ROBOTIC

MACHINE SAFETY DATA:

Bringing

ROBOTIC

Bringing

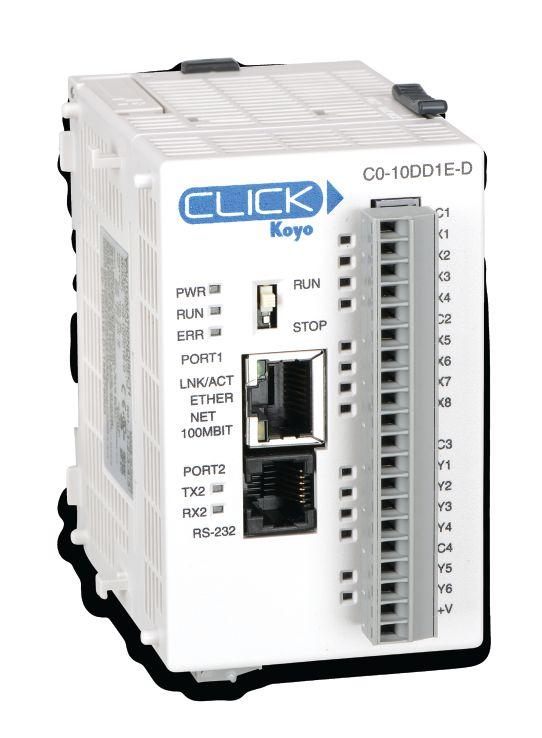

CLICK - The almost free PLC

The CLICK micro-brick PLC is undoubtedly the best PLC value in the industry. With basic models starting at just $69.00 and FREE programming software, CLICK is by far the most practical PLC for the smallest of applications.

• Basic PLC units with 14 discrete I/O points and 2 serial ports starting at $69

• Standard PLC units with 14 discrete I/O points, 3 serial ports and a real time calendar/clock - starting at $99

• Analog PLC units with 8 discrete I/O points, 4 analog I/O channels and 3 serial ports - starting at $129

• Basic Ethernet PLC units with 14 discrete I/O points, 1 Ethernet port and 1 serial port - starting at $129

• Standard Ethernet PLC units with 14 discrete I/O points, 1 Ethernet port and 2 serial ports - starting at $149

• CLICK PLC units can also be expanded up to 142 discrete or 52 analog I/O total

• All CLICK PLCs use our FREE programming software with a simple but practical instruction set

Web site for details and restrictions at: www.automationdirect.com/canada

“This little PLC is superb!!! Now with Ethernet and online programming it is almost unstoppable... I have 14 running and will be adding more. In Love with this thing!”

Paul in OCONOMOWOC, WI

“Have used this model Click in many small applications, and it has worked, reliably, for many years. We even talked some customers out of using “programmable relays” for they are not as versatile or as cost effective as this PLC.”

Todd in ONTARIO, CA

See more reviews under the Reviews tab on the CLICK PLC units’ product page at www.automationdirect.com Customer Feedback:

Get more than you paid for . . . www.CLICKplcs.com

Schuster

@Centerline_Ltd

Pleased to announce this exciting news for our company!

Thank you to our community for 60 years of support bit.ly/2vkAmuf.

@ItrisAutomation

Isolation is no longer a viable security solution for ICS. Now we need risk visibility and prevention buff.ly/2upFyix

@FairbanksScales

When Corey Farms established its #packing facility, we helped them expand and save money.

@AutomationMag tells how: bit.ly/2urUg9Y.

@WSN_News

In the news: “How supervisors can make a huge difference to your organization’s safety bottom line” via @AutomationMag ow.ly/ XUfQ30cUhNR.

BY ALYSSA DALTON

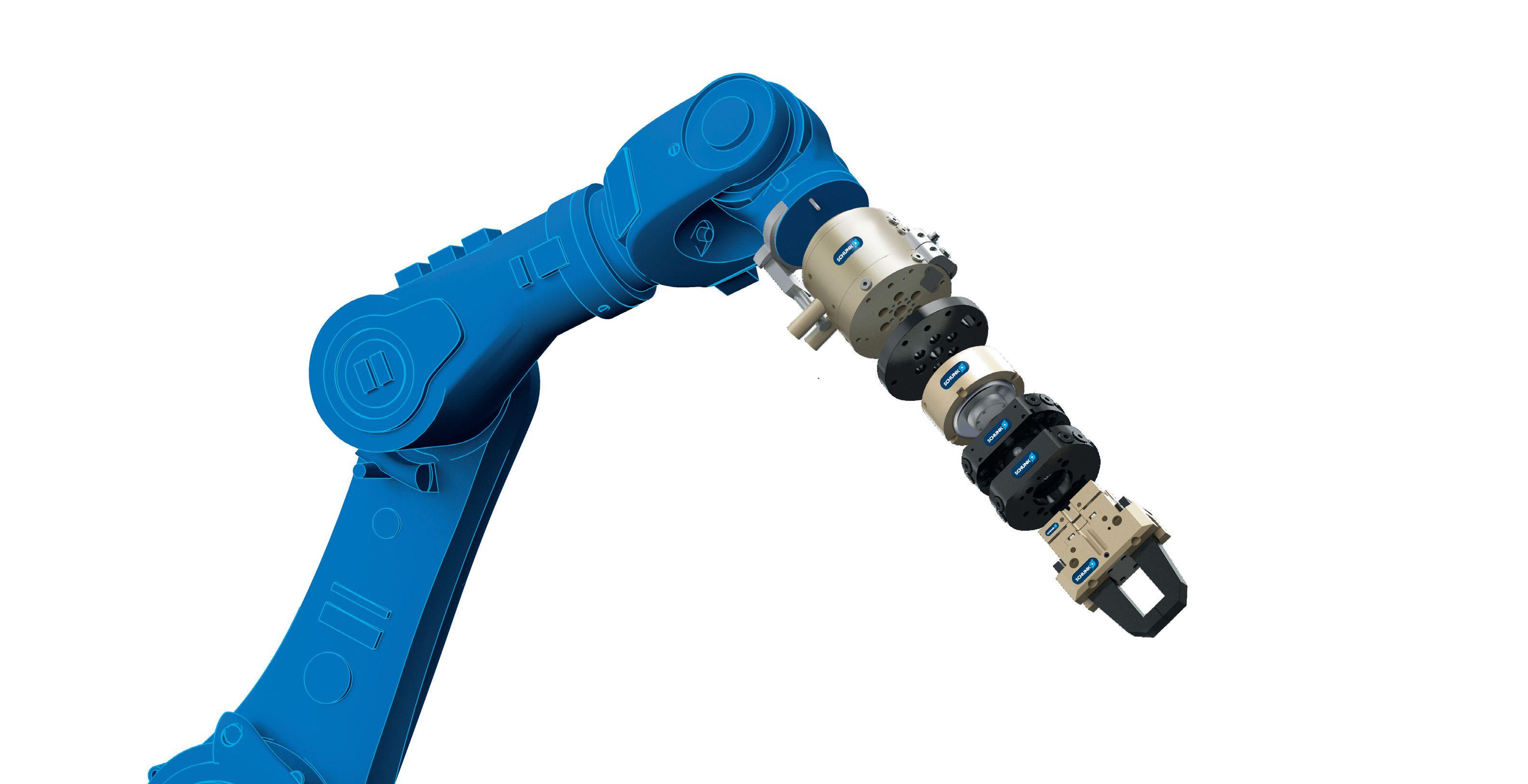

The robots are taking over. New research from the Association for Advancing Automation (A3) shows record numbers for robotics in North America in the first half of 2017.

The report finds the North American robotics market had its best opening half ever to begin 2017, setting new records in order and shipment units, and order and shipment revenue. In total, 19,331 robots valued at roughly US$1.031 billion were sold in North America during the first six months of 2017 – the highest level ever recorded to begin a year – representing growth of 33 per cent in units and 26 per cent in dollars over 2016.

Strong robot activity in recent months isn’t limited to the North American countries.

In Germany, robotics generated an 8 per cent increase in sales year-overyear reaching a total turnover of EUR 3.6 billion, climbing to a new record high, according to VDMA (Verband Deutscher Maschinenund Anlagenbau), an association representing the mechanical engineering industry. With an operational stock of about 189,400 industrial robots, VDMA forecasts a sales increase of at least 8 per cent to EUR 3.8 billion for 2017.

Meanwhile, the International Federation of Robotics (IFR) recently announced that in 2016, industrial robot sales in China surged 27 per cent to 87,000 units. Its stock of industrial robots has reached 340,000 units, making it the highest total in the world, it noted, adding that Chinese robot makers have increased their market share

to 31 per cent, up a whopping 120 per cent from the previous year.

“In the future, we have to embrace robotics. It allows us to reduce cost,” said Colin Parris, vice president at GE Software Research in an interview with TechCrunch. “If I reduce cost, I have more money that I can use for innovation. The more money I have, the more new products I can create. The more products I create, the more workforce I can hire.”

Simply put, robotics is one of the most significant disruptive technologies manufacturers can – and must – adopt.

The time to embrace disruption is now, according to the results of KPMG’s 2017 Canadian CEO Outlook. Three-quarters of survey respondents say they see disruption as an opportunity for their business, not a threat, and 86 per cent say they are not waiting to be disrupted by competitors.

“This year’s Outlook emphasizes that disruption has become a fact of life for Canadian CEOs and their businesses as they respond to heightened uncertainty,” said Elio Luongo, CEO and senior partner at KPMG in Canada. “Canadian CEOs see disruption as an opportunity to transform their business model, develop new products and services and reshape their business so it is even more successful than it was in the past.”

In today’s evolving manufacturing landscape, embracing disruption is a fact of business prosperity. | MA

CONNECT @AutomationMag adalton@annexweb.com AutomationMag.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, President and General Manager, Excellence in Manufacturing Consortium, and Chairman and CEO, Canadian Manufacturing Network

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, founder and owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexweb.com

PUBLISHER

Klaus B. Pirker kpirker@annexweb.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbizmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexweb.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbizmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbizmedia.com

COO

TED MARKLE tmarkle@annexweb.com

PRESIDENT & CEO Mike Fredericks

CONTRIBUTING WRITERS

Eric Esson, Eric Gardiner, Treena Hein, Paul Hogendoorn, Jennifer Rideout, George Schuster, Nigel Southway

Manufacturing Automation is published seven times a year by:

Annex Business Media 80 Valleybrook Drive, Toronto, ON M3B 2S9 Tel 416-510-5187 Fax 416-510-5170

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbizmedia.com Tel: 416-510-5187 Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES

Canada — $40.95 per year

United States — $71.95 (US) per year and Foreign — $82 (US) per year

Students — $20 per year

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2017 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

Siemens Wind Power Limited, as part of Siemens Gamesa Renewable Energy, will close the wind blade manufacturing plant in Tillsonburg, Ont., by early 2018.

The closure will affect 340 employees, and will be conducted in phases through the rest of the calendar year.

The company said the decision to close the plant is a result of “significant changes in the global and regional markets, combined with physical limitations at the existing plant.”

“Today’s market environment requires significantly larger blades, a critical requirement for our business to remain globally competitive. The Tillsonburg factory cannot easily be adapted to manufacture this product portfolio. The significant investments necessary to bring the plant in line with current market requirements would result in costs that could not be competitive in the global markets,” according to a company statement.

As well, Siemens notes that the market in Eastern Canada has experienced a “significant reduction” in the demand for blades in the last year.

“This was a very difficult decision that was taken only after assessing all the options,” said David Hickey, head of the Siemens Gamesa Business in Canada. “We have a great team of

employees at the plant who have produced quality work for the last six years, and we sincerely appreciate all their efforts. However, the harsh reality is that, in order to remain competitive, we must constantly evaluate our global manufacturing footprint.”

The plant began commercial operation in 2011 to provide wind blades for projects in Ontario and beyond.

HP and Deloitte Consulting LLP have announced a “first-of-itskind” alliance to help accelerate the digital transformation of the global manufacturing industry.

The companies will collaborate on the implementation

of HP’s 3D printing systems in large-scale manufacturing environments, applying their digital operations experience to help enterprises accelerate product design and production, as well as create more flexible manufacturing and supply chains, and enhance efficiency across the manufacturing lifecycle. The parties say this can help “increase innovation, accelerate

time-to-market, reduce costs and waste, and help large enterprises compete more effectively.”

New Ontario advanced manufacturing centre now open

The Walker Advanced Manufacturing Innovation Centre in Welland, Ont., has opened, providing more than 15,000 square feet of lab space for applied learning, innovation space for local businesses to work onsite, and office space.

The new Niagara College-affiliated centre will also aim to help small and medium-sized manufacturers reduce production time and costs by providing access to equipment and research facilities as well as the expertise and business services of faculty and students.

The Ontario government invested $4.2 million in the centre.

Great Place to Work (GPTW) has announced the 2017 list of Best Workplaces in Manufacturing.

The list is based on direct feedback from employees of the hundreds of organizations that were surveyed by GPTW. The data has a 90 per cent confidence rating and a plus or minus 5 per cent margin of error. Organizations must also be Great Place to Work-Certified in the past year and have manufacturing facilities in Canada to be eligible for the list.

This year’s winners are:

• 3M Canada

• Arc’teryx Equipment

• BASF Canada

• Kicking Horse Coffee

The new Model 58TP Programmable Accu-CoderPro™ encoder is so configurable, it will be the only compact, incremental thru-bore encoder you need. With the easy-to-use interface, you can program these specs:

CPR – any resolution from 1 to 65,536

Waveform – choose from 32 options

Output type – 6 different outputs

The Model 58TP offers:

Thru or hollow bore options

• Standard and metric bore sizes

• up to 5/8” and 15 mm

• and connector types

•

Variety of mounting options

Operating temp of -40º to 100º C

Call EPC today to learn how the Model 58TP can be your encoder solution.

• LMI Technologies

• Mercedes-Benz Canada

• Phoenix Contact Ltd.

• Rittal Systems Ltd.

• SC Johnson

• Vermilion Energy

“Rittal Systems always remains on the cutting-edge of technology, which makes us a great career choice for skilled technical people,” said Tim Rourke, president of Rittal Systems Ltd. “Above all, we value our employees in every department from our designers to our warehouse personnel, as we recognize that it is their dedication and commitment that enables us to keep satisfying our customers.”

“At LMI, we are committed to making our employees’ place of work an environment that they look forward to coming to everyday, a place where they are respected and given all the resources they need to excel in their chosen profession,” added Terry Arden, LMI Technologies CEO.

“The changes that we have been implementing at Mercedes-Benz Canada are founded on integrity and a sense of responsibility to our staff,” said Brian D. Fulton, Mercedes-Benz Canada president and CEO. “They are informed by our promise to deliver the best possible customer service, which starts with offering the best possible work environment.

That MBFC has been recognized among 2017’s Best Workplaces in Manufacturing is yet another sign that, as a company, we are heading in the right direction.”

Two Quebec manufacturers score $1.5 million in federal funding

A $1,455,000 investment from the federal government will maintain 225 jobs and create 40 new ones for two manufacturers in Quebec’s Lanaudière-region.

A $1,260,000 contribution will allow plastics manufacturer Plastiques GPR Inc. to purchase two injection molding machines.

“Our business is growing and the volume of demand from our main clients has been rising steadily. To meet this demand and position ourselves within our market, we are investing in our equipment fleet in order to increase our production capacity and remain on the leading edge of technology. Hence the importance of this project and our investment therein,” said Dany Belleville, vice president of Plastiques GPR.

Meanwhile, $195,000 in funding will help stainless steel products manufacturer Syri Ltd. acquire a laser cutting table, a bending machine, and ERP

software to improve its productivity, reduce costs and ensure greater flexibility in its production process.

M&R Automation Canada moves into larger head office

This summer, Manufacturing AUTOMATION attended M&R Automation Canada’s grand opening of its relocated headquarters in North York, Ont., which offers 32,000 square feet for sales, project management, mechanical and electrical design and assembly departments.

The festivities included speeches from M&R Automation Canada president Doug LoFranco, M&R Automation CEO Bernd M. Stütz, and PIA Group CEO Johannes Linden, as well as a BBQ lunch for all company

employees and guests. After lunch, participants enjoyed some friendly competition with a game or two of foosball, mini-put, or shooting hoops with a basketball shooting game.

M&R Automation is a custom automation machine builder with design and manufacturing facilities in Canada, Austria and China. In operation for nearly 30 years, it designs and builds equipment to assemble electromechanical parts in the automotive, electronics, consumer health and medical device industries.

Employees may be hiding IT security incidents from their bosses to avoid punishment, according

to a recent report from Kaspersky Lab and B2B International. The report, Human Factor in IT Security: How Employees are Making Businesses Vulnerable from Within, suggests that such behaviour occurs in 40 per cent of businesses. Forty-five per cent of enterprises (over 1,000 employees) experience employees hiding

cybersecurity incidents, with 42 per cent of SMBs (50 to 999 employees), and 29 per cent of VSBs (under 49 employees).

The report also indicates that carelessness and lack of knowledge is also a leading cause of potential cybersecurity incidents, second only to malware.

“The problem of hiding

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

incidents should be communicated not only to employees, but also to top management and HR departments,” said Slava Borilin, security education program manager at Kaspersky Lab. “If employees are hiding incidents, there must be a reason why. In some cases, companies introduce strict, but unclear policies and put too much pressure on staff, warning them not to do this or that, or they will be held responsible if something goes wrong. Such policies foster fears, and leave employees with only one option — to avoid punishment whatever it takes. If your cybersecurity culture is positive, based on an educational approach instead of a restrictive one, from the top down, the results will be obvious.”

Beijing selected as the home of Daimler’s new battery factory

Daimler says it will build its first battery factory located outside of Germany.

A project of Beijing Benz Automotive Co. (BBAC) — the Sino-German production joint venture between Daimler and BAIC Motor — the new Beijing, China, facility will be an “important step” for the development of a global battery production network, says the automotive company.

“Building another premium eBattery factory is the next step in the implementation of

our electric strategy. Thus, we have the first foreign location in our global battery production network,” said Markus Schäfer, member of the Divisional Board of Mercedes-Benz Cars, Production and Supply Chain.

Daimler and BAIC intend to invest roughly C$996 million in the production of Battery Electric Vehicles (BEVs) under the Mercedes-Benz brand and in battery localization at the site. According to a company statement, the new plant will combine the newest industry standards and latest production facilities with industry 4.0 technologies.

The Associated Press is reporting that General Electric will close its manufacturing facility in Rochester next year and the work will be moved to China.

According to AP, the company didn’t say how many people work at the facility, but GE officials estimate that less than 100 employees will be impacted.

GE officials say the work will be moved to China, where it will be done by Jabil, a GE partner supplier.

Pilz Canada partners with Manufacturers Automation

Pilz Canada has appointed Manufacturers Automation its new distribution partner for the South-Western Ontario region.

Located in St. Jacobs, Manufacturers Automation specializes in distribution of automation parts and systems.

“As Pilz Canada we continue to follow our ambitious growth plan for this and upcoming years. Manufacturers Automation Inc. will play a vital role in supporting our customers in the South-Western Ontario,” said Andreas Sobotta, CEO and general manager.

The Industrial Internet Consortium (IIC) — an organization working to accelerate the Industrial Internet of Things (IIoT) — and the Edge Computing Consortium (ECC) — an organization that aims to drive edge computing industry development in the Internet of Things (IoT) area — have signed a memorandum of understanding (MoU) to partner on shared interests of advancing the industrial Internet and edge computing.

Under the agreement, the consortia will work together to maximize interoperability and portability for the industrial Internet. Joint activities between the IIC and the ECC will include:

• Identifying and sharing IIoT best practices;

• Collaborating on test beds and

research and development projects; and

• Collaborating on standardization.

“We believe that an in-depth exploration of edge computing technology used in the industrial internet area will better meet the industrial customers end-toend needs to promote the global industry digitization transformation,” said Haibin Yu, chairman of ECC.

Motion Industries, a wholly owned subsidiary of Genuine Parts Company, has entered into a definitive agreement to acquire Numatic Engineering.

Founded in 1955, Numatic Engineering has more than 60 years of experience selling and supporting automation components.

With annual sales of $4.6 billion, Motion Industries is an industrial parts distributor of bearings, mechanical power transmission, electrical and industrial automation, hydraulic and industrial hose, and hydraulic and pneumatic components, industrial products, safety products, and material handling.

Siemens Canada has named Faisal Kazi president and CEO, where he will be responsible for leading the overall strategic direction of the company. Kazi replaces former president and CEO and current chair Robert Hardt, who departed the company in June to take on the role of Catalyst Partner at next47, Siemens’ separate unit for start-ups established in 2016.

Lafert North America has named Eric Cheung its newest sales representative. He brings seven years of experience in the power

transmission industry in technical support role. Meanwhile, Mario Hartard has been named account manager/business development. Hartard brings 17 years of experience in the electrical power industry.

David Doyle has been appointed president and managing director of Heidenhain Corp., where he will assume full responsibility for customer-focused operations for Canada, the U.S. and Mexico. Doyle offers brings more than 25 years of experience in international capital equipment business and technical support management to his new role.

The vertical side-seal design provides superior protection from debris.

Add an Aerotech award-winning singleor multi-axis control system for a complete motion solution.

Schneider Electric has announced the 2017 winners of its Global System Integrator Alliance Partner Excellence Awards. Special congratulations to True North Automation from Calgary, Alta., for being named the Global Telemetry Partner of the Year award winner.

For the first time in Pilz history, an international exchange program between the subsidiaries has been created. Pilz Canada has invited Owen Tucker from the Australian location to stay for a year and share his knowledge with the Canadian team. According to Pilz, he will be developing and executing business strategies and solutions for the Canadian team and customers.

Yaskawa Motoman has promoted Doug Burnside to VP North American sales and marketing, where he will establish and execute the strategic business direction to drive growth in the North American market, as well as leadership for all sales and marketing activities.

Excellence in Manufacturing Consortium (EMC) has named Tonya Starr the field service advisor for Ontario’s Brampton, Mississauga, Milton and Orangeville regions. Shawn Casemore has joined the EMC board of directors. With nearly 20 years in manufacturing, he has held leadership roles in operations, supply chain management, project management and sales. | MA

Aerotech’s PRO-LM series linear-motor stages offer a cost-effective, high-performance solution for positioning applications that require smooth, precise motion. A linear motion guide bearing system, highperformance brushless linear servomotor, protective hard cover and side seals make the PRO-LM series ideal for applications such as laser machining, medical component manufacturing, and other applications requiring high accuracy and extremely smooth motion in a production environment. With a wide variety of sizes and load capacities, there is a PRO-LM stage to match your needs and exceed your expectations. Contact Aerotech today to learn how a PRO-LM stage can improve your up-time and application throughput.

• Travel to 1.5 m

• Direct-drive linear motor for smooth, precise motion and high speed.

• Linear motion guide bearing system means long life and minimal downtime.

• Thirty-eight different models with travels ranging from 100 mm to 1.5 m to ideally match almost any application.

Unique side-seal design provides superior debris protection increasing up-time and keeping your process moving.

Also available with a linear motor or highspeed ball screw!

BY PAUL HOGENDOORN

Paul Hogendoorn is the co-founder of FreePoint Technologies, “Measure. Analyze. Share.” (Don’t forget to share!). He can be reached at paulh@getfreepoint.com or www.getfreepoint.com.

The province of Ontario is proposing to raise minimum wage to $15 per hour by 2019, up from the current minimum wage of $11.40. Predictably, the announcement has caused instant and intense debate, along equally predictable lines.

S ince the same arguments get replayed every time without changing anyone’s established opinion, I think it’s a good time to look at things differently, and in particular, how they could — or should — affect manufacturing.

First of all, there is an unappreciated underlying positive effect that even opponents may like. Radically raising the minimum wage for working people increases the gap between working people and non-working people. I know there will soon be a follow-on cry from many folks in the non-working community, but when it makes little difference to people whether they work or not, many choose not to work. Some would argue that decreasing benefits or support to the non-working group is the answer, but of the two possibilities, I’d rather reward those that choose to work rather than penalize those who don’t. Give people a fair and legitimate opportunity to look after themselves and their families, and there will be less reliance on society’s safety nets. Even Conservatives should like that!

From a manufacturing point of view, this issue may be a wakeup call for many. Manufacturing is a value-creating industry, the largest single value-creating sector in our economy. It is the economic engine that is responsible for the standard of living that North America has enjoyed for most of the last century. While the service

sector exchanges value and the retail sector largely exports value, the manufacturing sector creates value. Every hour of labour added to anything we produce increases the value of the thing we produce. Workers in manufacturing are not simply expenses or costs on the company’s accounting ledgers, they are value creators — every hour they work on the product creates additional value. The thought that some manufacturers may pay close to minimum wage for value-creating activity astounds me.

Workers in manufacturing are not simply expenses or costs on the company’s accounting ledgers, they are value creators.

I know the push back I am certain to get from some readers in regards to that last statement, but let me continue to take this conversation in a different direction. Henry Ford, in my opinion, created the middle class by paying manufacturing workers nearly twice as much as what workers outside of manufacturing were making. Whether it happened by design or by consequence, the result is that it helped build a national economy that could afford the products being produced. Before we start arguing the pros and cons of our society’s reliance on government and government policies, let’s examine the core issue leading up to this growing reliance: the failing or decline of the other institutions in our society — our families, our churches, our communities, and yes, our companies. And it’s that last one that we in manufacturing need to look at closely right now. If a raise in the minimum wage threatens the viability of a manufacturing company, there are other things that obviously need to be looked at.

L et’s start with value. Right now, we measure people’s time and that is what we pay them

for — how much time they spend on the job. The whole productivity conversation is primarily a management conversation; when it’s brought up with the workers, it’s usually as a measurement of their lack of performance, or the need for an increase in performance, or as a factor affecting the company’s profit and loss, or perhaps even the primary sustainability issue of the company itself. But, those conversations have nothing to do with creating value through the work they do on an hour-by-hour or day-by-day basis, not directly anyway.

My belief is that when we — everyone in the plant — put more attention on the measurable value being created by the efforts of each employee with the production of the product, there will be more focus put on the value-adding activities of every job, and less on all the other things we associate with work. Sound too altruistic?

My reply to that is that it does in fact work that way. In manual or operator dependent operations, we have seen value-adding activity (i.e. productivity) increase by often more than 30 per cent simply by

better connecting the efforts of the workers with the work they are doing. What gets measured gets improved, right? These are typically the lowest paying jobs in manufacturing — the closest to minimum wage — but they are also the ones where the effect of engagement is the greatest.

A s manufacturers, before we start arguing the potential negative effects of an increase in minimum wage to our industry, we need to first examine why we might be paying wages close to minimum wage in the first place. Remember, ours is a value-creating industry, unlike the service industry or retail sectors. The other sectors do not have the advantage of adding real value to their product by applying human effort, but we do. We have more options and opportunities to do better, and engaging our people in the value-adding process is one of them. Before we examine and debate policy, let’s be sure to examine ourselves. Our future is not in the hands of our governments, it’s in the hands of our customers and our employees. Let’s work with them first. | MA

National Manufacturing and Distribution Centres: Calgary, AB • Edmonton, AB • Airdrie, AB • Milton, ON Mississauga, ON • Etobicoke, ON • Perth, ON

Regional Manufacturing Facilities: Delta, BC • Calgary, AB • Winnipeg, MB • Mississauga, ON Lachine, QC • Dartmouth, NS Call toll-free: 1-800-268-3578 Learn more at eatoncanada.ca

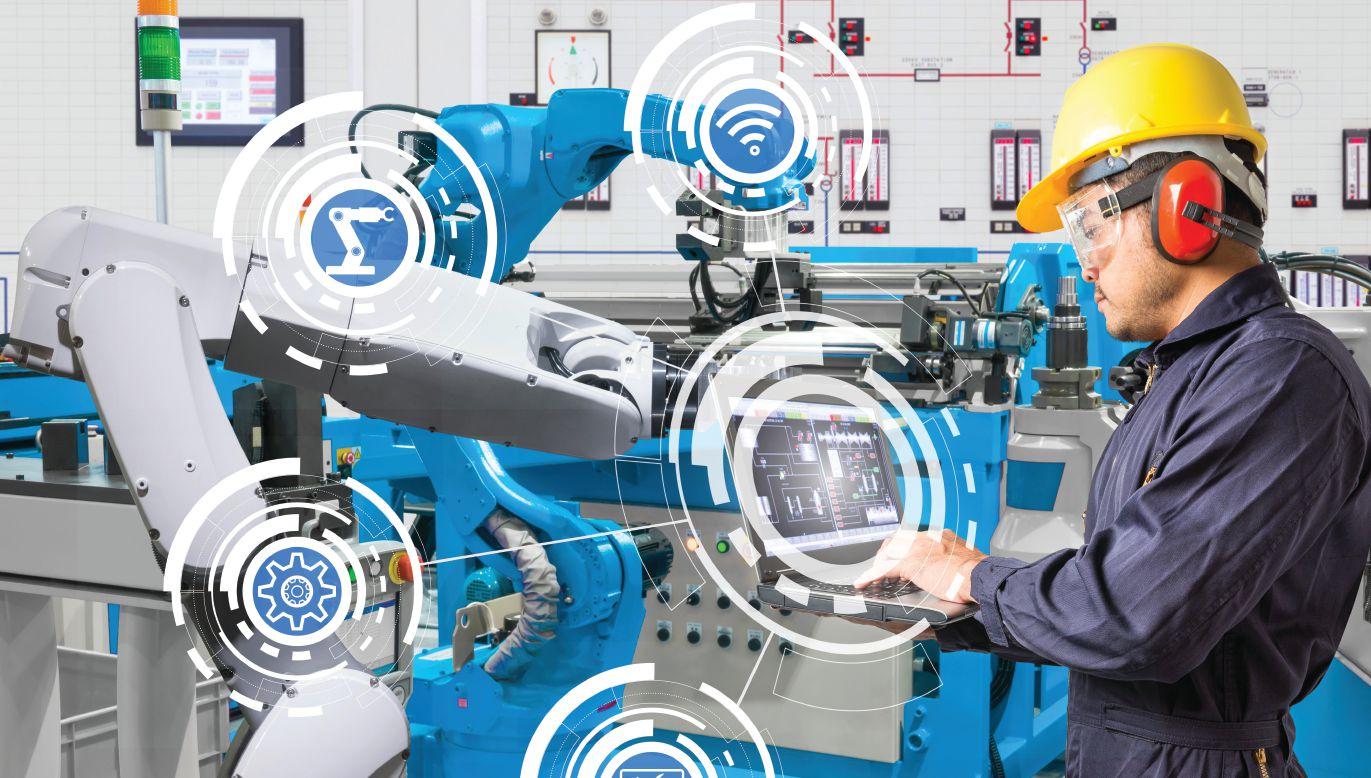

BY JENNIFER RIDEOUT

Factories around the world are becoming more automated, intelligent and connected. The outcome? As control seric essonystem connectivity increases and advanced technologies become pervasive, manufacturers are more productive, can better utilize assets, and optimize operations. Machine safety is no exception.

When lives are at stake, nothing else matters. According to the Association of Workers’ Compensation Boards of Canada (AWCBC), there were 177 fatalities in manufacturing across Canada in 2015. This was second only to the construction sector. The fact remains: manufacturing is a dangerous industry. Technology can help. With the right application of digital technologies, floor workers can trust that the operations and the machines around them are safe.

Your factory requires a defence-in-depth cybersecurity strategy to keep data secure. Part of keeping that data secure is ensuring your machines are protected from the vulnerabilities inherent to legacy equipment and industrial network design. The problem is that 40 per cent of manufacturers do not have a formal security strategy, according to the Cisco 2017 Midyear Cybersecurity Report, nor do they follow standardized security policy practices. Implementing a formal security strategy that includes your enterprise and industrial network is essential in protecting control systems and PLCs from attackers. By securing the floor, you can trust your data is accurate and machines are operating as reported. Access control should also be part of your defence-in-depth strategy. Digitally and physically, access control solutions limit access to data, assets and equipment based on a worker’s responsibilities. With the right access control policies in place, only properly trained workers can use this machinery.

More than ever before, it is critical for organizations to plan for knowledge retention. In a previous column, we

discussed how video solutions are essential to the training and retention of manufacturing employees. The same technology can be used to keep employees up-to-date on machine operation and safety. But continuous training via video extends beyond machine operation — employees can also be trained remotely on health and safety policies, industry trends, and standards. The bottom line is that employees with ongoing training are better prepared, and better equipped, for the factory floor. With advances in video technology, employees can be trained remotely, allowing manufacturers to best utilize their resources. And make no mistake — remote training works.

According to Librestream Technologies, a developer of mobile collaboration solutions for industries including manufacturing, one customer was able to train its field team 33 per cent faster through remote mentoring.

Video on the factory floor enables a whole new element of communications. If your floor is already equipped with Wi-Fi access, consider the difference that video technology for virtual collaboration can have on machine maintenance and safety. Through handheld devices, employees are able to view valuable information, such as equipment status, output and even if the machine is nearing a maintenance check. Taken a step further, if machine data indicates something may be amiss, employees can immediately video call a colleague or supplier and troubleshoot

If Canadian manufacturers want to stay relevant, they need to invest in digital technologies. But they aren’t.

a solution in real time.

All this means that machine defects — and potential signs of defects — are caught before something goes wrong. The real-time data from your machines is captured, made visible, analyzed, and acted on immediately — keeping your machines and employees safe.

T he manufacturing industry is changing. If Canadian manufacturers don’t change with it, they will be left behind. Digital solutions not only improve machine safety by providing the visibility, security, and training necessary to keep production running, they provide a foundation for manufacturers to compete globally. And if Canadian manufacturers want to stay relevant, they need to invest in digital technologies. But they aren’t.

According to a recent BDC survey polling Canadian manufacturing entrepreneurs, 42% of respondents said they have yet to begin planning for digital projects.

The Business Development Bank of Canada surveyed nearly 1,000 manufacturing entrepreneurs this year to understand how many have adopted digital technologies: only 3 per cent have fully digitized; 42 per cent have yet to begin planning for digital projects. There is much work to be done, but there is also hope. The same survey showed the results experienced by manufacturers who are utilizing digital technologies: 60 per cent experienced a boost in factory productivity; 50 per cent reduced operating costs; and 42 per cent improved product quality. Improved OEE. Lower operating costs. Improved product quality. There are many reasons to invest in digital technologies. Machine safety is one — a darn good one. Are you ready? | MA

Electric Drives and Controls, Linear Motion Technology, Assembly Technology, Tightening Systems: World-class automation solutions for advanced manufacturing.

Rexroth’s automation solutions drive your manufacturing performance with maximized productivity throughput, precision, repeatable and efficient motion control, and maximum uptime. We’re set to help you achieve this with the industry’s most advanced conveyor technologies, electric drives and controls, linear motion components and systems, as well as production tools and tightening systems. All are equipped for fast changeovers, and ready for Industry 4.0.

Smarter, more productive automation starts with the right technology. Make your move to Rexroth’s automation solutions.

BY ERIC ESSON

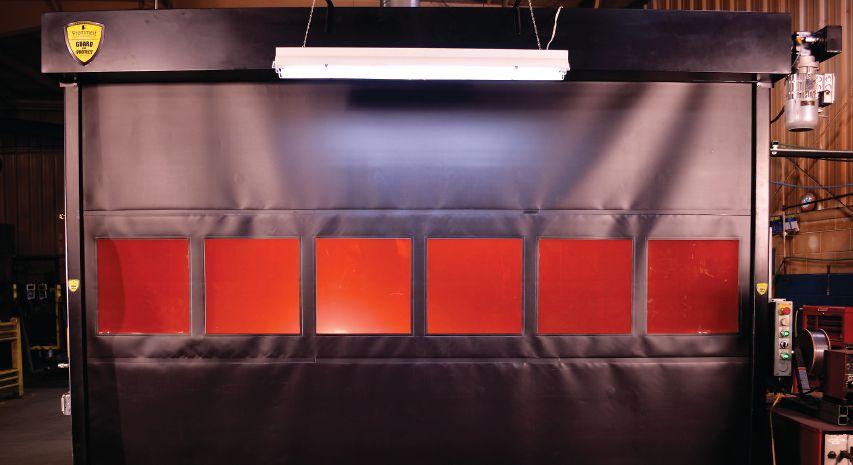

Working efficiently doesn’t mean safety needs to be sacrificed. In fact, more and more facility managers are learning that the latest technology actually improves safety along with efficiency.

Machine guarding is one of those areas that safety and efficiency don’t go hand in hand. Workers trying to get around safety measures in an attempt to increase throughput is why machine guarding — specifically related to robotic welding 29 CFR 1910.212 — is always in the top 10 most frequently cited OSHA standards violated every year. It’s also one of the most confounding aspects of manufacturing plants with risks in the interaction between automated processes and employees at points of operation. So where does a facility manager start?

When performing a proper risk assessment, which is now mandatory when adding a new machine or process thanks to ANSI/RIA R15.06, pointof-operation guarding is probably the most involved aspect. It is easy to place perimeter guarding around the entire process. However in most situations, a machine operator needs to interact with the process by loading or unloading materials (components to be welded) and “running” the machine.

This point-of-operation is where things can get tricky. Many details must be considered when it comes to this area, including the layout or design of the process, the limits of the system and properly identifying all associated hazards. Using the distance formula as identified in OSHA guidelines can help determine the best guarding device. Per this formula, the safeguarding product has a prescribed location based on a number of factors, including secondary hazards that might harm a machine operator.

The elimination of accidental entry into the cell is another benefit of interlocked automated barrier doors.

Light curtains, laser scanners and other presence-sensing devices are a commonly used and widely accepted method of machine guarding in manufacturing facilities from Tier 1 automotive to small machine shops and fabrication facilities. The automated process ceases once the safety device’s infrared beam is tripped.

In many instances, these devices provide acceptable safety. However, they’re not always the best choice in all applications, especially after a risk assessment is performed.

Light curtains may be the right choice in some applications, as they can limit exposure to the hazard and reduce risk. But, a fast-acting automated barrier door or roll-up curtain may be the better choice because they can eliminate exposure to both the dangerous movement of the machine and secondary hazards produced by the process, potentially eliminating risk and the severity of exposure.

Due to the nature of a properly interlocked automated barrier door, certain aspects of OSHA’s safety distance formula become moot because there is no depth penetration factor, allowing the safeguard to be placed much closer to the hazardous area. This correlates to less space being dedicated to a safety zone and directly results in reducing the manufacturing cell’s footprint. This space savings is a huge benefit in most facilities and it means workers can actually stand closer to the automated operation than with light scanners.

The smaller safety zone may also make for a better ergonomic situation for the machine operator by limiting required motion and help increase productivity, which is essential in today’s competitive market.

R15.06

The ANSI/RIA R15.06 standard provides guidelines for the manufacture and integration of industrial robots and robot systems with emphasis on their safe use.

Coupled with safety interlocks (up to PLe per EN ISO 13849-1 when integrated properly), automated barrier doors and roll-up curtains offer increased protection for point-of-operation guarding. Not only do they restrict access to the process, they also contain secondary hazards such as smoke, flash, splash, mist or flying debris associated with automated welding operations by placing a barrier between the operator and machine movement. These guards are an ideal alternative to light curtains and other presence-sensing devices.

T he elimination of accidental entry into the cell is another benefit of interlocked automated barrier doors. Because they provide safeguarding that can be seen — unlike invisible infrared beams — the opportunity for accidental work stoppage is greatly reduced. The physical separation they provide is a clear visual indicator that the machine operator needs to be on task.

Regardless of the safety device that ends up being selected for machine guarding, facility managers need to remember to perform a proper risk assessment. When it comes to material handling operations in industrial facilities, physical barriers can offer additional protection and are generally going to improve productivity. | MA

The most trusted brands, all under one roof. Phoenix Contact, TDK-Lambda, AP, SolaHD, Bel Power Solutions, SL Power, Cosel, Panasonic, Meanwell, Dantona Industries, Power-Sonic, XP Power, Traco Power, EOS Power, Altech Corp., and hundreds more.

Heidelberg Canada product manager Ray Fagan discusses automation in printing after its German parent, the world’s largest press maker, introduced a new operating philosophy, Push to Stop.

MA: What is the state of automation in the printing industry?

RF: I would say in general print shops are behind other industries in automating their processes. There is a trend toward getting away from the craft of printing more toward the manufacturing of printing. And that is a bitter pill to swallow for a lot of printers, more so for the commercial companies than in packaging. Packaging companies have been in a manufacturing mindset for a longer period of time, because of the nature of what they print.

MA: Are printers ready for Push to Stop?

RF: We are learning very quickly that most companies are not in a position to take advantage of Push to Stop automation. The press ends up waiting. There is a fellow who has joined Heidelberg by the name of Anthony Thirlby and he is head of Prinect now, driving some of these processes... He estimates 55 per cent of the time a job is in a printing company is before it even gets to the CTP. It’s in estimating, job costing and prepress – 55 per cent of the time before it is even plated and on the press. So if an average job time takes three days to get out the door, one and a half of those days is spent just getting the job ready to be plated.

MA: How does Push to Stop look beyond just the printing component?

RF: Push to Stop is part of what we call the Smart Print Shop, which is more holistic in the approach, where Push to Stop is the print processing element of it. To have a Smart Print Shop, you need to think about how do I align my jobs so that I can truly

manufacture at an acceptable operating equipment efficiency or an OEE number for a new press? How do I justify putting this piece of equipment on the floor?

MA: What is Heidelberg’s answer for creating an OEE number for a capital investment?

RF: You should only think in terms of throughput and you should only measure, in our opinion, cost per thousand sheets.

MA: Why has Heidelberg focused on cost-per-thousandsheet manufacturing?

RF: We are launching a big data platform this year in a couple of satellite plants as a beta test. We are going to be collecting every single piece of information from the press and any other automation that is in front of, or behind, the press that can provide data. Then you can start to do a few things like intensify your colour management, streamline your stock purchasing by big data analysis. You can

determine a lot to drive your cost per thousand sheets down. But it is not only based on capacity. If you can make every thousand sheets more profitable, a three-shift printer can become a two-shift printer and be more profitable even if they do not see an increase in print volumes.

MA: What is big data telling you about print?

RF: There are so many decisions now where you can try to remove the emotional element and just focus on what is happening. It is interesting to see the look on a customer’s face when you tell them their overall operating efficiency [OEE] is 18 per cent or 23 per cent. They have these big pockets of unexplained time.

MA: Is it common for printers to have an OEE below 40 per cent?

RF: Most are below 40 per cent for sure. A lot of people are getting hung up on overall operating efficiency. You can be the most efficient printer in the world but if you are a short-run printer your [OEE] is not going to reflect how efficient you are just based on your total volume.

MA: Why is Push to Stop a new operating philosophy for printing?

RF: I do not think anybody has ever gone from makeready to good sheet before without having a physical interference. To be able to process multiple jobs in sequence without interruption of a person has never been done before and now we have the capability to do it at a press level. What is new I would have to say is the ability to queue up multiple jobs from the prepress department into the queue of the press, all ready to go. | MA

Get ready for more than just a loan. With TD Equipment Finance, our relationship managers commit themselves to your business. We o er advice and services specific to your needs, including leases, lines of credit, conditional sales contracts and more. Talk to us today and see what we can do for your business.

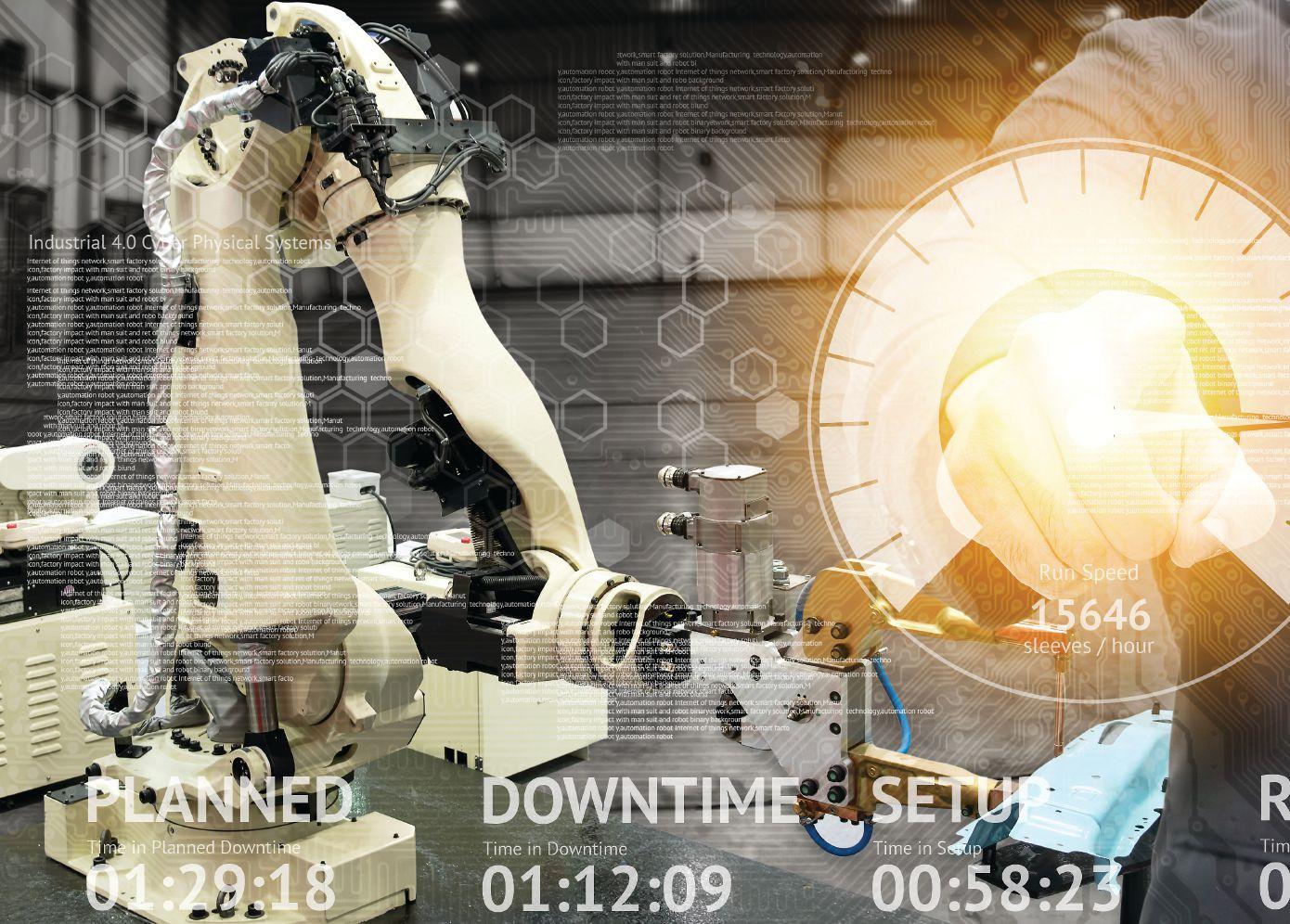

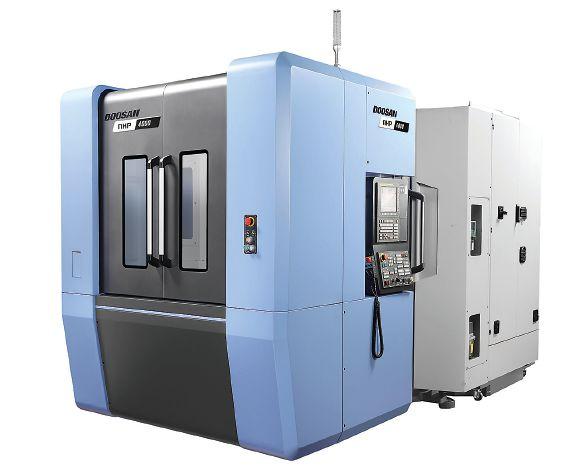

Bringing safety data into a Connected Enterprise can help identify risks and enhance safety

BY GEORGE SCHUSTER

Manufacturers are fundamentally changing how they operate in a Connected Enterprise. They’re gaining access to real-time insights, digitizing manual processes, improving collaboration through technology, and much more.

Agropur, a Canadian dairy processor, provides an excellent example. The company’s Don Mills, Ont., plant was hindered by aging automation technology that didn’t provide production intelligence. Instead, workers had to manually collect data then analyze and convert it into useful information. This was a time-consuming and error-prone activity.

As part of a modernization effort, the company moved to a standardized control and information platform that included a new controller, HMI and drive hardware, and new visualization software. The platform gives users access to real-time production data and helped to automate and error-proof the collection of production data.

Since modernizing, Agropur has eliminated 2,500 hours of manual data collection, improved OEE by 25 per cent, and discovered more than 33 hours of additional production time per year.

Success stories like this are increasingly common, providing a strong case for all manufacturers to get their equipment connected. But a Connected Enterprise also can deliver improvements

25%

Dairy processor

Agropur saw a 25% improvement of its OEE as a result of its modernization effort.

in areas outside of production. This is especially true in the realm of industrial safety management. Today, many safety professionals in manufacturing use outdated data-collection and reporting methods. They must manually enter safety data for incident reports, inspections, training, audits and other processes, and then store this data in systems that are isolated from the plant floor.

The Connected Enterprise upends this old way of managing safety and replaces it with a more connected, efficient and data-driven approach. It’s an approach that empowers safety professionals with a better visibility and understanding of their safety compliance and performance, while providing substantial opportunities for improvement.

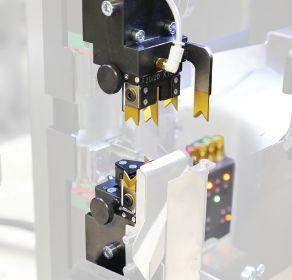

This begins with using contemporary connected safety technologies. These systems, which combine machinery and safety control in one platform, are less susceptible to nuisance shutdowns than traditional, hardwired

safety systems. But they also can provide access to safety-system data, including device and operational statuses, event sequences, fault and stoppage codes, event counters or timers, and more.

O nce this data is collected, it’s only a matter of how an organization wants to use it. They could, for example, use it to shine a light on safety-system misuse or evaluate the frequency of safety system demands.

Think about something as basic as an emergency-stop (e-stop) button, which is meant to be used in emergencies. In reality, it’s often misused to stop production at the end of a cycle or if a jam occurs. Plant-floor workers may not think much of this misuse, but it can lead to increased scrap, longer startup times, and dramatically reduced lifespan and compliance of safety systems.

Today, data detailing these actions isn’t captured in most plants — but it can be in a Connected Enterprise. The collected data could include the e-stop activation’s time stamp, the resulting downtime duration, and the line and shift associated with each activation. Stoppage codes can be created to describe why the button was pushed in each instance.

S afety professionals can use the alarmand-events and metrics software they already have in place to analyze the data and identify if an e-stop is being used at an abnormally high rate. They can then investigate the root cause of any misuse, and determine if higher activation rates are occurring with specific production lines or shifts. This example holds true for other safety functions of the machine as well.

Safety transformed Beyond safety-system misuse, greater data and connectivity can help drive safety performance improvement in numerous ways. Some key opportunities include:

• Better understanding of safety risks: Most manufacturers rarely, if ever, use their risk assessment data again after the design stage. However, this data can be put to good use in the form of a risk calculator. It’s a simple concept. Risk assessment data is stored as the baseline for safety performance and then compared against actual-use frequency data. Safety professionals could use this tool to identify process changes that result in higher-than-expected use frequency or, conversely, to pinpoint safeguards that are being defeated and result in lower-than-expected use frequency.

• Improving safety performance: The very action of connecting people, processes and equipment can create new opportunities to enhance safety and machinery performance. This could include providing visibility into process states, such as in ovens or refrigeration systems, to help reduce worker exposure to potentially harmful conditions. It also could include using wireless and mobile technology to deliver information to workers in more convenient ways, which could help reduce the physical strains put on an aging workforce.

• Reducing safety-related downtime: Safety and production data can provide important insights into safety-related shutdowns, including their frequency, duration, time and location. Safety and operations professionals

can then use this data and work together to tackle recurring issues, which may be as simple as having a discussion with a specific production shift where an issue is most frequent, or to implement best practices across all shifts. Maintenance technicians can also use safety-system data when failures occur to simplify troubleshooting and speed up downtime resolution. Or they can go one step further and use the data as leading indicators for predictive maintenance.

• Alleviating compliance demands: Many manufacturers use manual audits to collect safety data for compliance and reporting purposes. This takes up valuable worker time and requires production downtime. This process can also lead to human error.

These issues can be eased by integrating auditing functions into the control system. As an added benefit, any abnormalities that might arise during auditing can be conveyed in dashboards or reports to help workers quickly spot and resolve potential issues.

Industrial safety management need not exist in isolation or in the confines of yesterday’s technology, especially as production becomes smarter and more data driven. By capturing and contextualizing data from safety systems, manufacturers can get a clearer picture of their safety performance, and make changes to help improve operations and productivity. |

Automating pizzeria operations with the help of robots

BY TREENA HEIN

If anyone is a pioneer in the automation of food processes, it’s Alex Garden. A Canadian ex-pat and now-popular conference panelist, he founded Zume Pizzeria in Silicon Valley, Calif., with Julia Collins in June 2016.

“My original idea was actually to create a way to bake pizza enroute to your door and didn’t have anything to do with robots – that came later,” Garden recalls. “I developed the idea for ‘Baked On The Way’ technology after sitting next to an owner of several pizza franchises on a plane, discussing the downsides of the business: weak unit economics, rigid delivery structure, no room for flexibility with ingredients, customer complaints from cold, soggy pies, etc. From there, the idea sparked to take on the $40 billion per year pizza delivery market, but do it better.”

A few years later in 2015, Garden and Collins got together and fleshed out a pizza company based on one founding principle: high-quality food at a fair price.

“ We then developed our first team of robots,” Garden says, “to support that mission.”

There are no storefront Zume stores, only pizza delivered from a central facility, where robots ‘Pepe’ and ‘Giorgio’ dispense the sauce, ‘Marta’ spreads the sauce, and ‘Bruno’ puts the pizza in the oven for pre-baking (after a human puts on the toppings). A human transfers the pizza to one of seven delivery trucks, each with up to 56 onboard ovens. A software program maps the routes to customer addresses and automatically coordinates baking times so that by the time the truck gets to your door — brought to you by the driver — your pizza will have just finished cooking. Zume now delivers more than 400 pies a day.

Garden says that instead of focusing on stunts (he points to the unsuccessful use of drones and a cancelled plan to use reindeer in Japan, both by Dominos), they worked to develop a delivery process that would actually improve pizza quality and taste.

“Automation exists to improve the quality of human lives,” he notes. “Before we start any automation project, we must have the conviction that it will create a safer, more engaging work environment for our employees and that it will improve our margins so we can invest even more in delivering high-quality food to our customers.”

In the process, Garden and his team discovered there is an enormous selection of companies and equipment out there for process automation, and “with today’s CAD systems, flexible manufacturing and our imaginations to contend with, it’s really easy to engineer a complex system that checks the box of ‘so cool’ but fails in production,” he says. “In our experience, the best automations are the most simple.”

Garden also notes that once they automate something, the real stamp of approval comes later from Zume’s “amazing food and delivery workforce...when they tell us automation is really making their lives easier and safer.”

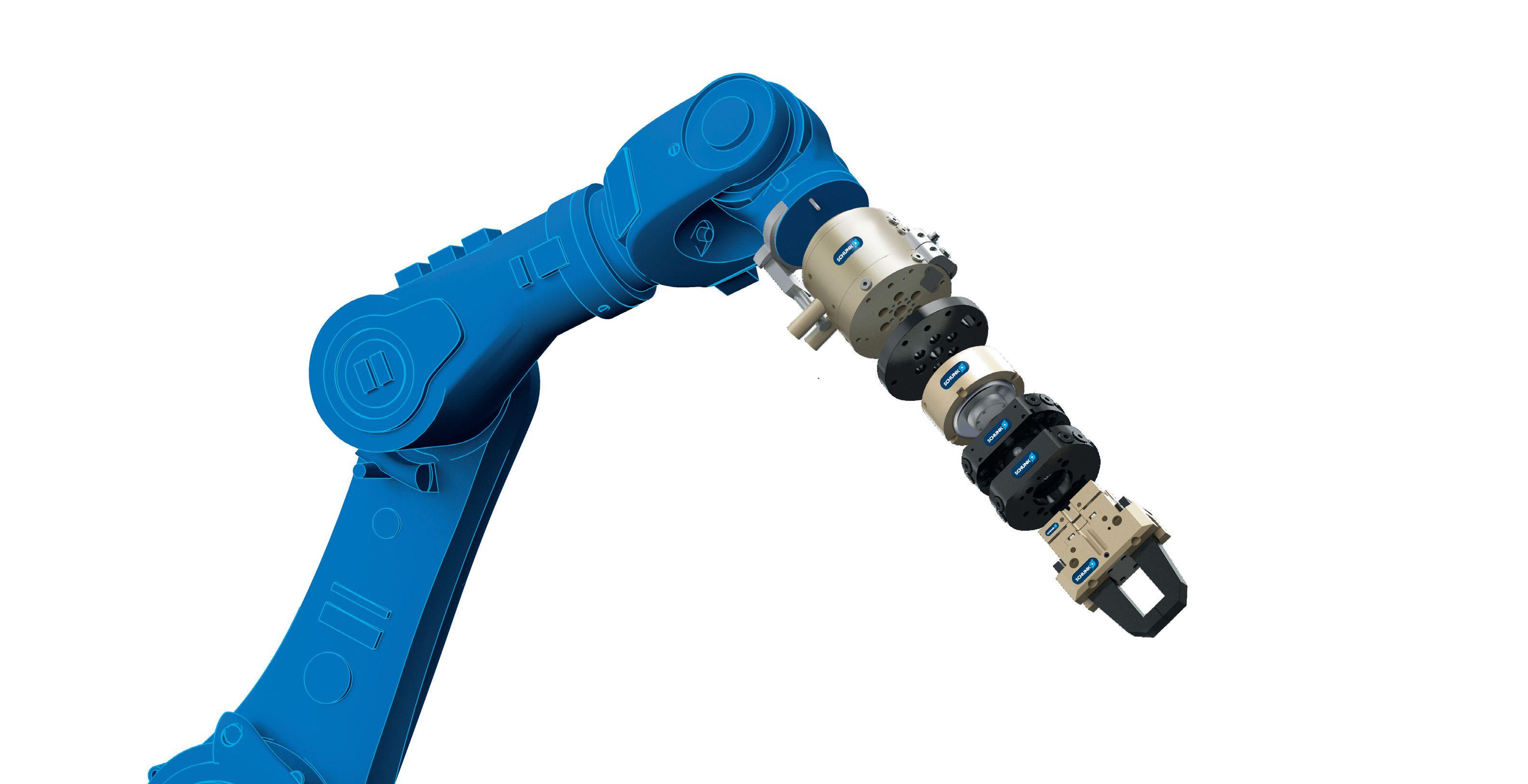

Bruno, the robot which picks up a topped pizza from the conveyor and places it in the pre-bake oven, is an ABB IRB 2600. Nicolas De Keijser, assembly and test business line manager for ABB Robotics’ North American division, says enabling Bruno to maintain a pizza’s round shape proved to be a significant challenge.

“ When transferring, dough can easily stretch or ripple up,” he explains. “This was addressed by developing an innovative gripper

“Automation exists to improve the quality of human lives. Before we start any automation project, we must have the conviction that it will create a safer, more engaging work environment for our employees.”

attached to the robot arm with a built-in conveyor.” De Keijser says it was also a challenge to perfectly synchronize the motion of the robot and the gripper with the movement of the main conveyor.

M arta, which spreads the sauce, is an ABB IRB 360 FlexPicker unit. This unit employs both a camera and sensor to detect a pizza’s arrival in front of it and its exact location. “This allows the robot to accurately spread the sauce in a specific pattern,” De Keijser says. “Depending on the type of pizza, the spreading pattern of the sauce varies.”

He says the use of robots in kitchens is very new, but that robots are being used around the world in similar applications such as spreading sauce in a frozen pizza plant and packing food items. For ABB, De Keijser says novel uses of robots in the service, entertainment and retail industry are “definitely” an increasing trend.

Zume has more than 130 full- and part-time human employees, and Garden says the use of the four robots has provided several “amazing advantages.” Labour savings allow Zume to provide an average hourly wage of $16.31, and all employees are shareholders with company benefits. Savings from robot use have also been reinvested in higher-quality ingredients. In addition, Garden says further automation of remaining repetitive pizza-making tasks will allow the replaced employees to get “involved in areas of the company that they are most

interested in.” As kitchen staff is eventually cut from six to two — with the two remaining humans slicing and preparing toppings and overseeing quality control — the four replaced workers will move into what Garden describes as “more stimulating roles in the company, like marketing or data science.” He adds that “jobs that require more advanced creative skills, like tasting and recipe development, will always be done by humans. Jobs are sacred to us, so we believe there’s room for people and robots to coexist.”

Not everyone shares that view. The topic of robots in restaurants came up in a May 2016 interview on Fox Business with former McDonald’s USA CEO Ed Rensi.

Commenting on a possible $15 minimum wage, Rensi stated that “it’s cheaper to buy a $35,000 robotic arm than it is to hire an employee making $15 an hour” to bag French fries. Rensi went on to call a $15 minimum wage “very destructive” and predicted it would “cause a job loss across this country like you’re not going to believe.”

For its part, Zume continues to automate. The firm has installed a dough-pressing machine that can turn out a pie every nine seconds, four times faster than without it.

“In terms of drones and self-driving cars, we’re always monitoring the latest technology and there may be room for those types of developments in the future,” says Garden. He adds that “eventually, we’d like to grow across the West Coast, then the entire country, then across the globe. Everyone loves pizza!” | MA

New Avnu Alliance document presents a TSN-enabled system architecture

BY ERIC GARDINER

As awareness surrounding IoT standardization continues to grow, more eyes are being drawn to the necessity of enabling interoperability for distributed measurement and control solutions. To foster such interoperability at the network level, the Time-Sensitive Networking

(TSN) task group in the Institute of Electrical and Electronics Engineers (IEEE) is producing a set of standards to add time synchronization and low-latency communication mechanisms to standard Ethernet, creating a foundation for advanced manufacturing and product models where data can be shared more predictably and flexibly between layers of the control system.

Avnu Alliance, a n industry consortium driving open, standards-based deterministic networking, saw the opportunity to provide the industrial market with a best practices document that offers a system architecture and implementation requirements for creating TSN-enabled systems and applications in support of a broad range of industrial use cases. Through member contributions and collaboration, Avnu Alliance Industrial Segment members published the Theory of Operation for TSN–enabled Systems Applied to Industrial Markets (i.e. Theory of Operations) best practices document. The technical document describes the requirements for several industrial use cases, including machine control and process automation, and presents a TSN-enabled system architecture that these applications can build on. The document also explains the role of TSN and related standards in the architecture, and describes implementation considerations for each component in the architecture, including end stations, bridges and software controllers.

As the application of TSN and related standards to industrial markets continues to evolve, the document will also evolve to add new capabilities.

Standard Ethernet has evolved to enable next generation control systems. Recent work by IEEE 802, the Internet Engineering Task Force (IETF), and other standards groups has extended the ability to operate time-sensitive

systems over standard Ethernet networks, supporting diverse applications and markets including professional audio/video, automotive and industrial. These standards, driven primarily by the IEEE 802.1 TSN task group, define new mechanisms for creating distributed, synchronized, real-time systems using standard Ethernet technologies that will allow convergence of low latency control traffic and best effort traffic on the same network.

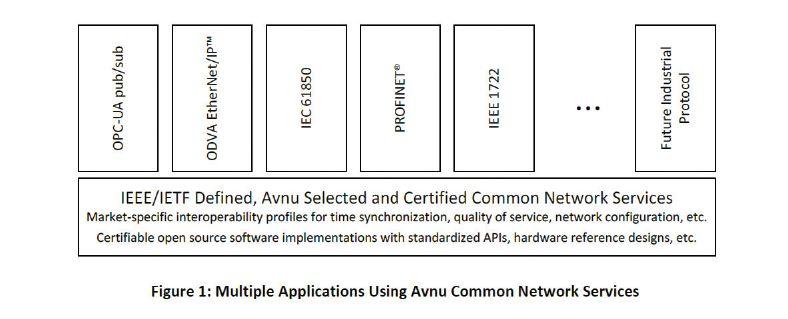

To enable interoperable use of a shared TSN-enabled network, Avnu selects and certifies a set of underlying mechanisms to meet a given market’s requirements. Avnu’s focus is to create a common network foundation so that multiple industry group or vendor applications and protocols can share a TSN-enabled network, as shown in Figure 1.

The intended audience for the Theory of Operations document is developers of products used to solve industrial control problems. Because the document specifically describes architectural reference models for bridges, end stations, and bridged end stations, product developers are given the knowledge they need to implement TSN-enabled products.

This section outlines the two industrial applications of TSN, noting that while the specific requirements for these applications vary, they share a common need for distributed sensing, logic and actuation.

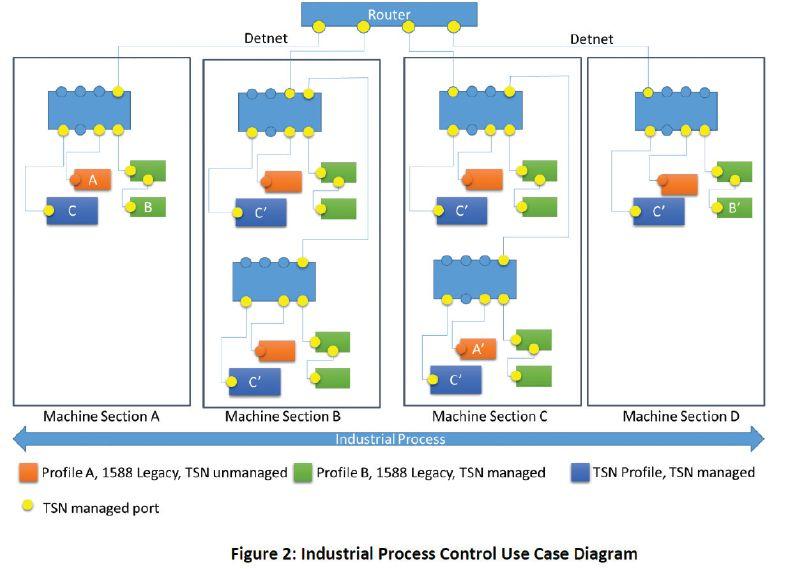

The diagram in Figure 2 (page 24) outlines the industrial process control use case, describing four machine sections that work together to comprise a single machine. In this example, the end user has seven manufacturing sites around the world, with 15 machines per site. Different OEMs deliver each section of machinery to the process, with each OEM specializing in the portion of the process it controls.

Each section of the machine is synchronized and coordinated to create a final product, with TSN-enabled switches supporting concurrent or translation between multiple IEEE 1588 time synchronization profiles, providing a migration path for existing products and technologies to be included in the wider TSN value proposition. At the router level, IETF’s DetNet

Pilz Services for Machinery Safety are international and customized. Our service professionals provide global support in all matters of functional safety in all industry sectors. From Risk Assessment to Safety Design to CE Marking. Profit from our high level of knowledge of national regulations and standards! We reduce risk, implement technical machinery safety and take responsibility with the certification services we provide.

initiative will inform how deterministic communication happens between separate layer-3 networks.

Companies creating industrial machinery used for fabrication, assembly and testing are constantly upgrading their machines’ capabilities. Increasingly, these upgraded capabilities depend on free-flowing data both within the machine and between machines, from the machine to the user’s enterprise, and on to the remote machine builder’s remote facilities. This flow of information reduces the cost of machine customization, enables increases in machine availability, and can provide the end user with simpler integration into their facility and logistics systems. It allows the machine builder to take greater ownership of operating efficiency, support servicing, and consumables management.

To meet the stability and reliability requirements of the high-speed motion control subsystem within a modern machine, a network needs to consistently deliver the control packets between the drives/sensors and the controller with a latency of <100 µs. The motion axes also need to be coordinated, requiring time synchronization between the nodes of <1 µs. Without TSN enhancements, achieving these performance requirements with standard, shared Ethernet

The real potential for IoT is a foundational common network infrastructure. With open standards, manufacturers are not reliant upon one company and their proprietary technology.

requires a high level of technical competence and can result in prescriptive network architectures. Using TSN enhancements to standard Ethernet, machine builders can offer convergence, performance and cost optimizations when compared to existing solutions.

Avnu’s TSN architecture for industrial systems presently focuses on three classes of mechanisms for creating TSN-enabled systems: time synchronization, quality of service, and network configuration. The Theory of Operations document acknowledges that as the IIoT continues to evolve and new foundational mechanisms are introduced, this system architecture will change to comprehend those mechanisms.

Achieving precise time synchronization is crucial for distributed industrial control applications to facilitate event coordination and data correlation. Instead of sharing timing signals directly, controllers in the system can periodically exchange synchronization information over a network, adjusting their local timing sources to match each other. Using mechanisms defined in IEEE 802.1AS-2011, a profile of IEEE 1588, industrial controllers can establish and maintain tight time synchronization using standard Ethernet networks.

Quality of service is necessary for

the proper operation of time-sensitive systems, since a bridged network connecting industrial controllers with sensors and actuators must ensure that high-priority traffic can predictably meet bandwidth and latency requirements, especially in the presence of same-priority or best-effort traffic. Using mechanisms defined in IEEE 802.1Qbv, a bridged network can schedule traffic such that high priority communication is guaranteed, with the lowest possible latency, even in the presence of best-effort traffic.

T SN systems require dynamic configuration based on application requirements. Using network configuration enhancements defined in IEEE 802.1Qcc, and borrowing concepts from Software Defined Networking (SDN), bridges and end stations in a TSN-enabled industrial systems can be configured in a manner that does not add significant cost or complexity and takes advantage of intelligence found in a centralized network controller.

For industrial markets, TSN and related standards support the ability to simplify development and deployment of distributed, synchronized control systems commonly found in a variety of industrial applications including machine control, factory automation, power generation and distribution, oil and gas exploration, etc.

The real potential for IoT is a foundational common network infrastructure. With open standards, manufacturers are not reliant upon one company and their proprietary technology. Avnu Alliance defines the technical foundation and certifies for interoperability. TSN allows all vendors in the industrial space to build on top of the common foundation.

In the future, the Theory of Operations will include additional technologies in support of a broader set of applications and markets as Avnu Alliance members continue to develop new ways for manufacturers looking to expedite advanced networking implementations and standard Ethernet continues to evolve. | MA

Eric Gardiner is the chief engineer at National Instruments, Avnu Alliance Industrial Segment. For a copy of The Theory of Operations document, email admin@avnu.org.

Power management company Eaton has launched its heavy duty safety switches with surge protection, the latest in its expanding portfolio of switching devices. Combining the safety switches with integrated surge protective devices (SPD) courtesy of the Eaton SP1 and CVX series, this packaged solution is designed to provide end-users and contractors with “significantly better” performance than externally mounted devices, resulting in a completely wired, UL-listed solution and better protection for connected equipment. Eaton’s heavy duty safety switches with surge protection, available in switches ranging from 30 to 1,200 amps, offer protection at the service entrance and/or branch circuit level. Other features of the solution include: integral SPD wired to the load side of the switch, which can be isolated from line-side power should the SPD require replacing; external viewing window and enhanced visible blade components for visibility over each pole; and modified safety switch with NEMA Type 12/3R and 4/4X enclosures, as well as a choice of Eaton Type SP1 or CVX surge devices.

www.eaton.com

Single-application remote racking system

CBS ArcSafe says its RRS-3 GMI single-application remote racking system is designed to operate the Siemens Type GMI and Type 3AF vacuum circuit breakers without having to make any modifications to existing electrical equipment, thanks to its magnetic latching system. Described as lightweight and portable, RRS-3 GMI allows technicians to remotely install and remove a breaker while standing up to 300 feet away. The

RRS-3 GMI is compatible with Type GMI and Type 3AF vacuum circuit breakers with ratings of 1200-3000 A, including 5-GMI, 7-GMI, 15-GMI, 5-3AF, 7-3AF and 15-3AF. Typical applications for the GMI and 3AF breakers include commercial, industrial and service entrance applications to protect and switch main, feeders and incoming lines. According to the company, the RRS-3 units are portable, fast and easy to set up; offer mechanical and/or electrical safety protection; are adjustable to fit unique electrical equipment configurations; reduce the requirements for personal protection equipment; and help customers with NFPA 70E arc-flash safety compliance. Optional features include 25-foot extension cables, 24 V DC LED light, wireless video camera system with LCD monitor, and rugged protective case assembly. www.cbsarcsafe.com

The Littelfuse MP8000/MP8100 series Bluetooth enabled motor protection relay promises to enhance worker safety while allowing for faster, easier control and troubleshooting. According to the company, the MP8000/MP8100 series allows maintenance personnel to communicate with the relay from up to 30 feet away using an app on an iPhone or Android smartphone or tablet computer. A worker can set up the relay, view real-time data and troubleshoot fault codes while the panel door remains closed, helping to minimize potential shock and arc-flash hazards and help create a greater level of safety, says the company. Littelfuse says the MP8000/MP8100 is the first fully programmable motor overload relay to offer integrated Bluetooth capabilities; earlier types required the purchase and installation of separate Bluetooth modules. If the relay is located in an outdoor cabinet, workers can interact with it while remaining warm and dry in their vehicles during inclement weather, notes Littelfuse. www.littelfuse.com

Time is money. Time saved in engineering can lower costs or be used to generate more revenue. Switching to EPLAN Electric P8 from CAD software typically reduces project time by 40% or more right out of the box – as much as 80% when using the feature-rich EPLAN portfolio to its fullest.

EPLAN automates time-consuming data creation and verification functions CAD users must perform manually, and often repetitively. And EPLAN has virtually unlimited scalability for managing the increasing demands of designing for the IIoT/Smart Factory environment.

EPLAN is the future of engineering. It’s freedom to concentrate on what matters most – engineering – so you or your team can quickly create high-quality machinery and plant designs and documentation.

or

Traco Power has released its TIB family of DIN rail mount power supplies boasting “industry-leading” efficiencies up to 94.5 per cent. According to the company, this generation of DIN-rail power supplies combines the “most efficient circuit topology with optimized cost/performance ratio for industrial environments and control cabinets.” The unit boasts a slim package design with a DIN rail clip that can be mounted on either the rear (typical installations) or side (flat panel installations) of the power supply with DC-OK LED indicators on both the front and side panels. Its reduced heat dissipation enables a -20 to 60 degrees C full load operating temperature range and up to 70 degrees C with 20 per cent de-rating, notes Traco Power. The company says the power supply offers 150-per-cent boost power for a minimum of four seconds to support stepper motors, solenoids or actuators with power-back immunity (no voltage over/under shoot). The TIB family is available in four power ranges of 80, 120, 240 or 480 W with 24 VDC outputs (adjustable from 23.5 to 28 VDC). All models are approved to meet UL/EN60950-1 and UL508 listed with compliance to EN61000-6-2 and EN61000-63 EMC Standards. www.tracopower.com

B&K Precision, a designer and manufacturer of test and measurement instruments, has launched its multi-range DC power supplies, models 9103 and 9104. The power supplies operate in constant voltage

(CV) or constant current (CC) mode and can deliver up to 320 W in any combination of its rated voltage and current – 42 V/20 A (model 9103) and 84 V/10 A (model 9104), the company notes. Boasting a lightweight, compact form factor, these models can replace multiple power supplies on a bench, making them suitable for a variety of applications in electronics manufacturing, engineering, service and repair, and education. According to B&K Precision, the supplies can provide any combination of higher voltage or higher current along a maximum power curve, adding that the 9103 and 9104 promise to save bench space while eliminating the purchase of unnecessary power. The front panel provides a dual four-digit LED display, On/Off control, and keypad and rotary control knobs for voltage and current. The front panel triple binding post output terminal connects

Steute Industrial Controls says it is now offering a wide assortment of wireless pushbutton and selector switches featuring internal electrodynamic energy generator with no battery required. Steute says actuation sends a unique, coded telegram to one or more compatible receivers. The receiver then sends confirmation of the received telegram. If the pushbutton actuator does not receive the confirmation signal within 15 ms, it transmits a second telegram. According to Steute, the receiver accepts up to 10

to double banana plugs or wires. The power supplies also feature three user-defined voltage and current presets for quick recall. Configurable square, triangular, or trapezoidal waveforms are available in transient operation mode. Both models offer adjustable voltage and current limits, built-in overvoltage protection (OVP), overtemperature protection (OTP), overload protection (OLP), and keylock function.

www.bkprecision.com

input voltage (450V to 800V operating range) to an isolated sine wave output of 115Vac continuous at 60Hz or 400Hz, or 230Vac continuous at 50Hz. The design topology allows for input voltages of up to 1200Vdc.

Absopulse Electronics has released the CSH-400-F6 series of heavy-duty, high input voltage DC-AC sine wave inverters. The units use microprocessor controlled, high frequency PWM technology to deliver 400VA pure sinewave output voltage, says the company, adding that they convert 600Vdc industrial

The CSH400-F6 inverters, according to Absopulse, are designed for industrial applications that require clean sine wave AC-output voltage and are suitable for industrial automation and control, transportation, power plants and electrical utilities. Absopulse says the high frequency conversion enables high efficiency, compact construction of 210 x 64 x 365 mm and low weight, noting that the inverters are cooled by conduction via baseplate and by natural convection through the cooling slots.

www.absopulse.com

discrete telegrams per channel. Other features of the switches include: available for operation at 915 MHz or 868 MHz; pushbuttons with six colour plates; bidirectional communication with receiver; an operating temperature range of -20 to 65 degrees C; as well as one, two, and three-position housings. www.steutewireless.com

The Harting M12 PushPull promises to offer rapid vibration-proof Ethernet connection with just one click. The company says the M12 PushPull brings the benefits of the Harting PushPull

in the form factor of an M12, adding that the connector’s housing and “reliable locking system makes it perfectly suited in harsh, heavy vibration environments.” An audible click indicates when connection is made and assembly that requires no special tools means installation in the field is “quick and easy.” As well, Harting says the M12 PushPull saves space by eliminating the need for additional access space for screwing the connector into position. The design also includes knurling on the side of the connector ensuring easy handling, it notes. The M12 PushPull boasts an IP67 rating and is suited for temperatures ranging from -40 up to 85 degrees C. It is available in A, D, and X-code versions and is suitable for Class EA up to 10 GB for the 8-poles X-coded version. It features 360° shielding and uses crimp termination. www.harting.ca