performance under pressure

INTRODUCING 1630 SS IR CURTAIN WALL – ELITE IMPACT RESISTANCE FROM KAWNEER

High Performance. Larger Spans. Increased Impact Resistance. Kawneer’s new 1630 ss Ir curtain Wall – an impact resistant 3" sightline curtain wall system – offers an additional line of defense against high winds, heavy rains and hurricanes. Having undergone rigorous testing, our new curtain wall meets increasing design pressure requirements in impact zones and can deliver larger spans. and, screw-spline architecture with both dry and wet glazing options makes the 1630 ss Ir easy and fast to install. Kawneer knows how to protect buildings and occupants. 1630 SS IR Curtain Wall is performance under pressure.

Aluminum Systems

+ Framing

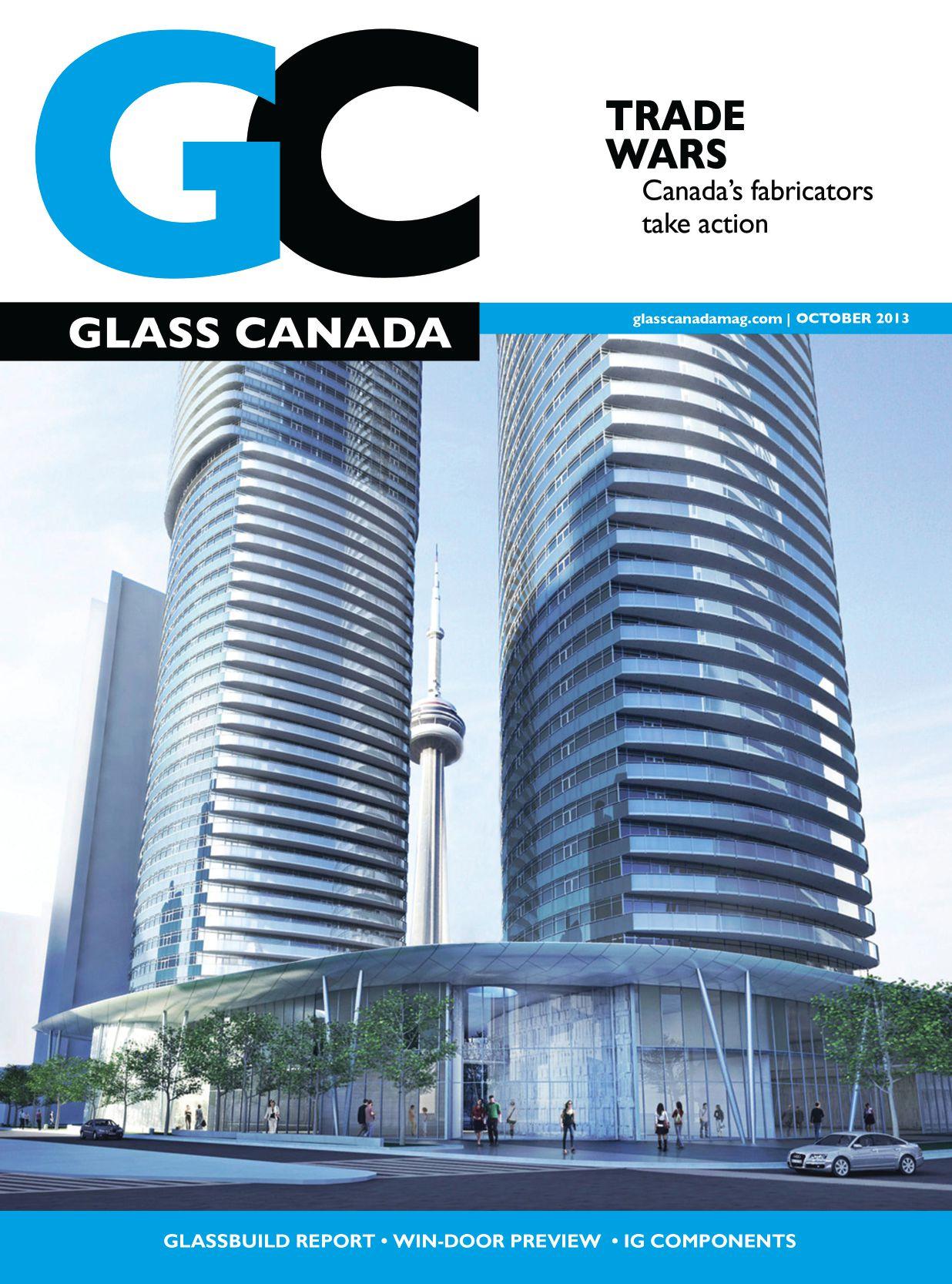

Canadian companies have won a key battle in the fight to protect our curtain wall fabrication industry from unfair foreign competition. The Canadian Border Services Agency investigation revealed some interesting facts about the glass industry here, and in China.

14

Win-Door preview

Is there any reason for an architectural glazier to go to Win-Door? We think so.

18

GlassBuild report

The buzz on the floor in Atlanta was that the recovery is over and growth is back. 22

Insulating glass showcase

From components to automated lines, find top products to improve IG quality here.

Let’s have a trade show

It is high time we had a real trade show for the architectural glazing industry in this country. Glass Canada is looking for partners to help make it happen.

I have some concern that a condition of isolation is creeping into the architectural glazing industry in this country. After all, where and when do we all get together? Garibaldi Glass puts on a nice event that attracts most of the glazing community in B.C., and Glass Connections Calgary will doubtless bring the southern Alberta glaziers together. And of course there are the various association meetings and golf tournaments across the country. But each of these events is regional in nature. Where is Canada’s GlassBuild?

NEXt IssUE

• starline architechtural windows

• PVC door frames

Whether this industry needs a national trade show is a fair question, but one I think is easily answered with another question: does Canada need a unified national architectural glass community? Our cover story in this issue goes some distance toward providing an answer. When China began dumping unitized curtain wall into this market, the nation’s largest curtain wall fabricators had to scramble to act together to alert federal trade watchdogs and convince them to take action before irreparable harm was done to this country’s capacity to produce its own building facades. Before it will hear complaints of this kind, the trade tribunal must be satisfied that it is hearing from companies representing a “major proportion” of Canada’s productive capacity in the sector. An isolated and fragmented industry will be in danger of not being able to respond to these threats. And it seems beyond doubt that more such threats are coming.

Those gloomy reflections aside, there are any number of positive reasons to have a national trade show. It is to be hoped that a truly national show would entice the world’s larger machinery manufacturers to attend and display their latest technologies. The right mix of educational speakers and exhibitors can draw suppliers, fabricators, specifiers and contractors together in a potent mix of business opportunity. This is what used to happen at the IMAGE shows in the ’80s. Everyone learns a lot, gets energized and has fun.

It is with all this in mind that Glass Canada magazine is exploring the idea of launching a national architectural glass industry event in the near future. We have been speaking to the Ontario Glass and Metal Association about the idea, and they are keen to participate. We will start small but grow this thing as far as it will go.

The only way we will succeed in attracting national participation in a country the size of Canada is if we offer great value that you cannot find anywhere else. I’d love to hear what event programming would get you on a plane to Toronto. Drop me a line and, who knows? Ask and you may receive. •

October 2013 Volume 25 • Number 5

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

SALES ASSISTANT | Jarah STEFEK jstefek@annexweb.com 519.429.5183 | 888.599.2228 ext. 219

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: subscribe@glasscanadamag.com

Tel: 866.790.6070 ext. 208 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST)

($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

INdUstry NEWS

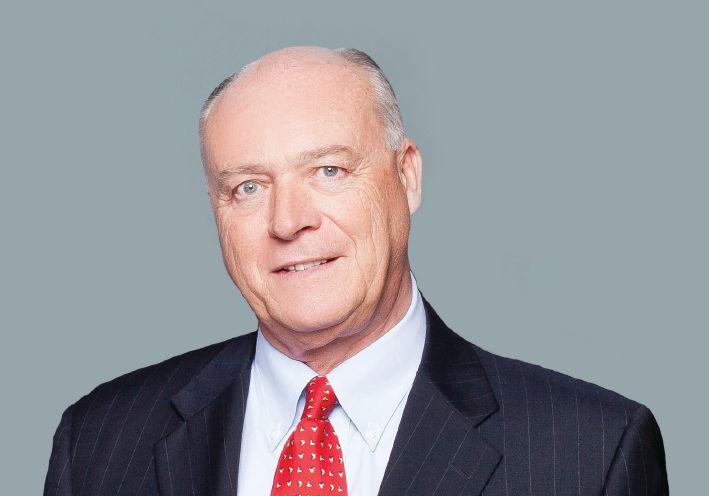

Griffiths named CEO at Quanex

Quanex building Products Corporation, an industry-leading manufacturer of value added, engineered materials and components serving the energy-efficient building products markets, has announced that its board of directors has elected William C. Griffiths, 61, as chairman, president and chief executive officer of Quanex, effective July 9, 2013. Griffiths has served on the board since 2009 and succeeds david d. Petratis who resigned to accept a position with another company.

“bill is a seasoned executive with experience in a wide range of industries including building products. he has been a valued contributor during his tenure on the board and we look forward to his leadership of Quanex,” said Joseph d. rupp, lead director, on behalf of the board. “the board is delighted in having bill to be Quanex’s next CEO, as he is very familiar with the operations and strategic direction of the company.”

“bill is the right executive to be the next CEO of Quanex as the management team focuses on making Quanex a significant force in the building Products industry,” said susan F. davis, Quanex board member and chairperson of the management development and compensation committee. “he is a well-rounded leader with a track record of positioning businesses under his stewardship with leading-edge manufacturing capabilities and driving impressive growth. his process based, results-oriented management style and knowl-

edge of the building products industry will be invaluable as he drives growth at Quanex.”

“I am excited to be leading Quanex building Products,” said Griffiths. “I have enjoyed working with dave as he and the board developed Quanex’s strategy over the past five years.We wish him the very best and thank him for his past service. My focus will be to continue to execute on that strategy and deliver superior customer service to our customers and long-term value to our shareholders. I look forward to working with the leadership team as we continue building strength across all of Quanex.”

Griffiths was most recently the managing director and member of the board of directors of sealine International, a privately held manufacturer of motor yachts based in the United Kingdom, until June 2013. Prior to joining sealine, he served as chairman of the board, president and CEO of Champion Enterprises, a producer of modular and manufactured housing, and president – fluid systems division of sPX Corporation, a global multi-industry company. Mr. Griffiths also served as a member of the board of Wolverine tube, from 2005 to 2007. he graduated from the University of London with a bs with honors in mining engineering. In addition, Mr. Griffiths is a graduate of the harvard business school’s PMd executive education program and serves as an advisory board member for graduate studies and research at the University of Notre dame.

New toys at Hartung

In addition to new cutting lines at h artung Wilsonville and h artung s alt Lake City, h artung Canada continues to grow and has welcomed the arrival of some beautiful, new glass fabrication equipment.

t here was a dedication ceremony for h artung Canada’s brand new Glaston rC200 tam tempering furnace now servicing western Canada and beyond. t he made-in-Finland, 94-by188-inch oven includes the acclaimed tamglass Vortex convection system, which is renowned for the highest quality, flat tempered product on the market.

the company has added additional equipment such as a new b avoni 1045 flat polisher and new Forvet CNC glass mill/drill/ notching machine.

state of the art machinery has been arriving for the last 18 months throughout the h artung enterprise which will allow for better quality control, faster lead times and more competitive pricing.

For more information on the acquisitions, visit www.hartung-glass.com.

CGA Newsletter

CANADIAN GLASS ASSOCIATION

the CGA has adopted an accelerated schedule of monthly board meetings for the first tuesday of every month at 1:00 p.m. Est. the new board is getting refocused and setting out new goals for the future while currently putting energy into the upcoming Glass Connections show in Calgary set for October 10.

PROVINCIAL GLAzIERS ASSOCIATION OF ALBERTA

the PGAA hosted its annual golf tournament at Alberta springs Golf resort in red deer, Alta., on Friday August 16. there were 138 golfers in attendance and it was a great day with fabulous weather. the tournament raised over $50,000 toward the creation of the Master Glazier program. the Master Glazier program is currently being developed by industry and the southern Alberta Institute of technology.

there will be nine courses and they are Air seal barrier, Project and site Management, blueprint reading (division 8 specialized), survey Field Work, specialty Glass, supervising and Mentoring, structural Glazing, doors and related hardware and Craftsmanship. It is our hope to have all of these courses created by June 2014 and to have our first enrollments in september 2014.

O NTARIO G LASS AND

M ETAL A SSOCIATION

theOntario Glass and Metal Association fall golf tournament, held sept. 19, was buzzing this year with news of a hole-in-one by Michael Arnott of Northern Facades. Arnott holed his tee shot on the 164-yard, par-three 12th at the Carrying Place Golf and Country Club in Kettleby, Ont. some debate ensued as to whether this feat qualified him to win the Prelcosponsored closest-to-the-pin prize, as his ball was technically not close to the pin but actually touching it. OGMA golf officials

eventually ruled that Arnott should win.your correspondent must have been in the bathroom when Arnott purchased the traditional round of drinks.

After golf and the usual delicious dinner provided by the course kitchen, some OGMA business was conducted. Ennio rea of saand started things off as usual with an off-colour joke.then steve ringler of Oakville Glass and Mirror, OGMA president, introduced the OGMA’s bursary winner for 2013, doug Cake. Cake was presented with a $500 cheque to be put toward his continuing education as a glazier. ringler told the crowd of 108 that Cake signed as an apprentice in 2009 after completing a pre-apprentice class at the Ontario Industrial and Finishing skills Centre. he has been active in the field, working for Millenium Glass, harding Glass and Impact Glass, each for approximately one year, and is very close to having the required hours to write his College of trades exam. In his advanced level training Cake received the highest mark for his

class. steve Laird, one of Cake’s instructors, said “All in all doug has been a pleasure to work with and I wish him well in the future.”

Following this, doug Morris of Morris Glass and Windows got up to announce a donation to a new charity for the OGMA: the holland bloorview Kids rehabilitation hospital Foundation. shannon boeckner was there from the hospital to accept the $1,000 cheque and thank the association, describing how its money would be pvut to work assisting children with disabilities. According to the hospital brochure, holland bloorview is Canada’s largest pediatric rehabilitation hospital, handling 600 inpatient and 52,000 outpatient visits each year. boeckner invited all OGMA members to visit the facility and see the work being done there. your editor was then given a chance to inform the group about a new trade show hosted by Glass Canada for the architectural glass industry being planned for next May. Members were asked to stay tuned for more details.

For more photos from industry events, visit the Glass Canada Facebook page

Truth and Amesbury under one roof

tyman, the parent company of Amesbury, has completed the acquisition of truth hardware of Owatonna, Minn., and Atlas holdings of brampton, Ont., from Melrose Industries. truth hardware is a leading manufacturer of window and door hardware for the North American residential and commercial fenestration market. Amesbury is an international leader in the fenestration market supplying hardware, sealing, and extruded products to residential and commercial markets.

“Combining Amesbury and truth creates an organization with an extensive product portfolio and global reach,” says Jonathan Petromelis, Amesbury president

and CEO. “Our priority and endeavor as an integrated organization will be to provide customers within the fenestration market even greater opportunity to seek engineered solutions.”

Jeff Graby, president and CEO truth hardware says, “At truth hardware we are very excited about working with Amesbury. Combined, our position of strength and the ability to offer our customer’s the breadth of an expanded and innovative product line will be our core focus.”

the acquisition of truth hardware provides the tyman group an expanded and highly complementary product portfolio especially in casement

Triple Seal changes name to Saand

triple seal group of companies, which includes triple seal Ltd., Independent Mirror Industries Inc., southwest Glass, Eastern Float Glass and the newly acquired triple seal rexdale, has announced a complete re-branding that will include the launch of a new name, logo, tagline and website. triple seal Group of companies will begin operating under the new trade name, saand, effective immediately. the re-brand is the positive outcome of continuous growth by acquisitions made over the past 40 years as well as a necessary means to unite its business units and eradicate the confusion associated with its current naming conventions.

“the rebranding represents our evolution over the past 40 years and signifies our future direction. We offer

our customers a variety of different glass and fabricated glass products and we needed a brand to reflect that” said hilton berger, vice-president of saand. “the stylized icon was designed from the microscopic glass crystal structure and represents an element that is at the core of everything we produce. the circular shape also represents the unification of our business units as one.” the new website saand.ca will be under construction until the fall. the rebranding will continue to foster saand’s unparalleled dedication to value, quality and service to its customers. saand is a regional glass fabricator and flat glass distributor. headquartered in toronto, saand has fabrication and distribution branches in London, Ont., rexdale, Ont., and Ottawa. saand is

hardware. It broadens relationships within a largely common customer base of North American window and door OEMs. It also creates an enlarged and strategically positioned manufacturing footprint, including a facility in Canada. the total number of Amesbury and truth manufacturing locations in North America is now 13.

“the key to both companies’ success has been, and will continue to be, provide world-class service to our customers and high quality hardware, seals and extrusions, and this acquisition will be a key element in the continued development of our strategy for North America,” says Petromelis.

one of the largest fabricators and distributors of glass products in Canada. specializing in insulated glass units and all aspects of residential and commercial mirror, while also offering a wide range of other product types, saand serves contract glazers working on commercial and residential projects, as well as glass fabricators, glass shops and window manufacturers. the company also focuses on commercial as well as residential OEM furniture and cabinet manufacturers across North America.

Greco hires new president of U.S. operations

Greco Aluminum r ailings (U s A), a subsidiary of Greco Aluminum r ailings, has introduced Jim Ellsworth as its president of U. s . operations. Ellsworth joined Greco in May of 2013. h e brings more than 30 years of executive management experience to the role.

“I’m extremely excited to be on board with Greco and to lead the company’s expansion into the U. s market,” said Ellsworth. “ t he company has had tremendous success in Canada and with its initial penetration into

the U. s . market. We will be pursuing strategic geographic markets in the U. s . to aggressively grow our business.”

to support Greco’s strategic growth in the U. s ., Ellsworth is currently developing a network of independent sales representatives in specific metropolitan areas who will be focused on both retrofit and new construction projects.

t he Greco U. s . rep network will be developed and managed directly by Ellsworth.

zoulek named VP of flat glass for Guardian

Guardian

Industries has named rick Zoulek vice-president for North American flat glass operations. Zoulek will oversee all aspects of the North American flat glass business and position the company for continued long-term profitable growth. he has established a strong track record of innovation and commercial leadership in growing businesses throughout his career.

“rick brings to Guardian leadership skills that will more strongly position us in the competitive and constantly changing flat glass business in North America. he has the innate ability to connect innovation and manufacturing to meet customer needs and will be instrumental in furthering our goal to be a world leader in providing value-added products and services,” said scott thomsen,

Guardian Glass Group president. “We look forward to rick demonstrating these same leadership qualities in our North American business.”

Zoulek says he welcomes the

Richelieu hits the coast

richelieu hardware has announced that it has acquired the net assets of hi-tech Glazing supplies. this Vancouverbased distributor of door and window hardware serving the b.C. market realizes sales of approximately $5 million per year. this acquisition will enable richelieu to enlarge its offer with products that feature in its shortand long-term strategy, in addition to reinforcing its position in a specialized client base. richelieu is a leading North American distributor, importer and

manufacturer of specialty hardware and complementary products. Its products are targeted to an extensive customer base of kitchen and bathroom cabinet, furniture, and window and door manufacturers plus the residential and commercial woodworking industry, as well as a large customer base of hardware retailers, including renovation superstores. richelieu offers customers a broad mix of high-end products sourced from manufacturers around the world. Its product selection consists of 100,000

Intermac to hold open house

biesse and Intermac Canada, world leading manufacturers of industrial machinery for wood, glass and stone, will be holding their grand opening and Fall One2One event on October 24 to 26 at their new Greater toronto Area showroom and service hub in Mississauga, Ont. this exclusive open house event,

Correction

In the Under the Glass story “Vision and Execution” in August Glass Canada, doug Lilja’s name is spelled incorrectly. Glass Canada regrets the error.

held only a few times a year in the United states and Canada, is a unique opportunity for industry professionals to exchange ideas, gain hands-on experience with biesse and Intermac’s cutting edge technology, as well as consult one-on-one with product managers, each with over 20 years’ experience in the industry.

opportunity to join the Guardian leadership team. “there is a principle at Guardian of adding value every day to our customers and that is a vision I completely share,” he said. “It is only through helping our customers grow their businesses that we can reach our ambitious goals for profitable growth. I very much look forward to the challenge.” Zoulek has demonstrated both technological leadership and a strong commercial track record during a long career at PPG Industries, where most recently he was vice president of industrial coatings for the Americas. he brings renewed focus and emphasis on Guardian’s home base. Zoulek holds a b s in Management Information systems from the University of Michigan and an MbA from Wayne state University.

different items targeted to a base of some 70,000 customers who are served by 62 centres in North America – 35 distribution centres in Canada, 25 in the United states and two manufacturing plants in Canada, specifically Cedan Industries which specializes in the manufacture of a wide variety of veneer sheets and edgebanding products and Menuiserie des Pins which manufactures components for the window and door industry and a broad selection of decorative mouldings.

TRADE WARS

the Canadian glass industry fights back against un

by PATRICK FLANNERY

There are 30 Chinese government programs providing subsidies to Chinese unitized curtain wall manufacturers, and another 142 that may be providing indirect or “upstream” aid, according to the Canada Border Services Agency. The assistance is in the form of direct grants, tax breaks, rebates, awards, passed-through price discounts and forgivable loans. How many Canadian programs are extending similar benefits to your business? The gap between the assistance Chinese exporters receive and that which you receive is what constitutes unfair trade. There is a myth floating around that Chinese companies are more competitive because of their low labour costs. Anyone who has ever tried to staff a manufacturing plant with people from the lowest economic strata, even here in Canada, can see the hole in that story. Poorly educated, disadvantage people with reduced access to life’s necessities do not make good workers. If the Chinese companies’ only advantage were cheap labour, Canadian fabricators would be able to run circles around them in terms of quality and service to the contractor, while still being competitive on price. Instead, about five years ago, Canadian architectural glass companies started to see unitized curtain wall products coming in from China at prices comparable to half-inch window wall. They smelled a rat, and joined together to fight against these practices which were causing price depressions so steep as to threaten the very existence of the Canadian industry. This fall, those efforts bore fruit when the Trade Tribunal reached a preliminary finding that Chinese unitized curtain wall manufacturers were engaging in dumping and being subsidized by various levels of the Chinese government. In response, the CBSA has slapped provisional duties of 30.3 and 36.3 percent on imports from two companies – Jangho Curtain Wall Canada and Yuanda Canada – and 57.3 per cent on all other Chinese importers.

fair practices.

It has also applied countervailing duties to offset the rate of subsidy amounting to 3.1 and 4.6 per cent on Jangho and Yuanda, respectively, with a 34.3 per cent countervailing duty applying to all other Chinese importers. At press time, it remains to be seen whether these tariffs will become permanent. Here’s how we got to this point.

The Canadian glazing industry started to push back against the threat from Chinese curtain wall module imports in 2012 by launching a complaint alleging dumping and subsidizing by 64 Chinese unitized curtain wall manufacturers with the CBSA. The list of nine complainants is a who’s who of the largest companies in our sector. Complaints of this kind are heard by the Canadian International Trade Tribunal, a federal government agency that adjudicates trade disputes on Canadian soil. That first complaint failed on the grounds that the tribunal did not see sufficient evidence that the Chinese unfair trade practices had caused “injury” to Canadian architectural glaziers. According to Paul Arnold of Starline Architectural Windows, one of the complainants in the case, the problem was essentially one of missing information and the investigation was halted on a “technicality.” By January of this year, the group had compiled the necessary documentation and filed a new complaint. This complaint satisfied the tribunal and it ordered the CBSA to begin an investigation into the group’s allegations. The CBSA considered a period of activity lasting

Where is the Canadian building envelope? Unfair trade practices by foreign governments could threaten the very existence of our industry as high-profile projects are snapped up by low-cost overseas fabricators. Photo courtesy of Michael Elkan.

from Jan. 1, 2011 through Dec. 31, 2012.

The investigation stretched into May, and was extended past its initial deadline by the CBSA because of the “complexity and novelty” of the issues involved. According to the 60-page Statement of Reasons issued by the CBSA in July, those issues were:

• the large number of related party transactions between importers and exporters

• unitized wall modules are not sold separately but as part of a building facade project

• each unitized wall module is unique and can only be used for the project for which it is designed

• the time lag between sale and importation

• many unitized modules were imported during the period of investigation for unfinished projects for which payment was not yet received

• the potential for upstream subsidies

• the size and complex nature of the organizational structure of the exporters

It is also clear from the statement that the Chinese government and the exporters named were usually less than cooperative with the investigation. The only response from the Chinese government to the CBSA’s several requests for information was a letter sent March 4, the day the investigation was due to begin, protesting the investigation, claiming the time between the first and second complaints was too short

and challenging the CBSA’s standing in the matter. Since this submission was received well past the deadline for such responses, the CBSA said it did not have to consider it. Of the Canadian importers of the curtain wall in question, only two bothered to reply to the CBSA’s inquiries: Jangho Curtain Wall Canada and Yuanda Canada Enterprises. Of the 64 possible exporters, only Guangzhou Jangho, Shenyang Yuanda and Shanghai Henry Yijian responded. In many instances, the statement reports that the information provided by these companies is incomplete, and request for further information were ignored. Both Jangho and Yuanda declined to comment on the case.

The reference to “size and complex nature of the organizational structure of the exporters” is borne out with a quick look at the companies’ websites. Yuanda, for instance, claims to be the largest curtain wall manufacturer in the world, employing 12,700 people and operating 1.3 million square meters of fabrication plant. It has grown to this size in just 20 years, and has built projects in 35 countries.

The CBSA investigation had to determine two things: whether the exporters in question were dumping goods into the Canadian market, and whether they were receiving subsidies from the Chinese government. Dumping is defined as selling goods at a price lower than what the profitable price would be in the exporter’s home market. So in order to find the Chinese exporters guilty of dumping, the CBSA needed to find evidence that not only were they not making any money at the price they sold their goods for in Canada, but that they also would be taking a loss selling for that price in China. This is an important point, because it belies

the notion that exporters with cheap inputs in their home country are not allowed to leverage those advantages in our market. They can use those advantages. It is only when they are selling so low that they would be unprofitable even in their home market that a charge of dumping is possible.

Before the CBSA could decided if the Chinese importers were dumping or not, it had to determine what price the exporters actually received for the products sold in Canada. This proved difficult, as the importing companies are owned by the exporter. In these cases, the CBSA applies a “reliability test” to determine if the price the exporter reports makes sense in light of the final sale price, less the importer’s costs. For both Jangho and Yuanda, the exporters’ reported prices were found to be “unreliable” - in other words, the price the importer was reporting on its books did not appear to be a realistic reflection of what the product actually cost. Under these circumstances, the CBSA was free to calculate a its own estimate of the real export price using the known price of inputs, sales of similar products in the Chinese market and other methods. Using these numbers, the CBSA was able to determine that the Chinese exporters were selling their products to their Canadian importers at prices far below what they would sell those same products for at home. In Canada, those price points would enable the importers to easily underbid any competing offer from a domestic manufacturer.

The CBSA then delved into a truly intimidating list of government programs funneling money to Chinese curtain wall fabricators through a variety of thinly disguised subsidy programs. The resulting duties from this part of the investigation were relatively small, but still significant in the case of the Chinese importers who did not respond to the CBSA’s requests for information. In fact, if there is a lesson for Chinese curtain wall importers in all this, it is that cooperating with the CBSA is ultimately very beneficial. Jangho and Yuanda will see their imports taxed as much as 25 per cent less than imports from other Chinese companies.

The Chinese importers still have an opportunity to prevent these duties becoming permanent. They have until the date of the final determination, slated for Nov. 12, to submit a written undertaking to revise their prices to remove the reported levels of dumping and subsidizing. Arnold illustrates the seriousness of the situation facing our industry: “We were losing significant projects to inferior Chinese wall modules at ridiculously low prices. We had lost jobs and those jobs are being delivered now, so in fact we are out of that revenue even as we speak. So we lost some work, but probably the biggest, more damaging part is that once they got a few jobs, we just got beat down. Our unit selling rates just got pummeled into the dirt. That is where the real issue has come. The market has been decimated to the point where, if this carries on, there won’t be a domestic market.”

Arnold adds that no one is happy taking this route, and that Canadian fabricators are keenly aware of the pain this may cause their customers. It is to be hoped that Canadian builders will see the larger picture and support the existence of a domestic source of unitized curtain wall for years to come. •

INDUSTRYEVENT

COME ON OUT TO WIN-DOOR

by PATRICK FLANNERY

Is there any reason why an architectural glazier or glazing fabricator would consider going to Win-Door? Well, maybe one or two.

Let’s start with the topnotch educational program. Fenestration Canada’s technical consultant, Jeff Baker, will present a seminar on the Ontario Green Energy Act’s requirements for energy efficiency in fenestration materials. This law applies to everyone who builds with glass, lowrise or high-rise. If you do not attend Fenestration Canada events, you may not be familiar with Baker’s act, but it is a

something for everyone who builds with glass.

good one. He is involved behind the scenes with many of the committees and task groups that actually make the codes and standards we have to follow. Baker’s talk may be slanted toward window and door fabricators, but he will happily answer questions from the commercial side as well.

On the second day of the show, Peter Norman of the Altus Group gives his economic forecast for the Canadian construction sector. He is careful to cover ICI activity as well as singlefamily construction, so there is lots there for the glazier. Last year, Norman didn’t think we were seeing a price bubble in the major metro condominium markets. Let’s see if he still thinks so after a year of unabated construction.

If your brain has not swollen uncomfortably after those two presentations, you can dare to sit in on Bill Lingnell’s talk, Design Considerations for Multiple-Cavity Insulating Glass Units. Lingnell is the Insulating Glass Manufacturer’s Alliance technical consultant, and has forgotten more about engineering with glass than many of us will ever know. Perhaps you were wondering how to calculate gas law problems for ideal gasses using

Boyle’s Law and Charles’ Law. This is your chance to find out.

On the show floor, there are any number of opportunities for glaziers to have potentially profitable encounters. Air-Ins test laboratories is certainly no stranger to the architectural glazing world, possessing a tower capable of mounting curtain wall mock-ups up to 18 by 30 meters and blasting those mock-ups with 170 km/h winds from a Pratt and Whitney DC-6 aircraft engine. Verick is exhibiting at Win-Door, carrying such familiar commercial brands as Henkel, Saint-Gobain, Shurtape, SAS Automation and Bostik. Need a restroom trailer for the jobsite? Check out Ameri-Can Engineering. And of course everyone can use EDTM glass inspection tools. Those are just a few examples out of over 100 exhibitors.

So while Win-Door continues to have a residential window and door focus, it is not a waste of time for the architectural fabricator or contractor. If you have some free time on Nov. 13 or 14, and you are in the downtown Toronto area, drop in to the south building of the Metro Toronto Convention Centre. If nothing else, you can stop at the Glass Canada booth and say hi. •

ABOVE: How about an automated IG line with a TV in it? Win-Door has been attracting more machinery manufacturers lately.

Win-Door North America 2013

Monday, November 11

2:00 PM – 5:00 PM Fenestration Canada Executive Meeting

6:30 PM – 10:00 PM b oard dinner ( by Invitation)

Tuesday, November 12

8:00 AM – 9:30 AM technical services Committee - 713 A

10:00 AM – 2:00 PM Fenestration Canada b oard Meeting - 713 A

5:00 PM – 8:00 PM trade show Opens - h all E

Wednesday, November 13

8:30 AM – 10:30 AM door Pre-hanger Compliance Update Ontario b uilding Code / NAFs - 08 seminar - Education Pavilion

10:00 AM – 5:00 PM trade show Opens - h all E

11:00 AM – 11:45 AM Ontario Energy Act requirements seminar ( bilingual) Jeff Baker - Education Pavilion

Win-Door

Five

Ws

When: Nov. 12-14, 2013

Where: Metro toronto Convention Centre, south building

What to see: vinyl, wood and aluminum window and door components, hardware, insulating glass manufacturing equipment, plant automation, door machining centres, adhesives and sealants, enterprise and production software, full window and door systems

Who should go: window and door fabricators, homebuilders, glazing contractors, window and door distributors and retailers, building engineers, architects, yOU

Why go: find new products, meet valuable business connections, make deals, learn, have fun, support your industry

12:00 Noon Jim Parker b ooth Award - Meeting Centre

3:00 PM – 4:00 PM Win- door show Committee Mtg. - Meeting room 1

Thursday, November 14

8:30 AM – 9:30 AM Fenestration Canada Fall Meeting - Education Pavilion 9:45 AM – 10:45 AM the Power hour - Economic Forecast) with Peter Norman Altus Group seminar - Education Pavilion

10:00 AM – 3:00 PM trade show Opens - h all E

11:00 AM - Noon Updates ( bilingual) on Energy Codes & Energy star Jeff Baker, JF Kogovsek & Steve Hopwood (NrCan) seminar - Education Pavilion 1:00 PM – 3:00 PM Energy Efficiency Fenestration steering Committee - Steve Hopwood / Jeff Baker - 713A

by AL dUECK

Al Dueck is the first vice-president -of Fenestration Canada and president of Duxton Windows and Doors based in Winnipeg.

Membership: an investment in your future

Today’s Canadian window and door manufacturing industry continues to move through an important developmental period and it is fortunate in being served by a revitalized leadership group and organization. This year saw Fenestration Canada launch an Ottawa-based industry office managed by newly appointed executive director Robert Rivard. This office provides an opportunity for strongly focused and effective management of the industry’s priorities. Activities include expanding membership recruitment strategies; creating suitable programming for events, including stronger shows; and fostering ever-important interaction and engagement with industry stakeholders.

Our newly elected president, Skip MacLean, along with a strong executive team of seasoned veterans from all facets of the window and door manufacturing sector, are well positioned to take on the challenges facing our industry. More frequent teleconference meetings for executive committee meetings have allowed a stronger level of communication and achievement of leadership/action items. A greater level of accountability is being developed at the committee level to ensure the industry is well served across a broad spectrum. Ongoing recruitment of candidates willing to give their time and effort to serve as volunteers is beginning to result in a wider and stronger range of membership representation at all levels. New initiatives on membership also have yielded some positive results, including stronger interaction with sister and affiliated organizations in Quebec, B.C. and Manitoba.

Fenestration Canada realized its largest-ever turnout for our annual conference program in

Your company’s membership investment value and results are directly proportional to the time and effort you invest.

St John’s, N.L. The conference featured a lot of excellent interaction and productive discussion. Responding to concerns raised by some members, the executive group launched a Fabricators’ Council initiative designed to attract a broader level of manufacturer involvement and help position fabricator members to take on the challenges of today’s and tomorrow’s market issues surrounding regulations, codes and standards compliance requirements. Lisa Bergeron of JeldWen Canada will chair a fabricators’ council meeting at Win-Door with a group of window and door fabricators who have expressed an interest in becoming involved. Together, they will begin the process of mapping out an action plan that will address the issues. Individual company owners and managers – no matter the size – need to realize and act on the fact that this is a very real opportunity to help determine the direction of their industry and organization.

Fenestration Manitoba will definitely be challenged to match the energy generated in St. John’s as host of the June 2014 AGM in Winnipeg. It is very clear that the annual AGM is proving to be a highly rewarding event where some very close bonds are developed amongst a wide range of industry members. Regular attendees have commented on how rewarding it has been to be able to combine networking with literally seeing our great country coast to coast. And the 2014 Winnipeg AGM will again offer some unique components as it centres upon North America’s “fenestration valley” and attracts some of the unique suppliers and resources of nearby companies. There will be opportunities to experience the infamous Exchange District, the nearby Forks and waterfront, and the monumental Canadian Museum for Human Rights. The 2014 AGM will be held at the Hotel Fort Garry June 11 to 14.

All of this and more can add value to your membership investment. Keep in mind that involvement and interaction leverages your benefits and ensures greater viability for your organization. Your company’s membership investment value and results are directly proportional to the time and effort you invest. We need you!

Merci and see you at Win-Door 2014. •

INDUSTRYEVENT

THE SLEEPING GIANT STIRS

by RICh PORAYKO

Economists presenting seminars at GlassBuild were urging glass businesses to borrow money now to expand business, open new markets, create new products and hire talent. You might want to put off buying that new Corvette for now, but it is a great time ramp up your business over the next 18 months for some serious pentup growth, they said. The overwhelming consensus is that the North American glass industry is out of recovery mode and the sleeping giant is starting to stir.

Evidence of a return to growth at Glassbuild.

Without a doubt, the 2013 GlassBuild America expo held this past September in Atlanta was the biggest and best GlassBuild since Atlanta in 2007. If you compare the size of the show catalogue, 168 pages in 2013 versus 270 pages in 2007, it’s clear that the event, like most businesses, was hit hard by the great recession. GlassBuild is still the single largest glass, window and door event in North America and this year’s show in Atlanta showed that while it might not be 2007, things are getting much better than they have been. The talented folks at the National Glass Association appear to be steering the event in the right direction.

Another sign that things are improving are the number of people on the move. It’s amazing how many professionals in the glass industry have changed employers in the last six months. Combined with bankruptcies, mergers and acquisitions, the face of the glass business is rapidly changing and members of the industry are lucky enough to witness the next chapter of the journey.

Some of the other more interesting chatter at the neverdisappointing Glazing Executives Forum networking lunch was the trend of American general contractors pressuring

glazing contractors to waive their right lien a project if things go south. It will be curious to see how this plays out or if this is makes its way to Canada.

Much of the show buzz was that every large piece of equipment on the floor was sold. It is obviously big for the equipment manufacturers but it also shows that the fabricators who are buying this equipment and are seeing real opportunity in the market and are anticipating growth. It’s also great for the GlassBuild show because there are already high expectations for GBA 2014 in Las Vegas.

Dave Marsden, operations manager for Diamond Sea Glaze, a Langley, B.C., marine window and door manufacturer and direct printing sister glass company DSG Custom Glass, says his team attended GlassBuild in order to bring an increased focus to the glass side of their business. “I’m at GlassBuild because I want to introduce myself to the glass business and find out what products and opportunities are available in terms of improving what we do,” says Marsden. “I also came to look at what equipment and process-related material is available on the market to help us get better at what we do.

“GlassBuild has been a complete eye opener. I’ve got more

ABOVE: Just about every indicator bounced back strongly at GlassBuild 2013. Equipment manufacturers reported every piece of equipment in the building was sold. Photo by Rich Porayko.

out of it than I expected. Every corner is something new and interesting. The educational opportunities, especially the Guerrilla Marketing seminar, have been excellent.

“I definitely want to come back to GlassBuild in 2014,” says Marsden. “Being held in Vegas, I hear it will have a higher representation from the west and have an even larger attendance. Here in Atlanta, most of the exhibitor sales reps and attendees are from the east coast and we need to be interacting with west coast people and get to know those players.”

According to Jeff Dietrich of ITR Economics, who was the keynote speaker at the annual Glazing Executives Forum held during GlassBuild, the timing couldn’t be better for Marsden and DSG. “We do see steady but mild growth ahead,” says Dietrich. “We don’t see anything changing over the next 18 months or so. The operative word is growth. It is not recession. It is a pothole, not a sinkhole. We do see in years beyond that – 2015, 2016 and 2017 – years of tremendous growth. So you have to be thinking long term.”

One of the reasons Dietrich is optimistic about the rest of 2013 and into the first half of next year is that the leading indicator signals are still going up. “The indicators are still showing signs of growth for the next eight to 12 months,” says Dietrich. “Interest rates are favourable. Inflation is relatively benign. Companies have right-sized and are profitable. Housing starts and prices have beat expectations. All of those are signs of a healthy economy.”

“It’s not going to be spectacular. It’s not going to break any records but it is growth, therefore you ought to plan for it. You

Peace Of Mind...

ought to hire and train for it. You ought to take the cream of the crop and prepare for growth in the future.”

Everyone wants to know when interest rates are going to go up. According to Dietrich, they have already have started. “Ben Bernanke, the chairman of the Federal Reserve, has said that interest rates are going to stay low at least through 2014. Maybe into 2015,” shares Dietrich. “Here’s the same message I said last year; you have about 16 months to borrow money at low interest rates. If you don’t want to borrow money at these low interest rates there will be no reason to complain when they go up six, seven, eight or nine percent. Today we have historically low interest rates but they are going to go up in 2015.”

According to Dietrich, for the last two years, the number one and two exports for the US have been petroleum and petroleum products. “The US is a net exporter of oil. We are using two million barrels of oil a day less than we did in 2005 and we are manufacturing much, much more. It’s a good news story. And I know how we can be completely independent of all foreign oil. We bring all the troops home from the Middle East, those countries can keep their oil and we’ll conquer Canada!”

So essentially until Canada is annexed by the U.S., expect slow but steady growth with low interest rates until 2015 when the real growth and much higher interest rates are expected to kick in until another possible major correction in 2018. Best take away of the show, in Dr. Deitrict’s professional opinion and ITR Economic’s cyclical theory, 2029 becomes the next great depression. •

Safety and security are of utmost importance for homeowners, especially those with small children. Truth Hardware has developed an engineered solution which meets ASTM F2090-10, the new industry guideline enacted to address the issues of accidental falls and egress opening.

SafeGard™ meets the following ASTM F2090-10 guidelines:

• Window Opening Control Device limits casement sash opening to 4" or less

• Easy two-step operation to release Window Opening Control Device

• Window Opening Control Device automatically reattaches itself when the window is closed

by bILL LINGNELL

Bill Lingnell has over 46 years of experience in the technical field of glass and architectural products. He holds three Masters of Science degrees in engineering. Lingnell is the technical consultant for the Insulating Glass Manufacturers Alliance.

Complex cavities

The Insulating Glass Manufacturers Alliance has recently released a new document to assist the industry in providing the appropriate technical procedures for multiple-cavity insulating glass units. The document is titled “Design Considerations for MultipleCavity Insulating Glass Units.” A preview of the publication was introduced back in the January issue. I advise you to obtain the entire publication from IGMA to get the complete flavour of the valuable information available regarding this subject.

In order to meet the challenges of current building codes and energy requirements, many designers, architects, engineers and builders are considering multiple-cavity insulating glass units to meet these needs. IGMA has recognized that the demand for increasingly energy efficient fenestration products continues to rise. One method for addressing this demand is by increasing the number of cavities in an IG unit. This method, while effective, does create new challenges. The guidelines presented in the new document are intended to illustrate and discuss many of these challenges and to assist those who design, specify, manufacture and install insulating glass units. The document is not intended to duplicate pre-existing guidelines for single-cavity IG. Rather, it is meant to expand upon those guidelines where requirements for multiple-cavity IG differ from those of single cavity IG.

One of the issues with all insulating glass units is the pressure and temperature changes that occur under various conditions. Recall that insulating glass units perform like pressure vessels and respond to changes in temperature and barometric pressure, and changes in elevation during transportation. IG units are dynamic in nature and the pressure, temperature and volume

Insulating glass units perform like pressure vessels and respond to changes in temperature and barometric pressure, and changes in elevation during transportation.

changes must obey the common laws of physics.

IGMA

As you will remember from your physics class the ideal gas law has some special cases that were related to us by Boyle’s Law and Charles’ Law. Boyle stated that pressure times volume is a constant for an ideal gas and Charles indicated that volume divided by temperature is a constant and thus the relationship for gas-law problems became P1V1/T1 = P2V2/T2. The temperatures have to be absolute temperatures for these conditions. By using these basic physics principles we can solve some of the complex conditions relative to glass stresses, loads on sealants and deflection properties. The glass flexibility has to be considered when determining the volume change and in some nonlinear conditions that part can become somewhat challenging.

“Design Considerations” illustrates many of the conditions we need to consider when analyzing multiple-cavity units. The situation is similar to two lite units with one cavity, however, the additional complexity requires us to give some thought to the variables (glass thickness, cavity dimensions, sealant strength, glass treatment, etc.). Diagrams in the document illustrate well why we need to give careful consideration to all these factors.

These guidelines have been developed from the collective experiences of insulating glass manufacturers, glass and glazing material suppliers, contract glaziers, design engineers, industry consultants and persons experienced in successful IG manufacturing. The document will reflect existing technology and be subject to periodic review and change when new technologies become available, as is the normal process in IGMA.

Coming Events

Oct. 23

Fenestration West burnaby, b.C. www.fen-bc.org

Oct. 28 - Dec. 6

b.C. Apprentice Glazier training - Level 2 Langley, b.C. www.itabc.ca

Nov. 12 - 14

Win-door toronto, Ont. www.windoorshow.com

Dec. 4 - 6

Construct Canada toronto, Ont. www.constructcanada.com

Jan. 6 - Feb. 14

b.C. Glazier Apprentice training - Level 3

Langley, b.C. www.itabc.ca

March 4 - 7

IGMA Annual Conference san Francisco, Calif. www.igmaonline.org

March 5

No Frills trade show toronto, Ont. www.csctradeshow.com

June 11 - 14

Fenestration Canada Annual General Meeting Winnipeg, Man www.fenestrationcanada.ca

June 24 - 25

Profiles Philadelphia, Penn. www.amiplastics-na.com For updated industry event

visit www.glasscanadamag.com > Events.

Azon Saves Energy

IGFABRICATIONSHOWCASE

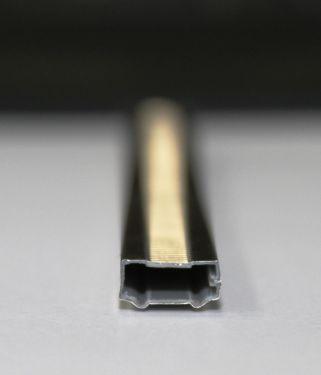

Stainless steel spacers

www.fenzi-na.com

Fenzi North America has added to its product base with the addition of the Chromatech and Chromatech Ultra stainless steel warm edge spacers. Manufactured by roll tech, a Fenzi owned company, these spacers are available with corner keys and connectors for those wishing to bend on bending equipment. With the everchanging need to meet more stringent energy codes, the Chromatech line of stainless spacers provide superior thermal performance to other spacers while meeting the need for better sightline temperatures: in excess of 17 per cent better for Chromatech and over 34 per cent for Chromatech Ultra when compared to traditional aluminum. both Chromatech and Chromatech Ultra spacer’s are available in a wide range of air space widths. the Chromatech Ultra has a polycarbonate bridge across the top, available in traditional white, grey and black colours. Combined with our Fenzi hotver 2000 hot melt butyl, Fenzi thiover polysulphide, Fenzi Molver 3A desiccant, Fenzi butylver PIb and Alu Pro aluminum spacer profiles, Fenzi North America has the range to be a single source supplier for all IG component needs.

Minimizes condensation

www.viracon.com

Viracon’s ExtremEdge warm edge spacer is designed to improve edge of glass U-value. ExtremEdge decreases thermal heat loss of windows, satisfying ever-more stringent energy codes and standards of sustainable design. to meet these requirements, the spacer is constructed with a biopolymer material and encapsulated in stainless steel. these materials reduce the edge’s conduc tivity and heat transfer into the building. In addition to improving U-values, ExtremEdge also results in a higher interior surface temperature than aluminum or stainless steel spacers when measured at the bottom edge of

the glazing unit. the increased temperature improves relative humidity values, minimizing interior condensation. spacers are placed between two or more lites of glass

to provide an insulating glass unit. Viracon offers glass spacers in a variety of materials, finishes, and thicknesses.

Mix of strength and esthetics

www.quanex.com

Quanex building Products’ super spacer triseal is a proven warm edge spacer system used globally to improve the energy efficiency and sustainability of buildings. Made from flexible, silicone foam, super spacer triseal features a unique triple-seal design that incorporates an inner acrylic adhesive seal for immediate unit handling, as well as a polyisobutylene primary seal for enhanced gas retention and low moisture vapour transmission. Customer-applied silicone

specifiers for more than a decade, supplying products and services created for the demands of the commercial market. With a dedicated team of commercial specialists, Quanex is helping manufacturers find the right mix of strength, performance and esthetics for commercial applications.

Custom colours

possible

www.tgi-spacer.com

tGI-spacer is a cold bendable warm edge spacer bar that offers the ultimate combination of thermal performance, high productivity, and value. tGI-spacer is a unique hybrid spacer system incorporating a high-performance polymer and low conductivity stainless steel to provide minimal heat transfer, and maximum protection against gas leakage and moisture penetration. thermally efficient building envelopes of today and tomorrow are critical to energy management, and tGI-spacer’s drop-in solution meets or exceeds the toughest industry expectations in all climates. the tGIspacer is an advanced warm edge solution that meets all relevant quality and safety standards including AstM E 773, AstM E 2190, AstM E 2188, AstM E 2189 and AstM G 154. technoform Glass Insulation does its best to fulfil all customers’ needs and welcomes all requests and customizations. tGI-spacer is currently available in a number of colours including black, white, light grey, champagne, bronze, and dark grey. Custom colours are also possible. tGI-spacer is available in 19 sizes from 1/4- to one-inch widths.

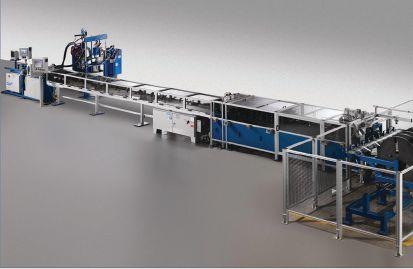

Just-in-time production

www.gedusa.com

the Intercept i3 frame machine from GEd Integrated solutions is designed to reduce material costs and improve unit quality with one complete system. this technology achieves higher energy efficiency ratings and better warm-edge performance. the revolutionary i3 technology platform is even more flexible. It includes a 10-station material uncoiler with automatic width adjustment on all elements with computercontrolled production. It applies a proven U-channel design, with millions of Intercept IG units in windows today. the integrated software permits direct downloading of batch information and the one-piece

Intercept spacer design accepts automatic muntin location punching through the integrated touch screen control station. the one-piece flow design provides 60-second changeover to improve flexibility and lean manufacturing. the i3 system is designed for accurate and consistent high quality throughput with no manual intervention and no manual width adjustment. IG systems produced by the Intercept system boast superior thermal performance, durability and strength. Fabricators can produce IG spacers just in time, in the order required, without operator errors. the system eliminates internal muntin grid wandering with precise notching and snap-

in keys. Integrated components eliminate a separate control cabinet and reduce operator movement. One i3 machine will process multiple metal and sealant options, including dsE, or produce single-seal or dual-seal units. the automatic application of desiccated matrix material ensures maximum performance. Fabricators also appreciate the automatic gas hole punching for single or dual-hole filling and the simple graphical user interface screens that reduce operator errors.

Dynamic drive

www.bystronic-glass.com

bystronic has introducesd the Flexspacertwinapplicator system solution for producing insulating glass with flexible spacers. the flexible spacer is applied directly on to the vertical glass plate. the dynamic drive guarantees an extremely high level of accuracy during this process. the system achieves synchronization of the frame production with the insulating production process. Fabricators can program a production sequence of rectangular or shaped formats as desired. Air cushion support walls provide non-

contact transportation of the glass plates. the Flexspacer-applicator includes storage for four spacer material reels and integrated air drying for the quick change of reels, even during operation. bystronic also offers the Cornersealer for the secure sealing of corners via fixing with tape strips as well as additional butyl sealing. the Cornersealer processes t-spacers via the application of polyisobutylenes on the edge of the spacer on both sides.

by brIAN bUrtON

Brian Burton is a business development consultant and is serving on the Personnel Committee for the CSA’s Certification Program for Fenestration Installation Technicians. His current interests include adaptive reuse of buildings, overcladding technologies, maintenance of the building envelope and the rapidly growing use of computers in construction. You can contact him at brianburton@live.ca or visit his new website at http:// burtons-pen.com

Repair and restore – or replace?

New windows are typically evaluated for performance characteristics in laboratories for structural adequacy, resistance to air and water infiltration, ease of operation, and sometimes resistance to forced entry. Heritage windows are generally expected to meet the same performance requirements when used in full-scale building restoration or renewal projects. Balancing the various options for bringing buildings with heritage windows up to code, which may include restoration and repair or full-scale replacement, requires an assessment of the various costs involved and definitely represents a challenge. Facility managers often wrestle with the need to ensure functionality and at the same time attempt to protect the heritage components.

When evaluating life-cycle costs and functionality, decision-makers need to assess the various costs of creating, operating, repairing and maintaining the units over their expected service life. These costs typically include the initial capital investment, the associated energy costs and the cost of repair and maintenance including access for cleaning.

There will be an investment required regardless of whether the decision is made to restore the windows or to replace them. Even if a designer or building owner decides to replace the windows, there will be a cost involved in removing and/or salvaging the existing windows and installing temporary protection over the openings. Some repairs will likely be required to the exterior portions of the building envelope as well as the interior trim around the window.

Heritage architects are often engaged during early stages of projects in order to consult on the

Once existing windows have been removed and replaced, the decision cannot be reversed.

range of modifications to the original buildings and prepare formal heritage interpretation plans describing the significance and history of the building or site. These plans include a justification for the proposed works, a description of any investigative work required and an assessment of the impact of any usage change. The architect will describe the material to be removed, including its age and significance, and indicate which components are going to be protected. Interested Heritage Committees must be consulted and their feedback included in the plan. The plan also lists the documentation necessary and the skills required to undertake the project.

For large heritage buildings, the range of costs across the various options can be significant. It then becomes an issue of determining the merits of preserving the heritage elements when the cost of either restoration or replacement is considered.

Some of the heritage architects I spoke to pointed out that energy savings resulting from the installation of new windows are often less than those realized from improvements in HVAC equipment, thermal performance of the roof and walls, or improvements to lighting and lighting controls. These same architects said that quite a bit of thought is also given to sustainability, durability, ease of maintenance and repair as well as the ease of operation of the units. In some cases, safety issues must also be addressed.

In many ways, these kinds of assessments can represent subjective evaluations and are difficult to quantify. However, heritage windows are an extremely important part of the building fabric and contribute tremendously to the overall look and feel of a structure. In cases where the windows are part of some significant piece of architecture, professional and skilled restoration of the windows to their original condition would almost certainly be considered good heritage conservation practice. The same would probably be true for stained-glass windows in both religious and university settings.

Once existing windows have been removed and replaced, the decision cannot be reversed. As a result, heritage consultants such as those at the Canadian Association of Heritage Professionals undertake a very thorough and comprehensive review before proceeding. •

by FrANK FULtON

Frank Fulton is president of Fultech Fenestration Consulting. He has been in the industry for 30 years and can be reached via e-mail at fultech.fc@gmail.com

Plan now, save later

Irecently had the good fortune to bump into an old crony, or should I say industry colleague, since women don’t often like being referred to as cronies, or old for that matter either. Yvonne Parker spent many years flogging glass fabrication equipment for Salem Distributing. She is a pioneer in the biz: one of the first women in sales for Guardian Industries and InKan, and also the first female director to serve on the board of the Metro Toronto Glass Association back in the early 1990s.

We got to talking about what’s new in each other’s lives and relationships and as it happens, Yvonne’s significant other and business partner, Craig Simpson, is a financial guy with Personal Solutions Financial in Caledon Village, Ont., who specializes in business succession planning. Well, this tweaked my interest, having gone through a long and involved process during the sale of Fulton Windows to Oldcastle a few years ago, I was well aware of how beneficial having the right information in advance would have been and how planning in advance could have saved a small fortune in taxes.

A large part of our industry across the country is made up of thousands of mom and pop glass shops and sole proprietorships It is inevitable that the day will come when the parents will want to pass the business on to the kids or the owner may want to sell the company to his employees or to an outside interest.

According to Simpson, while many business owners understand their businesses are their largest asset and critical to their financial future, they become so focused on the “here and now” they

Most business owners do not have a planned exit strategy, but rather find one thrust upon them due to illness, family circumstances or economic environment.

yOU bEt yOUr GLAss

fail to do any long-term wealth and business succession planning. As a result financial and tax opportunities are missed, shareholder disputes arise and the ability to provide for their retirement or families is compromised. Though many owners anticipate the disposition of their business will be a critical part of their retirement, there is typically no timeframe until it is too late. Most business owners do not have a planned exit strategy, but rather find one thrust upon them due to illness, family circumstances or economic environment.

It is critical that a business owner look at their own situation and ask “what needs to be done now and how can we improve the upside and minimize the downside?” It may be as simple as reviewing their will to make sure it reflects their current wishes. They may benefit from using something called the multiple will approach in order to reduce probate taxes. (Even though the government calls them probate fees, they are taxes).

Many business owners are entitled to capital gains exemptions, which reduces taxes payable upon the sale of the business. In order to take advantage of this the business needs to be properly structured. This needs to be done well before the actual sale takes place in order for it to be effective from a tax perspective.

Initiating or updating a shareholders agreement is always critical as part of any succession plan when you have multiple shareholders in a corporation. It can alleviate any disagreements that may arise when one shareholder is ready to sell their shares in the company.

An individual pension plan is a great tool to maximize retirement savings and ensure a steady predictable income in retirement years. This is a highly underutilized tax strategy that allows business owners an opportunity to improve their after retirement income.

We’re all up to our eyeballs keeping up with the day-to-day activities of running our businesses, but it is imperative that a business owner proactively manage their exit strategy from their business. It also takes time, so it is best to begin creating a plan long before it will be needed. If you want to investigate further, why not contact Yvonne at Yvonne@personalsolutions.ca. •

NEW! CRL14D DOORS

Showcasing the Largest Selection of Door Systems in One Catalog!

Features over 400 full color pages showing our complete line of doors and entrances for the residential and commercialdoor industry.

NEW! DC14 DOOR CONTROLS

Features over 240 full color pages of our complete line of door control products for the commercial door industry. Included are U.L. Approved Surface Mounted, Overhead Concealed, and Floor Mounted Door Closers, plus related mounting accessories. Order, View or Download both Catalogs at crlaurence.ca