MATT NICHOLLS is editor

of Helicopters

arlier this year, Helicopters highlighted OEMS, operators and industry leaders who are enhancing the safety landscape both here in Canada and around the world. In our special Innovation in Canadian Rotary Safety Week Aug. 21-25, Helicopters showcased companies such as Vector Aerospace, Heli-One, VIH Aerospace and more, who are innovating with new technologies and processes in the maintenance, repair and overhaul (MRO) space.

We followed that up with our Canadian Innovation in Rotary Safety Week Sept. 11-15, showcasing companies such as Airbus Helicopters Canada, who not only honouring the best and brightest safety leaders each year with their Innovation in Safety Award, but have created a series of safety seminars for a wide cross section of operators (For more, see “Innovating for Safety,” pg. 6.)

As Romain Trapp, president of Canada and COO North America, Airbus Helicopters aptly told Helicopters, every operator, OEM and end user connected to the helicopter industry is affected by an accident – all parties must work in unison to create functional safety cultures and best practices that get results.

Helicopters correspondent Walter Heneghan further highlights the need to take ownership and responsibility of your personal safety role in his piece, “Just Culture, SMS and You,” page 20. Heneghan notes that safety is a shared responsibility, one in which all members of an operation need to embrace and adhere to at all times. A proper

fatal accidents within the U.S. helicopter community. The industrygovernment based team has set its sights on reducing the number of accidents to .61 fatal accidents per 100,000 flight hours. The fatal accident rate for 2017 is .069. The USHST breaks its new recommendations into four categories: loss of control (five new safety enhancements); safety and management (seven safety enhancements); competency (six safety enhancements); and IMC and visibility (four safety enhancement). Some of its key objectives include:

• Develop and promote recommended practices for pilot and nonflying crewmembers to detect increased risk levels during the course of a flight; effectively communicate the increased risk level to each other; and make a decision on the appropriate risk mitigation

• Develop best practices for – and promote the teaching of threat and error management (TEM) – as part of initial and recurrent pilot training

• Research, develop, and promote the use of enhanced helicopter vision systems (EHVS) technologies (such as night vision goggles, enhanced vision systems, synthetic vision systems

• Develop training for recognition of spatial disorientation and recovery to controlled flight. Emphasize the use of all available resources installed on the aircraft, including automation such as increased use of autopilot

All parties must work in unison to help create functional safety cultures and best practices that get results.

safety culture is an “informed’ culture – one that’s not based on the adage of “that’s how we do things around here.” There’s infinitely more to it than that.

South of the border, the U.S. Helicopter Safety Team (USHST) is upping its game in the establishment of enhanced safety practices for the U.S. market – setting a sound course for the global helicopter community to follow. In September, the USHST released an in-depth analysis of the root causes of fatal accidents. It developed 22 measurable safety enhancements aimed at reducing fatalities.

From 2016-2019, the USHST is focusing its attention on reducing

• Develop guidelines and recommended practices for helicopter preflight inspection, final walk around, and post flight inspection and promote the recommended practices to the training community and general pilot community

• Promote the installation and use of data recording devices (such as HFDM, camera recording) for purposes of detection and monitoring of aircraft and engine limitations that were exceeded; collecting and preserving more data relevant to accident investigation.

Ensuring top safety levels exist in all facets of the industry is the driving force that unites industry-government partnerships such as the USHST and IHST (International Helicopter Safety Team), operators, OEMs and end users. Innovating in safety processes, technologies and procedures to help reduce accidents will always be the main objective.

Safety is paramount in the Canadian rotary-wing industry and Fort Erie, Ont.-based Airbus Helicopters Canada is leading the way in developing new processes, programs and technologies to keep the blades turning.

Several of these processes were highlighted in Helicopters special Innovation in Rotary Safety week Sept. 11-15. The week also showcased key initiatives from other OEMS and rotary wing operators and manufacturers. For more go to: http://bit.ly/2wY1Po

Airbus Helicopters Canada president and CEO Romain Trapp explained to Helicopters that programs such as its Innovation in Safety Award, annual Safety Seminar for private operators – held this May in Montebello, Que. – and the company’s International Powerline Symposium set for Nov. 14-15 in Alexandria, Va. all work in concert to develop best practices and a sound working environment both in Canada and abroad.

The Innovation in Safety Award is handed out annually at the Helicopter Association of Canada (HAC) conference to an individual or company that displays advancements and accomplishments that work to uphold safe flying practices.

Selected by a panel of esteemed industry professionals – including Helicopters editor Matt Nicholls – the Innovation in Safety Award is a reflection of the high level of professionalism that exists throughout the Canadian rotary landscape.

Previous winners of the award include Geoff Goodyear, president of Universal Helicopters; Paul Spring, president of Phoenix HeliFlight; Blackcomb Aviation; B.C. Hydro; and Don Wall, HNZ Topflight. A new winner will be selected at the HAC conference Nov. 9-11 in Ottawa.

“Safety is our No. 1 priority and when you approach safety with helicopters, you need to approach it though different angles because operators are different – and they all face different challenges,” Trapp said. “The Innovation in Safety Award highlights these challenges.”

Developing a pair of industry-leading safety events is another way Airbus

Helicopters Canada is taking a leadership role in safety innovation. Both provide classroom and training to operators from coast to coast, creating an ideal platform for enhanced training knowledge.

“The Safety Seminar provides a platform for private customers to discuss with one another best practices and more importantly to receive up-to-date training,” Trapp noted. “And promoting safety in a powerline environment is important because it is dangerous by definition –which is why we created the International Powerline Symposium. This was also developed out of necessity to bring the utility, powerline and hydro communities together,

including everyone from operators to end users. The goal is also to establish best practices.”

Airbus Helicopters Canada is also working to enhance its own productivity and efficiencies in Fort Erie. It has improved its safety footprint and enhanced productivity by adding 5,000 sq. ft. of MRO capacity at its home base for both domestic and international customers.

“Connecting maintenance data and aircraft data helps us to improve our support by being more proactive,” Trapp said. “And at the end of the day, it has helped us improve the reliability of our aircraft . . . we have learned what works well, and what doesn’t work as well.”

The 2017 Helicopter Association convention and trade show goes Nov. 9-11 in Ottawa and this year’s theme “Advancing Safety in Challenging Economic Circumstances” is fitting considering operators are striving for ways to survive and thrive in challenging market conditions.

HAC is stepping up its safety offerings this year partially in light of the relocation of the CHC Safety & Quality conference. CHC moved the popular safety event from Vancouver closer to its home base of Dallas, Tx. The event also moved to the end of September from its usual springtime slot.

The annual HAC convention and trade show is ready to rock the nation’s capital. (Photo by Matt Nicholls)

Building around its theme, one day of this year’s HAC educational lineup will be dedicated solely to safety. The association is also bringing in a number of heavy hitters to share their insights on improving the safety spectrum. Some of this year’s key presenters include:

• Dr. Scott Shappell, department chair and professor of human factors from Embry-Riddle Aeronautical University

• Graham Braithwaite, director of transport systems, professor of safety and accident investigation at Cranfield University.

Additional speakers and educational sessions worth checking out from this year’s program include:

• Fatigue Management Systems 101, presented by Transport Canada’s Rosalie Kamp

• Letting the Helicopter Air Taxi Accidents Speak for Themselves, Kathy Fox, Chair Transportation Safety Board of Canada

• Sharing the Sky with UAVs, Mark Aruja, Chair, Unmanned Systems Canada

• Significant Developments in Labour Relations for Helicopter Operators, Steven Williams, Emond Hamden LLP

For more information on the event, see www.h-a-c.ca/convention.html

Helijet International Inc. is installing Night Vision Imaging Systems (NVIS) in all three of its dedicated air ambulance helicopters. Helijet is the helicopter air medical contract service provider for the B.C. Ambulance Service.

Helijet operates a fleet of specially equipped Sikorsky S-76C+ medical helicopters on a 7/24 basis from its Vancouver International Airport and Prince Rupert/Seal Cove base facilities under long-term contracts with BC Emergency Health Services, which operates the B.C. Ambulance Service.

NVIS is a proven technology used primarily by first responder flight operations such as air medical, search and rescue and law enforcement.

NVIS is also referred to as night-vision goggles. The technology uses image intensifier tubes to produce an enhanced image of a scene in light conditions too low for the normal human eye to identify clearly during navigation and pilotage.

Under an agreement with BCEHS, Helijet will install NVIS into the HS abd three dedicated air ambulances, with the $1.6 million installation cost being financed by Helijet International.

Once operational, NVIS will enhance cockpit flight operations to provide greater pilot situational awareness with the objective of achieving safer mission completion during night flight operations.

To complete this complex

HELICOPTERS MAGAZINE

P.O. Box 530

105 Donly Drive South Simcoe ON N3Y 4N5 Tel.: 519-428-3471 Fax: 519-429-3094

Toll Free: 1-888-599-2228

Website: www.helicoptersmagazine.com

EDITOR MATT NICHOLLS email: mnicholls@annexweb.com 416-725-5637

MEDIA DESIGNER BROOKE SHAW

CONTRIBUTING WRITERS

RICK ADAMS, DAVID CARR, BRIAN DUNN, PAUL DIXON, WALTER HENEGHAN, FRED JONES, JAMES MARASA, CARROLL MCCORMICK, COREY TAYLOR

NATIONAL ADVERTISING MANAGER MENA MIU email: mmiu@annexweb.com 416-510-6749

ACCOUNT MANAGER KORY PEARN email: kpearn@annexweb.com 519-902-8574

ACCOUNT COORDINATOR BARB VOWLES Email: bvowles@annexbizmedia.com 416-510-5103

GROUP PUBLISHER MARTIN MCANULTY email: mmcanulty@annexweb.com

COO TED MARKLE EMAIL: tmarkle@annexweb.com

PRESIDENT & CEO Mike Fredericks

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO ANNEX PUBLISHING & PRINTING INC., P.O. BOX 530, SIMCOE, ON N3Y 4N5 CANADA. email: subscribe@helicoptersmagazine.com

Published five times a year by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0227-3161

CIRCULATION

Email:apotal@annexbizmedia.com Tel: 416-510-5113

Mail: c/o Circulation, 80 Valleybrook Dr. Toronto, ON M3B 2S9

aircraft installation, Helijet has partnered with Saanich, B.C.based VIH Aerospace, along with Rebtech Technologies and Night Flight Concepts, both of which are leading industry-recognized NVIS technology installers and service providers to the global aviation community.

“This equipment will significantly enhance our current air ambulance service delivery, allowing us to provide services where we couldn’t before and dramatically increasing safety where we have,” noted Helijet’s director of flight operations, Brendan McCormick.

Helijet’s flight crew plan to be fully ground and flight trained on the use of this technology by early 2018.

SUBSCRIPTION RATES Canada - 1 year $29.95 USA- 1 year $54.50 Foreign - 1 year 60.00 plus applicable taxes www.helicoptersmagzine.com/subscribe

Occasionally, Helicopters magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Helicopters Magazine is an associate member of the following Canadian aviation associations:

This issue let’s talk about our maintenance brethren. Often unappreciated, the fact remains that without our AMEs, we would have nothing to fly and no work. So, let’s address the safety side of maintenance in our daily helicopter operations.

Our industry tends to be “ops-centric” when it comes to the regulatory framework and most safety systems that I have observed also mirror this focus. Duty days, fatigue management, manning levels, programmed time off – all these areas are addressed for pilots in ops manuals but rarely in maintenance manuals. Safety management systems (SMS) address hazards and risks but often come up short when it comes to identifying and mitigating the real risks around maintenance activities. So let’s explore this matter.

For starters, the maintenance world varies considerably. Helicopters often work remotely, isolated far from home. We have urban bases that provide greater degrees of support for base and line maintenance and finally, major MRO centres for heavy, depot level maintenance activity. Each of these locations poses unique risks and should be managed accordingly. I will address those areas that are common to all maintenance activity: personal protective equipment (boots, eye and especially hearing protection), working from heights, exposure to chemicals and tool control. How many of you know someone who is missing a finger? There are a lot of moving parts around helicopters – and jewelry has no place being in their orbit.

equipment. The requirement for the use of some form of fall protection varies by jurisdiction and can be as low as 1.3 metres above ground level to a more common 1.8 – 2.0 metres above ground level. This means that either passive (handrails, climbing helmets, work stands) or active (yo-yo systems or full body harnesses with clip on tails) protection is required. I have observed too many occasions where a desire to “get’er dun” has trumped taking appropriate precautions. A fall from a height of two metres can cripple, paralyze or kill you. Here are some sobering stats: From July 2003 through 2011, a SafeWork Australia study showed that 11 per cent of all workers killed in that period died as a result of injuries suffered from falling, with workers aged 45 and over comprising 70 per cent of the fatality group.

In the same period, more than 7,500 claims for serious injury were lodged meaning that 21 employees per day filed a lost time injury claim for time off work. Closer to home, from 2010-2014 in Ontario, there were more than 6,500 lost time injuries from falls from heights.

Finally, a WorkSafe BC report from 2014 showed an average of eight fatalities per year over five years from falling from heights. Mitigation is available, is not necessarily expensive and is mandated by labour law. So, if your workplace plays fast and loose with working from height training and mitigation, stand your ground and ensure that you are protected!

An overlooked area for maintenance operations is the provision and use of adequate fall protection equipment. ‘‘ ’’

From a personal protective equipment perspective, perhaps the big items are safety glasses/goggles and hearing protection. There are plenty of solutions available for ensuring that your hearing is protected: standard ear defenders, “popcorn” and custom made earplugs.

This last item has proven to be a very effective, portable, and lightweight solution and many companies provide this service to their employees. Remember, hearing loss is cumulative and forever so wear protection for ground runs, compressor washes and anytime you are working with a running aircraft. An overlooked area for maintenance operations is the provision and use of adequate fall protection

Finally, I wanted to highlight something about human factors training, a Transport Canada mandate for all AMEs. Every few years all maintenance staff must undergo this recurrent training. More companies are now opting for e-learning or on-line solutions as a cost cutting measure. What is your personal individual commitment to brushing up on the human factors aspects of maintenance operations? For this type of training, I am not a fan of e-learning. The real advantage of human factors training is the interaction among course mates about their experiences on the job. Pay attention to this recurring event – it is important to take heed to the lessons provided, incorporate them into your personal practice and stay safe.

Walter Heneghan is an experienced and well-travelled pilot who has served as the top safety professional at Canadian Helicopters and Summit Aviation. He is currently working with CHC Helicopter in Kazakhstan as an SMS development specialist. He is a regular contributor to Helicopters and Wings magazines.

PAUL DIXON

Rain has finally arrived on B.C.’s south coast – and maybe, just maybe, there will be an end to the 2017 fire season. It’s been a record year for wildfires in B.C. and as we passed through the Labour Day weekend, the nominal finish line, there was no end in sight.

It is mind-boggling to get your head wrapped up around what has happened this year and what continues to happen in B.C. We may well have reached the tipping point. Are we going over or can we pull back in time? That’s a question that needs to be addressed and the sooner, the better.

The irony of this summer is that by most indicators there wasn’t much to worry about earlier in the season and then suddenly, at the beginning of July – WHAM! The fire season literally exploded during the first week of that month, forcing a wave of evacuations throughout central B.C. The irony of the situation it the evacuation centres that received fire victims were still dealing with people who had been driven out of their homes by flooding.

Think about that for a moment – from floods to wildfires in the space of little more than a week. There are three mega-fires from that first week in July, still burning well into September – all still classed as “out of control.” The Plateau fire, west of Williams Lake, is the result of a number of major and minor fires coming together as it were. Today, it is estimated to cover 525,000 hect-

who have lost their homes and everything that entails. Some 53 million cubic metres of timber are gone in B.C., lost forever. The economic impact on the forestry and resource sectors is incalculable at this time. The summer tourist season has been lost for a huge portion of the province and that is another key economic driver in the region. The reality is that as houses and businesses are lost and jobs put on hold or disappear altogether, the bills still have to be paid. Mortgages. Rent. Business loans. The damage is so much deeper than just the scars left by the fires.

The province of B.C. needs to reassess its entire firefighting philosophy. B.C. is not in this situation alone – it’s certainly a global occurrence and the future is going to get worse not better. One of the axioms of emergency management is that no matter what you are doing and no matter how dire the situation is, it can always get worse and you need to be learning from today to be better tomorrow.

The B.C. government has exclusive contracts for half a dozen medium and light helicopters, relying on call-when-needed agreements for additional resources, especially heavy-lift. For the time I’ve been following the rotary world on the West Coast, this is one issue that sticks in the craw of local operators that fly the big iron. They sign up at the beginning of the season, but I have to wonder how many machines are still in-province if and when the need arises. When they need those helicopters, they need them today, not tomorrow and definitely not next week.

Spending a little more money up front to increase available resources could pay huge dividends down the road.

ares, just slightly less area than Prince Edward Island. To the southwest of Williams Lake is the Hanceville Fire at 295,000 hectares, while the Elephant Hill Fire near Ashcroft is about 195,000 hectares. Based on the numbers released by BC Wildfire Service, there are approximately 1,400 firefighters and more than 50 helicopters engaged on those three fires.

Over the past 10 years, the average annual loss to wildfire has been 155,000 hectares. As of mid September, 2017 is approaching 1.2 million hectares, almost twice the size of Toronto by comparison. The losses are staggering. It’s not just the people

Adding to the frustration level in B.C. this year has been the slow-motion swing of the political pendulum from the Liberals to the minority NDP government. That only took about four months to happen and for much of that time, not to mention the run up to the election in May, there has been very little actual leadership from government.

It’s time to start thinking about a more strategic plan in terms of what resources will be contracted and where they will be placed. The time to start preparing for next year is now. Spending a little more money up front to increase available resources could pay huge dividends down the road. Just ask someone who’s home and job went up in smoke this year.

Paul Dixon is a freelance writer and photojournalist living in Vancouver.

COREY TAYLOR

One of the themes of this issue is innovation, and for some time I struggled to start, since the rate of advancement in aviation is breathtaking and we risk being replaced by robots in the not too distant future. Then it occurred to me, that innovation isn’t about just technology, or methods, or brilliant marketing schemes – it also applies to policy and to the direction an industry may move.

In 1919 Canada was the first country to enact legislation over all aspects of aviation. Yes, the first. Soon, we were home to the world’s largest helicopter company (70 years this past Aug. 9), making Canadians the first to learn how to fly in the mountains, the first to move drills with long lines (and the first to have drillers fast enough to avoid injury!), the first to run drip-torches and the first to throw water on that fire when it got away. We ought to be very proud of all the firsts Canadians have achieved.

These stunning achievements are even more remarkable considering they were accomplished through a regulatory structure that has no resemblance to anything one would design if commercial success was a consideration. The Federal Aviation Administration (FAA) is a common source of complaint south of the border, yet the FAA, from inception, was tasked with “fostering air commerce” (in its official charter).

Our American brethren like to say that nobody in the FAA is aware of that part of their mandate, but the U.S. has built the world’s largest helicopter industry in a country crisscrossed by roads and rail. I tried in vain to find anything resembling this in Canadian literature, but the closest I could find was, “Transport Canada is

it’s

by government, but rather by their peers – people who know what they know, who understand the challenges and limitations of the technology and the people, and who are bound together in common cause.

Well, I think it is high time we look backwards and borrow from the most innovative group that ever threw a tea party. I refer, of course, to the American Founding Fathers. With apologies to Thomas Jefferson, I declare the following:

When in the course of helicopter operations, it becomes necessary for the operators to resist the regulations imposed on them by their regulator, and to form a regulatory college as the doctors, lawyers and architects have done, a decent respect for the opinions of the public requires that they should declare what causes to impel them to the separation.

We hold these truths to be self-evident, that helicopters are not airliners, they do not fly long hours over dark oceans through many time zones, they have short legs, love to hover and move things through the use of vertical reference.

That to ensure the safety of helicopter operations, a regulator was appointed by the government, deriving their just powers from the consent of the governed. That whenever any form of regulation becomes destructive to these ends, it is the Right of Operators to abolish it, and to institute new government, laying as its foundation the principles established over decades of the blood and sweat of pilots and engineers, and organizing in such form as to those that will seem most likely to effect the safety and security of the industry.

We ought to be very proud of all the firsts Canadians have achieved. “ “

responsible for ensuring the regulations are current.”

Now, I understand where the desire to throw away our legacy of being first in all things, in order to enact European based regulations with regard to Flight and Duty limitations, arises from. I guess in some ways, if you know little about the industry you are regulating, it might seem logical to adopt another continent’s standards, regardless of how they fit our 3.8 million square miles of undeveloped splendour.

These disconnects between the governors and the governed are why physicians and other professionals are not regulated day-to-day

Prudence, indeed, will dictate that a regulator, long established, should not be changed for light and transient causes, and all experience has shown that operators will tolerate onerous and non-sensical regulation rather than right themselves by abolishing the forms to which they are accustomed. But when industry concerns of the greatest magnitude are ignored in favour of 705 operations that bear no resemblance to helicopters, this movement towards despotism must be stopped.

We, the operators, move to form the College of Helicopter Professionals. This innovative group will oversee and regulate all operations within Canada. It will promote commerce and safety above all. We cast off the yoke of the regulator, who have abrogated their responsibility in favour of political expediency. Resist.

Corey Taylor is the vice-president of business development for Newfoundland’s Universal Helicopters.

RICK ADAMS

When I caught up with Stephen Dengler in early August, he was a bit frosted. “The weather has been against us the whole way,” he commented. They were stuck in Nome, Alaska for a couple of days, and he had “no idea” when he, his father, and former Bell Helicopter test pilot Rob ‘Dugal’ MacDuff would complete their world circumnavigation in a Bell 429 GlobalRanger.

But 77-year-old W. Robert “Bob” Dengler was not to be denied his round-the-planet dream flight with his son. A year ago, Bob had been through cancer chemotherapy treatments. Their original third man, Bruce Laurin, also a former Bell test pilot, had died in September 2016. Fickle weather had dogged the Denglers from the start of the flight on Canada Day, July 1, causing several changes of flight plan, even grounding them for five days in Iqaluit. They decided to steer clear of Vancouver because of wildfires in central B.C, so as not to jeopardize the safety of the crew and add to the workload of air traffic controllers.

But Dad Dengler had been thinking about this mission since buying the 429 in 2010 (the first Canadian customer), and they’d been doing heavy-duty planning for two years. Bob had even tuned up for long-distance flying with a 4,400-nm jaunt from Toronto to Baffin Island in 2015 (with wife Patricia and Laurin).

The co-founder of Dynatec Mining also summited Mount

The Intrepid Denglers’, Rob MacDuff

at the Bell Helicopter Textron Canada facility in Mirabel, Que.

“It was the ideal aircraft for this Canadian-born odyssey,” said Bell president Cynthia Garneau.

The historic father-son flight also raised funds for Southlake Regional Health Centre in Newmarket, Ont., and the True Patriot Love Foundation, a national charity that helps Canadian military families.

“We had the honour of carrying the pride and spirit of the Canada 150 celebration around the world,” Steven said. “Over seven weeks, against the backdrop of a trip around the entire world, we experienced highs and lows, had adventures, surprises, saw unforgettable sights and amazing people.”

Twenty-five years ago, a Bell helicopter was the first to circumnavigate the globe. Ross Perot, Jr., famous at the time as the son of businessman U.S. presidential spoiler candidate Ross Perot, Sr., and Jay Coburn, a veteran Vietnam War helicopter pilot who had also helped rescue Perot employees from an Iran jail, flew a Bell 206L-1 LongRanger II 26,000 miles across 26 countries in 29 days.

Australian Dick Smith was the first to solo circumnavigate in a LongRanger III. He also took his wife, Pip, around the world in a Sikorsky S76 in 1994-95. Brit Jennifer Murray was the first female pilot to complete the circle, in a Robinson 44 with Quentin Smith, which was also the first piston-powered rotorcraft.

Despite the fact that it’s this big, powerful helicopter, it’s smooth as glass to fly. ’’

“

Kilimanjaro, at age 74.

Bob rotated as pilot-in-command with MacDuff, who has flown a dozen different Bell models. Steven, a fixed-wing pilot for a decade who is nearing his 429 certification, handled left seat duties.

He said of the 429: “Despite the fact that it’s this big, powerful helicopter, it’s smooth as glass to fly.”

The Bell 429, of course, is a Canadian-built aircraft, produced

The speed record is owned by Simon Oliphant-Hope of the U.K. in 17 days, 14 hours, 2 minutes, 27 seconds. The Denglers and MacDuff are the 12th to achieve the feat in a helicopter, and of course the first father-son combo. When the trio departed, the Canadian dollar was trading at 77.134 cents to the U.S. dollar, according to XE, the currency exchange website founded by Stephen Dengler.

By journey’s end, the CAD was up about 2.5 per cent. If they were to make another record-setting attempt soon, the entire Canadian economy would no doubt be appreciative.

Rick Adams is chief perspective officer of AeroPerspectives, an aviation communications consultancy in the south of France, and is the editor of ICAO Journal.

BY PAUL DIXON

n June of this year, Danny Sitnam, president and CEO of Helijet International Inc., was inducted into Canada’s Aviation Hall of Fame at the CAHF’s 44th annual Gala Dinner. The event was held on the departures level concourse at Vancouver International Airport (YVR).

The Vancouver Police Department Pipe Band behind an honour party that included The Honourable Judith Guichon, Lieutenant Governor of British Columbia, escorted the 2017 inductees, Errol Boyd, Robert Deluce, Rogers Smith and Sitnam into the dinner.

The formal notice from the CAHF of his induction began, “As a helicopter pilot and entrepreneur, Danny Sitnam has built Helijet International Inc., to become the world’s largest scheduled helicopter passenger service, also offering rotary and fixed wing aircraft for charter and medical service. Danny is known for leadership, professionalism and his interest in offering growth opportunity for his employees.”

In his remarks to the audience, Danny had little to say about himself and much to say about the people that have been there with him – and for him – on this journey. In a voice tinged with emotion, he spoke of his parents, brother, business partners and employees at Helijet, and his wife and children.

Ten days after the dinner, we sat in Danny’s office and he was still mulling over the evening. “It hasn’t hit me yet, but it will. I think about the inductees and what they’ve done, the stories I heard that evening and the people I met.” Danny Sitnam speaks softly and while he laughs easily, there is intensity within him. You can see it in his eyes, always alive and alert. On the wall of his office is a poster-sized photo of the Aérospatiale Gazelle, the acorn from which Helijet International sprouted.

The young Danny Sitnam trained as a machinist but got the

flying bug after his first ride in a helicopter. A week after completing his training, he found himself ferrying that same helicopter north to the Yukon. Jump ahead a few years, he was back in North Vancouver and owned that Gazelle with a couple of partners.

They tried to make a dent in the world of corporate aviation, but it didn’t go too well as he recalled. “It was just like pouring water down a hole. We were going nowhere with this helicopter,” he says. “That helicopter was more of a recreational toy that we really couldn’t afford.”

Where many others would have given up and gone to work for someone else, the partners came up with an even bolder plan. It was something even riskier and took even more money, but they saw it as a better business opportunity. They were going to start a scheduled helicopter service between Vancouver and Victoria.

The kinder bankers at least wished him ‘good luck’ before showing him the door.

The early years in the 1980s weren’t kind to businesses in B.C. as the province was riding its way through another recession that saw interest rates hit over 20 per cent for commercial lending. “It was a challenge,” Sitnam says in a slight understatement. “Everything had to be funded by ourselves, or at least by my partners. There was no way the banks were going to finance the deal.”

Thinking back on examples of operators who had tried scheduled helicopter services around the world, Sitnam chuckles at what a potential investor would have seen. “They all failed,” he said. “New York Airways, Chicago Airways, LA Airways, all the helicopter start-ups that tried to do urban, city-centre operations. They all failed for one reason or another and we wanted to start this business in Vancouver?” There was also the matter of competing with the established seaplane operators. The kinder bankers at least wished him “good luck” before showing him the door.

It was during the startup phase that Sitnam learned the value of human capital, making investments that cost little in terms of dollars and cents, but can pay huge dividends in the future. John Munro, then a member of fledgling Helijet’s board of directors, encouraged Sitnam to meet with Ian Harris of Air BC, which at that time operated Twin Otters on the Vancouver-Victoria route.

“It was at a little Italian restaurant,” Sitnam recalls. “We broke the news to him and he looked at us and said – you’re really going to do this? We said we were going to give it a try and after a brief pause he wished us good luck.”

Up to this point, Sitnam had only thought about the level of service he was going to offer and how operating standards and technology would be their selling point. “I really didn’t think much about price (in the beginning), but what he did (Munro) was give us a chance to get off the ground, so to speak. If he had wanted to, he could have slashed his prices and killed us in 90 days. He allowed us to get traction and develop the market and then we could ratchet the fares up to a point where we could live.”

LEFT: Helijet is still flying its two original S-76As, each with more than 40,000 hours of service. (Photo by Paul Dixon)

BELOW: Danny Sitnam has been honoured on numerous occasions for his innovative approaches with Helijet. (Photo by Paul Dixon) t

Finding a helicopter was the next hurdle. Aircraft owners were underwhelmed by the group’s prospects, Sitnam recalls. “Anyone that owned aircraft, just wasn’t interested,” he said. “They couldn’t understand how they were going to get paid. You’re starting at broke and you’ve got no revenue base.”

But fortune smiled, if only briefly, on the team. Sitnam knew a Vancouver-area business that had a Bell 412 coming back from an overseas lease and he was able to secure it. So, in November 1986, Helijet launched its passenger service with that one 412 offering working the Vancouver-Victoria route. The result? There was but one paying passenger on the first flight.

doing. He was an advocate for his aircraft being a better fit for Helijet and he was able to convince Sikorsky management to take a chance with us.”

Today, more than 30 years later, Helijet is still flying its two original S-76As, each with more than 40,000 hours of service. “They’ve served us well,” Sitnam says. “Sikorsky is a very solid aircraft, a very forgiving aircraft from a pilot’s perspective.”

At the 2017 HAI Heli Expo, Sikorsky recognized Helijet for 30 years of safe, scheduled airline and charter operations with its fleet of S-76 helicopters. From its very humble beginnings, the company has grown to 160 full-time employees and the fleet has expanded from its original pair of S-76 helicopters to a more diverse setup of several smaller helicopters and two fixed-wing corporate jet aircraft.

We spend a lot of time thinking about how to protect the people and the equipment. “ “

“It was four months later and we couldn’t pay our bills. I couldn’t make the lease payments on the aircraft and things got a little strained,” Sitnam says. The bills eventually got paid, and in one of those fortuitous strokes of timing, Sikorsky entered the picture in the person of Jack Donohue.

“Jack was instrumental in coming out here and paying attention to what was happening out here,” Sitnam says. “They had some aircraft at Sikorsky that they were redeploying and he convinced his higher ups to support this little company in Vancouver. He thought that the S-76 was the right type of aircraft for the mission we were

Scheduled service now includes a VancouverNanaimo route, with more than 300 weekly flights on the VictoriaVancouver route. And since 1998, Helijet has provided air ambulance service to BC Ambulance from bases in Vancouver and Prince Rupert. Over those 19 years, they have more than 25,000 flight hours with more than 50,000 patients, flying IFR 24/7 in some of the most challenging terrain in the world.

Over the same period, Helijet has established itself on the north coast of B.C., by providing service to many of the world-famous fishing lodges and resorts in Haida Gaia on B.C.’s Central Coast. The lodges are isolated in remote locations. The natural beauty of the

region is unmatched, but it is a very different environment that operating in the twopilot, IFR routes of southern B.C.’s controlled air space.

“The work is hard,” Sitnam says, “especially if you look at it from a risk perspective. It’s single pilot, VFR, without all the resources you have around you down here (in Vancouver). It’s raw flying, where you’re on your own (as a pilot) if something goes wrong. It’s pretty much always a full load both ways, with either people or fish on board. We spend a lot of time thinking

about how to protect the people and the equipment.”

Helijet operates a year-round base at Sandspit Airport, along with mission-specific helicopters and flight crew to serve a wide range of businesses.

The fishing lodge business starts up in late spring and runs through to early September, which makes it a good fit for the company, as the passenger load on the Vancouver-Victoria routes tends to drop over the summer. So, has there been any direct conflict with seaplane operators on

the scheduled routes over the years?

“Not really,” notes Sitnam. “I don’t think we took a lot of traffic from the seaplane operators back then or even today. We have a few that move back and forth, depending on the season. The seaplanes have more service in the summer with the longer days and we get them back in the winter because we can fly a longer day with IFR and in heavier weather.”

As much as anything, Helijet attracted what Sitnam calls “a new fan base” from the region. It’s mainly business travellers who understand the concept of time being money and not being willing to spend time travelling by ferry or airport-to-airport. Downtown to downtown becomes very attractive.

While Helijet’s corporate offices and hangar are on the south side of YVR, the “downtown” terminals in Vancouver, Victoria and Nanaimo are the domain of Pacific Heliport Services, a subsidiary of Helijet. The current heliport in downtown Vancouver was built by Transport Canada (TC) in 1986 for a number of corporate uses as well as Helijet. Ironically, after many years of lobbying TC for the facility, by the time it opened for business, many of the companies that had been operating their own dedicated rotary assets were getting out of the aviation business. By 1988, Helijet was the dominant user of the facility.

“We wanted to expand the facilities, but the management didn’t want to, so we bought them out,” Sitnam says. “It’s our people, servicing our own aircraft. It was academic and it seems to work.” The Vancouver heliport exists in a very desirable neighbourhood, adjacent to the SeaBus terminal and Vancouver’s Trade and Convention Centre.

For Sitnam, the induction to Canada’s Aviation Hall of Fame is one more in a long list of accolades, stretching back over time. In 1994, Helijet received the Community Service Award from Helicopter Association International (HAI) and in 2000, Sitnam received the Robert S. Day Trophy from the British Columbia Aviation Council (BCAC) in recognition of “outstanding contribution in the leadership and development of aviation in B.C.”

Two years ago, Helijet received the BCAC’s Environmental Award in Aviation in recognition of “environmental initiative, program or accomplishment in one of more areas of protection, rejuvenation, conservation and awareness.” Specifically, the award recognized Helijet for deliberately flying approach and departure routes in Victoria and Vancouver

that minimized the noise impact on local residents. Taking circuitous routes meant flying higher, more fuel burn and adding a few more minutes to the routes, but more importantly, the neighbours were happy.

In 2016 at the BC Aviation Councils Silver Wing Awards dinner, Sitnam received the BCAC Lifetime Achievement Award. He also announced that Helijet was establishing an annual $3,500 bursary to enable midcareer helicopter pilots or AMEs to complete further training or certification to further their careers.

In the community at large, Helijet has an equally long history of providing sponsorship or partnering with charities.

“Things I enjoy the most are on the sponsorship side,” Sitnam says. “For example, the 1994 Commonwealth Games (in Victoria), where we painted our aircraft up with their mascot. The (2010) Olympics was memorable, though our involvement was through the air ambulance side.”

On the charity side, Helijet supports breast cancer and prostate cancer, “giving back to the community.” As Sitnam notes, “we’ve raised more than $100,000 to date for breast cancer, with $.50 of every ticket going to the Breast Cancer Association. With Prostate Cancer, we’ve liveried out an aircraft and participate in as many promotions with them as we can do.”

Then there’s Helijet’s role in making sure that Santa gets to visit children in area hospitals when his reindeer are grounded. It’s a new initiative that has piqued the interest of Power To Be, a group with offices in Vancouver and Victoria that works with people who are disabled and can’t enjoy the outdoors.

So, what’s in the future for Helijet? “When I look at opportunities for growth, I don’t see that many,” Sitnam says. He has had inquiries from around the world about introducing the Helijet brand, but it’s a tough business to grow out. “Like everything in the airline business, it’s a tough place to make money, whatever you’re flying.” The problem is, as he explained, is that these people want you to put the money in to develop the business. At his point, he says they’re not interested in taking on that risk.

There are a couple of lessons that Sitnam has learned along the way and has taken to heart. For one, you need to take care of yourself, so that you can be there as a leader. “You can’t always be the caboose,” he says. “It took me a long time to learn that lesson. You need to make sure you’re healthy and your family is healthy and strong. We’re fine, but it could have gone

better.”

The second lesson is getting the right people around you. “That’s really important in business, having people in the company that have their particular skills and can do them better than you ever could.” This trait is reflected in the people who have been with Helijet from the beginning or soon after. Sitnam notes that Helijet indeed has staff turnover – just like any other company – but if you look at the top couple of layers there has been a remarkable degree of stability over the years.

What does the future hold for Sitnam? Danny and his family spent January and February in Africa, visiting his brother, who is the director of World Vision International in Africa. You can hear the impact this visit had on him when he speaks, just like that first Bell 412 so many years ago. The visit has also got him thinking again.

“I wonder how we could get involved in helping communities that are in need, using helicopters and technology?” Can we move into that area and add some value?”

Stay tuned . . . this story is far from over.

BY WALTER HENEGHAN

There are many key components of a fully functional Safety Management System (SMS), both for the individual players in the system and its institutional masters.

The four pillars of safety that encompass the 14 distinct elements, (as detailed in the ICAO SMS structure), include: a requirement for a safety policy and objectives, adequate safety risk management, safety assurance and safety promotion. The question about how we adequately manage risk and meet assurance criteria really are the keystones to a vibrant and evolving SMS and the entire system is completely informed by the company’s culture.

As SMS has advanced in Canada, so has the overriding culture of safety within our industry. There is much more awareness of what I have previously referred to as “active risk management” – the daily or regular

review of one’s activities before they begin, and the constant and regular awareness that conscious thought is required to be riskaware.

Risk-awareness is a precursor to risk management. James Reason, Patrick Hudson, and Sidney Dekker have all laid the foundations for us in understanding one’s safety culture and for affecting a strong safety presence. Prof. Reason’s elements of a safety culture include these components: an informed culture, a reporting culture, a learning culture, a just culture and a flexible culture. Further, he expanded in the Journal of Injury Control and Safety Promotion that: “. . . a safe culture is an informed culture, one that knows continually where the ‘edge’ is without necessarily having to fall over it. The ‘edge’ lies between relative safety and unacceptable danger . . . navigating this area requires considerable skill on the part of system managers and operators. Since such individuals come and go, however, only a safe

culture can provide any degree of lasting protection.”

For a simpler expression of safety culture, we can use what remains one of my favourite definitions: “Safety culture is the way we do things around here.” This rather simple definition captures the essence of “culture” in the context of each individual company’s operations, but it does not mean that the defined culture is actually a safe culture.

It may be that the prevailing way of doing things is archaic, backward, unsafe, unjust, blame-filled and wrong. One hopes this is not the case – and being informed about safe practices is a positive step forward in avoiding a toxic safety culture.

Furthermore, with an “informed culture,” there is an implication that there is more than just a wishful desire to actually be informed. This occurs only after risk assessment and risk management processes are put in place and only if the company management deems this

as a desirable outcome.

As Patrick Hudson has said of the notion of an informed culture, “Managers know what is really going on and [the] workforce is willing to report their own errors and near misses.” This takes real work and can only exist if other key elements of a safety management system such as good reporting and risk awareness/ assessments are developed and used.

Reporting systems are critical. There are many types of systems available in this day and age – and it really doesn’t matter what system you use in your organization – only that there must be a system in place that is easy to access, (can be anonymous) and generates an information flow in both directions.

Few companies today use paper-based systems but if that is what you have or need, then use it. Online reporting is “de-rigeur” and the ubiquitous smart phone/tablet makes this step a virtual no-brainer. Get your line and maintenance staff to develop a habit of reporting what is happening within your operation and your managers will be informed and able to respond appropriately.

Appropriate responses are very important. Knee-jerk reactions to reported anomalies will kill your reporting channels and any trust that has been created between management and staff. Encourage reporting. Respond accordingly. Provide feedback. These three elements are key to sustaining a reporting culture and developing an informed management team.

An established reporting culture aids in developing an informed culture. How management addresses these reports is the crux of a just culture. Effective safety management demands a move away from “blame culture” past a “no blame” culture into a “just culture.”

Just culture can be a tricky thing to achieve and to properly understand it, one needs some background. It is not my intention to recreate a treatise on the complete just culture paradigm – Hudson, Dekker, Reason, Marx et. al. have written considerably on those fronts, but a recap is important for context.

The old way of thinking regarding the management of errors in the workplace had a simple but largely punitive structure: rules and procedures are there for a purpose and company staff are expected to know them. There are clear expectations regarding these published procedures and non-compliant behaviour is considered to be a deliberate failure of an individual. These failures cannot be tolerated and non-compliance is best managed by making people aware of the personal consequences, from written warnings to dismissal.

This view assumes that all the published procedures are optimal but some studies

At StandardAero, we’re lowering our customers’ DOCs by implementing preventative practices that reduce unscheduled engine removal and emergency maintenance. As an OEM authorized Rolls-Royce AMROC, our comprehensive support programs are designed specifically to increase M250 MTBR, keeping you in the air with worldwide Service Centers and Mobile Service Teams available 24/7.

AOG and need it now? We have an extensive M250 engine accessory and exchange pool, supported by our fresh M250 rental fleet and quick turn-times.

www.standardaero.com/heli +1.204.318.7544

suggest otherwise. But there is substantial anecdotal evidence that much rule breaking is a result of a desire on the part of employees to “get the job done” or “to do the right thing.”

Often, this rule breaking is a result of a process or procedure being created that does not actually represent the daily norm for a given activity. It can also be a result of employees assuming the client wants something done a certain way; or a task that is completed for the “benefit of the customer.”

How then should rule breaking be treated? Reason, Hudson, Wiegmann and Shappell have written extensively about errors (slips, lapses and mistakes), violations and intentional and non-intentional acts. Slips are usually benign, not so dangerous on their own as one usually gets a reminder that you are doing the wrong thing.

Lapses are more dangerous and harder to contain – like forgetting to buy milk. Mistakes are even more dangerous as you intend to do one thing, but actually do something else. Violations are deliberate and break a fundamental assumption of a SMS: procedures will be followed.

Clearly, employees are acting in good faith, albeit in a non-compliant manner. A blame culture paradigm that is unflinching in dealing with these “bad actors” misses the point. The desire to inhabit a model that addresses these forms of non-compliance with reason was widespread and the concept of just culture was born.

Just culture models help navigate the world of error versus violation and provide aid in managing appropriate responses. A number of solutions such as Prof. Hudson’s “Hearts and Minds,” David Marx’ patient safety paradigm or the algorithms developed by Baines Simmons provide strong just culture processes.

Many larger companies have deployed these models with success since these models, when properly taught and implemented, can greatly enhance the effectiveness of a SMS, and will move the organization closer to a true safety culture. Top managers require an unwavering

commitment to sustaining just culture principles and employees need to believe in that commitment.

The just culture models discussed so far are really intended to be tools that assist management to address errors, mistakes and acts of individual actors and their behaviour. They require a strong and dedicated commitment on the part of management and need to be applied deliberately and in a consistent manner.

But what about the companies themselves? Can just culture principles apply to the larger organization as an “actor” in safety management or is the blame/liability model necessarily prevalent? Are the culpability constraints more appropriate to “bad actor” companies?

There is growing movement within hospitals, for example, to attempt to find the balance between the liability/culpability model and the development of a learning, generative just culture. Personal accountability balanced with legal liability with an eye to just improving the medical process is the ultimate goal in these medical organizations but it is a difficult path.

The goal of these models is improvement but they do not immunize individuals from non-compliant or deviant behaviour. What standard then is needed for organizations? Surely, when organizations act in a wilful manner, disregard best practices, ignore published procedures or plainly behave in a manner that is unsafe, then it is reasonable to expect a full accounting for their decisions. Can a “good faith” argument apply?

The substitution test, as first delineated by Prof. Reason, posits that if others, substituted into the same scenario and confronted with the same human factors liabilities, contributing and causal factors, would, or might, have committed the same errors, then the professional actions of supervisors and credentials committees should be moderated.

In such circumstances it is apparent that problems within the sys-

tems are at least in part, substantially responsible for the errors. The factors cumulatively resulting in errors become understandable and thus steps can be put in place to ameliorate or modulate circumstances contributing to error.

If an organization acts in a manner that is clearly outside the norms for safe or standard operations or outside of what other companies in the same or similar fields have done, then isn’t this a failure of the substitution test? And when this failure occurs, what steps should be taken? Just culture principles are designed for individuals and cannot be applied to organizations.

When organizations show intent and then carry out their intended actions, we are left with determining if those actions were deliberate (a violation) or a mistake. How does one determine the violation? Cleary, violations against legal codes and regulations or laws can be pretty straightforward and remedies are available via a legal or administrative process.

Aviation regulations and labour codes are in place for good reason. They protect employees and the traveling public and are intended to ensure minimum safety standards are in place. Compliance with these regulations and standards fulfills the company’s duty of care.

The next question to be posed is the notion of “the reasonable man” – in that, what would a reasonable person conclude that the observed behaviour was a reasonable action given the circumstances? These are important questions to be answered when evaluating how to respond to organizational misbehaviour. Many organizations develop a unique personality, and when this personality is one where advice is ignored or best practices are cast aside, then that organization and its component actors need to be held to account. Can there be violations against “best practices?” One potential remedy might involve bodies with which companies have been accredited. These organizations could then take steps to sanction where appropriate to correct the shortcomings of the

offending company.

Accountability is key. Companies that successfully engage in just culture processes in the face of human error related events show themselves willing to be transparent in the name of safety. These paradigms allow for a full review of the context or envelope surrounding a safety event and provide strong guidance to the organization to ensure an adequate and just response that serves the needs of the all the players in the process.

Don Norman, the author of The Design of Everyday Things provides a most succinct summary of why just culture may be the way forward.

“People make errors, which lead to accidents. Accidents lead to deaths. The standard solution is to blame the people involved. If we find out who made the errors and punish them, we solve the problem, right? Wrong. The problem is seldom the fault of an individual; it is the fault of the system. Change the people without changing the system and the problems will continue.”

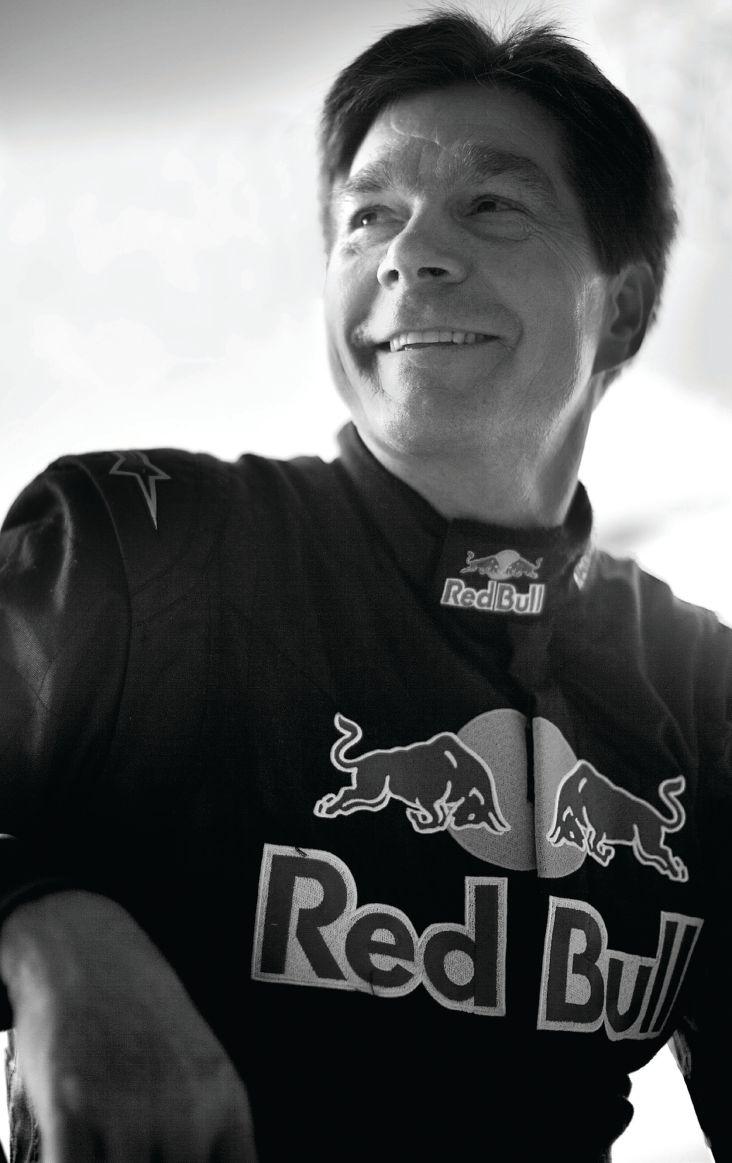

CHC president and CEO Karl Fessenden maintains CHC is well positioned to succeed in the current challenging oil and gas market.

BY RICK ADAMS

Once known as Canadian Holding Company, shortened to CHC, the once $800-million leader in offshore helicopter operations was devastated by the steep decline in oil prices and a pair of fatal accidents. CHC filed for Chapter 11 bankruptcy protection in April 2016.

The company emerged from the 10-month process in March with a smaller fleet, less debt, and a new branding scheme that hearkens back to its earliest days as Okanagan Helicopters.

CHC’s corporate headquarters is now located in Dallas, Tx., with four regional head offices, a Center of Excellence in Vancouver and the global sales office in oil and gas in ground zero, Houston.

The slimmed-down CHC is a private company with primary ownership through its bondholders.

Karl Fessenden was named president and chief executive officer of CHC Helicopter and a board member of its parent company, CHC Group, in February 2015. He came to CHC from GE, where he led multiple global-service business units at GE Energy and GE Aviation. Most recently he directed GE’s integration of the Alstom power-generation business, the largest acquisition in GE’s history. His background includes 15 years in the aviation sector with GE and Pratt & Whitney.

Fessenden shared his thoughts with Helicopters on CHC’s recent past and future.

With the smaller fleet and staff, you’ve adjusted to a more regional structure. What is the CHC market strategy over the next 5-10 years?

We are dedicated to serving both a global and regional customer base, leveraging our global standards and the local expertise of our four regions – APAC, EMEA, LAM, and NECC. We plan to maintain this focus as we continue to grow our business and aggressively pursue opportunities around the world.

We believe we are well positioned to succeed in the current challenging oil and gas market as well as attract additional customers with the eventual market recovery. We remain committed to maintaining a technologically advanced and reliable fleet that helps our customers reach their goals and will continue to raise the standard for safety, customer service and value across the industry.

The Chapter 11 process allowed us to rethink every aspect of our company and make sure we provide the best value for our customers while maintaining an unwavering commitment to a safe and reliable operation.

In the fleet makeover (shedding aircraft, possibly acquiring new types) what is the long-term fleet plan?

Our long-term fleet strategy is to maintain a fleet mix of owned versus leased aircraft that allows us the flexibility to meet the needs of our current and future customers. And we plan to invest in new aircraft such as the AW189 and EC175 in the coming months to support current customers.

What are current revenues from O&G, SAR, EMS, MRO? How do you propose to change the mix in the future?

Approximately 70 per cent of our revenue comes from oil and gas, 15 per cent from Heli-One/MRO and 15 per cent from SAR/EMS. We are expanding our SAR/EMS business and are also pursuing new opportunities such as transport for the renewable energy sector.

What did you do to shore up employee morale and motivation through the bankruptcy process?

When we started the restructuring process, we made sure to emphasize to employees that their main focus should continue to be meeting the needs of our customers. Our leadership team worked with advisors to manage the restructuring process, including the implementation of robust management of change and communications processes specifically designed to minimize any impact on our daily operations and our people. Our goal was to ensure our people understood the process and were aware of what was happening, while maintaining a 100-per cent, business-as-usual posture. Our commitment to each other and to our customers was to move through the restructuring process as quickly and efficiently as possible, while keeping our customers informed throughout.

We kept our commitment of completing the restructuring as quickly and efficiently as possible, and maintained the trust and support of

our customers, employees, creditors and stakeholders. It’s very gratifying that all of our customers stood by us during this time, when they could have easily walked away.

As we move forward as the new CHC, we are focused on making sure all of our employees have the information and resources needed to do their jobs effectively while also opening up additional channels for ideas and feedback. We want to encourage creative thinking and new ideas at all levels, and allow our people to take ownership of implementing them. For example, we’ve created a global employee ideas and feedback program that makes sure all ideas are shared with leadership and those that both share their ideas and help implement them receive recognition and possible compensation.

What major changes were there in key operational personnel?

We made significant organizational changes to ensure we had the right people in the right roles to manage the changes needed for a successful reorganization. Our reorganization included changes across CHC’s global structure in every corner of the business – across the regions and at the corporate level. This new structure has created better alignment with our customers, geography, language and culture, while driving greater accountability and improved customer relationships. As part of this approach, we implemented standard systems, processes and structures, which allowed us to strip out complexity and take advantage of technologies to make us more efficient.

One example of this was the creation of our Global Standards Group – a new organization to create and manage a single globally consistent process for standards development for Flight Standards, Maintenance and Training. We also implemented a regional “Centre of Excellence” (COE) model across our AOCs: In each COE, our Postholders are accountable for providing “subcontracted services” to our operations around the globe. Our fleet directors collaborate with Postholders on

fleet-specific issues and improvements. This simplifies our business by managing maintenance programs for each fleet type in a single location, streamline modifications, and process all required revisions to maintain compliance. The COEs also process airworthiness directives, service bulletins and other airworthiness instructions

What emphasis has been placed on safety and SMS through the bankruptcy? Safety is our business. It is at the core of our promise to our customers and employees. Throughout the restructuring process, we absolutely did not waiver in our commitment to safety. Our operations and safety and quality teams continued to focus on safely supporting our customers and were distanced from the specifics of the bankruptcy process to allow them to focus on running a safe and reliable operation.

We also continued to invest in leading-edge solutions to elevate safety and address potential safety issues. Several initiatives are directly focused on human factors such as Line Operations Safety Assessments (LOSA) – a groundbreaking program, looking at threat and error management in the cockpit, which complements our extensive helicopter flight data monitoring (HFDM) program. Other initiatives focus on proactively identifying, testing and breaking down any and all barriers to safety.

Every member of the CHC team – particularly our senior leadership team – plays an important role in making CHC a safer place to work and a safer company for our customers. We have hosted roundtable sessions of leaders across the company to identify areas for additional improvement and are building these goals and objectives into both their own performance objectives and those of the larger organization. Every leader, regardless of function, is accountable for advancing safety across our operation.

In what ways are you active in HeliOffshore? Safety through collaboration has long been a

philosophy championed by CHC and others in our industry, so we continue to play a very active role as a founding member of HeliOffshore. Dave Balevic, our senior vicepresident of engineering and operations, cochairs a work stream on systems reliability and resilience, focused on eEarly diagnosis and resolution of potential failure, improving equipment reliability, effective maintenance, and improved airworthiness management. Malcolm Garrington, manager, HUMS support has co-led work developing a Health and Usage Monitoring Systems (HUMS) Best Practice Guidance that was recognized with the HeliOffshore’s “Sharing and Learning” award last year.

Do you still have a training partnership with CAE?

Yes, we continue to partner with CAE. This relationship has not changed.

How “Canadian” is CHC today?

Our Richmond (B.C.) Center of Excellence houses more than 400 employees and includes key members of our safety, human resources, finance, IT, Heli-One and other teams. We are proud of our heritage within Canada all the way back to our Okanagan roots and will continue to house several functions in Canada that are essential to CHC’s global operations.

It was said the 2010 CHC senior leadership team was inexperienced in the aviation business; how does the current team differ, and why will you be successful?

Our current leadership team, including our new board of directors, is comprised of experienced leaders who have strong backgrounds in the markets we serve – including commercial aviation, oil and gas, and the helicopter industries. We also believe the people we have at all levels of CHC are the most talented and dedicated employees and we are all dedicated to providing safe and reliable service to our customers across our global operation.

AERO-SMITH HELI SERVICE

1020 Virginia Rd. Coombs, BC V0R 1M0

Tel: 250-954-0668

1-877-954-0668

www.aerosmithheli.com

Email: hugh@aerosmithheli.com

Personnel: Hugh Andrews, President / DOM, Sean Sinclair, General Manager, Lani Parr-Pearson, Parts

AIRBUS HELICOPTERS CANADA

1100 Gilmore Rd, Fort Erie, ON L2A 5M9

Tel: (905-871-7772

1-800-267-4999

www.airbushelicopters.ca

Email:

benoit.marcoux@airbus.com

Personnel: Benoit MarcouxDirector, Support & Services

CANADIAN HELICOPTERS

LIMITED

4500, 1000 Airport Rd. Edmonton International Airport, AB T9E 0V3

Tel: 780-429-6900

www.canadianhelicopters.com

Email: beaton@canadianhelicopters.com

Personnel: Bryan Eaton, General Manager, Third Party Maintenance Services

CHARTRIGHT AIR

2450 Derry Road East, Hangar 3 Mississauga, ON L5S 1B2

Tel: 905-671-4674

1-800-595-9395

www.chartright.com

Email: mro@chartright.com

CUSTOM HELICOPTERS LTD.

401 Helicopter Drive

Saint Andrews, MB R1A 3P7

Tel: 204-338-7953

1-800-782-0780

www.customheli.com

Email: info@customheli.com

Personnel: Jed Hansen; President & CEOTodd Tomecek; Vice President, CommercialBob Raymond; Director of Maintenance

DBC MARINE SAFETY SYSTEMS LTD./ SURVITEC VANCOUVER

1689 Cliveden Ave.

Delta, BC V3M 6V5

Tel: 604-805-2372

www.dbcmarine.com

Email: Bobby.Kirkley@survitecgroup.com

Personnel: Bobby Kirkley, Aviation and Fire Safety Sales Representative P.R.M

n n n n

Services: hangarage, pilot lounge, courtesy vehicle, GPU. Fuel: Jet A Maintenance: rotary wing, turbine, painting, sheet metal, mods, conversions. Approved Service Center: Bell 206, MD 500, Eurocopter AS350. Consulting: pre-purchase, import/ export. Component rentals/exchanges. Parts Sales, vibration analysis, salvage.

n 24/7 technical support and connected services as well as, innovative solutions for spare parts and MRO services. Airbus Helicopters offers a range of industry leading inspection and repair and overhaul capabilities, with guaranteed turnaround-times and cost efficiency.

n n n n n

n n n n n n n

n n n n

With over 30 years’ of experience supporting rotary wing aircraft across Canada, Airbus Helicopters’ dedicated team of licensed Technical Experts, Customer Service Representatives and MRO Specialists are committed to guaranteeing the highest level of service.

Airbus Helicopters provides comprehensive MRO services including; Dynamic components, blades, airframe and equipment repair, to keep our aircraft operating at peak performance.

At Airbus Helicopters we work tirelessly to ensure that our customers enjoy a seamless transition from the acquisition of their helicopter, through to-years of hassle-free flying. We are dedicated to ensuring the best interests of our operators, including but not limited to; Maximizing flight revenues, ensuring public safety and saving lives.

Import and Export Canadian Helicopters provides comprehensive helicopter support services - repair and overhaul for engines, avionics, NVG goggles, components, and structures. We service private, commercial and military helicopters within Canada and internationally. With over 65 years of experience, Canadian Helicopters is an industry leader in refining maintenance practices. We offer cost effective, flexible maintenance solutions. Canadian Helicopters is a Bell CSF.

n Components and servicing of life rafts, life vests, fire bottles, fire extinguishers, Hydrostatic testing, Sales.

Chartright is a Transport Canada Approved Maintenance Organization (AMO #196-92) with an approved FAA Supplement. Chartright has maintenance facilities in Toronto and Kitchener and are capable of performing maintenance on a wide array of fixed and rotary wing aircraft offering a full array of services from line maintenance servicing to large inspections, avionics, and structures. Chartright is an authorized AgustaWestland Service Centre. Contact us to discuss your next maintenance event.

Custom Helicopters is a top-notch Maintenance, Repair and Overhaul facility located in Winnipeg, Manitoba. Our services include: aircraft modifications and refurbishing; sheet metal work and structural repairs; engine repairs; component overhauls and repairs (transmissions, tail rotor gearboxes, freewheel units, rotor heads). Custom Helicopters is an authorized Bell Helicopter CSF for the Bell 206A/B, 206L, 407, 205 and 212 series helicopters, including the distribution of parts and accessories.

DBC Marine of the Survitec Group is a global organization and leader in safety services and sales in the Aviation industry. Our Vancouver location specializes in the sales and servicing of Aviation vests and rafts, as well as overhauls and sales of engine fire bottles, fire extinguishers, O2 bottles/assemblies and survival kits and spare parts. We are an approved ANAC & EASA service station with both TC and DOT H/T approvals as well.

R

FLYING COLOURS CORP.

901 Airport Rd

Peterborough, ON K9J 0E7

Tel: 705-742-4688

www.flyingcolourscorp.com

Email: info@flyingcolourscorp.com

Personnel: John Gillespie, Eric Gillespie, Sean Gillespie, Tony Barrett, Richard Dabkowski, Andrew Laba

HOPE AERO PROPELLER & COMPONENTS, INC.

7605 Bath Rd. Mississauga, ON L4T 3T1

Tel: 905-677-8747

1-800-268-9900 hopeaero.com

Email: goodtogo@hopeaero.com

Personnel: Dana Ladd, Michael Hope,Terry Hope, Gabe Marcucci, Jasper Megelink, Chris Howick, Craig Grant, Cathy Dunn, Joel Chlan, David Hope

PPG 12780 San Fernando Road Sylmar, CA 91342 Tel: 818-362-6711 www.ppgaerospace.com

Engineering and Certification, Structural repair and modification

Dynamic Balance Equipment sales, support & calibration as well a Non-Destructive Testing. We also overhaul Propellers, Wheels and Brakes,

Flying Colours Corp is an Aviation Services company with headquarters in Canada and other full service facilities in the USA, & Singapore. Flying Colours specializes in Green Completions, Interior Refurbishment & Modifications, Heavy Maintenance & Repair, Exterior Paint, Executive Conversions, Special Mission Modifications, and Avionics Installations. Flying Colours is a Bombardier Authorized Service Facility and Bombardier Preferred Completion Center.

Hope Aero specializes in the sales, support and function testing of Honeywell Dynamic Track & Balance Systems. We are also involved in Non-Destructive Testing for all helicopter and fixed wing parts. Our other capabilities include sales and service of propellers, governors, wheels, brakes.

Transparencies, Sealants, Coatings

PPG’s aerospace business is a leading manufacturer of aircraft transparencies, aerospace sealants, aerospace coatings, specialty materials, aircraft maintenance products, and packaging & application systems for military aviation. PPG also offers chemical management services and operates a global network of Application Support Centers.

STANDARDAERO

33 Allen Dyne Road

Winnipeg, MB R3H 1A1

Tel: 204-291-0502

www.standardaero.com

Email: helicopters@standardaero.com

Personnel: Brian Hughes - Director of Sales and Marketing

VECTOR AEROSPACE

Hangar 8, 800 Aerospace Blvd. Slemon Park, PE C0B 2A0

Tel: 902-436-1333

866-436-1333

www.vectoraerospace.com

Email: sales.esa@vectoraerospace.com

Personnel: Jeff HoldridgeDirector, Engine and Component Sales

n Repair Capabilities

PT6A, JT15D, PW100 and PW150ARepair- Overhaul- Hot section inspectionForeign Object Damage (FOD) repairEngine or module performance testingService bulletin compliance- Component repair- Engine and airframe

StandardAero is one of the world’s largest independent providers of services including engine and airframe maintenance, repair and overhaul, engine component repair, engineering services, interior completions and paint applications.

StandardAero serves a diverse array of customers in business and general aviation, airline, military, helicopter, components, energy and VIP completions markets.

Vector Aerospace is a global provider of aviation maintenance, repair and overhaul services. Through facilities in Canada, the USA, the UK, France, Australia, South Africa, Kenya and Singapore, Vector provides services to commercial and military customers for gas turbine engines, components and helicopter airframes. Vector’s customer-focused team includes over 2,200 motivated employees, half of which are located in North America.

Field Maintenance for Bell 206, 206L, 205, 212, 412 and Robinson R22 and R44.

Dynamic and hydraulic component overhaul and part sales for the Bell 204, 205, 206, 206L, 212, 407 and 412.

Structural Repairs Fixtures for Bell 206, 206L, 407, 205, 212, 412.

Approved Woodward HRT Licensed Repair Service Facility Approved Bell Helicopter Customer Service Facility

Transport Canada Approval # 3/86 EASA Approval Number 145.7106

Head Office: 18 Terry Fox Dr., Vankleek Hill, ON, K0B 1R0 T: 613.678.3027 F: 613.678.2776 Gerry@helitradesinc.com

Alberta Facility: Site 5, Box 7, RR2, Airdrie, AB, T4B 2A4 T: 403.912.4658 F: 403.948.6475 info@helitradesab.com