Maximize Profits with the Morbark® MicroChipper

Create micro-chips vital to the pellet mill market with the new Morbark® Whole Tree MicroChipper.

• Productive – Morbark’s exclusive enhanced Advantage 3™ drum creates uniform micro-chips, while the mechanically driven chip accelerator fully loads your truck.

• Practical – The operator-friendly, slide-in forestry grate system reduces oversized chips for a consistent, high-quality end product.

• Profitable – With an average fuel consumption of 2.25 tons of micro-chips produced per gallon of fuel used, the Morbark 40/36 MicroChipper allows you to reduce costs and maximize profits.

In customer tests, up to 95% of the micro-chips produced passed through a ½" grate, and an average of 65% passed through a ¼" grate.

The Morbark® MicroChipper is a new addition to our full line of heavy-duty Whole Tree Chippers from the leader in the industry. Learn more about our machines and our extensive product support network at www.morbark.com.

CANADIAN BIOMASS

11 Waste Reduction

Enerkem and GreenField to break ground on Québec’s first fullscale cellulosic ethanol facility.

From paper to power

Resolute runs a biomass turbine at its pulp and paper mill in Thunder Bay. 18 A booming

bioeconomy

Edmonton’s R&D focus drives its bioeconomy forward.

Safe wood handling

Explosion prevention and protection is key in pellet-processing facilities.

Large-scale conversion

The largest power station in the U.K. has completed the first step in its shift from coal to biomass.

Valmet Corporation is now an independent, listed company that was reborn through the demerger of the pulp, paper and power businesses from Metso Group in December 2013. We develop and supply competitive services and technologies for the pulp, paper and energy industries.

Valmet’s services cover everything from maintenance outsourcing to mill and plant improvements and spare parts. Our strong technology offering includes entire pulp mills, tissue, board and paper production lines, as well as power plants for bio-energy production. Valmet and Metso will continue to work closely together to offer winning automation solutions.

Our 11,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

ISustainable wood

Pellet conference considers certification

n mid-February, Canadian Biomass attended the Canadian Wood Pellet Heating Conference in Montreal. It coincided with the Montreal Wood Convention and benefited from sharing some seminars and networking opportunities the convention offered since the two conferences are such natural partners. Sawmills are now becoming pellet producers, which makes it beneficial for both industries to have the opportunity to gather together to consider opportunities and tackle issues of concern (see article about Resolute Forest Products on page 14).

again at the conference.

Standardization is required in all levels of the process from the harvest to the end product. This involves a high quality management system that keeps up to date records, proper employee training and daily in-house testing with standardized tests and equipment.

Gordon Murray, the executive director of WPAC and a regular contributor to Canadian Biomass, launched the pellet conference with a call to action. He urged pellet producers to coordinate efforts with appliance manufacturers to increase domestic use of wood pellets.

“We hardly sell any wood pellets at home despite being the coldest country in the world. We all do our own thing and not nearly as successfully domestically as we should be doing it together,” said Murray.

“Today, pellets make up 0.3 per cent of all domestic heating fuels. Let’s shoot for three per cent,” said Murray. To meet this goal, he suggested the industry work together to develop a marketing strategy to meet a 20 per cent annual growth.

But before the industry can grow and gain some momentum in Canada, it is important to ensure that the fuel sold to individual consumers is of a high enough quality to burn well in residential stoves. The standardization of fuel pellets is an important factor that came up again and

Word of mouth is the best advertising and a bad batch of pellets can sully the industry’s reputation. It is in pellet producers’ best interests to have all pellets sold for home heating conform to a minimum standard.

A standard that guarantees a high quality pellet is important to ensure the customer is burning a clean and efficient fuel but consumers would also benefit from knowing their pellets came from a sustainably-managed forest. Public perception is that pellets are being produced from whole trees and that North American forests are under pressure from pellet plants and their insatiable need for wood. Just as ethanol producers have been accused of driving up food prices, wood pellet producers are under suspicion for using too much wood.

Rather than fight the battle against misinformation alone, the forest industry has some publicly trusted standards in place to demonstrate when wood has been harvested sustainably. Building on these standards can only drive the industry forward.

Amie Silverwood, editor asilverwood@annexweb.com

Volume 14 No. 2

Editor - Amie Silverwood (289) 221-8946 asilverwood@annexweb.com

Associate Editor - Andrew Macklin (519) 429-5181 amacklin@annexweb.com

Contributors - Gordon Murray, Treena Hein, Ed Chovanec, David Grandaw, Nadine Block

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales

Josée Crevier

Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Chris Springle

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Business Media.

Printed in Canada ISSN 2290-3097

Circulation

Carol Nixon Ph: (514) 425-0025 ext 30 e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada - 1 Yr $49.50; 2 Yr $87.50; 3 Yr $118.50 Single Copy - $9.00

(Canadian prices do not include applicable taxes) USA – 1 Yr $60 US; Foreign – 1 Yr $77 US

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2014 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

BIOMASS update

BIOAMBER SECURES LOAN FOR SARNIA SUCCINIC ACID PLANT

BioAmber Inc. announced that its subsidiary BioAmber Sarnia Inc. has secured a $10 million interest free loan from Agriculture Canada for the 30,000 MT succinic acid plant currently under construction in Sarnia, Ontario. The loan, which was secured through the Department’s Agri-Innovation Program, will be reimbursable in equal yearly installments from 2015 to 2024.

BioAmber Sarnia had previously received $35 million in support from government organizations including Sustainable Development Technology Canada, the Federal Economic Development Agency for Southern Ontario and the Ontario Ministry of Economic Development, Trade and Employment.

“We are actively negotiating additional loans for Sarnia that will further ease the investment burden for BioAmber, which is an early stage company. Our goal is to get Sarnia operational in early 2015 and these loans will help ensure that we have the capital needed to ramp up production and become a profitable company,” added Mike Hartmann, BioAmber’s executive vice-president.

ONTARIO BIODIESEL PRODUCERS FORM ASSOCIATION

Representatives from three biodiesel manufacturing facilities in Ontario have joined together to form the Ontario Biodiesel Association (OBA).

The organization has been formed through a partnership that includes Methes Energies Canada Inc., Great Lakes Biodiesel and Noroxel Energy Limited. Paul Grenier, a biodiesel advocate and three-term municipal councilor in Welland, is the Association’s Executive Director.

OBA members currently produce 100% of the grain-oil based biodiesel in Ontario, which accounts for 75% of the total provincial production capacity of all biodiesel. OBA members have invested over $80 million in plant and equipment to produce biodiesel in the province. Besides environmental benefits, the biodiesel industry provides a direct and indirect positive economic impact on the province and its agricultural sector.

PORT HAWKESBURY MILL TO DEVELOP BIOPRODUCTS

The Government of Nova Scotia is investing in the development of bioproducts at the Port Hawkesbury Paper LLC mill. A test mill will be set up on the site that will extract sugars from wood fibres for a variety of biochemical products. The test mill is being developed in cooperation with FPInnovations.

The announcement of the financial support for the project comes as part of a $1.1 million by the Government of Nova Scotia to help develop new products and production processes in an attempt to help strengthen the forest industry in the province. The investment will help support eight initiatives in Nova Scotia.

“We are very proud to be associated with the Nova Scotia government as they lead the way in forest sector innovation across the Atlantic Provinces,” said Pierre LaPointe, CEO of FPInnovations. “These projects run a broad gamut across all aspects of the forest sector from investigating the impact of Nova Scotia’s harvesting guidelines, to improving yields at hardwood sawmills, to converting wood to biochemicals.”

IOGEN ANNOUNCES NEW DROP-IN

CELLULOSIC BIOFUEL

Iogen Corporation announced it has developed and patented a new method to make drop-in cellulosic biofuels from biogas using existing refinery assets and production operations.

The company estimates there is refining capacity in place to incorporate 5-6 billion gallons per year of renewable hydrogen content into gasoline and diesel fuel. Iogen will initially commercialize the approach using landfill biogas, and then expand production using biogas made in the cellulosic ethanol facilities it is currently developing.

The production method involves processing biogas to make renewable hydrogen and incorporating the renewable hydrogen into finished fuels in selected refinery hydrogenating units.

The company says it is planning to use the technology in association with two large-scale U.S. cellulosic ethanol plants it is developing, resulting in increased overall cellulosic biofuel yields per unit of feedstock, lower unit capital costs, and lower water usage per unit of biofuel production.

Vancouver energy company eyes switch to biomass

A Vancouver-based energy company, which supplies energy to over 200 buildings in the downtown, is making plans to convert from fossil fuels to biomass.

Creative Energy is in talks with the City of Vancouver to convert its power supply for the downtown core to low carbon fuel, a move that would be equivalent to removing

14,000 cars from the road annually.

Vancouver has already established its Greenest City Action Plan, which aims to reduce emissions by 33 per cent by the year 2020. Converting steam heat and central heat to low carbon fuels is seen as a significant step towards meeting that goal.

TTrading in Europe

Has the ETS failed to make coal expensive?

By Gordon Murray

he European Union Emissions Trading System is the largest multi-country, multi-sector greenhouse gas emissions trading system in the world. So how is this relevant to wood pellets? The short answer is that it is meant to make coal too expensive for power generators. Well then, how well is it working?

The European Union has mandated a 20 per cent greenhouse gas reduction from 1990 levels by 2020 and is working toward legislating a 40 per cent reduction by 2030, thus driving demand for Canadian wood pellets.

We export most of our pellets to thermal power generators in the UK, Belgium and the Netherlands. Since they cost more than coal, wood pellets are supported by a combination of “carrots” (incentives) and “sticks” (taxes and penalties). One such “stick” is the EU emissions trading system (ETS), which is meant to make using fossil fuels unaffordable. However, many believe the ETS has failed. The European Commission and the European Parliament have each recognized the ETS’s shortcomings and are working to remedy them. Established by an EU directive (similar to a Canadian legislative act), the ETS was launched in 2005. As of 2013, the ETS covers more than 11,000 factories, power stations, and other installations in 31 countries – all 28 EU member states plus Iceland, Norway, and Liechtenstein. Aviation operators flying into or from a European airport are also covered by the ETS.

The ETS works on a “cap and trade”

basis, so there is a “cap” or limit set on the total greenhouse gas emissions allowed by all participants covered by the ETS and this cap is converted into tradable emissions allowances. Participants covered by the ETS must monitor and report their emissions each year and surrender enough emission allowances to cover their annual emissions.

Participants who are likely to emit more than their allocation have a choice between taking measures to reduce their emissions or buying additional allowances; either from companies with a surplus or from EU member-state-held auctions. Emissions trading enable reductions to occur where the cost of the reduction is cheapest, lessening the overall cost of tackling climate change.

The ETS has been divided into a number of trading periods: the first period (2005 to 2007), the second period (2008 to 2012), and the third (2013 to 2020). Problems began during the first trading period and have persisted; more emissions allowances were allocated than necessary and a massive overcapacity has continued to build in the carbon market. At the start of phase three, the surplus stood at almost two billion allowances, which has kept the price of emissions allowances to a lowly 5 per tonne.

The current phase has been revised in an attempt to increase the price of carbon; the number of available allowances is to be reduced by 1.74 per cent each year. It remains to be seen whether these changes will raise the cost of emissions allowances.

In the UK, the consensus is that an allowance price of at least 30 a tonne is required to drive investment in low carbon projects so in April 2013, the government implemented a carbon price floor (a level below which the carbon price would not be allowed to fall). Under this mechanism, the government charges a tax on CO2 emissions meant to equal the difference between the carbon price floor and the market value of ETS allowances. It is the combined cost of ETS emissions allowances and the rising UK carbon price support that will eventually make using coal unaffordable for UK generators.

Although regulators have tinkered with ways to increase the demand and price of ETS emissions allowances, a nine-year record of poor performance would indicate that little is likely to change. On the other hand, as the UK carbon price support continues to increase, it will soon become uneconomic for generators to use coal. And since the UK’s treasury pockets all revenue generated from the carbon price support while the carbon price floor mechanism simultaneously helps the UK in reaching its climate targets, it would also seem that the UK government will be happy for the price of ETS emissions allowances to remain low for the long term.

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want to support and benefit from the growth of the Canadian wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-837-8821 or by e-mail at gord@pellet.org.

Waste reduction

Enerkem and GreenField Specialty Alcohols to break ground on Québec’s first full-scale cellulosic ethanol facility.

By Treena Hein

It’sa very positive development for Canada that as crops, trees and the amount of municipal waste continue to grow, so does our national ethanol production. And more and more facilities are now being built that can accept woody biomass and solid waste materials as feedstocks to produce cellulosic ethanol.

“Canadian Renewable Fuel Association members are integrating new technologies into their renewable fuels platforms as well as building first-in-kind standalone facilities,” notes CRFA President W. Scott Thurlow. One of these unique high-tech facilities will be constructed starting later this year in Varennes, Quebec near Montreal. The stateof-the-art waste-to-biofuels cellulosic ethanol facility is a joint 50/50 venture between Enerkem and GreenField Specialty Alcohol, christened VANERCO.

The government of Quebec is contributing $27 million to the project. In October 2013, the federal government (through Sustainable Development Technology Canada’s (SDTC) ‘NextGen Biofuels Fund’) contributed $734,500 as a repayable contribution. However, repayable SDTC funding could reach almost $40 million, based on subsequent project milestones.

“Several activities related to VANERCO project development and site preparation are currently taking place,” says Marie-Hélène Labrie, Enerkem’s vice president of communications. “Construction is currently planned to begin in the second half of 2014 and should be completed approximately 18 months later.” The facility, operated by GreenField and using Enerkem technology, will employ between 30 to 40 engineers, technicians, operators and other staff.

In addition to diverting solid waste from landfills, the plant will reduce the province’s greenhouse gas emissions by about

The waste to biofuel technology developed by Enerkem is at display in

Quebec.

110,000 metric tonnes of CO2 every year. It will help in meeting the government of Québec’s commitment to reduce GHG emissions to 20 per cent below 1990 levels by 2020, under the province’s 2006-2012 Climate Change Action Plan.

With a full-scale waste-to-biofuels facility under commissioning in Edmonton and another one under development in Mississippi, VANERCO is part of Enerkem’s first wave of full-scale commercial projects. The company currently operates both a pilot and a commercial-scale demonstration facility in Québec as well. Labrie explains that the Edmonton facility is the very first collaboration in the world between a waste-to-biofuels producer and a metropolitan centre (the City of Edmonton) to address waste disposal challenges. It will be operational by summer 2014.

But Enerkem is not planning to stop there in its quest to convert more municipal solid waste into biofuels and chemicals. “We see increased interest from cities to reduce landfilling and from large industrial groups, including chemical groups, to develop sustainable energy solutions and produce greener everyday products,” says Enerkem director of communications Annie Paré. “I can certainly tell you that Enerkem is currently developing additional biorefineries in North America and globally, but I cannot provide more details at this stage, unfortunately.”

Being located on the site of an existing GreenField ethanol plant, the Varennes project is unique in that it represents one of the

first integrations between an existing, first generation ethanol plant and a new cellulosic ethanol plant. “By building and integrating this advanced biofuels facility at GreenField’s current first-generation ethanol production site, we will be able to capture synergies with respect to roads, utilities and customers for example,” says Paré.

Jean Roberge, general manager at GreenField Specialty Alcohols’ Varennes plant, adds: “the plants will physically be interconnected to share things such as energy, chemicals, ethanol storage and other similar services. In addition, all of the GreenField existing facilities such as infrastructure, laboratory, maintenance shop and offices will be shared between the projects.”

FEEDSTOCK AND PRODUCTION

The VANERCO feedstock will consist of a wide variety of sorted non-recyclable industrial, commercial and institutional solid waste, in addition to construction and demolition debris. Enerkem’s proprietary thermochemical technology converts mixed textiles, plastics, fibers, wood and other non-recyclable waste materials into chemical-grade syngas, and then into ethanol (38 million litres per year).

Enerkem technology can also produce methanol and other chemical intermediates that form everyday products. “Methanol has many uses in the chemical industry,” says Pare. “It is also used for windshield washer fluid. The other chemical intermediates that

Enerkem is looking to develop in the future are used in products such as textiles, coatings, adhesives and paints, to name a few.” She references a ‘Chemical Markets Report’ from 2013 that says the renewable chemicals market is estimated to reach US$59 billion in 2014. It was US$45 billion in 2009.

“The cellulosic ethanol produced in VANERCO will be distributed by GreenField to refiners and blenders,” says Labrie. “They are required, by mandate, to include a five per cent minimum content (on average) of renewable fuels, such as cellulosic ethanol, in their gasoline pool.”

The first phase of the Enerkem process is auto-thermal, explains Labrie. “This means that the chemical reaction creates the energy needed. Also Enerkem uses low temperature and pressure to operate its system. Overall, Enerkem’s process produces more than four times the energy required to operate. This means for one unit of energy used to operate the plant, we produce four units of usable energy in the form of ethanol as transportation fuel.”

ETHANOL DIVERSIFICATION

At the first-generation GreenField Specialty Alcohols plant on site in Varennes, built in 2006 and employing 52, staff produce 175 million litres of ethanol per year from 12 million bushels of feed corn. GreenField has the leading market share of industrial alcohol and is the largest ethanol producer in Canada. Its Varennes plant also produces 140,000

GreenField produces a variety of products including ethanol, corn oil and dried and wet distillers grains that are returned to farmers for use as animal feed.

tonnes of Dried Distillers Grains with Solubles (DDGS) and 70,000 tonnes of Wet Distillers Grains (WDGS), returned to farmers for use as animal feed. Other products include CO2 valorized in dry ice, and corn oil. The federal government contributed $18 million towards construction.

SEMECS, a private company formed by three local regional municipalities and Biogaz EG, (GreenField’s subsidiary in anaerobic digestion) recently announced plans for the implementation of a 50,000 tonnes-per-year anaerobic digestion plant at Varennes. Feedstock will consist of municipal organic waste (‘brown bin’ collection) as well as organic commercial and industrial waste. GreenField Varennes will be the off-taker for the bio-methane and the digestate will be used by local farmers as fertilizer.

A digester is also in the works at Kawartha Ethanol, a plant that began operation north of Peterborough in Havelock, Ontario in 2011. Corn is used to produce about 80 million litres of ethanol per year (all purchased by MacEwen Petroleum of Maxville, Ontario), as well as WDGS. Approval for the digester project (called Kawartha Biogas) came in April 2013 from the Ontario Ministry of En-

vironment. The 9.8 MW digester will be able to accept feedstocks such as WDGS, ethanol syrup, glycerin from proposed bio-diesel facility on the same site, manure, whey from dairy farms, as well as locally-sourced organic matter, fats and grease.

This use of digesters is of course, part of a bigger diversification/synergy trend at ethanol plants across Canada and beyond. For example, GreenField recently installed a greenhouse at its ethanol plant in Chatham, Ontario, in collaboration with established vegetable producer Cedarline. The ‘Truly Green’ project utilizes waste heat and CO2 from the ethanol plant to grow over 20 million kilograms of fresh tomatoes each year.

At another site, GreenField sells steam to Bruce Power, which operates the Bruce Nuclear Generating Station in Tiverton, Ontario. GreenField also extracts corn oil that today goes to the biodiesel market. Other valuable proteins, fibres and minerals in corn can also be extracted.

And the market for ethanol itself will only continue to expand. In terms of cellulosic ethanol production in Canada at this point, the Canadian Renewable Fuel Association reports

that an Iogen demo plant currently runs on occasion and both GreenField and Lignol have pilot plants in part-time operation. In addition to the Enerkem Edmonton plant under construction, and the VANERCO plant in development, U.S.-based Mascoma is also developing a cellulosic ethanol plant in Canada (to use woody biomass).

“We at Enerkem believe that the demand for cellulosic ethanol will continue to grow in the coming years,” says Labrie. “The advanced ethanol market is driven by a number of factors such as government policies, private investments, infrastructure development such as higher ethanol blends, as well as technologies reaching the commercial deployment phase.”

She says consumers are continuing to ask for more choice at the pump while car manufacturers are working to improve fuel economy, an area in which ethanol can certainly help by delivering high octane ratings and lower emissions. “We equally observe a high level of interest and a growing demand on international markets for advanced biofuels and renewable chemicals,” Labrie adds. “Moreover, ethanol should continue to be cheaper than gasoline.” •

KAHL Wood Pelleting Plants KAHL Wood Pelleting Plants

From paper to power

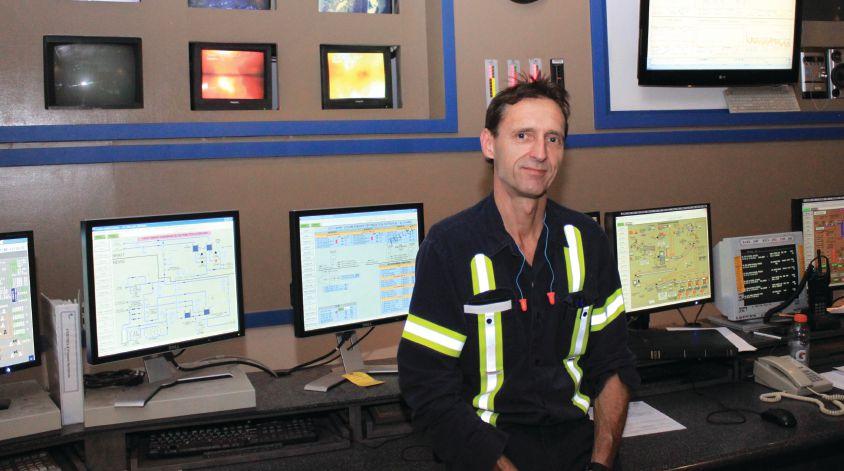

Resolute runs a biomass turbine at its pulp and paper mill in Thunder Bay.

By Amie Silverwood

Resolute

Forest Products is a giant in the forest industry. They’re based out of Montreal with operations all over eastern Canada and pulp and paper mills in the U.S. and South Korea. Recently, the company has installed a condensing turbine at its paper mill in Thunder Bay, Ontario to generate electricity from biomass to sell back onto the grid. Canadian Biomass had the opportunity to tour the paper mill in order to find out how power generation has fit into the company’s operations.

Resolute’s Thunder Bay Pulp and Paper mill is one of the three top complexes of its kind in Canada. It produces 566,000 metric tons of market pulp, newsprint and commercial printing papers and it also sells power from biomass. There are two biomass boilers in the mill with the capacity to generate 116 megawatts of electricity.

“It’s not a stand alone operation,” explained Terry Skiffington, the manager of the Thunder Bay Pulp and Paper mill, “we burn bark, make steam and make power but the operation of this facility is completely interconnected in terms of our overall steam and power systems in the mill. So that turbine goes up and down all day long, regulating and balancing the whole steam system in the mill.”

Not only is the biomass boiler integrated into the pulp and paper mill operations, the biomass burned at the facility supports local loggers and sawmills to make the whole company, and the region’s forest industry, more profitable. Resolute manages over 5 million hectares of forestland in Northwestern Ontario, 100 per cent of which are third party certified .Ontario operations are headquartered in Thunder Bay with plans to upgrade and restart the Ignace sawmill, construct a new sawmill in Atikokan and a new pellet production plant as part of the Thunder Bay Sawmill. Residue from the company’s managed forests and sawmills feed the boiler that powers the pulp and paper mill and sells power back onto the grid.

“In Thunder Bay, we have some tremendous advantages in terms of location and the forest that we have,” Skiffington asserted, “the boreal forest is the best forest for the pulp and paper industry and we’re relatively south but still actively working in and using the boreal. It gives us tremendous advantages in our costs and it’s a great place to play.”

The biomass boilers are fed sawdust, bark, and bush material from the company’s logging operations and sawmill and also the dead bacteria from the papermaking process. The chips are brought into the pulp and paper mill from

LEFT MAIN: A truck filled with chipper debris is unloaded in the biomass storage area.

LEFT TO RIGHT: Dwayne Tankula, one of the engineers that monitors the boiler takes a break to explain the equipment. “This boiler has been burning biomass since 1976 so we have some experience in burning biomass,” he said.

Paul DeGiacomo and Martin Kaiser examine the biomass mix as it heads into the boiler on a conveyor belt.

The industry standard for Sawmills, Pulp/Paper Mills, Panelboard Plants and Wood Biomass Refineries

• Vibration Resistant

• 560 TV Lines

THE DAILY GRIND

Renewable Forest Products, RFP, is one of the first of the local contractors that has taken on the job of supplying chipper debris and logging slash for the boiler. Mario Letourneau, the owner of RFP, saw the benefit of adding a grinder to his operations immediately.

He explains his reasons for jumping into the business: “biomass is a byproduct of forestry so I think it is a nice addition to our business. It’s good for the environment and it’s a good utilization of the fibre. It’s one of the operations I like the most – it really works with our business.”

The logging contractors that take on this additional work are more productive. They’ve built the same amount of road and harvested the same amount of area but they’re able to use more of the fibre from the roadside so the volume they’re getting for their effort has increased.

the sawmill and the forest and they get screened to remove any pins, slivers and fines. The rejected material that can’t be used for making paper gets collected as biomass for the boilers. Sawmill residuals (bark and sawdust) get collected from the company’s sawmill. Chipper debris and logging slash is brought in from the company’s logging operations by the truckload.

The mill currently has a core supply of six contractors who run grinders and send 35 trucks a day to the yard, five days a week to collect about 200,000 tonnes a year from the sustainable forest licences and almost 100, 000 tonnes from private land. The boilers consume about 700, 000 metric tonnes a year of green biomass.

Established 1973 World’s Toughest

“The U.S. housing market recovery means there has to be a home for biomass because as the sawmills spin up, the biomass [from the sawmills] has to go somewhere and the best thing to do is to make energy with it,” said Skiffington.

The industry standard for Sawmills, Pulp/Paper Mills, Panelboard Plants and Wood Biomass Refineries

• 560 TV Lines

• Waterproof, IP68 Rating

• 700 TV Line

• 2 9, 4 3, 6, 8, 12, 16 mm lenses

• 2.9, 3.6, 4.3, 6, 8, 12, 16 mm lenses

• All Weather, Extreme Environment

• All Weather, Extreme Environment

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Tri-Axial Mounting System

• –60°C to +60°C

• Tri-Axial Mounting System

• –76°F to +140°F

• –60°C to +60°C and –76°F to +140°F

• Waterproof, IP68 Rating

• Vibration Resistant Available from leading electrical wholesalers throughout North America

– Ph. 604-569-3240 • US – Ph. 269-966-2900 1-800-578-1853

A healthy regional forest industry requires a balance that has to be maintained in order for operations to be profitable. The market demands lumber from the sawmills but if the sawmills can’t sell chips or sawdust, they can’t compete over time with other sawmills that have a healthier ecosystem with customers for their leftovers.

• 2 9, 4 3, 6, 8, 12, 16 mm lenses

• All Weather, Extreme Environment

“It’s very important that this [pulp and paper] mill and other key mills in Ontario are in a position where they can be completing that balance otherwise, sawmills can’t run.”

• Heavy Gauge Di-Cast Metal Alloy & Titanium Components

• Tri-Axial Mounting System

• Waterproof, IP68 Rating

Approximately half of the volume of wood that goes into a sawmill comes out as chips. In Northwestern Ontario, the industry is in a balanced state where all the sawmills have customers to buy their chips. Installing a condensing turbine that also consumes some of the leftovers from sawmills helps to maintain this balance and gives the company the confidence to build more sawmills in the region (in Atikokan and Ignace).

• Vibration Resistant

• –60°C to +60°C [–76°F to +140°F]

Available from leading electrical wholesalers throughout North America

TECHNOLOGIES Inc.

Canada – Ph 604-569-3240 US – Ph 269-966-2900 www opticomtech com 1-888-410-2447 www.toughestvideocamera.com

The biomass is delivered in trucks from within 200 kilometres of the mill from Monday to Friday. It’s brought onto the site and dumped into piles that are constantly being turned over to keep them from overheating and causing a fire. Sawdust is mixed with bark and chipper debris to come up with the perfect mix to fuel the fire. Sawdust alone is too combustible to be put in the boiler; it would be like throwing gasoline on a fire.

“We have sawdust that is 42 per cent moisture and then we have

The biomass, a mix of sawdust, chipper debris and logging slash, is brought into the mill on a conveyor belt.

other material that is 52 and when we mix it all in together, we get a good product. The boiler is designed to burn biomass at 50 per cent moisture. So as long as we’re in the 46 to 48 per cent moisture, that’s where we want to be,” says Martin Kaiser, Fiber Optimization Manager for the Ontario operations.

Resolute has always burned biomass at the pulp and paper mill. From 1976 to 1997, it burned bark from the local sawmills but it was very homogenous compared to the material that is currently being burned. The sawmills liked to have the residue burned to avoid sending it to landfills and the pulp and paper mill liked the cheaper fuel. But in 1997, so many of the sawmills shut down and all of a sudden, there was nothing to feed the boiler.

The company took the opportunity to install a condensing turbine that would increase it’s biomass demand and started bringing in different products from the local forest: slash, tops and limbs ground up, chipper debris and ground full-tree birch. This new biomass brought with it different characteristics when thrown into the boiler and required active management. Now there’s a crew whose objective is to keep the steam generation constant; perfecting the recipe that feeds the boiler does it.

The mixed fibre is brought into the mill on a conveyer belt where it is combined with the sludge from the pulp and paper mill. Whatever isn’t used in the boiler comes back out and gets pushed back onto the conveyer to make another trip through. The fibre is fed into the boiler where it burns throughout the boiler on different levels: the sawdust will burn in the air while the heavier debris will fall to the bottom and

RESOLUTE TO BUILD A PELLET PLANT

Resolute is building a pellet plant on the site of its Thunder Bay sawmill where it will produce 50,000 tonnes per year of pellets from the softwood sawdust and shavings from its sawmill. Forty-five thousand tonnes of the pellets produced will be shipped by bulk in a truck to the OPG Atikokan Generating Station. Equipment was ordered at the end of 2013 for construction in the middle of this year. The company plans to begin commercial operation in the fourth quarter of 2014.

burn more slowly.

“The biomass travels up the conveyor and drops into a spout” says Kaiser, “that distributes the biomass onto an inclined, vibrating, boiler grate. Air is injected into the boiler above and below the grate, and the material combusts as it moves down the inclined grate.”

It’s all managed from the control room that has cameras pointed at different parts of the boiler to monitor how much air is shot in, any bark buildup or other potential issues. Every aspect of the burn is monitored from the temperature to the energy produced. The end product is green power for the city and a well-balanced forestry sector in Northwestern Ontario. •

Wood Hogs and Screens

Jeffrey Rader® EZ-Access® Wood Hogs are designed for safe, fast and easy access to hammers, rotors and liners, allowing routine maintenance to be performed safely, easily and with minimal downtime. Our EZ-Access technology even lets operators remove the wood hog’s rotor without moving the feed chute. Plus, our heavy-duty rotor discs allow maximum flexibility of hammer arrangements, up to 3, 4 or 6 rows for premium efficiency on smaller products, while our Duratip® high-alloy hammers with replaceable tips provide increased shredding action and quick change-outs.

Rader® Disc Screens (RDS) are the industry’s #1 scalping screens. When it comes to removing oversize rejects from unscreened wood chips, hog fuel or bark, our RDS is the undisputed workhorse of the industry. With more units in operation than all other suppliers combined, you can depend on us to select the ideal disc profile, interface openings and screen size for maximum screening efficiency.

CRUSH. FEED. PROCESS. CONVEY. STORE.

A booming bioeconomy

Edmonton’s R&D focus drives its bioeconomy forward.

By Andrew Macklin

Edmonton,

Alberta’s provincial capital, is at the heart of Alberta’s resource sector but it has also become the home of the province’s booming bioeconomy.

Alberta sharpened its focus on renewables 10 years ago. Already possessing a strong petrochemical sector, Alberta has strong forestry and agriculture sectors as well. That was where the primary focus of Alberta’s renewable sector began, looking for ways to add value to both agriculture and forestry.

At first, provincial funding was sought after by hundreds of entrepreneurs and researchers, all seeking to approach the same few industrial partners for working agreements. Money was being chased, but industry benchmarks were not being met.

It wasn’t until 2009 that a coordinated effort for research and development was established, thanks in large part to

the knowledge and network of Dr. David Bressler of The University of Alberta. Dr. Bressler had originally been hired by the university in 2003 in a cross appointment with Alberta Agriculture. By 2009, his research in the agriculture sector, along with his network throughout Canada’s growing bioeconomy, led him to form the Biorefining Conversions Network.

“It was always about finding value for the agriculture and forestry sectors,” says Dr. Bressler. “That was the focus of the initial investment.”

The investment that came from the Alberta Innovates program was a three-year, $3 million commitment. That money, in turn, was used to leverage close to $8 million in activity with industry partners and university faculties to grow a virtual applied science network for the province. The initial funding helped get the network built

and research partnerships in place between industry and academia.

The initial investment in 2009 was successful and led to a re-commitment in 2012, this time with $4 million in funds over a three-year period. The new funding commitment meant funds that weren’t already tied to research projects, allowing the BCN to reach out to industry for feedback on much needed research and development. That includes forestry, where six corporate partners came to the table to help produce a platform of projects that now includes research into tall oil, turpenes ash content, and cellulosic characterization separation. Working with forestry partners has also shrunk the communication gap between industry and academia, helping both parties work to discuss information using the same terminology.

The BCN funding is also helping to

The Advanced Energy Research Facility at the City of Edmonton’s waste management facility contains pilot plants for both Enerkem and Forge Hydrocarbons.

bridge the financial gap caused by the economic climate in Alberta. Bioenergy projects in Alberta are based on a successful economic model since there has been no movement to establish a government subsidy for such projects. That makes it difficult to get projects to the commercial stage. But with the BCN funding investing money and resources into development at the bench or pilot plant level, economic models for commercialization can be determined.

There is capital funding available in Alberta for projects that have a strong business case. That funding also falls in line with the successful industries already established in Alberta.

“In Alberta right now, our strengths have traditionally been thermochemical because of the oilsands,” says Dr. Bressler. “We also have a very hydrocarbon-dense economy. Everything we do is based around that infrastructure. Most of the projects we are looking at are going toward high value chemicals.”

In addition to studies looking at turpenes and tall oil, catalysts have become

a focus for the BCN. Hundreds of millions had previously been invested in the market because of the petrochemical industry, but now some BCN-funded projects are looking at how some catalysts can be tweaked for use with biomass.

BFN_Canadian Biomass ad FINAL.pdf 1 14/03/2014 1:45:00 PM

One project that has already emerged from the BCN program is a process that,

without using any fat or oil, breaks the molecules to remove the hydrocarbon. A one-litre continuous reactor pilot plant was built at the University of Alberta, and the process was stabilized. Dr. Bressler looked to expand the scale of the technology, but the original industrial partner backed away. The technology caught the eye of Biox

Construction of the $100 million Enerkem waste-to-ethanol plant is scheduled to complete by the end of 2014.

founder Tim Haig and, across the last four years, the technology has moved forward with Haig’s support. Two new patent technologies were developed through the program, one on emerging reactive designs and one for getting branching reactions for side chains.

The result was the technology being purchased from the University, and Haig is using the system as the foundation for Forge Hydrocarbons. Haig has since been able to work with Dr. Bressler, establishing a 20 litre per hour pilot plant at the Advanced Energy Research Facility at the City of Edmonton’s world class waste management facility. The City of Edmonton is able to provide brown grease and biosolids from municipal waste as a feedstock for the process.

The Forge Hydrocarbon technology on the waste management site is based on removing the glycerol from the grease, oil or biosolid, much like in the creation of biodiesel. But the Forge process also pops off the CO2 molecule and keeps it as a byproduct that can be collected and used for

other purposes. The resulting biofuel has a higher hydrocarbon density, lower cost of conversion, and a significant reduction in capital cost. The plant carries just a 10 ft. by 5 ft. by 14ft. footprint, as well as two distillation towers that were constructed by the U of A Faculty of Engineering.

A $100 million commercial waste-to-biofuel plant is on the same site as the Forge Hydrocarbons project. Currently in the final phases of construction, the plant will remove 30 per cent of Edmonton’s landfill waste for the production of cellulosic ethanol.

The commercial biofuel plant is expected to operate day and night, 24/7, in order to work through the amount of commercial and residential waste being generated from the surrounding area. It should produce somewhere in the ballpark of 4500 liters of fuel grade cellulosic ethanol per hour. The overall annual volume of 38 million liters is the per annum target, which represents roughly 14 per cent of the ethanol required by Alberta to meet Canada’s federal mandate of a five per cent

ethanol blend. That is the equivalent of the ethanol needed to fuel 400,000 cars a year.

Enerkem also utilizes a five per cent scale pilot plant in the Advanced Energy Research Facility, the same location at the Forge Hydrocarbons pilot plant. The Enerkem plant is used to test a broad range of feedstocks, breaking them down into syngas to be tested for use in other downstream technologies. That includes continued research on the use of CO2 to offset steam use in the ethanol production process.

The development of new bio-solutions for the petrochemical, agriculture and forest industries in Edmonton through the work of the Biorefining Conversions Network, and the addition of the Enerkem facility at the City of Edmonton’s waste management facility, makes this community one of Canada’s emerging bioeconomies.

For more on Alberta’s bioeconomy, visit www.canadianbiomassmagazine.ca or follow us on twitter @canadianbiomass.

Safe wood handling

By Ed Chovanec and David Grandaw

IndustrIal

explosions

are a constant threat to anyone who handles finely divided combustible dust. Most organic material will burn in a solid form, and if this same material is in a dust form, under the right conditions, it will explode. Combustible dust explosions happen frequently in the processing industry. Sometimes these explosions are confined to the process vessel in which they originate in, but more often than

not, the initial explosion will result in a secondary explosion with devastating results.

Companies that handle wood dust, including wood pellet plants, must deal with this risk daily. Having a comprehensive plan to prevent an explosion from happening under normal circumstances, and mitigating the effects of the explosion under upset

conditions, is critical to the safe operation of any facility that handles a combustible dust.

In order for an explosion to occur, five elements must be present: fuel, an ignition source, an oxidizing agent, confinement, and dispersion of the dust into the airstream.

In wood processing and handling plants, the process equipment most typically asso-

Active explosion isolation: Explosion isolation devices prevent a deflagration in a process vessel from propagating through a connection to other equipment where it could cause subsequent explosions.

Carborn Debt

Explosion suppression and isolation: Typically, explosion suppression systems include explosion isolation for interconnected ducts through which flame propagation may occur.

ciated with dust explosions include dust collectors, cyclones, storage hoppers or silos, mechanical and pneumatic conveying, milling systems, pellet coolers, and bucket elevators. All of these vessels can have wood dust in suspended form, either during normal operations or in an upset condition. Once the wood dust is suspended into a dust cloud, all it takes is an ignition source to initiate the deflagration. The pressure from a deflagration travels at the speed of sound, while the growing fireball initially propagates at a much slower speed.

A typical sequence for a dust explosion includes:

• Ignition of the dust cloud;

• The deflagration pressure results in rupture of the vessel;

• The shock wave from this ruptured vessel liberates dust that has accumulated on horizontal surfaces in the process area, such as atop beams, ducts, conveyors and even light fixtures, causing it to become suspended in the process area;

• The escaping fireball from the initial process vessel ignites the newly-suspended dust in the process area, causing a secondary explosion that can destroy the building;

• Flame propagation occurs through interconnected ducts, chutes or conveyors to connected equipment upstream and/ or downstream, with the resulting additional explosions.

EXPLOSION RISK MANAGEMENT

Managing this explosion risk requires a comprehensive understanding of the normal, abnormal and upset conditions in the processing equipment. The Canadian fire code follows the U.S. National

Fire Protection Association (NFPA), which suggests that a Process Hazard Analysis be performed. This is commonly referred to as a PHA, and includes an assessment of the combustible properties of the dust being handled, identifies where a dust cloud can occur in the process, and determines likely ignition sources. The PHA should include an assessment of the consequences of a deflagration should one occur, including both primary and secondary explosion scenarios. Identifying explosion prevention and mitigation steps that should be taken to reduce the risk of an incident is a critical part of a PHA.

Once there is an understanding of the explosion risks present in a process or process vessel, the first line of defence should be explosion prevention. This includes measures to minimize ignition source potential. Typical ignition sources include bearing failure/overheating, electrostatic discharge, tramp metal, and mechanical failure of product or air-moving equipment. Ignition prevention techniques commonly used are strategically-placed magnetic separators, electrostatic bonding and grounding, using the correct electrical equipment for the area classification, and robust hot work procedures.

Spark and ember detection systems are commonly used on dust and pneumatic conveying lines at wood facilities. These systems are designed to detect a burning ember traveling through the ductwork, then inject a water spray downstream to extinguish the ember before it reaches the air-material separator downstream. Diverter valves and abort gates are often used in conjunction with a spark detection system, to either stop airflow or re-direct it to a safe area.

Minimizing the residual dust layers on horizontal surfaces is an important part of any explosion prevention program. Diligent housekeeping to prevent the accumulation of dust outside the process equipment will reduce the risk that an explosion in a process vessel will result in a secondary explosion that destroys the facility.

EXPLOSION MITIGATION

Ignition control, proper housekeeping of residual dust, continuous training of plant personnel on managing the dust explosion risk, and management of change to address the effects of a process or product change, are all critical to helping prevent an explosion from occurring under normal operating conditions. Unfortunately, abnormal conditions that result in an explosion can occur in any process line. This is why NFPA requires the use of explosion mitigation techniques for vessels subjected to an explosion threat.

NFPA 69 lists a number of different mitigation methods that can be employed to deal with an explosion threat. Some of them, such as containment (building the process vessel strong enough to withstand the explosion pressures), inerting (operating in an oxygen-depleted environment), and dilution (injecting a non-combustible substance to create a mixture that will not explode) are not usually feasible in the wood pellet or process industry. The most common techniques include explosion venting, explosion suppression, and explosion isolation.

EXPLOSION RELIEF VENTING

Explosion relief venting, one of the most widely used methods for mitigating dust explosions, requires one (or more) explosion relief vent installed on the wall of a process vessel. The vent consists of a membrane that’s constructed of a material weaker than the vessel

wall. During a dust explosion’s incipient stage, the vent ruptures and directs the explosion’s overpressure, flame, burnt and unburnt material, and other combustion by-products away from the vessel to a safe location. The explosion relief vent is designed to ensure that the explosion’s pressure rise doesn’t exceed the vessel’s pressure shock resistance. These vents are designed according to procedures in NFPA 68: Standard on explosion protection by deflagration venting. NFPA provides an equation for estimating the vented fireball’s size; from this information, you can calculate the safe distance required in front of the vented vessel to protect workers, equipment, and the building structure from the ejecting fireball.

Flameless venting protects indoor equipment from dust explosions by combining an explosion relief vent’s weak membrane with a mesh trap that arrests flame and retains particles. Like an explosion relief vent, the flameless vent’s membrane, installed on the process vessel, ruptures during a deflagration. But unlike with a relief vent, the deflagration’s overpressure, flame, and material discharge through the membrane into the mesh trap, which prevents the flame and material from discharging into the surrounding area. Instead, the flameless vent discharges hot gas and overpressure. A safety perimeter must be established around the flameless vent to protect workers from this discharge.

Like the explosion relief vent, the flameless vent is designed according to procedures in NFPA 68. To ensure that the flameless vent can successfully protect the vessel, the ratio of room volume to vessel volume (that is, the ratio of the volume of the room in

which the vented vessel is located to the vessel’s volume) must also be kept below the flameless vent manufacturer’s recommendations. Since any dust or dirt blocking the openings in the mesh trap would compromise the vent’s operation, the mesh must also be regularly cleaned to ensure that the surface is free of dust or dirt at all times. Some vent manufacturers offer low-inertia, fire-resistant fabric covers to help keep the mesh surface clean.

It is important to understand that explosion venting only relieves the deflagration pressure from the protected vessel. It does not stop flame from propagating to any interconnected vessel, nor does it address the post-explosion fire in the vented vessel. Other protection measures are needed to deal with these threats.

EXPLOSION SUPPRESSION

Explosion suppression systems are often installed in applications where it’s not possible to safely vent an explosion away from process equipment. The system detects an incipient dust explosion very soon after ignition and discharges a chemical extinguishing agent quickly enough into the developing fireball inside the equipment to extinguish the deflagration before a destructive overpressure develops. Major components in a typical explosion suppression system are one or more explosion suppressors, one (or more) explosion pressure detector, one (or more) flame detector, and a control panel. Explosion suppression systems are designed according to NFPA 69: Standard on explosion prevention systems. Typically, explosion suppression systems also include

explosion isolation for interconnected ducts through which flame propagation may occur.

The major advantages of explosion suppression are that no flame is ejected from the protected vessel, and the risk of a post-deflagration thermal event is greatly diminished.

EXPLOSION ISOLATION

Explosion isolation devices prevent a deflagration in a process vessel from propagating through a connection such as a duct, chute, or conveyor to other equipment, where it could cause subsequent explosions. The devices work by mitigating the flame propagation and pressure piling between connected equipment. An isolation device can be active or passive. An active device has detection components, including explosion pressure and/or flame detectors, and a control unit. The detectors detect explosion pressure or a flame and send a signal to the controls to rapidly deploy the device. These active explosion isolation devices are either chemical or mechanical. A chemical isolation device works by rapidly discharging a chemical extinguishing agent, such as sodium bicarbonate, into connecting ductwork to mitigate flame propagation. A mechanical isolation option includes a high-speed gate valve. Milliseconds after the active high-speed gate valve’s detectors sense explosion pressure or flame, the controls rapidly deploy a mechanical barrier -- closing the valve’s gate across the connecting ductwork.

In addition to the active isolation options, there are passive

isolation means available to mitigate flame propagation. The passive valve, which can have a flap or float, is self-actuated by the airflow from a deflagration so it requires no detectors or controls. This device is typically used to isolate dust-handling equipment with relatively low dust loads.

Dust explosions at wood-handling facilities do not need to happen. Understanding where an explosion may happen in the facility, implementing ignition prevention systems, following rigid housekeeping standards, and proper employee training should all be part of designing and operating a process to minimize the threat of an explosion starting. Employing explosion protection measures such as explosion venting, suppression and isolation, will minimize the risk of an incipient explosion in process equipment from escalating into a catastrophic event in the facility.

Ed Chovanec C.E.T., C.S.P. is the Northeast Regional Manager of Fenwal – IEP Technologies and is located in Burlington, Ontario. David Grandaw is the Vice President of Sales for Fenwal – IEP Technologies in Marlborough, Mass. For more information, go to www. ieptechnologies.com, or email the authors at ed.chovanec@ieptechnologies.com or david.grandaw@ieptechnologies.com.

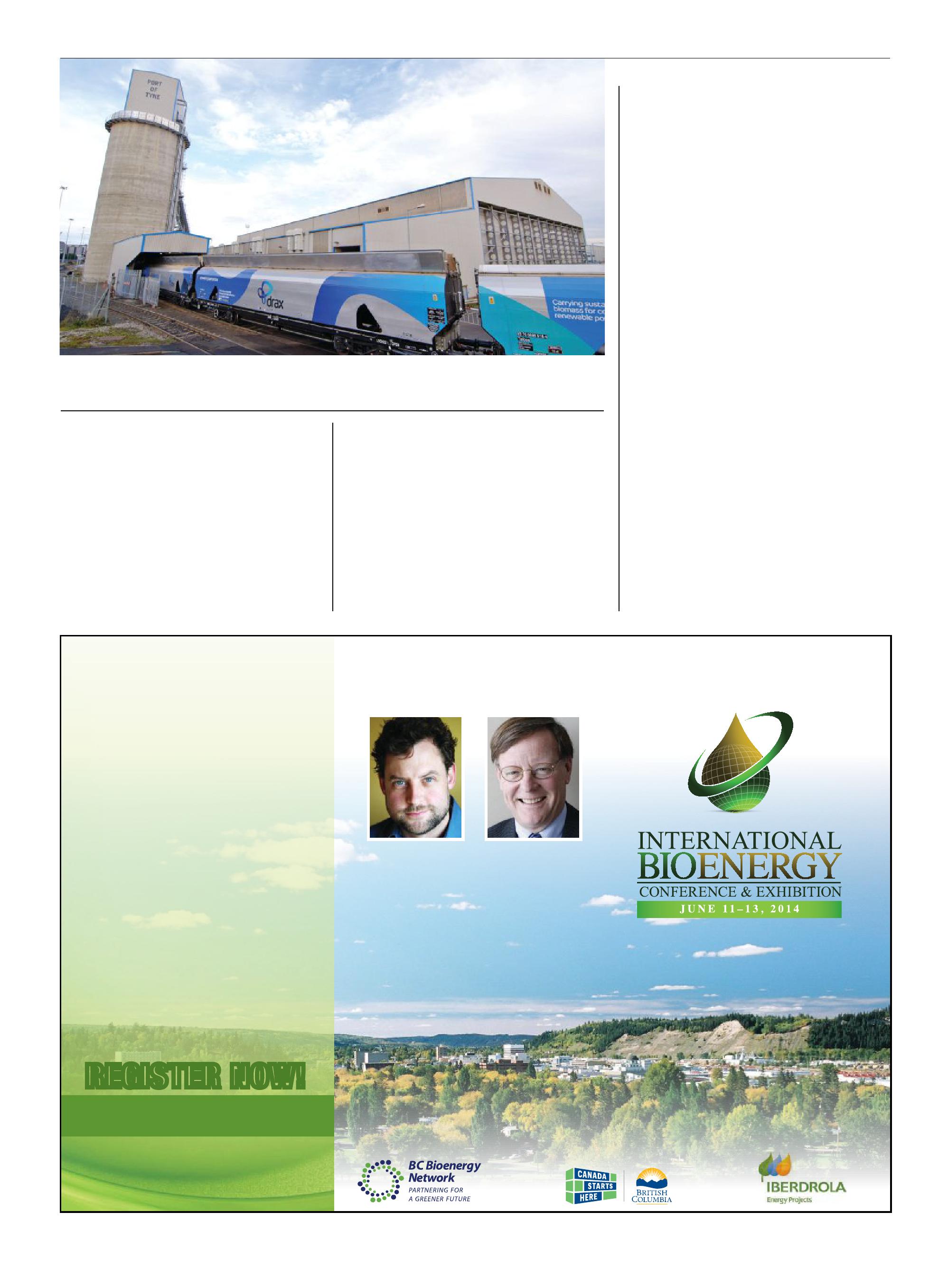

ILarge-scale conversion

The largest power station in the U.K. has completed the first step in its shift from coal to biomass.

By Gordon Murray

nApril 2013, Drax completed the conversion of the first of three coal boilers to fire exclusively on biomass. On Dec. 9, U.K. energy secretary Edward Davey visited the Drax Power Station to celebrate Drax becoming one of Europe’s biggest renewable electricity generators.

Mr. Davey said, “Our coal industry has powered Britain for more than a century, and today we’re seeing a clear roadmap for its future... by converting existing coal plants to cleaner fuels, or building stateof-the-art power stations that mean coal is truly clean.”

I arrived at the Drax Power Station three days later to visit two of Drax’s logistics team – Graham Backhouse and Gordon Lugsdin – to discuss strategy for improving international shipping regulations and to see the Drax biomass conversion first-hand.

Drax Power Station consists of six 660 MW power units, giving a total capacity of just under 4,000 MW, making it the largest power station in the U.K. The company typically provides enough power to meet seven to eight per cent of the U.K.’s electricity needs, sufficient to power around six million homes.

Originally built, owned and operated by

the U.K. Government-controlled Central Electricity Generating Board, the first three power units were completed in 1974 and the second three were completed in 1986. In 1988, Drax invested in flue gas desulphurization (FGD) equipment, making Drax the cleanest as well as the most efficient coal-fired power station in the U.K, according to Drax.

The U.K. electricity industry was privatized in 1990 and Drax then went through a series of owners until 2005, when the company became publicly listed on the London Stock Exchange.

In 2012, Drax completed an ambitious five-year £100-million ($170-million) project to improve the efficiency of its low-pressure and high-pressure turbines. According to Drax CEO Dorothy Thompson, “The low-pressure and high-pressure turbine modules of all six generating units have now been replaced and are operating as expected. This means we are operating at an overall coal-based efficiency for the power station of around 40

per cent, and through this upgrade alone we are reducing our CO2 emissions by one million tonnes a year. We have also taken the decision to upgrade the intermediate pressure turbines of the three generating units that will be converted to biomass. The first will be undertaken during 2014. This will deliver further efficiency improvement benefits.”

BIOMASS CONVERSION

In an effort to reduce its environmental impact, Drax began burning biomass in 2003, evolving to co-firing coal and biomass in all six power units. In July 2012, the company confirmed its plans to transform itself into a predominantly biomass-fuelled generator by converting three of its six generating units to run exclusively on sustainable biomass. The first converted unit began operating in April 2013. The company plans to complete the second unit in 2014 and a third in or by 2016, dependent on securing the rights to sufficient sustainable biomass. Drax calculates that this will reduce carbon emissions

Peter Emery, Drax’s production director, said, “Our transformation to become one of Europe’s largest renewable generators through the use of sustainable biomass means we need new, bigger and better rail wagons.

One of the key objectives in designing the new rail cars was for a wagon that would carry as much biomass as possible.

by 80 per cent compared to coal – a saving of some 10 million tonnes of CO2 a year compared to levels today. When all three units are done, Drax will use seven to eight million tonnes of wood pellets annually.

Not only will Drax be cleaner but the conversion is central to the company’s future prosperity. The U.K. Government has introduced a carbon price floor (CPF) – a tax on fossil fuels used to generate electricity.

Feature Speakers

Dr. William Strauss – Founder/Owner, FutureMetrics, Founder/Director, Maine Energy Systems

Joseph Seymour – Executive Director, Biomass Thermal Energy Council

Gordon Murray – Executive Director, Wood Pellet Association of Canada

Ken Shields – Chairman of the Board, Canadian Bioenergy Association

Deborah Elson – Vice-President, Stakeholder Relations, Canadian Renewable Fuels Association

Matt Bovelander – Senior Consultant Bio Solutions, Indufor Asia Pacific

Seth Walker – Associate Bioenergy Economist, RISI

Paul Lansbergen – Vice-President, Forest Products Association of Canada

Steve Price – Executive Director, Bio-Solutions, Alberta Innovates

Brent Boyko – Director, Biomass Business Development, Ontario Power Generation

It came into effect on 1 April 2013. The CPF for coal started at £0.44 ($0.75) per gigajoule, escalating rapidly to £1.63 ($1.77) by 2016, making the economics of coal power generation very challenging.

Total capital costs for biomass transformation will be in the range £650 million to £700 million ($1.1 to $1.2 billion), incorporating:

• Delivery, storage and distribution

infrastructure for biomass fuel, plus necessary plant modifications, for a three unit conversion;

• Two U.S.-based pellet plants (delivering 900,000 tonnes annually) and one U.S. port export facility; and

• Potential investment to support compliance with the Industrial Emissions Directive of the European Union

So far, Drax is pleased with the performance of its first converted unit – so pleased in fact that the company is now considering a fourth unit. Thompson said, “Evaluation of a fourth unit conversion at Drax is underway, including assessment of whether this would be best delivered through modification of our existing co-firing systems or investment in new bespoke facilities.”

The company is also on schedule with its U.S. projects in the U.S. Gulf region. Pellet plants are under construction in Amite, Miss., and Morehouse, La., as well as the port facility at Baton Rouge, La. These U.S. facilities will be operational by mid 2015.

WHErE THE BioEnErGy WorLD MEETS

Jeffrey Simpson Author and Globe & Mail National Newspaper Columnist

Chris Turner Author, “The Great Leap: How to Survive and Thrive in the Sustainable Economy”

PRINCE GEORGE, CANADA

BIOMASS TRANSPORTATION AND LOGISTICS

Obviously handling seven to eight million tonnes per year of wood pellets is enormously challenging. Brian Greensmith, divisional head of optimization and logistics, said, “It’s a complex project in terms of engineering and construction, mostly in terms of scale.”

Most wood pellets will be imported from North America. Multiple U.K. port terminals are required to be able to receive the large quantities of wood pellets and for redundancy in case of mishaps at any single port. Currently, pellets are being received at the Port of Tyne, which can handle two million tonnes of wood pellets annually.

Unloading, storage and handling capabilities are also being developed at the Ports of Hull (1 million tonnes annually) and Immingham (three million tonnes annually). Immingham will be capable of receiving Panamax-size vessels. Several other port options are actively being investigated to ensure enough capacity to receive eight million tonnes of wood pellets annually.

Biomass is a third lighter than coal but

susceptible to rain, a problem solved initially by retrofitting roof components to old, open coal rail wagons (called rail cars in North America). The difference in density meant that a complete redesign to produce a totally new type of wagon was necessary. Thus, Drax decided to find help to design its own specialized wagons.

Graham Backhouse, head of supply chain and logistics, said, “We decided to commission Lloyd’s to look at designing a new rail wagon. One of the key objectives we gave them was to design a wagon that would carry as much biomass as possible. This was to be the industry leading wagon and even NASA would not be able to come up with a better one.”

To produce a vehicle capable of carrying the maximum amount of fuel, Lloyd’s had to squeeze control equipment, pipework, etc. into otherwise redundant areas of a traditional hopper wagon while designing a viable steel/aluminium roof that could be operated pneumatically and automatically. The discharge of the fuel is also controlled by a patented product flow control system.

Work on two prototypes began in Janu-

ary 2013 and presented the design engineers with a number of challenges in achieving the increased wagon capacity within the limits of the Network Rail loading gauge. At 18.9 metres long with top doors stretching 18.2 metres and bottom doors of 3.7 metres, the supersize wagon has a capacity of 116 cubic metres. This allows a biomass load weighing 71.6 tonnes. Its volume is almost 30 per cent bigger than any freight wagon currently used in the U.K. WH Davis, the last independent British freight wagon manufacturer, met this design specification by working to a measurement tolerance of 5 mm, the highest possible and half that normally associated with wagon manufacturing.

Drax has ordered 200 wagons, for which it owns the designs. Peter Emery, Drax’s production director, said, “Our transformation to become one of Europe’s largest renewable generators through the use of sustainable biomass means we need new, bigger and better rail wagons. We need to keep the biomass dry, move more of it and speed up the process of delivery.”

Drax has engineered an innovative and complex system of fuel delivery, handling,

We have an experienced team at everystageofaproject. We provide design, manufacturing,installation for all your dust collection andairconveying needs.

storage and reclaim for the wood pellets. After delivery to the site by train, pellets are automatically unloaded as the train passes, without stopping, through a dedicated multi-level unloading building incorporating a 15 m deep sheet piled basement.

The fuel is transported via a system of

conveyers, most supported on steel gantries, to a maximum height of 65 m. A process building facilitates the screening of the fuel to remove oversized materials and ferrous contaminants. The fuel is then conveyed to one of four 63 m diameter, 50 m high storage domes, each one capable of storing

YOUR BULK BAG WOOD PELLET

more than 110,000 m3 of biomass.

BIOMASS SUSTAINABILITY

The U.K. Government has decided to bring in strict biomass sustainability controls that go beyond what is recommended or required in the European Union or internationally. Drax supports the government’s decision.

Mrs. Thompson said, “We firmly believe that robust, mandatory sustainability criteria are vital to maintain and enhance public acceptance and ensure that sustainable practices are implemented.”

FINAL WORDS

Drawing on its 10 years of biomass experience, 40 years operating the U.K.’s largest power plant, and the experience in executing its turbine upgrade, Drax appears to have completed conversion of its first boiler flawlessly. The Drax team expects that in its first year of operation, the biomass boiler will be at about 80 per cent availability, which meets its target.

The incredible size of this $1.2-billion project has to be seen to be truly comprehended. The Drax Power Station is the size of a small city. Construction is taking place on a huge portion of the site, at the three U.K. seaports, at the U.S. Port of Baton Rouge, and at its two large-scale pellet plants in Louisiana and Mississippi. And Drax has been able to remain operating and profitable as the project proceeds.

When the project is finished, Drax Power Station will likely be the world’s largest biomass generating plant, reducing emissions by more than 80 per cent relative to coal. In the words of Jason Shipstone, head of engineering, “We started design and engineering in 2011 and we started construction work in 2012. It’s been hugely enjoyable and as an engineer it’s a very cool project to be involved in.”

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want to support and benefit from the growth of the Canadian wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-8378821 or by e-mail at gord@pellet.org. Currently, pellets are being received at the Port of Tyne, which can handle two million tonnes of wood pellets annually. Unloading, storage and handling capabilities are also being developed at the Ports of Hull (one million tonnes annually) and Immingham (three million tonnes annually).

PETERSON INTRODUCES THE 5710D HORIZONTAL GRINDER

Powered by a Tier IVi Caterpillar C27 engine making 1050hp (783 kW), the new Peterson 5710D Horizontal Grinder has the power to handle the toughest jobs.

At 88,500 pounds (40,150 kg) the 5710D is designed for operations that require frequent moves between jobs without a special permit. An optional transportation dolly allows the Peterson 5710D to be easily moved, and then setup for operation within minutes.

May 27-29, 2014 • ADVANCED BIOFUELS SYMPOSIUM 2014

Ottawa, ON biofuelnet.ca/news-and-events/advanced-biofuels-symposium-2014/

June 3-5, 2014 • WORLD BIOENERGY 2014 Jonkoping, Sweden www.elmia.se/en/worldbioenergy

June 11-13, 2014 • INTERNATIONAL BIOENERGY CONFERENCE & EXHIBITION

Pringce George, B.C. www.bioenergyconference.org

July 27-29, 2014 • 2014 PFI CONFERENCE Orlando, Florida http://pelletheat.org

With a feed opening of 60 x 40 inches (152 x 102 mm) combined with Peterson’s high lift feed roll; the 5710D can readily reduce a wide range of material including stumps.

The 5710D utilizes Peterson’s Impact Release System that can be set in the detent mode to provide consistent product sizing or switched to the floating anvil mode for a primary reduction where accurate sizing is less critical. The floating anvil mode provides a high production primary reduction with more protection from contaminated feedstocks and reduced fuel consumption.

The 5710D’s new generation of controls includes Peterson’s high production Adaptive Control System and a fully adjustable feed system that can be optimized for a wide range of materials.

The 5710D features a large grate area that enables the 5710D to produce materials to exact specifications. Our quick-change multiple grate system makes it easy to customize grate configurations to produce a wide variety of finished materials. Grates are removed through an enlarged access door on the side-wall of the 5710D.

Another major innovation included on the 5710D is Peterson’s Impact Cushion System. Urethane cushions allow movement of the compression roll/ anvil housing pivot shaft, cushioning impacts due to contaminants in the feed material. Shear pins above the cushion and a sensing circuit that stop the engine help protect the shaft from catastrophic damage in the event of a severe impact.

September 9-11, 2014 • 2014 CANBIO CONFERENCE & TRADE SHOW

Thunder Bay, ON www.canbio.ca

October 1-3, 2014 • USIPA 4TH ANNUAL EXPORTING PELLETS CONFERENCE

Miami Beach, Florida http://theusipa.org/conference

November 17-19, 2014 • 2014 WPAC CONFERENCE AND AGM

Vancouver, B.C. http://pellet.org

December 1-3, 2014 • CANADIAN BIOECONOMY SUMMIT

Toronto, ON Http://greenfuels.org

Sustainable pellets

IEnergy should come from responsibly managed forests.

By Nadine Block, SFI

t all starts in the forest. The Sustainable Forestry Initiative (SFI) program is probably best known for our forest certification standards, which are based on 14 principles including provisions for forest productivity and health, protection of water resources and biological diversity, managing aesthetics and recreation, protection of ecologically or culturally special sites, compliance with applicable laws and regulations, public involvement in sustainable forestry, and more. We work with everyone who has a stake in the future of our forests – including economic, environmental and social stakeholders – to develop and continually improve our standards (in fact, we’re now in the middle of the open review process for the 2015-2019 Standard).

Recent trends point to promising growth in forest certification worldwide. For example, from 2007 to 2013, the number of hectares of forest certified to the SFI Standard in North America increased 75 per cent from 55.8 million hectares to more than 100 million hectares. We’re also seeing strong growth in certification in many other parts of the world, driven by consumer demand for sustainable products. In an encouraging sign, The World Business Council for Sustainable Development (WBCSD) released a statement last November that promotes the expansion of forest certification across the supply chain. The statement marked a significant step towards the growing trend of recognizing all credible forest certification programs as a proof point for responsible forestry.

Despite growth in certtification, some working forests will continue to remain uncertified. In North America, 60 per cent of private forests are owned by family forest owners, and for many such owners, managing timber is not the primary business activity. SFI’s unique fibre sourcing standard requires program participants who buy raw materials to show that the fibre in their supply-chain comes from legal and responsible sources, whether the forests are certified or not. This involves measures such as utilizing trained loggers, ensuring that best management practices for water quality are implemented and conducting landowner outreach to promote prompt reforestation and practices to protect biodiversity. Because a significant amount of fibre for wood pellets is sourced from uncertified forests, SFI fibre sourcing makes a significant contribution towards providing landowners with the knowledge to practice responsible forestry.

The United Kingdom and other European Union members are embracing bioenergy as a way to meet their climate change commitments and renewable energy goals. Wood energy – specifically the use of wood pellets – presents a viable renewable energy choice to meet demand on a sustainable and consistent basis. However, it is imperative that appropriate measures are in place to maintain healthy, thriving forests. U.S. and Canadian pellet producers are utilizing certification to the SFI Standard to demonstrate how they are addressing sustainable land management concerns.

Of note, the SFI Program is the only

forest certification standard in North America that requires participants to support and engage in research activities to improve forest health, productivity and sustainable management of forest resources. SFI’s Conservation and Community Partnerships Grant program supports projects that advance our knowledge of sustainable forest management in areas including carbon and bioenergy; forest health; water; capacity building; and biodiversity. One of SFI’s 2013 partnership grants was in support of an October workshop, hosted by the Pinchot Institute for Conservation and the International Energy Agency Bioenergy Task Groups, which examined the international trade in wood pellets between the U.S. and Europe and furthered the understanding of how forest fibre can be responsibly sourced.

Similar to the other products that forests provide, like clean water and wildlife habitat, forests have tremendous potential to contribute towards the world’s clean energy needs. SFI is excited to engage in this important conversation with energy producers, regulators, and conservation organizations to ensure we pursue a path that has economic and environmental value.

Those of us working for the future of sustainable forestry know that the future of our forests is tied to a shared responsibility and starts with our communities and the people who rely upon forests every day – if we work collaboratively to promote our shared goal of healthy, thriving forests for generations to come. •

Grinder + Hammermill