BARRIE BRANCH

35 LINE 4 SOUTH, RR# 1

SHANTY BAY, ON L0L 2L0 PH: 705-487-6488 F: 705-487-6460

MISSISSAUGA BRANCH

1655 BRITANNIA ROAD EAST

MISSISSAUGA, ON L4W 1S5

PH: 905-670-1655 F: 905-670-4129

STONEY CREEK BRANCH

760 SOUTH SERVICE ROAD

STONEY CREEK, ON L8E 5M6

PH: 905-643-4166 F: 905-643-3511

CAMBRIDGE BRANCH 365 INDUSTRIAL ROAD

CAMBRIDGE, ON N3H 5S1 PH: 519-653-2206 F: 519-653-2439

NORTH BAY BRANCH

3601 HIGHWAY 11 NORTH NORTH BAY, ON P1B 8G4 PH: 705-476-4700 F: 705-476-4590

SUDBURY BRANCH 199 MUMFORD ROAD, UNIT F LIVELY, ON P3Y 1L2

PH: 705-692-7272 F: 705-692-1420

DRYDEN BRANCH 329 KENNEDY STREET

DRYDEN, ON P8N 2Y5 PH: 807-223-5999 F: 807-223-5997

OTTAWA BRANCH

189 CARDEVCO ROAD, R.R.# 2 CARP, ON K0A 1L0 PH: 613-831-4044 F: 613-831-4045

THUNDER BAY BRANCH 1450 WEST WALSH STREET

THUNDAY BAY, ON P7E 6H6

PH: 807-474-2530 F: 807-475-5276

BANDIT’S NEWEST AUTHORIZED DEALER IN ONTARIO, NEWFOUNDLAND AND WESTERN

HEARST BRANCH 1500 FRONT STREET

HEARST, ON P0L 1N0 PH: 705-372-1261 F: 705-362-7485

PEMBROKE BRANCH 9 JORDAN AVENUE JUNCTION 41 & 17

PEMBROKE, ON K8A 6W5 PH: 613-735-4118 F: 613-735-4088

TIMMINS BRANCH 4087 HWY. 101 WEST TIMMINS, ON P4N 7X8 PH: 705-268-7933 F: 705-268-3465

LONDON BRANCH 19 ROYCE COURT LONDON, ON N6E 1L1 PH: 519-686-6400 F: 519-681-2195

PETERBOROUGH BRANCH P.O. BOX 2320 1003 HWY. 7 EAST

PETERBOROUGH, ON K9J 7Y8 PH: 705-742-5401 F: 705-742-6414

JULY/AUGUST 2010

At World Bioenergy 2010, Sweden once again demonstrated that it’s the place to go to learn about biomass for energy.

Covering residues

District heat, Pellet expansion

The old saying of “when one door closes, another one opens” could prove true for some woodlot owners near Fredericton, New Brunswick.

Eastern Quebec’s Norampac plant began using biomass for fuel in the 1980s and has had a supply agreement with a local forestry group since 2006.

All the latest upgrades in gear, gadgets, and services that were drawing interest from visitors at World Bioenergy.

Why are British Columbia power producers being given special access to biomass, but other biomass users are not?

“When BC’s government announced that it would be making some bioenergy tenures and licences available for the power sector, other biomass users were stunned.”

Read the full story on page 25

Biomass backlash

Feedstock supply

Phasing out coal

Our Cover

Vattenfall, owner of this large combined heat and power plant in Nyköping, Sweden, is Europe’s fifth largest electricity generator and largest heat generator. Story on page 18. Photo: Heather Hager/Canadian Biomass

North Americans would rather burn non-renewable fossil fuels than renewable biomass.

he contrast between Scandinavia and North America is stark. In Scandinavia, biomass is becoming a major renewable energy source that’s replacing non-renewable fossil fuels. In North America, people are increasingly finding fault with biomass as renewable energy.

Biomass news has been peppered lately with communities rejecting biomass power plants. At least seven U.S. proposals have been scrapped due to public opposition. The main complaint is that people don’t want a “dirty” plant in their neighbourhood that they say will spew particulates and toxins into the air their children breathe. A secondary concern is that large areas will be deforested to fuel these plants.

Why do they think these things? Education and communication continue to be stumbling blocks. An example is the misinterpretation of the recent Manomet study of biomass power production that had some media reports exclaiming that biomass is worse than oil (see Canadian Biomass Web Exclusives for the study summary).

There are many claims about the benefits of biomass, but where are the hard data? A collection of facts and figures covering combustion efficiency, emissions, sustainability, and harvesting regulations would go a long way in evaluating people’s claims. A good place to start would be with companies, institutions, and nations that have extensive biomass experience.

Heat and power plants fired by biomass, recycled wood, and municipal solid waste dot the European landscape. These plants aren’t your average wood stove and meet specific pollution standards. In Sweden,

forest management has increased timber stocks, even with increasing biomass use. According to the Nordic Forest Owners’ Associations website, recent annual growth of Sweden’s timber stocks has been about 120 million m3, with annual harvest of 85–90 million m3, illustrating that biomass is not synonymous with deforestation. Swedish policy initiatives support biomass heat and power by banning flammable materials from landfills and providing “green certificates” as supplemental income for renewable energy. Compare that with the U.S. Environmental Protection Agency’s plan to regulate CO2 emissions from large-scale emitters like power plants, regardless of whether they use fossil fuels or biomass. At the federal level, Canada hasn’t done much, but the biomass industry can influence whether its future policy will more resemble USA’s or Europe’s. Canadian biomass policy should set standards and provide support for efficient, sustainable biomass use. Standards should define sustainable biomass harvests and compel users to demonstrate a suitable, long-term supply prior to initiating large-scale projects. Policies supporting bioenergy should encourage efficient biomass use by requiring power generation to provide the excess heat for industrial processes and heating, making it much more efficient. These types of policy, based on valid data, are the way to gain public approval and promote biomass use in North America. •

Volume 11

Editor - Heather Hager (519) 429-3966 ext 261 hhager@annexweb.com

Group Publisher/Editorial Director- Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Contributors - Colleen Cross, Gordon Murray, Reg Renner, Mark Ryans, Bill Tice, Stefanie Wallace

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@forestcommunications.com

National Sales Managers

Tim Tolton - ttolton@forestcommunications.com Ph: (514) 237-6614

Guy Fortin - gfortin@forestcommunications.com Ph: (514) 237-6615 Fax: (514) 425-0068

P.O. Box 51058 Pincourt, QC J7V 9T3

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca 1660 West 75th Ave Vancouver, B.C. V6P 6G2 Ph: (604) 264-1158 Fax: (604) 264-1367

Production Artist - Emily Sun

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0318-4277

Circulation e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

Subscription Rates:

Canada - 1 Yr $48; 2 Yr $85; 3 Yr $115 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $44 US; 2 Yr $75 US Foreign – 1 Yr $75 US

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above..

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.com

The first commercial-scale plant to produce torrefied wood pellets is being built in Duiven in the province of Gelderland, The Netherlands.

The £15-million plant is a project of Topell Nederland, a joint venture between Dutch company Topell Energy and German company RWE Innogy. The plant is expected to begin producing torrefied biomass in early 2011, with a production capacity of 60,000 tonnes/year.

The process developed by Topell enables the continuous production of torrefied pellets on an industrial scale. The manufacturing process is highly feedstock flexible. Torrefied pel-

lets have a high energy density and, when co-fired with conventional coal, do not require additional infrastructure such as separate storage or pulverization equipment. RWE Innogy’s Dutch subsidiary Essent will be the first company to use the torrefied pellets over a period of five years for combustion in the Amer coal-fired power plants in Geertruidenberg.

Three financial contributions totalling $1,090,358 are being granted to businesses in La Matapédia regional county municipality in Quebec. The funding, from Canada Economic Development, is to support the forest biomass sector.

Service de recherche et d'expertise en transformation des produits forestiers (SEREX), a college-level technology transfer centre that supports the secondary and tertiary wood processing sectors, is receiving a non-repayable contribution of $705,000. The funding will allow SEREX to design and create a wood biomass boiler prototype and to share its expertise

with businesses operating in the biomass industry.

The Coopérative forestière de La Matapédia is receiving a repayable contribution of $360,000, which will allow it to purchase wood processing equipment for producing biomass to fuel furnaces in commercial, institutional, and multi-residential buildings.

Productions Gaëtan Roy, which specializes in manufacturing custom metal products for various markets, is receiving a repayable contribution of $25,358 to purchase and modify the equipment required to produce metal components for manufacturing biomass boilers.

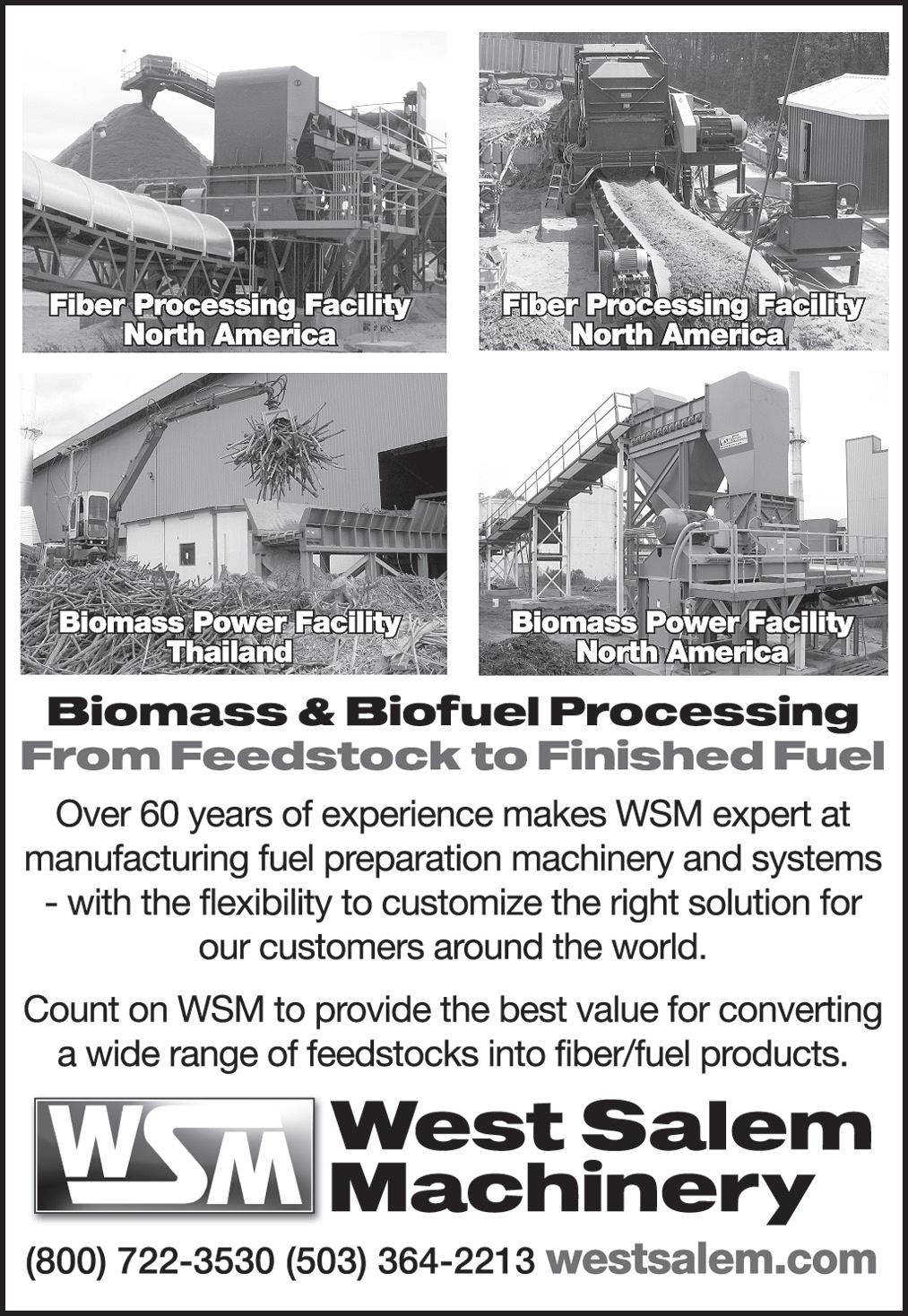

Our manufacturing and construction capabilities are extensive from vertical stationary hogs, portable systems to complete turnkey projects. We have in house engineering to provide onsite support before, during and after installation. We are very proud of our customer relations with 24/7 service for over 30 years.

For over 30 years Rawlings has designed and manufactured highly productive and cost effective wood waste recovery systems. We provide customized solutions, with support before during and after installation. Our systems are proven in various types of installations processing a wide variety of wood waste to the customer’s exact specifications.

For the best value and return on your investment turn to Rawlings Waste Wood Recovery Systems.

For the best value and return on your investment turn to Rawlings Waste Wood Recovery Systems a leader in fiber reclaim for wood to energy solutions.

The government of Canada is moving forward with regulations on coal-fired electricity generation to reduce greenhouse gas (GHG) emissions in the electricity sector. About 13% of Canada's total GHG emissions come from coal-fired electricity generating units. The proposed regulations will apply a stringent performance standard to new coal-fired electricity generation units, as well as coal-fired

units that have reached the end of their economic life.

Canada's fleet of coal-burning electricity plants comprises 51 units, with 33 coming to the end of their economic life by 2025. The gradual phase-out of traditional coal-fired electricity generation is expected to reduce emissions significantly. This policy is expected to reduce emissions by about 15 megatonnes, equivalent

Quality pellets, guaranteed. For perfect pellets the entire production system must work together flawlessly. Buhler enables total process control by providing a complete process design package and key equipment for drying, grinding, pelleting, cooling, bagging and loading. This, combined with Buhler’s integrated automation system, unrivaled after sales support and training provides a seamless solution, guaranteed.

Buhler Inc., 13105 12th Ave N., Plymouth, MN 55441, T 763-847-9900 buhler.minneapolis@buhlergroup.com, www.buhlergroup.com

to eliminating 3.2 million motor vehicles. Draft regulations to reduce GHGs from the electricity sector are expected to be published in the Canada Gazette early in 2011, with final regulations published later that year. This will allow time for consultations and outreach with industry and other stakeholders. Regulations are scheduled to come into effect on July 1, 2015.

Two separate items by Dan Schell in the Bancroft newspaper Bancroft this Week indicate that this central Ontario town may soon be showcasing two new biomass projects. A local school is preparing to install a wood pellet boiler to provide heating as one of four schools taking part in the Green Schools Pilot Initiative through the Ontario Ministry of Education. A deadline of September 2010 has been set for the installation. In addition, two investors from County Power Corporation have proposed a state-of-the art biomass power plant, with waste heat to be used in an associated pellet plant. The electricity generated would be provided to the province through the feed-in tariff program, but would require an exception to the rules, allowing the plant to supply 15 MW, rather than 10 MW, of power.

The solution behind the solution.

Nexterra Systems Corp. has won the Best Application of Technology Award from the British Columbia Technology Industry Association (BCTIA). The award recognizes Nexterra’s biomass gasification system at Kruger Products LP’s New Westminster tissue mill. The system converts wood residue into syngas that is being fired directly in a boiler to generate 40,000 pounds/hour of process steam, replacing about 400,000 gigajoules/year of natural gas consumption. This application of Nexterra’s gasification technology demonstrates the company’s ability to retrofit existing natural gas-, fuel oil-, or coal-fired boilers to run on syngas. Repurposing of existing equipment will cut the capital cost of implementing biomass energy systems at industrial and institutional customer sites.

The old saying of “when one door closes, another one opens” could prove true for some woodlot owners in a rural area near Fredericton, New Brunswick.

By Bill Tice

the challenge of a collapsing kraft pulp industry in the Atlantic region and the resulting limited market for low-grade logs, an entrepreneurial group of woodlot owners has joined forces with other community residents to build a pellet plant. The plant is located in the Nashwaak Valley in central New Brunswick, a pleasant 35-minute drive out of Fredericton on country roads. The enterprise, called Nashwaak Valley Wood Energy, hums along 24 hours/day, six days/week. It’s housed in an unassuming building that is situated in a forest clearing at the end of a long driveway near the community of Nashwaak Bridge.

Ken Thomas, who is the manager of the 2 tonne/hour pellet plant, says that many of the investors and owners of the facility are local woodlot owners. “Having reached the conclusion that the loss of markets for lower grade wood was likely to be permanent, pellet manufacturing seemed to be an emerging alternative for their fibre,” he explains. “We provide an outlet for low-quality softwood pulpwood and also a market for species that traditionally did not have a home in our province, such as hemlock, tamarack, and pine pulpwood.”

But Thomas says it’s not just the woodlot owners who have embraced the plant, which produced its first pellets in the fall of 2009 following a construction process

that took more than a year. “The community support for this project was very evident from the first meetings to discuss the project,” he says. “We had over 100 community members turn out during the early weeks of discussion, and most of them purchased some shares based on the plans that were presented. We now have 130 shareholders who have invested some capital in the project. Although some have a relatively small investment of a few hundred dollars, others have made a significant investment in the operation.”

Bill Hanson, who is a local woodlot owner and one of nine directors for the company, concurs with Thomas. “This is a local company that hires local people and puts money back into the local community,” says the retired Irving pulp mill maintenance foreman. Hanson is the selfprofessed troubleshooter at the plant, as he likes to solve the day-to-day technical issues that can occur in upstart operations like this one. “We raised about one-third of the funds needed to finance the almost

$3 million operation from the local shareholders, and the rest came from loans through financial institutions,” he adds.

Hanson also credits local Conservative MLA Kirk MacDonald for initiating the process. “He wanted to help the community increase employment, so he did up an initial business plan and started looking for people in the area that could make up a diversified board, which we now have. That board includes a former Minister of Natural Resources, an entrepreneur, an insurance expert, a technical person, and our chair, Peter deMarsh, who has been actively involved in woodlot owner organizations at both the provincial and federal levels.”

With the funding in place, building permit approvals from the local authorities finalized, an approved environmental study, and an operating permit from the provincial Department of Environment in hand, deMarsh and his board contracted Pellet Systems International (PSI) of Nackawic, New Brunswick, to help them build the facility.

“PSI was just a logical fit for us in terms of finding someone to work with,” Hanson says. “They are basically in our backyard, as Nackawic is just 45 minutes from Fredericton.”

In addition to supplying the plant’s pelletizer, Hanson says PSI sourced other equipment for the plant, providing a turnkey operation. Plant flow starts in the log yard, where self-loading log trucks deliver the fibre. The incoming logs are weighed

with Avery Weigh-Tronix drive-on scales. Once in inventory, they are moved around the yard and to the log deck with a Volvo L90 front-end loader and a Timberjack 230A forwarder. From the log deck, the logs are processed through a Forano ring debarker that was purchased second hand and reconditioned, before being directed to a PSI-designed drum chipper. From there, the chips are gravity fed to an inclined conveyor belt that fills a surge bin that can hold enough chips to keep the plant running for up to six hours, depending on production speed.

Next in line is a cylinder rotary dryer from Independence, Kansas-based Earth Care Products Inc. Hanson says that one of the aspects he really likes about the dryer is that it is self-sufficient, as it is powered by an Earth Care furnace that runs on the plant’s own furnish. “The dryer is really efficient,” adds Hanson. “It makes eight passes and takes our chips from 45 to 60% moisture content down to 12 to 15% moisture content.”

Once the chips meet the required moisture content, they are sent to a Schutte Buffalo hammermill and then to an Earth Care meal bin, which is a silo with four auger screws for feeding the pelletizer. Hanson says that at this point, 10 to 15% of the product from the hammermill is redirected to the furnace while the balance goes to a PSI pelletizer that can produce 2 tonnes/ hour of pellets. “We have tweaked it and squeezed a little more out of it if all is going well, but it is rated for 2 tonnes/hour,” notes Hanson with a sense of pride in the ability to maximize production.

A vacuum system with an outdoor bag house and two eight-inch lines pulls the finished pellets out of the pelletizer and into a silo, which is followed by a screening system to remove any unwanted fibre. A holding hopper and a metering hopper are then situated just above a bag line that features a McT air sealer system and a JEM International scale. Normally, the plant produces 40-pound bags of pellets. Any leftover air goes back to the bag house while fines and dust are reclaimed and directed back to the meal bin for recycling. Any residual hot air is used to heat the building, which is a 50 by 150-foot, 20 foot high, fully insulated, all-steel structure. Other major components at the plant include a Rockwell control system and a Spec Air dust collection system. For safety, the plant keeps a fire truck on site and has a number of fire extinguishers in key locations. They also have Hansentek spark detection systems installed by Spec Air and high-pressure water sprays installed by Viking Fire Protection at the bag house and dryer.

Like any start-up plant, the Nashwaak Valley facility has had its fair share of hiccups, says Thomas, but they are pleased with where they are today. “We have had our challenges with getting the different machinery components to work effectively together, and it took a while for our staff to understand and effectively use the equipment to its fullest, but we are getting there,” he explains. “With our fall start-up,

we also had to deal with external circumstances in terms of markets, such as a very warm winter last year, early buying by consumers to avoid shortages experienced the previous year, and low oil prices driving energy costs down. These all added up to lower sales than we had anticipated, but on the positive side, those that have used our product are telling us that it is one of the best in the marketplace. Our order book for later this summer is looking very promising, and in addition, there seems

to be a genuine move towards renewable forms of energy such as pellets.”

Hanson says the market for the company’s products is Atlantic Canada, mainly New Brunswick and Nova Scotia. “We sell a small amount of pellets to the local community as cash and carry, but most of our product is sold through a sales agent to distributors who supply retailers,” he explains. “Another market for our product is animal

bedding, as they were using shavings from the sawmill industry,” he continues. “But with the slowdown in the forest industry and the shutting down of some mills, our grade 3 product has become a popular substitute, especially since it is a littler shorter and provides more surface contact than our number one grade product, which means it absorbs moisture quicker.

As for the future, everyone at Nashwaak Valley Wood Energy is optimistic. “Although the plant was designed to produce 2 tonnes/hour, many of the components are able to do significantly more,” says Thomas. “Our intention is to expand to 5 tonnes/ hour over the next couple of years, which is something we would have considered right from the beginning if we had been able to raise more share and loan capital.”

In talking with Thomas, it’s evident that he believes in the product and the benefits of using renewable energy. “Now is the time that we must really push all levels of government to promote and encourage this type of renewable energy,” he explains. “Our forests and abandoned farmlands could be used extensively for the production of energy crops. This type of energy could be considered to be renewable, sustainable, and locally produced, while offering a marketplace for our low-grade forest materials.” •

Finnish research shows that covering residue piles in the field helps to keep moisture levels down.

his is the final column in a series on the importance of moisture content in forest-origin biomass, paying by energy content, and managing residues through the use of best practices to reduce moisture content in the field.

In my previous column, I discussed proper piling and handling methods. These methods can go a long way in reducing the moisture content of harvest residues and can provide direct financial benefits by increasing the energy content and facilitating a more efficient grinding operation.

One issue that I have not addressed is the timing between the harvest, the piling of residues at roadside, and the eventual comminution operation. To complicate matters, the material is usually needed in the winter, which is the worst timing for moisture content in forest residues because of fall wetness and the inclusion of snow in the pile and ice sticking to the branches. A complementary and beneficial practice to a proper piling technique and good timing is to use a covering material on the roadside piles.

There are a multitude of factors at play when it comes to drying residues in the field: for example, the season of harvest, sunny days, rainfall, snowfall, temperature, wind (airflow in the pile), location, species, proper pile formation and orientation, etc. FPInnovations has a number of trials on the go to examine some of these factors under local conditions, but it is too early yet to provide any results.

Nevertheless, a good example of the importance of covering and aging residues comes from a Finnish Forest Research Institute study. The trial included two treatment methods: fresh Norway spruce residues (Green) were immediately forwarded to roadside after harvest in early June; others (Brown) were left in the cutover to season

and then forwarded to roadside in August. Half the piles in each treatment were covered at roadside with a special paper. Fresh residues at roadside piles and in the cutover dried rapidly to below 40%. By August, when the Brown residues were forwarded to roadside, they had started to reabsorb moisture. The roadside piles continued to lose moisture and actually dropped to 20%. In the fall, however, the piles that were not covered from both treatments regained moisture rapidly. In the end, the covered piles (Green and Brown sources) maintained their low moisture content through the winter and were 15% lower in moisture than the uncovered residues. Although the species and other factors will be different, we expect similar trends in Canada.

so that it does not blow off. In full-tree operations, we envision that an excavator could lay the paper during a pre-piling operation, or the paper could be laid on top of roadside piles formed during the conventional harvest in a well-integrated operation. In these cases, there is a more substantial application cost, as an additional machine may be needed. Shipping 4 m wide rolls to the field is a burden as well.

Residue covering is now a common sight in the Nordic countries, especially Sweden and Finland. The wrap is designed for covering roadside piles of harvest residues or small trees and is made of exterior layers of wet-strength paper and two middle layers to provide reinforcement, tear resistance, and waterproofing.

Covering piles adds costs related to the price of the wrap and its application. Laying paper over residue piles is a relatively simple procedure. After cut-to-length operations, the application cost is minimal. The wrap is laid on top of the roadside pile as it is being formed using a wide “paper” dispenser and the forwarder’s crane. Some loose residues are placed on top of the cover

Despite these costs, we expect a positive return under Canadian conditions with only a 5% reduction in moisture content. A 15% reduction would result in a return of over 200%. Such a dramatic return will depend on the payment system and price for energy (power or heat), but is well within current energy pricing.

Using Mother Nature to dry harvest residues in the field with a little help by using a cover to reduce rewetting and ice forming within the pile will go a long way to increase the value of the feedstock and improve the overall efficiency of the supply chain. •

Norampac-Cabano began using biomass fuel in the 1980s and has had a supply agreement with Groupement forestier de l’Est du Lac Témiscouata since 2006.

forest residues for biomass means new hope for many sawmill owners and contractors, and many such projects have been announced recently. However, some four years ago, before this strong tendency to develop diversification strategies, an idea was born in the minds of the leaders of two organizations in eastern Quebec: the Groupement forestier de l’Est du Lac Témiscouata and Norampac. That idea now represents a supply of more than 23,000 tonnes of forest residues to fuel Norampac’s corrugated fibreboard plant in Cabano, Quebec.

The bulky residue, comprising unusable branches and other harvesting waste, is recovered and used to produce the process steam required for Norampac-Cabano’s operations. It supports the production of 220,000 tonnes/year of corrugated fibreboard. Harvested on Crown lands within a radius of approximately 100 kilometres, this forest biomass supplies the plant’s two boilers.

“Beyond 100 kilometres, the project would not be very green and also not really profitable,” says Clarence Dubé, NorampacCabano’s supply manager. “We do not want to move semi-trailers long distances, as we will not save on CO2,” he continues. With this thought uppermost in their minds, the plant’s leaders, in the spring of 2006, bought a 9,000-hectare woodlot located in the neighbouring county of Kamouraska.

Although the partnership between Norampac-Cabano and Groupement forestier de l’Est du Lac Témiscouata, a group of foresters and woodlot owners, began more than four years ago, the association was accredited in 2009 by the Quebec Department of

Natural Resources and Wildlife under an Action Plan regarding the harvest of forest biomass in public forests. The Groupement is mandated by the government of Quebec to harvest in Crown lands.

“We were qualified to harvest in the Timber Supply and Forest Management Agreements 01151 and 01152,” says Pierre Dumont, who is in charge of public forest operations for the Groupement. “Before that, we were involved in a pilot project.” Rights to these territories are granted to six companies: Les Bardeaux Lajoie, Tembec Matane, Groupe NBG, Felix Huard, Bégin et Bégin, and Norampac-Cabano. All of this represents 20,000 tonnes/year of biomass for Norampac-Cabano, plus another 3,000 tonnes/year collected from woodlot owners who are members of the Groupement.

Harvesting the biomass and providing it to Norampac-Cabano seemed like a good concept, but the Groupement had to find an economical and effective process if the idea was to prove profitable. After many tests and improvements over the years, the leaders of the Groupement settled on two methods of harvest: cut-tolength (CTL) and full tree. Harvesting is done by four contractors hired by the organization. The teams lay out the wood residues along the forest roads, and a fifth contractor is involved in secondary processing of the residues using a Woodsman 336 waste wood chipper.

Three of the contractors do CTL harvesting. They work with

CTL harvesters and transport the wood residues by forwarder. This method requires care to avoid contamination, says Pierre Dumont, who is in charge of public forest operations for the Groupement. “With the forwarder, the operators must be careful not to collect too much rock and dust because such material would cause problems for the chipper. This is what we have learned from experimentation,” says Dumont. Born, raised, and living in Dégelis, Dumont graduated as a forest technician from Cégep of Sainte-Foy in 1981 and has worked for the Groupement since 1987.

Rosaire Laplante is one of the three contractors who specialize in CTL harvesting. He owns two harvesters, a Tigercat 845D and an 845C, both fitted with Logmax 7000 harvesting heads. He also has a Rottne Rapid 16-tonne forwarder.

Les Chantiers du lac, another company, operates with two Tigercat models 845B and 860B, also with Logmax 7000 harvesting heads, and a John Deere 1110D forwarder. Lionel Rousseau, the third CTL contractor, uses a Tigercat 822 harvester as well as a Valmet 425 harvester. Both of those machines are equipped with Logmax 7000 harvesting heads. Rousseau’s company also uses two Eco Log forwarders, models 547 and 564.

In the full-tree operation, Berthier Beaulieu uses a Prentice 630 feller buncher and a Gilbert 1252 feller head, two John Deere 748G and 738G skidders, and two John Deere 790E and 2054 delimbers equipped with Propac delimber models 613 and 453.

Meanwhile, Camille Beaulieu works along Highway 185, processing wood residues left after the construction of the road. Living in Packington, Quebec, he is the contractor in charge of the operations, using a Woodsman 334 wood chipper. The Groupement

purchased the chipper new in 2006.

Having launched his own business 10 years ago, Beaulieu was formerly an operator. His team is made up of his brother Lucien, and Marc-Andre Picard, a young man who has just turned 20. “There are more restrictions when you use a chipper, compared to a grinder: We have to check carefully to be sure no rocks are introduced into the machine because that would slow down our production,” Beaulieu explains. “A full load made by this chipper weighs 34 tonnes in the semi-trailer and will take one and a half hours to process,” he adds.

Pierre Dumont considers this period of time much too long. “We discovered that the John Deere 375-hp engine was too small for our needs. It just was not strong enough and limited our productivity.” He says that the Groupement has purchased a second machine with a more powerful engine, a 30/36A NCL Morbark whole-tree chipper.

Beaulieu also has a 1986 Prentice loader that has recorded 10,000 hours of use, the engine of which was rebuilt in 2009. The company’s equipment also includes two semi-trailers and two Western Star trucks. As one loaded semi-trailer is in transit towards Norampac-Cabano, the other is being loaded by the chipper.

The partnership between Norampac and the Groupement took place for purely economic reasons. “We started when the price of fuel increased dramatically,” explains Luc Pelletier, director of Norampac-Cabano. At that time, the plant was using three boilers. The main boiler, made by Volcano, was installed in 1981. It was equipped with a Wellons-type biomass combustion chamber and had a capacity of 65,000 lbs/hour of steam. The other two boilers had a capacity of 80,000 lbs/hour each and were fuelled by number 6 oil. The proportion of emissions then was 38% from wood residues and 62% from heavy oil.

The purchase and installation of a new Groupe Simoneau boiler in 2004, an investment of $6.8 million, made it possible to reduce the CO2 emissions from fuel oil and save on energy costs. This new boiler has a capacity of 100,000 lbs/hour of steam and is equipped with a combustion chamber developed by Combustion Expert, a firm located in Trois-Rivières, Quebec. With the two biomass boilers, the management has noted a reduction of more than 90,000 tonnes/year of CO2 emissions from fossil fuels. “We avoided 96,000 tonnes of CO2 equivalent with our two boilers in 2009. Our forecast for 2010 is 120,000 tonnes because of better boiler efficiency,” says Pelletier.

A strict boiler maintenance schedule is required to maximize the boilers’ performance. Pelletier adds that the management of ash produced during boiler operation continues to be a challenge. “Our two boilers annually burn a total of 167,000 tonnes/hour of biomass. On a daily basis, that means 473 tonnes/hour of biomass,” he says. “That means a lot of ash!”

The biomass operation has also required certain adjustments. “It requires material not exceeding 50% moisture content during winter time,” he adds. "This is the kind of research and development we do. Biomass boilers require a lot of care in supply management. We must maintain sufficient inventories according to the season and the operations of the sawmills from which we purchase our wood residues,” he concludes.

In summary, Pierre Dumont and Luc Pelletier both share the same opinion as far as this method of heating is concerned: small volumes of biomass are unprofitable, and a significant supply is a must. They smile when they read articles in the regional press throughout the province announcing that 4,000 tonnes/year and lesser volumes are proposed for projects. “We did not hold any press conferences when we started our partnership in 2004. We quite simply decided to work together and use our best efforts to be profitable!” says Pelletier. He is amused to have seen various announcements from other companies over the past two years. “With the Groupement, we simply go on!” he says. •

Lenders are looking for projects that can demonstrate a secure, suitable, and sustainable supply of biomass feedstock.

tem number four in the ten-step checklist of “Strengthening your Bioenergy Project for Financing” is the biomass supply. I now discuss three ‘S’-words influencing your feedstock: security, suitability, and sustainability. Even though you may be attempting to finance equipment such as a biomass boiler or wood grinder, you will need to show that you have secure access to a suitable and sustainable biomass supply. Rest assured that Canadian banks and lenders know that your entire project is dependent on a reliable, cost-effective feedstock supply. Remember, the ultimate goal is to move your project to the head of the line.

Security should be addressed by obtaining a written formal supply agreement with a reputable, local supplier. A five-year signed supply agreement with pricing and minimum volumes can go a long way in helping to secure necessary financing. A bioenergy project that is totally reliant on only one source of feedstock will be at risk, so two supply contracts are even better. This will also allow you to negotiate a better feedstock price, as your supplier will benefit from a long-term relationship and a guaranteed market. An interested lender needs to know that both the feedstock supplier and bioenergy processor are committed to the project.

Suitability can also be defined within the supply contract and should include details such as acceptable moisture content, particle size ranges, and rights of first refusal. By defining the suitability of the incoming product, it will be easier to decide on the best equipment for processing and best marketplace for your end product. For

example, there might be a great supply of recycled urban wood waste available, but it will not garner a premium grade wood pellet pricing. Instead, it might be suitable for industrial grade chips, which have lower processing costs and revenues.

You might have to pay more for a very dry, uniform, high-quality feedstock, but your chipping and drying costs may be lower. It is not necessarily the cheapest feedstock that wins the day; it is the product with the best margins.

Sustainability has been gaining plenty of attention recently. Just check out the misinterpretation and furor related to the recent release of the Manomet Center for Conservation Sciences’ report on biomass for Massachusetts. As a first step, I recommend that you identify how much material your specific project requires. Recently, potential clients expressed concern that their biomass boiler project might not be sustainable. They did not know how many oven-dry tonnes (ODT) would be required on an annual basis. After doing a quick conversion from gigajoules (based on the current heating bill) to ODT, we estimated that they needed about 300 tonnes/year, which could be supplied largely by the sizable community forest that they own.

biomass in your area. It can be beneficial to hire an independent professional forester to verify your biomass supply projections and double-check that your feedstock supply is sustainable over the long term.

In my previous column, entitled “Where’s the Money?,” I suggested that project proponents build a financial plan in a computerized spreadsheet format. This spreadsheet should be able to handle various feedstock scenarios and look at break-even points for biomass procurement and processing costs. It will allow you to compare raw material and processing costs and determine the strongest

“A five-year signed supply agreement with pricing and minimum volumes can go a long way in helping to secure necessary financing.”

business case. After all, one of the key ingredients to long-term sustainability is profitability. If you are not able to sustain your business with an acceptable return on investment, then the importance of the other ‘S’-words will be undermined.

Do your research and prepare your answers based on relevant and local data. You already know what the questions are. You can impress potential funders with concise answers and signed supply agreements. •

My advice is, try not to get drawn into the much larger international debate of biomass sustainability, but focus on the specifics of your particular local project. You might be surprised to find that you have a tremendous amount of unused

IT DOESN’T TAKE AN ECONOMIST TO HELP SOLVE OUR NATION’S BIGGEST CHALLENGES. IT TAKES A LOGGER.

At World Bioenergy 2010, Sweden once again demonstrated that it’s the place to go to learn about biomass for energy.

By Heather Hager

Sweden, evidence is everywhere that using biomass is part of daily life. Those who made the trip to Jönköping for the World Bioenergy conference and exhibition this year had five full days of all things biomass, including preand post-conference tours and daily field trips to see biomass end-users in action. But in fact, the learning began even before the pre-conference tour commenced.

For international participants, arriving at the Stockholm Arlanda airport was the first experience of bioenergy the Swedish way, although few may have known it. Most of the airport’s buildings are currently warmed on a biomass-fuelled district heating system. It’s allowed the airport to reduce its heating-related CO2 emissions to a whopping 95% lower than 1990 levels.

Barely a five-minute drive from the airport and we’d already passed several piles of slash and a pile of stumps drying by the roadside. These were likely destined for the local district heating plant. Slash piles by the roadside might seem unusual to visitors, but it’s merely a fact of life in a country where bioenergy became the largest single source of energy in 2009. At 31.7% of energy use, it was the first time that biomass surpassed all other forms of energy, including oil, hydro, nuclear, coal, natural gas, heat pumps, and wind (at 30.8, 16.9, 12.9, 3.3, 2.9, 0.9, and 0.7%, respectively), according to an analysis of

Swedish Energy Agency statistics by the Swedish Bioenergy Association. Compare that to a lowly 8.6% of energy from biomass in Canada.

Electricity production in Sweden involves almost no fossil fuel, with only about 3% of mostly reserve capacity generation provided by fossil sources in 2008. The majority of electricity is generated from hydro, at 47%, and nuclear sources, at 42%. The remaining 8% is generated from biomass and recycled fuels at combined heat and power (CHP) plants.

“Combined heat and power plants are like the new cathedrals of Sweden,” remarked Kjell Andersson, our World Bioenergy pre-conference transfer tour guide. “They are now the largest buildings in many towns.” Our first stop on the tour

was no exception: the Igelsta CHP plant, which happens to be Sweden’s largest. It’s owned by the municipalities of Södertälje, Botkyrka, and Huddinge under the Söderenergi company and began commercial operations a mere half-year previously in December 2009. It joins a functioning district heating plant at the site that began operating in 1982.

The Igelsta CHP plant produces 85 MW of electricity and 200 MW of heat, power ing 100,000 and warming 50,000 homes. It takes a lot of biomass to fuel this plant – about 17,000 tonnes/week at full capacity and more than 400,000 tonnes/ year – and every load is analyzed for fuel quality. “We had to expand the area of storage dramatically for the volume of biofuels,” said company spokeswoman Madeleine Engfeldt-Julin. The harbour at the site was expanded to accommodate two

ships at once and receives about 200 shiploads/year. In addition, a fuel terminal was built at a nearby railway line located less than 50 kilometres from the plant. There, four trains/week each bring about 1,000 tonnes of biomass (equivalent to 30 truckloads) from forests in northern Sweden, meeting about half the plant’s fuel needs. Biomass is unloaded and stored at the terminal and later trucked to the plant.

This plant was designed to be fuel flexible, said Engfeldt-Julin. That allows Söderenergi to adapt to changes in fuel prices, scientific knowledge, and government regulations. The plant currently burns 75% wood chips and 25% recovered waste materials, comprising construction

and demolition waste, non-recyclable plastics, and other combustibles.

This 250 million Euro investment is estimated to become profitable in 8–10 years because of green certificates, said EngfeldtJulin. Under this system, electricity suppliers buy certificates according to their previous year’s sale and use of electricity. Electricity producers using renewable energy sources receive a green certificate for each megawatt hour produced, gaining extra income for renewable electricity production.

Indeed, green certificates almost double the value of electricity from renewable sources, said the spokesman at the second CHP plant we visited. The plant, located in Nyköping, is owned by Vattenfall, a large, state-owned energy company. Its 100-MW CHP unit generates heat and 35 MW of electricity, and two additional boilers produce up to 80 MW of district heat. It burns about 170,000 tonnes/year of biomass, depending on the moisture content.

Originally a coal-fired plant, the fuel has been all biomass since 1991, but the composition—recycled wood, chips, sawmill waste, energy crops—changes with what’s most economical. Currently, it burns a lot of construction and demolition waste, more than half of which is imported by ship from places like Norway, Poland, the United Kingdom, and the Netherlands. The waste usually contains non-combustible material, so it’s first processed through a screen, crusher, and two large magnets, recovering on average one to two kilograms of magnetic material per

tonne of waste. On-site storage capacity can fuel the plant for one and a half weeks at peak output, with three weeks of storage located five kilometres away.

Cities in North America that are running out of landfill space could take a lesson from Sweden. Swedish policy has banned combustible, non-recyclable waste from landfills since 2002, making it a valuable fuel source for CHP. One CHP plant in Linköping burns up to 420,000 tonnes/ year of sorted waste from over 30 municipalities and recycling companies. Less than 5% of household waste in Sweden goes to landfill. Just think how much heat and power could be produced from Toronto, Montreal, or Vancouver’s garbage.

Although only a small proportion of total electricity production is from biomass, over 62% of district heating is fuelled by biomass, according to the Swedish Ministry of Enterprise, Energy, and Communications.

District heating is huge in Sweden and accounts for about 40% of the heating market, so we could hardly drive between Stockholm and Jönköping without stopping at several district heating plants, ranging from 2 to 6 MW. Although a far cry from the 200 MW of district heat put out by Sweden’s largest CHP plant, these smaller systems serve residences, municipal buildings, and industries in their localities.

The smallest district heating system we visited, in Gränna, was in a building about the size of a single-car garage, dwarfed by two 80-cubic-metre silos containing wood pellets. That’s about a four-day supply for the 2-MW boiler in mild weather, we were told. The boiler is monitored remotely online, and a technician visits once a day during the workweek. This temporary, mobile plant, owned by Lantmännen Energi, is soon to be replaced by a permanent one. The company has about 15 similar heating plants throughout Sweden, which are handy in establishing an initial customer

big part of any conference involves networking and making new contacts. For this, the Canadian Trade Commissioner Service in Sweden organized an exciting side event, along with tasty hors d’oeuvres, that was a draw for Europeans and Canadians interested in forming or expanding bioenergy partnerships in Canada. Representatives from British Columbia, Ontario, and Quebec provincial governments talked about incentives and opportunities.

Rolf Fyne, director of business development in Europe for Invest British Columbia, kicked off the session by listing why British Columbia is a great place to invest in bioenergy. The province aims to become a leading supplier of renewable energy throughout its region and to the nearby United States and is creating a policy environment to foster that, he said. Incentives include an estimated availability of 500–700 million bone-dry tonnes of beetle-killed wood by 2013, and carbon tax and carbon trading schemes that make bioenergy more profitable. Funding for research and development and demonstration projects is available under the BC Bioenergy Strategy, for example,

and from the BC Bioenergy Network, said Fyne. And BC Hydro is soliciting renewable energy providers. Supportive policies and legislation include the Clean Energy Act of June 3, 2010; changes to boiler staffing requirements; a new ASME certification equivalency process for acceptance of approved European boilers; and the establishment of BC Timber Sales, which Fyne said is giving inexpensive, three-year contracts to remove beetlekilled wood and revitalize the forest.

The Ontarians came armed with a menu of six real bioenergy partnership opportunities from companies based in Ontario or with assets there. And “there are more where those came from,” said Douglas Clarke, business development consultant for the Ontario Ministry of Economic Development and Trade in London, UK, and Stephen Roberts from the Ontario Ministry of Northern Development, Mines, and Forestry in Ontario. They also discussed ongoing and upcoming initiatives to stimulate forest bioenergy in Ontario, including the Green Energy Act, mandating an end to coal-fired electricity production by the end of 2014 and providing a feed-in tariff for renewable

base and heating network in communities that lack such infrastructure.

Under the usual Swedish business model, one company (or municipality) owns the heat plant and another company owns the heating grid and distributes the heat. That’s not the case, however, in the small community of Malmköping, a town of about 3,500 inhabitants. There, two local entrepreneurs developed and own both the heat plant and the distribution grid, currently supplying 173 delivery points through five kilometres of pipeline. Customers pay a proportion of the cost to install pipeline to their residence and sign a five-year contract for heat. In turn, the company supplies the heat, owns the pipeline and residential delivery points, and provides equipment servicing.

The Malmköping plant was built with plenty of redundancy in case of breakdown. The 2- and 2.5-MW multi-fuel biomass boilers each have their own fuel storage silo and water distribution pump.

energy producers, as well as proposed forest tenure reform.

Finally, Michel Lachance, director of industrial bioprocesses and bioproducts for Centre Québécois de Valorisation des Biotechnologies, described Quebec’s bioenergy goals and opportunities. The province aims to reduce greenhouse gas emissions by 20% from 1990 levels by 2020. This will be done partly by using the 6.4 million dry tonnes/year of available forest biomass, through programs that allocate residual forest biomass, support research and demonstration projects, and provide financial assistance for biomass heating to replace heavy oil consumption, for example.

In backup is a 3.2-MW oil boiler, as well as an electrical generator to run the system in case of power outage. The main fuel is briquettes from a sawmill less than 50 kilometres away. The silos are filled three times/week at peak winter production, and the plant burns about 2,700 tonnes/ year of wood. The owners estimate that they could supply an additional 150 residences with this plant and are expanding into a new housing development.

The final district heat plant, at Skänninge, was actually shut down when we visited. One consequence of having CHP for electricity production is that there’s excess heat to get rid of in summer. Nearby communities that can tap into a CHP grid can take advantage of lower heating rates than they could produce themselves, which is what this community does. The Skänninge plant will fire up again in August, producing 6 MW of heat from wood chips, bark, and sawdust from local forests and sawmills within 100 kilometres.

Once arrived at the World Bioenergy venue, participants had three mornings of informative presentations from international speakers. Afternoons, participants stretched their legs at the exhibition or on one of the daily excursions to see real bioenergy operations at work. Excursions included heat and power, biogas, biodiesel, wood pellets, solarbiomass combined energy, a biomass train terminal, and forest operations.

In Sweden, the forest harvesting slash

isn’t considered waste—it’s a valuable product—so the forestry tour showcased some of the slash harvesting techniques used there. This demo took us to forest owned by Sveaskog, a state-owned company that’s Sweden’s largest forest owner, with 3.3 million hectares or 15% of Sweden’s productive forest. The company currently sells 1.4 million cubic metres of biomass and aims for 2 million cubic metres by 2013, according to biofuel coordinator Roger Johansson.

Swedish forests are managed intensively throughout their lifespan. In a 20-year-old stand, a contractor was thinning the largest and smallest trees by multi-stem harvesting

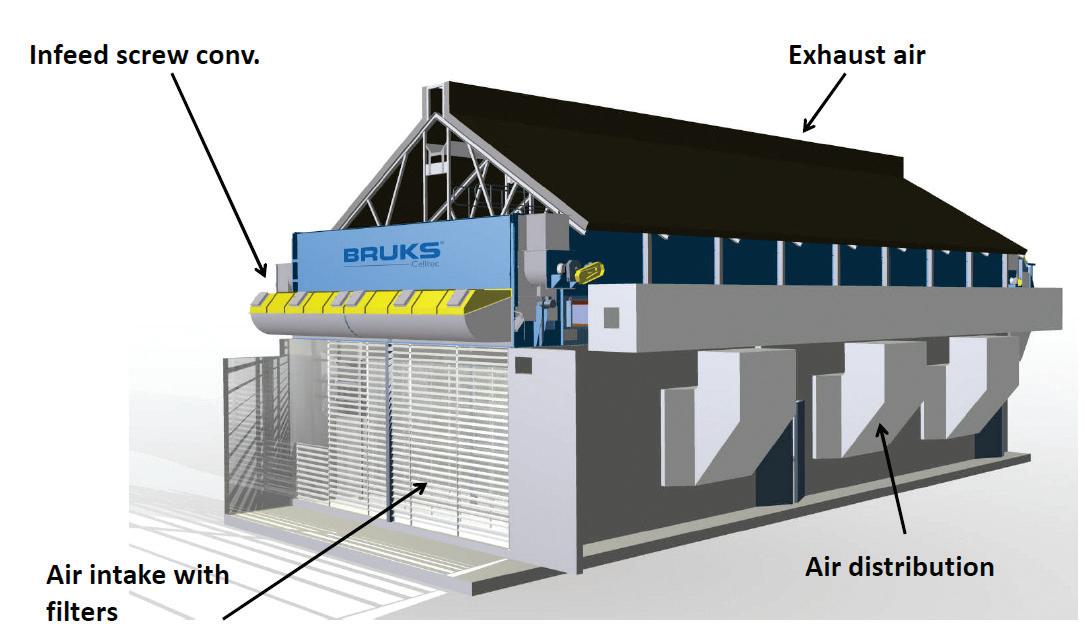

using a Log Max 4000 harvesting head on an Eco Log harvester. The roundwood was cut to length and sorted into pulpwood and energy wood for trucking to end-users, leaving the tops and branches to be collected and processed using methods such as chipping, bundling, or forwarding. In this case, a Ponsse 14-tonne forwarder with variable load space was collecting and transporting slash to small piles, to be covered by waterproof paper for six to nine months for drying. A Bruks mobile chipper completed the process, moving to the slash piles, chipping, and transporting the chips to a larger container at roadside, ready for delivery to a heat or CHP plant.•

trade show portion of World Bioenergy involved over 200 exhibitors from 19 countries, showcasing the latest upgrades in gear, gadgets, and services, as well as some of the older standards. Here’s a selection of items that were drawing interest from visitors.

Why are British Columbia power producers being given special access to biomass, but other biomass users are not?

eliable fibre supply is the most important factor in any biomass operation, whether the fibre is used for combustion or further fashioning into value-added products. When British Columbia’s provincial government announced that it would be making some bioenergy tenures and licences available for the power sector, other biomass users were stunned. They’re uncertain how this move will affect their businesses and their access to the fibre they need.

A mountain pine beetle infestation is killing many of British Columbia’s pine trees, and their quality and harvestability are deteriorating over time. Naturally, the provincial government does not want the trees to be wasted. With help from BC Hydro, the province is turning the beetle-killed timber into clean energy to power the grid. This solution was introduced through the BC Bioenergy Strategy, an important element of the BC Energy Plan, which was implemented in 2007 to reduce the province’s carbon footprint.

In the midst of these plans, other important industries seem inexplicably to have been forgotten. The wood pellet industry, in particular, has limited access to government-controlled timber under the province’s tenure allocation system, but had hoped to use the beetle-killed fibre as feedstock for pellet production. However, under the Bioenergy Strategy, the fibre will only be allocated to those who will use it to create energy to sell to BC Hydro. The unsettling thing is that there has been little explanation for this, leaving Gordon Murray, executive director of the Wood Pellet Association of Canada (WPAC), wondering why the wood pellet

industry has been overlooked.

“All of our producers have put millions of dollars out building these new [pellet] plants, and we’re relying on that mountain pine beetle killed timber. Without consulting us, the government has decided that this timber should be made available for power production for BC Hydro,” he says.

Murray says that a provision in British Columbia’s Forest Act allows the government to award timber directly to those with a bioenergy licence. The pellet producers are excluded from this, and no one knows why.

“On the surface, it seems very unfair,” he says.

He explains that the Ministry of Forests and Range and WPAC have a good working relationship, noting that the Honourable Pat Bell, minister of forests and range, has been a good friend to the WPAC. But in their few brief conversations, Murray hasn’t been given many answers. He was told that, in evaluating proposals from the power companies, the government will not approve any proposal that will interfere with existing manufacturing operations such as pellet plants. While the WPAC is happy to hear this, it’s not quite enough to satisfy them.

“We’ve had no proof of that yet; we need some stronger assurance. We think we should at least be on an equal footing with those power companies,” he says.

After several unsuccessful attempts to contact Minister Bell, Canadian Biomass was able to get a few statements via e-mail from Cheekwan Ho, a ministry spokesperson. With regards to the actions the provincial government is taking to avoid hurting the existing industries, Ho said, “The interests of existing industries are being protected wherever possible. For example, BC Hydro’s Phase II Bioenergy Call will focus where bioenergy fibre is most widely available, and there is little or no competition with existing pulp mills and OSB (oriented strand board) plants.” However, regarding the location of power plants and whether that will hinder or support existing biomass users, Ho says, “BC Hydro is seeking financially, technically, and operationally viable proposals from proponents capable of costeffective, reliable, long-term supplies of biomass electricity from ‘greenfield’ projects. Determining the location of the proposed plant is the responsibility of the project proponent.”

Quite confusing, however, was the response received when questioned why the pellet industry is not on an equal footing with power generators and district heating sectors when it comes to receiving biomass. Ho did not directly answer the question, but stated:

“We’re committed to a healthy and sustainable bioenergy industry for British Columbia. This means all aspects of

bioenergy – including wood pellets and district heating. B.C.’s pellet industry [is] a productive and quickly growing industry. British Columbia produced about one million tons of pellets in 2009 and is on track to produce about 1.1 million tons in 2010. Practically non-existent a decade ago, it now contributes about $185 million annually to the provincial economy.”

These facts are great, but without any straight answers from the government,

future options for the wood pellet industry in British Columbia are uncertain. Murray is worried about the investments made in an industry that’s having fibre taken from its basket.

“Somebody has determined that power has a higher value than any other use of biomass,” Murray says. Besides generating power from the damaged fibre, pulp chips and pellets can be made from it. Although he can’t speak for pulp and paper companies, he’s fairly certain they

want access to the fibre as well.

“We [wood pellet producers] rely on sawdust and planer shavings from the sawmills as well as harvest residuals and waste for our fibre. The pulp mills rely on the sawmills because they make wood chips,” Murray says. “It all comes full circle. We all need each other, and there should be a way to work the power producers in as well. You don’t want to be sacrificing one industry to promote another. Naturally, we’re concerned.” •

SEPTEMBER 7-8, 2010 • Pellets Industry Forum Stuttgart, Germany www.pelletsforum.de/industryforum/?L=1

SEPTEMBER 12-16, 2010 • World Energy Congress Montreal, QC www.wecmontreal2010.ca

SEPTEMBER 16-17, 2010 • Biomass Boiler Workshop Minneapolis, MN www.jansenboiler.com/workshops.html

SEPTEMBER 26-29, 2010 • International Bioenergy Days Rockford, IL www.bioenergydays2010.com/about.php

SEPTEMBER 30–OCTOBER 1, 2010 • CanBio Annual National Bioenergy Conference, Trade Show & Exhibition Vancouver, BC www.canbio.ca

SEPTEMBER 30–OCTOBER 1, 2010 • Bioenergy Markets Turkey Istanbul, Turkey www2.greenpowerconferences. co.uk/v8-12/Prospectus/Index. php?sEventCode=BF1006TR

OCTOBER 7-10, 2010 • RENEXPO Augsburg, Germany www.renexpo.de/index.php?id=7&L=1

OCTOBER 12-13, 2010 • Biomass to Fuels Summit Portland, OR www.biomassfuelssummit.com

n late June 2010, the Canadian federal government announced plans to phase out older coal-fired power plants to cut the country’s greenhouse gas (GHG) emissions. Draft regulations are expected in early 2011, with final regulations in effect July 1, 2015. “When each coal-burning unit reaches the end of its economic life, it will have to meet the new standards or close down,” said Environment Minister Jim Prentice

As proposed, the plants will have to meet the emissions standards of highefficiency natural gas electricity genera-

this could grow to 80 million tonnes by 2020. An estimated 66% of the EU’s renewable energy is from biomass. This success is largely due to aggressive policy initiatives at the EU level and by individual member states.

In 1997, the EU set a target of 12% of energy consumption from renewable sources by 2010. In 2001, it enacted a directive requiring all member states to adopt national targets for renewable energy. Co-firing increased significantly, with annual growth rates of 20% in 2002, 13% in 2003, and 25% in 2004.

“An estimated 66% of the EU’s renewable energy is from biomass. This success is largely due to aggressive policy initiatives.”

tion. The regulations are expected to spur conversion to more natural gas power. But why switch from coal to natural gas, another fossil fuel, decades from now when a better solution is available today?

Co-firing of coal with wood pellets can reduce GHG emissions by 91% compared to burning coal alone, according to a recent Ontario study. So, the Wood Pellet Association of Canada (WPAC) is urging immediate action on reducing emissions from existing coal power plants by implementing co-firing, as has been done in Europe for more than a decade.

The European Union (EU) accounts for 80% of global wood pellet consumption, at about 8 million tonnes/year. The European Biomass Association estimates that

In 2005, the European Commission published its Biomass Action Plan, with a main objective of doubling the share of biomass energy from 4% to 8% by 2010. The European Emission Trading Scheme was also implemented, requiring large CO2 emitters to monitor and report CO2 emissions annually and return an equivalent amount of emission allowances to the government each year.

In 2009, the EU enacted a new directive with mandatory targets of 20% renewable energy, 20% reduction in GHG emissions, and 20% improvement in energy efficiency by 2020. The directive includes ambitious individual targets for member states, and fines for those not meeting their targets. Each state must submit a national biomass action plan by June 30, 2010.

Many EU countries use feed-in tariffs to promote electricity generation from renewable sources. Some use green certificates, based on the principle of imposing mini-

mum shares of renewable electricity on consumers, suppliers, or producers. Compared to feed-in tariffs, green certificates are market oriented, based on the supply and demand of certificates. Electricity producers receive revenue from certificates in addition to the sale of electricity.

Today, more than 100 European power plants co-fire. In contrast, Canada consumes about 1% of the amount of wood pellets consumed by Europe, and none of our coal power plants co-fire. Canada is one of the world’s largest GHG emitters. Our coal-fired electricity generation units produce 19% of our electricity and 13% of our total GHG emissions. According to the Conference Board of Canada, we rank second-to-last out of 17 OECD countries for per-capita GHG emissions. In 2005, Canada’s GHG emissions were 22.6 tonnes per capita, almost double the 17-country average of 12.4 tonnes per capita, and almost four times greater than Norway’s, the top performer. Given Europe’s success and our own poor record, we should be looking to the EU’s experience for ideas as we develop new Canadian policy.

The federal government has made a good start by announcing plans for regulating coal-fired power plants. WPAC met with senior Environment Canada officials in Ottawa on July 7 to present evidence of the benefits of co-firing and to urge officials to provide for co-firing in the new regulations. If Canada co-fired at a rate of just 10%, we would replace 6 million tonnes of our annual coal consumption, eliminate 2 million tonnes of GHG emissions and other poisons, and quadruple the Canadian wood pellet industry. •

A

forward-thinking group in Ontario wants to establish a sustainable combined heat and power system in the province based on a profitable northern European model of district energy.

The Green Timiskaming Development Co-operative consists of municipal, First Nations, business, financial, and individual members promoting a district energy industry similar to that in Europe. The combined heat and power (CHP) system would comprise a plant where biomass is burned to generate electricity and heat, plus distribution networks of insulated underground pipes to circulate hot water to local buildings for space heating and domestic hot water. Such an industry could employ more than 50,000 people province-wide after a short five- to seven-year growth period, making Ontario less dependent on imported, fossil energy.

On March 2, 2010, Green Timiskaming met with, among other interested parties, the Ontario Sustainable Energy Association; the Ministry of Northern Development, Mines, and Forestry; and the Ministry of Energy and Infrastructure. The group toured machinery and mining fabrication plants in northeastern Ontario whose fuel-handling processes and high-temperature furnaces may be adaptable for district energy production.

The first step, says Ambrose Raftis, chair of the co-operative, is to convince the provincial government to adopt existing European operation and registration standards, which are much more advanced and comprehensive than North American standards. On June 15, the group briefed Ministry of Consumer Services officials, who are responsible for the Technical Standards and Safety Authority, on the disparity in standards. The Ministry promised to bring the Ministry of Energy and Infrastructure into the discussion.

Wholesale adoption of European standards will clear the way for a biomass demonstration project the group plans to develop. It’s a community-wide CHP energy system for a town of about 1,200 in northern Ontario that’s yet to be chosen. Green Timiskaming is in the process of signing a letter of intent to partner with Swedish companies Vision Power EU and Jarnforsen Energy Systems AB to create the system. Raftis says that this system will demonstrate more accurately than could Ontario Power Authority figures based on outdated standards that CHP’s return on investment makes it competitive with other forms of energy such as solar and wind.

Although movement on the initiative is slow, at least one obstacle has been cleared. Members initially calculated that they had 60–70% of the biomass needed for the demo (20,000 tonnes/ year). However, they are convinced they’ll have an ample supply, having since learned that thousands of hectares of “bypass wood” – lower quality wood left behind – exist in the Timiskaming region alone.

“CHP could displace about $850 million worth of imported natural gas, the equivalent of having 20,000 new people working in northern Ontario,” suggests Raftis. “There’s no reason that district heating couldn’t be as big as or bigger than forestry or mining.”

Raftis hopes to have overcome the initial hurdles by the end of the year, including prerequisites, standards, rate changes with the Ontario Power Authority, and better clarification of grid access by communities.

– Colleen Cross

Pacific Bioenergy’s Wayne Young has a simple analogy to explain what’s going on at the company’s pellet plant in Prince George, British Columbia. “It’s as if a bakery was designed to bake bread from processed flour, and all of a sudden, wheat started showing up at the door. We need to be able to turn that wheat into our own flour without slowing down production. We’ve been designed to run on sawdust and shavings, and in the past few years have had to deal with raw fibre. A large part of this expansion is to improve our flexibility up front to accept a broader range of raw materials without sacrificing throughput.”

Indeed, the investment does just that. It also doubles the

plant’s capacity. Built on this site at the edge of town in 2007, the expanded plant will go from shipping seven railcars of pellets out of its CN Rail spur each day to filling fourteen. Canadian Biomass had the chance to take a quick look at the project in progress while in Prince George for a Wood Pellet Association of Canada board meeting and the 2010 International Bioenergy conference and saw firsthand what the expanded plant will look like. Some of the changes take it down new avenues in key areas of biomass processing, drying, material handling, air quality, and safety.

Raw material handling: The large pile of “bush grind” on site confirms what Pacific Bioenergy is struggling with for raw mate-

rial. As the percentage of larger, wetter fibre coming from horizontal grinders in the woods increases, the plant will be prepared to handle it without flinching. Changes start with plans to pave the entire raw material storage area and continue through a massive Brunette Industries “BioSizer” hog, through secondary processing to the dryers, and then into five surge bins ahead of the new pellet mills. The plant already runs an electric Bandit Beast horizontal grinder for processing bush grind into finer material. Like a good sawmill, this new plant is all about uptime.

Drying: Pacific Bioenergy is moving from the conventional triple-pass dryers it uses to feed the original mills to a pair of massive 100 million BTU Solagen single-pass dryers. The expectation is that this technology will better handle the mixed feedstock supply and its varying moisture contents.

Handling: Rather than individual cooling towers out of each pellet mill, which is the case with the current five mills, the new bank of five Andritz pellet mills will feed a single Law-Marot MilPro cooler. Material handling in the new line is by Continental Conveyor vibrating and regular conveyors.

Air quality: The plant is located in a key airshed, so emissions are a concern. The expansion includes a wet electrostatic precipitator from Texas-based PPC Industries. The massive structure arrives in components that bolt together like a modern Meccano set.

Safety: This is not exactly new to Pacific Bioenergy, which is known for leading the safety charge in the pellet sector. The existing plant has Grecon and Flamex systems to manage both heat and sparks, and the expansion will include similar technology. “We’re aiming to be the poster boy for the insurance providers,” says general manager Tim Knoop.

The $24-million expansion was announced in February 2010 as part of a strategic partnership between Pacific Bioenergy Corp. and GDF Suez, a massive energy provider with 200,000 employees. GDF Suez has a minority interest in the Prince George plant and will buy 2.5 million tonnes of pellets over the next 10 years. This will guarantee a market for a large part of the plant’s expected 350,000 tonne/year capacity. At the time of the visit, the project was both on time and on budget. Look to a future issue of Canadian Biomass for a full report once the expansion starts up.

– Scott Jamieson