Get reliable linear motion at low prices with the award-winning customer service and support you expect from AutomationDirect! Our line of linear motion products is designed to provide smooth, precise and durable linear actuation. With supreme versatility and low maintenance, these affordable, motor-ready actuators can meet both your linear motion and budget requirements.

Value Line Linear Actuator

Low-cost, versatile linear slide actuator with hard-coated aluminum guide shafts. Unit can be mounted horizontally, vertically, or inverted without loss of load capacity.

• Max load capacity: 110 lb

• Max speed: 15 in/sec

• Travel: 6, 12, 18, 24 inches

• Ready for NEMA 17 motor

Self-contained linear slide actuator designed for light loads in harsh or wet conditions in a very small package.

• Compact design

• Stainless steel lead screw

• Max load capacity: 125 lb

• Max speed: 20 in/sec

• Travel: 6, 12, 24, 36 inches

• Ready for NEMA 17 motor

Create strong, secure shaft assemblies with high-quality shafts and shaft supports.

• Aluminum, steel & stainless steel shafting

• Linear or rotary shafts (with and w/o grooves)

• • Removable top maintains alignment

Twin Round Shaft Actuator

Continuously-supported round rail slide with ball screw actuation provides a very robust precision linear motion.

• High-accuracy ball screw

• Continuously-supported guide rails

• Max load capacity: 920 lb

• Max speed: 6 in/sec

• Travel: 12, 24 inches

• Ready for NEMA 23 motor

Passive sliding elements can be combined with actuators to build a huge variety of machine mechanisms.

• Linear ball bearings

• High-quality clear anodized aluminum blocks

• Carbon-steel shafts

Video Series on Linear Motion: http://go2adc.com/lm

Treena Hein

Vince Martinelli

@Raven Telemetry

According to a study, 6% of Canadian manufacturers invest in data analytics. This is the next step for competitive companies.

Great September issue, @AutomationMag!

@eC4energy

We’re providing power quality intelligence to food manufacturer in Ontario plant: http://bit. ly/2QxDIVK

@SachinAKher

Risks impacting manufacturing plant operations: http://bit. ly/2vY4uhC via @ AutomationMag

@Mentor_Works

Top reasons to adopt custom packaging solutions: optimize for success.

http://hubs.ly/ H0dtbhT0

@GE_Canada

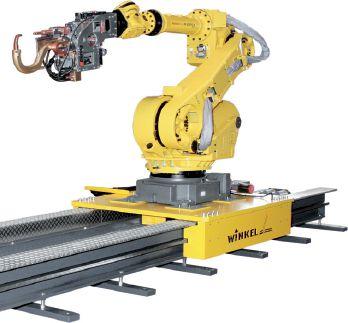

In Bromont, QC, we’re pioneering robotics for aviation manufacturing around the world.

Thank you, #teamGEcanada. pic.twitter.com/ uENn73Rzs8

BY KRISTINA URQUHART

Industry 4.0 and the Industrial Internet of Things (IIoT) was, unsurprisingly, the topic of conversation at last month’s International Manufacturing Technology Show (IMTS) in Chicago. We’ve been writing about this monumental shift in the industry for years now, but connected manufacturing is really only starting to trickle down to the SMEs that make up much of Canada’s output. The reason why it’s been a slow start is obvious: cost. So maybe the better question to ask is, why now?

At IMTS, Will Healy III, marketing management director for Balluff Inc., answered the million-dollar question in his presentation called “An Introduction to Smart Manufacturing, IIoT and Industry 4.0 & Why You Should Care.”

“ Why are we investing in automation? It is to improve productivity,” he said. He noted that modernization is long overdue, citing sobering stats from ARC Advisory Group that $65 billion in automation systems are reaching endof-life, with four in 10 manufacturers having little to zero visibility into the real-time status of their operations. And 50 per cent of manufacturers become aware of a problem only after a breakdown happens.

D ata and devices are what help move a manufacturer from mere maintenance or even preventative maintenance – which has an 82 per cent random failure pattern – to predictive maintenance, or anticipating problems before they happen for improved uptime. Those devices may be RFID readers that track parts, sensors that push data through I-O Link or tablets that run monitoring

or workflow apps. Healy sa ys that at this point, manufacturers need to be using tablets in their operations “or you will fall behind.” Our writer Treena Hein explores some of the ways tablets and apps are advancing the industry in “It’s All About Apps” on p. 18.

B ut before you go out and buy up a bunch of tablets, you need to figure out how they are going to fit into your organization. Determining your company’s objectives is fundamental to navigating the IIoT world, says Healy. Some of the common goals he mentioned are reduction of manufacturing costs, higher machine availability, traceability, reducing downtime and improving product quality, but there may be others.

He recommends several steps to incorporate mobile devices into your business. The first is to build a team composed of a variety of people in your organization, from plant managers to engineers to operators to maintenance to IT, to determine who needs what data. Establishing what you do and don’t need to know is key, because, as Healy says, “If you have too much data, you have zero data.”

Then you need to investigate that data and ascertain a strategy before you attempt to get buy-in and a budget from the powers that be. After you obtain the go-ahead, data is “about action. Make small changes every day,” Healy advises. The goal should always be to optimize the data to work for you.

Have you successfully incorporated mobile devices into your manufacturing business? Tell us about it at kurquhart@ annexbusinessmedia.com. | MA

@AutomationMag kurquhart@annexbusinessmedia.com AutomationMag

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com

VICE-PRESIDENT & EXECUTIVE

PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext. 3537

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Todd Mason-Darnell, Treena Hein, Paul Hogendoorn, Michael Joaquin, Vince Martinelli, Jennifer Rideout

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600

Fax: 416-442-2191

Printed in Canada

ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year Students — $20 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication. We acknowledge the [financial] support of the Government of Canada.

Handling Specialty supplies GE plant with production solutions

Handling Specialty, an Ontario-based custom engineering and material handling specialist, has supplied 24 pieces of equipment to the Brilliant Factory, a GE project in Welland, Ontario.

The Brilliant Factory – GE’s moniker for an IT/OT factory where machine intelligence, hardware, software and data converge – is beginning production of large-scale reciprocating gas engines for the power generation industry after breaking ground on the plant two years ago.

Handling Specialty’s contract with GE, valued between $12 and $14 million, is to design and build equipment to position the engines, technicians and manually guided vehicles that offer pathways to each assembly station.

The operator moves the vehicle with a handheld remote control until it reaches smart tape on the floor. The smart tape uses embedded QR codes and a laser to then automatically guide the vehicle to its final position.

Handling Specialty also provided a 15- and 30-ton engine rollover station that can rotate and slide reciprocating engines from side to side as technicians work on them.

In addition, the company created five personnel lifts,

which feature sliding bridges that technicians can use to position themselves all around the engine. The lifts can be operated from the ground or on the platform itself.

The contract has led to Handling Specialty working with GE on its Brilliant Factory in Jenbach, Austria to provide custom equipment solutions.

GE has implemented the Brilliant Factory concept in a

number of its 400 global factories with the goal of less waste and no unplanned downtime.

Cascades has announced its intention to close two sheet plants in Barrie (Jellco) and Peterborough,

Ontario by December 31, 2018.

The company says the plan is part of its ongoing efforts to optimize its corrugated packaging platform. Production will be deployed to other Cascades facilities in the province.

“This decision will enable us to better align our existing production capacity and to improve service for our valued customers,” says Charles Malo, president and

With the ultra-compact C6015 Industrial PC, Beckhoff has again expanded the application possibilities of PC-based control. Wherever space or cost limitations previously prevented the use of a PC-based control solution, this new IPC generation offers an excellent price-to-performance ratio in an extremely compact housing. With up to 4 CPU cores, low weight and unprecedented installation flexibility, the C6015 is universally applicable in automation, visualization and communication tasks. It is also ideal for use as an IoT gateway.

Processor: Intel® Atom™, 1, 2 or 4 cores

Interfaces: 2 Ethernet, 1 DisplayPort, 2 USB

Main memory: up to 4 GB DDR3L RAM

Housing: Die-cast aluminum-zinc alloy

Dimensions (W x H x D): 82 x 82 x 40 mm

chief operating officer of Cascades Containerboard Packaging.

The closures will affect approximately 65 employees, who may be transferred to other business units where possible.

manufacture

The transit commissions of Montreal and Laval, Que. have placed Canada’s largest-ever order for battery-electric buses, which will be fulfilled by North America’s largest transit bus and motor coach manufacturer.

New Flyer Canada, a subsidiary of NFI Group Inc., says it won the contract to build 40 zero-emission Xcelsior Charge transit buses over two other competitors. A notice to build the buses is expected after a nine-month review of a pilot bus, which is due to get the go-ahead on Oct. 31.

Thirty of the buses are going to Montreal’s transit authority (STM) and 10 to Laval’s transit agency. The order is supported by funding from the provincial and federal governments.

Both transit authorities plan to become fully electric in the future. In the meantime, they run pilot bus programs.

The Winnipeg-based New Flyer Canada says the Xcelsior Charge transit buses are already operating in Toronto, Vancouver and several large American cities.

KP Tissue and Kruger Products have released a plan for a capital investment of $575 million to construct a new state-of-the-art

tissue plant in the Brompton area of Sherbrooke, Quebec.

The project will establish more than 180 new jobs in the area and will feature Canada’s largest and most modern through-airdry (TAD) machine. TAD uses less fibre to achieve a softer and plusher product.

The new plant will be situated near an existing facility of the Kruger Group and will produce about 70,000 metric tonnes per annum of bathroom tissue and paper towels for the Cashmere, SpongeTowels and Purex brands.

Construction of the project is expected to begin in early 2019, and the plant is slated to commence production in early 2021. The project will generate over $250 million in direct expenses in Quebec and one million person-hours for the construction of the new plant.

The project is supported by the Quebec provincial government through Investissement Québec, which has agreed to invest $105 million by way of a convertible debenture. The remaining financing for the project is currently being finalized.

“This project is on an unprecedented scale for Kruger Products and will give us the additional capacity to continue to grow our business into the future,” says Dino Bianco, CEO of Kruger Products. “The Brompton site will also be part of a critical manufacturing hub in the region, working with our other locations in Crabtree, Gatineau and Sherbrooke.”

$1.2M in

The Canadian government has announced investments of more than $1.2 million for Temisko, Cardinal Equipment and 4229339 Canada Inc.- Les Jardins de l’Île. The funding, allocated under Canada Economic Development for Quebec Region’s Quebec Economic Development Program, will create five jobs in the region. It will also improve the companies’ production capacity, allowing them to acquire strategic equipment and continue to grow.

The total investment was over $2.2 million, but $1,022,146 is a repayable contribution.

Temisko specializes in the design and construction of customized semi-trailers and platforms to transport heavy, non-standard and extensible equipment. Its project is already underway with the acquisition and installation of production equipment such as aluminum welders, an automated welding robot, a forklift and overhead cranes.

Cardinal Equipment’s already-completed project involved acquiring and installing a new plasma-cutting table for use in manufacturing equipment for sawmills and biomass conversion.

Les Jardins de l’Île is a farming company that grows some produce and plants, all of which are certified organic. Its project will involve the construction of a building and the acquisition of new processing equipment

including a cold room, built-in freezer and packaging machine.

“My goal is to help businesses prosper and innovate so that they may be more competitive and create good-quality jobs and wealth for Canadians,” says Navdeep Bains, minister of innovation, science and economic development. “The support of these three businesses in the Témiscamingue RMC contributes, without question, to the achievement of these objectives and to the region’s economic vitality.”

The Excellence in Manufacturing Consortium (EMC) has announced that its two-year program to help manufacturers in Northern Ontario enhance their

productivity, competitiveness and business management capacity was a success.

In 2015, EMC began hosting lean management system (LMS) training sessions and “productivity cluster” events for senior management as part of a $427,945 investment from FedNor, the federal government’s economic development organization for Northern Ontario. They offered classes, discussions, coaching and

consulting assistance.

Lean manufacturing refers to a systematic process of small, incremental changes meant to reduce waste without affecting productivity.

“Knowing where to start is very important,” says Al Diggins, chair, treasurer and general manager of EMC. “A lean advisor worked with companies and recommended what tools they needed to accomplish their goals, focusing on one

specific area at a time. As part of this project, each company that participated in the LMS training selected a project that would result in a minimum return on investment of $50,000.”

Based on feedback from participating firms and managers, the LMS program generated significant return on investment, as well as significant economic, financial and employment benefits. In addition to boosting employee morale, enhancing staff engagement and reducing wasted time, the 10 companies that shared feedback cited initial annual savings of $10,000 to $499,000, depending on their area of focus.

Diggins says they started the program after realizing a training gap in Northern Ontario. “Intially, uptake was slow because the lean approach was new to many companies, so people were naturally skeptical. However, upon completion of the training, we

had created a pool of believers, many of whom are ready for the next round.”

Digital Engineering, a process management technologies firm in Thunder Bay, was one of 57 companies that participated in the productivity cluster program and encouraged its staff to take advantage of the training.

“For a long time we had realized that there was a definite need to improve our processes and drive efficiency,” says Les Perrault, president of Digital Engineering. “The productivity events that we attended provided us with information on how to evaluate our work flow and the tools that can be used to implement a continuous improvement program. Even more importantly, they have helped us understand the importance of creating an organizational culture that can motivate and engage our employees.”

Lorne McDonald, production manager at Metso in North Bay, has a similar outlook.

“When we first started talking about Lean, staff really did not understand. In many cases, they feared headcount reductions or added work. However, over the last two years, we have seen great change. We now have visitors – both company employees from other sites and vendors

– commenting on how much we have changed. For example, [we’re using] tool boards in place of large tool boxes and our safety stats are improving. We are now at over 932 safe days. So, the question is why?” says McDonald.

“It’s because people have an opportunity to suggest and implement ideas.”

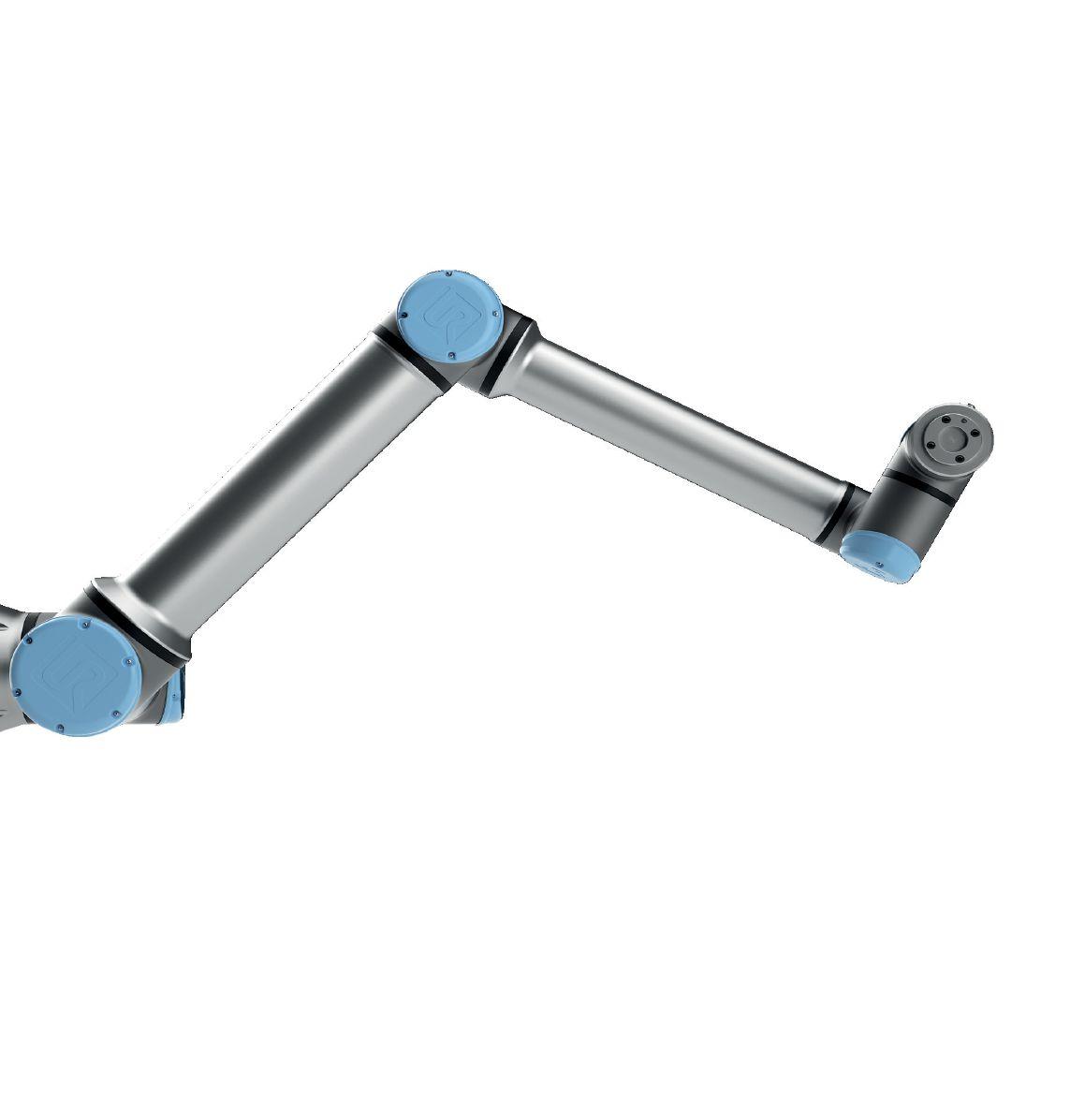

Canada is poised to become a future leader in robotics with the right government support in place, according to a new study conducted by CATAAlliance and Sciencetech.

The advocacy group and the engineering consultancy surveyed 465 Canadian companies for their report titled, “Automation of the manufacturing sector: Market study of Industrial Automation in Canada – 2017.” Almost 75 per cent of the respondents declared that they use robots or other advanced automation.

When it comes to robot density and deployment, Canada currently lags behind other major robotics centres such as the U.S.,

China, Japan and South Korea. But Canada does have 136 robots per 10,000 employees – well above the world average of 69 robots per 10,000 employees. That puts Canada at an estimated 26,000 robots with an average purchase and install price of $200,000, for a total investment of $5.2 billion.

Professor Clément Gosselin, director of the robotics laboratory at Laval University and the Canada Research Chair in robotics and mechatronics, says in the report that there’s no reason Canada can’t increase that total investment or even outpace foreign markets. He points to GE Aviation’s 2013 investment in a global automation and robotics R&D centre in Bromont, Quebec, as well as federal investments in university research throughout the 1990s as foundational in Canada’s nascent robotics industry. But Gosselin says any current government investment doesn’t do enough to discourage the purchase of foreign equipment or to promote a madein-Canada strategy.

“In order to have a complete robotics program, it is also important to consider injecting money into universities and research centres – not to increase the volume of research, but to link up with the commercial phase,” he notes. “We have excellent

research results in robotics. Now they have to be transformed into commercial products.”

One of the industry professionals surveyed was Patrice Charlebois, industry segment manager at Festo. He agrees with Gosselin, stating, “For too long, the government of Canada has shifted away from manufacturing jobs. Manual labour has been devalued. It is the opposite of Germany where manual labour has always been the object of all the attention of the government. The result is that Canada has many good engineers, but a chronic shortage of technicians.”

The CATAAlliance and Sciencetech study recommends ten actions that the Canadian government should undertake to strengthen the manufacturing industry and have it compete on a global level:

1. Establish a nationwide Canadian Manufacturing Day that recognizes and celebrates the manufacturing trades through open houses.

2. Collect and distribute case studies chronicling the use of robotics in SMEs, which were noted in the survey as trailing behind large and very small organizations in their adoption of automation.

3. Institute a tax credit for the

portion of SME investment that relates to the acquisition of automation equipment.

4. Mobilize the industry associations to be the conduits for information about the government programs.

5. Officially recognize the Group of Experts in Automation and Robotics (GEAR). The survey identifies Canada’s robotic integrator industry as one-ofa-kind but not well known. Using already-established manufacturing centres as hubs or “clusters” may prove to be attractive for new talent or investors.

6. Create a structure to support applied research for industrial automaton equipment manufacturers, as well as company-university partnerships.

7. Implement a “Made in Canada” strategy that puts high value on innovation here at home, rather than on exporting the

output of Canadian integrators.

8. Promote standardization among integrators and establishments embracing Industry 4.0.

9. Embark on pilot projects with integrators and universities to learn how automation can best be incorporated into different industries.

10. Fund a “FutureSkills Lab” to log the impacts of automation and to help employees displaced by automation access more varied training.

The survey shows that a lack of skilled labour is the main problem affecting Canada’s manufacturing industry. A greater level of involvement from the government would not only help to promote the industry as a viable career choice for those entering the workforce, but also ensure a robust, diverse strategy to position Canada as a global robotics leader.

Beckhoff Automation has opened its second Canadian location in Laval, Quebec to provide sales and service support in the region.

The 2,223-square-foot facility sits within Greater Montreal and features collaborative space for Beckhoff customers and employees to develop innovative automation and control projects. A dedicated training room is available for customers to increase their engineering knowledge of

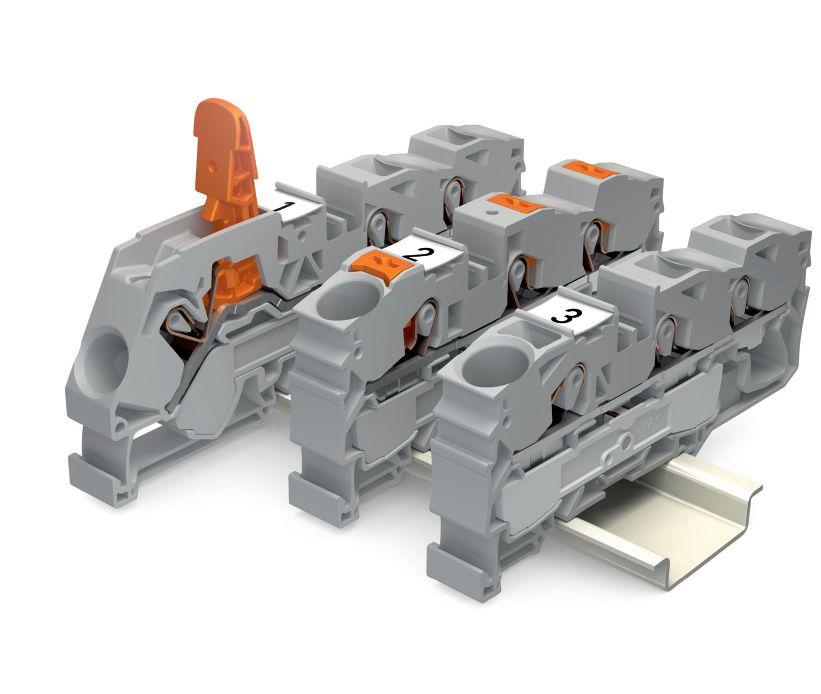

• Choose the right version for your application: lever, push-button, or open tool slot

• All three versions share the same Push-in CAGE CLAMP® technology for direct insertion of solid or ferruled conductors – no tools needed

• Mix and match technologies on the same rail and share accessories (jumpers, marking, etc.)

the company’s PC-based control solutions and to gain more programming expertise in areas such as PLC, motion control, safety technology and IoT connectivity.

“The strong legacy of manufacturing in Greater Montreal, and Quebec in general, spans a number of industries that increasingly rely on PC- and EtherCAT-based control technologies,” says Calvin Wallace, managing director of Beckhoff Canada.

Ted Sarazin, regional sales manager for Quebec and eastern Canada, runs day-to-day activities at the Laval facility. “Customers across Canada, and regionally here in Quebec, have recognized the benefits of control systems that feature PC-based hardware, EtherCAT networking and TwinCAT software technology,” says Sarazin. “This office location makes direct interactions with customers more efficient as we provide local product support and application engineering to help their business operations grow.”

The Canadian headquarters of Beckhoff Automation is located in Mississauga, Ontario.

Rockwell wins $50M contract for Chilean mine

Rockwell Automation has won a US$50-million contract to supply a mine control system to Codelco, the Chile state-owned copper mining company, for its Chuquicamata underground mine.

Rockwell Automation will help to transform the open-pit mine – which is considered the world’s largest by excavated volume – into a “super cave” mine that uses a block-caving extraction process. Block caving is a mining method in which blocks of ore are undercut to induce caving, allowing it to break up and be drawn off, pulled by gravity. The process is expected to extend the life of the mine by at least 40 years.

The contract includes a detailed engineering, supply, configuration and assembly of four structures that comprise the mine’s control system. This consists of an integrated operational platform, security system, supervision and control network, predictive maintenance and a general administrative network.

“We are pleased that Codelco has selected us for this epic mining project,” says Alejandro Capparelli, president, Rockwell Automation Latin America. “We are committed to helping our customers bring the connected enterprise to life. Our work together will increase mine throughput and lower operating costs.”

Rockwell Automation is currently working on the engineering and construction phase, in advance of a project start-up by mid-2019. Annual production is projected to be 320,000 U.S. tons of fine copper and 15,000 U.S. tons of molybdenum.

Cambridge, Ontario–based automation solutions provider ATS Automation Tooling Systems Inc. has entered into a definitive agreement to acquire KMW Konstruktion, Maschinen- & Werkzeugbau GmbH & Co. KG and KMW GmbH (collectively, “KMW”), a German-based supplier of custom micro-assembly systems and test equipment solutions.

The addition of KMW’s micro-assembly technology and expertise are expected to strengthen ATS’ current offerings in the electric vehicle (EV) market.

Micro-assembly systems are critical elements in the assembly of various components used in electric vehicles, including motors, power storage systems, braking, steering and electronic modules. KMW is expected to provide ATS with an internal source for complimentary conveyorized micro-assembly and test capabilities,

further enabling the company to provide full automation solutions and meet customer demands for a complete turnkey offering.

“The EV market is one of strategic significance to ATS,” says Andrew Hider, ATS CEO. “Having the capabilities that KMW offers in-house will enhance our offering in the EV market, while reducing supplier risk.”

Established in 1993 and headquartered in Koblenz, Germany, KMW has 68 employees and offers complete custom micro-assembly machines and solutions, clamps and tooling, as well as in-process test systems.

In its last fiscal year, KMW had revenues of approximately €14 million and an EBITDA margin of over 20 per cent.

ATS will pay €19.5 million for KMW in an all-cash transaction and expects the deal to close in the third quarter of its fiscal 2019, subject to closing conditions.

ATS specializes in custom automation, repeat automation and automation products. Founded in 1978, ATS employs approximately 3,800 people at 20 manufacturing facilities and over 50 offices in North America, Europe, Southeast Asia and China.

The company also recently announced that it landed a CAD $80-million contract from a global automotive manufacturer for a fully automated battery assembly system. The full order bookings include design, build, installation and post-delivery support, including training. The enterprise program is for a new customer, will involve three ATS facilities, and is expected to be delivered over the next two years.

OnRobot, the Denmark-based cobot technology provider, has purchased Purple Robotics, developer of the world’s first gripper specifically for cobots.

The acquisition takes place two months after the merger of OnRobot, Perception Robotics

and OptoForce.

Purple Robotics was established by Lasse Kieffer, Henrik Tillitz Hansen and Peter Nadolny Madsen, all of whom have a background as product developers at Universal Robots, the company behind the world’s first cobot. Kieffer, Purple Robotics CEO, says he looks forward to joining the OnRobot organization together with his colleagues.

“It has been really good fun to create a brand new robotics company and to disrupt the market for vacuum grippers with our invention,” he says. “It makes a lot of sense and creates significant synergy to join forces with OnRobot, which has already created a strong, global sales organization. This means that we can focus 100 per cent on developing the world’s coolest robotics products. Together, we can go far.”

Three months after launching the vacuum gripper, 40 partners in 25 countries have established partnership agreements with Purple Robotics to implement the patented innovation.

The Purple Robotics dual vacuum gripper can, so to speak, give a robot arm two “hands” and thereby the ability to handle several items simultaneously, solving multiple tasks in one movement. Additionally, it has an electric pump integrated in the gripper itself, meaning users do not need

to worry about hoses, compressed air and cables as with conventional vacuum gripper solutions. It takes less than 30 minutes to install the Purple Robotics gripper on a robot and start it up. The vacuum gripper is able to gently and efficiently handle items of many different dimensions, weights, materials and shapes. The lifting capacity is 10 kilograms (22 pounds) and the robot gripper is designed for use on a wide range of lightweight robots from all robot manufacturers.

Omron Canada has made three new appointments across the country. Michael Joaquin (top left) is the new safety services specialist in Toronto, responsible for Omron’s strategic and tactical actions to increase sales within all of the company’s Sean Garrity (middle left) takes the position of territory account manager for British Columbia, and will be responsible for building relationships and opportunities to collaborate on projects with end users, EPCs, system integrators and OEMs. Bashar Abuhamdan (bottom left) has been appointed account manager for Southern Alberta. Abuhamdan will be responsible for managing Omron’s end users, EPCs, system integrators and OEMs.

Mary Ramsey is the new executive director of the International Society of Automation (ISA), the non-profit professional association that sets standards in engineering and technology to improve the management, safety and cybersecurity of modern

automation and control systems used across industry and critical infrastructure. Prior to her role at the ISA, she served as the senior vice-president of process automation for the Americas at Schneider Electric.

Bombardier has appointed Danny Di Perna as chief operating officer, aerospace. Di Perna assumes

responsibility for leading the company’s aerospace engineering, procurement and transformation functions. Bombardier’s aerostructures and engineering services segment will also report to Di Perna. “We are thrilled to welcome Danny to the Bombardier leadership team,” says Alain Bellemare, president and CEO. “He is an exceptional

and engaging leader, with deep aerospace experience and a proven track record of success improving operational efficiency at leading industrial and aerospace companies.” Di Perna brings more than 30 years of aerospace and industrial experience to Bombardier. Most recently, he served as vicepresident of global sourcing for GE Power. | MA

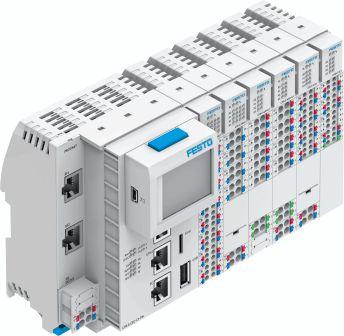

The Core product range from Festo featuring the Stars of Automation

Festo quality at a competitive price covering 80% of your automation tasks. From actuators to accessories for factory and process automation. Reduce your procurement complexity for both the electric and pneumatic control chain by simply following the stars. www.festo.ca/stars

We chat to CALVIN WALLACE, Beckhoff Automation’s new managing director for Canada, about how he plans to expand on the success of his predecessor.

MA: Congratulations on your new appointment as managing director. How have you settled into your new role?

CW: I started my new role on May 1 of this year. The first two or three months, I was working closely with Joe Ottenhof, who is the past managing director of Beckhoff Canada. At this point, I’m pretty much independent and Joe has been stepping back and cutting down his hours.

The Mississauga location is the Canadian headquarters and I’m based [there]. We have our training centre, our application specialists there as well, a complete customer service team, warehouse. It’s a fully transactional facility. Right now, we’re primarily focusing on Ontario, Quebec, Alberta and British Columbia.

MA: How has the Canadian market been for Beckhoff, and how do you plan on building on Joe’s success over the next couple of years?

CW: Certainly the Canadian market has been strong over the last three or four years. We’ve had a lot of success building business in Quebec primarily over the last two or three years – a lot of our growth has been coming out of there. [Ed: As of press time, Beckhoff had just opened an office in Laval, Que., to better serve the region. See p. 9 for more information on the new location.] Our focus moving forward would be expanding geographically west as well, and building our focus in B.C. and Alberta with our new process automation products.

MA: You’ve been working at Beckhoff for about 12 years. How did you get into the industry before that?

CW: I went to college for robotics and electronics control back in the ’80s. Before Beckhoff Automation, I was the vice-president of a local distributor in the London area for the automation market, focusing on control and mechanical products at Axiom Technologies. I was there for 14 years, and then was looking for more of a technical challenge. And Beckhoff attracted me because of the technical story and the innovative products.

MA: How have you seen the company shift over the past decade?

CW: We’ve grown from a reasonably small, privately held automation company to really a force now – getting close to one billion euros. Certainly in the industry, customers recognize the Beckhoff name and

they recognize what Beckhoff can do for their company and their machines. We continue to release more and more products, and it seems like we are releasing more innovative products at a faster rate than say, 10 years ago. That’s been the main change. The geographic or global coverage continues to improve and be strong. Where our customers ship machines, we have support for them.

MA: How have you seen the overall automation industry change?

CW: The machines continue to become more and more complex and users are expecting more from the machines they purchase. They are looking for, generally, very flexible machines that can run many different SKUs or products through. That

comes back to smart factory or Industry 4.0 concepts where they need to have the machine adjust to a customized product that’s being fed through it, or a customized product that they need to manufacture for a customer. Motion control is a big part of that, to be able to have many more actions of motion control on a machine to be flexible and adjust to the parts. That’s a big part of what we do in Canada.

An important part of our business over the last two years is one of our new products, the eXtended Transport System, or XTS [a mechatronic system that combines a linear motor with power electronics and position measurement], which is part of smart factory concepts. We’re seeing that product being used a lot in packaging and even more in assembly applications.

MA: What’s a common challenge that Canadian customers have when they come to you for a solution?

CW: Data is really important. The end users are expecting more and more data from the equipment, like how the machine is running, and where they can focus on improvements. Like I mentioned, they’re looking for more and more flexibility on the number of products that can run through the machine. And machine footprint – the size of the equipment – continues to be really important. Square footage within a facility is extremely expensive. The XTS is another example where using that product allows our customers to really reduce their footprint and still have the flexibility that they need. Of course, traditional high performance and precision is demanded and expected.

With our high-performance technology, we can provide that. But the real trends are data, flexibility and the physical size of the equipment.

MA: In your opinion, what’s one best practice that all manufacturers should implement if possible?

CW: Having machines that run efficiently. That’s not a new story, especially in the automotive industry. I’ve been to some meetings and sessions with business leaders, and one of the concerns they have is with the corporate tax structure changing in the United States, now their competitors who are manufacturing products have a much lower tax rate than they did a year ago. They have to revisit and double-back on efficiencies across the board, because we had almost a 20 per cent tax benefit in Canada.

And now that’s gone. I would say that’s probably the most urgent [for manufacturers], is to revisit their efficiencies and their cost structures because they’re going to have difficulties winning future contracts without relying on that cost advantage that they had before. That’s the biggest problem I see when I talk to business owners and end users.

MA: What are some future goals for Beckhoff?

CW: IoT is something we are focusing on. And machine vision is going to be a big deal for Beckhoff. I’m happy with the discussions I’m having with customers already. It’s still in the process of being released globally, so it’s not something that we are shipping at this point. But there is great demand on machine vision, and that comes back to quality

and efficiencies. We’ll have a complete system with the XTS, with vision – it’s a really, really tight, fully integrated system. We’re entering the HMI world as well and it will be another important category for us. It’s worth noting process automation as well. It’s a whole new market for us as we’ve been focusing on traditional factory or discrete automation.

From a global perspective, Hans [Beckhoff, managing director for Beckhoff Automation GmbH] talks about getting as close as we can to our customers, both expanding our facilities so we can be closer to our customers for relationships and training and support. Certainly I see a trend that we will continue to do that. There will be continued investment in facilities in Canada and globally as end users use more and more Beckhoff. | MA

BY PAUL HOGENDOORN

Regular readers of this column probably wonder if I am still working, or if I’m retired, given that so many of the columns I’ve written highlight my recent recreational pursuits and adventures, many of them with my granddaughter.

The truth is that not only am I still working, but also the last two years I’ve been working harder than I did in almost any other period in my 35year career. The difference, though, is that I have learned a few things on the ever-converging life and business journeys – and one of those things is how to keep things in relative balance, even when going full throttle. Along with the stresses and challenges of starting up a new business that is bringing new technologies to a conservative industry and challenging decades-old (centuries-old?) paradigms, I’ve taken small breaks here and there to climb famous towers and bridges, hike Niagara escarpment trails and drop anchor in places unchanged since before the first European settlers arrived here. And most of those things I did with my granddaughter (inset, at right).

O n our last such adventure, we talked about one day participating in the Amazing Race Canada reality TV show, and then concluded that, in effect, we were already doing that now. We were sitting on the back deck of a boat just off shore at Grand Bend, Ontario, and then a single moment later, we were soaring 550 feet in the air. It was spectacular, and the whole experience caused me to think about how different things would have been if I didn’t say “yes” to many of the unusual requests I’ve said yes to – with most of those really unusual requests coming from her.

It made me think of how the lessons we learn in life apply to us in business, and the lessons we learn in business can apply to us in life. Not every question should be answered with “yes,” but I’ve learned that my natural inclination for too many questions always seemed tilted toward “no.”

Sometimes it’s better to try and fail than never to have tried at all.

Often, these revelations come after long hours of hiking, climbing or

Paul Hogendoorn is president of FreePoint Technologies. “Measure. Analyze. Share. Don’t forget to share.” He can be reached at paul. hogendoorn@getfreepoint.com.

One minute we would be sitting on the back deck, and the next we would be soaring. If only getting a company off the ground was that easy.

riding – or they are epiphanies that come days later, upon reflection. With the parasail adventure, I knew the inspiration, whatever it may be, needed to come quickly, because the whole thing was only going to last 10 or 12 minutes; one minute we would be sitting legs forward on the back deck, and the next we would be soaring, feeling as if we were suspended, thumbtacked to a cloud. If only getting a company off the ground was that easy, I mused. But it’s not.

And then it hit me.

I wondered why it wasn’t that easy to get a company or new idea off the ground, and why people are more inclined to say no and resist a new idea than embrace it. And then I thought about the boat that was pulling us, with its 600-cubic-inch engine, and the sail that was suspending us, and the taut, thin line in between – and I realized it was the resistance of the wind that lifted us to the sky, and not the pulling of the boat alone. Without the resistance, there would be no lift. If it was just a matter of power and speed, we would be skipping along the surface of the water, at perhaps 70 kilometres per hour, but we wouldn’t get in the air. We wouldn’t be enjoying the experience – in fact, after only a short while, we would be exhausted, beat up and drenched. We needed

the right balance of speed and power, along with resistance, to get into the air. Resistance is good. In fact, it’s necessary. We also needed that taut, thin rope to keep it all connected. The best phrase to describe that rope when everything is working well is “under tension.” There is always tension whenever there is resistance – and there is always resistance whenever there is lift.

The person driving the vision, or idea, or company, is likely thinking primarily about the power and speed of the towboat and all of its capacity, and may actually be thinking of all the resistance as a bad thing. But some of that resistance is essential if indeed you want your idea, or business, to soar.

My takeaway advice from this recent 12-minute adventure: 1) say yes more often to more things that get out of your comfort zone (and this incudes recreational things); 2) expect resistance, even a lot of it, with a healthy dose of fear; and 3) learn how to find the kind of resistance needed to create the lift that gets you off the deck and soaring. | MA

As the inventors of the original safety light curtain, we have accumulated over half a century‘s worth of experience and expertise in all things safety. And what do we do with that experience? We continue to innovate – so our customers can take it to the next level. We used our expertise to create the deTec4 Prime: Versatile thanks to its flexible connection concept. Freely positionable with optimal resistance to interference. Extremely easy to use with a visualized display. And a minimum of connection work when cascaded systems are needed. It’s a masterpiece based on the original. We think that’s intelligent. www.sick.com/deTec4

BY JENNIFER RIDEOUT

On the factory floor, every new connection point is an opportunity for operations teams to monitor, analyze and optimize performance. It’s also a security risk.

As connectivity increases through networked sensors, devices and other Internet of Things (IoT)–enabled equipment, so does complexity – and so do security concerns. Providing operations technology (OT) teams with IT network connectivity, and not a cybersecurity backbone to ensure the network stays secure, is not enough.

Consider that every new asset you put on the network is another security consideration, and another risk that requires monitoring. In many factories, the sheer number of assets is making it difficult for OT professionals to understand their security posture, let alone have visibility across the entire network, at any given moment.

Many manufacturers also lack the digital tools to identify what normal network activity looks like, which makes it almost impossible to identify threats when an abnormal condition arises. Why? Industrial control system (ICS) environments consist of many types of equipment operating many different industrial IoT protocols. Getting a centralized view is difficult, to say the least.

These networked assets have made manufacturing environments an attractive target for cybercriminals, who understand that many are vulnerable to threats. These cybercriminals use ransomware to extract money from manufacturers, often by threatening to shut down production or delete intellectual property. And let’s not forget that much of the equipment in Canadian factories is more than 20 years old. It was never designed to guard against sophisticated cyberattacks.

So what does this all mean? It means that it’s time to give OT professionals the digital tools they need to keep factories secure. It means that OT must take ownership of cybersecurity. And it means that IT professionals need to help.

To start, many OT professionals do not have sufficient training or education in cybersecurity, which are necessary to manage and

protect against advanced ransomware and other threats. Manufacturers must make it a priority to educate their operations teams in this area. Because while your IT department can, and should, help operations teams understand and manage security policies, they are not familiar with the complexities of factory operations and manufacturing technologies.

The key, then, is for OT and IT professionals to work together to keep factory equipment and networks secure. IT has the expertise to provide operations with the tools and training needed to secure factory networks, and OT has the manufacturing expertise required to advise IT on the nuances of a production environment.

Here are four ways that IT and OT professionals can work together to provide OT with the digital tools that keep factories secure:

1. Empower OT while keeping IT in control of security

What: Allow IT to define security policies that dynamically apply themselves based on OT’s intentions and input.

Why: OT needs to be able to take ownership of security to ensure continuous operations, but requires IT expertise to do so.

2. Segment networks

What: Create discrete network zones within your overall topology that restrict access and prevent infection.

Why: Cybercriminals are looking for any entrance point they can find. For example, one case of the WannaCry ransomware attack in

May 2017 started from a single workstation that was connected to the network at large. Segmentation helps to prevent infections from spreading too far.

3. Provide a full view of industrial network topology for OT

What: Empower OT with a centralized network dashboard so they can stay abreast of conditions and deep dive into individual assets.

Why: OT needs better context around security to successfully enforce it.

4. Enable remote access

What: Enable secure, remote access to securely bring in remote expertise such as contractors and vendors to help solve issues, apply patches and more, without needing to involve IT in every incident.

Why: Allowing OT to enable access to select assets for third-party organizations helps increase agility and ensure continuous operations.

To maintain all processes and keep factories safe from cyber threats, OT professionals need to be more self-reliant. Without visibility into the network, they can’t understand activity or identify anomalies. And without the ability to manage and apply security policies, they’re too dependent on IT – slowing down responses, creating confusion and impacting productivity. By giving operations teams the right digital tools to understand and protect against threats, all manufacturers will sleep better at night. | MA

BY TREENA HEIN

Apps have been around for years in the manufacturing sector and their use is only going to expand, due to the way they add so much intelligence and value in the quest to better manage assets and processes.

“Apps were critical in the past, they are critical now and they will be even more critical going forward,” says Craig Resnick, vice president of consulting at ARC Advisory

Group. “It’s all about increasing productivity and profitability, as well as eliminating unscheduled downtime through gathering and sharing information effectively.”

A straightforward example of how an app adds value, says Resnick, would be a sensor detecting if a motor is running too hot or vibrating uncharacteristically. “This sensor data is then sent to the cloud or a local ‘edge’

device, which contains analytics software to convert this data to meaningful information,” he explains. “This information is then used to, for example, schedule a service call and a replacement motor to be shipped to synchronize with this service, which helps to avoid an unplanned downtime.”

This app example demonstrates the effectiveness of the Industrial Internet of Things (IIoT) – the ability to connect manufacturing by embedding sensors into assets and gathering immediate data, then sending a signal to the people who can check the process or service the asset. (In Resnick’s view, edge

“It’s all about increasing productivity and profitability, as well as eliminating unscheduled downtime through gathering and sharing information effectively.”

devices – data repositories physically situated close to where the data was generated – are used with apps where data is gathered in real-time; the cloud is mostly used for storage of data after a detected situation is dealt with.)

Some interesting real-life industry app examples are described in a recent report called “Five Manufacturing Companies with Mobile Apps that Got it Right,” from Atlanta-based app developer Stable Kernel. The Womble Company built an app that serves the firm itself, and its suppliers and customers, by integrating a barcode scanner that tracks every piece of pipe the firm produces. Through the app, Womble has seen significant improvements in customer relations and productivity, 100 per cent inventory traceability and

more. Another example in the report is Caterpillar Underground Mining, which built an app that tracks all equipment (locations, part numbers, lot numbers), warehouse inventory and more; it has reduced regular cycle count by 50 per cent.

Resnick cautions, however, that while in-house apps being made by some manufacturers can certainly be effective, all software is going to require updating and even overhaul. Therefore, there must be contingencies in place if, for example, the app designer leaves the company. That’s one of the reasons Resnick believes most manufacturers are using out-ofbox app solutions. They are both proven and cost effective (with training included, often through YouTube).

However, Alexandra Tregre, business development manager at Stable Kernel, is of the opinion that out-ofthe-box apps often do not properly address the unique challenges most enterprises face, nor are they always built for scalability or efficiency. “Even out-of-the-box solutions need to be modified to address the specific use case to solve business challenges and improve workflows,” she notes. She adds that “every company that wants to deploy mobile software must make the decision to either pay less for a cheaper, hybrid development solution and risk a poorly built, insufficient

product that produces technical debt, or to invest in the product up front and mitigate risk.”

Quebec-based Poka is an example of an app maker that has produced many customized solutions, helping manufacturers to drive performance and productivity with real-time information. For the Leclerc Group, a North American snack manufacturer with over 950 people employed across many facilities, Poka has reduced variation in production across eight plants. As a result of these improvements, Leclerc saw a reduction in downtime by 9.5 per cent, and start-up and changeover time accelerated by 31 per cent.

WestRock, a $14-billion paper and packaging company, issued iPads with Poka apps in 2016 to help deliver video-based training and work instructions to their workers across their global operations. The result is better comprehension and retention of information as well as a 50 per cent reduction in the time it takes to capture and document procedures.

In terms of how manufacturing apps are generally being sold, Resnick notes that a lot of them are now being marketed as a service, moving away from a model of paying once as a capital expense. “You pay a monthly fee that comes out of the operational side of budget, and updates are automatic,” he says. “For the app firm, it helps

secure the customer long-term.”

Going forward, both Resnick and Raman Chitkara – who recently retired as global technology industry leader at multinational professional services firm PwC (PricewaterhouseCoopers) – predict the increasing use of artificial intelligence (AI)

in app development – software programs that can make decisions based on huge amounts of historical data. Chitkara predicts that AI will be able to coordinate and integrate apps, directing them to work with each other to find proactive rather than reactive ways to produce desired

outcomes. For her part, Tregre also believes that combining AI/ machine learning and leveraging the Internet of Things provides limitless opportunities for apps in manufacturing. As manufacturers continue down the path of using high-tech to maintain a competitive advantage, she

We’ve compiled a roundup of some of the major apps in the manufacturing world. View the full list on automationmag. com. Companies not listed are welcome to alert us to your app.

Siemens

The Siemens Digital Innovation Platform integrates apps and software for product lifecycle management, application lifecycle management, electronic design automation, operations management and more. It supports open IoT, 3D modeling and manufacturing operations. plm.automation.siemens.com/ global/en/our-story/visiondigital-innovation/

Rockwell Automation

One app example from Rockwell is TeamONE, which both syncs and keeps industrial communications local, being designed for hybrid connected industrial environments. It incorporates worker knowledge with data from automation devices. rockwellautomation.com/ rockwellsoftware/applications/ factorytalk-teamone.page

ABB

Apps within the firm’s manufacturing execution system provide the orchestration and synchronization of all the entities involved in the manufacturing process, giving insight to operators, production engineers, plant managers and more. new.abb.com/cpm/ manufacturing-executionsystem-mes-mom

Schneider Electric

Apps and software provide a standards-based foundation that unifies people, processes and assets for continuous operational improvement and real-time decision support.

schneider-electric.com/en/ work/solutions/for-business/ food-and-beverage/ smart-manufacturing.jsp

Honeywell

Various apps and software provide a real-time view of all materials, parts and finished goods flowing through manufacturing operations to optimize processes, ensure product pedigree and maintain consistent quality control. honeywellaidc.com/solutions/ environment/manufacturing

Microsoft

The Microsoft Azure IoT suite of apps includes Remote Monitoring, Connected Factory, Predictive Maintenance and Device Simulation. azureiotsolutions.com

LeanApp and LeanMan

The LeanApp is described as “the Kaizen Event app for iPad,” designed to help Lean practitioners measure and analyze processes. Users enter measurement data, which is interpreted and generated into reports that can be shared instantly. Similarly, the LeanMan app allows manufacturing businesses to observe and measure their production process data in real time, and receive interpretation and

reports instantly to help identify where process improvements can be made. leanapp.info

SYSPRO

This system integrates, synchronizes and controls the manufacturing lifecycle, keeping finished inventory at a minimum, simplifying forecasting, planning for materials requirement and capacity, and more. There is an advanced scheduling functionality and the ability to track actual labour versus estimated labour. us.syspro.com

Oracle

Oracle Manufacturing Cloud manages processes and streamlines the production cycle as part of a supply chain system. The firm’s asset maintenance software and apps provide a complete view of assets. oracle.com/applications/ supply-chain-management/ solutions/maintenance-cloud .html

iFIX

This app helps deliver faster insight and operational efficiency in asset management. The overall interface layout is designed to provide operators with the most informed view of the problem or task at hand, personalized to them. ge.com/digital/products/ifix

Salesforce for Manufacturing

This firm’s apps can “make each interaction for inquire-to-order and field service operations a

sees “huge” opportunity for developing innovative high-tech solutions that meet the needs of workforces wherever they are, “and mobile apps are at the crux of that.”

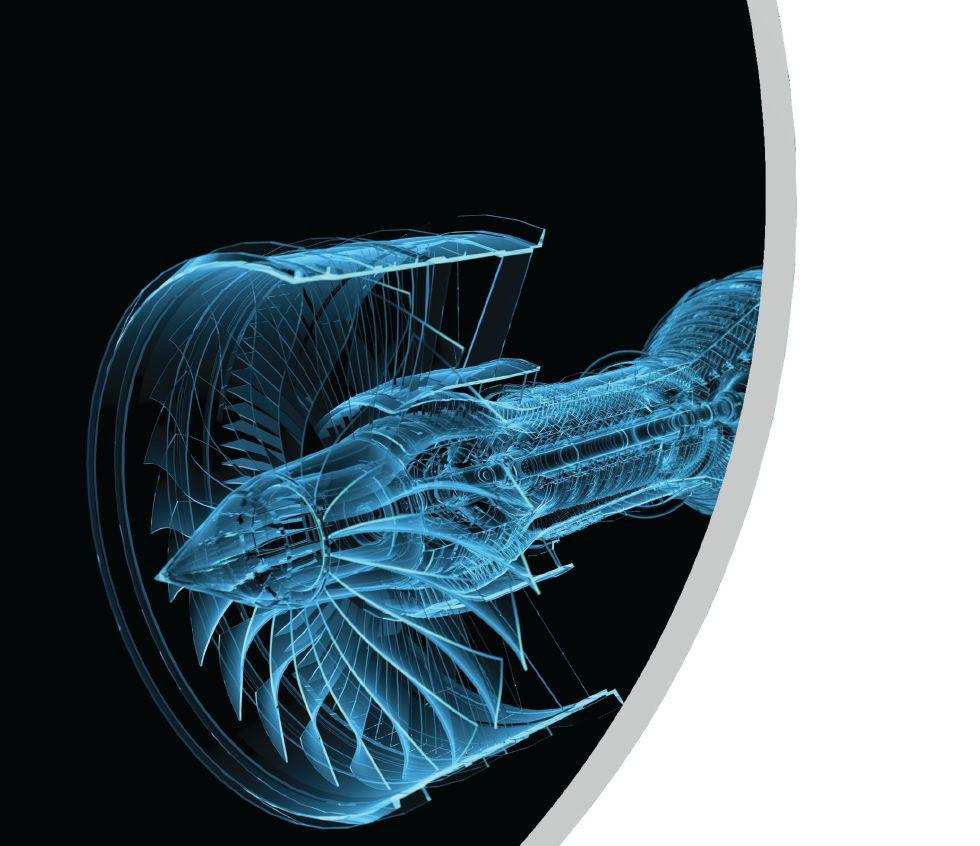

Looking ahead, Resnick lists another hot app trend to be digital twinning (when an asset

personalized experience [and] enable 24/7 customer-centered collaboration.”

salesforce.com/ca/solutions/ industries/manufacturing/ overview

Poka

Poka apps (for operations, health and safety, quality assurance, HR and more) allow access to real-time information to solve recurring problems, more easily train staff, digitize lockout tag-out procedures, standardize processes, assign maintenance tasks, follow-up, enable collaboration and more. poka.io

NetSuite Manufacturing Edition

NetSuite Manufacturing Edition is a cloud-based integrated manufacturing app that tracks inventory and warehouse activities and links them to the value chain. It provides manufacturers ways to manage inventory level stocking at multiple locations, and more.

netsuite.com/portal/industries/ manufacturing.shtml

Humanity

This app enables managers to spend less time scheduling as it includes the capacity to import and integrate business data to predict scheduling needs, to collaborate and communicate with coworkers, to create training programs to onboard new staff and facilitate staff development, and more. humanity.com | MA

“Every company that wants to deploy mobile software must make the decision to either pay less for a cheaper, hybrid development solution and risk a poorly built, insufficient product that produces technical debt, or to invest in the product up front and mitigate risk.”

is delivered to a plant, a digital simulation of the asset comes with it). “With a turbine, for example, you can run the turbine’s digital twin first and determine with the simulation if there are problems that can be solved before the actual turbine is commissioned,” he explains. “Such as additional heat or vibrations being generated above the design specification based on abnormal bearing wear, which could lead to unplanned downtime.” Two other major trends, says Resnick, are augmented reality (being able to see what’s in front of you but also wearing a device that provides additional information in your visual field) and virtual reality (an entirely virtual visual field) to do things like practice training scenarios.

Tregre agrees. “The continued application of VR, AR, touchless tech and so on all have great potential to be leveraged within manufacturing apps to further advance the value of mobile products by solving critical problems and challenges of the future,” she notes. “These technologies allow companies to further automate complex processes via apps while also responding real-time to the critical data that is gathered.”

H owever, while Chitkara acknowledges that further digitization and automation of the industrial world will be very transformational with numerous benefits, he stresses that it must also be prepared for challenges. Increasing digitization, he warns, will give industrial firms a “full taste” of what it means to be technology companies – which means navigating how to manage strong dependence on software, cloud computing and so on. He firmly believes that digitization

in the industrial arena is not going to be as easy and rapid as it

has been in the consumer sphere. Tregre adds a cautionary note on app development and use. “We see large enterprises neglecting a research phase at the beginning of a project,” she says, and without that solid research, “the app will be built on assumptions and fail to deliver the intended results or provide any value.”

And one last thought – also cautionary but empowering, too. Among others, Stable Kernel believes that the increasing use of apps will be critical to attracting young talent in the manufacturing sector – so much so that the company wrote a paper on the topic, viewable on their website, stablekernel.com. | MA

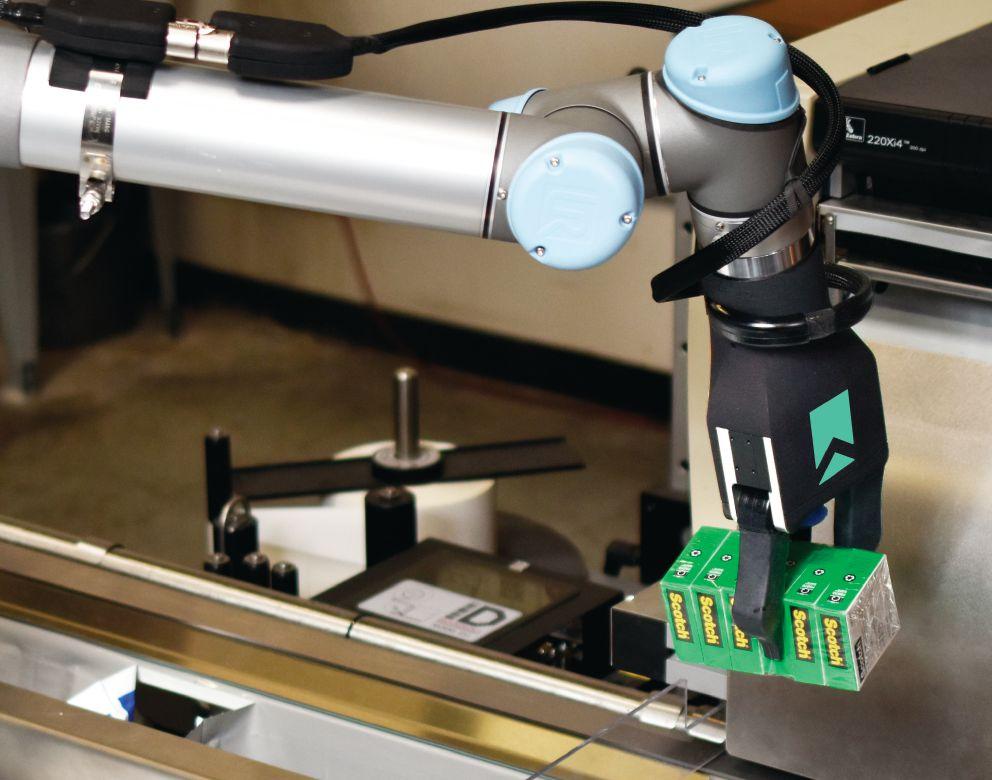

Robotic piece-picking supports logistics and end-to-end manufacturing operations

BY VINCE MARTINELLI

Traditional material handling processes focused on moving products by the case or pallet from distribution centres to brick-and-mortar retail stores, where customers would do their shopping. Today, with the convenience of e-commerce, people are shopping over the internet more

frequently and buying fewer items at a time. E-commerce has turned the traditional material handling and logistics landscape on its head, compelling us to rethink the overall approach to intralogistics operations within the four walls of the fulfillment centre.

The problem boils down to pieces and people. The “pieces” part of the problem comes from this shift towards

Range, rate and reliability are the key requirements for someone identifying a piece-picking solution for their business.

shipping individual items, driven by surging online order volume, with double-digit growth spanning millions of SKUs. How can automation cope with this flood of individual items?

The “people” part of the problem comes from tight labour markets in many regions, shrinking labour pools in others and a tendency for people to avoid sticking with mundane pick-and-place task-based roles. Even with automated storage and retrieval (ASRS) systems, intelligent conveyors and sorting systems, people play a key role in handling items as they move through the facility. How will retailers grow and sustain outbound volume with the human resource challenges they face?

The solution? Automation of

In a continuous cycle where a robot transfers items one at a time between two adjacent totes, rates of 1,000 units per hour or more can be sustained.

simple, menial warehouse tasks by way of robotic piece-picking, designed for the new realities of e-commerce and for integration with a wide range of warehouse systems.

T he adoption of robotic piece-picking for supply chain is still in an early stage, but many retailers and fulfillment centres are already testing and integrating this new technology into their warehouses in order to stay ahead of the competition.

The challenge for someone trying to pick the best option is deciphering the techno-babble and identifying a solution that meets the needs of their business in terms of three key requirements: range, rate and reliability, or simply, the 3Rs.

Range of items is a measure of the SKU variety and order diversity in your operation.

SKU count alone is not a perfect measure of variety in regard to size and shape of items. There are many identically packaged tubes of toothpaste, bottles of shampoo and cereal boxes, for example. Even so, it’s likely that the more SKUs your company stocks, the greater the variety of these classes of items and the greater the size options offered. People deal with this variety easily, but traditionally robotics have only been used when the range of items is very low, such as in a manufacturing production line.

But the sheer variety of items is not the only challenge. With demand shifting to direct-to-consumer purchases, your customer order profile may only have between one and two units on average, compared to traditional store -restocking orders that may

have 20 or even 100 order lines.

Even with some small sets of

HPN Harmonic Planetary® value series provides a low cost solution without the need to compromise on quality or performance. This new value series of planetary gears carry the reputation for quality and reliability for which Harmonic Drive® products are known throughout the world.

• Helical Gearing

• Available in 5 frame sizes

• Peak Torque: 9Nm to 752Nm

• Ratios: 3:1 to 50:1

• Quick Connect® mounting system

• High Efficiency

• Backlash: <5 arc-min (single stage), <7 arc-min (two stage)

• Fast Delivery

• Shaft output available with key and centertapped hole or with center-tapped hole

faster-moving (more popular) products, order diversity is high, especially when trying to process orders quickly to meet same- or next-day deliveries limits batch size. Combining these factors means that an associate doing ASRS tending or sorter induction may not see the same item twice in a row very often through the day. Does a robotic solution need to support 100 per cent of your products to have a reasonable payback? Probably not. Bicycle tires and toothpaste, for example, do not often flow through the same storage and processing steps in a warehouse. They are unlikely to be packaged together and will normally ship in separate boxes. A toaster oven may ship in its own box and always be processed as a single item. That said, the wider the range of items that your robot workcell can pick, the better. It simplifies material flow, and gives you flexibility to consider using such a system at one or more pain points in the operation.

Robotic piece-picking has gotten very fast. In a continuous cycle where a robot transfers items one

at a time between two adjacent totes, rates of 1,000 units per hour or more can be sustained. Commercial off-the-shelf (COTS) robot arms provide options for rapid picking, and task-specific path-planning algorithms improve efficiency. Intelligent solutions that integrate vision and smart grasping hardware with software intelligence are quick to identify items, select a motion path and execute the pick.

A sk prospective robotic piece-picking partners about benchmark performance measures for items similar to what you intend to run through the workcell. These results should be supported by both lab and field data, accounting for variations in solution design. The supplier should be willing to discuss trade-offs in order to optimize the system for your operation, whether an existing facility or a greenfield design. They may recommend changes to inbound procedures, including how items are presented in totes and how they are packaged, to make it simpler for an automated system to perceive and grasp items. Robotic piece-picking can meet the throughput requirements for

reliability and contributing to continuous improvement for your key quality metrics.

R obotic piece-picking also must achieve a high degree of robot independence, operating with minimal human intervention, in order to satisfy use requirements and maximize benefits for warehouse processes. Robot independence can be achieved by having high operational reliability, incorporating error and exception handling into the software control systems, and providing a simple, robust mission control protocol for interfacing to host systems in the facility.

many typical DC and FC processes – and it is improving rapidly.

Another consideration regarding rates and throughput is how quickly robotic piece-picking can be deployed and integrated into your systems. The best systems can be deployed in roughly a day by a single technician and feature simple interfaces. As the installed experience base continues to evolve and standardize, these systems will become even more plug-and-play. There is no need to wait for the operational savings afforded by robotic piece-picking.

Robotic piece-picking is reliable if it provides order integrity – always picking the right quantity, and successfully transferring it to the place location. Robots can also provide and contribute to order integrity by validating an item, such as via barcode scan or image matching, verifying that the proper inventory was presented to the piece-picking system. Similarly, robots can capture data regarding picking tasks, including images, that can be used to confirm task completion, improving overall operational

R obotic systems must be mechanically reliable. They should leverage highly reliable COTS technology and subsystems that are supported by data from production use at scale. For newer elements, such as gripper hardware, quick-swap designs and on-site spares programs help sustain continuous operation.

I n addition, a successful robotic piece-picking solution must be reliable even in the case of exceptions or errors. It’s easy to plan for happy-path scenarios, where everything is perfect. But this ignores the fact that even in the best-run facility or with the best robotic piece-picking workcell design, there can be errors. A well-conceived solution will have a simple message interface that can easily integrate with the warehouse control system (WCS) to coordinate and resolve issues –and the issue should resolve automatically, which requires robust error handling in the integration message protocol.

An early example pilot project involved a Canadian e-commerce company evaluating robotic piece-picking for the ASRS pick-tending use case.

The system was deployed and integrated with the existing WCS software and physically at the ASRS system port. The task included picking from different bins in sub-divided totes and placing

Reliability improved throughout the trial with attention being paid to how some items were arranged in the bins.

to the proper outbound carton or tote, for several orders that were in queue. The robotic system would receive pick missions from the WCS and would confirm mission success after placing the item in the appropriate container. In the event of an error, including empty source tote, misaligned tote dividers, or a missed pick, for example, the system would log and annotate the error, message the WCS with an error code and then the workflow would proceed based on a predefined set of error handling rules.

The robotic system was initially able to pick over 70 per cent of the SKU population with no modification to how the items were slotted in the storage totes and with no modifications to packaging. Keeping in mind that not all SKUs represent an equal proportion of volume, this was encouraging. Depending on the product details, robotic systems may be able to pick 90 per cent or more of the overall SKU set and an even higher per cent of volume, for products that are managed in ASRS.

An interesting example of a product that can be hard for robots to pick is men’s belts. If they arrive at the facility ready to hang on racks in a store, it’s not a great form factor for robotic perception and grasping systems. Rolling the belts and securing them in a snug plastic bag secured with an elastic makes them easier to pick and also prepares them for pack-out.

R aw rates for the robotic system were in the 400-500 uph range, including delay times in messaging between the systems – which can be reduced in future work – and time to reach to the

farthest outbound container. This range is fast enough to where the throughput is now limited by the upstream and downstream systems. It could be further optimized in stations designed with robot ergonomics in mind.

Reliability improved throughout the trial with attention being paid to how some items were arranged in the bins. If bagged t-shirts were packed tightly and arranged vertically in the totes, it would make it a two-hand pick for a person, as one hand separated the items and the other grabbed an item. For the robotic system, laying the items on their side enabled successful single gripper picks. These and other “lessons learned” are driving new feature development based on capabilities of the robotic vision system and machine learning, as well as adaptive hardware systems.

In this example project and others, suppliers and customers are quickly learning how to effectively leverage the capabilities of robotic piece-picking to tackle the challenges in the dynamic world of e-commerce.

Robotic piece-picking at work

Robotic piece-picking is automation in action. The basic value framework is driven by the 3Rs of range, rate and reliability as they apply to your business, and best-in-class solutions have a clear set of common characteristics that offer high levels of 3R performance. When these new and complex technologies are combined intelligently, the results are simple: items are picked and placed predictably, and customers receive their orders on time. | MA

MASON-DARNELL & MICHAEL JOAQUIN

Experienced safety managers are usually well versed in the consequences of poor safety practices, which may include fines, worker’s compensation costs, high turnover, lost productivity, worker injuries and even fatalities on the job. Even so, misunderstandings about machine safeguarding requirements place many facilities at risk for noncompliance and serious accidents.

Several trends are contributing to this disconnect. As older workers retire, many industrial facilities lack the engineering expertise required to ensure that their machines meet modern safety standards. In addition, the increasing use of automation may be leading to complacency at some plants. Manufacturers may not realize that even if a process is automated, the machines still may not be compliant.

Here, we discuss several misconceptions that industrial safety and facility managers often hold when it comes to machine guarding.

MYTH #1

Safety is something you can just take care of once and then forget about. Safety is an ongoing requirement, and companies must have regular risk assessments performed on their machines to ensure that they meet the most recent safety standards. Companies often wonder what they should look for in an assessment service provider. When selecting an assessment service, perhaps the most important thing is to make sure that the team is composed of safety experts and engineers rather than sales professionals. The provider needs to have a thorough understanding of machinery control systems and should hold relevant industry certifications from a professional organization (such as TUV Rheinland) and, in some circumstances, professional engineering credentials. The provider should also have professional liability insurance.

Good administrative controls and comprehensive employee safety training can replace good engineering.

This is a misconception that can put employees in harm’s way. The very foundation of machine safety consists of a hierarchy of controls that

regards engineered solutions as the preferred method. Administrative controls and employee safety training are necessary and helpful, but they are typically used as supplementary controls to mitigate residual risk. They don’t take the place of properly implemented safeguarding and safety systems.

MYTH #3

Older machines can be “grandfathered in,” so they don’t need safeguarding.

This is false. No equipment is exempt from current machine-guarding standards, and so-called “grandfather clauses” simply do not exist for machine safeguarding. An exemption does exist under some robot standards, and it applies to a robot’s safety circuit integration.

Managers at facilities with older equipment may believe their machines are grandfathered in because they were built before machine-guarding standards existed or that brand-new equipment is always compliant. These are common misconceptions that can lead to violations. New equipment is rarely compliant unless the customer specifies machine-guarding compliance in the design.

MYTH #4

If a Ministry of Labour inspector recently visited your facility and

didn’t say anything about a specific set of machines, then those machines must be compliant.