DISPLAY YOUR WAY

Features include:

Headless HMI

With the C-more headless HMI, you can display your factory floor data how and where you choose. The EA9-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device of any size to display real-time operational data or messages. Use the C-more Remote HMI mobile app or the embedded Web Server if you prefer no local display at all.

• All the functionality of a C-more Touch Panel without the display size limitation

• HDMI Video/Audio output with multiple resolutions

• VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720

• Compatible with ELO Resistive Touch screens

• Multiple connections

Remote access and control on the go!

• Ethernet and RS-232/422/485 serial ports support programming and device connections

• USB-B port for programming, monitoring and configuration

• USB-A port for USB HID devices such as pen drives, touch screen displays, keyboard, mouse and bar-code scanners

• SD card slot for log files, project memory or graphic media

• Get control on-the-go with the C-more Remote HMI mobile app and embedded Web Server

• 82MB of user memory

Available now in your app store.

price, buy at:

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Flexible

Jacob Stoller

Kristina Urquhart

Quebec’s

James Figy

methods have helped factories rise to

OVERHEARD ON TWITTER

@EMCCanada

MFG

@AutomationMag

Thank you for picking this up so quickly. We all have to work together to get through this. ow.ly/ S0tQ50yVm44

@SAPIMC

How real-time #supplychain visibility powered by Industry 4.0 can enable manufacturing companies to meet demands during unforeseen events: sap.to/60161xXQI

@Reko_Intl

Reko International Group is joining the fight against COVID-19 by 3D printing and assembling face shields to be donated to local hospitals in Windsor-Essex. Thank you to all frontline workers.

@a3automate

Thank you to our members who have shared their positive stories! Check out the latest from @Clearpath, who donated 3D-printed parts to help create plastic face shields for healthcare workers.

FROM THE EDITOR

BY KRISTINA URQUHART

Automation companies help in the fight against COVID-19

The COVID-19 pandemic has been among the most catastrophic events we’ve ever witnessed. The loss of human life is staggering, our global economy is reeling, and our collective wellbeing is being tested to new limits. Like most people, I have been trying to find the silver linings along the way. Tales of compassion, hope and help are what get us through trying times. Luckily, as an editor for a Canadian magazine about manufacturing, there has been no shortage of these kinds of stories crossing my desk. The manufacturing sector and the industrial automation market that supports it have been working 24/7 to ensure our frontline health-care workers have the medical devices and PPE they need to fight the coronavirus.

ATS Automation Tooling Systems in Cambridge, Ontario is collaborating with Brampton’s O-Two Medical Technologies to assemble critical ventilator components at ATS’ facilities.

Innovative Automation in Barrie, Ontario retooled to produce a Health Canada–approved ventilator called the TidalPump.

M agna International, Linamar Corp., and Martinrea International are among the companies that have been solicited by the Automotive Parts Manufacturers’ Association and the Ontario government to manufacture 10,000 ventilators.

Eclipse Automation in Cambridge is installing an automation system from China that will facilitate production of N95 masks. The system will allow manufacturers across North America to make mask designs including the N95 and KN95.

CONNECT

@AutomationMag

Ford Motor Company of Canada is producing face shields at its Windsor, Ontario operations, and Bauer Hockey is also manufacturing face shields at its Blainville, Quebec plant. Bauer has even made its design public so that other manufacturers can retool and produce them on their own. Writer Jacob Stoller takes a look at how Bauer was able to pivot so quickly on p. 12.

Not all manufacturers are able to retool, though. It depends on the industries they serve, the infrastructure they have in place and the size of their workforce. Automate Canada, the industrial automation arm of the Canadian Association of Mold Makers, has been sending out a weekly survey to about 90 of its members, mostly in Southern Ontario, to gauge the immediate impacts of COVID-19.

Over 90 per cent of the respondents say there has been a decline in operations, leading to layoffs. Nineteen per cent say they’ve almost completely shut down. And this is just a little sliver of what’s going on in Canada.

In the short term, our focus, like yours, is on getting through this crisis. It’s hard to know what the future is going to look like, but we do know that manufacturers will want to plan for stronger resiliency in crises. We will continue to supply content that helps you as you consider changes to your automation systems.

To those providing essential products to our frontline workers, we are proud of you. To those who have been laid off or lost their jobs because of the pandemic, we are thinking of you. Thank you for all of your work. Your peers had some words of encouragement, too –turn to p. 26 to read more. | MA

@mfgautomationmag /company/automation-mag kurquhart@annexbusinessmedia.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com Tel: 416-510-6757

VICE-PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

MEDIA DESIGNER - TEAM LEAD

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-510-5180

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Bernard Cubizolles, James Figy, Paul Hogendoorn, Gary A. Nelson, Jacob Stoller

Manufacturing Automation is published seven times a year by:

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600

Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: ugrzyb@annexbusinessmedia.com Tel: 416-510-5180

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2020 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

AUTOMATION UPFRONT

COVID-19 PRODUCTION

Eclipse facilitating N95 mask production in Ontario

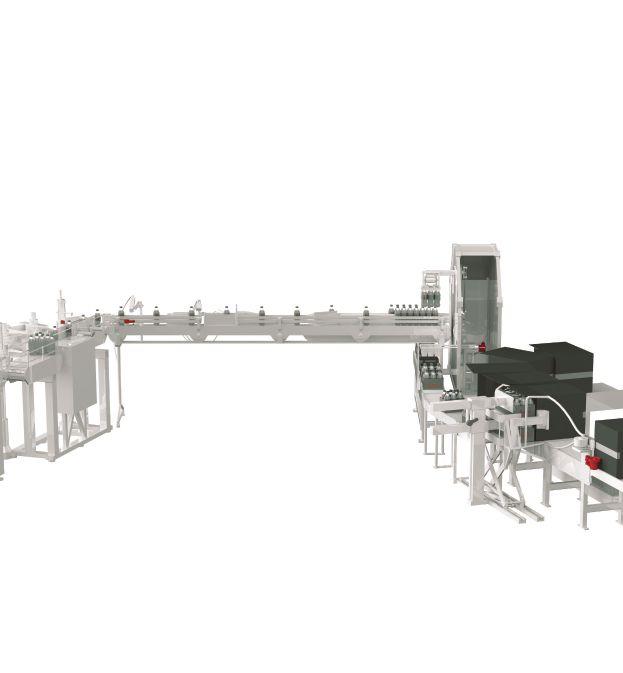

Eclipse Automation has secured the North American rights to a Chinese automation system for production of N95 masks.

The system will be installed and put into operation at Eclipse’s facility in Cambridge, Ontario by early May.

The masks, which filter out 95 per cent of microscopic particles, have been in short supply for health-care workers fighting the COVID-19 pandemic.

Eclipse has signed with Harmontronics Automation of Suzhou, China, to manufacture, sell, distribute, service, commission and modify the Harmontronics fully automated N95 Vertical FlatFold Respirator Mask Production Line system throughout North America.

This system will be used to work with manufacturers to customize the system for their specific needs and support qualification efforts for respirator designs, including the N95 and KN95 models.

“I am seeing a lot of companies, with the best of intentions, trying to get into this arena but without the experience in medical device automation, they may be chasing inferior systems that could be unsafe to run and produce faulty masks,” says Steve Mai, president and CEO of Eclipse.

“We can expedite this to provide a top-notch N95 mask automation system and lead the process to see that it can be scaled to all who need it. We can deliver a level of proactive control to the solution that is crucial for such an important product.”

The manufacturing will still scale from the Harmontronics facility in China, and Eclipse will work with their customers and Harmontronics to assure high standards for safety, spare parts and usability.

“Harmontronics has extensive experience in medical device automation and we are taking

effort to provide more mask automation systems to Chinese and overseas markets,” says Albert Cai, president and CEO of Harmontronics.

New company launches for face shield production

InkSmith, an educational technology manufacturer that has

Eclipse Automation has ordered a new automation system to help produce N95 masks.

been producing face shields for frontline health-care workers during the COVID-19 pandemic, has launched a new company to handle the production and distribution.

The Kitchener, Ontario–based company is called The Canadian Shield, and has the capacity to produce 50,000 face shields per day.

“Over the past few weeks, we have been extremely concerned about the critical shortage of medical equipment that our frontline health-care workers are facing during this unprecedented global pandemic,” says Jeremy Hedges, founder and CEO of InkSmith and The Canadian Shield.

“Using InkSmith’s existing tools and infrastructure, we realized we were in a position to help.”

With two manufacturing facilities in Kitchener fully equipped with state-of-the-art 3D printing and laser-cutting technology, the team shifted its efforts from educational technology to protective face shields.

The company is using its own laser-cut design that can be

washed and sanitized, reducing the overall cost on the health-care system.

Approved by Health Canada in March, The Canadian Shield has been deploying face shields to hospitals across Ontario, including Joseph Brant Hospital, Grand River Hospital, Cambridge Memorial Hospital and Queensway Carleton Hospital.

Once the company is able to supply enough shields to meet the needs of Ontario health-care workers, the focus will be on accelerating its efforts to address the critical shortage of medical equipment across the country.

In order to keep up with the growing demand, The Canadian Shield has hired 60 workers, all of which were recently laid off as a result of the financial impacts of COVID-19. The company plans to hire hundreds of additional workers throughout April.

“This is more than just a shortlived enterprise to combat the spread of COVID-19. We are making a long-term commitment to bringing Canadian manufacturing back to the Kitchener-Waterloo region and our hope is that we can help as many people as we can along the way,” says Hedges.

The Canadian Shield will be exploring opportunities for global distribution.

in the fight against COVID-19.

This personal protective equipment was designed and tested in collaboration with Hamilton Health Sciences and Mohawk College.

Production will ramp up to volumes of approximately 10,000 units per week.

Ford of Canada producing face shields

Ford Motor Company of Canada is producing face shields at its Windsor, Ontario operations in response to the need for COVID-19 protective equipment.

The company is working with the Ontario and federal governments on distribution throughout the province, and across Canada.

The plant’s union, Unifor, and Ford of Canada remain in communication at the national and plant level to ensure all safety actions and precautions are taken.

Burloak secures funding for face shields

Additive manufacturer Burloak Technologies is now among the companies producing face shields that will be used by frontline medical and health-care workers

The project was funded by Next Generation Manufacturing Canada, the Canadian government’s Advanced Manufacturing Supercluster, as part of its call for solutions to help fight the pandemic (read more on p. 8).

“Additive manufacturing is an ideal process to scale any design to commercial production in the shortest time possible, and applying our capabilities in this battle is the right thing to do,” says Colin Osborne, president and CEO of Samuel, Son & Co., Limited, the parent company of Burloak Technologies.

“NGen played a valuable role in the rapid response to get this project underway. Without this funding, it would not have been possible to achieve the same scale in this accelerated timeframe.”

“Working together in new and innovative ways will help to minimize the impact of the COVID-19 pandemic in our region, our province and across Canada,” says John Laughlin, CTO, Next Generation Manufacturing Canada. “This

The Canadian Shield and Ford of Canada are producing face shields similar to the one pictured.

project is an example of how we can succeed when we put the interests of the community first.”

Mohawk College will use the resources at its School of Health and other organizations to distribute these face shields locally and across Canada.

COVID-19 CONCERNS

Report: Layoffs increasing among manufacturers

Industry associations The Canadian Association of Mold Makers (CAMM) and Automate Canada have conducted several weekly surveys with approximately 90 manufacturers in Southern Ontario about the impact of the COVID-19 crisis.

Almost 2,700 employees had been laid off from respondents’ companies during the week of Apr. 6, which was double the number reported the week prior.

Lack of available staff was the most frequently cited reason for the decline in operations reported by 91 per cent of respondents.

“The situation for manufacturers is not good,” says Mike Bilton, CAMM board chair.

“We can’t sugar-coat things but we also aren’t sitting back wringing our hands. Everyone

is in this together so we gather data, we review and we come up with short- and long-term action plans.”

Responses have been primarily from the Southwestern Ontario region’s manufacturing, moldmaking and industrial automation cluster (CAMM and Automate Canada both operate out of Windsor).

Among manufacturers’ chief concerns are cash flow, employee anxiety and project curtailments.

In the survey from the week of Apr. 6, 19 per cent of respondents said their manufacturing has almost completely shut down, compared to eight per cent the week prior.

When asked, most respondents either didn’t commit to a date to returning to full operations, or stated it would be at least four more weeks before they could return.

Automate Canada Chair Shelley Fellows says that while the numbers have shown a decline, there are also positive outcomes, such as the increased production of personal protective equipment to help Canada’s medical community.

“So many are negatively impacted but we also know we need to tackle this one step at a time and work for our members and even those in the broader manufacturing world,” she says.

With our modular safety gate system you can build an individual safety gate solution optimally tailored to your application!

• Safety gate system PSENmlock: safe interlocking and safeguard locking in one product with optional escape release

•Safety gate system PSENslock: Safe position monitoring with process guarding in one system

•Pushbutton unit PITgatebox: Simple operation of your safety gate system

•Safety Device Diagnostics (SDD): Comprehensive diagnostics and economical series connection of the safety gate sensors PSENmlock

Pilz Automation Safety Canada L.P. - Mississauga, ON - www.pilz.ca - info@pilz.ca

EMC creates forum for manufacturers seeking COVID-19 support

The Excellence in Manufacturing Consortium (EMC) has launched a cross-country forum for member and non-member manufacturers in response to COVID-19.

EMC is using its Members Need Help forum, an email-based service, to provide COVID-19 information, support and a space for manufacturers to ask questions and receive answers from the EMC.

“We want to offer support to the entire Canadian manufacturing sector,” says JP Giroux, president of EMC in a statement. “During these unprecedented times, it is imperative that we come together and support the expanse of our manufacturing network.”

The Members Need Help email service provides an opportunity experiences of other members and to share information on subjects such as policies, procedures and information to enhance performance in workplaces.

Topics run the gamut from health and safety to HR practices, advanced technologies and everything in between. EMC has

a vast amount of information in the Member Needs Help Area to assist members with preparation for the upcoming weeks.

If you are a Canadian manufacturer and want to learn and understand how other manufacturers are reacting to the global pandemic, sign up for EMC’s COVID-19 mailing list at emccanada.org/member-needs-help.

CCOHS creates COVID-19 guidance

The Canadian Centre for Occupational Health and Safety (CCOHS) has put together a COVID-19 pandemic guidance tip sheet for manufacturers to help employees work safely.

The CCOHS has developed a series of tip sheets for high-risk occupations across multiple industries to help protect employers and workers from illness as well as prevent the spread of infection.

The manufacturing tip sheet includes information on how to ensure sanitation procedures are followed, what disinfectants to use, how to encourage physical distancing and an overview of general manufacturing site requirements.

The tips sheets are available in English and French and can be downloaded from the CCOHS website at ccohs.ca.

Modular safety gate system: Your gate. Our system. Your safety

FUNDING

Ontario pledges $50M for retooling

The Ontario government is allocating $50 million to help businesses retool their operations in order to manufacture essential medical supplies and equipment to fight against COVID-19, including gowns, masks, face shields, testing equipment and ventilators.

The Ontario Together Fund supports the development of proposals submitted online by businesses and individuals.

In addition, the province has worked with businesses across Ontario and the Automotive Parts Manufacturers’ Association to ramp up production of ventilators to meet the need in Ontario and other parts of Canada.

“The manufacturing expertise of automotive suppliers Linamar, Magna, Martinrea and ABC Technologies will be critical in making this plan achievable,” says Flavio Volpe, president of Automotive Parts Manufacturers’ Association.

The government has also recently placed an order with O-Two Medical Technologies who, with the support of Ontario’s manufacturing sector, will produce 10,000 ventilator units.

NGen invests $50M in COVID-19 aids

Next Generation Manufacturing Canada (NGen) is investing $50 million to support Canadian companies as they prepare to produce critical technologies, equipment and medical products needed in the pandemic.

NGen, an industry-led organization that administers Canada’s Advanced Manufacturing Supercluster, will fund projects that involve the rapid production launch of products in short supply.

These products include virus screening test kits, gloves, gowns, masks and other personal protective equipment, hospital equipment such as ventilators and peripherals, as well as cleaning and sterilization equipment.

Projects will be selected for funding according to critical needs identified by the federal government and the ability of manufacturers to produce products that are safe for both patients and health-care workers.

NGen will prioritize funding for projects that can have an immediate impact before the end of June 2020 and will fund eligible costs for projects within this timeframe up to 100 per cent (depending on the level of knowledge and information sharing to help Canadians).

Projects that will have an impact in the medium term – beyond the June 30 timeframe – may also be considered for funding at 50 per cent.

Projects are not expected to exceed funding of more than $5 million.

The organization says it recognizes that the rapid launch of safe medical products is no easy task. It will require expeditious product validation, secure supply of materials and components, regulatory approvals, and the scale-up of new manufacturing systems before full-scale production can be brought on line.

Companies looking for support in launching production of critical products to fight COVID-19 and experts who are able to assist can indicate their interest at ngen.ca/ covid-19-response.

ASSEMBLY

ATS receives $60M order for EV battery assembly

ATS Automation Tooling Systems has received an order from a global automotive manufacturer for a fully automated battery assembly system for their North American manufacturing operations.

The project is valued at approximately $60 million and includes the design, build, and installation of two turnkey battery assembly systems.

These systems are critical components of the customer’s electric vehicle (EV) strategy. The order is

expected to be delivered over the next 18 months.

The Cambridge, Ontario–based company will use its SuperTrak linear motion technology to complete the project.

ATS Automation is currently operating below full capacity as it implements measures to prevent the spread of COVID-19. The company is practicing social distancing across operations, including remote work and flexible schedules.

“While some customers are proceeding with strategic projects, as evidenced by the enterprise program we announced […] others have shut down their operations and some are placing ongoing programs on hold or deferring new projects to focus on preserving liquidity,” says Andrew Hider, chief executive officer of ATS Automation.

“Our first priority is to ensure the safety, health and mental wellness of our employees and ensuring they are informed on all matters related to COVID-19 and are equipped with the necessary resources.”

DEAL MAKERS

WESCO becomes distributor for Pilz Canada

Pilz Automation Safety Canada is now distributing its products through WESCO Distribution Canada.

The two companies signed a partnership distribution agreement in December 2019.

WESCO, an electrical distributor in Canada, now supports Pilz across the country through 130 locations and four distribution centres located in Vancouver, Edmonton, Toronto and Montreal.

“We are excited to be working with such a renowned distribution partner. The Pilz products and service offerings fit perfectly in the automation mix of WESCO,” says Andreas Sobotta, CEO and general manager of Pilz Canada.

WESCO Distribution Canada employs over 2,000 people and represents approximately 20 per cent of WESCO International’s total revenue.

Pilz Canada CEO Andreas Sobotta (left) and WESCO Distribution Canada VP and GM Michael Gross.

Proax acquires Ontario automation distributor

Proax Technologies has acquired Systematic Fluid Power Ltd. (SFP), a Kitchener, Ontario–based technical distributor of automation and motion control products.

The deal took effect on February 1, 2020.

SFP offers a range of standard and non-standard automation products.

As a result of the acquisition, Proax will increase its presence in the Kitchener, Waterloo, Cambridge and Guelph region. SFP will continue to operate under

MOVERS AND SHAKERS

Graybar Canada has appointed Cory Morris as its vice-president for the Atlantic region. Morris began his career with Graybar Canada in 2008 as a marketing assistant during a university co-op placement. Throughout his 12-year career in the industry, Morris has held many positions and completed Graybar Canada’s Manager in Development program in 2015. Morris then moved to the automation group, where he became a services and solutions specialist before being appointed to automation manager, Atlantic, in 2018. “Cory’s demonstrated leadership abilities, strategic mindset and customerfocused drive will help guide our business in Atlantic Canada in the coming years,” says Jason Taylor, executive vice-president and general manager of Graybar Canada in a statement.

Allied Electronics & Automation has named Mike Walker as vice-president and global leader of its sales team serving the U.S.,

the same name, but under the Proax banner.

“We want to ensure that the excellent customer service and quality products that SFP has provided to the customers in the past will continue,” the company says in a statement. “We are dedicated to maintaining the staff and providing our support and assistance during this transition.”

Proax Technologies has over 180 employees working at 13 branches across Canada and represents manufacturers in the industrial automation field.

The company says it plans to move the current Proax group in the area and SFP into one facility.

Canada, Mexico and Chile. Walker, who will be based in Fort Worth, Texas, joins Allied from Lennox International, where he spent more than 18 years in progressively senior sales, marketing and product management roles, most recently as the vice-president of sales. He will lead a recently expanded sales team of more than 450.

The executive board of the International Federation of Robotics (IFR) has elected

Milton Guerry of SCHUNK USA as its president, just months after naming a new president in December 2019. Steven Wyatt was elected IFR president in December, but is now leaving his position at ABB and has stepped in as IFR president. Klaus Koenig of KUKA Robotics has been appointed as IFR’s new vice-president, a role that had been held by Guerry. “I feel very honoured to serve as new IFR president and look forward to a successful collaboration with Klaus Koenig and our IFR members,” says Guerry. Guerry heads the SCHUNK USA team as its president based in Morrisville, North Carolina. | MA

Cory Morris

Mike Walker

Mike Walker

BY GARY A. NELSON

New clarity on contingency planning HOT

As the global manufacturing sector has been reminded during the COVID-19 pandemic, nothing tests the resilience of a manufacturer and a supply chain like a true disaster.

What has quickly become clear is that the unforeseen, unprecedented and unpredictable elements of a disaster can quickly expose vulnerabilities in even a painstakingly modelled and tested contingency plan.

What also became clear is that companies with the ability to collect, analyze and promptly act upon fresh data from across their enterprise and across their supply chain are better positioned to weather a disaster with minimal disruption – and even adapt their businesses in ways they never envisioned.

A manufacturer’s contingency planning is only as strong as its ability to capture, analyze, disseminate and mobilize on real-time data.

Here are some of the Industry 4.0 capabilities manufacturers likely will need to rely upon in their strategy going forward.

1. Manufacturers need a high degree of real-time supply chain visibility to keep current with rapidly changing markets, as well as potential disruptive issues.

The coronavirus pandemic conjures a distinct memory of the Great Recession more than a decade ago, when Jim Griffith, then CEO of the Timken Company, an industrial equipment manufacturer, was quoted as saying he had dubbed the crisis the “SAP recession.”

He did so not because of anything negative SAP had done to exacerbate the situation, but rather because the insight Timken had gained from supply chain analytics had prompted it to curtail manufacturing activity well in advance of others, avoiding costly inventory stockpiles.

The same type of supply chain visibility can enable manufacturers to ramp up production in response to shortages of certain materials, components/subcomponents and products, as companies like GE Healthcare are doing during the crisis, ramping up production of CTs, patient monitors and ventilators.

Having a highly networked and data-responsive supply chain enables a manufacturer to quickly pivot to help other manufacturers with their supply chain, as General Motors did in deploying its factories to help Ventec Life Systems produce ventilators.

2. Industrial Internet of Things (IIoT)-connected factories can enable dramatic product pivots. Intelligent digital factory capabilities give manufacturers the means to rapidly adapt their factories to ramp up production, or even to pivot into an entirely new line of business. Faced with a likely drop-off in demand for its vehicles, in March Volkswagen began preparing its manufacturing facilities to produce medical equipment like ventilators using 3D printers.

“Medical equipment is a new field for us,” the company said in a statement. “But as soon as we understand the requirements, and receive a blueprint, we can get started.”

Having production facilities that are sensor-equipped and IIoT-connected enables a manufacturer to pivot like this during a crisis to quickly and flexibly adapt its operations to produce the goods communities need.

By integrating intelligent factory assets and processes into a broader intelligent supply chain network, Volkswagen could link digitally with medical equipment manufacturers to access product blueprints, and with suppliers to get the materials and components required to produce those products.

Once production began, VW could collaboratively manage logistics with government entities, healthcare providers and its supply chain so products would get where they need to be in a timely manner.

3. Automated production and lights-off manufacturing capabilities are critical to maintaining supply chain integrity.

For their ability to continue producing goods without necessarily relying on human beings, automated production capabilities are critical to disaster response.

In some segments of manufacturing, full

automation is not only possible, it’s practical. Automated equipment on the floor can be connected to AI–equipped management tools, and monitored remotely to ensure production continues with minimal human intervention. This in turn frees people to focus on higher-priority tasks that inevitably arise during a disaster.

While a global pandemic that prevents humans from working in a factory wasn’t top of mind when factory automation took hold, it’s now clear that robots and selfdirected equipment will be more sought-after than ever.

Most manufacturers have already implemented distributed supply chains geographically, and rely on them during other crises such as natural disasters and tariff issues. However, even more manufacturers are reconsidering re-shoring production to North America. Factory automation helps to compensate for the higher labour costs of doing so.

Amid all the talk about the value of digital capabilities in the context of contingency planning and disaster preparedness, it’s easy to lose sight of just how critical human beings and their skill-sets are to a manufacturing business and the integrity of a supply chain.

It’s vital that manufacturers find ways to keep their employees ready to mobilize during and after a disaster. As a company, you don’t want to have to try to fight to get employees back, nor do you want to be left to train legions of new employees once normalcy is restored. Treat them like the indispensable resource they are. Manufacturers that do right by their employees during trying times are likelier to retain the talent they need to hit the ground running when the normal course of business does return. Let’s hope that happens sooner rather than later. | MA

Gary A. Nelson is the industry executive advisor for industrial machinery and components at SAP America.

INDUSTRY WATCH

BY PAUL HOGENDOORN

Pushing the reset button

Iwrite this column as I enjoy 14 days of self-isolation. It is a forced (and not entirely unwelcome) “pause” that has given me much time for reflection. It’s sort of like pushing the reset button.

It’s been sometimes said that “a crisis is too valuable a thing to waste,” or words to that effect. Crises always come at a very high cost, but we seldom look to extract the highest value that can come of them. A couple of days into my 14-day pause, I took the time to watch the movie Eric Clapton: Life in 12 Bars. It struck me that it took the biggest crisis of his life to change his life’s trajectory. It came at a very high cost – a cost that no one would want to pay – the death of his four-year-old son. His friends that had watched him pull through many a smaller crisis believed that this one would be the one that ultimately defeated him. But it didn’t; it set him on an entirely different trajectory, and he arrived at an outcome he wouldn’t have otherwise arrived at. It took a crisis, and it required making a determined choice.

And so it will be with the current crisis. The cost will be very high and the trajectories of a lot of businesses will be altered. The outcomes they arrive at will be to a large degree affected by the decisions and choices they make. Some are just aiming to survive this period –and of those, some will and some won’t. Some will be aiming to get back to where they once were and to recapture lost ground and momentum. But there will be some others that recognize the present situation presents an opportunity to do things they otherwise wouldn’t do and make decisions they otherwise couldn’t make. They get the chance to alter their trajectory.

What keeps companies from making these kinds of trajectory-changing choices under more normal conditions? I suspect it is because they are either modestly successful, or they are moderately failing – they are just managing to avoid complete failure. It takes a tremendous amount of desire, and courage, to abandon a comfortable position of moderate success. It is equally hard to let go of a failing situation, if you are somehow managing to hold on and

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. Contact Paul at paul.hogendoorn@getfreepoint.com.

survive. And that’s why a crisis is often a very valuable thing. We are forced to make a choice: simple survival, return to status quo, aiming for something else, or charting out a new route to get to where you are aiming to go.

There will be companies that recognize the present situation presents an opportunity to do things they otherwise wouldn’t do and make decisions they otherwise couldn’t make.

Crises also have the effect of bringing out the best in people. (The worst too –like hoarding toilet paper, of all things). It’s a good time to assess your people and see who you want to go into battle with. Character, dedication and their response to the vision will all be clearly evident. Who rallies to the cause, and who rallies to their own cause? A crisis is a defining moment – not just for the company, but for individuals themselves.

Every company is different, and their response to this current crisis will be different too, but every company has the opportunity to assess at least a few things they can do to make their company better. The three most common conversations I have had with manufacturers before this crisis were about the challenge of digitizing their work flow, gaining visibility into their production condition in real time, and the need to make their factories and jobs more attractive to a younger work force.

The first two topics fall squarely into the “Industry 4.0” conversation.

Perhaps this crisis is the singular event that causes many companies to actually take a first, concrete step. It doesn’t have to be big, and it doesn’t have to go plant wide, it just has to be something tactile – something that gives everyone confidence that bigger steps can be taken and bigger plans should be made. The last topic however, is key, and needs to be considered inside or outside of the Industry 4.0 conversation.

The manufacturing industry has been aware of a looming skills and labour shortage, as the current generation retires and the new generation is unenthusiastic about taking their jobs. The coronavirus crisis will exacerbate this problem, as the older generation will reassess what is truly important in their lives and many will opt to retire even earlier.

Unfortunately, the way to address this problem is not by trying to change the younger workforce to fit our factories and jobs, but rather by changing our factories and jobs to fit the next generation of workers. Our employment model hasn’t really changed since the later ’60s, ’70s and early ’80s, although technology has. It is time to push the reset button, and put our focus back on our people. And sometimes, it takes a good crisis to make it happen | MA

PIVOTING IN A PANDEMIC

Following the March announcement of the COVID-19 pandemic, governments began calling on manufacturers to step outside of their comfort zones to help ease the shortage of medical supplies. Flexible production methods have helped factories rise to the challenge.

BY JACOB STOLLER

Changing lines on the fly is one of the hallmarks of our national sport, so it seems fitting that Montreal-based Bauer Hockey was able to convert an equipment line from hockey to healthcare in just seven days.

T he project began when the COVID-19 pandemic forced a nationwide hockey shutdown in March and the company was inspired to take on a new challenge.

“We heard from Prime Minister Trudeau about the need for manufacturers to step up and see what they could do,” says Dan Bourgeois, VP product innovation, Bauer, who runs the hockey R&D department in Montreal as well as the company’s lacrosse division in New York, “and we heard the same thing from the governor in New York.”

O ver the following weekend, Bourgeois brought his teams together through a series of conference calls. By Monday, they had a design.

“We asked, ‘what can we do – what is our core expertise?’” says Bourgeois. “We know how to make protective equipment, and we make visors for hockey helmets, so we realized right away that the face shield is something that we’re capable of.”

While the Bauer healthcare shield looks somewhat like its hockey equivalent, the fabrication is completely different. Hockey visors, which are

safety-tested using a puck cannon, are injection molded from polycarbonate material, while the COVID-19 face masks are extruded from much lighter and more flexible PET.

“These are two different worlds,” says Bourgeois, “but we know plastics, and we know how to make protective gear.”

The teams worked around the clock to complete all the steps – preparing the working drawings, specifying materials, identifying suppliers, building and adapting equipment, reconfiguring workstations, recalling employees, creating safety standards and training –during the one-week period.

Leveraging resources in the company’s high-tech Innovation Centre in Blainville, Quebec, the teams were able to complete all work, including the 3D printing of parts for new machinery, in house. Experience was also key – Bourgeois notes that he has some 35-year veterans on staff.

Worker safety during the pandemic was a special concern, and the first step was to build protective masks for the workers on the line. As well, the line was converted from a conveyor system to build stations.

Initially, quantity was anybody’s best guess. Bourgeois initially committed to 10,000 units, but that changed when Service de police de la Ville de Montréal (SPVM) ordered 40,000 on the spot. As word got out, the forecast quickly grew to 100,000 and eventually to two

million, with requests coming in from around the world.

The company decided to offer the shield at cost, and to make their design available to other manufacturers. Details of the design, including a list of materials and suppliers, are posted on the company website. “We want to share our design and expertise,” says Bourgeois. “This is part of our DNA.”

Bourgeois knew other manufacturers were responding when one of his suppliers told him he was swamped with orders for a particular type of rivet specified for the shields. “Everybody’s looking for that type of rivet now,” says Bourgeois.

Pivoting is the new normal Advances in flexible manufacturing, spurred on by high-mix product environments and rapid development cycles, have made it easier for Canadian manufacturers to step up.

“One of the things that has impacted manufacturing is the movement to be able to accommodate mass customization,” says Shelley Fellows, chair of the Automate Canada board. “Manufacturers have to be nimble enough to accommodate a great deal of variability. This isn’t about aircraft wings to gummy bears, but flexibility within a range, so that they can be dynamic and responsive and efficient with their resources.”

As an example, Fellows cites the whiskey manufacturer Wiser, which has applied its expertise in alcohol manufacturing to produce a hand sanitizer product.

“They’ve taken something that they know about,” says Fellows. “They know the alcohol industry, and they have the facility to distill and purify and bottle and package and label. They’ve got the automation in place.”

Fellows believes, however, that more should be done to help manufacturers of complex equipment such as ventilators and test equipment, which is subject to lengthy regulation cycles. “What can we do from an automation perspective to help these companies ramp up their capacity rapidly?” says Fellows. “I feel that from an automation perspective, that really is where we can get the fastest benefit.”

Increasing capacity for manufacturers that are coping with reduced staff has been a major focus for Universal

Advances in flexible manufacturing, spurred on by high-mix product environments and rapid development cycles, have made it easier for Canadian manufacturers to step up.

Robotics (UR), and this has been accelerated by the pandemic.

“ We’re seeing steady requests from companies making anything medical to help them increase production or bring in a new product line,” says Joe Campbell, senior manager, strategic marketing and application development at UR. Collaborative robots, or cobots, which have been a major focus for UR, are well suited to making quick changes in a manufacturing environment. Cobots avoid the limitation inherent with traditional robotics where processes have to be fenced off from humans, making it necessary to automate an entire process at a time – a changeover that can typically take weeks or months.

With robots and humans working side by side, however, automation can be improved one step at a time. “We call this incremental automation,” says Campbell. “You don’t have to solve the million-dollar problem tomorrow –find the $75K problem and solve it, and then go find another $75K problem and solve it.”

In a recent example, UR was approached by a company making test equipment for COVID-19. The company had the capacity it needed on

two machine tools but didn’t have the labour to load and unload them. UR was able to ship two robots within five days, and these were up and running in four additional days. “This is one of our sweet spots,” says Campbell.

Another advantage of cobots is that you don’t need to be a robotic programmer to set one up – according to Campbell, anybody who can program a CNC machine can handle the task.

“Our programming is in the voice of the user, so it’s very easy for them to understand,” he says.

Labour shortages, however, are a permanent fixture in manufacturing –the COVID-19 pandemic is a warning of how dire circumstances can become. Hopefully, the lessons learned during these difficult times will spur new innovations that will help our manufacturing sector become more agile and use its precious labour force as productively as possible.

“Our philosophy has always been, ‘give us the dull, dirty and dangerous and let your skilled operators do skilled work,’” says Campbell. | MA

After initially committing to manufacturing 10,000 face shields to protect against COVID-19, Bauer’s forecast now sits at two million at the time of this writing.

Jacob Stoller is a journalist and author who writes about Lean, information technology and finance.

Flexible production and a hardworking team led to Bauer Hockey creating a face shield in one week.

COVID-19: WHAT’S THE IMPACT?

Pandemic calls for critical look at digital transformation, supply chain and robotics

BY KRISTINA URQUHART

The COVID-19 pandemic has changed the manufacturing landscape in North America.

M any companies have retooled to produce critical medical supplies and devices (p. 12), and supply chain issues and border controls plagued the Canadian government as they tried to bring in coveted N95 masks from the United States and abroad. Meanwhile, cases of the novel coronavirus have ticked upward day by day across Canada and the United States.

Some manufacturers – like those in the automotive industry – have seen demand for their products dwindle, while others that already produce items like hand sanitizer, disinfectant wipes, bath tissue and paper towel have ramped up production to churn out product as fast as possible to meet overwhelming demand.

According to public health officials, this coronavirus, left unchecked, could

strike between a third and three-quarters of Canadians – a massive portion of the total workforce. Manufacturers are juggling employees working on staggered shifts to encourage distancing, employees working remotely and even some have seen employees off sick or recovering from the virus.

The immediate economic ramifications of COVID-19 are being felt across the industry through layoffs, reductions in orders and stringent regulations about what companies are allowed to operate, grinding business to a halt.

While the long-term impact remains to be seen, this is the time for manufacturing companies to take stock of their operations, from production through the supply chain, and think critically about how they may be better prepared in the future.

“It’s kind of like a new world order,” Craig Resnick, vice-president, consulting at ARC Advisory Group, says in an interview. “The only certainty is uncertainty.”

$18B

Previous pandemics have caused losses of up to $18 billion for the global automation market alone.

Dealing with demand

Over the last few months, Resnick’s client list of manufacturers and automation suppliers have been contacting him for advice on scaling their plans for emergencies, whether they be pandemics, natural disasters or tariff wars.

“One of the things they want to take this time to do is to say, how can we be more resistant in the future?” he says. “How do we do a better job operating remotely, because the workforce is inaccessible either because of a weather disaster or because of a pandemic?”

One thing that makes the current situation differ from the 2008-2009 recession, Resnick says, is that demand continues for many products, especially in food and beverage and pharmaceuticals.

Companies are now asking how they can be more prepared for home delivery to keep business going –paramount to staying competitive when Amazon publicly announced it would hire 100,000 warehouse and delivery workers to offset the spike in e-commerce demand.

A new concern is how to be flexible and agile with the packaging of products so they can go straight-to-consumer, because there isn’t time for products to be tied up in the logistics chain.

“ The theory now is that maybe the

Digital transformation is what will offer manufacturers real-time visibility into the supply chain and give them the ability to be more flexible in times of crisis.

distribution centre model doesn’t really work for sending things to consumers,” Resnick says. “How can factories be asked to have deliveries going right to a consumer? [It] completely changes the way they have to package products because they’re not doing a bulk package to go to a distribution centre.”

Panic buying at the onset of the crisis challenged manufacturers and distributors in North America, with consumers flocking to grocery stores in droves to stock up on products. Resnick says consumer behaviour is likely to change long-term as well. Cleaning product manufacturers may need to increase their number of production lines if consumers start using more of these products even after the virus subsides.

“Companies in the pulp and paper industry are trying to make their operations more flexible to handle quick demand surges,” says Resnick.

Tissue manufacturers have been rushing to fill store shelves because shoppers have been hoarding toilet paper, facial tissue and paper towel – but at some point, demand will drop off as people work through their back stock. And packaging manufacturers, while having seen steady growth over the last few years with the rise of e-commerce, will see containerboard demand increase as people shop from their homes.

While many of the automotive plants in Europe are temporarily closed, Resnick says vehicle manufacturers in North America expect that while demand is low right now, there will be a “boomerang effect” – should the outbreak clear up by mid-summer, demand will spike for cars not purchased during the second quarter.

Value chain visibility required Long-term, digital transformation is what will offer manufacturers real-time visibility into the supply chain and give them the ability to be more flexible in times of crisis, Resnick says.

When all of China was hit with a mandatory quarantine following the initial COVID-19 outbreak in February, factory production ceased, workers were unavailable and transport of goods backed up.

Avoiding a similar bottleneck in the supply chain will be crucial for North American manufacturers in the future, Resnick says, whether they’re responding to a pandemic, a national disaster or an economic embargo.

Diversifying the supply chain across geographic reasons is the only way to guarantee that if operations are compromised in one region, they can continue to operate in another. “From a supply chain perspective, some of this actually had already been taking place over the last year because of trade and tariffs,” says Resnick.

U.S. companies in particular were looking at other alternatives for resourcing and manufacturing in Southeast Asia and Mexico to avoid high costs from the tariff war with China. “People were kind of figuring that they needed to be a little bit more flexible in supply chain and I think [the pandemic] really exposes this now –the long-term health of these companies.”

Digitalization key to future-proofing

In March, as the virus hit the North American continent, many smaller manufacturers and suppliers were caught off guard with no plan in place for their supply chain, their production or their workforce.

These companies will need to take a hard look at their operations coming out of this crisis, Resnick says, because they must be able to conduct business as seamlessly as possible going forward – which not only means becoming digitized, but becoming “digitalized.”

D igitalization means gaining insight and value from data collected by digitization of analog processes, and using it to improve business processes. Some digitalization tools that provide visibility include digital twins, augmented reality and virtual reality.

“It’s going to be mandatory that [Tier 1 manufacturers] will only do business with companies that have the ability to make fast, real-time decisions, like on whether they need to ramp up the supply chain,” he says.

“ These companies are going to say, I can’t take a chance on dealing with somebody who’s doing business if I can’t be connected in real time. It’s going to put more pressure on the smaller suppliers to make sure that they can connect to their customers.”

Robot

market could see upswing

One of the positive effects that may come out of the COVID-19 crisis is that manufacturers could become increasingly interested in how robotics and automation can help their business, both from a production and workforce augmentation standpoint, Resnick says.

With collaborative robots – which make up the fastest-growing robotics market – he says, “your robot becomes kind of like your avatar. They give the ability to actually control some of the processes that you’re responsible for in the plant, even if you’re not physically there.”

M ore robots and automation will be required to respond to those kinds of fluctuations – but companies will also need more human talent to manage them.

Post-crisis, manufacturers will need to ensure they have the flexibility to deal with portions of their workforce being out of the plant in case of emergency, and to be able to accommodate SKU changes on the go as production ramps up or down to meet demand.

Packaging and material handling requirements may change on a moment’s notice. More robots and automation will be required to respond to those kinds of fluctuations –but companies will also need more human talent to manage them.

An uncertain outlook

Analysts had started this year thinking that the economic climate was favourable. In a Mar. 5 presentation to media, Florian Güldner, an analyst at ARC Advisory Group, said that in the Americas, automotive-focused markets were in the middle of a downturn after plant closures in 2019, with the low point expected to be reached in Q2 or Q3 2020. The electronics and semiconductor manufacturing markets were flattening but stable, and machinery markets were contracting but expected to stabilize in mid-2020.

T hat was before the world changed. While the economic effects of COVID-19 on the North American manufacturing sector remain to be seen, according to ARC, previous global pandemics have caused revenue losses of up to $18 billion in automation markets alone.

On Mar. 16, The Associated Press reported that factory output in China had declined by 13.5 per cent – a record dip – in February after its mandatory quarantine period.

“Companies that will survive long term are the companies who have the best tools to be flexible, agile, nimble, and can do the best job of quickly changing runs, controlling their plants, monitoring their plants, adjusting their supply chains, and being able to deploy their workforce from really any location,” says Resnick.

“There’s no one on the planet who knows how this is exactly going to turn out. But they recognize that when this thing does subside, the old normal cannot be the new normal.” | MA

AUTOMATION, SQUARED

Quebec’s AGT Robotics enhances automated welding, cuts component costs in half with PC control

BY JAMES FIGY

Among all industries, construction uses the majority of steel produced globally. Beams for buildings require reliable, high-precision welding to ensure structural integrity and public safety.

McCombs Steel Company, Inc. in Statesville, North Carolina, fabricates and erects structural steel and miscellaneous metals. As such, the company faces the challenges of maintaining high quality, implementing lean manufacturing and meeting project timelines every day. One technology, the BeamMaster robotic welding system from AGT Robotics, has helped McCombs meet these challenges.

“ The lack of experienced personnel in the steel industry previously led to overworking our existing staff, which is unacceptable,” says Mac McCombs, president of McCombs Steel. “The BeamMaster, which is nicknamed Bruce, has increased safety, quality and throughput in production.”

with built-in artificial intelligence (AI) and a proprietary simulation engine to optimize weld schedules.

10K

B ased in TroisRivières, Quebec, AGT Robotics was founded in 1992 as a general automation integrator, but now specializes almost exclusively in robotic welding. The BeamMaster system, first released in 2015, uses AGT’s Cortex software

Relying on PC-based control technology, the system is modular and scalable to allow many mechanical configurations for end users. However, the standard version comprises two or more servo-driven beam rotators, a FANUC Arc Mate 120iC articulated robot that moves parallel to the beam along a track and an operator station with a multi-touch control panel. The circular rotators can handle beams from four to 48 inches wide and up

to 90 feet long with a maximum weight of 10,000 pounds. The rotators can turn 360 degrees to expose all surfaces on W beams and HSS closed rectangular columns to increase welding efficiency.

While similar robotic welding systems have become widely adopted for automotive applications, very few are designed for structural steel. AGT Robotics recognized this untapped market as a significant opportunity, but one with unique challenges, according to Louis Dicaire, general manager and co-owner at AGT.

“The automotive business produces a few parts maybe 100,000 times, so just a few robots repeat

the same tasks for years,” he says. “In structural steel, even though parts are similar, the beams have different widths, lengths, sections and accessories in an infinite number of combinations. That has slowed implementation of robotics in this industry.”

Through its inherent flexibility, the BeamMaster – distributed as the Ocean Challenger by Ocean Machinery in the U.S. – offers a solution.

Flexibility for automated welding

D esign of the BeamMaster presented unique challenges. Robotics can offset a shortage of

The circular rotators on AGT Robotics’ robotic welding system can hold a maximum weight of 10,000 pounds.

The standard BeamMaster comprises multiple servo-driven rotators and an articulated robot.

Hardware and software modularity was important to ensure that BeamMaster systems could be scaled up or down easily as required in the future.

qualified welders, but constant programming of custom parts often requires additional controls engineers, which are also difficult to find in today’s market. To avoid this, AGT wanted to produce a system that would automate not only the welding, but also the programming for McCombs and other fabrication shops.

“McCombs uses our machine 24/7, automatically welding most of their beams,” explains François Béland, automation and robotics specialist at AGT. “The structural steel industry relies on the Tekla CAD software, so we built a plugin that exports 3D beam models from Tekla into Cortex.”

Without requiring a single robotic technician to fine-tune or add to the program, Cortex automatically generates movements. The system offers a complete weld schedule for structural steel.

“All joint types are covered, whether multi-pass or single-pass, a quarter-inch weld or a half-inch weld. The sequencing and flipping of the beam are automatic as well,” Dicaire says. “So not only is the operation automated, but the automation programming is also automated: You could say that it’s automation squared.”

Transferring these software capabilities to a real-time machine control environment, however, required a similarly flexible automation platform. Hardware and software modularity was important to ensure that BeamMaster systems could be scaled up or down easily as required in the future; end users might want to add rotators or even a second robot to increase throughput. In addition, the platform needed to provide robust remote support capabilities for troubleshooting and updates, since the system is designed for end users around the world with limited engineering resources.

EtherCAT communications

While searching for an EtherCAT industrial Ethernet system master controller in 2015, the AGT engineering team chose PC-based control technologies from Beckhoff Automation. They began working closely with Ted Sarazin, regional sales manager for Beckhoff, to standardize the BeamMaster design. “The openness of the Beckhoff platform, from the company that invented EtherCAT and TwinCAT automation software, was key for AGT,” Sarazin says.

W hile BeamMaster systems can be quite large, AGT sought compact controller and I/O options to ensure small control cabinet footprints while remaining cost-competitive. “[EtherCAT] is deterministic and does not require IP addresses for each device. As such, it speeds up commissioning through automatic configuration of devices on the network and offers reliable, real-time communication,” says Béland. The BeamMaster system uses space-saving eight- and 16-channel EtherCAT I/O terminals and EtherNet/IP bus couplers to interface with FANUC robot controllers, as well as TwinSAFE terminals for integrated functional safety.

The robotic welding system includes several safety zones with light curtains, ensuring that operators approach the beam to perform quality inspection only when the robot is not active in that specific zone. The light curtains connect to TwinSAFE terminals using the TÜV-certified Safety over EtherCAT (FSoE) protocol to communicate safety data via a “black channel” method over the same EtherCAT network used for standard communication.

A platform for robotic welding TwinCAT 3 provides deterministic control from a software-based master for BeamMaster.

Programming of all functions, from PLC and motion control to safety and HMI, is directly integrated into Microsoft Visual Studio. Engineers can select the language they know best or that makes the most sense for the project, whether it is IEC 61131-3 with object-oriented extensions, function blocks or computer science standards. “We can develop our own applications – using .NET, for instance – that will communicate directly with the PLC,” Béland says. All PLC code and auxiliary software runs on a CX5130 embedded PC from Beckhoff, connected to a multi-touch control panel as the operator interface.

B eyond the robot equipped with a Lincoln Electric AutoDrive welding source, all other motion control takes place with Beckhoff’s servo drives and servo motors. These provide closed-loop control for accurate positioning of the beam.

Automatic results

Programming of the first system took two months, but with easy code reuse, that is sped up to just

half a day now. “Standardizing on Beckhoff also cut our component costs in half compared to previous solutions while providing more capabilities and options for customization,” Dicaire says.

B efore implementing the BeamMaster, McCombs Steel met with AGT and several customers, and carefully considered where it would fit in the shop’s three production bays before it went live in September 2019. “We have experienced a safer work environment, higher-quality construction materials and increased throughput through round-the-clock welding,” says McCombs.

The connectivity of PC-based control allows AGT to provide support and updates quickly. In addition, AGT includes an Android tablet with each BeamMaster so that customers can send images or video to the engineers in Canada assist in troubleshooting at facilities across the globe.

McCombs has appreciated these capabilities and the partnership both companies have developed, and has since commissioned a second BeamMaster system | MA

James Figy is the senior content specialist for Beckhoff Automation LLC.

Beckhoff’s Ted Sarazin (third from left) visits the AGT Robotics team.

ALL IN THE FAMILY

Armed

with a viable succession plan, a small manufacturer of custom material handling equipment is poised to grow its business

BY KRISTINA URQUHART

An unusual customer request 35 years ago led George Butty and his brother Frank to success with their custom machinery shop, Butty Manufacturing.

The customer was looking for an automated tire cutter – something that George Butty says he’d never seen at the time.

“ Then it ended up being a pretty logical thing – there’s a huge effort and cost in moving air,” says Butty, who has a background in engineering. “The whole goal was to reduce the bulk of the old rubber, so you’re not shipping air.”

The TC100 machine, which he designed on AutoCAD, kick-started Butty Manufacturing’s tire-cutting business. They signed with a distributor in the United States, pushing the tire cutter

out to 500 outlets. “We couldn’t make them fast enough,” Butty says.

T he tire-cutting line has since expanded into six machines that are capable of making different cuts suitable for many applications requiring recycled rubber, such traffic cone counter weights and blasting mats.

A s demand surged, Butty Manufacturing started to get a reputation for making quality equipment, and custom machine orders began to roll in. Now, tire cutters make up roughly 25 per cent of the company’s business, with custom fabrication and machining making up the other 75 per cent.

Early on, that meant a lot of batchof-one custom designs, but the brothers started doing less engineering work once the 2008 recession hit. “One-offs is a tough place to be in,” Butty says. “A lot of the industry dried

Tire cutting machines make up 25 per cent of Butty Manufacturing’s business. The other 75 per cent is custom fabrication and machining.

up and then we ended up focusing on doing as-built drawings. Now, people are getting us designs and we’re building them to whatever their specs are.

“ We’re doing a lot of automation and ergonomic tooling,” he continues. “And we’re simplifying the manufacturing of components.”

Succession planning

The Butty brothers took over their father’s steel fabrication business in 1986, and now employ a staff of 10 to build automated production equipment at a 12,000-square-foot facility in Ancaster, which is on the outskirts of Hamilton, Ontario.

T hey manufacture machines and material handling equipment for industries ranging from food to beverage to automotive to mining. They also build support tooling for handling components used by a large aircraft landing gear manufacturer. Most of the machines are manufactured directly in-house aside from some purchased parts including motors, gearboxes and bearings.

“ We design and manufacture both machining and fabricating,” says Butty. “[We want] to actually have a finished,

Alicia Butty, a CWB-certified welder, inspector and supervisor, works at her family’s custom fabrication shop, Butty Manufacturing.

“[Robots] are taking the jobs that you don’t want to do in general. It’s the repetitive, over-and-over-again stuff.”

fully functional piece of equipment when it leaves here.” The Buttys employ two designers, and the rest of the staff are in the shop, including welder Alicia Butty, who is Frank’s daughter and George’s niece.

Alicia, a CWB-certified welder, inspector and supervisor who officially started at the family business in December 2019 after spending two years at another shop, is learning the ropes as part of the family’s succession plan.

George and Frank are looking ahead to their retirement in a few years. “That’s where Alicia comes in,” George says. “She showed an interest in maybe continuing on and so that’s what the goal is here – to see what we can do to shift things over to her.”

G eorge and Alicia are working on a plan to streamline the machine shop’s workflow, now that they tend to manufacture several pieces of equipment per order instead of one-offs.

B ut for the most part, Alicia is spending her days poring over paper drawings so that she understands how each piece

of equipment works, and how problems may differ between the paper and the physical machine.

“She’s learning quickly how simple things are not so simple at times. Especially when they go wrong,” says George.

“ I’ve learned a lot,” Alicia says. “If a piece is made wrong from the start, like six steps in, your whole structure is going to be thrown off.”

Embracing automation

B ut her uncle and father are learning from her, too – Alicia, a millennial, has plans to bring the small shop into the digital age with a new website and a heightened social media presence. The company has posted a few YouTube videos demonstrating their tire cutters, and as Alicia says, “They’re selling like crazy. No advertising, just word of mouth.” She expects that with more promotion, the business could grow – and, down the road, lead to more automation opportunities on the shop floor beyond the current CNC machines.

A licia, who moonlights on social media as Canadian Welder

Girl to showcase her personal welding projects, says that as a welder, robotic welding excites her. In 2019, she attended FABTECH in Chicago for the first time, where she visited the Universal Robots booth and saw a camera attached to a collaborative robot’s end effector to help visualize pipe welds.

“When I posted a video on Instagram about [the] robotic welder, I had some messages saying,

‘Robots are taking my jobs,’” she says. “But they’re not! They’re taking the jobs that you don’t want to do in general. It’s the repetitive, over-and-over-again stuff.

“If I were a business owner, I would want to be more productive. Because you have someone that shows up every day, right? That robotic welder can run 24 hours. You either hop on the robotic train or you’re left behind. You have to stay up with technology.” | MA

Butty Manufacturing’s automation equipment includes tire cutters.

AUTOMATION AT THE EDGE

Much of the data used by Industrial IoT solutions comes from HMI/SCADA automation software. Accelerate your transformation journey with that in mind

BY BERNARD CUBIZOLLES

Au tomation technologies like HMI/SCADA software have been around for many years. They were the trigger for what many call the “third industrial revolution.” Now that we have reached the fourth one, known as Industry 4.0, many companies are rethinking their future and trying to understand how they can realize value out of their digital transformation.

Automation solutions are an intrinsic and key piece of the process, enabling an era in which operational data is immediately analyzed by artificial intelligence/machine learning algorithms. From there, it optimizes operations automatically through a “closed loop,” or it alerts a human for further action. HMI/SCADA drive smarter operator decisions for faster response and development. Transforming operational data into analytics that can then be used to optimize processes brings true value to the business, making automation the layer on which users can build their digital transformation. Automation essentially becomes the foundation of a company’s digitization strategy.

T here are three big drivers that have plagued manufacturers since the commissioning of their operations: how to simultaneously improve availability, manage risk and reduce costs. The ultimate goal is to ensure optimal

3asset performance to maximize the desired outcomes. Manufacturers can use HMI/SCADA to increase visibility, optimize operations and improve quality and output. With a quick glance, operators know what’s important and the right actions to drive increased efficiency and reduced costs.

Many users begin at the risk stage of this scenario. This involves a process of assessing the criticality of all the assets within their business as high, medium and low. Analytics solutions then deliver an optimized plan to reduce costs while appropriately mitigating the risk of failure based on consequences and probability.

R ecommendations issued by analytics are fed back to the process via the automation layer, whether through an HMI/SCADA, in which case the operator will be able to check the recommended parameters before they are sent to the actual process, or directly to a PLC. This transformation of data is all about making more informed decisions, being proactive and optimizing processes.

Why modern automation software matters

Eighty-five per cent of the data used by analytics tools, such as asset performance management (APM) software or operations management software (OPM), come from the field (OT data). So, getting the automation layer right is essential in enabling the power of Industry 4.0 solutions.

The main goal of automation software is to provide the operator with a window on their application using mimics, trend views, alarm views, etc. However, new technologies have made HMI/ SCADA more powerful, easier to use and more connected. Mobility is becoming increasingly important. During normal times, operators want to review operational data where the work is – on the floor, in the field – not in the office. The COVID-19 crisis has showed us how important working remotely is to keeping our mission-critical infrastructure businesses in operation. We all expect to be able to access our personal information from anywhere and at any time with our smartphone;

There are three drivers that plague manufacturers: how to simultaneously improve availability, manage risk and reduce costs.

Modern HMI/SCADAs can deliver content on any connected device in a plant, providing tools that fit a user’s needs while delivering the same experience to their own device.

the same applies to process or manufacturing data. A plant manager who is on the go, or needs to be separated from the business, needs to be able to keep an eye on the plant while away from the office.

D igital transformation doesn’t always mean having everything reside in the cloud. A lot of tools can be deployed on-premise as part of the company’s automation solutions or work process management – which in essence becomes an edge node for the Industrial Internet. Digital work process management software delivers huge outcomes and can be deployed on top of an existing automation layer, enabling an (almost) paperless plant. Typical applications range from standard operating procedures (e-SOPs) to maintenance procedures or operator rounds.

Key considerations

Digital transformation doesn’t happen overnight; it’s a journey. Like every journey, it must include a clear and achievable goal, whether it is financial, operational or something else. It must also include the rights steps to make the journey successful. To do this, it is recommended take one step back ahead of the IT and OT aspects to identify the main challenges. It never hurts to include a pair of

Cameras and Software

Eighty-five per cent of the data used by analytics tools, such as asset performance management or operations management software, comes from the field.

external, fresh eyes to ask questions. For example, how can you save in production losses to be more competitive? How can you optimize maintenance strategies and cut processing time? How can you mitigate risk and increase productivity?

O nce the goals are set, the next challenge is to draw an implementation roadmap. Many industrial sites have already embarked on the journey without knowing it.

B ut journeys can also have challenges. One of the key challenges identified by Industry 4.0 and the Industrial Internet Consortium is interoperability. With the emergence of standards like OPC UA, this is becoming less of a problem. When OPC UA is applied to the automation layer, not only does it deliver connectivity, but it also ensures the security of data transfer in a structured way. You can’t operate, analyze, or optimize what you cannot see.

It is key for existing plants or infrastructures to ensure that there will be no disruption in the production process or operation itself during digitization. Quite the opposite of implementing an ERP system, it’s recommended to start small and

for GE Digital.

deploy at your own pace. The first step is to modernize what exists, look at the gaps and build on top of it. Automation technologies can help mitigate the risk of disruption and then be the very valuable edge node of the deployment. They are mature and proven technologies that can deliver new capabilities while making sure that the application remains safe, available and compliant.