• CHILLERS 101 • HYDRONIC COOLING SYSTEMS • RESIDENTIAL CHILLERS

• CHILLERS 101 • HYDRONIC COOLING SYSTEMS • RESIDENTIAL CHILLERS

14

SERVICE VEHICLES

FUEL ECONOMY ON TREND IN 2020

From more diesel options to a mild hybrid and electric alternatives on the horizon, automakers are stepping up efficiency.

By Jil McIntosh

18

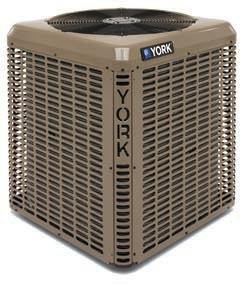

COOLING

SMALL-SCALE HYDRONIC COOLING

Using chilled water for residential cooling is becoming much more viable.

By John Siegenthaler

24

HVAC

CHILLERS FOR RESIDENTIAL AND LIGHT COMMERCIAL

Reconsidering the efficiencies of water for heating and cooling in common places.

By Ian McTeer

30

IEQ

COOLING FOR COMFORT

Designing and installing with compliance for ASHRAE Standard 55 in mind.

By Robert Bean

The inside story on chiller operations

By Dave Demma

COVID-19

SHINING LIGHT ON UV

From front line hospitals to residential HVAC, the search for disinfecting solutions is leading some to ultra violet.

By Aaron Engel

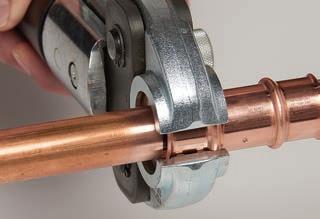

48 PLUMBING MAKING CONNECTIONS

Dealing with metal-to-metal and the corrosion that ensues.

By Steve Goldie

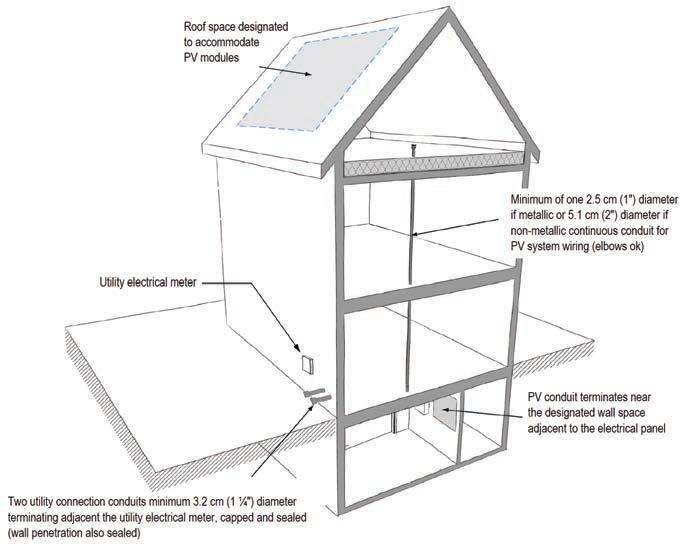

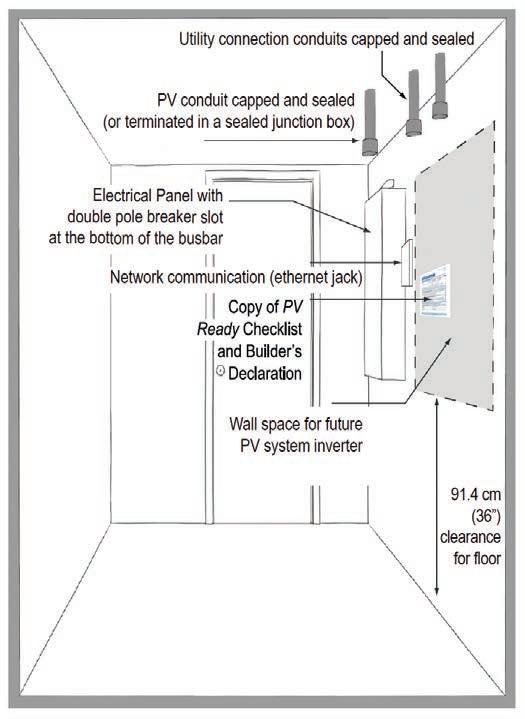

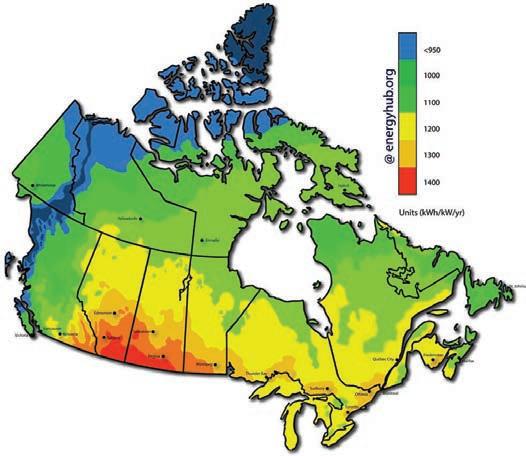

SOLAR PHOTOVOLTAIC SYSTEM BASICS

What the mechanical industry needs to know about this growing industry.

By Robert Waters

56 ELECTRICAL GET YOUR MOTOR RUNNIN’

An inside look at what’s driving your pumps and more.

By Curtis Bennett

CURVEBALLS: Speaking with an HVAC contractor about dealing with the new reality.

Now you can record your sewer inspection videos and photos instantly onto a ash drive. The powerful Command Module includes a USB port for added recording capability.

It’s packed with features like a big 7" LCD color monitor for crisp, clear pictures, one touch recording, 4X digital zoom, voice-over recording, date and time stamp, ash drive capacity indicator, and more.

Full size X-POD features 200 ft. Gel-Rod® for inspecting 3" to 10" drain lines. Compact Mini-Reel carries 100 ft. or 200 ft. of Gel-Rod for troubleshooting 2" and 3" lines.

Call the Drain Brains ® at 800-245-6200, or visit www.drainbrain.com/geneye

WELL, THIS IS CERTAINLY DIFFERENT. THE WORLDWIDE COVID-19 PANDEMIC has truly been effective at making the world seem a lot smaller, while at the same time drawing a larger focus to the things the matter most to each of us on a local and personal level.

It was no surprise that plumbing and HVAC/R workers were considered essential across the country when the pandemic restrictions were first coming into place. The interpretations in each province may have varied a little, but for the most part the trades were active.

Work on new construction sites did slow down, and homeowners undergoing renovations (or seeking to begin) weren’t calling trades to come into their homes unless there was an emergency. But still, where required, trade services were available.

One common thread I’ve heard from both contractors and equipment distributors over the past two months, is how important it was to make sure their coworkers were kept out of harm’s way. The concern was beyond having the right protocols and protective gear—business owners are questioning the prospect having to expose their employees to multiple people, or households, every day.

In the early days, one contractor was concerned about the “cowboys” out there willing to head out with no protection and continue working, putting themselves and those around them at risk.

As I’m writing this, Canada has recorded some 93,700 coronavirus cases and 7,635 deaths. Yes, that’s only 0.2% of our 37.7 million population having contracted the virus, but you likely don’t have to look too far to know someone who has been affected.

My own 93-year-old next-door neighbour suffered a slip-and-fall accident at home. While at the hospital he contracted the virus and died. It was a terrible blow for our community and devastating for his family.

Over 90% of the deaths in Canada have been people over 60, but that’s no reason to believe it can’t affect any one of us. The scary parts of this virus are the unknowns. There are still a lot of “What ifs?”

The upside for now is that every business person I’ve spoken with has been impressed with how their communities have responded and adjusted.

The national shelter-in-place requirements that started in the cool months of early Spring in Canada made every citizen a little more aware of the air quality in their homes, for better or worse. As I write this, we are slowly beginning the transition to summer and windows are opening up. Before long air conditioning will be kicking in.

Speaking only for myself, working from home since mid-March has made me much more aware and interested in getting my heat pump/furnace system tuned up and ready for the summer heat. It’s not just about making sure the system is operating at peak performance, I want to ensure we have clean air flowing through the house.

I’ve never been more interested in air quality, and I’m sure I’m not alone.

Plumbing and HVAC/R services are essential for the knowledge and comfort they deliver to the people occupying homes and buildings of all sizes. We’re living in a time now where those skills will really begin to shine. <>

– Doug Picklyk, Editor

HPAC MAGAZINE

111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

TEL: 416.442.5600 FAX: 416.510.5140 www.hpacmag.com

EDITOR

ASSOCIATE

PUBLISHER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

COO

PRESIDENT & CEO

Doug Picklyk (416) 510-5218

DPicklyk@hpacmag.com

David Skene (416) 510-6884

DSkene@hpacmag.com

Emily Sun esun@annexweb.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 442-5600 ext. 3537

ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847

PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbusinessmedia.com

Scott Jamieson sjamieson@annexbusinessmedia.com

Mike Fredericks

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2020 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com

Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

Navien, the leader in condensing tankless water heaters, brings endless hot water comfort to homes and businesses across North America. Keep hand washing and Navien will continue to supply plenty of hot water. Learn more at NavienInc.com.

BY DOUG PICKLYK

Just into the third week after the government of Ontario declared a provincial emergency, we caught up with Justin Boisvert, owner of Bi-Temp Ltd. in Belleville, Ont., a residential and commercial HVAC contractor, to find out how business had changed since COVID-19 altered everyone’s way of life.

Boisvert (34) acquired Bi-Temp in 2013, a local business that dates back to 1968. Bi-Temp serves an area within an hour radius of Belleville, handling all forms of natural gas, propane and electric heating, air conditioning, hydronics, heat pumps and geothermal, as well as sheet metal, duct designs, refrigeration and more.

As president of the company, Boisvert’s main role is managing the work load and overseeing day-to-day operations. We caught up with him at the end of the work day on Thursday, April 9.

How was business this year prior to mid-March?

Up to mid-March we were running six guys. It wasn't a very cold winter, and there are not a lot of people upgrading their furnaces or switching boilers. So, prior to the COVID slowdown it was a quieter January, February and March.

How many trucks do you usually have on the road?

Normally I would have seven guys on the road, myself in the office and my office manager. And I've got two other helpers on an as-needed basis.

How have things changed since midMarch?

Ever since COVID come into effect we're basically down to emergency service only. Right now, I've got myself and three other guys out in the field.

We've stopped all commercial preventative maintenance, just to limit our ourselves from entering these buildings, and we have a little bit of new construction that we've got to keep rolling with, because those projects haven't been stopping and people have closing dates on homes, and they need a place to live.

When the “essential services” list was announced by the province, was it clear to you where you stood as an HVAC services company? Where have you gone for clarity or information about what you can and can't do?

It's been a lot of conversations with other guys (business owners in the trade), and we’ve been referring to the government sites for the safety protocols and the measures to take as far as trying to do our part to protect ourselves and our customers.

How have you handled safety precautions with your employees?

That's actually been very challenging because we've got a fairly young crew and

two of our guys have pregnant wives right now. For one, his wife is due in a couple of weeks, so he was informed by their doctor that he has to be self-quarantined for 14 days prior to the birth and then for four weeks post birth. So that just eliminated him as of Monday this week.

Another one of our guys is considered a high risk because his wife is a nurse at the Belleville Hospital and is considered high risk. So now he's off for an unknown period of time, unless he wants to move out of his house, away from his wife.

You just have to take it on a day-byday basis, because every day you turn around and there's another curveball coming at you.

Has getting your hands on personal protective equipment (PPE) for your employees been a challenge? The only challenge we had was getting hand sanitizer. The Kinsip Distillery in Prince Edward County is producing some now, and we were able to get our hands on a case.

We ended up having some N95 masks sitting on the shelf, and our suppliers had some heavy-duty black rubber disposable gloves in stock, so we've got cases of those for all the guys to wear.

How about supply chains, are you getting the supplies you need?

That has not been an issue at all. So far, we had a couple snags getting some stuff out of Quebec, but as far as our other equipment goes, I'm finding our suppliers more efficient now than ever with the callin service and either having delivery to the shop or having your order set outside waiting for you ready to pick up.

How are you handling service calls?

We’re only doing emergency calls right now, and every job that we've been going to, we've got our own screening process in place.

As soon as somebody calls the office we do a screening over the phone, asking them all the relevant questions like whether or not they've been traveling, if they've been self-quarantining, whether they're sick, if they're showing any kinds of symptoms.

If they pass that test, then we'll arrive to the site for the service call, and we provide them with a form. Essentially, it’s asking them the exact same questions, and they've got to print their name, sign it and date it. This way we

have a paper trail so that if one of our customers were to show symptoms, I would hope they would reach out to us and vice versa.

“My biggest concern is that we have no idea how long this is going to last.”

Do you think this is going to change the way you do business?

Yes, the big thing I'm looking at right now is the economic impact on everybody. Let's say in a month we're allowed to work safely again. That's fine, but who's going to be putting money into their homes?

The impact on everybody's personal finances is going to be huge. That extra cash that was there is no longer there to upgrade a furnace or add new air conditioning.

I've got a feeling for the next year or two, unless the government comes out with some really good incentives and rebates to get the trades rolling again—

like that home renovation tax credit back in 2008—that it's going to be slow.

As you look forward, even just in the short term, what is your biggest concern?

My biggest concern is that we have no idea how long this is going to last, and then just understanding the risk that's out there.

As of right now, we're still going to be at least three weeks before we can even try to look at resuming somewhat normal operation. Even then, on our residential maintenance side, do I really want to be sending a technician into six different people's homes each day to do an air conditioning maintenance?

Is it worth exposing one of my employees and putting his health and safety at risk just so that somebody can have their AC tuned up? Or do we just stay with emergency service?

It's the uncertainty. It's just so uncomfortable.

Honestly, my stress level has been the highest it's ever been in six years. Because, again, as a business owner, we like to have control of things. And in this world right now, we have absolutely zero control. <>

The ASHRAE Annual Conference originally scheduled to run June 27 to July 1 in Austin, Texas has been restructured into a four-day live virtual event with a significantly reduced registration fee.

The cost to attend the 2020 ASHRAE Virtual Conference is US$99 for ASHRAE members (US$329 for non-members, which includes an annual ASHRAE membership) and includes:

• 12 live technical sessions with live Q&A with presenters

• an on-demand technical program of some 80 sessions

• live video chat sessions with speakers from on-demand sessions

• downloadable copies of all conference papers

• virtual networking happy hours

The technical sessions will be available starting June 22, with conference activities and additional live sessions addressing the latest information relating to the COVID-19 pandemic taking place daily starting June 29 and continuing through July 2.

Technical program tracks include:

• HVAC/R systems and equipment

• Multifamily and residential buildings

• Zero energy buildings

• Resilient buildings and communities

“While we realize that there is no substitute for the special level of interaction that face-to-face conferences provide, we are excited to present this unique format for our members to interact, collaborate and learn,” said ASHRAE president Darryl Boyce, P.Eng. “The unprecedented challenges of this year’s pandemic have afforded us a great opportunity to further our reach and level of engagement in a meaningful way.” www.ashrae.org

We’re in a recession, but according to economist Peter Norman, we’re not headed into a depression. “It’s not a regular recession, as it was caused by a health crisis, and parts of the economy will come back online quickly,” said Norman, vice president and chief economist with Altus Group, who led an hourlong webinar in mid-May hosted jointly by the Canadian Institute of Plumbing and Heating (CIPH) and the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI).

“By some measures this is among the deepest recessions ever,” said Norman, suggesting the Canadian economy is likely headed for three straight quarters of decline before bouncing back in 2021. He indicated that societal changes happening now could have lingering effects on housing demand and commercial real estate going forward.

For the Canadian economy, Norman sees something of a ‘V-shaped’ recovery, with 2020 ending with 7% drop in GDP and then an upswing beginning in 2021 with an overall growth rate of 5% for next year.

For the housing market, early 2020 saw the number of new starts growing and that momentum provided some insulation from the economic shocks, but a number of factors, including rising unemployment and a drop in immigration could lead to a steep decline in housing demand going forward.

Norman anticipates housing to rebound next year but not to the level anticipated prior to the recession. He suggests renovation spending will also be down this year and will rise next year, but again nowhere near what was anticipated.

In the commercial construction market, where growth has been steady, he notes that a possible outcome from the health crisis is a shift to more remote workers, leading to a decrease in the demand for office space. Some 50 million sq. ft. of office space is in the pipeline, and Norman believes we could see a pause in commercial development intentions over the next two or three years.

The work-from-home trend could also effect housing, as people chose to live outside of city centres if they no longer require a daily commute.

Retail, hospitality and entertainment segments may have to undergo dramatic changes to accommodate for enhanced social distancing for years to come, leading to construction opportunities.

The COVID-19 crisis has exposed vulnerabilities in seniors housing, where changes will need to be addressed through design and possibly policy changes.

On the bright side, there is hope that by next year as a society we can move beyond social distancing and worksites get back to the old normal.

And if and when a second wave of the virus takes hold, communities will be prepared with better infrastructure in place and a familiar grasp of the societal changes that will be required. Norman suggests we’ll be able to respond much more quickly, and subsequent waves may not have as much economic impact. www.hrai.ca www.ciph.com

One of the largest geoexchange projects in Canada, part of the 20-year $9.1 billion Vancouver International Airport expansion, has been awarded the Project of Year honour in the building and construction category of the 2020 Plastics Pipe Institute (PPI) Awards.

PPI, the North American trade association representing all segments of the plastic pipe industry, announced the winners of its projects during a virtual annual meeting held on May 5.

The Vancouver Airport project, entered by Versaprofiles of Saint-Lazare-de Bellechasse, Que., was the only Canadian award winner in this year’s program.

The geothermal borefield for the airport’s new Central Utilities Building geoexchange system includes 841 boreholes at 500 ft. each in depth totalling 79.64 miles of drilled borehole and 159.28 miles of 1.25-in. HDPE 4710 piping. The geothermal system is expected to reduce CO2 emissions from heating and cooling demands by 30- to 35%. www.plasticpipe.org

The Canadian Green Building Council (CaGBC) believes the current health crisis has precipitated what could be the tipping point needed to transition Canada toward a sustainable and low-carbon economy.

In early May, CaGBC provided its perspective to key federal ministers in a document entitled, ‘Ready, set, grow: How the green building industry can re-ignite Canada’s economy.’

The CaGBC brief provides guidance on how strategic investment in green building could play a significant role in re-igniting Canada’s economy while also helping the country meet its climate goals.

The recommendations target three areas of investment: workplace training and skills development; removing barriers and creating deep energy retrofit incentives; and shifting the industry to zero carbon building. www.cagbc.org/cagbcdocs/advocacy/CaGBC_Green_ Recovery_Strategy_EN.pdf

In mid-March the organizers CMPX, Canada’s largest trade show for the plumbing and HVAC/R industry, initially postponed the 2020 CMPX event scheduled for March 2527 due to COVID-19, but the biannual trade show has now been rescheduled to 2022. The co-owners of the event, the Canadian Institute of Plumbing and Heating (CIPH) and the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI), announced that CMPX 2022 will be held March 23-25, 2022 at the Metro Toronto Convention Centre.

In addition, the CIPH announced that the CIPHEX West trade show, scheduled to run Nov. 4-5, 2020 in Vancouver, has been postponed and will now take place November 3-4, 2021 at the Pacific Coliseum at the PNE in Vancouver.

Although the live trade show and conference has been shelved for a year, the show committee is promising to still hold a virtual event this November. The virtual event is expected to include eBooths with company and product information for exhibitors as well as webinars on technical and business topics presented by industry experts.

The rescheduled MEET Show, initally planned for May 6-7, is now set to run November 18-19 at the Moncton Coliseum, in Moncton, NB.

www.cmpxshow.ca www.ciphexwest.ca www.meetshow.ca

The Canadian Apprenticeship Forum, a non-profit organization that connects Canada’s apprenticeship community, is actively seeking more apprentices across the country to participate in the volunary Apprentices in Canada ePanel, a survey group that provides apprentices and early-career journeypersons with opportunities to share their experiences from inside the apprenticeship system.

Currently, to help CAF understand the challenges apprentices are facing as a result of the COVID-19 pandemic, a new survey is being launched to the existing 3,500+ members of the ePanel.

The CAF brings together apprenticeship stakeholders from across trades, across sectors and across Canada to share information, identify challenges and propose joint solutions. As a national voice for the apprenticeship community, CAF influences apprenticeship strategies through research, discussion and collaboration. apprenticesincanada.com

From more diesel options to a mild hybrid and electric options on the horizon, automakers are stepping up the efficiency of service vehicles.

BY JIL MCINTOSH

Just as with their consumer vehicles, automakers are tweaking their trucks and commercial vehicles to help improve their fuel efficiency. This has always been as important a consideration as capability, but now you have even more options for your selections.

In addition to the larger diesels in their heavy-duty trucks, Ford, GM and Ram all offer smaller-displacement diesels in their half-ton trucks. These provide more lower-end power, but with better published fuel figures than comparable gasoline engines.

Depending on the automaker, some gas engines include fuel-saving technologies such as cylinder deactivation, which shuts off some of the cylinders when full power isn’t needed. Some companies are offering smaller-displacement turbocharged engines, for the inherent fuel savings of a small engine but with larger-displacement power as needed (but a little more on that below). And more multi-speed transmissions are available, right up to ten speeds for extra economy.

No one offers a full gas-electric hybrid work vehicle, but Ram has a mild hybrid system available on its half-ton pickup, which primarily improves its fuel economy.

Fully electric vehicles are still in the future, but Ford is promising an electric F-150 pickup, as well as an electric Transit van by 2022. GM is working on an all-electric Chevrolet pickup truck. Mercedes-Benz has electric versions of its Sprinter and Metris in Europe, although they’re not planned for sale in Canada, at least in the foreseeable future.

But even when electric vehicles do arrive, operators are going to have to weigh them carefully, because they pose as

many questions as they answer. You lose your gas or diesel bills, and they require a lot less maintenance, but you have to factor in how long they take to recharge and where you’ll do it. As well, their maximum driving range is usually calculated under mostly-favourable conditions. In addition to batterysapping factors that already apply to consumers who drive electric cars, such as cold temperatures or hilly terrain, electric work vehicles will be further burdened with payload—and you might not know exactly how much that’ll take out of your range until you buy and drive one. There’s going to be a learning curve when these trucks come to market.

Of course, even with conventionally-fuelled vehicles, you have to factor in all the pros and cons when purchasing. Diesel trucks tend to hold their value, but they cost more to purchase and maintain, and are better suited to high-mileage buyers who can amortize those extra costs. And small turbocharged engines are touted by manufacturers for their fuel savings, but they’re most economical when they’re lightly worked. They can get thirsty when you’re towing or hauling, and that can add up significantly over the long run in a hardworking vehicle. You might be better off with a larger, naturally-aspirated engine, and leave the little turbos for those who buy trucks to occasionally haul their stuff to the cottage.

For lighter-duty work, such as service calls, you might also consider downsizing. Automakers now offer a wide variety of compact and midsize vans and trucks. Along with lower costs, these can also access jobs where a full-size doesn’t always fit, such as in underground garages or other tight quarters.

Following is a basic roundup of what’s on offer for 2020. <>

The Ram 1500 uses a mild hybrid system called eTorque, standard on the 3.6-litre V6 and optional on the 5.7-litre V8. It can’t run on electricity alone, but provides electric torque to the gas engine on acceleration for smoother operation and fuel efficiency. It selfcharges, no plug-in. The V8 gets 1.2 L/100 km better fuel economy with it, but it can be a pricey option.

The 1500 also offers a 3.0-litre V6 turbodiesel making 480 lb-ft of torque.

The Ram Heavy-Duty 2500 and 3500 use a 6.4-litre V8 gas engine, or regular or high-output 6.7-litre inline six-cylinder Cummins turbodiesel making up to 1,000 lb-ft of torque.

The F-150 offers six engines, including a 3.0-litre V6 turbodiesel that makes 440 lb-ft of torque and is now offered in the XLT trim level. The Super Duty F-250, F-350 and F-450 come with 6.2-litre or 7.3-litre V8 gasoline engines, along with an available 6.7-litre Power Stroke turbodiesel that makes 1,050 lb-ft of torque.

The midsize Ranger comes in SuperCab or SuperCrew configuration. Both use a 2.3-litre four-cylinder EcoBoost (turbocharged) engine, make 310 lb-ft of torque, and in 4x4 only. With an optional towing package, the Ranger can tow up to 7,500 lbs.

For 2020, the full-size Transit van is available in rear- or all-wheel drive, and an optional power sliding door. It comes in cargo or crew van; with two wheelbases, two roof heights and three lengths; and the choice of a naturally-aspirated or turbo 3.5-litre V6.

The compact Transit Connect comes with a 2.0-litre four-cylinder, but fleets can order a 2.4-litre four-cylinder. Max. payload is 1,550 lbs, and it will tow 2,000 lbs.

The full-size ProMaster van comes in three wheelbase lengths, regular or extended body, two roof heights, and in 1500, 2500, and 3500 configuration. It can tow a maximum of 6,800 lbs and has a 7,680-lb maximum payload. Unique among full-size vans, it’s frontwheel drive, for a low step-in height.

The compact ProMaster City van uses a 2.4-litre four-cylinder, and has a maximum payload of 1,883 lbs and towing capacity of 2,000 lbs.

“Even when electric vehicles do arrive, operators are going to have to weigh them carefully, because they pose as many questions as they answer.”

Comparable Chevrolet and GMC trucks and vans have different trim levels and features, but share their drivelines. The Chevy Silverado and GMC Sierra 1500 models come with six engine choices, including a 3.0-litre inline-six diesel that makes 460 lb-ft of torque. Depending on the gasoline engine, ranging from a turbocharged four-cylinder to a 6.2-litre V8, you get either Active Fuel Management, which shuts off specific cylinders, or Dynamic Fuel Management, which uses varying shut-off patterns for even more gas savings.

The Silverado and Sierra heavyduty trucks are all-new for 2020, with 6.6-litre V8 gas engine, or a 6.6-litre Duramax V8 engine making 910 lb-ft of torque. Maximum towing capacity is 35,500 lbs.

Nissan updates its full-size Titan pickup for 2020, now available only as a Crew Cab 4x4 with 5.6-litre V8 with nine-speed automatic. It’s advertised as 400 horsepower and 413 lb-ft of torque, but that’s on premium fuel. On regular it makes 390 hp and 394 lb-ft.

The larger Titan XD, which Nissan slots between a half-ton and heavy-duty, uses the same 5.6-litre V8, but loses last year’s optional V8 Cummins diesel.

The midsize Frontier pickup is eventually getting a complete makeover, but for now, it looks the same but carries the upcoming new model’s 3.8-litre V6 with nine-speed automatic. That should improve fuel consumption over the previous 4.0-litre V6.

standard- or high-roof configuration, and with 4.0-litre V6 or 5.6-litre V8. Maximum payload is 3,850 lbs and towing is 9,400 lbs. The compact NV200 van uses a 2.0-litre four-cylinder and offers payload up to 1,480 lbs.

Many don’t think of the SUV-based Ridgeline as a “real truck,” but it has numerous features for light-duty service, including a locking in-bed trunk and lots of interior storage. It uses a 3.5-litre V6 with all-wheel drive, and with maximum 5,000-lb towing and 1,570-lb payload capacity.

The full-size Tundra pickup comes in Double Cab or Crew Cab, and all models use a 5.7-litre V8 that makes 401 lb-ft of torque. The Double Cab has a top towing capacity of 10,000 lbs and 1,709 lbs payload, while the Crew Cab can pull up to 9,200 lbs and haul up to 1,567 lbs.

The full-size Sprinter comes in cargo or crew configuration, and in rear- or fourwheel drive. The 1500 comes with a 2.0-litre four-cylinder turbocharged engine, while the 2500, 3500, 3500XD and 4500 use a 3.0-litre V6 diesel making 325 lb-ft of torque.

The Sprinter comes in two wheelbases, with regular or extended body, and standard or high roof. Depending on the model, payload is up to 6,768 lbs.

The Metris is the only midsize van on the market. It uses a 2.0-litre fourcylinder turbocharged engine and comes in two wheelbases, with a maximum payload of 2,491 lbs and 5,000lb towing capacity.

Jil McIntosh is an automotive writer and reviewer with a specialty in trucks and commercial vehicles. McIntosh writes for numerous outlets including the National Post and AutoTrader.ca, and is a member of the Automobile Journalists Association of Canada (AJAC). Her work can be found at WomanOnWheels.ca.

The midsize Tacoma comes in Access or Double Cab, but only in 4x4 configuration. All use a 3.5-litre V6 that makes 265 lb-ft of torque. Maximum towing capacity is 6,504 lbs, and maximum payload is 1,146 lbs.

Adrian Steel’s Grip Lock and Drop Down Ladder Racks are designed with ergonomics and user safety in mind. Whether you’re upfitting a single van or an entire fleet, Adrian Steel has just what you need. Increased efficiency starts now.

The use of chilled water for residential cooling is becoming much more viable, but pay attention to the draining of condensate and sealing pipes to avoid unwanted condensation.

BY JOHN SIEGENTHALER

Most of the modern hydronics technology used in North America for residential and light commercial buildings is for heating. Hydronic heat sources ranging from boilers and heat pumps to solar thermal collectors can be combined with many types of distribution system and heat emitters. This allows systems to be configured for very specific comfort needs along with aesthetic preferences, budgets and fuel choices.

For decades, those interested in the versatility and superior comfort of hydronic heating have had to make decisions for cooling. Should it just be omitted? Should I install a separate forced air cooling system? Or, is there a way to provide residential cooling using a hydronic system?

Those who have dealt with the HVAC systems used in larger commercial or industrial buildings know the answer to that last question is yes. Chilled water cooling systems have been used in many larger buildings for decades. They leverage the vastly superior heat transport ability of water versus that of air.

Chilled water can travel long distances through insulated pipes that are very small in cross section compared to ducting of equivalent cooling transport capacity. The chilled water then passes through a coil in an air handler, where it absorbs heat from an air stream.

During the 20th century there wasn’t much interest in using chilled water for cooling smaller buildings. Part of this was due to the lack of devices that could efficiently produce chilled water in the relatively small capacity range needed for smaller building applications.

That situation has changed significantly over the last two decades. Today there are many water-to-water heat pumps and air-to-water heat pumps that can provide both heating and cooling. Most of these units are electricallyoperated using time-tested vapour compression refrigeration systems.

A smaller portion of the available chillers use absorption cycle cooling and are fueled by natural gas or propane. All of these devices can produce chilled water in the 45-50F range typically required for both sensible and latent cooling.

There are also several types of fancoils and small air handlers that can operate with chilled water to produce cooled and dehumidified air. Some are “console” fan-coils, such as the unit shown in figure 1 (next page)

Console fan-coils are mounted low on walls and typically sized on a roomby-room basis. They have a fan that blows air across a coil and can be used for heating when supplied with warm water, and cooling with cool water in the warmer months. As warm humid air passes through the coil it is cooled and dehumidified. The water removed from the incoming air stream condenses on the coil and eventually drips off it.

It is essential that any console fan coil that will be used with chilled water is equipped with a condensate drip pan. Not all console fan-coils are so equipped. The drip pan must be connected to a condensate drain pipe. Codes vary on where the condensate drain pipe can go. Some allow it to be connected to the building’s DVW piping.

Others may specifically prohibit this. I prefer to keep condensate drains separated from other draining systems. Terminating them just above a basement floor drain is one option. Running them outside the building, such as through a soffit is another. Even small console fan coils can produce several gallons of condensate when the system is operating on a muggy day.

Another type of fan-coil is often called a “high wall cassette.” An example is shown in figure 2 (right)

These units are very similar to the cassettes used in ductless mini-split heat pump systems. Their internal coils are designed for water rather than refrigerant. They are available with total cooling capacity ranging from about 6,000 to 24,000 Btu/hr (0.5 to 2 tons).

Most of these units have variable speed high efficiency fans, oscillating discharge air dampers, and a handheld remote control for setting operating modes. These units can also be used for heating.

The next step up is one or more airhandlers. The idea is the same as with a fan-coil, with the difference being air delivery through ducting versus directly from the unit. Chilled water flows through a coil made of copper tubing and aluminum fins.

Incoming air is pulled across this coil where it is cooled and dehumidified on its way to the inlet of a blower. That blower then drives the conditioned air through a duct system to multiple registers or diffusers.

Most air handlers, such as the unit shown in figure 3 (next page), are designed to be installed out of sight. Vertical air handlers can be mounted in basements, closets, under stairs or other accessible spaces.

Horizontal air handlers can be hung from floor framing in a basement, or mounted on platforms in attics or above door height in closets. Many small air handlers can be configured for either vertical or horizontal mounting with minimal field work.

The location of air handlers must provide accessibility for routine maintenance such as filter changes or other service work. It’s good practice to ensure that the entire air handler could, if ever necessary, be removed from its mounting location without sawing walls, framing or having to take the air handler apart.

Whenever an air handler is mounted above finished surfaces, such as drywall, I prefer to set it into a secondary drain pan, such as seen under the air handler in figure 3 (next page). This molded plastic pan would serve as a catch basin for condensate if the pri -

mary condensate drip pan within the air handler ever developed a leak.

The secondary drain pan usually connects to the same condensate drainage pipe as the drain pan in the air handler. In some systems these pans are equipped with a small float switch that can be wired to stop chilled water flow and the blower if it detects a rising water level, which would infer a failure of the primary drip pan.

There are several other details that should be included in small-scale chilled water cooling systems:

1. Be sure that all piping and piping components carrying chilled water are insulated, and that the insulation is vapour sealed. This is critical in preventing surface condensation on the piping and other components. All seams and joints in the insulation should be glued or otherwise bonded to ensure that moisture-laden air can’t contact the piping. Acceptable insulations are elastomeric foam or fiberglass provided the latter is wrapped with a sealed PVC jacket.

Don’t try to “cheat” on pipe insulation or vapour barriers. It only takes a few hours of operation on a humid day to lay down an ugly and costly water stain on drywall ceilings.

A Single Model Solves Multiple Installation Requirements. Simply configure a selected base model to meet your customer’s needs.

Available in Light, Medium or Heavy Duty from 6 to 119 Gallon Capacity. Perfect for any commercial application big or small.

When your commercial customer needs a water heater, come to the rescue FAST! Answer their call with the ElectriFLEX Series™ Field Convertible Commercial Electric Water Heaters from Bradford White. No need to wait for a special order - you can respond with lightning speed with the right solution, so customer down-time is greatly reduced.

Customize the Right Configuration – FAST! Phase, voltage and wattage are all shop- or field-convertible using a conversion kit.

Bradford White Quality & Performance. Engineered for efficiency, performance and heroic reliability.

To find out how you can be the hero for your commercial customer, visit our website dedicated to the Pro: bradfordwhite.com/electriflex

Continued from p20

“With constantly increasing interest in heat pumps it’s likely that small-scale chilled water cooling will see increasing use.”

Some components such as circulator volutes and valves don’t lend themselves to cylindrical insulation. They still need to be dealt with. A flexible elastomeric self-adhering tape is one possibility. Another is to purchase elastomeric foam in sheets and carefully cut out shapes to fit each component. These custom cuttings can then be joined with insulation adhesive. A high quality electrical tape can also be used to “jacket” pieced insulation assemblies.

2. Don’t oversize the coil in the air handler. Oversized coils will quickly drop the air temperature in a space and satisfy the room temperature setting without allowing sufficient time for adequate moisture removal. The result will be cool but “clammy” air.

3. If you’re planning a zoned cooling system, with multiple fan-coils or air handlers, and supplying them from a fixed speed heat pump, be sure to include a buffer tank. A 2-ton air handler supplied by a 4-ton heat pump without a buffer tank will quickly drop the water temperature to the point where the heat pump turns off on its own internal temperature or pressure limit. This is necessary to prevent the water from freezing inside the chiller and possibly rupturing piping.

4. Make provisions with owners to clean the drip pans in all

fan-coils and air-handlers at the end of the cooling season. There are several biocides on the market formulated to reduce mold growth in drip pans, but they’re not a substitute for a good cleaning with detergent followed by a wipe down.

5. Set up the expansion tank for a slightly lower air pressure so that some water remains in the tank at room temperature. The goal is to prevent the diaphragm from “bottoming-out” against the tank shell when the system is operating with chilled water. This is especially important in systems with buffer tanks. The greater the system volume, the more “shrinkage” as the water cools well below room temperature. If the diaphragm bottoms out against the shell of the expansion tank, the pressure in some parts of the system could drop sub-atmospheric and cause air to be sucked into the system through vents.

With constantly increasing interest in heat pumps it’s likely that small-scale chilled water cooling will see increasing use. A probable scenario is when modern hydronic heating is used in a building and supplied by one or more water-to-water or air-towater heat pumps. In these cases the “chiller” is already in the system. It’s just a matter of equipping the distribution system for cooling. <>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has more than 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

Reconsidering the efficiencies of water for heating and cooling in common places. BY

IAN McTEER

Iwill have to admit that my HVAC proclivities revolve around forced warm air heating systems combined with addon cooling units. It’s the way I was raised in HVAC; in fact, water and its tendency to leak all over the place or to restrict and or to corrode furnace vents have produced no end of headaches for me when troubleshooting nuisance units.

Water can be a truly nasty chemical. Yes, I said it, a chemical. And it’s almost always referred to by its common name, “water”, as opposed to its systematic name, dihydrogen oxide.

But then again, who doesn’t love water for recreation, bathing and simply drinking?

Water is also the universal solvent. Forced together, hydrogen and oxygen atoms share electrons creating a covalent bond. However, the oxygen atom has a greater attraction for electrons that tend to stay closer to the one oxy -

gen atom rather than the two hydrogen atoms. The oxygen atom gains a slight negative charge while the hydrogen atoms are slightly positive. As such, substances such as salt, sugar, alcohol and many other substances easily dissolve into water.

Even the other products of combustion of natural gas combine with water forming weak acids that ruin heat exchangers, vent connectors and chimney liners, aargh!

Having said that, chemistry has also given us strategies to deal with the most annoying properties of water. And, there is one other phenomenal property of water that is foundational to the HVAC industry. Once I started to take hydronic heating seriously, I learned from regular HPAC magazine contributor John Siegenthaler that “water is almost 3,500 times more ‘thermally concentrated’ than air, a hydronic system only has to

move about 1/3,500 of the volume of fluid that a forced air system does to convey the same amount of heat.”

That heat can be used for space heating or process heating and, of course, heat absorbed into water can be effectively removed from any process or building as well.

Chillers have long been used in larger commercial buildings including high rise office towers, institutional buildings and process cooling applications. Sometimes the building requires cooling only, but typically in a cold climate the chiller will be combined with a boiler to provide heating and cooling using common piping sup -

This single VRF line set above doesn’t exceed manufacturer recommendations for run and rise, yet it’s only part of a multiple indoor unit installation in which the total allowable tubing length for all piping is 197 ft. When counted in with the other line sets on this job, the total length of all piping is 212 ft. What sort of trouble might lay ahead for this system?

pling devices such as remote air handlers or terminal units within the space.

Interestingly, some buildings once thought to be perfect for combined chiller/boiler installations, are losing out to variable refrigerant flow (VRF) technology thanks to advancements in capabilities such as simultaneous heating or cooling utilizing variable speed compressors that provide significant energy savings. Regardless, water still moves a lot more btu’s per pound than refrigerant, thus the commercial chiller is likely to be a viable HVAC product for the foreseeable future.

Residentially, chilled water systems have not been forefront in the mind of neither contractors nor consumers. The best known residential chilled water system available today is undoubtedly a ground source heat pump, also known as a geothermal heat pump.

Water-to-air units also provide cooling with matched air handlers connected to a conventional duct system and water-to-water heat pumps are available with hydronic air handlers having optional electric back-up heaters meant for installation into new duct systems.

As far back as 1913, engineers have been concerned about the quantity and type of refrigerants used within confined building spaces. By 1978, ASHRAE and the American National Standards Institute (ANSI) had published a comprehensive document known as Standard 15 that specifies safe design, construction, installation, operation and maintenance of refrigeration systems.

Standard 15 aims to ensure that refrigerants will be kept within the system and, in the event of a leak, mitigation procedures will reduce or eliminate serious impacts on people. Standard 15 limits the quantity of refrigerant in direct systems and requires very large volume systems to be in machinery rooms.

ASHRAE Standard 34 is a companion document to Standard 15 that establishes a system to identify refrigerants by assigning reference numbers, establishing a safety classification and to publish refrigerant concentration limits (RCL).

Concentration means the full vaporization of a refrigerant released into a confined space without ventilation, dissolution or decomposition capabilities. System designers must make sure conditioned spaces do not exceed concentration limits. Refrigerant piping and tubing cannot be installed in prohibited spaces, such as, enclosed public stairways, shafts that have openings to living spaces or any means of building egress.

“Water still moves a lot more btu’s per pound than refrigerant, thus the commercial chiller is likely to be a viable HVAC product for the foreseeable future.”

Recently, VRF systems have become more popular for some commercial applications for several reasons:

• They can provide simultaneous heating and cooling

• VRF’s can be easily zoned

• Since the units are independent of each other, a single unit breakdown won’t paralyze an entire building as in the case of a centralized chiller

• There are a wide range of indoor distribution accessories, such as, terminal units, ceiling cassettes, wall mounted units and fan coils.

• Variable speed compressors are less expensive to operate However, in low ambient applications, VRF heating capabilities may not be adequate requiring supplemental heating equipment and the installation and maintenance costs might not be worthwhile in some applications.

VRF systems also have strict run and rise tubing limitations that must not be ignored. Complex tubing systems must be installed by licensed, experienced installers; nitrogen must be present during the brazing process and the completed tubing must be evacuated and dehydrated in accordance with manufacturers requirements

Granted, a residential or light commercial VRF system will

Continued on p26

never require the amount of tubing as shown in the photos on the previous pages. However, its worth remembering the importance of line set tubing size, length and elevation above the compressor; these three factors, as prescribed by the equipment manufacturer, mean poor performance or, even worse, catastrophic compressor failure will otherwise result from poor piping practice. Such requirements often lead to difficulties with outdoor unit placement not to mention line sets running all over the place outside the building.

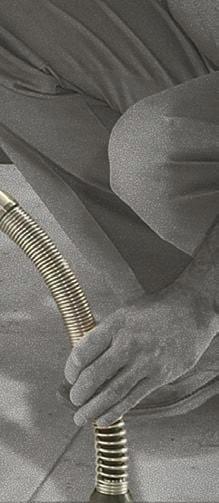

Manufacturers such as Multiaqua, SpacePak (Mestek) and Chiltrix, produce modular air to water outdoor units capable of heating or cooling glycol treated water. Like air source heat pumps, applications utilizing chillers for heating may need to provide supplementary heat in cold climates. There are several important reasons for HVAC contractors to consider specifying modular chillers:

1. Unfortunately, our trade is critically short of licensed technicians and installers, and the situation doesn’t appear to be improving, at least not anytime soon. A modular chiller does not require licensed mechanics to install the water piping systems or the indoor air handlers other than an electrician to provide electrical hook-ups. No refrigerant handling means licensed techs can be utilized elsewhere, such as for commissioning and servicing.

2. No refrigerant inside the building: ASHRAE Standard 15 and 34 do not apply. A modular chiller uses anywhere from 50% to 90% less refrigerant to accomplish the same heating or cooling task.

3. The insulated chilled water piping, typically oxygen free PEX, limits capacity losses allowing nearly unlimited linlengths to indoor hydronic air handlers or terminal units. Booster pumps can be used in exceptional situations.

4. Works with in-floor radiant heating systems but can also

provide “radiant cooling” with the addition of dew point controllers.

5. Hydronic branch distributor units allow for indoor zoning that might include individual high wall, fan coil or terminal units or combinations of each.

In cooling applications, chillers are not rated for seasonal energy efficiency ratio (SEER). Even a properly sized cooling system is oversized 99% of the time thus a chiller’s full speed efficiency is much less important that its average or part load efficiency.

Chillers are AHRI rated for Integrated Part Load Value (IPLV) based on a loop temperature of 44F. Manufacturers also offer a Non-Standard Part Load Value (NPLV) for situations where a 55F loop temperature can meet the requirements of a 44F loop and precautions have been taken to ensure proper dehumidification. A properly specified NPLV loop is dramatically more efficient than an IPLV loop.

A chiller’s IPLV is calculated using the AHRI 550/590 part load standard rather than the full-speed seasonal EER:

IPLV (or NPLV) = 0.01A + 0.42B + 0.45C + 0.12D

Where:

• A = COP or EER @ 100% Load (1% of the time unit requires operation up to 100% capacity)

• B = COP or EER @ 75% Load (42% of the time unit requires operation up to 75% capacity)

• C = COP or EER @ 50% Load (45% of the time unit requires operation up to 50% capacity)

• D = COP or EER @ 25% Load (12% of the time unit requires operation up to 25% capacity)

To roughly estimate the annual energy consumption of a 5-ton chiller (17.6 kW), with an AHRI rated IPLV COP of 4.56, use the following formula:

kWh/year = Chiller rated capacity (kW) x Run Hours ÷ IPLV COP efficiency x Estimated load factor, thus:

Energy = 17.6 kW x 3000 (example run hours) = 52,800 kWh ÷ 4.56 COP x 0.6 (rough average 60% load factor) = 6947 kWh/year. (Based on $0.18/kWh = $1,250 per year to operate)

Compare with a similar 5-ton chiller rated at an ILPV COP of 3.17:

Energy = 17.6 x 3000 ÷ 3.17 x .6 = 9994 kWh/year (Based on $0.18/kWh = $1,799 per year to operate)

No doubt that selecting a modular chiller with the highest AHRI rated IPLV COP is the most efficient choice for any potential customer.

Modular air source chillers are not necessarily meant for residential and light commercial applications. Indeed, larger commercial buildings, even process applications fall within the capa -

bilities of modular chillers.

In residential applications, I have recommended using VRF technology over the practice of installing an evaporator coil onto a new or existing furnace because too many older duct systems cannot efficiently distribute conditioned air, neither in heating but especially not in cooling mode.

To me, it makes no sense installing a 20 SEER inverter drive conventional split system air conditioner into such a system because inadequate air flow means loss of efficiency—that the consumer is paying for!

A modular chiller fitted into a residential application using an insulated loop could easily support a variety of delivery options like a VRF system. Free of refrigerant piping concerns, chilled water can easily be zoned throughout the residence.

Similarly, in a light commercial application such as a strip mall or standalone structure such as a restaurant or gymnasium, I’m thinking a modular chiller would have a crucial installation and operational advantage over a traditional ducted rooftop unit or even a multi-head VRF system.

John Siegenthaler introduced to me the idea of a hydronic system as a “conveyor belt for btu’s.”

I now understand how inherently beneficial my old enemy is at providing not only thermal comfort but exceptional energy savings too.

Water is the way to go! <>

Ian McTeer is an HVAC consultant with 35 years experience. He is a refrigeration mechanic and Class 1 Gas technician.

TSI is excited to announce the addition of ISO 17025:2017 accreditation for select TSI and Alnor® branded ventilation test instruments.

ISO 17025 accreditation is a globally-recognized benchmark for precision, accuracy, and reproducibility of analytical results. It is an international standard used as a means of determining the technical competence of laboratories to perform specific types of testing, measurement and calibration.

TSI offers accredited calibration for the following parameters:

+ Velocity

+ Temperature

+ Humidity

+ Differential Pressure

Designing and installing with compliance for ASHRAE Standard 55 in mind. BY ROBERT BEAN

Likely one of the most widespread misconceptions within the HVAC industry is that cooling load calculations are proxies for a comfort calculation, and that A/C design is comfort design. Though both are required for selecting equipment, laying out mechanical room components and for duct routing, none of these tasks identify the discomfort metrics experienced by occupants in buildings.

How can I say that? Because none of these activities are required to ask what people thermally experience based on what they are doing, what they are wearing and where they are positioned relative to the architecture and geometry of the occupied space. For that analysis, the practitioners must look through the lens of ASHRAE Standard 55 Thermal Environmental Conditions for Human Occupancy.

ASHRAE 55 requires the practitioner to evaluate two personal factors, four general factors, and five local factors, as listed in Table 1.

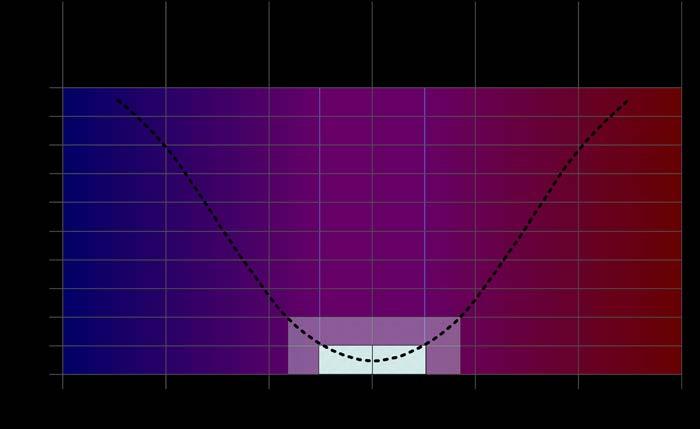

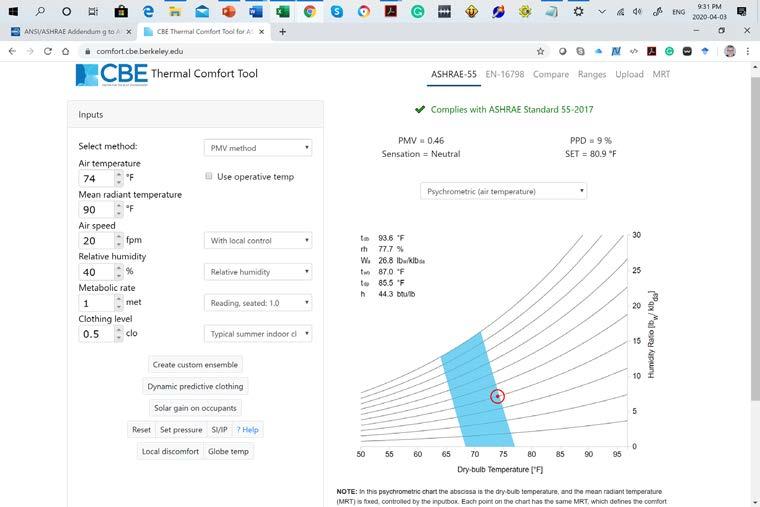

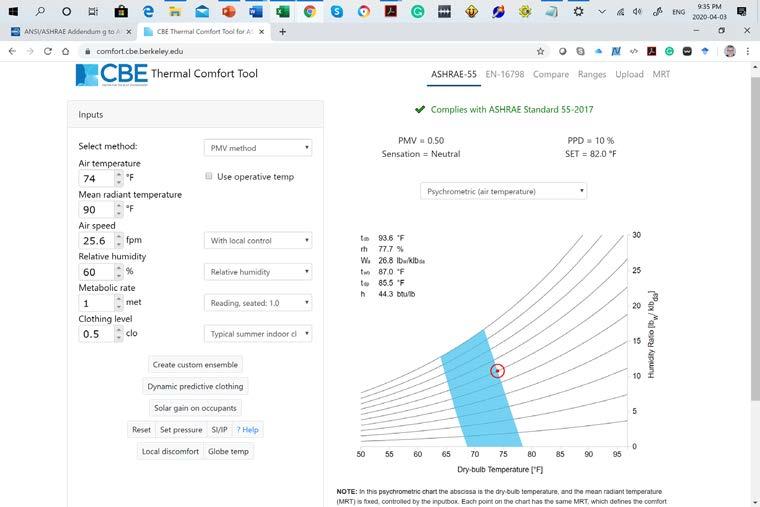

When correctly considered, combined and controlled, these factors result in compliance with Standard 55 based on the work of Dr. P.O. Fanger and two indices; the predicted mean vote and predicted percentage of dissatisfied occupants (Figure 1).

Dr. Fanger developed the Predicted Mean Vote (PMV, x-axis) and Predicted

Category Factor

Percentage Dissatisfied (PPD, y-axis) indices to illustrate that when architectural, enclosure, interior and HVAC design can get all the comfort factors from Table 1 right, that most people vote within a 0.0 +/- 0.5 range on a seven-point scale (top of the graph) in comfort assessments. This vote corresponds to a 10% dissatisfaction which is within compliance of ASHRAE Standard 55. Occupant discomfort exceeding 10% corresponds to votes outside the recommended range.

Identifying the source of discomfort and then solving it first with architectural, enclosure and interior solutions are the primary task of every indoor climate consultant.

Personal Metabolic rate (met) and clothing (clo)

General Discomfort Mean radiant temperature (MRT), dry bulb (air) temperature (tdb), humidity (%rh), air speed (fpm)

Local Discomfort Radiant asymmetry (Tasy), floor surface temperature (Tflr), temperature stratification (Tstr), drafts (fpm), ankle drafts

Table 1. Integrated Design Process and Professionals Role in IEQ Elements

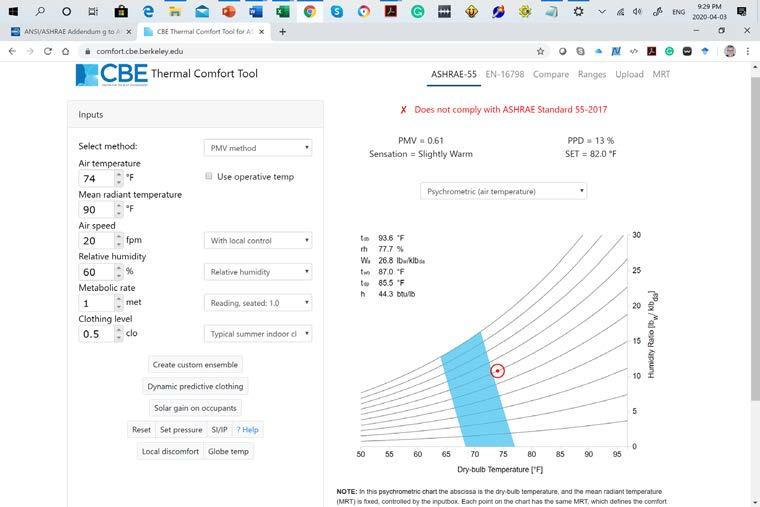

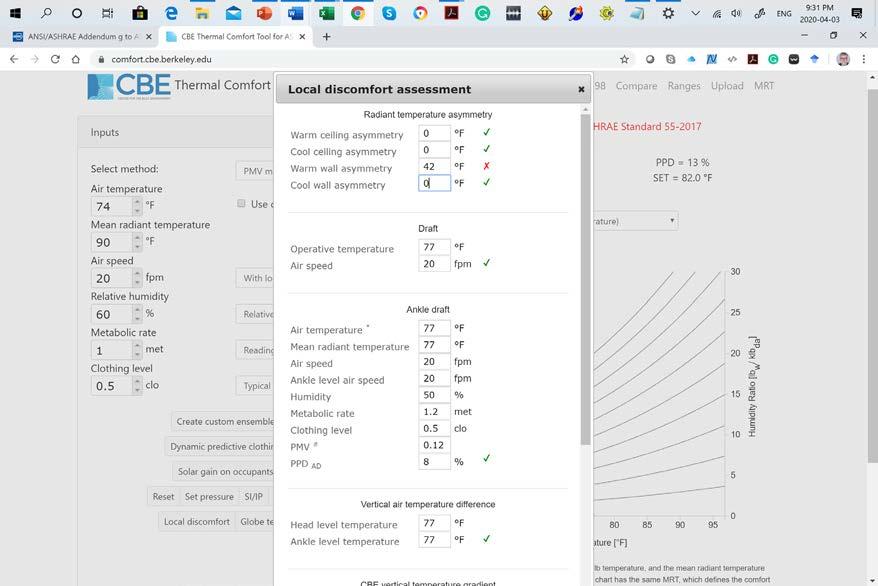

The 11 factors identified in Table 1, when known by calculation and specification, are inserted into the Centre for the Built Environment (CBE) online thermal comfort tool (Figure 2), which advises what a representative occupant might sense and perceive in a space and whether that experience would be in compliance with Standard 55. Equally important is that the assessment identifies sources of potential discomfort and can lead the designer to consider possible solutions.

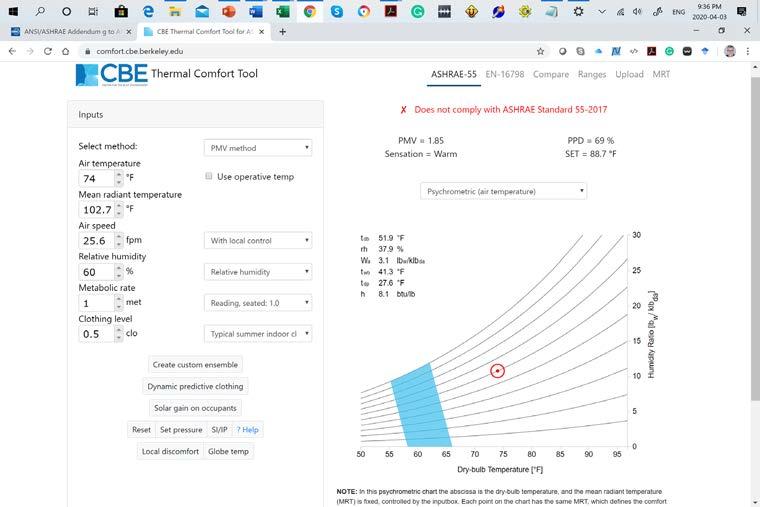

In cooling there are three primary concerns; the first two are illustrated in Figure 2 and Figure 3. These are the mean radiant temperature (MRT) and radiant asymmetry. These values determine the body's ability to discharge heat for cooling via radiation.

What causes the MRT to rise, and what causes radiant asymmetry? In the first case it is overglazed high U-valued flamboyant architecture with poor fenestration and without external shading. In the latter case it will most likely be the occupant with an overheated pane of

glass on one side of them and a cool conditioned space on the other.

The third concern is direct solar radiation absorbed by the occupant. This energy has to be accounted for in the MRT calculation, as shown later in Figures 8, 9, and 10

These three concerns exist because the predominant mechanism for controlling the release or absorption of energy in the form of heat from the body is via radiation followed by respiration and convection.

This shifts over to respiration and evaporation and convection under extremely hot and dry conditions. Under hot and humid environments, the evaporation process becomes muted depending on the vapour pressures on the skin relative to the room.

Under all other conditions, the temperature difference between the mean skin temperature and surrounding mean radiant temperature regulates approximately 60% of the sensible heat transfer from the body to the enclosures.

Overheating occurs when the inside surface temperatures begin to rise, which reduces the body's ability to discharge its excessive heat. It is the retention of heat that causes the perception of feeling hot.

To demonstrate these relationships, note of the following series of cooling challenges and compliances identified within an assessment for thermal comfort according to ASHRAE Standard 55.

Figure 2 shows inputs for the two personal factors and four general factors. Note the noncompliance PMV > 0.5 with a corresponding predicted percentage dissatisfied, PPD >10%. Note the red dot representing the person is outside the shaded comfort zone. This is due to the higher mean radiant temperature (MRT) and the upper end of the recommended humidity of 60% at a low airspeed, met rate, and clothing. The high MRT is usually due to a large window-to-wall ratio of poor performing fenestration without external

Continued on p32

Continued from p31

shading and no exterior insulation resulting in thermal bridging. The higher humidity under other circumstances would be acceptable, but with the combination of factors shown it is contributing to the discomfort. See in Figure 5 how dehumidification helps in this example for improving satisfaction.

In Figure 3 (previous page) inputs for four of the five local discomfort factors are shown. Note the noncompliant radiant asymmetry of 42F. This would occur when an occupant has a high surface temperature on one side and a cool surface or room on the other—common when large unshaded low performing windows are heated by direct solar radiation, raising the inside glass temperature well above room temperatures.

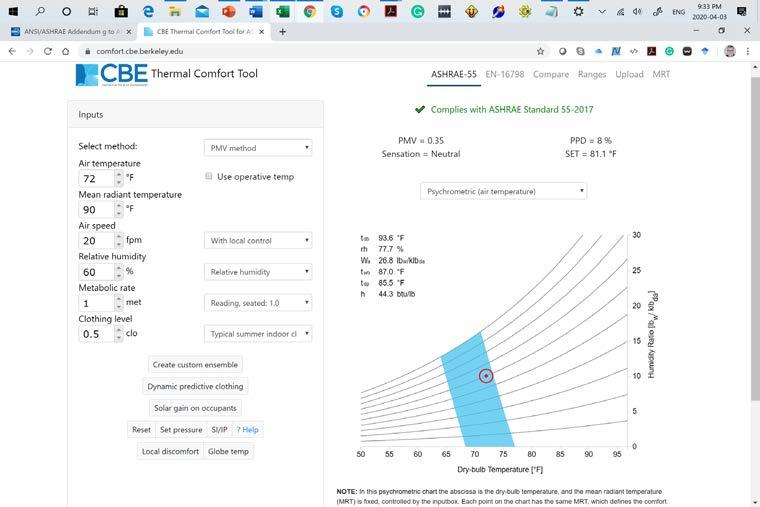

Figure 4, as per Figure 2 but with a change in air temperature from 74F to 72F. Note the compliance PMV < 0.5

with a corresponding predicted percentage dissatisfied, PPD <10%. This is due to the lower air temperature compensating for the higher MRT. Here dehumidification is not necessary for compliance, but cooling is necessary.

Figure 5, as per Figure 2 but with a change in relative humidity (RH) from 60% to 40%. Note the compliance PMV < 0.5 with a corresponding predicted per-

• One stop shop for air, water, temperature, humidity and electrical instruments

• Everything a balancing technician needs in a single case

• Best in class low flow velocity readings

• Durable, repeatable, and reliable in every instrument

• A certificate of NIST calibration is included for each instrument inside the kit

• Save time by sending everything back to us, we can recalibrate all equipment in the kit

centage dissatisfied, PPD <10%. This is due to vapour pressure on the skin exceeding the vapour pressure in the room, enabling latent cooling through room dehumidification. Cooling load calculations and A/C design do not pick these relationships up.

Figure 6: as per Figure 2 but with a change in the MRT from 90F to 85F leading to compliance. This is due to the lower mean surface temperatures, which comes from shading, lower enclosure U values or radiant cooling systems and occupants with low clothing and met rates. If the latter two increase, it is possible to shift into non-compliance. Cooling load calculations and A/C design would not pick up these relationships either, only a comfort assessment can assess these circumstances.

“Cooling load calculations and A/C design are not the same as comfort design.”

Figure 7: As per Figure 2 but with a change in airspeed from 20 fpm to 25.6 fpm. Note the compliance PMV = 0.5 with a corresponding predicted percentage dissatisfied, PPD = 10%. This is due to the increase in convective flow across the occupant, which is made possible with floor, desk, or ceiling fans. This illustrates that not all overheating challenges need be solved with energy-intensive refrigeration systems. Cooling load calculations and A/C design does not evaluate the use of personal fans but a comfort assessment can and does demonstrate their usefulness.

Figure 8: Next to increases in the MRT and radiant asymmetry, the third leading cause of overheating is the absorption of shortwave energy in the form of electromagnetic (radiant) energy transmitted through the glass. To evaluate this effect, the practitioner can use the SolarCal module built into the CBE tool. The results of this assessment adjust Continued on p34

the MRT experienced by the occupant due to direct solar gains. Here, based on the inputs, it results in an increase of 12.7F in the MRT.

Figure 9: as per Figure 7 but with a 12.7F upwards adjustment to the MRT (from 90F to 102.7F) due to the direct solar gain. Note the noncompliance PMV > 0.5 with a corresponding predicted percentage dissatisfied, PPD >10%. This demonstrates to the client and architect the need for external shading. Internal window treatments can convert the shortwave to longwave and reduce some of the effect, but they won’t reduce the cooling load.

Table 2 Passive/Low Energy Cooling Tactics

Seek lower MRT enclosures and avoid shortwave (solar) radiation by activating external shading, relocate to below grade and northside spaces. Closing internal window treatments will provide some relief though treatments usually become hot and will radiate energy into the space where it will get converted to heat.

Seek/create higher air velocities/drafts by using ceiling, floor, and desk fans; room air purifiers, and cross flow ventilation.

Decrease humidity with cross flow dry ventilation air (if possible) or use dedicated in space dehumidifiers. Use split systems for discharging heat to outdoors.

Decrease met rate through relaxation.

Decrease clothing to reduce insulation and expose more skin surface area to a cooler environment (if possible – see MRT above).

Stay hydrated, reduce blood viscosity for efficient flow to skin for radiant and convective cooling and to prevent dehydration from evaporative cooling (sweating/respiration).

Figure 10 : as per Figure 9 but with an increase in airspeed from 25.6 fpm to 60 fpm made possible with floor, desk or ceiling fans brings the environment into compliance.

As noted in all of these examples, cooling load calculations and A/C design should not be interpreted as being comfort design. Designing for thermal comfort requires the practitioner to focus on the occupant and not the building (see Table 2). This only makes sense since people sense the retention and gain of heat in their bodies ergo the building is not uncomfortable; people are uncomfortable.

For more on this subject, interested practitioners can obtain for no charge a new book on Thermal Comfort Principles and Practical Applications in Residential Buildings. This project was funded in partnership with BC Housing and can be accessed through this link: https://www. linkedin.com/groups/13843486/ <>

Robert Bean is director of www.healthyheating.com, and founder of Indoor Climate Consultants Inc. He is a retired engineering technology professional (ASET and APEGA) who specialized in the design of indoor environments and high performance building systems.

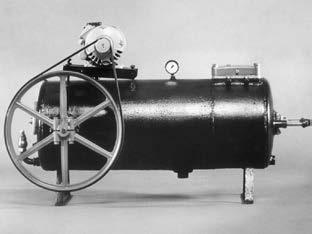

It probably goes without saying that anyone involved in the HVAC/R industry likely knows exactly what a chiller is. But for those outside of our industry, if there was ever a word that was completely inadequate in providing an accurate description of a process, it's chiller.

How do you even define ‘chill’. Perhaps someone has given you a stare that chilled you. Or have you ever been chilled to the bone? Chill doesn’t even come close to accurately describing a temperature range. But perhaps that’s ok, since there is no average range temperature application for a chiller.

OK, let’s chill out over the word thing, and talk about chillers.

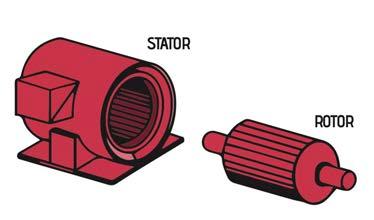

So, what is a chiller? To understand chiller operations it all starts with your basic refrigeration cycle, consisting of:

Function: Receive low pressure vapour from the evaporator and convert it to a high pressure vapour. As the compressor also adds heat to the vapour during the compression process, the end result is a superheated high pressure vapour.

Function: Transfer heat from the superheated high pressure vapour. First the vapour is desuperheated. Once the vapour reaches a saturated state, further heat transfer allows it to undergo a change of state into a liquid, and then become a slightly subcooled liquid.

Function: Allow the subcooled high pressure liquid to undergo a pressure drop. The resulting lower pressure will have a corresponding saturation temperature that makes it useful for transferring heat from the refrigerated/ conditioned space (or load).

Function: Transfer heat from the refrigerated/conditioned space (or load) to the low pressure, low temperature saturated liquid refrigerant, flowing through the evaporator.

The load on a typical evaporator in a refrigeration/air conditioning system is the heat content in the air from the refrigerated/conditioned space. The typical evaporator is a finned tube fan coil design. Heat from the air flowing through the finned tube evaporator is transferred to the refrigerant flowing through the evaporator tubes, resulting in a lower air temperature in the refrigerated/conditioned space.

What I've described is a typical single stage of heat transfer: heat from the refrigerated/conditioned space to the primary heat transfer fluid (refrigerant).

A chiller is quite different, in that it involves two stages of heat transfer. The heat load on the chiller’s evaporator is a secondary heat transfer fluid, such as water, or a mixture of water and propylene glycol.

This secondary fluid is brought down to the design temperature for the particular application, and is then pumped to secondary heat exchangers in the refrigerated/conditioned space.

The heat load from the actual refrigeration/conditioned space load is transferred to the pumped secondary heat transfer fluid. This heat is then transferred to the refrigerant flowing through the chiller’s evaporator.

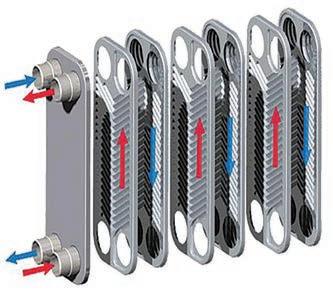

There are two main types of heat exchangers (evaporators) used in chillers:

In a shell and tube heat exchanger (Figure 1), the lower temperature saturated liquid refrigerant flows through the inside of the tubes in the barrel, and the secondary fluid is also pumped through the barrel. As the secondary fluid makes contact with the tubes, heat is transferred from it to the refrigerant flowing inside the tubes.

In a brazed plate heat exchanger (Figure 2), a series of corrugated plates are fastened together in a frame. The channel formed by two adjacent plates facilitates the heat exchanger’s high efficiency, as Continued on p36

the secondary fluid and saturated liquid refrigerant is distributed through alternate channels in a counter-flow arrangement. This counter-flow provides for maximum thermal efficiency

The major advantages of this design is that the higher heat transfer efficiency results in a much smaller sized heat exchanger.

A typical chiller application might be used for comfort cooling in an office building or hotel. Each zone (or hotel room) would have its own hydronic finned tube coil heat exchanger (see Figure 3) as a means to transfer heat from the space to the secondary fluid. The flow of secondary fluid through the heat exchanger is controlled by a solenoid valve, which is energized/de-energized by a thermostat in the space.

only. This reduces the charge from potentially several thousand pounds to perhaps a hundred or so.

ary fluid is very inexpensive compared to refrigerant.

Additionally, while there is a desire to eliminate the potentially environmentally damaging effects of refrigerant leaks, there is relatively little negative effect of a secondary fluid leak on a chiller.

In addition to comfort cooling, there are many commercial and industrial uses for chillers. The list is almost endless: bakeries, beverage bottling, breweries, dairies, food processing, fruit/vegetable washing, wineries, cement mixing, chemical plant processes, dry cleaning facilities, MRI testing, photo processing, plating processes, plastic injection molding, welding machines, and on.

One advantage to this design is the elimination of large refrigerant piping runs to each zone, with the tremendous amount of refrigerant which that would require. Instead, the refrigerant circuit is rather small, being contained within the piping circuit of the chiller

The secondary fluid for a chiller providing comfort cooling doesn’t require any measureable amount of glycol, as the application doesn’t have a significant chance of operating at refrigerant saturation temperatures below 32F. As such, the relative cost for the second -

Now, let me share a specific chiller application that was used to provide a stable environment for the storage of antique books and papers. The requirements were maintaining a temperature between 65F to 68F, and relative hu -

“In addition to comfort cooling, there are many commercial and industrial uses for chillers. The list is almost endless.”

midity (RH) between 40% and 55%.

While this wouldn’t seem to be too difficult, for some reason the onsite chiller was not able to maintain a constant leaving fluid temperature, which made it impossible to maintain a space temperature that was anywhere near what was required. The contractor was at his wit’s end, and he was willing to experiment.

The contractor used a discharge bypass valve to maintain a constant leaving secondary fluid temperature (see Figure 4), but not just any discharge bypass valve. You see, mechanical pressure regulating valves used to maintain precise temperature control are at best challenged.

First of all, you have the shortcomings of a mechanical valve (spring and diaphragm hysteresis) which limits the valve’s ability to control precisely.

Secondly, a system is always at a disadvantage when attempting to control temperature by controlling some other parameter, such as pressure.

In addition to the pressure of the refrigerant in the evaporator, there are other factors that will influence the leaving fluid temperature (or the space temperature), such as load demand and ambient conditions.

Simply relying on a constant evaporator pressure (constant refrigeration saturation temperature in the evaporator) to ensure a constant leaving fluid temperature (or space temperature) will always be less reliable than actually controlling the temperature itself.

So, the decision was made to use an electronically-controlled electrical step -motor discharge bypass valve.

Now, this was a valve which would travel 6,386 steps from fully open to fully closed (at 200 steps per second), which gave it an amazing wide range of resolution. And, the valve was responding to temperature, not pressure. And specifically, the fluid outlet temperature of the heat exchanger.

In addition to the electric discharge bypass valve, a variable frequency drive (VFD) was utilized to vary the secondary fluid flowrate, which facilitated maintaining the space temperature.

This method of control was able to maintain the leaving fluid temperature at 42F, with a differential of +/- 0.75F conditioned space at temperature of 65F, with a differential of +/- 0.5F.

Boom….problem solved…now time

to go get a chilled

Dave Demma holds a degree in refrigeration engineering and worked as a journeyman refrigeration technician before moving into the manufacturing sector where he regularly trains contractor and engineering groups. He can be reached at ddemma@uri.com

NAVAC now offers a three-year warranty, with product registration, for its next-generation NRDD recovery unit, whose twin-cylinder compressor and oversized condenser with two rows of microchannel coils offer efficient vapour recovery. The standard warranty, without registration, remains two years. The recovery unit features a brushless DC motor that allows it to provide substantial power in a compact size and weight of just 25 pounds. The DC technology also provides better starting performance under low voltage conditions. Its large LCD display is backlit for clear visibility. www.navacglobal.com

The SA Series from RenewAire is a factory-assembled, turnkey array of stacked static-plate enthalpy cores on a baseplate for energy recovery solutions inside OEM HVAC air handlers in most North American commercial applications. The packaged core with a plenum assembly is an alternative to enthalpy wheels for controlling latent and sensible load transfer in large airflow applications while also providing energy-recovery. The SA Series is available in 20-in. core modular stacks ranging from 3 (w) x 3 (h) (2,250-CFM) to 8 (w) x 8 (h) (70,000CFM). Custom sizes are also available. www.renewaire.com

Johnson Controls LUX KONOse smart thermostat is designed with seniors in mind. The Energy Star certified thermostat, part of the KONO suite of products for commercial facilities, has larger primary and secondary digits and enhanced backlight options. The large icons, like a flame and snowflake, call out heating and cooling functions. Users can rotate the thermostat’s dial to adjust the set temperature or push the dial to change HVAC modes. The thermostat is compatible with the LUX app so users can make temperature and scheduling adjustments from any device. pro.LUXProducts.com/KONOse