Labor-Saving

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available

Looking for the right shim?

Grove Shims has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com

Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

If participation in the Southern Alberta Institute of Technology’s glazing program is any indication, the future of Canada’s glazing trade looks bright. 18 Inbound

from Ireland

Offshore glass doesn’t just move west to east. Carey Glass is an Irish fabricator with designs on a growing chunk of the Canadian market.

Talking to architects

The AIA conference in Las Vegas was bigger than Rich Porayko expected, but he managed to boil it down into this report.

YOUR QUICK NEWS HIT Glass Canada subscribers receive our email news roundup every other Thursday. It’s the top stories from the last weeks gathered together for easy scanning and clicking. Not getting your e-news? Visit glasscanadamag.com > Subscribe to update your subscription and make sure the option to receive our digital products is selected. Then check your spam filter.

The uses of attention

EDITORIAL

There are productivity impacts from distraction.

My youngest daughter started high school the week and I’m writing this amid much discussion of the Ontario government’s proposal to require high school students to take four courses online in order to graduate. The goal is obviously to save budget dollars, which is needed given the state of the province’s finances, but which hands the teachers’ union a political baseball bat they are going to be able to bludgeon premier Doug Ford with all the way into the next election. I doubt very much the measure will be implemented, since just about everyone seems to feel it’s a bad idea. As far as my daughter’s grandparents are concerned, you might as well suggest the kids stay home and watch sitcoms instead of going to school.

But the surprising thing is, the kids aren’t big on it either. They are actually worried about being able to pass a test after having only watched a teacher lecture online without any of the interaction or help they would receive in person. They view it as a harder way to learn, not to mention one that takes them away from their friends and would probably have to be completed in their personal time after school. This from a generation that socializes almost exclusively on SnapChat.

I’m of two minds, mostly because I know how much corporate training happens online these days. The kids might as well get used to it early.

NEXT ISSUE

• Tariffs

I was chatting about this with a friend who had been taking some university courses and he commented that half the students were watching YouTube videos at the same time as the lecture and that he didn’t see how they could be paying attention to both. He said they must think they are good at multitasking.

• Energy savers • Profile

Multitasking. What evils have been visited on the world in that name? The fact is, people cannot multitask. At all. Humans have the ability to direct their attention to one thing at a time and one thing only. “Multitasking” actually means switching attention between different tasks. And the psychological literature is clear that every time this happens, it costs time and productivity. According to studies reported by the American Psychological Association, switching back and forth between tasks makes you slower than usual at every task and adds time in between as the mind prepares itself to make the switch. Some researchers estimated this “switch cost” at up to 40 per cent of productive time, depending on how often people need to switch. The more complex the tasks, the worse the effect. And other research suggests multitasking affects the quality of the work done. For instance, people’s retention of information learned is much lower if their concentration is broken then returned to the topic repeatedly.

People haven’t had any trouble absorbing the idea that multitasking while driving is not a good idea. Yet just about every job application out there includes a requirement for being able to multitask. And schools have gotten on board, allowing kids to use phones in class on the basis that this kind of multitasking is a skill they will need throughout their lives.

I’m going to suggest that you and your employees will do better if allowed to focus on one task at a time for as long as it takes to get the task done. And I’ll also suggest that a living human standing in front of you attracts more attention than a computer screen, and thus is more effective at training your workers. •

GLASS CANADA

October 2019

Volume 31 • Number 5

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER

| Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR

| Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Brooke SHAW

VP SALES/GROUP PUBLISHER

| Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax)

U.S.A. - 1 Year $65.50 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

Feds offering funding for energy retrofits

BY BONNIE

The federal Ministry of Environment and Natural Resources has introduced the Climate Action Incentive Fund (CAIF). This fund is to available to businesses in Manitoba, New Brunswick, Ontario and Saskatchewan. It provides rebates to small and medium-sized enterprises (between 1 and 499 employees) for retrofit projects improving the energy efficiency of their buildings and operations. The eligible rebate amount is up to 25 per cent of a project’s total eligible costs. No less than $20,000 and no more than $250,000 per project, per recipient, can be collected. A $250,000 funding cap will apply to any group of applicant franchisees who operate under the same franchise trade name in each eligible province. Eligible projects include enhancements to the building envelope (with direct energy savings), including energy efficient windows, doors, skylights, weatherproofing and glazing. Businesses can also receive rebates for installing energy-efficient lighting systems; upgrading heating, ventilation and air conditioning equipment, systems and controls; buying water heating retrofits, including high-efficiency condensing water-heating; and installing high-efficiency motors, controls and energy-management controls, including building automation systems. Other eligible projects include switching to lower-emitting energy sources in existing buildings; retrofitting and upgrading existing equipment used for industrial processes; and engaging in process changes and waste-heat recovery. Transportation retrofits are also available, including heavy-duty vehicle retrofits for energy efficiency and/or fuel switching to lower-emitting sources. The deadline to apply for the rebates is Oct. 15, or until funding is exhausted. The government has earmarked $218 million for this program.

AAMA and IGMA vote to merge

The memberships of the American Architectural Manufacturers Association (AAMA) and the Insulating Glass Manufacturers Alliance (IGMA) both voted to proceed with combining into one organization with a new name, the Fenestration and Glazing Industry Alliance (FGIA). The formal ballots of the AAMA and IGMA memberships were released on July 2, along with the full prospectus outlining the strategy for structuring, operating and branding the new organization, which included adjustments and clarifications to the proposal, based upon member feedback.

AAMA and IGMA announced unification discussions a year ago, with the goal of creating a new organization that can better serve the North American fenestration industry. During that time, an exploratory team from both organizations developed a framework for the new organization, and information was continually shared with members during development. Beginning in August, the two existing boards began working together to execute the unification implementation steps throughout the remainder of 2019. A strategic planning meeting will be held this fall to blend the vision and priorities for the new organization for the next three to five years and the new organization’s brand development will begin.

“The value of the new organization will be a stronger industry voice, offering members and the industry singlesource access to critical information,” said AAMA board chairman, Donnie Hunter of Kawneer. “With knowledgeable professionals from both the fenestration and glass industries, better synergy for the whole finished fenestration product will be available, as well as direct access to Canadian market, codes and regulatory expertise. A combined organization also delivers expanded technical competencies and a broader document base to support more extensive educational opportunities for members,” he continued.

IGMA president Nathalie Thibault of Prelco added, “These expanded technical competencies will further support educational opportunities. Plus, members can look forward to enhanced conference programming through an expanded content offering and broader networking opportunities through combined events. There will also be more resources available by harnessing the intellectual knowledge of the associations. A stronger financial position allows for future investments in industry research, technical resources and educational programs, which solidifies the new organization’s position as the single source for the industry moving forward.”

KOABEL

Donnie Hunter Nathalie Thibault

CGA Newsletter

Canadian Glass Association

We are trying to “activate” the association with certain issues as our driving force. One idea is to gauge interest within the national glazing community to work with the Canadian General Standards Board and re-write the CAN/ CGSB 12.20 structural standards for architectural glass. We need feedback from our provincial member associations to see if there’s interest in embarking on this long-term mission. Please email David Langton (dlangton@ compglass.com) or Zana Gordon (zgordon@fen-bc.org) with your feedback, suggestions or other ideas.

Fenestration Association of BC

FenBC

has been busy working on the program for the FenBC Industry Conference 2019 on October 23. Check out the fen-bc.org website for more details. FenBC is holding members-only meetings again. These meetings will be specific to each industry and be for members of FenBC only. Industry-specific speakers will be invited to attend. Save these dates: Jan. 16, FenBC Commercial Contractors Meeting; March 19, FenBC Suppliers Meeting; April 16, FenBC Manufacturers/Fabricators Meeting. All these meetings will be held at Northview Golf Course in Surrey. Feb. 27 is FenBC’S Technical Conference and AGM with a program to come soon. May 21 will be FenBC’s Annual Golf Tournament. You can find more information about all of these at fen-bc.org.

Canadian Glass Association PO Box 36117, Surrey, BC V3S 7Y5

Tel: 778.571.0245 fen-bc.org > Canadian Glass Association

Provincial Glaziers Association of Alberta

In the wake of the Master Glazier program initiative, the PGAA’s executive is currently collaborating to develop mandates and objectives for the rest of 2019 and beyond. A mission statement for PGAA is in the works and should come to fruition prior to year’s end. A political action committee meeting was held recently with regard to the harmonization movement for the glazier trade. A recommendation was tabled by the Canadian Council of the Directors of Apprenticeship to change our apprenticeship program from a four-year session to a threeyear session. Alberta’s PAC was against the recommendation for a number of reasons including the fact that the current content is already a challenge to fit into four periods and would be extremely difficult to fit into three periods. This would result in removing content from the program (a program that was just recently overhauled and updated over a five-year span from 2012 to 2017 by Alberta’s PAC). Alberta’s local associations (GAMA and GTA) are thriving with continued support from their members and the volunteers that donate their valuable time and knowledge to board positions, trade shows, school showcases and so on. GAMA held its first annual member appreciation barbeque in August, which despite the weather was a great success. GAMA’s association’s status is currently being overhauled due to some recent information regarding the status of the association at the government of Alberta level. More information to come as the matter unfolds.

Architectural

Glass and Metal Contractors Association

From

time to time the AGMCA uses this space to turn the spotlight on its volunteer directors or its member companies. This month, we salute Bill Byers of Transit Glass in Ottawa. Transit Glass & Aluminum was founded in September, 1999, by Bill Byers (president) and Denis Sicard (secretary treasurer). Bill and Denis worked together prior to that at Civic Glass where they carved out their expertise and gained invaluable experience in the glazing industry. Twenty years later the business has grown from the 3,000-square-foot starter shop in the east end of the city where it all began to 9,000 square feet on the west side of Ottawa in Kanata, Ont. A group of experienced and dedicated staff that tirelessly executes contracts makes Transit Glass who they are today. Bill began his career in 1984 and spent over 15 years with Civic Glass, starting out in drafting then working up to estimating, project management and management. Denis started in 1981 with Commercial Aluminum in Calgary as a draftsman, then moved back to Ottawa in 1983 where he worked for Fendor Glass. In 1993, Denis moved on to Civic Glass as a project manager. It was at Civic Glass that a strong relationship was formed with Bill. Today, Transit Glass specializes in glazed curtainwall, aluminum windows and entrances as well as skylights and many other specialized items, such as firerated curtainwall and structurally glazed walls. Bill gives back to our industry by volunteering as a board member on the AGMCA and provides us with excellent

insight, especially into the issues facing the eastern Ontario marketplace. Bill is also a valuable member of our negotiation committee and his input helped us gain a successful conclusion to our recent contract talks with IUPAT, ensuring labour stability in the province through 2022. Bill can be reached at wbyers@ transitglass.com. For more information on our association, please contact us at info@agmca. ca.

Ontario Glass And Metal Association

FALL

GOLF: The OGMA held its fall golf tournament at The Country Club on Sept. 12 and as usual a great day was had by all. At the event, Steve Ringler presented our semi-annual bursary to Michael Snyder, an apprentice working at Gage Aluminum and Glass, for his outstanding achievements at the Finishing Trades Institute during the past term. OGMA president, Andrew Dolphin, presented a $3,000 charitable donation to Shannon Chaplin with the Holland Bloorview Kids Rehabilitation Hospital. This facility is the leading facility in the country for helping children with disabilities.

JOINT OGMA/CSC SEMINAR DAY: The OGMA are teaming up with the Toronto chapter of Construction Specifications Canada to put on a spectacular program of informative and interesting topics. The event will be held on Thursday, Nov. 14, at the Richmond Hill Country Club. To find out what the day is all about please read Frank Fulton’s You Bet Your Glass column in this issue and make sure to attend.

THOROUGHBRED RACE

NITE: Please see your inbox for details or check out OGMA.ca.

INDUSTRY

AGMT certifies first cohort Alexander to lead sales at Walker

On July 31, the Architectural Glass and Metal Technician Certification Program (AGMT) certified 177 professional glaziers. These glaziers range from all over North America and are the first group to become officially recognized as AGMT-certified. AGMT is a personnel certification program that features an independent third-party assessment. The program earned ANSI accreditation earlier in the year. The program began officially testing candidates in February, 2019, and continues to test new participants in new locations. The testing to become certified includes knowledge-based and performance-based tests. The purpose of each exam is to assess a glazier’s knowledge, hands-on skills and ability. To earn certification, candidates must have 7,500 hours of glazing experience and demonstrate proficiency in all areas of the glazing test, including storefront, curtainwall, safety, sealing and a general knowledge of glazing. In a feedback survey from candidates who completed testing, the

Charles Alexander

Walker Glass has announced that Ross Christie, vicepresident of sales and marketing and member of the board of directors has decided to step down from his day-to-day sales and marketing duties at the end of the year. Charles Alexander will serve as vice-president of sales and marketing upon Christie’s retirement. Christie will take on the role of executive vice-president at Walker where he will remain active as a board member and take part in the strategic direction of the company. During his over 30 years as vice-president of sales and marketing, Christie was instrumental in Walker’s evolution. Under his leadership both the sales and the marketing teams have grown significantly.

“Ross is an iconic figure at Walker and is seen by many of us as a personal mentor. His

AGMT program asked each participant if they would recommend the exam to a fellow glazier, receiving a 100 per cent “Yes.” While still in its first year of operation, development of the certification began nearly three years ago and has included numerous members of the glazing industry. The goal has been to create a testing standard that will improve the glazing industry in the long-run and establish a higher-quality caliber for construction. AGMT program manager, Ben Beeler, explains: “It says that the glazing technician and the contractor who employs the certified technician is committed to an elevated quality standard. When a workforce has been fully evaluated and certified it will have a positive effect on the bottom line of all involved in the construction chain.”

To mark their designation, certified glaziers receive an official certificate, ID card and hardhat sticker. Additionally, each glazier is listed on the program site under Certified Personnel.

guidance, good humour and constant optimism has been something we can all count on. We are fortunate to be able to rely on his full support going forward.” said Alexander.

Alexander, who has been serving as business development director since 2017, has gained significant knowledge of Walker’s product line and the glass industry through his business travels and his involvement with the National Glass Association. Prior to joining the company, his experience came from the industrial products and the construction and green building industry sectors where he held senior management positions in sales, marketing, business development and operations for companies like the Canam Group.

“From the moment Charles joined Walker we knew that he was the right fit for us and that he would continue to reinforce the company culture. Our team and our clients will be in good hands with Charles,” said Christie.

Madico acquires distributors

Madico has announced the acquisition of its two Canadian distributors, Courage Distributing and Window Film Systems, and the formation of a new entity, Madico Canada. The company will operate both former Courage distribution locations in Oakville, Ont., and Richmond, B.C. Owned and operated by brothers Todd and Trent Courage, Courage Distributing has been a successful wholesale distribution company selling window film, paint protection film and accessories since it was founded in 1993. The Courage brothers were inducted into the Window Film Hall of Fame in 2015, receiving the Award of Excellence for their dealer service and support as well as philanthropic endeavors. All current Courage employees will become part of Madico Canada with both Courage brothers joining Madico in operations and sales leadership roles to ensure continuity and high-quality service to customers throughout the country. In 2018, Window Film Systems celebrated its 40th year distributing and installing Madico window films. Owner Peter Yates will continue to liaise with Madico Canada dealers. Window Film Systems will maintain its long-standing relationship with Madico in their successful film installation division. The company specializes in the Canadian decorative films market and has completed many notable architectural installations.

by MARGARET WEBB

Business as usual

With the approval vote by the IGMA and AAMA members to combine to form the Fenestration and Glazing Industry Alliance (FGIA), what can the members of IGMA expect in the coming months? Business as usual is the answer.

With so much work done in advance of the joint member vote to set the fee schedule, the organizational structure, the bylaws and the governanceframework, the next quarter will be focused on implementing the plan to launch the new organization on Jan. 1, 2020.

While this is a new name for IGMA, all current activities have been retained. The committees for certification, technical services, emerging technologies and innovation and education and safety will all remain. The IG Fabricator Workshop will be maintained and glass research and the glass R&D fund will be managed by the Glass Products Council, so work will continue on our research activities such as the joint IGCC-IGMA Rapid Assessment Chamber and the ASTM E 2190 Field Correlation Study Pilot Program.

The executive leadership of both IGMA and AAMA reached out multiple times over the past year to solicit feedback from both memberships to determine the “must keep” activities for both groups. I believe we have successfully retained those activities – including standards development, product certification, research and development, education, trademarks and marketing activities – that are of great importance to the two memberships.

IGMA members and non-members can still order publications and participate in either of the two IG certification programs. IGMA member activities including task groups and research projects will still meet as always, working to develop industry standards and next-generation product support.

Change can be managed and I believe we are heading to a bright future.

Some of the differences for IGMA members will be access to more information on Canadian and U.S. codes and standards so you will have the information you need to make solid business decisions for your company.

Another change is that all members will be able to vote on Glass Product Council ballots should they choose to exercise these rights. Under the existing structure, only the rostered committees formerly vote on a ballot, so we look forward to having more input into the development of our premier industry standards and publications. Members will have more access to staff resources with the combined staff but still be able to work closely with IGMA’s familiar faces and expertise.

So, come Jan. 1, members should see a fluid transition to the new organization. The new FGIA branding will be launched and ready to go while maintaining the AAMA, IGMA and IGMAC trademarks and programs the industry counts on.

Change can sometimes be difficult, but in this day and age, change is inevitable. By working diligently up front, over the past two years, IGMA and AAMA are managing this change to be as painless as possible for our members. There are no surprises. The new organization will be exactly as presented. It will be up to the members of the new organization to establish their culture within their product councils and for the new organization.

I encourage all IGMA members, come to the Annual Conference, scheduled next February in Fort Lauderdale, and put your individual stamp on the FGIA Glass Products Council. At IGMA, we have always looked to the members to set the direction of the organization and this is true of the new one as well.

It is an exciting time for the two organizations and our memberships. This is an opportunity to set the course, to develop the programs and activities that benefit your company.

The FGIA prospectus and the branding strategy video are posted to the IGMA Members Only portion of the website. If you haven’t had the opportunity to review these, I encourage you to do so. Change can be managed, and I believe we are headed to a bright future.•

IGMA

In-SAITable

In-SAITable

Demand for Alberta’s glazing program remains strong.

by ANDREW SNOOK

It’s no secret that getting young people into any of the skilled trades can present a significant challenge. From disinterested students to parents pushing only university and guidance counsellors that don’t recommend the career path, the skilled trades have their share of roadblocks. The glazier industry is no exception.

That said, a passionate instructor can really help a program go far. Just ask Natasha Hillestad, who enrolled in the Southern Alberta Institute of Technology’s (SAIT) glazier program in 2007. She was one of the first women to graduate the program and received her journeyman ticket in 2010. Now at 32 years of age, she is the shop foreman at Griffin Glass and the current president of the Glass and Architectural Metals Association (GAMA) in Alberta.

“I kind of got into the trade by accident,” she recalls while laughing, adding that the instructors played a key role in fuelling her interest in the program. “They’re very inspiring and motivational and encourage growth, so I always found that very helpful as someone coming in not knowing anything, and the time taken to explain. The program, year by year, was very beneficial to me.”

Hillestad still works closely with the SAIT instructors on behalf of GAMA, and says that the instructors still show same passion now to students as they did when they taught her more than a decade ago.

“We do school trade shows together, I’ll go with the instructor, like Gene [Aqulini], and we go and we talk to the next generation and it always amazes me how the passion of the instructors doesn’t seem to fade. He’s as motivational talking to these high school students now as he was when I was there,” she says. “A lot of people’s love of the trade kind of fades away and it’s just a job, but the instructors at SAIT aren’t like that. They still love it. And they still have a lot of knowledge and experience and love hearing all the new stuff from the workers now as to what’s different in the trade so they can evaluate change for the next class.”

Hillestad says she could watch Aqulini interact with people at these shows all day. And not just the students, but the people who have presented some of the biggest roadblocks to recruiting young people into the skilled trades as well: the parents.

< A well-equipped hands-on shop staffed by experienced journeypersons turns out qualified glaziers that employers rave about. And the program is seeing more interest from women.

“Just watching him interact not only with the students but with their parents and talking about the benefits of our trade and where you can really go with that career choice, I could just stand there and watch him talk to them,” she says. “I go for the female perspective when they’re young ladies that are interested in it. And I can give them that perspective and how being a woman in this trade is kind of not easy, but it’s manoeuvrable. And you can do career and you can do family and how that all works together. But watching him talk to the students I can get distracted, because I remember sitting in that classroom with that same level of excitement. It’s a good program and a program that I would recommend for anybody.”

Having Hillestad come and speak with young women about the industry is having an impact. Gene Aqulini, glazier instructor for SAIT’s School of Construction, says that more women are enrolling in the program than ever before. He says there are 24 women that are currently in the program and recently graduated.

“I believe 13 of them are now journeywomen,” he says. “Ladies have been flocking to our trade the last 10 to 12 years. We attend a lot of trade fairs, a lot of school trade fairs, and we’re finding the girls are going, ‘Wow, look at what you’re making. And I can go to school and not pay anything.’”

INTRODUCING THE COMMDOOR FOLDING DOOR SYSTEM

Designed for spectacular year-round enjoyment. Connect your outdoor oasis with the indoors: private residences, restaurants, cottages, patios, event centres, and entertainment complexes. Experience the full potential of your space today. commdooraluminum.com

SAIT is turning jobs into careers by helping young people get their Red Seal certifications as glaziers. The program is full again for the coming year with 328 students.

In his experience, Aqulini finds that women have a tendency to pay a little more attention to detail and that the female graduates have gotten rave reviews to date.

“For the ladies that have come through our program who I’ve stayed in contact with, there are never anything but good things said about them,” he says.

For students that are considering signing up for SAIT’s glazier program, Hillestad recommends dabbling in both fabrication and installation.

“Don’t pigeonhole yourself to one thing. The more knowledge you have, the better,” she says. “I’m going to be going back for more SAIT courses, so I definitely recommend the school.”

Aqulini says that SAIT’s glazier program has achieved not only the highest recognition, but also the highest pass rate (92 per cent) in all of its governmental exams, and an 86-per-cent passing rate on Red Seal exams.

“It goes to show the experience of the instructors,” he says. “There is no other program in North America that can match that.”

Changes ahead

Although the program at SAIT’s glazier program is going strong at the campus in Calgary, the school did recently announce some changes up north. SAIT dropped the glazier program in Edmonton, which was taken over by the Northern Alberta Institute of Technology. New registration for the NAIT program opened up this past May.

“SAIT’s program is solely based in Calgary now, and we’re full,” says Trevor Whyte, vice-president of Calgary-based Grif-

fin Glass, who sits on the board for the Provincial Apprenticeship Committee (PAC) and Local Apprenticeship Committee (LAC).

Whyte is also a SAIT graduate and earned his Red Seal back in 2003.

“The program itself teaches you a lot when you get in there, then you get the hands-on experience,” he says. “The program helped me immensely.

Griffin Glass currently has 16 installers and 10 of them are full journeyman ticketed, so they take education very seriously during their hiring procedures.

“It’s a bit top heavy but our end product shows our quality,” he says. “I’d rather pay a few bucks for more qualified people.”

As a local employer, Whyte says there’s no comparison when comparing a potential employee who has their ticket with a person who doesn’t.

“It’s self-explanatory,” he says. “If an apprentice put himself through school it shows a commitment to the industry. Especially in this market, which is so saturated with workers.”

Although the SAIT program is only based in Calgary now, the school is still a training partner for companies in Saskatchewan, Manitoba, the Northwest Territories and The Yukon.

“For the last four years, we’ve been drawing from Atlantic Canada as well, so we’ve had a few students come up from Halifax,” says Aqulini. “We have a super-strong program. We’re running about 328 students.”

Industry impact

Whyte says SAIT’s glazier program and the industry in general

has had a huge impact on his life.

“I’ve been doing this 23 years and it’s gotten me to where I am right now. It’s made me my life. I owe everything to the glazing field,” he says. “My father owns a glazing company. It’s just been in our blood. It’s done wonders for me in particular, and a lot of my workers, even if they move on to other places.”

As a member of the PAC and LAC, Whyte works regularly with the instructors at SAIT to ensure the program stays up to date and offers the latest training to its students so they are ready to enter the workforce when they graduate.

“Essentially both LAC and the PAC work together to keep everything up to date,” he says, adding that the whole program was updated over a course of about five years, except the handouts, which are being updated now. “The whole course outline is up to date as of two years ago. It’s a great program, its strong. It’s got great instructors, a very professionally taught program.”

Aqulini has been a glazier for about 26 years and was certified for Red Seal in 1996. He is currently in his 12th year as an instructor at SAIT. He says the most fulfilling part of being an instructor is becoming somebody’s mentor.

“It’s no different than being in the field and taking on an apprentice,” he says. “Watching them fulfill their life and get their raises and the smiles on their faces when they struggle and then succeed. I can’t tell you the feeling it gives you. I think number one is seeing the success of the student and watching them come in with pimples and leave married, owning a house, maybe having a child. Then they come back years later and say, “This is what’s happened in my life, and thank you for all of this… its the best job in the world.” •

Inbound from Ireland

Carey Glass is gaining traction in North America.

They’re big and they’re here. Carey Glass boasts an 850,000-square-foot plant in Ireland where it produces oversized IGU for shipping around the world. The company says it makes 98,000 square feet of fabricated glass products every year.

AT A GLANCE | Carey Glass

Founded in Ireland in 1965 by three brothers from the Carey family, Carey Glass, a major global glass processor, remains a family-owned and -run company. The business grew from fabricating furniture glass and mirrors to manufacturing insulating glass units and now claims to ship 98,000 square meters of glass products worldwide every week.

“With the advent and increase of tempering technology, the business went from strength to strength”, said Michael Carew, North American sales director for Carey Glass. “We currently have three locations. Our primary manufacturing site and headquarters is 850,000 square feet and is located in southwest Ireland in Nenagh, the second largest town in County Tipperary.”

Carey has another location in Northern Ireland, which is 100,000 square feet, and a third plant in Chester, U.K., which is 85,000 square feet. Both of these plants mainly cater to the residential market while the headquarters in Nenagh is configured for both commercial and residential projects.

Carew launched the company’s North

American expansion initiative which he likens initially to an R&D project. “Our strongest market is still the U.K. We have our own fleet and are sending an average of 23 trucks per week to cities throughout the U.K. including London, Manchester and Birmingham. With Brexit negotiations ongoing, there has been great uncertainty in the U.K. market. We entered the North American market before the U.K. voted to leave the EU, and, to be honest, like many others, we were surprised with the outcome of that referendum. So our entry into the North American market place was not in any way influenced by Brexit.”

“Each year we have grown significantly the volume of projects we are supporting both in Canada and the U.S.,” says Carew. “Coming into North America, our signature strength was our oversize glass capabilities. I never thought we were going to be competitive in the quarter-inchquarter-inch market or tower projects, but we soon discovered that when you get over a certain square footage of volume we become very competitive.”

“We obviously specialize in double-

Headquarters: Nenagh, Ireland

Production: Nenagh and Lurgan, Ireland; Chester, U.K.

Facility:

850,000 square feet

Volume: 98,000 square meters per year

Products:

Double and triple IGU, architectural glass facades, digital printing, internal glass partitions

and tripled-glazed high-performance products. We temper, heat soak test, laminate, curve, print and digitally print. We can fabricate a 14-foot curved IG with a simple CAD file or a PDF showing the radius.”

All of Carey’s capabilities are under one massive roof within the Nenagh headquarters, which provides benefits to architects and glazing contractors. says With the exception of the production of coated glass, which the company procures outside, all project execution

activities take place at headquarters. Unlike some of the other leading glass processors, Carey does not outsource the critical tempering and laminating processes to external suppliers. This allows it to retain total control of the attainment of the quality and delivery requirements of each project. “We’re doing such high volumes of glass that we obviously have big buying power,” Carew explains. “This coupled with our in-house processing capabilities makes us very competitive.”

Carew shares that the initial challenge in the North American market was getting the first jobs and growing their North American fan base. Importing glass has a huge fear factor. “Keep your two fingers crossed and let’s hope it all works out,” jokes Carew. “It was clear that most of the professionals we spoke with were interested in importing glass, primarily to explore opportunities to improve quality and of course profits. There was real interest in both our proposals and the quality of our product. However, we needed to give a level of comfort and confidence that there would be no disadvantage from a communication or service perspective when dealing with an overseas provider.”

One of Carey’s strategic operating priorities is to provide exceptional support to architects and glazing contractors during the design-assist and project delivery phases. Its customers say they greatly appreciate the work of Carey’s dedicated support team. For each project, there’s one dedicated point of contact, the project manager. Any questions or update requirements from a glazing contractor are dealt with in real-time by the dedicated project manager. Carey recognized early that it would not only need to match but exceed the levels of support the glazing contractors were accustomed to receiving from local suppliers. “There are so many glass processors in North America,” Carew says. “We knew we needed to provide world class service to further differentiate our offering.”

Carew admits it was a hard sell initially convincing organizations to change direction from only buying locally. Obviously, the bottom line is what most people are concerned about. “’Am I going to make money on this job? Am I getting a competitive edge? We were able to demonstrate in most cases that our solutions were very competitive even with the additional cost of transport.” So the initial barrier to overcome ultimately

systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass,

yield a fenestration system capable of upholding the highest efficiency and sustainability standards.

came back to trusting the service an overseas glass supplier would provide.

“Thankfully, we’ve done enough projects now that I can say to every potential new customer I meet, ‘Go on to the website, pick any North American job you want and I will give you the customer’s contact details,’” says Carew. “You can call them yourself and ask. I am very confident in providing any names to describe our customers’ experience of working with Carey Glass.”

Carey Glass has the interior and

exterior of the Washington State Convention Center project which is the biggest public project in the history of Seattle. “It’s a tricky job. It’s not your standard two pieces of glass. The complexities of this project are simplified with us having all processes under the one roof.”

Carey Glass has projects completed or in process in New York, Boston, Chicago, Toronto and Seattle. “We’re currently also finalizing an agreement to supply upcoming projects in Vancouver,” Carew reports.

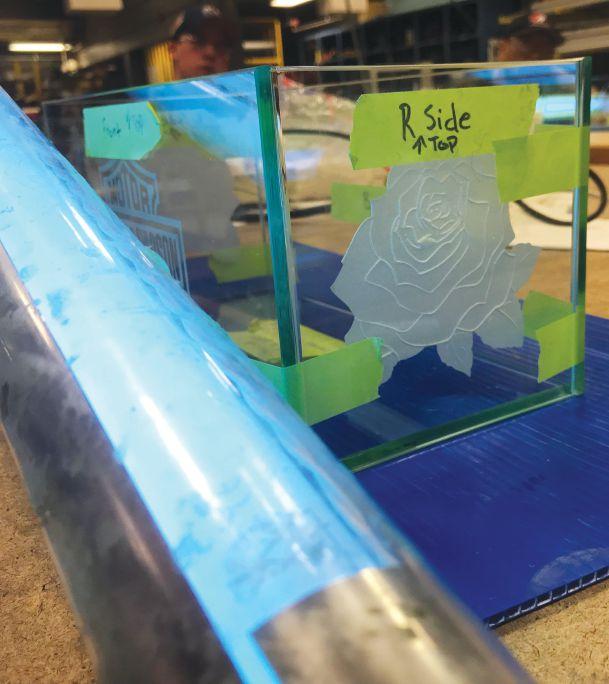

Specialty products such as curved and printed glass are part of the offering at Carey. Unlike many fabricators, it does not outsource tempering and laminating.

How does one get a commercial project’s worth of glass from Ireland to a jobsite in Vancouver? According to Carew, if the glass is oversized and is peeking out the top of the container, it has to go the Panama Canal route. “We have shipped IGs into Montreal and railed them across to Vancouver and down to Seattle, however we have to install capillary tubes because they’re going to go over the Rockies and we don’t want them popping.”

Carey Glass is only seeing a small ripple effect of the ongoing trade war which is mainly transportation-related. “The trade war congests the ports and adds to our lead time,” says Carew. “When containers leave our facility, we tell the customer it’s a three- to four-week lead time. Every time there is talk about tariffs, everyone in America starts stocking up and it causes congestion. That three to four weeks occasionally turns into five to six because the ship is out in the water and can’t even get into the port.”

“Guardian and Pilkington give us phenomenal support in Europe,” says Carew. “We find North American customers can be more demanding than European glaziers. They demand answers now. So, in turn, Carey Glass North America is equally demanding of our partners Guardian and Pilkington. But they give us answers straight away and it’s a great service they provide to us. This obviously enables us to provide very quick responses to our customer’s information requirements.”

“Toronto, Montreal and Ottawa are booming,” says Carew. “It’s a very exciting time. In fact I heard an interesting stat in recent weeks: there’s currently more cranes in the sky in Toronto than in any other North American city. There has been speculation that the U.S. is slowing down, which we obviously have to monitor closely. I had a meeting with a major U.S. glazing contractor earlier in the week and we had this same conversation about the slowdown. He says, ‘We’ve never been busier. We don’t have to quote work anymore.’ I guess talk of a U.S. slowdown is premature. •

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David.Heska@wsp.com

Searching for skill

Three quick facts: one, Baby boomers are getting older; two, the average age of a construction worker in Canada is 42; three, 69 per cent of contractors in Ontario expect to have difficulty finding skilled workers this year.

Like many other industries, we are asking “Where will the next generation of skilled staff come from?” We are already seeing the warning signs of a skilled labour shortage. Companies are turning down work, declining to bid on projects, raising prices or using less qualified labour.

The good news is that in a few ways we are ahead of some fields. The Ontario College of Trades already has a designation for Architectural Glass and Metal Technician and nationally the Red Seal occupational standard for glazier has been in place since 1986. At the recent Top Glass tradeshow I was interested to learn more about the Architectural Glass and Metal Certification Council’s third-party certification. Right now the program is predominantly U.S.-based but they are trying to make inroads here in Canada.

Is third-party certification the answer to our skilled labour shortage? I’m not convinced. Notfor-profit industry organizations are important for gathering like-minded individuals with similar passions. I’m involved in a few of these organizations and the benefits are numerous, including continuing education. But let’s not presume that there is a magic solution to this problem.

In other building construction disciplines the International Concrete Repair Institute has designated Concrete Surface Repair Technicians and the Exterior Insulation Finish Systems Council has created a Quality Assurance Program. However, neither of these has gained significant trac-

Is third-party certification the answer to our skilled labour shortage? I’m not convinced.

THE ENGINEER

tion across Canada. We are trying to improve the quality of our building stock and we are trying to reduce the number of poor contractors and suppliers, but it’s an uphill climb.

Let me propose a few solutions.

First, we must automate. Automation helps solve the problem of the skilled labour shortage by reducing the number of staff needed. The robotics in our window and glass manufacturing plants is only going to increase in the coming years and more building components will be prefabricated before arriving to site. We need to embrace this change and accept. Skilled labour will still be needed, but the tasks being completed will not be the same as they were 20 years ago.

Second, we need to improve our education systems. More work needs to be done in our secondary schools so that students know what to expect if they choose a career in the skilled trades and what opportunities there are for advancement. The government cuts to high school shop classes need to stop and we must engage with the co-op programs to provide hands-on experience for these young people.

Finally, we must look into gradual credentialing rather than all-or-nothing apprenticeship. The statistics show that Millennials are likely to have four job changes by the time they are 32 years old. We cannot expect them to be as loyal as their grandparents were to one company for an entire career.

To accomplish this, we must roll up our sleeves and embrace change. Are you ready? •

TALKING TO ARCHITECTS INDUSTRY

by RICH PORAYKO

With its everchanging landscape and excess, cities like Las Vegas capture the world’s imagination. Our industry’s work is influenced by their trends. As an incubator of transformation, Vegas was a fitting venue for A’19 AIA Conference on Architecture 2019.

Held in early June at the Las Vegas Convention Center, the AIA is enormous. With over 150 architect-led seminars, 24 workshops, 150 tours, 130 manufacturer continuing education sessions and 650 exhibitors, there is no way you could see it all.

Glass was relatively underrepresented in the over 500 sessions but did include “Designing with Fire-Rated Glass” presented by Tim Nass of Safti

Report from the American Institute of Architecture conference.

First, “Principles of Glass Selection for Façades” by Guardian Industries’ Jacob Kasbrick and “Critical Code and Design Considerations of Glass Railing Systems” by C.R. Laurence’s Brian Clifford and Kevin Perttu of Rice Engineering.

Big is better and biggest is best. Much to the mayor of NYC’s dismay, there is a heated race to see who can produce the biggest, most efficient window or door. The variety of oversize stackable walls, tilt windows, doors on display was insane.

Matte black finishes are still hot. Apparently bronze is growing. Oddly enough, dynamic glazing such as electrochromic glass was quieter than expected.

“There needs to be engagement with the architects,” said An-

drew Haring, vice-president of business development for the National Glass Association. “The specifications process is the point of entry for glass in the building so there needs to be awareness on the technical side about what glass can and cannot do. And they’re not getting a version that’s spun by a manufacturer. They are getting it straight from an association that doesn’t have an agenda. It’s about promoting glass as a building material.”

“There is an assumption that everyone is here for the continuing education but that can be achieved in a million different ways,” added Haring. He says that more and more architects want to see the real article. “They want to touch and hold products. There is always going to be that interest there. That firsthand experi-

ABOVE: The steady growth of the AIA Conference has turned it into a premier opportunity for Canadian architectural glass companies to interact with their most important clients: architects.

ence with the product and access to the manufacturers who are subject matter experts. We see more and more architects coming to the AIA show and in turn we’re seeing them show up at GlassBuild as well.”

“We’re here to raise awareness among the architectural and design community about the advantages of having an independent third-party prequalification for glazing contractors,” said Archiectural Glass and Metal Technician program manager, Ben Beeler. “At the end of the day, we’d like the North American Contractor Certification (NACC) specified as a requirement for the installation entity.” According to Beeler, NACC reduces exposure to liability to architect and glazing contractors and provides glaziers a way to secure additional projects by differentiating them from glazing contractors who have not had an independent evaluation or certification.

“We want to talk to architects,” said Danik Dancause, marketing operations manager for Walker Glass. “We want them to be able to see our products in a bigger form. It gives them an opportunity to see our first-surface bird-friendly glass. AviProtek is a clear glass with visual markers following the two-inch-by-fourinch rule established by leading scientists such as Daniel Klem.”

Walker’s AviProtek-E bird-friendly glass solution combines acid-etched visual markers on the first surface with Vitro’s Solarban high performance low-E on the second surface, creating a bird-friendly glazing solution while saving energy. “This innovation enables architects to achieve their environmental goals and earn LEED credits, while meeting solar performance targets,” said Dancause.

Walker has also partnered with Pilkington to offer AviProtekT, a discrete bird-friendly glass solution using Pilkington NA’s pyrolytic coated glass. According to Dancause, Walker Glass etches patterned contrasts on the pyrolytic coated outside surface that are visible to birds but barely perceptible to humans.

Dancause says all of Walker’s bird friendly products support the new CSA A460:19 Bird-friendly Building Design standard which requires first-surface application.

“By being at AIA, we have a chance of helping architects solve problems with different issues including daylighting and bird-friendly design. Ultimately, the goal is to meet with them and help support them in future projects. When you are not here, you don’t have the same opportunity to meet with them.”

If your world involves architects or designers, you need to be at the AIA Convention and Expo 2020 in the City of Angels. •

by FRANK FULTON

Frank

Fulton is a former principal of Fulton Windows and former president of the OGMA.

OGMA and CSC team up

In February 2019, the Ontario Glass and Metal Association and the Toronto chapter of Construction Specifications Canada entered into a memorandum of understanding between the two parties for the purpose of enhancing mutual awareness, co-operation and the promotion of the organizations’ events and initiatives. The associations share a dedication to professionalism and educational initiatives. This friendship to expand each others’ reach just made good sense.

The Specifications Writers Association of Canada was formed in 1954 in part to address the chaotic situation that existed with construction specifications at the time. By 1974, in addition to specification writers, membership had grown to include readers, suppliers, contractors and allied associations. This evolution led to the more inclusive name change to Construction Specifications Canada.

Education has always received a strong commitment from the CSC and the Construction Specifications Foundation was created to further education and research and to promote publication and distribution of construction documents of a high standard of excellence. The OGMA also has a long history of delivering educational seminars and bulletins on topics pertinent to the industry.

CSC and OGMA share a dedication to professionalism and educational initiatives.

The first major undertaking for the organizations is slated to take place on Nov. 14 at the Richmond Hill Country Club with four topics on the docket. “Share the Vision: An OGMA/ CSC Educational Collaboration” promises to be a highly entertaining and informative event with something of interest for people from both disciplines. The companies and people presenting are as follows...

YOU BET YOUR GLASS

Kuraray America is a world leader in the manufacture of interlayers for laminated glass who invests heavily in the development of new technologies. One of their latest inventions is a layer that is designed to reduce sound transmission through glazing.

The OGMA has been keeping the industry updated on developments with the Ontario Construction Act, the replacement for the Construction Lien Act, for the past five years. With the prompt payment and new adjudication systems due to be enacted by the end of October, the timing couldn’t be better for our speaker, Glenn Ackerley with Weir Foulds, to bring attendees up to date on how best to use the act to their advantage in protecting their interests and being paid for their work on a timely basis.

Guardian Industries, another world-class company in the development of emerging technologies, will open some eyes on what to expect in the future as they speak about vacuum glass. It’s going to have a huge impact on the energy efficiency of glazing. Guardian will also discuss the application of nanotechnology to virtually eliminate glare and reflections from glass.

Ted Kesik is a professor of building science at the Daniels Faculty of Architecture, Landscape and Design at the University of Toronto and will provide guidance on preventing building envelope failures through proper and proven protocols beginning at the conceptual design stage through all aspects of building envelope commissioning best practices. Ted will also look at how last minute “value engineering” often results in disappointing performance issues.

The OGMA and the Toronto chapter of CSC are very excited to bring this great program to our industries. We’re expecting a great showing from our respective memberships but are happy to welcome anyone from across the country who is interested in learning. Please visit the OGMA.ca website for more details and registering. •

This is Meghan. As a trusted and experienced architectural glass consultant, she can open your eyes to the world’s widest portfolio of products available from the world’s largest manufacturer of glass. The time-saving, hassle-eliminating services Meghan provides her clients every day help make using the glass products of tomorrow a reality – today. For example, her extensive knowledge of local regulations and energy codes results in an efficient and accurate recommendation, giving you peace of mind that you’re making the very best decision when it comes to architectural glass.

Discover AGC and meet your local go-to architectural glass pro today. Visit AGCglass.com/MyGlassGoTo

Meghan Beach, LEED AP BD+C, CSI CDT Architectural Glass Consultant AGC Glass

GLASS FOR SMART SPACES

Brighten interiors and minds.

Rajen Kilachand Center for Integrated Life Sciences & Engineering

BOSTON, MASSACHUSETTS with SunGuard® AG 50 and SunGuard® IS 20 on clear

©

See what’s possible™ on your next project with Guardian SunGuard ® Architectural Glass.

Keitaro Yoshioka Photography