SMART CLIMATE CONTROL

Artificial intelligence for optimal barn conditions

Pg 10

ESA 3000

Reduction of heating costs by up to 65%

Improvement of animal welfare

Fast payback (ROI of 2 to 3 years)

Reduction of CO2, humidity and ammonia levels

Better returns, more income

The future of farm ventilation starts now.

Nicole Stewardson, OntarioTim Cox, Nova Scotia

« This is the best my bedding has ever looked in a long time. »

« Thanks to my ESA-3000 air exchangers on my first four flocks, I reduced my propane consumption by 61%! »

esaseries.com info@esaseries.com 1 855 573-2877 Summit Technologies Inc. 26 Millwork Dr, Steinbach, MB, R5G 1V8 Phone: (204) 320-3276 www.summittechnologies.ca

Energy Solutions Air 4350 Robitaille Street, door B Sherbrooke (QC) J1L 0B5, Canada

899-3621 www.polsltd.ca IEL Technologie Agricole 552 Begin N Road, Sainte-Claire, QC, G0R 2V0 Phone: (418) 883-3030 www.iel.ca County-Line Equipment Ltd. 8582 ON-23, Listowel, ON, N4W 3G6

596202 Hwy 59, Woodstock, ON, N4S 7W1 Phone: (519) 291-5012

www.county-line.ca Agritech Farm Equipment Ltd. 2 Tantramar Ct, Amherst, NS B4H 4H8 Phone: (902) 667-5550 warehouse@lbjfarm.ca43 Minas Warehouse Rd, New Minas, NS, B4N 5A5 Phone: (902) 678-2430 newminasparts@lbjfarm.ca Jonkman Equipment Ltd. 28355 Fraser Highway, Abbotsford, BC, V4X 1K9 Phone: (604) 857-2000 www.jonkmanequipment.com

From

the Editor

by Brett Ruffell

Unravelling the mystery of avian influenza

In late 2021, the poultry industry in Canada faced a formidable challenge with the outbreak of the H5N1 strain of avian influenza (AI). Since then, this persistent threat has continued to loom over poultry farms, prompting urgent calls for enhanced biosecurity measures and a deeper understanding of transmission pathways.

In response, a collaborative project has emerged in Ontario, spearheaded by Claire Jardine, Associate Professor at the University of Guelph, and Al Dam, poultry specialist with the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA). This initiative aims to determine how avian influenza enters poultry barns, with the ultimate goal of fortifying preventative measures and safeguarding the industry.

“Wild birds are playing a significant role in the global spread of high path AI, especially during the spring and fall migration periods,” Jardine says. “However, it’s less clear how wild birds contribute to on-farm transmission. Understanding this dynamic is crucial for devising effective prevention strategies.”

Dam echoes this sentiment, highlighting the project’s broader implications beyond avian influenza. “What we learn from this research isn’t limited to AI; it holds relevance for understanding the transmission of

various infectious diseases. By unravelling these mysteries, we equip ourselves with valuable insights that can benefit the industry as a whole,” he explains.

At the heart of the project lies a multifaceted approach comprising three key components. Firstly, an ecology study will examine infected premises, delving into wildlife, animals, and environmental factors. “Our goal is to identify potential vectors and reservoirs of AI within the farm environment,” Jardine says

This comprehensive approach aims to shed light on the intricate interplay between wildlife and farm biosecurity.

Secondly, a case-control study will scrutinize the physical and management aspects of infected premises, juxtaposed with other farms to pinpoint potential risk factors. “By comparing biosecurity measures on infected and uninfected farms, we hope to uncover crucial insights into disease transmission,” Dam says. This analysis is vital for informing evidence-based prevention strategies.

Lastly, the project seeks to develop an epidemiological risk map – a tool crucial for assessing the risk of AI transmission across various operations. “By mapping out high-risk areas, we can proactively identify vulnerable points and implement targeted interventions,” says Jardine. This strategic approach

holds immense potential for mitigating the spread of AI within the poultry industry.

The collaborative nature of the project is impressive, with various stakeholders, including governmental agencies, research institutions, and industry bodies, joining forces to tackle this pressing issue. Jardine, underscoring the importance of collaboration, says, “By pooling our diverse expertise and resources, we can tackle this challenge more effectively and expedite the translation of research findings into actionable strategies.”

Looking ahead, the project aims to disseminate findings promptly, ensuring that valuable insights reach producers and stakeholders.

“Wild birds are playing a significant role in the global spread of high path AI... Understanding this dynamic is crucial.”

“Transparency and knowledge sharing are paramount,” Dam says. “Our goal is to empower farmers with actionable information that can help them bolster their biosecurity measures and protect their livelihoods.”

As we continue to navigate the complexities of avian influenza, this collaborative effort stands as a testament to the industry’s resilience and determination. By unravelling the mysteries of AI transmission, we pave the way for a more resilient and prepared poultry industry throughout Canada.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: (416) 510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

Brand Sales Manager

Ross Anderson randerson@annexbusinessmedia.com Cell: 289-925-7565

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Media Designer Brooke Shaw

Group Publisher Michelle Bertholet mbertholet@annexbusinessmedia.com

Audience Development Manager

Anita Madden amadden@annexbusinessmedia.com 416-510-5183

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates

Canada - Single-copy $10.00

Canada – 1 Year $33.15

Canada – 2 years $56.61

Canada – 3 years $78.54 (plus applicable taxes)

USA – 1 Year $93.33 CDN Foreign – 1 Year $105.57 CDN

GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

New! Low Profile Feed Pan

What’s Hatching

Dairy cattle in Texas and Kansas test positive for bird flu

Milk from dairy cows in Texas and Kansas has tested positive for bird flu, U.S. officials said in late March. Officials with the Texas Animal Health Commission confirmed the flu virus is the Type A H5N1 strain, known for decades to cause outbreaks in birds and to occasionally infect people. The virus is affecting older dairy cows in those states and in New Mexico, causing decreased lactation and low appetite.

Poultry leaders among Ontario Agricultural Hall of Fame honorees

Six distinguished leaders in Ontario agriculture will be honored at the 2024 Ontario Agricultural Hall of Fame induction ceremony in June. Among the honorees are Bill Gray and Tina Widowski, notable figures in the egg and poultry industry. Gray, the CEO and owner of L.H. Gray & Son Ltd., has been instrumental in advancing egg farming science and technology throughout Ontario and Canada. Widowski, a professor at the University of Guelph, is recognized as a leading expert in poultry behavior and welfare research globally.

Chicken industry hosts virtual farm tour for parliamentary interns

In a bid to foster understanding of Canadian agriculture practices among future leaders, Chicken Farmers of Canada (CFC) proudly sponsored a virtual farm tour for the twelve Parliamentary Interns participating in the Parliamentary Internship Programme (PIP). The initiative aimed to provide insights into Canadian chicken farming excellence and the significance of supply management in the industry.

Lynne and William (Bill) Gray’s foundation donated millions to the University of Guelph to help elevate Canada’s poultry and egg sector.

University of Guelph receives $3.5M gift to enhance Canada’s poultry and egg industry

The University of Guelph has received a $3.5 million donation from the William and Lynne Gray Foundation and L.H. Gray & Son Limited, aiming to bolster Canada’s poultry and egg sector.

The endowed Bill and Lynne Gray Chair in Advanced Poultry Technology Management will focus on innovative approaches to environmental control issues.

“This generous contribution marks a significant step towards advancing technologies and systems crucial for sustainable and profitable production, ultimately elevating the Canadian poultry and egg industry on the global stage,” said Dr. John Cranfield, acting dean of OAC, expressing gratitude for the Gray family’s commitment.

In collaboration with the School of Engineering, the endowed Bill and Lynne Gray Chair in Advanced Poultry Technology Management will focus on environmental control issues such as lighting, ventilation, sanitation, and biosecurity. “Our

goal is to utilize new and emerging technologies to mitigate the spread of avian diseases, further enhancing industry practices,” notes Cranfield.

L.H. Gray & Son, a renowned family-owned business serving various sectors across Canada, views this investment as a privilege to contribute to the university’s esteemed research and teaching endeavors. CEO Bill Gray emphasized that the donation will not only benefit the poultry and egg sector but also the broader public. “We are honored to make this investment in the University of Guelph’s research and teaching expertise, which is second to none,” Gray stated. Furthermore, the endowed chair will play a pivotal role in the planning and operations of the Ontario Poultry Research Centre in Elora, Ontario.

Inaugural Student Innovation Challenge produces fresh ideas for Canada’s egg sector

The Egg Farmers of Canada proudly unveiled the winners of its first-ever Student Innovation Challenge, a platform where post-secondary students nationwide showcased their inventive research ideas and solutions aimed at shaping the future of Canada’s egg sector.

Roger Pelissero, Chair of Egg Farmers of Canada, expressed his excitement about the students’ creativity and their dedication to addressing challenges and seizing opportunities within the egg farming industry. He emphasized the importance of evidence-based research in driving innovation in

the sector.

Students were tasked with submitting videos answering the question: “What is your research project that can shape the future of the egg industry in Canada?” The response was overwhelming, with numerous students sharing their fresh and inspiring ideas.

Advertisement

Mariève Dallaire-Lamontagne from Université Laval and Ravneet Kaur from the University of Alberta emerged as the joint winners, with Violet Hipkin from the University of Guelph securing third place. Dallaire-Lamontagne’s project focuses on giving egg

Egg

production residue a second life using insects. Kaur’s explores the potential of eggs to increase protein intake in individuals recovering from cancer treatment. And Violet Hipkin’s project focuses on pecking blocks for laying hens.

Drew Black, CEO of Egg Farmers of Canada, congratulated all participants for their contributions to the Student Innovation challenge, highlighting the significant role students play in positively impacting the sector’s future.

This challenge marks the newest addition to Egg Farmers of Canada’s research program, which includes various initiatives such as the Research Grant Program, a Research Chairs Network, and several research partnerships.

Mariève Dallaire-Lamontagne from Université Laval, speaking here at

Farmers of Canada’s AGM, was a joint winner of the challenge.

The Brooding Notebook

By Dr. Gigi Lin

provides diagnostic, research, consultation, continuing education, and field

High CO levels a silent threat

Case Summary: In the October 2023 issue, I shared a case that highlighting the impact of high levels of carbon dioxide on poultry health. In this issue, I would like to address another, even more dangerous and often-overlooked, toxic gas that can cause significant health impacts to poultry. This report details a case of suboptimal performance in three consecutive flocks of broilers, ultimately traced back to poor air quality in the barn.

Case History: It was early Spring in B.C. while I was working closely with a conventional broiler farm in Abbotsford. It was a well-managed family farm with an experience farm manager. I was consulted to investigate an on-going complaint of generalized poor performance, including poor feed conversion, poor uniformity, and failure to reach target body weights for three consecutive flocks.

Recent performance data showed that the average body weights of birds started to fall off the baseline as early as seven days old. However, there were no other clinical signs reported; the mortality levels and condemnation rates had been normal.

Diagnostic Approach: The investigation began with routine portmortem examinations and end-of-flock serology tests (a series of blood tests that help identify exposure to disease-causing agents) to help rule out underlying disease conditions. All the results came back insignificant. Routine in-

testinal health check was also performed, including coccidia lesion scoring. I did not find any prominent infectious disease conditions. The feed company also ran multiple feed analyses and did not identify any nutritional imbalance or deficiency.

Field Evaluation: When I received the initial complaint, the existing flock was in the grow-out phase. I went to the farm twice between the growout and finisher phases and did not identify any management or environmental stressors that could have explained the problems.

“Proper maintenance of heating systems, including regular inspections and timely

repairs,

is essential

for minimizing the risk of CO exposure.”

Unable to identify the underlying causes, I decided to shift the focus on the brooding period, which is the critical phase for establishing optimal conditions for chick growth and development. I went to the farm at different time every day between day one to day five to go through the brooding checklist (TFLAWS: temperature, feed, litter, air, water, and sanitation). With the farm manager’s help, we monitor the birds’ weight once a day by randomly selecting 100 chicks. By day four, we started to notice birds fell off the trajectory weight gain despite normal brooding parameters. At that time, I de-

PHOTO: KLEIN TOOLS

Dr. Gigi Lin is a board-certified poultry veterinarian. She

services to all levels of the poultry industry in Western Canada. In this column, she will share case-based reviews of brooding best practices.

A handheld carbon monoxide monitor can detect an unseen threat to your flock.

cided to return with a handheld carbon monoxide (CO) monitor. To everyone’s surprise, I found elevated CO levels ranging from 20 to 50 ppm throughout the barn, likely contributed to the suboptimal performance over the last few flocks.

The Dangers of Carbon Monoxide: CO is a colourless, odorless gas that poses a serious threat to both poultry and human health. At high levels and prolonged exposure, CO can cause death in humans and animals. Most reported CO cases in poultry have been related to prolonged exposure at low level due to poorly functioning brooders. It is a more common problem in the winter when the heating systems are running for long hours in under-ventilated barns.

CO has strong binding affinity to hemoglobin in blood, therefore replacing the transport of oxygen and prevent transport of oxygen from the lungs to body tissue. For this reason, birds’ growth can be impacted because normal growth and body function require a lot of oxygen, especially during the rapid growth period in the first week of life. Prolonged exposure to low level of CO can also contribute to a higher incident of ascites syndrome at older ages.

Clinical Outcome: Upon identifying the elevated CO levels, the farm manager increased ventilation immediately and sought professionally help to identify the source of CO emissions, which was later identified as a few faulty brooders, to ensure that the barn environment was safe for both poultry and farm personnels. Subsequent flocks showed improved general performance after proper maintenance and repair of the brooders.

Lessons Learned: Proper maintenance of heating systems, including regular inspections and timely repairs, is essential for minimizing the risk of CO exposure. This case also highlights the importance of evaluating environmental factors thoroughly. Particularly when evaluating air quality in the barn, other than the dust levels, air temperatures, drafty spots, do not forget to look for harmful gases such as carbon monoxide, carbon dioxide, and ammonia.

THE BEST BRANDS IN THE INDUSTRY

•

•

•

•

•

•

•

• Energy Efficient Multifan Motors

Smart climate control

Artificial intelligence-driven system ensures optimal barn conditions, boosting performance and cutting costs for poultry producers.

By Melanie Epp

Cutting edge technology from Agrimesh offers producers a new way to maintain poultry house conditions by automatically and proactively adjusting lighting, fans, ventilation and heating, as needed. The Agrimesh system uses artificial intelligence to analyse sensor data and weather forecasts to make real-time decisions that ensure poultry house conditions remain within pre-set parameters. Benefits include improved poultry performance, lower energy costs, and peace of mind.

Agrimesh markets itself as the only smart controller available in North America today. That’s because there are no other controllers on the market that use machine learning artificial intelligence to maintain poultry house conditions, Erik Longtin, acting CEO of Agrimesh said in a recent interview. Other controllers are hardwired and use binary programming. While they can be set to meet specific environmental targets, they

need to be manually adjusted when conditions inside and/or outside of the barn change.

“What we’ve seen – and we do a lot of side-by-side comparisons with other controllers – is there seems to be more variability in the environment in comparison to our system,” said Longtin.

What makes the Agrimesh system more reliable, he added, is that it’s proactive rather than reactive.

Wireless system uses sensors

Using a variety of wireless sensors, Agrimesh analyzes conditions inside and outside the barn. After taking weather forecasts into consideration, it decides when fans, heaters and inlets need to be turned on, in which zone of the barn they should be activated, and for how long. The goal is to create and maintain a stable environment throughout the barn.

“There’s no more relying on gut feeling for the grower,” said Longtin, adding that

adjustments made to compensate for environmental variability may only be efficient for a few hours. “If they don’t have a chance to go back and the environment outside changes, then that has a negative impact on the system operation down the road.”

EmHub is the nerve centre of the Agrimesh system. It contains the processor that controls, supervises and enables devices to interact with one another. It’s a dedicated computer that uses artificial intelligence to make final decisions based the data the sensors have gathered.

“EmHub basically replaces your controller,” explained Longtin. “Instead of having a big control panel, you only have this hub that looks like a router communicating to all of the control boxes and all of the sensors.”

Data is collected through a series of sensors that measure temperature, static pressure and humidity, as well as CO2 and ammonia emissions. Agrimesh also offers a wireless balance that measures birds’

Agrimesh optimizes barn climate with artificial intelligence, saving time and enhancing conditions.

weight, and a wireless sensor that conveys water consumption. The latter sends a message to the end user when problems arise.

EmHub needs to be connected to the internet, but doing so gives users remote access to the system at all times. If the internet falls out, the system continues to work without interruption. Once internet access is restored, emHub automatically updates and transfers collected data to the cloud.

Inside the barn, emHub manages heating, ventilation, air conditioning and lighting systems through a variety of controllers. For example, emPower R3 is a wireless device with three independent relays that power up to three 15-amp circuits to control fans, incubators, electric valves or other devices that require a power up. EmPower D1, on the other hand, controls variable output devices such as driveless fans, motors, and lighting. EmDrive allows emHub to change the speed on fans with a drive.

During the set-up phase, the system is programmed to meet producer-set targets based on the number of birds in the barn, their entry and exit dates, and the producer’s growth chart. It includes their lighting schedule and preferences for temperature and humidity, as well as set points for CO 2 and ammonia. Once set up, emHub takes over.

Thriving under tough conditions

Maintaining conditions in poultry houses is more complicated

Earny

Save heating costs and improve your house climate

The Earny from Big Dutchman is an innovative heat exchanger that offers optimized features so you can save heating costs, improve your house climate, and even reduce emissions. Contact your local distributor or sales representative to learn more.

FIND YOUR NEAREST AUTHORIZED DISTRIBUTOR:

AgPro West Supply

Walbern Agri Systems

Western Ag Systems

E nvirotech Ag Systems

Harkness Equipment

Clark Ag Systems

Dungannon, Ont.-based broiler farmer Harrison Burgsma installed the Agrimesh system in his 30,000-bird barn in December last year.

Technology

than one might think. No two barns are alike, not even on the same property, said Longtin.

“We have operations in Virginia right now that have 10 buildings on one farm, and I kid you not, none of the 10 run the same way,” he said. “Some of them have a dominant wind, and some of them have a strong impact from the sun… The system is really smart enough to learn the best way to ventilate this specific building.”

Where Agrimesh thrives, he added, is during the “shoulder seasons” when weather conditions fluctuate more. Utilising weather

forecasts in its calculations helps to improve efficiency, not just in terms of maintaining conditions in the barn, but in terms of energy consumption too. In-house trials show up to 30 per cent savings in propane use, and up to 20 per cent savings for electricity use.

“I’ve got a few growers that have openly said they used to spend four hours a day making adjustments just on ventilation alone, whereas now, they just don’t have to take care of that,” he said. “It kind of takes away that burden for them and gives them peace of mind.”

“It just makes sure things get done well, and it’s going to be doing that all season with every change.”

First-hand experience

Dungannon, Ont.-based broiler farmer Harrison Burgsma installed the Agrimesh system in his 30,000-bird barn in December last year. He’s on a 10-week cycle, and this is his second flock under the system.

The three-storey barn he moved away from was unpredictably hot between the months of May and August, and he was constantly worried about heat stress in the flock. During the “shoulder seasons,” Burgsma found it especially difficult to maintain poultry house conditions. Sometimes the nights would be cool, and then daytime temperatures would shoot up to 24°C.

“I’d run the heater until the incoming air started getting hot, and then all sudden I’ve got to turn the fans on and pull out the heat that I just put in there,” he said. Adjusting the temperature quickly was especially challenging in a three-floored barn. Burgsma’s new barn has just one floor, and he’s installed an air cooling system.

“You can increase gains and feed conversion even when it’s hot out,” he said. “It also keeps birds from getting heat stressed.”

Burgsma doesn’t yet know how much energy he’ll be saving per year. But he does think he’ll save money on electricity and on fuel for heating. “The Agrimesh system has some real potential to prevent overheating and over cooling,” he said.

What Burgsma likes most about the system, though, is the peace of mind it brings him. He no longer worries that someone has changed settings that could impact production schedules.

“The Agrimesh platform is kind of like having a better manager in place,” Bursgma concluded. “It gives me a level of confidence that the environment is going to be doing well, and during those big temperature fluctuations I don’t need to be there reactively. It just makes sure things get done well, and it’s going to be doing that all season with every change.”

Brought to you by DOES THE FUTURE OF AGRICULTURE SEEM GREY TO YOU?

Agriculture in the Classroom is cultivating curiosity by providing hands- on, immersive learning experiences to educate and engage students. The next generation of farmers, policy-makers, and innovators is in the classroom today. Together, we can inspire young people to drive our industry forward.

Change the future at aitc- canada.ca

TRACKING THE TOLL OF IBV

Canadian research informs vaccine protocols and other control measures.

By Jane Robinson

Infectious bronchitis outbreaks cost the Canadian poultry industry about $207 million every year in lost production. Losses from the highly contagious disease come mostly in laying hens because the infectious bronchitis virus (IBV) can lead to false layer syndrome, reducing egg production by as much as 40 per cent at peak of lay in infected hens. The virus also impacts broilers and breeder flocks.

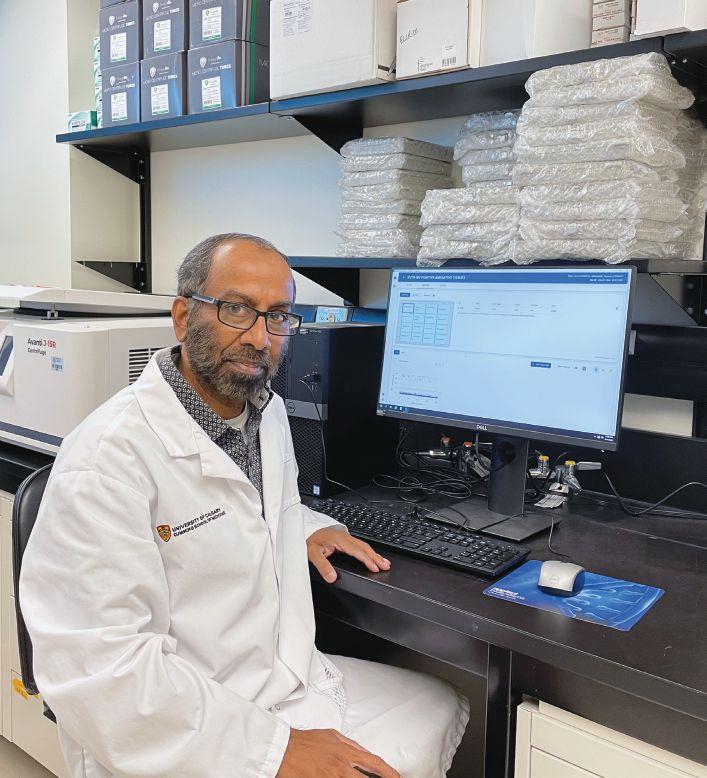

Dr. Faizal Careem has been studying IBV for more than 12 years. His research team at the University of Calgary is the only group in Canada focused on reducing the impact of IBV in Canadian poultry operations via experimental studies currently involving layers.

They were the first to isolate the currently circulating IBV strains and have made important discoveries about the extent of the damage caused by the virus, including vaccine protocols and other measures to help reduce its severity.

“When we started our research on IBV, there was one dominant strain – DMV1639 – among poultry flocks in Ontario and Quebec,” says Careem, professor of virology with the faculty of veterinary medicine at the University of Calgary. “IBV is able to rapidly mutate and create new strains, similar to what we saw with the human coronavirus.”

Lower production and false layer syndrome

Before they could look at the impact of IBV, Careem and his team needed to identify the prominent strains of IBV present in Canadian flocks. They successfully identified four major strains from clinical samples originating from commercial farms in

Canada – DMV1639, 4/91, Massachusetts and CA1737/04 – and were able to successfully isolate three of them in the lab for further studies. “Two of the strains we found had combined with IBV vaccine strains to generate new strains, demonstrating how the virus is able to change” says Careem.

Dr. Faizal Careem (middle), University of Calgary, is looking at probiotics as another IBV strategy to give birds a stronger defence against the highly contagious virus.

BOOSTS PRODUCTIVITY | UP TO 70% ENERGY-SAVINGS | IMPROVES ANIMAL WELFARE

PATENT PENDING

INTRODUCING THE NEW REVOLUTIONARY GRADIENT LIGHTING SOLUTION THAT IS ALL ABOUT RESULTS

Our scientists and engineers took a bird’s eye view to develop a gradient lighting solution that promotes freedom of choice and optimal performance in commercial broiler houses. It can improve feed conversion and animal welfare and decrease energy usage by up to 70%. Optient, our patent-pending lighting solution, truly offers the best of both worlds - best in class performance and proven animal welfare.

WE ARE SIGNIFY, THE WORLD LEADER IN LIGHTING

To measure the impact of IBV on productivity and bird health, they infected the birds in peak egg production under controlled conditions with the various strains. Of the four strains, only one was not associated with egg production issues (4/91). The other three strains of IBV contributed to a 35-40 per cent decrease in egg production. And when day-old pullets were infected with DMV1639, approximately 46 per cent had cysts in oviducts that lead to false layer syndrome where hens ovulate but do not produce eggs.

These findings – when combined with economic analyses – uncovered a high benefit-cost ratio from adopting IB vaccination practices as a preventative strategy.

“Layer chicks get infected with IBV in the first two weeks of life, leading to false layer syndrome” says Careem. “And we won’t know which ones go on to develop false layer syndrome until they are in lay

Dennis Pine dennis@county-line.ca 800-463-7622 x404 www.county-line.ca

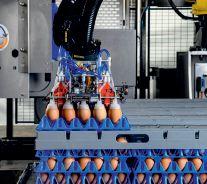

THE PACKERPAL, LA SOLUTION TOUT EN UN :

EMBALLEUSE, DÉPILEUR ALVÉOLES VIDES, EMPILEUR ALVÉOLES PLEINES, PALETTISEUR

THE PACKERPAL, AN ALL-IN-ONE SOLUTION

:

FARMPACKER, EMPTY TRAY DENESTER, FULL TRAY STACKER, PALLETISER

La cadence du Packerpal : 16000 oeufs/h - Rate up to 16.000 eggs/hour

INTÉRÊT

TECHNIQUE

1 bras robotisé avec 4 actions (prise des œufs, de l’alvéole vide, de l’intercalaire et palettisation des alvéoles) qui assure la fonction emballeuse de ferme, dépileur d’alvéoles vides, empileur d’alvéoles pleines et palettiseur.

TECHNICAL

INTEREST

1 single robotic arm performing 4 actions (picking up the eggs, the empty egg tray, the plastic divider and palletising the trays) in the place of a farmpacker, an empty tray denester, a stacker for full trays and a palletiser.

Our exclusive dealer in Canada

1 (780) 468-1350

info@kaiserag.com

Heath

and producers might be seeing production levels at 60 or 70 per cent of normal.”

These findings have driven an updated vaccine protocol for layers at hatcheries to use a live attenuated IB vaccine – administered by a spray. It was an easy win and is now common practice at Ontario and Quebec hatcheries. “This hatchery protocol is helping protect layer type birds for the first weeks of life and it’s easy to administer,” says Careem.

Ideally, producers would follow up with an inactivated IB vaccine before the start of lay, but the practicality is a challenge since handling individual birds is required to administer the vaccine intramuscularly. “I think producers are reluctant to administer pre-lay vaccines for continued protection against IBV, which is understandable, and why we are continuing to look at other options that could extend immunity for the entire duration of the production cycle,” says Careem.

The next step in IBV research

With a much clearer understanding of the IBV variants – and proof positive that the virus causes egg production to drop significantly – Careem and his team are moving into the next phase of their IBV research. They are focusing on three key areas – exploring the value of probiotics to strength bird immunity against IBV, tweaking IB vaccination protocols and looking for novel control measures.

“IBV affects broilers as well as layers and breeder flocks, and we’re starting our probiotic trials with broilers,” explains Careem. “When broilers are infected with IBV, it can damage lining in the respiratory tract and make the birds more susceptible to secondary bacterial infections.”

They are looking at probiotics as an option to give the birds a stronger defence against disease. “We are working with broiler producers in Alberta to see if we can manipulate the microbiome with probiotics to induce immunity against IBV infection,” says Careem. The study is initially limited to broilers, but if the results are interesting, they hope to extend the work to layer pullets.

On the protocol front, Careem and his team will continue to look at ways to optimize the recommended IB vaccinations with vaccines currently available to producers in Canada. They’ll be looking at ways to better protect birds from new IBV variants that are likely to come along, ideally by inducing cross protection and looking at enhancing a bird’s immune response when vaccines are administered long before the start of lay.

“We’re also looking at the value of IB vaccination in breeder flocks that will help pass on maternal antibodies in the next generation of commercial layer flocks,” he says.

Keeping viruses out of the barn in the first place, through tight biosecurity control measures, is another key area of their research. They haven’t started that project yet, but will look at how to adjust biosecurity to minimize the introduction of IBV into barns. “I cannot emphasis enough the value of tight biosecurity measures to prevent these new IBV strains from entering commercial flocks,” says Careem.

MAXIMIZE BIRD HEALTH AND PRODUCTIVITY

From the first day your chicks and poults are placed, water is one of the first things they look for, and for decades farmers and poultry have relied on our drinkers for a consistent flow of fresh water.

Our drinkers provide poultry the single most important ingredient for the BEST POSSIBLE START, AND A HEALTHY LIFE DURING LAY PERIOD AND GROW-OUT.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

CRAFTING COMFORT

Tailoring ventilation and airflow for broiler bliss.

By Andrew Bourne

In all regions, no matter if it’s extremely cold and or hot and humid, house design is critical to ensure optimal air flow for bird cooling and comfort.

When designing a modern broiler house, the first factor to consider is the optimum floor area for the best return on investment.

New longer and wider houses challenge the ventilation system’s ability to produce uniform conditions across the house. Secondly, providing the correct air exchange and speed to keep the birds comfortable is important, but also consider the impact of rising energy on costs.

Ventilation supports a good start

The primary goal of the broiler farmer is to stimulate feed consumption from chicks arrival on the farm to processing. The first seven days are the most important. The brooding period sets the precedent for good

performance and extra effort will be rewarded in final flock performance.

To ensure a good start, the grower must provide an environment that ensures optimum intake of feed and water. The perimeter ventilation system in conjunction with a circulation fan system, can be argued as the most important system in the modern broiler house. It ensures efficient air exchange and temperature management without creating excessive air movement at chick level.

Until broilers have full feather development, they are very sensitive to air speed, which will directly impact activity and feed consumption. Choice and installation of a high-quality inlet is often overlooked by growers in hotter regions. Price rather than the impact on early performance is often the driver of equipment choice that ultimately only represents about three per cent of total capital cost. Consider that for every

one gram of bodyweight improvement in the first week, will translate to an additional five grams or more at processing.

The other most challenging period is the grow-out phase (after 25 days). When the birds are fully feathered and stocking density is increasing rapidly, temperatures at bird level will increase running the risk of high body temperatures. The more heat that is removed from the birds, will lower the birds’ body temperature and make them more likely to consume feed.

Designing and building a ventilation system for good performance

Capital investment is often driven by the need for high returns on investment or fast paybacks. Access to good quality equipment, government import tariffs and freight costs can limit choice. Investment decisions may be made without optimizing design and air flow requirements needed to ensure

optimum bird performance and financial return. In today’s low margin environments returns depend on achieving performance in line with genetic targets. These are some essential design considerations:

• Good quality perimeter inlets for the minimum and transition ventilation stages for tunnel type housing, or in the case of cross ventilated houses, for both minimum and temperature control stages.

• The installation of the correct number of perimeter inlets.

• Adequate static pressure control, by thorough sealing of houses. All new projects should be commissioned only after a house pressure test.

• Fan choice should be based on efficiency – not cost! Fan choice will be the most important equipment decision, especially in hot climates.

• The roof and/or drop ceiling insulation is one of the most important aspects of any new house project.

The biggest challenge for tunnel ventilated houses longer than 120 m is maintaining an acceptable temperature pickup from the front to the back of the house, or commonly referred to as the ΔT, during the summer months with big birds. The level of bird comfort ultimately drives daily feed consumption. Even temperature distribution the length of the house will ensure uniform feed intake and processing weight uniformity.

To manage heat, consider the structure materials

The amount of heat the air collects moving down the length of the house will depend primarily on three factors:

• Metabolic heat added by the broilers;

• How quickly the air in the house is exchanged; and

• Thermal properties of the house.

Heat flows through surfaces from hot to cold, entering the house through the ceiling, side walls and curtains. The

Barn Management

higher the resistance to flow or higher the R value of the surface, the lower the emissivity.

As well as entering the house through all surfaces, heat is also produced by the birds which are by far the greatest contributors to heat load. The value of an insulated roof or drop ceiling cannot be underestimated, as it is vital to bird comfort and operational costs.

For example, improving ceiling R value from an R2 (simple plastic drop ceiling with no insulation) to a R10 should improve the ΔT by 1 or 2°C. Improving the ΔT will reduce the tunnel fan or air exchange capacity needed to achieve the goal of having an absolute maximum of 2.8°C temperature pickup on the hottest day of the season with the biggest birds. A broiler house should have a minimum insulation in the roof of R 10 in tropical regions, but in a region with cold winters this value needs to be in excess of R20.

Ventilation keys to keep the house cool

Heat is removed from the house by rapidly exchanging the air in conjunction with evaporative cooling in the form of evaporative pads or fogging systems. If the tem-

OPTIMIZING BIRD COMFORT AND PERFORMANCE

Here are some key things to consider when tailoring ventilation and airflow for broiler comfort.

Critical House Design: Regardless of climate extremes, house design plays a pivotal role in ensuring optimal air flow for bird cooling and comfort.

Floor Area Optimization: Modern broiler house design begins with maximizing floor area for optimal return on investment.

Ventilation Challenges: Longer, wider houses pose ventilation challenges, necessitating careful consideration of air exchange and speed to maintain uniform conditions.

Brooding Importance: The initial seven days set the precedent for broiler performance, emphasizing the importance of providing an environment conducive to feed consumption.

Perimeter Ventilation: Perimeter ventilation systems, alongside circulation fans, are crucial for efficient air exchange and temperature management, particularly in sensitive early stages.

Inlet Quality High-quality inlets are essential, especially in hotter regions, impacting early performance and overall flock success.

Investment Considerations: Investment decisions should prioritize design and airflow requirements to ensure optimal bird performance and financial returns in low-margin environments.

Amplify by Annex is a full-service custom content studio, helping companies share their story, build brand awareness and garner trust through original content.

There are so many ways to reach a target audience. We’ll craft you content for any medium:

• Thought leadership – long-form or short-form articles

• Blogs, whitepapers, infographics and case studies

• Webinars, podcasts and video

• Tradeshow marketing content, with in-house commercial printing services

• Automated content marketing supported by first-party data ....and so much more!

T:

Connect with an account manager or scan to learn more

“Correct

perature difference between the birds and the surrounding air is minimal, heat removal from the birds will be low. By increasing the temperature differential with evaporative cooling, bird heat removal will be increased. The evaporative cooling system will provide at best a maximum of 20 per cent of the cooling capacity for the broiler.

In a tunnel ventilated house air speed or

wind chill effect is by far the greatest contributor to cooling, in the form of sensible heat removal. In a house with only cross ventilation, maximizing the air exchange rate and having an perimeter inlet that can force air movement towards the birds is important.

Achieving significant airspeed requires very high operating static pressure and a

multi-directional design of perimeter inlet.

Removing metabolic heat from birds depends on a fast air exchange rate and creating good airspeed at bird level. In a well-designed tunnel ventilated house an air exchange rate of approximately 40 to 45 s is common.

In the colder regions with only cross ventilation, the air exchange rate should be close to tunnel ventilated houses for those few days in summer where temperatures rise above 28°C.

Unfortunately, a good air exchange capability alone in hot weather will not guarantee bird comfort. Air speed is the most important component, so many new houses built in colder climates are being designed with some tunnel ventilation capacity.

The major challenge is the design of the tunnel inlet. Very wide houses, (> 25 m), pose a significant challenge to achieving air speed uniformity during tunnel ventilation.

If tunnel speed is < 1.5 m/s, the tunnel inlet can be installed in the front wall of the house. Tunnel speeds higher than 1.5 m/s require u-shaped tunnel inlet which can negatively impact airspeed uniformity across the width of the house.

In very wide houses, the airspeeds along the house sides tends to be significantly lower than down the center. Higher air speeds through the side wall tunnel inlet forces most of the tunnel capacity to move down the center ultimately creating higher speeds in the center.

Summary

Correct house design will support optimal air flow for bird cooling and comfort, during both hot and cold weather when stocking density is at its highest. Birds that are comfortable will consume more feed than hot birds. Likewise, energy efficiency is improved in a house that is designed correctly. Well-ventilated houses support good flock performance, health and welfare outcomes and, in turn, provide the biggest return on investment.

Bourne is global genetic excellence – environmental specialist with Cobb-Vantress.

Andrew

Providing an environment conducive to feed consumption is crucial for brooding success.

Clearing the air

How one egg farm soared with heat exchangers, fostering healthier birds and higher profits.

By Ronda Payne

Building new barns comes with several major decisions. Not the least of which is heating, cooling and ventilation.

Government financial support, coupled with cost-offsetting benefits, has proven Pondeuses JL Inc. was right to include heat exchangers for its six barns built in 2021 under the Lebco umbrella of agriculture companies. It was a $12 million investment to build the barns.

While initial costs for the heat exchangers were higher than conventional HVAC systems and cost recovery had not yet been demonstrated in Canada, the resulting increase in production has made it all but a moot point in this case. The farm is an example of how well birds perform when they live in clean air.

Jocelyn Leblanc, owner of Lebco in Saint Hyacinthe, Que., says the project is a suc-

cess. He saw his first heat exchanger in use in a laying barn in Holland.

“We visited the farm in Holland maybe six years ago,” he says. “We decided to go with this project. We arrived at the conclusion it is better because we save energy. I think it is the best way to design a [laying hen and brooding] farm.”

Leblanc’s recently built farm has four barns for layers and two for brooding pullets. All six measure 42’ by 200’ and are arranged in sets of two, end to end. The laying barns are connected at their inside ends with a management and infrastructure building to form an H shape. The pullet barns are not connected.

The objective and specifics

The goal at the outset of the project was to improve air quality – primarily the reduction of ammonia and carbon dioxide – with

ventilation and to reduce harmful emissions without increasing energy costs. Suzelle Barrington, an engineer with Consumaj Inc.’s environmental division, took on the project.

“The cost, including installation, was $1.1 million for six exchangers,” Barrington says of the ECO Zero heat exchangers made by Vencomatic.

The project was financially supported in part by Technoclimat through its 20132020 Action Plan aimed at climatic change and by The Fonds Écoleader program, supporting ecoresponsible practices and clean technologies.

Heat exchangers work by transferring the warmth from the barn air being pushed out to the fresh air being pumped in. Using conduction, the heat is passed from one mass of air to the other without the two masses merging.

Heat exchangers work by transferring the warmth from the barn air being pushed out, to the fresh air being pumped in.

A YOUNG POULTRY INDUSTRY LEADER?

POULTRY’S TOP 4 UNDER 40 PROGRAM IS BACK!

The 2024 Top 4 under 40 program will recognize three outstanding poultry producers and one industry professional.

If you know someone worthy of shining a spotlight on, please nominate them before May 31.

Technology

In the ECO Zero units, some of the inside air can be recirculated and blended with the incoming outside air. If the outside air isn’t warm enough, heaters automatically kick in to warm it before entering the barn.

Each of Leblanc’s barns has its own heat exchanger. The laying hen barn units have a capacity of 8.3 cubic meters per second and have a long, flexible plastic tube down the centre of the ceiling. This design ensures fresh, heated air is distributed the full length of the barn and eliminates hot or stagnant spots. There is no space wasted and air pressure keeps the tube inflated.

The brooding barn units have a capacity of 5.6 cubic meters per second and are a centrally located, curtain-controlled system with two fans blowing the air towards both end walls.

Clearly, with that kind of capacity, these units are unlike the conventional low-flow heat exchangers and ventilation, which

struggle to control ammonia and CO2 levels. Barrington describes these systems as oversized for the winter to provide enough ventilation for summer. This size also allowed testing for how low ammonia levels could be in the winter. They are incredibly powerful, yet don’t have the cacophony of conventional heating units with numerous fans throughout the building.

“There is only one inlet,” she says. “Whereas with the conventional system

you’d have fans. You’d have many fans.”

Additionally, many of those conventional system fans can’t be insulated over their own area. The heat exchanger, however, has no cold spots in the barn, ensuring consistent temperatures throughout and less heat loss.

“The barn is more efficient and airtight,” Barrington says. “You have one unit and it does it all.”

Heat recovery is at least 80 per cent,

The Leblanc family had six heat exchangers installed, which they say has helped boost egg production.

YOUR TURKEY FARMERS OF CANADA BOARD

Executive Committee 2024/2025

Darren Ference

Chair

Calvin McBain

Vice-Chair

Jelmer Wiersma Executive Member

Board of Directors

Darren Ference - Alberta

Calvin McBain – Québec

Matt Steele - Ontario

Debbie Etsell – British Columbia

Jelmer Wiersma – Saskatchewan

Mike Reimer – Manitoba

Hugo Therrien – New Brunswick

Michael de Graaf – Nova Scotia

Doug Hart – CPEP

Michel Pépin – CPEP

Adam Power – FPPAC

Scott Olson - Alberta Alternate

Turkey Farmers of Canada’s 50th Anniversary

The year 2024 marks the 50th anniversary of TFC, established on February 14, 1974, under the provisions of the Farm Products Agencies Act through Parliamentary Proclamation.

We thank all turkey farmers, provincial boards, partners across the supply chain, elected officials, and many others that have brought us to this significant milestone.

Technology

compared to smaller, conventional heat exchangers, which would be about 50 per cent. Much of the reason for this is the length of the exchange unit itself, which is about 45 feet long.

“We figure the system pays for itself in about five years,” she says. “Even up to zero degrees Celsius, you have over 80 per cent efficiency. You could use a conventional system with high ventilation rates equal to this system, but the propane bill would be enormous.”

Too much of a good thing

The ECO Zero units can keep the ventilation rate high, even in the winter, when low-flow heat exchangers cannot. In fact, the ventilation rate can be set so high that it dries the barn’s air out too much, especially given the dryness of winter air.

This was the case when Barrington and Leblanc tried to get the ammonia rate down to 10 ppm.

“At 10 parts per million, the barn was too dry,” she explains. “The air flow required to reach 10 ppm of ammonia was too high despite the fact that heating costs would not necessarily be higher.”

Instead, they settled on the Canadian preferred standard of 25 ppm as a benchmark, which it handles easily.

“The higher flow rate with the lower energy costs with this system allows Monsieur Leblanc to keep the ppm rates below 25 ppm,” she says.

All of this is done through sensors and automation. Leblanc gets alerts and notifi

“The animals, the more you look after them, the better they will do for you.”

cations as needed. He says the control of the barns is very easy because there is only one heat exchanger unit per barn.

“The system’s data can be transferred to a mobile phone or similar device,” says Barrington. “[Information is] based on temperature, relative humidity, CO2 readings and more. This way, it is one big ventilation system which is the heat exchanger with the heat unit and those controls.”

Benefit to the birds

Happy birds are productive birds. “The animals, the more you look after them, the better they will do for you,” she says.

And ultimately, that was the result Leblanc was after. In the new barns, there is no stress from an HVAC system. It’s quiet, with a consistent temperature throughout and no moisture. “There’s absolutely no dust,” says Barrington. “And the laying hens are noisier than the system.”

The end result is more eggs. And as Leblanc notes, the quality of the eggs is very good. “We need to push more feed because we continue to get more eggs,” he says. “The feed rep comes to the farm and says, ‘reduce the feed,’ I say, ‘we can’t, we have good eggs,’ we have more eggs.”

With less ammonia in the air, birds stay

healthier. “With conventional ventilation systems, ammonia levels can remain above 40 ppm in the wintertime, which is very high,” says Barrington. “These high levels and even higher close to the floor where the manure lies, tends to burn the eyes of the birds is what I’m told. They can’t find the feed. This has a major impact on the birds.”

It also has a positive impact on employees who are no longer exposed to those high levels of ammonia and CO 2 .

The last word

But putting it all on paper, are the ECO Zero units worth it? Leblanc says so and so do the numbers. Barrington followed the project for two years to ensure results stayed positive.

The investment for the heat exchange system, broken down by bird, is much higher at $5.80 compared to $0.60 for a conventional system; the electricity cost is also slightly higher at $17.99 per bird compared to $14.01 in a conventional system.

However, medication costs have dropped to zero and fuel for heating dropped from $0.98 a bird to $0.66 a bird.

This represents a $24.45 cost per bird as opposed to a $15.83 cost per bird – an increase of $8.62 per bird. If that were the only outcome, it would be a short story. But as previously noted, healthier birds are happier birds and happier birds are more productive.

Leblanc and Barrington witnessed an increased revenue to $57.20 a bird compared to $37.64 per bird in a conventional system. At an increase in revenue of $19.56 a bird, Leblanc is netting $10.94 more per bird due to the heat exchange system.

Moving to a heat exchanger like ECO Zero as opposed to conventional HVAC systems or conventional heat exchangers is a large financial outlay at the start, but the benefits are there for the long term.

Eastern Canada: sales@county-line.ca 519-291-5012 www.omnivorecomposter.com

info@agprowest.ca 604-746-5376 www.agprowest.ca

Central Canada: info@caldorapoultryequip.ca 431-205-3365 www.caldorapoultryequipment.ca

Occasionally, Canadian Poultry magazine will mail information on behalf of industry-related groups. If you prefer not to receive this information, please indicate so by checking here ( ). We do not share our mailing list (print or digital). Publisher reserves the right to determine qualification.

What’s new in climate control equipment

Stienen Air Quantity Controller Fan

The Stienen Air Quantity Controller (AQC) is an air control unit designed to accurately measure and control room ventilation. Paired with Stienen’s automation controls, the AQC monitors airflow to create an optimal barn environment. By measuring airflow, the AQC helps prevent under-ventilating and over-ventilating your barn. When installed together with a chimney extraction fan, it constantly measures airflow through the chimney. This allows producers to regulate airflow. By regulating airflow, producers can save on heating costs by avoiding over-ventilating their barns during winter months as well as preventing under-ventilation in the summer. The AQC has up to four contra rotating slats that are operated with a 24VDC motor, allowing for accurate air control during minimum ventilation. Designed to be plug-and-play, it is easily retrofitted into existing systems.

EnduraMax Direct-Drive 57-inch Fan

Chore-Time’s EnduraMax Direct-Drive 57-inch fans are designed for low maintenance and efficiency. The direct-drive motor eliminates belts and bearings, reducing maintenance needs. Crafted with corrosion-resistant materials, they withstand extreme temperatures for reliability. Variable-speed capabilities optimize energy consumption, paired with a CHORE-TRONICS 3 Controller for efficiency. HYFLO Shutters maintain airflow efficiency throughout the flock cycle, maximizing performance. Featuring a black HDPE cone and durable composite

shroud, these fans ensure longevity. Easy to install and compatible with various fan sizes, they offer flexibility for retrofitting existing systems.

Munters Light Trap Extension Box

The Munters Light Trap Extension Box is tailored for Vortex 36, 51, and 55 models, optimizing airflow and managing light for poultry operations. With asymmetrical fourfoot and three-foot doors, maintenance is easy with tool-free access. Premium filters ensure superior light control, while its fiberglass construction guarantees excellent light reduction. The sloped design diverts water away, and flush mounting maximizes space efficiency. The two-door design simplifies maintenance, promising hassle-free operation.

Genius iTouch Series

The Genius iTouch Series revolutionizes the management of various environmental factors essential to agricultural operations. From ventilation, heating, and humidity control to monitoring static pressure, CO2 levels, animal populations, feed consumption, and lighting, this multifaceted system offers comprehensive oversight. With the FarmQuest Online Farm Management Tool, users gain seamless 24/7 access to real-time data, enabling them to monitor and adjust farm controls from anywhere with internet connectivity. This integration of cutting-edge technology not only streamlines farm management but also empowers farmers with unprecedented efficiency and precision in optimizing their operations.

FarmGuard Electrical Failure Monitoring System

The FarmGuard Electrical Failure Monitoring System redefines farm safety and efficiency. Beyond traditional fire prevention measures, it offers real-time detection of electrical anomalies like leakage current, serving as an early warning system for potential equipment malfunctions. This enables timely repairs before breakdowns occur, preventing costly downtime and ensuring uninterrupted operations. Seamlessly integrated with the Genius iTouch system, producers can effortlessly monitor their operation through the FarmQuest Online Farm Management platform. The system sets a new standard for safety and productivity.

BlueControl

The SKOV climate and production controllers feature user-friendly interfaces with large touchscreens and graphic icons. BlueControl’s latest release prioritizes productivity and animal welfare with its revamped user interface. Designed for ease of use, it eliminates the need for IT expertise to manage production. Tailored to individual needs, BlueControl provides timely and relevant information, sparing users from irrelevant data. With a comprehensive toolbox, users can access necessary tools seamlessly. By transforming data into actionable insights, the controller simplifies decision-making and provides clarity. Dynamic setpoints eliminate manual calculations, allowing users to focus solely on the animals’ well-being.

Barn Spotlight

Grandview Colony

Location

Grande Prairie, Alta.

Sector

Layers and pullets

The business

Grandview Colony, a Hutterite community based in Alberta, has been deeply rooted in egg production for generations. Jonty Hofer, who oversees the operation with help from his son Corey, notes, “Egg production has been a cornerstone for us across four generations.”

The need

Operating on 14,000 acres, they recognized the need for change to sustain profitability. Leasing out part of their egg quota for years, Hofer felt it would be more profitable if they used the quota themselves. Hofer explains, “We realized we weren’t maximizing our potential. It was time for a change.” Market demand, notably from Burnbrae Farms, pushed them towards investing in a free-run barn.

The barns

Their new barn boasts an advanced aviary system from Kaiser Ag, chosen for its bird-friendly design. “The transition to a cage-free system was essential for us,” Hofer insists. “The aviary system appealed to our commitment to bird welfare.” Cutting-edge ventilation, controlled by a Stienen controller, ensures optimal conditions year-round. And a Völker egg packing system streamlines collection, reflecting Grandview Colony’s commitment to efficiency. Hofer adds, “We’ve always valued our heritage, but we’re not afraid to embrace change.”

Jonty and Corey Hofer in their new aviary barn. A new Volker egg packer and stacker adds efficiency.

For summer ventilation, they switch over to cooling pads.

The barn includes tunnel ventilation with variable speed fans.

PHOTO: GRANDVIEW COLONY

STRENGTHENING BIOSECURITY AT BARN ENTRANCES

With Avian Influenza posing an increased risk to the poultry sector, improving barn entrance design has emerged as a crucial biosecurity measure. Epidemiology reports from the CFIA highlight its effectiveness in preventing disease transmission on farms.

By adopting enhanced biosecurity measures, the poultry sector can significantly reduce the risk of Avian Influenza outbreaks and safeguard flock health.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic IBD and AL-2.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative or visit PoulvacProcerta.com.