BE THE GO-TO PERSON FOR GREASE MANAGEMENT

SELLING LONGEVITY

When to make the case for stainless steel

DESIGN “SIMPLE IN CONCEPT” HYDRONIC SYSTEMS

THE CASE FOR STAINLESS STEEL

Despite the higher price tag, stainless steel tanks are often more cost effective when life cycle costs are compared. BY ROBERT WATERS

42 HYDRONICS

SIMPLE & SOPHISTICATED

Hydronic systems do not have to be complex to be state of the art. By John Siegenthaler

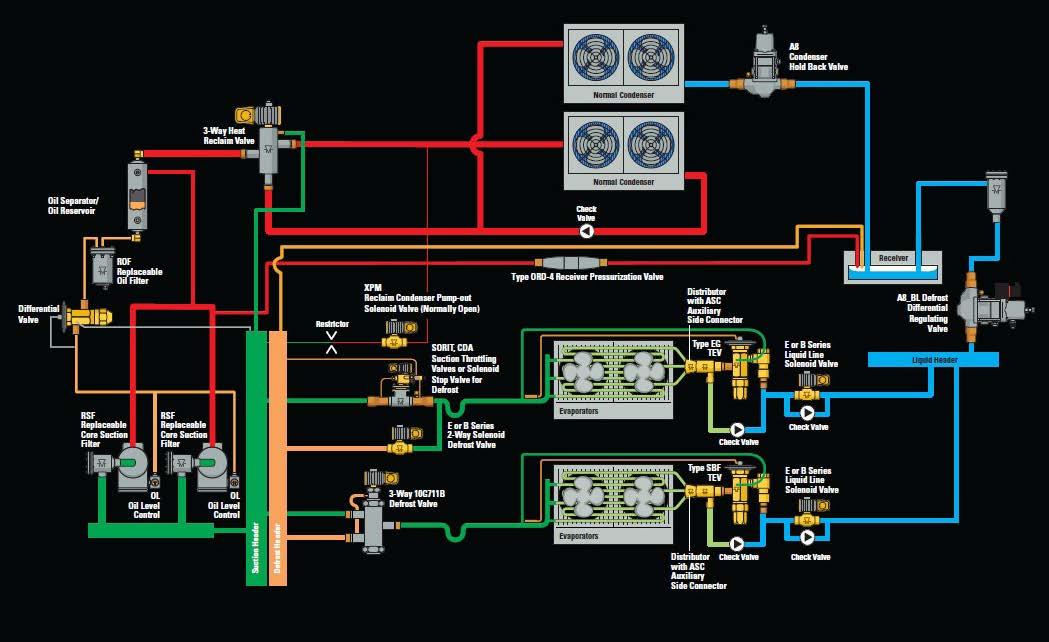

54 REFRIGERATION

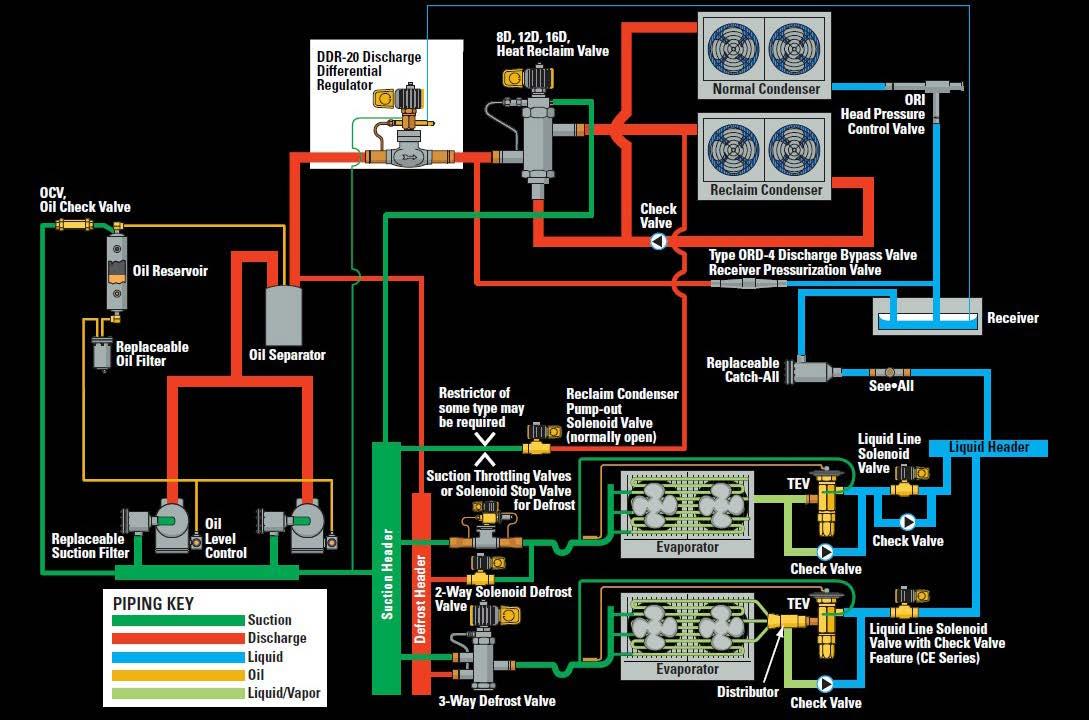

INTRODUCTION TO REFRIGERATION DEFROST METHODS–PART II

Modifications to basic defrost schemes add yet another layer of complexity for field service personnel. By Dave Demma and Bob Schindler

68 GEOTHERMAL DELIVERING ON THE PROMISE OF RENEWABLE ENERGY

It is time to take the leap and embrace geo for heating and cooling needs. By Ian McTeer

73 CONFERENCE REPORT

TECHNOLOGY, RELATIONSHIPS AND CLIMATE CHANGE PLAN FOCUS OF GEOTHERMAL FORUM

By Michael Power

74 HYDRONICS

CONTROLS: A LOOK AHEAD By Mike Miller

80 PLUMBING PITFALLS TO AVOID

How to position yourself as the go-to person for grease management. By Andrew Bird

84 SHOW PREVIEW

MCEE 2017: GENERAL INFORMATION, SEMINARS, EXHIBITORS LIST

98 SHOW REPORT

VEGAS PROVES TO BE A BIG WINNER FOR ASHRAE, AHR EXPO AND THE INDUSTRY

100 MANAGEMENT BEYOND BORDERS

What to consider when expanding your business. By Hank Bulmash

DEPARTMENTS

90 Mechanical Supply News

People

The Source

Calendar

Training

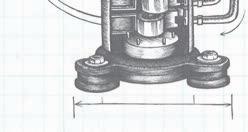

WHAT AM I?

HPAC ’s What Am I? contest returns in May. The winner of the last challenge will be featured in the May issue. Check out p6 in this issue to have a look at the February mystery product. It is not too late to enter to win a TLM99s Laser Distance Measurer from Stanley.

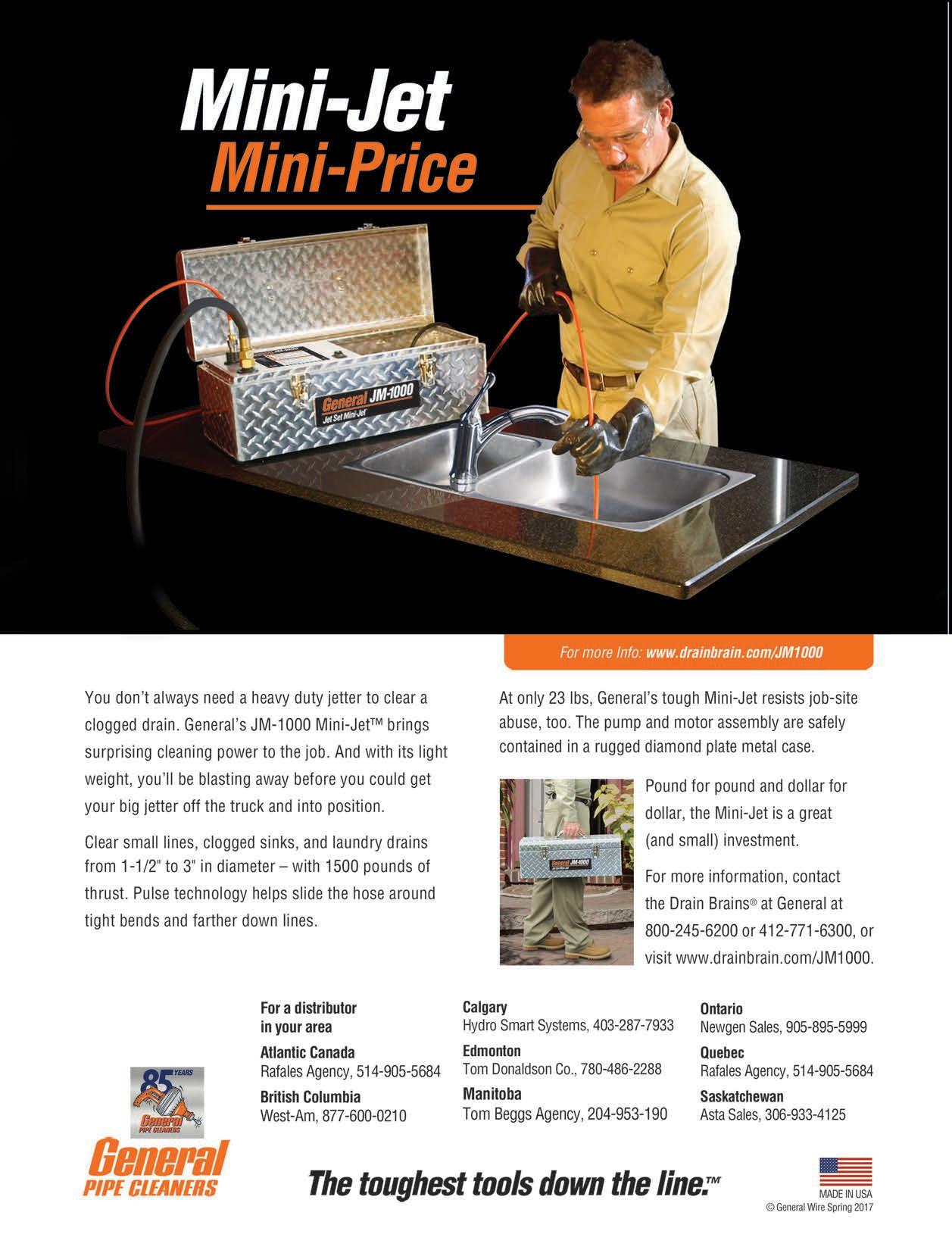

GENERAL PIPE CLEANERS

GENERAL PIPE CLEANERS Q&A

Recent equipment advancements from General Pipe Cleaners make spotting and clearing stoppages faster and easier than ever before.

With compact Gen-Eye POD® video inspection systems and the JM-1000 Mini-Jet™, your drain cleaning arsenal becomes more efficient, convenient and versatile – improving both productivity and profitability.

WHAT’S NEW IN VIDEO PIPE INSPECTION?

Wi-Fi!

The newest video pipe inspections systems from General offer the convenience of Wi-Fi. The optional Wi-Fi transmitter inside the monitor lets you send video to your tablet or Smartphone. Record the inspection. Send it to customers at your convenience. Or post it to You Tube – right from the job. Forget separate recording equipment!

Now General’s lightweight, popular systems offer optional Wi-Fi capability! Always easy on both back and budget, the convenient, compact Gen-Eye POD® combines camera, reel and monitor in a handy, all-in-one package.

The full size Gen-Eye POD sports a self-leveling camera and 200 ft. of Gel-Rod® for troubleshooting 3” to 10” drain lines. The MINI-POD® version carries 125 ft. or 175 ft. of push rod – with mini selfleveling colour camera small enough to troubleshoot 2” to 4” lines. Just grab it – and go!

IS THERE A BETTER WAY TO HANDLE GREASE BLOCKAGES IN TIGHT SPOTS, WITHOUT

BREAKING MY BACK?

Absolutely!

The compact, lightweight JM-1000 Mini-Jet™ is excellent for clearing grease, sand, sediment and ice from small, 1-1/2 to 3 inch lines – up to 50 feet long. It’s great for clogged kitchen, bathroom and laundry drains.

With 1500 psi of cleaning power, General’s powerful little water jet hits sticky stoppages with a wall-towall stream of high-pressure water – and flushes them away.

Pulse technology helps slide the hose around tight bends and down lines. It breaks the initial tension between the hose surface and pipe walls, increasing cleaning power. And that separates General’s Jet-Set® from ordinary pressure washers.

The JM-1000’s rugged, diamond plate metal case protects the pump and motor assembly – yet is as small as most toolboxes. At just 23 lb, it’s easy-to-carry, maneuverable in tight spots and takes up little room in the truck!

< UPFRONT

IT’S A TIMING THING

As I write this it is blustery and very cold outside – 20 degrees colder than the day before in fact. This unpredictable month gives most Canadians a taste of all seasons – that is the problem.

March could be referred to as the “never-land” by the mechanical industry. No matter what the HVAC decision is, it is either too early or too late for consumers. Few people are thinking forward to the cooling season (except in Ontario where electricity rates are in the limelight), and heating system improvements are something to be put off until the fall.

So here is your chance to catch up; to take a breather down south, and to take advantage of trade shows and conferences and other opportunities for growth.

This can be a good thing, particularly with this issue. You will want to allocate more than your usual HPAC reading time to check out the Show & Tells, a forum that allows advertisers to showcase their achievements.

The editorial-style copy, provided by suppliers, accompanies their advertisement and highlights innovative products, applications or company milestones. These stories, which are interspersed with our regular editorial, are flagged with the Show & Tell banner. We are sure you will find them to be a great read.

We also want to highlight that HPAC contributor and Modern Hydronics Summit keynote Robert Bean has been in the limelight recently as the recipient of two prestigious industry awards (see p10). Our congratulations Robert!

Editor

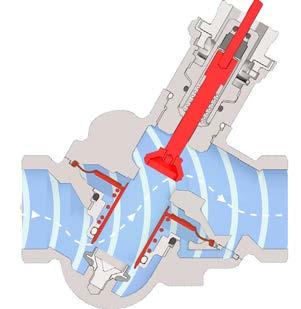

Editor’s Note: What Am I? contest returns next issue. Check out the image below (from our February edition) and take the challenge!

February

WHAT AM I?

Items will be featured in whole or in part and may be from any era–they may be appliances, fixtures, tools, pvfs, components, and so on. To enter, identify the product featured on the right and include what it is, where would you find it, how it works and who made it–bonus points to the entrant who has an interesting anecdote about the item. Send your response to kturner@hpacmag.com for your chance to win a Stanley TLM99 Laser Distance Measurer. The winner will be determined based on the accuracy and detail in the response, remember there are bonus points for entrants who share an interesting/ amusing anecdote about the item.

EDITOR

CONTRIBUTING EDITOR

SALES & MARKETING COORDINATOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT COO

PRESIDENT & CEO

Kerry Turner (416) 510-5218 KTurner@hpacmag.com

Michael Power mpower@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Stephen Kranabetter (416) 510-6791 skranabetter@hpacmag.com

Emily Sun esun@annexweb.com

Barb Vowles (416) 510-5103 bvowles@annexbizmedia.com

Urszula Grzyb (416) 442-5600 ext. 3537 ugrzyb@annexbizmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbizmedia.com

Ted Markle tmarkle@annexweb.com

Mike Fredericks

expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 800.387.0273, Fax: 416.442.2191; E-mail: vmoore@ annexnewcom.ca; or by mail: Privacy Office, 80 Valleybrook Dr., Toronto, ON M3B 2S9.

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Readers are invited to send photos for possible inclusion in the contest. If your photo is selected you will receive a 25-foot FATMAX tape rule.

Introducing the MOST EFFICIENT single-phase VRF system in its class

Up to 20% more efficient than the competition!

INTRODUCING THE NEW

208-230V, SINGLE PHASE

The single-phase J-II Airstage VRF heat pump serves heating and cooling applications requiring sizes from 3 to 5 tons, making it ideal for large residential and small commercial installations. This system is the most efficient single-phase VRF system in its class.

Efficiency Leader

At up to 19.8 SEER and 11.4 HSPF, the J-II efficiency significantly exceeds other equivalent VRF products and rooftop units of comparable size.

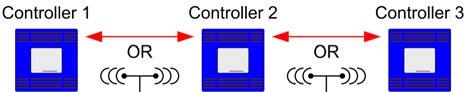

Networking

Non-Ducted

Provide advanced monitoring control of J-II systems with central controllers, and building management systems (BMS) over BACNet, LonWorks, or Modbus.

Individual Comfort

Connect up to 9 indoor units to each condensing unit and choose from 11 indoor unit styles to create individually zoned comfort for any size space or decor.

Long Piping

Long piping lengths up to 590 ft. - more than one and a half football fields - provide major installation flexibility.

Fujitsu offers an extensive lineup from 3 to 24 Tons with 45 different indoor units available in 11 styles.

EASIER & FASTER

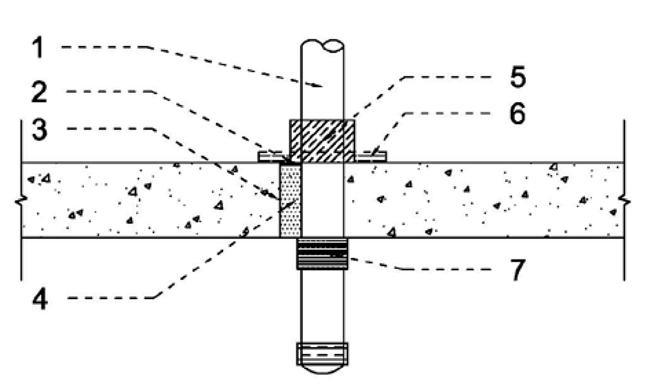

Rough & Concrete Floor Installation Box

combine with PVC piping for freestandings

Please come and visit us at booth 244 on April 26-27 at the MCEE show at Place Bonaventure in Montréal. Our experts will be on-site to present the Riobel Pro innovative products.

... designed for PROfessionals

DISCOVER THE PEX ADVANTAGE

PEX and expansion PEX valves:

No need to weld inside walls Eliminate the risk of water damage 3 to 4x faster to install

Also available, NPT or sweat valves

Universal rough and separate trims

No more worrying about damaging the trim: Rough for valves can be purchased separately from Riobel trims

Roughs for valves and freestanding faucets are universal

Come visit us at the MCEE at Place Bonaventure in Montréal, booth 244, April 26 and 27!

INDUSTRY NEWS

WELL-DESERVED VEGAS WINNING STREAK FOR ROBERT BEAN

HPAC columnist Robert Bean is the 2017 recipient of the Dan Holohan Lifetime Contribution to Comfort Award. The award was presented on January 30 at the AHR 2017 Show in Las Vegas, NV. Bean, who is an industry-leading expert on building sciences, indoor environmental quality, energy, and radiant-based HVAC systems, was also presented with the Canadian Hydronics Council’s (CHC) Award of Merit during the Radiant Professionals Alliance reception at AHR.

The CHC Award of Merit was created in 2012 to recognize individuals who have demonstrated outstanding commitment to the advancement of the hydronics industry in Canada. The Dan Holohan Lifetime Contribution to Comfort Award is given annually to an HVAC professional or company that has made a substantial contribution to comfort technology, advancement, or training while displaying the exceptional good humour and love of people exhibited by Dan Holohan throughout his career.

“This award is for someone who Taco has found to be influential in our industry,” said Taco’s executive chairman of the board, John Hazen White, Jr. “Robert Bean is tremendously committed to forwarding the hydronic business.”

Bean has been a leading voice in residential and commercial comfort and efficiency for nearly 40 years. He is the director of Indoor Climate Consultants, Inc., based in Calgary, AB. He also manages HealthyHeating.com, a volunteerbased, not for profit, online educational resource – serving as a technical interpreter and consolidator of academic research done within the building and health sciences.

Through his writing and speaking about the need to design comfort systems for people – not buildings – Bean has led the way to change how industry experts view the concept of comfort.

CIPH EXPANDS REACH OF ITS CAREERTAP PROGRAM

The Canadian Institute of Plumbing & Heating (CIPH) is now partnering with the Canadian Association of Business Students (CABS) as a part of long-term strategic plan aimed at students to raise awareness about the wide-ranging careers in the plumbing and heating industry.

CIPH recently sponsored JDC Central, an event that brings business students together in a multi-faceted competition, including academic cases for a variety of business disciplines, parliamentary style debates, sports tournaments, social competitions and charity contributions.

“Recruiting talent into our industry remains a priority for many of our members,” said Ralph Suppa, president and general man-

He is a graduate of the Building Construction Engineering Technology program from the Northern Alberta Institute of Technology, a Registered Engineering Technologist holding membership with the Association of Science and Engineering Technology Professionals of Alberta, and a Professional Licensee in Mechanical Engineering holding membership with the Association of Professional Engineers, Geologists and Geophysicists of Alberta. In addition to his training and professional practice in building construction engineering technology and HVAC engineering, he is a graduate of the Alberta School of Drafting (AutoCad) and The University of Calgary, Business Owner Transition Program. www.healthyheating.com www.taco-hvac.com www.canadianhydronicscouncil.com

ager of CIPH. “We want to attract people interested in accounting, engineering, marketing, sales and a whole host of other career choices. By engaging students at these events, we’re targeting the best of the best, who may not completely understand the exciting opportunities in our industry today and for the future,” noted Suppa.

CIPH had a significant presence in the career fair, as well as an opportunity to address a large student audience directly as a speaker series sponsor of JDC Central. JDC Central was hosted by Carleton University in Ottawa, ON.

CIPH returns to Ottawa for its annual business conference on June 25 to 27. www.ciph.com Continued on p16

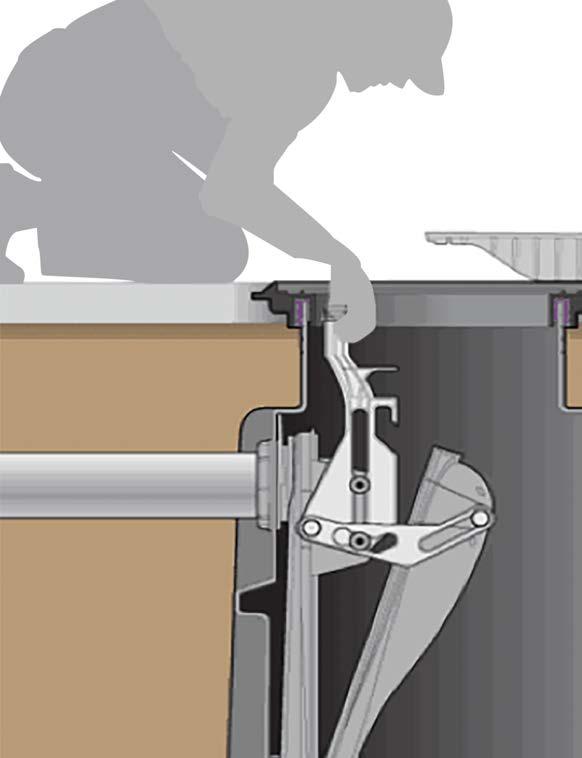

The Whalen Company’s WRX vertical stack fan coil

The Whalen Company has developed a vertical stack fan coil with a slide-out chassis, which is the first of its kind in the fan coil market. “Slide-out chassis have been available for years in heat pumps,” said Tony Landers, VP of Sales and Marketing at The Whalen Company. “Whalen has changed the way fan coils are serviced and installed by making the slide-out chassis available. When the WRX is opened, there are no additional fasteners to remove in order to slide the chassis out of the unit, making replacement effortless.”

By using a fan coil with a slide-out chassis, the time associated with maintenance and repair in occupied spaces is greatly minimized. Having the ability to slide out a chassis and not have to remove multiple fasteners and replace it with a spare allows maintenance personnel to get a unit up and running within minutes. The removed chassis is then repaired in the maintenance shop where time is not critical.

Other benefits of the WRX are reduced commissioning time, easier access to the drain pan and components, and ease of maintenance with minimal tenant disruption.

Wait Less & Waste Less With Rinnai

Rinnai’s SE+ Series Tankless Water Heater featuring ThermaCirc360™ includes thermal bypass technology. This state-of-the-art system delivers an endless supply of hot water wherever and whenever it’s needed, even for multiple tasks at once. By keeping a steady supply of heated water in the supply line during active circulation periods, the SE+ Series makes hot water quickly available for showers, sinks and appliances – no need for your customers to “orchestrate” their use of hot water.

Rinnai’s built-in recirculation technology means less water and money down the drain, saving natural resources and lowering utility costs. And customers can save even more energy by programming the unit’s 24-hour digital controller to align with usage patterns and ensure hot water is available during peak demand times.

WI-FI CONNECTIVITY

The new Rinnai Control-R™ Wireless module allows homeowners to control and monitor the unit with their smartphone through a downloadable app. For added convenience, wireless push buttons and motion sensors are available to interact with the Control-R™ module. Either the push button or motion sensor can be mounted near the point of use, reducing wait time and wasted water. The Control-R™ module can also be paired with a separately purchased temperature sensor, making it completely Title 24 compliant for California customers.

For dealers, Control-R™ serves as a remote diagnostics tool and saves time. The Control-R™ module pushes system codes and other service information automatically to dealers, enabling the dealer to proactively contact customers and arrive at a customer’s location with the right equipment and parts. Dealers are also able to reference diagnostic codes, product information and step-by-step instructions, with links to manuals, training videos and more.

CONDENSING TANKLESS TECHNOLOGY

Delivering our most energy-efficient performance, the SE+ Series features a condensing design with two heat exchangers to maximize heating value, enhance reliability and durability, and reduce maintenance.

UNIQUE FEATURES:

• Energy factor of up to .96

• Available in five sizes

• Allows for either concentric or twin-pipe venting using PVC/CPVC or PP

• Faster hot water provided by integrated recirculation pump and internal bypass line with or without a dedicated return line

• Easy maintenance is achieved with included isolation valves

Direct Air Heat Pump

Powrmatic of Canada Ltd. introduces new Direct Air Heat Pump with HeatExtrem technology.

The CS11M series of heat pumps with exclusive HeatExtrem technology can supply heat even when the temperature dips to-35°C. Perfectly adapted to our Canadian winters, CS11M models can reach 25 SEER and have an HSPF of 12 in zone IV. Energy Star and AHRI listed, their capacities are from 9,000 to 24,000 Btu/H and the 12,000 Btu/h indoor unit is only 33”. Different evaporator units are offered for residential and light commercial applications and are Wi-Fi ready. A 10 year limited warranty is standard with every CS11M series heat pump.

INDUSTRY NEWS

MECHANICAL CONTRACTORS ASSOCIATION MOVES ON UP

As of February 1, MCA Canada is located in Suite 701, just one floor up from its previous location at 280 Albert St., Ottawa, ON K1P 5G8. Contact information remains the same. www.mcac.ca

ENERGY EFFICIENCY REGULATIONS, 2016 COME INTO EFFECT IN JUNE

The Heating, Refrigeration and Air Conditioning Institute (HRAI) recently announced that Amendment 13 to Canada's Energy Efficiency Regulations had been published in the Canada Gazette, Part II.

The amendment to the Energy Efficiency Regulations, which comes into effect June 28, 2017, will increase energy performance standards for 20 products, including air conditioning units and chillers; heat pumps; furnaces fireplaces and unit heaters; boilers; gas- and oil-fired water heaters; and commercial refrigeration.

The amendment to the Energy Efficiency Regulations was published on December 28, 2016, in the Canada Gazette Part II, following a 75-day public comment period.

The regulations reflect input from business and consumer stakeholder organizations, including HRAI and the Canadian Institute of Plumbing & Heating. www.nrcan.gc.ca/energy/ regulations-codes-standards/18419

MAGNA INVESTS IN SKILLS INITIATIVES

Skills Ontario has announced that it will receive a $100,000 investment from Magna International in support of the 2017 Skills Ontario Competition, Skills Ontario Young Women’s Initiatives, and Skills Ontario Summer Camps.

The Skills Ontario Competition, held on May 1-3, 2017, has relocated to the Toronto Congress Centre – just down the highway from its longtime home in Waterloo, ON. The competition’s new venue will accommodate the steady growth Skills Ontario is experiencing.

Magna is a global automotive supplier with 312 manufacturing operations and 98 product development, engineering and sales centres in 29 countries. It has over 155,000 employees.

www.magna.com www.skillsontario.com

Continued on p20

Brant Radiant Heaters Limited

The Canadian leader in the manufacture of energy efficient natural gas, propane and electric heaters, Re-Verber-Ray heaters are ideal for industrial, commercial, agricultural and residential markets.

Headquartered in Paris, Ontario, Brant Radiant’s Canadian made products are supported across Canada with factory trained representatives. Superior tooling capabilities and technical expertise allow us greater flexibility in the design of our product offerings. In-house, we test and document every heater before it leaves the plant.

Our extensive distribution network is prepared to assist you with no-charge design analysis and answer any questions that you may have. These factory trained representatives are committed to bringing their expertise to your application.

34 Scott Ave., Paris ON N3L 3R1

Toll Free: 800-387-4778

Voice: 519-442-7823

Fax: 519-442-7321

Smart Wireless Refrigeration Scales – WRS110

UEi’s WRS110 is a Smart Wireless Refrigeration Scale offering accuracy down to 0.1 ounce with uncompromising repeatability regardless of how centred the weight is on the measuring platform. Featuring a 110 lbs. weight capacity the WRS110 only displays readings on smart device, eliminating the hassle of dealing with a wired remote. With the free iOS® or Android™ App, users can set a programmable alarm or measuring units. The WRS110 provides technicians an extended range helping to reduce dropped connections, while the battery life offers unprecedented performance needed for today’s wirelessly connected equipment.

The striking and strong body design makes this a very durable, compact and lightweight scale rugged enough to get the job done in rain, shine, and snow. Fortified with water and dirt resistant housing and built to withstand a 4-foot drop, the WRS110 is backed with a 1-year limited warranty.

AERCO Introduces Their Most Advanced Boiler Yet – Benchmark® Platinum

Benchmark Platinum Delivers Unprecedented Levels of Efficiency, Reliability and Reduced Operating Expenses for Greater ROI

AERCO launches the Benchmark® Platinum, its most advanced boiler yet that features a powerful bundle of innovative technologies, including AERtrim, AERCO’s patent-pending O2 Trim technology, dual returns, and onAER Remote Monitoring, plus an industry-best warranty.

“Benchmark boilers have been considered the gold standard in high efficiency, hydronic heating for nearly 20 years. With the Benchmark Platinum, AERCO raises that standard to a higher level, allowing customers to get the most out of their premium system through performance optimization, maximum efficiency and a significantly greater ROI,” said Peter Rimassa, Director of Boiler Value Stream and Application Engineering.

DUAL RETURNS

One advantage of the Benchmark Platinum series is its dual return capability which allows engineers to take full advantage of diverse load demands specific to a site to design the most efficient system possible. Benchmark Platinum’s dual returns keep cold water separate, creating a larger condensing zone in the heat exchanger that improves boiler efficiency up to 7%.

AERtrim (O2 TRIM TECHNOLOGY)

AERtrim monitors actual site conditions and self-adjusts its combustion process to ensure the boiler operates at optimal O2 levels despite environmental variations. Proper O2 levels provide greater uptime reliability, increased energy savings, lower emissions, and an additional 1%-2% seasonal efficiency gain.

onAER REMOTE MONITORING

Benchmark Platinum’s onAER Remote Monitoring continuously monitors the overall health of the system, helping customers maintain and protect their investment. onAER provides a convenient site that offers an instant, intuitive, easy-to-read overview of a system, including unit performance, plant efficiency, detailed technical data and more. It allows for quick resolution and prevents more serious problems from developing that can result in inefficient operation and increased expenses.

In addition, AERCO offers its industry-best warranty for the Benchmark Platinum.

INDUSTRY NEWS

MANUFACTURERS PROHIBIT THE USE OF FURNACES FOR CONSTRUCTION HEAT

On February 1, 2016 the Heating, Refrigeration and Air Conditioning Institute (HRAI) released a position paper stating that HRAI’s gas furnace manufacturers have adopted a position to prohibit the use of their furnaces by homebuilders for heating during the construction process prior to occupancy.

After learning of the concerns raised by homebuilders, the

“Blower wheels have been subjected to the rigours of residential new construction. An accumulation of drywall dust will put the wheel out of balance and result in an annoying vibration. Its ability to move the required amount of air across the heat exchanger and evaporator coil has also been completely compromised,” Ian McTeer, HPAC columnist.

manufacturers and contractors met with them on a number of occasions. Subsequently, manufacturers agreed to postpone the implementation date from September 1, 2016, to May 1, 2017. They also agreed to some standardized wording that will be included in their manufacturers’ installation instructions as follows: Gas furnaces manufactured on or after May 1, 2017, are not permitted to be used in Canada for heating of buildings or structures under construction.

HRAI furnace manufacturers have confirmed their support for this position. Several companies have already made revisions to their installation instructions. For more information, contact Caroline Czajko at 800.267.2231 ext. 234, or e-mail cczajko@hrai.ca.

HVAC, WATER HEATER RENTAL PROGRAM LAUNCHED BY SERVICE EXPERTS

Service Experts Heating & Air Conditioning recently introduced a program to allow homeowners to rent new, brandname heating and cooling equipment at each of its 15 Canadian locations. Additionally, water heater rentals will roll out to all 15 locations.

“Water heater rentals are widespread in Ontario, but not in

the other provinces – and renting a furnace or air conditioner is a newer concept throughout the country,” said Tim Inch, vice president/general manager national operations for Canada. “However, it is a market that we believe will experience increasing demand as we make this service available in all the communities we serve.”

Founded in 1996 and headquartered in Plano, TX, Service Experts has residential and commercial customers in 29 states in the U.S. and three provinces in Canada. www.serviceexperts.ca

CGC BOARD APPOINTS PRESIDENT AND CEO TO LEAD ASSOCIATION TRANSITION

The Canadian GeoExchange Coalition (CGC) board of directors has appointed Ted Kantrowitz as president. Kantrowitz joined the organization’s current board and assumed CEO duties immediately. His appointment follows the resignation of former president and CEO Denis Tanguay.

During CGC’s recent transition, staff has been addressing strategic, policy and operational challenges. CGC will soon communicate with members, allies and industry friends about recent operational improvements and CGC’s future.

Kantrowitz will provide a briefing to members on CGC activities and progress prior to new CGC board elections at CGC’s next annual general meeting. Specifics of the AGM, which will take place before June 30 2017, have yet to be announced.

The CGC is a national industry association for renewable, efficient heat pump technology. It recently relocated to 7240 Waverly Street in Montreal, QC. www.geoexchange.ca

RSES CANADIAN CAPITAL CHAPTER TO HOST ANNUAL CONFERENCE

The Annual Refrigeration Service Engineers Society (RSES) Canada Conference will be held at Algonquin College in Ottawa, ON on May 5 and 6, 2017. The program includes four speakers, opportunities to test for the CM, CMS designation, and a dinner at Algonquin College on May 6. Sign in for conference begins on May 5 at 3 p.m. The AGM will be held that evening at 8 p.m. following a hydronics session presented by Dave Digel.

Phil Boudreau leads the speaker program on Saturday with his session on CO2 refrigeration. Brynn Cooksey and Jamie Kitchen will address electrical and troubleshooting strategies respectively. www.rsescanada.com/conference.cfm

Consider using Uponor PEX-a for your next Hydronic Piping project.

Sponsored Case Study Profile

Engineers and contractors are recognizing PEX as a technology that retains all the advantages of traditional piping materials, while adding unmatched flexibility and strength.

If you’ve been on a commercial jobsite recently, you may have seen an opaque white pipe being used for the potable-plumbing system. This pipe, called PEX — an acronym for crosslinked polyethylene — is quickly gaining popularity in the engineering and trades sectors due to its flexibility, durability, stable material costs and performance. And now that the commercial plumbing industry has gotten on the PEX bandwagon, hydronic piping professionals are starting to look at it as well.

From an application standpoint using Uponor’s Wirsbo hePEX™ can work with any terminal unit in a hydronic heating system — fan-coil units, baseboards, radiators, chilled beams, VAV (variable air volume) reheat terminal units, radiant manifolds, etc. Also, because of its copper tube size (CTS)-controlled outside diameter, switching to PEX-a piping involves minimal process change. All the hangers, pipe supports, insulation, etc. can be the same, offthe-shelf components used in a copper piping system. Uponor complements the full offering of product with extensive design services to make this switch a reality.

piping applications. The use of Uponor PEX pipe supports permits hanger spacing that is similar to copper pipe, so it reduces the required amount of hangers by half. And since fewer hangers mean lower material and labor costs, Uponor PEX pipe

Bridging the differences between Wirsbo hePEX pipe and copper in most applications is the Uponor PEX pipe support, a galvanized steel channel providing continuous support in suspended

Want to learn more?

support results in a less-expensive installation.

A major criticism of — and misconception regarding — PEX-a in commercial piping applications is its perceived lack of visual appeal. Con-

For more information on using PEX-a piping for your next Hydronic project or to get a copy of Uponor’s Guide for Hydronic Piping email Jason Smith at jason.smith@uponor.com

tractors and building owners typically expect long, evenly spaced, rigid pipelines running through a building. It’s a look of solidity and durability that many associate with copper and believe PEX-a lacks. Fortunately, Uponor PEX pipe supports reinforce and cover the pipe, negating any aesthetic criticisms. Uponor PEX pipe supports also allow Wirsbo hePEX pipe to be run inside a plenum without spacing limitations between the horizontal runs.

But perhaps the most critical feature of Uponor PEX pipe support is its ability to control the natural expansion and contraction that occurs as the piping heats and cools. Installing anchors and using Uponor PEX pipe supports allow the piping system to function much like a copper system.

This ability to control PEX’s expansion and contraction is critical to allowing for a minimum redesign on a piping system when switching from copper. Thus, Uponor’s PEX pipe supports allow designers to leverage similar design schemes using Uponor PEX as they would for copper.

Engineers can be assured that, although Uponor PEX-a may still be new to them, it has been reviewed and approved as a reliable means of hydronic piping for more than 40 years. With its flexibility, durability and — in conjunction with Uponor PEX pipe supports — its ability to mimic copper’s rigid properties while offering several revolutionary improvements. The common hassles and uncertainties of switching from copper are completely alleviated, allowing the benefits of an improved piping system to stand out.

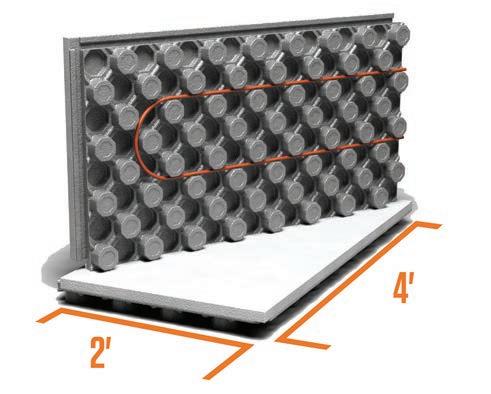

Amvic Insulated Pex Panel; Hydronic Radiant Floor Heating Systems

DESIGN

Amvic’s insulated PEX panel combines a number of unique elements making it one of the best panels on the market. The panel consists of expanded polystyrene insulation, moulded to high impact polystyrene film. This combination makes for a stronger, more resilient interlocking PEX panel. Additionally, the panel nubs form a mushroom shape, locking the PEX piping firmly in place. Once inserted, it guarantees that the pipe is properly positioned and seated in the panel. The innovative panel design with bridging and cavities ensures that the PEX tubing will be completely surrounded with concrete and not pushed to the bottom of the panel. This feature will allow for better heat distribution from the radiant tubing and a more efficient energy transfer.

CONTRACTOR SAVINGS

The design of the Amvic PEX insulation panel makes for a very durable and simple install on the job site. Because of its strength and stability, contractors can handle the material with ease eliminating breakage, replacement and additional labour. The film on the panel along with the nubs, allows the PEX tubing to be walked in and locked into place, rather than constant bending to wire-tie or staple the tubing firmly into place cutting labour time and material costs. The oversized four sided tongue and groove interlock system makes installation quick, easy and secure. The size of the panels also increase productivity and precision when placing the panels on the floor. The 2x4 panels become easier to maneuver, easier to place and easier to identify leveling inconsistencies.

APPLICATIONS

Hydronic heating can solve winter season problems by implementing a snow and ice melt system by circulating warm liquid through PEX tubing which is concealed in the concrete. These systems can be easily installed in residential, commercial or industrial applications such as driveways, sidewalks, stairs, entrances, parking lots, ramps, helipads and much more.

Homeowners can choose to have hydronic heating throughout their entire home which can eliminate the need for forced air units and reduce utility bills.

Common living areas for floor heating include the bathroom, the family room, the garage/driveway, entrances and even the kitchen.

Navien’s Award Winning NCB

Combi-boiler Evolves to the NCB-E

Navien’s NCB series is unique in that, as one unit, it is capable of providing a whole house heating system while also providing the domestic hot water output of a standalone tankless water heater. Proving that Navien engineers never rest on their laurels, the new NCB-E (E for evolves) will be a rolling replacement, now with a Grundfos pump, an integral air vent, a PRV top connection, a quieter fan and a new front cover bevel design.

Following the 2014 Canadian Institute of Plumbing & Heating Innovation Award at the MEET trade show of Mechanical, Electrical, Electronic Technologies in Moncton, NB, Canada, Navien’s NCB Combi-boiler Series was voted #1 in the 2014 Comfortech Product Showcase Awards contest, in the category of Plumbing.

This follows Navien’s motto of “Making the world more comfortable every day” said Eric Ashley, Marketing Product Supervisor for Navien.

Innovation: Dual inputs of 120k BTU/h of heating, 199k BTU/h of DHW capacity and the ability to link with NPE series tankless water heaters for expanded DHW delivery, featuring many firsts in the industry.

Value: The NCB-E series is priced competitively compared to other combination boilers but unlike others, the NCB-E series can deliver an impressive volume of domestic hot water to satisfy the demands of a large home. With an AFUE of 95%, the NCB carries the coveted Energy Star Most Efficient Rating.

Market Impact: The NCB-E is capable of providing up to 120k BTU/h heating capacity, and an impressive 199k BTU/h of DHW capacity. The contractor can now offer a complete package for whole home heating as well as endless hot water to satisfy the lifestyle of consumers today.

Training on all Navien products is available throughout Canada. To this end, Navien has recently hired Leo Vaillancourt, a 44 year veteran in the plumbing and heating industry, as Trainer for Western Canada. Leo’s knowledge and experience will help empower our customers to grow their businesses, says Mark Williamson, Navien’s Canadian General Manager.”

For more information on the new NCB-E series, visit www.WholeHouseCombi.com.

The loyalty program that’s only for our All-Star professional contractors

The Navien route: loyalty rewards and no detours around contractors

The road to greater profits runs through Navien, the leader in condensing technology for boilers and tankless water heaters. Our new NavienRewards program shows how much we appreciate working only with professional contractors. Unlike other brands, we won’t take shortcuts with alternate distribution channels.

NavienRewards not only gives you the resources that drive more profitable sales, it also provides incentives for you and your team. No other manufacturer can match our contractor support.

Check out all the NavienRewards advantages, including one of eight chances to win a seven day trip for two to South Korea in February, 2018. You’ll enjoy two days at the Winter Olympics, factory tours and sightseeing. To be eligible, sign up today at NavienRewards.com. #NavienAllStars

The case for stainless steel

Despite the higher price tag, stainless steel tanks are often more cost effective when lifecycle costs are compared and should be presented as such to customers. BY ROBERT

WATERS

Domestic water heating appliances are the real foot soldiers of the mechanical world. They are constantly exposed to a very hostile environment and their hard work is mostly ignored. On the water side of the heater, minerals, oxygen, chemicals and sediment can all attack. On the combustion side, high temperatures, thermal stress and flue gas condensate can all create havoc with the materials.

When it comes to maintenance, domestic hot water (DHW) heaters are virtually ignored. Most homeowners take their water heaters for granted and only notice them when they are not working or are leaking. Check the anode rod? Flush out the sediment? Have a maintenance program? Forget it, we are not bothering with that. It is no wonder that most DHW appliances have fairly short life spans. Could this short lifespan be improved? Using DHW heaters made of stainless steel is one way to improve life expectancy. Stainless steel is a strong, durable material that can better stand up to water side and fire side attacks, giving the heater a fighting chance to provide a long service life. Stainless steel’s only real drawback is its high material and fabrication cost. In the ultra-competitive DHW heater market, this high cost is a big challenge to overcome.

WHAT IS STAINLESS STEEL

Stainless steel is a generic name for iron alloys with a minimum of 10.5 per cent chromium. Other elements such as nickel, molybdenum, titanium, and carbon can also be added to provide corrosion resistance, strength and formability. There are many different combinations of these different metal alloys that produce a particular "type" and "grade" of stainless steel. Just saying something is made of stainless steel does not tell the whole story.

“Just saying something is made of stainless steel does not tell the whole story."

If someone said “Get me some plastic pipe” what would you bring? PEX, CPVC, polyethylene? All of these are “plastic” pipes, yet all have very different properties, strengths and applications. It is the same with stainless steels. There are over 150 grades of stainless steel, all having very different properties and applications. Stainless steel used in domestic hot water heaters are most commonly made from only a few grades of stainless steel, typically types 304, 316L, 316Ti and 444.

The difference between these grades is in what concentration of alloys is in them. All “300” grades of stainless steels contain approximately 18 per cent chromium and 10 per cent nickel. Both of the 316 grades also contain two per cent molybdenum, and 316Ti grade adds one per cent titanium to the

mix. The molybdenum gives 316 grades better overall corrosion resistant properties than 304 grade, particularly higher resistance to pitting and crevice corrosion in chloride environments. Titanium in the 316Ti grade gives it excellent formability and strength. 444 grade does have chromium and molybdenum, but it does not have any nickel. Generally speaking the more nickel, molybdenum and titanium there is in the mix, the better the corrosion resistance and strength, but also the higher the cost. Take a closer look at the grade when someone says they have a “stainless steel” water heater because they are not all the same quality.

USING STAINLESS STEEL IN DHW HEATERS

Stainless steel is used in all different types of water heaters. It is most often seen in use in indirect DHW heaters and in condensing tankless water heaters. Indirect water heaters incorporate an internal heat transfer coil connected to a boiler or a solar collector loop. They are more common in Europe than in Canada due to the predominance of hydronic and solar water heating systems in Europe.

Stainless steel construction makes up a big part of these European indirect markets. In Canada, both stainless steel and glass lined steel indirect tanks are available, with stainless steel tanks usually carrying the higher price tag. In noncondensing tankless water heaters the heat exchangers are typically constructed of copper. With the push to higher efficiency condensing units, heat exchangers are either all stainless steel, or a combination of a primary copper and a secondary stainless steel heat exchanger. The direct-fired tank type water heater is still king in Canada's water heater market. Carbon steel with glass linings dominates this sector.

Stainless steel is often used in tankless or direct-fired tank condensing water heaters. When squeezing more efficiency out of these appliances, the flue gases must be cooled below the dew point to release the latent heat of the fuel. The resulting condensate is basically distilled water vapour from the gas combustion products and it has a very low pH and high acidity. This acidic condensate water must be disposed of by piping it to a drain, but the bigger concern is its corrosive impact on the water heater heat exchanger surfaces. Heat exchangers made of regular steel or copper have a harder time standing up to this flue gas condensate for long.

Stainless steel is a great material choice due to its high corrosion resistance and flexibility, which gives it the ability to be formed into intricate heat exchanger shapes. There are currently numerous brands of condensing tankless water heaters employing stainless steel heat exchangers. This enables them to encourage complete flue gas condensing in the heat exchanger, and results in high EF ratings of up to 0.97.

Tank type water heaters with condensing technology are also now starting to be used more often, especially with

changes to some building codes requiring higher water heater efficiencies. There are two common types of construction seen in this market. Glass lined tanks are being constructed with fully submerged secondary condensing heat exchangers. Both the outside (water side) and inside (fire side) of the heat exchanger coil is glass lined, with the glass lining on the inside providing protection against flue gas condensation. Tank models with all stainless steel tank and coil construction are not as common, but there are several available with this type of all-stainless construction.

The glass lined tanks do carry a lower initial cost and only time will tell how well the heat exchangers stand up to the aggressive condensing environment. These new condensing tank type water heaters are able to achieve higher efficiencies than conventional direct-fired water heaters, with thermal efficiencies between 90 and 96 per cent. As governments push water heater efficiency regulations higher and higher, we are sure to see more innovative high efficiency tank type water heaters come to the market.

ADVANTAGES OF STAINLESS STEEL CONSTRUCTION

Looking more closely at tank type water heaters, you can find both glass lined and stainless steel construction for most types of direct-fired, indirect internal coil and straight storage tanks. So, what are the advantages of stainless steel over glass lined? How can you convince customers to invest more

Continued on p30

LIBERTY PUMPS

ProVore® Grinder Pumps

Grinder technology is advancing and Liberty Pumps is at the forefront of evolving sewage pump performance. The new ProVore® grinder from Liberty Pumps is designed for use in residential applications where an addition of a bathroom or other fixtures below sewer lines requires pumping. It features Liberty’s patented V-Slice® cutter technology utilized in its popular Omnivore® series of 2 hp. grinder pumps. This proven cutter design easily shreds solids - such as feminine products, rags and other unwanted debris. The new ProVore® brings this advanced technology down to a more cost effective residential level. Powered by a 1 hp. motor, this smaller grinder is designed to operate on a standard 115 or 230 volt circuit – requiring only a 20 amp breaker. No special wiring, as is necessary with larger hp. grinder pumps, is needed.

The pump comes with a 2” vertical style discharge (common on solids-handling pumps) and a standard leg pattern matching Liberty’s LE-Series. This allows for an easy retro-fit into already existing systems. Engineered with flow rates to 46 GPM – the ProVore® provides adequate scouring in 2” discharge lines with lower pumping heads commonly found in residential basement installations.

Compact factory assembled systems are available in both simplex and duplex versions. The ProVore®380 uses Liberty’s very popular PRO380 basin. This system features Liberty’s QuickTree® technology for easy field service of the floats without removing the cover or disconnecting the plumbing. A quick-removal access cover and heavy-duty integrally molded gaskets are also features found on this system. In addition, Liberty has just launched the new ProVore®680 – a compact duplex version of the 380. Standing only 24” tall, this small profile duplex system utilizes two ProVore® pumps for uninterrupted service. An advanced pump controller is included with the system to alternate pump operation and provide an alarm to the homeowner in the event of a failure.

Whether it’s a traditional solids-handling pump or a newer style grinder, Liberty’s broad offering of products can satisfy a variety of pump applications, and with its aggressive product development strategy, you can be assured Liberty will continue to meet the needs of today’s rapidly evolving market.

...You decide!

Stop the jamming associated with solids-handling sewage pumps and move over to the new ProVore® 1 hp. residential grinder - now available in compact simplex or duplex packages!

ProVore® residential grinders feature:

• Powerful 1 hp. motor

• Patented V-Slice® cutter technology –easily shreds feminine products and other tough debris known to jam standard sewage pumps

• No special wiring - runs on standard 115V or 230V, 20 amp circuitry

• 2ll discharge US Patent # 7,159,806 and Patent Pending

Patented V-Slice® Cutter Technology

< PLUMBING

in a stainless steel tank? The biggest advantage of stainless steel is its natural resistance to corrosion from fresh water resulting in a much longer service life. Due to their composition of corrosion resistant metal alloys, stainless steel tanks are stronger and more durable compared to glass lined ones. Stainless steel water tanks have a protective oxide barrier on the water side that prevents corrosion naturally.

On the other hand, glass lined tanks rely on the glass lining to provide a barrier between the carbon steel and the water. Given the chance, oxygen and chemicals in the water will attack the steel and rapidly corrode it. As it is very nearly impossible to apply any protective coating perfectly (without microscopic cracks or pinhole defects in the protective layer) glass lined tanks include a sacrificial anode rod installed inside the tank.

The sacrificial anode rod will become depleted over time and when this process has completed, electrolysis will begin to eat away at the exposed areas of steel on the tank interior. How fast the anode depletes will depend on the water quality, and the water usage rate. The sacrificial anode typically lasts from three to five years and it is possible to replace the anode to prevent further destruction.

In reality, the periodic check and replacement of the anode is often neglected and the tank develops a leak, resulting in the entire appliance being replaced. Unlike glass lined water tanks, stainless steel tanks do not need a “sacrificial anode” in order to prevent corrosion on its surface. This means there is no need for inspection or replacement of anodes, saving time and cost in maintenance over the life of the water heater. Due to this higher durability and resistance to corrosion, you will often find that stainless steel tanks have a longer warranty, with some manufacturers offering lifetime warranties on tanks.

Stainless steel water tanks also have the advantage of being lighter weight compared to glass lined tanks making them easier to transport, handle and install. The wall thickness of stainless steel used in tanks is typically much thinner than a comparable steel tank with glass lining. Add on top of this the weight of the glass lining itself, and the weight of a glass lined tank is often significantly more.

Stainless steel tanks require less attention when being transported, unlike glass lined tanks, which have the delicate glass lining that can be damaged when in transit. If the glass lining of a tank is damaged or cracked due to rough handling during transportation or installation, it may not be known until the tank suffers premature failure.

Stainless steel tanks are typically able to withstand higher temperature water than glass lined tanks, with temperatures in excess of 180F not presenting any issues. Some glass lined tanks are prone to stress when subjected to elevated temperatures, leading to a higher risk of damage to the glass lining. Temperatures above 160F can become an issue for some glass linings. Applications such as solar water heating and some commercial-industrial applications can see high temperature water storage requirements.

It is advisable to check with glass lined tank manufacturers to find out what the recommended maximum operating temperature is. Stainless steel tanks are often a better choice for high temperature applications.

There is no doubt that the initial cost of stainless steel tanks is higher than glass lined water tanks. But the lifecycle cost of glass lined water tanks may become higher for the reasons noted here. When those lifecycle costs are compared, stainless steel tanks are often more cost effective in the long run and should be presented as such to customers.

Robert Waters is president of Solar Water Services Inc., which provides training, education and support services to the hydronic industry. He is a mechanical engineering technologist graduate of Humber College and has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com.

Rheem Hybrid Electric Heat Pump Water Heater

The Rheem hybrid water heater is the most efficient residential tank water heater on the market and is Net Zero compliant. It is used in Net Zero projects across Canada. The product has an EF of 3.50 – making it the most efficient tank water heater in the market today! It is also Northern Climate

Tier 3 certified which means it has been tested to meet stated efficiencies even in Canadian climates. The product is EcoNet enabled, giving homeowners WiFi control of their water heater from their mobile devices to set the temperature and receive instant alerts in case of regular maintenance or service notifications.

AWARDS:

• 2014 AHR Expo Innovation Award, Plumbing

• 2014 Gold Dealer Design Award

• 2013 Comfortech Product Showcase Award

• 2016 Product of Choice for Net Zero Homes in Canada

WATER

It’s more than just innovation. It’s applying nearly 100 years of experience to today’s homes and improving the things that matter the most to contractors — Performance, Installability™ and Serviceability That’s why we evaluate every detail of our products from top to bottom, inside and out, and everything in between to help you deliver the best homeowner experience...And then we take it further. That’s 360°+1.

Rheem EcoNettm makes diagnostics easy for contractors and provides homeowners with ultimate air and water control using the FREE Rheem EcoNettm App Rheem.com/EcoNet

PLUMBING PRODUCTS

Milwaukee Tool’s Trapsnake porcelain auger system helps unclog toilets, urinals and floor traps. The tool offers multiple auger attachments that can be unified on one power source. The system’s driver is optimized for porcelain fixtures, and the electronics deliver low RPM and torque. There is a choice of 6-in. toilet auger and 4-in. urinal auger extension. Attachments feature a telescoping cable lock, fixed rubber boot for porcelain protection and replaceable cables. The augers are compatible with the entire M12 System. www.milwaukeetool.com

From Danze, Inc. comes the Foodie Pre-Rinse kitchen faucet, featuring a spring-action wand. The Foodie, which matches any sized home kitchen, has a 20-9/16-in. high spout and an 8-7/8-in. spout reach. Users can toggle between a single steady water flow and a spray. The Foodie comes in chrome, stainless steel and satin black finishes. Danze uses a ceramic disc valve in the faucet for a tight seal and drip-free performance. It meets low-lead content requirements and operates at a water efficient rate of 1.75 gallons per minute. www.danze.com

Gerber has added the Hinsdale suite of decorative products to its vitreous china product mix. Hinsdale styling is offered in: a two-piece high efficiency toilet operating at 1.28 gallons per flush/4.8 L, a 25-in. pedestal sink and a 21-in. petite pedestal sink. The sink basins are available with a shroud and all products come in white. The WaterSense-certified Hinsdale toilet features the QuietClean flushing system with dual-siphon jet technology that pushes water down through the top of the bowl. www.gerberonline.com

Continued on p34

PEACE OF MIND.

BACKED UP .

When the electricity goes out, have peace of mind knowing the homeowner,s investment is protected with the Little Giant Battery Backup System. This efficient pump puts less strain on the battery, and its proven switch technology minimizes mechanical hang-ups. They have a nice basement. Keep it that way.

Experience Innovation. Experience Franklin.

NEO VALVES

Lead free press valves from Jomar

Jomar lead free, press connection ball valves are the latest compliment to Jomar’s wide range of valves for plumbing, heating and industrial applications. The Jopress series is manufactured in Italy from heat treated, dezincification resistant brass. It’s designed to meet all CSA lead free requirements and provide a high level of durability and corrosion resistance. Jomar uses a patented triple stem seal that allows for a lifetime warranty against leakage through the stem. Premium materials like hostaflon seats and geomet handles are used to make this long lasting valve. The Jopress series is available from ½" – 4" XLC and is 100% factory tested. Jomar products are distributed in Canada by NEO Valves. For more info please contact info@neovalves.com or 1-888-515-8885.

Lead Free Press End Ball Valves

PLUMBING PRODUCTS

The Verge basin by Bradley Corp. has all handwashing elements accessible in one unit. WashBar technology includes a piece of chrome-plated stainless steel combining soap, water and dryer. Features include a one-gallon soap container that is replaced with a full container when an LED indicator illuminates. The dryer balances airflow and noise and air speed is adjustable. Water is dispensed at 0.5 GPM, also available at 0.35 GPM. Offered in single-, two- or three-user models, the Evero Natural Quartz basins are suited to commercial applications. www.bradleycorp.com

Chicago Faucets has updated its HyTronic and E-Tronic 40 series electronic sensor faucets to reduce the maximum flow rate. An optional 1.5 GPM flow rate insert will be included, replacing the 2.2 GPM insert. The majority of fittings in both product families come with a pre-installed 0.5 GPM outlet. The HyTronic and E-Tronic 40 Series faucets come in six styles and over 60 configurations. Three power options are available: AC, DC or self-sustaining. Accessories include the Commander Handheld Programming Unit for maintaining, monitoring and adjusting faucets. www.chicagofaucets.com

Newport Brass has added a freestanding tub filler to their architectural style Skylar collection. The filler features an integrated diverter and hand shower with flexible metal hose. The hand shower conserves water with 2.0 GPM at a 60 psi flow rate. The spout height is 38 in. (from floor) and the tub filler has an optional rough-in fitting for concrete sub-floor installations. Finish options include polished nickel, satin nickel and polished chrome. www.newportbrass.com

Continued on p36

BOILERS PEX

THE BEST OF BOTH WORLDS!

From a brand you have come to trust comes a new series of water heaters. Introducing our new Tank-Tankless Crossover TTX Series. The TTX Series from GIANT delivers a convenient way to increase hot water capacity as well as comfort without complicating installation as it installs just like a regular water heater making it perfect for same-day replacement.

Two standard products combined for an outstanding performance. Truly the best of both worlds! This new water heater combines the on demand heating technology of a Tankless water heater with an efficient storage tank resulting in more than twice the capacity of a standard traditional 50-gallon water heater.

The new Tank-Tankless Crossover TTX Series from GIANT. COMFORT AT YOUR FINGERTIPS.

A trusted brand. Innovation and comfort at your fingertips.

PLUMBING PRODUCTS

Viega offers a line of ProPress Zero Lead Ball Valve press x hose thread for copper fittings. The bronze ball valves are full port and designed for potable water applications and are available in ½-in. and ¾-in. press sizes and ¾-in. hose sizes. Features include a lockable metal handle, stainless steel ball and EPDM sealing element. The system comes in over 600 fitting configurations and sizes ranging from ½ in. to 4 in. Viega ProPress joins copper tubing without flame or heavy equipment and suits most residential, commercial, industrial applications from potable water to natural gas. Fittings are available with EPDM, HNBR and FKM sealing elements. www.viega.us

Uponor North America has launched the ProPEX connections for water service applications. Targeted for single-family homes and multi-family submetering, it’s available in engineered polymer (EP) straight or angle fittings and lead-free (LF) brass straight or angle valves for connecting ¾-in. and 1-in. Uponor AquaPEX pipe to ⅝-in., ¾-in. and 1-in. water meters. Both fittings and valves feature NPSM swivel connections found on all water meters sized ⅝-in. to 1-in. The offering includes mounting brackets to support the water meter system. www.uponor.com

DROP DOWN LADDER RACK

Exclusive twist-to-adjust feature

Easy to operate: Anyone 5’4” or taller can operate

Corrosion resistant design

GRIP LOCK LADDER RACK

Easy reach for anyone 5’7” or taller

Secure clamping mechanism

Corrosion resistant design

The right angle double bowl from Valley Acrylic Bath features two glass panel covers. It is handcrafted from a panel of T-304 stainless steel and features sound-deadening insulation, drain groove design and C/W basket strainers. The bowl is installed under the counter. Its dimensions are: 14.75" x 14.75" x 8" (375 x 375 x 203mm) bowl and 34" x 19.75" X 8" (864 x 502 x 203mm) deep. www.valleyacrylic.com

Geberit has revamped its product and parts catalogue, which features complete product details and a new replacement parts section combining Geberit installation systems, flushing systems and actuator and cover plate parts. Replacement parts are combined in one section so users can find replacement part information for any Geberit product. The 74-page catalogue includes in-wall systems, flush plates and push buttons, bath waste and overflow systems with exploded views, replacement parts identification and optional accessories. The catalogue identifies available Geberit model and replacement part numbers, along with list pricing and an index of part numbers with page references. www.geberitnorthamerica.com

Many Products…..One Source

The demand for stainless steel fittings, nipples and valves is growing rapidly as it replaces lower performing lead-free brass in plumbing and water well applications around the world.

Boshart Industries is pleased to offer more choices in stainless steel fittings to meet this new demand. We now offer a complete array of light-pattern, ISO 4144 fittings suitable for residential plumbing and light commercial applications, as well as heavy-pattern MSS SP-114 fittings which are suitable in heavy commercial and industrial piping systems in industries including chemical, pulp & paper, petroleum, food & beverage, sanitary and steam systems, just to name a few.

Both light and heavy pattern fittings are available in 304 and 316 grades to meet your corrosionresistance needs. 316SS adds 2% molybdenum and 2% nickel (with 2% less chromium) to assist in chloride corrosion resistance (salt).

Both our light and heavy pattern fittings are available in all common configurations in sizes 1/8" through 4". When added to our existing stainless steel nipples and valves, Boshart offers a complete solution to your stainless steel needs. To seal the deal, Boshart has available Gray Magic thread compound and PTFE tape specifically for stainless.

AquaPLEX - Not your Ordinary Stainless Steel Tank

PVI AquaPLEX domestic hot water storage tanks are constructed from duplex stainless steel, an alloy that combines the grains structures of austenitic (300 series) and ferritic (400 series) stainless and provides the benefits of both. After all welding is completed, the tanks are immersion pickle-passivated in a hydrofluoric and nitric acid bath to deep-clean the material to its original pristine condition and allow the recreation of a naturally occurring corrosion resistant chromium oxide layer on its surface.

AquaPLEX is ideal for potable water heating applications because the alloy is highly resistant to general aqueous corrosion in addition to being resistant to stress corrosion cracking, which can occur with 300 series stainless steels when dissolved chloride salts are present in the water supply. This inherent corrosion resistance results in tanks that require no supplemental lining and no anode rods of any type, regardless of stored water temperature.

PVI provides a 25-year tank warranty on potable water storage tanks and tanks used in electric, boiler water and steam-fired storage water heaters. AquaPLEX tanks range in size from 125 to 3000 gallons storage and are ASME stamped for a 150 psi working pressure. Vertical and horizontal tank configurations are available. For more information on the variety of models and energy sources available in AquaPLEX commercial water heaters, visit the PVI Industries website at www.pvi.com.

CONQUEST® GAS WATER HEATERS

100 GALLONS STORAGE

15-YEAR TANK WARRANTY IS STANDARD

CONQUEST® GAS WATER HEATERS

130 GALLONS STORAGE

399,000 to 800,000 Btu

Modulating Burners Available

TANK WARRANTY IS STANDARD

thermal efficiency

POWER VTX® GAS WATER HEATERS

225 GALLONS STORAGE

500,000 to 1,000,000 Btu

Modulating Burners Standard

199,000 to 300,000 Btu 15-YEAR TANK WARRANTY IS STANDARD www.pvi.com

ENGINEERED DUPLEX ALLOY

AquaPLEX is a remarkable new water heater tank material created by alloying 300 and 400 series stainless steels and capturing the benefits of both. Fully pickle-passivated after complete tank fabrication, AquaPLEX is naturally corrosion-proof in potable water regardless of stored water temperature.

• Tank walls are solid AquaPLEX. There is no lining, coating, cladding or plating of any kind. Nothing that can erode, crack, delaminate or wear through over time and expose a steel tank to water

• No anodes of any type are required. AquaPLEX tanks are unaffected by aqueous or galvanic corrosion so an anode rod has nothing to do. And this means tank life cannot be compromised by insufficient anode rod “reach” or condition

• AquaPLEX is immune to chloride-induced stress corrosion cracking; a known failure mode for 304L and 316L stainless steel in hot potable water

• AquaPLEX is as much a process as it is a material. Tanks and welds are designed to eliminate crevices and we employ unique fabrication processes to ensure maximum longevity of the tanks

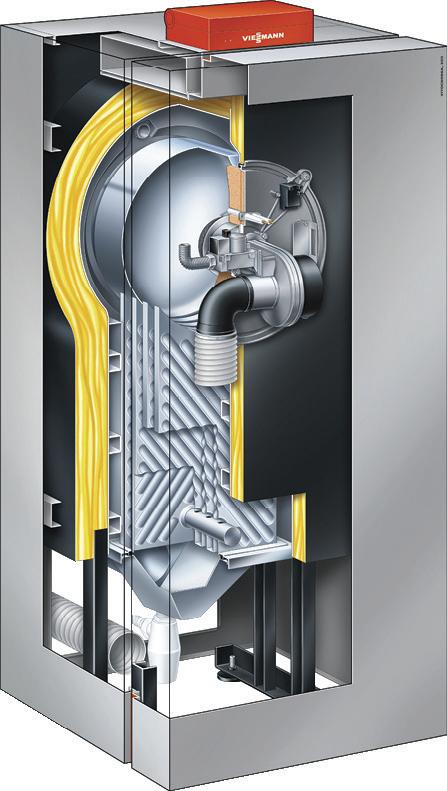

Vitocrossal 300, CU3A - The perfect “drop-in” solution for high-mass, high-temperature applications

Viessmann has a long history of consistently offering one of the most complete and flexible ranges of heating solutions on the market.

Continuing in this tradition, the Vitocrossal 300, CU3A gas-fired floor-standing condensing boiler combines proven condensing technology with quality Viessmann craftsmanship. With its high water content, the Vitocrossal 300, CU3A is the perfect choice for homes with high mass cast iron radiators or multi-zone high temperature fin tube radiators, as well as new installations with high DHW requirements.

A time-tested and trusted condensing boiler with over 20 years of performance credentials in European heating markets, the CU3A offers the following benefits to the heating contractor:

Ease of Installation

• The floor standing design and small footprint of the CU3A allows for trouble-free positioning within the boiler room and eliminates the need for concrete platforms, cement blocks, or the construction of a wall on which to mount the unit.

• High mass design and low pressure drop eliminate having to purchase and install special piping, dedicated boiler pumps, low loss headers, etc.

• The Vitocrossal 300, CU3A can simply be connected to the existing system piping, making it the perfect “drop-in” solution for boiler replacement projects.

Straight-Forward Commissioning

• The CU3A features boiler and system controls that are factory pre-set to handle virtually any application.

Hassle-Free Serviceability and Easy Access

• The smooth stainless steel heat exchanger surfaces allow condensate to simply run downwards, creating a permanent self-cleaning effect. This ensures continual high-efficiency operation, long service life, and reduced maintenance requirements.

• Inspection of the combustion chamber and burner components is easy. Simply remove the boiler’s front cover, break the gas union, remove a few bolts and disconnect plug-and-play electrical connections and you’re done. Just pull out the burner and rest it on the support hooks provided for that purpose. Any dust or debris that may have collected within the combustion chamber and heat exchanger can simply be flushed away using a simple garden hose.

Vitocrossal 300, CU3A – another powerful heating solution from Viessmann!

SIMPLE & SOPHISTICATED

Hydronic systems do not have to be complex to be state of the art. BY JOHN SIEGENTHALER

As the North American hydronics industry has grown, so has the complexity of its systems. Many installations that are now featured as award winning examples of hydronic heating contain thousands of parts and pieces. They can be so complex that only the person who designed and installed them understands how they operate, or can fix them when they do not. That is not good for the system owner or for the industry.

Although there are some buildings, perhaps even some single family homes that benefit from having a dozen or more heating zones, as well as a wide mixture of heat emitters, they do not represent

the mass market in which hydronics still only holds a single-digit share. Promoting the concept of hydronic heating with photos of elaborate systems containing lots of hardware can easily send the wrong marketing message. Instead of comfort combined with peace-of-mind reliability the average consumer may be thinking "expensive, complex and what happens when it breaks?"

CUTTING EDGE CONCEPTS

Instead of a wall full of circulators or zone valves, let’s look at a simple system that provides space heating and domestic hot water. It is simple in that only one type of heat emitter is used;

simple because the control logic is preengineered rather than customized; and simple from a piping layout standpoint.

Perhaps you are thinking that simple excludes being state of the art. This is not the case. The system discussed here uses cutting edge concepts such as outdoor reset control, boiler modulation and variable speed pumping. It personifies the state of the art in hydronics technology but with far fewer parts and pieces. A piping schematic of the system is shown in Figure 1.

We will examine each subsystem independently and then look at how they all work together.

HEAT SOURCE

The system’s only heat source is a mod/ con boiler. A wide assortment of such boilers is available in North America, and most are capable of operating with either natural gas or propane. All have internal control logic that allows them to regulate the water temperature supplied to the heat emitters in response to outdoor temperature (e.g. outdoor reset control). The warmer it is outside the lower the boiler temperature and the higher its efficiency. These “partial load” conditions represent the majority of the heating season. The system must be stable and efficient during these times, as well as under brief peak load conditions.

When it is time for domestic water heating a mod/con boiler temporarily ignores outdoor temperature and fires itself to an elevated “setpoint” temperature to drive all heat output through the heat exchanger in the indirect water heater. During this mode of operation circulator (P2) is turned off while circulator (P1) operates.

BUFFER TANK

This system provides room-by-room comfort control using individually controlled panel radiators. Each radiator represents a separate zone. There will often be times when the heating load (perhaps a single room) is far lower than the minimum heat output rate of the boiler. Under such circumstances any low mass boiler with minimal water content will short cycle. This can lead to premature failure of ignition and combustion components.

Short cycling is avoided by installing a well-insulated buffer tank in the system to provide additional thermal mass between heat production and heat release. The boiler maintains the temperature of the buffer tank based on outdoor reset control. This happens whenever the system is not in “warm weather shut down” mode, regardless of what the space heating demand happens to be. Thus, a small heat emitter

such as a bathroom towel warmer could operate at a “trickle” rate of heat transfer without forcing the boiler to operate until the buffer tank temperature drops below the required lower limit. Whenever space heating may be needed there’s always warm water in the buffer tank ready to immediately meet the demand.

A 25-gallon buffer tank would provide 44 per cent more thermal mass than a 400-pound cast-iron boiler with a 12-gallon water volume. With a reasonable temperature cycling range of 15F to 20F it provides very adequate thermal mass and can often be mounted directly below the wall-hung mod/con boiler as shown in Figure 1.

The buffer tank also hydraulically separates the pressure dynamics of the boiler circulator (P2) from those of the variable speed distribution circulator (P3). It provides a low flow velocity zone allowing air bubbles to rise to where they can be captured and expelled through an automatic float-type vent.

PANEL RADS

This system uses fluted steel panel radiators for all heat emitters. These panels offer several benefits:

• They are adaptable to different interiors. They come in a variety of heights, widths, and depths that allow them to fit into a wide variety of situations.

• They are one of the easiest heat emitters to install in new homes as well as retrofit applications. They are relatively light and can be supported by almost any wall.

• They lend themselves to room-byroom zoning using non-electric thermostatic radiator valves, as shown in Figure 2, providing fully modulating room-by-room comfort control without a mile of thermostat wires. This is a tremendous benefit relative to the complexities and installation time associated with wire-based thermostats in every room.

• Panel radiators have very low thermal mass and thus respond quickly to changing internal heat gain situations. In short, they warm up and cool down much faster than heated floors. This is especially desirable in buildings with significant internal heat gain potential.

• With proper sizing, panel radiators can operate at relatively low water temperatures and thus enable the mod/con boiler to operate in a condensing mode, even under design load conditions. I suggest sizing panel radiators for design load output with a supply water temperature of 120F. Operating panels at

Continued on p48

Hydronic Water Treatment Filling Units

HYDROFILL™ is a portable water treatment filling unit that produces from site sourced water, demineralized water of an ideal grade for use in closed hydronic systems. Salts and other soluble minerals are almost entirely eliminated so as to prevent premature equipment malfunction including reduced efficiency or component failure due to lime scale formation – a common affliction of heat exchangers. The treated water is also low in electrical conductivity to minimize corrosion due to galvanic attack. Lastly, by eliminating the variability of site produced water having different mineral content values from location to location, using treated water makes for more reliable dosing when chemical additives are used – such as glycol.

Site water contains soluble minerals which exist as positive or negative molecules. Mixed bed resin beads are charged with positive hydrogen (H+) and negative hydroxide (OH-) molecules. As water flows up through the column of mixed bed resin beads, the soluble minerals are “exchanged” with either hydrogen or hydroxide, the two then combine to form H2O (e.g., pure water). In effect, the soluble minerals are “pulled” from the site water and are replaced with pure water.

HYDROFILL’s high capacity premium grade virgin mixed bed resin has 40% positive charge Cations and 60% negative charged Anions. This special mixed blend increases demineralized water capacity over cheaper 50% / 50% blend commonly used in standard loose filled resin tanks.

The HYDROFILL™ unit incorporates an on-board TDS meter. TDS is a measure of how pure the water is. Water is considered demineralized when its TDS is measured at less than 30 ppm and is ideal for closed loop hydronic systems. When TDS levels reach over 30 ppm, the resin should be replaced. Changing the resin bags is quick and easy

HYDROFILL™ is a convenient tool for installers to use water available at a job-site to produce ideal grade demineralized water at an economical cost per gallon.

Read more about water quality in hydronic systems in idronics™18 design journal. Download or request your free copy at www.caleffi.com.

Hydronic water treatment filling units

Water is the “life-blood” of hydronic systems. Just as we strive to maintain the health of our own circulatory systems, it’s important to maintain the “health” of water and water based solutions that circulate through the hydronic systems we construct and maintain.

HYDROFILL™ portable water treatment lling units remove scale forming “hard water" minerals, such as calcium and magnesium from job-site water. Salts and other soluble minerals are eliminated to prevent reduced ef ciency and premature equipment failure due to scale build-up or galvanic attack.

HYDROFILL ™ is a convenient tool for installers to use job-site water to produce ideal grade demineralized water at an economical cost per gallon.

Heating & Cooling

Components for today's modern hydronic systems

IBC BETTER BOILERS

EASY TO USE BOILER CONTROL

• Express setup - program your boiler in seconds.

• Remote monitoring & diagnostics.

• Easy USB programmability.

• Intuitive alert system with detailed error messages.

• Visible flame current for troubleshooting.

EASY TO INSTALL & SERVICE

• With supply and return connection on both sides of 3 models your boiler installation can’t get any easier.

• Longest vent lengths – Up to 200 ft in 2” and 480 ft in 3”