Shim It Once and Done. SAVE

Shim It Once and Done. SAVE

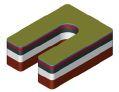

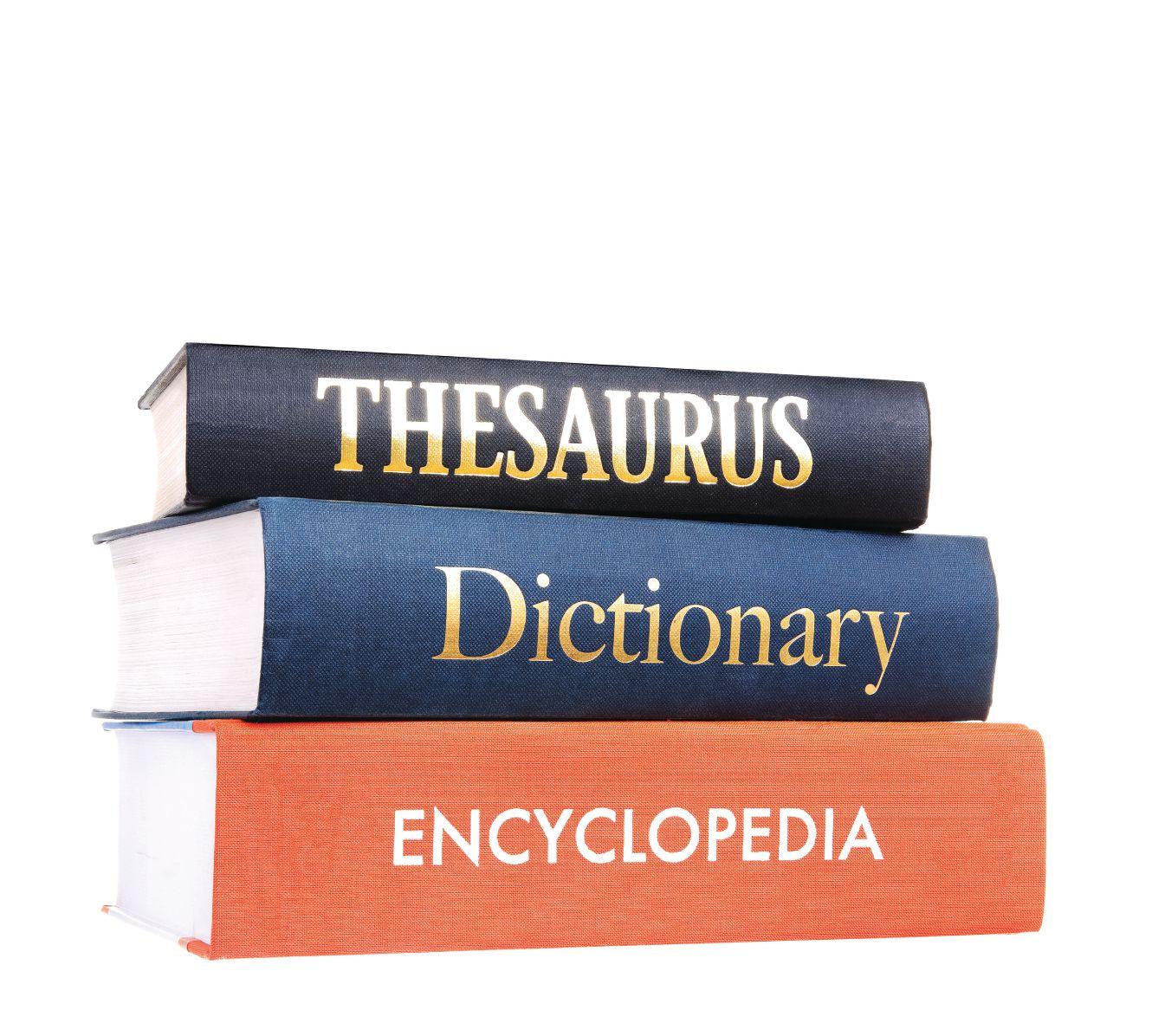

Grove Products, Inc. has the perfect shim for every job every time.

Grove Products, Inc. has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims.

www.groveproductsinc.com

Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Window wall has a bad reputation in some quarters for quality, energy efficiency and air/water tightness. In the second part of their series on window wall, George Torok and Yvon Chiasson look at ways window wall installations can be improved.

We’ve partnered with Indeed to upgrade the job board at glasscanadamag.com with listings related to the glazing trades from all over Canada. Posting a job opening is still free and easy. Find a great employee or career today!

Wake up the code machine

Sorry, we have to talk about codes and standards now. Canadian codes are getting some much-overdue refreshment.

GlassBuild America report

Even Hurricane Irma couldn’t wash away the good vibe at GlassBuild 2018 in Atlanta.

As seen at GlassBuild

Our showcase of some of the new technology on display in Atlanta.

Canadian author Margaret Atwood has been in the news lately over her opposition to a modest three-storey high-rise development proposed in her posh Annex neighbourhood in Toronto. It’s a leafy suburb that is one of the few remaining areas in the city with big houses, big yards and relatively convenient access to the downtown core. The papers love the story because of the whiff of hypocrisy. Atwood (author of The Handmaid’s Tale) is a noted liberal and environmental activist who we would presume is a proponent of urban densification. But when those densely packed masses are looking down into her multi-milliondollar back yard...not so much.

• Energy efficiency

October 2017 Volume 29 • Number 5

Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

DIRECTOR OF SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexweb.com

COO | Ted MARKLE tmarkle@annexweb.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

• Adhesives and sealants

It’s easy to chuckle over the prospect of Canadian royalty like Atwood looking out her kitchen window and seeing a guy like me doing Tai Chi in his Speedo on his balcony (Have you seen the Home Hardware commercial? Cracks me up every time). But I can muster up some sympathy because some substantial money is at stake here. Houses in her part of the Annex go for anywhere from $3 to $6 million. Having bought your little chunk of paradise, a high-rise getting plunked down next door could strip hundreds of thousands or millions off the value of your asset in one stroke. Even for people who can afford it, this seems a harsh fate. Yet conflicts of this kind will only become more common as cities struggle to balance their mandate to stop sprawl with the rights of existing homeowners.

Maybe there is something our industry can do to help. Judging from the aesthetics of the condos flying up along the Gardiner, I wonder if we are putting enough thought into how our new buildings look and how they integrate with the existing built environment. Would someone like Atwood complain if the new building was attractive and architecturally interesting? Well, probably, but maybe less. After all, she does live close to Casa Loma, which is quite a bit more than three stories high but could hardly be deemed an eyesore.

Short of building faux-medieval castles, perhaps there is an opportunity for more creative and attractive facades using custom-made curtainwall, windows and window wall solutions. Maybe the harsh straight lines and glinting metal of standard high-rise construction can give way to something more muted and homey that works on a suburban boulevard. It would seem the opportunity is there for anyone who wants to try, as multi-family residential projects continue to surge in all metropolitan areas.

If you are experimenting with new window wall designs, you’ll want to check out our cover story in this issue by the good men of Morrisson Hershfield, George Torok and Yvon Chiasson. Last issue, they told us how window wall has changed over the years and what the codes and standards are calling for now. This issue, they’re telling us how to go beyond the codes and achieve results that will meet the approval of even an angry novelist. •

CIRCULATION

email: asingh@annexbizmedia.com Tel: 416-510-5189

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

The boards of directors of the Glass Association of North America and the National Glass Association have unanimously approved combining the two associations into one strong and unified voice for the glass and glazing industry. The new association will combine the best elements of GANA and NGA to better serve members and the industry. GANA’s technical and advocacy work will be supported and magnified through NGA’s robust delivery platforms, including Glass Magazine, E-glass Weekly and GlassBuild America, the largest industry trade show in the Americas. Both organizations are committed to training the industry’s workforce and their dedicated volunteers will leverage the growing capabilities of MyGlassClass.com and other education resources.

“The combination of our associations will unify our industry, giving stronger voice to our advocacy and industry standards efforts, our technical resources and many other initiatives to ensure the continued use of glass in buildings the world over,” said Doug Schilling, GANA president.

GANA and NGA will continue to operate as separate and collaborative entities until

the transaction is complete and a closing date established, likely by the end of 2017 or early 2018. Between now and then, leadership will establish a joint integration working group to create a roadmap for the integration.

“The industry thanks the joint task force members who worked to get us to this important threshold,” said Ken Mariotti, NGA’s incoming chair.

The GANA task force was represented by Stanley Yee of Dow Corning; Doug Schilling of Schilling Graphics; Gus Trupiano of AGC Glass Company North America; Steve Marino of Vitro Architectural Glass; and Kim Mann, GANA general counsel. The NGA task force was represented by Michael Albert of S. Albert Glass Company; Angelo Rivera of Faour Glass Technologies; Nicole Harris, NGA president and CEO; and Jerry Jacobs, NGA general counsel.

Nicole Harris will continue as staff head of the combined association. Urmilla JokhuSowell and Sara Neiswanger will join her staff. “We’ve collaborated with Urmilla and Sara for many years; my staff and I look forward to working together as we transition to build the new association,” said Harris.

AmesburyTruth has announced that Cindi Freidhof has been appointed to the newly created role of director of industry relations. She will be responsible for managing AmesburyTruth’s engagement with industry associations and events such as the American Architectural Manufacturers Association, the Window and Door Manufacturers Association, the American Institute of Architecture, the World Millwork Alliance, WinDoor and GlassBuild. Cindi joined the legacy Truth team in 1987. In her most recent role as regional sales director for the western region, she led the integration of the Amesbury and Truth sales organizations.

David Johnson has accepted the role of regional sales director for the western region. Johnson started his career with Truth Hardware in 1991. He most recently managed the door hardware business unit and is based at the Owatonna, Minn., Center of Excellence. In his new role, Johnson will lead the western region territory sales managers and solution sales team to achieve the AmesburyTruth growth objectives.

TheCGA for the past few years has contracted GANA to act as our executive director and handle the day-to-day operations of the association. Under the new executive elected at the Annual General Meeting in Burnaby, B.C., in June, many cost-cutting measures were instiuted., the major one being the ending of our working agreement with GANA. At this time, the CGA has decided to get our hands dirty and do much of this management in-house. The CGA is now taking a closer look at what it does. With our “hands dirty” approach we will try to work closer with provincial and national associations such as Fenestration Canada, the Insulating Glass Manufacturers Alliance and Construction Specifications Canada. The key will be to give membership in the CGA a value for those who want a national perspective. Products used today on construction projects in the commercial and residential sectors share many of the same components but live under different code requirements. Starting the process to address this will take some time and as such no Glass Connections conference will be held in 2018.

It had to happen sooner or later. The great weather streak for the FenBC golf tournament was broken on May 11. What started as a light sprinkle turned to a spring shower then developed into varying degrees of storm weather. But

our FenBC golfers persevered. Some did leave the course in dismay but those that stayed had a great time.

The FenBC sponsors were Cardinal IG (Top Tier sponsor - golf clubs), Vetrotech Saint Gobain (air cannon – a new addition to our sponsorship package), Cascade Aquatech (putting contest), PFG Glass (beat-the-pro and the wine draw), Oasis Windows (scorecard – also a new addition) and Veka Canada (trivia contest –another new addition).

FenBC has been quite busy. We are updating our Glazing Systems Specification Manual to reflect the new National Building Code. Our conference takes place Oct. 26 at the Sheraton Guildford in Surrey, B.C. This year we have changed the format. The new format will include three streams of educational programming. Check out fen-bc.org for details.

We recently published an informational resource to assist architects with understanding NAFS labeling and Part 5 compliance for commercial glazing products. This guide is available on our website. Click on the news announcement link to download the guide.

As the administrator of the BC Innovative Clean Energy (ICE) funds, FenBC has recently funded a project aimed at helping Canadian window manufacturers increase their share of the growing demand for Passive House windows. The project aims to equip Canadian window manufacturers with the tools to derive Passive House window data from their existing NFRCbased simulation data. For more information check the news and announcements on the FenBC website.

Congratulations to the FenBC president, David Langton of Competition Glass, for

his appointment as the new president of the Canadian Glass Association.

Sinceour last update, the PGAA board has met twice and held our annual golf tournament in Lacombe on Aug. 17. While attendance was down for this years’ event, sponsorship was up, with proceeds again benefiting our Master Glazier Program. Our sponsors this year included:

• Gold sponsors: Alberta Glass Company, Alpine Glass, Ferguson Corporation

• Silver sponsors: All Glass Parts, Apex Aluminum, Oldcastle Building Envelope, Metro Glass Products

• Bronze sponsors: Capilano Glass 2000, Flynn Canada, Grant Metal Products, Kawneer, Supertint, Tremco Commercial Sealants, WesternOne Equipment Rentals

• Hole sponsors: Alumicor, Beacon Glass, Cal-Tech Glass Services, Cascade Aquatech, Desa (two holes), Insul-lite Manufacturing, Samuel & Son, South Hill Window, Supertint, Leyden’s Glass,Vitro Glass, Vitrum

Plus we would like to thank all those who have donated over $40,000 in material for the Door and Related Hardware course, including All Glass Parts, Alumicor, Apex Aluminum, Desa Glass, Kawneer, Metro Aluminum Products, Metro Glass Products and Stanley Access Technologies.

Development of the Master Glazier Program is progressing with our second course, Doors and Related Hardware,

being offered in December along with our first course, Reading Division 8 Plans, being rerun. We are in development of two new courses, Specialty Glazing and Structural Glazing, both expected in the new year with five further courses to follow in 2018 and 2019. The MGP is being developed to help journeypersons take the next steps in their careers within our industry.

This fall, both of our locals – the Glass Trades Association in Edmonton and the Glass and Architectural Metals Association in Calgary – will be back in full swing with dinner meetings and other events. Our calendar can be found at pgaa.ca/events.

The PGAA is actively seeking a new secretary.

TheOntario legislature is scheduled to vote on the new Bill 142 Construction Lien Amendment Act, 2017, during the fall. Updates to follow in the next edition.

The OGMA held its fall tournament at the prestigious Country Club in Woodbridge on Sept. 21. Not only was an outstanding day had by all, the OGMA made a significant charitable donation to the Holland Bloorview Kids Rehabilitation Hospital at the event. The OGMA also presented its Lifetime Achievement Award to long serving industry member, Frank Fulton.

Details of the Fall Seminar will be sent to members as the November date approaches.

Remember that under the Access for Ontarians with Disabilities Act companies had until the end of 2016 to put accessibility policies and procedures in place. Are you in compliance?

Emotions were running a little higher than normal amid the fun of the Ontario Glass and Metal Association’s fall golf tournament Sept. 21 at The Country Club in Woodbridge, Ont. Frank Fulton of Fultech Fenestration Consulting was presented with his Lifetime Achievement Award by longtime friend and fellow award recipient, Ennio Rhea of Trulite. Fulton was clearly moved by his induction into the OGMA’s equivalent of the Hall of Fame, and Rhea was excited enough to resort to physical displays of affection. Fulton reflects on the honour in his You Bet Your Glass column on page 30. In presenting the award, Rhea noted that Fulton has contributed more time to the OGMA than “everyone in this room combined.”

Adding to the good feelings of the evening was Ted Redlarski of Noram Glass. Doug Morris of Morris Glass presented the Holland Bloorview Kids Rehab Hospital with a $3,000

H.B. Fuller has announced an agreement to purchase Royal Adhesives and Sealants, a leading manufacturer of high-value specialty adhesives and sealants.

“This accretive acquisition accelerates realization of our 2020 strategic objective to focus and grow in engineering adhesives and other highly specified market segments, while exceeding our targeted cash flow, EPS and EBITDA margin targets,” said H.B. Fuller president and CEO, Jim Owens. “With Royal’s strong customer relationships and experienced team, we will add depth and breadth to our portfolio. Royal’s complementary offerings will expand our presence in North America, Europe and China, and add new technology and capabilities. We have identified $35 million in cost synergies and $15 million in growth synergies that we expect to realize over the next three years as a result of merging these two great adhesives businesses. Upon closing the transaction, H.B. Fuller will be a company with nearly $2.9 billion in revenue, focused on profitable growth in attractive engineering, durable assembly and construction adhesives markets.” All prices are in U.S. dollars.

Royal is expected to generate approximately $650 million in revenue and $138 million in adjusted EBITDA for H.B. Fuller’s fiscal year 2017. The company operates 19 manufacturing facilities in five countries, and employs approximately 1,500 people globally.

The agreed upon purchase price was $1.575 billion. H.B. Fuller believes this acquisition will support acceleration and over-performance relative to its objectives. Royal is a highly respected supplier of industrial adhesives in a diverse set of end markets, including aerospace, transportation, commercial roofing, insulating glass, solar, packaging and flooring applications. With this acquisition, H.B. Fuller will gain product technology and add people and skills that will result in a more capable and dynamic company for customers and employees.

donation from the OGMA. Redlarski then shocked the room by spontaneously offering to match the donation. It turns out that Redlarski’s family has been personally impacted by the work the hospital does. The donation was gratefully accepted by Michelle Cha on behalf of the hospital.

Oh, and some golf happened, too. About 100 golfers enjoyed warm weather and great conditions.

The Insulating Glass Certification Council (IGCC), the leading provider of independent IG certification globally, along with the Insulating Glass Manufacturers Alliance, has announced a new program to advance the long-term performance of insulating glass units. After several years of study, a motion was approved at the May 2017 IGCC/IGMA Certification Meeting to provide an option to help determine if changes or variability in supplied materials has occurred to better understand variability in IG total unit performance. The end goal is the improvement of quality of dispensed components. For fabricators to maintain IGCC/IGMA certification, IG units are tested to the ASTM E2190 “Insulating Glass Durability Standard Specifications” and must meet performance and evaluation criteria. However, if repeat testing produces unexpected results, what is a next step for the fabricator?

“IGCC/IGMA is working with a recognized independent laboratory to test sealant components using Fourier transform infrared spectroscopy analyses. We are setting up a program where the fabricator has an option to characterize the sealant components they use and create a data vault based on known-quality ‘chemical fingerprints’, in order to make future sealant comparisons,” said John G. Kent, the administrator for the IGCC/IGMA certification program.

The program is purely voluntary at this time. Fabricators are welcome to participate in the fingerprint process and create a vault for their company’s components, pre- and/or post-ASTM test weathering.

The American Architectural Manufacturers Association (AAMA) recently released an updated document to provide a standard water penetration test method using dynamic pressure. AAMA 501.1-17, the “Standard Test Method for Water Penetration of Windows, Curtain Walls and Doors Using Dynamic Pressure,” establishes the equipment and procedures for testing. In it, a section on test equipment has been updated to clarify what to do for laboratory testing versus on-site testing.

“The AAMA 501.1 dynamic pressure water test has been used as a laboratory test for over 50 years and is particularly useful when testing pressure-equalized fenestration systems when severe windblown rain is a concern,” said Greg McKenna of Kawneer, an officer on the AAMA Methods of Test Committee. “In more recent years, this test has been used in the field due to the added benefit that a separate vacuum chamber is not needed. This is an advantage if the building is occupied or if constructing a chamber at the building site is not a practical option.”

Additional edits to this updated standard include the addition of two figures showing images of acceptable water leakage, plus a definition for what unacceptable water penetration means. AAMA 501.1-17, as well as other AAMA documents, may be purchased from AAMA’s online store.

Architectural Glass has published third-party-verified, product-specific Type III Environmental Product Declarations (EPDs) for its flat glass and processed glass products. EPDs are voluntary and transparent reports made by companies regarding the life-cycle impacts of their products on the environment. Reporting and documentation for product-specific EPDs addresses energy use and emissions associated with a product’s manufacture and packaging, as well as the extraction, transportation and processing of related raw materials.

Paul W. Bush, director of technical services for Vitro Architectural Glass, said publication of the EPDs highlights the company’s commitment to sustainability and environmental stewardship. “EPDs continue to grow in value as green building certification programs and sustainable design becomes more mainstream. Today’s architects demand greater transparency and Vitro Glass is committed to meeting their expanded requirements,” he explained. “As part of

that commitment, we decided to pursue the publication of product-specific, third-partyverified EPDs and to post them publicly with the goal of making it easier for architects to confirm the information we provide and to include our EPDs in their sustainability and certification documentation.”

The product-specific flat glass EPD is valid for all annealed and untreated glass products manufactured by Vitro Glass. The product-specific processed glass EPD is valid for Vitro Glass products that undergo secondary treatment, such as the addition of magnetron sputtered vapor deposition coatings, heat-strengthening or fabrication into multi-pane insulating glass units. Both EPDs published by Vitro Glass are certified by ASTM International as conforming to the requirements of ISO 14025. Life-cycle assessments for flat glass and processed glass products were performed according to ISO 14040, ISO 14044 and EN 15804 following the product category rules for each product type.

Saand has announced new roles for Michel Lacoste and Shane Lucas. Lacoste is now plant manager at its Ottawa facility. Lacoste is respected leader within the industry with a successful track record and extensive background, having held management positions with both PPG and Guardian before joining Saand Ottawa in 2012. He will be responsible for executing sales strategy throughout eastern Ontario, Quebec and the Maritimes. Lucas has worked as a production and operations manager in various industries over the past

10 years. He brings a wealth of knowledge about the principles of lean manufacturing to significantly improve line performance, productivity, safety and housekeeping. He will be responsible for developing and executing a plant-specific vision, mission and objectives.

Oct. 15 - 18

AAMA National Fall Conference Tucson, Ariz. aamanet.org

Oct. 26

Fenestration West Surrey, B.C. fen-bc.org

Jan. 31 - Feb. 2

IGMA Winter Conference Tucson, Ariz. igmaonline.org

Feb. 19 - 22

AAMA National Annual Conference Orlando, Fla. aamanet.org

March 1

FenCon18 Winnipeg, Man. fencon17.com

March 4 - 6

Building Envelope Conference Las Vegas, Nev. glasswebsite.com

March 21 - 24

Fensterbau Frontale Nuremburg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

April 23 - 28

GANA Annual Conference Napa, Calif. glasswebsite.com

June 11 - 14

AAMA National Summer Conference

Olympic Valley, Calif. aamanet.org

by RICH PORAYKO

t the Canadian Glass Association’s 2017 Glass Connections in Burnaby, B.C., CGA past president Jim Brady announced new code changes to a room full of people largely unaware of the changes. “The Canadian Glass Association needs to get involved with code changes so we can get them revised and not rely on other codes,” said Brady. “The important thing for people to realize is that while the Canadian General Standards Board withdrew seven glass codes including the code for strength and design, it can still be referenced. Additionally we can also look at the CSA A500-16 for guardrail glass. It’s a new standard and excellent resource that will be implemented in the National Building Code as well as the provincial building codes.”

Many of the glass standards CGSB publishes haven’t had a proper review since 1990. The CGSB requires standards to be reviewed every five years. Since it has almost been 30, the CGA’s Technical Committee participated in a joint review of the glass codes and either withdrew, reaffirmed or updated the CGSB standards. See the sidebar for a list of the changes.

According to Brent Harder, chair of the CGA technical committee and senior design engineer/estimator for Calgary-based Ferguson Corporation, standards are withdrawn when there is a lack of funding to revise and update standards as required.

“There was not enough support from the Glass Committee to withdraw CAN/CGSB-12.20, however it was noted that the cost of the changes that the committee required for CAN/ CGSB-12.20 were too great for CGSB to undertake without funding in place,” says Harder. “Therefore, the CGSB had no other choice but to comply with their requirements and withdraw CAN/CGSB-12.20 due to it being more than five years

old. The CGSB would like to see this standard updated.”

“So the question will be asked, what does the industry do when standards are withdrawn?” queries Harder. “The opinion of the Technical Committee is that we will either continue to rely on the withdrawn standards or move to reference standards from the U.S., which is already happening, or find funding to update the standards. Some U.S. standards are already referenced in Canadian codes. Some consider this unfortunate and would like a ‘Made in Canada’ solution, although many U.S. standards are adopted in other jurisdictions. Finding funding stands in the way of adopting new revisions of the old standards. In my opinion, CAN/CGSB-12.20 is still a useful standard and addresses some things not found in the ASTM standard, however it does need to be updated.”

“I have been informed that the National Building Code can still reference withdrawn standards,” says Harder. “They will independently evaluate whether or not the standards still meet their needs. It should be noted that there are other withdrawn CGSB standards still referenced in the NBC from areas other than glass.”

According to Harder, there was a National Building Code

ABOVE: This is a dry topic, no question. But industry inattention to codes and standards can lead to falling behind technological progress, degradation in the built environment and even tragedy.

FOR EVERY BUILDING THAT DESERVES THE BEST, IN SIZES UP TO 110" X 190"

The result is a heat treated glass product that not only provides the performance required by code, but also delivers the aesthetics you demand. That’s the beauty of TrueForm™. With every lite digitally measured Vitrum can guarantee distortion levels below +/- 120 millidiopters over 90% of the glass surface, a measurement that is nearly indistinguishable to the human eye. Learn more by visting vitrum.ca or call 1.888.391.1166.

• CAN/ CGSB-12.6-M91 Transparent (One-Way) Mirrors

• CAN/ CGSB-12.9-M91 Spandrel Glass

• CAN/ CGSB-12.10-M76 Glass, Light and Heat Reflecting

• CAN/ CGSB-12.11-M90 Wired Safety Glass

• CAN/ CGSB-12.12-M90 Plastic Safety Glazing Sheets

• CAN/ CGSB-12.13-M91 Patterned Glass

• CAN/ CGSB-12.20-M89 Structural Design of Glass for Buildings

REAFFIRMED

• CAN/CGSB-12.2-M91 (R2017) Flat, Clear Sheet Glass

• CAN/CGSB-12.3-M91 (R2017) Flat, Clear Float Glass

• CAN/CGSB-12.4-M91 (2017) Heat Absorbing Glass

REVISED/UPDATED

• CAN/CGSB-12.1-2017 Safety Glazing

• CAN/CGSB-12.8-2017 Insulating Glass Units (approved/published) The CGSB has recently decided to make all active standards available for free on the government of Canada website (publications.gc.ca) over the next few months.

representative on the Glass Committee who is aware of the withdrawn standards that are still available from the CGSB. In fact, the latest edition of the National Building Code (2015) already references both CAN/CGSB-12.20 and ASTM E 1300 with different adjustment factors on wind loads.

Harder adds that the new CSA A500 standard (Building Guards) is up for future adoption in the building codes. “This is a timely publication for the design and use of glass in guards. The use of glass and technologies has changed since CAN/CGSB 12.20 was written in 1989. ASTM E1300 has been maintained and updated, however it does not cover some of the items that are covered in CAN/CGSB 12.20 and E1300 does not cover glass balustrades.”

In addition, Harder states that the design standard for aluminum in Canada (Update to Strength Design in Aluminum – CSA S157-17), which is referenced in building codes, was recently updated and contains significant changes. There is also the adoption of the National Energy Code of Canada for Buildings that sets out requirements for the energy-efficient design of new buildings.

CGA technical committee member Andrew Crosby of Read Jones Christoffersen notes important changes with the CSA A500-16 building guards standard, including clarification that a top rail is not required with laminated glass. “There is also guidance on the post-breakage requirements for glass, separating out the conditions of monolithic and laminated glass,” says Crosby. “And less stringent guidance on the assembly of guards at slab edges compared to what was presented in SB-13.”

While good work has been done on some Canadian standards lately, other areas have languished due to lack of funding. CGA technical committee member Rob Botman, general manager of Glassopolis Specialty Glass in Toronto, points to the lingering problems with wired glass as an example of what happens when old standards are allowed to hang around.

“In the United States, they made a code change around 10 years ago that banned wired glass,” says Botman. “The Americans recognized that the wired glass was dangerous and removed it from their building code. Wired glass is a firerated glass, but it never was a safety glass in the modern sense. When you fall into

wired glass, you break through the glass, which, since it’s annealed, becomes a mesh of broken glass shards held together by the wires. It’s like falling through a set of guillotines. And when you pull yourself out of there, you shred yourself a second time.”

“Americans get a lot more lawsuits than we do, so wired glass was squeezed out of the U.S. building codes in 2003 and 2006,” says Botman. “Turns out it’s banned in most developed countries around the world. England got rid of it 15 years ago. Pilkington shut down their factory that made it there. Europe banned it, the U.S. banned it. Basically Canada is the last western country standing that still allows the stuff.”

According to Botman, the University of Toronto School of Public Health did a study that reviewed hospital records of wired glass injuries and estimated that one student per day is being injured enough to go to the hospital. “An Edmonton high school student died because of wired glass,” says Botman.

Health Canada got involved and worked with the CGSB to come up with a new standard in early 2017. “The new standard changes how we define safety glass whether it’s made from tempered, laminated, or even wired glass,” says Botman. “To be called a ‘safety glass,’ it has to pass the new standard. Traditional wired glass can no longer be considered a safety glass. And the building code says that you cannot use glass that is not a safety glass in places where people might fall into it, like doors and corridors. So traditional wired glass is out.”

“It took a decade before Canadians started addressing this problem. Then it took three years to get the standard changed. Now it can take up to five years or even longer for the building code to properly process these changes. When a kid a day is getting sliced and sent to the hospital because of this glass and it takes years for the rules to change, that’s ineffective. The Canadian standards and code process doesn’t respond fast enough.”

According to Botman, wired glass leaves glass companies in Canada vulnerable to lawsuits in the meantime. “The injuries are still happening and people still follow the old practices. That leaves them terribly exposed to being sued. I know of at least a dozen wired-glassrelated lawsuits that are going on right now. People think they are following the code and have a defense, but the lawyers

go right through it. You have a duty to not install a dangerous product and it has been known around the world for 15 years that wired glass is dangerous. Even the manufacturer warns against its use!”

“The national standard has now changed. And how ever the change is rolled out across the country, you cannot hide behind what your local province allows because the ambulance chasers are going to get you. The lawsuits are ahead of the regulations in some respects. Following the code will not protect you, so what is it worth? If the code process takes 10 to 15 years to fix an obvious problem, is it serving our needs? Is there something wrong with the way we do our regulations? How can we make it better?”

There are still 10 more national standards for glass that have to be reviewed, however the Canadian General Standards Board has no budget to work on them. Many of them have already been withdrawn. “All of the Canadian versions of these standards are being withdrawn and, in their absence, people are going to have no choice but to point to the American standard,” says Botman. “Before you know it, Canada has lost all sense of selfregulation in this industry.”

“We need to step up and work together as an industry on getting these madein-Canada regulations done in a more timely and cost-effective way. Because if we don’t get together, we’re going to lose our jurisdiction to Americans. Some people like that, some people don’t. As a Canadian, I’m not so keen to have the big U.S. companies tell us how we are going to do our glazing up here. Our climate is different, our economy is different, our needs are different.”

So what are glass contractors to do? Botman recommends following the new standard for CAN/CGSB 12.1- M17 Safety Glazing even if your local code has not formally adopted it. Tempered, laminated or surface-filmed glass can pass this standard. Remember, though, that most wired glass applications are also fire-rated, so make sure your replacement for wired glass is fire-rated if required. Firerated glass must be third-party certified and labeled by an agency such as UL, so in most cases the replacement for wired glass must be a UL-certified and labeled product. If it’s not labeled, it’s not legal.

For news about codes and standards updates, visit glasscanadamag.com > codes and standards

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

Dustin Anderson President, Anderson Glass, LLC Waco, Texas

by BRIAN BURTON

Brian is a construction writer from Ottawa Ontario who served on the CSA’s Fenestration Installation Technician Certification Program Personnel Committee.

You can contact Brian at Blueblade49@gmail.com or learn more by visiting burton’s-pen.com

It makes good business sense to take full advantage of continuing educational opportunities if you want to remain competitive. Training and education also improves employee morale and increases productivity, key elements in maximizing corporate profitability.

An excellent opportunity to improve your understanding of technical issues, installation principles and to gain formal certification was recently introduced by the American Architectural Manufacturers Association, a well-known source for the dissemination of fenestration-related information in North America and internationally.

This educational opportunity spearheaded by AAMA is supported in Canada by the Canadian Standards Institute and Fenestration Canada. The program dovetails nicely with the Fenestration Installation Technician program and the Siding and Window Dealers Association of Canada’s Window Wise program. The new courses are also recognized by the Insulating Glass Manufacturers Association and a number of other industry associations and government bodies.

In addition to scrutinizing a glossary of terms used in fenestration applications, the course material covers a diverse range of technical topics, including glazing and glass selection; performance and material requirements for various applications; code requirements for various jurisdictions; and principles of daylighting and thermal performance for fenestration products. The course materials and examination questions also address various on-site installation principles, including health and safety issues for residential, commercial and institutional fenestration applications. Students’ understanding of the course material is evaluated with a multiple-choice exam.

Given the complexity of today’s fenestration marketplace, continuing educational opportunities are a prudent investment.

These new educational programs feature three distinct streams which are designed to address the continuing education needs of different stakeholders and sectors in fenestration markets. Students are offered a choice between the entry-level “Fenestration Associate” title or a more advanced designation as a Master or Advanced Fenestration Professional.

AAMA is offering tuition discounts for members of various associations. Check their website at aamanet.org to see if your membership qualifies.

This formalized educational opportunity allows companies to enhance their staff’s understanding of fenestration principles and formalize their professional standing in the industry. Training of this nature enables firms and employees to maintain an up-to-date understanding of industry issues and trends. Improved training is also one way that smaller companies can better equip themselves to compete more effectively against larger firms, while improving quality at the same time. Because training can improve your communication skills, it enables you to make better sales presentations. Improving your overall understanding of technical issues can enable your business to adapt to technical changes and take full advantage of opportunities which otherwise might be overlooked.

Taking advantage of available educational opportunities like this one can be considered an important component of a continuous improvement process. Continuous improvement involves identifying challenges or shortcomings and determining the best options available to fix them. Part of that is recognizing how specific tasks can impact your business’s overall performance, along with determining how limitations can be overcome or eliminated. Given the complexity of today’s fenestration marketplace, continuing educational opportunities like this one are a prudent investment. Successful completion of the course also serves to enhance the professional credibility of your sales and technical employees.

According to the experts quality is never an accident. Rather than happening by chance it’s usually a habit that involves doing the right thing when no one is looking. Improving your knowledge of all things fenestration combined with applying the proven principles of continuous improvement are two excellent ways to distinguish your company. •

by GEORGE TOROK and YVON CHIASSON, Morrison Hershfield.

In August Glass Canada, we discussed the development of window wall systems and the relevant past and current building codes and standards. This month, we look at examples of installation detail, showing examples of past practice and current good practice, highlighting state-of-the-art techniques that leaders in the window wall industry are using to take performance to a higher level.

Attachment methods for Canadian window wall systems evolved from methods originally used for punched windows set into two-wythe face brick on concrete block mass walls. Strap anchors are still favoured by many Canadian window wall manufacturers because of their flexibility, allowing installers to adjust variations in the frame to structure gaps by bending or repositioning the strap (when it isn’t fixed in place) if the fastener installation is frustrated by hard aggregate or embedded reinforcing steel. The length of the strap anchors is usually short to minimize interference with the interior finishes. These benefits can also be a liability if the strap is too short to bridge the frame over the structure gap. Another danger is that repositioning straps may compromise their structural performance.

Strap anchors at the head have flexibility for vertical movement but little for lateral movement, such as might be caused by seismic activity. In seismically active regions, some manufacturers have adopted head receivers (and in some cases, jamb receivers) such as may be found in American-style window walls. Receivers may also have benefits because they allow easier relocation of the fasteners away from the design locations to avoid hard aggregate, embedded reinforcing steel, damaged concrete and similar obstacles. To accommodate variations in floor-to-floor height, head receivers can be shimmed down from the slab soffit to provide the required overlap to the head rail.

At the floor slab, it is common to secure window wall systems with a continuous, extruded aluminum back angle, fastened to the sill rails and the bottoms of mullions with self-drilling, self-tapping screws, and to the floor slab with concrete screws. Since these connections are rigid, allowance for building frame shrinkage and creep, ther-

mal movement, inter-storey drift and seismic movement can occur only at the head and jambs. Variations in floor-to-floor height may lead to the problems with the strap anchors being too short to overlap the sill rail for installation of the anchors, requiring an on-site adjustment.

Window wall panels are often manufactured in widths similar to unitized curtain wall panels: 48 to 60 inches wide, or the typical width of one fixed-glazed insulating glass unit or operable window. The panel width is limited by the rail’s capacity to support the dead load of the insulating glass units to within allowable deflection amounts; by the overall panel weight that can moved manually and by hoist; and by the overall panel size that can be accommodated by shipping services, along with other factors. Adjacent panels are joined together by some form of mechanical interlock between the jamb mullions. These methods vary by manufacturer. One common approach is to nest the open-back mullions with one mullion being slightly deeper than the mating mullion on the adjacent panel. Another is to use connector plates that are H-shaped in cross-section (called H-bar connectors) that slip over the exterior and interior faces of the open back mullions, tongue-and-groove style. These joining methods typically increase the depth of the mullions beyond the exterior and interior faces of the rails, which can cause some difficulties when installing air and water seals and heads and sills, as will be described later.

Where window walls pass in front of columns and shear walls there may be conflicts with the installation of the strap anchors, head receivers and back angles. It may be possible to offset the strap anchors laterally, but the head receivers and

Window wall has surged in popularity with designers because of its ability to deliver wide-open vistas and indoor/outdoor living spaces. But integrating it into typical building envelope designs has been a learning process for many contractors. As the industry’s experience with these products increases, new ideas are emerging for how to make window wall better.

back angles must be continuous not only for structural anchorage but also to maintain the air- and water-tightness of the wall/ window interface. Columns and shear walls should be recessed behind the slab edge sufficiently for the anticipated width of the anchor system plus working room to install fasteners and also for the air- and water-leakage control membranes, sealants and other materials. This requires careful forethought during architectural and structural design. Unfortunately, the window wall manufacturer may not be selected early enough in the construction process to provide the necessary design input, so modifications may need to be made on site. Any modifications affecting the structure of the wall panels should be reviewed and approved by a licensed design professional.

A defining feature of Canadian window wall is the slab bypass. Typically, the sill extrusion inboard of the thermal break is anchored to the upper surface of the slab with a continuous back angle and mullion extrusions. The sill extrusion outboard of the thermal break is extended down to the head rail of the window panel below, concealing the slab edge. In early window wall systems, the bypass was face-sealed with composite panels consisting of metal skins sandwiching a rigid core (either extruded or expanded polystyrene) glazed into the frame from the exterior. Such systems often had poor water-leakage resistance. Today, most Canadian window wall systems employ rainscreen design principles, including at the bypass. The spandrel infill is a cladding that needs to resist gust wind loads. Air leakage and water penetration control are provided by waterproofing membranes and sealants behind. These functions will be discussed in more detail later.

Examples of strap anchors at the head rail of a window wall. On the top, the straps are secured with concrete screws to the underside of the floor slab with one-component polyurethane foam air sealant foam in the rough opening gap as an air seal. On the bottom, the rough opening gap exceeds the length of the strap so the straps are extended by stitching them end-to-end. A gunned sealant was applied over the foam to ensure the continuity of the air barrier. Encapsulating the perimeter of the straps might be needed if it is hard to get behind the strap to apply sealant.

Examples of interference/lack of coordination between the structure, mechanical services and window wall systems. On the left, the column was not recessed to allow the window wall frame to pass in front. The installer’s solution was to cut away horizontal components including the rails and head receiver. On the right, the kitchen and bathroom exhaust duct bulkhead was installed before the head rail and the underside of the floor slab joint air seal was complete.

As surrounding wall systems have changed from mass masonry construction to rain screen systems, window design and assembly and installation detailing has also changed. Today, most Canadian window wall systems are designed and installed according to the rainscreen principle. This consists of designing the systems so that exterior surfaces and sealants present a deterrent to precipitation ingress with the barrier air and water seals located inboard. This protects the barriers from direct wetting, gust wind pressure, solar radiation and other damaging factors, which promotes long service life. The interstitial space between the exterior surfaces/sealants and the internal seals is typically vented to moderate wind pressures and drained to remove moisture that may penetrate behind the exterior.

Leaders in window wall are using state-of-the-art techniques to take performance higher.

Generally, window wall panels are factory prefabricated with the infill glazing, vents and spandrel panels. On-site fabrication is limited to connection details such as the inside and outside corners and the junctions to adjacent enclosure systems. Frame openings are individually sealed, drained and vented to the exterior. Cascading, internal drainage to a subframe or sill pan that is wept to the exterior is common in the U.S., but unusual in Canadian window wall systems. However, allowance for leakage through the frame joinery and through the interface joints between the window wall system and the adjacent wall systems is provided at the sill. The interface joints are typically waterproofed with gunned, liquid-applied sealants (caulking, bead-applied polyurethane foam) and membranes (self-adhesive, field-applied adhesive and/or thermofusible). Window wall systems used on the Canadian west coast and bound for the U.S. are likely to incorporate head receivers and sometimes jamb receivers instead of gunned sealants and membranes.

The insulating glass units are typically laid-in glazed from the building interior side of the frame. The rainscreen design at the perimeter of the insulating glass units is accomplished with gunned, liquid-applied sealants and/or preformed elastomeric rubber gaskets around the full perimeter of each unit to the surrounding frame mullions and rails. Each frame opening in a window wall assembly (both in the vision and opaque areas) is usually wept directly to the outside through openings in the horizontal rails below, similar to a rainscreen-designed curtain wall. Opaque areas (spandrel panels) are constructed similar to Canadian-style rainscreen curtain walls with a sheet metal backpan sealed to the surrounding mullions and rails, with the insulation mechanically secured to the outside face of the backpan and with a cladding at the exterior glazed into the surrounding frame. The interstitial space is drained and vented to the exterior.

When the strap anchors project beyond the interior of the building interior face of the window wall system they breach the interior seal at the head and often at jambs, also. To maintain air leakage and water penetration control, each strap must be carefully encapsulated, which is tedious, time consuming and expensive work. It is difficult to apply sealants to the edge of open

KEEP IT DRY

Examples of a continuous sill angle with self-adhesive membrane waterproofing on the exterior. On the top, a continuous angle is installed at the edge of the floor slab. On the bottom, a membrane was installed at the curb on a balcony with the self-adhesive membrane overlapping the thermofusible waterproofing membrane for the balcony.

Careful thought in 3D is required to ensure continuing of airand water-leakage control. On the left, a head receiver butts against a self-adhesive air barrier and WRB returned into the rough opening from an adjacent envelope enclosure system. A gunned sealant was applied to ensure continuity. On the right, at another junction condition, the continuous sill angle and selfadhesive waterproofing membrane are extended past the jamb mullion into the adjacent wall assembly. Continuity between envelope systems was not adequately considered during design and construction.

back frames because the frame edge is narrow and provides little bond area for the sealant to the frame. A more robust fillet bead application to the room-side face of the frame provides more certainty of adhesion and long-term performance. However, such sealant application may interfere with interior finishes. An alternative is to use a head receiver with preformed elastomeric rubber seals to the frame head to permit inter-storey drift and seismic movements and gunned, liquid-applied sealants for the static connection between the head receiver and the structure. Head receivers are available from most manufacturers serving the Canadian west coast markets. Some manufacturers can also supply jamb receivers.

At the sill, air- and water-leakage control is typically provided by application of a membrane over the edge of the floor slab behind the slab bypass, extending from a head flashing or head receiver above the panel on the floor below to the vertical upturn leg of the continuous back angle used to anchor the sill. The membrane upturn is sealed to the window wall sill rail with gunned, liquid-applied sealant. The quality of the back angle membrane or window wall sill rail seal can be affected by the joining method between adjacent window wall panels. As described previously, nested mullions or H-bar-connected mullions are deeper than the rails. When the mullions are set against the back angle, gaps are created between the upturned membrane on the back angle and the rails. The gaps must be filled with sealant. A common installation technique is to apply sealant to the membrane upturn prior to moving the panels into place, relying on squeezing of the sealant to fill the joint. This “smash glazing” approach may not completely fill the gaps. A similar problem occurs at the head when head receivers are used. Preformed elastomeric rubber gaskets typically provided between the receiver and the window wall panels must be sufficiently flexibile to seal the narrow gaps at the mullions and the wider gaps at the rails. These installation techniques should be reviewed carefully during construction and the method adjusted if inadequate sealing is detected.

A weakness of using different methods to seal the interface joints between the window wall perimeter and adjacent wall systems at sill, jamb and head is ensuring continuity at the junctions. Architectural and window wall manufacturer shop drawing details are almost exclusively two-dimensional, so junctions between different sealant systems must be discerned through careful study. If not addressed in the drawing review stage, the installer is left to figure out a solution on site. The knowledge, experience and skill of the installer greatly affects the quality of the solution, which can range from simply applying more gunned sealant to bridge or fill gaps to well-thoughtout and installed flexible membranes or brake-shaped aluminum closures. In this regard, the common approach in the U.S. of using head and jamb receivers and a sub-frame or sill pan at the sill, designed as a system with similar components, is superior to the Canadian approach.

To be fair, it should be noted that the success of window wall systems in the U.S. also relies to a great extent on gunned, liquidapplied sealants to prevent air and water leakage. Both families of window wall systems need good design and diligent shop and site personnel to correctly assemble and install the frames and infill. A good quality assurance program should identify issues of concern in the shop and on site to ensure successful performance of the window wall and the building envelope as a whole. •

Looking for a pioneering glass railing that combines easy installation, a stainless steel finish and proven safety all in one? Q-railing’s Easy Glass® Slim is the answer! This lightweight aluminum base shoe comes with a brushed aluminum effect finish and is an ideal choice for stairs, balconies and landings. Plus, thanks to its unique Safety Wedge system, installation is extremely quick and easy.

For more information on Easy Glass Slim, contact one of our Canadian distributors, or - for specification projects - consult our architectural partner.

PRODUCT ENQUIRIES:

All-Glass Parts Inc www.allglassparts.com

Cascade Aqua-Tech Ltd. www.cascadeaqua.com

Geo. Bezdan Sales Ltd. www.geobezdan.com

201 5

PROJECT SPECIFICATION ENQUIRIES:

GlassCan Inc. www.glasscan.ca

by RICH PORAYKO

Irma came, saw and kicked some serious glass. Without a doubt, Hurricane Irma had a major impact on the 2017 GlassBuild America trade show held in Atlanta, Ga., from September 12 to 14. Attendance figures weren’t available at press time, however pretty much every attendee had some sort of flight casualty story including cancellations, major delays and insane landings. For the most part, many exhibitors were spared Irma’s travel nightmare because they arrived a day before the storm hit to set up their booths. Before the event opened, some shared that they had hoped the show would have been cancelled. National Glass Association president, Nicole Harris, made the right call and opened the show. It must have been a hard decision but it was absolutely the right one. With what was expected to be the largest show since the Great Recession made up

of 483 exhibitors and 10,000 registered attendees, only a handful of exhibitors cancelled (barely noticeable on the huge show floor). Day One was quiet but the storm passed, the sun came out and the second day was solid. Equipment suppliers exceeded their sales expectations signaling confidence in the market. Several exhibitors moved their receptions to Day Two so the show floor was a party in the afternoon.

Credit should be given to the NGA for going over and above

the call of duty and turning what could have been a disaster into a tremendously successful event.

Some of the educational opportunities took a hit with presenters cancelling, however organizers scrambled and found solutions to make the sessions work. Glazing Executives Forum keynote speaker, Julie Schimmelpennigh of Eastman Chemical Company couldn’t make it in person, however she provided her excellent State of the Glass Industry presentation live via video conference.

ABOVE: At 483 exhibitors and 10,000 registered attendees, even a hurricane can’t keep GlassBuild from being the annual must-see event for the North American glass building industry. Exhibitors and presenters were bullish on the market’s prospects for the near term.

The biggest news of the event was the announcement that the NGA and GANA associations have come to an agreement on merging their organizations and are putting the proposal to their memberships for a vote. Assuming the proposal is adopted, the long overdue merger will surely strengthen and unite the North American glass industry. There were also a lot of rumours about a CEO from a major multinational fabricator stepping down in the near future and other chatter of additional mergers and acquisitions.

Keynote speaker, Cam Marston, presented a hugely insightful opening session on the multigenerational workplace. Marston provided vision and takeaways for managing Millennials, Generation Xers, Baby Boomers and, in some cases, Matures, who may all be working under the same roof. Turns out, one size does not fit all. Marston also raised the flag on the mass exodus of Baby Boomers out of the workforce. “In the US, there are 2.5 million Baby Boomers set to retire – 10,000 of them a day,” said Marston. “The baby boomer generation has paid its dues and earned the right. They are looking forward to retiring. Many are leaving earlier than expected due to health issues. The Baby Boomers have wisdom. They have skills as well but most importantly for your business, they have wisdom.”

The economic forecast “Navigating the Crust,” provided by Alex Chausovsky of ITR Economics, was an absolute highlight. “The U.S. economy is going up a wave and will crest in early 2018 and then decelerate over the course of next year,” said Chausovsky. “We’re going to face some mild recessionary pressures but nothing to be too worried about. In 2019, we are expecting a couple of quarters of negative activity. So by traditional economic definitions, that’s a recession. In reality, it’s just a mild pause in the growth of the U.S. economy. It’s not going to be anything as turbulent as what we went through back in 2008 and 2009.”

“I want you to walk away with an optimistic view of the next six to nine months with a view towards expansion of your business through the end of next year. Then prepare to make the necessary decisions to get you through the mild recession and get your company ready for more growth in 2020 and 2021.”

On politics, Chausovsky isn’t overly concerned about political implications for the U.S. economy until something concrete comes down from Capitol Hill. “Warren Buffet’s response to politics is ‘Red or blue, I can still make green.’”

According to Chausovsky, the oil market is still fairly oversupplied. “We have massive inventory levels and unless some crazy black swan event happens, we’re not expecting any major movement in the price oil over the next 18 to 24 months.”

Originally from Russia, Chausovsky told the audience that Russia is coming off a two-year recession but is still overly dependent on oil as a driver of their economy. “The position and actions of the Russian president, Mr. Putin, do not make any economic sense. People ask me all the time ‘What is your expectations for Russia?’ my response is always ‘I don’t know, I can’t forecast crazy!’”

The economists at ITR Economics strongly believe that the United States is facing the prospect of a Great Depression and have been sounding the alarm in their forecast every GlassBuild for several years. “I’m talking about 1929 by the time 2030 rolls around,” said Chausovsky. “We have a significant change of demographics happening in this country. On top of that, we continue to live beyond our means. We continue to be a debt-

driven economy. Until we fix those things, the reality is we’re going to have a significant price to pay. Politicians are going to have to cut spending across the entire federal government in a meaningful way. And they are going to have to raise taxes. Whatever tax reform they are talking about now is not longterm sustainable. They are going to have to raise personal and corporate taxes. When you have the combination of cutbacks in spending and higher taxes, we have 1929 all over again.”

Key actionable takeaways recommended by Chausovsky include budgeting for continued economic expansion through 2018. Be willing to take risks and invest in your business over the next two quarters. Hire sales people to grow as the economy accelerates then slows. Add new products as new ventures buck the business cycle decline. Make sure your training and retention programs are top-notch. Budget for higher wages and costs. And raise your prices!

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, BC. richp@constructioncreative.com For more reports from events around the industry, visit

by MARGARET WEBB

The IGMA Summer Conference in Montreal heard about the significant progress our many active committees and task groups are making. Here’s a look at some highlights. The Quality Management System task group reported that the new quality manual, TM‐4500, Quality Management System for the Fabrication of Insulating Glass Units to the ISO 9001:2008 Standard is available from the IGMA publication store. The second manual, TM4510, Quality Procedures for the Fabrication of Insulating Glass Units to the ISO 9001:2008 Standard has now passed all the approval levels and will be published this fall.

Working jointly with the GANA Insulating Division, the Glazing Guidelines task group is developing a technical bulletin (TB‐1800‐XX) to address load resistance (glass strength) and dead load support for IGUs with unsupported edge conditions. This bulletin does not address butt glazing. All sections of the document have now been written and the document will be balloted to the IGMA Technical Services Committee this fall.

The Guidelines and Tolerances for IGU Cavity Width task group is developing a manual, TM‐4400‐XX, Voluntary Guidelines for IGU Cavity Width Manufacturing Tolerances, which establishes tolerances in cavity width reduction at the point of manufacture and provides guidelines for the evaluation of the manufacturing of IGUs at the plant. It does not address reductions in the cavity width after the IGUs are shipped from the plant or installed in the field, as these are factors beyond the control of the manufacturer. The document was balloted to the IGMA Technical Services Committee and there have been some proposed changes that will require the attention

Many new manuals and educational materials are flowing from the strong efforts of our volunteers.

The IG Cavity Compensation task group is a new task group developing a technical manual providing generic design alternatives for cavity compensation for insulating glass units and determining conditions that impact the pressure in the IGU cavity. Items included in the document are capillary and breather tubes, one-way valves, desiccant adsorption/desorption, pre-inflating/pre-deflating the unit, temperature manipulation during fabrication and the use of bladders.

The PIB Migration task group, working jointly with the GANA Insulating Division, is developing a glass information bulletin on the compatibility testing of glazing materials related to the performance of PIB in insulating glass units. This document is substantially complete, however the task group will need to collect data to support some of the proposed changes to the test. A second document is close to completion: a technical bulletin specific to PIB as a primary sealant. This second technical bulletin (TB‐1250‐XX) includes the chemistry of PIB, proper handling of the sealant, performance parameters, methods for examination of conditions when PIB does not perform as expected and possible root causes.

Working jointly with the AAMA Glass Materials Council, the Visual Quality task group has developed a consumer guide to understanding glass standards which will be posted as a webpage rather than a technical publication. It is anticipated that this will be completed soon for final review by the AAMA Marketing Steering Committee.

A new task group called Do’s and Don’ts of Plant Safety will develop a document similar to the Preventing IG Failures manual for each area of the plant and for plant processes. It will be meeting this fall to start development of the manual. Information from prior safety webinars will be included in the new document.

The next IG Fabricator Workshop has been scheduled for Nov. 7 to 9 at the Intertek Test Facilities in Plano, Texas. Registration for the fourth workshop is now available. Our Leadership Development Program launched in February and the sixth webinar has just been completed. All sessions have been recorded and registration is still available. Go to igmaonline.org for more information or to register for these events. •

crlaurence.com

C.R. Laurence has introduced its new hydraulic patch fitting for interior all-glass entrances. The system features an innovative hydraulic self-closing mechanism that is integrated into the patch fitting. The fitting eliminates the need to cut into the floor to install a conventional floor closer because the closing mechanism is housed in the patch itself. It only requires anchoring of the base plate to the substrate. Not only does this simplify installations, it also enhances esthetics by reducing the amount of visible hardware such as cover plates and overhead closers. The new patch fitting features adjustable closing and latching speeds as well as a 90-degree hold-open option for added convenience. The system is designed for 3/8- or 1/2inch monolithic tempered glass. It can hold doors up to 220 pounds and 39 inches in width. The hydraulic patch fitting is part of a suite of innovative self-closing entrance systems from C.R. Laurence including the DRS 1202 swinging door system and the Vernon Series hydraulic door hinge.

the other with a combined maximum flow rate of 120 litres-per-minute using the patent-approved Smartstart lance system. Featuring a touchscreen menu, the Smartstart system allows an operator to remotely start the gas filling process by pressing a button on the lance body instead of having to return to the machine. The lance body incorporates an LED light, which on activation of the filling process turns green then red on completion of the fill cycle. To match the increased emphasis on quality and production traceability, the Smartfill 4 is also available with data logging and a print facility that records the date, time, gas fill level, fill cycle time and line number of every gas-filled IG.

walkerglass.com

inagas.com

With strong roots in the North American IGU markets, Inagas was back at GlassBuild America 2017 with more innovations. It showcased its range in conjunction with distributor partner, Quanex Building Products. Visitors saw live demonstrations of the SmartFill 4. The Smartfill 4 is a fourline machine designed for high production of argon-gas-filled insulated glass units. Each line operates independently from

Walker Textures Traction is a line of anti-slip acid-etched glass. It consists of two well-known patterns – 406 and 407 – as well as Force: a full-surface etch without any pattern at all. The demand for acid-etched glass in pedestrian areas has steadily increased over recent years. Its remarkable qualities of light transmittance and esthetics have unquestionably contributed to this situation. The Walker Textures Traction anti-slip acid-etched glass products ally discretion, light transmittance, durability, safety and add an undeniable sophisticated touch of design. The coefficient of friction for the three Traction options has been calculated based on “ANSI A137.1:2012 Section 9.6 - Procedure for Dynamic Coefficient of Friction (DCOF).” Traction glass is typically used as part of a multi-layer glass assembly requiring appropriate engineering. Walker Textures Traction offers many advantages, including a superior coefficient of friction with no restriction of light flow; superior resistance to surface contamination from dirt, oils, chemicals, liquids and food; and a sophisticated touch of design. Conducive to high quality edgework, Traction exhibits excellent wear-resistance properties and a consistent acid-etched finish. The glass is free of iridescence. Clear and ultra-clear colours are available, with other substrates available on demand. Thicknesses are six to 12 millimetres for the 406 and

407 patterns, six to 19 millimetres for Force. Available dimensions are 96 by 130 inches standard for all three options with a 96- by 144-inch maximum size for Force. Tempering of ultra-clear glass is recommended for pattern 406 and 407, to correct slight colour variances caused by the Walker Textures Traction manufacturing process.

baileycranes.com

Brandon glass lifters from Bailey Specialty Cranes and Aerials feature a rock solid boom with more reach and glass side shifting. The 6,000-pound lifting hook operates safely with an included load indicator/limiter and winch attachment. A man basket attachment is available, as are engineered solutions for specific applications.

sinometalresourcesinc.com

Sinometal offers two kinds of extrusions with many variations in between. Its integrated production facilities include 30 extrusion presses with an annual production capacity of more than 200,000 metric tons. With checks and balances in place throughout the manufacturing process and ensuring that business associates adhere to strict specifications, Sinometal consistently delivers products of superior quality. Aluminum extrusions come in the following surface treatment options: anodizing in different colours, bright dip, powder paint in different colours, wood surface finishes, brushed nickel, polished nickel, buff surface finish and mill finish. Customized mould design and machining is available on request.

•

STANDARD DOORS

THERMAL DOORS

THERMALLY BROKEN STOREFRONT HIGH PERFORMANCE CURTAIN WALL

• COMPETITIVELY PRICED

• SHORT CYCLE LEAD TIMES

• INDEPENDENTLY TESTED TO INDUSTRY STANDARDS

• INSTALLS FASTER AND WITH FEWER COMPONENTS

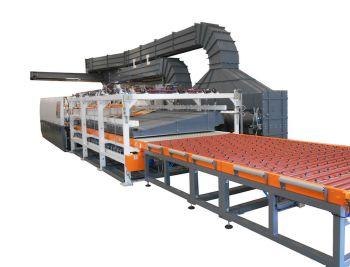

tkitaly.com

Oscillating Master temper ovens from TK cover a size range suitable to meet any production requirement with openings from 1,300 to 3,300 millimeters. The lines are equipped with advanced process control technologies to always guarantee the best quality. In addition to the wide range of tempering glass, the Master temper oven is suitable for coating low-emissivity glass (both magnetron and pyrolytic). Excellent results are obtained with the 0.01 low-E soft system.

The Master temper range has two systems for tempering low-E glass: convection by hot air directly inside the heating chamber, and pre-heating the chamber with hot air. For both solutions, the automatic convection system allows tempering low-E glass with excellent results. Key features include ceramic rollers in fused silica handled by double belts. Loading, furnace, tempering and unloading cycles are independently powered and driven by an inverter. The heating elements are assembled and fixed on panels for long-life and stability with the Greek system.

Power control is provided by SCR in independent zones on both the upper and lower side. The blower groups are driven by DC and/or AC motors with an inverter.

The Master features certical separate adjustment of the bowing ducts with independent pressure-checking for each blowing duct. Process control is run by PLC and a supervision PC. Operation and setting of the processing parameters is easy. The furnace includes an independent UPS system that supplies power to the furnace and completes loading by discharging the glass. Each line can be custom configured, for example, the side chamber for the fan can be placed in the position most suited to the work space. An integrated system equipped with an infrared thermocamera checks, records and stores the temperature of the glass surface, allowing the operator to trace every load when the work is finished.

jeberkowitz.com

JEB debuted the JEB 3Seal HM Plus warmedge spacer system for insulating glass units. The new JEB 3Seal HM Plus spacer features triple-seal technology, including an advanced high-strength and ultra-high-modulus silicone secondary sealant, which improves argon gas retention and delivers a sleeker sightline allowing for diverse, bold and esthetically appealing architectural designs and energy efficiencies. With its no-metal design, the JEB 3Seal HM Plus spacer has shock-absorbing properties that counteract glazing stresses caused by wind, while also minimizing thermal conductivity and enhancing condensation resistance.

bystronic-glass.com

The B’Vario TPS and B’Jumbo TPS from Bystronic are individual production solutions for all types of orders providing unique versatility. They are system solutions for insulating glass with thermoplastic spacer (TPS). The thermoplastic spacer is applied directly onto the glass by the machine from a single drum as part of insulating glass production. The width of the spacer can be changed as desired during operation without any time loss. Separate

production processes for the sawing, bending, connecting, desiccant filling and butylation are no longer needed, saving both time and money. The system eliminates the need to stock different spacer profiles and connectors. With the B’Vario and B’Jumbo systems, suitable spacer is always available and no offcut, dirt or waste is produced. Production can mix manufacture on a single line, removing the need to split orders into standards and specials. Continual, uninterrupted operation is achieved thanks to the dual-drum pump system with the material drum change taking place during production. The patented bevel joint ensures a perfect primary sealing of the thermoplastic spacer, even on the joint. There is no production interruption when changing the spacer width or when dealing with triple insulating glass units with asymmetric structure.

lisec.com

This year, Lisec presented a new horizontal washing machine that has been specifically designed for glass lites with different types of sensitive coatings.

The washer also handles glass sheets which are dedicated to be coated after the washing process as well as any monolithic or laminated glass with optimum results and no residues. Thanks to its intelligent design, the machine ensures easy maintenance, reduced noise levels and considerable energy savings.

cassosolartechnologies.com

Continuous laminating lines from Casso Solar may consist of an entry washer; a temperature-controlled lay up room with PVB unwind stands; overhead glass transfer assists and pop-up caster tables; preheat ovens to bring laminate to 110 to 120 Fahrenheit prior to first de-airing the press; an oversized roll de-airing press; a tacking oven to bring the laminate to 160 to 180 F; a final tacking press; and an unload conveyor with overhead assist. Full PLC recipe control is included. For customers processing coated or low-E products, Casso-Solar full top convection systems reclaim the lost production volume over uncoated products. Casso-Solar Technologies systems are available to run with and without an autoclave. Production requirements determine which system works best for each customer. Recommendations for new and used autoclaves can also be provided. Batch laminating systems can process PVB, EVA, urethane and DuPont SentryGlas without the need of an autoclave. Productivity packages can provide up to 1,500 square feet of sixby-six millimeter product per eight-hour shift. Standard, hurricaneproof and noise-reduction glass are easily produced.

For the latest in glass fabrication technology, visit glasscanadamag.com > Technology

by FRANK FULTON