Poultry flooring system yielding positive manure management results Industry, government and researchers in the United States are designing the poultry house of the future that could result in better manure management for poultry producers.

A Canadian broiler producer in Ontario develops an effective solution for removing excess water after cleanout.

A mobile training unit in Ohio is helping to instruct pork producers on how to better utilize their ventilation systems.

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Tony Kryzanowski, Diane Mettler, Kristy Nudds, Michael Czarick

Advertising Manager

Laura Cofell • (519) 429-5188, (888) 599-2228, ext 275 lcofell@annexweb.com

Production Manager Angela Simon

Circulation Co-ordinator Marie Weiler mweiler@annexweb.com

Vice-President/Group Publisher

Diane Kleer • (519) 429-5177 dkleer@annexweb.com

Website: www.manuremanager.com

US Subscriptions:

$37 US one year

$64 US two years

International Subscriptions

$70 US one year

Canadian Subscriptions (GST included)

$37 Cdn one year

$64 Cdn two years

Canadian Publications Agreement #40065710

Return undeliverable addresses to:

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, ON N3Y 4N5

Reproduction prohibited without permission of the publisher.

By Margaret Land

I’m not a very good problem solver. Remember those word problems in grade school math involving two trains leaving a station at certain times? I could never figure them out. Instead, I’d get bogged down in the details – Who was on the train? Where were they going? Why are they taking a train rather than an airplane? Why not just drive?

All these questions – I guess that’s why I became a journalist.

My husband is the problem solver of the family. He can look at an issue or problem and find the solution quickly and cheaply. He’d probably make a very good farmer.

Being a successful farmer means possessing a lot of faith in yourself and your abilities; there’s really no safety net in agriculture. Wobbling on a decision or second-guessing your next move while balancing a barn full of livestock and fields full of crops can lead to disaster. Sometimes, there’s only time for one decision and it needs to be the right one.

Recently, I had an opportunity to visit a dairy in western Wisconsin where the operators had an opportunity to correct a problem that had been plaguing one of their barns. When the original building was constructed years ago, it was designed as a naturally ventilated structure. But as the dairy expanded over time and new barns were added, adjacent buildings started blocking the natural airflow.

“It was a hard barn for us to ventilate,” admitted one of the farm owners.

In order to combat this, they decided to retrofit their naturally ventilated barn to a cross-ventilated one. The roof ridge

openings were covered up and exhaust fans were installed along the north side of the barn. A drop ceiling was installed on the south side to help funnel air coming in from the drop curtain across the backs of the cows before exhausting it out the fans. A roll-up door was also installed in order to maintain static pressure when the ventilation system is in use.

According to Dr. Larry Jacobsen, a livestock housing specialist and engineering professor with the University of Minnesota who studied the new ventilation set-up, the retrofit is an “interesting” one. “The cross ventilation is helping production,” he explains. “They are getting better milk production and improved feed efficiency.”

It’s a sentiment shared by one of the farm’s owners. “It’s been a good retrofit for us,” he says. “Our cull rate has dropped by four to five percent.”

This is problem solving at its best. They recognized the issue, they found a solution and implemented it with much success. They weren’t afraid to take a risk. Check out this issue of Manure Manager for other problem solvers, including: researchers investigating a solution for poultry litter issues, a poultry producer who developed a new way of cleaning excess water from his barn floors, and a mobile trailer that helps livestock producers solve ventilation issues. You can also learn about the latest innovations in ventilation and fans.

Enjoy and don’t hesitate to contact us or visit the magazine’s web site – www.manuremanager.com – for more information to help you solve your manure management problems.

• ICA reviewing proposed regulations for applying manure to frozen ground

• Iowa manure applicators need training by Dec. 31

• Methanization on the farm – Integrating nitrogen treatment

• CLEANmp-East now available for eastern producers

• MSU leverages funds for farm waste-to-energy project

• Federal grants available to assist livestock producers

• Future uncertain for California egg industry

• New manure, compost directory in Alberta

Excessive doses of organic residues in agricultural fields could be dangerous for plants, invertebrates and microorganisms living in the soil.

This is the finding of a study carried out by the Autonomous University of Barcelona (UAB) in Spain, which has shown that the use of appropriate levels of fertilizers would prevent this toxic impact on the soil biota.

Although controlled amounts of organic residues, sewage sludge and animal waste are a good choice for soil fertilization, they can have damaging effects on soil biota when applied in excessive doses. In an effort to prevent these toxic impacts on soil, a team of researchers from the UAB’s Centre for Ecological Research and Forestry Applications (CREAF) has carried out a test that sets the maximum safe doses for organic fertilizers.

“We based this on bio-trials in the laboratory using soil-based organisms that are representative of agro-ecosystems, and which need to be protected: plants (Brassica rapa, Lolium perenne and Trifolium pratense), earthworms, annelids, collembola and micro-organisms,” explained the study’s lead author Xavier Domene.

Read the full story at www.manuremanager.com

Nooyen Manufacturing’s Tri-Bar Weep Wall

Manure Management doesn’t have to mean keeping up with the latest technology. It can be as simple as using gravity to separate solids from liquids.

Nooyen Manufacturing has developed the Tri-Bar Weep Wall system. A weep wall system consists of two basins separated by a drainage channel. With the Tri-Bar system, at each side of the drainage channel are Tri-Bar galvanized steel panels. When manure is added to a basin, liquids drain through the TriBar Weep Walls into the drainage channel, while retaining solids in the basin.

Siemens introduces sludge belt dryer

Siemens Water Technologies is adding the new Sludge Belt Dryer to its array of sludge dewatering options. This convective dryer is supplied in a one- or two-belt design that provides uniform evaporation and has an adjustable speed belt to vary residence times. System advantages include efficient operation in minimal space, low emissions, low dust, a granular final product and a low thermal requirement with possible heat recovery from low temperature waste energy sources.

The 2009 Manure Manager Buyers Guide is your key reference tool to bring the entire industry together in just one directory.

To sign up for a free trial of Manure Manager’s digital version, go to www.manuremanager.com.

Chickens raised on a new poultry house plastic flooring system actually increased in weight by 5 to 15 percent.

By Tony Kryzanowski

Industry, government and researchers in the United States are cooperating on a project to design, “the poultry house of the future,” research that could result in a more positive manure management situation for poultry producers.

The project is being conducted at the University of Maryland, Eastern Shore (UMES) campus with the objective of providing the industry with poultry house design improvements that address a variety of challenges. Researchers are taking particular aim at flooring, heating, managing relative humidity, and growing birds with multiple ages on the same farm.

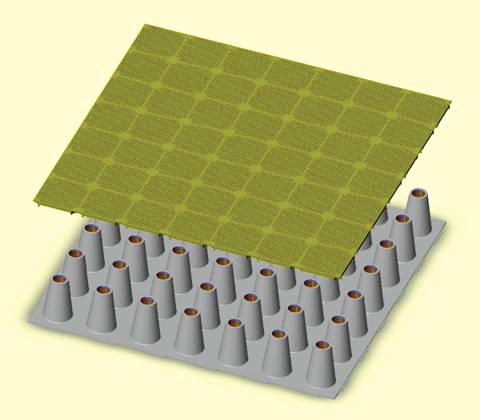

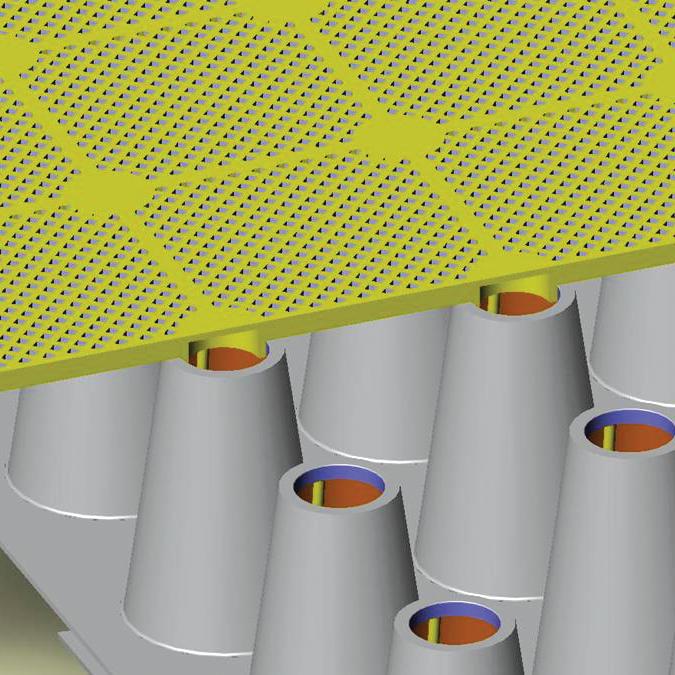

A key aspect to the research is a new plastic flooring and ventilation system designed by engineering firm AviHome LLC, located in Salisbury, Maryland. The flooring system consists of plastic interlocking squares, measuring about 18 inches by 18 inches. It sits about three inches off the ground,

and is supported by peg legs located on the corners of each plastic section. There are tiny holes in each section. Coupled with a ventilation system, air funnels through the holes and results in the drying of the chicken fecal matter.

“Because of the ventilation and the wicking ability of the water through the fecal material, the newer material on top of the old continues to dry,” says UMES re searcher and project leader Dr. Jeannine Harter-Dennis.

The plastic flooring system is sturdy enough to allow equipment to be driven on it so the manure can be scrapped between growing cycles.

During research trials, chickens were on the plastic flooring on a six-week cycle in what Dr. Harter-Dennis described as an “environmental house,” where researchers were

able to raise a flock of about 500 chickens in environmentally controlled chambers. They measured such critical items as air input, air output and air quality insofar as the functioning of the flooring and ventilation system was concerned.

The new poultry house flooring system eliminates the need to use litter, such as sawdust and wood chips on the floor. This results in a much drier and more concentrated type of manure between broods.

Results so far are better than expected. No expensive floor litter is required and moisture content in the chicken excrement has been reduced to as low as 20 percent in some cases, versus the typical 35 to 40 percent.

Moisture is a key ingredient in the production of ammonia gas, and moist, nitrogen-rich, poultry house litter is ideal for growing the bacteria that are critical in the production of ammonia. If producers can reduce the moisture, bacterial growth is greatly reduced, resulting in less ammonia production. Less ammonia also solves the perpetual problem of odor emissions from conventional poultry houses. Right now, industry handles the ammonia problem by applying an acidic product to the litter between production cycles to lower the pH in the litter, which also acts as an inhibitor.

“When chickens were grown in an environment with the new flooring and ventilation system, our preliminary results show that the ammonia was totally eliminated,” says Dr. HarterDennis. “I’m very pleased about that because when the fecal material hits the ground, it dries very rapidly and the lack of litter keeps the pH down below seven most times.”

Researchers have also witnessed between a five to 15 percent improvement in growth of the chickens.

However, Dr. Harter-Dennis acknowledges there are some design challenges related to poultry litter and manure falling through the holes in the plastic flooring onto the floor below. AviHome is aware of the problem and is working on a solution, looking at a new hole design or a water permeable layer that could be placed over the flooring.

With the production of a drier, more concentrated waste product from the use of this flooring and ventilation system, a new scenario for poultry manure management could be created for the future. The industry could find itself producing large amounts of concentrated and nutrient rich manure instead of the usual mix of bird excrement and litter.

“It’s a much more concentrated product that could be maybe trucked off the eastern shore (of Maryland) to some place that needs it,” says Dr. HarterDennis. The resulting manure could be used as an organic fertilizer.

At present, the area’s poultry industry is producing more manure than it can absorb and applies most of it as fertilizer on local cropland in

The flooring system sits about three inches off the ground, and is supported by peg legs located on the corners of each plastic section.

the spring. Over time, this has led to a significant phosphorus build up in local farmland, which is another reason why less manure volume and the ability to store it over a longer period of time is a positive development. Growers will have less waste to manage. Perdue, one of four major poultry producers in the area, accepts a lot of the area’s excess manure, pelletizes it and exports it as a lawn amendment for residential use. With this more concentrated product, the whole concept of its disposal and commercial potential needs to be revisited, Dr. Dennis-Harter says.

In the past, growers used a four to six inch thick layer of wood shavings and sawdust litter as an absorbent floor material in poultry houses, adopting this practice because these materials were readily available as a byproduct of the timber industry. However, that situation has changed.

“Now, we cut down trees just to make litter,” says Dr. Harter-Dennis. “It’s become a product, it’s expensive, and sometimes hard to get if not impossible. So if we can grow chickens without litter, we save a resource, plus we don’t have the volume of a waste product that we would have if we were still using the wood chips and sawdust.”

The litter used in a poultry house on a contract grower’s farm will actually remain in that house for several years. Between each flock, which is usually a period of seven to eight weeks to grow a broiler chicken from a one to two ounces to 5.5 pounds, there is about a two week period where the crust on top of the litter is removed and stored. Because the litter is used over and over again, there is a build up of nitrogen content that leads to the production of ammonia gas. This is a major challenge for the industry as it can affect a bird’s respiratory system, lead to blindness within the bird population, impact negatively on growth,

AviHome LLC of Maryland developed the flooring system, which consists of plastic interlocking squares, each measuring about 18 inches by 18 inches.

impact human health among industry workers, and present both odor and environmental challenges when vented.

The current method to manage the ammonia gas is to exhaust it from the poultry house. Research has shown that vented ammonia contributes to the formation of particulate matter that through a cascade of events leads to the development of smog. The U.S. Environmental Protection Agency (EPA) is looking at air quality and aiming to limit the exhausting of ammonia from intensive farm operations in particular.

“If we don’t self-regulate, we’re going to get governmentally regulated for the ammonia emissions,” says Dr. Harter-Dennis. “We’ve got people in Washington that don’t know very much about agriculture or animal production in general, making laws for us and we as producers want to be pro-active rather than reactive and present them with something that is reasonable and feasible that won’t destroy the industry.”

Researchers hope the poultry house floor and ventilation system will control emissions at a level acceptable to the EPA, and can be retrofitted into existing poultry houses.

The flooring and ventilation system research program is currently entering a new phase, moving from 500 chickens to a facility that can house 12 groups of 500 chickens each. Six groups will be raised in conventional growing conditions and six will be raised in the new plastic flooring and ventilation environment. The plan is to eventually install the system into four commercial broiler houses on the UMES farm where chickens are grown for Allen’s Family Foods, to test it in an actual commercial application.

By Kristy Nudds

Like many poultry farmers, Hans Veurink and his wife Diane were left with the daunting, laborious task of removing a huge amount of water from their barn after cleanout.

According to the On Farm-Food Safety Assurance Program (OFFSAP) – followed by broiler producers in Ontario, Canada – after broilers go to processing, barns – including walls, ceilings, feed and water lines – must be thoroughly washed out using a high-pressure washer. For the Veurinks’ two-storey, 27,000-squarefoot barn, large amounts of water would accumulate on the floor.

Removing excess water can be done in two ways – turning up the heat and letting the barn air-dry, which increases energy costs, or using handheld squeegees. Like many others, the Veurinks were using two-foot-wide hand squeegees; a two-day, back-breaking job that left them sore and exhausted.

Hans says he thought the process was ridiculous and that “there had to be an easier way.” So, four years ago, he began working on an invention at his Creekside Poultry farm, located in Jarvis, Ont., that has transformed the clean-out

process for his family and nearly 100 other producers.

What he did is fabricate an extended squeegee that can mount onto any blade implement.

His “Blade Mount Squeegee” is a lightweight attachment that removes water effectively, but most importantly, quickly and without physical exertion.

Made from steel and rubber, the Blade Mount Squeegee weighs approximately 60 pounds and has brackets that easily hook to the back of a blade on any type of machine, whether it is a tractor, skidsteer, or four-wheeler.

The Blade Mount Squeegee angles with the blade and applies constant, uniform pressure. It can even be manoeuvred right up to a wall’s edge, says Hans. The attachment is quick to mount (in minutes or less), he adds, and can easily be hung on a wall when not in use. Hans says he hears from customers that they are amazed at how well it works, and how much time they save.

At first, Veurink, a former dairy farmer from Thunder Bay who relocated to Jarvis eight years ago, used his creation on his own farm, but soon realized that other farmers could benefit. “I wanted to share this with others right away,” he says.

He “did a lot of driving” the first year, starting in his own county and expanding into other counties with high poultry farm densities, cold calling on poultry farmers to try to sell them on his invention.

His efforts were successful. He sold 30 squeegees in the first year. After several satisfied customers encouraged him to market the creation more widely,

The Blade

can be easily attached to any blade and efficiently cleans water and manure from floors, reducing energy and labor costs.

he brought the Blade Mount Squeegee to the 2005 Poultry Industry Conference and Exhibition in London, Ont. He has marketed the squeegee at each show since then.

Since he first started marketing the Blade Mount Squeegee, Hans has sold nearly 100 of them to farmers all over Ontario and several in Alberta with 99.9 per cent positive feedback.

His ingenuity was recently recognized by the Ontario Ministry of Agriculture and Rural Affairs (OM AFRA), which presented him with a Premier’s Award for Agri-Food Innovation and

Excellence. According to the ministry, his innovation reduces labor and energy costs, is affordable and makes it easier for farmers to increase the frequency of barn cleanings, improving the impact on food safety and animal welfare.

Customer comments on the squeegee are also testimony to it’s ingenuity and benefits for the farmer. Satisfied customers have told Veurink “there is a lot of labor savings with great results,” “it’s well-made, durable, easy to install,” “fast and efficient,” “the floors are so clean,” and that the cost is recovered quickly in the amount of time it saves.

Hans Veurink, pictured here with Ontario’s Minister of Agriculture, Food and Rural Affairs, received a Premier’s Award for Agri-Food Innovation for his unique invention.

Veurink manufactures the squeegees on his farm and offers them in seven, eight and nine foot lengths, but says he could alter the size depending upon need. He also offers replacement rubber edges. A seven foot squeegee costs $450, a nine-foot $500. He also uses it for pushing manure, which further aids cleanout. He says the squeegee never catches on the barns’ plywood floors. “It works great and saves a lot of time,” he says. Some of Veurink’s customers use it to remove the last bit of dust in the barn, before washing, instead of using the dust blower, as well as for levelling shavings.

Additional benefits of the squeegee include a reduced risk of bacteria because the water doesn’t sit long enough to soak into a floor. He says there is virtually no residue left and concrete floors are left clean and dry.

Veurink’s next step is to build a shop so he can manufacture a larger volume of squeegees. He sees “more potential” for the squeegee, such as removing ice and slush from lock stone and concrete walkways or driveways, ice rinks, and removing liquid manure on dairy barn floors. “Anywhere where there is a lot of water or liquid, the squeegee can be used,” he says. With the help of their daughters, the Veurinks have produced a video, which can be ordered from the family, of the Blade Mount Squeegee in action so that producers can see what it can do. Hans encourages producers to “just try it. It really does make life easier.”

Contact Hans and Diane Veurink for more information via: telephone: 519-587-4676 or e-mail: hdveurink@execulink.com

Now, more than ever, pork producers recognize the impact their operations can have on the world around them. Proactive eco-management with MicroSource S can help reduce environmental burdens. By feeding MicroSource S, producers benefit from:

• Reduction in noxious manure gases, like ammonia and VFAs, for less odor — resulting in better community relationships

• Increased nitrogen retention in manure — resulting in an improved N:P ratio

• Lower manure viscosity — resulting in less power required for pump outs and the ability to pump out more manure

• Decreased stickiness of manure — resulting in reduced labor requirements due to easier/less cleaning.

MicroSource S contains selected microbes that digest the solids in hog manure. It begins to work even before the manure hits the floor and continues to act on manure during handling and storage. Fed throughout the pig’s lifecycle, MicroSource S can help you better balance the challenges of efficient pork production with environmental stewardship.

To learn more, contact your feed supplier or go to www.unlimitednutrition-na.dsm.com

By Diane Mettler

Mobile training unit instructs pork producers on how to better utilize their ventilation systems.

The difficult part about getting a handle on your ventilation system is that air is invisible. In a big barn, it’s hard to see what’s really taking place. Dale Ricker, swine program specialist with Ohio State University Extension, and his colleagues have made it easier to visualize this problem. He and his team have built a trailer that uses smoke to let farmers see up close how to improve their systems.

“The trailer was an idea we borrowed from Dr. Mike Brumm who

was at the University of Nebraska at the time and Steve Pohl from the South Dakota State University,” explains Ricker. “They really developed the idea of constructing a hands-on training model and have been very successful out west with this concept.”

Building the trailer was a team

effort. The $13,000 to construct it came from a number of sources, including: the Ohio Pork Producers Council, Ag Credit, Farm Credit Services of Mid America, Farmer Boy Ag Systems Inc., and other sponsors. Once the funds were raised, the trailer was built in the engineering shop at the Ohio Agricultural Research

and Development Center in Wooster, Ohio, under the direction of Dr. Mike Brugger, P.E., Ph.D. It was completed late in 2007.

In January 2008, training began for the instructors. “We invited Dr. Steve Pohl and Dr. Mike Brumm to come train us,” recalls Ricker. “At the same time, we invited some of the producers around Ohio to come in and sit through the training and see the ventilation trailer. As a result of that, the producers saw the potential and scheduled workshops, which we took to their farms.”

Ricker, along with Dr. Brugger and Glen Arnold, an OSU Extension educator, began taking the trailer out to farmers in June.

“The three-hour training workshop begins with a Powerpoint presentation in a classroom setting,” explains Ricker. “We want everyone to understand the principles of ventilation — how air is supposed to flow, what speed it is supposed to flow in inlet, among other things.

“After the classroom portion, we take them out to go through the handson portion or the visualizing of what they had just learned.”

The “hands-on” portion takes place at the trailer, which incorporates exhaust fans and air inlets, as well as a controller for the fans and inlets.

The attendees are asked to go through a number of “tasks,” including:

• Reviewing common tools for measuring air speed at a swine building’s inlets.

• Seeing how common smoke tools show air speed and direction.

The trailer was built with exhaust fans and air inlets, as well as a controller for the fans and inlets, providing livestock and poultry producers with a hands-on education tool.

• Reviewing common tools for measuring relative humidity in swine buildings.

• Operating the trailer at low, high and normal static pressure, and using a smoke tube to demonstrate how incoming air reacts under different conditions.

• Using a smoke tube to look for unplanned air openings into the ventilation trailer.

• Using a manometer to measure various levels of static pressure.

• Reviewing the importance of properly operating fan shutters.

Ricker’s goal is to have farmers walk away with the skills to make improvements to their own ventilation systems and experience better performance.

“The whole idea of proper ventilation in a building is to not only create the optimum environment for workers and pigs, but to create the optimum environment to reduce energy costs,” he says. “Proper ventilation will create that optimum zone where pigs will convert feed more efficiently and, as a result of that, they’ll stay healthier. So, potentially

Producers tour through the portable ventilation trailer during a workshop. The goal of the program is to have farmers walk away with the skills to make improvements to their own ventilation systems and experience better performance.

it can reduce expenses in terms of antibiotics or treating pigs, as well.”

Ricker says they try to customize the course as much as possible to meet the needs of the group. “If we’re working with an integrated system, say with their contract growers, we try to modify our presentation so that we’re using inlets and we’re talking about buildings that they operate.”

Once the workshops are completed, Ricker likes to get an evaluation from the participants. He’s interested in the economic impact this information could have on their farms. “Our most recent evaluation, where 15 producers attended, the economic impact they felt to their operations was in excess of $20,000 — about $1,000 per user. With a $25.00 registration fee, it’s a pretty good return on investment.”

One of the biggest savings the farmers thought they would experience was fuel related. “With rising energy costs — especially propane bills — when you start putting dollar and cent values to energy

savings by proper setting of ventilation controls and heater on/off set times, it’s an eye opener,” says Rickers. “Especially if you have larger buildings or your talking about integrated systems with 80 or 100 barns, the savings are huge.”

The course came about because Ricker says there was lack of knowledge out there on how to operate mechanically ventilated buildings.

“As buildings have gotten larger and controls have gotten a little more sophisticated, I think a lot of people are under the impression that we have this technology and it’s just going to create the perfect environment on its own. But it doesn’t always do that,” he says. “Farmers need to have the knowhow to be able to figure out whether it’s performing correctly. That’s hopefully what this training does.”

Ricker and his team were scheduled to take the trailer to farms and other locations throughout the fall. At the time of this interview, they had conducted three and there were two more scheduled.

“We have had interest from several of the surrounding states, but to this point, we’re not really soliciting that very heavily. We want to make sure we offer it to more people in Ohio first,” says Ricker.

The course is getting favorable responses from attendees. Steve Stitzlein, production supervisor at Heimerl Farms Ltd., near Johnstown, Ohio, brought 60 individuals to attend the “hands-on” ventilation program.

“We split them into several groups and worked them through, giving them time both inside and outside the trailer. It worked well,” he says. “We have a lot of contract growers that are still learning how to manage their buildings, so our focus was getting them to understand how air flows and that sort of thing. Inside the trailer, they could really observe what goes on in the barns. With the trailer, you can make some adjustments and see what happens as the air comes in — something that’s tough to do in a big barn.”

Stitzlein believes the producers, which represented more than 50 barns, left with information that can improve their bottom line. “Ventilation is important because it affects the pig’s performance. We’re trying to make sure that the ventilation is right so we have maximum performance.”

He’s also hoping they can save a little on fuel. “If farmers over ventilate in the wintertime, then they’re going to use more propane. We want to move enough air in the wintertime, but yet not too much, so that we’re not taking all the heat out and burning a lot of propane.”

In the end, he felt the money spent on the course was well worth it. “The cost was minimal. And if you can train the growers to do a better job, it saves us money in the long run.”

Continue to page 22

January 8-9, 2009

South Dakota Pork Congress, Ramkota Exhibit Hall, Sioux Falls, South Dakota. Visit www.sdppc.org.

January 13-16, 2009

OMAFRA Biogas Systems Operator Course, Woodstock, Ontario, Canada. Visit www.ontario.ca/biogas.

January 20-23, 2009

Banff Pork Seminar, The Banff Centre, Banff, Alberta, Canada. Visit www.banffpork.ca/

January 20-21, 2009

Tennessee Pork Producers Annual Meeting, Murfreesboro, Tennessee.

January 21-22, 2009

Minnesota Pork Congress 2009, Minneapolis Convention Center, Minneapolis, Minnesota. Visit www.mnpork.com/porkcongress.

January 26-29, 2009

U.S. Composting Council Annual Conference & Trade Show, Westin Galleria, Houston, Texas. Visit www.compostingcouncil. org/conference/details/php.

January 26-28, 2009

2009 Wisconsin Manure Management Symposium & Annual Meeting. Visit www.wimanuremgt.org.

January 27-29, 2009

Northwest Agricultural Show, Portland Expo Center, Portland, Oregon. Visit www.nwagshow.com.

January 28-30, 2009

2009 International Poultry Expo & International Feed Expo, Georgia World Congress Center, Atlanta, Georgia. Visit www.ipe09.org.

January 28-29, 2009

2009 Iowa Pork Congress, Iowa Events Center, Des Moines, Iowa. Visit www.iowaporkcongress.org.

January 29-20, 2009

Wisconsin Pork/Corn/Soy Expo, Kalahari Resort, Wisconsin Dells, Wisconsin. Visit www.wppa.org.

February 3-4, 2009

2009 Illinois Pork Expo, Hotel Pere Marquette & Peoria Civic Center, Peoria, Illinois. Visit www.ilpork.com.

Joe Higgins, sow division manager at Cooper Farms, also had a group of 30 attend the program — both pork producers and turkey breeders. He says both groups walked away better informed.

“We deal with a lot of ventilation in our facilities,” says Higgins. “So any time we can learn a trick or two, it’s nice.”

What Higgins found most helpful was having someone with knowledge about the control panels and seeing the different aspects of the controls when correctly or incorrectly aligned.

“We have an argument every winter about losing money out the fans,” says Higgins. “What happens without the proper control set- ups is that we have the heaters heating the room up, and then the room gets too hot. And then the fans come on, and they suck all the hot air out that you just spent to put in there. So the object’s not to suck the heat out and still ventilate the rooms.”

Cooper Farms now has the ability to track fuel usage and electric costs. Their goal this year, after this ventilation course, is to “knock off about three percent of our winter fuel costs,” says Higgins.

Cooper Farms is also hoping this ventilation knowledge will benefit the

The “hands on” portion of the ventilation workshop provides participants an opportunity to practice the skills they’ve learned and developed before applying them on-farm.

animals as well. “If you don’t have proper ventilation, the animals will get sick. And because we have sows and pigs within a room, we’re trying to create two comfort zones — one for the pigs and one for the sows. And it makes it really difficult for us. Proper ventilation is very important.”

Since the courses have only been taught this summer and fall, it will take time

to find out the real dollar value they’ve had for farmers. But to-date, everyone involved has seen value — even if just to review ventilation basics.

Expect more courses in the future. “We still have integrators that are building new barns. As ventilation controls and technologies change, we will most likely need to update our model. But there will still be a need for education,” says Ricker.

Acropping systems trial at North Dakota State University’s (NDSU) Carrington Research Extension Center shows manure has promise as fertilizer and is beneficial to the soil.

The research also shows long-term manure use has a positive impact on soil chemical properties, says center nutrient management specialist Ron Wiederholt.

Center researchers have been conducting a cropping systems trial since 1987 to compare crop rotations, tillage and fertility treatments. The fertility treatments include an annual supply of 40 and 80 pounds of commercial nitrogen per acre and beef feedlot manure at 40 pounds of nitrogen per acre. The tillage treatments include no till, minimum till and conventional till.

“Since the inception of the trials, a lot of data has been gathered and some trends are starting to materialize,” says Wiederholt. “Using data from 1999 through 2006, the behavior of the manure-treated crops versus those fertilized with commercial fertilizer is very interesting.”

During that eight-year period, the yield of nonleguminous crops, including barley, corn, sunflowers and hard red spring wheat, grown under the manure treatment were at least equal to and in some instances out-yielded crops grown with commercial nitrogen treatments.

“This fact is not too surprising until you realize that the manure applied at a rate of 40 pounds of nitrogen per acre behaved similarly to or better than the 80 pounds per acre commercial nitrogen treatment,” says Wiederhol. “In only one time period (1999-2002) and for one crop (barley), yields obtained from the manure treatments were less than for the 80 pounds of commercial nitrogen per acre treatments.”

Wiederholt says what is even more interesting is the impact manure had on soil chemical properties during the same time. One result that may help explain why the crop yields from the manure plots were competitive with crops with a higher rate of commercial nitrogen is that soil organic matter levels in the manuretreated plots were significantly higher than levels in commercially fertilized plots.

“When you throw tillage into the mix, the soil organic matter levels also are significantly higher for no till and manure

Trial conducted at NDSU Carrington Research Extension Center

than any of the other treatments,” he says. The soil nitrate levels at all depths sampled were significantly lower for the manure plots versus the 90 or 45 pounds per acre commercial nitrogen treatments,

showing a more efficient use of nitrogen by the crops fertilized with manure. Soil pH (alkalinity or acidity) for the manure plots also was significantly higher than in the commercially fertilized plots.

The U.S. EPA has finalized a rule helping to protect the nation’s water quality by requiring concentrated animal feeding operations (CAFOs) to safely manage manure.

This is the first time the EPA has required a nutrient management plan (NMP) for manure to be submitted as part of a CAFO’s Clean Water Act permit application.

Previous rules required a CAFO operator to use an NMP for controlling manure. The regulation builds on this rule by requiring the NMP to be submitted with the permit application. The submitted plan will then be reviewed by the permitting authority and conditions incorporated as enforceable terms of the permit. The proposed NMP and permit will be available for public review and comment before going final.

The regulation also requires that an owner or operator of a CAFO that actually discharges to streams, lakes, and other waters must apply for a permit under the Clean Water Act. If a farmer designs, constructs, operates and maintains their facility such that a discharge will occur, a permit is needed. The EPA is also providing an opportunity for CAFO operators who do not discharge or propose to discharge to show their commitment to pollution prevention by obtaining certification as zero dischargers.

In addition, the final rule includes technical clarifications regarding water quality-based effluent limitations and use of best management practices to meet zero discharge requirements, as well as affirming the 2003 rule requirement for reducing fecal coliform through the use of best conventional technology.

The EPA worked closely with the U.S. Department of Agriculture during the development of the rule and will work closely with states during implementation. The rule deadline for newly defined facilities to apply for permits is Feb. 27, 2009.

Information on the concentrated animal feeding operation rule is available at http://www.epa. gov/npdes/caforule.

To help connect producers wanting to buy, sell or trade manure, Alberta Agriculture and Rural Development have created the Manure and Compost Directory.

The Manure and Compost Directory is an online site designed to facilitate transactions between producers wanting to move manure or compost off-farm and those looking to apply manure to their land as a source of nutrients for crop growth. Producers can easily post a wanted or for sale listing on the site by going online at http://www.agriculture. alberta.ca or by calling the Ag-Info Centre (310-FARM (3276) in Alberta, 403-7427901 out-of-province). The listing will indicate on a map of Alberta where the manure or compost is located and provide details regarding the amount and type of manure available, plus the desired price or arrangements of sale.

The Manure and Compost Directory can be found under the General Store tab on Ropin’ The Web: http://www. agriculture.alberta.ca.

Also new to Ropin’ The Web is the Manure & Compost Handling Custom Services Directory for custom applicators to post their services and contact information (search for “custom manure services” on the website).

For more information, please contact Alberta Agriculture and Rural Development at the Ag-Info Centre tollfree in Alberta at 310-FARM (3276) or at 403-742-7901 from out-of-province.

After a very successful 2007 national conference in Sacramento, Calif., the U.S.

Environmental Protection Agency’s (EPA) AgSTAR program is looking forward to its next national conference Feb. 24 to 25, 2009 at the Baltimore Hilton in Baltimore, Md.

Interest in manure digesters and associated energy production is increasing, and new issues are arising every day – new technologies, regulatory hurdles, and financial incentives.

In 2007, the AgSTAR conference had more than 300 attendees and 38 exhibitors and planners are expecting at least that level of participation in Baltimore.

The conference is a must for livestock producers, project developers, regulators, energy professionals, financiers, and others interested in manure digesters and energy projects. The conference is a great place to learn, identify potential projects, and network with others in the industry.

The conference will highlight the latest projects, technologies and financial incentives, and will once again include technical presentations, a conference luncheon, exhibits, and a tour of local manure digesters.

For more information, visit www.epa. gov/agstar/conference09.html

The farm, food processing and rural sectors are displaying increased interest in opportunities to conserve energy, develop sources of renewable energy, and produce or use bioproducts and byproducts to advantage. Actions taken to address important environmental concerns are commendable; however, in these demanding economic times, attention is focused on the bottom line as producers of all types are looking for ways to improve operating costs and land use.

This interest is reflected by a series of conferences called Growing the Margins: Energy, Bioproducts and Byproducts from Farm and Food Sectors. The Third Annual GTM conference,

scheduled for March 10-13, 2009 at the London Convention Centre, London Ont., will continue to explore the technological, operating, regulatory, financial and other challenges and opportunities facing farms and related food processing and rural industries as they strive to improve their energy efficiency, better utilize byproducts, and improve their bottom lines.

The conference will also feature the First Annual Canadian Farm and Food Biogas Conference and Exhibition. The biogas conference will run parallel to GTM #3, share plenary sessions and a common exhibition, but have a dedicated technical program of informative presentations and highquality speakers.

There will be two special networking sessions on March 10, immediately prior to the conferences:

• the European Union/Ontario Biogas Networking Forum, designed to bring EU and other suppliers of proven biogas technologies together with potential Ontario collaborators interested in developing projects here, and

• a Biomass Heat Networking Forum, which will provide an occasion for all stakeholders – agricultural producers,

technology providers, utilities, rural municipalities and all levels of government – to discuss and explore the opportunities for a biomass heat industry in Ontario.

There will also be a Building Your Biogas System Workshop. This hands-on session is aimed at equipping farmers and food processors with the knowledge and tools that they will require in order to effectively design and construct an agricultural or agri-food based biogasfor-energy system.

The week will end with technology tours. Three tours are planned for next year, each covering projects and technologies (biogas, biomass, wind, solar and others) in different parts of Southwestern Ontario. Tours at last year’s GTM conference were sold out.

Anyone interested in learning more about the two conferences and associated activities should check out the websites at www.gtmconference. ca or www.biogasconference.ca.

The International Journal of Chemical Reactor Engineering recently printed a

research article describing a proposed kinetic and reactor model for aerobic composting of poultry manure and wheat straw.

The article, written by Dr. Ivan Petric of the University of Tuzla in Bosnia-Hercegovina, is entitled: “Aerobic Composting of Poultry Manure and Wheat Straw – Kinetic and Reactor Model.” It describes laboratory-scale aerobic composting tests with mixtures of poultry manure and wheat straw and compares the performances of the composting process in both reactors to obtain the parameter values in the kinetic model and to validate proposed kinetic and reactor model in this work. An abstract of the research paper is available at www.bepress. com/ijcre/vol6/A95.

The Willmar Wrangler 4550 Loader is engineered to deliver the power, maneuverability and performance that operators demand, perfect for farmers who expect their tractor to be a jack-of-all-trades.

Four bucket capacities from 20 to 45 cubic feet let operators move all types of materials – up to 2,450 pounds – quickly and effectively.

The articulating loader features an 83 hp, 178 cu. in., Deutz diesel engine; single-speed, hydrostatic four-wheel drive; and joystick control for easy lift and tilt operation. In rough terrain, the 16 degree frame oscillation keeps all four wheels on the ground. The universal tool carrier accommodates most existing skid steer attachments from pallet forks and buckets to grapple forks and sweepers. Electronic shuttleshift and precise foot pedal speed control mean the Wrangler loader will be a reliable, productive addition to any farming operation. www.willmarloader.com

Manitou BF S.A., a manufacturer and distributor of material handling equipment based in France, recently announced the purchase of Wisconsinbased Gehl Company, a manufacturer of compact equipment for the agricultural and construction market.

The transaction, which went through in early September 2008, had a value of about $450 million.

It is expected the current management team at Gehl will be

retained following the transaction.

“We are pleased to announce the next step in the evolution of Gehl Company toward becoming a significant player in the global compact equipment marketplace,” said William Gehl, chairman and CEO of the company. “The combination of Gehl and Manitou offers a substantial value to our shareholders while affording our dealers and employees with future opportunities for continued success.”

Gehl was founded in 1859 and is headquartered in West Bend, Wis. It markets its products under the Gehl and Mustang brand names.

www.gehl.com

When purchasing equipment, versatility and dependability usually top the list of necessary features. The newest M-Series drive, the KMD 175, brings Keith ® Walking Floor ® technology into smaller agricultural applications. Ideal for installation in manure spreaders, commodity trailers and feed wagons, the KMD 175 drive boosts the efficiency of agricultural equipment with its horizontal self-unloading system.

Designed for light-duty loads, such as compost, sod, mulch, seed, and other bulk products, the KMD-175 drive unit powers the Walking Floor® self-unloading system. Weighing in at 280 pounds, it is one of the lightest drive systems available in the moving floor industry.

“In addition to the increased payload capacity, the drive is easier to install and service than comparable systems, and is appropriately sized for these applications,” said Scott Cloud, a sales representative with Keith Mfg.

Unlike dump trailers, which are limited by vertical height restrictions, a Walking Floor system can be used to unload material near or inside buildings, as well as in areas where trees and overhead power lines pose hazards.

A Walking Floor system is a horizontal unloader, eliminating the

need for tipping or dumping. Aluminum slats run the length of the trailer or truck box floor. Actuated by a fourphase hydraulic drive, slats move in groups of three, then together. This sequence “walks” material out. Systems are bi-directional for both loading and unloading product.

www.keithwalkingfloor.com

Manure management doesn’t have to mean keeping up with the latest technology. It can be as simple as using gravity to separate solids from liquids.

Noonyen Manufacturing has developed a weep wall system, which consists of two basins separated by a drainage channel. At each side of the drainage channel are Tri-Bar galvanized steel panels. When manure is added to a basin, liquids drain through the Tri-Bar Weep Walls into the drainage channel, while retaining solids in the basin. Having two basins allow a filled basin to drain and dry while the other is being filled. The consistency of the solids is dry enough to allow removal with a skid steer or loader. The solids from the basin can then be recycled as bedding, soil amendments, or marketed for additional income.

Mechanical systems are major contributors to energy use on the farm. Weep Walls do not require additional energy, equipment or labor. Gravity does the work for you. In addition to start-up costs, most manure separation systems require maintenance, repair, and training for employees to operate the system. With a weep wall system, there are no mechanical parts to keep up. Call 859-497-4429.

New for 2008, the Leon Silver Spreader is now available with dual vertical beaters and Autogate.

The new vertical beaters are balanced and synchronized, delivering a fine, wide and consistent spread of more than 40 feet. They are constructed of long-lasting, wear resistant paddles that are replaceable. The beater drive mechanism features a top-mounted, heavy-duty gearbox, providing more under clearance and protection from foreign objects.

The spreader box is made from steel, uniframe construction, featuring a corrosion-proof, solid poly box and

hydraulic push off technology.

The exclusive Autogate feature lifts the end gate of the spreader so the operator doesn’t have to. The spreader easily converts to a material trailer.

The new dual vertical beaters are available for models 425V, 575V, 655V, and 755V.

www.leonsmfg.com

Firestone Specialty Products Company is moving toward a global brand standard for all of its rubber liner and geomembrane products.

This standardization will include updates to the current product lines

➤ Manure Pits,Channels & Covers

➤ Suspended Slabs - up to 40’ clearspan

➤ Hog & Cattle Slats - up to 25’ clearspan

➤ Weeping Walls - manure separation

➤ Milking Parlors

➤ Strainer Boxes

➤ Commodity Storage

➤ Bridges

➤ Bunker Silos (8 types)

➤ Syloguard Concrete repair

➤ Retaining Walls

➤ L & T Walls up to 16’ high

About

• Built to engineers’ specifications

• All sections are high strength, pre-stressed,reinforcedconcrete for longer life

• Quick & easy to build

• Air-tight seals and protectant using Syloguard products

Call Toll-Free

to better serve the distribution and retail channels. This transformation will result in two internationally recognized brands — PondGard for the decorative/ residential sector and Firestone EPDM Geomembrane for the commercial/ industrial sector.

“Currently, the same quality products we sell in the U.S. are sold under a different brand name in Europe and other parts of the world,” said Mark Munley, vice-president of sales and marketing for Firestone Specialty Products. “By eliminating brand confusion, we will maintain the highest level of consistency for our customers, the world over.”

As Firestone standardizes its global offering, it will maintain universally acceptable conformity standards, recognized for the applicable sector the product is used in. The company will also continue to adhere to strict manufacturing guidelines, providing customers with the most appealing, dependable and costeffective product solutions.

These changes, as well as updates to the overall look of logos, brochures, advertising and website, will be seen in the coming months.

www.firestonesp.com

Fancom recently introduced the F35, a new climate computer, designed especially for naturally ventilated poultry houses. The F35 is suitable for all forms of natural ventilation and can also work in situations with a combination of both natural and mechanical ventilation. When used in conjunction with Fancom’s Minimum Transitional Tunnel (MTT) Natural system, the F35 can control the minimum ventilation with controllable fans in combination with air inlet or curtains and provide efficient cooling by tunnel ventilation, with or without pad cooling.

Fancom’s MTT Natural ventilation system features very accurate minimum ventilation. The system is based on a gradual transition from minimum to maximum ventilation without interrupting the airflow. Intelligent wind correction with storm protection avoids wind influences on the house

climate. The system provides the right conditions to increase occupancy rates and to limit the heat stress suffered by the animals. The result is a controllable production climate throughout the entire growth process from one-day old chickens to adult birds.

Extra features of the system include:

• Energy saving light control with dim and dusk function

• Energy saving Optisec™ heating control

• EasyFeed™ control for accurate dosing and registration of feed and water

• PC link to farm management and analyzing software www.fancom.com or 604-504-7296

Berg has introduced a new line of ventilation fans called the B Series, featuring redesigned bracing to minimize the flex of the fan frame. This added rigidity helps to decrease vibration and noise while increasing the life of the fan, adding value and reducing overall ventilation costs for the producer.

B Series fan models include:

• The 48B Basic unit, which features a galvanized, four-wing

blade heavy steel frame, and eyebolts for hanging with chains. It can also be mounted to a building column.

• The 48B Wall Box Fan unit, featuring a heavy galvanized steel square wall box with shutters and aluminum louvers plus a welded wire mesh inlet and side outlet guards. The high efficiency unit can be used for tunnel ventilation exhaust.

• The 48B Cone Fan, which comes with all the features of the 48B Wall Box Fan plus a galvanized diffuser cone. All units are available in an optional six-wing blade design, which provides quieter operation and high efficiency at low speeds.

www.bergequipment.com

The Agrifan ceiling fan continuously circulates the air in dairy and poultry operations. Designed with a heavy-duty motor, the fan can move and mix air at up to 330 RPM, 43,500 CFM, virtually eliminating heat stratification. The warm dry air that naturally rises is forced down to floor level in a continuing circular process. When used with an existing ventilation or heating system, the company states Agrifan can increase the efficiency of that system by 30 percent.

In summer, Agrifans create a wind chill effect that helps to cool livestock and poultry. Vertical airflow blows down on, and between, the animals to break up the heat halo.

The continuous air movement generated by Agrifans also speeds the drying of floors, bedding, walls and ceilings, helps prevent condensation and dissipates ammonia and gasses.

Agrifans feature triple neoprene rubber seals to make them dust and spray proof. A one-way condensation plug on the bottom of the motor housing keeps moisture from accumulating and corroding the motor components. www.envirofan.com

Better Air produces the Aircool Centrifugal Cooling System, an evaporative cooling unit that utilizes a centrifugal spraying system without nozzles, high-pressure pumps or compressors. Using normal water pressure, a spinning disc creates ultrafine particles that evaporate as they disperse into the air. Using water flow adjustment, livestock and poultry producers can regulate the amount of water to each unit and lower the temperature of the air. When cooling is not required, the water-dispersing unit can be shut off and the fan can be used alone to circulate room air only. Aircool is available as a cart-mounted or hanging system. The hanging system has two options: a 90-degree rotator to increase coverage by 25 percent, and a water recirculation kit to minimize water usage and shut off the water in case of a power interruption. The system can be used for cooling, humidifying, ventilating, disinfecting and controlling dust and odor. www.betterair.ca

A F.I.T. Ventilation system is designed for years of service and manufactured from non-corrosive materials. The patented design grabs air from in front and on either side to create a wall of air. The system merges two air streams into a singular mass of air, allowing for increased efficiency by displacing a greater volume of air. The airflow is constant and spreads into a 160-degree (80-foot) wide pattern. The F.I.T. fan system is available with variable speeds, allowing the producer flexibility to control the environment to meet animal demands, plus optional misting. It is available as a floor, pole or wallmounted system and is made from high-density plastic. It features a 0.5 HP, 115/230-volt, single-phase, electric motor with 1165 RPM, 11,310 CFM. Self-contained units with a generator are also available if electricity is an issue. www.fitventilation.com

Canarm’s 50-inch panel fans are ideal for dairy cooling and can be post or ceiling mounted through an innovative design. The simple, low cost design provides 28,000 CFM and requires little maintenance. The blades are cast from aluminum and are powered by a one HP, 230/460 volt three phase motor or a 1.5 HP, high/low two-speed 230 volt single phase motor.

Canarm also produces ceiling mounted, 36-inch Poly Round (PR) fans that can be hung quickly and point anywhere. The blades are covered with a strong, powder coated steel guard and are powered by a 0.5 HP, 115/230 volt single phase motor.

www.canarm.com

Chore-Time's high-capacity 52-inch (132.1 cm) diameter

Turbo® Fan with HyFlo® Shutter delivers 29,700 CFM at 0.05 inches of static pressure in independent wind tunnel tests. The HyFlo Shutter minimizes obstructions during fan operation and seals tighter when not operating, delivering up to 10 percent more air with 75 percent less opportunity for air to leak through compared to a traditional louver shutter. The HyFlo doors do not suffer loss of efficiency and air speed overtime, which can occur with louver-style shutters, so air speed is maintained over time.

Additional features include:

• A sturdy, corrosion-resistant fiberglass housing with cast aluminum blade and corrosion-resistant components

• One-piece, impact-resistant, polyethylene cone with 64-inch (162.6 cm) outside diameter that can be compressed for 60inch-on-center (152.4 cm) installation

• Automatic belt tensioner for consistent belt tension

• Heavy-duty, cast iron, air-handler type bearings that are selfaligning, pre-lubricated, and include a zerk fitting, as well as being shielded from moisture and dust

• The HyFlo Shutter consists of only two moving parts for greater reliability and easier cleaning

The fans, which are only available in 52-inch diameters, are shipped fully assembled, including shutter doors. At installation, simply attach the fan to the house sidewall, add the one-piece cone, and snap the grill in place. Units install flush on the inside of the house.

The fans were selected as an AE50 Outstanding Innovations Award winner for 2006 and are backed by Chore-Time’s extended warranty, including limited lifetime coverage for the housing and blade, and a bonus year on motors. www.ctbinc.com

If you have a large space that needs a cost-effective way to stay cool in summer and warm in the winter, Big Ass Fans may have the solution. According to the company, a Big Ass Fan can supply 25 times the airflow of a standard industrial ceiling fan, ultimately blowing the competition away. During the summer, Big Ass Fans provides a steady, gentle breeze, improving cooling by increasing the rate at which perspiration is evaporated from the skin’s surface. During the colder months, the fans help to gently drive ceiling-level hot air down to the floor.

Big Ass Fans feature 10 light-weight airfoils that slowly revolve, creating a massive – but gentle – movement of air in all directions. The company reports the fan can cover up to 20,000 square feet of area. This high volume/low speed operation, powered by a one- to two-HP motor and a variable frequency drive, results in a quiet and high efficiency fan. The fans use an in-line helical gear reducer to provide almost frictionless power transmission, meaning smoother operation and less wear and tear. www.bigassfans.com

Prairie Pride has been serving the hog, poultry and dairy industries’ ventilation needs for more than 30 years with its fan and air inlet products.

The company produces wall and roof exhaust plus recirculation fans using rugged components to reduce maintenance and operating costs. Prairie Pride wall exhaust fans are mounted flush on the inside barn wall to eliminate alleyway obstruction. The polyfan is available in 12- to 48-inch sizes with energy efficient motors matched to provide the most effective airflow. The company’s roof exhaust fans allow the fan to be placed anywhere within the barn to draw air efficiently. The fans work with the thermal effect and the wind to create an efficient exhaust system. It is available in various sizes and CFM outputs. Prairie Pride’s recirculating fans mix fresh, contaminated and heated air to provide consistent air quality. They are available in various panel fan sizes and poly-T transitions and easily fit in the company’s poly recirculation ducts.

Prairie Pride’s air inlet products are manufactured from durable plastic, smooth surface materials that allow easy

www.prairie-pride.com

cleaning and maintenance-free service. The company’s preheat inlets are actuator controlled to provide accurate control for proper directing of the airflow pattern. They are available in 900 and 1200 CFM models. Prairie Pride’s ceiling inlets are designed to fit between 24-inch centers and allow fresh airflow from the attic into the animal space. The company’s wall inlets operate either mechanically or as a self-positioning inlet, according to the room’s negative pressure.

Phason Electronic Control Systems recently updated its Supra 16-stage environmental controller. Version 2.0 is now available and features:

• A startup timer that allows users to delay the startup of the Supra’s loads when the control returns from a power failure, allowing the distribution of the initial startup load the backup generator must handle.

• Temperature setback that allows users to automatically change the temperature set point for a specific period during the day.

• Variable DC Expansion Kit that allows the user to connect equipment that requires a zero to 10-volt input (variable frequency drives, etc.). The kit installs in seconds and has four outputs that can be configured for cooling or heating.

• Tunnel ventilation mode that can be configured to close inlets and/or curtains, switch off relays and set variable stage output to zero when the zone temperature is at or above the tunnel set point.

• An improved status display that includes relay run durations and the day’s high and low temperatures.

• A daily log that lists the high and low zone, outside temperature and humidity, total water usage and total relay on durations.

www.phason.ca

Osborne’s Agri-Aide Ventilation System provides ventilation solutions based on more than 40 years of practical experience creating comfortable, productive livestock environments in all types of farm buildings. The company offers equipment options to match any ventilation requirement and its engineering and manufacturing systems meet ISO 9001 international quality standards.

Whether farmers are managing pigs, poultry, dairy, or other livestock, fresh air is vital to the health of the animals, the operation’s staff, and the financial health of the farming business.

The Agri-Aide system can provide an integrated combination of exhaust fans, fresh air inlets, circulation fans, and automatic controls that match each operation’s building and the animals being managed.

Osborne Industries operates its own demonstration farm, including an air movement laboratory. The company also collaborates with universities, allowing product developers to harness the latest technology and offer livestock producers different combinations of ventilation components.

www.osborne-ind.com

3RD ANNUAL GROWING THE MARGINS CONFERENCE AND EXHIBITION

3292 Victoria St., Oakville, ON L6L 5R3

Tel: 905-465-3147

e-mail: john.mcmullen@teksavvy.com

Mr. John McMullen

ACCENT MANUFACTURING INC.

602-30731 Simpson Road, Abbotsford, BC V2T 6Y7

Tel: 604-850-7799 Fax: 604-850-7909

Toll Free: 1-877-855-4890

e-mail: info@accentmanufacturing.com

website: www.accentmanufacturing.com

Darryl Loewen

ACM - TEXAS, LLC

PO Box 270941, Fort Collins, CO 80527

Tel: 970-203-0005 Fax: 970-203-1090

website: www.neutracite.com

Mr. Bob McCreeless

ADVANCED AERATION, INC.

102 Midway Industrial Park

Angleton, TX 77515

Tel: 281-595-3456 Fax: 281-595-3458

e-mail: thickey@advancedaeration.com

Thomas Hickey

AERATION INDUSTRIES INT., LTD.

Box 59144, Minneapolis, MN 55459-0144

Tel: 952-448-6789 Fax: 952-448-7293

Toll Free: 1-800-328-8287

Tod Martin

AEROMIX

7135 Madison Ave West Minneapolis, MN 55427

Tel: 763-746-8400 Fax: 763-746-8408

Toll Free: 1-800-879-3677

e-mail: aeromix@aeromix.com

web site: www.aeromix.com

AERWAY/SAF-HOLLAND

Box 339, Norwich ON NOJ 1P0

Tel: 519-863-3414 Fax: 519-863-2398

Toll Free: 1-800-457-8310

e-mail: aerway@aerway.com

web site: www.aerway.com

Matt Mayer

AGCO CORPORATION AG-CHEM EQUIPMENT

202 Industrial Park, Jackson, MN 56143

Tel: 507-250-2271 Fax: 507-847-4981

e-mail: craig.jorgensen@agcocorp.com website: www.agchem.com

AGPRO®, INC.

859 Airport Rd., Paris, TX 75462

Tel: 903-785-5531 Fax: 903-784-7895

Toll Free: 1-800-527-1030

e-mail: info@agprousa.com website: www.agprousa.com

AGPROFESSIONALS, LLC

4350 Highway 66, Longmont, CO 80504

Tel: 970-535-9318 Fax: 970-535-9854

e-mail: tharen@agpros.com website: www.agpros.com

Thomas Haren

AGRI DRAIN CORPORATION

1462 340th St., Adair, IA 50002

Tel: 641-742-5211 Fax: 641-742-5222

Toll Free: 1-800-232-4742

e-mail: info@agridrain.com website: www.agridrain.com

AGRI-WASTE TECHNOLOGY INC.

5400 Etta Burke Ct., Raleigh, NC 27606

Tel: 919-859-0669 Fax: 919-233-1970

e-mail: mmottern@agriwaste.com website: www.agriwaste.com

Melissa Mottern

AGTECH PRODUCTS

W 227, N 752, Waukesha, WI 53186

Tel: 262-521-1717 Fax: 262-521-2442

Toll Free: 1-800-999-3899

e-mail: info@agtechproducts.com website: www.agtechproducts.com

Maryanne Bellot

ALBERS MANURE HANDLING SYSTEMS INC.

14470 S. Euclid Ave., Chino, CA 91710

Tel: 909-597-5537 Fax: 909-393-8784

Toll Free: 1-800-872-5441

e-mail: sales@albersdairyequipment.com website: www.albersdairyequipment.com

Teo Albers Sr.

ALLIANCE TIRE USA

4 - 2nd Ave., Ste. 106, Denville, NJ 07834 Fax: 973-664-9105

Toll Free: 1-877-978-4737

e-mail: mshah@alliancetireusa.com

web site: www.alliancetireusa.com

Manjri Shah

Alliance Tire is a worldwide technology leader in rugged, reliable tires for heavy-duty agricultural use, including fast, durable flotation tires for manure spreaders as well as high-performance tractor tires.

ANGUS FIRE USA

141 Junny Rd. Angier NC 27501

Tel: 919-539-6151 Fax: 800-334-3156

web site: www.angusfire.com

ARMORED TEXTILES, INC.

9 Vose Farm Road, Peterborough, NH 03458

Tel: 603-924-2122 Fax: 603-924-2322

e-mail: mdonovan@armtexinc.com

Mark Donovan

ASSINIBOINE COMMUNITY COLLEGE

1430 Victoria Ave. East, Brandon, MB R7A 7E4

Tel: 204-573-3593 Fax: 204-725-8740

Toll Free: 1-800-862-6307

e-mail: nowosad@assiniboine.net

Trent Nowosad

ATD WASTE SYSTEMS INC.

3095 West 24th Ave.

Vancouver BC V6L 1R7

Tel: 604 736-4474 Fax: 604-736-4493

e-mail: 1cleanfarm@hogmanure.com web site: www.hogmanure.com

BALLAGH LIQUID TECHNOLOGIES INC.

121 North St. West, Wingham, ON NOG 2W0 Tel: 519-357-4600 Fax: 519-357-4630

Toll Free: 1-877-312-4600

e-mail: info@bliquidtech.ca website: www.bliquidtech.com

Mr. Byron Ballagh

BALZER, INC.

Co. Rd. 27E, Mountain Lake, MN 56159 Fax: 507-427-2364

Toll Free: 1-800-795-8551

e-mail: balzer@iowatelecom.net website: www.balzerinc.com

Jason Liechty

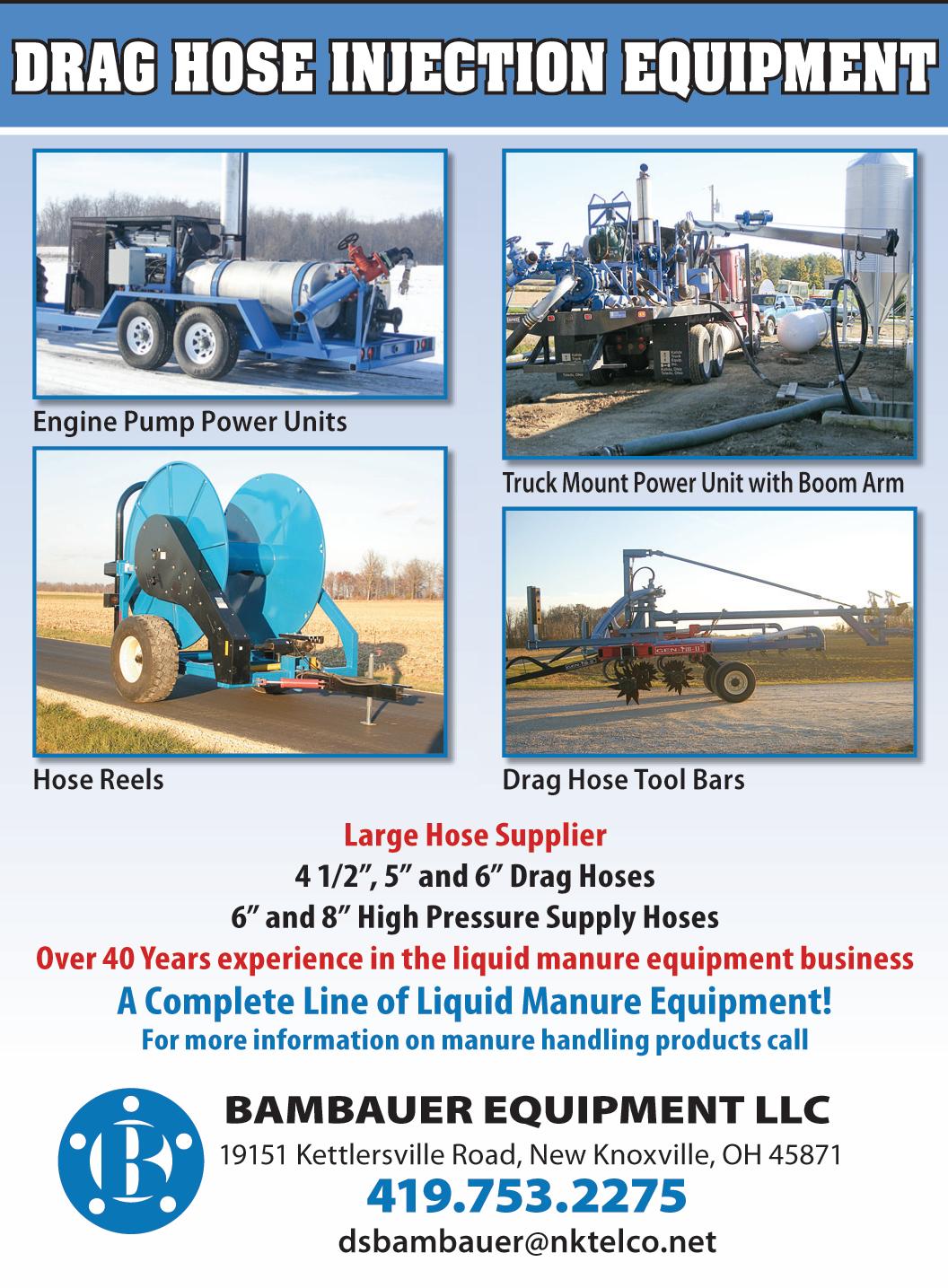

BAMBAUER EQUIPMENT LLC.

19151 Kettlersville Rd., New Knoxville, OH 45871

Tel: 419-753-2275 Fax: 419-753-3116

e-mail: bambauerequipment@nktelco.net

Doug Bambauer

BAUER NORTH AMERICA/FAN SEPARATOR

107 Eastwood Road, Michigan City, IN 46360

Tel: 800-922-8375

e-mail: rhultgren@bauer-at.com website: www.bauer-at.com OR www.fan-separator.de

Mr. Rob Hultgren

BAZOOKA FARMSTAR INC.

Box 869, 1901 E. Washington St., Washington, IA 52353

Tel: 319-653-5080 Fax: 319-653-5806

Toll Free: 1-800-775-7448

e-mail: salesbfinc@iowatelecom.net

Steve Pittman

Bazooka Farmstar manufactures manure injection equipment, hose reels, power units and accessories needed to apply from 2,500 to 30,000 gallons/acre. Call 1-800-775-7448 or email salesbfinc@iowatelecom.net for more information.

BIG TIMBER SALES

400 - 16th St., Corning, IA 50841

Tel: 641-322-4358 Fax: 641-322-5411

e-mail: bigtimb@frontiernet.net

Gerry Walker

BIOTHANE CORPORATION

2500 Broadway, Camden, NJ 08104

Tel: 856-541-3500 Fax: 856-541-3366

e-mail: sales@biothane.com website: www.biothane.com

Mr. Ryan Johnston

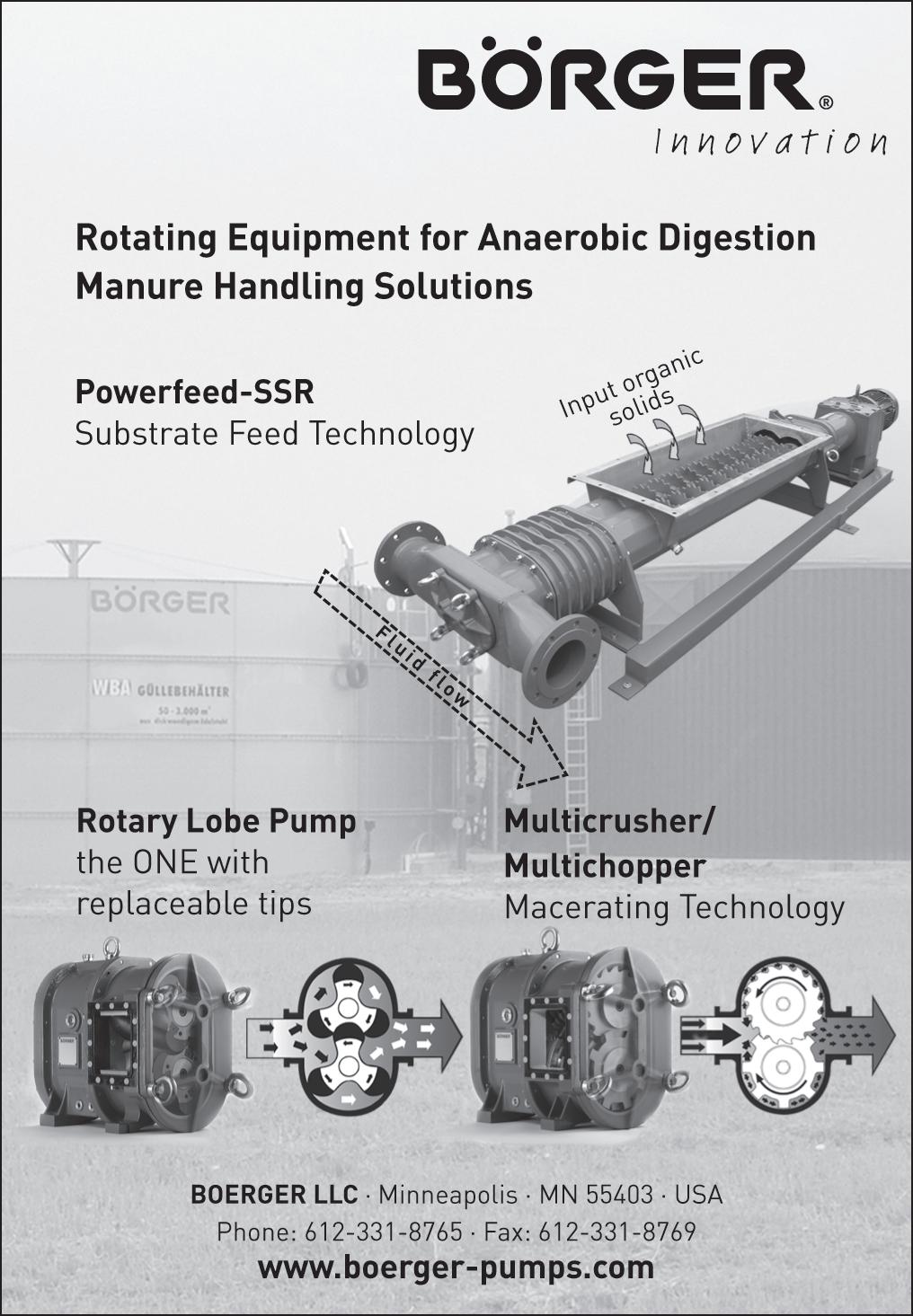

BOERGER, LLC

740 NE Harding Street, Minneapolis, MN 55413

Tel: 612-331-8765 Fax: 612-331-8769

Toll Free: 1-877-726-3743

e-mail: bwe@boerger-pumps.com website: www.boerger-pumps.com

Bernhard Wessendorf

BRANSON’S (TBHS)

Box 328, Strathclair, MB R0J 2C0

Tel: 204-365-2213 Fax: 204-365-2201

Ian Branson

BRAUN ELECTRIC INC.

209 North Fourth Ave., St. Nazianz, WI 54232

Tel: 920-773-2143 Fax: 920-773-2724

Toll Free: 1-800-876-2234

e-mail: rbraun@braunelectricinc.com website: www.braunelectricinc.com

Alecia Braun

BROWN BEAR CORPORATION

PO Box 29, Corning, IA 50841

Tel: 641-322-4220 Fax: 641-322-3527

e-mail: brnbear@mddc.com

website: www.brownbearcorp.com

David Gebhardt, Phil Brown

CADMAN POWER EQUIPMEN

38 Main St., Courtland, ON NOJ 1E0

Tel: 519-688-2222 Fax: 519-688-2100

Toll Free: 1-866-4CADMAN

e-mail: tim@cadmanpower.com

website: www.cadmanpower.com

Mr. Wayne Cadman

CADY INC.

383 Illinois Highway 92

Tampico IL 61283

Tel: 815-438-5678 Fax: 815-438-5681

Toll Free: 1-877-999-CADY

e-mail: cady@cadyinc.com

Randy Cady

Cady Inc. specializes in Above Ground Positive Containment Slurrystore ® Systems, Nutristore® Liquid Fertilizer Storage, Houle Manure Handling Hquipment, Flygt

Submersible Manure Pumps, along with Parkson Sand Separation Systems and Houle Manure Separator Systems.

CANAMER SERVICES INC.

S. 2964 Indian Creek Rd. Fountain City WI 54629

Tel: 608-687-9800 Fax: 608-687-9901

e-mail: bob@canamerservices.com

web site: www.canamerservices.com

Robert Dotterwick

CAWI CANADA LTD.

Site 12, RR 6, Box 49, Calgary, AB T2M 4L5

Tel: 403-569-9481 Fax: 403-569-8490

e-mail: cawi@telus.net

Kase van Ittersum

CLAAS OF AMERICA INC.

8401 South 132nd St., Omaha, NE 68138

Tel: 402-861-1000 Fax: 402-861-1003

e-mail: inquiry@claas.com website: www.claasofamerica.com

TC Truesdell

CLI

1062 Singing Hills Rd., Parker, CO 80138

Fax: 303-951-1971 Toll Free: 1-800-524-8672

e-mail: rvigil@coloradolining.com website: www.coloradolining.com

Mr. John Heap

CORNELL PUMP COMPANY

PO Box 6334, Portland, OR 97228

Tel: 503-653-0330 Fax: 503-653-0338

e-mail: bjansen@cornellpump.com website: www.cornellpump.com

Mr. Bob Jansen, Lloyd Spanke

Cornell Pump Company, a leader in the pump industry for 60 years, now offers over 25 waste handling pump models with unique and innovative design features for low head transfer to high pressure field applications.

D & H FIELD SERVICES, INC.

15433 Cardinal Rd., Osakis, MN 56360

Tel: 320-352-6746 Fax: 320-352-7838

e-mail: dhfieldservices@hotmail.com

Darrin Herickhoff

DARITECH, INC.

8540 Benson Road, Lynden WA 98264

Tel: 360-354-6900 Fax: 360-354-7522

Toll Free: 1-800-701-3632

de BIE MANUFACTURING

RR #2, Tillsonburg, ON N4G 4G7

Tel: 519-842-6216 Fax: 519-688-3072

e-mail: debiemfg@execulink.com

Mr. Stephan de Bie

DFK EQUIPMENT SALES, INC.

PO Box 938, St. Marys, ON N4X 1B7

Fax: 800-752-0934 Toll Free: 1-800-881-3794

e-mail: sales@dfkequipment.com web site: www.dfkequipment.com

DGH ENGINEERING LTD.

12 Aviation Blvd., St. Andrews, MB R1A 3N5

Tel: 204-334-8846 Fax: 204-334-6965

Toll Free: 1-877-334-8846

e-mail: dgh@dghengineering.com website: www.dghengineering.com

Ms. Irene Kutzak

DM MACHINERY INC.

1875 St-Edouard Rd., Saint - Simon, QC J0H 1Y0

Tel: 450-798-2922 Fax: 450-798-2914

Toll Free: 1-888-798-2922

e-mail: info@dmmachinery.ca website: www.dmmachinery.com

Marcel Depeault

DODA U.S.A. INC.

255 16th St. S., P.O. Box 316 St. James, MN 56081

Tel: 507-375-5577 Fax: 507-375-5578

e-mail: dodausa@embarqmail.com website: www.DODA.com

Rich Miller

DODA U.S.A. Inc. is the distributor and marketing arm of all DODA products. Products consist of Vertical and Horizontal Chopper Pumps, Agitators, Separators, Bio Gas Mixers and accessories.

DON THEMM ENTERPRISES, INC.

P.O. Box 146, Almont, MI 48003-0146

Tel: 810-798-8311 Fax: 810-798-8311

Toll Free: 1-800-808-4366

e-mail: donaldthemm@gmail.com

Don Themm

DOWDY’S SALES & SERVICE

15185 Ave 224, Tulare, CA 93274

Tel: 559-688-6973 Fax: 559-688-5988

e-mail: brad@dowdys.com

web site: www.dowdys.com

Brad Dowdy

DRAEGER SAFETY INC.

101 Technology Drive, Pittsburgh, PA 15275

Tel: 412-788-5671 Fax: 412-787-2207

Toll Free: 1-800-615-5503

e-mail: prodinfo@draeger.com

website: www.draeger.com

Shelli Cosmides

DSI, INC.

250 CR 1425 E., Goodfield, IL 61742

Tel: 309-965-5110 Fax: 309-965-2532

e-mail: bill@dsiag.com website: www.dsiag.com

Bill Dietrich

DSM NUTRITIONAL PRODUCTS

45 Waterview Boulevard

Parsippany, NJ 07054-1298

Tel: 973-257-8396 Fax: 973-257-8653

e-mail: robert.stock@dsm.com

web site: www.unlimitednutrition.na.dsm.com

Dr. Robert Stock

DUSKE DRYING SYSTEMS

6901 Industrial Loop, Greendale, WI 53129

Tel: 414-529-0240 Fax: 414-520-0362

e-mail: ty.hogue@duskeengineering.com website: www.duskeengineering.com

Michael Uzelac

ENCON TECHNOLOGIES INC.

12 Aviation Blvd., St. Andrews, MB R1A 3N5

Tel: 204-338-2514 Fax: 204-334-6965

Toll Free: 1-866-345-2148

e-mail: info@enconcovers.com website: www.enconcovers.com

Mr. Dennis Antony

ENVIRONETICS INC.

1201 Commerce St., Lockport, IL 60441

Tel: 815-838-8331 Fax: 815-838-8336

e-mail: info@environeticsinc.com

web site: www.environetics.com

Steven Winters, V.P. Operations.

ENVIRONMENTAL CREDIT CORP.

101 S. Fraser St., State College, PA 16801

Tel: 607-288-4020 Fax: 607-288-4049

Toll Free: 1-800-770-8039

e-mail: aaldridge@envcc.com website: www.envcc.com

ENVIRONMENTAL POWER CORP.

One Cate Street, 4th Floor, Portsmouth, NH 03801

Tel: 603-431-1780 Fax: 603-431-2650

e-mail: info@environmentalpower.com website: www.environmentalpower.com

Diane Marcinonis

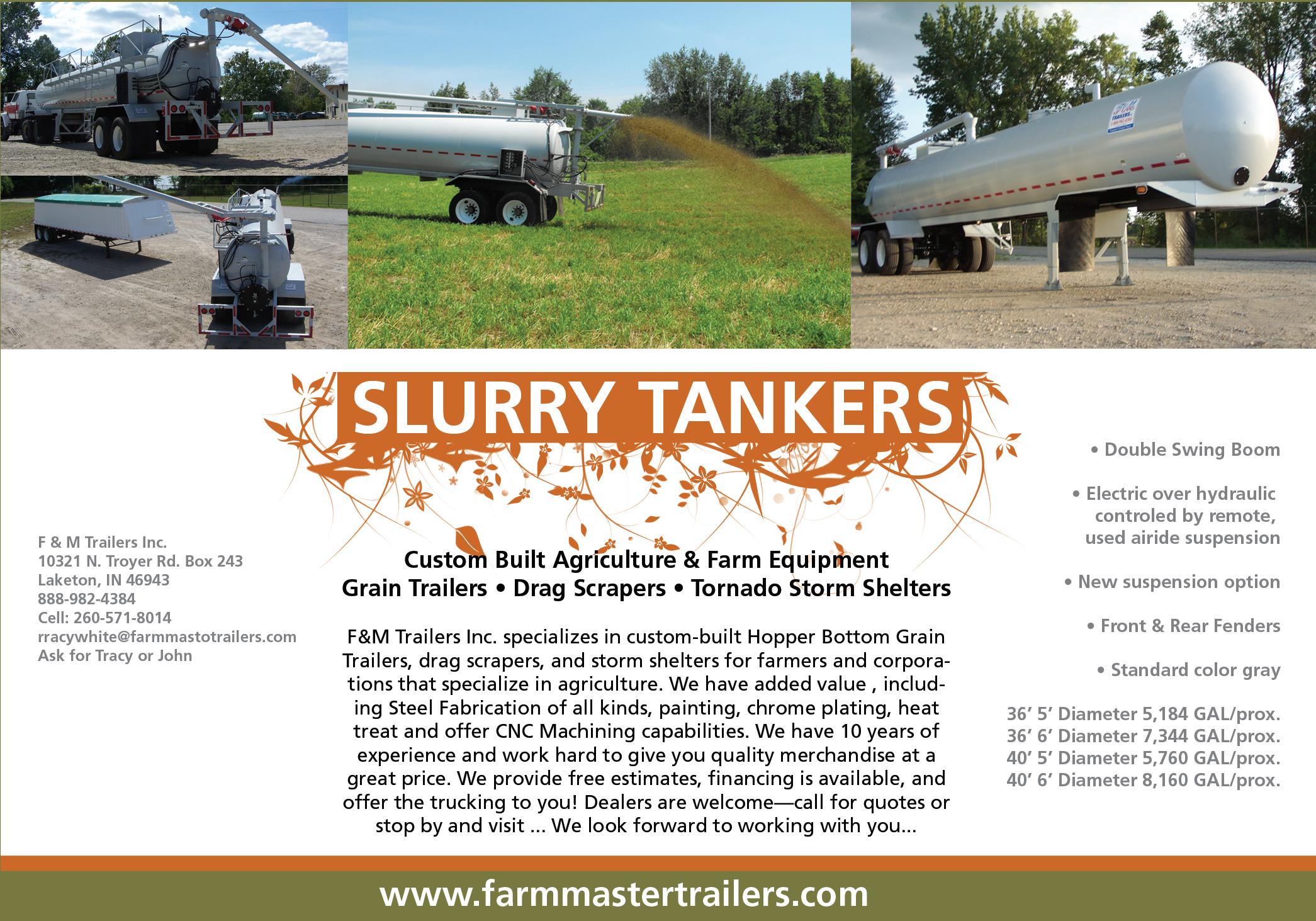

F&M TRAILERS INC.

10321 N. Troyer Rd. Box 243, Laketon, IN 46943

Toll Free: 1-888-982-4384

e-mail: tracywhite@farmmastertrailers.com web site: www.farmmastertrailers.com

FARM TEK

1440 Field of Dreams Way, Dyersville, IA 52040

Tel: 860-289-7261 Fax: 860-289-4711

Toll Free: 1-800-327-6835

e-mail: sales@farmtek.com website: www.farmtek.com

5571 South State Road 25, Rochester, IN 46975

Tel: 574-857-3116 Fax: 574-857-2112

e-mail: dleavell@farmerautomatic.com

David Leavell

Farmer Automatic of America, with 23 years of research and development, currently has 5 models of in-vessel and 2 windrow composting machings that can handle 2 to 96 cubic yards per day.

250 W. 96th St., Indianapolis, IN 46260

Tel: 317-575-7000 Fax: 317-575-7002

Toll Free: 1-800-428-4442

e-mail: info@firestonesp.com website: www.firestonesp.com

Firestone Specialty Products manufactures high-quality, durable geomembrane systems used in a wide variety of agricultural, critical containment applications including animal waste containment, anaerobic digesters, irrigation canals and constructed wetlands.

2024 E. 8th St., Greeley, CO 80631

Tel: 970-353-6962 Fax: 970-353-0839

e-mail: rich@fisherpumps.com website: www.fisherpumps.com

Mr. Rich Helzer

FLAME ENGINEERING INC.

Box 577, LaCrosse, KS 67548

Fax: 785-222-3619

Toll Free: 1-800-255-2469

e-mail: mel@flameengineering.com

Mel Limone

FLO TECH PUMP

D1, 3911 Brandon St. SE, Calgary, AB T2G 4A7

Tel: 403-236-2886 Fax: 403-225-8446

Toll Free: 1-866-248-2886

e-mail: ddarker@flotechpump.com website: www.flotechpump.com

Don Darker

GEA HOULE INC.

4591 Boul. St-Joseph Drummondville, QC J2A 0C6

Tel: 819-477-7444 Fax: 819-477-5565

e-mail: jhoule@jhoule.com website: www.jhoule.com

GEHL COMPANY

143 Water St., West Bend, WI 53095

Tel: 262-334-9461 Fax: 262-334-6689

e-mail: lheidecker@gehl.com website: www.gehl.com

Ms. Lori Heidecker

GES CORP.

26000 Richmond Rd., Cleveland, OH 44146

Toll Free: 1-800-234-9686

e-mail: paf1222@bellsouth.net

GLOBAL REPAIR