Although it features many refinements, today’s CME-55 has been a standard of its class for over 50 years. The popularity and high resale value of this machine bear testimony to its performance record and durability in the geotechnical, environmental, mineral exploration, and water well drilling industries.

With 28,275 pounds of retract force and 18,650 pounds of down pressure and available 9,400 foot pounds of spindle torque, the CME-55 is capable of drilling holes up to 14.75 inches in diameter using conventional or hollow-stem augers. It can also be equipped for productive air or mud rotary drilling and diamond core drilling.

The CME-55 can be mounted on a variety of carriers and two-wheel or all-wheel drive, single or tandem-axle trucks. It can also be mounted on the CME-55T trailer or on the CME-300 rubber-tracked carrier.

There’s even two low clearance models, including the CME-55LC and the powerful CME-55LCX with a 130 horsepower diesel engine that produces 11,950 foot pounds

of spindle torque. Both models are equipped with a standard quick-disconnect mast for normal operation. When overhead clearance is limited, you can quickly convert to low clearance mode by disconnecting the mast and installing the low clearance hoist line sheaves. The auto hammer also has a secondary lifting cylinder for limited overhead operation.

If you’re looking for a drill with proven performance, reliability, durability, and versatility, give us a call. Find out how the CME-55 can improve your production and your bottom line.

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

Editor | Colleen Cross ccross@annexbusinessmedia.com (519) 428-3471

Advertising Manager | Sharon Kauk skauk@annexbusinessmedia.com (519) 429-5189, (888) 599-2228, ext 242

Account Coordinator | Barb Comer bcomer@annexbusinessmedia.com (519) 429-5171, (888) 599-2228, ext 210

Media Designer | Curtis Martin esun@annexbusinessmedia.com

Group Publisher/VP Sales | Martin McAnulty mmcanulty@annexbusinessmedia.com

COO | Scott Jamieson

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@groundwatercanada.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0383-7920

Circulation

e-mail: lmalicdem@annexbusinessmedia.com Tel: 416-442-5600 ext. 3547 Fax: 416-510-6875 or 416-442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Subscription Rates

Canada - 1 Year $21.00

U.S.A. - 1 Year $46.00

Annex Privacy Officer: Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Ground Water Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Serving the Canadian Ground Water industry for 45 years.

www.groundwatercanada.com

13

Tips from drilling businesses on getting your office, and your business, in order

Experts share the latest noise -reducing methods and tips for using them

A novel technique has potential to build resiliency in water supply 21

How to move from confrontation to conversation about performance 24

Obtaining a water level in a well that produces gas can be fraught with errors

Federal government supports Ontario flood mitigation projects

The federal government has announced more than $7.75 million in funding to support work on new projects in Ontario under the National Disaster Mitigation Program.

New Hampshire to test hundreds of private wells

New Hampshire is sampling 500 private wells to test for around 250 toxins and natural pollutants ranging from bacteria and salt to PFAS and pesticides, creating an unusual, sweeping view of the quality of residents’ drinking water and what affects it. Valley News reports.

by Colleen Cross

Heading into fall seems a good time to get our offices in order.

I had a chance to purge twice this spring – once when I moved desks and again when our company repainted. I tossed old paper files that hadn’t been looked at in three years, I changed my desk setup so it makes more sense and helps me get things done.

I did a quick re-organization of my filing cabinet – with the tabs in the right positions – and so far I’m keeping up the simple system. It’s helping me find things, make better use of that space and save time that is better spent talking to water-well drillers.

I made decisions about various mysterious piles of papers. Making decisions, I find, is an acquired skill in itself that can improve every aspect of your work and life.

It felt good knowing I had taken control of my workspace. And I now feel more confident that it makes a good impression on co-workers, managers, visitors to the company.

If this sounds smug, I must tell you I’m no Marie Kondo, I don’t enjoy organizing and cleaning, my handwriting looks like hieroglyphics when in a rush and I have found things behind my filing cabinets that, quite frankly, are best left to the imagination. I tell you all this to make the point that every person – and every industry –has a unique way of working. Everyone can make changes to their routine that make them more productive and help the bottom line.

If what you’re doing is working for you, more power to you.

Just be sure it truly is working. Some signs that it may not be:

• Customers call to update details on a job and you can’t find the file.

• The glue is coming off your army of sticky notes with phone numbers and they are threatening to float away.

• You find yourself or your team having to re-do tasks.

• You’re often scrambling and not getting to parts of your job that make you money – the things you need to be working on to grow your business.

Worse than the signs you recognize are those you don’t. Because you may deal with a customer only once, return customers may not seem a problem: either they call you with questions or hire you to deal with well issues down the line. But you can’t take them for granted because they are connected to new customers.

What if past customers aren’t recommending you to others? What about the new customers you don’t get because you forget to phone them back or their first visit leaves a bad impression?

Our goal this issue is to help you towards a smoother operation. Writer Lynn Fraser talked to drilling companies about best practices in their office and reveals in “An organized office” (page 10) that it’s about much more than paperwork. As Kim Friesen of Friesen Drillers puts it, “Success is not an individual component of a company, but a team effort from our frontline receptionist to scheduling to bookkeeping and every aspect in between that has made us successful.”

Hiring and customer service are two important cogs in the wheel. “The gift of feedback” (page 21) provides tips on dealing with staff performance issues. “Proactive customer service” (page 30) offers ideas on how to get to customers before they need you by anticipating their needs.

For further reading, try Business Development Bank of Canada’s Entrepreneur’s toolkit, found at www.bdc.ca, a good resource to help you get your office in order.

ISSUE: The next issue of Ground Water Canada will highlight pumps and related technology. Also included are our 2020 pull-out calendar and buyers guide!!

Rotary

Threaded

Sizes 2” to 36”

University of Guelph researchers will receive almost $11 million from the federal government and local government and industry partners for ground water studies focused on Wellington County in Ontario.

The new funding will enable investigators monitoring local bedrock aquifer wells to learn more about ground water and its interaction with surface water –information that will ultimately help the City of Guelph and nearby municipalities manage resources more sustainably, said engineering professor Beth Parker (pictured) in a news release from the University of Guelph.

The project will be supported by research chair and project funding from the Natural Sciences and Engineering Research Council of Canada (NSERC), which will provide $3.125 million for renewal of an NSERC Industrial Research Chair held by Parker since 2007. Her chair renewal will be supported by matching industry funding.

A separate NSERC grant worth just over $2 million

will support the ground water monitoring project. That funding will also be matched by industry and municipal support, including $400,000 from the City of Guelph and $460,000 from Nestlé Waters Canada.

Fractured bedrock aquifers provide drinking water for more than one million people living in some of southern Ontario’s fastest-growing communities, including Guelph, which is projected to grow to almost 170,000 people by 2031, the release said.

Over the past decade, a University of Guelph team led by Parker has installed high-resolution monitoring systems in bedrock aquifer wells around Guelph and southern Wellington County.

She directs the U of G-based G360 Institute for Groundwater Research, which studies complex local aquifers, including how natural features protect this water resource and how wells affect ground water.

“The sustainability of groundwater as source water for communities ultimately depends on the quality and quantity of local ground water,” Parker said, adding that “municipalities need more and better-resolution information to understand the status and vulnerability of our water resources so that good science can underpin water protection and management.”

Project funding will also come from the Town of Erin and local geophysical company Paterson Grant and Watson.

On July 11, Grundfos Canada broke ground on a $3.5-million expansion of its Oakville, Ont., location that will more than double warehouse and assembly space to accommodate expected growth.

“This investment underlines our continued commitment to the Oakville community and will have a long-lasting impact on the local economy and beyond,” said a news release from the company, which was established in 1981 to distribute in Canada pump, motor and other products from Grundfos plants worldwide.

Grundfos Canada is the Canadian distributor of Grundfos products made in Denmark, the U.S. and other Grundfos locations.

The company employs more than 100 people. The expansion of its current facility by Maple Reinders Construction will more than double warehousing and service capabilities to 48,000 square feet. This will enable the company to add new skilled jobs and apprenticeships.

The expansion is being done to accommodate $150 to $170 million in sales that is expected, said Simon Feddema, president of Grundfos Canada.

“We are betting on growth in the ground water sector,” said Dieter Sauer, regional managing director for the Americas, who helped officiate the ground-breaking ceremony. Also on hand were Stéphane Simonetta, group executive vice-president and chief operating officer, and Eric Boutot, regional operations vice-president for the Americas.

Attendees heard from Feddema, Simonetta, Oakville mayor Rob Burton and other Oakville dignitaries.

Grundfos staff led tours of the office, assembly plant and warehouse.

Based in Denmark, Grundfos employs 19,000 people worldwide and produce more than 16 million pump units, circulator pumps, submersible pumps, and centrifugal pumps.

The expansion is expected to be complete by July 2020.

A new study published in the journal Nature and Sustainability finds water wells are being drilled deeper and deeper since the 1950s and that the practice is an unsustainable stopgap to ground water depletion.

Study authors Debra Perrone and Scott Jasechko tackled a number of different questions about ground water use. According to UC Santa Barbara’s The Current, they set out to determine both where in the country wells are located and what purposes they serve – domestic, industrial or agricultural. They also wanted to track the depths of wells in different areas and test to see if wells are being drilled deeper over time.

Focusing on regions known to depend on ground water, such as California’s Central Valley, the pair collected a wealth of information about different types of wells across the country. Ground water is generally a matter of state management, so they had to cull their data from a variety of sources. “[That was] one of the biggest hurdles,” said Perrone, an assistant professor in UC Santa Barbara’s environmental studies department.

“It took us about four years to collect and quality-assure all these data sources,” added Jasechko, an assistant professor based in the Bren School of Environmental Science & Management.

Perrone and Jasechko found that new wells are getting deeper between 1.4 and 9.2 times as often as they are being drilled shallower.

What’s more, the researchers found that 79 per cent of areas they looked at showed well-deepening trends across a window spanning 1950 to 2015. Hotspots of this activity include California’s Central Valley, the High Plains of southwestern Kansas, and the Atlantic Coastal Plain.

The reasons for drilling deeper are varied and include people drilling deeper to avoid contamination seeping into aquifers from the surface, to access aquifers that have less stringent withdrawal regulations or to source more water.

“What we’re finding is that in places where water levels are declining, some people are drilling deeper, maybe to avoid having their primary water supply go dry,” Perrone said. “Regardless of the reasons why Americans are drilling deeper, we suggest that deeper well drilling is an unsustainable stopgap to ground water depletion.”

Four major factors explain why deeper drilling won’t solve water woes indefinitely: it costs more, it requires more energy to pump water from deep underground compared to water closer to the surface, deeper strata are generally less conducive to ground water extraction, and the ground water, which tends to get saltier at depth, will become unusable if not treated.

This issue hits rural communities particularly hard. “Ground water is a crucial resource for rural communities,” Perrone said. “Our previous work found that rural ground water wells are especially vulnerable to going dry.” What’s more, she added, these communities often have less capacity to update their ground water infrastructure.

Franklin Electric Co. Inc., based in Fort Wayne, Ind., has acquired First Sales, an Indiana manufacturer of water treatment and filtration equipment for the residential and commercial markets.

First Sales designs, manufactures and distributes its products under the Sterling Water Treatment and Avid Water Systems brand names, primarily for customers in the United States. In fiscal year 2018, First Sales had annual sales of approximately $14 million.

“First Sales has developed industry leading products for the professional installer of in-home and commercial water treatment systems,” said Don Kenney, president of Franklin Electric’s North America Water Systems business unit, in a news release. “These products are sold through some of the same channels as Franklin’s existing products, and we look forward to continuing to serve First Sales’ customers with best in class quality, service, availability, innovation and cost.”

Franklin Electric produces and markets systems and components for the movement of water and fuel, and serves customers around the world in residential, commercial, agricultural, industrial, municipal and fuelling applications.

Standardized procedures in an organized office cut down on lost time and money. In turn, this consistency increases client and employee confidence in a company’s ability to produce reliable work.

by J. LYNN FRASER

Technology makes businesses efficient, but there is more to business than just efficiency. Up-to-date technology and the human voice help to maintain business relationships.

Standardized procedures in an organized office cut down on lost time and money. In turn, this consistency increases client and employee confidence in a company’s ability to produce reliable work.

An organized office runs smoothly when staff, records, communications, training and safety are governed by standardized routines.

Ground Water Canada spoke with three established drilling businesses in Canada about how they keep their offices, and their businesses, in order.

At Drillwell Enterprises, a custom-made book keeps track of jobs that are “ready to go, or are in progress, or are to be billed,” according to Shawn Slade, a partner at the British Columbia-based company. A large magnetic board is used to

organize jobs that require attention before they go out, Slade says.

“We have found that success starts at the first visit or first phone call,” says Kim Friesen, manager at the company based in Steinbach, Man. “Even though we have a fully automated phone system that is integral to our company, we have found that the human interaction from a personal visit or phone conversation is the foundation of building a good relationship with our clients, that can last generations.”

“We have a multifunctional online scheduling program that was developed by local IT to meet our specific needs,” she adds. “This customized colour-coded program organizes quoted, scheduled, dispatched and completed jobs and allows us to see, at a glance, the status of all our projects. This program also allows our drillers to access their daily schedule, which includes maps, job information and any applicable permits required before they head out for their day.”

Paperwork for jobs is printed out every morning at Aaron Drilling of Black Diamond, Alta. The company also uses a daily work chart, timesheets and work orders that are sent to the “guys in field,” president Tyler Crawford says.

You don’t know where you are going if you don’t know where you have been.

“We keep hard copies of all project material (notes, quotes), drillers logs and history for easy access among all staff for review or maintenance purposes,” Friesen says. “For security and backup, we have all documentation electronically archived.”

“We have found that completing our well reports electronically in house makes for cleaner, more professional and efficient documents that we send to our clients.”

Aaron Drilling’s well records are initially handwritten by drillers in the field or created on the crew’s cellphone or laptop. Records are then sent to the company’s office manager and saved on Alberta Environment’s database, says partner Tyler Crawford. The company has a custom-built database for its driller reports.

Keeping and storing an offsite inventory of field notes, invoices, trucks, office equipment and digital devices, for example – in case of fire, flood or theft – will help you file a claim with your insurance provider. It will also be your backup for tax and legal disputes.

Safety certification and training is about more than ticking a box on a list of requirements.

“It’s very important to invest the time in safety. We spare no expense to educate guys in the field,” Aaron Drilling’s Crawford says. “Our office manager tracks certifications in skills and first aid on a PC.” Aaron Drilling also uses a safety location system to track crews in the field.

“We use Excel alerts,” Drillwell’s Shawn Slade notes, to track employee training and to monitor expiration of safety certifications. At Drillwell copies of safety meetings are kept in both paper and electronic formats. Back-up copies are kept in a file folder in the office and older copies are kept in storage.

“Safety has become a huge component in the industry,” Kim Friesen says. “We are a front leader, being the first COR-certified drilling company in Manitoba. We now have three of our five drilling companies in Canada COR certified and are currently working on getting our fourth company certified. With the help of our safety co-ordinator, who manages the safety system for all five of our companies, we have been able to streamline our safety program. This has given us the advantage in procuring contracts.”

You wouldn’t leave your office unlocked at night, so don’t leave your digital devices open to digital “pirates.”

Modern-day pirates can use malicious software to take control of your business’s

computer files. These people can encrypt your files to hold your business hostage. A ransom may be demanded in return for gaining renewed access to your files. The RCMP warns that paying the ransom may not guarantee access to your files.

All it takes is one click on an email from an unknown source or on a pop-up ad or an attachment whose source you can’t verify to expose your devices to malware or ransomware. Be wary of phishing scams, that is, ploys to find out personal information about you by telephone or through unfamiliar websites. According to the RCMP’s website during each day in 2015 over 1,600 Canadians were affected by ransomware attacks and that number doubled in 2016. The RCMP advises training your staff on security procedures.

Standardized procedures in an organized office cut down on lost time and money.

Keep your anti-virus software and antimalware software up to date on all devices connected to your business. Back up your systems on a removable device or on the cloud. It should be a regular office routine to disconnect your back-up devices when not in use.

In an organized office specialized software and staff are essential.

“We stay on top,” Crawford says. “Our year end is scheduled for tax season. “We use QuickBooks daily and we have an office manager who handles payroll and payables.” Aaron Drilling also uses a parttime chartered accountant and a thirdparty accounting firm. “Accounting is a tremendously large expense,” he adds.

“Bringing someone in on filing, invoicing, and accounts receivable” is a best practice for a business, Slade notes. He advises owners to “be comfortable” with Microsoft Office. Drillwell uses Sage accounting software and QuickBooks for quoting and accounting. The company also has an in-house certified accountant “who never stops organizing for tax season,” Slade says.

“Word and spreadsheets don’t talk to

each other,” says Rick Oberle, president of Geographic Insights, based in Lansing, Mich. Oberle’s company offers Well Magic, a software program designed for the well industry. It generates reports, work orders, estimates and invoices. “It is an integrated system that is more efficient and substantial than paper-and-pen procedures,” he says. Oberle believes that “software takes less time. A computer program is like any other tool. [People’s] phones are more complicated than their PCs.”

“Best practices is bringing someone in for filing, invoicing, and accounts receivable,” Slade adds.

Technology makes businesses efficient, but there is more to business than just efficiency. Up-to-date technology and the human voice help maintain business relationships.

Kim Friesen notes, “Success is not an individual component of a company but a team effort from our frontline receptionist to scheduling to bookkeeping and every aspect in between that has made us successful.”

“We’re dealing with people’s houses and properties. [Being able to communicate] is important for customer service, to answer questions, for accurate documentation, and [being able] at a fingertip to explain charges,” Tyler Crawford points out. “When jobs come in we can intercept crews to send them work orders. We have the ability at any time to know where they are,” Crawford says.

Aaron Drilling uses cellphones with boosters. Their employees are responsible for checking in regularly.

At Drillwell, local crews in the field have two-way radios and use satellite phones when they are at remote locations.

“Our most valuable asset is our employees, Tyler Crawford says. “We care about getting them to their families every night. Keeping our employees happy, healthy and safe helps everything run smoothly.”

Lynn Fraser is a technical editor with academic, non-profit, government, industry, and corporate experience. She specializes in academic reports, journal articles, and grants. For 20 years her writing, over 300 articles, has appeared in national and international magazines and newspapers

Rising health claims due to increasing hearing loss among Canada’s military personnel is a cautionary tale for industries with high noise levels.

by JEAN LIAN

A 2016 study obtained by Radio-Canada found that the rising incidence of hearing loss is due in part to military members’ reluctance to wear protective equipment and not being provided with suitable hearing devices. Almost a third of them have chronic hearing problems by the time they retire, according to surveys by Veterans Affairs.

Like the military, industries such as manufacturing, construction and resource extraction have high noise levels. According to Claudio Dente, president of Dentec Safety Specialists Inc. in Newmarket, Ont., noise generated in the general industry ranges between 500 and 4,000 Hertz (Hz). “The human voice probably has 500 Hz; 4,000 Hz is a type of tool running at high speed,” Dente says. Noise-induced hearing loss (NIHL) is the gradual and irreversible loss of the ability to hear sound. In most Canadian jurisdictions, the maximum permitted noise-exposure level over an eight-hour period is 85 decibels or dB(A).

Quebec allows a maximum noise-exposure level of 90 dB(A), while federal work-places cap it at 87 dB(A).

A scientific way to conduct noise-level tests is using a sound-level meter, which is a handheld instrument with a microphone to measure sound that travels through air, says Beverley Borst, an advanced safety specialist with 3M Canada in London, Ont.

Another method is to use a noise dosimeter to measure the specific noise exposure of a worker:

a dosimeter is placed on the worker’s shoulder with a microphone near the ear to calculate noise exposure over an eight-hour average. Figuring out the amount of protection needed for a work environment is the very first step, followed by selecting a hearing protector to filter down the noise below the allowed limit for the provincial requirements. “The objective of hearing protector is not to eliminate sounds so that you can’t hear anything,” Dente says. “It is to reduce it below a dangerous level that will start to affect your hearing.”

ABOVE: The 3M Peltor electronic earplug improves situational awareness, while Dentec’s Connex combines a premium hearing protector with the latest Bluetooth technology. DSI’s new NP 106 has a bell shape to reduce pressure inside the ear canal.

There are two types of hearing protection: earplugs are inserted into the ear canal, while earmuffs have soft ear cushions that fit around the ear and are held together by a headband.

The different types of earplugs available include foam roll-down, pushto-fit, reusable, disposable, banded and custom-moulded. For earmuffs, they can be worn over the head, attached to a hard hat or worn with a back band. “All of them are available in communication devices too,” Borst says.

According to Borst, the attenuation or noise-reduction rating (NRR) for earplugs in general ranges from 25 to 33 decibels, while the rating for earmuffs hovers between 20 and 31 decibels. “What we know is workers receive about 50 per cent of NRR for earplugs,” she says. That means for an earplug rated at 30, most users will get 15 decibels of that protection. Earmuff users get about 70 per cent of the protection.

One possible reason earmuffs seem to offer a higher protection is that it is comparatively easier to put an earmuff over the head than to insert an earplug properly into the ear canal. Borst cites research indicating that about 60 to 70 per cent of users wear their plugs correctly. That translates into a whopping 30 to 40 per cent of people not getting it right, which is “a fairly high percentage,” she suggests.

Earplugs may seem like a simple hearing protector, but it’s one that people may not necessarily know how to use properly. Part of the reason is lack of training and taking the time to insert earplugs properly.

“I don’t think people realize how important it is to actually roll a foam earplug down, and how important it is to reach over with your opposite hand and pull the pin up and out,” Borst says. “If a foam earplug is inserted properly, it will provide a very high level of protection.”

Dente agrees that not inserting an earplug correctly can give people a false sense of protection. Unlike an earmuff that is straightforward to don, “an earplug is a lot of work to get it in place by comparison to be effective.”

Dente recommends giving employees training or a refresher course once a year on the negative consequences of not using hearing

protection properly. “People really need to be attentive to make sure they insert it properly so that it is providing an effective seal,” he says.

When choosing hearing protectors, several factors need to be considered: fit, comfort, ease of use and compatibility with other personal protective equipment (PPE); the attenuation (noise-reduction rating) needed; and environmental factors such as humidity, ambient temperature or even the need for something compact if the wearer needs to access tight or confined spaces or is wearing a welding helmet.

According to Dente, the problem with earmuffs is that they can be hot to wear for a prolonged period. Its weight and the tight grip of the band can also exert

Dente recommends giving employees yearly training or a refresher course on the negative consequences of not using hearing protection properly.

pressure on the sides of the head. If this situation occurs, a user will likely bend the wire of the earband to ease the pressure on the sides of the head, which can compromise the NRR, cautions Mino Alkhawam, product manager of DSI Safety Inc. in Laval, Que.

As for earplugs, they can cause pressure in the ear canal. “Everyone doesn’t have the same ear canal size,” Alkhawam says. “This is why it might act differently from one person to another.”

Some earplugs have a higher expandable foam that generates more intense pressure in the ear canal, while others have lighter pressure and expand slower, hence exerting less pressure, he adds. DSI has a new hearing protector, the NP106, which is designed with a bell shape to reduce pressure inside the ear canal but continues to offer noise attenuation with an air pocket between

both ends of the earplug to absorb noise and vibration.

Getting the right level of noise attenuation can avoid overprotection of a worker that results in their inability to hear warning signals, noise from machinery and other sounds in the immediate environment. “You can have possible overprotection when sound level reaching your ear is less than 70 decibels,” Borst warns. “It is important to match how much protection you are getting with the noise level, and you need to consider any existing hearing loss because they may be at a higher risk of being overprotected.”

3M carries a new electronic earplug – the EEP-100 – that provides hearing protection and improves situational awareness in challenging environments. The earpieces are small and lightweight, making them compatible with most head-borne PPE. The earplug can be recharged via a micro-USB jack on the charging case, which stores the earpieces when they are not being used. It also offers different earplug tips: reusable and a comfortable push-to-fit that does not

need to be rolled down.

The other type of earpiece 3M offers is a push-to-fit earplug. “What is nice about them is they are a foam plug, but they have a handle. So I don’t need to roll them down, and it is easy and fast to insert even for a novice user,” Borst says.

3M™ E-A-R™ Push-Ins™ Earplugs are available corded, non-corded and in metal-detectable options. The soft, flexible foam conforms to the unique shape of each ear for comfortable noise reduction. Its flexible stem requires no roll-down and makes it suitable for use by people who have difficulty rolling and inserting disposable foam earplugs, such as when their hands are soiled.

For any PPE to be effective, users need to know the requirements of the work conditions and determine if there might be issues with compatibility.

For example, a worker who already has hearing loss as a pre-existing condition should consult a physician before using any hearing protection, Alkhawam

For employees who need to wear a hard hat, most earmuffs are designed to fit most hard hats with a sided slot. Some earplugs come with cord so that they will not fall off onto a production line, while certain earplugs are required to be visible when worn, such as by those who work in the food industry. Some earmuffs come with an antenna so that a worker can listen to radio or plug into an iPod, Alkhawam explains.

One trend Dente observes is that more and more hearing protectors can be hooked into communication devices such as cellphones. “The thing that is really happening in the marketplace is technology is touching these products too,” he says, citing increasing affordability as another trend.

PROUDLY SERVING THE GROUNDWATER INDUSTRY SINCE 1992: Lackner McLennan Insurance has made it their business to protect other businesses, and their specialty program for the groundwater industry has been making waves.

PROGRAM DESIGNED FOR:

• Water Well Drilling Contractors

• Pump Installation Contractors

• Geo Thermal Heating Contractors

• Hydro Geologists / Geo Scientists

• Manufacturers / Suppliers

COVERAGES INCLUDE:

• Automobile & Fleet

• Property & Commercial Liability

• Environmental Impairment Liability

• Errors & Omissions (Professional) Liability

• Bonding

Directors & Officers / Employment Practices COVERAGE: A liability program designed to provide you with defense costs arising from an employee dispute or issue with one of the Ministries. (Labour, Environment, Revenue)

STEPHEN BLEIZEFFER 519.579.3330 ext. 311 sbleizeffer@lmicanada.com www.lmicanada.com

Dentec offers Connex, a premium hearing protector with an NRR of 25 equipped with the latest Bluetooth technology. This hearing protector with a built-in microphone provides exceptional sound quality and can be connected to iPhone or Android devices with Bluetooth, allowing users to listen to music or take cellphone calls up to nine metres away from any Bluetooth device. Proper maintenance is also important. “Every time you put your earplug or muff in, you need to inspect it,” Borst advises. “For foam plugs, make sure they are not excessively soiled or contaminated, and they return to original shape. For earmuffs, inspect for cracks or worn

The outside of an earmuff can be wiped down regularly with warm water and mild soap, and it is recommended that the cushion and the inner foam be replaced every six months or earlier if they are damaged, she adds.

One thing to look out for in an earmuff is the ring inside it, typically made of polyvinyl chloride or some composite material. “Look at them every day to make sure there is no tear in the seal because it will allow vibration or sound to get through if torn,” Dente cautions.

This article was originally published in OHS Canada magazine.

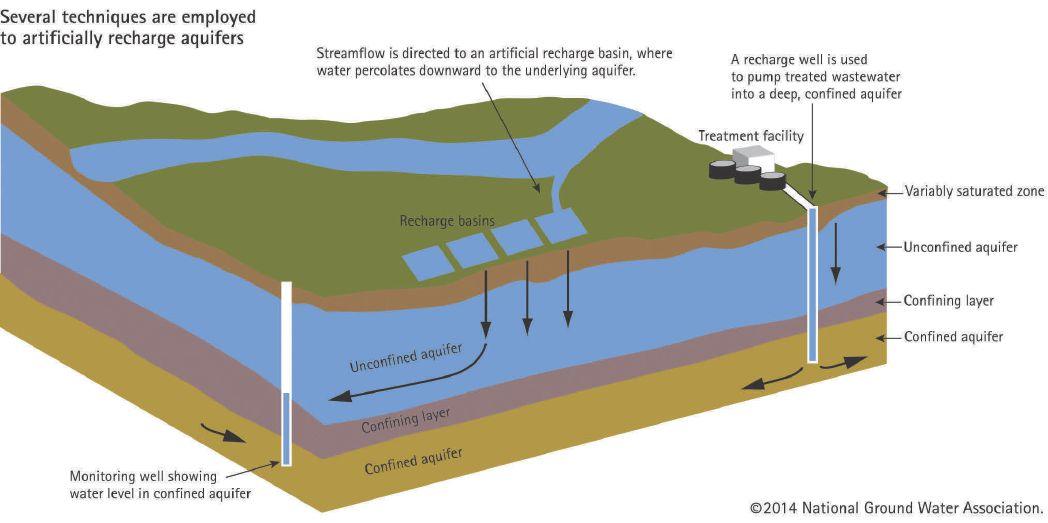

Simply put, managed aquifer recharge (MAR) is the process of taking water, typically excess surface water, and putting it into an aquifer for later use.

by CAROLYN CAMILLERI

As Don Corbett, senior hydrogeologist for the Regional Municipality of Waterloo, explains, MAR is a fairly broad category, with roots going back to the ancient Persians, who captured water coming down off the mountains, detained it, and tried to get it to percolate into the ground.

“Any way you can slow down surface water or capture surface water, or even in some cases treated waste water, and kind of force it into the ground, that’s basically managed aquifer recharge,” Corbett says. “And there are lots of different ways you can do that.”

Within MAR, there are subsets, including flood MAR, which captures flood flows, detains the water in surface basins, then allows it to recharge aquifers. MAR processes are increasingly a best practice with new

developments in sub-watershed and greenfield areas, where efforts are made to ensure the development doesn’t “shortchange” aquifers and nearby water features that depend on ground water. Another subset within MAR is ASR – aquifer storage and recovery – where instead of using recharge basins, treated water is injected into aquifers using flow wells.

“Some people think it’s a little bit like cheating the hydrologic cycle, but I liken it more to actively managing the hydrologic cycle in a way that we’re taking advantage of every little bit of surplus water that’s available to us,” Corbett says, noting that eventually it all finds its way back down to the bottom of the cycle.

“We’re just recycling it a few times on its way and using it and then letting it go where it would normally go.”

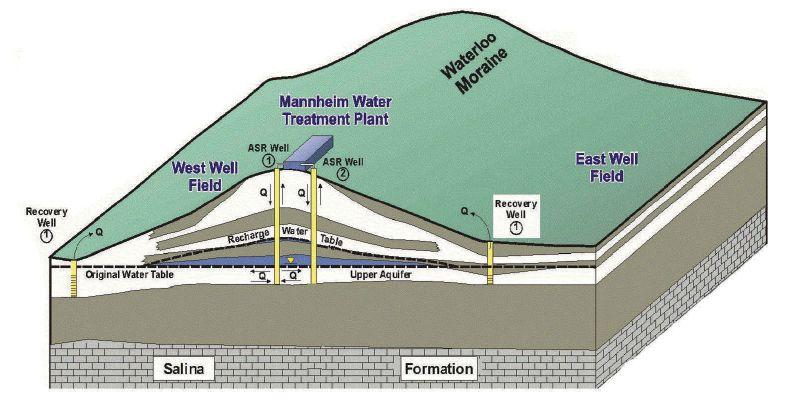

Waterloo Region’s Mannheim Water Treatment facility has an ASR system and is located on a moraine – a natural geographic feature of course sand and gravel – with an aquifer beneath it. It’s an integral part of the long-term water plan for the region, which has relied on ground water for hundreds of years. While the first test well was constructed in 1996, the construction and detailed design of the expanded ASR system didn’t occur until 2003, with the full system of four ASR wells commissioned in 2005.

“These are the wells that do both injection and pumping, and they’re large, 16-inch wells, about 220 or so feet deep,” he says, adding that there are also three recovery wells for just extraction and pumping. The whole system is designed to produce roughly 23 million litres of water per day, and with the 60-day storage capacity, it’s equivalent to about 1,400 million litres of additional water that can be drawn upon during periods of high demand.

“Lots of people are surprised that we have an ASR system here, but it’s something this community got behind as part of our long-term water supply strategy,” Corbett says. “It’s preventing us from having to spend a lot more money to expand our treatment plant and look for new water sources, and

even postpones the need for a pipeline. It gives us a lot of flexibility in the way we operate our water supply system, so that’s a huge benefit.”

So why is MAR so rare in Canada?

Because there has to be a need, as there is for landlocked Waterloo and for parts of B.C.’s lower mainland, but that may

One challenge is the interaction between the geochemistry of the water and the minerals in the materials in the aquifer.

“Generally, of the thousands of [MAR] projects that have been implemented worldwide, very few are in Canada but interest is increasing,” says Scott King, NGWA president and a hydrogeologist with Wood Environment and Infrastructure Solutions.

“Southern Ontario and Alberta seem to be areas where MAR development

could have benefits,” says King.

MAR is a much bigger deal in the U.S., especially the southwest, where it has been proven to help with seasonal demand.

“When it’s hot and dry and access to surface water is less available, it helps sustainability, and the other term we often use is resiliency – being able to work your way through drought periods by having additional water banked in an aquifer, which you can draw on as needed,” King says.

Many examples of U.S. MAR systems could be looked at as models. Tim Parker, president of Sacramento-based Parker Groundwater and a nationally recognized ground water expert, has been working in the MAR space for years and offers a list.

“Being from California, I always point to Orange County Water District, Water Replenishment District of Southern CA, Santa Clara Valley Water District, SemiTropic, Kern Water Bank, Fresno Leaky Acres, to name a few,” Parker says, adding Texas (San Antonio ASR, El Paso ASR, and Desal), Idaho (Eastern Snake Plain), and Florida (multiple ASRs). “Oregon and Washington and Colorado all have good examples and lessons learned.”

Parker wrote about the Orange County Water District (OCWD) in his

article “Managed Aquifer Recharge: California and Beyond” for the September 2017 issue (Vol 190, No. 5) of Water Resources Impact, an American Water Resources Association publication. The OCWD recharges approximately 300,000 acre-feet per year, using both percolation ponds and injection wells supplied by advanced treated recycled water, storm flows, and imported water. This replenishes the basin and maintains a hydraulic barrier along the coast to minimize seawater intrusion.

While there are some impressive examples in the U.S., Parker says not enough is being done to implement MAR.

“[There] needs to be a ‘paradigm shift’ in how we think about water management,” Parker says in an interview, explaining that current thought is to use available surface water first then ground water when less surface water is available. “I believe we need to redesign our water supply systems so we incorporate refilling aquifers – MAR – continuously when surface water is available, using all the methods – from direct to indirect, on stream, off stream, injection, and infiltration – in lieu of surface water use.”

Parker says, in general, where surface water is abundant, MAR is less prevalent, which may explain its rarity in Canada – for now.

Ken Hugo, a hydrogeologist with Groundwater Information Technologies in Calgary, says ASR has been discussed as a workable solution to some water issues in Alberta, including an overall shortage of surface water supply.

“We typically get a large amount of river flow in the late spring due to snowmelt and spring rains. Often, the flow in the late spring is 10 to 100 times the average flow throughout the year,” Hugo says, adding that in parts of southern Alberta, total water flow is sufficient but much of it is only in one month of the year and not available year-round. “It’s tough to see all this water leave the province in June and to see the creeks and rivers turn to a trickle in early fall or winter.”

One solution is dams, but dams have high costs and reservoirs take large areas.

Dams are also politically problematic.

“We are trying to build a flood control dam west of Calgary, but the dam is meeting a lot of opposition,” Hugo says. “So an alternative is pumping the excess water into an aquifer during the late spring and withdrawing it over the year.”

Hugo says there are aquifers in the area that would likely be suitable, typically, buried valley aquifers – former valleys filled in with a combination of sands, gravels, silts, and

clays – noting that proper identification of a suitable buried valley aquifer would have to be made.

“Society tends to respond to the most recent crisis – in Alberta, we had a severe flood in 2013 so most of the emphasis is on flood effect mitigation –but I have talked to a few hydrologists, and I am of a similar opinion, that a drought is much more worrisome in Alberta,” Hugo says. “I would foresee that ASR is thought of as something we should consider.”

KEEP THE ADVANTAGES OF YOUR RIG AND ADD:

• Accuracy in overburden

• Better performance in tough overburden conditions

• Allows better sampling

• Allows screen installations

• Facilitates the extraction of the casing

• Easy operation

• Allows cleanliness on sites

MAR projects are not without their challenges. One of them is the interaction between the geochemistry of the water and the minerals in the materials in the aquifer.

“It is important to understand how they will react, because there can be some chemical reactions,” King says. “Those sorts of issues need to be looked at, but they can be understood and dealt with without too much difficulty.”

Parker also points to the importance of managing the differences in source water and aquifer water. “There will always be water quality changes and determining whether those are significant and unreasonable comes into play and requires iterative bench-topilot scale efforts to prove the recharge project before major capital is invested, especially for public agencies.”

In addition to being mindful of water chemistry, Corbett says monitoring aquifer levels is important to ensure there’s no negative impact on the aquifer. He adds that some unique challenges may be associated with ASR permits. “Essentially, the permits are set up to almost be revenue neutral, in that you’re only withdrawing the same volume that you’re putting in.”

Hugo says a lack of clear regulatory guidelines for ASR projects creates some uncertainty about how onerous the approval process would be on a project. However, changing demand may prompt action.

“I think as demand [for water] increases, and water resources come under more stress, then people start looking to ways to maintain their aquifers,” King says. “From our point of view as ground water people, we think there’s a resource here that can be developed in a cost-effective way that can help in the sustainability in ground water supply.”

For example, consider the cost of building a surface water reservoir or a dam, compared to the cost of wells and pumps to put water in the ground.

“There’s a real cost benefit to look at MAR as a way to go in some places,” King says.

MAR may also be a good consideration for smaller, localized activity, King says, naming Lake Mead and Lake Tahoe, where water loss is significant. Corbett concurs,

saying ASR projects can start at any scale.

“The rule of thumb I’ve learned through my work with ASR is that you start small, learn as you go, then expand as needed,” Corbett says. “You could start with just one well, and you could have that one well down close to one of the rivers. In the winter or spring time, where there’s an excess flow in that river, you can take some of that water and you can inject it in your aquifers. And then in the hot, dry summer, when you need additional water, you could withdraw that water from the well and use it.”

As for how these types of projects impact well drillers, Hugo says any ASR project would require a large amount of work from drillers: drilling and installing wells (injection/production wells and observation wells) and pumping tests to describe aquifer conditions, as well as long-term well and pump maintenance.

Corbett notes that the dual-purpose ASR wells have a value system called a Baski downhole flow control valve, but otherwise, the wells are like any other well, though they can be fairly deep sometimes. “Any water supply driller that’s set up to do that could drill ASR wells.”

The NGWA sees MAR as a strategic area of work for the association and for society in being able to sustain and manage aquifer systems. Moreover, it’s a process that can involve all their members: scientists, who would develop understanding of the aquifers and the properties; drillers, who would drill the wells and create the screens and ways to recharge the aquifers; and manufacturers and suppliers, who deal with the pumps, piping, and materials to get the mechanics working.

“All of us can work together to do this,” King says. “To us, it’s something that our members can really contribute to, in terms of water resources and ground water, in particular.”

Carolyn Camilleri is a Toronto-based writer, editor, and content strategist. She has been writing for consumer and trade magazines, as well as businesses and organizations, for more than 15 years

“Global Inventory of MAR Schemes, created by the International Groundwater Resources Assessment Centre based in Delft, the Netherlands, is a portal containing information on about 1,200 MAR case studies from more than 50 countries. https://www.un-igrac.org/ ggis/mar-portal

“Managed Aquifer Recharge: A tool to replenish aquifers and increase underground water storage” is a downloadable factsheet of basic, public-friendly information about MAR written by Katja Luxem in September 2017 for the American Geosciences Institute. https://www. americangeosciences.org/geosciencecurrents/managed-aquifer-recharge RESTORE: Research for Subsurface Transport and Remediation, a research group out of Western University in London, Ont., has a number of water remediation projects underway, including one in Bangladesh, using a type of MAR called aquifer storage, transfer and recovery (ASTR), where water is injected directly into the aquifer through a well and extracted at a distance to aid in bacteria removal. https://www.eng.uwo.ca/research/ restore/MARresearch.html

“Aquifer Storage and Recovery: Best Suggested Practices” by the National Ground Water Association provides guidance for those considering getting involved in MAR or ASR projects. It is available for purchase at https://my.ngwa.org/NC__ Product?id=a185000000BYugHAAT

“Recharge Roundtable Call to Action: Key Steps for Replenishing California Groundwater” is a report, published in 2018, that aims to identify the changes needed in infrastructure, knowledge, and institutions to substantially increase recharge in California within approximately the next five years. The report can be downloaded from http://ucwater.org/ rechargeroundtable. For technical articles, visit groundwatercanada.com

Feedback is a gift that anchors your relationships in honesty. Everyone depends upon the feedback they receive to appreciate and reinforce their areas of strength, and to identify areas for personal and professional growth and development.

by DAVID CHINSKY

Do not give in to the temptation of answering a question for the other person. What you think may be causing the problem is not always the case.

While many people miss opportunities to provide more frequent positive feedback that is specific, timely and genuine, the bigger challenge for most people is providing constructive feedback that reduces the wall of defensiveness that often accompanies their feedback.

The seven-step constructive feedback process outlined below offers a framework that converts the typical constructive feedback confrontation into a more productive feedback conversation.

Employees (or colleagues or bosses) must first understand the problem you’re experiencing

with them before they can be expected to improve. In this step, you should describe the actual performance and/or behaviour and contrast it with the expected performance. To begin, simply describe the problem in a sentence or two. Remain as objective as possible and stick to one point – do not talk about multiple performance issues in the same feedback discussion.

Here’s an example: “Tom, I’d like to talk with you because I’ve noticed that you’ve been late to four of our last five meetings.” That’s it. If you can’t describe the performance problem in 30 seconds or less, you don’t know what the problem is yourself. In Step 1, state the performance problem in a concise, simple-to-

understand fashion. There should be no ambiguity as to why you’re having this conversation.

During the typical feedback discussion, leaders often jump from the description of the problem directly to the development of an action plan. They want to know immediately what the employee is going to do to resolve the problem. To have meaningful feedback conversations, employees must know how their behaviour is impacting others. In this step, convey the unacceptable impact of the behaviour, or the unacceptable performance, on colleagues, the organization and perhaps even the individual himself or herself.

Let’s go back to the previous example of Tom being late to meetings, as described in Step 1 above. Step 2 would continue the conversation with: “When you are late, it causes us to have to stop what we’re doing while everyone acknowledges your late arrival, and this interrupts the momentum of our meeting and lowers our productivity.”

Once you have described the problem and explained the impact, then you can work with the employee to identify the cause of the performance problem.

a negative impact. If you don’t describe how his behaviour affects others, he might quickly dismiss the problem, saying something like, “Yeah, so what’s your point? A lot of other people are late, too.” So, rather than just talking about the problem of being late, help him understand the impact he’s having by being late. It’s not just the lateness you’re talking about. It’s the diminished productivity, the lack of momentum, the interruption – and some might even say it’s the dishonouring of the punctuality of the other people who arrived on time.

Here’s another example, incorporating both Steps 1 and 2: “Jen, I wanted to talk with you today because I’ve noticed that you are the first to dismiss the ideas of other members of our team. Before you ask questions and try to understand someone else’s position, you immediately go on the attack.”

That’s the problem, or Step 1, in 30 seconds or less. The impact might be stated as follows, in 30 seconds or less:

This second step is very important because many times the employee doesn’t even realize his behaviour is causing

“When you are so quick to judge, it causes other members of the team to withdraw and withhold their input because they are afraid that when they speak you’re going to cut them off or give all the reasons why their idea is stupid. This works against the environment I’m trying to create where everyone feels comfortable sharing their unique perspectives.”

Once you have described the problem and explained the impact, then you can work with the employee to identify the cause of the performance problem you described in Step 1. Don’t jump in and immediately propose what you believe is causing the problem. Let the employee take the lead here. Your job is to ask one good open-ended question that invites him to think about what might be causing his lateness – or what might be preventing her from listening before she shoots down a teammate’s idea.

The goal with this step is to develop a shared understanding of the situation and to identify causes of performance problems. Encourage the employee to discuss the performance from his or her point of view. Once you’ve asked your one open-ended Step 3 question – such as “What’s preventing you from getting to our meetings on time?” or “What is preventing you from asking questions first before becoming critical of others’ ideas?” – your job is to let “silence do the heavy lifting.” Do not give in to the temptation of answering this question for the other person. What you think may be causing the problem is not always the case.

You will develop a more meaningful action plan once you’ve clearly described the problem, explained the impact and identified the cause. If you simply leap from performance problem to action plan, you’ll miss out on a

customize the specific elements of an action plan.

In Step 4, you’re looking for the employee to tell you what he will commit to doing differently to ensure he’s able to get to meetings on time or what she will do to take time to listen first to her colleagues’ ideas before jumping in and being negative.

Step 4 leads to the identification of a solution, a timetable for any followup actions and an action plan that is specific and measurable.

Before the conversation ends, ensure that both you and your employee are on the same page. This is a chance for you or the employee to summarize what was discussed, who has agreed to what, and when you expect these changes to occur. If there is any misunderstanding, you can identify it and resolve it during Step 5 – not two weeks or a month down the road when you expect something to be done and then realize you misunderstood each other.

Take a few minutes to document the conversation, even if this is the first time you’ve had to talk with an employee about an issue – and certainly if it’s the second time you’re having the same conversation. When you document the conversation you’ve had, you’ll have the information available should this develop into a more serious performance management issue.

More than likely, you or your employee will make some kind of commitment during the feedback conversation. It’s incredibly important to follow up on these commitments. This helps you determine if the employee has actually improved or changed behaviour. Your efforts are wasted if you don’t take the time to follow up as needed.

When these seven steps are performed in the order in which they are presented above, you will be able to provide constructive feedback more confidently and effectively when the need arises.

In about a minute, you will have set up the conversation by describing the problem, explaining the impact and asking one good question to turn the conversation over to the person receiving your feedback. This will ensure you maintain control of the beginning of these conversations when others may attempt to derail your efforts or change the subject.

Dr. David Chinsky is the founder of the Institute for Leadership Fitness, a celebrated speaker and author of The Fit Leader’s Companion: A Down-toEarth Guide for Sustainable Leadership Success. After spending nearly 20 years in executive leadership positions at the Ford Motor Company, Nestle and Thomson Reuters, he now focuses on preparing leaders to achieve their highest level of professional effectiveness and leadership fitness. For more information on Dr. David Chinsky, please visit: FitLeadersAcademy.com.

For more on employee issues, visit groundwatercanada.com

Obtaining a water level in a well that produces gas can be fraught with errors

No well driller wants to encounter a water well that produces gas. Besides the danger associated with gas production, which may be flammable or explosive, problems can also arise with gas locking of pumps and/or pressure tanks.

by KEN HUGO

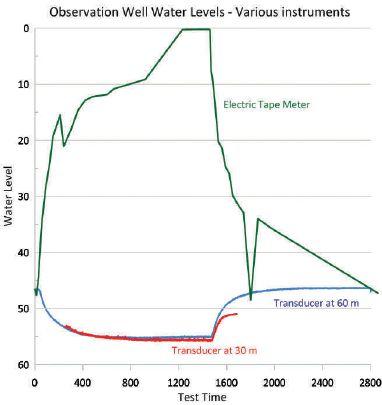

LEFT: Fig. 1. A graph shows water levels with time in the observation well during the pumping test with a transducer at 60 metres (blue line), a transducer at 30 metres (red line) and with an electrical tape meter (green line).

Fig. 2. The water “surging” to the surface as a frothy mixture of gas and water.

In addition to these problems, obtaining a water level in a water well that is producing gas is a process that can be fraught with errors.

Water-well drillers are frequently called upon to undertake pumping tests where measurement of the water level, often to accuracies of one inch or less, is required. Pumping test analyses using data from a water well that produces gas yield water-level data that do not “behave” properly, making interpretation difficult.

This article shows that using pressure transducers placed near the bottom of the well produces satisfactory results. Other waterlevel meters, such as electrical tape, acoustic well sounders or pressure transducers placed

near the static water level, produce less than satisfactory or unusable results.

To illustrate this behaviour, a recent welltest program was undertaken on a well in southwestern Saskatchewan that obtains water from sandstones of the Cretaceous-aged Judith River Formation at approximately 200 metres’ depth. Overlying this formation is at around 150 metres of shales termed the Bearspaw Formation and 50 metres of silt and clay tills.

The Judith River Formation is known in the area to produce gas as well as water. In other parts of Saskatchewan and Alberta where the formation is deeper the Judith River is sometimes an exclusively (or largely)

BY

gas-producing zone. Within this area the gas seems to be comingled with the water, either flowing with the water or exsolving out of the water as the pressure is lowered, similar to gas coming out of a carbonated beverage when the cap is removed.

As the well was known to contain gas an opportunity was presented to more carefully study the water levels in two wells – a production well and an observation well – during a 48-hour pumping test with the well pumped at a rate of 310 cubic metres/day for 24 hours and water levels read for the

Satisfactory water-level readings seem to result when using pressure transducers placed as low as possible in the well.

24-hour pumping period and a 24-hour build-up period after pumping ceased.

The instrumentation installed to record water levels in the observation well consisted of a pressure transducer at 60 metres, another transducer at 30 metres, and measurement of water levels using an electrical sounder and a barometric pressure recorder. The

observation well was located 60 metres away from the production well.

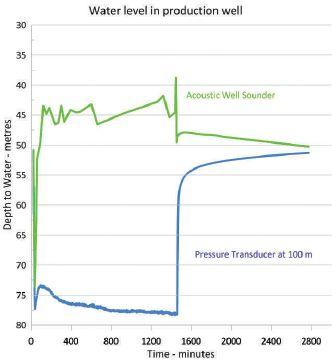

Water levels also were read with a pressure transducer in the production well and readings taken using an acoustic well sounder in the production well.

A graph showing water levels with time in the observation well during the

pumping test with a transducer at 60 metres (blue line), a transducer at 30 metres (red line) and with an electrical tape meter (green line) is shown on Fig. 1. The two pressure transducers show good response and curve form typical for a well test and the results can be interpreted with some confidence. The water-level meter shows a rising water

SEPT. 3

Protect Your Groundwater Day

SEPT. 7

Grundfos Walk for Water Mississauga, Ont.

SEPT. 7

AWWDA Golf Tournament Ponoka, Alta.

SEPT. 20

OGWA Scholarship Golf Tournament Conestogo, Ont.

SEPT. 24-25

Canadian Hydronics Conference Ottawa, Ont

SEPT. 28

Nova Scotia Ground Water Association Annual General Meeting Dartmouth, N.S.

OCT. 29-30

World Water-Tech North America Los Angeles, Calif.

NOV. 3-6

National Water and Wastewater Conference Banff, Alta.

DEC. 3-5

NGWA Ground Water Week Las Vegas, Nev.

(including Canadian National Ground Water Association annual information meeting)

For more events, updated regularly, visit groundwatercanada.com

level during the pumping portion of the test (where water levels would be expected to decline).

The water in the well was predicted to rise to the surface during the pumping portion of the test, which did in fact occur approximately 10 hours into the pumping portion of the test. Fig. 2 shows the water “surging” to the surface as a frothy mixture of gas and water. The froth can be seen on the pressure transducer when removed from the well at the end of the test (Fig. 3).

Fig. 4 shows water levels read in the production well with a pressure transducer at 100 metres (blue line) and water-level measurements taken at intervals using an acoustic well sounder (green line). As before the meter reading, the uppermost surface of the water does not show the expected response during a pumping test, with the froth mixture rising in the well during the pumping test as gas comes out of solution.

Although the water-level readings from the two pressure transducers in the observation well track closely together, as shown on Fig. 1, some divergence is observed. The scales were expanded to show this divergence more closely in Fig. 5. As can be seen, the divergence is real and seems to be increasing with time. As also can be observed, the “noise” of the shallow transducer (red line) is greater than the noise of the deeper transducer (blue line).

Although the data is presented as a water level, pressure transducers do not directly measure water level but measure (as one would expect) pressure. The pressures are converted to a water level using a density value for water. Typically, a value of 1,000 kilograms/cubic metre of water is used, although slight variations of this density may be present due to changes in water temperature or (more importantly) salinity.

With gas in the water, however, the frothy water column results in a thicker column of water (as observed by the electrical meter) but at a much lower density, two factors that tend to counteract but not quite cancel out each other with respect to pressure at some depth. The change in density due to this frothing is likely quite variable throughout the well, with the result that pressure transducers placed higher up may experience quite a bit of noise and error as variation in the intensity of the froth moves throughout the well.

It is possible to estimate the amount of gas production by the varying waterlevel readings; indeed, the difference in readings can be taken as evidence of gas production.

In summary, care must be taken when performing a pumping test where gas along with water is produced.

ABOVE: Fig. 4. Water levels read in the production well with a pressure transducer at 100 metres (blue line) and water-level measurements taken at intervals using an acoustic well sounder (green line).

BELOW: Fig. 5. The scales were expanded to show this divergence more closely.

Satisfactory water-level readings seem to result when using pressure transducers placed as low as possible in the well.

Instruments that measure the water surface in the well give the least reliable results, but the rising water levels during the pumping portion of a test can be used as an interpretative tool to suggest that gas production is present in a well. This is a piece of information that can be of value when using a water well as a long-term water source.

Ken Hugo is a technical director and hydrogeologist with Groundwater Information Technologies (GRIT).

The NivuLevel Mobile is a selfsufficient system that provides

power management for reliable level measurements, data logging and convenient data transmission.

T he GPRS/UMTS data logger, manufactured by Nivus, is a system for automated transmission of measurement data with simultaneous sensor power supply. The system is designed to make operators independent from available power or data lines.

A built-in LTE modem

helps the data logger provide a consistent connection from the sensor up to the provision of measurement data online including the option to automatically create individual protocols. The data logger is equipped with a multi-roam SIM module per default. Data transmission is provided free of charge for the first year of use. Because the devices are already registered in the Nivus Web Portal prior to delivery, they can be called

up there instantaneously.

Flush Joint

Pipe Clamps Kwik Klamps 3 klamp sizes available: KK1 (adj. 1”-2”) KK2 (adj. 2 ½”-4”) KK3 (for 6” PVC)

The measurement system has options to automatically adjust the measurement cycles to custom-defined events such as the overshooting of a certain water level. Alarms can be triggered automatically at certain events or in case of sensor errors as well. In addition to tables and charts on readings, the Nivus Web Portal provides information on the battery status of the NivuLevel Mobile, which J&K Tool also designs & manufactures:

PVC Screen Slotting Machines

PVC Pipe Threading Machines

Vertical Slotting Machines

Perforating/Hole Drilling Machines www.jktool.com · 320 - 563 -4967 · sales@jktool.com

can be used to schedule efficient maintenance visits.

Because the level sensors and mobile unit have an IP68 protection rating, the system can be used even under extreme conditions. Sensors as well as the data logger can be used in Ex zone 1. Parameters can be set and the data logger can be operated wirelessly via smartphone, tablet or notebook on site.

In case of bad weather, strong sunlight or difficult access to the measurement place, it is possible to set the device parameters from a protected area such as a service vehicle.

Typical applications for the NivuLevel Mobile are event logging in stormwater overflow tanks, and level measurements in water bodies or in storage sewers. nivus.com

Franklin Electric Co. Inc. recently introduced the MagForce High Efficiency Motor System in a 60-horsepower model. The product line offers three distinct models capable of covering pump horsepower ratings from 7.5 to 60. It is a high-performance alternative to a traditional induction motor and control, providing electrical cost savings via a 90 per cent motor efficiency rating that is 10 to 12 per cent higher than previous submersible motor designs, the company said in a press release.

Permanent magnet technology, used in the construction of the MagForce motor, allows three distinct models to cover pump horsepower ratings from 7.5 to 60, maximizing contractor flexibility – especially if the water table drops. In this case, the system can compensate for additional total dynamic head requirements. The MagForce motor is capable of a 13.6 per cent horsepower boost, increasing the motor’s shaft speed to a true 60 hertz, 3600 rpm (not to exceed the high efficiency motor’s max amp rating). The power boost means that pumps can stay in the ground even longer despite adverse conditions, such as dropping static water levels or pump hydraulic wear.

Because these motors maintain higher efficiency and cooler running temperatures, users can expect more water, lower electrical costs, and greater system flexibility through many years of operation, the company said.

Long- and continuous-run applications ideal for this motor system include ground water remediation, drainage water level control, municipal and utility water supply, construction site dewatering, high volume and industrial livestock operations, mine site dewatering and tank level control, well supply geothermal HVAC systems, and pivot irrigation systems.

franklinwater.com

Flomatic has a new Wafer Style Silent Check Valve that is compatible with VFD controlled pumps in an all 316 stainless

steel valve body, stainless steel poppet, seat ring and spring.

The Silent Check Valve is the only of its kind that can be closecoupled with a butterfly valve, thereby eliminating the need for a spool piece, manufacturer Flomatic said in a press release.

The valve is designed to minimize flow losses and hydraulic shocks in the pump system. The patented springloaded poppet system is guided in an oversized sleeve for stability, resulting in a quiet and efficient operation regardless of flow rate.

In addition to a quiet operation, the valve design provides a fast closure, which helps prevent check valve slam and alleviate water hammer. Ideally suited for demanding clean-water, VFD-controlled pump booster systems, Model 888S6VFD is available in six different sizes (two-inch through six-inch). Model 888S6VFD two-inch through six-inch are designed to fit ASME Class 125/150 & ASME 250/300 flanges and they meet MSS-SP 125 standards.

Additional technical specifications include a pressure

max of 400 PSI, a maximum temperature of 180 F (82 C).Certified NSF/ANSI 61 and 372 and covered by a three-year warranty, model 888S6VFD is manufactured under a certified ISO 9001 and 14001 quality management system at Flomatic’s Manufacturing Plant in Glens Falls, N.Y. flomatic.com

Versa-Drill has developed its new V-12 water-well and geothermal drilling rig with maintenance costs in mind. Built on a lightweight frame, with a user-friendly control panel and fuel-efficient engine, the rig’s design incorporates components that are simpler than ever to troubleshoot and easier to replace or fix.

The rig, which has 12,000 pounds of pullback and 7,000

pounds of pulldown, employs the company’s patented lowmaintenance direct cylinder driven feed system.

Features include a highperformance variable speed/ torque top head; a drill rod carousel rod/stabilizer box; a seven-rod carousel; and a Ram 5500 Tradesman 4 x 4 6.7-litre Cummins diesel engine with 360 horsepower and six-speed automatic Aisin HD.

Customers can choose either a 2,000-pound or 4,000-pound main winch; and either a 4 x 3 x 13 centrifugal Mission Magnum or a 4 x 5 piston pump. A 200 cfm/150 psi Vanair air compressor is also available as an option.

versadrill.com

Numa has released a range of HDD drilling systems designed for productive and efficient drilling in hard rock and fractured ground formations.

The systems consist of a

variety of HDD components including hammers, bits, sideload sonde housings, bent subs and adaptors capable of drilling holes 102 to 191 millimetres (4 to 7-1/2 inches) in diameter. Benefits of the hammer line include improved steerability, fast penetration rate, simplified field maintenance, reduced air requirements and lower overall cost per foot, the company said in a press release.

Numa purposely designed its HDD hammers to drill longer in difficult rock conditions. A single bore design allows for a maximum bore diameter in conjunction with providing optimum life against abrasion.

The line consists of the following models:

• HDD 35 for drilling holes 98 to 102 mm (3-7/8 to 4 in.) in diameter

• HDD 40 for drilling holes 121 to 127 mm (4-3/4 to 5 in.) in diameter

• HDD 50 for drilling holes 146 to 156 mm (5-3/4” to 6-1/8 in.) in diameter

• HDD 60 for drilling holes 178 to 191 mm (7 to 7-1/2 in.) in diameter numahammers.com

by Shep Hyken

Irecently wrote about the concept of predictive customer support. Now, we take a slightly different angle with the concept of proactive customer support.

The concept is simple. The company reaches out to the customer before the customer has a chance to reach out to the company. More often than not, the customer may not even know they have a problem.

As an example, when does a typical customer find out their cable TV is out? Usually when they turn the TV on. Then there’s frustration and even anger. Typically, the customer will pick up the phone to report the problem and hope the customer service agent can help them restore their cable TV.

However, before the customer can even ask about the problem, the support agent must ask the standard questions to confirm the customer is who they say they are. All the customer wants to find out is when they can start watching TV again. That’s an example of friction, which is the opposite of convenience.

I was working with a client in the cable TV business. When they know the cable and Internet is out in a certain area, they proactively reach out to the customer. They use every communication channel available to them. They know the customer’s cell number, email address, Facebook handle, and more. They broadcast an announcement to their customers across every channel, hoping customers will see that they are aware of the problem and actively trying to fix it.

They also provide updates so the customer doesn’t feel compelled to repeatedly call and ask when the service will be restored. That’s a waste of time – for both the customer and the customer support rep.

When a company knows about a problem before the customer does, it can let the customer know before they call the company. Another

way to be proactive is to take care of a problem before it’s even a problem.

If we know a light bulb has a life expectancy of 1,000 hours, and there’s a way to track how many hours the bulb has been on, be proactive and just replace it once it hits 1,000 hours. The option to wait until it burns out (which would probably happen at an inopportune moment, forcing you to stop what you’re doing to replace the bulb) is not worth the extra few hours of light. My favorite example sums up this idea perfectly. A server at a restaurant is carrying the water pitcher, looking not for empty glasses to fill, but for almost empty glasses to fill.

In other words, get to the customer before the customer realizes they need you. That’s what proactive customer support is all about

Shep Hyken is a customer service expert, keynote speaker and New York Times bestselling business author. For information, contact 314-692-2200 or hyken.com. For information on The Customer Focus customer service training programs, go to thecustomerfocus. com. Follow on Twitter: @Hyken.

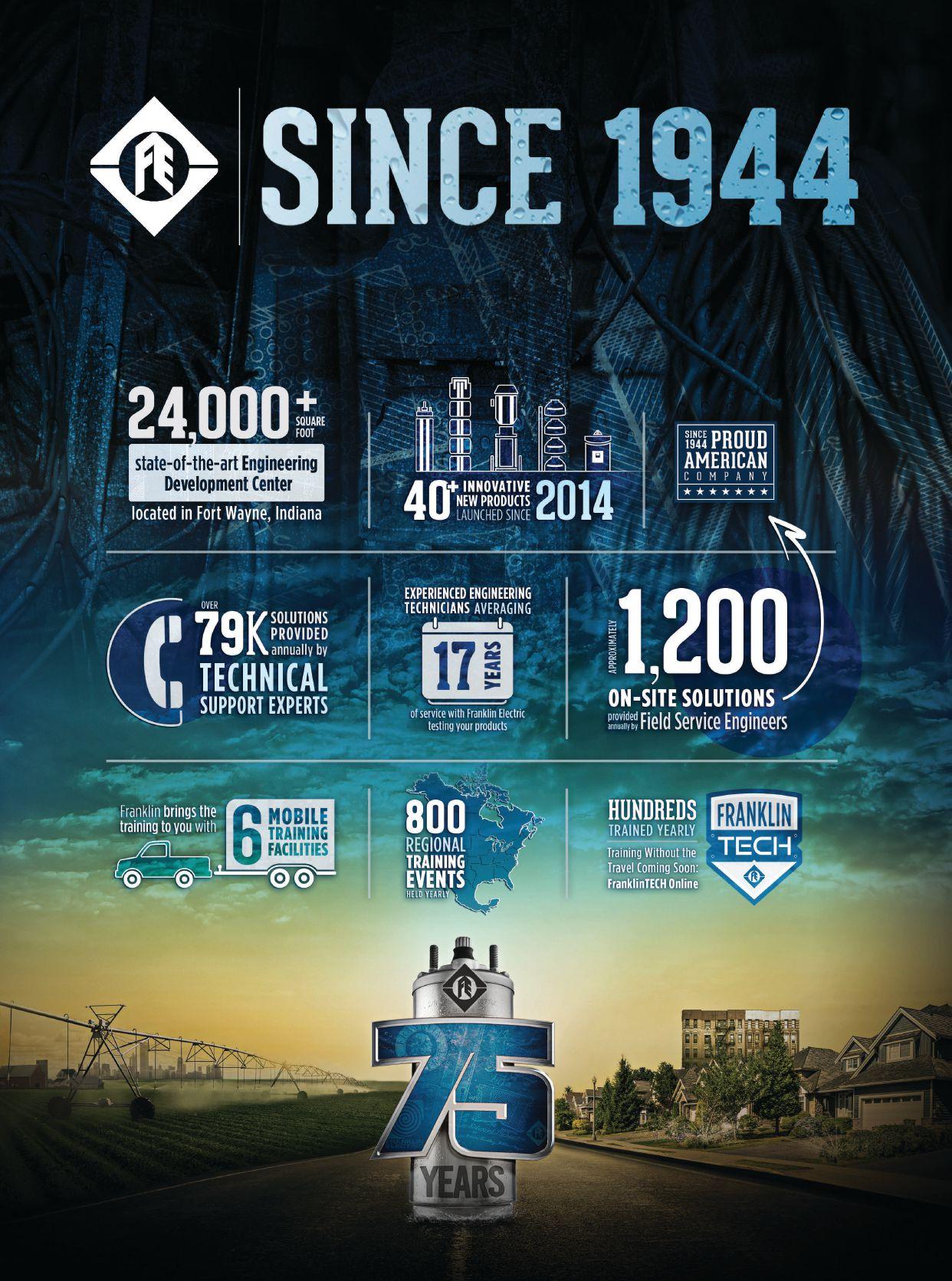

For 75 years, we have fixated our efforts on providing the optimum customer experience, including innovative products focused on quality and industry-leading technical and customer support. The company has evolved, but to this day our customers remain at the forefront of our focus. Here’s a snapshot of what a partnership with Franklin Electric offers you…