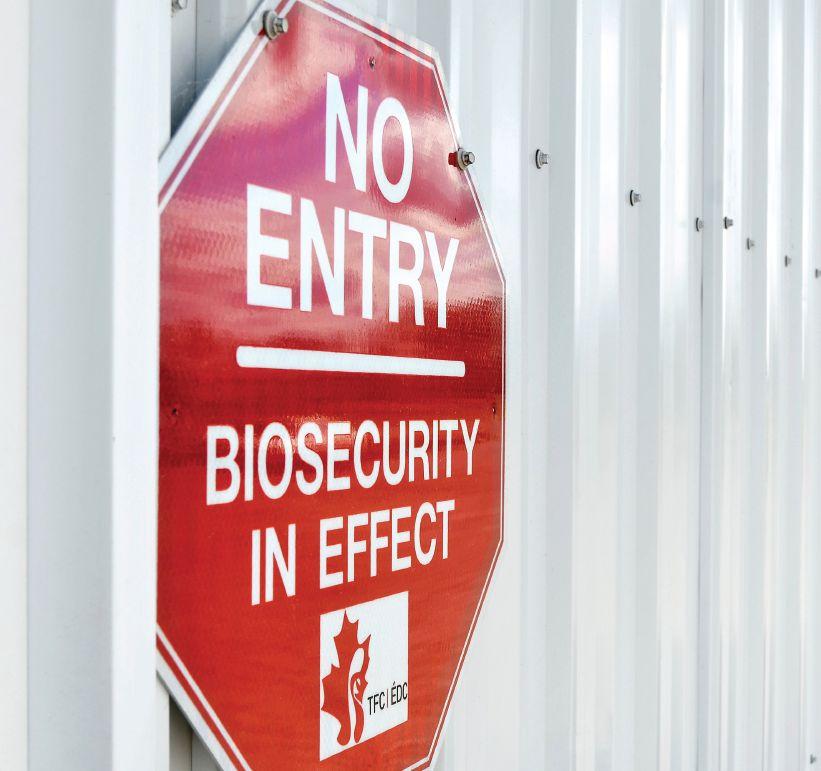

Wearing the proper protection every time is critical for you, your employees and your family.

by Brett Ruffell

Wearing the proper protection every time is critical for you, your employees and your family.

by Brett Ruffell

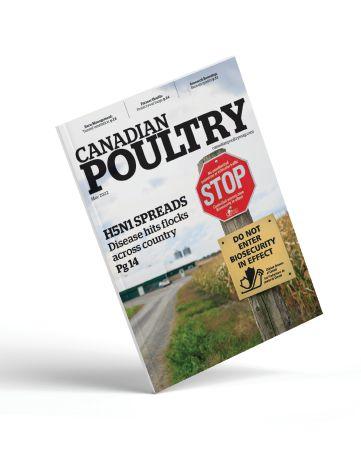

In my last column, I left off on a positive note about Canada’s avian influenza situation. At the time, the H5N1 strain that has been spreading around North America had only been detected in one commercial barn here – a turkey barn in Nova Scotia where 12,000 birds died or were culled due to the disease. Stateside, things were much worse, with the disease being detected in dozens of flocks. Canada, in contrast, went several weeks without another commercial poultry barn been struck with the disease.

The situation caused some experts to be cautiously optimistic that the worst might already be behind us.

Then, in late March the state of affairs suddenly changed. In the span of a week, the disease was detected in a handful of commercial poultry premises in Ontario. It has since been discovered in every province and hit several commercial barns from coast to coast, leading to tens of thousands of birds dying from the disease or being culled. Indeed, the worst was still ahead of us.

The exact ways the disease has been spreading to commercial operations is still under investigation. However, Dr. Tom Baker, manager and incident commander with the Feather Board Command Centre, says outbreaks almost always follow a certain

sequence of events. “It’s remarkably consistent,” he told me during one of our two Feather Forum podcast interviews on the situation.

Firstly, it gets detected in a dead wild bird that’s found and sent for testing. About two weeks later it shows up in a small backyard flock. A few weeks after that it’s found in a larger commercial facility.

“If someone’s using contaminated clothing or boots, the disease is going to spread like wildfire.”

Baker said there are numerous ways the disease enters a barn. In some cases, a producer hasn’t properly maintained their barn and a wild bird is able to fly in, bringing the disease with it. “That has happened in past outbreaks,” he noted.

Other times, it could be entering the barn door through contaminated feed. Perhaps it wasn’t stored properly or there was a spill that led to it being contaminated.

If farmers are using surface water for their birds and the water isn’t properly treated, there’s a chance the virus could enter the barn that way.

But Baker said some experts insist the disease usually ‘walks in’. For instance, a farm worker is wearing footwear that is contaminated

with bird droppings – maybe they didn’t cover up or change their boots before entering the barn. “If someone’s using contaminated clothing or boots, the disease is going to spread like wildfire,” he said.

Other things that risk spreading the disease are sharing equipment or leaving equipment outside where it could get contaminated.

“So, there are multiple ways,” Bakers said of how avian influenza could enter a barn. “But they’re all preventable with care.”

One piece of advice he has is to avoid anything that would attract wild birds onto the farm. For example, leaving feed out.

“It is important to keep it clean around the poultry areas,” Baker advised. “You don’t want piles of debris or anything that could attract contaminated droppings and so on from wild birds.”

Another piece of advice from back during the 2015 outbreak: if you’re using a piece of equipment out in the fields don’t park it near the poultry barn.

In the end, Baker said every barn has certain vulnerabilities that make it suspectable to disease spread. “Part of your biosecurity plan is to make sure you’re covered off on those and are mitigating those risks.”

The industry is facing a fastchanging situation this spring with avian influenza. Be sure to monitor canadianpoultrymag. com for daily updates, helpful advice and podcast interviews with disease experts.

canadianpoultrymag.com

Reader Service

Print and digital subscription inquiries or changes, please contact Anita Madden, Audience Development Manager Tel: (416) 510-5183

Email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Brett Ruffell bruffell@annexbusinessmedia.com 226-971-2133

National Account Manager Ross Anderson randerson@annexbusinessmedia.com Cell: (289) 925-7565

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

Media Designer Graham Jeffrey

Group Publisher Michelle Allison mallison@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 1703-2911

Subscription Rates Canada – 1 Year $32.50 (plus applicable taxes)

USA – 1 Year $91.50 CDN Foreign – 1 Year $103.50 CDN GST - #867172652RT0001

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Even though we currently design and deliver the best drinkers and egg conveying systems in the world, we are always on a relentless pursuit to make the best better. Before it arrives at your farm we take every product into our own hands with careful assembly and inspection.

FROM OUR HANDS TO YOUR FARM. YOU CAN DEPEND ON LUBING.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664-3811

Fax: (519) 664-3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263-6222

Fax: (450) 263-9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963-4795

Fax: (780) 963-5034

This week, the federal government announced it has launched the Supply Management Processing Investment Fund, worth $292.5 million, to help processors of supply-managed commodities increase their competitiveness and resilience in the face of evolving markets. The Supply Management Processing Investment Fund is part of the federal government’s commitment to support processors in these sectors to address the impacts of international trade agreements.

Chicken Farmers of Canada (CFC) recently unveiled its 2022 Executive Committee, which was elected by the CFC board of directors at its annual general meeting this week. The appointments include: Tim Klompmaker, Ontario, chair; Nick de Graaf, Nova Scotia, 1st vice-chair; Ray Nickel, B.C., 2nd Vice-Chair; and Luce Bélanger, Quebec, executive member.

The Canadian Food Inspection Agency and the United States Department of Agriculture’s Animal and Plant Health Inspection Service have officially agreed to implement an Emergency Transit Policy for Regulated Animals. The policy makes it easier and faster to evacuate regulated animals across the border during emergencies such as flooding or when routine transportation routes are impaired without feasible alternatives.

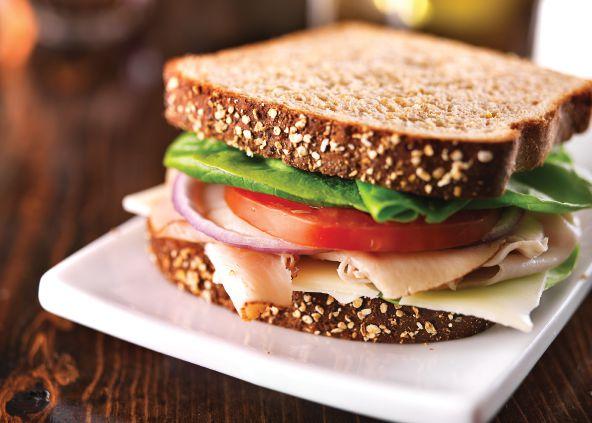

The funding is intended to help increase domestic demand and consumption of Canadian turkey and chicken products.

Recently, the federal government announced $3.5 million in funding under the Market Development Program for the Turkey Farmers of Canada (TFC) and Chicken Farmers of Canada (CFC).

3.5M iis the amount of funding TFC and CFC will receive from the federal government under the Market Development Program.

Funding through this program is intended to help increase domestic demand and consumption of Canadian turkey and chicken products.

It will do so by supporting industry-led promotional activities that differentiate Canadian products and producers, and leverage Canada’s reputation for high quality poultry products.

TFC will receive up to $2.5 million to expand Canadian consumer awareness of the benefits of turkey meat as a primary and alternative protein.

CFC will receive up to $1 million to promote Canadian chicken to the public and highlight how committed farmers who raise them are to providing safe, high quality chicken.

“We are pleased with this announcement of the Market Development Program for Turkey and Chicken,” says TFC chair Darren Ference.

“The program will go a long way to support the turkey sector’s work in reaching consumers, and in promoting the wholesome and high-quality turkey raised by Canadian farmers.”

“This program will enhance consumer engagement and continue to showcase Canadian-made products to Canadians,” adds CFC chair Tim Klompmaker.

By Lilian Schaer

Livestock Research Innovation Corporation (LRIC) fosters research collaboration and drives innovation in the livestock and poultry industry. Visit www.livestockresearch.ca or follow @LivestockInnov on Twitter.

There is no lack of big issues facing the livestock sector – ones that go beyond a single livestock species and can’t be tackled by any individual commodity association on its own. Climate change, antimicrobial resistance, the “animal-free” movement, and regenerative agriculture are just a few topics that fall into that category – and the solutions the industry needs could well be found outside of the sector.

That’s according to Brian Lindsay, Director for the Dairy Sustainability Framework and UK-based owner of a global consultancy focused on sustainable food systems.

“In agriculture, we are very good at talking to ourselves, but we need to widen the blinkers, take in what others are doing and listen to the experiences of other organizations and what they are doing,” he explains, adding that agriculture for example could learn from other sectors who are actively working to reduce plastic waste. “Could we work together on a common outcome? In the UK, we are recycling silage wrap into signs and benches – so what could we achieve by exploring and listening to others?”

Ultimately, a large part of dealing with disruptive forces is trying to change behaviours and encouraging the farm community to try new things. That means finding ways to help farmers have the confidence to try new things and reducing the risk associated

Experts advise the poultry industry to ‘look sideways’ to other industries for solutions to big issues.

with change.

“ We’ve largely lost extension services and they are critical if we are going to make the difference we need to make,” Lindsay says. “Farmers are tangible people – they like to know somebody else has done it and survived. Changing to something new that they don’t know will work is scary.”

Former Ontario Deputy Minister of Agriculture, Food and Rural Affairs Dr. Deb Stark also encourages the livestock industry to look sideways to other sectors of the economy for solutions to the disruptors that lie ahead. She recently spoke on the topic at a Horizon Series webinar hosted by Livestock Research Innovation Corporation (LRIC).

“ We can look at disruptors in two ways: those that are nature-based events, and those that are based in innovation or social change,” says Stark, currently a board member with the Canadian Agri-

“The world is so intertwined, so we need to look within the industry and to others for solutions.”

Food Policy Institute. “The world is so intertwined, so we need to look within the industry and to others for solutions.”

D isruptors that stem from technology or societal change, like cellular agriculture, advances in automation, or consumer pressure for more welfare-friendly production practices are complex, Stark notes, but those who don’t act risk finding themselves on the wrong side of the disruption.

“ Technology and the attitudes towards it are changing and some of the most interesting things are happening beside us,” she says. “In livestock, for example, we are moving towards gathering data on each individual animal instead of the herd or flock and developing precision management, which is coming from human

medicine beside us.”

Stark believes Ontario agriculture has a unique opportunity at its doorstep: the southern Ontario technology corridor, which includes the Waterloo Technology Triangle, Toronto Region Human Health & Sciences, and Canada’s Advanced Manufacturing Supercluster.

“ More could be done to build those relationships. We often look to what the Guelph (agriculture) grads are doing, but what are the (University of) Waterloo grads doing, for example?” she said, adding that although foresighting to anticipate future scenarios takes time and resources, the industry should be more putting more emphasis on this.

LRIC has been leading the charge on behalf of the livestock industry to identify these emerging issues and disruptors, bring balanced perspectives to the discussion, and start to work collaboratively on the search for solutions rooted in research and innovation.

“These are all issues that are bigger than a single livestock commodity can handle on its own – both from the scope of the issues, as well as the fact that most organizations are busy worrying about the more immediate, but equally important ongoing issues that face their individual sectors,” says LRIC CEO Mike McMorris.

This article is provided by Livestock Research Innovation Corporation as part of LRIC’s ongoing efforts to drive innovation in livestock production.

YOU HAVE AN INSTINCT TO PROTECT. WE HAVE AN INSTINCT TO PROTECT FAST.

Introducing Poulvac® Procerta™ HVT-IBD. Timing is everything in a poultry operation, and Zoetis created its newest vector vaccine to put time back on your side. Backed by the latest science resulting in excellent overall protection, studies found that Poulvac Procerta HVT-IBD protected chickens fast against classic and important variant IBD strains.1-3 It’s a quick way to full protection from infectious bursal disease. Contact your Zoetis representative.

By Mary K. Foy

The dreaded headlines are back. We have all been put on high alert for avian influenza – again. Many of us remember the 2015 outbreak where we were all reminded and/or taught what to do, and not do when highly pathogenic avian influenza virus (HPAIV) is detected in our area or even in our own flock.

Every meeting had the “biosecurity talk” the “notification talk” the “cleaning and disinfecting talk” – all valuable points of discussion and information. We did not see much of the inclusion of the water system in these discussions at that time. I’m not talking about the water source – pulling from surface water is a huge no-no when you have migratory birds infected with HPAIV in a flyway over your farm – I’m talking about the water system in your barn.

My company was asked to be a consultant for a grower that had been hit by Avian In-

fluenza at that time. They were wanting to make sure they had done all they could before placing birds again even though they had been cleared for placement and were just waiting out the days they had to be on “hold”.

Before we were involved, a contracted, trained cleaning crew had come into the barns to do the final cleaning and disinfecting. This group had submitted their plan to the appropriate government entity and it had been approved. The working crew was well trained in biosecurity issues. They wore biohazard suits and cleaned everything in the barn beginning with the removal of organics, then washdown with a cleaning agent and, in the final steps, they sprayed everything from the ceiling to the baseboards with a disinfectant.

Government officials had to approve the process and were involved in the concluding inspection. When all was said and done the grower was pre -

sented a list for his records of all that had been cleaned and disinfected. Two pages of single line items had been cleaned, removed, and/or disinfected. Guess what was not on that list? The inside of the water line.

This becomes an especially important point with the H5N1 subtype we are facing again this year. Different subtypes of viruses have different types of shedding patterns. For example, the H9N2 subtype typically can be detected in fecal droppings or cloacal swabs but is not often detected when only tracheal swabs are done.

The opposite is true of the H5N1 subtype. Because this virus survives well in the trachea there is a higher possibility that it will be found in the drinking water. Keep in mind that the water system is not a closed system. Every time a bird triggers a drinker, they open the system – and they leave whatever was on their beak on the drinker.

Anything that is in that barn, be it a mold spore or a bacterium or a virus, can wind up inside the water line. Once inside the water line, a virus can survive for days or weeks.

The ability of that virus to survive will also depend on available water treatment. If the water lines are full of organic build-up, any treatment added to the water is going to be quickly bound to those organics and ineffective against a virus that may now be buried under a few layers of buildup in the water line. The cleaner the water lines, the more effectively your water treatment can help you fight what gets introduced into the water lines by the birds or the opening of the nipple drinkers during the flock.

Recent reviews of how the 2015 outbreak was handled have led to the emphasis of some steps that may have been missed then. One of those steps is water line cleaning. In a May 2018 article of “Ask the Vet” in Canadian Poultry, Tom Inglis includes water line cleaning in the steps of recovering from an HPAIV event. Several poultry sites also now include water line cleaning in their biosecurity suggestions or in the cleaning/ disinfection guidelines for a poultry facility that has had an HPAIV event.

Don’t forget the water system when the discussion turns to biosecurity, keeping the barn clean, or recovery from a disease event. It could be the one place that is harboring the enemy.

For references, view the online version of this article at canadianpoultrymag.com.

By Crystal Mackay

and resources.

Have you considered the scope of the gaps between the people who grow our food and the average Canadian and what it means for the poultry industry? I believe public trust and support are fundamental building blocks that our sector needs to continue to grow and thrive in the future.

As referenced in my last article, we build bridges to help us get over obstacles and serve as a

“Building bridges takes time, effort and expertise – and is well worth all three.”

means of connection. I’ve spent my whole career thinking and practicing ways to better connect with most Canadians who don’t even know anyone who works in agriculture.

So what are the easy answers? Wouldn’t it be simple if we could just take out a big advertising campaign that says, “Trust us. Your food is good. We are doing a great job. Nothing more to see here. Move along.”

Unfortunately, we can’t advertise our way to trust and support. Advertising can even generate a greater negative reaction if it isn’t positioned carefully with today’s critical thinkers who are looking for authentic communications. And of course, when we think about gaps strategically, there isn’t one bridge or option that will cover all the gaps and all the audiences.

S o what to do? The good news is it doesn’t have to take a fortune to pay for approaches that work. It does take strategy, collaboration, and the spirit and dedication to a longterm effort. I truly believe that Canada is leading the way in the world when it comes to those attributes for earning trust in food and farming.

Leadership by poultry groups and non-profit groups such as Agriculture in the Classroom, Farm & Food Care (ON, PEI, SK) and the Canadian Centre for Food Integrity are first-class and making a difference with long term goals and a growing base of support from across the food system.

So what can you do? We need to embrace the model of tribal communications. You’re reading this publication so you’re in the poultry tribe and the agriculture tribe already. Now you need to get to know the food tribe. Think about all the places you can become part of the conversations on food that can lead back to the farm.

M illions of people are already talking about food somehow, somewhere. You just need to find them and join in! Seriously, that’s it. Literally start or join in conversations online, in social media, in person, at local events, or with a local politician to name just a few ideas.

Regardless of the channel or location, think of it as a giant conversation about food – and you want to be part of it as a trusted expert. Not as a salesperson or an annoying Cliff Claven, “It’s a little-known fact” or stats kind of way. You want to be more of an ‘interesting person who sits at their table that they would want to

hear more from’. You know you’ve achieved your goal if they start asking you more questions about your farm or industry experience. The gold star? If they ask for a tour or a visit or follow up after your interaction.

But what if you don’t have all the answers to all their questions? Of course you don’t.

Agriculture and food is a complex business. “I’m not sure but let me get back to you or direct you to someone who knows” is always an A+ answer.

My best advice? Think about what you do and how to explain it related to putting healthy, affordable food on our tables. Share your why. What gets you out of bed in the morning and

makes you optimistic about the future? Now that is interesting! Give that a share in your next conversation or on your social media channels and you’ll be surprised at the reactions you might get.

A s we all know, building bridges takes time, effort and expertise – and is well worth all three.

• Nutrients are re-allocated from growth toward minimizing the effects of stress

• Performance can be negatively impacted

More developments in the ongoing situation, with hope for containment still high in Canada.

By Treena Hein

When highly-pathogenic avian influenza (HPAI, subtype H5N1) was reported on a hobby farm in Newfoundland in late 2021, seven years since the last time HPAI was detected in Canada, everyone in the North American poultry industry held their breath.

This strain was sure to spread, but how much damage would be done was – and still is – the question on everyone’s minds. As Dr. Tom Baker, incident commander at Ontario’s Feather Board Command Centre (FBCC), stated in the FBCC Disease Update in early March, “The coming weeks will test the biosecurity upgrades that farms, businesses and government agencies have made since 2015.”

This HPAI strain has been confirmed in wild birds in all North American migratory flyways and all the way across Canada in a bald eagle in a B.C. rehabilitation centre. Since early December, the strain has made its way into several Canadian poultry premises, affecting a mix of backyard and commercial flocks. As of mid-April, Manitoba was the only province left that was free from the disease.

The situation is rapidly changing. But at the time of this issue going to

print, Canada had lost about 260,000 production birds lost to the highly contagious virus thus far. That’s according to the Canadian Food Inspection Agency (CFIA).

Alberta has been the hardest-hit province. As of mid-April, around 166,000 farm birds died or were culled there in what federal officials are calling an unprecedented event.

Ontario has also been hit hard. As of mid-April, CFIA confirmed the presence of the disease on 12 Ontario premises. About 84,000 birds in Ontario have died or been destroyed since H5N1 was detected in the province in March.

In Newfoundland and Nova Scotia, some 13,268 birds were affected with mortality as high as 85 per cent. In Nova Scotia, HPAI has been confirmed in a backyard flock, a turkey barn (12,000 birds euthanized) and a mixed farm.

When asked about how the pathogen entered these premises, CFIA states that the outbreak investigations are ongoing and conclusions have not been drawn. “Transmission can occur through many means such as a breach in biosecurity, windborne transmission and the transfer of animals (e.g., breeding stock) or things (e.g., equipment) between premises.” Due to privacy reasons, the CFIA also cannot disclose information about the biosecurity set up in place in barn entrances of affected farms.

After the early February confirmation on a Nova Scotia turkey farm, Canada had no outbreaks at commercial facilities for several weeks. However, during the very last few days of March, outbreaks were confirmed on three turkey farms in southern Ontario, in the townships of Zorra, Guelph/Eramosa and

Woolwich. It subsequently spready to several other premises in the province.

Dr. Mary-Jane Ireland, chief veterinary officer for the Canadian Food Inspection Agency (CFIA), stated that, “We are concerned. This is a high-risk period and birds are migrating.”

Although most chicken produced in Canada is consumed here, the outbreaks here have led to 24 countries instituting temporary import bans of Canadian birds or poultry products from some areas of the country or the entire country.

In the U.S., there have been over 50 outbreaks in commercial poultry barns and backyard flocks with over 13.3 million domesticated birds lost across over 20 states. Commercial operations in Indiana, Kentucky, South Dakota, Maryland, Missouri, and Delaware, Iowa, Wisconsin and Nebraska have been infected, according to the U.S. Department of Agriculture’s Animal and Plant Health Inspection Service.

Baker reports in the FBCC Disease Update that in Europe, things improved somewhat in February. That month, there were 236 poultry flocks (over nine million birds) destroyed, the lowest amount since October 2021. Since September 2021, globally there have been a total of 1,687 flocks infected with HPAI (almost entirely H5N1) and some 46.7 million commercial birds have died or were culled. “France was very hard hit in March,” Baker adds.

In wild birds since October 2021, Europe has detected almost 2,500 infection incidents in 34 countries. Germany has detected the most outbreaks in wild species, about

1000, followed by The Netherlands, U.K. and Denmark.

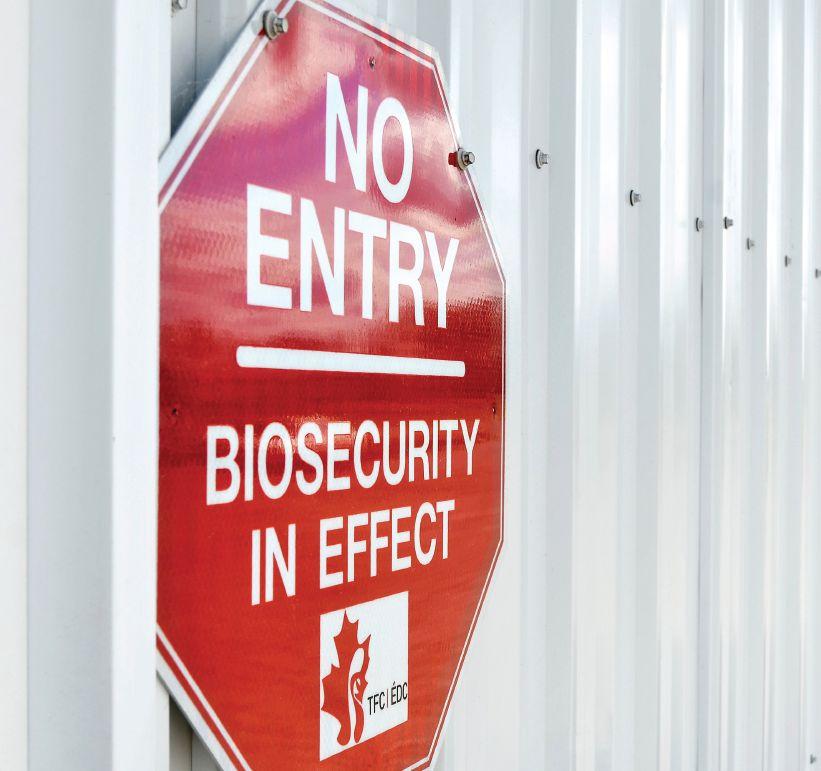

All commercial poultry farms across the country have heightened their biosecurity status.

With regard to small flock owners, there have been various education campaigns. For example, the Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) has reached out to backyard flock owners, educating them on what to look for with HPAI and sharing tips for prevention of infection.

OMAFRA spokespersons did not provide answers to the question of what’s at stake if small flock owners don’t do their part to prevent infection in terms of potential impact on the commercial poultry industry in Ontario and beyond, nor the biggest risk or concern in terms of spreading infection.

The FBCC Advisory released March 22 states that in Ontario, the risk of an AI incursion into poultry that come in direct or indirect contact with infected wild bird droppings is high.

“The risk to individual flocks will

depend on biosecurity vigilance of individual farmers and service providers. All poultry growers and service providers should strictly enforce their required basic biosecurity standards and identify heightened measures that could be implemented if needed in the future.”

The advisory also cautions that, “For the sake of your flock and that of your neighbours, please ensure you are exercising an abundance of biosecurity caution, on and off the farm. Poultry industry personnel should avoid any direct or indirect contact with wild birds, for example, hunting, feeding. Avoid introducing wild bird droppings into barns on hands, boots, apparel and equipment.”

While it’s impossible to predict what will happen with this strain of HPAI in wild bird populations, some insights can be gleaned. According to Environment & Climate Change Canada (ECCC), as of midMarch, HPAI has been confirmed in multiple wild bird species in North America, including gulls, waterfowl, raptors and corvids.

ECCC spokespersons add that in Europe, this strain has infected a wider range of wild bird species compared to other strains of HPAI.

In terms of how surprising the speed of spread has been in wild birds in North America, ECCC representatives first point out that there are already a wide variety of AI strains that do not cause disease in wild birds that circulate naturally. These strains change over the years as new variants emerge, and “although this specific strain of HPAI is spreading quickly…it’s consistent with known wild bird movements and the natural movement of other strains of AI that do not cause disease.”

For his part, Dr. Andrew Lang, professor in the Department of Biology at Memorial University in Newfoundland, says he didn’t expect such quick movement of the strain around North America during the winter months. But, he points out, “With spring bird migration, we can expect tremendous and fast virus movements.”

He adds that, “The AI virus that showed up in 2014-2015 magically seemed to disappear after a while.

H5N1 outbreak by the numbers

The following is a roundup of some key facts and figures around the current avian influenza outbreak in North America as of mid-April.

260,000 is about how many production birds Canada has lost to the highly contagious virus thus far.

166,000 is how many farm birds died or were culled in Alberta thus far, making it the hardest hit province.

84,000 is the number of birds in Ontario that have died or been destroyed since H5N1 was detected in the province this time around.

1,700 is about how many flocks have been infected with HPAI (almost entirely H5N1) globally since September 2021.

46.7 million is the number of commercial birds that have died or been culled because of the virus globally since last September.

8 weeks is about how long Canada went before a second commercial barn was found to have the virus.

• Exacon’s brand name since 1987

• Polyethylene or fiberglass flush mount housings available in white or black

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan, MFlex, or AGI motors

• Available in sizes ranging from 12” to 72”

• Produced out of high-quality polyurethane, TPI inlets are designed to optimize airflow

• High insulation value is ideal for cold weather climates

• Easy to assemble, maintain, clean and adjust to meet your specific ventilation needs

• Wall inlets, ceiling inlets and tunnel inlets

• TPI wind hoods are available with a builtin light trap option

• The V-FloFan creates a uniform climate in poultry houses

• Equipped with a water and dust resistant IP55 rated, low noise Multifan motor

• Helps control the humidity of the litter resulting in an active microclimate at bird level

• Special aerodynamic shaped conical outlet optimizes vertical airflow contributing to lower energy costs

• 3 year warranty on complete fan

• Available in natural gas(NG) or liquid propane(LP)

• CSA Certified variable heat output and highly efficient direct-fired design

• Manufactured with high quality, corrosion resistant components and Tri-Shield coating to provide years of worry-free performance in even the harshest livestock environments

• Features high temperature protection, air proving switch and a totally enclosed motor to assure safe, dependable operation

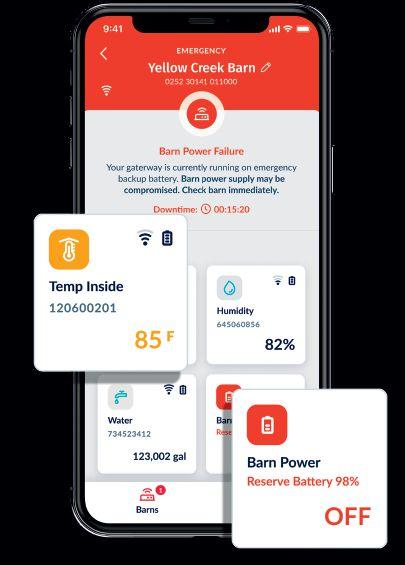

• User-friendly livestock production control equipped with a 10” colour touch screen for easy navigation

• Cutting-edge technology facilitating the management of ambient air(ventilation, heating, humidity, static pressure, CO2), animal populations, feed levels/consumption, lighting, and more Access real time data 24/7 and manage your operation remotely from anywhere you can access the internet using the FarmQuest online management tool

• Lightweight, corrosion resistant and easy to assemble on site using PVC spacers

• Provides maximum light reduction with very little resistance to air flow

• Also available assembled with a galvanized frame

“This virus that came now is behaving very differently in Europe and circulating widely and continuously.”

However, this virus that came now is behaving very differently in Europe and circulating widely and continuously. I think we need to assume it will do the same here.”

According to Dr. Valentina Caliendo, a scientist at the Erasmus Medical Center in the Netherlands, the virulence of this HPAI strain compared to past strains is similar. She has studied AI extensively, including this strain, which has been present in parts of Europe since October 2020.

“However, while this strain is genetically related to the 2016 strain, it’s very different,” she says. “For reasons that are not completely clear, it’s able to be maintained in wild bird populations. Maybe it’s found a species that can maintain it longer than previously.”

As to how this strain may evolve, ECCC representatives note that viral evolution is driven by many factors, including host factors (for example species, host densities, host behaviour, immune function) and environmental factors (season, factors that concentrate bird densities, factors that permit virus to survive in environment, the presence of other AI viruses which would increase opportunities for viral recombination and reassortment, etc.).

There are also viral factors, such as genetic characteristics that impact transmissibility, replication, pathogenicity and so on, including random chance of mutation.

Therefore, she explains, “Any virus, including AI, can become less virulent or more virulent depending on a wide range of interacting factors.”

Executive Committee 2022/2023

Darren Ference Chair

Darren Ference - Alberta

Calvin McBain – Québec

Matt Steele - Ontario

Calvin McBain Vice-Chair Jelmer Wiersma Executive Member

Shawn Heppell – British Columbia

Jelmer Wiersma – Saskatchewan

Mike Reimer – Manitoba

Marco Volpé – New Brunswick

Steven Eadie – Nova Scotia

Doug Hart – CPEPC

Michel Pépin – CPEPC

Adam Power – FPPAC

Scott Olson - Alberta Alternate

2021 marked the end of year three of the national Think Turkey™ marketing campaign, which continues to raise awareness of the versatility and benefits of turkey year-round.

You can follow along with our campaign at: thinkturkey.ca and on social media.

By Marvin Brubacher

Proper ventilation is well recognized as one of the most important aspects of poultry production in promoting bird health. A main contributor to high bird stress and low bird weight is an overheated or poorly ventilated poultry barn.

A very effective type of ventilation system for cooling, known as tunnel ventilation, has seen increased adoption by Canadian poultry producers in recent years because of its positive effect on air quality, especially during hot, humid weather.

In a typical ventilation system, such as cross ventilation, fans are located on one side of the barn and inlets on the other, which can create dead zones because of low air movement. In wider barns, there might be fans and inlets on both sides, but in both cases, air is cross ventilated. Or, in some cases, cross-ventilation systems have ceiling inlets, with fans on the sidewall. Ridge ventilation or chimney ventilation can also have inlets in the sidewalls or have ceiling inlets to let the fresh air in.

In contrast, a tunnel ventilation system brings in fresh air through tunnel inlet doors at one end of the barn and exhausts it at the other end. The system acts like a wind tunnel, creating high-speed air movement that helps cool the birds while also removing dust and harmful gases, such as ammonia, from their environment.

The cooling effect can be further enhanced with the use of evaporative cooling pads. As air is pulled through the

evaporative cooling pads with the tunnel fans, water evaporates from the pads and cools the air going into the barn. More Canadian poultry producers have been installing tunnel ventilation, either in new or retrofitted barns, in regions that have experienced high temperatures and humidity during recent summers.

When the weather is extremely hot and some traditional systems are challenged with heat stress, a properly designed tunnel ventilation system gives peace of mind to producers who have experienced challenges with their previous system. Not stressing about the heat is a huge asset to a properly designed tunnel ventilation system. How do you put a price on or measure the value of peace of mind?

In many barns, tunnel systems are used in conjunction with conventional systems to transition from cool to warm weather. Variable speed fans can be used to control the rate of air movement inside the barn, based on environmental conditions inside and outside the barn.

All of these systems will draw the air

from the sidewall or ceiling inlets until the tunnel system starts to run. And then, for true tunnel ventilation, the cross-ventilation fans will turn off, and the sidewall and ceiling inlets will close. The air will then come in one end and exhaust out the other.

A tunnel system should not be used with young birds, since prior to feathering they are more sensitive to the wind cooling effect. It is not required and would be stressful to these animals.

A cr oss-flow ventilation system or sidewall/ceiling inlet system should be sized to supply at least 40 per cent of the summer ventilation required. This supplies adequate ventilation during the cooler weather and also provides the younger birds ideal air quality without creating drafts prior to going to tunnel.

If the cross-flow ventilation system is not adequate, it can create challenges with the ventilation system transitioning prematurely from cross to tunnel or potentially creating drafts when not yet desired.

Tunnel ventilation is not recommended when ambient air temperature is below 15°C. However, tunnel ventilation should be introduced prior to your animals being exposed to heat stress, not after.

This is where it is important to automate the system since the controller is there to monitor the conditions of the barn 24/7 where you might not be there at the right time to make the transition.

Typically, the tunnel ventilation system is automated and factors in the bird’s age and temperature conditions. Where evaporative cooling is used with the tunnel system, the barn controller should also look at the humidity levels and activate the ventilation system accordingly.

Producers also need to consider barn design factors when installing tunnel venti

lation. Key factors, especially in new buildings, include ensuring that the correct air speed is maintained, that air inlets are properly designed and maintained, and that there are no obstacles restricting air movement in the barn.

Also, ensure that fresh air gets through the building efficiently, without lingering. Years ago, some used to insist that the air speed for poultry in a tunnel should be 250 feet per minute. Tunnel systems were being designed with that air speed, but at that time there were very few barns longer than 150 to 200 feet. Then barns got longer and were still in some cases designed for 250 feet-per-minute air speeds. In this era is where the tunnel ventilation got a bad name in the industry because barns got longer and air speed was not increased.

Today there are systems designed with 600 feet-per-minute air speeds or more. It is extremely important to design a proper system for your specific application as not all barns are created equal.

Sometimes, offices, utility rooms or overhead doors have been built on the end of a barn and create challenges regarding where to install the tunnel inlets or fans around these existing obstacles in a retrofit. But, if there is a will, there is a way.

L ayer barns can present challenges, even for a tunnel system. Unlike the open environment of a broiler operation, conventional stacked cages can diminish the rate of air movement through the barn. However, combining tunnel and conventional ventilation can help producers promote sufficient air movement through the cage aisles, while also picking up and

For over 25 years TPI has been a producer and supplier of air inlets, with the experience we’ve gathered we developed this unique design. The shape of the house and inner valve guarantee optimal control under all circumstances. The combination of design and material quality helps to make this inlet suitable in many different climates.

“ air jets created by the curved valve of the aeron help to deliver fresh air far into the house

For most farmers getting the minimum ventilation right is a challenge. Minimum ventilation is especially tricky in cold climates. The difficulty lies in bringing small volumes of air up to speed, to prevent the air from dropping directly onto the animals. With a minimum as low as 80m3/h at 20Pa the Aeron still guides air upwards to the centre of the house.

The Aeron performs very well at maximum capacity. When animals are heavier or the temperatures are rising, the air jets are directed straight into the house. At this stage, the air is also guided underneath the valve towards the floor of the house. This helps create a wind-chill effect that cools the animals. A great way to transition into tunnel ventilation. At the maximum opening, this air inlet has a capacity of 4400m3/h at 20Pa.

New audit app latest step in digitization of Ontario’s chicken industry.

By Lilian Schaer

Chicken Farmers of Ontario (CFO) is launching a digital auditing app that will streamline the on-farm audit process for its members. The app is the latest enhancement to CFO Connects, a digital platform the organization first launched in 2015 to transform the chicken business.

COVID-19 has accelerated the drive towards digitization in the poultry sector, as well as right across agriculture, although CFO CEO Denise Hockaday says the vision to simplify the farm audit process required under the organization’s quality assurance programs predates the pandemic.

“ This was an idea that came before that; it’s a requirement for us to do the audits and, by default, that means you have to have all sorts of documentation. So, we were looking for a better way we can do that to help farmers and our (audit) team and improve communications between CFO and farmers,” Hockaday explains.

“If you’re spending less time churning through paperwork during the audit, you can spend more time talking about the different things that are discussed during audits like animal health, operations, etc. That’s the opportunity,” she says.

CFO’s Raised by a Canadian Farmer Animal Care Program (ACP) and Raised by a Canadian Farmer On-Farm Food Safety Program (OFFSP) set the standards farmers have to follow to help guarantee food safety as well as ensure the humane treatment of birds.

Currently, auditors review all of a producer’s documentation during the farm visit. With the new app, all required

documents can be submitted electronically in advance, giving the auditor a chance to review the paperwork before visiting the farm. Many auditing functions can also be completed in real time in the barn using a smart device.

The intent is to make the audit time more efficient for farmers, as well as lead to more productive and useful conversations around critical aspects like physical environments, biosecurity, animal care practices and on-farm procedures when the auditor visits the farm. Longer-term, better reporting will make the industry better prepared to respond to potential avian disease outbreaks.

The new digital audit app is the latest step in CFO’s digitization process that first began almost a decade ago, when the board decided in 2013 to transition away from its traditional, paper-based reporting systems.

The resulting CFO Connects platform – a leader in Canada’s chicken industry –connects farmers with CFO, transporters and processors and both simplifies and standardizes reporting.

For each producer, the system includes information like crop quota, audit history, contract information, business transactions, feed data collection, quota transfer details and more.

“Internally at CFO, we are very digital. There is not much that is still done on a physical piece of paper and COVID has

certainly accelerated that transition,” Hockaday says. “With farmers, too, more and more has become digital, especially since COVID. Our meetings are virtual, and communications is by email.”

Although chicken farmers miss the in-person networking and interaction of face-to-face events, she notes that one benefit of virtual CFO district meetings has been the opportunity for producers to attend any meeting of their choosing without being limited by geography or travel time. This gives the opportunity to interact with other people in the industry than would normally have been possible.

“ We’ve been moving paperwork to digital and the audit process will strengthen that even more,” she says, adding that the new app underwent extensive testing in 2021 before starting on its rollout to producers this year.

“It’s pretty exciting; it definitely will be a change, but a change for the good and we will need to focus our efforts at CFO to help farmers navigate that change. But we’re committed to that because it’s the right thing to do,” she says. “Whenever there is change, there is an element of learning. But if you were to ask farmers today if they want to go back to before CFO Connect, they don’t want to go back.”

CFO plans to continue to update and enhance the capabilities of CFO Connects to keep pace with changing industry needs and evolving technologies. The original development of the system was supported by a Growing Forward II grant; development of the audit app was funded in part by the Canadian Agricultural Partnership.

There are no national projects currently underway to digitize information at the farmer level. According to Chicken Farmers of Canada, digitization in Canada’s chicken industry is driven by the provincial organizations.

Wearing the proper protection every time is critical for you, your employees and your family.

By Treena Hein

Idon’t always mask up when I go into the barn. I know I should but it’s inconvenient to do it if I’m just completing a short task and it’s at a point in the flock cycle where the dust level is pretty low.” Those are the words of a poultry farmer who wishes to remain anonymous – an admission that could likely be echoed by many poultry farmers in Canada if asked about frequency of masking up, an admission that’s to the definite detriment of their health.

To put it simply, poultry farmers should remember that the barn environment contains many dangerous components and wearing the proper mask or respirator is very important for farmers, their family members and employees, each and every time. “Lung damage from particulate matter can be cumulative and irreversible, but even one exposure can cause serious permanent damage,” explains Jessica De Leo, a registered respiratory therapist with the Lung Association. “Prevention is critical. Strict protocols should be put in place. I am located in Northern Alberta and a lot of

my patients are farmers. There is a lot of lung disease here.”

In general, poor air quality can lead poultry farmers to experience a range of symptoms including sore throat, irritated eyes, wheezing and shortness of breath. Serious respiratory diseases that can result include chronic bronchitis, occupational asthma and pulmonary fibrosis.

Dust is obviously a large hazard. Poultry barn air can contain particulate matter from feed, feces, poultry litter materials, feathers, decomposing poultry skin cells, as well as mold, mold toxins, fungal spores, bacteria and other microorganisms. It also contains asthma-causing agents known as asthmagens. And ammonia, as poultry farmers well know, is especially prevalent during the winter months and can be particularly damaging to the health during

“Prevention is critical. Strict protocols should be put in place.”

periods of minimum ventilation.

Here is what happens when dust enters the human lungs, as explained by the US Centres for Respiratory Health. Dust travels into the tiny air sacs called alveoli where exchange of oxygen/carbon dioxide occurs and their surface blocks dust from entering the bloodstream. However, our lungs also contain immune cells called macrophages which remove dust particles found in the sacs and push them up with the aid of ciliary action in the upper respiratory tract to be coughed out. In situations where large amounts of dust are inhaled, any particles not handled by the macrophage brigade pile up in the tissue, which causes irreversible damage.

Barn dusts “also contain what is known as endotoxins, which are toxins of gram-negative bacteria,” according to the factsheet Respiratory Health on the Poultry Farm published by the University of Delaware. “These inflammatory substances can cause toxin fever which is similar to influenza. Symptoms include headache, nausea, coughing, nasal irritation, chest tightness

“Consider protecting your lungs a part of farming life and just do it.”

and phlegm. Endotoxins are responsible for a number of work-related acute and chronic illnesses.”

This document also point to the many factors affecting dust concentrations in barns, ranging from bird and litter age, temperature, relative humidity, ventilation rate, time of day and bird activity. “Respiratory protection becomes especially important when dust levels rise in the barn, such as during colder weather when ventilation is reduced, with built-up litter and during the grow-out period.”

Farmers need to protect themselves, their family members and obviously their employees. As employers, farmers are responsible for supplying the proper masks or respirators for their workers and contractors and making sure the right fit is achieved.

Children, pregnant women and the elderly are at higher risk of acute inflammatory reactions from poor air quality, and also having attacks of acute illnesses such as asthma, hypersensitivity pneumonitis and catching Avian Influenza. “Even one exposure can lead to scarring, chronic conditions like COPD (chronic obstructive pulmonary disorder) and permanent damage,” says De Leo. “Because children have smaller airways, their reactions can be very fast and severe. It’s really important that even if they – or anyone else – only go into the barn once a week for a half hour, they need to wear the right protection with the right fit.”

A fit-tested disposable N95 masks is the absolute minimum for visiting the poultry barn. “It must be airtight, so it needs to be the size that fits you and attached properly to your face and head,” says De Leo. “Adults

should get a fit test every two years because as you age, your face can change. If you are going into the barn for extended period, removing dead animals, spraying cleaner, etc. respirators should be used. Again, they must be properly fitted and cleaned, handled with clean hands, etc. There is actually a lot of training required to ensure proper fit, maintaining hygiene, so that the respirator actually does its job.”

Respirators should be checked before each use and filters changed regularly. The service life of the filter is limited by hygienic (or non-hygienic) handling, damage and clogging (indicated by increased breathing resistance). Anyone with a heart condition, asthma, emphysema or other chronic lung condition should check with a doctor before using a respirator.

Outside the barn, don’t forget that air quality hazards such as dust also exist in the fields, so don’t forget to mask up when you are harvesting, applying crop protection products and at other appropriate times.

In terms of what holds farmers back from donning the

right protection in the barn, De Leo says it’s likely that it’s time-consuming and tedious.

“However, I strongly urge anyone reading this to consider protecting your lungs a part of farming life and to just do it, each and every time,” she says. “People really don’t understand or accept the degree of risk that’s involved, even with one exposure. Lung damage is irreversible. We don’t think the barn is dusty, we can’t physically see the particulate matter that’s there, and when we can’t see something, it’s easy to ignore. Please don’t ignore your lung health.”

The Canadian Lung Association may roll out an awareness campaign about lung health among farmers, says CEO Terry Dean.

“We’d like to raise awareness of the consequences of not protecting lung health as many lung conditions are preventable and environmentally-driven,” he says. “We now have PPE available like never before and it’s important that it’s used every time it’s needed. Lung health is best protected by making protection an automatic habit.”

Big Dutchman’s AirMaster Blue 140C poultry house fan offers variable speed and a direct drive motor, giving you high air performance and mininum energy consumption. Contact your distributor or sales representative today for more details.

Anany’s research is funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster which is supported by Agriculture and Agri-Food Canada as part of the Canadian Agricultural Partnership, a federal-provincial-territorial initiative. Additional in-kind contributions have been provided by Maple Leaf Foods and Exceldor Foods.

Century-old technology may be the solution to modern resistance issues.

By Lisa McLean

In the modern fight against antimicrobial resistance, one Canadian researcher is working with a promising new technology from an unlikely era: the past.

Dr. Hany Anany, research scientist with Agriculture and Agri-Food Canada, is developing tools using bacteriophages or “phages,” naturally occurring, highly specific viruses to target two major foodborne pathogens. In the most recent stage of his three-year research project, Anany is developing phage-based food packaging prototypes that reduce the risk of foodborne contamination in poultry meat post-harvest.

“Phages are an old antibacterial tool that are coming back as a new tool,” says Anany. “This green technology presents a novel antimicrobial option during processing and at other points across the food supply chain to enhance food safety.”

First discovered in 1917, scientists were developing phage therapy for diverse human medical conditions. But once penicillin was discovered in 1928, many scientists turned their focus to antibiotics.

“Now that the industry faces development of antimicrobial resistance and tolerance to sanitizers, we need a different solution,” Anany says. “The use of phagebased products on foods is accepted and approved by several health agencies around the world, including the United States and Canada.”

Anany’s most recent work focuses on finding ways to incorporate phages during

poultry carcass processing to control Salmonella and Campylobacter contamination. He sees potential in adding phages to the absorbent pads found under raw poultry products, to allow phages to target or “eat” specific pathogens at their source.

Both phages and bacteria are living organisms that have coexisted for billions of years. Anany’s early work focused on finding phages that can specifically infect foodborne poultry pathogens, and isolating them from their natural environment. Since Salmonella and Campylobacter commonly begin in the gut, he collected fecal samples from farms to “hunt” for phages against Salmonella and Campylobacter strains associated with previous

foodborne outbreaks and illness.

“Phages and their pathogens coexist, so it’s very important to hunt for the phages in the environment where we expect to find the pathogen,” says Anany.

Once he isolated dozens of phages, he used genome sequencing to examine each phage for specific traits. Anany was looking for phages that offered a broad host range, low development of resistance, good stability, and an ability to kill bacteria in a short amount of time.

“ Before we could rely on phages, we needed to overcome two main challenges,” says Anany. “We had to make sure the target pathogens don’t develop resistance to the phages, and we needed to ensure the phages won’t be inactivated due to disinfectant procedures in the processing environment.”

After isolating phages with the bacteria-fighting traits he was searching for, Anany combined selected phages to create a phage cocktail that would bind to different bacterial surface components to minimize the chance of resistance development. He tested the mixture in different concentrations on raw chicken and turkey skin that was inoculated with Salmonella, and found that over three days at various temperatures, the phage cocktail reduced bacteria counts without developing any phage-resistant mutants.

“ The more we increased the phage count, the more we saw complete inhibition of the bacteria,” says Anany.

He notes that while the team had good success developing a phage cocktail for Salmonella, they have faced delays in developing a similar mixture for Campylobacter due to the COVID-19 pandemic. He expects to use the same method to

“The use of phage-based products on foods is accepted and approved.”

develop a viable cocktail against that pathogen in the coming months.

While phages are not currently used in poultry production in Canada, Anany sees potential to use them as a processing aide once his phage cocktails are produced on a larger scale. First, his team is finding ways to incorporate phages where they will not be deactivated when exposed to sanitation practices such as chemical disinfectants normally used in poultry processing environment.

“ Phages are living organisms that would be destroyed by chemical and physical antimicrobial agents, so it’s important to understand at what point in the process we would use them and how we apply them,” says Anany.

The estimated cost of phage applications for poultry is one to four cents per pound, compared with 10 to 30 cents per pound for high pressure processing (HPP). Anany suggest that although it’s unlikely phages alone would replace the currently used

antimicrobial technologies, it is envisioned to be used as part of a hurdle technology along with other antimicrobial approaches to enhance safety throughout the poultry supply chain.

“Phages have minimal effects on quality and sensory properties of food. We think if we wash the carcass with the phage before and after chilling step during processing, and also add it to the package, it

might enhance the safety of raw poultry products over its shelf life,” says Anany. “Even if bacteria survive the treatment, I expect it will not be as virulent or pathogenic as it was clearly demonstrated in many cases that development of phage resistance has a negative impact on virulence fitness of several bacteria.”

Anany is adding his phage cocktail to the absorbent pad underneath raw product to allow for phages to be released over the shelf life of the product. Eventually he plans to produce the pads on a larger scale to test them in an industrial setting, combining phage cocktails to allow for control of both Salmonella and Campylobacter.

“Antimicrobial resistance is a serious issue, and phages are an opportunity to use a natural technology that has no impact on the environment or humans,” says Anany. “There is potential to incorporate phage technology at all stages of the poultry supply chain to reduce contamination and growth of these two bacterial pathogens in poultry meat.”

By Lisa McLean

For egg and poultry meat farmers, achieving optimal air quality inside the barn may mean a trade-off with profitability. That’s because the easiest solution to managing the two major threats to clean air in a poultry barn – ammonia and particulate matter – are best controlled with ventilation, a costly solution in Canadian winters.

In his 10-year-old research program based largely at the University of Guelph, Bill Van Heyst, new Dean of the faculty of Engineering at University of Windsor and adjunct professor at the University of Guelph, continues to put various air quality control strategies to the test so producers can understand which tools are most effective at helping produce eggs and poultry meat that meet environmental, economic and animal welfare requirements.

“Ammonia is a tough one to manage because it’s formed when poultry excreta with high concentrations of nitrogen re -

acts with with microbes under moist conditions,” says Van Heyst. “In barns where the birds are present for longer periods of time – especially broiler breeders and layers – it’s important to keep ammonia at an acceptable level.”

Canadian animal care requirements related to poultry require ammonia levels below 25 parts per million (ppm). In a recent project, as part of his CPRC cluster work, Van Heyst used his advanced monitoring equipment to test ammonia readings in a broiler breeder barn that had incorporated a seemingly novel solution: an alley scraper under the roosting area.

“Broiler breeder facilities typically don’t have a way to remove excreta more frequently, and the thought was that with this solution there would be less volume and less ammonia overall, but that wasn’t necessarily the case,” says Van Heyst.

During his team’s measurement campaign, Van Heyst says the agitation of the chains caused the surface to break up and emit ammonia, requiring quick action from the producer to get it under control.

In the coming months, his team will conduct a similar measurement campaign in a broiler breeder barn that does not use an alley scraper, to see how ammonia levels compare.

While drier conditions can help manage ammonia, a barn that is too dry can be at risk of another major air quality concern in a poultry operation: particulate matter. Van Heyst says fragments from bedding materials can be a major factor in poor air quality.

In an upcoming project, he will measure particulate matter to compare two types of bedding in identical broiler barns, using birds from the same hatchery placed on the same day. One barn will use a traditional bedding type such as chopped or pelleted straw, and the other barn will use peat moss – a material that is gaining popularity among chicken farmers for its ease of use and low cost.

“Particulate matter isn’t always easy to see, and the most harmful type is not

visible to the naked eye,” says Van Heyst. As part of this project, his team will partner with the Animal Health Lab, which will perform lung biopsies on birds from both environments. Specifically, they will look for the presence of fibres in lungs from both straw and peat moss bedding types.

“As a general rule, if you can see a lot of dust in the air, you have higher levels of all kinds of particulate matter – including the harmful kind,” says Van Heyst. He says handheld analyzers that measure ammonia levels may be worth the investment, especially if a producer has multiple sites to walk through. If ammonia is high, most people will feel a stinging in their eyes, but it’s possible to build up a tolerance over time. Van Heyst notes handheld

instruments don’t always provide accurate readings, but they will provide a reliable indication of whether ammonia levels are acceptable or too high.

“Once you know you have an air quality problem, you really need to increase ventilation and flush it out the barn,” says Van Heyst. “But heating the replacement air with propane or natural gas, if you’re lucky enough to be on a natural gas line, is costly.”

Looking ahead, Van Heyst expects emerging challenges from climate change will lead to better barn design. Currently he is working with a graduate student to model airflow in barns and identify stagnation zones. With that information, he says it’s possible to design better poultry barns for ventilation and heating in winter.

“I think in the coming years we’ll move

toward making barns a better energy system, with the ability to pre-heat or pre-cool, so we’re better prepared for climate change, climate adaption and weather perturbations,” says Van Heyst. “There’s always another project on the way, as we test new strategies to make eggs and poultry meat as sustainable as possible.”

This research was funded by the Canadian Poultry Research Council as part of the Poultry Science Cluster, which is supported by Agriculture and Agri-Food Canada (AAFC) as part of the Canadian Agricultural Partnership (CAP) program. Additional support was received from Egg Farmers of Canada, Canadian Hatching Egg Producers, Ontario Ministry of Agriculture, Food, and Rural Affairs, and the School of Engineering, University of Guelph.

The purpose of this book is to educate the readers on the role of dietary fats in poultry on: production aspects, health effects, growth and product quality. In addition, the role of poultry food products in meeting the human requirement of much needed functional nutrients such as omega-3 fatty acids is discussed.

The book also includes a chapter on appropriate techniques for lipid analysis. The authors have attempted to include as much up to date and relevant information on the roles of fats and fatty acids in poultry nutrition, health and product quality in this book.

$59.99 Item #1899043378

Location

Haldimand County, Ont.

Sector Turkeys

The business

Third-generation poultry farmer Cody Snyder founded Snyder Turkey Farm in 2018 with his fiancé Deanna Simpson. It consists of one turkey barn that the couple runs with help from Snyder’s parents, Paul and Nancy Snyder.

The need

Snyder grew up on a broiler farm but for their own barn the couple chose to grow turkeys instead. They went this route because both have off-farm jobs as well and they felt producing turkeys for seasonal demand would better accommodate that schedule, allowing them to ease into poultry production. And so they bought a former broiler breeder barn in 2018 to convert for turkeys.

The barn

The barn was structurally sound. However, they discovered a few challenges that required attention. They replaced the insulation, walls and electrical. They also added a new service room. And then they started working with Clark Ag Systems on a new design layout that preserved the infrastructure in place while upgrading their equipment. For instance, they kept the existing cross-ventilation setup but had new fans installed as well as a new Genius control system. “There’s been a lot of learning,” Snyder says of his foray into turkey production, adding that they’ve been fortunate to have a diverse team of people they could turn to for support and advice.

Chicken Farmers of Canada recently sat down with Dr. Kirsten De Keyser from Huvepharma to learn more about their Clostridium perfringens Type A vaccine, now on the market in Canada and the US. She shared results from recent on-farm studies as well as helpful background information about the biology of necrotic enteritis.

Check