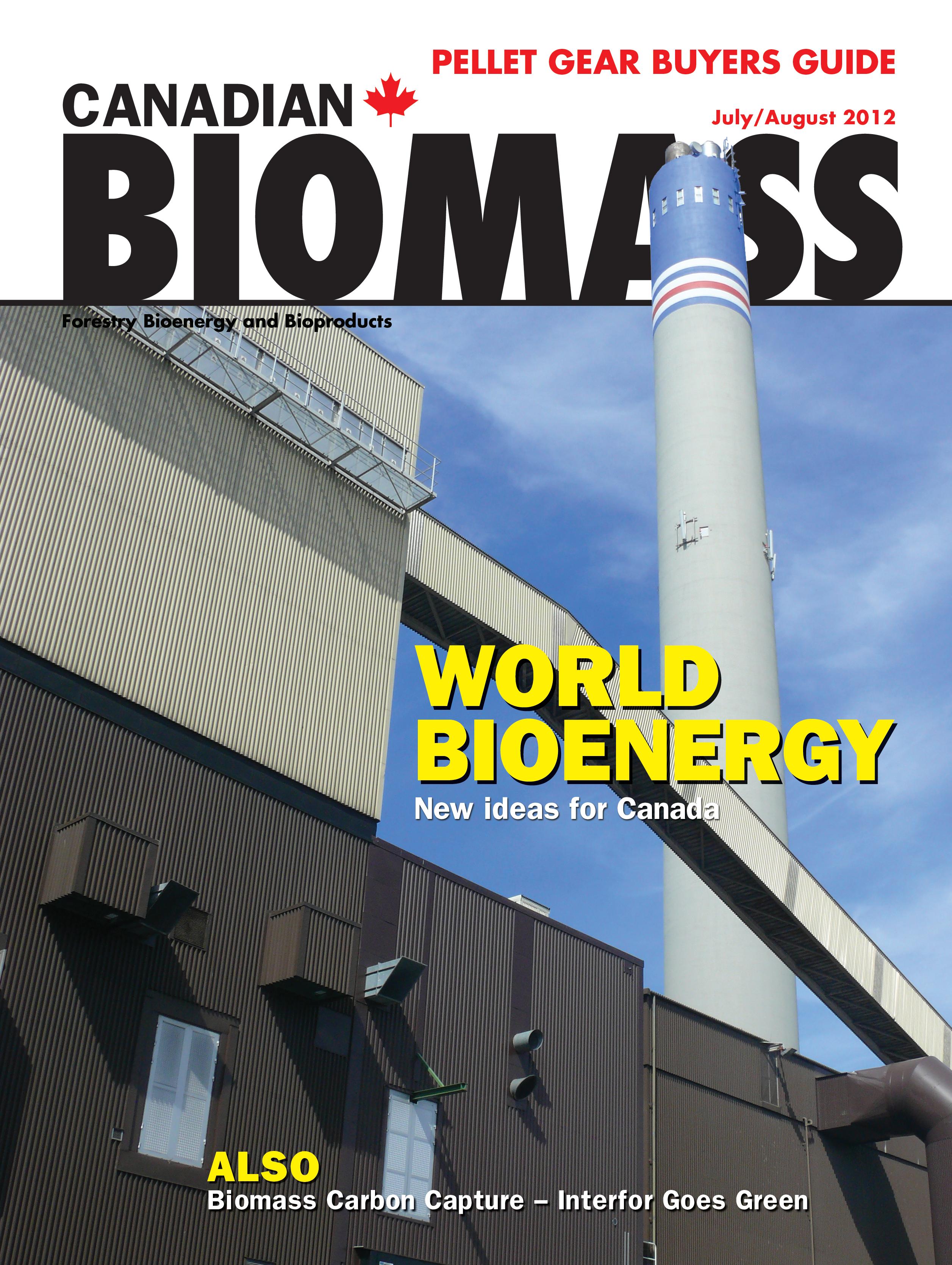

Despite B.C.'s fibre crunch, analysts see promise for bioenergy producers.

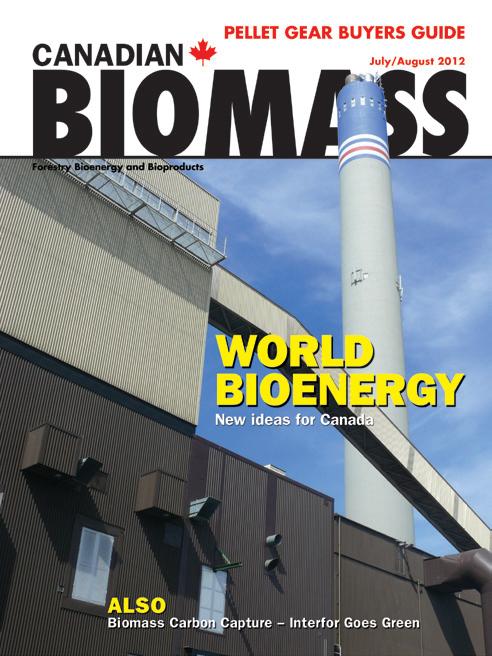

Interfor turns wood waste into clean energy at its Adams Lake, B.C., sawmill.

New Canadian technology is an all-in-one solution that helps growers reduce fuel and energy costs.

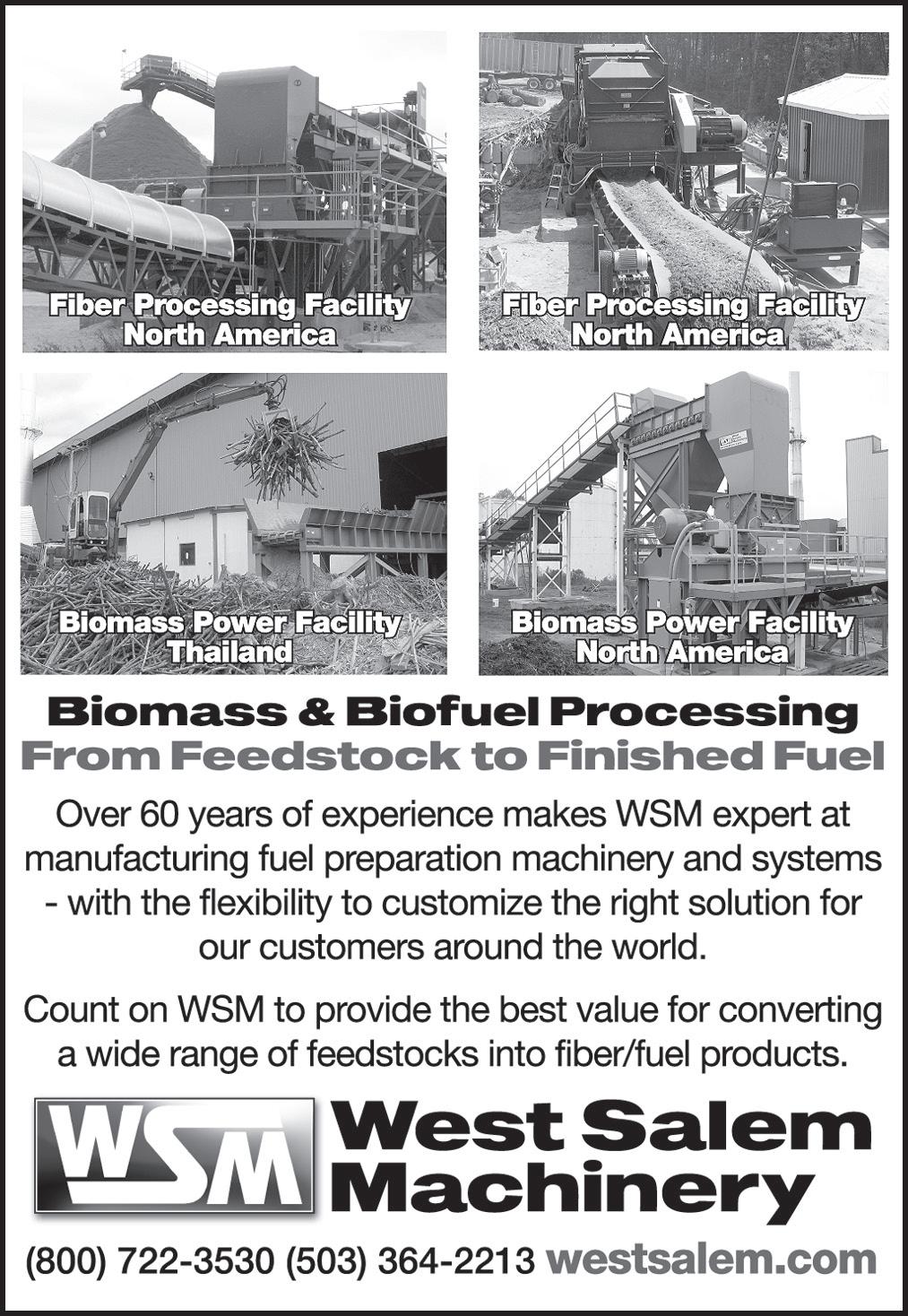

Our annual Pellet Gear Buyers Guide is a resource for anyone in the wood pellet manufacturing industry, providing information about major manufacturers and service providers.

Are “fire-proofing” community stands and biomass two sides of the same coin?

hen the insurance industry starts talking about biomass, you know we’ve made the big time. In part, that’s just what the Insurance Bureau Of Canada (IBC) is doing in Telling the Weather Story, a report released in June 2012.

Prepared by the Institute for Catastrophic Loss Reduction, the report looks at climate change trends, and the whole gamut of resulting weather-related risks facing the insurance industry. These include intense rainfall and flooding, extreme storms and prolonged drought. They also include the trend to more frequent wildfires in much of Canada.

The IBC’s warnings on wildfires are objective and mercenary. The IBC has no horse in the bioenergy race. The association cares about one thing – the odds and likely cost of property loss.

Of course, the actual impact of climate change varies from region to region. When it comes to wildfires, however, the expected impact in the next 35 years is predicted to be significant and widespread. The report predicts significantly more wildfires in Quebec, Ontario, Alberta, British Columbia and the territories in the coming decades. In BC alone wildfire frequency is expected to increase by 50% between now and 2050. Between now and 2030, the biggest expected increase in wildfire frequency is predicted to be in Ontario, more specifically northwestern Ontario.

The report authors acknowledge that Canada does a great job of suppressing small fires. The concern is the 3% of fires that cannot be controlled. A greater number of fires means a greater number of uncontrolled fires. Moreover, as conditions in some of these regions get drier, winds increase and fuel loadings climb, the percentage of uncontrolled fires may climb, making a very expensive double whammy.

What they fear is an increase in such tragic and expensive fires as the massive Slave Lake fire ($700-million loss), for example, and the Okanagan Mountain Park fire of 2003 ($210-million loss). Add to that the hundreds of millions that the aforementioned provinces are spending every year in fire suppression, and you’ve got a costly problem that is predicted to get far worse in the coming decades.

The report does not provide solutions, but instead highlights areas of concern so that government, hopefully, can act. There are ways to mitigate many of these risks, the report says, but no cheap ones. One big step is renewed infrastructure investment, in modernized storm drains, for example.

Looked at from that infrastructure perspective, is there an opportunity to start treating stands around vulnerable communities to reduce the impact of wildfires on life and property? True, we can’t currently make money harvesting such stands for biomass utilization. Yet, communities don’t expect to make money installing new storm drainage, trimming trees near power lines or burying utility lines. They are an investment in safety and loss control. Is there a place where renewable community power and wildfire safety meet? • Scott Jamieson, Editor/Group Publisher sjamieson@forestcommunications.com

Volume 5 No. 4

Editor - John Tenpenny (905) 713-4351 jtenpenny@annexweb.com

Associate Editor - Andrew Macklin (519) 429-5181 amacklin@annexweb.com

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Contributors - Gordon Murray, Catherine Cobden, Robin Brunet, David Schmidt, Seth Walker, April Van Ert

Market Production Manager Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0318-4277

Circulation

Carol Nixon

e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates: Canada - 1 Yr $49.50; 2 Yr $87.50;

prices do not include applicable

Occasionally, Canadian Biomass magazine will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above..

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.com

FEATURES OF BEAST® RECYCLERS: PATENTED CUTTERMILL SYSTEM AVAILABLE AS TRACK OR TOWABLE UNIT KNIFE SET-UP FOR CHIP PRODUCTION ALSO AVAILABLE WITH ELECTRIC MOTOR THROWER ATTACHMENT FOR END-LOADING

Experience for yourself the economic benefits that the Beast® can bring. No other grinder offers the versatility and range of end products like the Beast! The uniformity of the product is a result of the Beast’s unique patented cuttermill system, which allows you to cut, split, grind or chip material in a single pass. A more uniform product means lower fuel production costs! Drive one of our track Beasts to the material, and drive down your biomass fuel costs. With four models to choose from and engine options up to 1,200-horsepower, you can’t go wrong.

When it comes to the grind, don’t get left behind. Find out why Bandit horizontal grinders outperform the competition everytime.

It gives me great pleasure to announce the newly reorganized editorial team at Canadian Biomass. John Tenpenny joins us as editor starting with this issue. John has an extensive background in trade publishing in both manufacturing and professional services. Working with John is associate editor Andrew Macklin, who has been working on our sister publications in forestry and infrastructure.

– Scott Jamieson, Group Publisher/Editorial Director

Chatham, ON – A five-year contract with Green Energy Group LLC representing an Italian company for biomass fuel pellets is launching Canadian Biofuel Inc. into the European market.

Ian Moncrieff, Canadian Biofuel Inc. president and CEO, said the contract will generate about $36 million in gross revenue for the Chatham, Ont.-based company. It will also expand the company’s workforce.

“Fifteen people will be hired and the plant will add another three shifts when the production increases to a 24 hour-six-day-aweek schedule to meet the demand for the Italian contract,” said Moncrieff.

The Italian contract is already paying dividends for the company. “We are in serious contract discussions with a second company from Italy,” said Moncrieff. “The increasingly high export demand for biomass fuel to Europe has us planning for the future and the possibility of a second and third plant somewhere in southern Ontario.”

The Ontario government is moving forward with the conversion of the Atikokan Generating Station from coal to biomass, creating 200 construction jobs and helping to protect existing jobs at the plant. The conversion is the first of its kind in the province. The project will create new economic opportunities for Ontario's forestry sector, which will provide the biomass fuel to the plant, located near Thunder Bay. Demand for biomass pellets from the plant is expected to create or support about 200 jobs. The converted plant will be able to deliver more than 200 megawatts of clean, renewable power and is expected to be complete in 2014.

n CRANBROOK, BC

The St. Mary’s Indian Band’s biomass project will benefit from the fourth round of funding from the First Nations Clean Energy Business Fund with equity funding of $200,000. The project will consist of the construction and operation of a biomass thermal heating system, which will initially hook up two buildings with future plans to hook up the entire village. The St. Mary’s Indian Band has over 5,000 hectares of dense conifer forest and proposes to supply the heating system with wastewood chips. It will also provide the band with an opportunity to receive revenue through wood-chip delivery.

Prices for woody biomass in the U.S., whether sawmill byproducts, forest residues or urban wood waste, have been sliding for most of the past three years, but were still higher late in 2011 in most regions than they were five years ago, according to the North American Wood Fiber Review. Wood fiber demand for all planned biomass projects in the U.S. dropped in the first half of 2012 as compared to early 2011. Most of the decrease in wood usage the past year has been that wood used in the generation of electricity for the domestic market in the U.S., while the pellet industry has continuously expanded capacity to serve the growing demand in Europe.

n VANCOUVER, BC

Nexterra Systems recently opened a biomass gasification energy plant at the U.S. Department of Energy's Oak Ridge National Laboratory (ORNL) in Tennessee.

In the May/June 2012 issue, the story “Ontario pellet production” incorrectly states that Canadian Biofuels Inc. is Ontario’s first production pellet mill. It should have read Southern Ontario's. Canadian Biomass regrets the error.

The system is the sixth Nexterra system to enter commercial operation. The Nexterra system is a cornerstone of a $94 million Energy Savings Performance Contract (ESPC) for Johnson Controls at ORNL. Nexterra supplied the complete energyfrom-renewable-waste system, from fuel handling and storage through to the exhaust stack. The system converts low-cost waste biomass into a clean burning syngas to produce 60,000 lbs/hr of saturated steam, reducing fossil fuel consumption by 80 per cent.

Introducing our new integrated high-capacity debarking and chipping system that takes in-the-woods pulp chip production to a whole new level!

The Magnum Force Flail 604 is a 4-roll flail design that provides the highest volume debarking and production level while reducing fiber loss, chain wear, and fuel consumption. The independant Tigercat loader allows operators to feed more wood efficiently in perfect comfort, while remotely controlling both the chipper and the flail from the cab.

Our Flail is designed to work in unison with our new Magnum Force Disc Chipper 754. Featuring a 4-knife, 75” chipper disc, a large 26” feed opening - and is designed specifically to move the flail in field! Trash separator and bark discharges on the opposite side of the chip discharge, allowing a trailer to park parallel to the chipper. Each unit is built to be legally transportable, yet designed to work together as one when coupled together in the field.

By Gordon Murray

n May, WPAC president Robert Tarc n and I visited the London offices of CME Group to learn about their new central clearing service for over-the-counter (OTC) wood pellet swaps. CME Group is the world’s largest operator of financial derivatives exchanges, which include the Chicago Mercantile Exchange, the Chicago Board of Trade and the New York Mercantile Exchange. CME Group has now entered the world of wood pellets. We met with CME representatives Richard Stevens, Louise Croucher and Lisa Kallal. Brodie Govan of Argus Media also attended.

CME Group is now offering central clearing for OTC wood pellet swaps through its subsidiary CME Clearing Europe (CMECE). A swap is a financial derivative in which two parties trade cash flows with one another, but not the actual physical underlying commodity. This is different from what occurs on the APX-ENDEX wood pellet futures exchange where physical product ultimately changes hands.

A clearing house is a financial institution that provides clearing and settlement services for financial and commodities derivatives and securities transactions. These transactions may be executed on a futures exchange or securities exchange, as well as off-exchange

in the OTC market as in the case of CMECE’s clearing of wood pellet swaps.

A party who wishes to trade uses the services of a broker who is a member of the clearing house. The clearing house stands between two brokers and its purpose is to reduce the risk of one (or more) broker failing to honour its trade settlement obligations. A clearing house reduces the settlement risks by netting offsetting transactions between multiple counterparties, by requiring margin deposits, by providing independent valuation of trades and collateral, by monitoring the credit worthiness of the broker-members, and by providing a guarantee fund that can be used to cover losses that exceed a defaulting broker’s collateral on deposit.

Once a trade has been executed by two counterparties, the trade can be handed over to a clearing house, which then steps between the two original traders’ brokers and assumes the legal counterparty risk for the trade. As the clearing houses concentrates the risk of settlement failures into itself and is able to isolate the effects of a failure of a market participant, it also needs to be properly managed and well capitalized in order to ensure its survival in the event of a significant adverse event, such as a large clearing firm defaulting or a market crash.

Description Cleared, cash settled European wood pellet swap

Underlying reference Argus pricing for wood pellets, CIF Northwest Europe, quoted in Euros per metric tonne

Contract size 100 metric tonnes

Tick size/tick value 0.05 per metric tonne / 5 per lot

Available contract months Nearest 12 calendar months listed

Last trading day Last Wednesday of the month

Final settlement Arithmetic average of weekly index published during the contract month rounded to the nearest 0.01

So what is a swap? A swap refers to an agreement between two parties to exchange a series of payments on predetermined terms. A commodity swap refers to an agreement between two parties under which the cash flows that need to be exchanged are dependent on the price of the underlying commodity. The underlying commodity can be anything from coal, oil or natural gas to agriculture products, metals, and – in this case – wood pellets. Commodity swaps can be used by a commodity buyer (i.e., a power utility) in order to hedge against the rising prices of commodities, so, for example, if a power utility needs to purchase wood pellets but is concerned about rising wood pellet prices, it can opt for a commodity swap where it agrees to receive payments linked to a pellet price index and pays a fixed rate to the other party in exchange.

Commodity swaps can also be used by the producer of a commodity (i.e., a pellet producer). If a producer is concerned about being protected from falling prices, then the producer can go execute a commodity swap where the producer will agree to pay the market price to a financial institution in return for receiving fixed payments for the commodity.

Wood pellet markets are continuing to grow rapidly. Price volatility is expected to increase. Wood pellet swaps may prove to be a useful tool for both producers and consumers to reduce price risk. Certainly CME Group’s new clearing service will be essential for such OTC swaps to take place in a stable low-risk trading environment. •

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want to support and benefit from the growth of the Canadian wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-837-8821 or by e-mail at gord@pellet.org.

This event will attract the leaders of the industry featuring the latest technologies in equipment, products and services covering all aspects of woodlands operations, from small to large scale.

Thursday, September 20 9am-5pm

Friday, September 21 9am-5pm

Saturday, September 22 9am-4pm

Don’t miss the Demo International® Conference “Canada’s Forest Sector at a Turning Point” September 17-20, 2012 at the Loews Le Concorde Hôtel in Quebec City, sponsored by the Canadian Woodlands Forum and the Canadian Institute of Forestry in association with the Ordre des ingénieurs forestiers du Québec. Visit http://democonference.cwfcof.org for details!

By Catherine Cobden

he Canadian forest products industry is on the move.

Recent columns from the Forest Products Association of Canada (FPAC) have alluded to the dynamic transformation in a sector that has become more innovative, environmentally friendly and global in its reach.

However, FPAC member companies are now stepping up their game with the unveiling of Vision2020, which sets ambitious goals to propel the industry forward in the area of products, performance and people. It is not a public relations exercise,

game-changers are now in the pipeline.

The forest products industry has already had remarkable success in diversifying markets. For example, forest products are now Canada’s number 1 export to the Asia Pacific region, including China. Still the industry is setting its sights much higher for new innovations and growing markets.

“Canada needs to build on the work already underway to research and develop new and innovative products made from trees.”

but a vigorous effort by industry officials to ensure a vibrant path for the sector in the years ahead.

The first goal is to generate an additional $20 billion or about a 35% increase in economic activity from new innovations and growing markets by 2020. Canada needs to build on the work already underway to research and develop new and innovative products made from trees. Pulp mills are already producing dissolving pulp to make rayon for clothing, adding on the production of methanol, the production of specialty cellulose for pharmaceuticals and more. FPInnovations brought the world’s first state-of-the-art demonstration plant to produce nanocrystalline cellulose from wood fibre for use in everything from bone replacement to cosmetics. Other firsts and

The second goal is in environmental performance – to deliver a further 35% improvement in the industry’s environmental footprint. The Canadian industry is emerging as the “greenest” forest products sector in the world. For example, Canada has the most third-party certified forests on the planet – 151 million hectares –demonstrating the industry’s commitment to opening its doors to scrutiny and transparency in its forest management practices.

The industry has also cut its greenhouse gas emissions by two-thirds since 1990 and mills currently produce the bioenergy equivalent to the output of three nuclear reactors. The forest industry has also received global recognition for working in concert with environmental groups in the landmark Canadian Boreal Forest Agreement. Still, FPAC has identified 12 parameters where the industry will attempt to further its environmental credentials, including greenhouse gas emissions, forest management practices, caribou action planning, energy and water use, recycling, air contaminants and waste.

The third goal relates to “people” and a desire to hire at least 60,000 new recruits, including women, aboriginals and immigrants. After a decade of decline, the

Canadian forest products industry is now recruiting and offering solid careers for those with the skills, knowledge and desire to work in the sector. There is a pressing need for workers with traditional skills such as millwrights and electricians, but as the industry transforms, it will also need technologists, chemical engineers, innovators and more.

There will be challenges, but forest companies are determined to reach the goals outlined in Vision2020 to chart a bold new future for Canada’s forest products industry.

But companies can’t do it alone. We intend to talk to governments both provincial and federal, as well as to innovators and researchers. Partnerships must also be made with the chemical, plastic, auto sectors and more to find innovative new ways to use wood fibre especially for pioneering bioproducts.

The Canadian forest products industry is aiming high and determined to succeed. We fully intend to be a global leader that will create new jobs and prosperity for Canada well into the future. •

Catherine Cobden is the senior vice-president for FPAC. With over 20 years’ experience, she is responsible for files affecting economic competitiveness in Canada’s pulp, paper and wood products sector. She is also responsible for the bio-pathways project, an innovative look at the opportunities available for the forest products industry in the emerging bioeconomy.

By Andrew Macklin

anyone attending World Bioenergy 2012 in Jönköping, Sweden, it was clear that Canada has become a market of interest for investment and innovation in the biomass industry. Canada represented one of the largest international groups of pre-registered delegates, with a wide array of business leaders, innovators, researchers, and project coordinators representing the national interest in the bioenergy marketplace.

With an abundance of valuable information for the Canadian and North American bioenergy industry through a mixture of site visits, educational sessions, networking opportunities and B2B discussions, the conference lived up to its billing as the premier international bioenergy showcase.

One of the most notable parts of World Bioenergy 2012 was the variety of conference tours that provided opportunities to see CHP, wood pellets, biogas and waste-to-energy solutions that are providing clean energy for the people of Sweden. The sites visited were a glimpse at some of the solutions that could soon enter the Canadian landscape based on size, volume, available resources and cost.

The Öresunds Kraft facility in Helsingborg, on the southwest coast of Sweden, has been producing electricity plus district heating and cooling for over 150 years. In 1997, the plant began to introduce wood pellets as an alternative fuel, and by 2006, the plant moved to 100% pellets to fuel its boilers. The boilers run on wood powder, with 200,000 tonnes of pellets being ground at their facility per year.

Using pellets, the plant produces 1,200 GW of power each year for the eighth largest municipality in Sweden. Ten years ago, a large portion of those pellets were imported from the United States. However, a growing pellet industry in Europe has changed Kraft’s purchasing patterns, with only 30% of its pellets now coming from North America. The other 70% are imported from a variety of European markets, all of which arrives at the quay that it owns as part of its operation. No local pellet options are available, with the closest

LEFT MAIN: Vermeer was one of the few companies that held outdoor demonstrations of chipping equipment at World Bioenergy.

INSET: A large conveyor system takes chips and sawdust from the Derome sawmill to the Derome pellet mill; Inside the Derome pellet mill; The BioBaler, produced by Quebec’s Anderson Group, was one of the Canadian innovations on display at World Bioenergy.

pellet provider nearly 300 kilometres away. Those shipping lanes were of great interest to many of the Canadians, as affordable transportation of pellet products is a major concern when considering potential supply demands in heavily populated markets like southern Ontario. That combined with the cost of pellets, which Operations Manager Fredrik Joelsson commented was around €120-130 per ton (C$155-$175), are helping to determine the financial feasibility of a similar scale plant in some Canadian cities.

At the hem CHP plant in Halmstad known as Oceanen, approximately 80 kilometres north of Helsingborg along the west coast of Sweden, the recent addition of a second wood boiler is helping to offset the increased heat demands that are not met by a nearby plant using biomass. The newest boiler, which has a 22-ton-per-hour capacity, provides 17.5 MW of heat. Three additional boilers use primarily natural gas with some oil as fuel, as well as provide electricity and district heating and cooling in concert with the two wood boilers. In total, Oceanen is able to produce 130 MW of heat energy and 3.2 MW of electricity. Some of that electricity is sold to market, which earns the company green energy certificates.

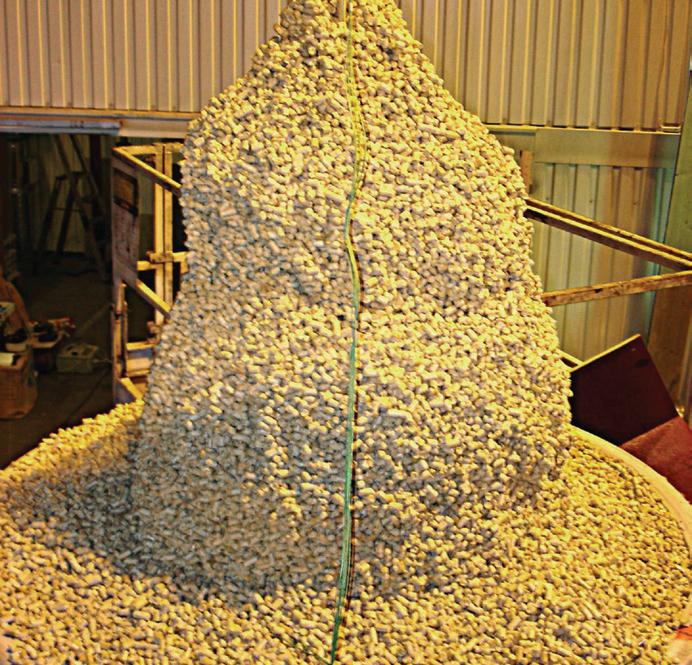

At Kinnared, in the southern interior of Sweden, the Derome family-owned pellet production plant integrates an on-site sawmill with its facility. Whole trees, 95% of which are spruce, are debarked, chipped and planed, and the chips are then sent across a system of conveyors before arriving at the pellet processing facility. Heat recycled from the sawmill’s boiler is used to dry the chips, which are then combined with shavings and sawdust to create pellets. The hammermills are run off a boiler system that primarily uses the tree bark as fuel. The pellets are then stored in a silo for two weeks to create a higher quality and denser product, and then made available for sale. The company produces over 50,000 tonnes of pellets per year, with 70% bagged for household use and 30% sold in bulk.

At the Lantmännen Agroenergi district heating plant in Ödeshög, located on the eastern shore of Lake Vättern, a small CHP plant has eliminated the dependence on fossil fuels for this tiny community. The plant, which has a 3.5-MW wood boiler with a 3-MW oil boiler backup, uses 20,000 cubic metres of wood chips each

year to supply homes and businesses with heat across a six-kilometre pipeline. That’s 12.5 GW of heat production annually from a small-scale plant that cost approximately $3 million Canadian to build back in 2001.

Similar to the plant in Ödeshög is the district heating plant in Trosa near Sweden’s east coast. Possessing a 6-MW wood boiler with oil boiler backup, the plant provides heat for 4-5,000 homes and businesses at a cost of around €$6 million (approximately C$8 million) for the facility. The plant was installed by JernForsen, a Swedish company that has developed district heating systems that are meant to be simple across all elements of the operation. As a result, only two full-time staff are manning the plant at any given time.

The plants at both Ödeshög and Trossa are meant to be user-friendly, making it simple for workers to transition from fossilfuel based energy to biomass. Throughout the tour of both plants, representatives from several countries that have small towns in remote areas with dense wood supply expressed significant interest in pursuing these ideas further as potential solutions for their energy needs.

For the separation of particulate matter from dryer emissions, wet electrostatic precipitators represent the best available technology. Our extensive experience in wood processing applications ensures the most reliable design and economical operation.

• SENA - single and multi-field wet ESPs

• Energy Recovery Systems

• Dust Collection and Conveying Systems

Working together with our customers, we keep technology on the move and offer complete solutions that are extremely reliable and cost effective.

Biological Scrubbers | Wet and Dry Electrostatic Precipitators | Press Exhaust Systems | Dust Collection and Conveying Systems | Sifters

There is a reason why over 50 countries were represented at World Bioenergy 2012. Walking the floor of the trade show, listening to the experts in the plenary sessions and speaking to people at B2B socials, it was evident that all of the people had one thing in common: the need for a solution.

For attendees needing to enhance their knowledge of specific elements of the bioenergy business, the plenary sessions did not disappoint. There were five parallel conferences that were offered, targeting current issues affecting the industry: the global pellet market, overall market outlook, energy systems, transportation and biorefining. Each featured informative lectures and discussions from experts around the world, giving attendees a real understanding of the status of the industry in leading, developing and dormant markets.

One of the side events that provided valuable insight into the development of the biomass industry was the poster exhibition. With presentations from leading research institutions around the world, the poster exhibition educated attendees on the innovations in research and development that are

driving bioenergy initiatives forward.

Of particular interest was a presentation done by Olga Petrov, a PhD student at the University of British Columbia, on district energy system initiatives and applications in B.C. Petrov is researching the feasibility of three distinct bioenergy initiatives in the province. This research should provide hard data that can be used when speaking with government officials at all levels about the viability of bioenergy solutions in communities across Canada. Petrov hopes to present her research at World Bioenergy 2014.

Not only did the conference tours provide opportunity to make valuable contacts from other countries, but the official dinner, icebreaker reception and business-tobusiness matchmaking services provided both casual and formal settings to help each attendee meet the person, organization or business who could help provide the business solution needed.

The Canadian Embassy in Sweden provided an extra B2B networking opportunity, hosted by Canada’s Ambassador to Sweden, Kenneth Macartney. The session provided an opportunity for Canadian

attendees to meet and discuss bioenergy opportunities with senior business interests from other countries. With the support of additional Canadian dignitaries from other embassies across Europe, delegates were introduced to valuable international contacts to help drive national business interests forward.

The presence of the Canadian government extended well beyond the networking reception. In fact, the work of the Government of Canada’s Trade Commissioner Service helped create some of the best buzz on the trade show floor. The service helped organize the Canada Speaker’s Corner, featuring daily presentations based on national capabilities, innovations and investment opportunities in bioenergy.

There was great interest shown by international delegates in the research and development being done in the bioenergy industry in Canada. Mark Ryans, the research manager for FPInnovations, spoke about the number of facilities across Canada that are conducting leading international research

on products like nanocrystalline cellulose (NCC). That discussion also included talk of the pilot lignin precipitation facilities located at the Bioeconomy Centre in Thunder Bay. Promotion of Canada’s emerging bioenergy innovations was also at the heart of a presentation from Rolf Fyne, the director of business development Europe, trade and invest British Columbia. Fyne talked to the crowd of international delegates about the 1,300 clean tech companies that currently operate in the province, which is also home to 24 clean tech research centres and institutions. He also made special mention of companies in British Columbia doing innovative work gaining international attention, for example, Nexterra, Dynamotive, Lignol and Altentech Power Inc.

Fyne also pushed British Columbia as an optimal location for foreign investment in the bioenergy industry, as it is one of the only Canadian provinces that had international trade representatives promoting opportunities in the expanding market.

With 16 million hectares of “red attack”

and “grey attack” lands holding unused fibre that needs to be collected, and 54 million hectares of certified wood, there are opportunities in B.C. for removal of the high-quality wood sources through fibre supply agreements. It was stressed that corporate partners are already coming on board, with over 500,000 tonnes of annual pellet production already committed. However, new foreign investments had to happen under the purview of the EURO 20:20:20 agreement according to Fyne.

In addition to the investment opportunity in wood supply and wood sources, British Columbia was touted as an excellent place to invest in small district heating plants for some of the smaller communities spread throughout the province. Stressing the high cost of B.C. Hydro’s import of diesel fuels for power generation, district heating using woody biomass was pitched as a sound investment.

For Ontario, advantages offered through the province’s feed-in tariff system provide excellent opportunities for foreign investment in bioenergy according to Angela Spreng, commercial officer with the Ontario

We have an experienced team at everystageofaproject. We provide design, manufacturing,installation for all your dust collection andairconveying needs.

prOducts are designed and manufactured tO the highest standards in regards tO market specificatiOns.

International Marketing Centre in Munich, Germany. She pointed to two projects in development that show the strength of the investment opportunities that the province possesses: the Olympiad Renewable Energy Centre in White River and the conversion of the Atikokan coal plant to pellets and biofuel.

Quebec’s bioenergy sector continues to see solid growth through innovation according to France Bourdon, the director of business development Europe, at Investissement Québec. One of the projects showcasing growth is the NCC Celluforce plant developed in Windsor through a partnership between FPInnovations and Domtar.

Members of the corporate bioenergy community in Québec who had come to World Bioenergy looking to expand their business interests also spoke to opportunities for foreign investment. For example, Airex Energi of Drummondville plans to break ground later this year on a torrefaction demonstration plant. With an estimated capacity of two tonnes per hour, the plant will be a stepping-stone towards a

larger plant by the end of 2013. Also looking for investment in the pellet production industry was Atlantic Fibre Resources, which has plans to expand its facility in Chandler to support production of 250,000 tonnes of pellets per year. Both companies spoke about the strategic value of investing in the Quebec bioenergy industry, a province that has both the resources and innovation to sustain industry growth.

Atlantic Fibre Resources was one of three Canadian companies that had a booth on the trade show floor in an attempt to increase its business.

The Anderson Group of Chesterville, Quebec, is the company behind the BioBaler. One of the few companies to have its equipment as part of the outdoor demonstration area, the company pushes the product as a solution to clean up wood residue, vegetation and invasive plant species and turn it into bales for use as a fuel source. The units have already sold on three continents, and company president Patrice Desrochers came with his team to World Bioen-

ergy looking to expand its current clientele.

The other Canadian company on the show floor was Vancouver-based InterWrap Papers Ltd., the manufacturer of BioBlanket, which covers wood products in the forest before collection, helping to dry the product and prevent additional moisture from getting to the wood. With the majority of its customer base in Finland and Sweden, the company took World Bioenergy as an opportunity to both meet with current customers and look for additional customers.

As the global push for the development of sustainable energy continues to grow in both developed and Third World countries, the resources and expertise presented at World Bioenergy will become even more valuable to the international community.

With Canada being one of the most prominent areas of potential growth in the bioenergy industry, World Bioenergy will continue to be one of the best places to gain knowledge, expertise, and business connections that will help drive business forward.•

Despite B.C.’s fibre crunch, analysts see promise for bioenergy producers.

By Robin Brunet

MichaelWeedon, executive director of the Vancouver-based B.C. Bioenergy Network, greets newcomers while clutching a copy of a presentation he authored, Partnering for a Green Future. Ask him a question about the bioenergy sector, and he’ll riffle through it for facts supporting his answer.

The presentation, which was published last November, is an overview of what’s happening with bioenergy generation in British Columbia. It also serves to assuage fears about bioenergy’s future in the wake of the bad news of April, when it was disclosed that the Interior’s Annual Allowable Cut (AAC) would drop from 60 million cubic metres to 40 million within the next 13 years.

Sitting in the Network’s boardroom with the report open before him, Weedon remarks, “certainly the cutbacks will have

enormous impact on sawmills and other components of B.C.’s logging industry. But for us, the fact of the matter is that the size of our wood pellet sector – to take just one example – could be doubled based on what’s in the woods.”

The 170-page “B.C. Mountain Pine Beetle: Evolving Impacts & Opportunities (to 2031)” co-authored by International Wood Markets Group president Russell Taylor, states that the Interior is nearing its peak economic saw log availability and that lumber and veneer production will decline beyond 2014, with the annual allowable timber harvest falling from 60 million cubic metres to 40 million by 2020-25. It also states that despite over 22 mills having closed in the Interior since 2005, few of them are likely to reopen due to lack of available timber – and some of the 66 remaining mills in the province will face

more pressure from curtailment and/or closures in the near future.

The report’s findings coincide with a B.C. forests ministry document leaked in April, “Mid-Term Timber Supply Project,” which predicts that the Lakes district’s AAC will drop from two million cubic metres currently to 500,000 once the beetle wood becomes unusable, and forest employment will drop from 1,572 jobs before the beetle epidemic to 521. Prince George’s harvest total will drop by almost half, and the economically viable supply of dead pine in the Quesnel region could last for as little as another 18 months.

Weedon believes the ultimate outcome of the Interior cutbacks will be a substantially smaller industry – but not one that is detrimental to the bioenergy sector. “In fact, it will probably be more aligned than ever to our goals, with the overall objective

ABOVE: Waste and breakage left behind processing beetle kill wood is a productivity cost for conventional operators but can be an opportunity for the biomass market, if access and ownership can be resolved.

of using every part of a tree and leaving very little if anything behind on the forest floor subject to biodiversity needs and good reforestation practices,” he says. “Granted, current economics make it unfeasible to take this approach, but the industry is steadily moving in the direction of a totally integrated approach to forestry – and more cutbacks will only speed the process.”

Doug Routledge, vice-president of forestry and northern operations for the Council of Forest Industries, agrees that “recent

developments in the economic viability of non-saw log products are increasingly allowing us to adopt a full-fibre forest management mentality, whereby the portions of trees we harvest that can't be made into traditional lumber and veneer products can be used for new biomass-related products such as pellets, heat and energy, and the newly emerging product area of biofuels.”

Routledge goes on to say that most of the inventory and timber supply analysis in B.C. has had saw logs in mind. “But when one

A hammer blow to your operating costs. The hammer mill Granulex™ is the new dynamic grinding machine from Buhler. Designed for ultimate power, Granulex™ delivers high capacity grinding up to 15 t/h for wood and 75 t/h for biomass. Heavy design and supreme ease of maintenance minimize downtime, so you can make maximum use of this productivity. It’s an investment in quality that is sure to show a rapid return – and deliver a hammer blow to your operating costs.

Bühler Inc., PO Box 9497, Minneapolis, MN 55440, 763-847-9900, buhler.minneapolis@buhlergroup.com, www.buhlergroup.com

Innovations for a better world.

considers the portions of trees that are harvested but are non-saw log and so not in the current inventory figures, there’s a significant amount of material potentially available for the biomass subsector while still leaving sufficient woody debris behind on the forest floor to meet environmental objectives.”

This optimistic view is echoed in the International Wood Markets report. It says of the huge supply of biomass, “If new businesses can afford the cost of the fibre, then new opportunities may develop. In addition, several regions of the province are not impacted by the mountain pine beetle and significant volumes of fibre remain underutilized, including the Peace and West Prince Rupert regions in the Interior.”

But these are blanket statements.

Gordon Murray, executive director of the Wood Pellet Association of Canada (WPAC), is more concerned with specifics, and he calls the AAC reductions a huge problem coming down. “In the short term we’re reliant on the cheapest fibre from sawmills, then the next option is procuring the harvest residuals, which is indeed voluminous but more costly. After that we’re faced with harvesting standing round wood – and nobody I know can make that pay, at least not yet.”

Murray adds, “the explosion that destroyed the Babine sawmill in Burns Lake definitely impacted our sector, so just imagine the problems more sawmill closures will cause. Hopefully, some mills will come back on line thanks to our improving economy and trade with China – but we can’t base our future on something so tenuous.”

Also tenuous is the longevity of the biomass that experts believe is in so much abundance. “We predict it will all be used up by mid-next decade,” notes Taylor. “There will be fibre shortages on a regional level for existing plants that use biomass.”

Robert Gray, fire ecologist for Chilliwackbased R.W. Gray Consulting Ltd., has a slightly different view of biomass supply. He thinks that climate change, insect epidemics, drought and wildfires threatening forests will result “in the necessity of landscapescale intervention in the form of thinning and restoration, and the only market outlet for the majority of this material is bioenergy.”

But Gray is discouraged that government hasn’t done more to ensure that current or future biomass is accessible to users. Considering the NDP could be voted into power next year, how would he inspire policy-makers?

“The issue suffers from a couple of key problems, one being a general lack of accurate data on biomass supplies and the economics of accessing it,” he replies. “To move this forward we need to build a solid business case, engage the existing industry, and play the political game. Engaging industry means finding those players that are

willing to actively work with new enterprises and demonstrating the strength of those arrangements to the elected officials.”

For his part, Weedon prefers not to dwell too heavily on the fibre debate triggered by the International Wood Markets report. “Fibre has been an easy hit for us up until recently,” he says. “We need to look at other

things too if we are to sustain and grow our industry.”

Weedon uses examples in his presentation to reinforce the argument that the B.C. Bioenergy Network can evolve further with help from what he calls underutilized waste streams.

“For example, we invested $1.5 million in

a pilot project with Paradigm Environmental Technologies, which is taking sludge from Catalyst Paper Corp.’s pulp and paper mill in Crofton and using anaerobic digesters to turn it into methane. The pilot is nearing completion and so far the results are promising.”

Not surprisingly, Weedon also strongly

“To

supports the development of torrefied wood processes. “This has great potential in B.C., partly because it’s an ideal opportunity to use the stands destroyed by the pine beetle. Plus, the torrefied materials can be densified into pellets or briquettes, which have the energy density of coal, can be produced to be resistant to water and therefore wouldn’t require specialized transport or

storage like wood pellets do. So far, three small producers in this province are making torrefaction fuels and about six other companies are contemplating investment in torrefaction technology.”

Other innovative B.C. bioenergy endeavours outlined in Partnering for a Green Future include Nexterra, which is using a thermo chemical process to turn woody biomass into clean syngas to produce electricity, and International Composting Corporation which is transforming lawn, garden and food waste into

a clean, synthetic biodiesel. “There’s no single magic bullet to replace petroleum, so we have to develop processes that produce a variety of energy forms,” says Weedon. “This naturally means that in addition to solid wood and forest residuals, we need to use low-cost feed stock like municipal biosolids, wastewater, landfill gases, and agricultural animal and crop wastes.”

Murray agrees – to a point.

“Yes, there are lots of interesting projects and proposals,” he says. “The one that really intrigues me is the prospect of purpose-grown crops such as fast-growing willows being planted on private lands or sites not suitable for saw logs located near processing facilities,” he says. “Lots of attention is being paid to this strategy globally because it solves the problems of economical access and transportation, and I’m sure we’ll give it a shot after it’s tried out in the U.S. or Brazil. However, for the time being we’ll continue to be reliant on the primary sector to secure raw material, and on that score more sawmills will reduce capacity or close.”

He concludes by saying that sawmills will continue to close, no matter what. “That said, they won’t close all at once, and as each one closes there will be a lot of hand wringing while we’ll get more of the residuals and push up the price of our products as much as possible in Europe. The bottom line is we’ll manage. We’re in a tough industry in which a pellet will never be as valuable as a board foot of lumber – so we have to work doubly hard to make it viable.” •

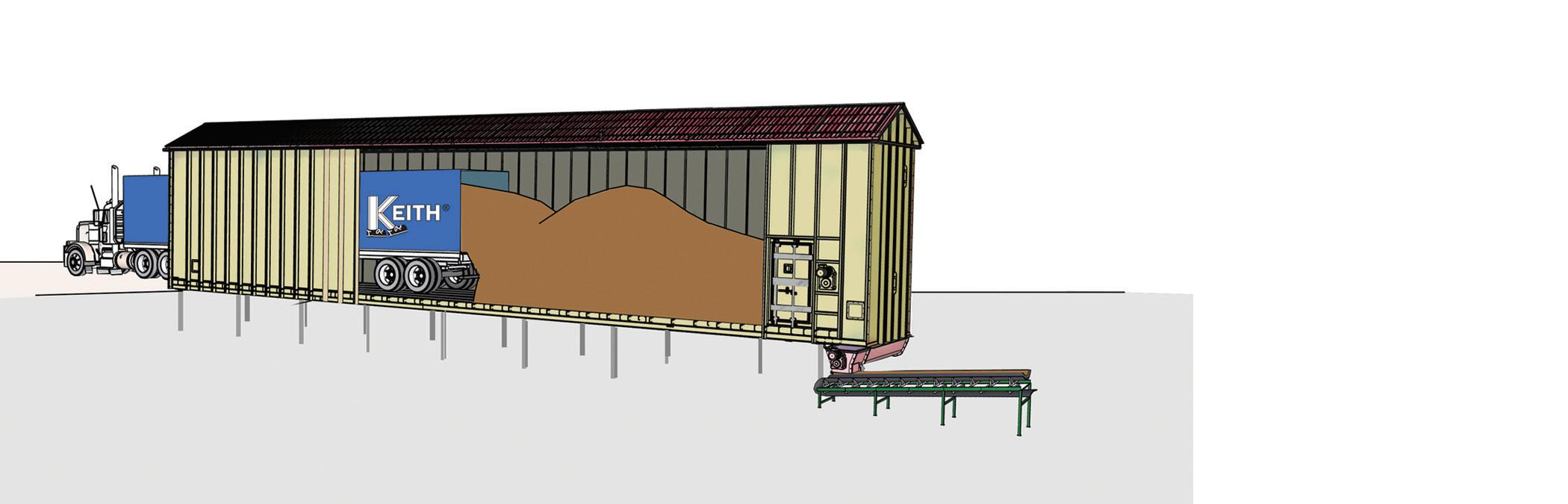

A worldwide leader in size reduction technology, Vecoplan works with individual customers to design, engineer, manufacture and implement technologically advanced, material specific, and application specific shredding, ferrous and nonferrous removal, size and density separation, screening and classification technologies and extremely efficient conveyor and bulk material handling, metering, storage and unloading technologies.

Contact Vecoplan today to learn more about our existing systems or to arrange a visit to one, or several, of our installations.

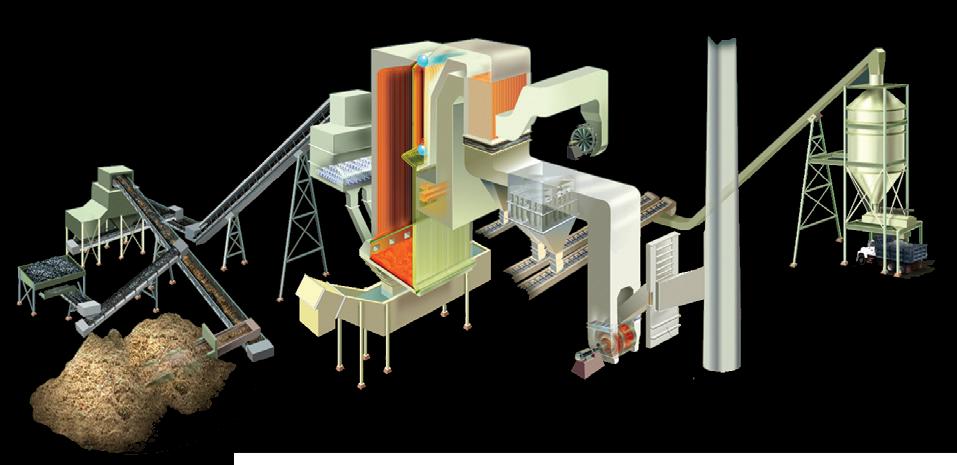

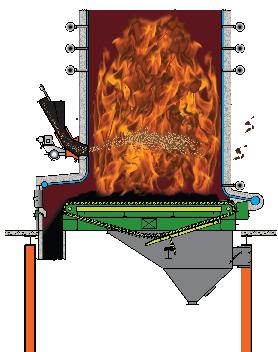

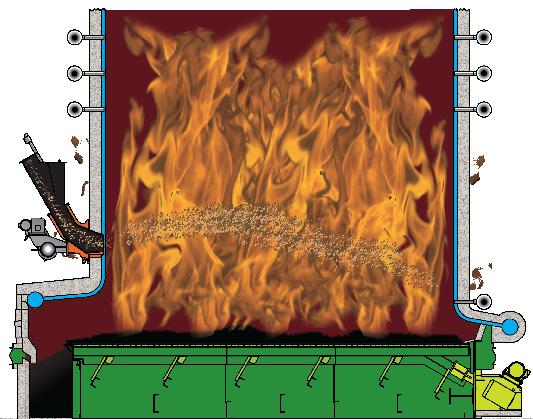

Interfor turns wood waste into clean energy.

By April Van Ert

WhenInternational Forest Products Ltd. (Interfor) decided to invest in the installation of a biomass-fired energy system at its Adams Lake Sawmill in British Columbia’s interior, sustainability was certainly on the minds of Interfor’s management. But for them, sustainability went far beyond the environmental benefits of the investment.

“The investment coincided with the company’s master plan for modernizing the entire mill site,” says Ric Slaco, Vice President and Chief Forester for Interfor.

Interfor’s investment in switching to cleaner technologies involved not just installing a biomass-fired energy system, but

also modifying its existing lumber-drying kilns and space-heating systems. The upgrades allow Interfor to use wood waste from the lumber manufacturing process to dry lumber and heat buildings during cold winter months.

“Our investment at Adams Lake underscores Interfor’s ongoing commitment and confidence in the future of the forestry business in BC,” notes Slaco. He points out Interfor made a concerted effort to engage local suppliers while committing to growing the province’s low carbon economy. This fuel-switching project brought multiple benefits to the environment and supported the spread of cleaner technologies in BC.

By using wood residue from its lumber manufacturing process as a fuel, Interfor replaced liquefied natural gas – and its associated emissions – with wood. The key to cleaner air was an investment in sophisticated technology: the waste wood was combusted at extremely high heat in a highly-efficient energy system, with emissions control equipment that reduced particles in the air well below provincial standards. Today heat vapour is primarily all that drifts out of the mill’s thermal plant. While switching to a cleaner-burning fuel improved air quality in this important recreational and salmon-spawning region, it also diverted wood waste from landfills. To top it all off, Interfor purchased the

To date, the Interfor Adams Lake project has meant the avoidance of nearly 41,000 tonnes of carbon dioxide emissions.

technology from BC-based manufacturer of turnkey biomass installations Wellons Canada, further supporting the growth of the local green economy.

With the Adams Lake Mill providing all of its own fuel, Interfor was able to eliminate another expense and ongoing source of emissions: those from the weekly 750-kilometre round trip diesel truck journey needed to supply the mill with liquefied natural gas. As the consumption of 500 litres of diesel results in some 1.3 tonnes of emissions, cutting out this weekly trip from BC’s Lower

MegaDome® pre-engineered fabric buildings give you practical and cost effective space for any industrial or environmental application.

BuildWorks delivers innovative design-build solutions. MegaDome structures are CSA-A660 certified and building code compliant.

Interfor’s installation of a biomass-fired energy system and modifications to its lumber-drying kilns and space-heating systems have eliminated the use of liquefied natural gas at the site. The system is extremely efficient; the combustion process reaches 1,800°F. and is controlled precisely to allow for complete combustion. The resulting ash can be disposed of safely in landfill or used as fertilizer.

Project Type: Fuel Switching

Total Offsets: 95,000 tonnes over 7 years

Equivalent # of Cars Off Road for One Year: 18,627

Region: Thompson/Okanagan

Location: Adams Lake, BC

Project Proponent: International Forest Products

Validator: KPMG

Verifier: Conestoga-Rovers & Associates

Mainland to the interior of the province is of undeniable benefit to the environment.

“It was a feel-good project all around,” Slaco says, adding there was a “real sense of pride” when our employees saw Interfor was thinking about the future on so

Despite all the benefits of the project, implementing it was not a given because

many fronts. Not only were we investing in equipment but in people as well. To ensure that the company had the expertise to effectively manage the new clean energy system it provided training for 15 employees to become Class 5 certified power engineers. Slaco says this additional training was integral to making sure the company had the expertise to manage the new clean energy systems.

ProcessBarron has 30 years of experience in designing and fabricating biomass fuel, air & ash handling systems. ProcessBarron has the know-how to get the most out of your biomass systems.

www.processbarron.com/biomass (888) 663-2028

of the substantial capital investment it called for. The sale of carbon offsets was identified as one of the requirements to justify the investment. “The potential for receiving offsets were certainly considered as a factor in helping to decide to go ahead with the project,” says Slaco.

In 2007, the government of British Columbia made the bold decision to become carbon neutral and thereby provide the framework for a low carbon economy. A

key component was the creation of Pacific Carbon Trust. Pacific Carbon Trust was established in 2008 to help companies, public sector organizations and individuals reduce their carbon emissions and usher in a new clean economy standard in the province. Pacific Carbon Trust both acts as a reliable provider of verified carbon offsets and facilitator for those seeking to implement a project.

“Pacific Carbon Trust has been instru-

The new Morbark ® Advantage 3™ high-performance chipper drum gives you improved biomass fuel chip quality, reduces your costs, and is backed by a limited three-year warranty. It comes standard on most new Morbark drum chippers and can be retrofitted to most Morbark units without modification. Either way, you get three significant advantages:

• Higher-Quality Chips – The Advantage 3 is wider, has higher inertia, and incorporates Babbitt-style counter-knives, so it produces better, more consistent chips.

• Dramatically Lower Costs – The drum’s AR 400 heat-treated steel skin, enhanced knife design, and recessed pockets provide wear-part and maintenance cost savings of more than 70%.

• World-Class Warranty – The Advantage 3 comes with a limited three-year warranty, and is supported by Morbark’s extensive dealer network for unsurpassed peace of mind.

The exceptional Morbark Advantage 3 chipper drum comes standard with most units in our full line of heavy-duty industrial drum chippers. Learn more at www.morbark.com or call 1-800-831-0042.

“The investment coincided with the company’s master plan for modernizing the entire mill site,” says Interfor’s Richard Slaco.

mental in terms of moving British Columbia in this direction,” Slaco says. He highlights the rigorous accountability standards that anchor Pacific Carbon Trust’s decisions to proceed with offset projects. “We’re all paying close attention to how to implement the methodology,” he says, referring to the stringent process of ensuring that the switch to biomass did indeed constitute a verifiable reduction in carbon emissions. To date, the project has meant the avoidance of nearly 41,000 tonnes of carbon dioxide emissions through the switch to the cleaner burning, on-site fuel source in the form of wood waste.

For Slaco, Interfor’s involvement in this project also showcases unrecognized potential for innovation in the forestry sector. “I’m just glad to see that there is encouragement for companies either on their own or through initiatives like this to be moving forward with projects that demonstrate what we can do to provide quality products that are also good for the environment.” •

New Canadian technology is an all-in-one solution that helps growers reduce fuel and energy costs.

By David Schmidt

growers have long eyed biomass as a cost-effective “green” alternative to natural gas. Some, like the Krahn family of Sun Select Produce in Delta and Aldergrove, British Columbia, have gone past just eyeing wood, and actually installed wood-burning boilers in their greenhouses.

Using wood instead of natural gas is most appropriate in British Columbia. Not only do the province’s forests yield a huge supply of wood waste (boilers use a lot of wood – Sun Select burns 75 to 125 tonnes of wood waste/day to heat its 40-acre Delta vegetable greenhouse), but also the province’s carbon tax has added to the cost of natural gas. The B.C. government is now rebating that extra cost – $1.3657/gigajoule – to greenhouse growers but the rebate only applies to 2012.

Despite that, two things have hindered the wholesale adoption of biomass boilers in greenhouses:

First, biomass boilers release far more particulates than natural gas boilers. This is a particular concern in a confined air-shed like the Fraser Valley, which already has to cope with heavy pollution from automobiles and has led to strict emission standards for wood boilers.

Second, vegetable growers supplement their environment with carbon dioxide to generate yields required to make their expensive greenhouses viable. Although growers can buy CO2, the most common and cost-effective way to obtain it is from a boiler, since burning fuel generates CO2 as a “waste” product. Natural gas produces “clean” CO2, which can be easily captured and released in the greenhouse. Unfortunately, CO2 from a wood boiler has been “dirty” and difficult to capture.

Until now.

ABOVE: Many dignitaries attended the ceremonies launching the Pro Select technology, including Reinhold and Victor Krahn of Sun Select at left.

ProSelect Gas Treating Inc., a partnership between Sun Select and Procede BV of the Netherlands, has unveiled the GC6 Carbon Capture System, which they claim is the world’s first carbon capture system for the greenhouse industry.

“It’s an all-in-one solution for the environment and economical for greenhouse growers,” says Reinhold Krahn of Sun Select. “It eliminates emission of pollutants and transforms the captured carbon into food grade CO2.”

Wood waste is burned in a Vincke boiler. The 180°C gas from the burning process goes to a flue where it is filtered and cooled to 60°C, then into an absorption chamber where the CO2 is absorbed by a fully reusable patented organic solvent, which effectively glues itself to the CO2

The remaining vapour, now stripped of its carbon, exits from the top of the column (“Don’t call it a smokestack because it’s just harmless vapour,” insists Reinhold’s brother Victor, CEO of ProSelect).

The CO2 is then sent to a desorption column where it is “boiled off” at 120°C and sent to the plants as required. Two computers control the entire system, one at the boiler and the other in the greenhouse.

“It’s really quite simple,” Victor says. “First we absorb the CO2, then we desorb it. We can strip out up to five tonnes of CO2 per hour.”

ProSelect spent about $5 million developing the system, aided by grants of $2.24 million from B.C.’s ICE (Innovative Clean Energy) Fund and $1 million from Sustainable Development Technology Canada’s SD Tech Fund.

Noting government’s role is to “support green innovation,” B.C. Minister of Jobs, Tourism and Innovation Pat Bell (a former minister of agriculture), is “excited” about the opportunity the new made-in-Canada technology offers B.C. greenhouse growers. “Our goal is to create a sustainable legacy for growers in B.C.,” Reinhold says, pointedly telling Bell, “We hope governments will continue to support this initiative by offering growers incentives to adopt it.”

But it is not a cheap option.

Even though development costs are no longer part of the equation, Victor estimates it would cost “about four million dollars” to install a system large enough for a 40-acre greenhouse from scratch. “The cost would be less if you already have a wood boiler and want to retrofit it.”

Despite the cost, the Krahns are now planning to install it at their 30-acre greenhouse in Aldergrove, which already has a wood boiler.

The reason?

They believe it is cost-effective.

“It reduces our energy and carbon cost by 50 per cent,” Reinhold says.

Part of that reduced cost is the carbon credits they will be able to sell, says James Tansey, CEO of Offsetters. A leading provider of carbon-management solutions, Offsetters is working with ProSelect and Sun Select to bundle carbon credits from the new technology.

“I hope this serves as an example for other industries,” Tansey says. “A challenge can be a huge opportunity.” •

David Schmidt is a freelance writer and photographer in British Columbia.

The 2012 Canadian Biomass Pellet Gear Buyers Guide is a resource for anyone in wood pellet manufacturing industry, providing information about major manufacturers and service providers for this industry in Canada.

Much like our 2011 edition, the Buyers Guide is organized into two sections. The first section is an alphabetical listing of

companies that provide the relevant products or services for each of the following categories: dryers, pneumatic conveying, hammermills, pellet mills, screens and coolers, fire/spark detection and suppression technology, bagging and palletizing, dies and rolls, quality control equipment and services, and building contractors and engineering firms.

We have also added four new categories this year: process control, bulk storage, emissions/dust control and energy systems. The second section is an alphabetical listing that provides contact information for each company.

The Pellet Gear Buyers Guide is also available online at our website: www.canadianbiomassmagazine.com.

Altentech

Amandus Kahl

Andritz

Anhydro

Astec Industries

Baker-Rullman

Bruks Rockwood

Buhler Aeroglide

Büttner

Certified Labs

Dieffenbacher

Earth Care Products

Energy Unlimited

GEA Barr-Rosin

Kesco

M-E-C Company

Münch-Edelstahl

Saimatec Engineering

Silvana Import Trading

Solagen

Stela

Swiss Combi

Western Pneumatics

Allied Blower

Amandus Kahl

Astec Industries

Buhler

Certified Labs

Clarke’s Industries

Concept-Air

Jeffrey Rader

Kesco

M-E-C Company

Rodrigue Métal

Silvana Import Trading

HAMMERMILLS

Amandus Kahl

Bliss Industries

Bruks Rockwood

Brunette Industries

Buhler

Buskirk Engineering

Certified Labs

Comact

CPM

Dieffenbacher

Kesco

La Meccanica

M-E-C Company

Münch-Edelstahl

Schutte-Buffalo Hammermill

Silvana Import Trading

West Salem

Amandus Kahl

Andritz

Bliss Industries

BTI

Buhler

Buskirk Engineering

Certified Labs

Comact

CPM

Dieffenbacher

Kesco

La Meccanica

Münch Edelstahl

Pellet Systems International

Pelleting Technology

Nederland

Silvana Import Trading

Zheng Chang

COOLERS

Amandus Kahl

Andritz

Astec Industries

Bliss Industries

BM&M Screening Solutions

Bruks Rockwood

Brunette Industries

Buskirk Engineering

Certified Labs

Comact

CPM

Dieffenbacher

Jeffrey Rader

Kesco

La Meccanica

Law-Marot

M-E-C Company

Münch-Edelstahl

Pelleting Technology

Nederland

Silvana Import Trading

West Salem

Zheng Chang

FIRE/SPARK DETECTION & SUPPRESSION

Allied Blower

Amandus Kahl

Clarke’s Industries

Concept-Air

CV Technology

Fike

Firefly

Flamex

Grecon

Hansentek

Kesco

M-E-C Company

Rodrigue Métal

Silvana Import Trading

BAGGING & PALLETIZING

Amandus Kahl

Buhler

Bulldog Bag

Certified Labs

Creative Packaging Inc.

Hamer

Möllers North America Inc.

Premier Tech

Primary Packaging

Rethceif Packaging

Silvana Import Trading

Trinity Packaging

DIES & ROLLS

Amandus Kahl

Buhler

Certified Labs

Comact

CPM

Dorssers

La Meccanica

Münch-Edelstahl

Silvana Import Trading

Zheng Chang

QUALITY CONTROL EQUIPMENT & SERVICES

Amandus Kahl

Buhler

Domosystem

Electromatic Equipment

Grecon

Kesco

Münch-Edelstahl

Silvana Import Trading

Timber Products Inspection

Twin Ports Testing

ENGINEERING & CONSTRUCTION SERVICES

Andritz

Astec Industries

Bruks Rockwood

Buhler

Buskirk Engineering

Comact

DelTech

Dieffenbacher

Earth Care Products

Energy Unlimited

Kesco

Pellet Systems International

Process and Storage Solutions

Solagen

Stolberg Engineering Ltd.

TS Manufacturing

PROCESS CONTROL

Amandus Kahl

Astec Industries

Earth Care Products

Robovic

BULK STORAGE

Amandus Kahl

Astec Industries

Jeffrey Rader

Rodrigue Métal

EMISSIONS/DUST CONTROL

Allied Blower

Amandus Kahl

Andritz

Astec Industries

Rodrigue Métal

Western Penumatics Inc.

ENERGY SYSTEMS

Allied Blower

Amandus Kahl

Astec Industries

DelTech

Jeffrey Rader

ALLIED BLOWER

www.alliedblower.com 604-930-7000

ALTENTECH BIOVERTIDRYERS www.altentech.com 604-512-9063

AMANDUS KAHL GMBH & CO. KG

www.akahl.de 905-778-0073 (Sarj Equipment, Canada)

ANDRITZ FEED AND BIOFUEL www.andritz.com +45 (72) 160 470

ANHYDRO INC. www.anhydro.com 708-747-7000

BAKER-RULLMAN www.baker-rullman.com 920-261-8107

BLISS INDUSTRIES, LLC www.bliss-industries.com 580-765-7787

BM&M SCREENING SOLUTIONS www.bmandm.com 800-663-0323

BRUKS ROCKWOOD www.rockwood.net 770-849-0100

BRUNETTE INDUSTRIES LTD. www.brunetteindustries.com 604-522-3977

BTI

www.rockbreaker.com 519-901-2434

BUHLER INC. www.buhlergroup.com 763-847-9900

BUHLER AEROGLIDE www.aeroglide.com 919-851-2000

BULLDOG BAG LTD. www.bulldogbag.com 800-665-1944

BUSKIRK ENGINEERING www.buskirkeng.com 260-622-5550

BÜTTNER www.buettner-dryer.com 704-522-0234

CANADIAN BIOENERGY CENTRE UNIVERSITY OF NEW BRUNSWICK www.unb.ca/fredericton/forestry/ wstc/cbec 506-453-4507

CERTIFIED LABS

www.certifiedlabs.com 905-691-0492

CLARKE’S INDUSTRIES, INC. www.clarkes-ind.com 541-343-3395

COMACT INC. www.comact.com 418-228-8911

CONCEPT-AIR

www.concept-air.ca 866-644-0041

CPM

www.cpm.net 800-428-0846

CREATIVE PACKAGING INC.

cp22243.tripod.com/baggingsystems 423-825-5311

CV TECHNOLOGY, INC.

www.cvtechnology.com 561-694-9588

DELTECH www.deltech.ca 250-564-3585

DIEFFENBACHER www.dieffenbacher.com 770-226-6394

DOMOSYSTEM

www.domosystem.fr/en +33(0)1 45 87 29 09

DORSSERS INC. www.dorssers.com 519-676-8113

EARTH CARE PRODUCTS, INC. www.ecpisystems.com 620-331-0090

ELECTROMATIC EQUIPMENT COMPANY INC. www.checkline.com 516-295-4300

ENERGY UNLIMITED INC. www.energyunlimitedinc.com 608-935-9119

FIKE CORPORATION www.fike.com 816-229-3405

FIREFLY AB www.firefly.se +46 (0)8 449 25 00

FLAMEX, INC. www.sparkdetection.com 336-299-2933

GEA BARR-ROSIN www.barr-rosin.com 630-659-3980

GRECON, INC. www.grecon.us 503-641-7731

HAMER LLC www.hamerinc.com 763-231-0100

HANSENTEK www.hansentek.com 905-607-5780

JEFFREY RADER CORPORATION www.jeffreyrader.com 514-822-2660

KESCO, INC. www.kescosolutions.com 803-802-1718

LA MECCANICA SRL DI REFFO www.lameccanica.it +39 049 941 9000

LAW-MAROT

www.lawmarot.com 800-461-6276

M-E-C COMPANY

www.m-e-c.com 620-325-2673

MÖLLERS NORTH AMERICA INC.

www.mollersna.com 616-942-6504

MÜNCH-EDELSTAHL GMBH

www.muench-edelstahl-gmbh.de 02103 58996

PELLET SYSTEMS INTERNATIONAL INC.

www.pelletsystems.com 506-575-2231

PELLETING TECHNOLOGY NEDERLAND www.ptn.nl +31 73 549 8472

PREMIER TECH CHRONOS

www.ptchronos.com 418-867-8883

PRIMARY PACKAGING

www.primarypackaging.com 800-774-2247

PROCESS AND STORAGE SOLUTIONS www.processandstorage.com 256-638-1838

RETHCEIF PACKAGING www.rethceif.com 866-298-1876

ROBOVIC www.robovic.com 819-364-2022

RODRIGUE MÉTAL LTÉE www.rodriguemetal.com 418-839-0400 ext. 231

SAIMATEC ENGINEERING

www.saimatec.fi +358-10 525 8100

SCHUTTE-BUFFALO HAMMERMILL, LLC

www.hammermills.com 716-855-1555

SILVANA IMPORT TRADING INC.

www.silvanatrading.com 514-939-3523

SOLAGEN INC.

www.solageninc.com 503-366-4210

STELA LAXHUBER GMBH www.stela.de +49(0)8724-899-0

STOLBERG ENGINEERING LTD.

www.stolberg.com 604-273-1915

SWISS COMBI

www.swisscombi.ch +41 56 616 6030

TIMBER PRODUCTS INSPECTION

www.tpinspection.com 770-922-8000

TRINITY PACKAGING CORPORATION

www.trinitypackaging.com 914-273-4111

TS MANUFACTURING www.tsman.com 705-324-3762

TWIN PORTS TESTING INC.

www.twinportstesting.com 715-392-7114

WEST SALEM MACHINERY CO. www.westsalem.com 800-722-3530

ZHENG CHANG

www.zhengchang.com/eng +86 21-641 85529

Is your listing missing? Does your information need to be changed? Contact Ross Anderson at randerson@annexweb.com

Vecoplan’s V-EBS 2500 was designed for the production of refusederived fuels (RDF) from MSW and other waste streams. It is especially adept at re-shredding low bulk density plastics, such as PET bottles, producing a very homogeneous particle size. Heavy-duty industrial screens on the V-EBS, can be quickly, easily, and inexpensively changed allowing you to determine and change the output particle size. The V-EBS has an infeed opening of 2510 mm X 1400 mm, a rotor dimension of 1000 mm X 2510 mm and has 54 cutting inserts on its rotor. It employs two counter knives for precise cutting of feedstock. Powered by Vecoplan’s patented HiTorc®, electromagnetic drive, the shredding rotor turns at 150-250 rpm and features a throughput capacity of 10-22 t/h. The V-EBS is one of the machines often integrated into Vecoplan’s complete WTE and RDF feedstock preparation systems.

Altentech has completed a full-scale demonstration centre in Princeton, British Columbia, for its highefficiency, small-footprint dryers, which have been patented (or in patent process) in 48 countries. Noram Engineering is beginning a comprehensive third-party validation engagement but detailed data already collected indicates that the Altentech D10 model Biovertidryer is using significantly less thermal and electrical energy to dry the biomass

feed stock than incumbent drying systems, while reducing particulate emissions. The inherent design of the dryer – particularly how it strictly controls the biomass being processed – reduces, if not practically eliminates the potential for explosions and fires associated with other widely and commonly used equipment. Altentech's smallfootprint Biovertidryers are modular in design and range in processing capacity from approximately 10 to 30 tons per hour in-feed, and five to 15 tons per hour output based on an in-feed moisture content of 45 to 50% and a moisture content of 10 per cent at discharge – although the computerized control system can be easily set for a variety of outcomes to match the operations needs.

Superior Industries’ newest conveyor design, known as the Geotrek conveyor, is a track-mounted radial stacker that can be directly linked with portable crushing and screening equipment in applications that require material stockpiling. Equipped with independent hydraulic cylinders at both the head and tail ends of the conveyor, the unit can also be used as a mobile transfer or link conveyor. Other common applications include bulk material loading to ships, barges and trucks. The unit is equipped with proportional track drive controls and feature the company’s patented powerfold design. During unfolding, the stacker’s hydraulic cylinders retract, protecting the cylinder rods from damaging dust and debris during operation. The new trackmounted stacker also comes equipped with a remote control to operate the unit’s belt and tracks.

www.jeffreyrader.com/videoB

One of the global leaders in open area dust suppression has announced the introduction of a new component in its arsenal of custom solutions: a family of tower mounts for the company’s atomized misting equipment, which extends droplet hang time and range, while providing more precise aiming capability. Complementing a product line that already includes wheeled carriages and skid mounts, by delivering millions of 50-200 micron droplets per minute from above dust-generating activities, tower-mounted units help commercial operations achieve superior particle control and prevent dust from migrating off-site. Dust Control Technology developed the new tower designs specifically to address ongoing operations that generate dust in fixed locations. They are well suited for slag handling, aggregate processing, recycling operations and coal handling.

OkoFEN is one of the leading producers of pellet-heating systems in Europe and relies strongly on innovative products. The company has now been awarded for its new heating circuit controller Pelletronic Touch in four categories with the “Plus X Award 2012” – the world's biggest innovation prize for technology, sports and lifestyle products – and also honoured with the special title of "Best Product of the Year 2012.” The heating circuit controller Pelletronic Touch was awarded for "innovation," "design," "ease" and "functionality.” With the Pelletronic Touch, OkoFEN upgrades its heating controller series to a modern touch screen system. The newly designed control panel with clear colour display allows a quick and intuitive navigation, and thereby an optimum user experience.

Premier Tech announces the acquisition of the vonGAL Corporation, as of June 29, 2012. Located in Montgomery, Alabama, vonGAL delivers quality, reliable, and high-performance conventional palletizer solutions to diversified industries, including baking, bottling, brewing, paint, pet food and publishing. This transaction strengthens IEG’s position as a North American leader in the field of rigid packaging and adds another leg to IEG’s commercial offering to the marketplace. This second manufacturing facility in the U.S. adds to the existing four plants IEG has in North America.

Vermeer has enhanced its popular HG6000TX track undercarriage horizontal grinder with a new dolly transport system, longer load-out conveyor and Tier 4i/Stage IIIB engine to help improve jobsite efficiency. The dolly transport system, or DT6, eliminates the need for a drop-deck trailer to transport the machine from jobsite to jobsite, helping to reduce operating costs by saving time. The dolly features an anti-lock braking system (ABS) and air ride suspension. The suspension provides 7 in. (17.8 cm) of ground clearance under the track undercarriage, allowing for transport over uneven ground. The dolly also features a brake release valve that can release the park brake and allow the dolly to be moved by a loader at the jobsite using designated tow points.

SEPTEMBER 2, 2012 • Canadian German Bioenergy Conference Vancouver, British Columbia http://kanada.ahk.de/en/events/ canada

SEPTEMBER 12-13, 2012 • Biomass Pellets Trade Asia Seoul, South Korea www.cmtevents.com/eventschedule. aspx?ev=120935&

SEPTEMBER 16-18, 2012 • Waste-to-Fuels Conference & Trade Show Mystic, Connecticut www.waste-to-fuels.org

SEPTEMBER 18-29, 2012 • Biomass Power Generation Brazil Sao Paulo, Brazil www.worldbiofuelsmarkets.com/ BP1209BR

SEPTEMBER 20-22, 2012 • Demo International 2012 Saint-Raymond, Quebec http://masterpromotions.ca/PreviousEvents/demo-international-2/

OCTOBER 9-10, 2012 • Annual Pellets Industry Forum Berlin, Germany www.pelletsforum.de/

OCTOBER 14-17, 2012 • International Symposium on Biomass and Bioenergy Vancouver, British Columbia www.csche2012.ca/

OCTOBER 17-19, 2012 • Timber Processing & Energy Expo Portland, Oregon www.timberprocessingandenergyexpo.com/

OCTOBER 22-24, 2012 • The World Energy Forum Dubai, United Arab Emirates www.worldenergyforum2012.org/ index.php

OCTOBER 29-31, 2012 • Advanced Biofuels Markets 2012 San Francisco, California www.advancedbiofuelsmarkets.com

By Seth Walker

f you trust U.S. Department of Commerce statistics, you might think that U.S. pellet exports have declined during the last two years, as only 332,444 tons of pellets were exported from the United States in 2011. However, if you aggregate pellet imports of all of the European countries from the United States you will see a modest increase in trade, but still not nearly as much volume as expected. In fact, this figure will be just over 900,000 tons (an estimate only, as the European Union lags behind when releasing trade statistics).

If you dig deeper into the data and looks at individual customs declarations for wood pellets, you will find more than a dozen different Harmonized Commodity Description and Coding System (HS) codes were used for pellet exports from the United States over the past five years. The most common HS code used was 83, miscellaneous articles of base metal. Other codes used included wood pallets and wood ornaments. With all of the confusion and misinformation, it is no wonder that it has been so hard to put a finger on an exact figure.

It is important that the U.S. wood pellet industry adopt a consistent methodology for reporting pellet exports. Since 2009, the European Union has used HS code 440130.20 for wood pellets and seen some success. American producers need a consistent approach in order to make the industry more transparent and easier to monitor.

Putting the statistical problems aside, based on the best available data and industry intelligence, RISI estimates that approximately 1.3 million tons of pellets were exported from the United States in 2011. This falls short of our 2011 forecast of 1.882 million, but validates many of our assumptions. Chiefly, capacity-based forecasts can give an accurate depiction of the industry in the absence of any reliable trade data.

Now, I know what you are thinking, don’t toot your horn too much; you overestimated exports by nearly 50%. So, what happened?

Frankly, we estimated capacity wrong.