PROBLEM SOLVING

TROUBLESHOOTING TALES FROM THE FIELD

No matter the job site, equip your team with the tools to communicate effectively.

Rugged durability in a sleek and lightweight build

Large 6.3” display that works with gloves and in wet conditions

Dust and water resistant design

Paired with Bell Push-to-Talk, you can instantly and efficiently communicate with your team at the push of a button.

Get the Samsung Galaxy XCover Pro with Canada’s best Push-to-Talk solution.

CON TENTS

FEATURES

14

HYDRONICS

FIXING THE FIX

The pressure was on to find a second solution after solving one issue in a two-pipe buffer tank configuration.

By John Siegenthaler

20

IEQ

HEATING THE HISTORICAL

Designing for human comfort under the constraints of a heritage home in the mountains.

By Robert Bean

24

HVAC

THE TROUBLES I HAVE SEEN

Sharp eyesight, inquisitive minds and deductive reasoning are all required when solving HVAC problems. By Ian

McTeer

34

PLUMBING

BUILDING CROSS CONNECTION

CONTROL AWARENESS

Annual photo contest draws attention to the Bad and Ugly as a way to promote safety and assurance.

By Doug Picklyk

CON TENTS

46 REFRIGERATION

BACK IN THE DAY

Retelling of an early service call to solve a grocery store’s meat freezing issue that required deductive reasoning, a look at the manuals and a sense of touch.

By Dave Demma

50

CONTROLS

THERMODYNAMICS … HUMBUG! Troubleshooting controls issues require taking methodical steps, but sometimes the solutions are more obvious than you think, like a simple hole in the wall.

By Curtis Bennett

SYSTEM XFR® DWV IS RIGHT AT HOME in a 40-story condo building.

System XFR® DWV from IPEX is an engineered PVC DWV system available in diameters from 1.5” to 18”.

It delivers greater corrosion resistance, flow rates and carrying capacity, and lower thermal conductivity than metal. It also has higher impact resistance, lasts longer, costs less to maintain AND weighs less than cast iron.

System XFR® DWV… fast becoming the preferred choice across Canada.

Certified for use in noncombustible construction, high buildings and air return plenums.

Ask for System XFR® DWV by name. Be sure to check out our entire line of DWV System pipe and fitting products. For more information please contact 1-800-463-9572 or visit ipexna.com Open your IOS or Android device and scan here for more information.

< UPFRONT

LOOKING FORWARD

WELL, SO THAT WAS 2020. AS THE NEW YEAR APPROACHES MANY PEOPLE CAN’T WAIT TO SAY “GOOD-BYE” TO THESE PAST 12 MONTHS. For all of the disruption the deadly coronavirus has caused around the world, it’s important to take some time for serious reflection and also consider what effect the pandemic will have on the year to come.

“Volatility,” was the word Peter Norman, chief economist with the Altus Group, emphasized when delivering his forecast for what’s ahead in 2021. Norman delivered an economic update webinar hosted jointly by the Canadian Institute of Plumbing and Heating (CIPH) and the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) in late November.

Focused on areas most effecting our industry, Norman called his presentation “Housing, Real Estate and the Pandemic—8 Months In.” He suggests the “ripple” effects of what’s happened already will have an impact going into 2021 and beyond. The non-residential sector of construction—including commercial, industrial and institutional buildings—is where he sees the greatest uncertainty, especially when it comes to planning for downtown office and retail spaces, as the cultural shifts towards work-from-home and accelerated online shopping are expected to linger.

The 2020 boom in the housing market was real, hitting its highest third quarter activity ever, and new housing starts remained steady. Norman’s concerns are that unemployment rates and reduced immigration may slow demand for new homes in the year to come. What remains to be seen is how government support programs will spark new activity in these areas.

If there is one thing that I witnessed in 2020, it was the underlying issues in HVAC/R and plumbing that often go unnoticed rising to the forefront of the public consciousness.

The heightened awareness of ventilation requirements will continue to drive conversations across all sectors of the construction market, and energy efficiency in the built environment continues to gather momentum as federal commitments to combat climate change lead to actions. This is where the resilience and problem-solving abilities of the mechanical industry will continue to shine for years to come.

So farewell to 2020. You presented change and challenges to us all, but coming up with solutions is what this industry is all about. Our team here at HPAC magazine is already making plans to bring greater learning and networking opportunities to you, our readers, in the New Year.

We’ll be continuing our 30 Mechanical Minutes webinars in 2021, and be on the lookout for more details on our Modern Hydronics Summit that will be delivered online March 30 and 31. We’ll be taking advantage of a superb new virtual event platform that will enable engaging interaction with our speakers, sponsors, exhibitors and other attendees. We’re already excited about this new online experience and we’re sure you’re going to enjoy it as well.

So please take time over the holiday season to unwind, refresh and get ready for a successful 2021. From our entire HPAC Magazine Team: Season’s Greetings and Happy New Year. <>

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE PUBLISHER MEDIA DESIGNER

ACCOUNT COORDINATOR

PUBLISHER

COO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Emily Sun

esun@annexbusinessmedia.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online)

Contents Copyright © 2020 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES:

To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

NEWS FEATURE

ASHRAE MOVES INTO NET ZERO RETROFIT HEADQUARTERS

ASHRAE, the global society advancing human well-being through sustainable technology for the built environment, is walking the talk as the society’s approximately 110-person staff officially moved into its new Net Zero energy ready Atlanta-area global headquarters at the beginning October.

The society began renovations in January 2020 on an existing 66,700 sq. ft. building, originally built in 1978 on 11 acres of land. “ASHRAE’s new global headquarters is a prime example of how we are helping to pioneer a movement that many expect will ultimately make net-zero energy the ‘new norm’ in sustainable design and construction,” said ASHRAE building ad hoc committee chair Ginger Scoggins, P.E.

“Although new construction of netzero energy buildings makes a lot of headlines, reuse of existing structures is a basic tenet of sustainability—the energy performance of existing buildings must be addressed to substantially impact the 40% of primary energy consumed by buildings,” added Scoggins.

“ASHRAE’s goal for this project was to renovate a three-story 1970’s era, cheap energy period building into a high-performing net-zero-ready facility

ASHRAE’s retrofit Net Zero energy-ready headquarters: (l-r) Ginger Scoggins, P.E.; Charles E. Gulledge, P.E., 2020-21 ASHRAE president; and Jeff Littleton, ASHRAE executive vice president.

in a cost-effective way that can be replicated in the built environment industry,” noted Tim McGinn, P.E.

Examples of technical features of the new ASHRAE headquarters include:

• Radiant ceiling panel system: This is used for heating and cooling and a dedicated outdoor air system for outdoor air ventilation with enthalpy heat recovery.

• Overhead fresh air distribution system augmented with reversible ceiling fans in the open office areas and displacement distribution in the learning centre.

• Six water source-heat pumps: There are four on basement level and two on an upper level atrium that will be used to condition these spaces.

• Demand Control Ventilation (DCV): This will be used for high occupancy spaces in the meeting and learning centre. Air distribution is constant volume in office areas and provided by fabric duct, reducing diffuser count and duct branches.

• Modeling Energy Use Intensity (EUI) of 17 kBtu/sq.ft./yr.

• Roof-top and ground mounted photovoltaic solar energy system planned for installation March 2021.

“ASHRAE’s first-of-its-kind headquarters building was designed as a living showcase of what’s possible through technology integration to increase effi -

ciency, protect people and property, and enhance the occupant experience,” said 2020-21 ASHRAE president Charles E. Gulledge III, P.E. “In addition to supporting ASHRAE’s technical standards, innovative product integrations from our generous donors also provide a scalable and repeatable model for a net-zero energy building design.”

Prior to the COVID-19 pandemic, ASHRAE had already planned to provide 30% more outside air to the building than the required minimum ventilation rates from ASHRAE Standard 62.1 and will implement other applicable guidance that has been developed by the ASHRAE Epidemic Task Force (ETF) for commercial office buildings.

“ASHRAE’s new global headquarters is an example of an effective built environment that fully considers the importance of effective operations by installing the systems and equipment in a manner that facilitates operation and maintenance,” said 2019-20 ASHRAE president Darryl K. Boyce, P.Eng.

“We are grateful to our donors for their generous support and partnership. It is this support that not only shows our donors’ alignment with ASHRAE’s sustainability goals, but helps us to address the challenges of designing and operate buildings in a technology driven environment.” <> ashrae.org/newhq

INDUSTRY NEWS

MCEE 2021 CANCELLED

Due to the uncertainty related to the pandemic, the Mécanex/Climatex/ Électricité/Éclairage (MCEE) partners have decided to cancel MCEE 2021, the bi-annual trade show scheduled to take place at the Palais des congrès de Montréal on April 7 and 8, 2021.

The show’s partners include the Canadian Institute of Plumbing & Heating (CIPH) and the Corporation of Master Pipe Mechanics of Quebec (CMMTQ) along with Corporation des en treprises de traitement de l’air et du froid (CETAF) and Corporation des maî tres électriciens du Québec (CMEQ).

The next MCEE trade show will take place in 2023. mcee.ca

The AHR Expo will return in 2022 at the Las Vegas Convention Center.

The 2021 ASHRAE Winter Virtual Conference will take place February 9-11, and will include a mixture of live and ondemand sessions. Additional details about the conference and committee meetings will be available in the coming weeks at ashrae.org/Chicago.

ahrexpo.com

CONSTRUCTION ROBOT FOR MECHANICAL/PLUMBING APPLICATIONS

Hilti has introduced the Jaibot, a semiautonomous robot for mobile ceilingdrilling.

The construction robot is designed to assist mechanical, electrical and plumbing (MEP) installation contractors tackle

productivity, safety and labor shortage challenges.

For commercial applications, the Jaibot operates based on building information modeling (BIM) data, accurately locating itself indoors, drilling holes with dust-controlled functions and marks the holes according to the trade.

Completely cordless, the robot can work an 8-hr day and is navigated by a worker via remote control. hilti.ca

Continued on p12

AHR EXPO 2021 CANCELLED

AHR Expo show management announced that “after exhausting all possibilities to tentatively reschedule the show for March 2021, we regret to announce … the forced cancellation of the 2021 AHR Expo in Chicago.”

With continuing surges of the COVID-19 pandemic across America and local restrictions that prohibit mass gatherings over 50 people in many states, it was determined that hosting an in-person event will not happen 2021.

THE EASY WAY TO BOOST PRODUCTIVITY.

Adrian Steel’s Grip Lock and Drop Down Ladder Racks are designed with ergonomics and user safety in mind. Whether you’re upfitting a single van or an entire fleet, Adrian Steel has just what you need. Increased efficiency starts now.

STUDY CONFIRMS UV-C KILLS 99.9% OF VIRUS THAT CAUSES COVID-19

Third-party lab tests have proven that residential and commercial UV-C disinfection equipment for HVAC systems from Fresh-Aire UV are >99.99% effective in inactivating SARS CoV-2, the virus which causes COVID-19 disease.

The “SARS CoV-2 Neutralization by Germicidal UVC Light Systems” study conducted by Innovative Bioanalysis in Costa Mesa, Calif., validated a 4-log, >99.99% coronavirus inactivation in less than two seconds of exposure to Fresh-Aire UV’s germicidal UVC 254-nanometer light system.

The exposure time is comparable to a moving airstream model within a facility’s HVAC or ventilation system. The lab used Fresh-Aire UV’s ADS airstream and BlueTube XL coil and airstream disinfection systems designed for healthcare, education, office and other commercial facility applications. The residential and

commercial APCO-X coil and air disinfection system also exhibited the same positive results.

The study is one of the first successful SARS CoV-2 inactivation tests in the HVAC industry.

Innovative Bioanalysis is now executing a second phase of testing. www.freshaireuv.com

CIPH AND MCAC SUPPORT FOR INFRASTRUCTURE BANK’S GROWTH PLAN

In a joint statement the Mechanical Contractors Association of Canada (MCAC) and the Canadian Institute of Plumbing & Heating (CIPH) voiced their support of the federal government announcement on October 1 that $10 billion will be invested over the next three years as part of the Canada Infrastructure Bank’s Growth Plan, including $2 billion earmarked for retrofits of buildings to make them more energy efficient.

“We are delighted to see that the government acknowledges retrofits are a key part of Canada’s low-carbon transition. Retrofitting is not just good for business, it will help to reduce the proportion of greenhouse gas emissions from the built environment, conserve water, and make places healthier and more com-

SWEET HEAT CONTEST RECOGNIZING HYDRONIC TALENT

We’re calling on hydronic contractors across Canada to get out their cameras and show off their work. Entry is simple, visit hpacmag.com and look for the Sweet Heat logo, fill in the online form and attach it along with installation photos (before and after shots will work best) of a project completed between June 1/2020 and Feb 28/2021.

We’re asking for a limit of one submission per contractor, and it can be a new installation or a retrofit. Deadline to enter is March 12, 2021.

Important: Entries must include the online form which asks for a description of the particular challenges faced, how obstacles were overcome and innovations involved.

The winning entry, and two runners up, will be announced at the end of the Modern Hydronics Virtual Summit (March 30 and 31, 2021) by HPAC contributors John Siegenthaler and Robert Bean. In addition, the winning entry will be profiled by HPAC and be featured on the cover of the August 2021 edition of Modern Hydronics. hpacmag.com/wp-content/uploads/2020/11/Sweet-Heat-form.pdf

fortable to live and work in,” stated Ralph Suppa, president and general manager of CIPH.

“This acceleration shows that the government is already following through on Throne Speech commitments,” added Tania Johnston, CEO of MCAC.

CIPH and MCAC are also encouraging the government to invest in skilled trades training, support efficiency by addressing trade barriers, and partnering with provinces and municipalities on public projects. ciph.ca mcac.ca

SMACNA LAUNCHES SYSTEM AIR LEAKAGE TEST STANDARD

The Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) based in Virginia has announced the official launch of the first edition, System Air Leakage Test Standard.

The 96-page standard is a resource for leakage testing of any portion of, and up to, the entire forced air system. Since 1965, SMACNA has included a procedure for leakage testing of ductwork, a process that has evolved over time based on research and feedback from the industry.

The new system air leakage test standard goes beyond the duct and includes procedures for any item included in a forced air system.

The pass/fail criterion are based on research specific to testing conditions, and distributes the responsibility of system performance equitably. smacna.org

HRAI FORMS IAQ EXPERT PANEL

The Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI) has established an expert advisory panel on indoor air quality in commercial and institutional buildings.

The panel, chaired by Joe Muchynski of Arvin Air Systems, also includes members of the contractors division of HRAI and members from each of the three HRAI member divisions, as well as repre -

LETTER TO THE EDITOR

Greetings!

We read with interest the article “Material Knowledge” by Jonathan Simon in your October 2020 issue.

As a residential plumbing manager, Mr. Simon is obviously well-versed in the residential side of the plastic piping market. However, the article doesn’t make it clear that what is being discussed is only the residential side; the article makes no mention of the innovative and durable plastic piping products that are available in the commercial market.

As you’re probably aware, polypropylene (PP) pipe has been used in thousands of HVAC and plumbing installations (including residential) worldwide for nearly five decades ... It is ideal for both new construction and re-piping projects.

We’d like to encourage your readers in the commercial market to look into the benefits of PP pipe!

Thanks,

Barry Campbell, VP of Marketing, Aquatherm North America

sentatives from the Building Owners and Managers Association (BOMA), the Public Health Agency of Canada (PHAC), the National Research Council (NRC), the University of Toronto and University of Alberta, ASHRAE and the Air-Conditioning, Heating and Refrigeration Institute (AHRI).

One objective for this group is to produce materials on the best practices currently in place to limit the transmission of COVID-19 through HVAC systems.

“Over the months ahead we will work together to make sure Canadians have better information about the risks of transmission in an array of environments and conditions,” said Muchynski in a media release. “We want to ensure business owners, building managers, and institutional administrators can confidently assess risks and make good choices for indoor environments while navigating the impacts of the pandemic.” hrai.ca

QUEBEC RELEASES $6.7B GREEN ECONOMY PLAN

On Monday, Nov. 16th Québec Premier François Legault and the province’s Minister of the Environment, Benoit Charette, unveiled Québec’s 2030 Plan for a Green Economy along with its first five-year implementation plan covering 2021-2026, backed by a budget of $6.7 billion over those five years.

The government is launching a major electrification push in the transportation industry, but also in the building heating and other industrial sectors.

The province will inject more than $550 million to reduce GHG emissions linked to heating residential, commercial and institutional buildings by 50%.

This target is to be achieved by what it calls ‘optimal complementarity’ between the electricity and gas networks and by the use of bioenergy, energy efficiency, and converting from fuel oil to electricity, as well as through the use of renewable natural gas and other renewable energy sources.

Energy efficiency is also a priority, as more than $307 million will be invested over the next five years through the EcoPerformance program which will see $113 million invested to support energy conversion and efficiency in commercial and institutional buildings. An additional $75 million is set aside to encourage heat recovery and re-use.

Internally, the government will be reducing its carbon footprint with the objective of reducing emissions from its real estate holdings by 60% by 2030, compared to their 1990 levels—a target higher than the one set for Québec as a whole.

quebec.ca

FEDS FUNDING BIOMASS BOILER PROJECTS IN NEW BRUNSWICK

The Government of Canada and the Federation of Canadian Municipalities (FCM) are investing $417,400 in a pilot project to replace existing fossil-fuel burning heating furnaces with high-efficiency biomass boilers in four municipality facilities in New Brunswick:

It’s anticipated that this model could generate a ripple effect on other small towns in Northern New Brunswick, as well as the rest of Canada, where residual forest or agricultural biomass is available.

This pilot is expected to generate a 70% reduction in GHG emissions, a 70% reduction in energy consumption and a reclamation of 64 tonnes of residual forest biomass per year.

Upon completion of the project energy efficiency measures will be put in place in each building; following which several months of monitoring will be carried out to assess the results of the project.

ONTARIO APPOINTS SKILLED TRADES PANEL TO ADVISE ON TRAINING AND CERTIFICATION

The Ontario government is investing an additional $75 million over the next two years to help apprentices cover living expenses during their in-class training time and is also appointing a five-member Skilled Trades Panel to provide advice and recommendations on developing a new approach to training and certification as a replacement of the Ontario College of Trades.

This $75-million investment includes: a grant for apprentice learning to support those ineligible for EI while attending in-class training, a $24 million commitment to increase the maximum benefit rates for EI-eligible apprentices attending full-time in-class training. There is also a commitment to support training providers and upgrades to their their facilities with modern equipment. ontario.ca/page/skilled-tradespanel-consultations

FIXING THE FIX

The pressure was on to find a second solution after solving one issue in a recent two-pipe buffer tank configuration scenario.

BY JOHN SIEGENTHALER

Have you ever been involved with a project where a “fix” for one situation created a “glitch” elsewhere? I suspect that many of you can answer in the affirmative. In most cases the “glitch” forced another modification that - hopefully - solved both it and the original problem. This month’s article is all about one such scenario.

SOME BACKGROUND

In past articles I’ve discussed the advantages, and limitations, of “two-pipe” buffer tank configurations, especially as they relate to biomass boiler systems.

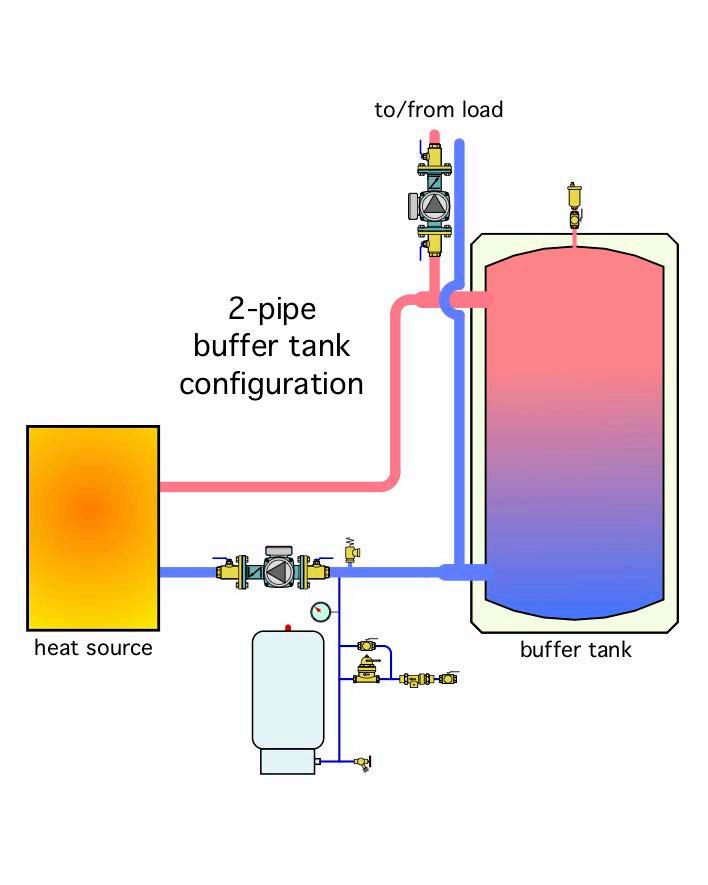

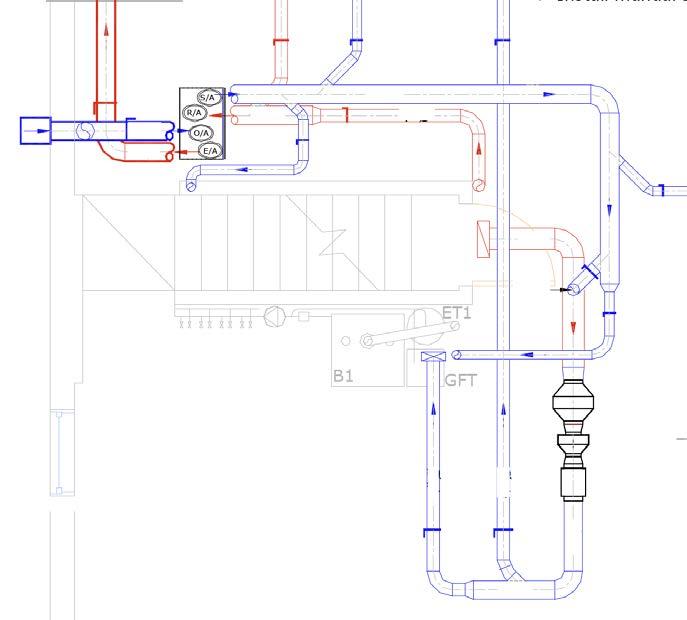

Figure 1 (top left, opposite page) shows a typical two-pipe configuration for reference.

The advantages of a two-pipe buffer tank configuration are:

1. Heated water can move directly from the heat source to the load without first passing through the buffer tank when the heat source and load are operating at the same time.

2. When the conditions described in 1 above are present, the flow rate into and out of the buffer tank is only the difference between the heat source flow rate and the load flow rate. Lower flow rates into and out of the tank reduce mixing and help preserve beneficial temperature stratification.

The “Achilles heel” of a two-pipe buffer tank configuration is that it’s possible, when appropriate measures are not taken, for some of the flow returning from the load to pass through the inactive heat source rather than through the buffer tank. This creates heat loss in the mechanical room and also reduces the supply water temperature to the load.

Preventing this undesirable “ghost flow” through the inactive heat source(s) requires hardware that can create a suitable pressure threshold before forward flow is allowed.

One way to do so is to install a motorized two-way valve that closes when the heat source is off, and opens when it’s operating.

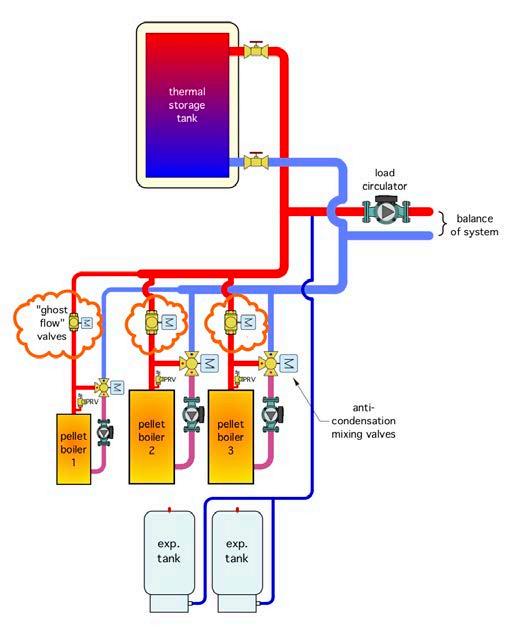

On one project that I’m familiar with these motorized two-way valves were added as a last-minute means of preventing flow through any of three pellet

“The “Achilles heel” of a two-pipe buffer tank configuration is that it’s possible, when appropriate measures are not taken, for some of the flow returning from the load to pass through the inactive heat source rather than through the buffer tank.”

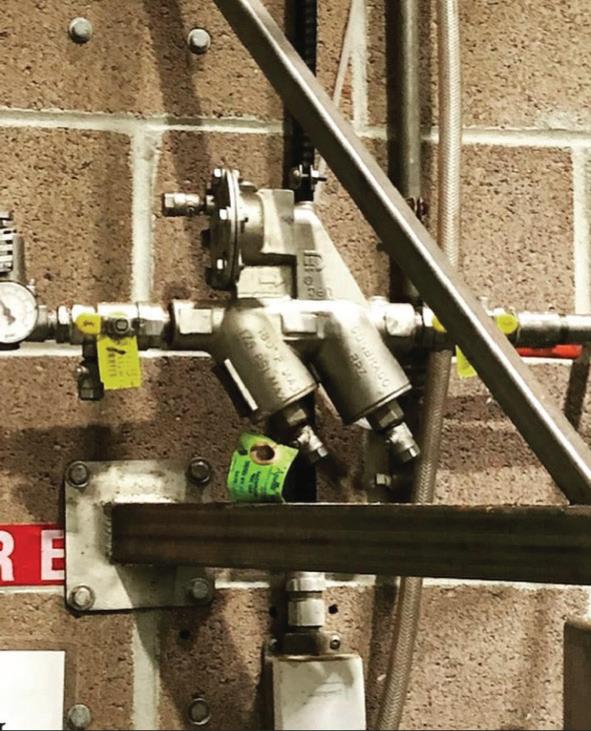

2. Installation location of “ghost flow” valves on a pellet boiler installation: motorized two-way valves that close when the heat source is off and open when it’s operating.

boilers when they were not operating. The valves were signaled to open when the boiler’s circulator turned on, which, based on internal controls in each pellet boiler, would not occur until the boiler water reached some initial temperature indicating that the combustion was established and stable.

Figure 2 (above right) shows where these “ghost flow” valves were added.

In this system, each pellet boiler has a motorized three-way that serves as an “anti-condensation” mixing valve. The cool water inlet port of this valve is fully closed until the inlet of the pellet boiler reaches a temperature of 130F.

If the water temperature in the boiler continues to rise, as it should, the cold port of the valve continues to open allowing increasing flow from the boiler to the load. If the return water temperature drops back toward 130F the cold port of the valve decreases cool water flow into the valve in an attempt to keep the inlet water temperature high enough to prevent sustained flue gas condensation within the boiler.

Study the details in Figure 2 carefully. Do you see any issues?

If not, here’s a clue: as a boiler warms up fluid begins to “dribble” from its pressure relief valve (PRV). This occurs well before the water in the boiler reaches 130F.

WHAT’S HAPPENING?

I’m sure some of you spotted the problem. During a cold start the anti-condensation valve is in full bypass. This effectively blocks the piping path from that valve’s cool port to the balance of the system.

The motorized “ghost flow” valve is also closed until the boiler warms up. Because this valve was installed on the supply pipe from the boiler it also blocks any “pressure communication” between the boiler and the balance of system, where the expansion tanks are located.

The result is a volume of incompressible fluid being heated without any communication with the system’s expansion tank. Under those conditions the PRV did just what it was supposed to do—relieve rapidly increasing pressure inside

Continued on p16

Figure

Figure 1. Typical two-pipe buffer tank configuration.

< HYDRONICS

Continued from p15

the boiler before that pressure could be released in a far more dramatic and perhaps “explosive” manner.

If the ghost flow valves had been installed on the boiler’s return pipe this problem would not arise.

The pressure inside the boiler could communicate with the system’s expansion tank through the boilers outlet pipe. Unfortunately, this detail was not spotted prior to the installation of the ghost flow valves.

“The fix of the fix resolved a dribbling pressure release valve situation. It also prevents flow returning from the load from passing through inactive boilers.”

THE FIX

There are a couple of potential ways to fix this situation. One would be to see if the actuator on the anti-condensation valve could be adjusted so that the cold port was never 100% closed. This might or might not be possible depending on the actuator and valve used.

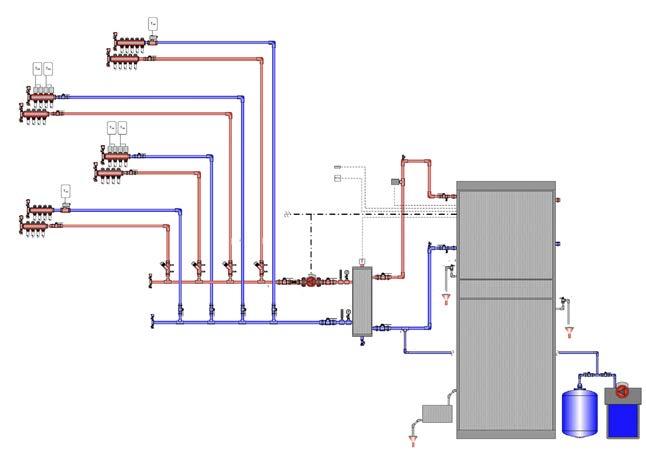

Fortunately, there was a pressuretesting tapping installed on each side of each ghost flow valve. One of those tappings was equipped with a small ball valve. This allows a very short length of ¼-in. copper tubing to be installed as a pressure equalizing tube around the closed ghost valve as shown in Figure 3 (above).

The ball valve in the pressure equalizer tube is cracked open very slightly to minimize flow rate through the bypass while still allowing the expanding fluid to reach the system’s expansion tank.

Once set, the handle of the ball valve was removed to reduce potential for tampering.

I recommended this solution because in an emergency replacement situation, a technician may not realize that the actuator of the replacement anti-condensation valve requires an adjustment to prevent the cold port from being fully closed. Without such an adjustment the problem would reoccur. There’s also a possibility that the replacement parts might not allow such an adjustment.

The fix of the fix resolved a dribbling PRV situation. It also prevents flow returning from the load from passing through inactive boilers.

The take-away: Always check your piping layouts to ensure that any heat generating equipment can never be isolated from “communication” with the system’s expansion tank. The same goes for chillers. <>

John Siegenthaler, P.E., is a mechanical engineering graduate of Rensselaer Polytechnic Institute and a licensed professional engineer. He has more than 35 years of experience in designing modern hydronic heating systems. Siegenthaler’s latest book is Heating with Renewable Energy (visit www.hydronicpros.com for more information).

Figure 3. Pressure equalizer tubes with ball valves installed: the ball valve is cracked open very slightly to minimize flow rate through the bypass while still allowing the expanding fluid to reach the system’s expansion tanks.

& presents...

THE INSTALLATION CONTEST

Get your cameras ready. Be a part of Canada’s first ever hydronic installation contest.

Proud of your work? Better than the rest? It’s time to bring it on!

ENTRY IS SIMPLE – send us pics (before and after shots will work best) of an installation between June 1/2020 to Feb 28/2021. Include a brief description of the particular challenges that you faced with this installation and how you overcame the obstacles to deliver your customers Sweet Heat. This can be a new installation or a retrofit. Submissions are limited to one per contractor. Remember that aesthetics are only one part of the judging criteria. Deadline to enter is March 12, 2021. Show us your problem-solving ability too! The winning entry, and two runners up, will be discussed and announced at the end of the Modern Hydronics virtual Summit (March 30 and 31) by none other than our very own John Siegenthaler and Robert Bean. In addition to having your winning entry shared across our social media channels you’ll also be interviewed by HPAC’s editor and featured on the cover of the August edition of Modern Hydronics –

OIL DEAERATORS

The oil heat industries’ best kept secret to safer, more reliable, optimal efficiency operation.

Benefits to using Oil Deaerators

The use of an oil deaerator will increase the Annual Fuel Utilisation Efficiency (AFUE) of any oil-fired heating appliances, keep heat exchangers cleaner and soot-free, increase oil burners’ reliability, eliminate nuisance burner lockouts, lower the amount of late nights and weekends service calls, all while reducing risks of environmental oil spills for inground and top-draw oil tank installations.

“I used an oil deaerator for the first time 25+ years ago to eliminate a fuel supply problem. Oil deaerators fixed all my burner pumps oil supply issues every time!”

— Mario Bouchard, 35+ years experience in oil combustion.

Eliminating air from oil

Today’s generation of oil burners can run 100% smoke-free and provide optimal oil combustion. The only way oil burners can achieve that is by being supplied with clean, deaerated heating oil. Clean, deaerated heating oil allows for better nozzle oil atomisation and keeps nozzle oil lines free from air bubbles preventing nozzle after-drip during every burner shut down cycles. Upon each burner call for heat, oil deaerators provide room temperature, deaerated heating oil for smoke-free, smooth, and precise burner ignition. Clean burner ignition maintains combustion chambers and heat exchangers cleaner maximizing the heat exchange thus optimizing the heating appliance’s annual efficiency.

Oil pump : one-line, the benefits of two

Todays oil burners are designed to operate more reliably and at greater performance. This reliability and performance can only be achieved if the oil burner operates in a two-line configuration. This would usually require running two oil lines between the oil tank and the oil burner, but with an oil deaerator, only one line is necessary between the oil tank and the oil burner. This can be easily installed on any new and existing installation. EVERY oil-fired equipment should be installed with an oil deaerator!!

With environment in mind

Certain applications such as underground and top draw oil tanks would normally require the use of a supply and return oil lines between the oil tank and the burner. The use of two oil lines poses twice the risks of creating an oil line environmental spill than having only one oil line travelling from the oil tank to the oil burner. An oil deaerator takes care of removing the need of a return oil line and contributes in preventable environmental oil-line spills.

• Easy installation of a TOP DRAW outside oil tank with using a single oil line to the oil burner.

• Also available with 10gph or 17gph integrated oil filter.

• Large oil and air compartments for greater de-aeration capacities.

• Manufactured with a “Fluorinated” plastic, exclusive to Granby to prevent odors from seeping through the plastic container.

• B-100 Ready

Granby OptiFuel oil de-aerator is 100% UL/ULC certified and meets CAN-CSA B139 requirements.

HEATING THE HISTORICAL

Designing for human comfort under the constraints of a heritage home in the mountains.

BY ROBERT BEAN

It was no surprise that clients attracted to our engineering firm, Indoor Climate Consulting, were mostly other engineers. In fact, almost 90% of our clients had professional design backgrounds, another 8% were healthcare professionals—primarily physicians—and the additional 2% had various researchbased backgrounds. Knowledgeable clients receptive to our firm’s "design for people – good buildings follow" philosophy were the lubricant for designing and building better indoor environmental quality (IEQ) buildings.

In the following case study, a family sought us out by searching online for IEQ professionals. Their project was a single-family home designated as a historical building. Located in a campus town nestled in the Rocky Mountains, it was the home they were going to be retiring in.

After our initial interview, it was clear they wanted to improve the home's thermal comfort and air quality through a

full renovation of the its interior ergonomics. Still, requirements for maintaining the historical elements prevented them from adding exterior insulation and changing out the windows.

Another firm was initially hired to reduce infiltration and improve u-values with blown-in cavity insulation. Yet, a subsequent thermal imaging survey revealed areas that still needed remediation work (see Figure 1).

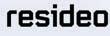

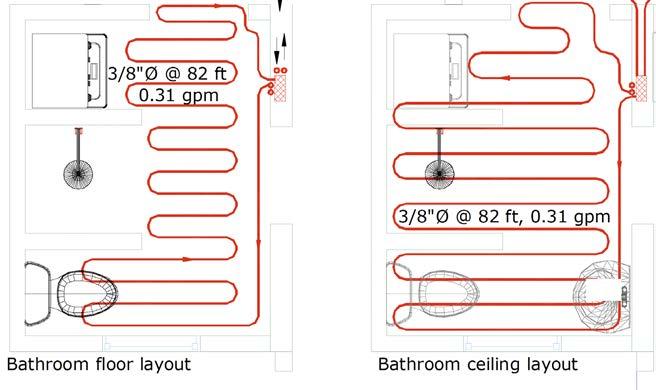

Load calculations based on the final remediated work, verified by another survey and blower door test, led us to recommend a combination of radiant ceilings, floors and walls and panel radiators for thermal comfort. For air quality, we worked with the client to use low VOC finishes and a combination of an ERV and fan/coil fitted with an external MERV 13 filter box.

HEATING DESIGN

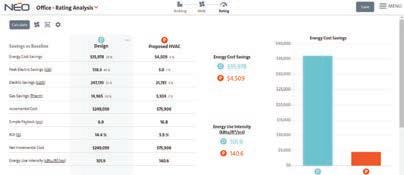

Our practice designed the heat terminals for the heating system around the lowest possible fluid temperatures. This enabled us to extract the maximum efficiency from the boiler when in the space heating mode while avoiding the costs of multiple temperature strategies involving the use of more circulators and controls (see Figure 2).

To do this, we base loaded using radiant ceilings on the main floor and radiant floors upstairs. The trim for design days was radiant walls and panel radiators. Engineering these additional radiant surfaces takes a little more tweaking. Still, the payoff in system simplification and improved efficiency is well worth the outcomes.

The one exception was a rogue zone on the main floor. For this area of the

Figure 1. A thermal imaging survey revealed thermal challenges with this historic building.

Figure 2. A single low temperature system serving radiant panels, walls, floors and ceilings.

Speakers include: Siegenthaler, Bean, Miller, Goldie, Bennett, MacNevin

Topics include:

- Air-to-Water Heat Pumps

- Reducing Water Temperature in Existing Hydronic Systems

- Energy Metering

- Selling Hydronics to Builders

- Buffer Tanks

- Snow and Ice Melt

< IEQ

house we custom designed a system comprised of a filter box, electric coil and in-line fan. This assembly provided heat for peak loads and constant filtration of recirculated mixed air from the room and ERV.

VENTILATION SOLUTION

Our three focus areas for ventilation

were the house proper, each of the bathrooms and the kitchen. For this, we used an ERV supplied with air filtered through a MERV 11 to 13 inline filter box. The ERV supplied air to each room and extracted air from hallways and rooms from under generous undercut doorways (see Figure 3).

The upstairs bathroom had a dedi-

cated exhaust air fan. In the kitchen, the clients were receptive to using an induction cooktop rather than a gas range, and with the hood covering more than 120% of the stovetop and sufficiently low enough, we could reduce the exhaust hood flow to 275 cfm.

DISCUSSION

On a relative scale, this was one of our firm’s smaller but more interesting projects, driven first by doing whatever was possible to the enclosure within the historical buildings' limitations.

Engineering the radiant surface areas to fit a common lowest temperature was a welcome solution. Some zones required both radiant floors and ceiling surfaces, or a combination of radiant floors and walls or panel radiators to achieve thermal comfort (see Figure 4) We also had to develop a site-fabricated fan/coil with electric heat for the rogue main floor zone's peak load.

The use of induction instead of a gas range and a generous sized deep sump range hood enabled a low exhaust flow for more effective and quiet operation.

The ERV worked to ventilate the home plus serve the fan/coil filtration unit on the main floor. This turned out to be especially useful for improving indoor air quality in the past years of forest fires.

None of this would have happened had the clients not prioritized this historic home's indoor environmental quality. By seeking out the IEQ professional, they achieved a lifetime of desired outcomes. <>

Robert Bean is director of healthyheating.com and founder of Indoor Climate Consultants Inc. He is a retired engineering technology professional who specialized in the design of indoor environments and high performance building systems.

Figure 3. The ventilation system included an ERV with external high performance filter box and a supplemental system for constant filtration and secondary heat for main floor.

Figure 4.The high heating load in the main floor laundry/bathroom required both radiant ceilings and floors.

The cost-effective, time-saving alternative to metal systems.

AquaRise®, a nonmetallic potable water distribution system for commercial and high building construction. Based on over 15 years’ experience designing and manufacturing industry-leading CPVC systems, AquaRise offers numerous benefits over metal with a system that’s fully-approved for noncombustible applications.

A SOLID ALTERNATIVE TO METAL BETTER LONG-TERM PERFORMANCE FULLY-CERTIFIED COMPLIANCE FULL FLAME & SMOKE LISTINGS

PERMANENT JOINING SYSTEM

PROJECT SAVINGS

Learn more about thermoplastic potable water piping systems, review system design, installation and solvent welding steps, watch the product videos or schedule your lunch and learn. All you need to get started!

THE TROUBLES I HAVE SEEN

Sharp eyesight, inquisitive minds and deductive reasoning are all required when solving HVAC problems.

BY IAN McTEER

We all make mistakes, nobody’s perfect! Such a common refrain seemingly illustrating a universal human truth. Mistakes lead to consequences: this morning I mistyped my computer PIN code twice (caps were on) and got locked-out for half an hour. Minor mistake, minor consequence.

An industry of psychologists, also known as “life coaches”, help us to deal with missteps, mess-ups, and misunderstandings under the banner of learning from one’s mistakes. On the other hand, Einstein said that a person who never made a mistake never tried anything new.

Mistakes inevitably lead to some sort of trouble, maybe just a minor consequence like my typing error, but trouble tends to exhibit itself on a sliding scale with not much more than a little ouch at one end of the scale escalating to property damage, injury or death at the other.

Thus, avoiding trouble in the HVAC world means mistakes must be minimized by utilizing an on-going commitment to quality control. Taking the time to specify equipment appropriately, installing and commissioning it correctly and to maintain a service routine is the best way, in my mind, to avoid trouble.

It is true that some contractors have little regard for quality work, but it’s

also very true that equipment owner’s too often have an unrealistic expectation of the product (perhaps related to a miscommunication mistake) or otherwise abuse HVAC systems through lack of maintenance. I long ago learned to never side with either the contractor or the equipment user; my job is to understand why the equipment is causing so much trouble. (Insider secret: sometimes it IS the equipment!)

I want to describe two situations in which furious end-users combined with frustrated contractors all at war over what appeared to be faulty equipment led to troubles galore.

THE RELUCTANT TXV

Our government decided back in 2006 that residential split system air conditioners should operate at a minimum efficiency of 13 SEER going into the future. I’m all for efficiency, however, this particular requirement had an unusual consequence in that many outdoor unit and indoor coil combinations now required a TXV metering device in order to meet the updated requirement. I have been a TXV champion ever since I learned how they worked, yet industry members thought capillary tubes and metering pistons did an acceptable job at a much lower price, therefore, TXV’s were rarely used in residential application up until 2006.

Far too many contractors and technicians had either forgotten or were unaware of the subtle differences in charging requirements and troubleshooting techniques between the different devices.

Add to that, some TXV’s started com -

ing onto the market with manufacturing defects at the very same time. Some TXV’s had diaphragm failures, others had leaking sensor bulbs, some even had contaminated desiccant inside the sensor bulb.

All these defects caused the valve to fail closed or partially closed leading to a diagnosis of unacceptably high superheat. Service bulletins were issued describing the problem, specifying model numbers, date codes and troubleshooting guides. But, once the bad news started winding its way through the HVAC community, too often valves, even entire evaporator coils, were coming back for warranty exchanges all indicted with the high superheat menace.

I received a call from our parts department one day. A technician was at the counter looking for his fourth replacement TXV on the same unit.

The counter person told me the third valve’s date code was outside of the range specified in the service bulletin, so I suggested they give him another one and that I’d meet the technician on the job.

Upon arrival at the jobsite, there was no technician just a furious homeowner who told me the installing contractor was no longer welcome. A blistering hot day, to be sure, and the old system recently dispatched to the recycler had at least been working.

Going into his second week without cooling, and no solution in sight now that he had fired the contractor, the frustrated customer allowed me to inspect the job. The system charge had been removed so the tech could unbolt the third replacement TXV from the

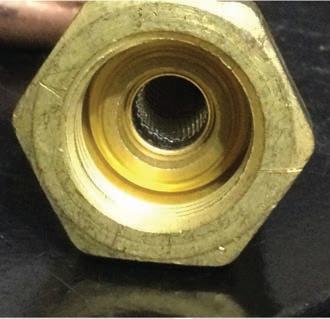

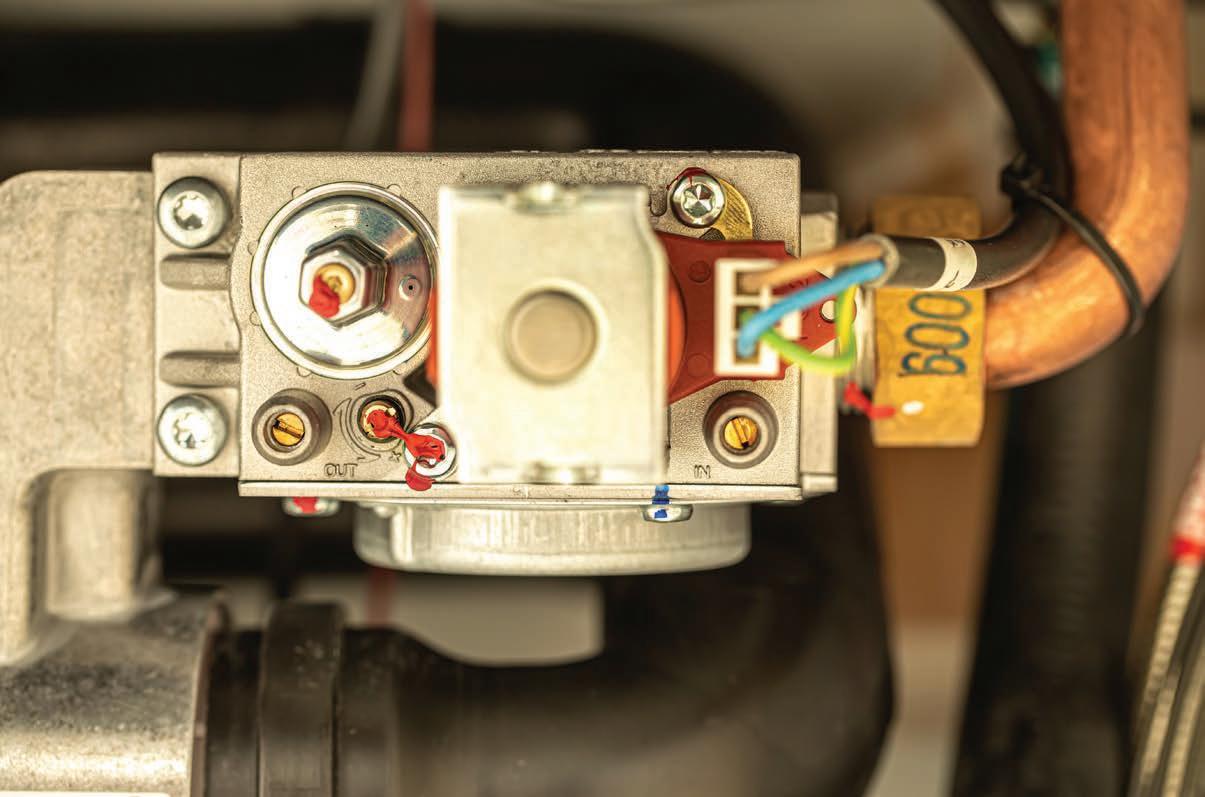

evaporator coil. I noticed the brass female connector standing open in the evaporator coil case had a small amount of compressor oil inside the fitting with a brownish tint and gritty feel: not good! (see Figure 1, next page)

I extricated the filter strainer from inside the open fitting using a small screwdriver (not recommended, use a pick tool). Yes, there’s a removeable strainer in there! (see Figure 2)

The strainer contained enough dirt and debris to create a substantial blockage, no wonder high superheat appeared to be the trouble (see Figure 3). Because the tech was aware of the service bulletin implicating some TXV’s as problematic, in his mind, all TXV’s were suspect.

It turns out the homeowner asked the installer to place the unit in a different location from the original unit. The interconnecting line set had to be run underneath a closed-in deck. The installation crew made no attempt to seal the tubing as it passed through the dirt under the deck – both the liquid and suction tubing contained debris. In the end, we had another contractor replace the entire system at no charge to the homeowner. Problem solved.

THE CASE OF THE WRONG FURNACE

Fortunately, it was not every day that furious homeowners contacted me threatening legal action, but one time was too many in my mind. However, taking the heat is what I was getting paid for.

“In most HVAC disputes there are three parties: the contractor, the end user, and a silent party—the equipment.”

In most HVAC disputes there are three parties: the contractor, the end user, and a silent party—the equipment. Initially, my main concern caused me to take the side of the installed products. This situation had all the hallmarks of serious trouble related to miscommunication on all sides: installation errors, lack of commissioning and even the municipality failed to pick-up on the real issue at the time of occupancy.

Another blistering hot summer’s day pushed the homeowner, a retired accountant, to dig deep into the HVAC industry’s team roster eventually finding my contact information. Once on the line with me, the homeowner informed me that a lawyer’s letter would be on its way shortly demanding satisfaction for extremely poor heating and cooling performance from his essentially brand-new comfort system.

The well-off senior lived in a newly-established gated community, his roomy townhouse featured a loft with windows facing west and a partially finished basement.

“I’ll arrange a meeting with you and the contractor,” I told him.

Continued on p26

“Not a chance, the site contractor is not welcome—his tech has been here many times and the problems have not been corrected, that’s why I’m calling you,” he replied.

I managed to get a well-qualified technician from another company to meet me at the jobsite. The homeowner allowed us to inspect the system. Considering the size of the house, optional loft included, and its large windows, I thought the two-ton air conditioner might have been undersized for the application.

It was operational, but the room temperature and humidity level hadn’t been mitigated to an acceptable level of comfort. We found that the cooling system employed a non-AHRI matched evaporator coil, that, technically speaking, wouldn’t have been a major problem.

We did find the furnace blower wheel and secondary heat exchanger covered in drywall dust. During a second visit, we replaced the evaporator coil with a matched component, cleaned the furnace, set the system charge correctly, and determined (without documentation) that airflow to the loft should be adequate as he told us there was practically no air to the loft previously. Problem solved, I thought!

During one of the many visits by the installing contractor’s service technician, the homeowner learned from the tech, and rightfully so, that cooling sys -

tems work best when window curtains are kept closed during the day.

Not wanting to spoil his view, the homeowner spent thousands of dollars having heat mirror window decals installed, although I’d argue the effect proved to be marginal at best. All our efforts made only minor comfort improvements, he had even covered the south and west facing windows with blankets to further reduce passive heating.

Back to the drawing board. I had noticed something about the ductwork on my first visit. It seemed to be much larger than required for a 60K btuh furnace and 2.0-ton cooling unit.

There is no good reason to oversize the duct system, no contractor would spend extra dollars on unnecessary sheet metal.

“Let’s talk to the building inspector,” I suggested.

I wanted to see the approved HVAC plan for his house. The municipality reluctantly agreed to send an inspector with the plans, whereupon we discovered the furnace should have been 80K btuh and the cooling unit should have been 2.5 tons. How could that have happened?

I know the contractor did not intend to install undersized equipment. My theory worked this way: the building site featured similarly-sized linked semi-detached bungalows. Some models had the loft option thus requiring a

beefier HVAC system.

Having started-off in HVAC by delivering furnaces and duct jobs to new construction sites myself, I can attest to the fact that sometimes the housing units under construction are poorly marked or the delivery information is sketchy; whatever, I suspect the delivery crew got the ductwork right but the equipment wrong.

Somewhere on that site, to this day, exists a non-loft unit with an oversized furnace and air conditioner no one has ever complained about. And because the 60K model furnace and the 80K model are in the exact same sized cabinet, the sheet metal installers simply plugged the 60K unit sitting there waiting for them into the duct job they found in the basement. The installers nor the technician who came along later had any idea the equipment was incorrect.

The inexperienced technician tried and tried to make a silk purse out of a sow’s ear, and even though he made an effort, however misguided, the initial mistakes meant he could never satisfy the homeowner.

I have long thought a laminated copy of the approved heating plan, including the worksheet load calculation containing room by room air flow values, should become part of every residential installation. Such information is an

Figure 3. The strainer contained enough dirt and debris to create a substantial blockage.

Figure 2. The filter strainers are removable.

Figure 1. Note the strainer in the brass female connector.

ACCURATE MEASUREMENTS IN A TIME OF UNCERTAINTY

When the COVID-19 pandemic hit, Nick Postolache, owner of Enviro Balance, Inc., felt fortunate to be working in an industry that is still in high demand during this time of uncertainty. Enviro Balance, Inc. is a firm that provides testing, adjusting and balancing (TAB) services in the Greater Toronto Area and Southern Ontario region. Postolache started the company in 2013.

Aside from wearing masks and sanitizing instrumentation more frequently, the pandemic has changed the nature of some of the work the technicians perform. Just before the pandemic hit, the team at Enviro

TSI’s capture hood stand and LogDat™ Mobile app to aid the technicians in reaching diffusers and grilles on high ceilings easily, allowing for a more efficient workflow.

Postolache and his team found the reporting features of the instrument beneficial as well.

“The reporting is required to be either in metric or imperial, and having an instrument that provides both of these, that was a help as well,” he said.

Balance received calls from hospitals to check the ventilation systems in isolation rooms.

“It was that period of time where everyone knew it was coming and they were trying to get ready,” Postolache said. “Having reliable and accurate instrumentation provides us the confidence that we’re accurate in our measurements.”

The team at Enviro Balance uses TSI equipment as their main tools to complete measurements in hospital settings, among other locations.

One instrument the team at Enviro Balance used pre-pandemic, and is still using today, is TSI’s Alnor® Balometer® Capture Hood EBT731. They also use

The team at Enviro Balance utilizes everything on the EBT731 Capture Hood, down to the inside storage pockets.

“The rotating vanes are going in there − the technicians are using those pockets to store just about everything,” Postolache said. “I have other instrumentation from competitors, but my technicians are asking for the Alnor capture hoods.”

For more information about TSI’s ventilation test instrumentation, visit tsi.com/comfort-HPAC

<

invaluable guide for proper commissioning, future equipment troubleshooting, potential renovations or future additions to the house.

Had such data been left behind in my circumstance, perhaps the error would have been corrected sooner saving the homeowner countless hours of frustration and expense. Yes, the equipment was replaced at no cost to the homeowner two years after the fact.

Some mistakes are truly doozies: a tiny grinding error in the primary mirror of the Hubble Space Telescope amounting to 1/50th the thickness of a human hair cost nearly $1 billion to repair. And in the HVAC world, a study authored by Sarah Lynn Garrett of Kansas State University described how an oversized cooling system combined with a plethora of errors during the construction of the Polk County court-

“Upon arrival at the jobsite, there was no technician just a furious homeowner who told me the installing contractor was no longer welcome.”

house in Bartow, Florida cost $35 million to repair, millions more than the original cost of the entire 10-storey building!

Philosophers call it schadenfreude: those who experience pleasure, even joy, in hearing about the troubles, humiliation or failures of others. Such an attitude was not top of mind as I thought about how I could describe several very problematic situations I’ve experienced.

Trouble often results from more than just one error; yes, some are carelessly caused, even reckless, yet we are all

capable of misadventures; unfortunately, sometimes those that end very badly.

Thus, learning from mistakes is one thing, but what one does or doesn’t do about them makes all the difference. <>

Ian McTeer is an HVAC consultant with 35 years of experience in the industry. He was most recently a field rep for Trane Canada DSO. McTeer is a refrigeration mechanic and Class 1 Gas technician.

Plumbing is an unpredictable business, but the quality of the pumps you install shouldn’t be. Generations of plumbers have trusted our hard-working, reliable pumps to get the job done right the first time. Make a Big Impact on your next job with Little Giant.

Daikin Applied’s SmartSource dedicated outdoor air system (DOAS) is heat pump technology for heating and cooling using 100% outside air. The unit’s SmartBoost Heat Technology allows air as cold as 0F to enter without pre-heating. The DOAS taps a water source heat pump’s hot gas reheat coil in addition to the unit’s primary DX coil. The heating efficiencies are coupled with ECM and shaftless blower technology help performance. www.daikinapplied.com

Venmar Ventilation’s Canadian-made Venmar AVS N series and vänEE AI series heat recovery ventilators (HRV) and energy recovery ventilators (ERV) feature new VIRTUO air technology offering improved performance and quick installation. Their smart, built-in, auto balancing allows quick set up, continuous self-adjustment optimizes operation and simple touchscreen controls allow simple settings. They come standard with MERV 8 filters and MERV 13 are an option.

www.venmar.ca

Pioneer HVAC Systems introduces its patentpending Self Locking Damper (SLD), an adjustable damper for more accurate residential air balancing. Unlike conventional dampers that tighten with a wing nut that often gets hidden under dry wall after construction, the SLD allows for simple manual re-adjustments inside the supply line after installation. This sleeve is made of 26-gage and damper of 22-gage galvanized iron sheet. www.pioneerhvac.ca

RenewAire’s EV Series Premium is a static plate enthalpy core-based ERV for single-family, multi-family and light commercial buildings. Standard EC motors allow variable speed ondemand and continuous operation. The units accommodate spaces of up to 4,000-sq.-ft with a minimum 165-CFM of outdoor air and have operating ranges of 30 to 225-CFM (med.) and 30 to 280-CFM (large).

www.renewaire.com

ESAB Welding’s Miniarc Rogue ES 180i is a portable stick/lift TIG inverter with advanced arc performance and controls. The unit weighs 18.2 lbs., measures 13.5 x 6 x 10.4 in., has a maximum output of 180 amps at 25% duty cycle and uses 115 – 230V 50/60 Hz primary power. It produces a smooth welding arc with all types of Stick electrodes, and it delivers a stable TIG arc down to 10 amps. esab.com

NAVAC’s new cordless NEF6LM power flaring tool weighs less than three pounds and produces precise, automatic flares in a fraction of the time compared to traditional flaring methods. It can create flares in five sizes, ranging from ¼-in. to ¾-in. Using one-button operation and a LED flashlight, it can complete a flare in just 15 seconds and can make over 100 flares per charge. It’s fully charged in 30 minutes. navacglobal.com

HVAC PRODUCTS

Centrotherm Eco Systems now offers Air Excellent, a dedicated air management system for HRV and ERV. The system can independently control the air quality in each room. Balanced air exchange for every room is achieved using a proprietary pressure configurator that continuously calculates the pressure drops over the duct runs. The low-profile system can support open concept floor plans. www.centrotherm.us.com

The York mission critical horizontal computer room air handler (YORK MCH CRAH) is designed to meet cooling requirements for demanding data centers. Offered in three standard capacities (105 kW, 210 kW and 315 kW rated at a 22F delta air temperature), the units are designed for minimal footprint and feature left or right-hand connections to minimize field piping. www.york.com

NIBCO PressACR fittings are designed for use in copper tube systems for AC and refrigeration applications. Approved for a range of refrigerants and lubricants, the fitting are UL recognized to 700 psi. They are engineered to install with the NIBCO PressACR 19kn tool which creates a round crimp pattern. Straight and reducing couplings, 45- and 90-degree elbows, caps, Y-joints, and tees are available from ¼-, to 1-1/8-in. nibco.com

Franklin Electric’s new Little Giant brand high-temperature condensate pump, the HT-VCL series, is designed to handle difficult plenum and commercial applications. It comes in 1/8 and 1/3 hp models with flows up to 575 gph at 5 ft. with a maximum of 62 ft. of head. Its 14-ft. lead wires connect to a power supply with separate leads for overflow detection switch. littlegiant.com

Fujitsu General America has introduced new multi-position air handler units that combine Fujitsu’s inverter heat pump technology and side discharge outdoor units with a modular design indoor unit. Available in four sizes from 24,000 to 48,000 Btu/h, the new systems include aluminum indoor unit coils, high static pressure capability, indoor sound levels as low as 24 dBA and adaptive fan motor control. www.fujitsugeneral.com

Johnson Controls new economical LUX CS1 Smart Thermostat requires minimal setup with flexible installation using either a Power Wire, C-wire or LUX Power Bridge. It offers a simple interface and connects to the Amazon Alexa and Google Assistant and is compatible with the LUX App to control temperature from a smart phone, plus geofencing and smart scheduling for energy savings. pro.luxproducts.com

BUILDING CROSS CONNECTION CONTROL AWARENESS

Drawing attention to the Bad and Ugly as a way to promote safety and assurance. BY DOUG PICKLYK

For the sixth year running the Western Canada Section of the American Water Works Association (WCS AWWA) has conducted its annual National Bad and Ugly Cross Connection Control photo contest, a project launched in 2014 as part of an ongoing campaign to raise the level of awareness of potentially dangerous cross connections in Canada’s potable water systems. Administered by the Cross Connection Control committee of the WCS AWWA, the contest also serves to educate water industry representatives in the field.

The Western Canada Section of the AWWA includes all members residing in or having business activity in Alberta, Saskatchewan, Manitoba, the Northwest Territories, and the Territory of Nunavut. Other AWWA sections across the country include Atlantic Canada (ACWWA), B.C. and the Yukon (BCWWA), Quebec section (SQ-AWWA, Réseau Environnement), and Ontario (OWWA).

The annual WCS AWWA Bad and Ugly contest attracts photos from across the country, and once again the committee

awarded two winning entries, one in the inspector/regulator category and one in the active backflow tester in the field category, with this year's winners coming from Québec and Alberta respectively.

INSPECTOR CATEGORY

This year's winner in the inspector category was Jean Lalanne, a cross connection control inspector for the Régie du bâtiment du Québec (the building board in Québec).

Lalanne's photo was from a new-build three-story 12-unit building, where the owner and the general contractor didn’t want the water main situated within one of the dwellings.

Faced with those restrictions, the plumber decided to conceal the main water stop valve, the premise isolation double check valve assembly (DCVA) backflow, and the four risers stop valves in the same pit with no drainage, in a hallway, under the stairway (see image, opposite page, left).

Because all those devices were installed in the sequence

This backflow preventer was installed upside down with its relief port facing up instead of down.

This multi-unit building’s isolation device was installed at an angle and inaccessible behind riser shut-off valves.

WHAT IS A CROSS CONNECTION?

A cross connection has been defined is any actual or potential connection between a potable water system and any source of pollution or contamination through which backflow may occur.

Backflow, in turn, is the reversal of the normal direction of flow in a potable water distribution system. There are two types of backflow: back-siphon, and backpressure. Backsiphon is caused by negative pressure in the supply piping, possibly as a result of a water main break (pictured above) or due to high water withdrawal rate such as fire fighting or water main flushing.

Backpressure is caused whenever a potable system is connected to a non-potable supply operating under a higher pressure such as a boiler system, a high pressure car wash or a chemical feed system in an industrial plant.

In these situations some type of backflow prevention device needs to be installed and maintained at the point of cross connection in order to protect the potable system from contamination.

of the construction, the result was that the riser stop valves blocked the access of the DCVA backflow and the water main stop valve, and the DCVA was tilted sideways to make more room for the risers valves.

Following a conversation with the plumbing inspector, the plumbing contractor admitted it was a very bad installation. The setup was redone properly, in a blown wall under the stairway, with an access panel. The final solution respected the general contractor and owner's restrictions to keep the access outside of the dwellings, and more importantly the change respected the code.

For his bad and ugly photo entry, Lalanne received a gift certificate from the backflow manufacture representatives on the WCSAWWA CCC committee, and in return Lalanne decided to give back the amount to United Way for the diabetes foundation.

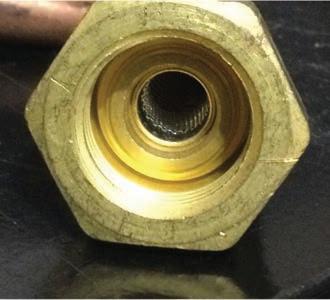

TESTER CATEGORY

The winning photo entry for the tester-in-the-field category was received from Shayne Makin, a plumber with DMT Mechanical in Lethbridge, Alberta.

Makin's photo came from a building where he was testing backflow preventers and noticed that the relief port (RP) on one of the preventers installed on a chemical feed line was upside down (see image, opposite page, right).

The client was notified that the backflow preventer was installed incorrectly and that the discovery resulted in an automatic

fail. A new backflow was installed and the issue was corrected.

For his bad and ugly photo, Makin received a new pressure differential gauge from Apollo Valves.

PROMOTING PREVENTION

In a statement attached to the announcement of this year’s winners, the WCS CCC committee said: “Our water industry representatives, inspectors, plumbers and testers all share a responsibility to protect our water supplies. Cross connections do exist and are a potential to contaminate or pollute our potable water. Let’s do our best to find and correct these cross connections before the damage is done.”

The committee also expressed its appreciation to all of the testers and inspectors who submitted bad and ugly photos for the 2020 contest, and they also recognized the support the annual contest receives from backflow manufacturers Conbraco, Watts and Zurn for providing the contest prizes.

For those interested in participating in the 2021 "Bad and Ugly Cross Connection Control" photo contest visit: www.wcsawwa.net under the Cross Connection Control tab. <>

For more information on cross connection control training and certification visit the AWWA section within your region: B.C./Yukon: www.bcwwa.org Alta/Sask/Man/NWT/NT: www.wcsawwa.net Ontario: owwa.ca Quebec: reseau-environnement.com/secteurs/eau/awwa/ NB/Nfld/NS/PEI: www.acwwa.ca/

Shayne Makin from DMT Mechanical in Lethbridge, Alberta, was this year’s Bad and Ugly photo contest winner in the backflow tester category.

Catch and control water issues. Anytime, anywhere.

Get alerts to your phone instantly if a leak is detected, and use the remote shut-off feature to stop leaks in their tracks. You can also view live and historical water usage. Everything you need to control your home’s water system is in the palm of your hands.

Home & Away

Protect yourself by while away or home by putting the Control in Away Mode. While in Away mode, the Control will alert and automatically shut the water off if a leak is detected. Home mode uses your normal leak detection settings.

Intelligent Leak Detection

While in Home mode, Smart Alerts™ allows your device to learn your unique water usage patterns so it can send notifications when it detects abnormal use.

Smart Home Compatibility

The Control integrates with Amazon Alexa and the Google Assistant™ so you can ask your smart home device about water usage, tell it to change among multiple locations on one app.

Multiple Locations, One App

Protect and control water in second homes or vacation properties.

Scan to see how you can control the water in your home!

Real-time leak protection, complete peace of mind.

The StreamLabs Control is a whole-home smart water leak detection device that uses ultrasonic technology to detect leaks as small as 0. m . The Control pairs to your Wi-Fi network to provide real-time water usage and other alerts such as pressure, temperature and humidity to provide a healthy and well-protected home. The Control has a brass full-flow valve with a stainless steel ball valve and performs monthly valve checks for continuous long-term operation and reliability. Illuminated Membrane Switch with Push Buttons 12V Gearbox with Stainless Steel Final Gears Double Union Connections - FNPT or SharkBite

Want to be a StreamLabs Pro?

The StreamLabs Control comes with a two-year warranty that is extended to four years when installed by a StreamLabs Pro contractor. Start saving your customers money and apply today!

Robust ABS Housing

PLUMBING PRODUCTS

Geberit North America offers a hands-free version of its Type 50 series of flush plates for inwall urinal systems. The touchless actuator uses sensors to automatically flush the urinal when the user walks away. They have a flush volume of 0.5 GPF (1.9 LPF) and are made from die-cast zinc and feature four finishes: brushed chrome, brushed PVD red gold, brushed PVD black chrome and brushed PVD brass. www.geberitnorthamerica.com

RIDGID’s RP 350 press tool is engineered to be 5% lighter and almost three inches shorter than its predecessor. It features a brushless motor, 360-degree swivel head and advanced LED interface and lighting. It is compatible with the full line of RIDGID jaws and rings, including: ½ – 4-in. ProPress for copper and stainless steel, ½ – 2-in. PureFlow for PEX, and ½ – 2-in. MegaPress for carbon steel. RIDGID.com

Dearborn’s True Blue Bath Waste line is now available with finished drain spuds in designer finishes. Along with the chrome drain spud, they also come in brushed nickel, oil rubbed bronze, white and matte black. Constructed out of brass, built for durability, finished drain spuds are available in full, half and trim kits with options for ABS or PVC and touch toe, uni-lift and push n’ pull stopper options. oatey.com

The Series e-82 twin vertical in-line centrifugal pump from Bell & Gossett delivers space savings and energy-efficient pumping for commercial HVAC and plumbing applications. It provides a wide hydraulic range with 22 models and features a changeover valve to operate pumps separately or in parallel. In parallel mode, they handle flows up to 1600 gpm with head up to 130 ft. total dynamic head (TDH) and 175 psi standard. bellgossett.com

The Watts Pronto! line of adjustable cleanouts come in PVC and cast iron. They feature a patented integrated bubble level concrete cover for a level installation and to protect the cleanout. Designed for light to medium duty commercial and residential use, they include pipe connections of 2, 3, and 4 inches and come complete with an anchor flange, with up to 1-1/2-in. pre-pour and 1-in. post-pour adjustability. www.watts.com/pronto

The Electric Eel eCAM Ace 2 SL pipeline inspection camera system now comes standard with a battery cradle that accepts a Milwaukee M18 or equivalent battery (battery not included). The cradle adds convenience and allows easy access to power for remote field work or where electricity is not available. Other features include a self-leveling colour camera, one-touch USB recording, on-screen footage counter and wheels for easy transport. www.electriceel.com

Webstone has two new Pro-Pal three-way ball valves to divert, select, or mix fluids based on application needs. Flow options include a 90-degree handle operation to divert or select, or a 180-degree handle operation to divert, select, or mix. Products are forged from leadfree DZR brass, available in sizes ½ – 2-in., and feature dual stem seals and press connections that are compatible with popular press tools. www.webstonevalves.com/propal

The Korky Beehive Max Hideaway toilet plunger and Beehive Mini sink & drain plunger are the latest additions to the Beehive plunger line. The Hideaway comes with a drip-free caddy and collapsible handle, while the Mini is designed for clogs in sinks, shower drains, and tubs. They come standard with a T-handle and the patented beehive shape head design for any drain type. korky.com/beehive

HoldRite, an RWC company, has launched HydroFlame 300 self-leveling (HF300SL) and HydroFlame 300 caulk-grade (HF300CG) silicone firestop sealants for areas subjected to high levels of moisture or when UL listed W ratings are required. As quick curing silicone sealants, they can be used across a variety of pipe types. The self-leveling HF300SL is designed for floor applications, while the HF300CG is designed for use on both floor and wall penetrations. holdrite.com

Caleffi North America is offering the LEGIOMIX Station featuring a 6000 Series LEGIOMIX electronic mixing valve to provide temperature control for commercial domestic hot water (DHW) systems. The pre-built stations include the digital mixing valve with union connections, serviceable stainless steel check valves, purge test ports, isolation valves and a LEGIOMIX controller, pre-mounted on a powder-coated painted steel strut frame. Stations are available in five sizes from 1-in. to 2½-in. copper pipe connections. www.caleffi.us

The 7th Edition of Aquatherm’s North America Installer Manual covers best practices, safety and planning for the proper installation of its polypropylene piping systems. Significant updates include: information on the adoption of the latest DVS polypropylene fusion parameters; a new chapter on butt fusion with photos and “Pro Tips”; updated charts for approved butt fusion tool manufacturers; and an updated section on unions. aquatherm.com/installer-manual

Taco Comfort Solutions’ VT Series vertical turbine pumps are available with 6-in. to 18-in. bowl diameters, and provide quiet performance for cooling tower, chilled water, water transfer, pressure boosting and water supply applications. All impellers are investment cast stainless steel to provide longer life and better abrasive and corrosive resistance. All bowls and discharge heads are ductile iron for higher hanging weight and better tensile strength. www.TacoComfort.com

MECHANICAL SUPPLY NEWS

MANUFACTURERS • DISTRIBUTORS • WHOLESALERS

DESCHENES GROUP ACQUIRES POWRMATIC

Deschenes Group Inc. has acquired Powrmatic of Canada from Powrmatic’s parent company Stamm International Corp.

MANUFACTURER ACQUISITIONS

Powrmatic, headquartered in Montreal, distributes residential, commercial and industrial supplies to the HVAC, electrical and hearth industries with six branches located in Montreal, Toronto, London, Ottawa, Quebec City and Halifax and has over 100 employees.

“This acquisition fits well with our development and growth strategy across Canada,” said François Deschênes, president/CEO of Deschênes Group, in a company release. Powrmatic will become DGI’s 13th business unit and will continue to operate under the leadership of Claude Lapierre. groupedeschenes.com powrmatic.ca

REP AGENCY OPENS IN ONTARIO

CENTRIC Sales and Marketing Inc. has launched in Ontario. Headquartered in Toronto, the independent manufacturer’s representative agency, founded by Jeremy Torra, will serve HVAC/R, plumbing and mechanical verticals into wholesale distribution and the trades. Current brands include Navac, Midland Industries and Brymark. centricsales.ca

NEW PRESIDENT FOR WOLSELEY CANADA

Wolseley Canada named Sébastien Laforge, formerly vice president, Eastern Canada, as president taking over from Kevin Fancey who retired at the end of October.

Laforge joined Wolseley Canada in 1996 as finance manager and became finance director in 1998. From 2009 to 2020 he was general manager, Quebec plumbing and HVAC. wolseleyexpress.com

MASTER GROUP CONTINUES TO GROW