MODERN HYDRONICS FALL 2019

DEALING WITH THE PRODUCTS OF COMBUSTION

F ORWARD THINKING PROS USE CEILING RADIANT

CHOOSE WISELY: FACTORS TO BE CONSIDERED WHEN SPECIFYING BOILERS

DEALING WITH THE PRODUCTS OF COMBUSTION

F ORWARD THINKING PROS USE CEILING RADIANT

CHOOSE WISELY: FACTORS TO BE CONSIDERED WHEN SPECIFYING BOILERS

ALSO IN THIS ISSUE:

IOT PERMEATES THE MARKET

HYDRONIC MARKET NICHE POISED FOR GROWTH

TIPS FOR BOILER RETROFITS

HYDRONIC PRODUCT SHOWCASE

Your customers demand it.

The NEW Vitotrans 300 provides it!

Commercial high-output DHW heating station

The new Vitotrans 300 is a compact, pre-assembled and self-contained DHW heating station, designed to provide large volumes of on-demand hot water to commercial and industrial applications.

Powerful. Cost Effective. No Downtime.

Works seamlessly with any new or existing hydronic heat source to provide a reliable and consistent supply of endless hot water at flow rates of up to 180 GPM.

Eliminates the need for dedicated DHW heating boilers, batteries of direct or indirect-fired DHW tanks, or cascades of tankless water heaters for maximum cost savings.

Multi-heat exchanger design provides built-in redundancy and eliminates costly downtime during service and maintenance.

MH4 GUEST EDITORIAL

Think ahead…

Hydronic system designers need to think carefully what their systems will look like 25 years, or perhaps 50 years from now.

BY JOHN SIEGENTHALER

MH7 VENTING

Dealing with the products of combustion: Part 1

Look closely at a project’s unique venting requirements to avoid venting woes.

BY ROBERT WATERS

MH14 BOILERS

What factors should be considered when specifying boilers

The smallest design details may have the greatest impact on a boiler’s value and performance over time, so choose wisely.

BY JOHN MILLER

MH16 ENERGY EFFICIENCY

Benefits similar to a new system

Tips on major retrofit options available to minimize energy loss and maximize fuel savings.

BY RAKESH ZALA

EDITOR

ASSISTANT EDITOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

ACCOUNT COORDINATOR

ART DIRECTOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

COO

Kerry Turner (416) 510-5218 KTurner@hpacmag.com

Jillian Morgan

David Skene (416) 510-6884 DSkene@hpacmag.com

Vince Naccarato (416) 510-5118 VNaccarato@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Brooke Shaw

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbizmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Tim Dimopoulos

Scott Jamieson

MH26 NEW TECHNOLOGY

Embracing the inevitable IoT has permeated the market and contractors have no choice but to get on board.

BY CURTIS BENNETT

MH30 CEILING RADIANT

The forgotten solution

Forward thinking and creative professionals use ceiling radiant as a supplement or as the primary radiant source.

BY STEVE GIBBS

MH34 HEAT EMITTERS

Have you considered panel radiators?

This hydronic market niche is poised for growth in North America.

BY JOHN SIEGENTHALER

Hydronic system designers need to think carefully about what their systems will look like 25 years, or perhaps 50 years from now.

BY JOHN SIEGENTHALER

Although I have worked with hydronic heating for four decades and designed systems around just about every possible heat source, I would be hard pressed to predict what might be available as hydronic heat sources 25 years from now. Fifty years from now I doubt that I will be predicting anything, and yet, hydronic heating, in some form, will hopefully still exist. If comfort, efficiency, and lasting value, rather than first cost, become established as the market “drivers” hydronics might even be the dominant method of heat delivery. Imagine that.

By the latter half of the 20th century, the North American hydronics industry got used to the fact that some hydronic heat sources could last for several decades. It was not uncommon for a well-applied cast-iron boiler to have a useful life of 30 to 40 years. These boilers usually became technologically obsolete before they were incapable of operating due to some major failure. This was just fine when fuel prices were reasonably cheap and stable, and product development occurred at a somewhat slower pace compared to today. Back then, most North Americans cared little about the “box in the basement,” provided it responded when the dial on the T-86 got turned up in the fall.

Today, some fuel costs are approaching 400 per cent of what

they were 15 years ago. Predictably, more consumers are interested in what’s happening within that box in the basement. Our industry has responded with a wide spectrum of heat sources from boilers, to heat pumps, to solar collectors. Still, you won’t find many manufacturers, who, in all candor, will tell you these contemporary heat sources are likely to last over 20 years.

In contrast, a well-designed, correctly installed, and properly maintained hydronic distribution system can last for many decades, potentially even longer than the building it is installed in.

So, based on these differences in expected life, it appears likely that most of the hydronic distribution systems currently being installed will be supplied by different heat sources over their useful life. This raises an obvious question: What can designers do today to ensure that the distribution systems they create are compatible with future heat sources?

The answer should consider the materials used in the system, how the system will be maintained, and at what conditions will the system operate?

From the standpoint of materials, most of the present-day polymer tubes, when applied at temperatures and pressures well below their maximum ratings, should last upwards of 100 years. I have even heard speculation of 200-year lifetimes for PEX. To achieve such lives, these materials should be installed so that

they are not abraded due to expansion/ contraction movement. They should also be protected from ultraviolet light, and not exposed to hydrocarbon solvents. In my opinion oxygen barrier tubing should be used on all hydronic systems.

Copper and copper alloys such as brass should not be exposed to acids such as contained in residual soldering flux, or degraded glycol antifreeze. They should also not be exposed to water with high concentrations hydrogen sulfide. Flow velocities in copper tubing should be limited to four feet per second.

All piping circuits containing soldered copper or threaded iron or steel piping should be internally cleaned with proper hydronic detergents to remove residual solder flux and cutting oils that would otherwise remain in the system, potentially causing corrosion or impaired thermal performance due to fouled heat transfer surfaces. Systems should be operated with demineralized water. When glycol-based antifreeze is used it should be tested annually to verify a pH between 7.5 and 8.0.

Magnetic particle separation should be used to gather up iron oxide and allow it to be periodically flushed from the system. This is especially important for the new generation of circulators using permanent magnet motors.

From the standpoint of design, the concept can be summarized with three words: low water temperature.

The one prediction that I am willing to make about future hydronic heat sources is that they will operate best at low water temperatures.

So, when you size up radiant panels, panel radiators, and even fin-tube baseboard, I recommend that you design all you hydronic heating systems so that they can supply design load conditions using water no warmer than 120F (about 49C). Even lower

supply water temperatures are preferred when possible and practical. This allows those distribution systems to be compatible with a wide range of contemporary hydronic heat sources.

I urge those who design hydronic systems to think carefully what your systems will look like 25 years, or perhaps 50 years from now.

Will those who install the next heat source in these systems see that you considered the long lifespan of a well-planned and easily maintained distribution system, or will they find it necessary to “shoe horn” in supplemental heat emitters?

Will the controls that operate this system still work, or will they add to the growing tonnage of electronic waste that we are already producing?

Are your present distribution system designs truly “sustainable,” or will they succumb to a “tear out and replace” by the

next generation of hydronic pros? Do what you can now to “future proof” the hydronic distributions systems you create. Those who follow will appreciate your forethought. <>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has more than 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

• See the newest hydronic products

• Take part in a variety of seminars delivered by your favourite HPAC writers on the hottest hydronic trends

• Enjoy lunch, dinner and drinks

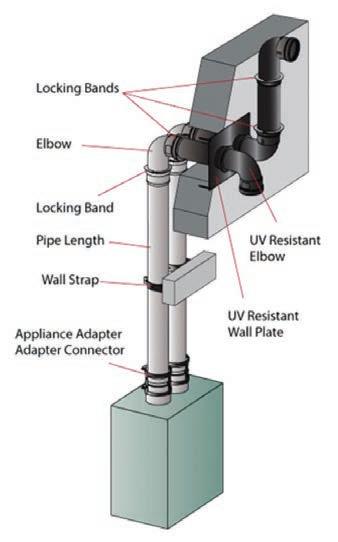

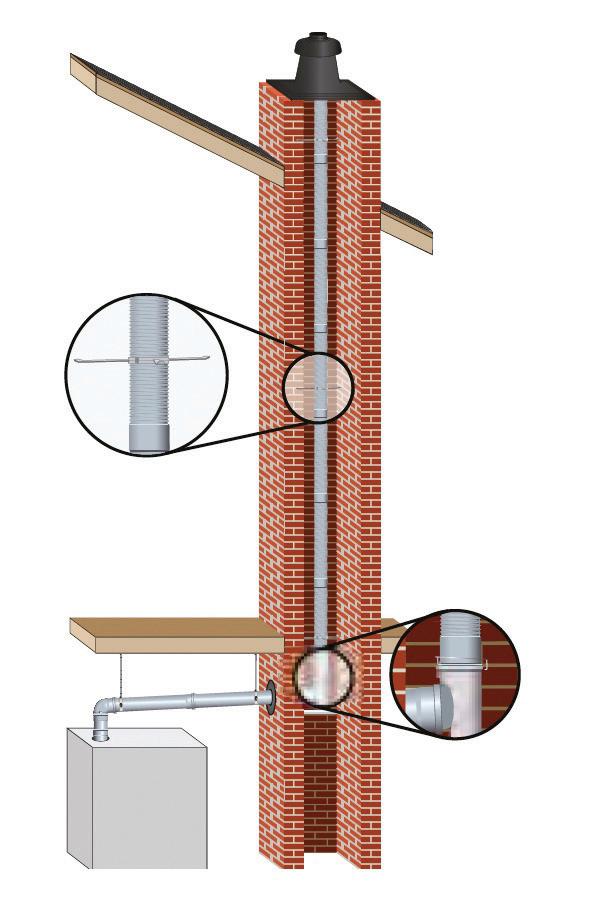

Look closely at project’s unique venting requirements to avoid venting woes.

ROBERT WATERS

Contractors who install gas-fired condensing boilers know that dealing with the products of combustion is a big challenge when installing these appliances. Flue gases exiting the appliance are laden with moisture, and liquid condensing from the combustion chamber and vent pipe is acidic and corrosive.

Dealing with this low temperature flue gas and liquid condensate must be done properly to avoid damages to the building and the appliance, costly call backs and angry customers. This is especially true when retrofitting new modern condensing appliances into old buildings, where contractors face challenging building and lot restrictions, and difficulty accessing drainage.

Part 1 of this article will look at the issues and solutions for dealing with venting of flue gas from condensing appliances. Part 2 in HPAC October will look at disposing of liquid condensate.

Condensing furnaces, water heaters and boilers have been gaining market share steadily over the last 15 years. Recent changes to the federal energy efficiency standards mean that the push to condensing products is going to get even stronger.

NRCan Amendment 15 was published in the Canada Gazette, Part II on June 3, 2019 and introduces higher minimum efficiency regulations for a wide range of HVAC products.

Condensing level regulations have been introduced for gas boilers and certain sizes and types of gas water heaters. For gas-fired boilers, all products must be condensing (>90 per cent) by 2023 for residential (<300 MBH), and 2025 for commercial (>300 MBH). Gas-fired instantaneous water heaters are also all going to condensing levels in 2020.

Approximately 75 per cent of the new residential gas boilers currently sold in Canada are already at or above this efficiency level so the issues of dealing with flue gas and condensate are not new to the industry. However, now with these new regulations in place, all installations must go with condensing

boilers and contractors will no longer have the option to install non-condensing. Many existing buildings that currently use non-condensing boilers will have to be upgraded to condensing boilers when it is time for replacement of the old unit. In some cases, this will result in very challenging retrofits.

Over the last 15 years many lessons have been learned related to dealing with the products of combustion from condensing appliances. Venting products and techniques have been introduced to provide solutions for new heating technology. Consultations with many experts in the venting field has shown me this is an area where the good, the bad and the ugly certainly applies. Currently industry veterans that have been at it for many years see many issues going on now with installations.

The most common venting materials used for condensing boilers are PVC and CPVC pipe, polypropylene pipe and stainless steel with the latter two materials both available in rigid and flexible pipes. All of these products have different temperature ratings, and long-term safety must be considered when choosing. What happens if the boiler set point temperature is turned up to the maximum, or the boiler heat exchanger scales up over time? Both of these conditions can cause the flue gas

temperature to go higher than what would normally be expected. Will the vent material safely stand up to these conditions? Vent pipe operating above its rated temperature may become compromised over time and create unsafe situations.

All of these venting materials have pros and cons and it is usually up to the individual contractor to choose which product they prefer and which is best suited for the application. The installer must consult the appliance manufacturer’s installation manual to check what venting is approved for the specific appliance. For commercial buildings, the combustible (plastic) vent piping must meet all Part 3 requirements of the Ontario or National Building Code, especially related to Flame/Smoke Ratings and firestop requirements. Installation problems can occur with any material if the manufacturer’s installation guidelines are not followed properly.

Contractors must carefully follow all the guidelines related to making fitting connections, pipe support requirements, wall and roof penetrations and terminations, etc. The reality in some projects is that sometimes not a lot of thought is put into the choice of vent product. Whatever is the cheapest, whatever is readily available at the distributor and whatever is fastest and easiest in terms of installation are sometimes determining factors. This does not always lead to the best longterm results for the customer.

PVC vent pipe is generally the most commonly used product due to its lower cost and wide availability, however it is only rated up to 65C/149F and can only be used for certain appliances. CPVC is rated up to 90C/194F which makes it suitable for a wider range of products, but it carries a higher price tag.

PVC/CPVC pipe and fittings are very rugged Schedule 40 thickness and provide excellent beam strength, durability and resistance to puncture. PVC/CPVC

both rely on solvent welded joints which provides a very permanent and reliable connection.

Problems can occur when care is not taken with the installation, especially if the wrong solvent is used or if the solvent welding procedure is not followed. Joints cannot be taken apart once welded, and in cold weather, joints must be primed prior to gluing below 0C.

Polypropylene venting material is rated up to 110C/230F and is gaining favour with some due to its higher temperature rating, ease of use, lighter weight, versatility and fast installation time. The connection joints use a gasketed male-female connection that require the use of a locking band after the fitting has been installed. Problems can occur if the bands are not used or installed improperly. If the pipe is sloped incorrectly then it is possible for the joints to leak. One industry veteran told me he no longer uses CPVC as the gluing of joints can be messy and he likes polypropylene as it is fast and easy to work with and uses simple non-glued joints. Stainless steel venting offers the

highest temperature rating of up to 249C/480F, and also uses a gasket connection on rigid pipe. Flexible pipe for relining chimneys is available in both polypropylene and stainless steel, with stainless steel being the most popular. Care must be taken when cutting any plastic pipe to length. The pipe end must be cut as square as possible to provide the best seal with the fitting. A wheel cutter is recommended for use on CPVC rigid pipe, but these cutters do create a raised edge on the pipe end, which must be removed with a reamer.

If a blade or chop saw is used on any pipe, the pipe end must be completely de-burred inside and out, and the end may need to be bevelled on the outside. Failure to do this can create problems with a glued fitting or damage the gasket on a polypropylene fitting.

Side wall venting has become the most common method of venting condensing appliances, to the point where everyone just thinks “that’s the only way it’s done now right?” The reality is that this is the area where most venting

Continued on MH10

problems and issues occur. Flue gas exiting at the side of the building close to the ground comes in contact with walls, windows, driveways, swirling winds, plants and sometimes people. This can create issues with large visible plumes of moist flue gas, damage to the façade, angry neighbours, dead plants, ice formations and flue gas recirculation.

The issue is exacerbated by how little space is between houses in new subdivisions, and the fact architects love open plans and make no allowances for vertical venting. The issue has become severe enough that municipalities in Alberta and BC are starting to put restrictions on side wall venting of appliances. Minimum distances have been increased and redirecting of the vent plume must be addressed.

One of the most serious side wall venting issues in relation to the appliance itself is flue gas recirculation. This is where flue gases are drawn back into the combustion air inlet pipe then re-enter the appliance. Flue gas recirculation is usually caused by problems with the location of the vent terminal. Swirling wind can whirlpool flue gas, causing it to have a tumbling effect and hang close to the ground.

It is important to recognize and avoid vent terminations that are too close together, located in building corners or with unusual wind patterns. Recirculated flue gas can be very damaging to the appliance and can eat away components such as the inlet venturi and radial fan bearings.

Recirculation often results in very poor combustion, high CO levels and unsafe conditions. Intermittent burner lockouts will often result due to this recirculation and they can be hard to diagnose. By the time the technician gets in to service the appliance, the wind may have dropped and the appliance can be running fine again.

Frost and ice formation is the other major issue with side wall venting. Ice and frost can form on the walls, windows and landscaping near the vent terminal. When the vent terminates in the space between two buildings ice and frost can form on the walls and windows of the adjacent buildings. Ice that

builds up on driveways and sidewalks creates very unsafe conditions. These ice and frost issues are often very contentious issues with neighbours.

Icing issues can be made much worse when the venting is sloped incorrectly. Venting should always be sloped continuously back towards the appliance so it can be easily drained away inside the building. When the slope is in the wrong direction, condensate will run towards the outside of the building and drip out the vent pipe. This will result in large formations of ice at the terminal, and it is not uncommon to see huge icicles forming all the way to the ground.

Although not as common, frost can also build up on first 6 in. of the inlet air pipe of the appliance. This can sometimes build up to the point of a burner lock-out.

All the venting professionals I consulted advocate for vertical venting as being the best option for almost any situation. Vertical venting may not be the cheapest or easiest solution, but it can successfully make all of the problems listed earlier disappear. When flue gas is terminated up above the roof line, flue gas is dispersed into the atmosphere well above the level of people, plants and buildings.

Two pipe and concentric pipe options are available for vertical venting. Some contractors will use a hybrid approach with the vent exhaust pipe going vertical and the inlet air pipe coming horizontally from the side of the building.

When retrofitting an older building with an existing chimney, Continued on MH12

Save time and money by reducing install, startup and operating costs

Simplify startup and maintenance

Strengthen system performance and efficiency

Edge Controller and Mobile App

With advanced features such as EZ Setup and Combustion Calibration Assist, AERCO’s Edge Controller saves time and money with simplified startups and maintenance. Edge mobile app offers additional capabilities and enhanced diagnostics with freedom to move around while setting up and operating the unit. Together with AERtrim patented O2 trim, dual returns and onAER Predictive Maintenance, Benchmark Platinum optimizes your hydronic system and delivers the lowest cost of ownership.

flexible liners of polypropylene or stainless steel offer a reliable vertical venting solution. Flex venting can be run up existing masonry or B-vent chimneys. However according to one vent supplier, many contractors are not aware, or do not often consider this method as a venting option.

A service contractor in Toronto I spoke with says he sees too many instances where contractors don’t think about the neighbours when venting. He loves flexible chimney liners and refers to them as a “peacekeeper,” as it avoids any issues with sidewall venting and dealing with neighbours in tight retrofits.

I have heard many side wall venting horror stories involving driveways covered in ice, seven-foot long icicles, stucco and masonry walls severely damaged by water egress and freezethaw cycles, trees killed, appliances locking out and internally damaged, and neighbours almost coming to blows. After listening to these tales of venting woes, I believe that it is prudent for contractors to take a long hard look at the unique logistics of each job and inform their customers of their venting options, both horizontal and vertical. Most customers are not aware of the issues of sidewall venting, and are relying on the contractor to guide them to the best option for their building.

Dealing with the products of combustion from high efficiency equipment must be re-evaluated by everyone involved in the mechanical world. Architects and engineers must reconsider side wall venting and avoid open plans with no allowance for vertical venting.

Contractors often do not look closely enough at the project’s unique venting requirements and get caught underpricing the job. This is what leads to the quick, inexpensive venting job, and can end up leaving the building owners stuck with hefty façade or equipment repairs, angry neighbours, unsafe ice buildup, and unsightly flue gas plumes, and equipment lock-outs. We should all strive to make sure these things do not happen. <>

Robert Waters is president of Solar Water Services Inc., which provides training, education and support services to the hydronic industry. He has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com.

Copied by some, equaled by none.

• Number one condensing tankless water heater in North America

• ComfortFlow® exclusive built-in recirculation system with internal buffer tank and recirc pump

• Up to 0.96 UEF/0.97 EF Energy Star rating

• Leading commercial and residential warranties

• Cascade and common vent

• Proven easier to sell, easier to install with 2" PVC venting and 1/2" gas pipe capability

• Unparalleled technical support

• Endless hot water and endless advantages

The smallest design details may have the greatest impact on a boiler’s value and performance over time, so choose wisely.

BY JOHN MILLER

Whether for a single-family home, large-scale apartment complex, or commercial or industrial facility, building owners, facility managers, engineers and contractors seek boiler systems that meet specification requirements, installation ease, serviceability, reliability, lower operating costs and higher performance. Once these major parameters are met, buyers also should consider design details that may set one boiler apart from another.

The installation process can significantly impact the overall cost of any new boiler system. Look for a boiler with design features that aid in simplifying the installation process, thus saving time and money.

Boilers with a “door-fit” design are suited for applications that have limited access. Not having to tear out a wall or door frame can save thousands in installation expense. Likewise, boiler room floor space is always at a premium so zero clearance boiler designs where boilers can be placed side-by-side with minimal clearance is also desired. The key here is that the boiler still remains serviceable.

Sometimes getting a fork lift at the installation site is harder than one would think. Smart packaging and mobile design features that mitigate this need should be a purchase target. Integrated unloading ramps as part of the shipping container make the unpacking process quick and easy. Couple this feature with integrated roller casters and the boiler rolls on to the site and is easily positioned into place. If the boiler install includes a concrete pad, the shipping ramp can be used to move the boiler on to the pad as well.

For efficient operation with multiple boilers consider a control system that will fluidly connect different systems to work synchronously to ensure the highest level of performance and efficiency.

Having a correctly-leveled surface is a prerequisite to proper boiler operation and performance. Boiler designs with integrated leveling legs perfectly level the area. Simply position the boiler in place and adjust the leveling legs, which are very similar to the leveling legs on a household appliance but are industrial grade to support the weight of the boiler.

There are a variety of boiler controls on the market that offer varying setup processes and functionality, ranging from simple to complex. An integrated control system with a userfriendly setup wizard with intuitive controls will simplify the installation process for contractors.

Multiple pre-set systems are another popular boiler control feature. These units feature pre-set heating systems for typical operating conditions built into the controller so installers do not have to enter specific supply or return temperatures during installation, but rather a specific application, which reduces installation costs and time while increasing reliability.

Simple, user-friendly controls are essential for efficient boiler operation long after setup is complete. Whether managing a single boiler or multiple boilers, contractors must understand how to leverage system features to optimize performance.

In a multiple boiler system, user controls will manage multiple units to deliver the desired heat and adapt accordingly as the environment changes. For variable primary flow and hybrid boiler system applications, specifically, it is important for user controls to offer configurability between different products and technology. If one boiler in a system goes down, the unified controls will communicate across the units and vary output to adjust for the loss.

With a straightforward interface and simple navigation, contractors should seek controls that provide at-a-glance boiler status, diagnostics, troubleshooting and integration with building automation systems. The right control system will fluidly connect different boilers to work synchronously and ensure the highest level of performance and efficiency. Similarly, when expanding a boiler system, controls that maximize energy across all boilers on a system reduces energy costs.

Boilers must be well-maintained for their benefits to be fully optimized, and the design of a boiler can have a significant impact on its serviceability over time. Proper inspection and regular native maintenance are vital to ensure uninterrupted, reliable and safe boiler operation. Therefore, contractors will appreciate boilers designed to make annual servicing easier. Tasks such as cleaning heat exchangers, replacing worn out

“Boilers must be wellmaintained for their benefits to be fully optimized…”

components, adjusting air fuel mixture, adjusting combustion controls, and maintaining water PH balance will improve boiler efficiency and reduce costly failures, while extending the lifecycle of the unit. Easy access to boiler components will make it easier for contractors to complete these and other critical maintenance activities that support a high-performing unit.

Something as simple as selecting a boiler with features designed to simplify service can make the inspection and regular wash down process easier. In addition, consider a design with a serviceable condensate tray that collects condensation during combustion. A boiler designed with a replaceable condensate tray allows for a vulnerable part of the unit to be swapped out quickly and efficiently before an expensive impact to the entire heat exchanger occurs. This improves the longevity of the boiler and reduces maintenance costs considerably.

Commercial-sized boilers are rated according to thermal efficiency, which is the measurement of output heat from the boiler that is transferred into the overall heating system. Higher efficiency boilers offer the most by reducing annual fuel consumption and capturing energy cost savings. Opting for a higher-efficiency boiler will result in significant fuel savings for customers, particularly when replacing an older system with a much lower efficiency rating – such as upgrading from 80 per cent thermal efficiency design to 95 per cent or higher.

Boilers can account for about 55 per cent of annual energy bills, and building owners with high-efficiency boiler systems often report energy cost savings up to 25 per cent or more on heating expenses. In addition, many jurisdictions offer efficiency rebates for installing high efficiency boiler systems.

With more boilers on the market offering similar functionality and performance metrics, it can be difficult to differentiate which design is the best for each application. All the particulars that impact a boiler’s installation including usability, serviceability and efficiency can set the superior unit apart from the rest of the field, showcasing a design developed specifically with contractors’ needs in mind. <>

John Miller is the commercial boiler senior product manager with Weil-McLain.

Tips on options available to minimize energy loss and maximize fuel savings.

BY RAKESH ZALA

One-third of a facility’s energy bill stems from the boiler room, and system inefficiency just adds to high energy costs. If replacing a boiler is not an option due to budget constraints, retrofitting an old boiler is one way to bring it nearly up to par with today’s new systems.

The main cause of energy inefficiency is system heat loss. The average level of efficiency for industrial boilers is only 75 per cent to 77 per cent. The first place to look for improvements is in the control system. The following control developments produce measurable efficiency increases and fuel-cost reductions.

1

Parallel Positioning – in the control system is a process using dedicated actuators for the fuel and air valves. Burners that incorporate parallel positioning can be set with lower excess air levels. Energy savings of up to five per cent may be realized.

2

O2 trim - an oxygen sensor/transmitter in the exhaust gas continuously senses oxygen content and provides a signal to the controller that “trims” the air damper and/or fuel valve, maintaining a consistent oxygen concentration. This minimizes excess air while optimizing the air-to-fuel ratio.

3

Variable speed drives - enable a motor to operate only at the speed needed at a given moment, rather than a constant 3600 RPM as a drive runs. This speed variance results in a reduc -

Instead of replacing the two nearly 30year old boilers at First Canadian Centre in Calgary, GWL Realty Advisors chose to replace the burners with high-efficiency ones and upgrade the controls to a PLCbased system with oxygen trim and parallel positioning.

tion in electrical energy consumption. A variable speed drive can be used on any motor but is most common on pumps and combustion air motors of greater than 5 HP. These drives also produce quieter operation and reduce maintenance costs by decreasing the stress on the impeller and bearings.

4

Lead lag – sequences the operation of multiple boilers, matching system load. Boilers operate at peak efficiency, reducingcycling and decreasing maintenance and downtime.

Incorporating heat recovery retrofits into the boiler system will please budget scrutinizers while improving energy efficiency.

1

Economizers – transfer energy from the boiler exhaust gas to the boiler feed water in the form of “sensible heat.” Sensible heat is created by the transfer of the heat energy of one body, in this case exhaust gas, to another, cooler body – the boiler feed water. This reduces the boiler exhaust temperature while preheating the boiler feed water. Economizers typically increase energy savings by 2.5 per cent to 4 per cent.

2

Two-stage condensing economizers – combine the functions of a standard non-condensing economizer and a condensing economizer. The first section of the economizer recovers energy by preheating boiler feed water. The second section recovers energy by preheating a cool liquid stream such as make-up water. Sensible and latent energy is captured from the flue gases that leave the boiler. Energy savings of up to 10 per cent may be realized, depending on design and operating conditions.

3

High turndown burner – Increasing burner turndown rate reduces on-off cycles. Each on-off cycle is followed by purge cycles where large volumes of room air pass through boiler, resulting in heat being blown out the stack.

4

Blowdown heat recovery – boilers must remove dissolved solids from the boiler to maintain water purity. Many boiler rooms route blowdown to a flash tank that allows safe discharge of the steam by reducing (flashing) the steam pressure in an enclosed tank. Lowpressure steam is vented from the tank and condensate is discharged to the drain. In many cases, these tanks are not insulated nor do they allow recovery of the lost heat. A blowdown heat recovery system transfers the blowdown steam energy to the boiler feed water, recuperating about 90 per cent of this energy. <>

Rakesh Zala is vice president, product engineering-packaged boiler systems for Cleaver-Brooks.

We could tell you about the numerous benefits of Aquatherm polypropylene pipe. How it’s lightweight, durable, and lasts about three times longer than steel pipe and even comes with a warranty. How it will never scale or corrode. How its properly performed heat-fusion connections will never leak. How it can handle any size commercial HVAC project. How Aquatherm brought PP pipe to North America in 2005, educated the industry, and remains the PP piping leader today with unparalleled products, service, and support.

Laars Mascot FT boilers and combination boiler/ water heaters feature an advanced fire tube heat exchanger. The FT’s modulating technology automatically adjusts fuel usage to match heat demand. The boilers are available in space-saving wall hung and floor standing models. www.laars.com

Turbomax instantaneous indirect water heater from Thermo 2000 is available from 26 US gal. to 119 US gal. Features include an ASME copper heat exchanger and ASME steel tank. The flow of boiler water is from the top of the tank to the bottom and the flow of fresh domestic water inside the copper coils is from the bottom of the heater to the top. The counterflow motion is intended to increase the efficiency of heat transfer. www.thermo2000.com

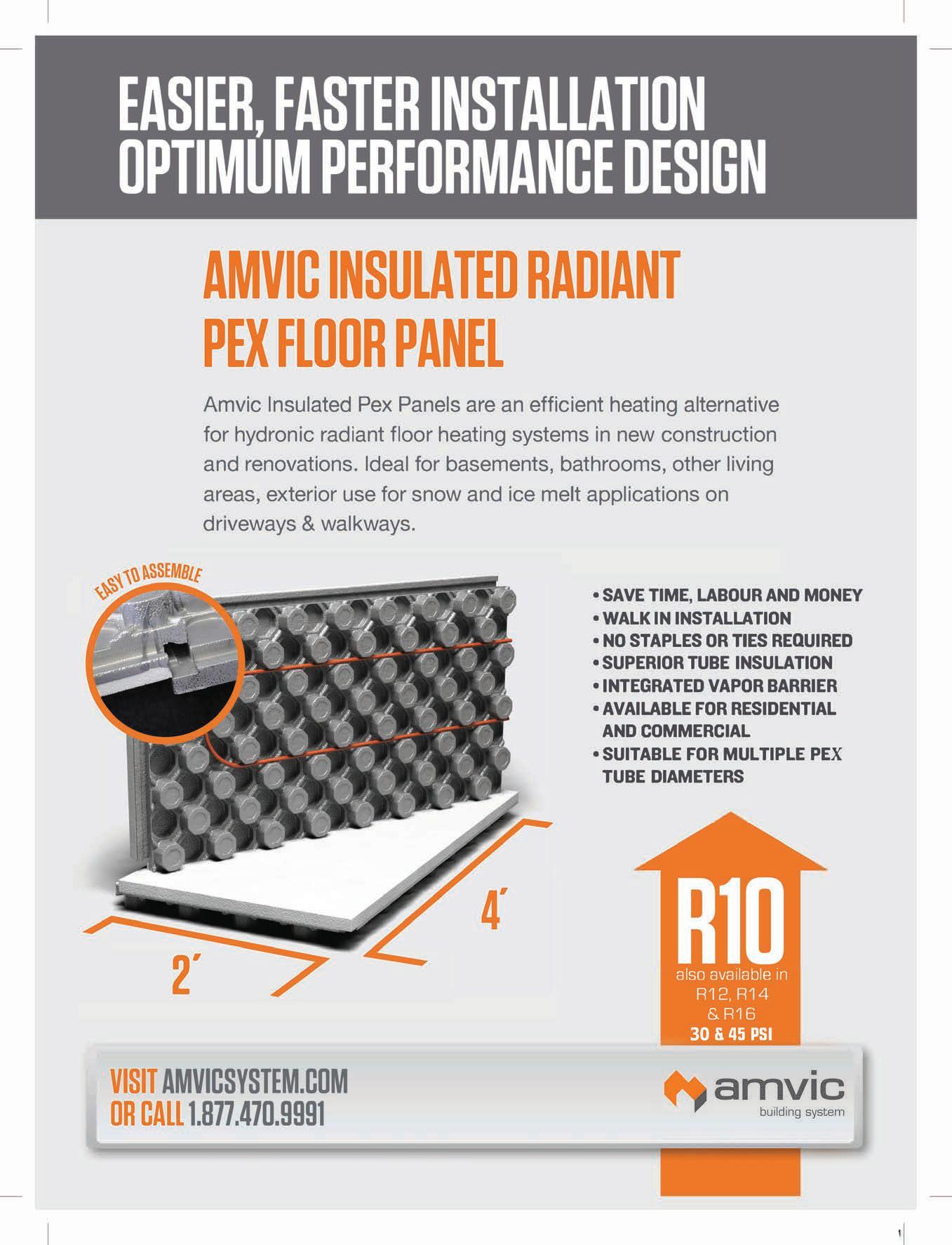

Nudura Hydrofoam high density expanded polystyrene (EPS) boards are designed to maximize radiant heat insulation for residential projects by ensuring the heat is dispersed evenly throughout the entire floor area. The 4 ft. x 4 ft. (1.2 m x 1.2 m) boards are 21 2 in. (64 mm) thick and are installed with an overlapping interlock on all four sides to ensure the boards are locked in place during installation. The boards utilize a 360° multi-directional friction fit anchor system in to which radiant heat piping is stepped into place in any direction required. The boards can be cut to meet any angle or radius while providing R-10 of insulation value. www.nudura.com

Weil-McLain has introduced the Evergreen, Ultra Series 4, and GV90+ cast iron gas boiler. The condensing boiler line is available in six sizes, ranging from 70 to 300 MBH. The Ultra Series 4 boilers are also available in six sizes, featuring a heat exchanger with nanotechnology coating. The GV90+ cast iron boiler line features a corrosion resistant stainless steel condensing secondary heat exchanger designed to recoup heat energy from exhaust. www.weil-mclain.com

The Grundfos TPE3 vertical In-line pump provides a range of intelligent functionalities. TPE3 has a built-in heat energy meter as well as flow limiting functions eliminating the need for a pump throttling valve. Smart control modes allow the pump to begin learning about the system’s pressure, temperature and flow characteristics the moment it is installed, using system conditions, preloaded data and your input to gradually optimize performance. As it learns, the TPE3 continuously collects and logs performance data. www.grundfos.com

Taco Comfort Solutions’ 0018e high-efficiency, Bluetooth-enabled circulator provides real time control, diagnostics and reporting, such as installation history, power consumption, performance and runtime. Installers can select between multiple constant speed, proportional pressure, and constant pressure modes as well as activeADAPT self-adjusting proportional pressure mode. The 0018e features 18 ft. maximum head with a maximum flow of 16 GPM. It is double insulated. www.tacocomfort.com

The Arctic heat pump integrates with multiple heating sources such as: radiant floor heating/cooling, central air handlers for forced air, split fan coils for individual room heating, low temperature radiators. The outdoor unit requires an electrical connection with an outdoor rated disconnect (weather proof). The system needs a 240 VAC connection with a 20, 30, 40 Amp dedicated breaker depending on the model. A backup heating circuit in the buffer tank can be automatically controlled from the heat pump itself. It will be given the signal from the cold weather heat pump only when the heat pump cannot keep up. www.arcticheatpumps.com

The Edge controller in Aerco’s Benchmark Platinum condensing boiler simplifies startups and maintenance, and strengthens system performance. Features, including AERtrim patented O2 trim technology, dual returns and onAER Predictive maintenance, are designed to result in the lowest cost of ownership. The Edge Mobile App for iOS and Android devices enables full unit control with enhanced diagnostics and configuration capabilities. www.aerco.com

95% AFUE, Wall Mounted, Modulating Condensing Boiler with “THINK Intelligence Within”.

Combustion

The THINK combustion management system continuously monitors the gas and air mix and adapts its output to e ciently suit requirements.

Webstone, a brand of NIBCO, has released a new magnetic boiler filter. Designed to protect system components and maintain efficiency, the 12,000 Gauss magnet captures ferrous debris from the system before it reaches the boiler. G1 union connections, with choice of Press, FIP, MIP, or SWT, join to system piping. A service tool is included and optional isolation valves are available on G1 unions. www.webstonevalves.com/mbf

Navien’s NFC series stainless steel fire tube combi-boilers is available in two sizes: NFC-175 (175,000 Btuh) and NFC-200 (199,900 Btuh). An in-house designed and manufactured heat exchanger, low profile burner, advanced controls and built-in DHW module (pump, flat plate heat exchanger, 3-way valve, mixing valve, water adjustment valve and auto water fill valve) are included. Common venting capability is up to 8 units (1 NFC and 7 NPEs) and cascading capability is up to 16 units (1 NFC and 15 NPEs). Built-in hardware allows up to 3 zone pumps to be connected without additional external controllers. www.navieninc.com/series/nfc

Blue Pipe polypropylene piping system is sized from ½ in. to 24-in. It is rust-proof, scale resistant and lighter than steel. The multi-layer faser-composite blends glass fibres with PP-R and PP-RP (RCT) to minimize the linear thermal expansion. The pipe is installed using heat fusion, there is no glue, solder or gasket on the connection. www.aquatherm.com

The EPIC fire tube boiler and fire tube combi boiler for residential applications is available in four models ranging from 80,000 to 199,999 Btuh and three combi models ranging from 110,000 to 199,999 Btuh. The boilers are designed to offer easy installation and serviceability. They feature instantaneous response time and a user-friendly interface in addition to 10:1 turndown. The EPIC boiler and boiler combi are equipped with Lochinvar’s Smart Control with an intuitive setup wizard. An air handler interlock switches from space heating to domestic hot water mode. www.aquatech.canada.com

The Viessmann Vitotrans 300 is a high-capacity domestic hot water heating unit, featuring single or multiple heat exchangers (single or dual wall). The self-contained and pre-assembled unit features flow rates of 5 to 180 GPM and is suited to commercial and institutional applications. Models with 2 or 3 integrated brazed plate heat exchanger(s), provide built-in redundancy and eliminate downtime during heat exchanger maintenance. The unit can be set up for continuous direct hot water heating or in combination with a buffer tank. www.viessmann.ca

The PIQCV from Belimo is a small pressure independent control valve. It combines a differential pressure regulator with a two-way control valve to supply a specific flow for each degree of ball opening regardless of system pressure fluctuations. PIQCV performs the function of a balancing valve and control valve.

A calibrated ultrasonic flow sensor incorporates glycol compensation technology. www.belimo.us

SensorLinx is a customizable sensor solution incorporating the WFS-0100 wi-fi flow and temperature sensor and the WPS-0100 wi-fi pressure and temperature sensor. The sensors can be used individually to track many system parameter configurations to record daily, monthly and yearly total usage in real time using the HBX Thermolinx app. In addition to BTU metering, applications include calculating flow rates, system pressure, and measuring supply and return temperature. www.hbxcontrols.com

The Armstrong Compass R is a variable speed dry-rotor circulator. Designed to replace existing fixed speed circulators, with popular flangeto-flange dimensions, Compass R can be considered a universal replacement for circulators in its capacity range. Applications include residential heating and cooling, and potable water supply. www.armstrongfluidtechnology.com

Legend® delivers a total radiant hydronic system for almost every project application. Design services, innovative products, engineering support, and training/education are the pillars we use to complete a radiant heating system. Our products are designed and engineered with efficiency in mind, for system layout, installation and operation. Contractors appreciate our labor-saving features allowing them to minimize time on the job site. System designers benefit from Legends innovative and multipurpose functionality. We design and provide products for projects from single-family homes to large commercial applications, including heating and cooling for floor, wall, ceiling, snowmelt, and turf warming. We’ve got your back®

The GMP4 from Calefactio features a 15 L (4 gal.) tank suited for mid-sized residential applications. The glycol makeup package can be used for glycol heating or cooling for systems holding up to 300 L (79 gal.). Its compact rectangular design allows it to occupy less space and a wall-mount rack simplifies installation. The GMP4 is equipped with an alarm floater; users can hook up a sound alarm and be notified when liquid levels fall too low. www.calefactio.com

The I-Series Condensing Gas Boiler from Rinnai contains a proportional valve, which allows for simultaneous delivery of domestic hot water and central heating without interruption of the heating flow. Compact design (18.5 in. x 26.4 in. x 11.45 in.), PVC, CPVC, PP and SS venting, simplified parameter settings and NG with LP conversion option make for flexible installation. Features include stainless steel heat exchanger, servo-based temperature controller for DHW, and integrated condensate trap. www.rinnai.us

Designed to handle offsets, BlitzFlex from Centrotherm allows for a continuous run of the airintake system for residential heating appliances. It should be used in conjunction with InnoFlue polypropylene vents and accessories. Made from flexible polymer, BlitzFlex can be dispensed from its BlitzPack master carton as needed at the point of use, eliminating a bulky coil. A single carton provides enough air-intake conduit to complete three to five standard residential systems. www.centrotherm.us.com

The Oventrop R-Tronic wireless programmable thermostatic radiator valve controller has programmable daily and weekly settings and the temperature can be displayed in either Fahrenheit or Celsius.The wireless radiator control is based on the EnOcean standard with one thermostat controlling up to three operator heads. If contact is lost with the thermostat the operator head will keep the air temperature at 68F. www.oventrop-us.com

The MACH aluminum condensing boiler from Patterson-Kelley is now available with 10:1 turndown capability on natural gas models C750, C900, and C1050. The boilers fit through a standard 36-in. doorway or a standard elevator and the largest models (1,500,000 Btuh and larger) are equipped with wheels. They are suited to new installation and retrofit projects, requiring only 4 hookups–gas, water, electric and venting. www.harscopk.com

Heat-Sheet offers 2 ft. x 4 ft. radiant floor panels designed for slab-on-grade, retrofit and snow-melt applications. The panels are available in R8/R10/R12/R14 for slab-ongrade and under slab applications and 7/8 in. nodules protect and secure up to 5/8 in. piping. The panels have a compressive strength of 20 PSI or higher. For SIM and commercial floors, 1 1/4-in. nodules protect and secure up to 3/4-in. piping. No additional vapour barrier is required. In overlay and retrofit applications thin profiles minimize overall slab thickness. www.Heat-Sheet.com

Chemline offers Asahitec PP-RCT pipe, butt/ socket fittings, valves and Widos fusion machines for the hydronics market. PP-RCT has a strong crystalline structure for greater pressure capabilities at higher temperatures making it suitable for boiler systems. PP-RCT is corrosionfree, light weight and long lasting with naturally insulating properties. www.chemline.com

Z-one valves from Caleffi are available with 1/2-in. to 1-in. press fittings. A slotted EPDM O-ring allows fluid to leak during testing if unpressed and is designed to provide a leak proof seal when completely pressed. Low-lead brass models are available for domestic hot water applications. www.caleffi.com

THE ORIGINAL INNOVATORS DELIVER THE FUTURE IN HIGH-EFFICIENCY BOILERS

An all-stainless steel fire tube heat exchanger available in three Solo sizes - 110, 155, 199, and two Combi sizes - 155 and 199.

LOWER PRICE POINT

BREAKTHROUGH MARKET-LEADING WARRANTY PROGRAM with up to 6-year part, 3- year labour and 10-year heat exchanger warranty

ENHANCED QUALITY CONTROL and built with reliability in mind

Learn more about our Three-Point Warranty Program at our website.

The Eco-King Supreme Boiler is available in two models. Combi boilers supply on demand hot water and home heating needs and the H model provides heating and hot water via an indirect tank. This made in Canada product has universal parts on all models. Unique construction simplifies servicing. The boilers have Grundfos variable speed pumps, 12L pre-charged expansion tanks and stainless steel heat exchangers. The cleaner burning gas valve is self-adjusting and interchangeable between NG & LP. Other features include simple to use controls and an LCD screen. www.eco-king.com

FAR modular manifolds for radiant panels are available in 1 in. and 1 1/4 in. sizes and are used for the distribution of heat transfer fluid to radiant panels. Thermo-electric actuators can be installed on the return manifolds to control opening/closing of the outlets by means of a thermostat. www.far.eu

Modular Hydronics Shop offers a variety of standard integration diagrams that are matched to its modular hydronic zone systems so that boilers operate at the lowest possible operating cost point. This Design Advisor is a System Layout Assistant which will guide everyone who is installing regular hydronic heating or highly customized solutions. Users select a system design to receive a customized layout diagram in just a few clicks. www.modularhydronics.com

The Buderus SSB offers cascade outputs from 800 to 8,192 MBH and can be utilized in many applications. Each boiler has two fully independent heat exchangers. Up to four boilers may be directly connected with no external piping or venting, and almost no field assembly. www.bosch-climate.us

ISORAD V2 from Isolofoam Group is a rigid expanded polystyrene insulation panel with a multidirectional tube retaining system and a 4-sided interlocking system. The panels are 48 in. x 48 in. R3 and R5 versions are primarily intended for new construction of residential, multi-units and commercial buildings when a radiant heating system’s tubing embedded in concrete is installed on upper storey floors. The panels facilitate installation of 1/2 in. or 5/8 in. tubes. www.isolofoam.com

The Baxi 60GA offers 164 MBH Input in CH Mode and 205 MBH in DHW Mode. Domestic hot water flow rates are 4.65 GPM at 77F temperature rise. Turndown modulation ratios are 7:1 in DHW mode and 5.5:1 in central heating mode. Features include the THINK combustion management system, gas adaptive control, a three speed, electronically controlled pump, an iron-chromium stainless steel burner and brazed plate heat exchanger with a pre-heating function. It measures 17.75 in. (w) x 21.5 in. (d) x 30 in.(h) and weighs 125 lbs. www.baxiboilers.com

Flexmaster’s Z-Vent double self-sealing special gas vent system with self-sealing gasket connections is designed to reduce installed cost. Singlewall and doublewall is manufactured in diameters from 3 in. to 24 in.

Vent stack/breeching is suitable for use with boilers, high efficiency furnaces. Venting is for both spa heaters and pool heaters, unit heaters, water heaters and Category I, II, III, IV heating equipment. www.flexmaster.com

Viega ProRadiant solutions are suited to industrial, commercial, and residential platforms. Systems are designed for retrofit and new construction, commercial building tempering and snow and ice melting systems with pre-insulated distribution. It includes a full line of mixing, manifolds, sensors and controls and is vertically integrated with Viega plastics and metal offerings. www.viega.us

Agilia Screed by Lafarge is a ready-mixed, pump-applied, free flowing floor screed that can be integrated into any type of floor system. The range of underlayment products in the Agilia Screed brand are designed to meet the floor leveling challenges on any type of project; new build or renovation, and residential, commercial, or institutional. The products are installed by trained and authorized floor leveling and floor topping experts. www.lafarge.ca/en/agilia-screeds

BY CURTIS BENNETT

Iliterally remember hearing that 9600 baud modem squeal for the very first time. Reerascheeeram, yes that is how you actually spell it, so do not try to look it up. It was weird –I thought why the heck is it making noise? Then as soon as something popped up on the screen I forgot all about it. Netscape was bliss. If you were an AOL person, and you know who you are, well Netscape was better, that is why AOL bought them.

It was crazy times – we heard about the internet and what it could do, where

it could take us and how it was going to be awesome. Remember the saying your father said when he wanted you to hurry up: Slower than molasses in January. That was actually our first experience with the internet. At the time you did not know just how slow it was until the world began to accelerate.

Along came DSL and the onslaught of cable, we could download songs at a blistering 10k per second. Napster, awe Napster. Of course, none of us used it because it was not legal.

Speeds did progress very rapidly as more and more people moved online,

users got e-mails, users started to understand this new technology but the catalyst it needed was still missing. There must have been a few guys from MIT (everything cool comes from MIT), who foresaw the world as we know it now. People walking and talking, connected all the time. It really was not until then, that I think, the world really started to understand the power of not only the internet, but the power of being “plugged in” at all times. This aspect of mobility, brought on by companies basically making computers that happened

Continued on MH28

Demanding conditions call for reliable equipment.

Patterson-Kelley continues to transform the commercial boiler industry by offering the highest quality, most efficient, condensing products available. Designed for maximized comfort during those long cold winter days, without sacrificing savings, visit harsco.com/p-k-storm to learn how Patterson-Kelley is taking the industry by STORM.

to have phones built in, that drove us into the world of Wi-Fi.

Wi-Fi is the term that is synonymous with being connected. Without Wi-Fi… I can’t even recall how it was before Wi-Fi. Most of us think Wi-Fi stands for Wireless fidelity or some term like that. It actually does not. It is literally just a trademarked term for the wireless specification of 802.11x. It is a specification that has a great deal of parts to it. Once again, thank you MIT. No reason to get into them, but just know some really smart people figured it all out for us, they wanted to make our lives easier.

Almost all cell phones come with Wi-Fi. Wi-Fi is free, when you are in a building and data is not. Well most of the time it is not. There is also another discussion on 5G wireless sometime in the future, but not now. At this point I want you to look at your cell phone screen, if you had to “flip it” to see the screen, you really need to start embracing the future. Flip phones are so 1998. Seriously 1998. Anyways it is not just our phones that are now connecting. You probably have started to hear this term IoT thrown around. I say it all the time, I makes me feel smart. Come on we all have one of those industry terms that we like to throw into conversation. Mine is IoT.

IoT means internet of things. It is an amazing idea. Seriously amazing. Everything is connected to everything else. Your fridge knows when you need milk and it texts your phone. Your alarm system knows when someone unlocks the door and it lets you know, by texting your phone. I know what you are thinking right now, “but then google and Apple will know everything about us.” I actually chuckle a little when I hear people say that. The reason is it is too late. They already know everything about you. Every move you make, every step you take, they will be watching you.

So HVAC and Wi-Fi. I believe in the next few years they will be mentioned

“When each item has all the information from the other, it can make more informed decisions about what it is currently controlling.”

more and more in the same sentence. Do you remember trade shows five years ago verses trade shows now? There used to be barely any Wi-Fi devices. Now, they are everywhere.

Why now? What advantages does it give us? Is it just another way to sell us new stuff? No it is not. It is literally changing the landscape of our industry. Running LAN connections is a thing of the past. We are reaching speeds of 1Gig per second on Wi-Fi, five years ago you could barely do that on a hard line connection. With this we can do more, do it faster, manipulate more data and run algorithms to make the best products possible. Like the old saying goes “Information is power.” It rings so very true when you literally have billions of devices collecting data all the time. You don’t really believe Google bought Nest because it was a good thermostat do you? No, Google bought Nest because it collects information. Information drives our world like it or not.

It has been 15 years since I designed my first logging software for boiler controls. We thought it would change the world right away, but sometimes you have to wait for a very special inflection point, a point where many little items come together, many ideas come together, many technologies advance enough that people finally jump on the train. Wi-Fi actually did this by connecting items to each other in a very easy and reliable way.

When each item has all the information from the other, it can make more informed decisions about what it is

currently controlling. Or many items can gather multiple points of information and relay that information back to a single unit that will then analyze that’s data and make a decision. It is not that we could not do this before Wi-Fi, it is just that Wi-Fi has made it easier and when things get easier to do, more people start using it. That is human nature.

Wi-Fi is not the enemy, as far as science has researched so far, we are not going to grow horns because of it, although there has been some interesting articles come out lately. I would like to say “it’s coming so get ready,” but actually if you are not already on the train, you will be left behind.

We are already connected to the Matrix, you just need to decide which colour pill you are going to take, the red one or the blue one. <>

Curtis Bennett C.E.T is product development manager with HBX Control Systems Inc. in Calgary, AB. He formed HBX Control Systems with Tom Hermann in 2002. Its control systems are designed, engineered and manufactured in Canada to accommodate a range of hydronic heating and cooling needs commonly found in residential, commercial and industrial design applications.

SEE CURTIS AT THE MODERN HYDRONICS SUMMIT 2019. VISIT MODERNHYDRONICSSUMMIT.COM FOR DETAILS.

Meeting the water heating needs of every homeowner calls for industry-leading efficiency and installation flexibility. That’s why the world’s top contractors carry the new and improved KNIGHT® Residential Boiler by Lochinvar. With 6 floor-mount and 7 wall-mount models available, the KNIGHT boiler ranges from 55,000 to 399,000 BTUs and features an energy-saving ECM variable speed pump as standard equipment—all while operating at up to 95% efficiency. That’s one more reason no one brings it all together like Lochinvar.

Forward thinking and creative professionals use ceiling radiant as a supplement or as the primary radiant source.

BY STEVE GIBBS

In providing a comfortable living or working space, installing a radiant heat source in a ceiling is often overlooked. The promotion of warm floors has always been at the forefront of North American radiant marketing and the vast majority of customers and installers focus solely on the floor as a radiant panel. Hence the ubiquitous use of the term “in floor heat.”

A number of forward thinking and creative professionals have used ceiling radiant as a supplement or as the primary radiant source to provide the comfort desired by the customer. The reluctance to employ this application stems from some misunderstandings of heat transfer.

The thought is that the customer would experience a “hot head and cold feet.” The saying “heat rises” is not completely true. Heat is actually electromagnetic energy and one of the basic concepts of electromagnetic energy is that it always seeks equilibrium. It travels from a state of high energy to a state of low energy until equilibrium is obtained. In addition, the rate of travel is directly determined by the degree of variance between the two states.

Simply put, heat energy travels from hot to cold in any direction. The direction of travel–up, down or any direction in between–is determined by the degree of temperature variance between the two surfaces. To be clear, hot air rises and hot water rises but that is a result of the heat energy causing the medium to be less dense and therefore lighter.

A radiant panel installed in a ceiling

will generate high energy which will naturally travel to everything in the room that is cooler, including the floors, furniture, equipment, people and animals. It will eventually provide the same even, comfortable heat in the space as a floor radiant panel.

There are a number of advantages of installing ceiling radiant. Unlike floorbased radiant, there are few, if any, obstructions to heat transfer. The heat energy has a clear path to all cooler surfaces. As heat energy travels in a straight line by electromagnetic waves (similar to light), some areas, such as floors beneath a table, may take a little longer to heat up as they will be heated secondarily by other heated objects in the space.

Another advantage is that a higher supply fluid temperature can be used. Drywall can withstand 125F under continuous operation. It is possible to deliver up to 50 Btus./hr./sq. ft. to the space. In addition, due to the relatively small resistance to heat transfer associated with drywall, the panel will heat up faster, which results in a faster response time.

Ceiling radiant may also be easier and less expensive to install in retrofit applications.

There are a number of applications where ceiling radiant makes sense. Bedrooms make an ideal application for ceiling radiant. With a large bed and multiple dressers in the room the actual ratio of available floor space for radiant heat to square footage of the room is

quite small. In addition, bedrooms with thick padding and carpet place additional restrictions on the amount of heat transfer from a radiant floor panel.

A large great room with high ceilings and large window surfaces typically requires supplemental heat when radiant floor heat is installed. Ceiling radiant is ideal because it can provide the extra heat and generate a quick pick-up during extreme cold times.

Basement and garage retrofits are a great application for ceiling radiant. The relative ease of installation and fast response time make this a favourable application.

In commercial spaces, rooms with multiple storage cabinets or equipment have a small amount of floor space therefore ceiling radiant is a great solution. Ceiling overhead panels can also provide required spot heating.

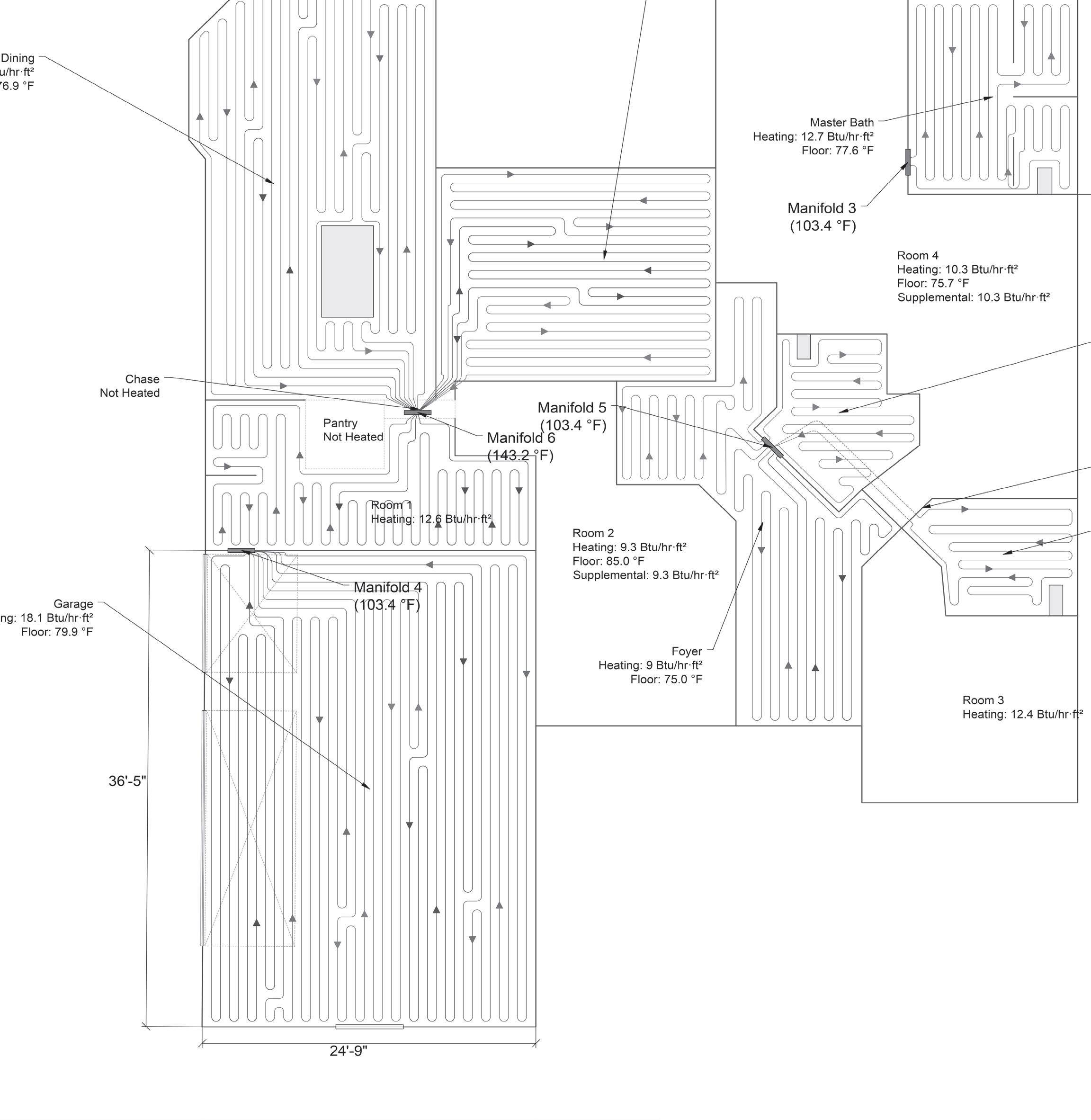

Designing a ceiling radiant system is no different than a floor system. Whether the radiant panel will be used as the primary source or for supplemental heat the first and most crucial step in any radiant design is determining the heat load of the space. Once the heat load is determined, the flow rate and supply fluid temperature can be determined.

•

• Eliminates multiple fittings

• Creates

• Avoids reduced-port alternatives

• Also available in FIP, SWT, Press and Push on select models

The flow rate can be determined using formula 1: Where:

f = Flow rate (gpm)

Q = Heat Output - Btu/hr.

C = Constant based on specific gravity of fluid, weight conversion to gallons (8.33lbs/gal.) and time conversion (60 min/hr.) (C of water - 1 x 8.33 x 60 ≈ 500)

∆T = Difference in temperature between supply and return in circuit

Figure 1 can be used to determine the supply fluid temperature.

Example

Family room with an area of 740 sq. ft. and a heat load of 16280 Btu/hr or 22 Btu/hr/sq ft.

Fluid - water

Flow rate

Supply temperature

22 Btu/hr/sq ft correlates to approximately 50F differential temperature. With an indoor design temperature of 70F the average water temperature would be 120F. With a ∆T of 10F you would add 5F to the average to get the supply temperature–125F.

Installation methods range from suspending tubing in a ceiling joist cavity to the use of pre-engineered panels. As in all radiant systems, proper insulation ensures the heat energy travels in the direction intended to provide comfort in the space. This is particularly important if the ceiling is adjacent to an unheated

attic, crawl space or the structure’s roof. Suspending the tubing between ceiling joists or attaching tubing to the sides of the ceiling joist are the least efficient methods.

The use of aluminum heat transfer plates is one of the preferred methods for installing ceiling radiant. In this method, tandem furring strips are attached to the ceiling joists with a gap for the aluminum plate groove and tubing. The aluminum plates are then attached to the furring strips and the tubing is installed in the groove of the plate between the furring strips. The drywall can then be installed over the tube and plate system.

Always pressure test the tubing to check for leaks before installing the drywall.

Another installation method uses preengineered panels. The panels are installed directly on the ceiling joists. The panels can be cut to fit different ceiling configurations and can also be cut or drilled out with a hole saw for lights, fans and sprinkler heads. The tubing is snapped into the panel or secured with straps.

Commercial pre-engineered radiant ceiling panels are commonly manufactured with extruded aluminum or other metal with copper tubing inserted into the grooves and connectors on the inlet and outlet. The panels are modular and can be assembled on site and then attached to the ceiling or suspended.

Although not a discussed in this article, the use of ceiling installations for radiant cooling presents an additional opportunity for professionals. As hot air rises it creates a greater temperature differential with the cooled radiant panel and results in a greater heat transfer rate.

Ceiling radiant is a viable solution for many applications and should be a part of every radiant professional’s “playbook.” With reduced resistance to heat transfer, high available supply temperatures and quicker response times it can make the difference in providing the comfort customers expect. <>

Steve Gibbs is a product manager, trainer and a radiant designer with Roth Industries.

This hydronic market niche is poised for growth in North America. BY

JOHN SIEGENTHALER

Ihave often described radiant panel heating in North America as “the tail wagging the hydronics dog.” Over the last 35 years radiant panel heating was largely responsible for leading the North American hydronics market out of the doldrums of the 1970s. Given the consumer familiarity and myriad of products available for radiant panel heating one might wonder if there is any future for other types of hydronic heat emitters. I firmly believe the answer is yes.

What follows is not an attempt to convince you to completely switch from installing radiant panels to installing panel radiators, but rather to expand awareness of the possibilities of designing with panel radiators and to compare their attributes to those of radiant panel systems.

When the term “panel radiator” is mentioned to a client as a possible heat emitter option for their project, the client will often ask what it is. At present, panel radiators are not well known outside of modern hydronics trade circles in North America. This is sharp contrast to a relatively high consumer awareness of radiant floor heating and the fallback standard of fin-tube baseboard.

All panel radiators release a combination of radiant and convective heat into a room as hot water flows through them. Beyond this fundamental function is a virtually unlimited range of forms, sizes, colors, and artistic themes. Let’s start with a basic “utility grade” panel radiator, such as shown in cross section in Figure 1.

The front of this style panel radiator is called the “water plate.” It consists of two formed steel sheets welded together at the perimeter and across the face. The upper and lower portions of the water plate acts as headers. Several vertical flow channels run between these headers.

A sheet of thin folded steel is welded to the back of the water plate to create fins that enhance convective heat transfer. The water plate and fin assembly are then framed with side and top trim panels. Some panel radiators of this type have supply and return piping connections at the bottom and a preinstalled flow control valve in the upper right corner as seen in Figure 1. Water flows into the bottom left connection, up a

riser tube, through the flow control valve and then out across the water plate. After flowing downward through the water channels flow exits through the bottom right connection.

The internal volume of the water plate is very low relative to a typical cast-iron radiator of similar frontal area. For example: A 24-inch high by 48-inch wide panel radiator with a single water plate only holds about 0.7 gallons of water. The empty weight of this panel is about 75 pounds.

This low thermal mass characteristic allows for fast response, both warming up and cooling off. A panel radiator can quickly begin releasing heat to a cool space and quickly stop releasing heat should internal gains occur. This is in marked contrast to the response characteristics of many radiant floor panels, especially those with tubing embedded in concrete slabs. These slow response characteristics often rule out slabtype floor heating in situations where loads change rapidly due to variable and often unpredictable internal heat gain.

To increase heat output without changing frontal dimensions, most panel radiator manufacturers offer units that join two or sometimes three water plates together into a single assembly. Figure 2 shows a cutaway of a two water plate panel radiator. Panel radiators with two or three water plates have a higher percentage of convective heat output than do single water

Continued on MH36

• Feature-rich portfolio of thermostatic and digital mixing solutions.

• Over 50 years of proven, reliable service worldwide.

• Broad assortment of union connections for piping flexibility.

• Compliance with ANSI/NSF 372-2011 low lead, ASSE 1017, ASSE 1070 (anti-scald), CSA B125.3, UPC, IPC, IRC, NPC for the USA and Canada.

Controlling and protecting your water

plate panels operated under the same conditions. They also project farther out from the wall as shown in Figure 3.

Another advantage panel radiators offer is the ability to operate at relatively low flow rates and higher temperature drops. Many panel radiator systems in Europe are designed for 20C (36F) temperature drops at design conditions, almost double the design temperature drop used in most radiant floor panel systems. Radiant floor panels need lower circuit temperature drops to reduce variations in floor surface temperature to enhance the desired “barefoot friendly” feel. Some suppliers suggest limiting design temperature drops in radiant floor panels to 10F. Although this reduces variations in floor surface temperature, it also requires larger circulators and substantially more circulator power. Designing a panel radiator system for higher temperature drop has several benefits:

• It allows most radiators to be piped with small diameter (3/8 in. to ½ in.) PEX, PERT, or PEX-AL-PEX tubing. Such tubing is easy to route throughout a building, especially in retrofit applications

• The flow rate required by the panel changes in inverse proportion to the temperature drop (e.g. doubling the temperature drop allows the flow rate to be cut in half). This allows for significantly smaller circulators, and even more importantly, significantly reduces the circulator energy required to distribute heat through the building.

• The smaller flow rates and pipe sizes also reduce heat loss from distribution piping.

• Panel radiators are light. Unlike some suspended slab radiant panels, they have virtually no effect on structural loading.

• Panel radiators do not affect flooring height.

• All radiant floor panel systems must address is the thermal resistance of finish flooring materials. This is an issue when the system is first designed and remains an issue through -

out the life of that system. The wrong choices can have devastating effects on heat output and owner satisfaction. This is obviously not an issue with wall-mounted panel radiators.

• Because they are not an integral part of the building structure, panel radiator installation is easier to coordinate with other trades and less subject to damage due to negligence on the part of other trades.

• The installed cost of a properly-designed panel radiator system will be hard to match with a properly designed radiant floor heating system. This is especially true when room-byroom zoning is needed, or in retrofit applications.

Panel radiators can be used with many piping layouts including series loops, diverter tee loops, two-pipe parallel direct return and two-pipe parallel reverse return. One of the easiest and most versatile piping layouts for panel radiators is the “home run” system using PEX, PERT, or PEX-AL-PEX tubing to and from each panel radiator as shown in Figure 4. All the supply and return runs come from a manifold station – just like in a radiant panel system. The manifold station could be in the wall, or under the floor.

Homerun distribution systems provide the same water temperature to each panel and thus simplify sizing. They also allow each circuit to be balanced for proper flow. The latter can be done using valves built into the manifold station, or with integral balancing valves built into certain types of panel radiators Room-by-room comfort control is achieved using a homerun distribution system in combination with panel radiators equipped with non-electric thermostatic radiator valves. For radiators such as those shown in Figure 1, the thermostatic operator just screws onto the radiator’s flow control valve as shown in Figure 5. This operator uses the expansion and contraction of a wax or liquid-filled actuator to move the stem of the radiator valve as needed to maintain the room setpoint temperature.

The floor of a building is often the most ignored surface when it comes to insulation. The floor, when insulated with HYDROFOAM®, completes the building envelope and increases comfort and energy efficiency.

HYDROFOAM® maximizes radiant floor heating by ensuring the heat is dispersed evenly throughout the entire floor area, providing building occupants with a comfortable living and working environment.

HYDROFOAM® is the ideal radiant floor insulation product for residential and commercial construction projects. Visit nudura/hydrofoam.com today to start your next project!

VDC. Their speed can be adjusted manually, or automatically based on the water temperature in the panel. Fan-assisted panel radiators can also be equipped with non-electric thermostatic valves allowing each radiator to operate as an independent zone.

Suppose you need a system that provides room-by-room comfort control, utilizes a high efficiency modulating/ condensing boiler, is simple to install and is economical to operate. Consider the layout shown in Figure 6.

This design provides room-by-room comfort control using a homerun distribution system. Each radiator is equipped with a non-electric thermostatic radiator valve. A pressure-regulated circulator automatically adjusts its speed to maintain the required differential pressure as the radiator valves modulate between open and closed. The high-mass mod/con heat source maintains the proper supply water temperature to the distribution system based on outdoor reset control. This type of heat source also eliminates the need for a separator buffer tank and a separate boiler circulator.

A very similar arrangement can be used with a hydronic heat pump as the heat source. Just use the heat pump to maintain a suitable range of water temperature in a buffer tank, and draw warm water from that tank to supply the panels.

The number of homerun circuits can be increased or decreased as needed. I like to specify manifold stations with at least one extra set of ports so that another panel can be easily added in the future.

Several panel radiator manufacturers have expanded beyond traditional offerings, which were primarily designed to operate with boilers, into “low temperature” panels that are well suited for used with low temperature heat sources, such as hydronic heat pumps.

To boost heat output at low water temperatures, these panels incorporate a rack of small “micro-fans,” as seen in Figure 7, which draw about 1.5 watts each at full speed to enhance air flow over the convective fins. This significantly boosts convective heat transfer. The micro-fans typically operate on 12

Both radiant panels and panel radiators have their place in the hydronics universe. Both have optimal application scenarios in which the other simply is not an option. For example, using panel radiators to heat a 10,000 square foot vehicle maintenance garage does not make sense. Likewise, installing radiant floor heating in an existing building with inaccessible floor structure and expensive surface finishes is virtually out of the question.

There are also situations where it makes sense to combine the attributes of radiant floor panels and panel radiators. An example would be use of radiant floor heating in a basement slab in combination with panel radiators on the main floor. Seasoned hydronic pros recognize these situations and apply each technology to maximize performance and benefits to the customer.<>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has more than 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

AIR HANDLER UNIT

AHU - 800