There are few opportunities to use this biomass in Alberta at present, but these will expand if economic stumbling blocks are removed.

New England Wood Pellet’s newest 100,000-ton/year facility makes it the oldest and largest producer in the Northeastern United States.

Optimism is high in the Canadian biomass industry, with a majority of respondents expecting revenues to increase in 2011.

Pyrolysis oil from wood is being used to make new asphalt that costs less than the old standby.

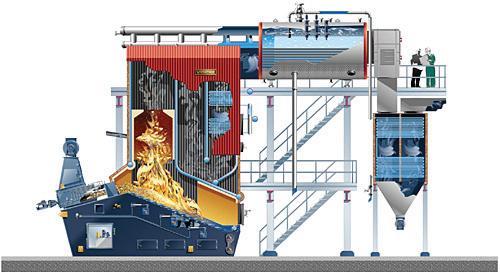

Our listing of biomass boiler manufacturers and suppliers, as well as companies that offer retrofits and contract biomass heat, is a comprehensive range of what’s available in Canada for 150 kW to 100 MW thermal and 250 kW to 25 MW electrical.

“People are taking a hard look at fuel and other products made from petroleum, and some are coming up with exciting renewable alternatives. One of these is Bioasphalt.”

Read the full story on page 21

The

forest products industry faces radical change to maintain sustainability and economic prosperity.

he stage is being set for the biomass, bioenergy, and bioproducts industry to take some giant leaps forward. Difficulties with other sources of energy, e.g., unrest in Middle East oil-producing regions, skyrocketing gasoline prices, and nuclear energy troubles in Japan, are reinforcing that wood can play a role as a reliable, renewable energy source. U.S. President Barack Obama is pushing for an end to oil subsidies; the European Union is looking at a 200–260-million cubicmetre fibre deficit by 2020 under its current renewable energy policies; and China has a growing demand for wood that can’t be met by its own stocks.

The increasing need for wood-based heat, power, transportation fuels, chemicals, and other products will result in fierce global competition for wood fibre supply, according to a February 2011 PwC report entitled Growing the Future: Exploring New Values and New Directions in the Forest, Paper & Packaging Industry. Although the production and use of traditional paper products is expected to decrease, novel uses of wood fibre will increase, says the report. And fibre demand is expected to increase faster than supply. That will increase the value of forests, both for their fibre supply and their conservation value, affecting the way we access fibre and creating a paradigm shift from the mindset of simply obtaining fibre to that of collecting and using it in the most efficient and effective manner possible. And that will involve changes in three key areas: business models, value chains, and fibre markets.

The current forest products industry will need to strengthen its core business performance while exploring opportunities for new partnerships outside the forest industry. Many corporations in the biotech,

petroleum refining, and chemical industries have the capital, experience, and expertise to invest in developing complementary bio-based products. An example is Weyerhaeuser and Chevron’s 2008 joint venture to develop renewable transportation fuels from wood. The value chain from fibre to end product will expand and become much more complex. Traditional operations will need to consolidate to remain competitive, while expanding into novel products. Fibre use will be designed with its end of life in mind, likely ultimately heat and power, with no waste and no landfill, predicts PwC. There will be new competitors, but also new opportunities for new types of business collaboration and research. Many pulp mills may become biorefineries, producing multiple products such as heat, power, chemicals, fuels, and pulp, allowing product switching based on market demand and price.

PwC expects changes not only in the way fibre is used, but also in the way it’s traded in the marketplace. The energy sector will likely set the base demand for biomass, so international fibre exchanges should emerge to provide determinable pricing mechanisms as for other internationally traded commodities. Biomass aggregators might also gain importance in providing customers with a steady, dependable fibre supply.

So there look to be some great opportunities for continued success in the biomass industry for companies that are looking ahead, building the necessary relationships within and outside the forest industry, and adapting their business models accordingly.

Heather Hager, Editor hhager@annexweb.com

Volume 16

Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Group Publisher/Edistorial Director- Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Contributors - Gordon Murray, Reg Renner

Market Production Manager

Josée Crevier

Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@forestcommunications.com

National Sales Managesr

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@forestcommunications.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0318-4277

Circulation

Carol Nixon e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada -

Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

Occasionally, Canadian Biomass magazine will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2011 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Two Canadian ventures have begun selling lignin for research and development purposes. British Columbia-based Lignol Energy Corporation is selling tonnage quantities of high-performance lignin (HPL) to development partners for industrial production trials. Its pilot-scale biorefinery and inventory of HPL position it as a supplier to companies looking to incorporate the renewable material in their product lines, says president and CEO Ross MacLachlan. This is a significant step in developing a commercial biorefinery to produce HPL and cellulosic ethanol, he says.

In Ontario, partners FPInnovations, the Centre for Research and Innovation in the Bio Economy, Natural Resources Canada, and AbitibiBowater are producing the first batches of operational lignin for Canadian researchers. The partners are developing an evaluation centre in Thunder Bay, Ontario, for black liquor

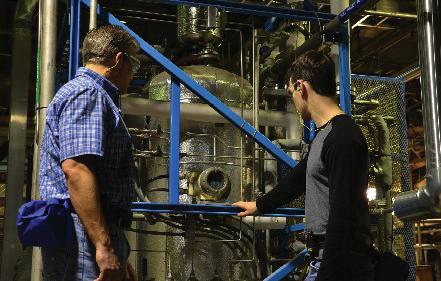

FPInnovations employees Lou Morrow (left) and Peter Holt-Hindle (right) examine a lignin reaction vessel in the demonstration plant at AbitibiBowater’s Thunder Bay, Ontario, facility.

and lignin byproducts of the pulping process at AbitibiBowater’s nearby kraft pulp mill. The lignin demonstration plant ties directly into the black liquor stream and will produce up to 100 kg/day of lignin when fully operational.

Lignin can be used as a renewable alternative to many petroleum-derived substances such as fuels, resins, rubber additives, thermoplastic blends, and nutra- and pharmaceuticals.

Alberta researchers have determined that mountain pine beetle is using jack pine as a host. The beetle was suspected to be invading hybrid tree species in addition to its usual host, lodgepole pine. However, DNA testing indicated that the beetle and associated blue-stain fungus are invading pure jack pine. “Our research team used molecular markers to conclusively show that the latest pine species to be attacked are indeed jack pine,” says lead researcher Catherine Cullingham. This has raised concerns that the beetle could move further east across the boreal forest, as jack pine ranges east from Alberta all the way to the Maritimes.

Biomass-to-gasoline developer Core Biofuel has signed a memorandum of understanding (MOU) with a renewable energy project developer. The MOU provides for the development of four Core licensed biorefineries following a review of the Toronto-based company’s technology and pilot production of bio-gasoline. Meanwhile, company officials are checking out potential locations for biorefineries,

including Houston, Terrace, and other forestry-based communities in northern British Columbia, according to several local news reports. The name of the project developer has not yet been revealed.

Biomass-to-jet fuel developer Rentech has accepted an Ontario wood supply offer of 1,146,000 cubic-metres/year of wood fibre for its proposed Olympiad Project, to be developed in White River, northern

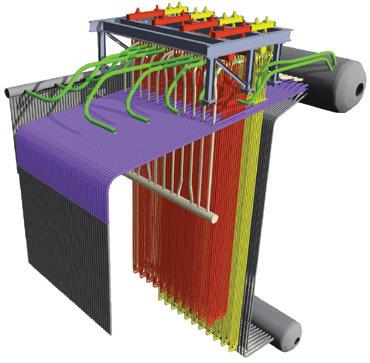

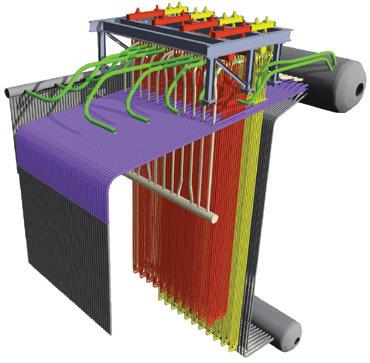

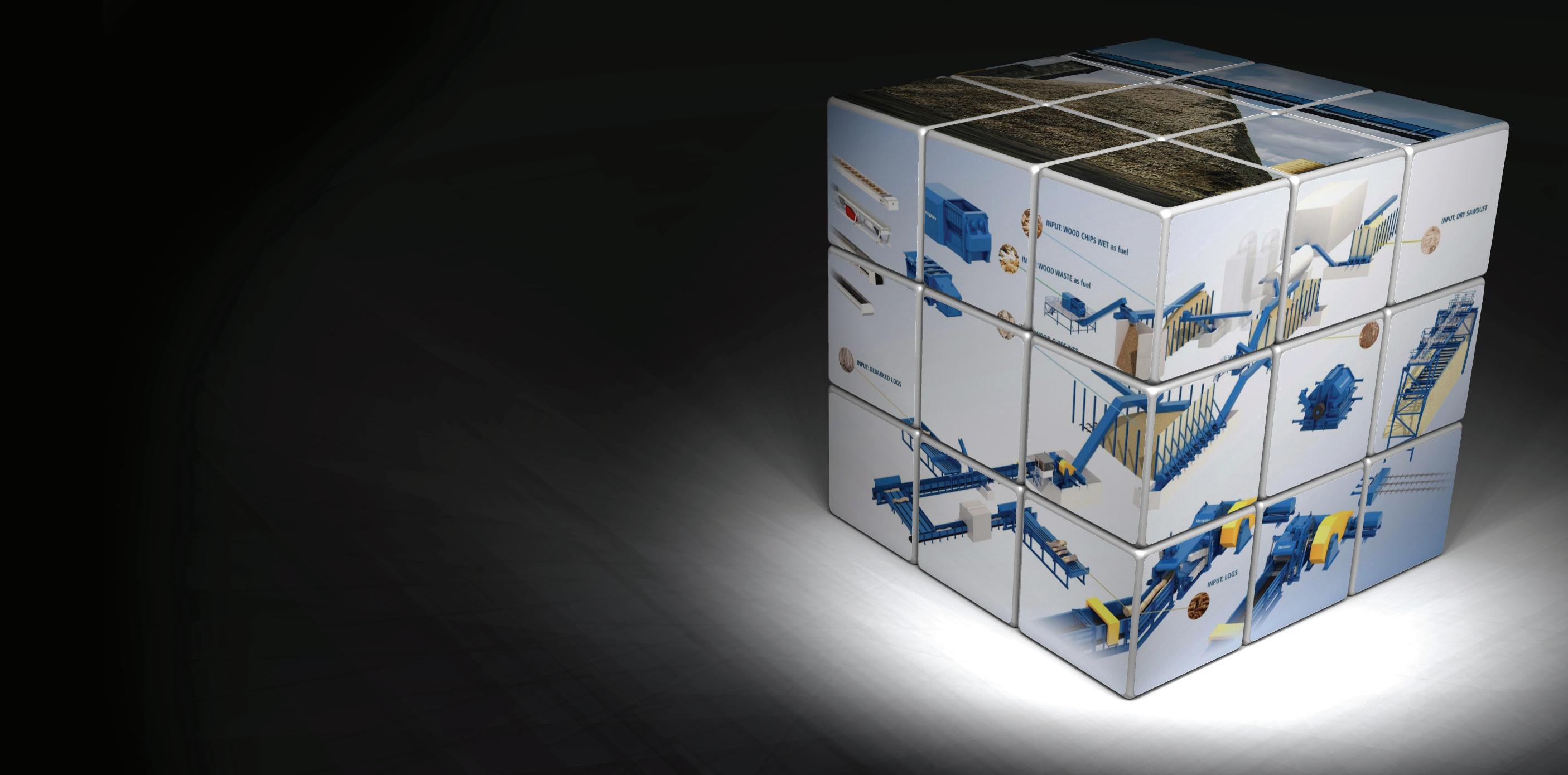

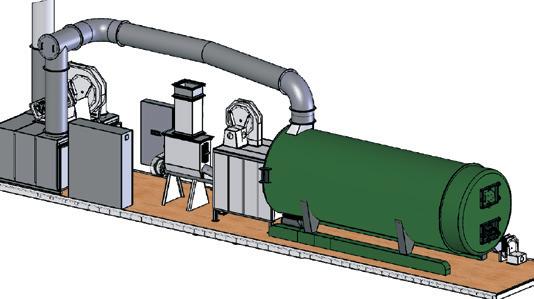

Maximize value from your raw materials. For perfect biomass and wood products the entire production system must work together flawlessly. Buhler Inc. and Buhler Aeroglide enable total process control with a complete equipment package that includes drying, grinding, pelleting, cooling, bagging and loading. This, combined with Buhler’s integrated automation system, unrivaled after sale support and training provides a seamless solution to biomass and wood processors.

Buhler Inc., 13105 12th Ave N., Plymouth, MN 55441, 763-847-9900 buhler.minneapolis@buhlergroup.com, www.buhlergroup.com

Ontario. The company would use the wood to produce about 85 million litres/year of low-carbon, biodegradable, synthetic jet fuel and 43 million litres/year of renewable naphtha, which can be used to produce biodegradable plastics. The proposed Olympiad Liquid Fuels Plant would also produce approximately 40 MW of renewable electricity from forest biomass. Rentech expects the plant to be completed in 2015.

A biomass-fuelled district heating system will be developed, tested, and commercialized in Sherwood Park, Alberta. The Canadian government is investing $1.5 million towards the Resource Industry Suppliers Association and Strathcona County for the project, with the latter two organizations each contributing $675,000.

BioEnergy Inc., Cape Breton University, and Target Hydraulics and Machine Works have been awarded $1.7 million in funding to construct, test, and commercialize torrefaction technology. Torrefaction creates a solid, hydrophobic product that weighs less than the original biomass and has physical properties more similar to coal.

EcoTech Energy Group has acquired the primary site for the ecoTech McBride ecoIndustrial Park and its planned biomassfuelled, combined heat and power (CHP) plant. The site is located northwest of McBride, British Columbia, and the finished eco-Industrial Park is expected to have a variety of tenants from initiatives requiring reliable and adequate heat and power services from the planned CHP plant.

Innovations for a better world.

Russian pulp and paper company Vyborgskaya Cellulose exported its first shipment of wood pellets in mid-March 2011 from its 900,000-tonne/year production plant in Vyborg, western Russia. The pellets were destined for a Swedish utility. Shipments of several thousand tonnes are expected to occur almost weekly.

By Reg Renner

ur latest federal election in Canada has shown that numerous politicians and supporters are willing to spend many hours knocking on doors looking for your support. So too must you prepare if you are to obtain suitable government support for your project.

First of all, government support, like political parties, can come in many shapes and sizes, and you need to do your research before you cast your vote or fill out the appropriate grant application form. It is also advisable to recognize that governmental support could be in the form of an approved environmental permit, a biomass fibre award, or a new piece of legislation such as the Ontario Green Energy and Green Economy Act.

If you are involved in bioenergy, you are probably aware that there are many challenges with pursuing and finding the appropriate government grants. The list of potential challenges includes tight timelines, limited eligibility, long approval delays, and untimely cash flows. When I think of all the time that has been spent by project developers pursuing government grants in spite of these challenges, it can seem like a poor return on their time investment. Yet I often come across groups that have just received a substantial grant from a previously unknown governmental agency. Remember, you can only get a government grant if you are willing to put in the work and apply to the appropriate programs. Many people say this about grants: “There is no free money.” They are right; you will have to work for it, just as a politician will have to earn your vote to get elected.

So allow yourself sufficient time to meet the requirements and deadlines, as it is a competitive process and you must submit a compelling argument as to why

your project should be supported. I recommend that you start by calling your Regional Economic Development Officer, as they are often very well connected and may know which programs are best suited for your specific requirements. The executive director of a Provincial Innovation Council once told me that his staff was tracking more than 100 government grant programs. It is a lot easier to call a couple of well-placed experts than it is to start the process from scratch, especially with new programs being added, deleted, and changed monthly.

It is also advisable to treat the government grant as only part of your finance package and to continue working with other financial groups to obtain a complete funding package. There is nothing worse than waiting 12 months to be awarded only one-third of the required project financing and then have to start looking for the remaining required financing. No matter how good the government grant is, you will need equity capital to get the project off the ground, and you must be careful not to spend all your equity during the grant process and subsequent waiting period.

did not understand the cash flow requirements until after the long awaited “good news” announcement. Timing can be more important than the dollar amount.

Given these various challenges, it is often advisable to look at other forms of government support that can be just as valuable as a non-repayable loan or grant. Government support can come from various levels of government, including municipal, provincial, and federal, so do not lose focus by only being concerned with one agency. Check out all the levels of governmental involvement, make sure that you understand all the rules and regulations,

“Instead of complaining about government like so many others do, check it out and work hard to see how it can help you achieve your goals.”

and create a regulatory checklist. As an example, can you get a timely building permit and an acceptable environmental impact study from your local building inspector? No matter how much money you might have, a project can be stopped in its tracks if the proper authorities have been ignored or bypassed.

Also early in the process, find out how the proposed grant is paid out during the project construction phase. I remember a project developer who called and told me that he had just been awarded a grant for $2.3 million, but the funds were not available until 90 days after the project was completed. That was the end of that project developer’s dream, as unfortunately he

Another critical role for governmental support can be in the awarding of a supply contract. As an example, the recent Ontario Ministry of Natural Resources’ allocations of wood fibre have been key to launching new value-added sawmills and wood pellet plants. Without a secure wood supply contract, there would be no business case for the local entrepreneur. In this context, local provincial ministry

Make sure you know the timing of government grants you are pursuing, as some are not paid out until after the construction phase.

staff may be very important to the success of your project. Sometimes it is hard to be patient, but you must understand their issues while continuing to move your project forward during the inevitable waiting periods.

Governmental support can also come in the form of new policies and initiatives that are designed to launch a new industry. A great example of this is the Ontario

Power Authority (OPA)’s Feed-in Tariff (FIT) program and micro-FIT, which created immediate demand for small solar generation systems. In less than 12 months, OPA had 3,000 applications and had to put the program on hold temporarily due to the unexpected uptake from individual power producers. The great part about the huge success of this program is that it showed that entrepreneurs are willing to make decisions and invest in a new industry with the right support from government.

At the same time, the challenge for governments is to predict the level of support required and acceptance needed to make a program successful. With too much support, the program can get out of control quickly, and subsequent dramatic changes can create uncertainty. An example is the U.S. Department of Agriculture’s Biomass Crop Assistance Program (BCAP), which initially gave biomass producers a matching subsidy of up to $45.00/ton of biomass. BCAP was designed to encourage new biomass producers to start delivering biomass feedstock to pellet plants, co-generation facilities, and ethanol producers. It was budgeted for only $70 million in

the first fiscal year, but about $230 million was actually allocated in the first fiscal quarter alone. The program has since been suspended, reworked, and now restarted, yet the resulting uncertainty and delays have caused many complaints and problems. Government support programs can be very beneficial, but they can also be damaging if they are not well crafted and controlled.

In closing, I encourage you to research the various government grants that are available by contacting your local experts. Then make an informed decision about whether they are worth pursuing based on the risk and reward and your current situation. Even if you do not need or receive a grant, you will still need other kinds of government support if you plan to be successful. So, instead of complaining about government like so many others do, check it out and work hard to see how it can

equipment. With 38 years of horticultural experience, he recently helped secure carbon offset credits for four green-

There are few opportunities to use this biomass in Alberta at present, but these will expand if economic stumbling blocks are removed.

By Treena Hein

Economicheartache and headache—

that’s what mountain pine beetle (MPB) initially represented for the forest industry in Canada’s West. But beetle-killed wood also represents an avenue for governments and companies in British Columbia and Alberta to move forward with biomass energy projects. And if conditions change in Alberta, there could be a lot more going on in this arena in the future.

While beetle-killed wood bioenergy projects are booming in British Columbia (see the cover story of our January/February 2010 issue; www.canadianbiomassmagazine.ca/content/view/1555/), there are several reasons why there’s only a small amount of activity in Alberta at the present time. For one, the area of MPB infestation is much smaller in Alberta than in British Co-

lumbia, a fact everyone hopes will remain true going forward. In addition, bioenergy projects using beetle-killed wood in Alberta have yet to take off because it’s just so much farther to transport pellets or other forms of bioenergy to overseas markets than it is from British Columbia.

“Mountain pine beetle arrived about 10 years ago in the south of Alberta (south of Highway 1) and about 5 years ago in the north,” notes Duncan MacDonnell, a public affairs officer at Alberta’s Ministry of Sustainable Resource Development (SRD). The south also faced infestations in the 1940s and late 1970s. In west-central Alberta (the so-called “wood basket” of the province, where pine is very plentiful), the beetle arrived from the Prince George, British Columbia, area through windflight in 2006, and then again in 2009.

In this area of the province, 170,000

Only about one-fifth of the beetle-killed wood is used for biomass. The remainder is burned in situ to kill mountain pine beetle because of transport cost limitations.

trees were culled this year and 150,000 last year. “We’ve had a policy of trying to remove every infested tree that’s found,” says MacDonnell. “We’ve asked forest companies to adjust their harvest and instituted single-tree cut-and-burn methods, and we’ve seen a significant decrease in the number of trees now being attacked by the beetle.” The affected acreage is 6 million hectares in Alberta compared to a whopping 14 million hectares in British Columbia. “In BC, they say it’s in decline, which is good,” notes MacDonnell, “but our biggest threat is still more beetles arriving from there by wind-flight.”

SRD has no policy on beetle-killed trees being removed for biomass. “In cases where infested trees are not cut and burned on site, the forest companies are in some cases harvesting them and/or harvesting susceptible trees for various uses,” notes MacDonnell. “It’s up to individual companies how they use or market the wood.”

MacDonnell notes that unlike British Columbia, where large areas are infested, Alberta features “pockets” of infestation. Also, almost all timber in Alberta is allocated under quota Forest Management Agreements or area-based tenures. “There is no situation here where you can say, ‘This

whole area is dead, the forest companies don’t want it, it should go for biomass’,” he says. It’s safe to say that no companies are harvesting beetle-killed trees specifically for biomass at present. “Typically, tenure holders would be harvesting beetle-killed volumes to be used in their normal course of production (e.g., lumber, pulp, etc.),” MacDonnell observes. “There likely are side deals that they enter into to sell off unused volumes (or waste streams like hog fuel or bark) to other companies who can use it.”

The MPB tends to attack large, highquality pine trees, and reforestation is now very much the focus of the province’s Mountain Pine Beetle Action Plan. “But we are encouraging companies to bring biomass energy propositions forward,” MacDonnell says. “The forest industry knows it has to do different things than it has traditionally done in order to move things forward.”

Canadian Northern Timber (with subsidiaries Atlantic Fibre Resources in the east and Great Western Forestry in the west) was one of the first companies to begin harvesting MPB-killed wood in Alberta five years ago,

mostly in the area around Grande Prairie and east of Slave Lake. They use Tigercat and Timberjack equipment for felling and Mobark when chipping, but the vast majority of wood is burned in piles on site.

“The Alberta government began putting out annual beetle-wood salvage tenders, and we bid on those,” says Canadian Northern Timber director of operations Kevin Dudka. “The government also offered MPB survey and control contracts, and we bid on those as well.” Government personnel monitor the completion of the contract to ensure the wood is burned properly or chipped and taken away for burning or further processing.

“We only started chipping the beetle trees during the last three years,” says Dudka. “On average, a fifth of what’s harvested has been chipped.” The chips go to various places: a couple of Canadian Northern Timber hog fuel facilities in Grande Prairie to provide heat for kilns; a few large dairy and hog farms for heat production; and some to the local Canfor facility for making heat and electricity for its mill, but Dudka notes that Canfor mostly uses its own mill residues.

Dudka says that his company tries to ship the chips within a 300-km radius at most. “Transportation is the biggest issue for us in making bioenergy feasible,” he notes. Transportation costs are also the critical factor in whether Canadian Northern Timber builds a pellet production plant in Grande Prairie. Over the last two years, the company has done a lot of research into the question and has determined that the economic picture has to change for a plant to proceed. “It comes down to the market for the pellets,” observes Dudka. “It would be next to impossible to sell them in this

area for commercial and residential heating because natural gas is readily available and cheap in comparison.”

The company is therefore actively looking for partners to work with to create a plan to ship pellets to British Columbia and/or Asia at a price that’s worthwhile.

“Some time ago, we did experimentally transport some chips and had them manu-

factured into pellets at a facility in Vancouver, then shipped them from the Port of Vancouver to Europe through the Panama Canal,” Dudka explains. “It cost from $64 to $74 per tonne for transportation and $80 per tonne to make the pellets. They won’t pay enough in Europe to cover it.”

To proceed with a pellet plant, transportation costs must become much lower

than manufacturing costs. “We have lots of material here, but there needs to be someone who needs a large amount of biomass—not likely in BC—and there needs to be something that happens that would level the energy playing field,” Dudka asserts. “There are lots of incentives for oil and gas companies to do exploration and development, but these don’t exist for forestry. What would change things most effectively is a carbon tax.”

On the east coast, the company’s pellet activities are going strong. In Chandler, Quebec, situated on the Gaspé Peninsula, its Atlantic Fibre Resources subsidiary started construction of a pellet and dimensional lumber plant in May 2011. “It will be completed by September and will be the largest pellet facility on the east coast,” says Dudka. “It will provide 158 full-time jobs, 250,000 tonnes of pellets, and 6 million board feet of lumber that meets European standards.” All lumber and pellets from the plant will be shipped to Denmark, the United Kingdom, Ireland, Finland, and probably Germany as well. Atlantic Fibre Resources is also looking into several other projects, with announcements expected later in the summer. •

New England Wood Pellet’s newest 100,000-ton/year facility makes it the oldest and largest producer in the Northeastern United States.

By Jennifer McCary

nEwEngland Wood Pellet (NEWP) operates two pellet plants and has recently started up a third. The newest facility is located at the former Norbord panel mill site in Deposit, New York. It will add 100,000 tons/year of capacity, bringing NEWP’s total production to 260,000 tons/ year (about 236,000 tonnes/year), making it the region’s oldest and largest producer in operation today. Its other two facilities in Jaffrey, New Hampshire, built in 1999, and in Schuyler, New York, built in 2008, each produce 80,000 tons/year of pellets.

Steve Walker, CEO of NEWP, is an 18year industry veteran. Now finishing his fifth pellet plant project, the 43-year-old entrepreneur continues to refine the art of making wood pellet fuel.

Recalling the challenges and unpredictability of his first pellet mill ventures in the early 1990s, Walker says, “You would have some days you couldn’t make pellets and some days when you could, but you

didn’t know why.” Weather, temperature, wood species, and even the way the wood is ground are among the variables that directly affect pellet making, he explains.

Walker built his first pellet production facility in Acton, Massachusetts, with a capital investment of about $200,000. That operation produced around 2,000 tons of pellets annually. “It was an economic disaster,” he laughs. “The more we made, the more we lost. But I learned a lot. It turned out to be more of a laboratory than a production plant.”

Walker’s second plant was NEWP’s first in Jaffrey. Production and financial performance improved significantly, and Walker could see potential for strong market growth. That site was only permitted for up to 18 hours of daily operation, however, so NEWP purchased a larger parcel across town and relocated to a new facility in 1999. It was permitted to run 24/7. The initial investment in 1996 was $1.5 million. The relocation, plus a series of up-

grades, has brought total investment up to $16–17 million.

The latest upgrade at Jaffrey, completed in 2010, was a $3-million update of all electrical systems to improve fire safety and control. All lighting was converted to dustproof fixtures with low surface temperature enclosures to prevent ignition of airborne dust. The upgrade meets or exceeds the U.S. Occupational Health and Safety Administration (OSHA)’s more stringent enforcement of safety regulations in the wake of various factory dust explosions and fires elsewhere in recent years.

Walker contends that part of the problem in the pellet industry has been that participants are often from a sawmill background and are used to dealing with high-moisture sawdust. Pellet manufacturing deals with a much finer, dryer material that is exceptionally explosive. He

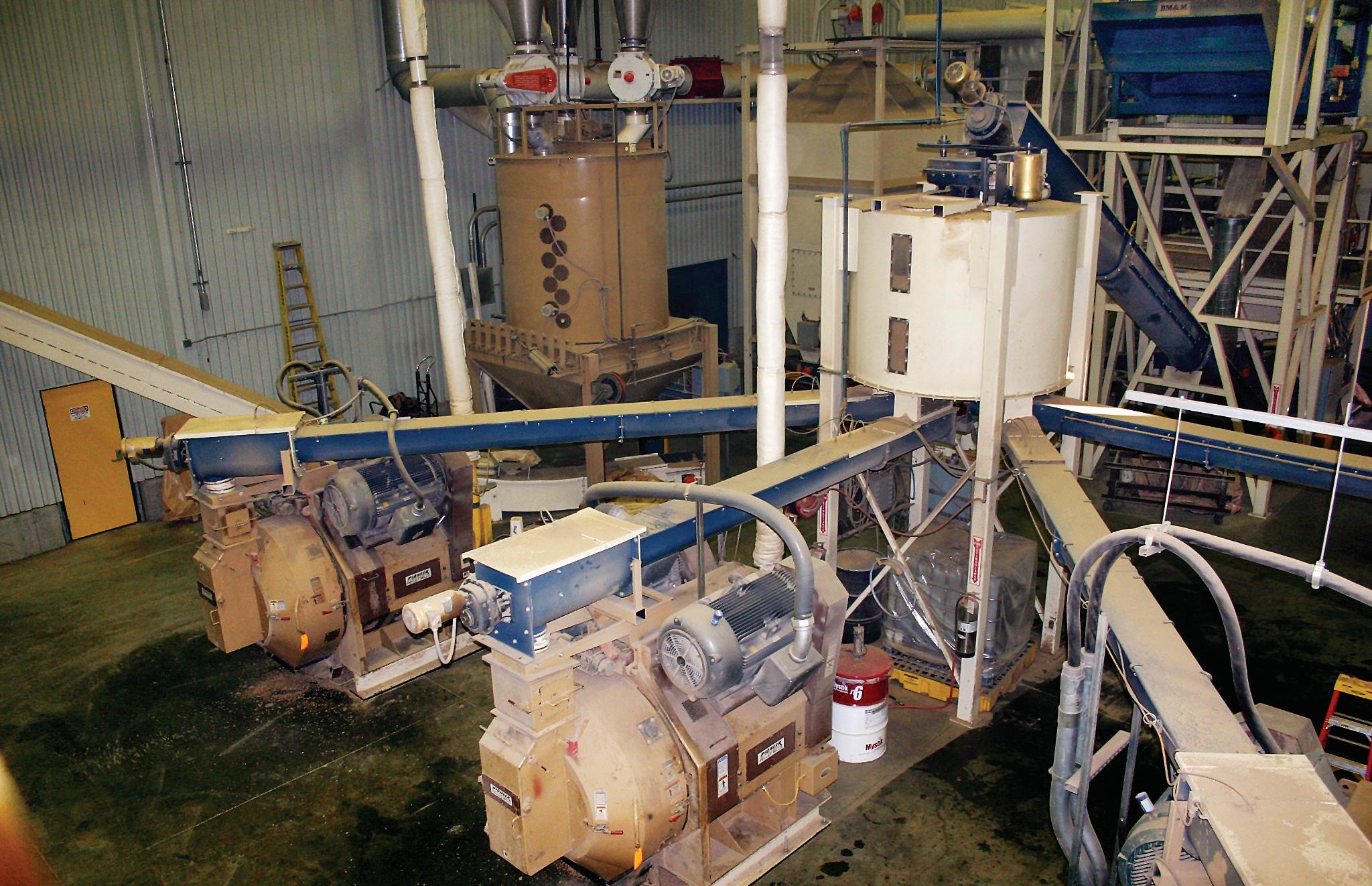

The Bliss pellet mills at the Schuyler plant are configured radially from a single, central fibre metering bin.

equates pellet making with the discipline and process controls of a fuel refinery. He recommends that mill owners seek assistance from a consultant or OSHA (in Canada, the Canadian Centre for Occupational Health and Safety, CCOHS) to make sure all potential hazards and compliance issues are adequately addressed. “If we, as owners, don’t take this seriously, that alone could end a business and end it in a very disastrous way with people getting hurt. That is inexcusable,” he says.

As the demand for pellet fuel grew, NEWP began to expand, starting up its Schuyler facility in 2008. It has proximity to the wood resource, easy highway access, and consumer markets in major metropolitan areas in Pennsylvania, New York, and New Jersey.

Walker is a self-taught engineer and has done all the engineering and design for each plant. Much of the pellet mills’ material handling and emission control systems have been designed and fabricated at NEWP’s fabrication shop in Jaffrey, which was built in 2006. That shop has helped to reduce project costs, keeping the total

investment in the Schuyler plant at $13 million.

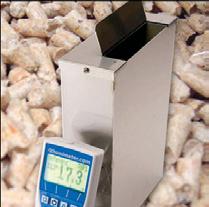

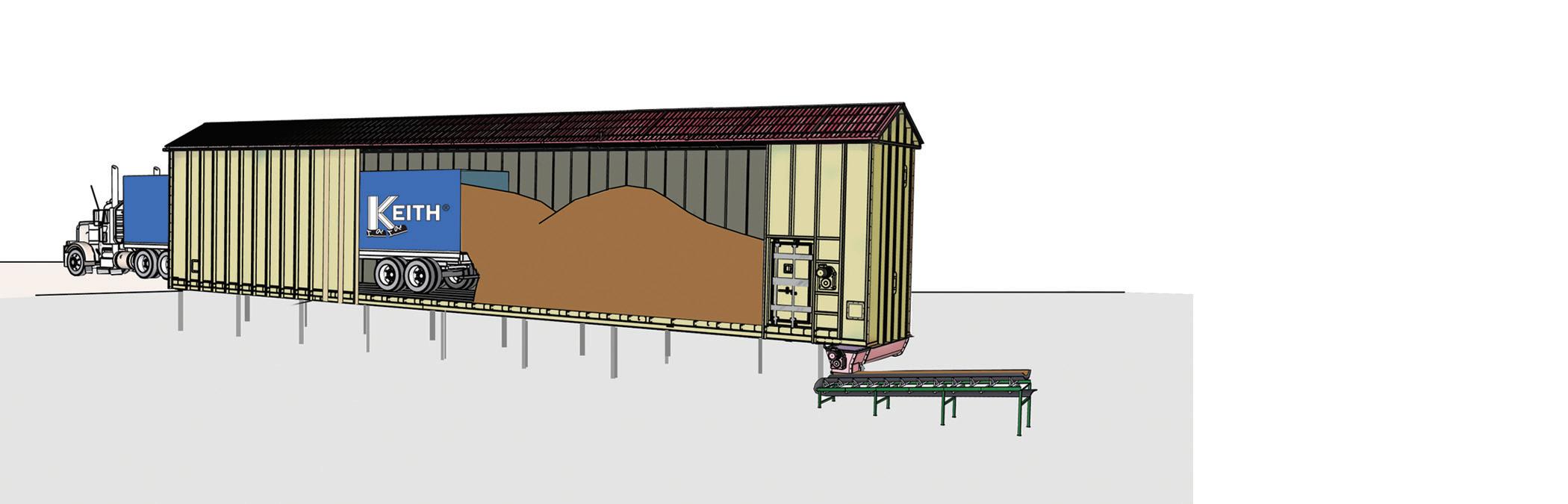

The mill is currently operating on a 24hour, five-day workweek with a three-man team per shift. Green and dry chips and sawdust are purchased from local mills. Arriving trucks cross a Fairbanks scale and unload at a Peerless truck dump. Operator Rick Waterbury uses a Volvo L110 bucket loader to carefully blend raw materials to achieve the right proportion of hardwood chips, green sawdust, pallet grindings, softwood, and other dry trimmings. Targeted moisture content for the blended material is in the mid-30% range, and the feedstock is stored under cover to maintain that level. Moisture is measured several times throughout processing to ensure proper levels for binding quality pellets.

A live floor infeed delivers the material to a conveyor belt, which passes under a large Industrial Magnetics magnet and through BM&M shaker screens to remove oversized wood slabs and fines. Oversize wood is ground and used in pellet production, whereas the fines feed the biomass furnace that supplies process heat for the dryer.

The pellet feedstock is processed by a

500-hp Bliss hammermill, which grinds it into a uniform pea size. The material then enters an M-E-C triple-pass dryer capable of drying about 10 tons/hour. Targeted moisture content at the dryer outfeed is 15%. Fines are removed by two Kice cyclones, and the dry feedstock is stored in two storage silos. The storage silos were built in-house to address previous issues with frozen wood and concerns about meeting safety codes. The units feature a metering system and robust silo motors that continuously mix the contents.

Dried wood that is purchased from local sawmills and furniture and flooring factories goes directly to two storage silos. Reclaimers incorporated with each silo feed the fibre into a 500-hp Bliss hammermill for final sizing.

From storage and initial processing, the fibre enters a large distribution bin, where augers distribute it to each of three Bliss pellet mills. Drag chain conveyors deliver the pellets to the cooling tower and then to the pellet storage silo. Fines and oversized pellets are removed by a BM&M shaker screen before the pellets go to the automatic Hamer bagging system. Filled bags fall to a conveyor belt on the packaging line that’s

Since 1976, Jansen Combustion and Boiler Technologies, Inc. (JANSEN) has provided customized engineered solutions to owners/ operators of boilers in the Forest Products and Waste-to-Energy Industries.

Our mission is to improve the operating performance (fuel burning capacity and economy, efficiency, and emissions performance) of existing boilers that burn difficult fuels such as biomass, chemical spent liquors, municipal solid waste (MSW), refuse derived fuel (RDF) and tire derived fuel (TDF).

equipped with a Conveying Industries EC201 Fuji Ace robot stacker and a Wulftec shrink-wrap palletizer turntable.

JANSEN has conducted engineering performance evaluations of over 300 boilers, worldwide, and has provided combustion system and/or superheater upgrades of over 80 biomass, chemical recovery, MSW, and RDF boilers.

JANSEN has the capability and experience to function as your one-source solution to boiler retrofit projects. With the ability to define, engineer, contract and manage design-construct projects, we offer EngineerProcure-Construct (EPC) capabilities.

The 30,000-square-foot facility is protected by a Firefly fire detection/prevention system with spark detection and fire extinguishing capabilities. When sensors located throughout the process detect a fire, alarms sound, and the system automatically starts backing everything out of the building, where small amounts of water are sprayed to put the fire out.

A synopsis of our broad range of services:

> Full service engineering design for steam, power, and combustion systems

> Biomass, MSW, RDF, TDF, fossil fuel, and chemical recovery boiler performance evaluations

> Effective overfire air (OFA) delivery system upgrades on biomass and other waste-fueled boilers

> Replacement or upgraded superheater design and supply

> Boiler circulation analyses

> Computational Fluid Dynamics (CFD) modeling

In 2009, Walker received a call from Norbord, which had determined that its aging mill in Deposit was no longer economically viable and would have to be closed. Norbord went the extra mile to seek out prospective buyers who would continue to manufacture a wood product to try to save as many jobs as possible and also keep the established wood supply chain intact. NEWP purchased the mill in late 2009, barely more than a year from startup of the state-of-the-art Schuyler plant, and hired 20 of Norbord’s workforce well in advance of project construction and completion. Walker says the community has been excellent to work with and very supportive of trying to save the plant.

> Feasibility studies and cost/benefits analyses

> Emissions reduction (CO, NOx, PM, SO2, TRS, VOC)

> Operations support and training

“Getting this built-in team was a major deciding factor in taking on this old facility,” states Walker. “It takes a long time to get a group of people to operate a complex plant, so I was really excited to have them.” None of the previous plant’s machinery, including the flash tube dryer, was used in

the new pellet mill. Much of the physical facilities and equipment were sold, scrapped, or torn down. About the only thing left is the forming line and 200,000 square feet of buildings that are used as warehouse space.

The new plant has several innovative design features, especially in safety and cost efficiency. The mill floor is a compact layout housing an M-E-C triple-pass dryer, two 500-hp Bliss hammermills, four Andritz pellet mills, an automated Hamer bagger, and a Wulftec shrink-wrap turntable. Only the plastic covering is manually positioned onto the stacked pallet before it enters the Wulftec system.

Key design improvements include a Wellons furnace with an oversized dryer that allows a reduced drying temperature of just 315°C. This is considerably lower than in conventional drum dryers, which helps reduce volatile organic compound emissions. The in-house fabricated storage silos have fabric tops that allow the cloth to disintegrate in the event of an explosion and prevent structural damage to the storage cylinder. A Kice baghouse and six customized Fisher Klosterman cyclones help the plant meet New York’s stringent emissions permit requirements.

NEWP worked with equipment vendors to incorporate a centralized process control system that manages every motor and control throughout the plant. Standard machine controls were either eliminated or bypassed so that one system controls the entire plant and there are no communication problems from one machine to the next. “We did this basically for mill

Since 1976, Jansen Combustion and Boiler Technologies, Inc. (JANSEN) has provided customized engineered solutions to owners/ operators of boilers in the Forest Products and Waste-to-Energy Industries.

Our mission is to improve the operating performance (fuel burning capacity and economy, efficiency, and emissions performance) of existing boilers that burn difficult fuels such as biomass, chemical spent liquors, municipal solid waste (MSW), refuse derived fuel (RDF) and tire derived fuel (TDF).

JANSEN has conducted engineering performance evaluations of over 300 boilers, worldwide, and has provided combustion system and/or superheater upgrades of over 80 biomass, chemical recovery, MSW, and RDF boilers.

JANSEN has the capability and experience to function as your one-source solution to boiler retrofit projects. With the ability to define, engineer, contract and manage design-construct projects, we offer EngineerProcure-Construct (EPC) capabilities.

A synopsis of our broad range of services:

> Full service engineering design for steam, power, and combustion systems

> Biomass, MSW, RDF, TDF, fossil fuel, and chemical recovery boiler performance evaluations

> Effective overfire air (OFA) delivery system upgrades on biomass and other waste-fueled boilers

> Replacement or upgraded superheater design and supply

> Boiler circulation analyses

> Computational Fluid Dynamics (CFD) modeling

> Feasibility studies and cost/benefits analyses

> Emissions reduction (CO, NOx, PM, SO2, TRS, VOC)

> Operations support and training

uniformity and simplicity to make it easier to learn, easier to maintain, and cheaper to maintain,” says Walker. “But it is definitely not cheaper to put in.”

In contrast to the Schuyler facility, each Andritz pellet mill has an inhouse fabricated metering bin above it and a cooling box below it. Walker says that having the cooler below the pellet mill is safer because it eliminates dock and chute conveyors and the spark detectors normally needed when conveying hot pellets to a central cooling tower. Fires can occur in the cooler, and Walker says that he would prefer to deal with containing one to a cooler that is one-quarter the size and mated to its own cyclone.

This combination of metering bin, pellet mill, and cooler is also more economical. It helps keep the required enclosed space to a minimum for a more compact and cost-efficient layout. In addition, large windows reduce or eliminate lighting requirements during the day. Keeping costs in line is mandatory if the industry is to remain competitive with other energy sources.

The company markets its bagged and bulk delivery services in a two-step distribution channel geared to consumer consumption in the Northeastern United States. •

JULY 24-26, 2011 • Pellet Fuels Institute Annual Conference Ponte Vedra Beach, Florida http://pelletheat.org/events/pfi-annual-conference

JULY 26-27, 2011 • Biomass ’11: Renewable Power, Fuels & Chemicals Conference Grand Forks, North Dakota www.undeerc.org/Biomass11/

SEPTEMBER 5-9, 2011 M• International Nordic Bioenergy Jyväskylä, Finland www.nordicbioenergy.finbioenergy.fi

SEPTEMBER 8-9, 2011 M• North American Biomass Pellet Export Conference New Orleans, Louisiana www.exportingpellets.com

SEPTEMBER 14-16, 20M11 • International Biorefining Conference & Trade Show Houston, Texas www.biorefiningconference.com

Biomass Handling Equipment

Complete Engineered Systems

Pulverized Coal Boiler Conversions

CFB Boiler Feed Systems

at www.jeffreyrader.com/videoB

EA glimmer of hope has appeared for co-firing wood pellets at Canadian coal plants.

By Gordon Murray

uropean utilities co-fire wood pellets with coal to reduce CO2 and other emissions. From about 1 million tonnes in 2000, European wood pellet consumption will reach 10 million tonnes in 2011 and is expected to exceed 100 million tonnes by 2020. The Wood Pellet Association of Canada (WPAC) has been promoting wood pellet co-firing to the Canadian coal power industry and regulators, so far without success. Here’s why.

1. Coal is cheap and plentiful. Canada produces nearly 70 million tonnes annually, of which about 60 million tonnes are consumed domestically. It has 8.7 billion tonnes of coal reserves and 193 million tonnes of known deposits.

2. Coal power is well entrenched in Canada. It has been around for about 100 years. The coal power industry is conservative and resistant to change and has powerful, well-funded lobbyists.

3. The coal industry is huge. Canada’s 22 mines provide 5,000 direct jobs and thousands of indirect jobs. Coal is top in commodity volume handled by Canadian railroads and ports, which are opposed to anything that could be perceived as a threat, i.e., substituting wood pellets for coal.

4. If the cost of environmental damage is not taken into account, coal power is extremely cheap. In fact, many Canadian coal power plants are located right beside the mines that fuel them.

5. Canada’s federal and provincial governments are unwilling to implement policies to reduce emissions from coal. Nevertheless, WPAC is starting to see a glimmer of hope. It has begun dialogue with the Canadian Clean Power Coalition (CCPC), a group of coal power producers who think that coal power is here to stay but needs to be cleaner. CCPC’s purpose is to research technologies to reduce coal power

plant emissions, and members include Basin Electric Power Cooperative, Capital Power, Nova Scotia Power, SaskPower, Sherritt International, and Trans-Alta. WPAC recently became a collaborative partner.

CCPC is considering both coal and biomass solutions. Some coal-based solutions being researched include:

Carbon capture and storage: CO2 and other emissions are removed from flue gas and pumped deep underground for permanent storage, a technology that’s still under development and hugely expensive;

Amine scrubbing: Flue gases are passed through an amine solution to absorb CO2 and concentrate it for more efficient storage;

Oxyfuel combustion: Coal is burned in oxygen, rather than air, resulting in flue gas that’s mostly CO2 and captured more readily by amine scrubbing; Integrated gasification–combined cycle: Coal and steam produce syngas (hydrogen and carbon monoxide), which is burned in a gas turbine with secondary steam turbine (i.e., combined cycle) to produce electricity (if the gasifier is fed with oxygen, the flue gas contains concentrated CO2, which can be captured post-combustion);

long-term permanent solutions requiring substantial resources to commercialize. Such solutions could not be justified in older power plants with limited life. Thus, CCPC sees biomass co-firing as a potential short-term solution that could extend the life of older power plants. However, before the members embark on biomass co-firing, they plan to study it in some detail. Study topics include: economics of co-firing; pros and cons of various forms of biomass fuel, e.g., briquettes, wood pellets, chips, agricultural residues; review of the design, benefits, and costs of feedstock and co-firing configurations on

“WPAC has begun dialogue with the Canadian Clean Power Coalition, a group of coal power producers who think that coal power is here to stay but needs to be cleaner. ”

a few coals at specific sites; and burn tests of torrefied material.

Coal beneficiation: Coal is cleaned using water, chemicals, or biological means before combustion to remove impurities; and Supercritical and ultrasupercritical technology: Pulverized coal boilers operate at higher temperatures and pressures and to achieve higher efficiencies.

CCPC views these technologies as

As a collaborative partner, WPAC will help to ensure that CCPC obtains an accurate picture of biomass co-firing and will also promote the benefits of wood pellets over other forms of biomass. Although WPAC would prefer to see the Canadian power industry adopt co-firing like its European counterparts, if we are successful with this process, we may finally see the practice adopted in Canada. •

Gordon Murray is executive director of the Wood Pellet Association of Canada (www.pellet.org) and can be reached at 250-837-8821 or gord@pellet.org.

Optimism is high in the Canadian biomass industry, with a majority of respondents expecting revenues to increase in 2011.

By Heather Hager

ThEresults are in for our first industry survey, giving a snapshot of current activity in the Canadian biomass industry. While reviewing the results, keep in mind that this was a non-scientific survey relying on the initiative of individuals to participate. Of 321 respondents, 253 completed all questions. For biomass consumers and generators, the scale of use ranged from 10 to 2-million oven-dried tonnes/year, with the largest fraction in the 10,000 to 100,000 oven-dried tonnes/year range.

Who are the respondents?

Respondents were asked to select the category that best described their job title. A large proportion (but less than half) were equip-

ment or service providers, sales and marketers, government employees, and researchers. “Other” included engineers, educators, business and economic developers, funders, laboratory personnel, woodlot owners and licensees, and boiler operators and engineers.

Where are they located?

Not surprisingly, the majority of respondents’ Canadian enterprises were located in British Columbia, Ontario, and Quebec. Less than 1% of respondents were from the Yukon. There were no respondents from Prince Edward Island, Northwest Territories, or Nunavut, even though biomass heating is well developed in areas of PEI and NWT. A small number of respondents were from outside Canada (not shown).

The largest single fraction of respondents, at 15%, were not yet involved in the biomass business, but were considering or looking for opportunities. Around 27% were biomass suppliers, harvesters, or transporters, whereas about 21% were biomass consumers, producing heat and/or power, pellets, briquettes, chemicals, and liquid fuels from biomass. “Other” included researchers, emissions monitoring, and policy development. Slightly more than half of respondents had multiple roles in the biomass industry.

History of involvement

Most respondents were either recent entrants into the biomass industry (1 to 5 years) or longtime biomass industry veterans (more than 10 years). Why

By far, the need to diversify was the main reason for entering the biomass industry.

Of the respondents that use biomass, many access multiple source streams. The most cited single source of biomass was from wood-processing operations such as bark and wood shavings from sawmills.

A little more than one-quarter (27%) of respondents that use biomass transport it up to 200 km or more as the furthest distance. Maximum transport distances of 50, 100, and 150 km were cited almost equally, at about one-quarter of respondents each.

Of the 74 respondents who purchased biomass-related equipment in the past 12 months, many spent less than $50,000, although some major multimillion-dollar investments were made. The most-purchased items were boilers and furnaces, loaders, grinders, pelletizers, chip trucks, and dryers.

The outlook for biomass equipment-related spending in the next 12 months is more positive, with 100 respondents noting planned purchases. Big-ticket spending is expected to increase significantly for purchases of more than $100,000 and particularly for purchases of more than $1 million. The top items that respondents noted on their planned purchasing wish lists were

grinders, boilers and furnaces, chippers, pelletizers, loaders, and buildings.

More than $5,000,000

$1,000,001 to 5,000,000

$500,001 to $1,000,000

$100,001 to $500,000

$50,001 to $100,000

Less than $50,000

More than $5,000,000

$1,000,001 to 5,000,000

$500,001 to $1,000,000

$100,001 to $500,000

$50,001 to $100,000

Less than $50,000

Number of respondents

Of those who generate revenue from a biomass-related business, slightly more than half saw an increase in revenue between 2009 and 2010. Optimism is high, with three-quarters of respondents expecting to see biomass-related revenue increase in 2011. •

From dry shavings, sawdust or similar material –

Silvana specializes in providing turn-key, small-scale pellet press solutions from SPC Sweden to fit your specific needs. Talk to us and start making more profit now!

Pyrolysis oil from wood is being used to make new asphalt that costs less than the old standby.

By Treena Hein

AlmosTeverywhere on the planet, people are taking a hard look at fuel and other products made from petroleum, and some are coming up with exciting renewable alternatives. One of these is Bioasphalt, made from woodbased, fractionated pyrolysis oil and currently being tested on a bike trail near Iowa State University (ISU).

“I was down at the trail last week with other people and we couldn’t discern any difference between Bioasphalt and the petroleum-based material,” says Dr. Christopher Williams, associate ISU professor of civil, construction, and environmental engineering, who created Bioasphalt. “It was placed October 6 and has made it through the winter with no low-temperature cracking. We’re also doing lab test comparisons and have so far found that moisture sensitivity is better with the Bioasphalt.”

The idea came from Williams’ thinking on the plastics industry. “In plastics, they use lignin as an antioxidant; it prevents materials from losing their pliability and elasticity,” he says. “This is the same thing we want to have with asphalt. We want to protect it from temperature-related crack-

ing and oxidative aging cracking, and so testing a wood-based bio-oil to replace the crude petroleum component of asphalt was a logical first step.”

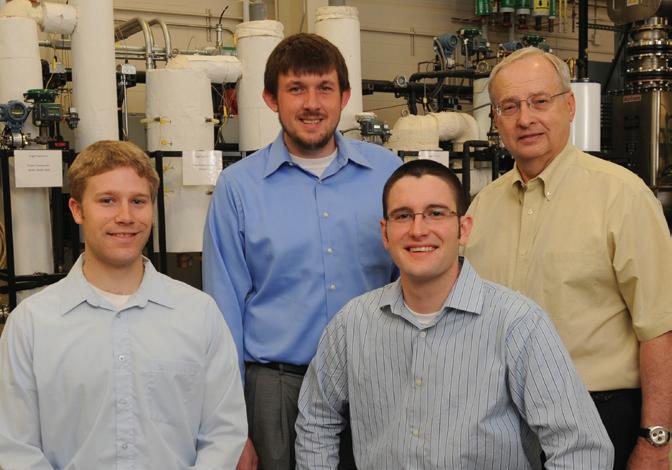

The pyrolysis oil used by Williams to make the Bioasphalt was produced at the fast pyrolysis pilot plant at ISU’s BioCentury Research Farm. The research and development of the technologies used at this facility were led by Dr. Robert C. Brown, an Anson Marston Distinguished Professor of Engineering, the Gary and Donna Hoover Chair in Mechanical Engineering, and director of ISU’s Bioeconomy Institute. Three of Brown’s former graduate students, Jared Brown, Cody Ellens, and Anthony Pollard, have created a startup company called Avello Bioenergy Inc., which is currently leasing ISU’s pyrolysis pilot plant (see sidebar on page 22).

Fast pyrolysis is a thermochemical process in which some type of biomass is quickly heated without oxygen, resulting in liquid pyrolysis oil, solid biochar, and other products. “Avello fractionates this in a process analogous to petroleum refining,” notes Williams. “With the bio-oil used in Bioasphalt, the heavy fractions with low moisture content are taken, and all the water is removed. At the same time, a polymer

matrix is created.”

The bike trail Bioasphalt contains 3% Avello pyrolysis oil and 97% crude petroleum. These proportions were mainly due to the small size of the pilot plant. “It took two weeks to produce the 600 pounds (272 kilograms) of bio-oil we needed,” says Williams. “If we had wanted to use 25%, it would have taken two to three months with our pilot plant. Avello is in the process of planning and building a demonstration-scale facility capable of producing much larger quantities for additional demonstration projects.” He believes a little more tweaking of lowtemperature performance is needed before 100% Bioasphalt could be used throughout the United States and Canada.

Williams sees the product as providing many important benefits. “It could create a new market for crop residues and provide jobs in rural areas,” he says. “Bioasphalt can be mixed and paved at lower temperatures than conventional asphalt, and once you get above 10%, the cost savings really start to become realized.” Bioasphalt costs $400

Grimes Asphalt and Paving Corp. of Grimes, Iowa, uses an asphalt-pyrolysis oil formulation to test-pave a bike trail near Iowa State University.

The Avello team includes (front, left to right) Cody Ellens, Jared Brown, (back, left to right) AJ Pollard, and Dennis Banasiak. The fast pyrolysis plant is behind them.

a ton, and petroleum asphalt is $550 a ton.

Scott Schram, a bituminous engineer with the Iowa Department of Transportation, adds, “Any state department of transportation is going to be looking for alternative sources for binders, whether that’s from non-petroleum or recycled sources. This is because the more petroleum-based binder you use, the more the cost of asphalt is tied to the price of oil.” Price fluctuations will not be as dramatic if other sources are used, Schram observes, and using less petroleum-based asphalt therefore allows a state better financial stability and planning with regard to transportation. •

Avello Bioenergy Inc. is one of several players in the North American pyrolysis game. Avello has exclusive rights to the pyrolysis oil separation technology developed by Brown and the Bioasphalt developed by Williams.

“We currently operate a pilot plant at Iowa State University,” says Avello president Dr. Dennis Banasiak. “The facility can process up to a quarter ton of biomass per day.” The company has also been approved by the Iowa Power Fund for a $2.5-million grant to begin building a 2.5 ton/day (2.3 tonne/day) demonstration unit early in 2012. Avello is focused on using feedstocks with “near-term commercial potential,” says Banasiak. These are mainly woody biomass and corn stover. Pyrolysis oil can also be made from dedicated energy crops.

Banasiak says that the pyrolysis oil they made using different feedstock categories (hardwood, softwood, herbaceous crops, agricultural residues) varies only slightly in terms of chemical and physical properties. It is also very similar for different types of biomass within each category. Yields of pyrolysis oil and biochar, however, vary to a larger degree with biomass type. “This feedstock flexibility is an important benefit provided by our process and fast pyrolysis processing in general,” Banasiak notes. “Being able to produce a similar end-product from different feedstock types means it is possible for us to provide customers with a consistent product.”

In addition to producing pyrolysis oil that can be used to make asphalt, Avello is producing “biofuel oil” (a stable, low carbon liquid fuel oil for direct fossil fuel replacement or blending), biochar (a soil amendment, renewable heat and power fuel, and potential carbon sequestration agent), and various chemicals for specialty markets.

A worldwide leader in size reduction technology, Vecoplan designs, engineers, manufactures, and implements complete biomass feedstock preparation systems, including pre-shredding, separation, screening, air classification, re-shredding, storage, unloading, sampling, and fuel delivery.

Working with individual customers, Vecoplan delivers technologically advanced, material specific, and application specific shredding, ferrous and non-ferrous removal, size and density separation, screening and classification technologies and extremely efficient conveyor and bulk material handling, metering, storage and unloading technologies.

Contact Vecoplan today to learn more about our existing systems or to arrange a visit to one, or several, of our installations.

ACT BIOENERGy, LLC

www.actbioenergy.com

Tel: 518-377-2349, Toll free: 1-877-228-2465

ACT Bioenergy manufactures high-efficiency biomass boilers ranging from 150 to 500 kW thermal. Our underfed grate, gasificationtype hot water boilers are user-friendly, with automated ignition, feed control, and ash removal. High efficiency and exceptionally low emissions are achieved by constant monitoring of combustion chamber temperatures, oxygen levels, and pressures, and automatic adjustment of fan speeds and fuel feeding rates to maintain optimal operating conditions. Typical fuels include wood chips, wood pellets, and selected agricultural residues. ACT Boilers are ideal for commercial, institutional, and multi-family residential buildings. An ACT boiler project in New York State was recognized as the North American Bioenergy Project of 2011.

www.advancedrecyclingequip.com

Tel: 814-834-4470, Toll free: 1-800-611-6599

Advanced Recycling Equipment, Inc., located in St. Mary’s, Pennsylvania, manufactures Challenger Biomass Combustion Systems, ranging from 1-million to 60-million BTU (240 kW to 17.6 MW). The systems are capable of burning a wide variety of biomass materials with up to 50% moisture content for energy recovery through hot air, hot water, steam, and cogeneration. Challenger thermal combustion systems offer advanced controls, full automation, and rugged design to ensure long life. The systems are very clean burning. Challenger systems are an ideal fit for greenhouses, production/manufacturing facilities, or any other commercial, private, or institutional application.

www.aesintl.net

Tel: 316-201-4143

AESI delivers commercially proven modular, plug and play biomass energy systems that perform reliably from day one and require low operation and maintenance attention. Using a

Asthe price of oil continues to rise and enterprises, institutions, and municipalities look for renewable energy options, biomass furnaces and boilers are becoming ever more attractive. Canadian Biomass’ listing of biomass boiler manufacturers and suppliers, as well as companies that offer retrofits and contract biomass heat, is a first stop for those looking to determine what’s available in Canada. Thermal options range from about 150 kW to 100 MW, and electrical capacities range from 250 kW to 25 MW.

two-phase process of gasification followed by combustion via a fire-tube boiler, AESI’s scalable applications offer thermal output between 1 million BTU/h (290 kW) and 20 million BTU/h (6 MW) and power generation between 50 kW and 1 MW electric and more through multiunit staging. The systems are suitable for agricultural, municipal, industrial, and institutional applications. They fire various fuel types up to 55% moisture content, including wood, agricultural residue, industrial process waste, sludges, manures, and MSW. Systems feature automation from fuel reception to ash extraction, remote monitoring, and water-cooled grates.

www.falmecboiler.com

Tel: 418-662-3663

ASI Énergie specializes in thermal plants fuelled by biomass or municipal solid waste. It has developed a new concept of small, modular, packaged systems that are built and installed, producing up to 5 MW. Its biomass boilers are designed to burn pellets or woodchips, producing 25 kW to 1 MW (hot water or steam). Hybrid boilers are designed to produce 100 to 2000 BHP. Cogeneration plants are equipped with fluidized bed combustion technology.

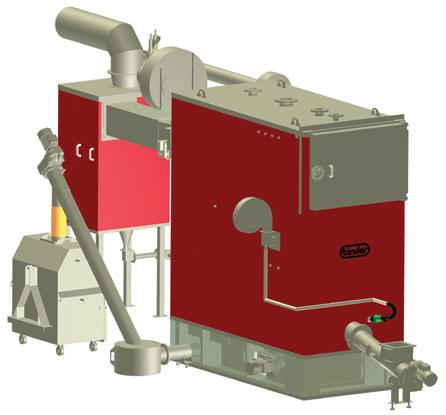

www.binder-boiler.com

Toll free: 1-888-475-4858

Binder Boiler Sales USA is the North American distributor for Austrian company Binder GmbH. Binder’s water tube boilers range from 150 kW to 10 MW hot water, all ASME and CS certified. The step-grate furnaces and underfed pellet boilers range from 150 kW to 3 MW thermal. The systems are suitable for a variety of applications, including greenhouses, schools, municipal buildings, sawmills, and others. They are fuel flexible, burning hog fuel or wood chips up to 50% in moisture content, as well as pellets made from wood or agricultural residues. Containerized pellet boiler and wood chip systems ranging from 150 kW to 1 MW are available. Cogeneration capacity is at the research and development stage, with plans for 300 kW thermal and 30 kW electric output from a steam boiler with small-scale steam turbine. Several Binder pellet boilers, 300 kW to 1.5 MW in capacity, have been installed in the Northwest Territories. Binder offers biomass heat and steam contracts in North America with our partner Wood4heating Inc. (see listing).

www.biomasscombustion.com

Tel: 508-798-5970

Biomass Combustion Systems (BCS) relies on its own horizontal zoned grate combustion system to burn both green and dry wood in boilers from 1 to 8 MW. BCS has been working with this design for over 15 years because it is simple to operate and gives the operator good control over both fuel and air delivery to the firebox. BCS also manufactures a line of wood-fired hot air furnaces from 75 to 250 kW. The 25-year field-tested design, with compact all-steel construction, is ruggedly built to withstand long-term industrial use. BCS fireboxes are engineered with extra thick end-walls, which unlike refractory fireboxes, will not crack and break with repeated hand firing.

www.blueflamestoker.com

Tel: 204-803-8209

Blue Flame Stoker offers multi-fuel boilers ranging from 1.4-million to 17-million BTU/hour (400 kW to 5 MW) system capacity. The chain grate design provides a large grate area and large combustion volume, assuring complete solid fuel combustion. It offers type “C”, three-pass, fire-tube-style boilers designed for hot water and steam applications up to 250 psig. The systems are proven to combust: wood pellets, oat hull pellets, wood shavings, wood chips with up to 55% moisture content, flax straw, demolition wood, and a mixture of turkey manure and wood shavings. Typical applications include central heating systems, greenhouses, schools, kilns, grain dryers, poultry and hog barn heat, and steam generation.

ChIPTEC CORP.

www.Chiptec.com

Toll free: 1-800-244-4146

Chiptec Corp. produces Chiptec Wood Energy Systems. These fixed-grate, close-coupled gasifier systems range from 300 kW to 20 MW thermal output. Cogeneration capacity is available at 300 to 900 psig. The gasifiers can fire almost all boiler types, from low-

pressure fire-box to high-pressure scotch marine systems. The systems are suitable for many applications, including greenhouses, municipal buildings, and industries, and use biomass fuels 6 to 60% moisture content. The systems have exceptionally clean gasification and combustion and are very carbon efficient, producing minimal emissions. They have long run times and low maintenance requirements.

www.combustionexpert.com

Tel: 819-379-2954, Toll free: 1-888-379-2954

For over 15 years, Combustion Expert Inc. has manufactured biomassfired boiler systems from 200 kW to 30 MW and greater. Its expertise in combustion allows it to create systems that use any type of woody biomass as fuel, with up to 55% moisture content. Combustion Expert finds the solution, whatever the need: hybrid boiler, water or fire-tube boiler, low or high pressure, etc. Its goal is to innovate and improve on combustion technology, as well as to satisfy the various needs of commercial, industrial, and institutional clients across Canada and abroad, such as sawmills, pulp and paper industries, hospitals, and municipal buildings.

www.compte-fournier.com

Tel: 418-423-4241

Compte-Fournier is the biomass boiler technology supplying renewable energy to the London 2012 Olympic Games. Compte-Fournier offers fully automated, high-efficiency biomass boilers with Compte-R technology in North America. Hot water boilers range from 250 kW to 10 MW, steam boilers have output of 2 to 12 t/h at pressure of 10–24 bar, and there are overheated air and water solutions, all using biomass at 5–60% moisture content. Boiler installations range from small and

large district heating networks to large energy companies. Compte-Fournier’s worldwide experience is based on more than 1600 installations. Its first Canadian installation will be inaugurated this fall: a greenhouse installation of two 6-MW boilers.

www.deckerbrand.com

Tel: 204-764-2861

Decker Manufacturing makes Decker Brand Boilers, available in six sizes from 146 kW to 1 MW thermal capacity, as well as chain grate steam/hot water boilers from 2 to 5.9 MW thermal capacity. The boilers are designed for multiple fuels, including agricultural and forestry residues. Decker provides complete heating systems for greenhouses, barns, shops, grain dryers, and many other applications. Boilers feature automatic tube cleaning, and furnaces have automatic ash removal systems. Add-ons include economizers to increase boiler efficiency, multi-cyclone collectors to remove particulates, and dalamatic dust collectors to remove other emissions. Complete engineering and design services are available.

www.deltech.ca

Tel: 250-564-3585, Toll free: 1-800-736-7733

Deltech offers biomass boilers in the range of 500 kW to 50 MW (1.7-million to 170-million BTU/hour) thermal output, with available cogeneration capacity typically 0.2 to 5 MW electrical. Furnaces are pile, pellet fixed-bed, or step-grate burners, heating low-pressure hot water or thermal oil boilers. Applications include sawmills, wood fibre drying (e.g., pellet plants), and building heating. A variety of biomass can be burned, including hog fuel up to 50% moisture content, wood pellets (typically 8% moisture content), and planer shavings (typically 15% moisture content). Deltech offers a full range of services, including full life cycle, turnkey

systems; consulting and needs analysis; engineering and design; and manufacturing and installation.

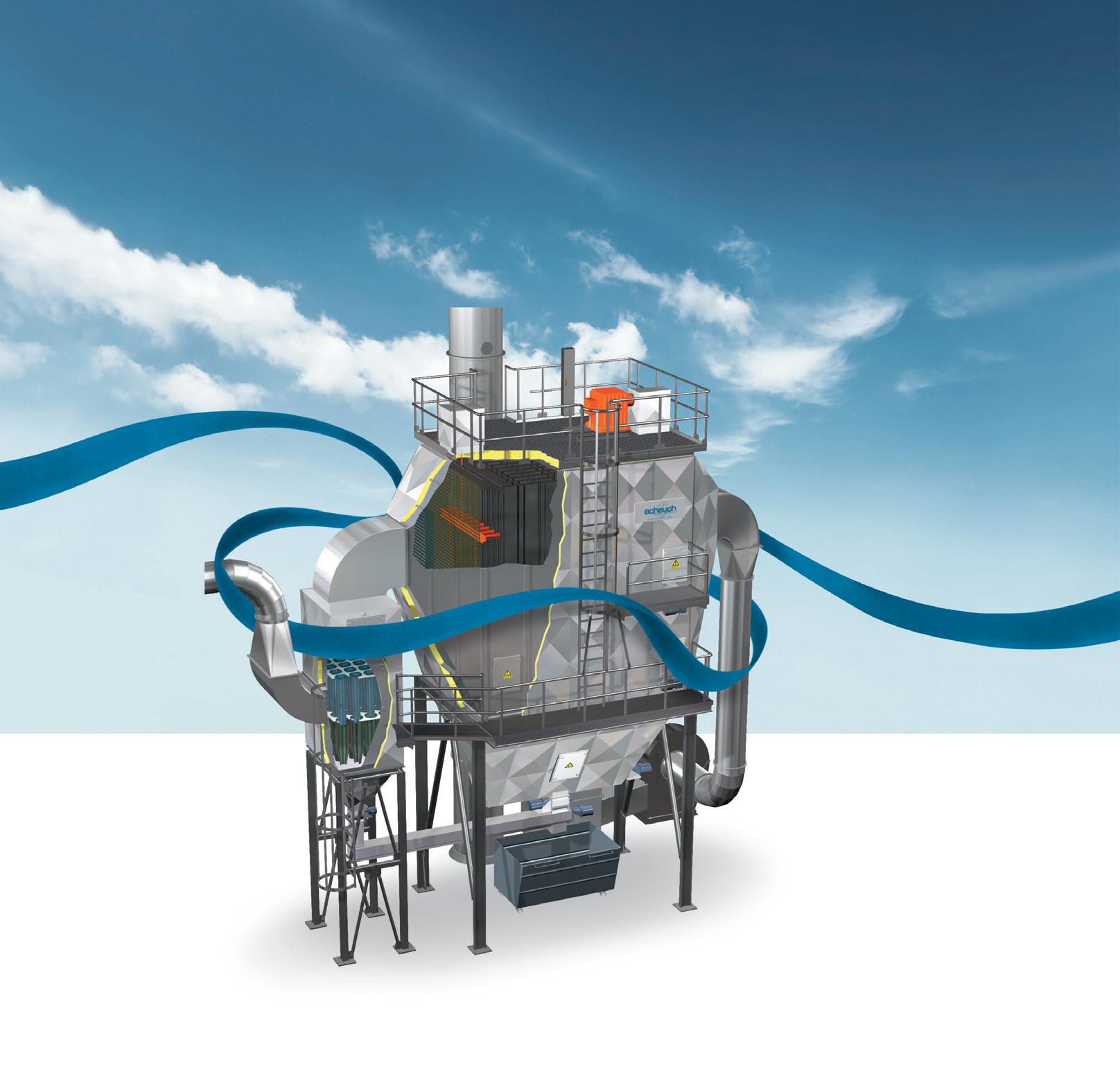

EBNER-VyNCkE

www.ebnervyncke.com

Tel: 330-335-1778

From boiler supply to turnkey solutions, Ebner-Vyncke provides boiler systems from 3 to 100 MW thermal for steam, hot water, thermal oil, or hot gas production, with cogeneration experience up to 12 MW electric. Its furnaces are watercooled step-grate; boiler types include hot water, steam, superheated steam and hot water, thermal oil, hot gas, combination water-tube/fire-tube, and vertical and horizontal water-tube. Ebner-Vyncke boilers are installed in greenhouses, sawmills, and other industrial and commercial facilities. They use a wide variety of fuel types and moisture contents, from sawdust and hog fuel to rice hulls and empty fruit bunches. Based on nearly 100 years of biomass combustion experience for energy applications and around 4,000 installations worldwide, EbnerVyncke is well positioned to support a client’s industrial energy needs.

ENERGy PRODUCTS OF IDAhO (EPI) www.energyproducts.com

Tel: 208-765-1611

EPI’s fluidized bed boiler systems convert renewable biomass and other solid or liquid fuels into steam energy and range from 5 to 60 MW thermal output. From major superheated utility power boilers to small heat recovery boilers, EPI systems feature a state-of-the-art fluidized bed thermal oxidizer combined with advanced heat transfer technologies to cleanly and efficiently generate steam energy. With more than 100 EPI fluidized bed boilers burning over 200 different varieties of fuels, EPI has vast fluidized boiler experience on a wide variety of fuels. EPI systems handle fuels ranging from 5 to 65% moisture content and over 50% ash content.

www.ensightbioenergy.com

Tel: 902-621-2254, Toll free: 1-800-742-4256

Ensight Bioenergy distributes Woodpecker boilers in the Atlantic region. The new Thermon series pellet boilers come in 150, 200, and 300 kW thermal output, suitable for commercial-scale heating. The boilers are manufactured in Ontario to ASME standards and assembled in Vermont, south of Montreal. All Thermon boilers can be monitored by computer or smart phone.

www.evergreenbioheat.com

Tel: 604-943-4671

Evergreen BioHeat Ltd. provides full-service engineering and is a supplier of Austria’s high-efficiency boilers by Fröling. It offers a wide range of fully automated, hydronic, lowpressure boilers, including the P4, FHG, TX, Turbomat, and the Lambdamat, which accommodate pellets, chips, or logs as fuel while providing output capacities up to 1 MW. Over the past 50 years, Fröling has developed wood-heating technology featuring Lambdatronic control optimization, facilitating varying fuel moisture contents, minimizing emissions, and maintaining high output levels.

www.finkmachine.com

Tel: 250-838-0077

Fink Machine is an authorized sales and service agent for Viessmann-KOB commercial boilers from Austria. The Pyrot and Pyrotec lines range from 100 kW to 1.25 MW thermal, offer 4:1 turndown ratios, and use both wood pellets and wood chips with 50% moisture content with a thermal efficiency of 90%. Recirculation flue gas technology, lambda (oxygen) sensors, temperature sensors, and walking floors controlled in unison by an automated panel allow for this range of fuel types. They offer numerous fail-safe features on a safety chain program. These are 100°C boilers with optional ASME vessels from 30 to 60 psi. Over the past 10 years, Fink Machine has installed more than 40 boilers for district heating loops, hospitals, greenhouses, schools, municipal buildings, waste facilities, universities, and other facilities across Canada and the USA.

www.hurstboiler.com

Tel: 229-346-3545, Toll free: 1-877-994-8778

Hurst Boiler Co. specializes in the manufacturing of modular biomass boiler systems with outputs ranging from 28 kW to 52 MW thermal. Boiler vessel designs (CRN registered) include firebox, vertical tubeless, hybrid water/ fire-tube, and water-tube. Operating pressures range from 15 to 900 psi, with steam superheat available. Modular biomass thermal to electric cogeneration systems are offered in 250 kWe, 500 kWe, 1 MWe, 3 MWe and 5 MWe packages. Hurst manufactures seven different types of biomass stoker/gasifiers, which have used almost 2,000 different types of biomass fuels over the last 40 years. Hurst has grown with >350 employees, becoming an experienced, reliable, and stable biomass thermal system supplier.

www.icminc.com

Tel: 316-796-0900, Toll free: 1-877-456-8588

ICM has commercial gasification equipment available in three unit sizes capable of processing 150, 300, or 450 tons/day of biomass and producing 5, 10, or 15 MW, respectively. Cogeneration can be readily integrated into the process. ICM’s gasifier can use either low- or high-pressure heat recovery steam generators based on water tube design, depending on customer needs. The technology is suited to a wide range of applications, with current focus on waste-to-energy and biomass-to-energy products. ICM expects to serve industrial applications, municipalities, sawmills, etc., and can customize the equipment to fit a variety of applications. Feedstocks with 20–50% moisture content have been successfully tested, including refuse-derived fuel (RDF) from MSW, RDF blended with tire-derived fuel, wood chips, bark, trimmings, construction and demolition waste, agricultural residues, energy crops, poultry litter, paper sludge, and plastics.

www.ideal-combustion.com

Tel: 819-566-5696, Toll free: 1-888-656-5472

Ideal Combustion offers biomass gasification combustion technology with horizontal reciprocating grate furnaces in the range of 150 kW to 30 MW thermal and cogeneration capacity from 1 to 5 MW

electric. The systems are suited for greenhouses, schools, hospitals, sawmills, and more. They accept any type of fuel, and up to 60% moisture content. The systems feature hydraulic ram biomass feeders for trouble-free operation, double combustion chambers, automatic boiler tube cleaning and ash removal systems, and fully computerized controls with VFD. Low headroom space is required. The systems use biomass gasification technology for cleaner combustion gases, and have high overall efficiency due to the cleanness of the exchanger. The systems are compatible with any type of heat exchanger, including steam, hot water, thermal fluid, and hot air.

kMW ENERGy INC.

www.kmwenergy.com

Tel: 519-686-1771

KMW Energy Inc. offers heat energy only or combined heat and power (CHP) plants complete with power generating equipment. Thermal-only systems range from 150 boiler hp (1.5 MW thermal) to over 4,000 boiler hp (40 MW thermal); CHP plants range from 1 to 25 MW electric. Heating mediums can be hot air, high- or low-pressure steam, hot water, or thermal oil. Furnaces are reciprocating grate-type; the grate cycling pattern achieves a high degree of gasified-combustion efficiency, resulting in minimal stack emissions. The boilers are typically custom-designed and built to specifications to ensure trouble-free operation. The systems accept a wide variety of solid fuels, including sawdust, bark, wood chips, agricultural waste, rice husks, sewage and mill sludge, RDF, and construction debris. KMW supplies the greenhouse, forestry, and wood products industries, as well as the municipal waste-to-energy and bio-solids sectors. It has completed more than 100 biomass energy projects in Canada, USA, Mexico, Chile, and Australia.

For the separation of particulate matter, centrifugal separators for pre-separation and dry electrostatic precipitators for final cleaning represent the best available technology. Take advantage of our single source system solutions.

• Single and multi-field ESPs

• Energy Recovery & Cleaning Systems (ERCS)

• Fabric Filters in combination with Dry Sorption Processes

Our extensive industry experience ensures the most reliable design and economical operatioln.

Scheuch Inc.

531 Admiral Drive, lSuite 200 London, Ontario, N5Vl 4L6, Canada Phone: 519 951-770l0 I Fax: 519 9l51-7711

office@scheuch.ca www.scheuch.ca

kRANN

www.krann.ca

Tel: 604-538-8113

Krann offers biomass boiler systems in the 1 to 10 MW range for both hot water and steam, heated by Krann gasification furnaces. Typically, no filters are needed for flue gas handling because of the low emission levels. These systems can be used to generate electrical power through either a steam turbine or an organic Rankine cycle module. Fuels include hog fuel, shavings, recycled wood waste, and others, with up to 55% moisture content. Applications include sawmills, greenhouses, drying facilities, municipal buildings, hospitals, and others. These turnkey systems are fully automated from fuel storage to exhaust and require minimal supervision. Krann also offers the conversion of existing fossil fuel boilers to biomass.

www.burnchips.com

Tel: 906-466-9010

Messersmith Manufacturing provides design, fabrication, installation, and startup of biomass boiler systems with thermal outputs ranging from 600 kW to 6 MW. The systems can use fire-tube or watertube boilers, providing hot water or highpressure steam for electricity generation. A fixed, sloping grate system combines with preheated combustion air to provide clean, efficient combustion with less than

100 ppm of CO. Messersmith also provides particulate removal equipment and stacks to meet air quality regulations. Most users fire green fuel up to 45% moisture content to produce the cheapest unit of heat output. Travelling auger fuel-handling systems prevent bridging and use little electrical power. Automatic chip sorting removes over-length pieces before they encounter an enclosed auger, reducing the chances of jamming.

www.gkmoss.com, www.biomassboilers.com

Tel: 205-408-2929, Toll free: 1-800-759-6677

Moss builds waste-to-energy systems ranging in size from 75 kW to 120 MW. In addition to thermal energy, Moss can provide co-generation with turbines ranging in size from 50 kW to 25 MW electrical. The company offers a variety of combustion designs, including suspension burners and gasifiers with fixedhearth, gravel-grate, reciprocating/step-grate, and fluidized bed design. Its combustor can fire into rotary dryers or produce steam in fire-tube, watertube, and hybrid boilers. Typical installations include sawmills, textile plants, and any facility with high steam demands (low-pressure or high-pressure/ superheated). Moss has experience with a wide variety of fuels, including wood chips, coal, various biomass types, MSW, etc. Moss strives to build lasting business relationships positively impacting both the environment and its clients’ bottom line.

www.nexterra.ca

Tel: 604-637-2501, Toll free: 1-866-247-8159

Nexterra supplies fixed-bed updraft gasification systems ranging from 2 to 30 MW thermal output. Cogeneration capacity is available, depending on the application. Applications include “inside the fence” biomass heat and power systems for industrial facilities, universities, hospitals, municipalities, and government institutions; direct firing of syngas into limekilns, boilers, or dryers; and gasification to internal combustion engine biomass combined heat and power systems. The systems run on clean wood fuels 3 inches or less in particle size, including hog fuel, bark, wood chips, clean construction debris, and pellets, and can handle 6 to 60% moisture content in a single vessel. The systems have ultra low emissions, suitable for urban environments, and high fuel flexibility.

www.pw.utc.com

Tel: 860-565-3051