WORKING WITH REFRIGERANTS

CHANGE IS ON THE HORIZON

SUMMIT 2022 IS BACK LIVE!

LEARN FROM OUR TOP-NOTCH HYDRONICS EXPERTS

SPEAKERS

HAVE A CHANCE TO WIN TOOLS AND BLUE JAY TICKETS! (Blue Jays vs NY Yankees)

John Siegenthaler Siggy covers hot button topic Hydronics for Net Zero Homes

Mike Miller Circulators and Valves

Jeff House and Brian Morgan team up to discuss the critical nature of proper boiler chemistry

Tom Gervais

Regulatory Outlook for Boilers and Water Heaters

ENJOY REFRESHMENTS, LUNCH, DINNER & DRINKS

• Do you have new members of your team looking to improve their knowledge of hydronic systems and the components that make them work?

• Perhaps you are primarily an HVAC or plumbing contractor who is considering adding hydronics to your repertoire. Then Hydronics 101 is made for you!

• Industry experts will walk you through the basics of hydronic systems and help you understand why this technology is growing so rapidly.

• Topics include: Boilers | Circulating Pumps | Piping | Controls | Heat Emitters | Boiler Chemistry

• Hydronics 101 sponsored by

Platinum Sponsor Supported by

Sponsors

NETZERO

HVAC

WORKING WITH REFRIGERANTS

A look at where we’ve been and preparing for the introduction of more climate-friendly, mildly-flammable, alternatives.

By Ian McTeer

HVAC

PRODUCT SHOWCASE

A selection of the latest in equipment and supplies for HVAC techs.

52

PLUMBING

THE “NEW-SCHOOL” PLUMBING BUSINESS

Vancouver’s Impetus Plumbing & Heating is embracing social media and breaking down old-school perceptions.

By Dan Vastyan

REFRIGERATION

WHAT’S NEW IN REFRIGERATION?

Smart electronic technologies are improving installation and operational efficiencies for large refrigeration projects.

By Dave Demma

Terence Chan, owner of Impetus Plumbing & Heating in Vancouver.

ALSO INSIDE

MODERN HYDRONICS

SYSTEM DESIGN DIFFERING DELTAS

Both temperature control and pressure control of circulators can work when matching flow rate with heating demand, but there are important distinctions.

By John Siegenthaler

MH10 PUMPS

BRIGHT IDEAS – TROUBLESHOOTING 101

From home maintenance to commercial mechanical room operations, problem solving always requires a plan.

By Mike Miller

MH15

SHOW PREVIEW

MODERN HYDRONICS 2022 - THE SUMMIT

The sixth edition of the Summit returns as a one-day in-person event with new twists.

By HPAC Staff

MH20

DISTRICT HEATING HEATING YELLOWKNIFE

New pellet boiler district energy system helps NWT government reduce its carbon footprint.

By Ellen Cools

MH26

COOLING DEW DROP INN

A quick lesson in condensation prevention when it comes to radiant cooling.

By Curtis Bennett

MH28

HEAT EXCHANGERS OPPOSING CURRENTS

When it comes to designing systems with brazed plate heat exchangers, stick with counterflow piping.

By John Siegenthaler

STRENGTH IN NETWORKS

IN LATE JUNE I HAD THE OPPORTUNITY TO ATTEND THE 89TH EDITION OF THE CANADIAN INSTITUTE OF PLUMBING AND HEATING'S ANNUAL BUSINESS CONFERENCE held this year in picturesque Jasper, Alberta. It was my first live CIPH national conference experience, as it was the first in-person edition held since 2019.

As an association, the CIPH consists of manufacturers, wholesalers, distributors, manufacturer’s agents and others who make and sell products and services for all aspects of the plumbing and heating industry in Canada.

Around since 1933, the group maintains some of the traditional character that would be expected from such a long-standing organization, but the topics of discussion at this year’s conference were very ‘of the moment.’

Supply chain expert Ian Heller from Distribution Strategy Group in the U.S. addressed the current supply problems all industries are experiencing. His message to plumbing and heating distributors is to continue striving to make purchasing convenient and easy for contractors, (while acknowledging you’ll never be as seamless online as Amazon), and remember your greatest value is being able share knowledge and create personal relationships with your customers—connections that can’t be duplicated online.

The CIPH, like most associations, draws its strength from member volunteers, a blend of partners and rivals who together aim to raise the level of the industry they serve. It’s refreshing to see competitors sitting around the same table, sharing ideas, and also enjoying downtime in social settings.

A nice touch at the CIPH event is the recognition of members whose legacy forms the building blocks of the industry in many ways. This year Honourary Life Membership Awards were presented to: Harald Prell, retired president of Viessmann Canada; Bill Palamar, president/CEO Aqua-Tech Sales & Markeing/ Weil-McLain Canada; and Joe Senese, retired from Groupe Deschenes. Both Prell and Palamar were at the event, continuing to share their knowledge and experience with others.

The idea of competitors getting together to elevate an industry is not new— it's the foundation of most any association—but what I've seen lately is a greater effort among a new generation of passionate contractors in the HVAC and plumbing sector who are making efforts to promote and improve the industry. In this issue we have a profile of Terence Chan, founder of Impetus Plumbing & Heating in Vancouver. Chan uses his energy towards creating more exposure and improving the image of the plumbing profession.

He’s not alone. There are many brilliant tradespeople sharing techniques and tips over social media channels and promoting the message that plumbing and HVAC is valuable and cool, all while also trying to raise their game.

We are fortunate to have a number of these social media professionals/influencers joining us the Modern Hydronics Summit on September 15th in Toronto, along with the the regular thoughtful speakers and knowledgeable exhibitors who also form the collective network of industry supporters.

Also, as we were closing this issue I found out CIPH president Ralph Suppa will be retiring at the end of 2023. Ralph is the ultimate supporter of this industry. It's still early, but thank you Ralph for all you do. <>

– Doug Picklyk, Editor

Reader Service

Print and digital subscription inquires or changes, please contact

Angelita Potal, Customer Service Administrator

Tel: (416) 510-5113 Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

NATIONAL ACCOUNTS

ACCOUNT COORDINATOR

AUDIENCE DEVELOPMENT MANAGER

MEDIA DESIGNER

PUBLISHER

COO

Doug Picklyk (416) 510-5218 dpicklyk@hpacmag.com

Logan Caswell (416) 728-6209 lcaswell@hpacmag.com

David Skene (416) 510-6884 dskene@hpacmag.com

Kathryn Swan (416) 510-6797 kswan@hpacmag.com

Kim Rossiter (416) 510-6794 krossiter@hpacmag.com

Urszula Grzyb (416) 510-5180 ugrzyb@annexbusinessmedia.com

Emily Sun esun@annexbusinessmedia.com

Peter Leonard (416) 510-6847 pleonard@hpacmag.com

Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLICATIONS MAIL AGREEMENT NO. 40065710

Heating Plumbing Air Conditioning (established 1925) is published 7 times per year by Annex Publishing & Printing Inc. HPAC Magazine is the leading Canadian business publication for the owner/manager of mechanical contracting businesses and their supply partners.

ISSN: 0017-9418 (Print) ISSN 2371-8536 (Online) Contents Copyright © 2022 by Annex Publishing & Printing Inc. may not be reprinted without permission.

SUBSCRIBER SERVICES: To subscribe, renew your subscription or to change your address or information please visit us at www.hpacmag.com

Subscription Price per year: $44.00 (plus tax) CDN; Outside Canada per year: $112.00 US; Elsewhere: 1 year $123.00 (CDN); Single copy Canada: $5.00 CDN. Heating Plumbing Air Conditioning is published 7 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

MAIL PREFERENCES: From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us via one of the following methods: Tel: 416-442-5600 ext. 3552, Fax: 416-510-6875 or 416442-2191; E-mail: blao@annexbusinessmedia.com; or by mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

HPAC Magazine receives unsolicited materials (including letters to the editor, press releases, promotional items and images) from time to time. HPAC Magazine, its affiliates and assignees may use, reproduce, publish, re-publish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

NOTICE: HPAC Magazine, Annex Publishing & Printing Inc., their staff, officers, directors and shareholders (hence known as the “Publisher”) assume no liability, obligations, or responsibility for claims arising from advertised products. The Publisher also reserves the right to limit liability for editorial errors, omissions and oversights to a printed correction in a subsequent issue. HPAC Magazine’s editorial is written for management level mechanical industry personnel who have documented training in the mechanical fields in which they work. Manufacturers’ printed instructions, datasheets and notices always take precedence to published editorial statements.

Proud member of:

www.hpacmag.com

IT’S A WIN-WIN.

With Bradford White’s residential products, you’ll get the best of both worlds: the performance and features your customers want and For The Pro® engineering for an easy, trouble-free installation.

Infiniti® Series Tankless Water Heaters: Delivers an endless supply of perfectly hot water. Available in both indoor and outdoor models, with or without recirculation pump.

Upright & Utility Electric Water Heaters: Uprights available in gas or electric in a variety of capacities. Utility models for tight spaces, garages, workshops and more.

eF Series® Gas Water Heaters: ENERGY STAR® certified for year-round energy savings. Easy to install and service. Available as power vent or power direct vent.

To learn more, visit bradfordwhite.com/canada-contractors

INDUSTRY NEWS

CANADA LAUNCHES GREENER HOMES LOANS UP TO $40K

The Federal Government has launched its interest-free loan program to help homeowners and affordable housing providers complete deep home retrofits.

The Canada Greener Homes Loan is designed to help up to 175,000 eligible homeowners undertake deeper, more costly retrofits that will have a significant impact in reducing a home’s environmental footprint, energy bills, and improve home resiliency. Interest-free loans of up to $40,000 will be available per household.

The first phase, which launched on June 17, 2022, is open to eligible homeowners who are applying or have an open application (pre-retrofit stage) to the Canada Greener Homes Grant. The second phase, starting in early September 2022, will expand the eligibility to homeowners who have closed their application (those who have requested their post-retrofit evaluation or grant), but still have remaining eligible retrofits they are interested in pursuing, that have not yet commenced.

The Canada Greener Homes Loan is part of the Canada Greener Homes Initiative. The program builds on the Canada Greener Homes Grant launch on May 27, 2021.

As of early June, the Greener Homes initiative has already issued $38 million in grants to 10,300 homeowners. So far, heat pumps are the top retrofit taken up for the grant. Almost 3,200 Canadian homeowners have received $13.2 million in grants for installing heat pumps.

Since the launch of the program, further air source heat pump and cold climate air source heat pumps installation requirements have been further clarified. Clarifications to the program includes a note stating the air source heat pump or cold climate air source heat pump must be installed by a licensed and trained professional.

The Canada Greener Homes Grant initiative also requires that the heat pump system be capable of distributing heat throughout the entire conditioned space in the house, including the basement (for basements where the distance from the top of the floor slab to the bottom of the ceiling joist is 1.8 m or higher). This applies regardless of whether the heat pump system is a central ducted, mini- or multi-split ducted or ductless system.

The mechanical system contractor is responsible for specifying (including load calculations, sizing and selection) and installing the new heat pump system to meet this requirement.

Additionally, a minimum of one warm air supply outlet or indoor head is required on every floor, including each level of a split-level, mezzanine level, etc., of each dwelling unit in a building. More than one warm air supply outlet and/ or indoor head per floor may be required to ensure heat distribution to the entire building. (A transition period is in place, since this clarification came after the launch of the Canada Greener Homes Grant). nrcan.gc.ca

GRAHAM PROKOPETZ WINS RED SEAL INDUSTRY AWARD

Graham Prokopetz, a Red Seal Plumber and field operations supervisor with Botting and Associates in Calgary, has been awarded the 2022 Darryl Cruickshank Red Seal Industry Award.

Named to honour the life-long impact of the late Darryl Cruickshank, the award recognizes an individual from industry who has made an outstanding contribution to the promotion or development of apprenticeship training in Canada.

Prokopetz was selected for the award based on his extensive work and volunteer history, and his inspirational leadership to the next generation of skilled tradespersons.

With over 45 years in the trades, he has achieved excellence by obtaining his Gold Seal Certification in addition to his Red Seal Endorsement, but most notably through his extensive mentorship to apprentices.

Since 2010, Prokopetz has mentored 13 high school students participating in Alberta’s Registered Apprenticeship Program, one of whom was the first woman to obtain a Journeyperson certification in plumbing. red-seal.ca

ONTARIO COLLEGES PARTNER TO LAUNCH 4-YEAR BUSINESS DEGREE FOR TRADESPEOPLE

Algonquin College, George Brown College and Mohawk College have joined resources to launch a new fouryear honours degree in Business Administration, focusing on people working in skilled trades occupations.

The partner colleges will deliver this

PHOTO: NIKOMSOLFTWAER /ADOBE STOCK

first-of-its-kind degree in September 2022, with all instruction provided remotely and virtually. The program, approved by the Ontario Ministry of Colleges and Universities, is intended for people working in the skilled trades sector who are looking to grow their own businesses, take on greater responsibilities in their current work environments, or pursue management careers in medium-to-large organizations.

The online Bachelor of Business Administration (Trades Management) (Honours) degree will concentrate on business administration, managerial skills, accounting, project management, leadership, marketing, communication and applied research competencies. This theoretical instruction will be combined with 420 hours of structured work experiences (or equivalent), for which students receive credit. tradesmanagementdegree.ca

ASHRAE HOSTS ANNUAL CONFERENCE IN TORONTO

ASHRAE, the global professional engineering society committed to advancing the state of HVAC/R, held its 2022 Annual Conference in Toronto June 25 to 29.

More than 1,800 industry professionals attended the conference in-person and virtually. Topics discussed among the over 80 technical sessions included changes to buildings influenced by the pandemic and the broad topic of decarbonization.

During the conference Farooq Mehboob

What If Water Heaters

of Karachi, Pakistan took on the role of ASHRAE president for 2022-23 and introduced the theme for the year, “Securing our Future.”

“The future does not belong to those who sit and watch,” said Mehboob. “A meaningful and powerful future will not come to us…we must collectively seek it…create it…secure it. And that’s what we’ll do because that’s who we are.” ashrae.org.

FORTISBC INTRODUCES COMMERCIAL REBATE FOR GAS ABSORPTION HEAT PUMPS

FortisBC is introducing a new commercial prescriptive rebate offer for gas absorption heat pumps.

The program is being offered to commercial, multi-unit residential and institutional buildings, including office buildings, hotels, schools, hospitals,

Continued on p10

Toronto welcomed the global ASHRAE conference in June.

recreation centres and care homes. The program is available for retrofit applications, and the building must have a dedicated outdoor space either on the ground level or roof for the gas absorption heat pump units. Commercial customers can receive up to $35,000 in rebates depending on the scope of the project. fortisbc.com

STUDY: GREEN RETROFITS REQUIRE TEAMWORK

The Canada Green Building Council (CaGBC) and the Delphi Group released a new report, Green Retrofit Economy Study that profiles pathways that will equip the green building community with insights into the workforce and supply chain needs across Canada’s retrofit economy.

The study anticipates that Canada will have a shortage of skill workers in the near term. The federal government plans to stimulate economic growth, and over $3.6 billion has been committed to finance energy efficiency upgrades and low-carbon retrofits for large buildings as a way to meet GHG emission reduction targets. To achieve these results the green building workforce will need to triple by 2030 to meet the demand for sustainable building construction and renovation.

The report acknowledges that Canada will need to lean heavily on a skilled, qualified, and growing workforce, as well an accessible and affordable supply chain of low-carbon products, materials, and equipment. Among the key technologies and products identified are heat pumps along with heat and energy recovery systems. cagbc.org

IAPMO UPDATES STANDARD ON PRESS FITTINGS

The International Association of Plumbing and Mechanical Officials (IAPMO) has published IAPMO/ANSI/ CAN Z1117, Press Connections as American National Standards (ANS) and National Standards of Canada (NSC).

The new IAPMO/ANSI/CAN Z1117 supersedes the widely used IAPMO PS 117, which is a standard referenced in the model plumbing codes including the ANSI-accredited Uniform Plumbing Code (UPC). It specifies requirements for materials, physical characteristics, performance testing and markings.

Products covered by this standard include fittings, tube and pipe with press connection ends combined with other types of connections (e.g., threaded, soldered, and push-fit). iapmo.org

ASHRAE TAKES ON BUILDING DECARBONIZATION

ASHRAE has issued a position document on building decarbonization and the group's role on mitigating the negative carbon impact of buildings on the environment.

ASHRAE’s position is that the decarbonization of buildings and its systems must be based on a holistic analysis including healthy, safe & comfortable environments, improved energy efficiency, environmental impacts, sustainability, operational security and economics.

By 2030, ASHRAE hopes all new buildings are net-zero GHG emissions in operation, widespread energy efficiency retrofit of existing assets are well underway and embodied carbon of new construction is reduced by at least 40%. <> ashrae.org/decarb

WORKING WITH REFRIGERANTS

Where we’ve been and how we're preparing for more climatefriendly, mildly-flammable, alternatives. BY IAN

McTEER

After Billy Durant purchased the Guardian Refrigerator Company with his own money in 1918, he incorporated the business into General Motors (GM) and renamed it Frigidaire. By 1929, Frigidaire had sold over one million refrigerators, the

only trouble was, the nasty nature of refrigerants like sulfur dioxide, methyl chloride and even ammonia, kept Billy awake at night. Thus, GM created a subsidiary company designed to monitor the exploration of alternative refrigerants. One scientist, Thomas Midgley

fashioned a team of researchers that developed dichlorodifluoromethane, branded Freon 12 (R-12). Midgley, a shameless self-promoter, loved to boast the compound was completely safe. So much so, he demonstrated his claim publicly by inhaling a lung-full of R-12 and then exhaling the chemical onto the flame of an open candle. No fire, no explosion, and Midgley was unharmed. Must be safe, no?

The chemical was deemed safe, but unbeknown to anyone, including Midgely, the Ozone Layer was being attacked.

EARLY DAYS

As residential air conditioning became more popular and affordable in the early 1980’s, some air conditioner manufacturers opted to provide threepiece systems charged with R-22 refrigerant. The evaporator coil contained a vapour holding charge with the bulk of the charge contained in the outdoor unit. Contractors would purchase a pre-charged, pre-insulated copper interconnecting line set of the appropriate length and size for the job. These pre-charged systems were popular since no brazing or system evacuation was necessary.

But pre-charged systems brought frustrating problems:

• Wholesalers often ran out of shorter line sets forcing installers to purchase longer line sets; excess tubing would be coiled up (horizontally!) somewhere in the furnace area.

• Line sets were often work-hardened and difficult to bend due to improper handling and storage.

• Line sets too often were out of round.

• The tubing insulation often proved inadequate allowing condensate to form on the outside.

To avoid some of the problems associated with pre-charged line sets, some contractors (including this one) would purchase a ZERO-kit containing just

the brass connectors and then fabricate a line set to manufacturers’ specifications out of bulk copper and better-quality insulation, even sweating elbows when needed to make a neat and tidy installation.

By connecting the evaporator coil section to the field fabricated tubing, I would pump a deep vacuum into the suction line, liquid line and the evaporator coil. I would then pressurize the evacuated components with vapour to bottle pressure before connecting to the outdoor unit thus releasing the bulk of the charge into the fully open system. Once started, I would charge the capillary tube metering system to superheat.

MEA CULPA

I mention all of this because, from my experience, too many pre-charged systems were overcharged. At start-up, refrigerant regularly needed to be released from the system; in fact, one manufacturer even provided a chart informing the installer how many seconds to leave the suction service valve open to the atmosphere so the charge might be corrected for a specific set of components.

Many service calls to malfunctioning units required vast amounts of R-22 be removed from the unit after a previous servicer loaded the poor machine with enough R-22 for several units. Why? Because the prevailing theory among poorly trained servicers was that to stop the evaporator coil from icing over just add more R-22. “Pump it in until you get 70 on the blue gauge.”

Midgley convinced HVAC/R practitioners (as well as those using chlorinated refrigerants as blowing agents) that atmospheric discharges of his invention were harmless.

Refrigeration textbooks of my era stated, “Saving the refrigerant is not recommended in small systems. The low cost of the refrigerant does not jus -

tify the time it takes to store it. The service technician may exhaust it into the air or into an approved exhaust system…never into a sewage disposal system.” Of course, the technician was warned to use goggles and gloves especially when venting to the atmosphere. Such a waste.

As our industry quickly rushed to sell the benefits of central cooling (and there are many benefits), the complex relationship between a well-designed and properly installed duct system and the refrigeration unit meant to operate in conjunction with it was not fully understood.

Far too often, this one seemingly insignificant shortcoming led to premature system failures often caused by overcharging. Inevitably, quantities of chlorinated refrigerant large and small were regularly “vented to the atmosphere.”

SOME GOOD NEWS

Recent scientific studies show the ozone hole in the Antarctic has closed. Certainly we’re doing the right thing by eliminating chlorine from refrigerants. By recovering refrigerants, even from the smallest systems, the efforts started in 1988 to reduce this type of environmental damage have also been taken seriously.

There’s no going back. Refrigerant

recovery equipment is now an important tool in every technician’s and installer’s kit. Unfortunately, refrigerants continue to escape into the atmosphere, most often through system leaks, physical damage and by fires.

Although the ozone depletion problem has been largely put to bed, scientists worry about refrigerants causing further damage by contributing to global warming.

Chlorinated refrigerants such as R-12 were phased out in the 1990’s and hydrochlorofluorocarbons (HCFCs) are either phased out or in the process. The most common replacement refrigerant for HCFC-22 is a hydrofluorocarbon (HFC). Even though its Ozone Depletion Potential (ODP) is zero, R-410a has an uncomfortably high Global Warming Potential (GWP) of 2088. To counter the ODP/GWP conundrum, scientists and engineers are developing better methods of using some of the chemicals Midgley worked so diligently to dismiss as too dangerous for public consumption.

Natural refrigerants such as ammonia and CO2 along with hydrocarbons such as propane (R-290) and isobutane (R-600a) are back in specialized applications that incorporate new safety standards aimed at equipment designers, installers and technicians.

Figure 1. Ozone depletion and global warming comparison.

A2L MILDLY FLAMMABLE REFRIGERANTS

As time goes on, aging units containing HCFC and HFC refrigerants will need to be replaced. I’m thinking our industry will make a concerted effort towards adopting man-made lower GWP products. Hydrocarbon refrigerants are not likely to be used in residential and commercial air conditioning applications, at least in the near term. Why? Standards developed by ASHRAE and ULC specify the amount of system charge that might be released into a given area based on the Lower Flammability Limit (LFL) of the refrigerant.

Too much flammable refrigerant leaking into too small an area could see the LFL reached; in the case of R-290, the LFL is 2.1% in air. Systems requiring large volumes of R-290 or R-600a are simply too dangerous. However, I had no qualms with my recent purchase of a chest freezer con -

taining 1.6 ounces of R-600a. A mere 1.64 ounces leaking into the 8,000 cubic foot area of my house means the LFL will never be reached.

“As time goes on, aging units containing HCFC and HFC refrigerants will need to be replaced.”

SO, WHAT’S THE PROBLEM?

Developing a refrigerant which meets environmental standards, behaves in a traditional manner within most systems, and is relatively safe to use is the proverbial tall order. ASHRAE Standard 34 classifies refrigerant toxicity and flammability classifications:

• Toxicity, or the inherent poisonous characteristic of a substance, is denoted by letter code. The letter “A” denotes lower toxicity while the letter “B” indicates higher toxicity.

• Flammability describes the ability of a substance to burn. The number 1 means a refrigerant will not propagate a flame while those coded with 2, 2L, or 3 will burn or even explode.

• A2L refrigerants, however, have been formulated to be difficult to ignite. Minimum Ignition Energy (MIE) measures the amount of spark energy needed to ignite a flammable mixture of gas and air. A2Ls typically require 100 times more spark energy than an A3 refrigerant such as R-290, meaning that everyday items like cordless drills or electric heaters will not ignite A2Ls.

• A2Ls require higher concentration levels in air to reach their LFL and

Continued on p14

Reimagine your rough-in

Return Air Frames

Plastic alternative to traditional return air frames

Filtered and windowed models keep system clean during rough-in

Tested and trusted since 1992

‘Anywhere you can pan a joist space, you can use our Thermopan.’

Our Mechanical Contractor Hub was built for you thermopan.ca

Snap Clamps

Linesets, PVC, PEX and more

‘So easy, one person can hang a lineset.’

have a much lower heat of combustion meaning a combustion event is less likely to spread.

Handling any refrigerant requires the use of ingrained safety practices. With A2Ls, concern about flammability and toxicity should still be top of mind, consider these points:

• Potential exists for ignition of a refrigerant leak during operation, so find and repair any leaks.

• There is a potential for refrigerant ignition during servicing.

• Structural fires causing catastrophic system destruction will release A2Ls.

• If, for example, R-32 should catch fire from a torch flame during a service procedure, Hydrogen Fluoride is released which is toxic.

• Beware of A2L released into a service vehicle during transit or a large leak into a confined space.

WHAT CHANGES WILL HAPPEN?

The U.S. Environmental Protection Agency is authorized to phase down the production of HFC refrigerants starting this year. Initially, manufacturers of high GWP HFCs like R-134a, R-410a, R-404a among others, were required to phase down

production by 10% on January 1, 2022.

By 2024, a 60% phase down will be enforced and, no doubt, the price of such HFCs will become astronomical. Even the newest refrigerants such as Honeywell’s Solstice and Chemours Opteon XL41 HFO/HFC blend (Hydro FluroOlefin) are still considered to be transitional refrigerants: until the GWP number gets much closer to zero, the scientists will keep on looking.

As of this writing, R-454B and R-32 will most likely be ad -

EVER FEEL LIKE YOU MISSED SOMETHING?

On June 24, 2022, HPAC, along with sister publication Electrical Business, hosted an educational webinar on how to work more effectively in a Virtual Design & Construction (VDC) environment.

A number of very interesting state-ofthe-art applications designed to benefit progressive contractors working in the commercial HVAC and plumbing sectors were discussed

If you missed the webinar or wish to view it again simply click on the QR code.

Learn from Trimble experts about the power of SysQue—a modelling solution for the Revit environment—and Connect2Fab estimating, procurement and fabrication solutions.

Figure 2. Chart showing flammability classes.

and Questions

Comments

Can I reuse existing line sets? Yes – when properly sized and leak free A2Ls are POE compatible however always check with manufacturer for line set compatiblity

Embedded leak sensors? No Yes

Flammable labelling? No Yes

Units likely to have mitigation starategy in case of a leak: start an air dilution fan lock out unit operation, etc.

ISO warning triangle & flame symbol & labels, installer to provide charge info, test pressure & evacuation data

Safely remove refrigerant for repair or replacement? Required Required Use A2L compatible recovery equipment

Purge Circuit with nitrogen? Good Practice Required

Repeat as necessary

Evacuate system Required Required Pump outlet must not be near ignition source

Leak & Pressure Test Required Required No different from what you're doing now

Cylinder Colour Rose Gray/Green/ Red A2L cylinders to have red band around the top

Cylinder Storage Upright, prevent tipping Upright, prevent tipping

A2L cylinders pressure relief can open and reclose to relieve pressure: storage temperature must not exceed 50˚C. No smoking in service vehicles, vehicle flow through ventilation may be required.

Training Required Best Practice Absolutely Required Installation and Service Requirements as noted by equipment manufacturers

opted for use in residential and commercial air conditioning applications. Carrier and Johnson Controls have announced plans to build equipment based on R-454B while Daikin, Lennox and Panasonic prefer R-32.

While pure R-32 is an HFC refrigerant, it’s lower GWP (675) makes it suitable for use in residential and commercial applications.

NOTE: A2L refrigerants are NOT dropin replacements. They can only be used with equipment specifically designed for them within designated applications as determined by the equipment manufacturer.

So far, A2L units can do anything R-410a units have been doing. R-410a, classified as an A1 refrigerant, is a blend of R-32 with R-125 added to sup -

press flammability but unfortunately exacerbates the GWP problem (see Figure 3).

TECHNICIANS AND INSTALLERS: WHAT’S NEW AND DIFFERENT

As with anything new, some of your everyday HVAC activities will have to change, but not so much. Installation procedures for A2L equipment are like those of A1 products although everyone must abide by manufacturer's instructions, governmental regulations, and local codes.

Obviously, anyone handling A2Ls must take the appropriate training offered by manufacturers, trade schools, and organizations such as HRAI and ESCO.

• Main differences have to do with pre-

installation safety inspection.

• Maximum charge for A2L equipment will be limited by the cubic feet of available air space.

• Space must be large enough with enough air to keep the percentage of the LFL below that required to support combustion should the entire charge empty.

• ASHRAE Standard 15 and a new standard for residential applications Standard 15.2 are updated or in the works.

• New ULC standards published in 2019 cover design and test standards for HVAC/R equipment.

• Canada’s B52 Standard along with provincial building codes will soon be updated to cover A2Ls.

Many of the tools used by techs and installers currently working with R-410a will be suitable for use with A2Ls including gauge sets, manifolds, and scales. Tools such as leak detectors, recovery machines and vacuum pumps will have to be rated for use with A2Ls.

Digital gauges might require a software update. A2L cylinders will come with a left-hand thread, thus a lefthand thread hose adaptor will be required for connection to the cylinder.

Figure 4 is a chart of some additional A2L requirements and differences. Take note, because these changes are coming so it’s best to be prepared. <>

Ian McTeer is an HVAC consultant with over 35 years of industry experience. He was most recently a field rep for Trane Canada DSO. Ian is a refrigeration mechanic and Class 1 Gas technician. He can be reached at imcteer@ outlook.com.

Additional Product Information and Training Resources:

HRAI: hrai.ca/refrigerant-landscape ESCO: escogroup.org/training/ lowgwprefrigerant.aspx

Figure 3. Comparison of R-410a characteristics with R-32 and R-454B.

Figure 4. Additional A2L requirements and differences.

HVAC PRODUCT SHOWCASE

Westinghouse has expanded its mini-split heat pump systems for the North American market. The company offers single-zone outdoor units ranging in capacity from 9,000 to 36,000 Btuh, and multi-zone outdoor units between 18,000 and 42,000 Btuh. Single-zone outdoor units are compatible with the new line of Westinghouse indoor units, which includes ceiling cassettes, horizontal ducted, multi-position air handlers, and wall-mount units of various capacity. Multi-zone outdoor units are also compatible with wall-mount units, ceiling cassettes and horizontal ducted. westinghouseac-usa.com

Fujitsu General America has introduced Airzone system, a new communicating zoning system for ducted mini-split and VRF heat hump and heat recovery systems. Available with wireless or wired communication, all Airzone dampers and optional zone modules are connected by a 4-wire cable which provides power and communication. Dampers are positioned to provide optimum airflow into a zone based upon demand monitored through zone controllers. The indoor unit fan is adjusted tomeet the demand of all calling zones. A variety of damper sizes (six to 14 inches) are available. fujitsugeneral.com

The CoilPro CC-400HF from Goodway for cleaning (air-cooled) condensers, chillers, gas coolers and dry coolers operates on AC power and connects to a ¾-in. water line for continuous operation. It offers siphon technology to draw from CoilShine, Goodway's expanding foam detergent (or other non-acidic cleaners), laying on a thick layer of foam and then using the CC400HF technology to blast dirt, grime, and biological matter from coils. The unit includes a sectional three-piece wand for cleaning behind coils and sprays with a 90-degree nozzle attachment for hard-to-reach areas. goodway.com

Napoleon has added the NS18 heat pump and air handler. The heat pump features a variable inverter compressor and vapor injection technology to heat a home in temperatures as low as -30C (-22F). The air handler offers a low and quiet with multiple installation options, it blends into the background as it maintains a balanced, comfortable temperature. The NS18 is compatible with any standard heat pump thermostats, smart thermostats or smart home systems working on 24V. napoleon.com

SunTouch has unveiled SunStat ConnectPlus thermostat. The new connected thermostat allows users to remotely access and control their electric floor warming system, using voice control with Alexa and Hey Google. Other features include a new design with glass front and capacitive touch screen, and remote access through the Watts Home mobile app. In addition, features include a voltage level detector and ammeter with diagnostic screen and wireless technology of 915MHz for connecting accessories (SunStat Relay R4 and ConnectPlus Smart Sensor). suntouch.com

Midea has launched its new EVOX central inverter heat pump system. The side discharge outdoor units support heat pump and dual-fuel heating capabilities, are up to 36% quieter than conventional units, are less prone to natural debris and require less rear clearance (12-in. vs. 24 in. with traditional units). The EVOX AHU includes computational constant airflow (constant CFM Blower) enabling airflow to automatically adapt to the existing ductwork designs and issues caused by blocked coils, dirty filters and improper duct sizing by adjusting output power and fan speeds. midea.com

MODERN HYDRONICS FALL 2022

DISTRICT ENERGY IN NWT

Pellet boiler fires up heating system in Yellowknife.

OPTIMIZING BRAZED PLATE HEAT EXCHANGERS

CIRCULATORS: TEMPERATURE OR PRESSURE CONTROL

TROUBLESHOOTING TIPS & LARGE PUMPS

MH6 SYSTEM DESIGN Differing Deltas

Both temperature control and pressure control of circulators can work when matching flow rate with heating demand, but there are important distinctions.

By John Siegenthaler

MH10 PUMPS

Bright Ideas – Troubleshooting 101

From home maintenance to commercial mechanical room operations, problem solving always requires a plan.

By Mike Miller

MH15 SHOW PREVIEW Modern Hydronics 2022 - The Summit

The sixth edition of the Summit returns as a one-day in-person event with new twists.

By HPAC Staff

MH20 DISTRICT HEATING Heating Yellowknife

New pellet boiler district energy system helps NWT government reduce its carbon footprint.

By Ellen Cools

MH26 COOLING Dew Drop Inn

A quick lesson in condensation prevention when considering radiant cooling.

By

Curtis Bennett

MH28 HEAT EXCHANGERS Opposing Currents

When it comes to designing systems with brazed plate heat exchangers, stick with counterflow piping.

By John Siegenthaler

MODERN HYDRONICS

EDITOR

ASSOCIATE EDITOR

ASSOCIATE PUBLISHER

ACCOUNT COORDINATOR

MEDIA DESIGNER

CIRCULATION MANAGER

PUBLISHER

COO

Doug Picklyk (416) 510-5218 DPicklyk@hpacmag.com Logan Caswell (416) 728-6209 LCaswell@hpacmag.com

David Skene (416) 510-6884 DSkene@hpacmag.com

Kim Rossiter (416) 510-6794 KRossiter@hpacmag.com

Emily Sun esun@annexbusinessmedia.com

Urszula Grzyb (416) 442-5600, ext. 3537 ugrzyb@annexbusinessmedia.com

Peter Leonard (416) 510-6847 PLeonard@hpacmag.com

Scott Jamieson

HEATING UP TO 150,000 BTU/h DHW UP TO 210,000 BTU/h

NCB-H

High capacity, High performance combi-boilers

Navien NCB-H high efficiency combis bring the highest level of whole house comfort to any size home...big or small

• Highest DHW maximum BTUs in residential condensing combi-boilers... up to 210,000 per hour

• Highest DHW flow rate @ 70°F rise... up to 5.4 gallons per minute

• Highest number of BTU sizes for the North American residential combi-boilers

• Highest residential combi-boilers domestic hot water turndown ratio...15:1

• Highest residential combi-boilers heating turndown ratio... up to 11:1

• Highest number of built-in zone controls for valves or pumps... up to three

• Highest full lineup 2" venting lengths... up to 65 feet

• Highest number of cascade capable units with up to 15 tankless water heaters

• High altitude certification... up to 10,100 feet (NG or LP)

Aim high with Navien NCB-H combi-boilers... To learn more visit Navieninc.com

The leader in condensing technology...does it again.

DIFFERING DELTAS

Both temperature control and pressure control of circulators can work when matching flow rate with heating demand, but there are important distinctions.

BY JOHN SIEGENTHALER

Over the years I’ve had a lot of questions asking if I prefer to operate zoned hydronic systems based on a set temperature drop between supply and return water temperature (e.g., ∆T control), or a set pressure drop across the distribution system (e.g., ∆P control).

Both methods of speed control attempt to match the flow rate in the system with the current heating requirements of the building. The ultimate goal is to reduce electrical energy use without compromising comfort.

The choice between ∆T and ∆P control of a circulator has, at times, been the subject of rather “heated” debates. It’s almost as if a few Toronto Maple Leaf fans are disputing superior goaltending with some Calgary Flames fans.

There appears to be some strong opinions involved. Maybe it derives from selfjustification that refuses to believe any opposing view. Perhaps there’s a bit of brand loyalty mixed in, or some mathematical manipulation that “proves” what nature will surely do whenever the system being analyzed is put in operation.

Being someone who’s not ready for a fisticuffs defense of how a circulator operates, or interested in faceless banter on the Internet, I tried to look at this subject from a sterile engineering perspective.

I used software that is based on very accurate empirical models of heat emitters such as finned-tube baseboard to

see what happens to the heat output of a hydronic distribution that is forced to operate at an assigned (and fixed) ∆T as the supply water temperature is decreased. I refer to this as “constrained ∆T” operating logic.

IT WORKS WHEN… What I found is that imposing a fixed ∆T between supply and return can work when the following conditions are all present:

1. Multiple heating zones are controlled

Imposing a fixed delta-T between supply and return requires certain conditions are present in the system. These two examples meet those conditions.

with valves, or multiple secondary circulators supplied from a common primary loop.

2. The system uses low thermal mass heat emitters.

3. The heat source maintains a constant supply water temperature, at the design load value, whenever any zone is calling for heat. Figure 1 shows examples of two systems that meet these criteria.

Consider a low thermal mass hydronic heating system that supplies design load heat output when all zones are active and the supply water temperature remains constant at the design load value. If the heat emitters were not oversized for the design load, all zones would, in theory, remain on until the design load condition subsided (or other factors such as internal gains or intentional thermostat setbacks began influencing the zone loads).

When design load is no longer present in one zone, and the associated thermostat turns off the zone valve or secondary circulator, less heat is being removed from the distribution system. This change reveals itself as an increase in return water temperature (assuming that the supply water temperature remains constant). The temperature difference (e.g., ∆T) between the beginning and end of the distribution system decreases.

A circulator operating based on constrained ∆T logic would sense this decrease and respond by reducing speed so that the design load ∆T was reestablished for the zones that remain active. This process would repeat when another zone turned off. This method of control reduces circulator energy use during partial load conditions.

When a zone turned on, and the supply water temperature remains fixed at the design load value, the return water temperature decreases because more heat is being removed from the distribu -

“∆P control does require the installer to set the circulator for the required ∆P (or in some cases the required head) of the distribution system at design load conditions.”

tion system. A circulator operating based on constrained ∆T logic would sense this increase in ∆T and respond by increasing speed to reestablish the design load ∆T.

MASS MATTERS

The requirement that the distribution system have low thermal mass heat emitters implies that the temperature changes on the return side of the system would appear quickly as zones turn on and off.

A high thermal mass distribution system, such as a heated concrete floor slab, could significantly delay these temperature changes due to heat being absorbed into or released from the thermal mass.

The mounting of the temperature sensors could also affect how quickly the electronics in the circulator respond to the change in temperature.

The constrained ∆T method of control forces the active portion of the system to operate as if it is always at design load conditions. When a zone doesn’t require design load heat input the thermostat for that zone would have to cycle the zone valve or zone circulator on and off to avoid overheating the space.

This, in effect, directs “pulses” of heat into each zone whenever its thermostat calls for heat. The rate of heat delivery during each pulse remains at the design load rate. The duration of each pulse is the time that the zone valve or zone circulator is on.

The design load heat transfer rate multiplied by the “on-time” of the zone determines the total heat added to the space during each pulse.

This method of heat delivery has been

used in millions of North American hydronic systems over many decades. It is generally acceptable if the thermostat differential and boiler high limit differential are reasonable.

It’s important to understand that not all hydronic systems meet the three previously stated constraints.

Many modern systems use outdoor reset control to vary the water temperature supplied to the distribution system based on outdoor temperature. When outdoor reset control is combined with a circulator operating on constrained ∆T logic, the heat output from the distribution system decreases faster than it should based on outdoor reset control theory. This could lead to a reduction in building comfort under partial load conditions.

For this reason, I recommend that circulators using constrained ∆T control only be used in systems that meet all three of the previously stated constraints.

∆P CONTROL

Differential pressure (e.g., ∆P) speed control is intended for use in hydronic systems that use any type of valvebased zoning (e.g., zone valves, thermostatic radiator valves, or manifold valve actuators).

A ∆P circulator operates by continually comparing its pressure differential against some reference condition. The latter could be a fixed value (e.g., constant ∆P control), or a calculated value based on flow rate (e.g., proportional ∆P control).

Constant ∆P is preferred when most of the head loss of the distribution system occurs in the branch (e.g., zone) piping, rather than the “common piping” through

which all system flow passes. This is typical for “homerun” distribution systems.

Proportional ∆P control is preferred when the head loss in the piping mains (rather than the branches) is a large portion of the overall head losses. The latter is typical for “2-pipe” direct-return or reverse-return systems.

A ∆P circulator determines its current ∆P based on the electrical load on the motor, specifically the position of the rotor shaft relative to the magnetic field applied to stator coils.

It uses this information along with a “mapping” of motor operating characteristics to infer both its flow rate and ∆P. It then adjusts motor speed up or down to bring its operating condition as

ducers or variable frequency drives. Response time is short—a few seconds. This is an advantage over ∆T control that depends on the temperature response of two sensors.

∆P control does require the installer to set the circulator for the required ∆P (or in some cases the required head) of the distribution system at design load conditions.

Some installers balk at this requirement, claiming they have no way of determining it.

My response is:

How do you know what size circulator is needed if you haven’t attempted to estimate its operating point when all zones are operating?

IN SUMMARY

Both ∆T and ∆P methods of circulator speed control can work, given the right application and adherence to the constraints mentioned above. Both have been used in the field for several years. Looking ahead, it’s likely that even more refined methods of circulator speed control will be developed, based on multiple sensed inputs, as well as coordination with other hardware in the system, such as boilers or heat pumps. <>

John Siegenthaler, P.E., is a professional engineer with more than 40 years of experience designing hydronic heating systems.

BRIGHT IDEAS –TROUBLESHOOTING 101

From home maintenance to commercial mechanical room operations, problem solving always requires a plan.

BY MIKE MILLER

We have all had opportunities to do troubleshooting.

It seems as though I have been in the troubleshooting business the majority of my professional career. I am often asked, “What is troubleshooting? Where do I start? And what do I do?

In its purist form, troubleshooting is the process we go through to solve a problem. As for where to start? My response is always: start at the beginning.

And when it comes to, “What do I do?”, the answer is, “Develop a plan.”

I’m going to share a simple example of my thought process when it came to solving a small problem at home, and then I will provide you with a real pump troubleshooting situation that I was asked to solve not too long ago.

So, earlier this year I left the office on my way home. The commute is little over an hour. When I first got on the road, I called my wife to give her an estimate as to my arrival time. She informed me that one of the lamps in the living room was no longer working.

She also said that she replaced the light bulb with a new one that she knew was working because she tested it in another lamp. The new bulb did not illuminate. I told her that I had about an hour or so of driving and would think about it on my way home.

Following my own advice, I started at

the beginning and started to list the things that I knew and those that I did not know.

I knew there was electric power available because my wife tested a bulb in another lamp. I also knew there were two lamps in the living room. One lamp was activated by a wall switch and the other lamp was plugged into a live electrical outlet. I know that the lamps are about 26 years old which is the same age as the circuit breaker, the wiring and the receptacle.

What I did not know was which lamp was not working, the wall switched lamp or the live receptacle lamp.

Time to do some interviewing. I called my wife and asked several questions. Her answers revealed the following: the lamp in question is connected to the live receptacle, and that the lamp was working fine the day before.

I could now focus my attention on the lamp connected to the live receptacle which allowed me to develop a plan.

I had about 45 minutes of commuting left, plenty of time to develop a comprehensive plan. I now knew that the problem was either with the house electrical system or the lamp. The house electrical system consisted of the circuit breaker, the house wiring and the receptacle. The lamp consisted of the electrical cord, the lamp switch and perhaps the light bulb.

To eliminate the house electrical system, my plan upon arriving home was to turn off and on the electrical breaker at the electrical panel. The next step was to inspect the lamp switch, the lamp wiring and the receptacle. I have a digital volt/ohm meter, which would make testing the receptacle, the lamp wiring and the lamp switch a breeze.

By this time I was almost home, and I felt confident that I had worked out a comprehensive plan to diagnose and solve the problem.

Upon arrival I asked my wife to put the

Working Smarter Not Harder with Air-to-Water

The latest innovations in air source technology + the clean and efficient characteristics of hydronics = the most capable and highest performing heat pumps available

SpacePak’s Inverter Series of Solstice Air-to-Water Heat Pumps

Heating and cooling for your green building goals, fit for even the coldest of climates.

• Industry leaders of air-to-water technology since 2011

• The most complete line-up on the market for residential and light commercial applications

• Industry proven for reliability, performance, & longevity

• Thousands of installations across the US and Canada

• All-in-one solution for year-round whole house heating, cooling, and DHW offset

• All the advantages of a hydronic system without the use of fossil fuels

• High performance heating capabilities down to -20°F

• Perfect match for radiant and solar applications

• Industry leading 10-year compressor warranty and 5-year parts for certified contractors

Solstice Inverter Monobloc SIM

Solstice Inverter Split SIS

Solstice Inverter Extreme ILAHP

wall switched lamp on so that I could check the circuit breaker. I went into the basement, walked over to the electrical panel and identified the breaker for the living room. Fortunately for me the breakers were well labeled, and I immediately found the appropriate switch.

On and off went the breaker, and on and off went the wall switched lamp. The breaker was not the problem.

I grabbed my volt/ohm meter and went upstairs to the living room. Before proceeding any further, I decided to replace the lamp bulb just in case. I removed the illuminated bulb from the wall switched operating lamp and installed it in the offending lamp. Just as my wife indicated earlier, the bulb did not light up.

The next step was to use my volt/ohm meter and test the receptacle that the lamp cord was plugged into. In order to access the receptacle, I had to move the sofa away from the wall because the receptacle was hidden by the sofa. As soon as I moved the sofa to reveal the receptacle, I had my answer.

At this point you might have guessed that the lamp cord was not plugged into the wall. But you would be wrong.

You see, several years earlier, I purchased a digital timer which can be programmed to activate and deactivate a device such as a lamp based on the time of day. The digital timer has an override switch (or on switch) which allows the digital timer’s outlet to be on continuously. I removed the digital timer and plugged the lamp directly into the wall receptacle and the lamp bulb immediately illuminated.

Problem solved. The digital timer failed and no longer provided power to the lamp.

My troubleshooting steps were correct, and I followed my plan. However, I could have determined the problem earlier if I had been more comprehensive during the interview process.

I should have asked my wife to look behind the sofa to see if the lamp was plugged in. That simple request would

have revealed another possible course of action and I would have modified my plan. Lesson learned.

As promised, let me walk you through a real-life pump troubleshooting problem that I was asked to solve.

I received a call from one of our customers regarding what was perceived to be a pump problem. I asked the customer to provide a brief verbal description of the issue. He revealed the following:

1. The pumps were installed about 10 years ago and have been in service since.

2. The customer is concerned that the flow is less than the original design (approximately 850 GPM) and that the flow may have been less than design for the entire 10 years.

3. There are five pumps installed, four operating in parallel one standby.

4. The original design flow was 1,200 GPM and 25 FT for each pump.

5. The pumps serve a condenser water system with an open cell cooling tower.

6. The cooling towers use an indoor sump.

7. The flow was estimated by measuring the pressure drop across the chiller condenser water barrel with one pump running.

8. The pressure differential was measured across the pump at approximately 25 FT.

I asked for some additional information, including:

1. One line diagram of the piping system.

2. Photos of the piping and pumping system.

3. Water level in the sump relative to the centerline of the pump.

4. Photos of the pump and motor name plates.

5. Pump speed in RPM.

6. Water temperature.

7. Suction pressure with the pumps off measured at pump suction flange.

8. Suction pressure with the one pump running at pump suction flange.

9. Discharge pressure with the one pump running at pump discharge flange.

10. Voltage and amperage at the VFD input with motor operating at design load.

After my initial interview on the phone, while waiting for him to send along his information, I collected some documentation including pump data, motor data and drive data.

Now it was time for me to develop a plan.

I decided to create a four-step plan. The first was to review the published data along with the drawings, and the second was to review the information provided by the customer. I needed to evaluate the data before moving on to steps three and four.

The line diagram along with the photographs indicated that the suction header was at the same elevation as the pump suction connection. In other words, the centerline of the suction header was at the same elevation as the centerline of the pump suction.

The photos also revealed that the discharge gage was reading 11 PSIG (approximately 25 FT) and the suction gage was reading 0 PSIG (0 FT) for a differential pressure of 25 FT at 60 Hz.

The elevation of the water level in the sump was 4 FT above the centre line of the pump. At this point I had a hunch that the suction gauge may not be giving us the actual suction pressure. I contacted the customer and asked for a short video of the suction gauge while the pump was running. The video revealed that gauge dial was resting on the gauge pin at 0 PSIG with no movement.

Time to do some calculations.

The suction header was 20 inches in diameter and approximately 30 feet long and was connected directly to the cooling tower indoor sump. Calculations

Continued on MH14

with installers in mind...more powerful and user-friendly interface. • EZ Setup Wizard

• Wi-Fi, remote access to programming, monitoring, diagnostics and troubleshooting (including access to complete error log)

• Easy-to-read, 7'' touch screen with full color graphics

• Three Zones + DHW control. Expand to six zones with optional N-Link Control

backed by NTI’s legendary support, reliability, and technology. Contact your nearest NTI Distributor or visit ntiboilers.com

proved that with one pump operating, the pressure drop was negligible in the suction header. Therefore, the pressure at the pump suction pipe where it connected to the header should be + 4 FT.

Again, back to the drawings and the photos to determine what was between the pipe connection at the header and the pump suction connection. This revealed a butterfly isolation valve and a basket strainer. I now had enough information to complete my plan.

I asked the customer to replace the conventional suction gauge with a compound gauge. A compound gauge can read pressure values both above and below 0 PSIG.

I also asked the customer to take suction pressure readings with the basket strainer screen both in and out.

Here is what he recorded:

• With all the pumps off the suction

pressure at the pump flange read + 4 FT (basket strainer screen in)

• With one pump running at full speed (1760 RPM) the suction pressure at the pump flange read – 25 Inches of Hg (approximately – 12 PSIG with basket strainer screen in).

• With one pump running at full speed (1760 RPM) the suction pressure at the pump flange read + 3.5 FT (basket strainer screen out).

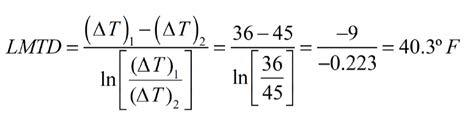

These new readings proved that the actual pump pressure differential was 25 FT – (-12 FT) or 37 FT.

At this pressure differential the pump curve indicated the flow to be approximately 850 GPM. The problem was not the pump but the unanticipated pressure drop of the basket strainer (with screen in).

I recommended that the customer investigate replacing and/or relocating

the basket strainer—problem solved. Admittedly not all troubleshooting problems will be this easy to solve, but the principals are the same.

First, identify the problem. Second, collect data including manufacturers data, drawings, diagrams, field measurements, photos and videos (you can never have too many photos and videos). Third, do some calculations (if appropriate), and finally develop a plan.

Have fun on your next troubleshooting adventure and drop me a line to let me know how you are making out. <>

Mike Miller is vice president of sales, Canada with Taco Comfort Solutions and a past chair of the Canadian Hydronics Council (CHC). He can be reached at hydronicsmike@tacocomfort.com.

MODERN HYDRONICS 2022 - THE SUMMIT

The Sixth edition of the Summit returns as a oneday in-person event.

BY HPAC STAFF

Since 2013 HPAC Magazine has been hosting a one-day Modern Hydronics Summit every two years in the fall, with the event getting bigger and attracting larger crowds every time.

With the pandemic placing all live events on the sidelines in 2021 the HPAC Team made a pivot to hold a virtual two-day Modern Hydronics Summit in March of 2021 attracting viewers from across Canada – drawing the larg-

Continued on MH16

Schedule

The 2022 Modern Hydronics Summit includes five educational sessions delivered by industry experts on topics that will set contractors up for success. Location: Universal EventSpace (6250 Hwy 7, Vaughan, ON)

Thursday, September 15

9:30 am - 10:30 am Registration and Trade Show Floor Open

10:30 am - 11:30 am

11:30 am - 1:00 pm

KEYNOTE Part I: Hydronics for Net Zero Homes (John Siegenthaler)

Lunch & Trade Show

1:00 pm -1:45 pm Zone Circulators or Zone Valves? (Mike Miller, Dave Holdorf)

1:45 pm -2:00 pm Break/Trade Show

2:00 pm 2:45 pm

Critical Nature of Boiler Chemistry (Jeff House, Brian Morgan)

2:45 pm -3:00 pm Break/Trade Show

3:00 pm -3:45 pm

3:45 pm -4:00 pm

4:00 pm -5:00 pm

5:00 pm -5:15 pm

Regulatory Outlook – Boilers & Water Heaters (Tom Gervais)

Break/Trade Show

KEYNOTE Part II: Hydronics for Net Zero Homes (John Siegenthaler)

Sweet Heat Contest Results

5:15 pm -8:00 pm Dinner/Bar

est attendance in the event’s history.

This year, the 2022 Modern Hydronics Summit returns to a traditional one-day in-person format, Thursday, September 17 at the Universal Eventspace located in Vaughan, Ont., just north of Toronto.

THE LIVE EXPERIENCE

While the virtual Modern Hydronics Summit in 2021 provided access to industry professionals from coast to coast, there is no replacing the value of personal interactions at our live hydronics events. Meeting up in person with colleagues who share a passion for this industry, whether it’s sharing a laugh with an old friend or meeting up with new contracting pros, making connections and networking is how this segment of HVAC business continues to grow and prosper.

The trade show portion of the Modern

THANK YOU TO OUR SUMMIT SPONSORS

Platinum sponsor: Resideo.

Keynote sponsor: Caleffi

Hydronics 101 sponsor: NEXT Supply

Tool sponsor: Kane Canada

Event Sponsors: Lochinvar (AquaTech); Roth; Taco; Uponor; Viessmann

And over 60 exhibitors for the trade show featuring all you need for your next hydronics projects.

PLUS: Meet a line-up of HVAC social media influencers as they work on a live pre-fab boiler panel build. In attendance will be: Jess Bannister (@hvacjess); Aaron Bond (@bond_aaron); Terence Chan (@the_impetus); Gary McCreadie (@hvacknowitall1); Tyler Dynes (@dyneshvac); Kiefer Limeback (@toolaholic); Mike Flynn (@flynnstone1); George DeJesus (@Georgetheplumber).

Hydronics Summit will feature over 60 tabletop exhibitors, all specialists in the field featuring technology and services dedicated to this market niche.

And of course the line-up of educational sessions will once again set up attendees for success. Our featured keynote speaker, HPAC writer John

Siegenthaler, will be detailing how hydronic heating and cooling fit into modern Net Zero buildings. He’ll be identifying the advantages of hydronics systems for these applications and how to put the systems together with off-theshelf components to create simple, re -

Continued on MH18

peatable designs. Attendees will also be entered into a draw to win a signed copy of Modern Hydronic Heating for Residential and Light Commercial Buildings (4th edition) which was released this spring.

Other presentations will include: the pros and cons of zone valves and zone circulators; a dive into boiler chemistry; and a look at current and pending regulatory changes and how they will effect new and retrofit hydronic system design.

There will be draws for useful tools after each session, and there will also be Blue Jays tickets up for grabs. Along with a day of education and networking, registration also includes lunch, dinner and a post-event drink.

SOCIAL ENGAGEMENT

Also, live on-site a team of HVAC social media influencers including Gary McCreadie, Aaron Bond, Terence Chan, Jess Bannister, Tyler Dynes, Kiefer Limeback, Michael Flynn and George DeJesus will be working on prefabricating three boiler panels. These HVAC pros will be interacting and live streaming action from the event while also sharing their own tips and tricks using the latest products and tools available.

“There is no replacing the value of personal interactions at our live hydronics events.”

HYDRONICS 101

For the first time this year’s Modern Hydronics Summit is adding a special track for those who are new to the industry or looking to improve their knowledge on hydronic systems and the components that make them work.

This parallel track is being designed for HVAC or plumbing contractors who are considering adding hydronics to their repertoire, or those who want to get their technicians up to speed.

We have dedicated space at the Summit where industry experts will walk attendees through the basics of hydronic systems and help them understand why this technology is growing so rapidly. Each session will be hosted by a product expert and every session will be very interactive and a lively Q&A will be encouraged!

SWEET HEAT

In the Fall of 2020 HPAC magazine launched the first ever Sweet Heat contest, inviting hydronic contractors across Canada to get their cameras out and share their creativity, artistry and resourcefulness in delivering “Sweet Heat” to their customers.

The response was great with over 30 entries last year. For 2022 a generous sponsorship has been attached to the contest, with winners this year (one commercial and one residential project) will each be receiving a $3,000 spending spree courtesy of their local EMCO location.

In addition, the winning entries will be featured in the October 2022 edition of HPAC.

The Sweet Heat prizes will be awarded after the final session at this year’s Modern Hydronics Summit.

REGISTER NOW

The 2022 Modern Hydronics Summit takes place September 15th. Registration is $99 (plus tax & service charge, $119.84 incl.) for the main event, special pricing is available for groups and Hydronics 101. For more information and to register today visit: modernhydronicssummit.com. <>

You expect your boiler to provide enough hot water for both your kitchen and bathroom, as well as enough heat to make your home cozy and snug. Combining DHW & space heating in a single compact design featuring two independent copper waterways embedded in a cast aluminium heat exchanger, the SFC Combi is designed to do just that.

The SFC Combi contains cutting-edge, solid-state electronics to control its gas valve, fan and ignition. By doing so, we’ve succeeded in reducing the number of moving parts, made servicing simple, and increased reliability.

www.ibcboiler.com

HEATING YELLOWKNIFE

New pellet boiler district energy system helps NWT government reduce carbon footprint.

BY ELLEN COOLS

As more communities become aware of the benefits of using biomass to heat and power their buildings, more district energy systems are coming online in Canada. Remote northern areas in particular have recognized the opportunity to use bioenergy to reduce their reliance on fossil fuels and lower their greenhouse gas (GHG) emissions.

J&R Mechanical, a plumbing and heating contractor in Yellowknife, NWT, is one of the companies leading the charge. Last year the company began operating a new $1.1-million district energy system, called the Woolgar District Heating System, to provide heat to a government of NWT (GNWT) warehouse and three other private businesses, helping to reduce the government’s reliance on fossil fuels.

BRINGING BIOMASS NORTH

This is not the first time that J&R Mechanical has installed a district energy system. According to owner Ken Miller, the company, which was founded in 1977, has been installing biomass boilers for over 12 years. When these types of boilers started becoming popular in the NWT, the territorial government embraced the potential environmental benefits of using wood pellets instead of fossil fuels.

Consequently, “Our government contracts were specifying installations with biomass – in schools predominantly, at first – and that’s how we got involved in biomass,” Miller says. “In the years after

that, when tenders would come out for different systems, we focused on that as part of our regular scope of plumbing and heating. The heating became biomass, and we became a prominent installer of biomass boilers for the government and the private sector.”

Around the same time, J&R Mechanical began installing district heating systems for different government clients. Their first system was for an Indigenous government client in Behchok , NWT, installing a plant that

Continued on MH22

This 200-kW heat transfer station at the GNWT warehouse in Yellowknife allows J&R Mechanical to meter the heat for billing clients. It also provides a hydraulic disconnect between the client building heating system and the district heating system.

assistant

Introducing Viguide

Our new Viguide app connects to any Vitodens smart generation boiler to streamline and simplify each installation.

+ All-in-one app for installation, service, maintenance & monitoring

+ Enhanced customer experience maintenance reminders

with annual automated

+ Faster installation with guided step-by-step start-up and commissioning reporting

+ Simplified maintenance with replacement parts guide

+ Proactive monitoring with remote diagnostics & notifications

DISTRICT HEATING

provides heat to eight buildings from one biomass boiler.

“As we continued to do more and more of those, we had this opportunity to propose a project that was literally right in our backyard – the Woolgar District Heating System – and the main client is the GNWT warehouse,” Milller says. “They have a list of buildings they wanted to switch to biomass, and this one was on their list.”

The territorial government agreed to their proposal to switch the warehouse over to a district heating system. J&R Mechanical also approached other businesses in the area that could benefit from the system, which led to 30% of the block coming on board.

The project took two years from proposing the idea to completion, including the planning and design, permits and installation.

J&R Mechanical ran into a few issues during the construction and installation process, mainly permitting issues, Miller says.

“You can only dig in the summer here, so we started the project too late to get everything – the permits and all of that – on time in the previous summer (2019),” he explains. “Even into the con -

struction season, in the summer of 2020, we were delayed because of permits. We didn’t have everything in place. So, it took us into the winter, which caused some issues for us and left us with some seasonal deficiencies.”

But, the system officially came online in March 2021, and has since been providing heat to the three businesses, the GNWT warehouse and a GNWT data centre that is connected to the warehouse.

FROM WOOD PELLETS TO HEAT

The system itself is fairly simple, with two main components: a shipping container housing a 1330 MBH (390-kW) Viessmann Vitoflex 300-UF boiler and a silo to store the wood pellets.

Fink Machine of Enderby, B.C., the supplier, assembled the boiler in the containerized plant, which was then shipped to J&R Mechanical, who installed it and connected it to their own systems. Meanwhile, the wood pellets came from a pellet plant in Alberta.

According to Miller, the system is very similar to any other hydronic heating system: “You heat water and you transfer the heat to buildings through various different types of heat exchangers, whether it be baseboard radiation or

unit heaters, radiant in-floor heaters or radiant panel heating.

“The process of burning wood pellets to create the heat source is the only real difference,” he continues. “We unload and load them, redistribute them to different silos in the community where these pellets are then extracted by augers or different devices to feed the boiler, based on the demand for heat.”

The boiler produces heat, water vapour, carbon dioxide and ash. The heat from the water vapour is transferred to each building’s space heating system through underground pipes, Miller explains.

Yellowknife, of course, is extremely cold in the winter, which means the system has to be able to operate in a harsh climate. So far, there have been no issues with the boiler, Miller says.

“The average design temperature here is to -45C; we’ve seen the boiler operate just perfectly in those tempera -

J&R Mechanical in Yellowknife has been installing biomass boilers for over 12 years.

The pellet boiler fired up.

PHOTOS COURTESY

tures,” he says. “It’s operating as it was designed to operate, with low maintenance and fairly high efficiencies. It’s worked out well.”

REDUCING FOSSIL FUEL RELIANCE

The system has also had a big impact on the NWT government’s fossil fuel use, as it has cut oil use for the warehouse by 92% – from 60,000 litres per year to just 4,800 litres. The system has also reduced the warehouse’s GHG emissions by 145 tonnes of carbon equivalent.

The project, which cost $1.1 million, was a big capital investment for J&R Mechanical. The NWT government gave the contracting business a $274,000 grant for the project, but the company footed the rest of the bill. However, Miller says their business plan calls for paying off that investment in four to five years of operations.

So far, the feedback from the community and the territorial government has been very positive, Miller says. He believes there are opportunities for other northern communities to develop simi -

“The average design temperature here is to -45C; we've seen the boiler operate just perfectly in those temperatures.”

lar district energy systems using woodburning boilers to reduce their reliance on fossil fuels.

“I think everyone is looking at them as a better solution – looking at biomass boilers to heat buildings – so I think it has been kind of proven that this is a good way to go,” he says.

Nevertheless, there are a few barriers to overcome when installing a system like this. One such challenge is understanding the potential impact on a community’s infrastructure.

“We bury pipes in the ground, and that can be very disruptive,” Miller explains. “There’s other stuff in the ground that you don’t see – power lines, water and sewer pipes, telephone lines and things like that, depending on where you’re trying to install it. So, engineering

design can be a big challenge.”