The

17

Canadian Biofuels Inc. has built its first wood pellet plant, despite delays and challenges.

Removing biomass could help BC forests.

Everything you need to know for the upcoming International Bioenergy Conference & Exhibition in Prince George.

32

The BC Bioenergy Network is working to build a world-class bioeconomy industry in its province.

36

Tembec Chapleau Operations has done experimental harvesting to determine impacts on biodiversity, productivity and more.

40

Dust is a big problem in the biomass industry, but Martin Engineering has a solution.

Using Canadian biomass closer to home benefits everyone.

Irarely agree with Greenpeace. In the case of bioenergy, they have become a shrill, and at times, inconsistent, voice. I distrust their motives, and in return, they question mine. Still, I have to agree that it would be better for everyone if we did a better job of using bioenergy at home.

Don’t get me wrong (or quote me out of context) as our current model of exporting bioenergy around the world works. Evidence supports the carbon balance of the current pellet export business model and we are using our wealth of resources to help other jurisdictions reduce their reliance on nonrenewable fossil fuels. We also create meaningful employment in remote and rural Canada in the process.

products for heating?

District heating: This is an efficient model that may be too “socialistic” for many Canadians. However, it is time to get out of that 20th-century mindset and make this a growing reality.

Combined heat and power (CHP): Co-firing and district heating are good, but thermal efficiencies are only in the 40 to 45% range at best. In contrast, modern low-emission CHP systems can approach 90%, all using biomass sourced within 150 km. Multiply that several hundred fold, and we’ve made a significant change to our energy mix.

Volume 5 No. 3

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Associate Editor - David Manly (519) 429-3966 ext 261 dmanly@annexweb.com

Contributors - Gordon Murray, Mark Hubert, Robert W. Gray, Hakan Ekstrom, Paul Hazlett, Dave Morris, Rob Fleming, Martin Engineering, Michael Weedon

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales

Josée Crevier

Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0318-4277

Circulation

The bottom line is that Canada’s nascent biomass sector is doing the best it can with the markets available.

As a nation of energy consumers, we have the opportunity, perhaps even the obligation, to make so much more of the resources we are blessed with. Here are just some of the uses we can implement at home, with the right combination of innovation, leadership and encouragement.

Canadian co-firing: Where fibre is available (and it is in many areas) and coal is the alternative, this is a no-brainer.

Residential pellet heating: Modern systems are both low-emission and convenient. Do we really need to use petroleum

The greenhouse sector is rife with opportunity. I dropped in on a grower in southern Ontario in March that was using high-efficiency Cat generators to heat its greenhouses, push power on the grid, and create CO2 for the plants at over 90% thermal efficiency. They were on natural gas, but the concept holds true for biomass.

Bioproducts: Now combine all of the above methods by producing valuable bioproducts, with the process heat and steam being used for local needs, and we’ve attained the Holy Grail of bioenergy. Are we heading in that direction? Yes. Are we moving there with a clear plan, orchestrated government support and adequate speed? Not at all.

That’s our challenge, and the vision of

Scott

Jamieson, Editor/Group Publisher sjamieson@forestcommunications.com

Carol Nixon e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada

(Canadian prices do not include applicable

Occasionally, Canadian Biomass magazine will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above..

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Prince George, BC – The Wood Pellet Association of Canada (WPAC) has launched its all-new website (www.pellet.org), providing members and the public with all new information and functionality in a modern design. Redesigned and built in conjunction with Canadian Biomass, the site includes up-to-date information on wood pellet manufacturing, the benefits of using wood pellets in a number of applications, membership information, contact information on members and associate members, and more. New features include:

Upfront news and views section, including articles from Executive Director Gordon Murray.

Live news and industry event feeds, updated daily courtesy of Canadian Biomass.

Pellet primers on Canadian production, sustainability, and environmental benefits.

Market feeds on pricing for natural gas and oil, and coming soon, wood pellets.

Industry links

Vancouver, BC – Nexterra Systems Corp. is poised to significantly expand its fleet of biomass energy systems as it officially opens two large new projects at the US Department of Energy’s Oak Ridge National

Laboratory (ORNL) in Tennessee and at UBC in Vancouver.

The $27 million UBC plant will demonstrate at commercial scale a new renewable combined heat and power (CHP) solution that combines Nexterra’s gasification and unique new syngas conditioning technologies with General Electric’s Jenbacher internal combustion engine.

Nexterra says the resulting power system will be significantly more efficient, costcompetitive and cleaner than conventional biomass combustion-to-steam or combustion-to-ORC power plants. This will make the system economically viable at a scale of 2 to 10 MWe – one-tenth the size of conventional biomass-to-steam power systems.

QUEBEC

The province of Québec may link its cap-and-trade system with California to create a joint market to trade greenhouse gas emission permits.

SAINT JOHN, NB

Master Promotions Ltd. is expanding its BC trade show portfolio by acquiring a highly successful British Columbia Trade Event, Resources Expo, held in Prince George.

VANCOUVER, BC

Lignol Energy Corporation has announced that it has become a member of the Oak Ridge Carbon Fiber Composites Consortium, which is devoted to the development and commercial deployment of new carbon fiber and composite materials.

POINT TUPPER, NS

The former NewPage Port Hawkesbury mill site for the $208-million biomass cogeneration plant has received a steam turbine generator that will produce electricity, with aims to be operational during the first quarter of 2013.

Fibrek Inc. has concluded an agreement for the sale of green energy produced at its cogeneration facilities in Saint-Félicien, QC, to Hydro-Québec.

Toronto, ON – The Agri Investment Forum is encouraging emerging (First Look Showcase) and growth stage (Investment Ready) companies to apply to present at the Agri Investment Forum on June 27, 2012 at The Delta Chelsea Hotel. The Agri Investment Forum will provide visibility to the following sub sectors:

Forestry Products & Management

Crop Science & Yield Optimization

Nutraceuticals & Functional Foods

Biofuels, Renewable Feedstocks &

Energy Bio Pesticides & Bio Herbicides

Aeroponics & Aquaculture

Limited spots available and applications are reviewed on an ongoing basis. Please visit their website for more information: http://www.agri-investmentforum.com/ apply_to_present.php

By Gordon Murray

he third Argus Biomass Trading Conference on April 19-20 in London was a great way to get caught up on the pellet industry’s latest intelligence and network with many of the major players in the global wood pellet industry.

Argus Media has been providing price assessments, business intelligence and market data for oil, gas and electricity markets since 1970. In 2009, Argus began coverage of biomass, publishing the weekly Argus Biomass Report which includes a wood pellet price index. The annual Argus Biomass Trading Conference has become one of the

Following the fire at RWE’s Tilbury Power Station, oversupply caused the ARA price to drop to 128/T as of late April.

Two price indices track the ARA pellet market – the Argus Index and APX ENDEX. They follow similar trends, but there can be as much as a 5/T difference between them.

“It is essential that we convince governments and the public to continue supporting bioenergy”

Jorrit Hachmer of RWE pointed out that wood pellet prices have been remarkably stable. The ARA price as reported by APX ENDEX has stayed within a 10/T range since Q4 2010. As volumes grow, he expects spot trading and the use of derivatives to increase, which will lead to more price volatility.

it, the bioenergy industry could vanish overnight.

A task force has been formed consisting of the European, U.S. and Canadian trade associations, along with power utilities Dong Energy, Drax Power, EON, GDF Suez, RWE and Vattenfall. The task force is collecting all relevant scientific literature regarding bioenergy, and a strategy for effective communication to governments, non-governmental organizations, and the media is under development.

top European events in the pellet industry.

Attendees included all European power utilities presently co-firing and those planning to, U.S. and European pellet producers, equipment suppliers, trade assocations and more, but no Canadian producers.

The beginning of the conference was largely concerned with estimates of current and future production/consumption, trade flows and likely price trends. Some highlights were:

Argus estimated global wood pellet consumption in 2011 at 14.4 million tonnes (Mn T). Europe accounted for 11.4 Mn T.

The Argus wood pellet price index showed that the CIF Amsterdam Rotterdam, Antwerp (ARA) price reached a low of 116/T in August 2010, and then rose gradually to peak of 137/T by February 2012.

It is expected that European pellet demand will increase to 15 Mn T by 2015 with pellets supplied by: Western Canada (2.1 Mn T), Eastern Canada (0.9 Mn T), Southeast US (8.2 Mn T), Brazil (2 Mn T), Baltics (1 Mn T) and Portugal (0.65 Mn T). Indonesia and Malaysia continue to ship palm kernel shells (PKS) to Europe. But PKS require more handling at the power stations (drying and pulverizing), and are controversial with respect to sustainability. There was also an important discussion on how environmental groups are increasingly opposed to bioenergy. We must counter those claims because the entire bioenergy industry is based on the dual premises of GHG reduction and sustainability. It is essential that we convince governments and the public to continue supporting bioenergy, because without

One very important issue that has come to our attention is the European stance on primary forests. Primary forest means “woodland of native species, where there is no clearly visible indication of human activity and ecological processes are not significantly disturbed.” Both the European Union’s Renewable Energy Directive and the U.K.’s Sustainability Criteria for Solid and Gaseous Biomass Generators prohibit biomass from primary forests. Because a substantial portion of Canada’s working forest is classified as primary forest, we must urgently come to an agreement with the key regulators – the European Commission Directorate General for Energy and the U.K. Office of Gas and Electricity Markets – as to how Canadian biomass is to be treated.

The Argus conference was a great opportunity to gain all the latest intelligence on our industry, and all the European utilities were eager to meet producers. I recommend Canadian pellet producers give this confer-

those who want to

pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-837-8821 or by e-mail at gord@pellet.org.

By Mark Hubert

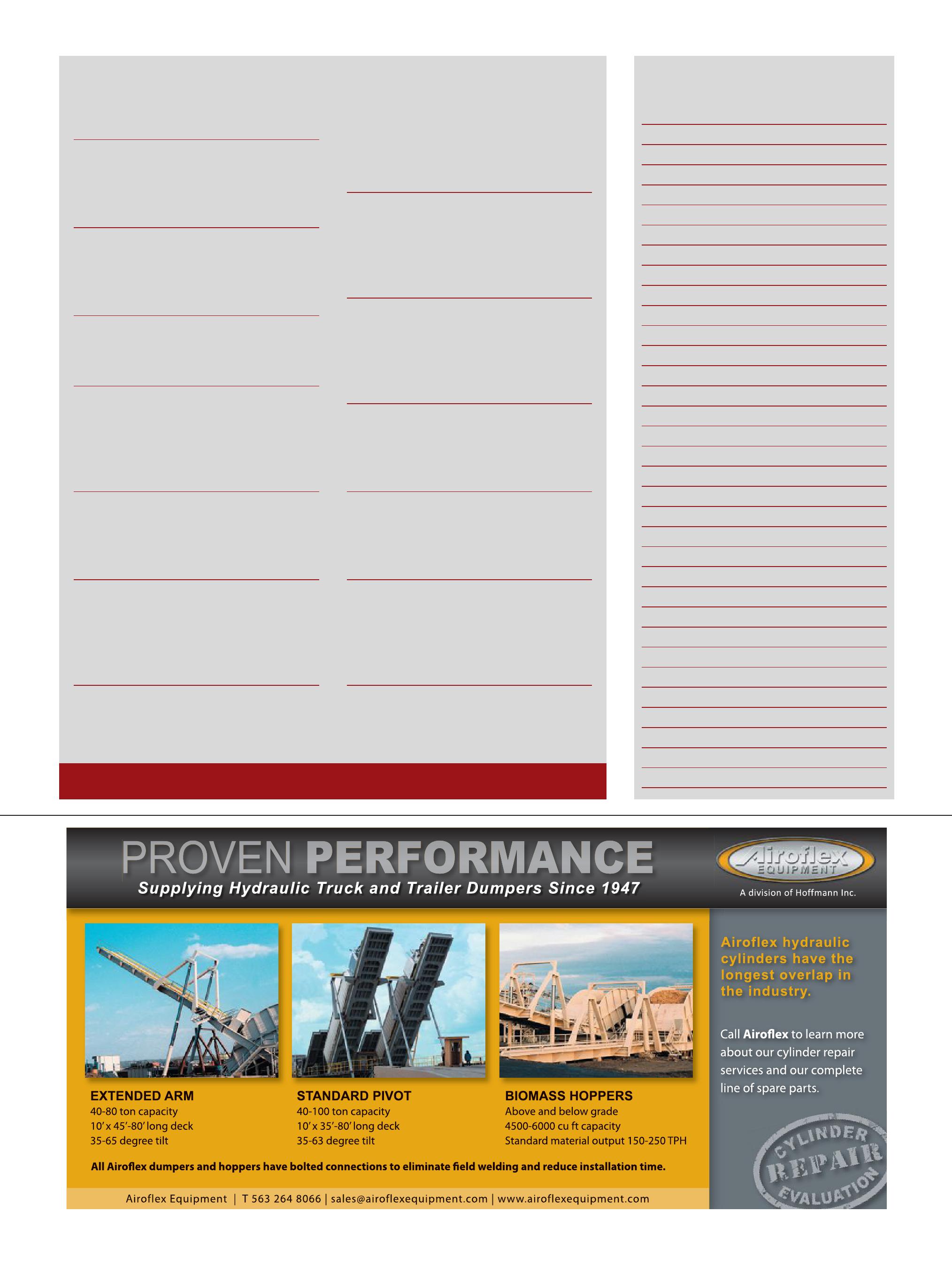

urning a waste stream into a revenue stream and an environmental advantage is how the Canadian forest products industry approaches the use of mill and forest residues.

FPAC believes in the importance of maximizing the value from every tree harvested for economic, social and environmental reasons. One of the ways to do this is by making use of fibre residues – the bark, logging debris, sawdust and other waste products from pulp and paper plants or sawmills – for beneficial use. Using this stream is consistent with views expressed

source in Canada, with the forest industry’s use accounting for the largest share. With large reserves of agricultural and forestry resources, Canada has a clear economic strength to use to its advantage.

“After hydro-electricity, biomass is the second most important renewable energy source in Canada”

by environmental groups.

The forestry sector has a long history of using harvesting and processing waste to heat facilities. But residues such as bark, sawdust, wood chips, branches and tree tops are now also being used for sophisticated steam and electricity cogeneration facilities, lumber drying kilns and new bioenergy products such as wood pellets, syngas, cellulosic ethanol, biodiesel and bio-oil.

Forest biomass supplies more than 60% of the fuel used to generate heat and electricity in select Canadian pulp and paper mills. This figure is set to increase as governments and industry recognize that it makes good sense to replace fossil fuels with renewable energy sources and more efficient technologies.

After hydro-electricity, biomass is the second most important renewable energy

Bioenergy also represents about 5% of Canada’s total primary energy resources. Every year, more than 138 million megawatt-hours of bioenergy are used in the industrial sector. From a social perspective, bioenergy also creates more permanent employment than other energy sources. Considering the same capital investment, bioenergy creates twice as many jobs as other types of renewable energy and three times as many jobs as fossil fuels. This comes from a human resources study undertaken by the Canadian Forestry Service as part of the “Bio-pathways” project.

FPAC recognizes that the use of biomass for energy is not without its critics. Some believe that the increased use of biomass for energy puts forests and climate at risk. If the process were approached carelessly, we would agree. But, if done wisely, there is a strong environmental benefit.

When biomass-based products are used instead of more CO2-intensive alternatives, we avoid the increases in atmospheric CO2 that would have occurred had biomass not been used. Our renewable forest resource is part of nature’s cycle, and progressive forest management in Canada helps to ensure equilibrium, as growing trees store carbon or remove it from the atmosphere, offsetting the release of carbon from the use of the wood resource. This phenomenon does not exist with the use of fossil fuels, and therefore

the forest biomass carbon cycle is currently a net sink for carbon dioxide from the atmosphere.

FPAC worked with FPInnovations, Natural Resources Canada and scores of economic and scientific experts on the Biopathways study to examine the benefits of integrating new biotechnologies within the traditional forest products industry. The study concluded that producing bioenergy, biochemicals and biomaterials as well as traditional lumber and pulp and paper would both boost employment and strengthen Canada’s economy and rural communities. The key to the industry transformation is maximizing the value from every tree, by doing everything from producing solid wood to exploiting the hemicellulose and nanocrystalline cellulose and more, as well as extracting value from waste doomed for the landfill.

In addition, our analysis of the carbon footprint of products completed under the Bio-pathways study suggest that many of the emerging products, including bioenergy, can have neutral or even negative carbon footprints. That carbon footprint report is available on our FPAC website.

The Canadian forest industry is looking to the future with confidence thanks to the utilization of renewable biomass from forests while ensuring that sustainable forest management will help propel the sector towards growth and prosperity

Mark Hubert is the Vice President of Environmental Leadership for the Forest Products Association of Canada. He is the former director of Sustainable Forest Management for FPAC and previously was an advisor with the British Columbia Ministry of Forest Economics and Trade. Markment and holds a degree in international relations from the University of British Columbia.

How the University of Northern British Columbia quickly came to embody its own slogan – “Canada’s Green University.”

By David Manly

biomass to produce its own heat and power is a natural fit for the University of Northern British Columbia. Located in Prince George, the university is close to vast tracts of pristine forests and a host of forestry operations. Although the school is a long way from being energy self-sufficient, the process is in full swing.

Back in 2007, the university committed to becoming a leader in renewable energy in the province through the introduction of a multi-year green energy plan. Soon after, it implemented two projects – a wood pellet boiler and a wood residue gasification system.

the introduct projects – a woo

Danielle Smyth, sustainability manager at the University of Northern British Columbia (UNBC), says the shift towards green heat and power was not due to some large initiative, but something much simpler. It came about, she says, primarily because a large number of the university’s students were enrolled in environmental programs.

SM Danielle Colum to som primari environ

“We have always had some strength in our research and teaching in the areas of environmental issues, sustainability, ecological issues and resource-based economy,” says Smyth. “We’re in a place that has an intersection of relying on our natural resources for jobs, but also needing to balance that with sustainability and ensuring that we have resources long-term.”

This manifested itself in the formulation of a green energy plan in 2007, when area wood pellet producers first approached the university to create a pilot wood pellet-heating project. In 2009, the first university-owned and -operated biomass-heating system in Canada was installed, which was designed to provide all the heat necessary for the Enhanced Forestry Lab greenhouse.

David Claus, the assistant director of facilities for UNBC, says

LEFT MAIN: The wood pellet biomass boiler is the first university owned and operational system in Canada and is used to heat the I.K. Barber Enhanced Forest Laboratory.

INSETS:

that the boiler has a 400 kW peak capacity using pellets from Pacific Bioenergy in Prince George, but the output for the relatively small system fluctuates depending on the season.

“While running, the pellet system is providing all the heat for the building, and most days, the heat demand of the building is not high enough for it to reach its max output capacity.”

After the success of the wood pellet system, the university decided to take another step and find a technology provider that could produce energy from wood residues. Vancouver-based Nexterra Systems Corp. was selected. Following that, $15.7 million was raised from three sources –the Knowledge Infrastructure Program, the Public Sector Energy Conservation

Agreement and the Innovative Clean Energy Fund, with the project becoming operational in January 2011.

The goal of the system was to displace a significant portion of the natural gas used for heating the core UNBC campus through local wood residues from a five-year supply plan with Lakeland Mills, a sawmilling company in Prince George. The residues vary in content depending on what the

supplier is sawing, which gives the university a large variety of test material to determine which mix works best.

“The gasification process had a number of things going for it,” says Claus. “It was developed in B.C. and it was all part of the plan: the pellet system was Phase 1, the biomass gasification system was Phase 2 and we have a plan in mind to

go to a Phase 3, which would generate electricity.”

One option for Phase 3 that is being considered is the process that the University of British Columbia is using – diverting the syngas accumulated from the top of the gasifier, cleaning it and generating electricity via an internal combustion engine. However, that is only one option

for the problem and still very early in the planning stages.

One area of research that the university is also looking into is heat recovery, as the gasifier radiates significant amounts of heat while in operation. If this heat were captured, it could be used to heat other buildings, such as the student residences, says Claus. However, there are still challenges

that must be overcome to accomplish that.

“The way we utilize that heat is we pipe it throughout the district heating system on buildings across campus, and that heating system operates at 115 C (240 F),” he added. “And in order to utilize any waste heat that we recover from the gasifier, we would have to raise the temperature of the heat to a higher temperature than the water loop, which would require an

additional input of energy.”

Another issue would be how often the heat would be needed during the summer, when the gasifier is not running at full capacity.

Still, even in the current configuration, the gasification system saves the equivalent of around 63,000 GJ of fossil fuels, or the energy required to drive a car around the world 391 times.

Continued on page 35

The new Morbark ® Advantage 3™ high-per f ormance chipper drum gives you improved biomass fuel chip qualit y, reduces your costs, and is backed by a limited three-year warrant y. It comes standard on most new Morbark drum chippers and can be retro fi tted to most Morbark units without modi fi cation. Either wa y, y ou g et three si g nificant advanta g es:

– The Advantage 3 is wider, has higher inertia, and incorporates Babbitt-st y le counter-knives, so it produces better, more consistent chips.

– The drum’s AR 400 heat-treated steel skin, enhanced kni fe desig n, and recessed pockets provide wear-part and maintenance cost savin gs of more than 70%.

– The Advanta g e 3 comes with a limited three-year warrant y, and is supported by Morbark’s extensive dealer network for unsurpassed peace of mind.

The exceptional Morbark Advantage 3 chipper drum comes standard with most units in our full line of heavy-duty industrial drum chippers. Learn more at www.morbark.com or call 1-800-831-0042.

At UNBC, there are a vast number of other green initiatives that do not have to do with energy generation. The students and faculty simply want to create a greener and more environmentally friendly environment, says Danielle Smyth, sustainability manager at the University of Northern British Columbia (UNBC).

“There is a compost and food-scrap program that has been maintained and operated by students since 1995,” she added. “And the compost is used in the organic garden located near our student residences and throughout our campus grounds.”

One of UNBC’s largest initiatives is the “Green Fund,” which is a funding program for projects carried out by staff, faculty or students of the university. The program receives $50,000 per academic year to distribute, and interested individuals can apply.

According to Smyth, 10 projects have been funded since the fund’s inception in 2009, with students and staff outfitting residences with recycling bins, conducting research on renewable energy on campus and helping students plan, create and build a new geodesic dome greenhouse.

All of these initiatives were put in place because there was a distinct lack of outreach and programs that would help students become more engaged in their studies and in helping the environment.

“I think what we’ve realized from these projects, as well as our green energy initiatives,” says Smyth, “is that this topic of renewable energy and sustainability is of interest to students. And maybe they aren’t getting these opportunities in the classroom, so they are seeking out other opportunities such as directed studies and internships.”

There are also a variety of studentdirected research projects on topics such as renewable energy, sustainability and optimization, all of which could be used to make UNBC a greener place to be.

Ontario’s first production pellet mill starts up despite delays and challenges.

By Scott Jamieson

an odd place to build a wood pellet plant, but then the original goal wasn’t to make pellets from wood. The pellet plant in Springford, Ontario, owned by Canadian Biofuels Inc. started production in March 2012 as an energy supplier surrounded by orchards and farmland, hundreds of kilometres from any serious wood products industry.

The one-mill plant is currently running on wood waste from communities across southwestern Ontario, which has turned out to be an excellent raw material, explains president and CEO Ian Moncrieff. Still, it’s not quite the feedstock the entrepreneur had in mind when he cooked up the idea over five years ago.

“I’m an environmental planner by trade, and was working part time as a professor with the University of Guelph at the time,” Moncrieff explains. In fact, that aca-

demic background is not hard to believe as he settles in to recount the history of Canadian Biofuels and agro-biomass 101.

“I was approached by several greenhouse operators from Leamington, a vegetable growing area south of here. They had switched to biomass in the face of $8 and $10 natural gas,” he says. “They were using ground wood waste, and at the time the Ministry of the Environment was looking at some onerous regulations that would have discriminated against biomass. Here were a bunch of growers trying to divert 250,000 tons of wood waste from landfill to displace fossil fuels, and the government was trying to do whatever it could to discourage it.”

Moncrieff was part of a successful lobbying effort to avoid the new regulations. In the process, he was introduced to a group of small to medium-sized greenhouse operators who wanted access to

pellet boiler technology, but had no local industrial pellet supply.

The first step was to look at the massive supply in British Columbia, but the westto-east rail costs made the option more expensive than the inflated natural gas prices. Moncrieff was looking for other options when his wife Roberta, who has been involved in the operation since the beginning, came across examples from Austria of pelletizing purpose-grown energy crops.

“The criterion was that they were to be grown not on good crop land, but marginal land. At the time the local tobacco industry was vanishing, and local development agencies were looking for something to replace part of it using the region’s sandy soils. This seemed to fit the two needs.”

Moncrieff started looking into government programs aimed at diversifying the region away from tobacco, and approached several communities to gauge interest. It

all seemed to click, as he found a very receptive audience in the Township of Norwich, about 40 minutes south of London, located a site and got financing lined up. And then the bottom fell out like it did for so many alternative energy projects.

“The fall of 2008 hit, and all credit basically evaporated, putting everything on hold,” Moncrieff recalls.

When the dust cleared in the spring of 2009, it was back to the drawing board. By December, Canadian Biofuels had acquired a new site, an old Cargill grain elevator operation in Springford,

Approximately

World-class

Multi-disciplinary

and had sold an associated grain dryer to generate enough cash to start designing the mill. In the spring of 2011, the company sealed a financing mix that included an investor, the Royal Bank, and the Sand Plains Development Fund (a tobacco diversification program), and started putting the plant together.

By the summer of that year, Canadian Biofuels was running a pilot pellet mill, complete with feed hoppers, conveyors, a vertical mill and cooler. The main goal was to test feedstocks prior to committing to any one option.

“We’ve got a number of feedstock options, from recycled wood to agricultural by-products and purpose-grown crops,” says Moncrieff.

“The small mill is noisy, but it makes high quality pellets, and on a good day it’ll make 300 to 400 lb/hr, which allows us to mix and match feedstocks, run them through the lab and test them in our own stoves.”

One early option was a local supplier, but test runs, lab work and test burns proved that it was too contaminated. “Ash was above six per cent, and our stoves

were basically choked after an hour.”

Soon after, however, they found a supplier willing to put the work at creating a clean supply – a local waste management company, Norfolk Disposal, set up a sorting system and grinder at a nearby greenhouse. The mixed or contaminated recycled wood stream goes to the greenhouse’s more forgiving boilers, while the clean manufacturing off cuts and stock is ground to the 1/4-in size range and delivered to Canadian Biofuels.

“They want to work with us, they’re sorting, it’s all on an asphalt pad, so there is no contamination, no rocks, no grit. From that supply we’re in the less than one to 1.5 per cent ash range.”

The resulting pellets also test in the 8,500 to 8,800 btu/lb range. When running full tilt, the mill will require three to four walking floor trailers a day of ground material, and Moncrieff says the supplier has more than enough in the pipeline.

“We started off thinking we’d be using agricultural feedstock, and we eventually will, but right now we have a quality supply that is costing well within our

economic model, and on top of that we’re diverting significant volumes away from landfill. It’s not a bad model.”

The production process itself is about as simple as a pellet mill gets. Fibre is delivered by the contractor in walking floor trailers and unloaded under the cover of a brand new MegaDome structure. The arched building was affordable, supplies excellent natural lighting and is easily expanded, says production manager Russ Carroll.

“Material arrives at between eight and 11 percent moisture, although the mill has handled up to 15 percent without issue,” he explains. “To date, we have not needed a dryer, but we have priced one should we change feedstocks and require one.”

The company is looking at adding a hammer mill to create a more consistent raw material, and it would be located outside for safety, even though the fibre makes quality pellets.

Currently, fibre is carried right into the mill via two stationary walking floor trailers, a unique system that was driven by

the need to control cost and complexity.

“We looked into various infeed options, which were pricy, and in the end they all served the same basic function as a walking floor. We got that one at $6,000 and the other at $15,000,” he says while pointing at the two reconditioned trailers. “We added power packs and tied them into the PLC, and we were off to the races.”

From here, fibre goes across an Eriez magnet to pull out tramp metal, and then to the solitary Muench pellet mill. The

Muench unit was chosen after discussing options with local pellet mill supply and service experts at ANBO and Dorssers.

“We’ve been very lucky to have these two pellet industry suppliers close by in Blenheim, to sound off design and equipment ideas, and ANBO helped out with design and start up. We were looking for something that would give us a long life, was easy to maintain, reliable, and reasonably priced. This was one of the designs they suggested.”

A hammer blow to your operating costs. The hammer mill Granulex™ is the new dynamic grinding machine from Buhler. Designed for ultimate power, Granulex™ delivers high capacity grinding up to 15 t/h for wood and 75 t/h for biomass. Heavy design and supreme ease of maintenance minimize downtime, so you can make maximum use of this productivity. It’s an investment in quality that is sure to show a rapid return – and deliver a hammer blow to your operating costs.

Bühler Inc., PO Box 9497, Minneapolis, MN 55440, 763-847-9900, buhler.minneapolis@buhlergroup.com, www.buhlergroup.com

Innovations for a better world.

Pellets are conveyed to a reconditioned counter-flow cooler acquired from ANBO, and then off to a 72-ton storage facility via a Farm King screening system. The mill’s bagging line is designed to keep up with two pellet mills, as the facility was designed to easily add a second mill right next to the first as sales grow.

Annual production capacity is currently 25,000 tons, and Canadian Biofuel was already building inventory in both bags and totes when we were on site in late March. While the initial goal was to supply local greenhouses, the recent collapse in natural gas prices means that most of these would-be clients are burning very little biomass these days.

“We’ve looked elsewhere as a result,” Moncrieff says. “We’re marketing to consumers who are off the natural gas grid, so competing with oil, propane or electricity. In those cases we can shave 50 percent off their heating bills. There are also some greenhouses still using biomass. We’ve also been in discussions with locally-run hardware chains who are intrigued by a local supply.”

Of course the 25-degree weather southern Ontario was enjoying in March was not helping matters, but Moncrieff remains confident. Nor has he forgotten his dreams of growing tomorrow’s energy in the sandy soils off Lake Erie.

The company is involved with several local players and trials evaluating purpose-grown crops like miscanthus, and in fact has done some pelletizing and burning trials using a local supply. It is also the aggregator and pelletizer for a $2.6 million research trial involving the Ontario Federation of Agriculture (OFA), Ontario farm research organization OMAFRA, Ontario Power Generation and 900 test acres of fuel crops. Canadian Biofuels is also discussing participating in torrefaction trials with researchers at the University of Western Ontario in London.

“We still see that as the end game. With 12,000 to 15,000 acres of miscanthus, we could make 100,000 tons of pellets here no problem, and that would all come from within a 20-kilometre radius on marginal soil. We have some projects on the side to get us there, but right now the focus is on the core business. We need to get the mill running full out as is,

Forest health dictates that we make more of the biomass available

By Robert W. Gray

THEREis a significant volume of biomass on the landscape in British Columbia that needs to be removed to improve ecosystem resilience and sustainability, and reduce the threat of wildfires. Standing in the way of dramatically increasing biomass extraction are market impediments and access to feedstock constraints.

Recently, the Commissioner of Public Lands for the State of Washington, Peter Goldmark, announced a Tier Two Forest Health Hazard Warning. The concern is that tree mortality is predicted to increase significantly across 900,000 hectares of eastern Washington due to a combination of climate change and past management, which has left forests overcrowded and highly stressed. And the same can be seen in British Columbia.

Another warning came during the American Association for the Advancement of Science conference in February 2012 when Dr. Mike Flanagan from Natural Resources Canada predicted that climate warming is already leading to longer fire seasons and more intense fire behaviour.

Restoring ecosystem sustainability and resilience in the face of a warming climate, and countless disturbance agents, is predicated on reducing the stress to the system. It means reducing density through lowering competition for moisture, nutrients and sunlight to make healthier trees, as well as reducing fuel loading to help make more resilient forests.

Unfortunately, the material we need from the forest has very little economical value as a sawlog, which is one of the forest’s higher value-added products. It does, however, have value as a raw resource in the bioenergy sector, where it can be converted into such forms as wood pellets, syngas and biochar.

There is a complicated set of variables involved in determining how economically feasible it is to access biomass on the landscape, such as the costs associated with getting the wood to the landing, sorting and processing, and transporting it to a manufacturing facility. Difficult terrain, low-volume stands and long transport distances all combine to increase the cost of the raw resource and dictate which stands can be treated. Obviously, the higher the value of the end product, the more biomass you can access economically.

Currently, much of the waste biomass is being steered toward power (electricity) production. At current rates, the sale of power from cogeneration plants is so low that the production of electricity is subsidized. The subsidies come in many forms, such as reduced stumpage on Crown timber sales, harvest operations and hazardous fuel treatments that provide free feedstock, free mill site waste and more.

This fact has led to a scramble on the part of the industry and government to identify all the sources of low-cost feedstock currently residing in the system. As a consequence of this focus on the electricity market and its limitations, significant volumes of biomass on the landscape are not being accessed, and will continue to be a significant fire hazard. Most importantly, the province is losing out on a potentially lucrative global demand for solid and liquid bioenergy products that could in turn generate significant employment and tax revenues.

Reports such as the recent Bio-Economy Report, commissioned by the B.C. Ministry of Jobs, Tourism and Innovation, and Dovetail Partners, Inc.’s 2011 report, Potential Impacts of Climate and Energy Policy on Forest Sector Industries: Providing Incentives for Bio-Energy While Protecting Established Biomass-Based Industries, have correctly identified the problem as one of transition and transformation out of old industries and into new ones.

For the forest health crisis in British Columbia, the B.C. government should lead the process of sector transformation, determine the highest and best use of the biomass so that it constitutes a social and economical benefit to not only Canadian and multinational corporations but also the rural communities of British Columbia, and begin the transformation sooner rather than later.

For more information, please see the complete article online at:

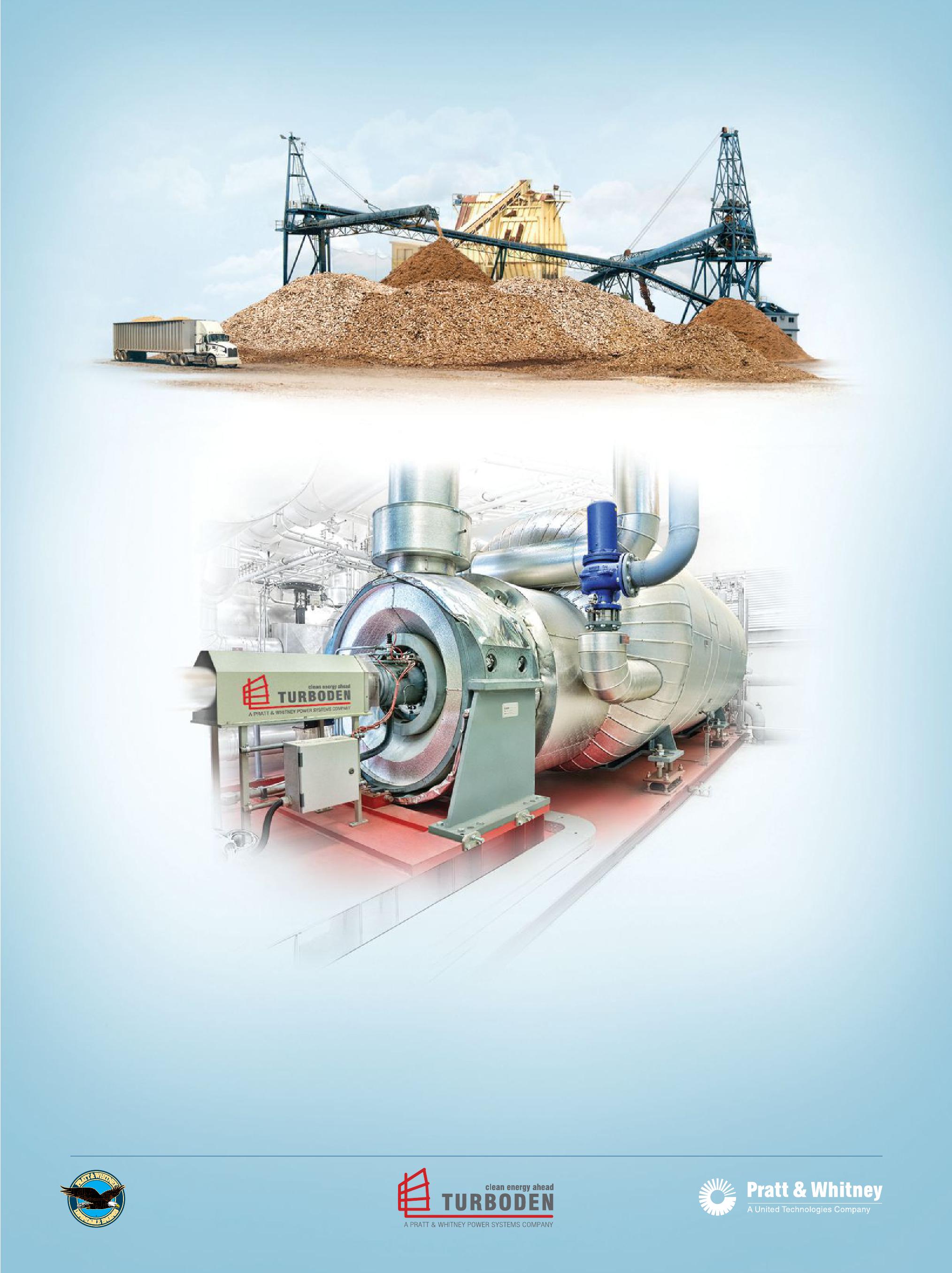

Don’t lose the megawatts trapped in your waste wood. Install our Organic Rankine Cycle (ORC) biomass system to convert logging and mill residues or insect-affected wood – virtually any high-organiccontent waste – into clean, renewable electricity. ORC units generating 1 to 10 megawatts can be easily integrated into your process. Find out how to turn biomass into megawatts, reduce your carbon footprint and bring savings to your bottom line. Visit www.turboden.com or call 1-866-769-3725 to learn more.

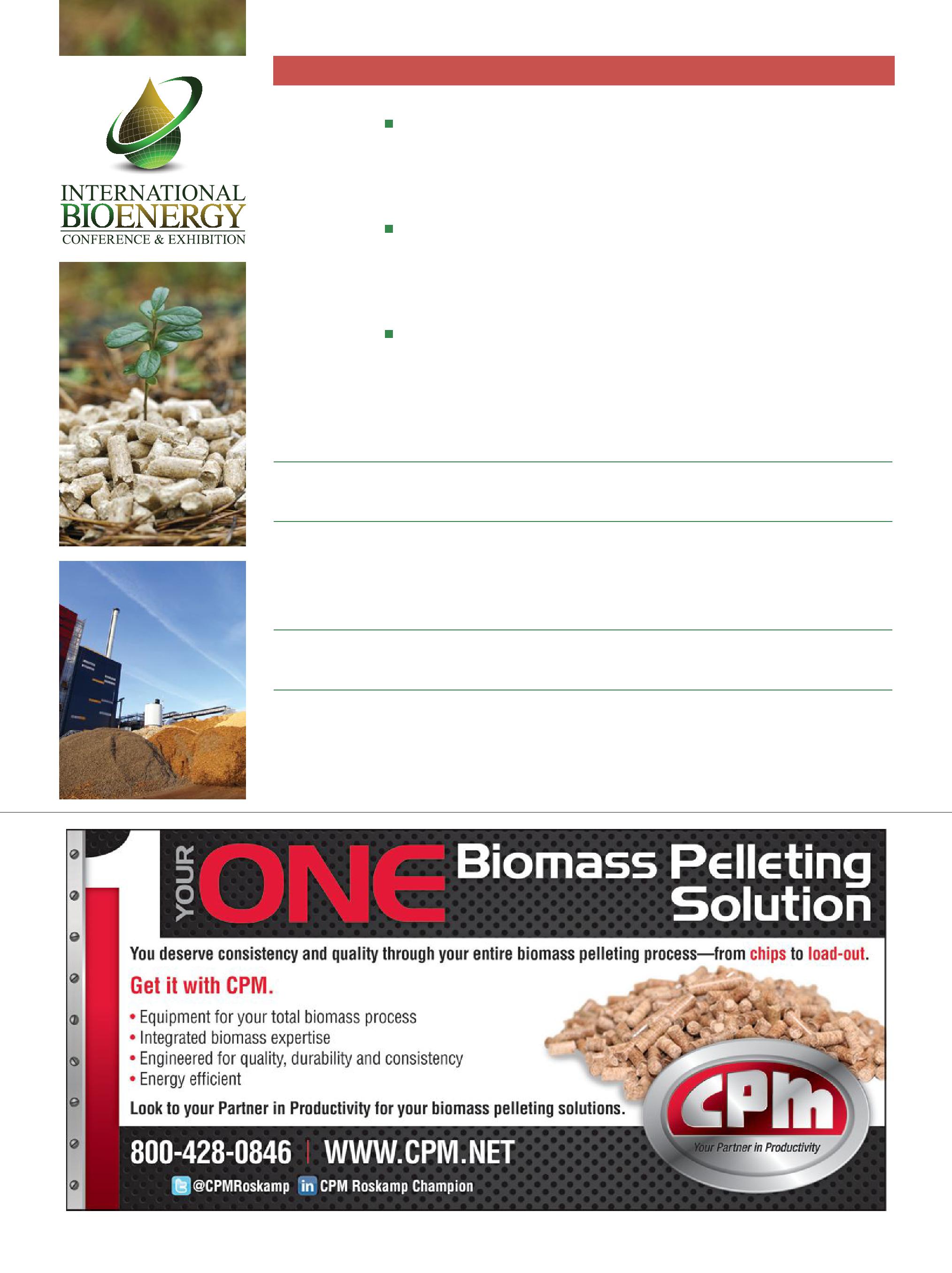

WEDNESDAY, JUNE 13

10:005:00 International Partnerships Forum Sponsored by Northern Bioenergy Partnership and Business to Business Meetings

Location: Coast Inn of the North

5:307:30 5th International Bioenergy Sponsored by University of Northern British Columbia Conference and Exhibition Opening Reception

Location: University of Northern British Columbia

THURSDAY, JUNE 14

7:00

8:00 Welcome

8:30

9:45

10:15

Around the World in Half a Day: Global Game Changers

Sponsored by RBC

12:00

Overview of the issues facing the bioenergy industry worldwide. Moderator: Doug Bradley, Executive Director, Canadian Bioenergy Association

The European Union on its Way to 202020

Perspectives from North America

Industry Perspectives on New and Emerging Markets

The Future of Fibre

Bioenergy, forest products and the availability of fibre

BC Forest Tenure System and Options for Fibre

B.C. Interior Bioenergy Fibre Supply–The Economic Balancing Act

Sponsored by Deloitte

Resolving Wildfire Risk in BC Through Development of Community Based Bioenergy

Forest Products Sector View on Fibre and Bioenergy

FP Innovations’ Fibre Outlook and Use for Bioenergy Applications

Keynote Speaker: Andrew Soare, Analyst, Lux Research, United States Global Biomass Value Optimization

1:30 Sustainability: The International Experience

Finding the balance between environmental and economic sustainability Moderator: David Moffat, Managing Director, Business Development, Pacific Carbon Trust, Canada

Opportunities and Options for BC in the Global Carbon Market

European Perspectives on Burning Biomass Sustainability Issues

Bioenergy: Carbon Neutral or Not?

2:50

3:20

Outlook Bioeconomy

6:00

Sponsored by Scotiabank

Adding value to the bioenergy industry in BC and around the world.

BC Bioeconomy: Opportunities and Challenges

Sweden’s Story: Evolution of a Bioenergy Leader

Trees: New Zealand’s Future Oil Wells?

Global Market Pulp Industry : Implications of Bioenergy/Bioproducts on Pulp Industry Cost Structure

Sponsored by Deltech

FRIDAY, JUNE 15

7:00

8:00 Concurrent Sessions

Bioenergy Deployment Today

Sponsored by BC Safety Authority

Sponsored by Radloff & Associates

Moderator Pearse Walsh, Director Business Development, BC Safety Authority

Advancements in Municipal and Community Energy

Moderator: David Dubois, Green Heat Initiative

Pellets in the New Bioeconomy

Sponsored by Wood Pellet Association of Canada

9:40

Sponsored by BMO Financial Group

FRIDAY, JUNE 15

10:10 Concurrent Sessions

Advanced Bioenergy Technologies

Sponsored by Sustainable Development Technology Canada Moderator Russell Girard, Manager, SDTC

First Nations, Remote Communities and the Bioeconomy Moderator Angeline Nyce, Davis LLP

Pellets for Power and Heat Sponsored by Wood Pellet Association of Canada

12:00 Sponsored by Pacific Bioenergy

Keynote Speaker: Doug Konkin, Deputy Minister, BC Ministry of Forests, Lands and Resource Operations

1:30 Torrefaction Technical Session

Moderator: Michael Weedon, Executive Director, BC Bioenergy Network

1:30 Site Tour Sponsored by Nexterra

VAS Energy Systems GmbH 1 www.vas.co.at

Cdn Manufacturers & 2 Exporters www.cme-mec.ca

Pratt & Whitney 3 www.pw.utc.com

Bioenergy 12 Partnership www.bioenergypartnership.ca

Northland Chipper Sales Ltd 13 www.northlandchippers.com

Pinnacle Renewable Energy 14 www.pinnaclepellet.com

Biomass Energy Lab 4 www.biomassenergylab.com Davis LLP 15 www.davis.ca

Metso 5 www.metso.com

Jansen Combustion 6 www.jansenboiler.com

Wellons 16 www.wellons.ca

University of Northern BC 17 www.unbc.ca

Manufacturing 24 www.viessmann.ca

Ltd. 25 www.uponor.ca

26 www.cogentpowerinc.com

Power 27 www.altentech.co

Power 28 www.altentech.co

www.westernbioheat.com

Pellet Mill 47 www.cpm.net

48 www.tsi-inc.net

www.brunetteindustries.com

50 www.andritz.com Scheuch Inc 7 www.scheuch.ca

LSJ Publications 8 www.forestnet.com/lsj

Combustion 18 www.mpcpsystems.com

BioHeat 29 evergreenbioheat.com

51 www.andritz.com

Biomass Magazine

www.canadianbiomassmagazine.ca Bandit Industries 9 www.banditchippers.com

Buettner 10 www.buettner-dryer.com

Proton Power 11 www.protonpowerinc.com

By Hakan Ekstrom

exports from North America to Europe reached a new record high in the fourth quarter of 2011. Shipments have increased practically every quarter for four years, up from 130,000 tons in the 1Q/08 to almost 600,000 ton in the 4Q/11, according to the North American Wood Fiber Review (NAWFR).

Export data collected by NAWFR (www.woodprices.com) from exporters and customs information in both North America and Europe show that wood

pellet shipments reached just over two million tons in 2011, up almost 300% from 2008.

Pellet producers in British Columbia have been the major exporters since the first shipments 12 years ago, but this changed in the second half of 2011, when expanded investments in capacity in the US South put US shipments on par with Canada.

Six pellet export plants, widely varying in capacity, are now operating in the U.S. South. Four others have shipped trial

shipments the past six months and six additional export-oriented pellet plants have been announced, making it highly likely that there will be significant export growth over the next 24 months.

In Eastern Canada, exports in the 4Q/11 remained unchanged from the previous quarter, when volumes declined primarily due to the closure of the Enligna pellet plant in Nova Scotia. However, there are plans to re-start the idled plant later this year by a new owner.

In 2012, small increases in volumes

from both the United States and Canada will likely occur, with more significant export growth due in 2013. At that time, new export-oriented pellet plants being constructed are scheduled to begin operations.

On the receiving end of pellet exports to Europe, utilities in the Netherlands, the U.K. and Belgium continue to be the largest consuming destinations of North

American pellets, with the U.K. showing the steadiest and most vigorous growth.

The North American Wood Fiber Review has tracked wood fiber markets in the United States and Canada for over 20 years and it is the only publication that includes prices for sawlogs, pulpwood, wood chips and biomass in North America. The 36-page quarterly report includes

wood market updates for 15 regions on the continent in addition to the latest export statistics for sawlogs, wood pellets and wood chips.

Hakan Ekstrom is the president of Wood Resources International, market analysts and consultants out of Seattle, Wash. He can be followed on Twitter @barr09.

Dieffenbacher USA, Inc.

2000 McFarland 400 Blvd. | Alpahretta, GA 30004

Phone: (770) 226-6394 | mail@dieffenbacheratl.com

www.dieffenbacher.com

Funding organizations can often be the difference between exciting innovations moving forward or sitting on a shelf.

By David Manly

Columbia is well known for its natural resources, especially its beautiful forests that seem to stretch endlessly into the distance. Therefore, it is no surprise that bioenergy and biomass have found a perfect home here.

In mid-February, Canadian Biomass visited BC Bioenergy Network (BCBN), a not-for-profit society that specializes in funding bioenergy technologies and capacity-enhancing programs for industries, private companies and communities throughout British Columbia.

“Our mandate is focused on networking to build a world-class bioenergy industry in British Columbia,” says Michael Weedon, executive director of the network. “And developing such an industry is really quite a huge challenge – you need

assertive companies, creative communities, and you need visionary policy, leadership and support.”

BCBN achieves this by investing in and supporting companies and innovations through a $25-million grant provided in 2008 by the B.C. Ministries of Environment, and Energy, Mines and Petroleum Resources. In the four years since it was founded, BCBN has allocated roughly half of its funding through investments, loans and contributions for capacity-building projects.

Since BCBN only funds a partnership portion of the total cost for each project, the accrued value of all investments is $78 million from spending a total of $13.2 million, or just slightly over half of its budget. By leveraging its investments with other partners at a ratio of 6:1, BCBN is able to invest in much larger projects than it would normally be able to do on its own.

According to Weedon, the goal of these investments under the mandate is to advance technology and thereby generate jobs, trigger economic and social development, produce real environmental benefits, and create a sustainable energy export business, with BCBN acting as a catalyst to help foster and grow these opportunities.

The projects that BCBN supports fall under three main categories: forestry, municipal and agricultural, with the bulk of initial funding split between municipal and forestry initiatives. However, each project has applications that can influence or improve the others.

The network currently has 23 projects in various stages of development, with the distribution split into 11 large technological development/demonstration projects and

12 capacity-building projects (such as providing staff and equipment).

One of BCBN’s largest investments is with Nexterra Systems Corp. for $3 million. It comprises two parts.

The first focuses upon research and development to demonstrate and produce ultraclean synthetic gases that can be used as low-emission gases for heating or use in a reciprocating engine to produce electricity at Nexterra’s Kamloops research and development centre. The second is to support a commercial demonstration for the installation of a gasifier and reciprocating engine at the University of British Columbia to produce both hot water and electricity.

With these types of projects, the biggest obstacle is not the technology, but people’s misconceptions about the emissions from woody biomass renewable fuels, says Scott Stanners, director of research at BC Bioenergy Network.

“Most of the general public are not aware that biomass can be combusted or gasified and result in emissions of particulate matter that are cleaner than natural gas. Many people believe that burning wood residues will generate dangerous emissions that can be toxic,” says Stanners.

“In fact, with the development of new technology and appropriate emissions abatement systems, emissions from woody biomass have reduced 1,000-fold over the past 40 years and can demonstrate energy efficiency upwards of 90% with technology available today.”

Another area of research that BCBN is excited about is in partnership with Lignol Innovations Ltd., representing another $3 million investment.

The project aims to covert lignocellulosic biomass into fuel ethanol at a demonstration plant, according to Weedon. The plant will also be able to produce specialty chemicals such as high-purity lignin that could be used to replace carbon fibre.

“The future of energy is going to be based upon local use of resources, local transformation and local consumption,” he said. “It will be increasingly difficult to afford to ship energy all over the world as fuels become more expensive.”

With a growing concern about the current global energy supply, BCBN selects projects to invest in that have both present benefits and future potential.

When a project is submitted to BCBN for approval, the researchers or companies create an expression of interest to describe the research or project, how it fits the mandate, and how it can be further developed.

From there, the ideas are explored, researched and examined for suitability, innovation and feasibility by the board of directors before a decision is made on an economic, environmental and social basis. One of the best criteria to judge by, according to Weedon, is if the research is truly novel and will broaden the use of the energy source through using low-cost feedstock or

Since 1976, Jansen Combustion and Boiler Technologies, Inc. (JANSEN) has provided customized engineered solutions to owners/ operators of boilers in the Forest Products and Waste-to-Energy Industries.

Our mission is to improve the operating performance (fuel burning capacity and economy, efficiency, and emissions performance) of existing boilers that burn difficult fuels such as biomass, chemical spent liquors, municipal solid waste (MSW), refuse ( SW) f derived fuel (RDF) and tire derived fuel (TDF) JANSEN has conducted engineering performance evaluations of over 300 boilers, worldwide, and has provided combustion system and/or superheater upgrades of over 80 biomass, chemical recovery, MSW, and RDF boilers

JANSEN has the capability and experience to function as your one-source solution to boiler retrofit projects. With the ability to define, engineer, contract and manage design-construct projects, we offer EngineerProcure-Construct (EPC) capabilities.

A synopsis of our broad range of services:

> Full service engineering design for steam, power, and combustion systems

> Biomass, MSW, RDF, TDF, fossil fuel, and chemical recovery boiler performance evaluations

> Effective overfire air (OFA) delivery system upgrades on biomass and other waste-fueled boilers

> Replacement or upgraded superheater design and supply

> Boiler circulation analyses

> Computational Fluid Dynamics (CFD) modeling

> Feasibility studies and cost/benefits analyses

> Emissions reduction (CO, NOx, PM, SO2, TRS, VOC)

> Operations support and training

reducing the cost of energy production.

“We look at technology that fills a gap or is very appealing,” says Stanners. “Then, if it has a good chance of being implemented as claimed, we go through

a contracting stage where we either make a contribution agreement with milestones or go through a loan process. Then we follow up and track the results and share a company’s success with others.”

Allied brings 35+ years experience in industrial air systems. Allied’s combination of design, supply, installation & maintenance services provides lower project cost, on-time completion, smoother start-up and less downtime – adding value and safety to your operation.

Complete solutions with extensive experience

But, direct funding is not the only way BCBN can help.

While most expressions of interest seek funding, the network has other ways to help, such as networking, bringing in other funding agencies and making future recommendations about the project.

“We try to provide value in some form to every potential project,” says Stanners, “even if we do not provide direct funding.”

Recently, BC Bioenergy Network was invited to present to the British Columbia Bio-Economy Legislative Committee on 10 bioenergy opportunities that show great potential across the province. The presentation highlighted a variety of technological and industrial innovations that have the potential to advance the bioeconomy.

In the presentation, the first two opportunities discussed utilizing organic waste streams to displace fossil fuels and torrefacted wood to displace coal. These processes have the greatest potential for growth in British Columbia because they allow for the continued use of existing infrastructure, which can reduce overall project costs.

“You want to use existing infrastructure or plants,” said Weedon, “and the oil and gas industries have long been experts at this – taking fossil fuels and using every component – the same principles need to apply to energy from biomass.”

Other options discussed included district heating systems, supporting off-grid remote communities, biochemical production, improved biomass drying and finding uses for underutilized/damaged wood.

Ideally, BCBN would like to fund every one of these projects, but with a limited budget, members have to select those that meet their mandate and seem the most likely to succeed within a near term time frame.

But, that is not their ultimate goal.

The network’s role is to kick-start a bioenergy industry, both within British Columbia and across the rest of Canada that has the potential to create affordable, safe and renewable energy. And the best way to accomplish that, added Weedon, is through fostering growth, development and innovation.

“Our ultimate legacy will be the investments, growing them and having others

Continued from page 16

At UNBC, the total amount of energy used per year is approximately 179,000 GJ, with 60% provided by natural gas and the rest from electricity via BC Hydro. But, with the implementation of the gasifier, the bioenergy plant replaces about 85% of the natural gas used for district heating, says Claus.

“The other 15% is used for peak load, for when it is too cold for the bioenergy plant to supply all the heat, and also during the two one-week shutdowns per year. During those times, we will take heat from the original natural gas boilers.”

Claus does not see the natural gas boilers going anywhere anytime soon, as the university still needs a back-up system in place for the core buildings. As well, there are several areas of the campus that are not connected to the bioenergy loop yet and still require natural gas for heat and/or fuel.

“When you buy natural gas, pretty much your entire energy dollar is spent on fuel with fairly low maintenance and operation costs. When you make the shift towards biomass, your fuel costs typically go down, but your maintenance and operational costs go up.”

And in the warm summer months, when little heat is needed, the biomass solution begins to make less economical sense when compared to natural gas. The reduced energy needs of a building in the summer may mean that the fuel cost savings are insufficient to offset the maintenance and operational costs that are constant through those months.

In the future, UNBC would like to continue to operate and improve both the pellet system and the gasifier, as well as continue the education and research mandates already in place. In addition, there has been a push towards creating an electrically self-sufficient university.

To do so, says Claus, would require further expansion of the biomass system to include up to 2 MW of power generation. And once the university figures out how to create such an isolated and selfsufficient system, it can be put into use for remote communities all across British Co-

Visit www.britishcolumbia.ca/!bioenergy

Biomass harvesting in the Northeast Superior

Community examines impacts on and implications for productivity, biodiversity and the bioeconomy.

By Paul Hazlett, Dave Morris and Rob Fleming

Acomprehensive biomass harvesting experiment is taking place in northeastern Ontario thanks to Tembec Chapleau Operations. The Island Lake Biomass Harvest Research and Demonstration Area in the Martel Forest is a collaborative project designed to examine the impacts of intensified biomass harvesting and provide a venue where forest community members can observe and learn about the process. Project results will be used to refine forest management guidelines to ensure forest sustainability.

Tembec has teamed with community partners, the Northeast Superior Forest Community (NSFC) and the Northeast

Superior Regional Chiefs’ Forum (NSRCF) in addition to Ontario Power Generation (OPG), FP Innovations, Forest Research Partnership (FRP), Ontario Ministry of Natural Resources (OMNR) and Natural Resources Canada – Canadian Forest Service (NRCan-CFS) to implement this large-scale field experiment.

Canada’s forest bioeconomy is developing at a rapid pace and in the coming years, may become an even more important part of local forest economies.

Currently, a seven-megawatt wood-fired thermal electric generating facility at the Tembec Chapleau site provides electricity to the Ontario grid and steam for sawmill operations. Stakeholders in forest communities across Canada and around the world are concerned about the possible long-term impact of biomass harvesting on long-term site productivity and biodiversity, and therefore thoughtful initiatives are required to steer bioeconomy research to ensure that forests remain healthy and sustainable.

Scientists from the NRCan-CFS Great Lakes Forestry Centre in Sault Ste. Marie and the OMNR Centre for Northern Forest Ecosystem Research in Thunder Bay are co-leading research activities at the Island Lake site, where an irregularly spaced 40-year-old limby jack pine stand on a sandy, glaciofluvial outwash soil was targeted. While these site types have flat terrain and all-season accessibility well suited to more intensive utilization, there are concerns that intensive biomass removal may result in excessive nutrient depletion and loss of

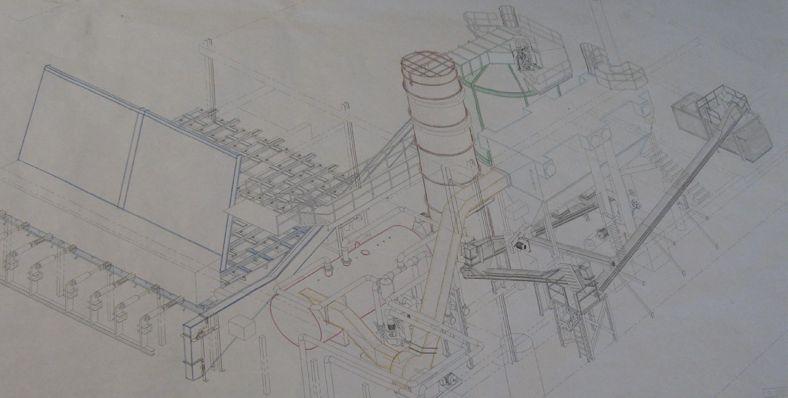

The overall silvicultural objective of the project was to provide stand improvement through biomass harvesting of the 40-hectare block, followed by site preparation, planting and vegetation control. Harvesting at the site recovered 5040 m3 of tree-length sawlogs (10% over forecast) and this was complemented with grinding and hauling of 4373 green metric tonnes of previously unutilized biomass (more than 100% over forecast).

During 2011, Tembec Chapleau led operations to provide experimental plot treatments that spanned the broad range of potential biomass harvest intensities using the clearcut silvicultural system.

These included tree-length (stem-only) harvest, full-tree operational commercial biomass harvest (including unmerchantable material as well as tops and branches), full-tree biomass harvest plus stump removal and full-tree biomass harvest with removal by blading of coarse woody debris (standing and downed), stumps and forest floor. Increased utilization of the

INSET: Tembec Chapleau provided wood ash waste from the cogeneration plant to apply at various levels to the additional full-tree biomass harvested plots.

aboveground portion of the forest stand during full-tree operational harvest was the most likely scenario for biomass harvesting, and was therefore applied across the harvest block outside the core experimental plots.

To add greater value to the overall project, Tembec Chapleau also provided wood ash waste from the cogeneration plant to apply at various levels to the additional full-tree biomass harvested plots.

In this supplementary experiment, the application rates were selected with the goal of fully replacing the additional nutrients removed by the full-tree biomass harvest, as well as providing it at one quarter, one half and two times this amount.

Wood ash waste is currently landfilled at a cost to the forest industry, but site remediation using it could potentially maintain

or increase soil fertility and forest productivity as well as save on disposal costs. The research is also addressing the concern that wood ash waste applied as a soil amendment could have adverse effects on water and biodiversity in forest ecosystems.

Working with skilled harvest operators and the OMNR, Tembec Chapleau was also able to test the practical implementation of new Stand and Site guideline

residual retention parameters during the harvest at the Island Lake site.

A portion of the stand left as residuals was stubbed during harvest operations to provide wildlife trees and emulate the physical properties of trees killed by wildfire.

Researchers are now commencing to evaluate the productivity and biodiversity responses to the treatments, and will continue to do so at various times throughout

the course of stand development.

Measurements will include tree growth, soil properties, water quality, plant community dynamics, microbial processes and terrestrial fauna. Long-term monitoring is a critical component of this type of experiment as physical, chemical and biological constraints to productivity and

biodiversity vary over time. The impacts of intensified biomass removal detected early on in stand development may diminish or increase as trees grow.

For example, seedlings have low soil nutrient demands in the early years after establishment, but after the canopy closes and demand increases, further nutrient limita-

tions to growth could be detected.

Results from this project will provide insight into potential harvest and mitigation treatment responses and effects, as well as making important scientific contributions to clarify the implications and opportunities for biomass harvesting in

See How We Helped a Plant

A power facility in Minnesota has taken the first step in decreasing dust reaching nearby homes and businesses.

By Martin Engineering

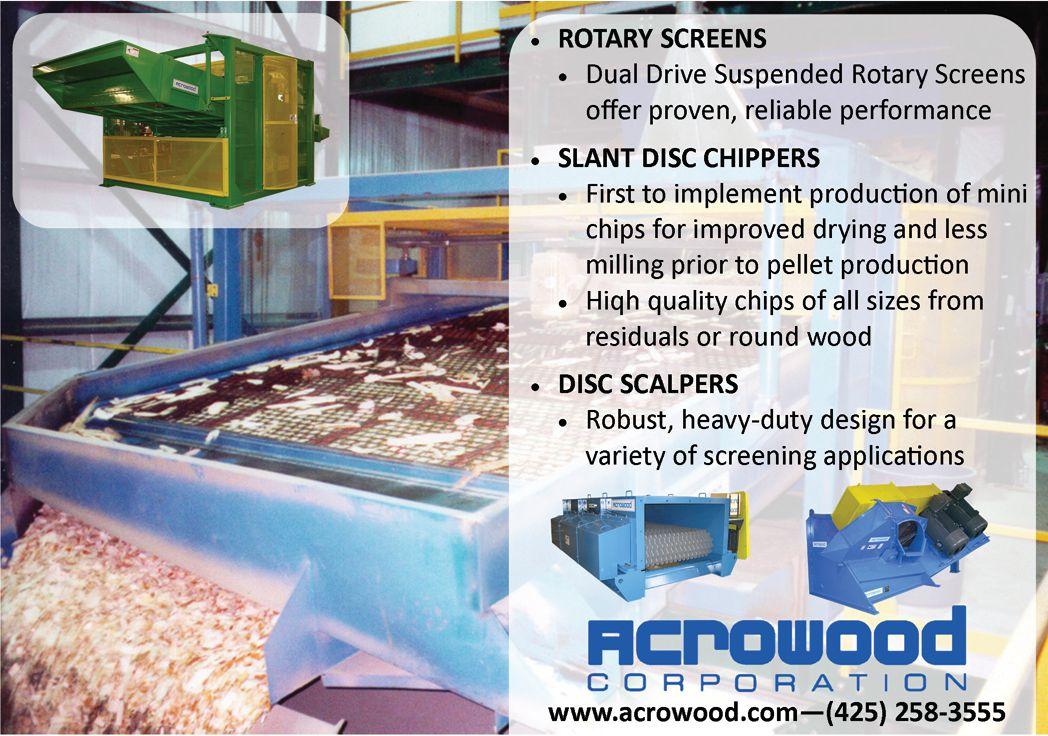

INthe first phase of the cleanup, the complex project at Hibbing Public Utilities (HPU) included the addition or retooling of belt cleaners, new transfer points and modified chutes, settling zones and apron skirts, as well as vibration technology to improve material flow. Company officials have been so satisfied with the upgrades that they are considering additional system enhancements to several other conveyors.

Hibbing Public Utilities has been providing electricity to the city of Hibbing, Minnesota, and surrounding area for more than 100 years, and currently owns and operates a co-generation plant that brings both steam heat and electricity to its service area. Under a 20-year contract with Xcel Energy, the firm currently produces about 300,000 MW hours of electricity per year, approximately 70% of it from biomass. The fuel includes wood from open-loop sources (such as waste wood, limbs and agricultural waste) and closedloop sources (dedicated crops of trees), with the goal being an average of 75% of the power generated from biomass fuels over the life of the agreement.

The material-handling system at the Hibbing site is critical to the plant’s efficiency, but from the time it began in 2007, controlling dust and spillage has been a challenge.

“When construction of the biomass operation was completed, we had three air-

supported conveyors and one bucket-type conveyor feeding the material,” explained Gary Myers, assistant general manager and director of power production.

Because of the largely residential area in which the facility is located, controlling carryback and spillage were among the first priorities. After a thorough evaluation of the material-handling system, Martin Engineering technicians began by installing primary and secondary belt cleaners on all four conveyors.

“We installed electric brush cleaners on each conveyor,” observed Martin Engineering territory manager Tom Hines. “The rotating brush delivers good cleaning performance in difficult applications, including belts with ribs, grooves or chevrons, and belts carrying sticky materials or stringy fibres.”

“Part of the problem occurred on the

three air-supported conveyors,” Myers recalled. “Some of the sections were at steep angles, and with the variable size and moisture content of the fuel, there were always chips that would fall back down.”

To address the issue, Martin Engineering technicians removed troublesome sections of the air-supported conveyor and replaced them with specially engineered transfer points. They also modified existing transfer points, installing drop chutes to help eliminate dust and transfer chutes with a hood-and-spoon design to improve the material flow.

“Reducing the material turbulence during transfers is key to preventing fugitive dust,” Hines observed. “By managing the material speed and direction, transfer chutes help minimize impact and wear on liners and belts, while containing the dust and spillage that are often generated

at transfer points.”

The transfer chutes employ special geometries that capture and concentrate the material stream as it travels through. Each unit is customized to suit the specific material characteristics and conveyor systems of the individual customer. They provide the dual benefits of minimizing aeration and preventing buildup within the chute, which are particularly important when dealing with combustible materials.

The installation team also placed electric rotary vibrators in key locations inside drop chutes to reduce the potential for plugging. To further ensure control of fugitive material, settling zones were created at the transfer points to slow the air speed, with dust curtains to contain airborne particles.

Finally, skirtboard sealing systems were installed on the sides of the loading zones to contain dust, eliminate spillage and reduce cleanup.

With the modifications in place, HPU reports significant reductions in spillage and airborne dust. “We’re very pleased with the results we’ve seen in fugitive ma-

terial control,” Myers concluded.

“We’re now reviewing several other conveyor sections to determine the opportunities for additional dust control measures. Our goal has always been to provide the Hibbing area with safe, reliable power that’s produced and delivered in an envi-

ronmentally responsible manner, and this work is a reflection of that commitment.”

Founded in 1944, Martin Engineering is the world leader in making bulk materials handling cleaner, safer and more productive. For more information, visit www.

Vecoplan Midwest, a subsidiary of Vecoplan LLC in High Point NC, recently relocated to

New Albany, IN. According to Bill Miller, COO of Vecoplan Midwest, the move was necessitated by continuing growth of their shredder sales and service business and the complete pelletizing systems to their product offerings in 2010. Vecoplan shredderstems are used in the production of alternative fuels. “In order to meet the demandslighted to move into this new space and are excited to be a part of the growing

Feedstox (a KABB company) has purchased seven new pieces of agricultural

LB34BXD high-density pull-behind balers manufactured by AGCO Corporation. The machinery will be used to harvest biomass materials such as corn, wheat, corn stalks, wheat straw, switchgrass and miscanthus. KABB plans to lease the biomass materials.

Tri-Mer Corp. has introduced Tri-Flow, a new performance with a MERV 16 rating. Tri-Flow

ters, which are typically rated MERV 10-13. They have a small footprint, and an excep-

Inc. to distribute a line of knuckleboom self-loaders produced by Epsilon Krantially, the line will include multiple models and will be marketed through select distributors experienced with truck-mounted loaders. “This collaboration allows us to extend our Prentice product offering in North America and give loggers more opForest Products. “The Prentice brand has always represented reliability, durability

MegaDome® pre-engineered fabric buildings give you practical and cost effective space for any industrial or environmental application.

BuildWorks delivers innovative design-build solutions. MegaDome structures are CSA-A660

John Deere announces the addition of a 9.0-liter John Deere PowerTech Plus 6090H Engine to its 700-Series Tracked Feller Bunchers and 700-Series Tracked Harvesters, replacing the existing 8.1-liter engine. The 9.0-liter engine is smart and reliable, featuring an electronically controlled high-pressure common rail fuel system to provide maximum power and fuel economy. The engine delivers 241 horsepower at peak power, giving loggers maximum productivity and uptime, shift after shift. An extended, 500-hour engine oil service cycle, paired

A global leader in dust suppression technology has announced the introduction of a new low-turbulence design for applications in which a fan-driven mist would be undesirable. Developed in response to extensive customer input, the DustBoss DB-M is well

generates an umbrella-shaped cloud of atomized droplets averaging 50-200 microns in size, projecting the mist about 30 feet (9.14 meters) under calm conditions. The powerful misting head is supplied standard with 9 atomizing nozzles and mounted on a 15-foot boom, but the designhaviors or operating environments.

Bandit Industries President Jerry Morey received the Tree Care Industry Association (TCIA) Award of Merit this past February, presented during the associa-

honor, considered by many to be the most prestigious and exclusive award

presented every year. The TCIA Award of Merit is a very special recognition that honors achievements and contributions throughout the tree care industry.

Martin Engineering has unveiled a new design for a track-mounted, pivoting, return-side idler that allows service and replacement from one side of the con-

service fast and easy. As a result, one person can replace the roll in less time, reducing the risk of inju-

self is 1-piece, and the assembly includes a 3-piece adjustable hanger bracket and swivel/pivot component, which allows the roll to be swung away from its support prior to removing the entire assembly.

The new LW-300 Rotary Arm Stretch Wrapper from Premier Tech is a fully automatic system designed to to a pallet load. Its overhead rotary arm eliminates the need to rotate the load and allows for high-speed wrapping, reaching up to 95 loads per hour. Depending on the model chosen, it can replace up to 5 turntable stretch wrappers. An optional top sheet dispenser is also available.

in Preston MN. These commercial boilers (up to one million BTU) along with a carbon neutral, and exceed stringent clean air standards worldwide.

Forest2Market announced that Stan Parton, formerly of The Parton Group, has practice. Parton will be responsible for the expansion of Forest2Fuel, the commanaging product evolution and derivative product development. These services include biomass supply availability studies, tipping point analyses, site selection studies, wood fuel indexing for supply and off-take agreements and a price benchmark that buyers and sellers of wood fuel use to compare their performance to, and improve their positions in, the market.

JUNE 18-22, 2012 • European Biomass Conference and Exhibition Milan, Italy www.conference-biomass.com

JUNE 21, 2012 • Second International Lignin Biochemicals Conference Toronto, ON www.bioautocouncil.com

JUNE 25-27, 2012 • Third AEBIOM European Bioenergy Conference Brussels, Belgium www.aebiom.org/conference2012

JUNE 27, 2012 • Agri Investment Forum Toronto, ON www.agri-investmentforum.com/contact_us.php

JULY 29-31, 2012 • Pellet Fuels Institute 2012 Conference Mashantucket, CT www.pelletheat.org

SEPTEMBER 17, 2012 • Pre-DEMO Conference Loews le Concorde, QC www.cwfcof.org/workshops/predemo-conference

SEPTEMBER 18-19, 2012 • Biomass Power Generation Brazil 2012 Sao Paulo, Brazil www.worldbiofuelsmarkets.com/EF/?sSubSystem=Prospectus&sEventCode=

BP1209BR&sSessionID=ce4ef4e6f06 15591577647e448c

SEPTEMBER 20-22, 2012 • Demo International 2012 Saint-Raymond, QC www.masterpromotions.ca/PreviousEvents/demo-international-2

SEPTEMBER 20-21, 2012 • Jansen Biomass Boiler Workshop Savannah, GA www.jansenboiler.com/biomassboiler-workshops

OCTOBER 9-10, 2012 • 12TH Annual Pellets Industry Forum Berlin, Germany www.pelletsforum.de/

October 14-17 • International Symposium on Biomass and Bioenergy Vancouver, BC www.csche2012.ca/

OCTOBER 17-19, 2012 • Timber Processing & Energy Expo Portland, OR www.timberprocessingandenergyexpo.com

OCTOBER 22-24, 2012 • The World Energy Forum Dubai, United Arab Emirates www.worldenergyforum2012.org/ index.php

UNBC’s award-winning bioenergy plant is reducing our fossil fuel consumption by 85%.

Talk to us about our plans to make UNBC’s Prince George campus a model for communities and industry eager to integrate energy production with housing, food production, and forest sustainability. Our researchers and students will make it happen.

Contact us to hear more: (250) 960-5622

Top campus sustainability project in North America (2010)

- Tied with Harvard University

Voted #1 in Canada by students for environmental commitment (2011) - Globe and Mail

Environmental Stewardship Award (2011) -Clean Energy Association of BC

By Michael Weedon

iomass-based energy, long ignored in North America, is finding its place in today’s energy business.

As fossil oil prices broke through $60 per barrel and now regularly see prices at $100, scarcity concerns and the expectation of prolonged higher prices create just the environment necessary for bioenergy projects to flourish. Those projects that use existing waste streams with low or negative feedstock prices, particularly in the municipal sector, are being developed in many major cities and innovative small and medium-sized municipalities. Add to this

U.S. Environmental Protection Agency Administrator Lisa P. Jackson got it right when she said, “Today we’re taking a common-sense step to reduce pollution in our air, protect the planet for our children, and move us into a new era of American energy.” Environment Canada is also working on regulations to reduce pollution from coal-fired power plants here in Canada.

New markets are on the horizon with Korea leading the pack with the implementation of the 2012 2% Renewable Fuel Standard (RFS) increasing to 10% by 2020. With heavy reliance on coal in Korea, B.C. biomass stands ready to provide a clean, sustainably sourced solution.

“Torrefaction, bio-char, bio-coal and black pellets are promising renewable fuel sources”