some of the resulting compost is spread on the Diestel farm’s pastures but the majority is sold to both small and large growers. Contributed photo

me that we’re on the right track for making a quality product and that’s essentially stabilizing nitrogen rather than nitrogen attaching to hydrogen. We want to attach it to oxygen and that stabilizes it, but then also the next step of that is to buffer it with humic acid — the long-chain polymer carbon of humus — which will hold that nitrogen in the soil stable where it’s not going to leach and won’t volatilize into the air.”

In short, with this process Jason is able to keep 96 percent of the nutrients in the root zone, whereas with manure 60 percent of nutrients are leached or escape as odor.

The process

The 10-week process is straightforward. First, manure, feathers and some brown material (ground wood) are combined. During the next two weeks they turn the row every day, except Sunday. The following weeks they reduce the number of turns with a total of 20 to 30 turns during the life cycle of the row.

“We decide whether we’re going to turn a row based on the temperature, CO2 and moisture,” says Jason. “We have critical control limits on each of those areas and if they fall out of the limit, then basically there’s a problem that needs to be addressed.”

For example, if the compost goes over 140 F, it could hurt some of the beneficial microbes, so they will quickly turn the row. And if the carbon dioxode is above 10 percent then they know that half of the oxygen is used. “If I’m testing every day, and half of the oxygen is used, then I turn so I don’t use up all my oxygen to keep everything aerobic.”

Two employees work full time on the compost. They use a digital temperature probe as well as a standard dial temperature probe to track the temperature. They also use a carbon dioxide meter, but haven’t found a good moisture meter yet and test by hand. If it feels like a sponge, but you can’t get a drop of water out of it, it’s at about 45 percent moisture.

All the manure and the feathers from the processing come to the centrally located, 15-acre composting site. Fall and spring are normally the busier time, but the Diestels compost year round. The final product is OMRI listed and the company is also a U.S. Composting Council’s Seal of Testing Assurance (SAT) member.

Selling the product

The farm uses a small portion of the compost on its pastures, but the majority is sold.

“We deliver small quantities and we work with other guys to haul it,” says Jason. “We’ve had a lot of success in

Diestel Turkey Ranch processes 200,000 organic turkeys every year. Contributed photo

the gardens, backyard farming, and with community supported agriculture (CSA) farmers. Also large commercial nurseries are including it in their blend because they’re seeing some noticeable benefit.

Getting those first sales wasn’t easy though.

When I first started going out, nobody had heard of me, the product or what we were doing. I just kept lining up all these contacts and saying, “Hey, I’m still here, and I’ve got stuff that works.”

“It was about a year before I sold them some product,” says Jason. “Fortunately, I was young and I didn’t really know what it meant to get a product off the ground.”

While Jason was building up a customer base, compost was building up at the farm. Diestels made arrangements with larger farmers to take the compost.

“We actually got a little business out of that,” says Jason. “They saw that it was different and it changed the soil in a better way than manure did.”

Staying focused

Quality compost requires a diligent site manager who is going to make the critical calls every single day. It also requires investing in the right equipment. “The efficiency gained by being able to handle material efficiently is well worth it and we went along for a while trying to avoid that reality,” says Jason.

Jason expects it won’t be long before people see how compost can make a big difference and become more willing to make the investment in our soil.

“The most rewarding thing I’ve ever experienced was seeing this concept working – one that 99 percent of folks have no idea is out there. It’s an incredible technology.

“I think that in our culture, we have a very mechanical view of the world. If the wheel bearing goes out on your car, you can wait a year or two years. It’s still going to be broken; it’s a mechanical organism. Our farms and our manure and our composting systems aren’t mechanical organisms – they’re biological organisms, which means that they are self healing when the right conditions are available. Farmers understand this process. It’s exciting to have people come back to me who are using the compost and have them say: “I reduced my water usage by 25 percent and I doubled my yield!”

Dynamic duo Dynamic duo

By Tony Kryzanowski

Partnership eases path to composting for large Minnesota dairy

The compost you produce from your manure may be a valuable product, but is it a marketable product? Farmers ask experienced compost manufacturer Brad Matuska that question all the time. The correct answer, he says, is “that depends.” It depends on how the compost will be used.

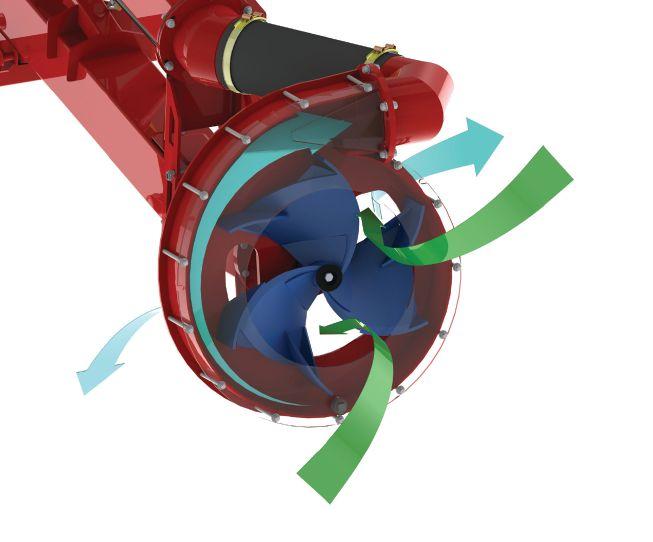

Through his company, Mississippi Topsoils, headquartered in Cold Spring, Minn., Matuska and his partner, Math Miller, have been producing compost from poultry bio-solid material and, more recently, cow manure, since 1998. Its products are marketed under the Soil Essentials Premium Soil Products label and distributed through landscape, greenhouse and garden center supply companies.

Mississippi Topsoils has partnered with one of the state’s largest dairy operations, Riverview, in Morris, Minn., to purchase a portion of the stabilized manure that exits from the dairy’s anaerobic digester, which the compost manufacturer converts into high-quality compost. It is marketed to independent landscapers, greenhouses and garden centers throughout the states of Minnesota, Iowa, Wisconsin, North Dakota and South Dakota.

“Composting manure is a step in the right direction in that we are managing these concentrated centers of waste products in a way that is creating value and it is essentially truly sustainable,” says Matuska. “It’s socially responsible, environmentally responsible, and economically responsible. It isn’t just a fad that’s going to be happening for the next five years. This is the direction I think we are heading.”

Matuska says the marketability of compost really depends on the quality and stability of the final product. It looks like and acts like peat moss, but unlike peat moss, it has a nutrient value.

“There’s a learning curve and anybody can do it if they invest the time, energy, and money into it,” he says. The question is whether

or not it is worthwhile for farms whose main focus is on dairy, poultry, cattle or hog production.

“It is another business that essentially would require the same amount of time and commitment as your milk business,” says Matuska. “The biggest downfall of on-farm composting is the assumption that if you make a product, people are going to fall over themselves to buy it. That’s not true.”

So if the goal is to produce a high-quality, stable, and marketable compost product, farmers may want to consider duplicating the model that has evolved between Mississippi Topsoils and Riverview. One concentrates on producing high-quality compost while the other focuses on its milk business and deriving an extra income from selling the raw material needed to make compost to a dedicated compost producer.

Matuska says by taking this approach, it is like hiring a stockbroker to buy your stocks instead of you doing all the research yourself. While the do-it-yourself approach might yield good results, sometimes the best results are achieved by working with an expert.

Located next to the Gold’n Plump poultry business in Cold Spring, Mississippi Topsoils started out by converting poultry biosolids from this operation into compost.

“We began making compost and quickly discovered that we needed to have a complete line of soil products to be competitive in the market,” says Matuska. So in addition to compost, the company also developed a potting soil blend and a planting mix.

At this point, the owners also discovered a market for a manure-based compost product and started working with some horse stables as a source of raw material. However, that source eventually dried up. Fortunately for the business, that’s when Matuska met Riverview representative Adam Zeltwanger at a trade show. Riverview was interested in finding other markets for the stabilized manure coming from its anaerobic digester. The dairy was producing considerably more of the material than it was using for animal bedding in its dairy operation.

The partially stabilized manure purchased from one of Minnesota’s largest dairies, Riverview, is helping Mississippi Topsoils complete its conversion to high-quality compost more easily. Submitted photo

“The significant market for that product is using it as bedding,” says Matuska. “Using it as a value-added soil amendment in the green industry is something new. What’s attractive to them (Riverview) is that they can generate more revenue.”

Riverview operates a 21,000-cow dairy, and four years ago they invested in an anaerobic digester than collects biogas, which is used as fuel for several 1,000-horsepower generators. The power produced by the generators is sold and

to good use in his compost business.

eventually ends up on the state power grid. It takes 21 days to process its dairy manure through the digester and the process creates enough biogas so that the generators can operate 97 percent of the time. The byproduct that exits the digester is processed through a screw press where the water is separated from the solids. The nutrient-rich water is collected and used to fertilize crops and some of the dry byproduct, or stabilized manure, is used for bedding. The rest was looking for a home, and that’s where

Mississippi Topsoils co-owner Brad Matuska is putting his university degree in biology

An indication of the heat generated by organisms converting manure to compost is the steam rising from this partially composted heap. Submitted photos

is how well Riverview manages its anaerobic digestion process, which provides the compost company with a clean and consistent material that it can then take further and add more value.

Once a load arrives from Riverview, it is placed in a pile inside a building on top of two, four-inch PVC lines with holes in them that are hooked up to a blower. The blower assists in supplying oxygen into the mass, which encourages organisms responsible for converting the manure into compost to do their job in a healthy environment.

“It is essentially an aerated, static pile,” says Matuska. The pile is aerated for a minimum of two weeks and the temperature is monitored to make sure that it stays consistently in excess of 131 F for seven days. Maintaining this heat, produced by the activity of the organisms, further reduces the pathogens in the composted manure.

After this conversion process, the compost is placed into a non-aerated, static pile for curing,“like a good wine or a good beer. The food is running out for the organisms that are working the pile and they basically begin dying off, readied to become plant food,” Matuska says.

From beginning to end, the process takes three to four months before the compost is ready to bag and ship to customers.

Through scientific growth studies and field tests that Mississippi Topsoils has conducted over the past four years on the compost’s value as both a soil amendment and slow-release organic fertilizer, the company has been able to demonstrate its value to their customers. Sales for its compost products have grown by double digits every year over the past four years. Compost sales in the past year alone improved by 20 percent. Matuska says that the compost provides much more than nutrient value to plants. It helps to create high-quality soil and better growing conditions by improving the physical, chemical and biological properties of the soil. Matuska’s degree in Biology from St. John’s University helps him to improve his understanding of how it benefits a soil growing system.

The amount of stabilized manure that Mississippi Topsoils currently purchases from Riverview is being driven by the market, but based on demand so far, the company has high hopes for strong growth going forward. It only started selling the cow-based compost product last year and is on pace to triple its sales volume this year as compared to what it sold last year over the same period.

Mississippi Topsoils entered the picture.

Matuska says the stabilized manure that he purchases from the dairy is about halfway along its journey to becoming high-quality compost when it arrives at his composting business. The process employed by Mississippi Topsoils takes it the rest of the way. The company produces compost year round.

“The resulting product that Riverview produces has been anaerobically digested, but it still has an ammonia odor to it and it’s still not totally stable for unlimited application in the gardening industry,” Matuska says. “We sell it as is right off the digester to some limited markets, but we also compost it. That opens up almost every market in that our process further stabilizes it. We can bag it and blend it with other materials for nursery stock or greenhouse production.”

What helps Mississippi Topsoils produce a high-quality product

What has Matuska excited from a business perspective is the potential profit in creating high-quality compost from all the raw material that Riverview can provide. He says the dairy has the potential to be able to provide as much as 1000 truckloads of the raw material annually with each load representing 22 tons of material. This potential high volume of raw material has him and his partner seriously contemplating the construction of a high-volume manure compost production facility right at the dairy. Right now, transporting the stabilized manure 100 miles from the dairy to Mississippi Topsoils’ facility in Cold Spring is having a significant impact on the overhead cost of producing the compost. Matuska says the idea of building a facility right at the dairy has evolved beyond the concept phase and he believes Mississippi Topsoils could have a plant situated at the dairy within three to five years. One of the factors motivating the company in that direction is regulations restricting the amount of compost it can process at its current location.

“There will be a tipping point at which time the market will be demanding more than what we can produce here,” he says. “So that will be the time when we will build the plant closer to the production point.”

He anticipates that at the same time, the company, which currently has three employees, will consider a completely automated bagging system and a completely new line of products, with distribution that includes large, retail box store chains on a regional or even national distribution scale.

Mississippi Topsoils produces compost from both cow manure and poultry bio-solids.

In addition to bagged, retail product, Mississippi Topsoils sells compost in bulk. Submitted photos

ThermoEnergy’s Thermo ARP™ high-efficiency ammonia recovery system is an unbeatable option for operators of anaerobic digesters who want to both comply with nitrogen regulations and recover ammonia as a valuable product. Thermo ARP recycles the ammonia in digester wastewater into ammonium sulfate or ammonium nitrate for the production of valuable fertilizers and industrial products. Thermo ARP is energy efficient, extremely robust, and compact – suitable for even rugged field conditions.

For more information email info@thermoenergy.com or visit our website at www.thermoenergy.com .

New York’s largest biogas power project online

U.S. Sen. Charles Schumer (D-N.Y.) joined state and local officials recently at the grand opening of New York state’s largest on-farm, co-digestion biogas power project. The facility is located at Synergy Dairy, a 2,000-head dairy farm in Covington, Wyoming County, southwest of Rochester, N.Y.

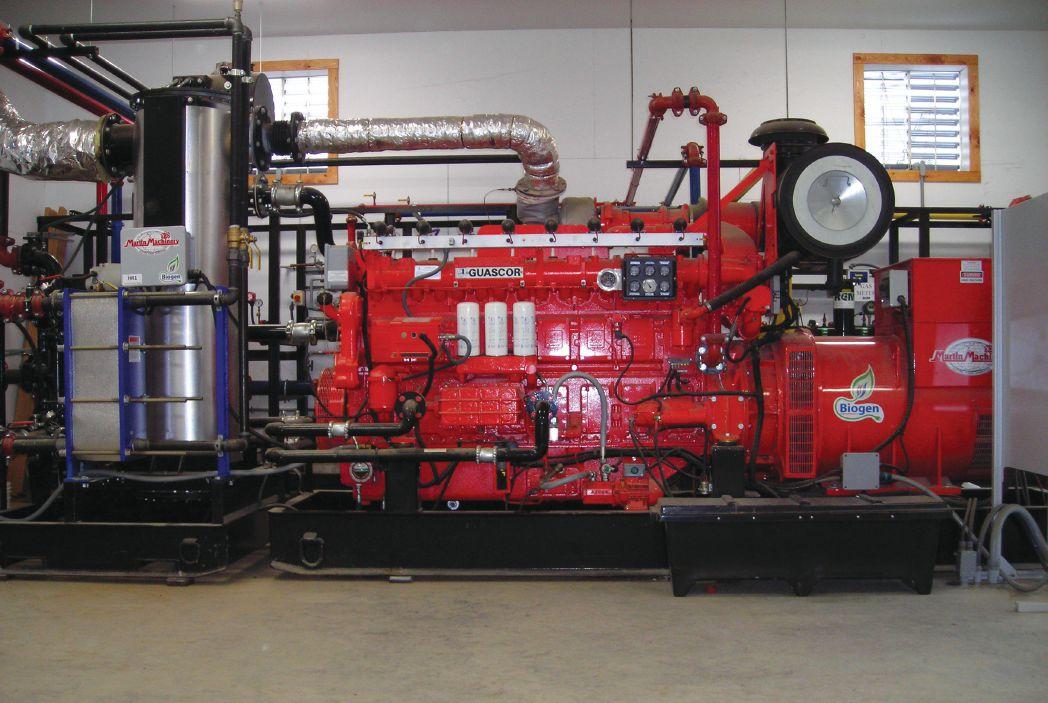

CH4 Biogas LLC built, owns and operates the project under the name Synergy Biogas LLC. The Synergy Biogas LLC plant also is the state’s first biogas project specifically designed for the co-digestion, or processing, of animal and food wastes. The biogas created in the 120,000-gallon codigester is fueling a GE Jenbacher J420 biogas engine to generate 1.4 megawatts (MW) of renewable electricity.

By anaerobically digesting waste from local food processors in addition to the dairy’s cow manure, the 425 ton per day, mixed-waste facility is more cost-effective. The facility has created about a half-dozen jobs while enhancing the efficiency of the 30-employee farm’s operations and sustaining area food manufacturers and haulers.

The New York State Energy Research and Development Authority (NYSERDA) is providing $1 million in incentives for the facility.

The project is expected to reduce the dairy farm’s base load greenhouse gas emissions by about 8,500 tons of carbon dioxide annually, which is equivalent to the carbon dioxide

emissions of 1,700 automobiles. The facility also will produce an estimated 17,500 cubic yards of bedding material for livestock while reducing manure odors and helping the farm manage nutrients applied to cropland.

Through its partnerships with local food manufacturers, Synergy Biogas LLC already has diverted more than 1.14 million gallons of food waste from landfills and wastewater treatment facilities, highlighting another environmental benefit of the project.

“We are excited to launch our new co-digestion biogas project that will optimize the recycling of agricultural biomass waste into a valuable renewable energy resource to help reduce our operational costs,” said John Noble, president and CEO of Synergy Dairy.

The Synergy Biogas LLC operation is the first of several N.Y. dairy farm digester projects that CH4 Biogas and GE Energy plan to build.

According to the New York State Department of Agriculture and Markets, in 2011 the state had 5,300 dairy farms with more than 600,000 dairy cows. However, fewer than 20,000 of those cows were being utilized in energy production, through the use of 17 digesters that produce a combined 3 MW. As of 2011, an additional 17 digester systems were awaiting installation to generate a combined 6 MW.

U.s. ePa launches biogas tool

The U.S. Environmental Protection Agency’s Pacific Southwest Region has launched an online “waste to biogas mapping tool” to support the use of organic waste for energy projects.

“This innovative mapping tool, the first of its kind in the nation, helps restaurants, hotels and other food waste generators to connect with large energy producers,” said Jared Blumenfeld, the EPA’s regional administrator for the Pacific Southwest. “Harvesting this energy prevents waste from ending up in landfills or clogging sewer lines.”

The tool is an interactive map created to link food and other biodegradable waste sources with facilities such as wastewater treatment plants that can enhance energy production with their existing infrastructure. Wastewater treatment plants and some dairies manage waste using anaerobic digesters, which produce methane-rich biogas as a natural byproduct.

By adding food scraps, or fats, oils and grease, to an anaerobic digester, facilities can increase biogas production to make money while providing a renewable energy source, thus reducing greenhouse gas emissions. These business and environmental opportunities may present a largely unrealized potential.

The tool is designed for decisionmakers with technical expertise in the fields of waste management, wastewater treatment and renewable energy. This includes businesses, state and local governments, and non-profits. The tool allows users to determine the types of facilities in their area, where clusters are located, and the distance between a waste producer and an anaerobic digester. The tool also functions in reverse – allowing generators of organic waste to find partner facilities that will accept it.

Features include:

• fats, oils, and grease (FOG) hauler information for California, Arizona and Nevada

• California landfill information

• on-site energy generation for California dairies with digesters (in kilowatt-hours per year)

• energy estimates for wastewater treatment facilities, with and without co-digesting FOG (in kilowatt-hours per year for California, Arizona, Nevada and Hawaii)

• a “correct record” option that allows facilities to change information presented on the map

A study performed by the Northern California Power Agency in 2008 determined that agricultural, wastewater, and food processing wastes could be digested to obtain 453 megawatts of energy – enough to run a utility-scale power plant while also preventing 3.7 million dry tons of

organic material from ending up in a landfill. This use of biogas to displace natural gas would have a climate change abatement potential equal to taking approximately 160,000 cars off the road.

Financial assistance provided by federal, state and private sources can make on-site generation affordable and practical.

The mapping tool is found at: www. epa.gov/region9/biogas.

Decades of digester development

By Diane Mettler

RCM has taken its technology from a simple idea to a leader in the industry

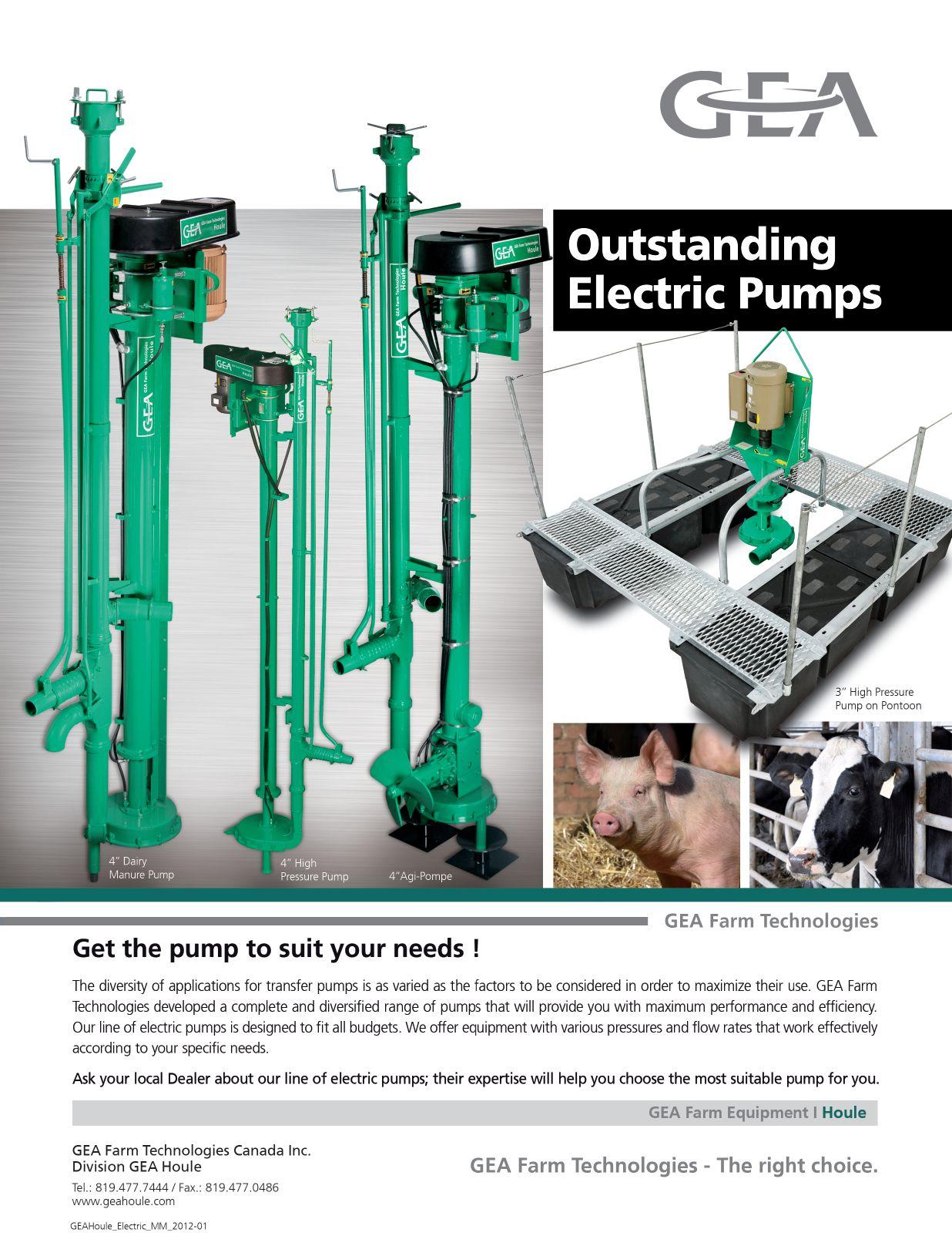

RCM turns 30 years old this year, making it one of the most established digester manufactures in the field.

President and agricultural engineer Mark Moser recalls those early days, when it was just two guys and a vision.

“Not much was known about digesters in the commercial sense,” he says. “There’d been laboratory work and there were municipal digesters, but ag digesters just weren’t available. So, I got out of Cornell (University) and convinced them this would be a cool idea.”

Mark made his case and was soon building digesters for industry leaders

willing to work with the new technology. As expected the first couple of digesters had some bugs, but the third one was “pretty good,” says Mark. “In fact, it was good enough that it’s still running today.”

Today RCM has more than 85 digesters in operation on dairy and hog farms. And, being one of the original companies in the market, RCM can also lay claim to the oldest digester continuously running. In its 30 years of operation it’s been running almost flawlessly. The engine has been rebuilt five times, but it was only down once 17 years ago to be cleaned.

Challenges

As the industry matured, the ongoing challenge was to produce a better, more reliable digester.

“In the early days, if you made gas 90 percent of the time and electricity 80 percent of the time, you were considered good,” says Mark. “Today, most of our digesters produce electricity 92 to 95 percent of the time. It’s been years and years of incremental upgrades. We would see a need for an improvement and make it.

“One of the focuses was creating a digester that worked well with minimal supervision, because that’s what farmers need. Back in the ’80s and into the ’90s, everything was manual operation. With today’s computer technology, this is a great time for automatic operation. Not that it can run itself, but it has gotten to the point where if there is a problem, the digester will call you and you can get out your iPhone and see how the engine is running.”

EPA comes calling

There have been plenty of highlights for the company over the years. For Mark personally, it was in the mid-’90s when he was selected as the senior technical advisor of the U.S. Environmental Protection Agency’s agSTAR Program.

RCM is celebrating 30 years in business in 2012. The California-based business has anaerobic digester installations around the world, including this digester at Patterson Dairy Farms in Auburn, N.Y. Contributed photo

HAUL CHICKEN MORE MANURE

RCM tends to install anaerobic digesters in areas where there are high electricty prices. That’s why RCM has a strong presence in New York, Pennsylvania and some New England states, for example, on Chaput Farms in Vermont. Contributed photo

“At the time, 80 percent of the digesters failed and 20 percent of them worked and it just happened that the 20 percent were ours.” That led to Mark’s invitation and his involvement in the program over the next five years.

“We were able to create an education program and develop demonstration digesters that allowed people to believe that digesters were reliable,” he says.

The program was a success. Through it more successful digesters were introduced, more companies entered the market building reliable digesters, and the industry grew.

Digester dollars

RCM has digesters operating worldwide, including Japan, Chile, Ecuador and Mexico. In fact, RCM built the largest hog digester in the world in Chile that handles 238,000 pigs and has been running since 2003.

The reason farmers turn to digesters is the simple fact that it makes them money, says Mark. Energy produced is used to run the hog or dairy farm and the excess can be sold and put on the grid. A dairy with 1,000 cows could save/earn a $100,000 in electricity.

“We’re working in mostly states with high electric costs, because that’s the easiest cash value for an owner to realize.”

For that reason RCM does a lot of business in states like New York, Vermont and Pennsylvania.

Many benefits of digesters

Although creating power is the primary reason to purchase a digester there are numerous benefits once one has been installed.

Bedding – Digester solids can be used as bedding. A dairy with 1,000 cows could make up to $50,000 a year in bedding.

Somatic cell count – Two years ago in Pennsylvania, RCM conducted a study of top dairymen. All reduced their somatic cell count after switching to digester and solids bedding, and a lower cell count results in better prices for milk.

Odor control – Odor is eliminated through the digestion process. “In New York, in order to get a dairy built near a town, the owners decided to put in a digester to mitigate the animosity from a nearby neighborhood,” says Mark. “We took a busload of residents to another of our digesters that was about 30 miles away. As they stood beside it, we asked, ‘If you’re 500 feet away from this, is this going to be a problem for you?’ The neighborhood opposition was satisfied and that dairy got built.”

Manure spreadability – Manure that’s been through a digester is thinner and doesn’t clog machinery as much. “And because of the change in the manure’s characteristics after digestion, you can haul it shorter distances because you don’t have to avoid the neighbors,” says Mark.

Heat – In colder areas digesters can offset a good amount of building heating. One farmer was able to heat his home because the digester was nearby. “We provide heat and hot water at most all of our dairy installations. We also have people using the waste heat to dry corn and pasteurize milk,” says Mark.

Receiving food waste – By receiving food waste from food processors, farmers get more energy from their digester, tipping fees from the processors, and also keep waste from landfills.

Designing the digester

Today, RCM employs about 14 people. It’s headquartered in Oakland, Calif., and has offices in Mifflintown, Penn., and near Clymer, New York. They partner with local engineers and equipment suppliers to take the products to the farmers.

Because each farm is different, RCM believes each digester should be tailored for the operation.

“Our goal is to integrate the system so it works with the farm versus being an appendage” says Mark. “We work to design it into the farm and make it easy to operate. That’s the key to success – easy operation. An operator doesn’t want to walk an extra 100 yards just to look at an engine.”

Of course some farms offer more design challenges than others. For example, if manure is headed from the barns in different directions, it’s

RCM can build four different styles of digester and match the technology to the operator’s needs. Contributed photo

a more complex design than if the manure is already being collected in one spot. Topography can also create unique challenges. But designing the right digester also requires looking and planning ahead – installing a system that will work for the farm 30 years from now.

“The majority of our clients are family farms in the U.S.,” says Mark. “They are people who are going to stay in business, who believe in farming as

a lifestyle – not just to subsist, but to prosper.”

The clients are also the larger farmers. With this kind of technology there is no “smaller size” says Mark.

“It starts to make sense at 400 cows. The sweet spot in dairies is about 1,000 cows. That’s where all the equipment is optimized. Bigger than that, it gets a little better, but from 400 to 1,000 the return on investment rapidly improves. And

with pigs, about 10,000 finish hogs is the sweet spot.”

The next 10 years

As RCM turns 30, it’s hard not to look ahead and wonder where it will be when it turns 40 in 2022. Ideally, Mark would like to see a couple hundred more digesters out there – in the U.S. and abroad.

Over the past three decades, RCW has learned that sales depend not only on the economy, but on the country too.

“Sometimes the economy isn’t so good in the U.S., but it’s great somewhere else. For that reason, we have lot of international work, but the majority of our work is still here in the U.S.”

At the end of the day though, Mark says for him it all comes down to installing the right technology for the farmers.

“We build four different types of digesters depending on what the owner needs. We look at what works for them, and the best economics. We can build a complete mix, a plug flow, and even covered lagoons. We can do that because it’s our own technology that we developed. We understand it and know how to apply it.”

He doesn’t believe he’ll ever get tired of watching the day it all comes together at the farm.

“It’s always a big day. We’ve been working on construction for a year and then suddenly – shazam – it’s making gas. That’s when they believe.”

National dairy event coming to Canada February 2013

The Canadian Dairy XPO (CDX), a new largescale dairy event and a first for Canada, will mix dairy agribusiness, breed associations, and the research community under one huge roof with dairy producers and global industry stakeholders.

In addition to hundreds of dairy product and service providers in the trade show halls, the event will feature a world-class speaker program, a live milking robot showdown, a working cow showcase, and an evening networking social. All will take place in the new Stratford Rotary Complex located in Stratford, Ont.

Perth and surrounding counties make up one of the most important dairy regions in Canada. Within an hour’s drive of Stratford there are almost 3,000 medium- to large-scale dairy operations and that number is growing.

Major industry partners have already signed on with CDX. EastGen, a partner in the Semex Global Alliance, is one of several genetic companies that will showcase their best dairy daughters from across Canada live at CDX.

Other founding partners that have made three-year commitments to the project include Jaylor, Grand Valley Fortifiers and POST Farm Structures.

In addition, CDX is in the process of assembling a steering committee comprising progressive producers and CDX founding partners. This committee will give CDX management input and direction on all facets to ensure continuous improvement and national growth of the project.

Get updates at www.dairyxpo.ca as momentum builds for the inaugural Canadian Dairy XPO, Feb. 6 and 7, 2013.

In the NEWS

ASABE revises manure odor management standard

The American Society of Agricultural and Biological Engineers (ASABE) recently announced the publication of a newly revised standard on management of manure odors.

The revised standard – ASAE EP379.5 APR2012, Management of Manure Odors – corrects outdated information and includes updated reference information as noted in the most recent periodic review of the document. Additional wording clarifications, and format changes were also included in the revision.

ASABE members with standards access and those with site-license privileges can access the full-text via electronic download on the ASABE online Technical Library at elibrary. asabe.org/.

Others can obtain a copy for a fee directly from the library or by contacting ASABE headquarters at martin@asabe.org.

New regs in Indiana make NMPs more important

Indiana’s impending revised regulations for confined feeding operations and nutrient application have put an even greater emphasis on nutrient management in the state, says Purdue

Extension dairy specialist Tamilee Nennich.

The new regulations take effect July 1, 2012, and will apply to both mediumand large-scale operations.

“Some of the new things producers need to pay attention to include requirements for manure application rates that will be based on soil phosphorus levels,” Nennich said. “Producers need to do soil tests to determine phosphorus levels.”

The updated regulations state that soil phosphorus levels on cropland where manure will be applied cannot exceed 200 parts per million, as opposed to old rules that were based on the nitrogen needs of the next planted crop. A seven-year phase-in period is included to provide producers a chance to adjust to the new soil phosphorus application standard.

Another change producers need to be aware of involves the application of manure to frozen or snow-covered soils.

“The requirements state that applying manure to frozen or snow-covered ground is no longer going to be allowed for most operations,” Nennich said.

The only exceptions will be in cases of emergency or for older, medium-sized farms originally permitted with only 120 days of manure storage capacity.

Beginning with new farms, confined feeding operations will be required to have 180 days of manure storage capacity.

For both larger operations affected by the new rules and smaller livestock farms, Nennich emphasized the importance of keeping records of all manure management and application activities.

“Detailed records are really important for operations of all sizes,” she said. “When it comes down to it, nutrient management records are really the only way producers can prove that they are making an effort to protect the environment.”

To help producers keep better

records, Nennich, Purdue Extension, the Indiana Corn Marketing Council and the Indiana Soybean Alliance are offering free nutrient management recordkeeping calendars.

Print versions of the calendars are available by contacting Nennich at 765494-4823 or tnennich@purdue.edu.

University of Nebraska Extension recently adopted the calendars, and the U.S. Environmental Protection Agency now has similar calendars available for free download at http://cfpub1. epa.gov/npdes/docs.cfm?document_ type_id=8&view=Permit%20 Applications%20and%20 Forms&program_id=7&sort=name.

New air quality resources for livestock producers

Good air quality in livestock facilities can have a positive impact on the health and well-being of animals and humans.

Alberta Agriculture and Rural Development (ARD) recently updated its resources regarding air quality in livestock production. The ministry is committed to working proactively with the livestock industry, government and non-government partners to address air

quality concerns and keep producers well informed and aware of technologies and management practices that will help them improve air quality in their operations.

The air quality resource website can be accessed at http://www1.agric. gov.ab.ca/$department/deptdocs.nsf/all/ epw10940.

Bernardin Lochmueller awarded patent for CAFO treatment

Bernardin Lochmueller & Associates (BLA), a company specializing in sustainable infrastructure design, recently received a method patent for its Eco-Treatment constructed wetland system to treat wastewater from animal confinement operations.

Constructed wetlands, whether used as a stand-alone system or in combination with land application or other treatment alternatives, can offer a cost-effective solution to assist CAFOs in meeting the zero discharge requirement, according to BLA. Using plants and a variety of filter media, the system provides a natural approach to reducing or eliminating nutrients and other

chemicals from manure and wastes. The system can be fine-tuned to provide effluent with nutrient loads that match the needs of specific crops.

To date, BLA’s water resources team – led by Mark Harrison, PE, LEED AP –has designed more than 80 constructed wetland systems for the treatment of animal waste, site and municipal sewage, and combined sewer overflows (CSOs).

“Constructed wetlands offer a variety of benefits,” says Harrison. “Because nature does the work, it reduces the energy used, be that energy needed to transport manure or run a mechanical treatment system, not to mention cutting the cost of additional chemicals to treat waste. In some instances, we’ve even designed wetlands to provide habitat for wildlife or walking trails. It’s just an allaround great solution.”

www.blainc.com

For the latest news and information affecting manure handling and management, visit www.manuremanager.com.

Centrifuge supplies reconditioned or new centrifuges for manure dewatering and fine particle separation. Benefits include: uses no screens / filters, separates particles to less than 50 microns in size, and reduces phosphorus, nitrogen and potassium in wastewater.

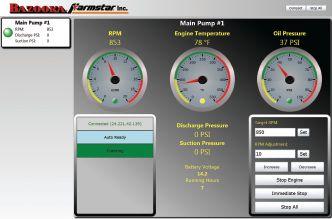

Bazooka Farmstar Electronic Control System (ECS)

The Farmstar Electronic Control System (ECS) can control and manage all the pumps in line without being at the engine source. It is as easy as turning on a laptop and viewing the simple, user-friendly website interface, which allows users to view the fully functional gauges, which include engine RPM, engine temperature, engine oil pressure, pump suction PSI, and pump discharge PSI. The ECS will also allow operators to wirelessly idle the engine RPM up and down for the most desirable performance, saving time and money.

Benefits include:

• Wirelessly controls pumps

• Minimize the need for people and labor

• Internet based

• Off site pump management

• Can be adapted to most mechanical and electrical engines www.bazookafarmstar.com

Parkson launches big Aqua WashPress

Parkson Corporation has introduced an even larger version of its Aqua WashPress, which integrates with Parkson screen systems to handle some of the biggest jobs in wastewater treatment.

“This new Aqua WashPress is a heavy-duty system that we designed to satisfy the demands of special, largescale applications,” said Dave Mitchell, commercial director of Parkson’s headworks systems. “We see a trend toward plant designs that incorporate sluiced flows with high water volumes,

and this product can manage the load.”

In these designs, water-driven sluices carry the screenings to a WashPress, replacing conveyor systems thus creating a simpler system with fewer moving parts. The end result can be a more cost-effective design with minimal maintenance needs.

“Parkson has been building screens for more than four decades, and we know that it’s crucial to have all these systems work together in unison for the headworks to operate successfully,” said Mitchell.

In all sizes, the Aqua WashPress is a low-maintenance system that ties in directly with the screen, to operate only when the screen is active, and as needed. By minimizing the size and weight of dewatered solids, the design is an efficient way to save money on disposal costs.

The Aqua WashPress also incorporates a wash zone that uses water to separate organics, keeping them out of the screenings and inside the plant for additional processing. www.parkson.com

Pichon launches spinning deck on Muck Masters

Pichon solid manure spreaders can now receive a spinning deck on all models from 12 to 24 m3

This new system, built upon the idea of deflectors, fits onto the rear frame of all Muck Master range spreaders. It enables an even and wide spreading while minimizing wind resistance onto manure.

The spinning deck is particularly designed to spread light materials at low rate (less than 10 T/hectare), such as dry manure and compost.

Made in two parts hydraulically controlled, each side deflector can be

used independently while spreading traditionally near hedges or roads. It’s also used as a full rear protection on the road.

Two small left and right deflectors located at the bottom adjust spreading width. The manure is crushed and crumbled by the high diameter beaters and drops onto the spinning discs. Specific blades are fitted onto the discs to get an accurate application from 15 to 20 m wide.

www.pichonindustries.com

Dinkel’s JCB joins JCB North American dealer network

JCB’s North American dealer network continues to expand with the addition of Dinkel’s JCB. Formerly known as Dinkel Implement, Dinkel’s JCB’s two locations in Scribner and Norfolk, Neb., will provide JCB equipment to the northeastern part of the Cornhusker State.

“As an innovative dealer, we’re focused on continually identifying and satisfying customer needs,” said Larry Dinkel, owner of Dinkel’s JCB. “That’s just one reason we’re very proud to partner with JCB to offer our customers the best construction, industrial and agricultural products available on the market today.”

Dinkel’s JCB will carry a wide range of JCB’s equipment, including skid steers with patented PowerBooms and safe side-entry doors. Other JCB products to be found at Dinkel’s JCB are wheel loaders, industrial and compact backhoe loaders, loadall telescopic handlers, rough terrain forklifts, mini excavators, and utility tractors. Both Dinkel’s JCB locations also feature full-service maintenance facilities, professional mechanics and parts departments.

“Dinkel’s JCB shares our mission of providing quality equipment and service,” said John Patterson, CEO and deputy chairman of JCB North America. “As a result, this new partnership is an excellent fit for both of us, and we look forward to a very bright future.”

To learn more about Dinkel’s JCB, call 402-371-5092 (Norfolk) or 402-6642556 (Scribner).

www.jcbna.com