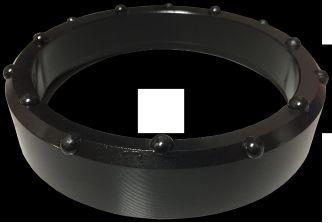

The CME-750X is the culmination of over 30 years of experience in ATV drill technology. It’s been designed and refined from the ground up to provide the best combination of mobility and drilling performance you can get with a rubber-tired all-terrain drill rig. There are no compromises.

All-terrain means you can get to jobs inaccessible to truck mounted rigs without building costly access roads. And with its built-in auger racks, tool boxes and water tanks, the CME-750X carries everything you need to get the job done when you get there. Of course the rubber tires won’t damage most pavement so you can use this rig on city streets as well.

The dependable mechanical rotary drive is available in standard, high torque or high speed models. The high torque version provides up to 12,950 foot pounds of torque while the high speed model gives you spindle speeds up to 930 rpm. And 30,000 pounds of retract force let’s you take on those big drilling jobs.

The CME-750X is available with the same options as our truck-mounted drills, like automatic SPT hammer, hydraulic rod holder and breakout wrench, quick mast disconnect, various hydraulic hoists and many more.

If your jobs call for a rig that can get through mud, snow, sand and rough terrain, check out the CME-750X. It’ll get you there and then, it’ll get the job done.

45, No. 2

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

Editor | Colleen Cross ccross@annexbusinessmedia.com (519) 428-3471

Advertising Manager | Sharon Kauk skauk@annexbusinessmedia.com (519) 429-5189, (888) 599-2228, ext 242

Account Coordinator | Barb Comer bcomer@annexbusinessmedia.com (519) 429-5171, (888) 599-2228, ext 210

Media Designer | Brooke Shaw bshaw@annexbusinessmedia.com

Group Publisher/VP Sales | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@groundwatercanada.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0383-7920

Circulation

e-mail: lmalicdem@annexbusinessmedia.com Tel: 416-442-5600 ext. 3547 Fax: 416-510-6875 or 416-442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates

Canada - 1 Year $21.00

U.S.A. - 1 Year $46.00

Annex Privacy Officer: Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Ground Water Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Serving the Canadian Ground Water industry for 45 years.

Wellen Boring and Drilling Ltd. has provided fresh water to Saskatoon for over 40 years

NGWA’s new president is on a mission to help all ground water professionals work together

Learn two new angles on drilling in less than ideal conditions

The OGWA gathered in London, Ont., to network, learn and elect new leadership

Federal budget renews vow to end drinking-water advisories

Federal finance Minister Bill Morneau announced $4.7-billion in spending for Indigenous people in Canada in the new federal budget and promised to end all drinking-water advisories on reserves by March 2021.

Five-year aquifer research project launched by U of Memphis

A Lowe’s store recently sold 300 plastic buckets to the University of Memphis that are part of a much broader effort by the university to map breaches in the aquifers that hold Memphis’ ground water. The Daily Memphian reports.

by Colleen Cross EDITORIAL

What you do when you think no one is watching matters

What does professionalism mean to you? Does it mean drilling safely and following all the regulations? Does it stand for honesty, integrity and fair dealing? Does it mean giving the customer a high-quality water well?

Does it mean keeping your training credentials up to date and making sure your employees are up to date as well?

Is it about supporting your association? Meeting or exceeding industry standards? Learning about new techniques and technologies? Playing fair with the competition?

You know the answer to these questions: all of the above . . . and more.

Some of these principles are borrowed from the Ontario Ground Water Association’s code of ethics and conduct, a worthy document that says what needs to be said in as few words as possible.

Professional habits help you as a business owner develop a sense of pride about your work.

There are other less obvious habits that may not be enshrined in any code but are just as important. There is setting a good example for employees by not badmouthing customers (or other employees or the competition). There is keeping your paperwork in tidy order so that nothing slips through the cracks and you’re quick with an invoice and a tax filing.

Professional habits are good for your customers, good for your employees and good for the industry’s image.

But the bottom line is they are good for you and your business. They help you as a business owner develop a sense of pride about your work. That filters through everything you do.

It’s fair to say the trades don’t always get the respect they deserve considering the work they do is always in demand and, in the case of water-well drillers, essential. Parents encourage their kids to get university degrees, often not presenting skilled trades training as a good alternative.

But respect begins with self-respect – including what you do when you think no one is watching –and it begins at the top of any business, whether it be a business of two, 20 or 200.

It’s all about how we see ourselves. And because ground water is a largely hidden resource, it can be hard to explain and show to the public.

We at Ground Water Canada want to know how you see yourselves, ground water and your industry. That’s why we are launching a cover photo contest to gather interesting snapshots of the well-drilling industry. Send your crew out with their smartphones (on the high-resolution setting, please) and get behind this fun contest! Show us the challenges, successes and ins and outs of your drilling season, and your photo could be featured on the cover of our Fall 2019 issue!

Turn to page 9 for details and photo ideas. Get your photos in to us by July 31, 2019 – I know, I know, it’s the busy season with drillers going dawn to dusk. That’s part of the point: we want those photos as the work is happening and while it’s fresh on your mind!

We look forward to seeing your photos, learning your stories and hearing your comments about the magazine. Have a good season!

Speaking of photos, in my Atlantic convention article last issue I misidentified Bill Kyte as Ron White in a photo on page 13. As organizing committee members, both Bill and Ron were in attendance, but it was Bill, who operates Bill Kyte Well Drilling of Sussex, N.B., reminiscing with Val Le Blanc. My apologies to both for the mixup. If I’m invited back, I’ll get a picture of you too, Ron!

facebook.com/groundwatermag

GroundWaterCanada_magazine

Cable Tool

Rotary

Threaded

Weld On

Sizes 2” to 36”

The Water Quality Association has collaborated with Health Canada and the Standards Council of Canada to write the standard in preparation for Health Canada’s issuance of a new health-based maximum allowable concentration (MAC) for manganese that will apply to drinking water supplies in Canada, the Water Quality Association said in a news release.

The standard will allow manufacturers to test and certify their products for health-based manganese removal claims.

Private wells and many small drinking water systems in Canada rely on certified point-of-use or point-of-entry drinking water treatment products to meet their national Canadian drinking water requirements, according to the release. Authorities in Canada reached out to WQA because there was no published standard that would allow certification of health-based manganese removal claims.

The new WQA standard, WQA ORD1901, will avert an implementation gap with point-of-use and point-of-entry systems needed for compliance to the proposed Canadian MAC for manganese. In addition, the new standard will help companies address growing concerns about manganese in the U.S. and other countries.

“Other contaminants have recently captured the spotlight in the U.S., but manganese is discussed at almost every U.S. drinking water conference that I attend,” said Eric Yeggy, WQA technical affairs director. “Beyond just the negative aesthetic impacts, there is wellestablished science behind the health impacts, which is why Health Canada decided to move forward with issuing a health-based MAC.”

Kevin Wong, Canadian Water Quality Association Technical Advisor, said that, “the quick and efficient development of this standard will help protect Canadians impacted and give the water treatment industry in Canada something to measure and apply. Health Canada working with the industry on this topic is a marked step forward in the relationship and trust we share.”

Manganese in small amounts is essential to human health; however, elevated levels in drinking water have been associated with negative health impacts such as changes in behaviour, lower IQ, speech and memory difficulties, lack of coordination and movement control.

WQA’s research showed that four POU/POE drinking water treatment technologies have the potential to remove manganese down to the new MAC: cation-exchange, distillation, filtration and reverse osmosis. If new technologies are later shown to remove manganese, those technologies could be added to the standard.

The American National Standards Institute (ANSI) was consulted during development, and the standard can be used to test and certify health-based manganese claims under existing North American Standards, such as NSF/ANSI 44, 53, 58, or 62. WQA will not charge certification bodies to use WQA ORD1901.

Manufacturers who wish to have their products tested and certified for the removal of manganese should contact the certification body of their choice. Certification bodies accredited to offer this type of testing and certification include WQA, CSA, IAPMO, NSF International, Truesdail and UL.

Questions about WQA ORD1901 should be directed to Eric Yeggy (eyeggy@wqa.org) at the Water Quality Association.

Health Canada, in collaboration with the provinces, territories and other federal departments, has updated the drinking water guideline to reduce the maximum acceptable concentration of lead in drinking water from 0.01 mg/L, set in 1992, to 0.005 mg/L.

The move is based on the latest science, Health Canada said in a news release. Lead levels in Canada have fallen dramatically over the past 30 years, the government said. It is usually found in drinking water after leaching from distribution and plumbing system parts, and was historically used in service lines (that is, pipes connecting a home or business to a street’s water main) and in plumbing fittings and solders. Until 1975, lead was an acceptable material in pipes based on the National Plumbing Code of Canada, so it is more likely to be found in older homes and neighbourhoods. Since lead was regularly used in these plumbing system parts for many years, drinking water systems in Canada may still have some of these lead components in place today. As such, it is expected to take time before all jurisdictions are able to meet the new guideline for the maximum concentration of lead in drinking water.

All jurisdictions in Canada agree on the need to reduce exposure to lead, the release said.

Health Canada will continue to support provinces, territories and other federal departments in implementing the new guideline. The department will also work with provinces, territories and other federal departments, including Indigenous Services Canada, to provide accurate and relevant information to municipalities and Canadians concerned about the health effects of lead levels in drinking water.

LOOKING FOR A LITTLE INSPIRATION?

Here are some possible photo ideas to get you started:

E WELL DRILLERS AT WORK

E FLOWING WELLS

E STAFF AROUND THE SHOP

E WELL REHABILITATION

E REMOTE OR PICTURESQUE WELL LOCATIONS

E DOWN-THE-HOLE SHOTS

E TRICKY PUMP INSTALLATIONS

E PUMP TESTS

E WATER TESTING

E DIFFERENT GENERATIONS OF THE BUSINESS

E COMMUNITY OUTREACH

GROUND WATER IS LIFE-GIVING BUT IT IS OFTEN INVISIBLE . . .

TOGETHER LET’S ILLUSTRATE THIS PRECIOUS RESOURCE AND THE SKILLED INDUSTRY THAT BRINGS IT TO THE PEOPLE!

GROUND WATER CANADA PROUDLY PRESENTS ITS FIRST COVER PHOTO CONTEST

Show us the challenges, successes, ins and outs of your drilling season and your photo could be featured on the cover of Ground Water Canada’s Fall 2019 issue.

Photos will be accepted until July 31, 2019, and the winner will be chosen by the Ground Water Canada panel of judges.

Deadline to submit: July 31, 2019

Submit your photos online at: Groundwatercanada.com/photo-contest

Heron Instruments recently hired Jeff Tweedy to the position of quality/production supervisor. Tweedy has more than 25 years’ experience in manufacturing operations management, Heron Instruments said in a news release.

As a certified ISO auditor, he has implemented quality systems in large and small companies.

“With Jeff’s knowledge of Product Lifecycle Management, we are looking forward to what his experience will bring to Heron,” the company said.

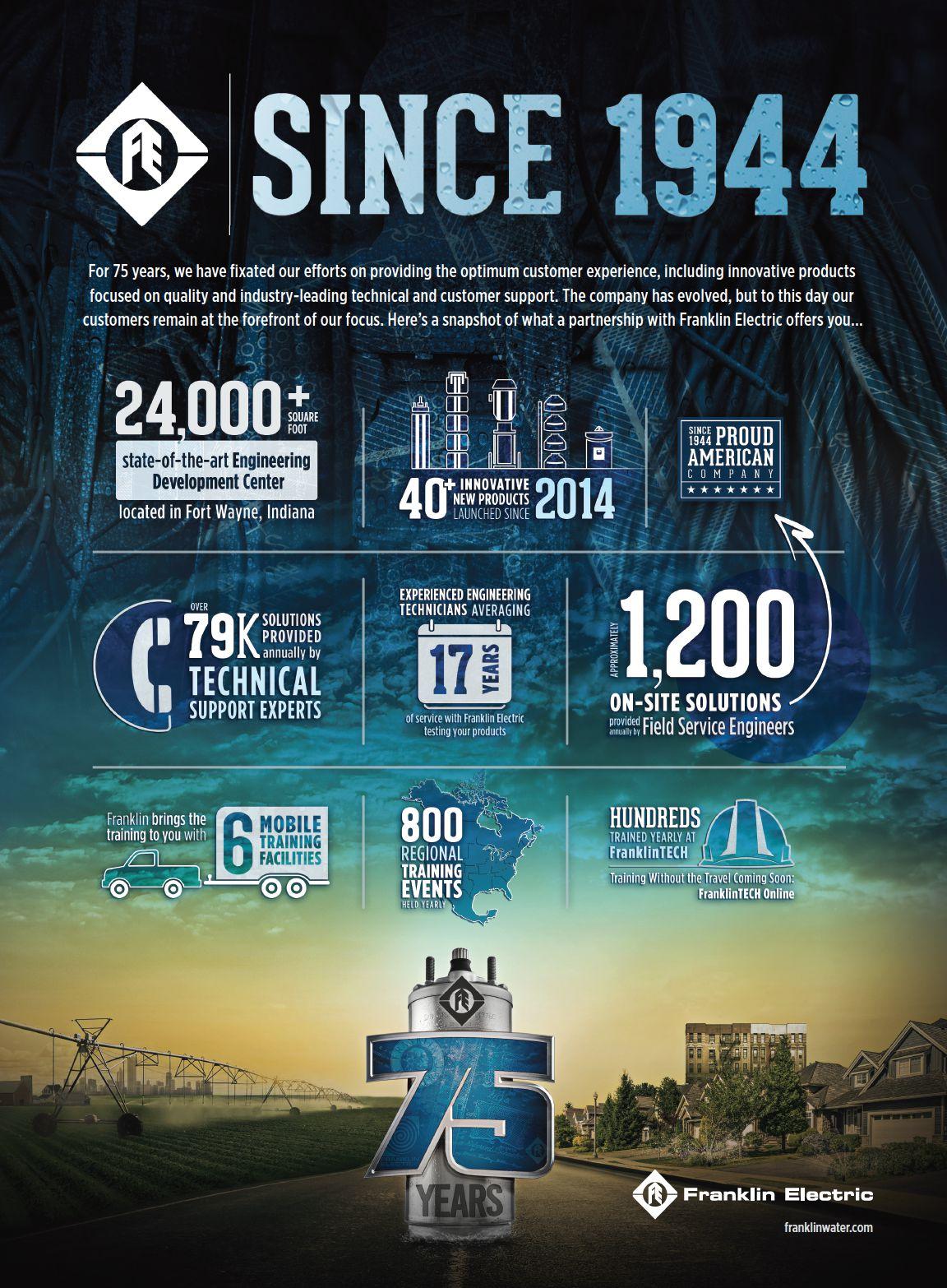

Franklin Electric Co. celebrates 75 years in business in 2019.

Since E.J. (Ed) Schaefer and T.W. (Wayne) Kehoe founded Franklin Electric in 1944 in Bluffton, Ind., the company has grown from a small motor manufacturer into a leading international provider of systems and components for moving water and fuel, Franklin Electric said in a news release.

Its core product is the first reliable submersible electric motor for water systems, which has remained a staple of the water-well industry. Franklin manufactures and distributes improved versions of the motor design internationally and also creates pumps, electronics and related products.

“We would like to recognize and thank all of our employees, customers, partners, and investors that have played a role in helping shape Franklin Electric into the company it is today,” said Gregg Sengstack, chairman and chief executive officer.

The Southern Alberta Institute of Technology, along with industry partner Imperial, has created a program to give students the tools and expertise they need to work on solutions for global water issues.

Integrated Water Management is a twoyear diploma program for students with a passion for water and the environment.

Graduates will have transferable skills for working in such industries as energy, government, non-profit, agriculture, education, food and beverage, manufacturing, engineering and construction, SAIT said in a news release.

The program will focus on such areas as water monitoring program development and execution, site assessment and identifying sources of pollution and contamination; project management and communication; and hands-on learning experience including field school, classroom and virtual reality labs.

The college recognized the need for new programing in responsible water management after consulting with industry partners, including Imperial, which invested $1 million toward program development and implementation.

“SAIT has a clear interest in ensuring sustainable water management, which includes not only exploring new water usage technologies and less water-intensive uses, but also talent development in water,” said Pablo Pina Poujol, SAIT academic chair of the Water Sustainability department.

Franklin Electric Co. welcomes Ryan Johnson as its vice-president of sales in Canada and the United States. for the North America Water Systems Business Unit.

Johnson will manage all aspects of sales activities for Canadian and U.S. markets.

He has 20 years of industry experience in motors, sales and management with Regal Beloit and General Electric. His diverse background includes expertise in marketing, Six Sigma, operations and in every aspect of the sales process.

“Ryan brings a proven track record of building strategies and sales teams focused on providing its customers with clear, differentiating value,” says Don Kenney, president of North America Water Systems and vice-president of Franklin Electric.

Born and raised in Indiana, Ryan will be located at Franklin Electric’s Fort Wayne, Ind., headquarters.

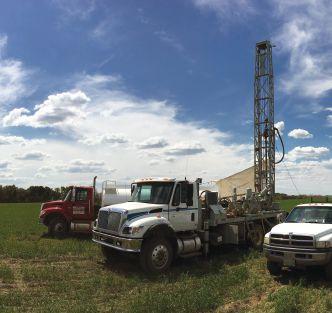

When Wellace Johnson incorporated Wellen Boring and Drilling Ltd. in 1975, he based his business on family, integrity and trust. Four decades later, these continue to be the founding principles of the company.

by JULIE FITZ-GERALD

Father-and-son duo Garth and Myron Johnson are proudly carrying on the family business, bringing fresh water to the people of Saskatoon and beyond.

In a true story of succession, Wellace’s sons, Garth and Lowell Johnson, followed in their father’s footsteps when they took over the business, located in Saskatoon, continuing to build its reputation for great customer service and reliability with every drilled well.

After 30 years with the company, Lowell retired in 2017 and handed his share of the reins over to his nephew (and Garth’s son) Myron Johnson. Today, father-and-son duo

Garth and Myron are proudly carrying on the family business, bringing fresh water to the people of Saskatoon and beyond. Lowell remains active in the business on a part-time basis and continues to provide his insights from his years of experience.

Myron grew up working with his dad and uncle out in the field, but pursued a career in finance following university. After five and a half years in the business world, and with his

uncle considering retirement, Myron’s entrepreneurial spirit took hold and he jumped at the chance to become a co-owner in Wellen Boring.

“We run a business that we’re proud of and we want to have very high integrity and be very customer-oriented in terms of how we run things,” Myron explains. “At the end of the day, water is a hugely important resource and we do take on the weight of that burden and take it seriously that we’re not settling – that we’re getting quality sources of water for people

•

•

•

•

•

•

•

that will last them and that they’re happy with. In agriculture, it’s a critical piece of any infrastructure plan, so we take that seriously.”

Myron’s mother, D’lee Johnson, manages the office and books, while his cousin, Nathan Salt, works in the field alongside him and Garth. Valentine Corlan, who has been with the company for 16 years, contributes much to the company’s field work, and in the off-season has been a key part of the team, managing the maintenance of the company’s equipment. With between eight and nine full-time employees during the busy season, the business operates four rigs: two test rigs, a large boring machine and a drilling rig.

While the company does some environmental and geotechnical work with commercial subcontractors, the core of its business is in rural and agricultural drilling, including acreages and cabins. It’s these customers that make the job so fulfilling.

“I feel like we are very fortunate to be able to work with good people constantly. Our agriculture sector here is made up of people who operate with a very high level of integrity and in the rural setting we couldn’t be more fortunate to work with the customers that we have. Our work zone covers quite a few square miles so we get to see people from all over the province, which is one of my favourite parts of the job,” says Myron.

Drilling in Saskatchewan means working with the province’s Water Security Agency (WSA), which is a unique, centralized organization that provides critical information to drillers.

According to its website, the agency brings together “the majority of government’s core water management responsibilities in one place” to “manage the province’s water supply, protect water quality, ensure safe drinking water and treatment of wastewater, own and manage 69 dams and related water supply channels, reduce flood and drought damage, protect aquatic habitat and provide information about water.”

It works in the fields of engineering, hydrology, hydrogeology, public policy, habitat protection, water resource allocation and regulations.

For Wellen Boring and Drilling, the agency has been a

‘The logistical side of things has changed slightly – the mapping and how it’s all gone to digital has made our lives easier to co-ordinate projects – but the business hasn’t changed.’

–Myron Johnson

According to Myron, giving the transition the time it deserves is crucial. “In my prior work being in business-to-business corporate finance, I’ve seen how business plans can break down very quickly if the two parties don’t fully trust each other. It creates a very negative, tense, unhealthy work environment, so a very high level of integrity and honesty is critical to making any succession plan work.”

Another important tip:

huge asset to its day-to-day operations. “It’s fantastic from an information standpoint,” Myron explains. “Really who wins at the end of the day is the customer. Having a centralized database that has the key geological and aquiferrelated information gives drillers a lot of insight. If a farmer’s looking for a well, you can zoom into his land location and see what’s been put in, what’s worked . . . it gives you some insight into what you can expect when you’re drilling.”

Being in business for 44 years, one is bound to see some changes, but apart from the WSA and improvements in technology, Myron says the field work hasn’t changed all that much.

“The logistical side of things has changed slightly – the mapping and how it’s all gone to digital has made our lives easier to co-ordinate projects – but the business hasn’t changed. In the case of large-diameter bored wells, it’s still drilling a test hole, then bringing a boring rig out and boring a large-diameter well. That being said, since Wellen Boring first started we have gotten updated equipment that’s more powerful: it does the job a bit better.”

Drilling high-quality water wells is what Wellen prides itself on and it’s where Garth and Myron will continue to focus the business. “I would say for us, although we’re open to growth opportunities, we also want to make sure we are focused on delivering a really good product in wells, so we’re trying to balance those things.”

The key to this business’ success has been providing a positive customer experience with every well drilled. And that’s been achieved through those three founding principles mentioned earlier: family, integrity and trust. “Those principles were

present from the start of the business and will continue to be at the core of how we operate. There’s an implicit trust that we all have with each other,” Myron explains. “We try to run a really good business and we don’t really have employee turnover, so we’re pretty lucky in that regard. To be able to come to work every day and trust the people you work with, you can’t put a price on that. That’s why we can deliver the service that we do, because of how we function as a group, as a business with integrity.”

This camaraderie and belief system also is ensuring a smooth succession as Lowell passes the torch to Myron.

“Communication is key. Through our transition time we had numerous meetings and planning sessions over coffee to hash out details that really make everybody feel very comfortable with it, respected and heard. Those are critical pieces in doing a succession well.”

With these beliefs forming the core of Wellen Boring, it really is their customers who win in the end.

Julie Fitz-Gerald is a freelance writer based in Uxbridge, Ont., and a regular contributor to Ground Water Canada.

For more success stories, visit groundwatercanada.com

PROUDLY SERVING THE GROUNDWATER INDUSTRY SINCE 1992: Lackner McLennan Insurance has made it their business to protect other businesses, and their specialty program for the groundwater industry has been making waves.

PROGRAM DESIGNED FOR:

• Water Well Drilling Contractors

• Pump Installation Contractors

• Geo Thermal Heating Contractors

• Hydro Geologists / Geo Scientists

• Manufacturers / Suppliers

COVERAGES INCLUDE:

• Automobile & Fleet

• Property & Commercial Liability

• Environmental Impairment Liability

• Errors & Omissions (Professional) Liability

• Bonding

Directors & Officers / Employment Practices COVERAGE: A liability program designed to provide you with defense costs arising from an employee dispute or issue with one of the Ministries. (Labour, Environment, Revenue)

STEPHEN BLEIZEFFER 519.579.3330 ext. 311 sbleizeffer@lmicanada.com www.lmicanada.com

help

Scott King, PG, P.Geo., LHG, took the helm of the National Ground Water Association’s board of directors as president late in 2018. We talked with the Canadian hydrogeologist from his home office in Buffalo, N.Y., about his professional experiences and his passion for getting water-well contractors, manufacturers, suppliers, scientists and engineers on the same page for the good of ground water.

GROUND WATER CANADA: WHAT IS THE S IGNIFICANCE OF YOUR ELECTION AS THE FIRST NGWA PRESIDENT FROM THE SCIENCE SECTOR?

SCOTT KING: Being elected president is a great honour for me and electing a scientist is a good thing for the association. It’s a signal that our association is going to look for the best leaders from different sections of our industry to work with the board of directors and move us forward. We all have something to contribute. At NGWA we’re trying to create a community of ground water professionals. “Better together” has been our theme for many years now and I want to continue with that.

WHAT SPARKED YOUR INTEREST IN GROUND WATER?

It goes back to when I was a student in earth sciences and geology at the University of Waterloo. I was looking for a course to take in the final year of my undergraduate degree. Someone suggested hydrogeology. I didn’t really know what that was. Turns out it was being taught by John Cherry, who is a

tremendous professor and one of the most well-known ground water people in Canada, perhaps the world. He is just such a great teacher and the material was so stimulating and that really got me interested

This was in the early 1980s and at that time there were lots of stories about contamination of ground water in the news, such as Love Canal – not far from where I live now – so the whole concept of contaminant hydrogeology and material contaminants moving through ground water and affecting people’s wells was just fascinating to me. I’m really happy I took that elective. It wasn’t on my radar at all but it changed my life. Being in the earth sciences program, I had been more focused on structural geology and the chemistry of rocks and big-Earth picture things rather than movement of water.

ON WHAT AREAS OF GROUND WATER SCIENCE HAS MOST OF YOUR WORK FOCUSED?

After graduating from university, I worked with a consulting company, Golder Associates, with offices in Mississauga, Vancouver and

Waterloo, and I worked there for 10 years. I started out in Toronto. Most of my time was spent doing ground water investigations around the Keele Valley landfill north of Toronto, which at that time was Canada’s largest landfill. They were building a liner to prevent leachates landfill from getting into the ground water. I was involved in developing monitoring programs for that and assessing how well the liner was working. I spent a lot of time working around landfills, uranium mining tailings in northern Ontario and other industrial properties in southern Ontario. I spent a couple of years working in Vancouver on the remediation of the former Expo 86 site, which was former industrial land on the waterfront that we were turning into land where people want to live. That has great challenges from an environmental protection point of view – both soil and ground water contamination issues.

I spent 10 years living and working for my own consulting company, King Groundwater Science Inc., in Pullman, Wash. My wife, Richelle Allen-King, was a professor of hydrogeology at Washington State University. This is in eastern Washington, which is underlain by Columbia River basalt aquifers, and this was a completely new and different area of interest for me. I also worked in the Seattle area on contaminated site issues while living in Washington State.

In 2003 we moved to Buffalo, N.Y. and have been based in Buffalo since then. My wife is now a professor at the University of Buffalo. Richelle is a terrific ground water scientist in her own right. Her area of expertise is in the movement of organic contaminants in ground water. I’m very proud of her because she was also the 2003 Henry Darcy Distinguished Lecturer for NGWA.

I worked on my own as a consultant for six years doing various projects. Niagara County, near Buffalo, has had some historical legacy issues relating to nuclear waste that date back to the Second World War and the Manhattan Project. I worked on a community project to help members of that community understand and deal with some of the issues relating to this contamination.

For the last 10 years I’ve been working with Wood Environment & Infrastructure Solutions (formerly known as AMEC, then Amec Foster Wheeler) for their Calgary office primarily focused on ground water issues associated with oilsands development in northern Alberta and other ground water issues in western Canada. It was surprising to me that oilsands mining had such a strong need for ground water management and that was interesting to me because it fits into the energy-water nexus of issues. It’s been a real challenge: most of my career has been dealing with contaminant hydrogeology or environmental issues, but this work has been primarily involved with ground water aquifer hydraulics and ground water control around open pits and tailings facilities on a very large scale. I have been travelling between Calgary and Buffalo since starting with Wood in 2009.

We’ve been using wells to pump ground water and control migration of contaminated water away from tailings facilities. It’s environmental protection. It’s been a huge challenge and it’s something I really enjoy because it’s important for me to keep learning.

I guess the big lesson I’ve learned from working with drilling contractors is that they usually know what they’re talking about. As a young person I was pretty confident that I knew what I was doing, but when it comes to putting a well in the ground, the people who deal with this every day are the people who know what they’re doing. Even though I know what I want to have accomplished, the way to get it done is through the contractor. And contractors, typically, are very professional, very knowledgeable and very interested in what they’re doing and in helping me as a scientist get the information I need. So I’ve been very impressed with the drillers I’ve worked with. We all need to have respect for the knowledge of the other person because we all bring something to the table to solve a problem with ground water. That took me years to figure out.

What’s right front and centre for people in the U.S. is perfluorinated compounds, or PFCs. A subset of those are called perfluorinated alkylated substances, also known as PFAS. These are compounds which are found throughout our society, often used in firefighting foams, Teflon materials, and other great products that we use throughout our lives. We’re finding these compounds have toxic properties at very, very low concentrations, and are very mobile in ground water. This is going to be our next challenge in terms of the contaminants

that come our way to deal with. Over the years we’ve dealt with chlorinated compounds, such as solids, trichloroethylene. Another area of real concern is nitrate from fertilizers, which has been applied for the last 60 years and in some parts of North America we’re seeing lots of storage of nitrate compounds and salts, which are gradually working their way down into the ground water system. I think it’s going to be a long-term issue for many rural agricultural areas.

We’re looking carefully at PFAS issues and NGWA is taking steps to pull together information and educational materials for government as well as homeowners and contractors so that we can share knowledge about how to deal with these. It’s going to take the entire community of ground water professionals – from those who investigate and design cleanup methods to those who install wells and treatment systems – to solve these problems. It’s manufacturers, it’s suppliers, it’s

scientists and engineers and it’s drilling contractors – they’re all going to have a role.

I think the biggest threat to ground water is that people take it for granted. Ground water is such an important, cost-effective and clean source of drinking water for our society. The public needs to understand that it’s important to protect ground water quality in terms of not allowing contamination and it’s important to manage ground water pumping so we can maintain a sustainable supply of drinking water.

I’ve visited a few state associations and, so far, what people are interested in are some of the educational and certification offerings that NGWA provides: very practical questions like “How do I take this test?” or “Can you help us get information?” That’s an area we’re focusing on by working with our affiliate state and provincial associations to help them get the information they need. We’re encouraging members to consider getting certified. Certification is an indication that they’ve met a certain standard as a contractor and can be a good marketing and distinguishing tool for them.

I want to highlight a few wins we’ve had in our advocacy programs. In the last year, we’ve had tax credits restored for geothermal pumps, there has been brownfield legislation expanded, we’ve created a working document to help people understand PFAS and we’ve had some wins in terms of funding for investment in rural wells in small communities. Recently we’ve developed a water-well construction standard through ANSI, which is a great development and feather in the cap for NGWA and should benefit our members.

Continued on page 25

Challenging conditions are par for the course for water-well drillers. While one drilling company is restoring non-functioning and abandoned wells near Milan, Italy, with the help of diesel technology, another is using a new angled drilling technique to get water for desperate farmers in Quebec.

by COLLEEN CROSS

In 2016, when a farmer and livestock producer in Quebec asked for help to save his cattle farm from a lack of well water, Simon Massé came at the problem from a new and unexpected angle –with great results.

Massé, owner of drilling company Groupe Puitbec Inc., based in Victoriaville, Que., offered farmer Jonathan Lampron of Alampco dairy farm in Sainte-Séraphine hope for his livelihood in the form of a drilling technique he calls “maximized oriented drilling.”

Lampron had spent $50,000 to install a half-dozen wells with very little yield and was thinking of moving his herd of 130 head of cattle because of the lack of water, Le Journal de Montreal reported in September 2018.

Puitbec found the farmer a volume of water four times greater than he was getting from previous wells, that is, more than 600 gallons per hour for two years since it was installed.

Massé has filed a patent for the technique in Quebec, which involves targeting angled rock rather than drilling vertically or horizontally. It is best done on sedimentary or metamorphic rock layers that lie on an angle. “We try to cross those layers,” he says.

Since that first successful job, Puitbec has completed about a dozen other projects on farms. All of the wells were productive. In fact, all but two have yielded more than the volume of previous vertical wells – and some have yielded many times more, Massé says.

The driller and professional geologist technician says he had wanted to try the technique for a while, but he needed a customer with an open mind, a site where vertical wells have not been productive and sloping rock.

He got a written opinion from the Ministry of Sustainable Development, Environment, and Fight Against Climate Change that the drilling of oriented wells was not prohibited.

Puitbec’s DR-10-A dual-rotary crawler is well suited to these jobs because its mast will slide down to the ground, Massé says.

“The best proof of the rock orientation is by sight. You need to see the rock at the surface,” he says. “Otherwise, we have to trust the maps.”

Ideally, they drill at a 90-degree angle to the rock formation. But they can sometimes drill at about 45 degrees on certain vertical formations. The technique is cannot be used on horizontal rock.

The technique has been very successful and the company has several jobs lined up for this summer.

“Drilling is getting better and better,” Massé says. “At first it took three times longer than to drill a regular well and now the time required is about the same,” he adds. He expects to improve on that time by setting up six or seven drilling sites at once to allow crews to move from job to job smoothly.

“This creates efficiencies and they don’t have

Continued on page 24

Lone Star Drills, a division of Little Beaver Inc. and manufacturer of portable drilling equipment, has new high-torque Rineer rotary vane hydraulic motors for its LS400T+ water-well and geothermal drill.

The new hydraulic motor reduces rotary service time from days to less than an hour for the LS400T+, which drills as deep as 400 feet through hard rock and volcanic formations, Little Beaver said in a press release.

The Rineer motor and Super Swivel combination is easier to work on, provides greater torque and is priced right, making it economical to keep a backup swivel on hand for emergencies, said Joe Haynes, Little Beaver president.

Lone Star offers the LS400T+ with two different Rineer motors, both providing greater torque than the drill’s previous hydraulic motor. The MV037 operates at a maximum speed of 125 revolutions per minute and is ideal for mud-rotary drilling. The motor generates up to 1,030 foot-pounds of torque at 3,000 pounds per square inch. The larger MV057 operates at a maximum speed of 60 revolutions per minute and is ideal for down-the-hole hammer drilling.

lonestardrills.com

Heron Instruments recently debuted its new dipperLog SMART, an independent, wireless, real-time data transfer system requiring no cell or Wi-Fi coverage and no costs in monthly subscriptions.

The turnkey system allows for collating, viewing and recording the remote data on any computer, tablet or smartphone from anywhere.

The Cooperative Mesh Network allows for the deployment of an unlimited number of sensors for pump control, water detection, water levels, temperature readings and more.

The system is scalable to adapt to any project.

heroninstruments.com

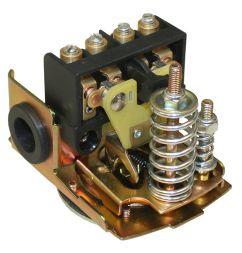

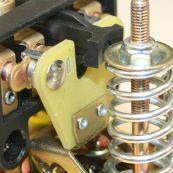

Flomatic Corporation’s new constant pressure pump control valve, Cycle Gard model C153SS, has an added pressure setting of 70 pounds per square inch.

The corrosion-resistant, stainless steel valve body has national pipe thread (NPT) connections and heavy construction. It requires nonfield adjustments.

The valve is designed to reduce rapid pump cycling. It maintains a preset system operating pressure of 40, 60 or

70 pounds per square inch in low or high conditions, which results in a longer service life. The model C153SS nonclosing and self-cleaning valve seat design supports heavy hanging loads of up to 3,400 pounds and fits in a four-inch well casing.

It is available in two different sizes: one-inch F by one-and-a-quarter-inch M and one-and-a-quarter-inch F. The one-inch F by one-anda-quarter-inch M has a flow range of one to 20 gallons per minute (dual-purpose threaded connection) and the one-and-a-quarter-inch F has a capacity flow range of two to 50 gallons per minute. flomatic.com

The Monitor high-efficiency pitless spool is new from Baker Hughes Water Systems. Each design integrates the manufacturer’s patented Monitor Flow Divider (U.S. Patent No. 8.960.275).

The Flow Divider design is located within the spool to efficiently direct water flow from a vertical to a horizontal direction, reducing pressure head loss and increasing

the energy efficiency of the pitless unit system. The units, which have a small footprint, can attach to a wide range of well casing diameters ranging from six to 36 inches.

The units, one of which is pictured here with Baker Hughes representative Nick Norgaard, are certified by NSF to NSF/ANSI 61 and 372 standards.

bakerwatersystems.com, bakermonitor.com

Canature WaterGroup has a new Aqua Flo High-Efficiency Reverse Osmosis system.

Known as the H.E.R.O., it wastes virtually no water, offering a 99.9 per cent recovery rate by collecting purified water in the storage tank and recycling the rinse water back for use throughout the house rather than sending it to the drain, said Canature in a press release.

The system also flushes the membrane with pure reverseosmosis water every time the tank is full to ensure that high TDS water never creeps through the membrane during low pressure times.

After this flush, the controller de-pressurizes the membrane so that only pure, high quality reverse-osmosis water is produced when the system restarts.

novowater.com

by GROUND WATER CANADA STAFF

The Ontario Ground Water Association held its convention and annual general meeting in London, Ont., in March, electing as its new president Matt Wilson.

Wilson, of J.B. Wilson and Son Well Drilling, in Springfield, Ont., told an audience of water well contractors, suppliers, scientists and engineers that he will listen to their issues and concerns, work diligently to address them, and lead the association in advocating for and educating the public about the ground water industry.

Scott King, president of the National Ground Water Association, in his address to the annual general meeting earlier that day, echoed that willingness to work with all professionals in the industry to further their interests and to strengthen the ground water industry as a

whole. “Working together is our mandate,” he said. The NGWA is a large U.S.-based association of which the OGWA is an associate member.

The two-day event began on Friday, March 22, with a continuing education training course for credit followed by a trade show and reception in the atrium of the Best Western Lamplighter Inn. Saturday morning was given over to division meetings and the AGM along with more opportunities to visit suppliers’ booths, including Grundfos’ popular virtual reality competition that challenged contractors to test their driving skills and pump knowledge.

After n extensive buffet lunch, many members attended technical talks by Grundfos, Baroid and Franklin Electric.

During the AGM, Jim Smith, Fleming College liaison and professor of Fleming’s drilling and blasting program in Lindsay, Ont., thanked the OGWA for its donation of scholarship funds raised at the association’s annual golf tournament in September. Smith updated members on the college’s activities, among them development of a post-graduate new initiative that gives high school students volunteer hours in exchange for promotion of the drilling program to their classmates.

A silent auction featured a wide array of donated items, including rental of an Epiroc rig, a utility cart from Wellmaster and an interesting steampunk-style lamp donated by Rideau Pipe that turned some heads. Proceeds from the auction help support the association.

The highlight of an elegant dinner and awards ceremony was a presentation by Joel Gagnon, professor and head of the earth sciences department at the University of Windsor. Gagnon and his students have been investigating waterwell turbidity and other quality issues associated with wind-turbine construction in the Chatham-Kent, Ont., region.

Some 40 rural property owners on Bay Line Road in the county have reported problems with their water wells since wind turbines were constructed. A citizens group called Water Wells First drew attention to those problems starting in 2017. The investigation Gagnon

led focused on two of those wells and has revealed significant information. Although there are clearly quality issues it is still not known if those issues – among them the presence of metals in the shale of the Kettle Point aquifer – are a risk to human health, for example, if there is an inhalation hazard. Gagnon walked a very interested audience through a slide show describing the diagnostic steps the team has taken to pinpoint the issues.

Following the presentation, executive director Craig Stainton presented three awards. Kevin Constable of Fred Constable and Son Drilling in Bradford, Ont., was given the Earth, Wind, Fire and Water Award.

Two longtime attendees, known affectionately as “The Bobbsey Twins” were given the Tenacity Award to recognize their interest in and support of the industry. Friends Clark Watson, of G. Hart and Sons Well Drilling in Fenelon Falls, Ont., and John Wilson, of J.B. Wilson and Son Well Drilling, in Springfield, Ont., happily accepted the award together.

The Archie Watt Award went to outgoing president Bryan Watson, of G. Hart and Sons, who thanked members for their support during his time as association president.

For more photos, visit our Facebook gallery.

Available on all length cable. Backwards compatible for all Well-Vu units.

• Full side view and down view at the same time!

• No need to switch cameras!

• Now shipping 3500’ submersible systems!

to relearn each time they do angled drilling,” he says. “The crews develop tricks as they go.”

Currently three crew members are needed, but the goal is to streamline things so that only two are required.

Although an oriented well costs approximately 15 to 20 per cent more than a typical water well, the customers in desperate need of water feel it’s well worth the added cost to find a reliable source of water in a place that previously seemed dry.

Idrogeo Srl, a drilling company in Fiorenzuola d’Arda, in the province of Piacenza, Italy, about an hour’s drive from Milan, is collaborating with Milan Underground Integrated Water Services on the restoration of many non-functioning and abandoned city water wells. The goal is to refurbish them and make them function to the highest standards while adhering to city regulations on air pollution.

To achieve this goal, Idrogeo acquired the first zero-emission drilling rig, the MI55-E, manufactured by Massenza. “The rig has no diesel engine on board so it has no emissions of its own,” says Matteo Massenza, engineering manager. “It is powered by electricity that can also be collected by the electric system of the city with the right permissions.”

“Electric rigs are more suitable than diesel rigs when they have to work in cities or towns, where there are severe regulations for emissions and acoustic level,” Massenza says.

“If a drilling company works often within city centres they always have to face problems for permission and regulations for pollution and noise,” he explains. “They will have no issues with an electric rig.

“Moreover, since the regulations for diesel engines continue to change (Tier IIIB, Tier IV interim, Tier IV final, V, etc.), if a drilling company buys a rig with a diesel engine this year, in two or three years it may be considered old already. Changing an engine already mounted on board, is difficult and expensive.

“With an electric rig like the MI55E this problem is solved, he says. “If they cannot use the public electricity, they can rent a generator, and [thus] it will always be in compliance with the latest regulations.”

Apart from regulations, there were other challenges.

“They had to design a special cutting tool to make a horizontal release cut down in the hole through the existing casing tubes, which had to be taken off and replaced with new casing,” Massenza says.

The well was 450 to 400 millimetres in diameter. After a first inspection with a video camera, a reverse-circulation method was used to drill over the old well casing and remove all the debris from the hole. A specific “fishing tool” was lowered to remove the old 219-millimetre-diameter well casings. The rig had the necessary pull required during this phase. However, this was still a substantial amount of weight, causing the casings to become cemented both internally and externally.

A rig mast height of 8.4 metres (27 feet, seven inches), allowed the driller to remove the column in 16-metre sections.

After the columns were extracted, reverse-circulation drill techniques were employed in standard phases that included:

• Circulation and reconditioning of the drilling mud.

• Supply and installation of 304 stainless steel casings with continuous spiral screens with robust structure, placed from 66 metres to 93 metres.

• Saturation to ground level of the remaining hole with clay and cement injection.

• Start of well activation operations with airlift and simultaneous production and development using Hydropuls.

• Completion with payload tests at various levels from 10 to 64 litres/second via a submerged pump of 60 constant voltage placed 36 metres from ground level.

• At 40 litres/second, the specific payload reached was 8.49 litres/second/metre, which were compliant with the conditions of the design project.

Using the MI55-E, Idrogeo is ease challenges encountered with drilling projects while meeting carbon regulations.

Continued from page 16

As president of the board of directors, our first duty is to take care of the business of our association. We have fiduciary responsibilities we need to look after to make sure our association can carry on and prosper.

And then, we need to provide value to members – otherwise, why would they want to be part of an association. I see part of that value is going to be advocacy within the political process for the benefit of various parts of our membership and the protection of ground water. I really want to continue with our “Better together” theme for all members of our association. For me, that’s a real opportunity for me as the first scientist to lead the board of directors.

We want to become the lead ground water resource for federal, state and local governments and regulatory agencies and be a source of information for contaminant problems such as PFAS and managed aquifer recharge, which we think is going to be a very important issue in the future. All that comes out of developing a comprehensive advocacy plan so we can advance the goals of the ground water community, in the United States and, where it applies, in other parts of the world.

Managed aquifer recharge, or MAR, is the process of taking excess water, primarily surface water, putting it back into the ground for storage and then being able to take it out when you need it. In North America, we often have excess water in the spring from snowmelt or rainfall. Once we’ve protected our needed base flow in streams, we can take some of that excess water and put it in the ground – at times when we’ve got lots of water – store it, then use it later in the year when we don’t have much rainfall. This can be a really cost-effective

way to use aquifers as part of ground water infrastructure and maintain the sustainability and resilience of our water supply. The strategy is already being used in some parts of Canada and the U.S. and could be enhanced in the future. To do this effectively, this is another area where all parts of our ground water community could be involved. One aspect is to drill appropriate wells for injection. Another is for scientists and engineers to design, manage and model how this might work. And then there are certain products we’re going to need –for example, pumps, piping and infrastructure – that our manufacturers could help with.

I’m really pleased to see the formation of a new Canadian association and I’ll be happy to support it in whatever way I can. NGWA is also pleased to see an association move forward. NGWA’s mission is to create a community of ground water professionals and we’re working together to advance ground water knowledge and success for our members. I think one of the ways the Canadian ground water industry can do that is through a national association.

I like to ski in the winter. Richelle and I enjoy cross-country skiing and we like to get outdoors and go hiking and camping. For the last few years since I’ve been working for the Calgary office, we’ve spent time in Banff, Jasper and Yoho national parks hiking.

The other hobby I have is woodworking. I’ve been trying my hand at making furniture and small pieces for the house as well as making repairs to our old house. It gets me out of my office and away from a computer monitor. It’s nice to do something different with your hands and your brain. Editor’s note: This interview has been edited and condensed.

by Jeff Wahl

by Jeff Wahl

TIn my 20 years of experience in the field of water quality, I have heard many perceptions expressed by people regarding the water at their home or cottage. Some of these beliefs are inaccurate.

For some, the idea that their well water is clean, clear and safe is passed from generation to generation. For others, there has been no development on the lake for years and they believe the water must be safe. Often I hear that “my shore well is lake water as it is fed directly from the lake.” In new home construction I often hear, “When they drilled the well the test was good, it is deep and cannot have any bacteria.”

he drilling of a well is a welcomed act for many people as it provides the necessity of water for their home or cottage. In Canada we are fortunate to have an abundance of ground water that can provide a reliable, year-round source of water for many municipalities and rural owners. Provincial well regulations indicate what is required including the depth, well casing and well yield, recommendations for the pumping rate and pump size. Wellhead protection is completed to ensure that surface contaminants do not enter, and proper disinfection procedures are performed. There is no debate over this process and regulations clearly spell it out. Once the well tag is installed, records are given and water is flowing, the owner is left to their own responsibility for the well water quality.

Many people believe the water is safe just the way it is. I believe this is the way many people want to see their water.

How can an owner be sure that the water in their well is safe? The options include routine bacterial testing at the local public health unit for bacteria, water sampling with an accredited laboratory or sampling by a qualified water treatment professional. More recently there has been the advancement of do-it-yourself test kits available for purchase. All these options provide a snapshot of a specific time and are not indicative of ongoing water quality.

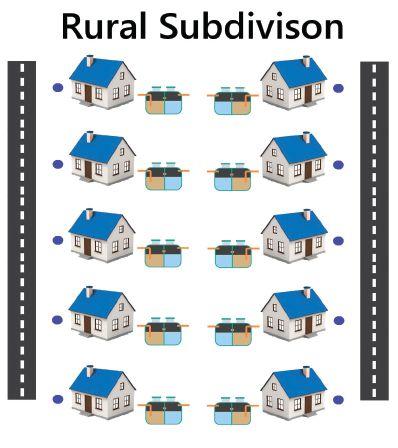

The most common perception I have observed is this: “My septic system is at the back of my house and the well is out front. It cannot contaminate my water as it is too far away.” This notion is commonplace for many people who live in rural “subdivisions” that have no municipal water and sewer services and are a grouping of homes side by side and back to back, each with a well and septic system. In reality, all septic effluent is discharged from the system through weeping tile into the ground. How it travels after entering the ground is subject to layers of soil, rock formations and the ground water table.

Experience has shown that the costs for laboratory testing and the inconvenience of collecting and delivering a water sample to the health unit or water treatment company often deter many people from doing it at all. This is amplified in rural areas where access is limited, and time constraints and distances are increased to submit a sample. Often sampling is conducted only when there is a noticeable change in water quality or when a real estate transaction occurs.

Consider the following analogy: Five drops of arsenic are deliberately placed in a water sample bottle prior to submission. (This would be intentional and for the purpose of illustration only.)

• The sample is taken to a health unit for bacterial testing. It passes, as no arsenic test was conducted.

• The sample is taken to an accredited laboratory. Arsenic is detected, as it was tested for.

“I had the water tested at the health unit and everything is good: it passed the test.” This idea is also commonplace with many people never testing the water again after the initial test or unless the house is up for sale. The idea of a health-unit test being a good indicator of overall water quality is also common. Many perceive the test is for everything and that authorities would let them know if the water were not safe. They are surprised to learn the health-unit test is just a bacteria test for coliform and E. coli and not for arsenic, lead, chemicals, pharmaceuticals or any other water contaminant.

The sample is taken to a water treatment company. Tests for hardness, iron, sulphur, total dissolved solids, pH and manganese do not detect arsenic, as no arsenic test was

It is easy to substitute arsenic with any contaminant that may enter a ground water source and ultimately flow from a consumer’s tap. Even with “common testing” the contaminant may never be identified, as it was never tested for. No water source remains in a constant state of quality without fluctuations due to seasonal changes, changes in the surrounding environment, human influences and changes in ground water flow patterns.

It is generally perceived that deep water sources – that is,100 feet and deeper – cannot contain bacteria as they are too far into the ground for bacteria to survive. This is something I have heard repeatedly and is a reason many people do not test their well water. Areas with heavy rock formations are subject to a series of deep fissures that can bring surface water deep into the ground to the water table. I have seen bacteria present in wells as deep as 200 feet.

Whatever your customer’s perception of water is, ensure it is based on accurate information about the water source. The risks to water quality are diverse, with most contaminants invisible to the human eye. You cannot judge the quality by the taste, smell or colour alone. Have the customer contact a qualified water treatment professional for water testing and treatment options.

Given the vast uncertainty of any ground water source over a calendar year, it is critical that a homeowner be given the information necessary to make an educated choice by a qualified source. The idea of “one test a year and my water is safe” is an antiquated one that does provide a snapshot of water quality but not of ongoing changes. The need for properly installed water treatment devices is no longer one of perceived need but one of necessity to ensure the safety of water for the consumer. This article originally appeared as Volume 2, Issue 3, of Wahl H2O – Educating Through Awareness

Jeff Wahl has 20 years of experience in the water treatment industry. He is the chief executive officer of Wahl Water and a water educator. For more information, contact Jeff at jeff@wahlwater.com.

Jeff Wahl has 20 years of experience in the water treatment industry. He is the chief executive officer of Wahl Water and a water educator. For more information, contact Jeff at jeff@wahlwater. com.