Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the per fect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions

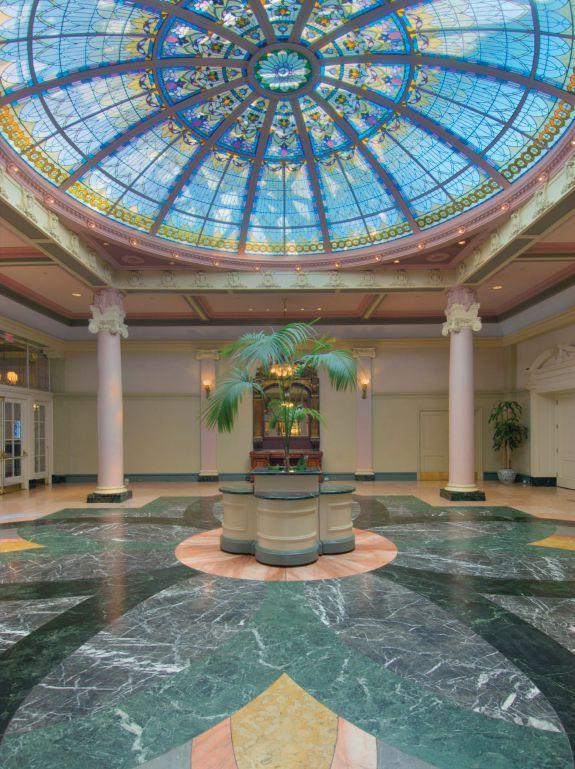

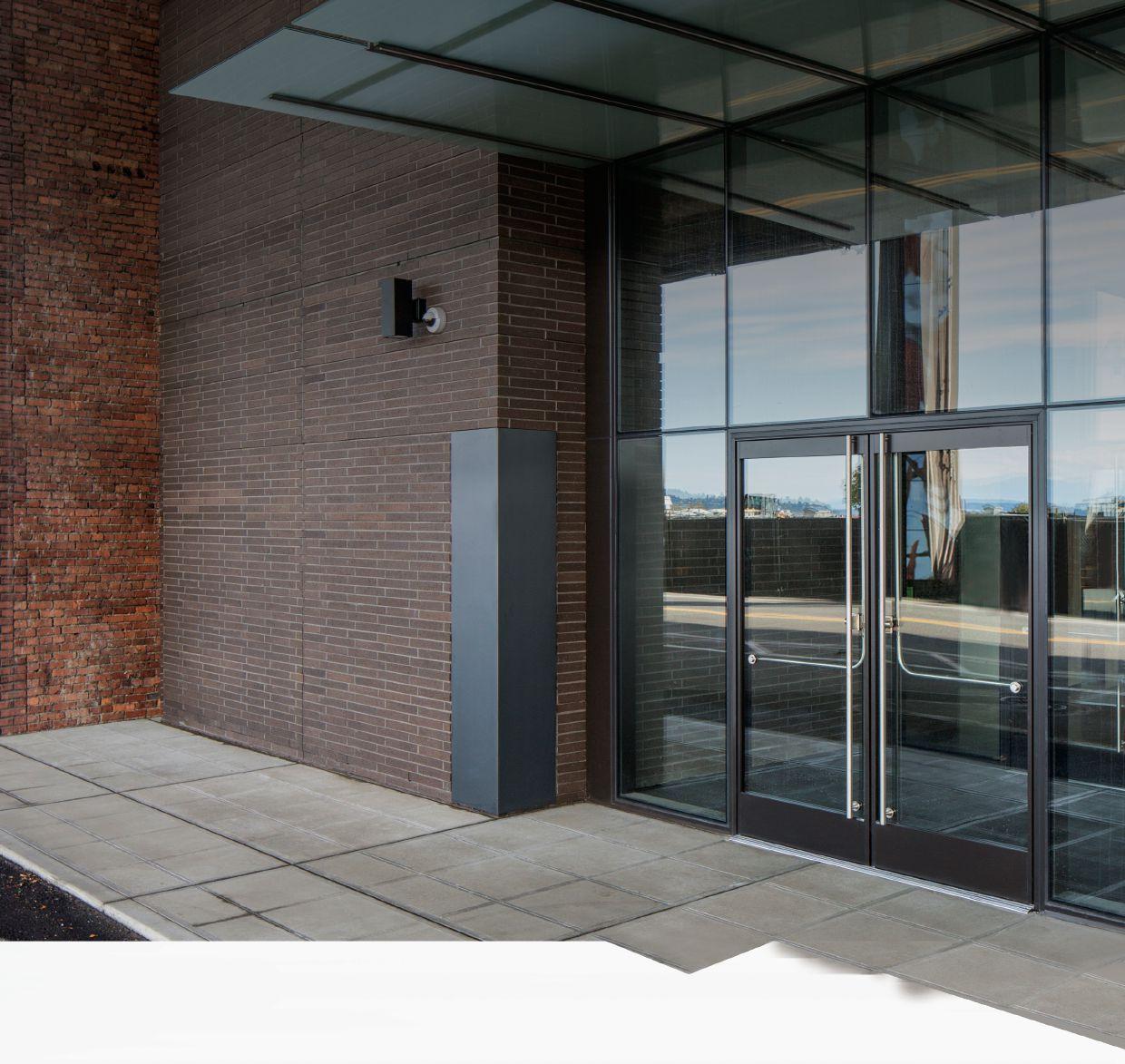

Kits Glass has landed some of the highest profile installations in B.C. with a facility for meeting the challenges of unique installations that combine architectural integrity with artistic beauty. Above: The Empress Hotel’s Palm Court in Victoria.

FEATURES

22 Report from GlassBuild

Roving reporter Rich Porayko took in the big show in Las Vegas. Here’s what he saw and heard.

26 Facade technology showcase

INNOVATIONS

18 The eye of the moth

BUYER’S GUIDE

Better than Google

ASSOCIATIONS

A look at what’s new in curtainwall, store front and other glazed building facade components. 7 Canadian Glass Association 12 Insulating Glass Manufacturers Alliance

Montreal tech startup Edgehog is using nanoscale glass etching inspired by nature to create surfaces that are non-reflective, water-repellent and condensation-resistant.

COLUMNISTS

The Engineer By

David Heska

You Bet Your Glass By

Frank Fulton

Google is great, but what if an expert local supplier hasn’t been doing so well with its search engine optimization? The Glass Canada Buyers Guide has been collecting listings from Canada’s top suppliers to the architectural glass industry for over 40 years. Find a diamond in the rough!

GLASS CANADA

Event horizon

Education events are multiplying.

EDITORIAL

GLASS CANADA

October 2018

Volume 30 • Number 5

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

Six years since we launched Top Glass, it now seems apparent that a lot of other people in other places were noting the same need for industry education and networking events. At the time, the only events in Canada specific to the glass industry were the Canadian Glass Association’s Glass Connections conference – which moved around the country and didn’t occur on a regular schedule – the Insulating Glass Manufacturers Alliance conference and the Quebec glass association’s annual meeting. WinDoor was traditionally a residential show for vinyl fabricators. The various architectural and construction shows only touched on facade glazing as an afterthought. Even the U.S. was limited mostly to GlassBuild, the American Architectural Manufacturers Association conferences and the American Institute of Architects conference.

NEXT ISSUE

• Energy efficiency

• Insulating glass

• Buyers Guide

Today, the field has exploded. I was at the IGMA conference in Vancouver in late July and the education program was provided by the Facade Tectonics Institute – a not-for-profit organization that will be putting on four full-day seminar programs in locations across North America next year. US Glass has launched GlassCon Global. Fenestration B.C. hosts Fenestration West, which now touches the commercial sector following the merger of the B.C. Window and Door Manufacturers Association and the Glazing Contractors Association of B.C. Winnipeg’s FenCon is targeted at both commercial and residential. And WinDoor is making a renewed push to attract commercial fabricators and contractors to its Quebec City edition with a commercial-specific education stream. The number of opportunities you have to take in some expert education, visit with vendors and network with peers has easily doubled since we first saw a need in the market.

Why has this happened? Partly, it’s because times have been pretty good in the industry for a while now coming out of the 2008 recession. Strong revenues for suppliers means larger marketing budgets for booths and sponsorships.

Another reason is a change in marketing philosophy. In the Information Age, marketers are challenged to make their message cut through a barrage of noise. The old strategy of simply making more noise than your competition doesn’t work as well when the noise-making apparatus (the Internet) is so cheap that just about any voice can equal your volume.

I also happen to think there’s a certain hunger for face-to-face contact in this time when you can go years only communicating with an important business contact via email. When worthwhile events happen, they seem to attract a pretty good crowd. When one organizer sees another having success, the natural effect is to try to replicate it.

These things run in cycles. As the success of industry events causes them to multiply, a point will be reached where there are too many for each to draw a large enough crowd and supplier supporters will rebel and start picking favourites. It’s a good spur for organizers like myself to keep working hard to provide the best possible experience so we’re the last ones standing when the inevitable cull comes.•

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Curtis MARTIN

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

RCI, an association for building envelope professionals, held a Building Envelope Technology Symposium for the first time ever in Canada on Sept. 13 and 14 in Mississauga. Here, Kevin Knight of Red River College in Winnipeg presents his research into building airtightness.

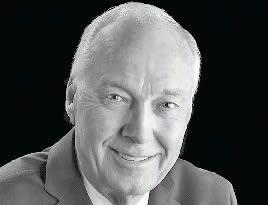

Friese retires

After58 years of dedication to his customers, business and team, Don Friese, chairman and CEO of CRL, will retire at the end of September 2018. His successor, Lloyd Talbert, has been with the company for over 25 years and will maintain his role as president along with assuming CRL’s leadership. Don joined CRL as its sixth employee in 1961 and by 1997 he had progressed to become CEO and owner of the company. Through both acquisitions and organic growth, Don grew CRL into North America’s largest manufacturer and distributor of custom hardware products and supplies for the glass and glazing industry. Today, the company makes or distributes more than 65,000 products for the architectural, construction and automotive industries - from frameless shower door hardware to commercial entrances and transaction hardware. Friese sold CRL to Oldcastle BuildingEnvelope in 2015 for a reported $1.3 billion.

Talbert comments, “Don’s leadership and contribution over almost six decades has been

instrumental in expanding the business from a small company to a global manufacturer and supplier of architectural glazing systems for commercial and residential applications. Over the years, Don consistently focused on growing the company, expanding its reach and improving its products and services, while building a strong team and surrounding himself with exceptional talent.”

Talbert joined CRL in 1991 as vicepresident of finance and CFO and is an experienced industry and business leader, most recently in his role as president and COO of the company.

In other CRL news, the company has announced Vimac Distributions has become more closely integrated with it.Vimac, based in Montreal, has a well-respected name in the glass and glass industry with over 30 years of hardware distribution experience in tools and supplies for glass.Vimac’s operations are now integrated into CRL’s Montreal service center, located at 8200 des Batisseurs Street.

COMING EVENTS

October 15 - 18 AAMA National Fall Conference Tucson, Ariz. aamanet.org

October 24

FenBC Industry Conference Surrey, B.C. fen-bc.org

December 3 - 5

WinDoor Quebec City windoorshow.ca

2019

February 4 - 7

IGMA Winter Conference Austin, Texas igmaonline.org

February 21

Fenestration West Surrey, B.C. fen-bc.org

March 18 - 21

Fensterbau Frontale Nuremberg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

June 6 - 8

AIA Conference

Las Vegas, Nev. conferencearchitecture.com

June 16 - 28

Glass Performance Days Tampere, Finland gpd.fi

CGA Newsletter

Canadian Glass Association

National activities of the Canadian Glass Association are on hiatus pending discussions of a new direction for the association. The association will be meeting at the upcoming WinDoor show in Quebec City in December to explore options going forward. To help chart this course, please contact David Langton at dlangton@compglass.com

Fenestration Association of B.C.

October 24 is the date for the FenBC Industry Conference at Sheraton Guildford in Surrey. We are working on our agenda at this time. Please visit our website at fen-bc.org to get updated information. If you are interested in sponsoring or being an exhibitor check out the link on our website.

At the FenBC Annual General Meeting in February, David Langton reported to the attending FenBC membership that the FenBC board had to make the decision to let the FenBC Red Seal Glazier Apprentice Training program fold. This decision was not made lightly. It was a decision made based on finances and industry suppor t. Simply put, there was just not enough industry support to keep the school going. Financially, it would continue to be a considerable strain on the association resources. With the help of a few FenBC members we were able to get some interim funding in 2016 which helped us get this far. But it would not and could not last without the

Canadian Glass Association

3759 York Durham Line, Stouffville, Ont. L4A 7X4

Tel: 250.258.0578

canadianglassassociation.com

industry, and by industry we mean available apprentices that could fill 48 seats per fiscal year. After much consultation it was realized that this was just not achievable. August 31 marked the official end date for the FenBC Red Seal Glazier Apprentice Training Program.

FenBC has maintained the curriculum for future uses.

Journeyperson upgrading, Level 1, 2 and 3 challenge support programming, apprentice specific training, webinars and seminars are just a few of the ideas being considered by your FenBC board of directors.

I [Zana Gordon, executive director] would personally like to thank all the FenBC and Glazing Contractors Association of B.C. contractors who supported the program over the years. We were successful in training 140 Level 1 apprentices, 110 Level 2 apprentices and 72 Level 3 Red Seal Journeypersons. It was a great run while it lasted.

Provincial Glaziers Association of Alberta

With summer seemingly behind us and fall’s grip already upon us, our members are back to work trying to end a mediocre year on a strong note. The PGAA did hold a golf tournament in Lacombe in August. Our numbers were down this year, as no one had time to organize or attend events, but all in attendance had a great day. An uninvited guest, B.C. Smoke, left a bit of a damper on the skies but it was a good day nonetheless.

For the past few months, in conjunction with the Alberta Construction association, we have met with the Alberta

government to battle changes to the Labour Act, OH&S and WCB that are having a detrimental effect on business and costs. While the NDP believes that these changes will have positive lifestyle changes for workers, the reality is that they will result in less jobs, less hours, less benefits and employers taking less risks. There will be no winners here.

On the Master Glazier Program, after years of work, it is now on hold. In the end, a delivery method of ongoing education paid for by employees and employers on personal time has not been well received or supported. So it is back to the drawing board. Perhaps we can alter the delivery to resemble an enhancement of the existing Red Seal program (like a Master Electrician’s designation), but time will tell.

Hopefully we will have more to report over the coming months.

Architectural Glass and Metal Contractors Association

From time to time the AGMCA will use this space to turn the spotlight on its volunteer directors or its member companies. This month, we celebrate the 90th birthday of long-standing director and

treasurer of the AGMCA, Al Jones.

Our association officially gained designation from the Ontario Ministry of Labour as the employer bargaining agency for the unionized glazing contractors of Ontario in 1979. It wasn’t long afterwards that Al joined our board as a director. Al started in the glass business in the late 1940’s as a draftsmen for Pilkington Glass in Toronto.

Following some time spent with Scarborough Glass, Al joined Fred Fulton Sr. at Sealite as a sales rep. Al bought Jessup Glass in 1971 and changed the name to Parkway Glass, where he, along with his son, Steve, successfully carried on business for 47 years until his retirement this year.

Anyone who has met or dealt with Al in his over 70 years in our industry will always comment on his kind demeanor, his professionalism and his quick wit, which remains intact to this day. Well-wishers can reach Al by emailing our association at noel@agmca.ca. All emails will be presented to Al on your behalf.

For more information on our association, please contact us by email or through our website at agmca.ca.

Ontario Glass and Metal Association

We will be notifying members of the details of our fall seminar to be held in mid-November in the next while. Topics planned for this event include the Certificate of Recognition (COR) program as well as the new bonding provisions contained in the Ontario Construction Act.

Rea to Imagic

Imagic Glass in Concord, Ont., has announced Ennio Rea has joined the team as vice-president of sales. Rea, a wellknown figure in the Ontario glass industry and recipient of the Ontario Glass and Metal Association’s Lifetime Achievement Award, will be responsible for leading Imagic’s sales efforts in the glazing community and developing Imagic’s sales team. Rea’s experience in the glass industry stretches back to1968, covering such companies as Moore Glass, Tempglass, Clearex, Royal Building Systems, ProTemp Glass, Triple Seal and, most recently, Trulite Glass and Aluminum. He served terms as a director of the former Metro Toronto Glass Association and as director and president of the OGMA.

“Ennio has been a high-profile member of the glass industr y throughout his career,” said Adam Shearer, president of Imagic. “He is widely respected throughout the community and has an extensive network. Ennio fosters strong relationships and is known as a man of integrity. He is well known for his warmth and sense of humour. Our values align with Ennio, which is a critical factor for Imagic Glass in all partnerships we establish. Imagic has been experiencing rapid growth over the past six years. Having Ennio join our

team will allow us to continue our growth plans and enhance our position in the market as a fabricator of very high-quality architectural glass solutions.”

“I’m excited and looking forward to joining the Imagic Glass team,” Rea commented. “ They are committed to producing high-end, top-quality architectural glass products. I want to contribute to their continued success and be part of this dedicated and professional team.”.

AAMA, IGMA merger talks Don Ward,

The boards of directors for the American Architectural Manufacturers Association and the Insulating Glass Manufacturers Alliance have engaged in formal discussions with the hope of creating a new unified organization that can better serve the Nor th American fenestration industry. This agreement follows the recommendation made by a joint AAMA and IGMA exploratory team after 12 months of careful thought and collaboration. Moving forward, the team will focus on developing a comprehensive proposal. The team’s priorities are two-fold: how to best serve the needs of the current membership and to develop a new organization that best serves the industry as the new organization progresses into the future. The first combined event has been targeted for the summer of 2019 in Victoria, Canada.

“AAMA and IGMA are both strong associations with distinct strengths and influential members of the glass and fenestration industry. A combined organization can be even stronger by harnessing the synergies of the back-office and the intellectual knowledge of the associations. One of many strategic advantages for all of our members will be comprehensive, consensus-based, standards for the whole, finished, fenestration product – from glass to framing members, and all the related components. Members will have access to the critical information they need from a single, cred-

ible source,” said AAMA board chair, Mike DeSoto of MI Windows and Doors. He continued, “A combined organization also delivers expanded technical competencies and a broader document base to support more extensive educational opportunities for members.”

IGMA board chair Nathalie Thibault of Prelco agreed and added, “Within the structure of the new combined organization our strategy will emphasize maintaining a strong presence in both the U.S. and Canada with an appropriate balance to support all members across North America. We anticipate improved efficiency and time savings through potential sharing of combined events and networking opportunities as well as expanded staff support.”

While there are many combined benefits to the AAMA and IGMA members, the organizations also acknowledge the value in retaining separate brand equity in certain services such as the insulating glass certification programs.

Thibault concluded, “A new combined organization further strengthens our financial position allowing for future investments in industry research and for more efficient, effective delivery of risk management, new product ideation and industry thought leadership among member participants. Together, we will have a stronger industry voice for our members.”

1943 - 2018

Don Ward, former president of Griffin Glass in Calgary and longtime leader in the Glass and Architectural Metals Association (GAMA), passed away unexpectedly at the age of 75 on Sept. 3. Ward began his career with PPG and became famous for his tireless volunteer work both in glass associations and provincial and national construction associations. He joined Griffin Glass in 1981 and took over as president in 1985, retiring in 2003. In addition to his work with GAMA, Ward represented that association as a director on the Calgary Construction Association board and received its Ted Walden Award in 1988 and Person of the Year in 2002. He sat on the Alberta Bid Depository committee and was the first chair of the Alberta Construction Tendering System. He also chaired the Trade Contractors Council, where he was recognized with the Ernest Dobbelsteyn Memorial Trophy.

New guidance for structural glazing

The American Architectural Manufacturers Association (AAMA) recently released a new document to describe proper guidelines and glazing procedures for structural glazing. AAMA SSGDG-1-17

“Structural Silicone Glazing (SSG) Design Guidelines,” reviews a glazing that offers a unique appearance and simplicity of construction that often cannot be achieved any other way. Prior AAMA publications included TSGG-04 “Two-Sided Structural Glazing for Skylights,” and CW-13-85

Xinyi float glass plant rejected

T“Structural Glazing Design Guide.” However, it was decided to combine them into a single guiding document regarding structural glazing, for both vertical and sloped applications.

“Combining two documents that discussed structural glazing made learning about the process simpler for those seeking that information,” said Kelly Broker (Dow Performance Silicones), chair of the AAMA Structural Sealant Design Guidelines task group. “We feel this makes the knowledge

he council of Guelph-Eramosa Township in Ontario refused the application for bylaw amendments by Xinyi Canada Glass in June, effectively killing the Chinese manufacturer’s plans to build a float glass plant in the area. The proposed project would have constituted a $450 million investment and employed about 400 people. It also would have meant the return of float glass production to Canada after a 10-year hiatus following the closure of PPG’s Owen Sound, Ont., plant.

Xinyi’s statement following the decision said, “We are very disappointed with the council’s decision. Our commitment to build our first North American float glass facility to serve the increased demand of the North American market remains unchanged. We will review our position and consider possible options going forward. Over the past months, we have received strong support from many local residents, the business community as well as post-secondary institutions. We want to express our appreciation to them all for their valuable support and advice.”

The application was rejected on the grounds that the plant would draw too much water from the local water table. For a full discussion of the issues around the application, see Frank Fulton’s You Bet Your Glass column on page 30.

New leadership at LiSec

Othmar Sailer has been CEO of the LiSec Group for more than six years. Now he leaves the company. Sailer comments, “I really enjoyed working for LiSec and have been able to make significant progress over time. An impor tant task was, among many others, to build a reliable and competent management team, which I managed to do. Now is the time to devote myself to new tasks.” Sailer has put a strong focus on the devel-

formerly contained in both more accessible.” Properly designed and installed, structural silicone has performed well in the presence of UV exposure, adverse weathering conditions and in extremely harsh environments. These qualities allow structural silicone sealants to continue as the only type of sealant approved for structurally adhered glazing applications. AAMA SSGDG-1-17, as well as other AAMA documents, may be purchased from AAMA’s online store.

Tariffs on offshore curtainwall to expire

The Canadian International Trade Tribunal has begun a review of its 2013 decision to impose tariffs on Chinese curtainwall imports to Canada. The tariffs are due to expire on Nov. 11. According to the CITT notice, the tariffs will only be renewed if the Canadian Border Services Agency determines expiry of the tariffs will “result in the continuation or resumption of dumping and subsidizing of the subject goods.” If the tariffs are renewed, they will remain in place for another five years. The CBSA has issued questionnaires to the parties participating in the 2013 process, including Allan Window, Ferguson Neudorf, Flynn Canada, Aluminum Curtainwall Systems, Oldcastle BuildingEnvelope, Sota Glazing, Starline Architectural Windows, State Windows, Toro Aluminum and Windsor Glass. The government of China, Jangho Curtain Wall and Yuanda will also be invited to participate. The investigation closes Nov. 7 and the CBSA’s decision is due Jan. 24. “If industry doesn’t respond to show that this is injurious dumping then the tariffs will be scrapped and we will be competing against the Chinese for large projects,” commented Jim Brady of Cal-Tech Glass Services, former Canadian Glass Association president.

opment of strategy, culture, structures, the introduction and optimization of processes and above all the further development of product management. Business units that shape the respective product groups were founded and the innovation rate rose sharply. Other focal points were the successful expansion of the service business and intensive work on digitization in the glass business. Gottfried Brunbauer, who has been COO of the LiSec Group since November and previously served as CTO of Rosenbauer (a leading manufacturer of systems for firefighting and disaster protection) will be the new CEO.

New sales help at Saand

Saand has welcomed Larry Iacovino as regional sales manager at its London, Ont., facility. Iacovino has extensive experience serving the construction industry in both the window and building supply industries. Iacovino will be responsible for providing direction and guidance to the sales and customer service teams to ensure they are meeting Saand’s sales objectives and customer satisfaction levels.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David.Heska@wsp.com

With tariffs, nobody wins

While we all enjoyed some time off this summer, others were contemplating the current predicament we find ourselves in because of the short-sighted decisions made south of the border. On May 31, President Trump decided to impose tariffs on imports of certain steel and aluminum products from Canada at the rates of 25 and 10 per cent, respectively. Not to be outdone, our government responded on July 1 with similar tariffs.

Let me be clear: tariffs are a bad idea. In the globalized society in which we live, imposing penalties on a critical trade partner is just plain stupid. Many voices – such as Fenestration Canada, the Canadian Manufacturers and Exporters and the U.S. Window and Door Manufactures Association – have expressed their displeasure with the tariffs. It’s disappointing that after many years of successful trade and collaboration across the border a decision by one administration can overturn decades of achievement.

Who are the winners and losers in this current trade war? From the rhetoric we hear on the news and read in our Twitter feeds, a small number of leaders in the U.S.A. seem to think they have the upper hand. But in reality, there are no winners. Tariffs only increase the cost of goods sold. Not once has the imposition of a government tariff ever lead to lower costs for consumers. Therefore, it is the consumers who will suffer most in all of this.They will feel the pressure of rising window and door prices in both Canada and the U.S.

Here in the glass industry we also have our own stories to tell of the ways in which the tariffs are impacting our companies and projects. My team has already had some projects post-

Not once has the imposition of a government tariff ever led to lower costs for consumers.

THE ENGINEER

poned and others re-tendered when the products we had specified (that were not 100 per cent “made in Canada”) were proving impossible to source in the required timeline for the original budget. In these situations, we had to communicate the cause of increased cost and schedule delay to the owner. The reason was clear but that did not make it any easier for the client paying the bill to swallow (especially when the project cost was increased by $500,000).

So where do we go from here? I encourage each of you to reach out to your local Member of Parliament and inform them of the impact these tariffs are having on our industry. In addition to speaking to our elected officials we should be continuing our industry dialogue. How have these tariffs impacted you? Is there anything that your company has been able to do to minimize their impact? I look forward to hearing from you and engaging in discussion at the upcoming WinDoor show in Quebec City at the start of December. This may all be settled by then, but either way our industry has much to discuss.

Finally, I would encourage everyone to be patient. Change will come. Remember that in 2002 President George W. Bush imposed tariffs on steel hoping to revive steel production in the U.S. Instead of reviving the industry, the opposite occurred with job losses, material shortages and increased costs. Then, in 2003, the tariffs were reversed. Our tariff issue today will pass over like a storm cloud as well. Have faith that our elected officials will make the right decisions and that the excessive nationalistic zeal of a few will be overcome.•

GLASS THAT STANDS OUT

Making a statement in the Toronto skyline. See what’s possible™ with Guardian SunGuard® Advanced Architectural Glass for your next project.

EY Tower

TORONTO, ONTARIO

with SunGuard® AG 50 and SunGuard® SuperNeutral® 68

© Edvard Mahnic Photography

by MARGARET WEBB

Report from Vancouver

The Insulating Glass Manufacturers Alliance held its Summer Conference on July 31 through August 2 in Vancouver. The event attracted over 100 insulating glass fabricators for three days of informative presentations and discussion. It was a great gathering of our membership – thanks to all the delegates, sponsors and IGMA staff who made it all happen. And thanks to the Facade Tectonics Institute who gave the event some extra educational punch with a fantastic full-day seminar the day before we started. Here are some brief highlights from the event.

Helen Sanders of Technoform and David Cooper of Guardian co-chaired a meeting of the Emerging Technologies and Innovation Committee. IGMA technical consultant, Bill Lingnell, led off with a report from the thermal stress standard task group. Lingnell discussed the group’s efforts to create a standard for the amount of stress insulating glass should be able to take from changes in temperature. With the modelling work mostly done, they are turning to writing a standard, which the group hopes will be accepted by ASTM in the future. Another goal is to develop a software tool telling fabricators how much thermal variation their designs will tolerate.

Cooper told the committee that a guideline document for vacuum insulating glass is now available on the IGMA website and the task group has moved to working on a standard.

John Kent of AMS reported from the ASTM E2190 field correlation study task group, which is seeking to establish an accelerated pressure/temperature/UV stress test that can provide a provisional E2190 certification for fabricators until full testing can be done. The work to evaluate the

The Summer Conference

was a big success, with some added educational punch.

IGMA

test on solid seals is done, but more work may be needed to show it agrees sufficiently with the results of a full E2190 test. In the next round of research, the group wants to look at semi-rigid sealing technologies, but getting samples and access to a testing apparatus remains a challenge. Anyone out there able to help, hands up, please!

The life cycle assessment task group reported that California has introduced a bill called the Buy Clean Act that will require companies to report the contribution to climate change that their product represents. I have published an article explaining that creation of an industry-wide Environmental Product Declaration for flat glass may be the only way for the industry to ensure a fair standard for environmental authorities to refer to.

Kent gave the Certification Committee an update from the Safety Glazing Certification Council. He reported that ANSI and CGSB standards are now harmonized, bringing over 2,800 tempered and laminated products into registration.

Kent also reported that the Insulating Glass Certification Council is working on several changes, with 810 insulating glass products now certified and numbers rising slowly. Efforts to establish certification for individual internal components, enabling fabricators to construct a certified unit rather than test each configuration, are making progress. The IGCC has also introduced an “inactive product” category that allows fabricators to let the certification for rarely produced products to lapse without being removed from the record and to be reactivated in the event the manufacturer gets an order for that product.

I reported on efforts to have IGMAC certification accredited by ANSI. The application was well-received and we anticipate the accreditation will go forward with few changes to the existing program.

Lots more went on but that’s all we have room for here. Our Winter Conference takes place Feb. 4 through 7 in Austin, Texas.•

December 3-5, 2018

Quebec City Convention Centre Quebec City, QC

Register Online Today: windoorshow.ca

Don’t miss the opportunity for:

• Education

• Newest technology

• Networking

3 au 5 décembre 2018

Centre des congrès de Québec Ville de Québec, QC

Inscrivez-vous en ligne aujourd’hui : www.windoorshow.ca/?lang=fr

For more information on exhibiting at WinDoor contact Danielle Labrie - dlabrie@annexbusinessmedia.com

Ne manquez pas cette chance :

• Formations

• Technologies les plus récentes

• Réseautage

Pour en savoir plus sur les expositions pendant WinDoor, communiquez avec Danielle Labrie - dlabrie@annexbusinessmedia.com

Use Promo Code GLASS2018 to attend the show for free!

Utilisez le code promotionnel GLASS2018 pour obtenir votre billet gratuit!

Proudly presented by / fièrement présenté par

UNDERtheGLASS | BY

Working art

Kits

Glass takes the fancy designs and makes them stand up.

Paul Snelling has been at it for 37 years with no slowing in sight. He lands the artsy projects, but doesn’t have much interest in design himself.

Achurch in Guam. The airport at Anchorage, Alaska. The Great Wave piece that everyone sees arriving from international destinations at Vancouver International Airport. The Cristal Valley Radiation Oncology unit sculpture at University Hospital’s Seidman Cancer Center in Cleveland.The large Christ Church Cathedral project in downtown Vancouver. Or that little Catholic church outside of Vernon, in B.C.’s Okanagan Valley.

Asked if there was any one project that stood out in his 37 years as owner of Richmond, B.C.’s, Kits Glass, Paul Snelling doesn’t stop to ponder. “No,” says Snelling, 61, in his office at the facility on Viking Way in Richmond. “We’ve done so many projects. Each and every one of them has its own interest. My interest is not as a designer. Mine is getting it built on time, on budget and getting it completed.”

After doing commercial glazing for a few years, Snelling split off and started his company, named after the popular Kits Beach on the Pacific Ocean off Vancouver’s waterfront. He opened in 1981

with a small 800-square-foot place on Cornwall Street – the main drag of Vancouver’s Kitsilano-Point Grey region – and remained in Vancouver for a decade or so before heading out to Richmond.

The original Kits Glass shop in Richmond was 17,000 square feet and Snelling stayed there for more than 10 years before moving to its current location in an industrial area of the city, a stone’s throw away from the Vancouver airport. The shop features a production facility, offices and a showroom.

“We used to be a lot larger but due to style changes in the decorative industry –where a lot of people are going for more textured kinds of panels versus traditional stained glass panels – we downsized that end and kept people that have been with us forever,” said Snelling. Kits Glass, today, employs 17 people, most of whom average more than 20 years of service with the company.

In 1981, Kits Glass produced decorative glass for commercial, residential and ecclesiastical markets in Vancouver. Before he even started manufacturing, the first thing Snelling was doing was repairs and

Founded: 1981 Employees: 17

Serves: Nor th America

Location: Richmond, B.C.

Focus: Specialty architectural glass fabrication and installation

restorations. He did all the main churches in Vancouver in the first few years.

“Over the years, they’ve sent me a bunch of business from design and manufacture and protective covers,” he said. “We do a lot of protective covers now because it’s so expensive for them now with vandalism, the heat loss through a single-glazed stained glass window and the noise.

“What we do is a protective cover made of a sheet of laminated glass that protects the windows from the weather and outside noise. They use laminate in sound studios to dampen the noise. The protective covers are also energy efficient, which is an added bonus.”

As Kits Glass became known for its high-quality products and reliable service, the company’s work began spreading across North America and overseas

KITS GLASS AT A GLANCE

into Europe and Asia.

A natural progression for the business was to make its services available to door and window manufacturers who were unable to source a supplier offering a highquality range of product at competitive pricing.

“Other than us selling residential, a very large part of our business is selling to door companies,” said Snelling. “We sell to all the wood door manufacturers in the Lower Mainland.”

Whether it’s a one-off custom piece for a homeowner or a proprietary line for a manufacturer, Kits Glass can and will design, manufacture, deliver and install. And do it in timely fashion. They are proud to be one of the premier full-service custom and production glass suppliers in the industry. Their products include wrought iron, sealed insulated glass units, blinds

between glass, sandblasting and carved glass, stained and bevelled glass. As mentioned, they do a lot of commercial and architectural projects and install glass at churches and institutions. They also do exterior architectural glass for buildings outside, or lobbies inside.

“A lot of times, in commercial spaces, architectural glass is used for a lot of functions because it makes obscure something the owner doesn’t want to see while still letting in lots of light,” said Snelling. He gives an example of a Vancouver building his company worked on where you can’t see hydro poles and lines that were on the other side of a window, although the window is three storeys high.

“After 36 years, we are probably the most diverse company in the country,” said Snelling. “There are people that have specialties and they are usually one- or

The bell spire at Vancouver’s Christ Church Cathedral was made up of 204 stained glass panels designed by Canadian artist, Sarah Hall.

two-man studios, but we’re fairly large scale in the country. After all these years, we have a stable of customers we work with. Our work gets seen and people call us because of it.”

Work schedules depend on the size of the project. “Project work could be three weeks,” said Snelling. “Our residential projects we turn around in three, to five, to eight weeks, depending on what the project is. We work very closely with a factory offshore that provides us with custom bevels we could not afford to make here.

“We fly in the parts. The question is, does the person want it quickly, or do they want it not as quick and a little bit cheaper? Then, we bring in an ocean shipment. Our big projects are about two to three years, but there’s probably only six months of fabrication.”

As we said at the outset, Kits Glass has done lots of work nationally and internationally. In Canada, its work can be found in buildings and residences in Calgary, Edmonton, Toronto and Ottawa. They’ve been to the U.S., where Kits Glass products adorn an oncology unit at a Cleveland hospital – a piece that started with strips of glass the height of the window, then every strip was cut to a shape so that when it stood up it filled the shape. There were hundreds of individual templates that had been cut, so the project required three-dimensional computer-aided design software. There’s also a piece at Ted Stevens Anchorage International Airport in Alaska.

Just down the road from its production facility, Kits Glass’ beautiful work can be seen at Vancouver International Airport, a piece called The Great Wave, which complements a sculpture by renowned B.C. artist, the late Bill Reid. “It’s the first thing people see when they arrive from international flights,” says Snelling. “It’s approximately 30 metres by 10 metres and probably took us, in actual fabrication time, about eight months. Usually these projects span a couple of years from start to finish. We did the install on it, as well. We worked with another designer, which is what we usually do on these projects.”

photo credit: Martin Knowles

The original stained glass dome in the Palm Court of the Fairmont’s Empress Hotel in Victoria B.C collapsed during a snow storm on New Year’s Eve in 1968. After over two decades, Kits Glass reconstructed, designed and manufactured this masterpiece from old photographs.

Kits Glass’ most recent large project, in 2016, was an award winner. The company cut stained glass sheets made in Germany, which were placed in each of the 204 panels of the Bell Spire project at Vancouver’s Christ Church Cathedral, located in the heart of downtown at Georgia and Burrard Streets. Built in 1894, Christ Church Cathedral is Vancouver’s oldest surviving church building. The bell tower is three-sided with one open side so people can see the bells that were brought in from France and the sound transmits better. For its efforts on the project, Kits Glass was awarded the Heritage Award (along with Deltic Electric, Scott Construction Group, Solid Rock Steel Fabricating Company and Tek Roofing) at the 2017 Vancouver Regional Construction Association awards.

Kits Glass’ colour glass comes primarily from two sources: machine-made which, up until recently, was made by a Seattle company: Spectrum Glass, the largest in the world in that industry. Spectrum, though, closed its Seattle operation and factory and moved to Mexico. The cathedral uses antique glass, meaning it’s hand-blown.

“It’s very expensive and comes from Europe, mostly from Germany,” said Snelling. “You’ll see a church with coloured squares and that could be Spectrum glass. If you see a church with a painted figure in it, it’s painted and fired. That’s traditional stained glass.”

Examples of the Bell Spire project can be found on the company’s website, kitsglass.ca, which also displays many examples of the standard designs

available from the company. It also shows the range of colours and materials that can be created on-site to capture the perfect showpiece reflecting the customer’s personality and character. All designs can be customized with matching sidelights, windows, transoms, partitions and room dividers. Sales and marketing employee Hala Helmy helps maintain the website, which gets Kits Glass noticed worldwide.

It’s been a great 37-year run for Snelling and his company, and he sees no reason why Kits Glass won’t be around in another 37 years. “Yeah I think so,” he says, again without hesitation. “With the depth we have here, we would be crazy not to be. We’ve paid our dues, we are very well known, and the work comes in on a pretty regular, steady basis.” •

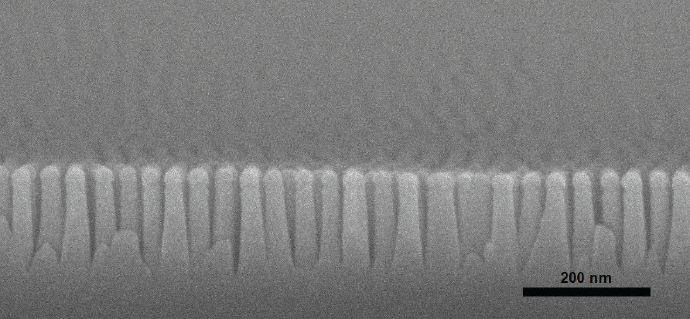

THE EYE OF THE MOTH INNOVATIONS

A Montreal tech startup looks to commercialize

by CALVIN CHENG, CO-FOUNDER AND PRODUCT LEAD, EDGEHOG

Nano-sized modification on the surface of glass brings huge reductions in the reflection of light and keeps the glass water-repellant and clean.

Invented at Brookhaven National laboratory in New York, the technology is now being commercialized by a team of entrepreneurs based in Montreal. Applied to architectural glass and solar panels, the broad-spectrum technology promises to achieve an unparalleled look of invisible glass, increased energy conversion in panels and self-cleaning properties for outdoor glass.

New innovations in functionalized glass is revolutionizing industries, but antireflective glass remains elusive. A wave of new innovations in glass is sweeping through many industries. Consumers are seeing new functionalities throughout their daily lives such as anti-scratch cell phone displays, interactive holographic projections on transparent screens, smart windows and many more. However, one inherent property of glass continues to irk designers. The reflection of light, or glare, ruins the visual experience in all such applications. Especially in transportation applications, safety can be compromised.

Reflection arises out of abrupt changes in the index of refraction as light travels between the air and glass. This four per cent reflection at each interface is omnipresent. There exist several technologies to address the challenge, but none have yet adequately addressed all applications.

Micro-structured “anti-glare” glass is a time-honoured technique for blurring and decreasing glare. By scattering light in all directions, less light is reflected to the viewer. However, the micro-structures also blur visuals, rendering them unsuitable for storefront windows, mobile phone screens and other applications where clarity is required.

Another mature approach, optically interfering thin films, eliminates the reflection at a narrow band of wavelength. With film thicknesses at half or a quarter of the targeted wavelength, light is transmitted rather than reflected. However, the reflected colour changes with the angle of viewing and, even with multiple layers, the ideal flat spectral response or broad wavelength anti-reflection cannot be achieved.

Left: Regular glass showing glare from ceiling light. Right: Edgehog antireflective glass, featuring clearly visible background graphics. Edgehog achieves this non-reflective surface without coatings or films, and the surface is non-reflective from almost all angles.

commercialize bio-inspired nano-textured glass.

Finally, because such films are often softer than the substrate and chemically and thermally different, they are susceptible to peeling and damage from environmental exposure or wearand-tear.

Bio-inspired nanostructures

In the biological evolution race, nocturnal moths have evolved anti-reflective eyes and wings to escape detection by predators. By growing sub-wavelength nanostructures on smooth surfaces, light throughout the visible and near infra-red wavelengths is absorbed. One can imagine these structures as densely packed pyramids with sub-100-nanometer lateral dimensions and over 200 nanometers vertical depth. From the perspective of light, such small size scales cannot be perceived. As a result, no light is scattered.

In these nano-sized “moth-eye” patterns, an originally flat interface between air and the material is replaced with a fuzzy layer of pyramids. There is a gradual change in the index of refraction from the top of the pyramids to the bottom, which characterizes the essence of moth-eye patterns. Because the abrupt change in the index of refraction from glass to the material is replaced with a gentle index gradient, all wavelengths of light are transmitted through the pattern.

Learning from moths, scientists at Brookhaven National Lab successfully reproduced this bio-pattern on the surface of glass. Applied to both sides of glass, the nano-features render the glass almost invisible. With more than a decade of research and advances in manufacturing techniques, the moth-eye glass is now ready to take centre stage. Working in Montreal, a team

of technology entrepreneurs at Edgehog is scaling up this innovation for mass adoption.

Currently manufactured at relatively small size scales, Edgehog is making anti-reflective glass for sensor windows, small displays for smart phones and watches and specialty solar panels. As a transmissive window, the Edgehog glass allows more than 99.8 per cent transmission of visible light. Importantly, the spectral transmission is uniform throughout the entire wavelength range and can be tuned for near-infra-red regions. Used for display covers, the Edgehog glass eliminates unwanted reflection, enabling improved screen readability even in sunlight or other bright conditions. With a flat spectral response, the colour of the display image remains unchanged despite wide viewing angles. In solar panels, greater energy conversion is achieved by increasing the amount of visible and near-infrared light entering the solar cell.

Superhydrophobicity

A complementary effect of the Edgehog glass is the superhydrophobic self-cleaning property. Inspiration once again comes from the bio-world: the superhydrophobic leaf of a lotus plant floats on the surface of water and as waves wash over the lotus leaf debris and contamination is continuously washed off. Here, the nanostructures again play a critical role. Water droplets on the small surface protrusions act much like a performance artist walking over a bed of needles. The surface tension of water keeps droplets disposed on top of the needles rather than sinking into them and the droplets easily roll off the surface.

With the self-cleaning property of the solar panel surfaces, the Edgehog technology prevents the typical 25 per cent decrease in performance resulting from months of fouling in outdoor conditions. Applied on windows, labour-intensive and costly cleaning processes are largely avoided.

Feasible mass manufacturing

The Edgehog approach selectively removes material from an initially flat glass surface via dry etching. In other words, no additional material is added and the surface is only composed of the native glass material. Unlike coatings, the resulting nanostructured surface has uniform chemical and physical characteristics, which ensures the longevity of the structures under environmental exposure. Because the nanostructures are composed of the native glass material, their bulk mechanical property remains intact.

Moth-eye patterns were first documented half a century ago. Early efforts to reproduce this pattern in man-made materials relied on slow and costly techniques such as electron beam lithography. Aided by advancements in polymer and plasma fields, the team at Edgehog has demonstrated a scalable process.

The Edgehog process first applies a pattern of metal nano-dots on the surface of the substrate by taking advantage of certain polymers’ ability to self-assemble into semi-periodic patterns. Because the organization occurs

thermodynamically without exter nal intervention, this approach easily scales up to large surface areas. Following the metal patterning, plasma etching is used to selectively etch away the exposed glass, with the metal nano-dots acting as protective masks. At small size scales, the plasma etching occurs simultaneously on the entire surface of the glass, enabling fast production. At larger scales, however, the challenge lies in achieving a large, stable field of plasma. There is no physics limitation in this endeavor, only an engineering task, which Edgehog is currently working to achieve. Alter natively, the plasma etching may be done in a raster or scanning manner, enabling large surface area treatment and potentially roll-to-roll treatment of flexible glass. Because the technology etches away material rather than adds material to the surface of glass, it is compatible with a myriad of other technologies. For example, in multi-pane windows, the Edgehog approach can be applied to each interface of glass. For low-E and other coatings, the Edgehog etching technique can be applied to the coating itself, and in ultra-clear lowon glass, the Edgehog etching further enhances the clarity.

Edgehog is also adapting this approach for other materials such as plastics and metalloids such as silicon. Due to the differences in etching rate and selectivity, unique nano-dot masking material and etching recipes are required for each material. Development in these areas opens the door to novel applications in anti-reflective eyewear, camera lenses and more efficient solar cells. The team will be demonstrating their technology at many upcoming shows, including the International Consumer Electronics Show (CES) in January 2019, held in Las Vegas. •

RUNNING OF THE INDUSTRYEVENT

by RICH PORAYKO

Your company. Your industry. Your community. Now in its 16th year, GlassBuild America, the largest annual gathering of the glass, window and door industries in North America, returned to Vegas from Sept. 12 through 14.

Presented by the National Glass Association, now combined with the Glass Association of North America, along with association sponsors, WDDA, AAMA, and IGMA, this year’s GlassBuild was a massive success compared to 2017’s GBA in Atlanta, which was nearly a disaster due to Hurricane Irma.

2018 was a comprehensive event with the usual educational forums, free “Express Learning” sessions, abundant networking opportunities and a trade show floor full of the latest and most innovative glass machinery, equipment, products, technologies and services.

GANA’s Fall Conference was once again paired with GlassBuild America which was attended by the glass industry’s leading experts and included

GlassBuild forecasters feel their oats.

the first Fabricating Committee meeting of the newly combined NGA and GANA association.

More than 200 glazing professionals gathered at the Las Vegas Convention Center Wednesday for the 13th annual Glazing Executives Forum which tackled supply chain issues, recruiting millennials, exit planning and smart growth. Max Perilstein, founder of Sole Source Consultants, led the Navigating the Supply Chain panel discussion made up of heavy hitters from the three main components of commercial glazing: metal, glass and fabrication.

“Tariffs. It’s a question that is coming in from quite a few people here,” said Perilstein. “Obviously, a major political issue right now. The initial focus of the tariffs has been on aluminum, however I think there are 20,000 glass-related products that are following in the latest round.”

“There is such a level of uncertainty,” said Allen Mathis, vice-president of operational excellence for YKK AP America. “It’s not just aluminum. It’s not just steel. Right when you wrap your head around one set of tariffs, legislation comes out with

ABOVE: GlassBuild 2018 in Las Vegas featured an array of learning and discussion opportunities in addition to the usual huge show floor. The challenge was prioritizing just what to see among the many options.

BULLS

new tariffs. You are chasing the rabbit so to speak. Customers are concerned with what the cost impact will be on erecting a new building. Ultimately that rolls up to the end user: the building owner. It could have a negative impact on the construction market. That’s not something that would benefit anybody in the room.”

“This is impacting people’s buying decisions in real time,” agreed Garret Henson, vice-president of sales and marketing for Viracon. “Do I buy or do I not buy? There are a lot of offshore options out there in today’s environment and there is a reason they are here. This is the busiest market in the world. If you understand the fluctuation of currency and the strength of the U.S. dollar, you’ll know that is why those guys are here knocking on our door. But now the risk of tariffs is changing people’s buying behavior. I think that’s what is impacting some of the short term supply activity in the market right now. I can walk into someone’s office and they are looking at multiple choices and an offshore product might be one of them. They are trying to make the decision about what might happen right now, three months from now or in six months when it comes time to order the material.”

The economists from ITR Economics always do a great job of combining entertainment with economics. This year, Connor Lokar, the self-proclaimed Doogie Howser economist, did not disappoint and came out guns blazing. “Canada, our wonderful neighbour to the north. Their entire economy is matched by the state of Texas. And dwarfed by the state of California. You Texans certainly have more guns so I think we can take ‘em.”

Lokar told the audience that India is seen as the growth engine for the next 20 or 30 years that China has been for the last 20 or 30. “With 1.3 billion people in their economy, they are matched by the state of California,” said Lokar. “To put it into perspective, America is great. America’s economy is immense. We are the King of the Hill. We are the six hundred pound gorilla. We are on the top of the global economy

and China is still a distant second. We feel that is a position that America is going to hold for at least the next few decades. There are headwinds that we are going to experience in the next 20 or 30 years but we are in a much better position to succeed in the future than in all of western Europe, Japan and in China.”

Lokar expects growth to continue for the rest of the year and for the headwinds to bite next year. “The preponderance of evidence says that the U.S. economy is going to start slowing down next year,” said Lokar. “It’s not a disaster. Statistically, this will be the mildest period of decline in the last 100 years. This is very much a speed bump. A pause. I’m afraid to use the word recession because this is not the Great Recession. It’s a breather. A slight pullback. An opportunity to catch your breath where you’ve just been desperately trying to keep up for the last 18 to 24 months.”

According to Lokar, companies tied to the commercial side won’t feel the slowdown in 2019. “You’re going to start hearing those whispers of slowdown around this time next year as you start looking into 2020.”

Lokar told the audience that the ongo-

ing tariffs could theoretically be expanded by up to seven times the current rates that the U.S. and China are currently facing, in which case it would be hugely inflationary for the U.S. consumer. Lokar said that in a consumer-dependent economy, it would be a threat to the business cycle growth and the acceleration of the U.S. economy. “Our thinking of 2019 has been on what we’ve seen to this point. Hopefully we run out of posturing and cooler heads prevail. If we go full bore on China and $200 billion on automobile tariffs, that could be detrimental to the 2019 forecast.”

With that caveat firmly inserted, ITR forecasts mild headwinds next year and then the next three years after look awesome. “Right now is awesome,” Lokar told the audience. “Longer term, not so much. It’s a problem when you cut taxes and you don’t also cut spending. We are approaching a one trillion dollar deficit this year with the strongest economy we’ve had in a decade.”

ITR feels that this is problematic from a long-term standpoint. “Our debt-to-GDP ratio is an astronomical 120.5 per cent,” said Lokar. “In the last near-decade of recovery and growth since the Great Reces-

sion we have done nothing to address this in the United States. In fact, it is on a trajectory to get worse over the next five to eight years. That is a long-term problem. That’s a not a 2023 problem. That’s not even a 2025 problem. We have a pessimistic look into the 2030’s. In fact, in 2030, we think that there is an economic depression coming. Not the R word. The D word. A disaster that will make the Great Recession look pleasant by comparison. At the core of that is debt and demographics. We are very good at kicking that can down the road. It would take an immense amount of leadership to tackle that and I just don’t think we’re going to get it until it’s too late.”

If there was one complaint about the 2018 GlassBuild is it might be argued that it was too big and too busy with too much information. It was a challenge to see the seminars, do the meetings, attend the receptions, network, watch the demos and fit everything in. It’s almost like an amusement park, you can’t do everything so you have to pick your attractions and manage your time. Bottom line is that you always walk away from GlassBuild America with knowledge and information to help you build a better business. •

CANADA HAS A NEW ARCHITECTURAL GLAZING SYSTEM

FACADESYSTEMS

Longer thermal break

alumicor.com

The Integra 6000 integral rain screen system from Alumicor uses an integral design that allows for many configurations without the need for additional sub-frames. Fully fabricated by Alumicor, Integra gives designers the option to choose various depths of frame (2 3/8, four or six inches) with horizontal and vertical intermediates to create architectural detail. With a large size capacity, it’s ideal for the institutional market, as well as commercial and residential. Available in fixed, awning, hopper, casement open-in and combination units, as well as large size capacities, Integra features a split finish for unique interior and exterior design considerations. The modern handle for open–in designs includes various finish options including grey, white, black and brushed stainless steel. Integra 6000 rain screen accommodates one-inch double-glazed sealed units with sloped sills for better drainage. Protected condensation drains allow water to escape to the exterior and concealed hinges offer sleek sight lines for open-in vents. Multi-point locking open-in hardware

with polyamide connecting rods offer quieter operation. This advanced rain screen technology reduces the cost of caulking and backer rod installation and makes glass replacement easier. The polyamide thermal break is 23 per cent longer than other designs for greater thermal performance and increased resistance to condensation. Optional insulating foam in the frame, sash and around the glazing delivers accredited laboratory-confirmed 10-per-centimproved thermal system performance, as well as increased condensation resistance and acoustic performance. The system also incorporates a central gasket system with vulcanized corners for superior air/ water performance and a true thermally broken open-out window adapter with no exposure to a cold air-filled cavity. Rated to NAFS-AW-PG85 for open–in and fixed installations.

Accessible entrance

crlaurence.ca

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

Accessibility is an important consideration in building design. To make specification easier for architects and designers, CRL-U.S. Aluminum has engineered a 1/2-inch low-profile threshold for its Series 900 terrace doors.The low-profile threshold is exclusively for single outswing Series 900 doors.The system meets accessibility standards and virtually eliminates floor-level protrusions to provide unobstructed passage for individuals using canes, crutches, walkers or wheelchairs. An optional 10-inch bottom door rail is available to further enhance accessibility. Despite the 1/2-inch low profile threshold, Series 900 terrace doors deliver exceptional protection against invasive weather conditions.The doors are AW-PG 80-ATD AAMA rated, and have been ASTM E331 and E547 water-tested. In addition, double weatherstripping within the doorframe mitigates air infiltration. Series 900 doors are equipped with several performance enhancements. For example, they’re thermally broken and incorporate one-inch insulating glass to minimize heat transfer. Four-point stainless steel locking devices for single doors maximize security and meet AAMA 1304 forced-entry requirements. Series 900 terrace doors provide elegant, high-end esthetics and are well suited for applications such as condominiums, high-rise residential, mixed-use developments, hotels, and resorts. Several configurations are available including standard or low-profile thresholds; single or double doors (inswing or outswing); standard five-knuckle hinges and optional adjustable hinges; impact-resistant and acoustically rated models; and multiple door handle styles in premium finishes. Variety

of finishes

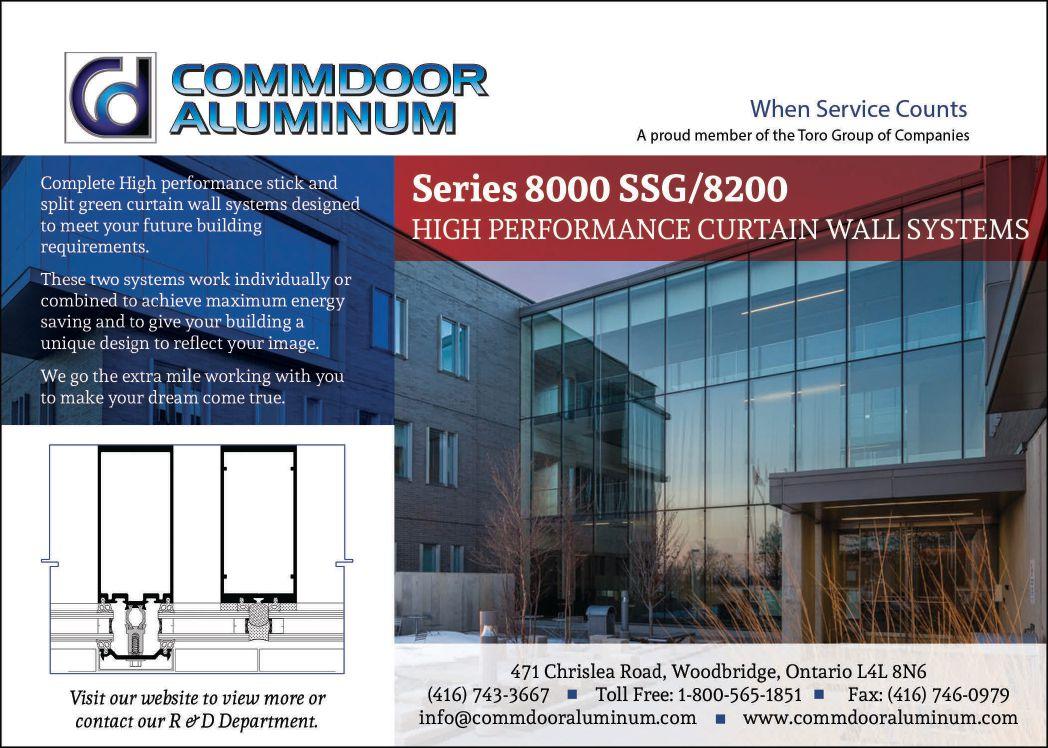

commdooraluminum.com

Series 8000 split capped curtainwall from Commdoor Aluminum is a thermally broken wall system 2 1/2 inches wide with glass sealed on both the exterior and interior surface.The mullion section comes in four-, 5 1/4- and 6 5/8-inch sizes. Profiles are stocked in mill finish and clear anodized finish with other anodized and paint finishes available upon request.The stock length is 24 feet by two inches.The split capped version is designed for screw port assembly. Users should refer to wind load charts for the maximum allowable span and consult a structural engi-

FACADESYSTEMS RESOURCE

anchoring requirements. 8000 Series is an exterior-glazed system that accepts 1/4- or 1/2-i nch single glass or a 1-inch sealed unit.

Proprietary profile

azonintl.com

Azo-Core thermal barrier is a design concept from the technology, Azo-Core adapts the time-proven use of polyurethane foam as its thermal barrier insulator for aluminum fenestration. The unique high-density foam is strengthened umbrella.

Two infill options

obe.com

Reliance curtainwall from Oldcastle Building Envelope is a high-performing, pressure-equalized curtain wall system. Zone glazing allows for exceptional water control and outstanding thermal performance, as well as straightforward fabrication and easy installation. It comes

maximum utility and versatility. Both systems offer structural silicone glazed vertical options for two-sided applications. Reliance provides two gasket options. The standard option utilizes an EPDM dense gasket

the EPDM dense gasket on the exterior and an EPDM sponge gasket on the interior to accommodate moulded corners when necessary. Other installation features include roll-over and roll-under horizontals -

or both – to maximize U-factor and condensation resistance factor ratings.

Window wall alternative

sotawall.com

Hybrid-Wall from Sotawall was developed as an alternative to window wall systems. Window wall systems can be architecturally limited and lacking in long term performance. Hybrid-Wall allows -

In addition, Hybrid-Wall provides the exceptional weather and seismic performance of a pressure-equalized, rainscreened curtainwall. HybridWall is a 100 per cent fully unitized and pre-glazed curtain wall system in performance and appearance with the important distinction of being

of slab edge metal panel covers. Because it is a true unitized curtainwall system, Hybrid-Wall uses a horizontal expansion assembly incorporatslabs and window wall systems obsolete. It also has fully integrated installation while allowing for construction slab tolerances and vertical

by FRANK FULTON

Frank Fulton is a former principal of Fulton Windows and former president of the OGMA.

AND THERE THEY WERE – GONE

It was not that long ago, November 2017, that our then-Premier of Ontario, Kathleen Wynne, called a press conference in China to announce business agreements exceeding $1 billion between Ontario corporations and Chinese organizations. One of those was $450 million for the building of a float glass production plant in the province. The Chinese company doing the investing was Xinyi Glass Holdings, a huge glass manufacturing company headquartered in Hong Kong and listed on the Hang Seng Composite Index. They employ over 12,000 people, do more than $2 billion in annual sales and have factories throughout China as well as Indonesia. After researching locations throughout North America, they chose Guelph Eramosa Township (GET) in Ontario as the place to launch their foray into our continent. GET is primarily a farming community with a few small villages with a total population of about 13,000 that surrounds the City of Guelph, population 130,000.

The plan was to build a two-million-square-foot, seven-storey tall manufacturing plant with two float glass lines that would employ 400 people. This would be the only glass manufacturing facility in Canada. The last one closed about 10 years ago. There are 20 float glass factories in the U.S.

The GET municipal council was ecstatic with the prospect of creating 400 jobs in their community and the $4 million tax revenue this industry would provide. Township planning consultant, Don Currie, said, “The industrial use is exactly what’s permitted, what’s planned for on this land and the proposal or requests for zoning bylaw amendments will be reviewed in light of that policy framework.” Councillor Mark Bouwmeester gushed “This is what we’re dreaming for, this type of application, these types of developments. It’s a rarity really to see a plant this size; it’s rare that you hear about

The Guelph-Eramosa Township councilors were clearly content to remain small fish in a small pond.

these things in Canada, let alone in Ontario. The fact that it’s in Guelph-Eramosa, that’s fantastic.”

And then the fear mongering began. NIMBYists got involved and formed a group called GET Concerned, whose sole reason for being was to oppose the plant’s development. They cited traffic problems. They argued that train traffic may block an ambulance from reaching their parents. They feared that an on-site residence would house slave-like migrants. But at the top of the list was one legitimate concern: that the facility would use 1.6 million litres of water per day in its cooling process, although two thirds of that would evaporate into the atmosphere and one third would be returned into the ground.

Opponents to the project dug through the archives of the often-contradictory county and township bylaws to discover that one of them mandated the proposed factory site must be “dry industrial use.” This caveat was obviously not known by anybody previously as all the other businesses in the area use water. Xinyi argued correctly that the facility actually qualifies as “dry industrial” under Ontario law. According to the Ministry of the Environment and Climate Change (MOECC) definition, “dry industrial use” is considered as less than 9.84 litres of water per minute, per acre. Xinyi’s usage of 1.6 million litres translates to nine litres per minute per acre.

So, the real question should be, “Is the taking of 1.6 million litres a day a cause for concern and a risk to the population?” By comparison, the City of Guelph has permits issued by the MOECC to take up to 122 million litres per day but uses only 45 million litres. Nestle Waters Canada located in nearby Aberfoyle takes about 2.1 million of the 3.6 million litres allocated for its use. The average recharge rate for the Upper Speed River sub-watershed, one of Guelph’s water sources, is about 315 million litres per day.

The Guelph Eramosa Township councilors, clearly content to remain small fish in a small pond and fearful of the backlash that may come their way in this fall’s municipal elections, chose to ignore the facts presented by Xinyi in their application, didn’t research the impact existing plants have on the environment, didn’t consider amending their bylaws and instead succumbed to the vocal minority obstructionists and turned down the application to build. Xinyi expressed their disappointment, purposefully allowed the appeal deadline to lapse, and there they were – gone. •

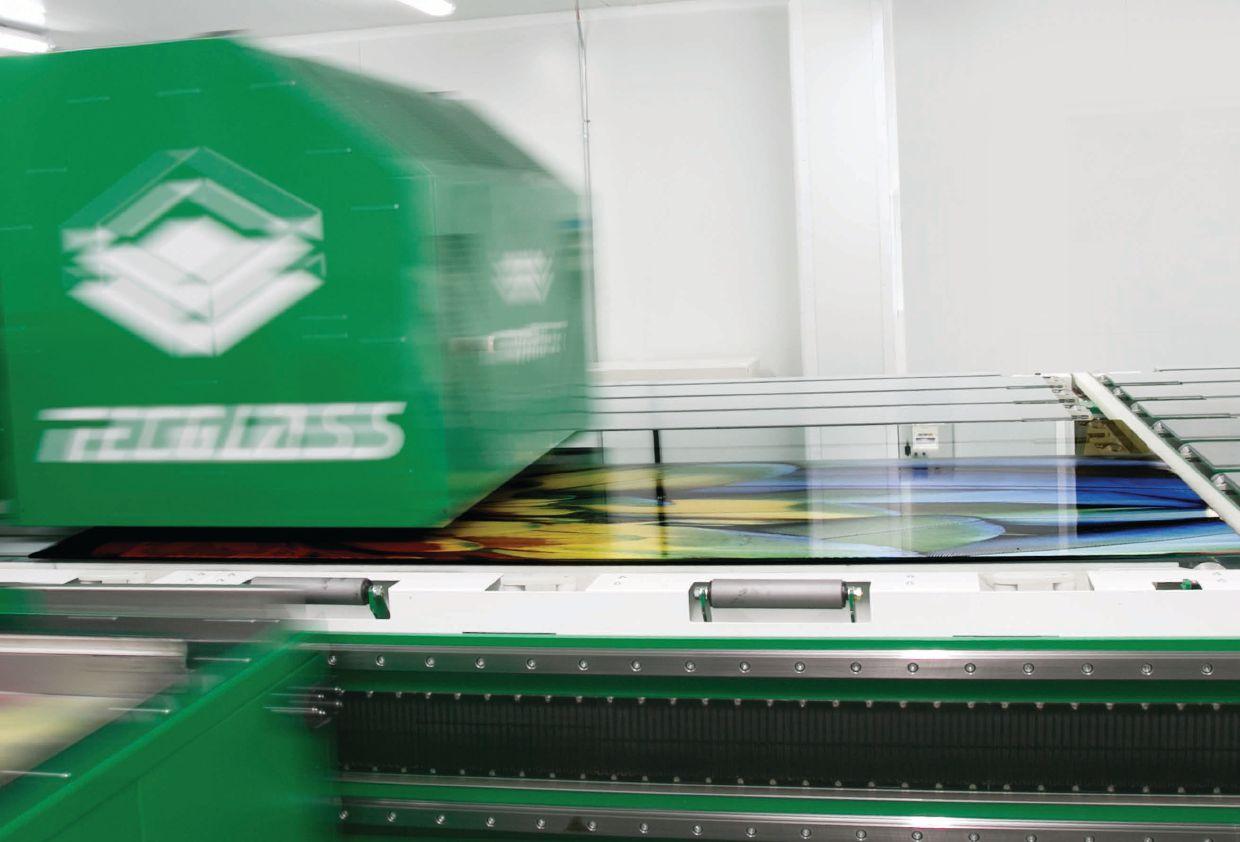

PRINTED DESIGNS

IN SIZES UP TO 110" X 200"

PROJECT: 450 Alaskan - Seattle, WA

ARCHITECT: NBBJ

CERTIFICATION TARGET: LEED® Gold

SPECIFICATION: Entice® Thermal Entrance U.S. Patent 9,074,413

For the first time, all-glass aesthetics and full-frame thermal performance in one entrance system. Entice® meets stringent energy codes and looks great doing it, satisfying the most discerning designers, owners, and code officials.

• Ultra-Narrow 1-1/8" Vertical Stiles

• Thermally Broken with U-Factors as Low as 0.33

• NFRC Rated and Satisfies ASHRAE 90.1-2016 Air Infiltration Criteria

“Best in Category - Openings”

“The cleanliness in lines is equaled by the sophistication of the hardware and performance.” — Product Innovation Awards Judge