QUADRIK COLLECTION

NOW AVAILABLE IN BLACK FINISH

CONIK COLLECTION

NOW AVAILABLE IN BLACK FINISH

Designed for plumbers, loved by designers!

NOW AVAILABLE IN BLACK FINISH

NOW AVAILABLE IN BLACK FINISH

Designed for plumbers, loved by designers!

Setting

12

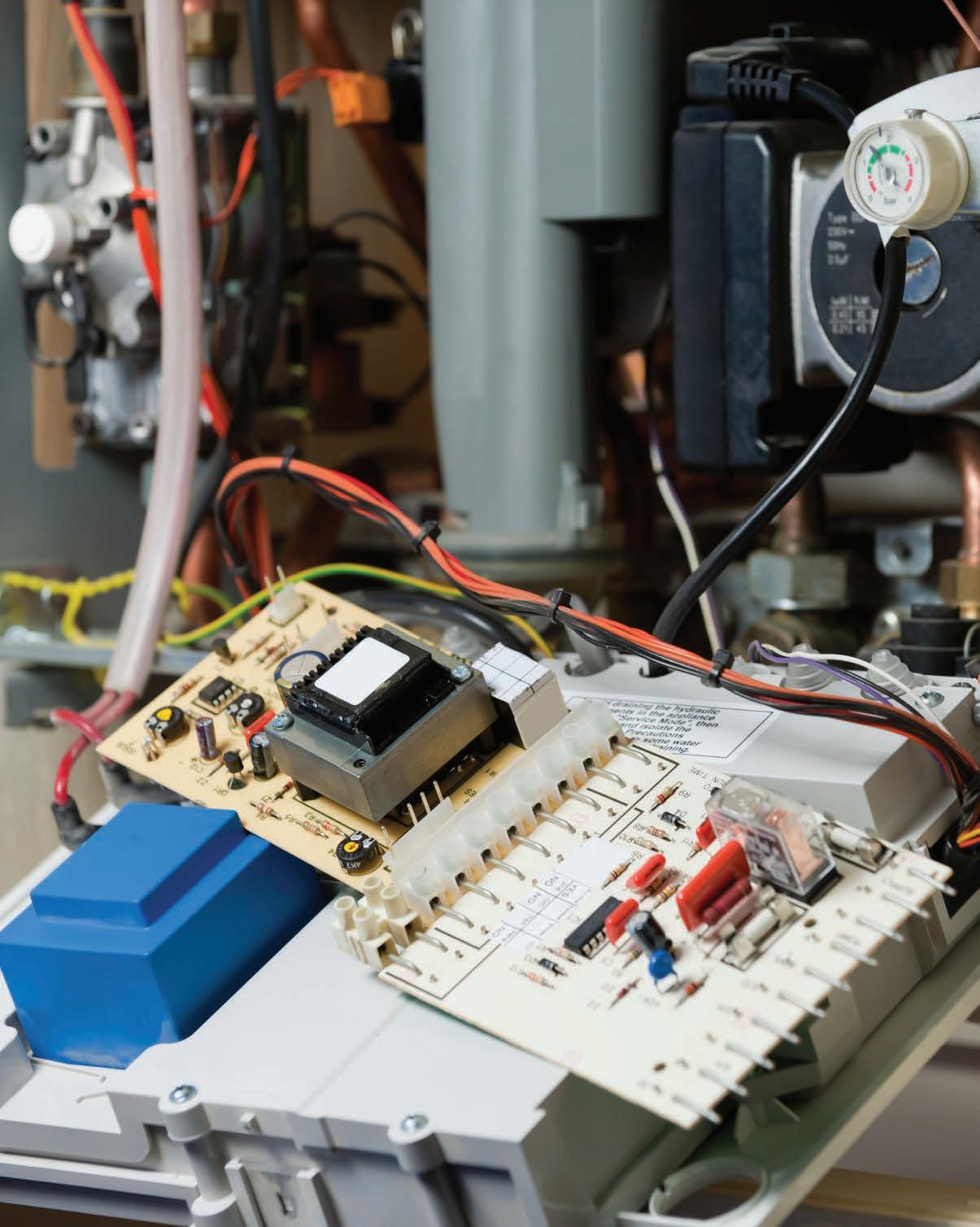

COVER STORY

HEATING

RESIDENTIAL HVAC WARRANTIES: WHERE IS THE VALUE?

Offering regular maintenance to ensure products perform at peak efficiency and maintain warranty coverage.

By Ian McTeer

18

PLUMBING

HOT TRENDS, COOL FEATURES

Modern commercial washroom designs call for more inclusive spaces with luxurious and sustainable touches.

By Steve Goldie

62

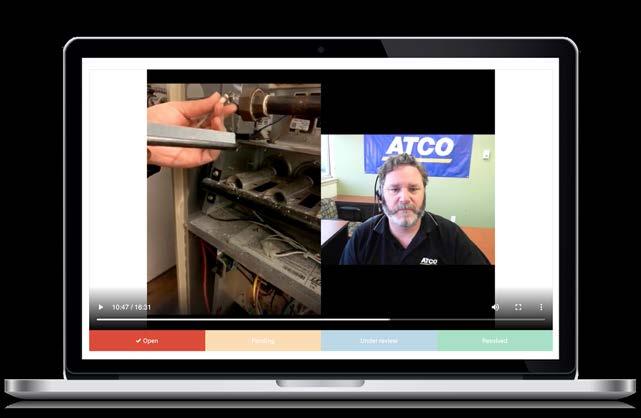

SMART SOLUTION

CALLING IN SERVICE CALLS

Calgary-based startup introduces augmented reality platform that changes the way HVAC technicians deliver service.

By Megan Hoegler

64

PLUMBING

KBIS PRODUCT SHOWCASE

Highlighting award winners at this year’s Kitchen and Bath Industry Show.

By Megan Hoegler

68 TECHNOLOGY WHY FI?

With the proliferation of connected devices in our industry, everyone needs to understand the basics of a Wi-Fi set up and the common challenges involved.

By Curtis Bennett

70 MANAGEMENT UNDERSTANDING ADJUDICATION

What construction stakeholders need to know to navigate Ontario’s new adjudication system

By Catherine DiMarco

72

20TH ANNIVERSARY FOR RMC

The unique industry-run Refrigerant Management Canada program continues to be the only program of its kind in North America.

By Doug Picklyk

74

A SEAT AT THE TABLE

Changing the project design lens to focus on whole life-cycle value.

By Anil Sawhney

With the dependable versatility of Transit and Transit Connect, plus the power and capability of F-150 and Super Duty, Ford’s lineup of commercial vehicles makes achieving your ultimate business goals possible.

• Super Duty has best-in-class*

available payload of 7,850

• F-150 has available features like Pro Trailer Backup Assist^

• Transit has 3 lengths, 3 heights and 58 cargo congurations

• Transit Connect has a compact footprint, and a maximum cargo space of 145.8 cu ft†

SOMETIMES, WHEN WE GET CAUGHT UP IN OUR DAY-TO-DAY WORK WEEKS we can lose sight of what’s going on outside of our small corner of the world. Every day brings new challenges and adventures, but there can also be a repetitive nature to a work week.

I do believe that for people at all stages of their working lives, from newcomers to seasoned veterans, taking the opportunity to attend any industry events—open houses, trade shows, conferences or association gatherings— goes a long way to improving both the person and the business.

Ideally, industry-related events combine educational and social benefits. Some sessions and presentations can get vendor focused, and even in those sessions we’re all looking for that one or two nuggets of information we can glean to make our working lives better.

Walking a trade show floor is one sales pitch after another, but it’s also a true opportunity to see competing products side-by-side and even discover new tools, appliances or services that weren’t on your radar.

It’s also an opportunity to get questions answered. Yes, the Internet has become a fantastic resource for problem solving, but finding experts in person who can solve specific issues is priceless.

Whether you’re the outgoing type or not, it’s hard not to meet new people when you attend any events, and making connections can prove very helpful down the road. Getting involved in industry associations isn’t just an opportunity to network and mingle with a small group, it’s an opportunity to be part of industry change and get a true pulse of the business conditions around you.

I believe the greatest impact industry events have on everyone attending isn’t in the knowledge gained or the relationships formed, it’s more the palpable energy that’s generated by assembling a group of like-minded people together. It’s a reminder that you are part of something larger—that we’re all in this together—and that’s invigorating. It’s hard not to get inspired.

Check the calendar of events in this magazine, or online, and make a point of attending something, somewhere. And then, when walking to the parking lot on your way home, consider what just happened. Did taking a little time away from the day-to-day prove insightful or uplifting? Did you smile at least once?

If you’re attending the CMPX show in Toronto this March, I’ll be there. Stop by, maybe we can share a laugh. <>

– Doug Picklyk, Editor

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

MEDIA DESIGNER

ACCOUNT COORDINATOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

COO

PRESIDENT & CEO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

Megan Hoegler (416) 510-5201 MHoegler@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Vince Naccarato (416) 510-5118 VNaccarato@hpacmag.com

Emily Sun esun@annexweb.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 442-5600 ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbusinessmedia.com

Scott Jamieson sjamieson@annexbusinessmedia.com

Mike Fredericks

without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com.

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Free Services Include:

• • Cost Comparisons

•

• Equipment Detail Packages

• Equipment Detail Packages

Learn More at: www.aipsdesignservices.com

www.aipsdesignservices.com

ASHRAE begins retrofit project at new Atlanta headquarters

The global organization dedicated to advancing the arts and sciences of heating, ventilation, air conditioning and refrigeration, ASHRAE, kicked off the new decade in a big way with a groundbreaking ceremony to celebrate renovations to its new global headquarters.

Top ASHRAE officials, including Canadian Darryl K. Boyce, P.Eng., the 2019-20 president of ASHRAE, gathered at the two-storey, 66,700 sq. ft. facility on Jan. 10, with shovels and hardhats.

Located in a suburb of Atlanta at 180 Technology Parkway in Peachtree Corners, Georgia, the new headquarters

building will feature energy efficient upgrades including: upgraded plumbing; energy-efficient HVAC systems; and new LED lighting systems.

The new site will also have the ability to harness on-site energy production. ASHRAE also has its sights set on ensuring the new facility becomes LEED certified by promising a net-zero-energy ready facility.

“Our new headquarters project will showcase ASHRAE’s best practices and will help us to achieve our vision of a healthy and sustainable environment for all,” said Boyce in a media statement.

In addition to LEED certification, ASHRAE also hopes to achieve Green Globes, Fitwell and/or WELL Building or Living Building Challenge certifications as part of the organization’s goal to be more sustainable and eco-friendly.

At the time of the ground breaking, ASHRAE released a series of defined requirements to help the US$10 million renovation project reach its net-zero-energy goal. Aesthetically speaking, the society has made space utilization and good acoustical qualities a priority, along with a unified interior style and high durability of finishes.

Design criteria for the renovation meet, and in some cases exceed, requirements outlined in ASHRAE’s newly

updated Standards 62 and 90.1.

At the core of the renovation project is the creation of the best possible work environment for employees, focusing on aspects such as general health, fitness and overall well being. These renovations are also following guidelines set forth in the new ASHRAE Advanced Energy Guideline for Office Buildings.

“The plans for this project incorporate some of ASHRAE’s most well-known indoor air quality and energy standards and the end result will be a building that will offer a cutting edge, tangible example of sustainability in action,” said Technical Advisory Subcommittee chair, Tim McGinn, in a company release.

Also present at the groundbreaking were representatives from Houser Walker Architecture and Integral Group, the architectural team working on the project, along with several members of Collins Project Management, the build's acting project management team, Skanska’s construction manager at risk for the project and Epsten Group’s commissioning agent. McLennan Design is also involved but was unable to attend.

The project is expected to reach completion by late summer, with ASHRAE’s approximately 125-person staff scheduled to move into the new headquarters by October 2020. <>

Four cities in the Greater Vancouver Area, Burnaby, Richmond, Surrey and Vancouver, are engaged in a pilot project that tracks and discloses the energy emissions of participating commercial buildings.

Beginning January 21, 2020 participating building owners and managers have begun to disclose energy and emissions data from their properties.

Participants receive detailed energy and carbon performance data for a clear picture of how their building’s performance stacks up on carbon emissions. This information will help them make more informed decisions on capital investments and upgrades.

The Building Benchmark B.C. pilot project is helping all participating parties identify areas and building types that will need extra support from energy efficiency rebates.

“Within the past year we’ve seen unprecedented support for climate action; dozens of cities have declared climate emergencies,” David Ramslie, vice president of sustainability for Concert Properties, one of the project participants, said in a release. “As a result, building owners and managers are paying attention to energy and emissions. The companies that choose to benchmark and disclose their energy and emissions at BuildingBenchmarkBC.ca will not only understand where they rank relative to oth-

Raising awareness of potentially dangerous cross connections in water systems, the Western Canada Section of the American Water Works Association (WCS AWWA) has awarded the winning entries of its 2019 Bad and Ugly Cross Connection Control photo contest.

This is the fifth year the section’s cross connection control committee has held the national contest. The 2019 winners are Brendan Miller, a backflow tester working for SASK Water, and Fred Ramackers, a cross connection control inspector in Regina. Ramackers’ entry included a washdown water closet underneath a prep table at a funeral home, while Miller’s included cross connections at a village water treatment plant.

“Our water industry representatives, inspectors, plumbers and testers all share a responsibility to protect our water supplies. Cross connections do exist and are a potential to contaminate or pollute our potable water. Let’s do our best to find and correct these cross connections before the damage is done,” says the committee.

The group is inviting entries for its 2020 contest. www.wcsawwa.net

ers, they’ll be contributing to a community of practice and research that could help to transform the whole building industry.”

The pilot was developed by OPEN Green Building Society, which convened a range of stakeholders to help. The project is funded by Natural Resources Canada and BC Hydro.

www.BuildingBenchmarkBC.ca

The Government of Ontario has launched a marketing campaign to highlight careers in the trades under the slogan ‘Find a Career You Wouldn’t Trade.’

The campaign, which launched January 10, includes video ads that will run digitally in movie theatres and on Tim Hortons TVs across the province.

“We need to do a better job at enticing young people and their parents to the skilled trades,” said Monte McNaughton, the Ontario Minister of Labour, Training and Skills Development, in a release.

The ad campaign features skilled tradespeople in their work environments.

The ads are one part of the government’s strategy to open up the trades for young people and businesses. The province is also investing approximately $75 million in three programs to expose high school students to the trades: $12.7 mil-

lion in the Ontario Youth Apprenticeship Program, $42 million in the Specialist High Skills major program and $20.8 million in a pre-apprenticeship program.

“The reality is that the skilled trades offer exciting and challenging careers that often require solid math and problem solving skills, and expose people to the latest technologies such as 3D printing and robotics,” said McNaughton. “When it comes to opportunity, to earning potential, to having a chance to start your own business, the skilled trades come out on top.”

According to the Province, over the first nine months of 2019 Ontario employers had, on average, 204,000 job openings across all occupations and industries. Of these, 13,000 were in the construction sector. www.ontario.ca/page/skilled-trades

In a New Year’s welcome note to members, Sandy MacLeod, president/ CEO of the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI), reflected on his first full year in the role, noting, “These are exciting times for the HVACR industry; while the challenges facing our industry continue to grow, the business remains strong.”

Despite challenges, he indicates member satisfaction is up, and by June mebership is expected to have grown by 10 per cent over a two-year period.

Through surveys and continual communication with membership, he shared that government relations and advocacy are top priorities for members, and in response over the past year HRAI has allocated more resources towards

those efforts, investing in new personnel as voices in Ontario, B.C. and Quebec, and is working on arrangements—in partnership with AHRI—on filling a role to satisfy cross-border needs of manufacturer members serving the Canadian market.

In the note, Martin Luymes, vice president, government and stakeholder relations with HRAI, outlined several outreach activities HRAI was involved in over the past year, including: partnering with Natural Resources Canada on the roll-out of the federal-provincial market transformation road map for energyefficient equipment in the building sector and advising Environment and Climate Change Canada in the development and roll-out of its Climate Action Investment Fund (CAIF). www.hrai.ca

Offered in 41, 61 or 99 imp. gallon capacities (184, 279 or 451 Litres).

Field convertible

Convertible voltage (208 V, 240 V, 480 V and 600 V), phase (3 to 1) and wattage input ranging from 3kw to 54kW on all models and up to 63 kW on 112 models. Allows multiple electric configurations for your hot water needs.

Two (2) high quality magnesium anodes

Oversized on 112 models, they provide excellent protection against the corrosive effects of water and extend the tank life.

Easy service access to components

Designed with a single panel junction box for a fast electrical supply. Equipped with a hinged door and a removable element panel. Allow access to all of the electrical components.

Learn more about our commercial water heaters www.giantinc.com

It’s important to understand manufacturer warranties and be able to identify how you can provide additional value to customers.

BY IAN McTEER

You purchase a pair of pliers from your local HVAC supplier and discover the pliers don’t work for some reason. Regardless of whatever written warranty the tool may carry, the pliers should work as you might expect. Asking for and receiving a replacement tool at no charge is the basis of an implied warranty: the implication is the good should be of merchantable quality, it should function for its designed purpose and it should last for a reasonable time period.

It seems almost counter intuitive that a well-made product would even require a warranty: “buy my machine because it will never let you down,” a manufacturer could claim. Yet, there are so many components in modern HVAC machinery and controls that something could easily go wrong.

The adage commonly known as Murphy’s Law is a form of rubbish confirmation bias but its main tenant, “anything that can go wrong, will go wrong”, is firmly established in the minds of many consumers. Any given manufacturer would likely go out of business without a strong competitive product warranty well known to the marketplace.

Prior to 1975 all product warranties in Canada and the U.S. were very poorly defined leaving consumers in precarious situations far too often. It wasn’t uncommon to find the term “full warranty” in many product advertisements and documents. Consumers quickly found out that sometimes a full warranty might not cover any labour, travelling time,

diagnostics, refrigerant or even shop rags. Shouldn’t a full warranty cover most, if not all, of those things?

Less dependable manufacturers were very aware that advertising a full product warranty might easily allow them a foothold in a very competitive marketplace. Ambiguous warranties created confusion and turmoil even destroying relationships between consumers and contractors.

While there isn’t really a direct upfront cost to offering a warranty, its value is really defined by how manufacturers or their agents act when a product fails. In 1975 the Magnusson-Moss Warranty Act (MMWA) was signed into law in the U.S. This bill created standards for writ-

ten warranties, regardless of the industry, thus protecting consumers from the misleading or otherwise unscrupulous practices plaguing the market. MMWA requires that a “full warranty” means parts, labour, service and transportation of the product must be free of charge provided the consumer has performed any and all related duties within the specified timeframe of the warranty.

Limited Lifetime Warranty means a manufacturer will provide a replacement part(s) that failed due to a defect in manufacturing at no cost for the lifetime of the product. A subsequent purchaser may be entitled to the balance of the same warranty for a shorter time period since purchased by the original owner.

Limited express warranty is a written warranty that defines the length of time specific parts of a product will be covered for defects in material and workmanship under normal use and maintenance.

Starting in the late 2000’s some HVAC manufacturers opted for a registered warranty system. Left unregistered, the base limited warranty provides only five years coverage on specific parts (20 years on gas furnace heat exchangers) that fail due to workmanship and manufacturing defects.

A registered limited warranty requires the warranty to be registered with the manufacturer within a set time period after start up (often 60 days) and the base five-year warranty may be doubled: parts go to 10 years, compressors in premium units might get 12 years of coverage, while a gas furnace heat exchanger gets a 20-year warranty once registered. Manufacturers want to collect installation information for not only marketing reasons, but for legal protection in the event of a product recall.

A registered warranty means the manufacturer can communicate directly with the end-user ensuring timely repairs can be made without relying on contractor installation records that may or may not be up to date.

Our Canadian provinces have individually harmonized the requirements of Magnusson-Moss into provincial consumer protection laws. As with the MMWA, provincial legislation does not require a manufacturer to offer a warranty only that any warranty offered must comply with current legislation. However, express (written) warranties are specific legal contracts that identify who is covered and what the company will do in the event of a failure. There are many exclusions, here are just a few:

• Limited warranties do require enduser input, the product must be

maintained and not forced to operate outside its normal function

• Labour is rarely covered unless specifically mentioned in the contract and typically applies to certain parts and repair functions tabulated separately

• Filters, fuses, fluids, corrosion, abrasion and appearance items are often not covered

• Typically, no coverage for parts supplied by others, improperly installed parts, used parts or damaged parts

• Products exposed to flooding, fire, lightning, misapplication or serviced by unqualified personnel

• Transportation of goods, service calls or diagnostic time

• Products re-installed at another site

• Cost of regular maintenance Manufacturers make further disclaimers such as the company will not be liable for any incidental or consequential damage and that the express warranty included with any product exists in lieu of all other warranties expressed or implied. Since the warranty is a contract between the manufacturer and the end-user, no other party can modify or nullify the terms and conditions; for example, a technician cannot void someone’s warranty for any reason. A technician could, for example, refuse to replace a part at no charge on an in-warranty unit citing any of the published exclusions contained in the warranty. The primary takeaway is that HVAC warranties cover defects in material and workmanship, that’s all.

Long limited warranties make consumers feel more comfortable buying a product, but HVAC service contractors would prefer a shorter time frame in order to profit from parts sales. Extending the manufacturer’s registered limited warranty to cover additional labour costs, for up to 12 years in some cases, could prove to be a beneficial sales tool thus providing the contractor with an

additional revenue stream and revenue from part mark-ups that otherwise may not have existed.

However, historically speaking, extended warranties, especially those offered by third parties, have a less than stellar reputation given reports of provider bankruptcies and claim rejections. Indeed, the Consumer Council of Canada released a study last year and executive director, Ken Whitehurst, said, “they [consumers] don’t understand how it’s being sold, they don't understand the complex agreement, they don’t understand how the agreements are financed and secured.”

Whitehurst goes on to say, “that many [warrenties], if not most of them, are of questionable value, but there are some that are of value in some circumstances.”

I’d argue that extended warranties sold through HVAC manufacturers do provide value and necessary consumer protection in these days of $1,000 circuit boards and very expensive inverter drive compressors.

A geothermal system often consists of a warranty package that may include the ground heat exchanger, indoor components and factory-approved accessories. The ground heat exchanger, or loop, must be properly specified and installed by competent drillers or loop installers using materials such as high density polyethene pipe (HDPE), which carries its own 50-year warranty.

I’ve seen quality loop installers offer limited 10-year warranties that cover materials and workmanship related to the installation of the loop including the header and grouting.

But perhaps the greatest expense, namely excavation and site remediation or any other consequential costs not related to parts and material, are not covered. Assuming the loop is pressure tested and flushed correctly, this

potential horror-show should never become an issue.

One Canadian manufacturer of geothermal heat pumps offers this limited warranty on newly-installed equipment:

• Five years on heating and/or heat pump starting on date of installation

• Five years on factory-supplied or approved thermostats, electric heaters and pumping modules

• Ten years on sealed refrigerant circuit components such as the refrigerant to air/water heat exchangers, reversing valve body and metering device and the compressor

• Five years on parts or accessories that are factory-installed

• One year on other accessories purchased separately from the geo unit manufacturer.

• And, according to a schedule published by the manufacturer, some labour will be paid to “authorized personnel” for repairs to specifically listed components for two years from the date of installation

• Sealed refrigeration system components qualify for five years of labour coverage.

• Extended warranty is available.

Regardless of the limited or extended warranty coverage for an HVAC product, contractors can benefit from offering extended warranty coverage along with a maintenance program. Regular maintenance is a must, not only to assure the product performs at peak efficiency, but also to maintain warranty coverage.

A geothermal unit contractor should consider amortizing the longest possible extended warranty into his or her offering. The service plan might include a fee for a yearly tune up or monthly payments that could include a couple of yearly visits. Key plan offerings should include all services that tend to preclude warranty problems, such as:

• Servicing by licensed technicians

• Coil and blower wheel inspection

• Filter maintenance

• Data collection

And may include bonus features like:

• Priority status for emergency service

• No overtime charges

• Discounts on diagnostic fees and repairs not covered by warranties

• Discounts on parts out of warranty

Since I’m not a lawyer, I’d urge contractors to be fully aware of the socalled fine print contained in written warranties and to be sure all custom -

ers are aware of their obligations. Manufacturers make mistakes and things go wrong with processes, but that’s why we do what we do. <>

Ian McTeer is an HVAC consultant with 35 years experience in the industry. He is a refrigeration mechanic and Class 1 Gas technician.

The Whalen Company has always been known for reliability, performance and innovation of fan coils and heat pumps. But we also have a complete line of replacement products, service parts, and the knowledge to support your HVAC system. By offering true replacement parts, refrigeration chassis or complete units, The Whalen Company can save you time and money by supplying exact replacements that don’t require field modifications.

Combine that with a flexible product offering for new construction or renovations and you have an HVAC manufacturer that works with our customers to meet all of their needs. Does your HVAC manufacturer offer this much?

The Geniox air handling units from Systemair for commercial, school, healthcare and industrial applications feature thermally-insulated double wall casings and ABS designed corners to prevent thermal bridging. The 2.4-in. foam injected insulation also reduces sound transmission. The modular units can handle airflows from 2,700 to 16,300 CFM in five casing sizes. www.systemair.net

Johnson Controls line of York YLAA air-cooled scroll chillers range from 40 to 230 tons. The scroll chillers are equipped with two independent circuits for partial redundancy. Brazed plate evaporators and microchannel condensers aim to enable more efficient heat transfer. www.york.com/ylaa

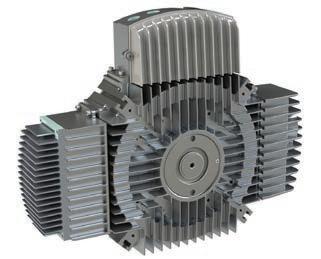

From Regal Beloit Corporation, the UlteMax axial integral horsepower motor can achieve 3to 15-hp. The motor includes an integrated configurable control. It offers speed from 300 to 4200 RPM, and is 4.5 in. thick. www.regalbeloit.com

Friedrich Air Conditioning Co. is now offering its VRP (variable refrigerant packaged) heat pump system in a three-ton size. Designed for multi-family and light commercial applications, the system features MERV-8 filtration and onboard sensors that monitor and adjust compressor speeds. www.friedrich.com

The Smarter Building Controller by Fujitsu General and Ventacity Systems offers a building management system for use with Fujitsu’s Airstage heating, ventilation and cooling systems. The controller offers integration with installed equipment, and control is performed via Internet connection from a connected device. www.fujitsugeneral.com

Daikin’s Fit Heat Pump systems are ductless and use inverter compressors and smaller, lighter cabinet designs, for a compact heat pump option. The systems feature a cooling efficiency of up to 18 SEER and a heating efficiency of up to 10 HSPF and require just 4-in. of clearance for installation. www.daikincomfort.com

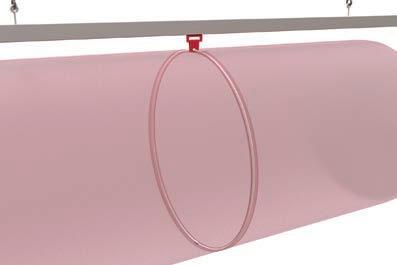

FabricAir has released its Internal 360 Hoops System for shape retention in fabric ducts. Constructed from flexible fibreglass rods, connected by custom-length steel rods, the Hoops system is designed to hold fabric HVAC ducts in a 100 per cent inflated appearance even when air handlers are off or in variable fan speed modes. FabricAir fabrics are UL and CSA-listed and accepted by all building codes in compliance with NFPA 90A-2018. www.fabricair.com

Modern commercial washroom designs call for more inclusive spaces with luxurious and sustainable touches. BY STEVE GOLDIE

Having been a plumber most of his life, my father had lots of plumbing opinions and stories. One of my favourite stories did not come form his years as a plumber but rather from his time in the British army. My dad grew up in Glasgow, Scotland, and back in those days the United Kingdom still had mandatory military service that required healthy young men to serve Queen and Country for 18 months.

James Goldie could best be described as a reluctant recruit who simply ignored his draft notice for almost two years; he could not however successfully ignore the two military policemen who rudely dragged him out of his bed one Saturday morning to escort him to boot camp.

Once he was there he resigned himself to his fate and went about the business of training and peacetime soldiering

along with all the other lucky draftees. Apparently boot camp does not afford an individual any opportunity for free time, free expression or any type of individuality whatsoever. Every minute of every hour of every day was regimented and scheduled, filled with training and drills and such. You woke up when they told you, you ate when they told you and you went to the bathroom, or loo, when they told you.

Life can get pretty harried and busy in this day and age, so much so that at times we feel we barely have a moment to ourselves. Sadly, on days like that the washroom break may be the only quiet alone time one gets. However, in boot camp even this opportunity for a peaceful sit down is removed. The communal army latrine my dad had to use back in the day was a fairly crude set up with a long trough urinal on one wall, and a

long trough drain communal toilet along the other wall.

Yes, you read that correctly, the toilets were basically a long bench seat with about 10 openings with toilet seats, each separated by a divider. Underneath ran a continuous sloped trough drain, with a single flush valve on one end that would clear the entire trough when activated.

Since the day was regimented and scheduled nobody had the luxury of coming and going as they pleased. When a bathroom break was permitted the stalls would be quickly occupied and the line up would form. On one of these occasions my father was lucky enough to be in the drivers’ seat, so to speak, occupying the end stall, the one with the flush valve.

I am not sure what inspired him this particular day, but he decided he would take advantage of his position of power by sending a surprise down the trough.

He rolled up a bunch of newspaper into a soccer ball sized wad, lit it aflame and sent it down the trough. His unsuspecting army mates all had their arses singed as the ball of fire passed by underneath. Whatever repercussions or discipline he faced afterward must have been worth it because he would still get a hearty chuckle out of telling that story even 50 years later.

Thankfully modern bathrooms, as with most things in life, have evolved. They bear no resemblance to the bathrooms of yesteryear, especially those favoured by the British army back in the 1950’s. The name “Water Closet” (or WC) reveals how discreet and utilitarian bathrooms used to be. Through the past several decades that I’ve been working in this industry, bathrooms have steadily become bigger, more luxurious and more comfortable. Residential bathrooms are no longer Continued on p20

EZ Gear Sensor Faucets deliver reliability, precision, and efficiency to your commercial restroom. Thanks to the dual action of the ceramic disc cartridge and motor gear-driven operation, they outperform and outlast solenoid operated faucets. They intuitively sense the user without delay, too much force, or wasting water. Gear up for the next generation of sensor faucets with EZ Gear Technology.

You can expect up to 20 plus years of trouble-free performance.

tucked away closets, they have become more like home spas where we go to relax, refresh and revive; places we actually want to spend time.

In recent years we have also seen this trend crossing over into the commercial side as well. Clients, customers and employees’ expectations have been substantially raised when it comes to what they expect, and even demand, in public washroom facilities.

The look and feel of a commercial washroom can be a deal breaker for many consumers. No matter how comfortable your guests and customers may feel in your shop, hotel, restaurant or facility, if they don’t feel safe and comfortable in the washroom they may not come back. Successful business and building owners understand the appearance and usability of bathrooms has a significant impact on how patrons perceive them. This is probably most keenly felt in the restaurant industry for obvious reasons. That being said, I could probably fill many pages with restaurant washroom horror stories.

Another trend we see is the move to public or commercial washrooms becoming more universal. Where most buildings would have one washroom designated for men and another for women, we now see this expanding and changing. Many spaces have added family bathrooms, typically larger and including diaper changing stations. More and more we are seeing gender neutral designated washrooms. A growing trend, again with restaurants leading the way, is to provide a number of individual universal bathrooms that resemble a powder room you might find in a high-end custom home.

If meeting these rising expectations and demands is not challenging enough, the modern bathroom designer also has to be mindful of the importance of sustainability. Water-efficient fixtures and carefully chosen materials show the business cares about the environment.

“Touch-free fixtures also cater to the perception of cleanliness.”

Touch-free faucets and flush valves help satisfy this requirement; ensuring valves cannot be left running. Touchfree fixtures also cater to the perception of cleanliness—the less we have to touch in a public bathroom the better.

Sometimes all of these competing requirements can butt heads with each other however. Take the beautiful new and modern washroom facilities in our head office for example. We have touchfree flush valves and faucets installed in all of the washrooms. These valves have small solenoid valves in them that are battery operated, and they also have photovoltaic cells installed on them to ensure the batteries stay charged. Those smarty pants environmentally savvy designers covered all the bases and checked all the right boxes!

Unfortunately sometimes we are too smart for our own good. Those photo voltaic panels on the faucets are not very effective in the dark, and that is exactly where they are more often than not thanks to the motion detector light

switches that ensure the lights stay off when nobody is in the washroom. I guess the designer’s left brain didn’t tell their right brain what they were doing.

When you think about it, designing, building and maintaining commercial washrooms is quite a complex challenge with so many factors to be considered. Not only do they need to look clean and comfortable but they have to be accessible to everyone without offending or excluding anyone. In addition, they have to be durable and vandal resistant; oh and don’t forget to provide facilities to change the baby’s diaper, and if you do retain separate gender designations, the diaper change station better be in all of them.

Well at least nobody has to be afraid of having their morning sit down disturbed by a flaming fireball anymore. RIP Dad, I hope that story can still make you chuckle wherever you are. <>

Steve Goldie learned his trade from his father while working as a plumber in the family business. After 21 years in the field, he joined the wholesale side of the business in 2002. His expertise is frequently called on to troubleshoot systems and advise contractors. He can be reached at sgoldie@nextsupply.ca.

Aquatherm’s updated version of its North American Installer Manual covers safety, best practices and planning for proper installation of Aquatherm systems. The manual is divided into three chapters with new sections on updated product information, references to new resources such as Aquatherm TechTV videos and new technical data. www.aquatherm.com

OS&B has introduced FRZERO50, a new offering of non-combustible PVC shower drains, island tub drain and waste & overflows. The products meet flame and smoke requirements of CAN/ULC S102.2-10 for noncombustible buildings and will not support combustion in the presence of an ignition source. www.osb.ca

The CloudBox from reed is designed to monitor and control plumbing features. It can be synced to control up to two valves, two meters and two sensors for risk management, water conservation and improved operational efficiency. The set of devices control and monitor domestic plumbing systems while working with many existing plumbing valves, meters, sensors built for use in commercial properties. www.reedwater.io

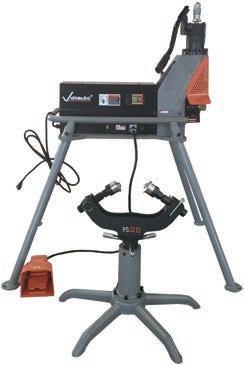

Victaulic’s latest grooving solution tool, the RG3212 roll grooving tool is capable of grooving 2-in. to 12-in. steel piping. Designed to reduce jobsite errors and increase productivity, the RG3212 features an integrated drive motor and discreet design to damper sounds for quiet operation. www.victaulic.com

FEBCO’s ArmorTek Advanced Coating System protects its ductile iron backflow preventer valves with three layers of protection to guard against corrosion. FEBCO’s three-pronged coating solution consists of an anticorrosion primer layer, followed by a microbial inhibitor to prevent bacteria growth and a topcoat to bond to the primer and create a high-strength barrier between the iron substrate and water. www.febcoonline.com

NAPCO Royal Pipe and Fittings has launched NAPSYS-HR PVC DWV, a new system for high rise DWV pipe and fitting applications. The system meets all low smoke and flame requirements of the Canadian Building Code and is available in sizes 1.5-in. to 10-in. in diameter. The low rise system currently in the market will be rebranded under a new name - NAPSYS-LR PVC DWV. www.napcopipe.com

The new StormCell® series of battery backup pumps from Liberty feature advanced professional-grade chargers, energy e icient pumps for longer run times, and optional NightEye® wireless technology for remote monitoring through your smart device.

• Available in both standard and wireless connected models

• Single and dual battery systems

• Energy e icient DC pump (manufactured in the U.S. by Liberty) *

ThermaSol has added three apps to its Smart Shower system; TSN, Radio Canada and Global News Skytracker. The upgrades are part of the Smart Shower System, which features water temperature controls, steam therapy options, sound and lighting as well as TV access to video streaming applications like Netflix and YouTube. The system can be installed up to 30 feet from the actual shower and managed by fully digital touch control. www.thermasol.com

Caleffi’s LEGIOMIX digital mixing valve for commercial domestic hot water (DHW) temperature control is now available with ANSI 150 flanges in sizes 2 ½-in. for 17 to 470 GPM flow rate and 3-in. for 22 to 537 GPM. These new sizes will complement NPT sweat and union connections. The LEGIOMIX also features a “master” electric mixing valve that automatically self-cleans, preventing scale formation. www.caleffi.com

Flomatic has expanded its Flow Control Valves range, The Flo-Trol CD900, to include new sizes and flow ranges. Featuring a stainless steel body, Flo-Trol automatic flow control valves is a self-cleaning and flexible orifice available in a range of sizes (0.25 GPM up to 30 GPM). Flow rates are maintained to within ±15 per cent between 15 and 125 PSI. Each valve is engraved with the flow rate, size and certification and comes sealed and pre-labelled. The Flo-Trol Model CD900 is available in seven different sizes (⅜-in. thru 1 1/2in.) The Flo-Trol CD900 are all NSF/ANSI 61 & 372 certified and covered with a three-year warranty. www.flomatic.com

The Neera family of kitchen faucets from Pfister feature the company’s Pforever Seal ceramic disk technology providing a never-leak guarantee. The premium faucet includes an advanced spray head docking to ensure the faucet head fits snug to the spout, the spray head has three settings — spray, stream and pause — and it is made with EZ Clean technology to help resist hard water build up and water spots. The forward-handle design is an ergonomic function. Available finishes include: brushed gold, stainless steel, matte black and polished chrome. www.pfisterfaucets.com

IPEX has extended its line of MJ Grey DWV products to include mechanical couplings in three new sizes; 14-in., 16-in., and 18-in. The new couplings will have the familiar grey rubber lining to indicate their use with IPEX System 15 or System XFR. These couplings are advantageous in cold weather as an option to solvent welding, repairs or tie-ins and for limited joint deflection in difficult installation areas. www.ipexna.com

MAKING THE CASE FOR OUTDOOR RESET

RESIDENTIAL AIR TO WATER HEAT PUMP: PART 1

INTEGRATED DESIGN: ACHIEVING IEQ AND EFFICIENCY PRODUCTS THIS MARKET NEEDS

INDUSTRY DEFINITIONS: HEAD VS. DELTA-P

Products we need Suggestions for five technologies/ products that could help move the hydronics industry forward.

BY JOHN SIEGENTHALER

Making the case for installation in every hydronic space heating system.

BY ROBERT WATERS

MH14 NEW TECHNOLOGY

Residential Air to Water Heat Pump Systems

The rise of electrification in residential HVAC will lead to greater adoption of heat pump technologies.

BY MIKE MILLER

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

ACCOUNT MANAGER

ACCOUNT COORDINATOR

ART DIRECTOR

CIRCULATION MANAGER

PUBLISHER

VICE PRESIDENT

PRESIDENT & CEO

MH16 INTEGRATED DESIGN Achieving IEQ and Efficiency with Human Factor

A case study featuring a multi-family project using hybrid HVAC systems using heated and chilled water from the central plants.

BY ROBERT BEAN

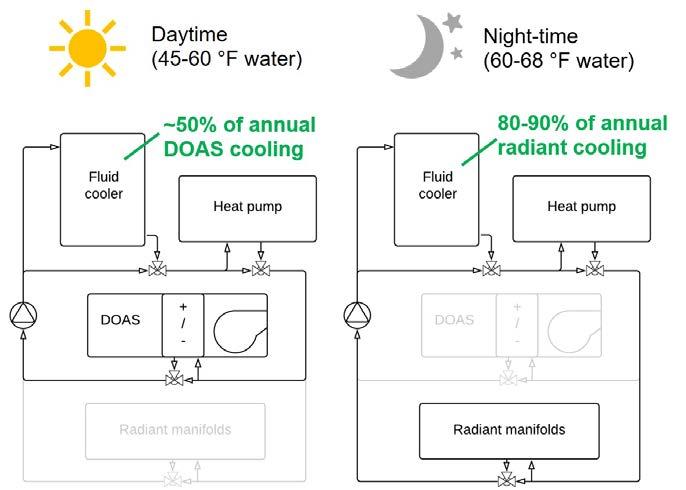

MH22 SYSTEM DESIGN Considerations for Operating Hybrid Radiant-DOAS Systems

Three important considerations for designing a sequence of operations that makes the most of this technology.

BY SANJIL KARKI

MH28 TECHNICALLY SPEAKING HEAD VS. ∆P

Important differences between these two commonly used terms.

BY JOHN SIEGENTHALER

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

Megan Hoegler (416) 510-5201 MHoegler@annexbusinessmedia.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Vince Naccarato (416) 510-5118 VNaccarato@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbizmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Tim Dimopoulos (416) 510-5100 tdimopoulos@annexbizmedia.com

Mike Fredericks

Navien designs and manufactures all the key components and uses advanced robotics to assure manufacturing integrity

Discover the new standard for compact high efficiency commercial boilers by visiting navieninc.com/series/nfb-c.

• Advanced stainless steel fire tube heat exchanger

• 7" Touch screen and smart controls

• 97.5% Thermal efficiency

• Common venting and cascading capability

• Top and bottom piping connections

Suggestions for five technologies/products that could help move the hydronics industry forward.

BY JOHN SIEGENTHALER

Product innovation has moved the North American hydronic industry a long way over the last 50 years. In the 1970s, a typical residential hydronic system used a fossil fuel boiler to supply two or three zones of baseboard with scalding hot water. Today, some systems use geothermal or air source heat pumps, possibly supplied by renewably-generated electricity, to supply room-by-room comfort using bathtub temperature water circulating through radiant panels.

Continuous improvement is essential to maintaining a healthy industry, especially if that industry expects to gain market share against competing technologies. To promote future growth, new products and installation methods should (in no particular order):

• make systems easier and faster to install.

• deliver equal or better comfort than their predecessors.

• demonstrate increased efficiency.

• improve system reliability and reduce maintenance.

• correct deficiencies in existing products or installation methods.

With these objectives in mind, the following are my thoughts on five products I think could further enhance North American hydronics technology.

If you’ve used cast-iron circulators in any type of chilled water cooling system,

or in earth loops for geothermal heat pumps, you’ve likely seen what happens to the volute, steel flange bolts and even steel handles on isolation flange valves when they rack up a few operating hours well below the dewpoint temperature of the surrounding air. All these components quickly develop surface oxidation. (figure 1 shows an example.)

Over time the orange condensate drips onto anything below it. This “superficial” rust doesn’t compromise the circulators performance, but it does make a mess.

The obvious solution is to add a vapour-tight insulation envelope around all parts of the circulator other than the motor can and wiring compartment.

Some manufactures offer molded foam clam shells that fit specific circulators— usually commercial-sized ECM products. These can limit condensation if they are properly sealed at all locations where air could contact any chilled metal surface.

Wouldn’t it be nice to have an insulation/vapour barrier system that could fit any circulator that may have to operate at sub-dewpoint temperatures?

Perhaps a block of solid insulation

material that could be easily molded, on site, to the shape of the installed circulator, and then attached as two mating parts. Maybe a hollow plastic shell that could be fit around the installed circulator volute and flange joints and then filled with expanding foam.

An elastomeric gasket would be part of either approach to provide the air-tight seal with the circulator’s motor can. The portion of the circulator that contacts the insulation could be sprayed with a “release agent” that prevents strong bonding in case the insulation had to be removed to service or replace the circulator.

Over the last 25+ years I’ve designed many hydronic systems that had one or more circulators with standard PSC motors operated by variable speed controllers. The controllers used a combination of AC wave chopping and frequency control to vary the speed of the circulator.

However, the circulator world is changing. Those familiar wet-rotor circulators with PSC motors are about to go the way of 100 watt incandescent light bulbs. I suspect they will be out of production within the next five years. Circulators with higher efficiency ECM motors are quickly becoming the new normal.

Variable speed controllers using wave chopping and frequency control cannot be used with ECM circulators, so it’s just a matter of time until those controllers follow PSC circulators into the annals of hydronic history.

The good news is that many of the new ECM circulators can be speed-controlled using a 0-10 VDC input signal (not to be confused with the standard

120 VAC electrical power supply). A typical scenario is for the circulator to remain off until the control signal reaches 2 volts. The circulator’s speed increases in direct proportion to the control voltage, reaching full speed at 10 volts.

What’s needed are simple and inexpensive controllers that generate a 0-10 VDC output signal in relationship to some temperature-based condition. The latter could be a user-set “target” temperature, with circulator speed selectable as increasing or decreasing as the temperature measured by the controller varies from the target value. This function allows for supply water temperature control as well as boiler anti-condensation protection.

The controller should also handle differential temperature control, such as used in solar thermal systems or biomass boiler systems. It should also be able to provide variable speed injection mixing based on either a fixed target supply temperature or a target temperature calculated using outdoor reset logic. All these functions are just selectable code within the controller’s firmware. The controller should have connections for up to three temperature sensors, as shown in figure 2

3 A multi-function controller for biomass boiler systems

There are lots of applications for boilers burning wood pellets or chips. These “biomass” boiler systems require several control functions including boiler anti-condensation protection, boiler firing based on two or more temperatures within a thermal storage tank, variable speed injection of heat into a distribution system, differential temperature control to prevent auxiliary heat from entering storage, coordinated operation of an auxiliary boiler and zoning.

All of these functions can currently be provided by combining several independent single-function controllers along with an assortment of relays.

Although these “multi-box” control systems work, their installation and programming can be challenging. I can attest that this has been a significant barrier to successful biomass boiler installations, especially in residential or light commercial applications.

This situation could be greatly improved if the market provided an integrated controller to handle all necessary control functions for these systems. The functionality exists, it’s just a matter of repackaging it in one box.

4

Indirect tanks with larger coil heat exchangers

The future of hydronics is low water temperature. Contemporary heat sources such as geothermal water-to-water heat pumps or air-to-water heat pumps typically max out at water temperatures in the range of 120-130F. That’s hot enough for many types of heat emitters, such as well designed radiant panels or panel radiators. It’s also sufficient to create domestic hot water at perhaps 110 to 115F—if there’s a suitable heat exchanger between the source water from the heat pump and the domestic water.

Most of the currently available indirect water heaters in North America are very limited in such applications. The internal coil heat exchangers in these tanks don’t have sufficient surface area to transfer heat from a much lower temperature heat source to the domestic water at the heat output rate of the source and at a minimum temperature differential of only 5 to 10F. The result will be short-cycling, heat pumps locking out on fault conditions and complaints about inadequate domestic hot water.

Most North American indirect water heaters were developed assuming a boiler would be the heat source, supply-

ing water to the coil heat exchangers at temperatures of 180-200F. Swap in a heat pump and you have a very significant heat transfer “bottleneck.”

One solution is to use an external stainless steel heat exchanger sized for very low approach temperature differences. This works, but it’s arguably more complex than an indirect water heater.

Another solution would be to increase the surface area of the coil heat exchanger inside indirect tanks. Coils with three to five times the surface area of a typical indirect are needed. Such coils would likely span from the bottom to the top of the tank as depicted in figure 3.

The coils could be made of either stainless steel or copper. The water passing through them could be from the heat source, or it could be domestic water. The later “reverse-indirect” concept allows the tank to provide domestic wa -

ter as well as buffering for zoned space heating loads. It also allows the pressure vessel to be made of carbon steel, which is more affordable than stainless.

I would also suggest that such tanks have R-24 F•hr•ft 2/Btu insulation on all surfaces and ample ports for a variety of applications. Think of such tanks as high quality “Thermos bottles,” capable of storing heat for several hours, or perhaps a couple of days with minimal temperature drop.

Peel & stick elastomeric foam pipe insulation that sticks

My last plea is born out of frustration. I’ve had many occasions to see (and fix) peel & stick elastomeric foam pipe insulation with seams that have reopened only a few weeks after installation. I suspect that I’m not the only one who has experienced this problem.

I’ve fixed it using 1.5-in.-wide highquality vinyl electrical tape centered along the slit line. This works, but it shouldn’t be necessary. Perhaps the product branding should change from “peel & stick” to “peel, stick and stay.” Perhaps some of these ideas will come to fruition to advance the North American hydronic market. <>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has more than 35 years experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (see www.hydronicpros.com for more information).

Representing Lochinvar branded residential and commercial hot water and heating boilers, Aqua-Tech Sales and Marketing Inc. provides top of the line branded solutions and support services to its clients across Canada. Our people bring experience, skills and commitment to supporting our distributors and installers to help them grow their businesses.

From many different product solutions to help you meet your customers’ needs, to technical engineering support, design and bid assistance, extended hours technical support, customer and market insights, well stocked inventory, training, support programs and so much more.

BY ROBERT WATERS

Outdoor reset control technology for hydronic heating systems has been around for decades. I learned about the technology when I started working for CanaPex (predecessor of Uponor) in the late 80’s. I was designing hydronic radiant floor heating systems and was taught to recommend a Tekmar four-way mixing valve with motorized actuator and outdoor reset control for every system.

Later, when I moved to Viessmann in the mid 90’s, I learned about the Trimatik-MC, the Viessmann boiler control system that combines separate outdoor reset controls for both the boiler and the system via motorized mixing valve. Both of these European-based controls were examples of the rapidly growing market for digital outdoor reset control technology.

Outdoor reset control has been mandated for both new and existing boilers in many European countries since the 1990’s. The digital control market certainly has changed and grown significantly since those early days of my

career, but the benefits that outdoor reset technology provides are still very much the same; namely reduced energy use and cost while improving occupant comfort.

You would certainly expect a very mature and established technology like this, with such great benefits, to be widely used for all hydronic heating systems. However, based on my discussions with several industry veterans about the current usage rate of outdoor reset controls, this is not the case.

I was told that outdoor reset controls are still only being used sporadically on residential hot water boiler installations. They are more common in commercial applications where engineers and owners have recognized the significant energy, cost savings and comfort level increases that can be achieved.

This control technology is especially important and timely with new pending NRCan efficiency regulations. As most may already know, NRCan Amendment 15 regulations that just passed into law last year will require all residential boilers <300 MBH to have an annualized fuel utilization efficiency (AFUE) ≥ 90% in 2023 (this means only condensing appliances). This regulation will also require that all residential boilers be equipped with an automatic water temperature adjustment device and must not be able to operate without the device.

Outdoor temperature reset controls, also referred to as weather responsive controls, work for both non-condensing and condensing boilers. They can also be used with heat pumps or biomass hydronic systems by controlling the temperature in the buffer storage tank.

As mentioned, outdoor reset controls provide two great benefits: 1) a dramatic reduction in energy use and cost, and 2) an increase in occupant comfort.

The energy savings result from the fact that the efficiency of any hydronic heat source is always higher when operating at a lower water temperature. This is due to lower stack temperatures, lower standby heat loss, and with condensing boilers, higher amounts of flue gas condensation. Another efficiency factor that also comes into play is that a boiler will be less likely to short cycle on and off in warmer times of the heating season when it is controlled with outdoor reset.

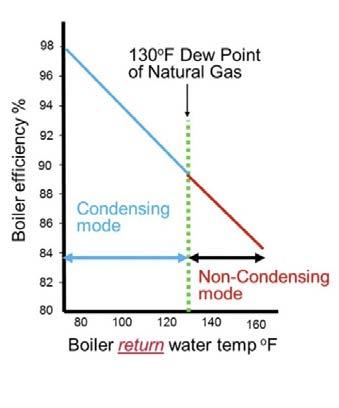

For any gas-fired condensing boiler the operating efficiency will vary in the range of 85% to 98% depending on the water temperature it is operated at (see figure 1).

Many are not aware of this efficiency range because they only look at the AFUE efficiency rating of the boiler. While a condensing boiler may have an AFUE rating of 95%, this rating was established in a test lab with a constant

140F supply temperature. If the boiler is operated in the real world, with a constant high temperature set point of 180F all heating season, it will very rarely condense and likely only have an efficiency in the 85% range.

However, if an outdoor reset control is used the supply water temperature is modulated all winter increasing the efficiency of the appliance in the shoulder seasons providing typical energy savings of 5 to 30%. They are also likely to extend the boiler lifespan by minimizing short cycling.

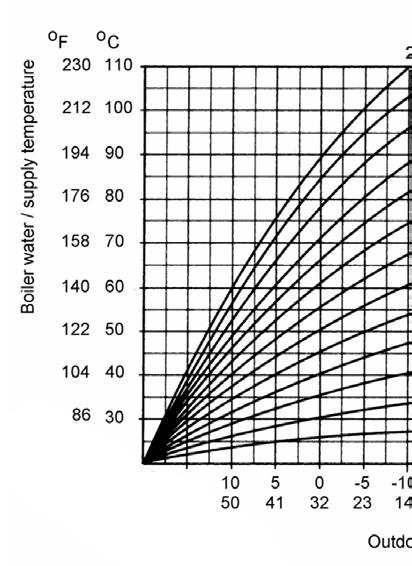

On the other hand, outdoor reset controls provide great energy savings while at the same time providing a more comfortable living environment for the building occupants. This is primarily achieved by eliminating the dramatic temperature swings that inevitably occur in any home whose heating boiler is operated at the same water temperature all year long. In order to provide consistent and even indoor temperatures, the heat supplied to the building must equal the heat loss from the building. The biggest factor affecting how much heat a building requires is the

outdoor temperature.

Even in a well-insulated building heat loss increases as the outdoor temperature falls. A hydronic heat source must be set to the highest water temperature setting that will satisfy the coldest day of the winter (design conditions). Design conditions however occur for a very small number of hours per year (less than 5% of the entire heating season: see ASHRAE data, following page), so for the vast majority of the heating season the heat source will be operated at a much higher temperature than is required to meet the load. So what happens when the outdoor temperature is warmer in the fall and spring? At these times the system inevitably overheats the building, creating temperature swings and poor control for the occupants. Overheating will be especially noticeable in high mass hydronic systems such as those with cast-iron radiators and radiant floor systems. In commercial or apartment buildings, where occupants do not directly pay for heating bills, energy use and costs increase even more as occupants open windows to compensate for overheating conditions. By continuously adjusting the system supply water temperature with an outdoor reset control the hydronic system is able to more closely match the exact heating requirements of the building at all times. The results are more consistent, comfortable space temperatures throughout the entire heating season. An added benefit in homes with fin-tube baseboard systems is a minimization of ticking expansion noises in baseboards by preventing large temperature swings.

Outdoor reset works by utilizing an outdoor temperature sensor mounted on the building’s exterior, ideally on the north wall and located away from anything that can give it a false reading such as a dryer or ventilation exhaust vent.

This electronic ambient air sensor actively monitors the outdoor tempera -

ture, and based on its reading a microprocessor calculates the heating demand and adjusts the output water temperature of the boiler accordingly. This results in the boiler only running as hot as necessary to achieve the desired indoor temperature.

There are two major categories of outdoor reset control; one being direct boiler reset control and the other being mixing reset control. Some controls will incorporate both boiler reset and mixing reset into one package. A mixing reset control utilizes either a motorized mixing valve or an injection pump to provide a mixed supply water temperature to an individual heating circuit.

Hybrid hydronic systems that have radiant floor heating (RFH) and fan-coil heating are the most common type of system that requires multiple supply water temperatures. For these systems the boiler reset control will provide a higher temperature to the fan coil circuit, and the mixing reset circuit provides a lower temperature to the RFH circuit.

There are many manufacturers today that provide both boiler and system outdoor reset controls. Most controls combine many other features and control capability such as multiple boiler control, wireless outdoor sensors, Wi-Fi connectability, and room temperature feedback. Many condensing boiler manufacturers now integrate the outdoor reset control directly into the boiler so there is no extra added cost.

Outdoor reset controls must be set up and calibrated at the time of installation to meet the jobsite specific system requirements. The primary adjustment for any outdoor reset control is the heating curve setting. This setting determines what the maximum supply water temperature will be on the coldest day, and what the lowest supply temperature will be on the warmest day.

Continued on MH12

The heating curve is determined primarily by the type of heat emitter used in the system (see figure 2 above).

The control may come with a factory defaulted heating curve, but this will not meet the requirements of all types of systems. Different heat emitters such as high mass radiant floor, cast-iron radiator, and fin-tube will all require unique settings. When using a non-condensing boiler the minimum supply temperature must be set high enough to avoid flue gas condensation in the boiler and chimney (usually a minimum supply temperature of about 140-150F).

Other adjustments such as parallel shift, warm weather shut down (WWSD), and desired indoor temperature may also need to be adjusted. I do not have space in this article to get into the fine details of setting up an outdoor reset control, but there are many sources for those who want more information. Most manufacturers and distributors of hydronic equipment offer training and advice on how to do this properly, so reach out if you need help.

All of these adjustments must be done by the installing contractor at the jobsite, and I believe the lack of understanding of these settings is one of the primary reasons why some shy away from using outdoor reset controls.

In commercial hydronic systems outdoor reset control technology is being used extensively because it makes sense financially. Designers and building owners are seeing that savings can be substantial providing great ROI’s to the owner.

This same acceptance and use level has not spilled over into the residential hydronic market. Many hydronic installers still don’t use outdoor reset controls, even when the control is integrated into the boiler. Many don’t activate the outdoor reset control or bother to install the outdoor temperature sensor and wiring. They prefer to just set the boiler at one temperature and enable and disable it with a room thermostat through the TT connection.

Scott Boutilier, technical advisor/instructor with Viessmann-BC told me, “For many contractors, if they can get away without

using the outdoor reset control they will. Contractors just want to get in and out of jobs quickly, and they don’t want the hassle of running the sensor wire and setting up the control. Even with our boilers that have factory installed outdoor reset controls, many contractors don’t bother to install the outside sensor and just run the boiler at one temperature.”

Like many areas of the HVAC market, margins are always tight and very competitive, and many contractors want to make projects fast and easy. Many don’t want to ever have to return to the job after they are finished the installation. This usually results in a single thermostat, constant temperature boiler, and NO outdoor reset control. For many projects this means that the full potential of a new condensing boiler is not being optimized, and the customer is left with higher fuel bills and sub-optimal comfort levels.

It’s not all doom and gloom though, as everyone I spoke to say the true “wet-heads” are the exception to this trend and have definitely adopted the use of outdoor reset controls. According to Boutilier, “Good hydronic guys have taken the time to learn about outdoor reset technology, understand how it works, and they know how to adjust and fine tune the controls. They know how to make the controls work, can explain the benefits to their customers and they can easily sell the extra cost required to set up and configure the control.”

Unfortunately these hydronic contractors are not the majority. To those who are using them already, keep it up. These simple controls increase appliance efficiency, reduce greenhouse gas emissions, while at the same time make buildings more comfortable. This potent combination seems like a no-brainer to me!

It is time for everyone in the hydronic heating industry to step up and fully utilize this powerful, yet inexpensive, technology. This not only includes hydronic installers, but also regulators who inspect and enforce code and standards. No hydronic space heating system should be installed without one. <>

Robert Waters is president of Solar Water Services Inc. which provides training, education and support services to the hydronic industry. He has over 30 years experience in hydronic and solar water heating. He can be reached at solwatservices@gmail.com. <>

The rise of electrification in residential HVAC will lead to greater adoption of heat pump technologies.

BY MIKE MILLER

As we all said goodbye to last year on December 31, for the HVAC industry this isn’t just the beginning of a new year, a new decade or an opportunity to set new personal and professional resolutions, 2020 and the years to follow will also represent further changes in our marketplace. And although we saw things change in the last decade, the one to come will be even more dramatic — of that I am sure.

The global conversations about a ‘greener’ world—electrification, carbon neutral or net zero buildings—is really starting to resonate across our continent and some geographic regions are already adopting rules and regulations that will prevent or make difficult to use fossil fuel fired equipment moving forward. These changes will, as has already been the

case in Europe, shift the landscape of heat sources away from fossil fuels as the primary energy provider.

Did you know that 2017 was the first time that heat pumps outsold the number of boilers as heat generators in Germany, and this shift continues to move faster and faster over there?

Like many other technologies in this industry, Europe sets the trend and North America typically follows. In the past it would take a number of years for

North America to catch up, but with the world becoming a smaller place, the transition is happening a lot sooner.

Heat pumps will likely lead the way in the immediate future as heat source replacements for fossil fueled radiant systems in the residential market. Geothermal heat pumps are a well tried and tested technology that works extremely well, if installed correctly, but the costs of drilled ground loop wells (depending on geographical location) has kept the adoption of this technology limited to high-end homes.

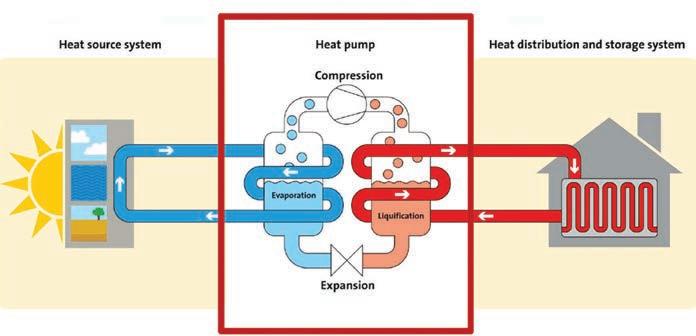

Air to water heat pumps (ATWHP) on the other hand have come a long way in recent years and can offer a much more cost-effective alternative for many structures, big or small, residential or commercial. Heat pumps, unlike boilers, can be reversed to provide cooled fluid for cooling applications in the summer to make this generation of equipment usable all year round. Heat pumps can also provide domestic hot water for a building.

Figure 1 illustrates a very basic heat pump cycle consisting of a source (outdoors), a load (building or fluid storage) and the guts that makes it all happen, including the evaporator, compressor, liquefier and expansion valve.

Refrigerant pressure changes its ability to absorb heat or cool and either put heat into the building in heating mode or pull it from the building and put it outdoors in cooling mode. A reversing valve in the heat pump is used to make the cycle responsive for heating or cooling needs, depending on the requirement.

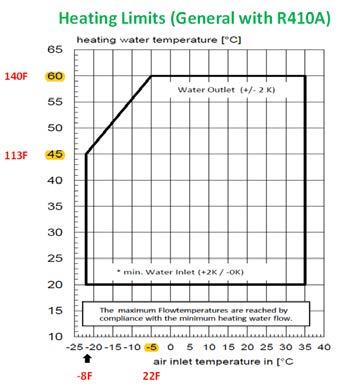

Using outdoor air as a source of energy is limited to ambient conditions. Today many ATWHPs have inverter driven compressors for added efficiency that can modulate to draw energy out of the ambient outdoors as long as it is above -22C (-8F) for heating operation and below 45C (113F) for cooling operation. That’s a pretty wide range, but in many of our regions some additional backup heat generation is required to supplement the ATWHP during extremely harsh conditions outside of that range. ATWHPs also have a limited fluid temperature that it can generate. The refrigerant used in most of these systems, R410A, limits its output capacity as described in figures 2a and 2b.

The maximum fluid temperature a typical ATWHP can provide is 60C (140F) in heating mode, but its output capability is reduced when the ambient outdoors drops below -5C (22F) and is somewhat in a linear relationship from there down to about -22C (-8F) with the fluid temperature of 45C (113F), as is shown in figure 2a

In cooling mode, the output capacity is pretty stable and can be anywhere between 7C and 20C (45F and 68F) for fluid temperature as long as the outdoor temperature is below 45C, as is shown in figure 2b. These limits must be considered when choosing the terminal units for heating and cooling of the building.

Of course, ambient outdoor temperature and fluid temperature provided affect the output capacity and efficiency of the ATWHP. This can vary from manufacturer to manufacturer, and it is important to understand the ranges when considering your design options and requirements. An example of how it may impact a system is shown in figure 3 for heating.

As the outdoor temperature drops the output capacity drops. In this particular example, at -5C outdoor temperature the output capacity is shown at about

9.5 kW or 32,000 BTUh and operating at a COP of 4. At -20C outdoor temperature, the output capacity is shown at about 6 kW or 20,500 BTUh and now operating at a COP of 2.5.

For the cooling operation, as the outdoor temperature rises the output capacity drops. As an example, at 15C (59F) outdoor temperature the output capacity will be about 14 kW or 4 tons of cooling and operating at an energy efficiency ratio (EER) of 5.5. At 45C (113F) outdoor temperature, the output capacity will be about 7 kW or 2 tons of cooling and operating at a EER of 2.

Understanding these limitations is absolutely necessary when designing a system. In the next issue of HPAC (Part 2 of this article) I will go through a very high level system design example using an ATWHP for a 2,000 sq. ft. home in Canada, looking at mechanical system and control logic that could be employed.

Mike Miller is director of sales, commercial building services, Canada with Taco Inc. and a past chair of the Canadian Hydronics Council (CHC). He can be reached at hydronicsmike@tacocomfort.com.

Figure 1: Conservative and practical architecture offers long-term resiliency and simplified control over noise, thermal transfer, air and light. Note the landscaping and foundation drainage plane to mitigate moisture issue and the low window-to-wall ratio to control sound, light, solar gains and radiant asymmetry and drafts.

BY ROBERT BEAN

Iwas recently in Vancouver participating as a guest speaker at an integrated design process (IDP) workshop held at the British Columbia Institute of Technology (BCIT) High Performance Building Lab. The event was a collaboration of BC Housing with BC Hydro, FortisBC and the Province of BC. The day-long function was facilitated by Andy Oding from Building Knowledge Canada and Gary Hamer from BC Hydro. There is no single right or wrong definition of an of an IDP, and for the purposes of the workshop BC Housing’s Wilma Leung identified the group’s objectives as:

1. Describe, test, and refine an IDP that can be used to optimize the design of a home that will serve occupants for 100-200 years;

2. Describe the attributes of a home that is built to serve the needs of the occupants—including comfort, health and safety;

3. Agree upon the essential participants needed for a design charrette (IDP professionals) and the role of the engineer/ architect in leading the builder’s team process to deliver high performance/net zero homes.

I have worked on integrated design teams on many projects and see the process much like a business planning process I have used for years: It begins by identifying the business’s compass (the geography of the playing field and its sense of direction). Then you identify its purpose (why does it exist?), supported by a collections of visions (the pieces of the puzzle that must be achieved in order to fulfill the purpose). Those visions are achieved by a combination of executed strategies (the “what” that needs to happen to make the visions a reality) and tactics (the “work” required to complete the strategy) and goals (the “when” for the time-driven tactics). It is an integrated business planning method that is transparent, easy to

understand and it works; and as I’ve discovered, it applies to the design and construction of buildings.

I have written before about the evils of the traditional design process where the architect/builder/owner segregates the project professionals.1 With the IDP it is all about integrating knowledge through the collaboration of the experts.

The differences are important. In the traditional method the building design is typically based on compliance with the minimum requirements of mandatory codes written for safety and reducing the risk of illness. However, with an IDP (in my experience) it adopts human based indoor environmental quality (IEQ) standards and philosophies around sustainability and earth stewardship. As noted by Pearl (2004), “In professional practice, IDP has a significant impact on the makeup and roleplaying of the initial design team. The client takes a more active role than usual, the architect becomes a team leader rather than the sole form-giver,

and the structural, mechanical and electrical engineers take on active roles at early design stages. The team includes an energy specialist (simulator) and hopefully, a bio-climatic engineer.”2