Internet of Things technology may become relevant to building facade design as demands increase for data on energy performance, material longevity, spaces useage and more. Here’s a look at how wireless communications might be integrated into your glazing in the future.

GLASSTALK EPISODE #48

Embodied in Law – Caroline

16 The internet of facades

Microprocessors have advanced to the point where they can be integrated into building materials without significantly complicating fabrication and installation. Treen Hein looks at the latest technology.

22 The data-driven project

The demand for facade data is driven by more than performance and material tracking. New contract concepts will reward subcontractors who can collect and organize more information than ever before.

7 Canada’s Glass Associations

20 Fenestration and Glazing Industry Alliance

21 Fenestration Canada

15 The Engineer By Claudio Sacilotto

26 That’s Rich By Rich Porayko

A new world of sustainable building practices is bearing down upon us, with embodied carbon considerations pushing to the fore. Air/water tightness and insulating factors are so last century. Here to explain it all is Caroline Butchart, a structural engineer with a PhD in structural glass and program manager for the Carbon Leadership Forum British Columbia, a non-profit group assisting the B.C. construction industry to meet sustainable building goals.

EDITORIAL

I was at the Ontario Construction Secretariat State of the Industry conference earlier this year when I heard a disturbing comment. One of the contractors for the Parliament Hill renovation project was delivering an excellent presentation to a room full of mostly other ICI contractors. My interest perked up as he addressed the big new skylight over the West Block. He mentioned the glazing contractor – Seele – and threw in that they had to go to Europe for the work because the capacity to do such a technically challenging project didn’t exist in Canada. When challenged on this premise (by me), my colleague overheard someone in the audience saying, “There’s no way a Canadian company could do that.”

This incident was disturbing on two levels. First, it is apparently the opinion of at least some in the Canadian general contracting community that domestic glass fabricators and installers have some limit to their technical capabilities compared to other parts of the world. If this is wrong, we have a communication problem.

• Great Glazing

• FGIA Summer Conference report

But an even more disturbing notion is that it might be right. If it is, I can’t think for the life of me why it would be so. Canada is not poor. We can afford the most advanced technology in the world. Our engineering programs are top-notch, producing people who do internationally recognized work in facade and glass engineering. Just look at our Great Glazing features (coming in the next issue) for examples of the amazing work our industry does. We are in constant contact with the American market where, one would assume, some of the most expensive and advanced projects in the world are happening. It seems to me that if challenged with a project more difficult than the run-of-the-mill, there are many Canadian companies that could rise to that challenge and learn what they need to in order to get it done. Or am I hopelessly blinded by patriotism?

One narrative I hear frequently is that Europe is way ahead – some use the figure 10 years – in glazing design and technology. Many reasons are floated for this. Relatively expensive oil has driven interest in energy efficiency in Europe for a lot longer than here. Government subsidies for sustainable construction are more common in Europe and have a longer history. Europeans invest more heavily in R&D. European trade schools and unions do a better job of generating workers and engineers with advanced knowledge. Higher prices for land and housing mean owners hold their properties longer in Europe and spend more on them.

I can see where all of this might add up to Canadian companies not making the same investments in product design. But equipment can be purchased and learning can happen. Last I checked, there were flights to Germany and a big show that happens there every year where the latest European technology can be seen. Also, there’s this thing called the internet. It would be sad indeed if our market conditions have created a structural deficit in our capabilities when we have, in my view, people and infrastructure the equal of anywhere else in the world. •

June 2023

Volume 35 • Number 2 Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: 416.510.5113 Fax: 416.510.6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

BRAND SALES MANAGER | Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

AUDIENCE DEVELOPMENT MANAGER | Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

MEDIA DESIGNER | Curtis MARTIN PRESIDENT/COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $85.00 (in CDN dollars)

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

Top Glass, Canada’s trade event for the architectural glass and metal industry, surged back to pre-COVID levels on April 19, welcoming over 400 attendees and vendor representatives to the International Centre in Mississauga, Ont., for an action-filled day of networking and education.

Industry leaders chimed in:

“Top Glass was another great event,” said Brett Lucier, president of Provincial Glass. “We need events like this in our industry and the ripple effect to help each other may not be known that day but past experience has shown me the value of making connections at these events. This year, I took the opportunity to bring along some of my estimators and project managers to give them the chance to come to the suppliers and discuss things that matter most to them. Overall, it was a great day of learning and team building. This is definitely an event I look forward to every year and am excited to watch it continue to grow.”

“It was a really good turnout this year,” reported Andrew Dolphin, general manager at BV Glazing. “Great to see people from eastern Ontario and Quebec and other parts of the country make the trip. I think future shows will be even bigger and better as this momentum in the glass and metal industry continues to grow.”

“We had a great show this year, lots of interest from potential new members and the

amount of traffic that passed the Association Row was impressive,” said Steve Ringler, president of the Ontario Glass and Metal Association. “We truly appreciate the partnership between our two [organizations] and look forward to many more years together. The opportunity to present our awards at Top Glass helps draw attention to both our organizations. Absolutely we wish to continue supporting Top Glass and our partnership.”

Over 40 exhibitors displayed the latest technology for designing, building and installing beautiful glazed facades on a buzzing and busy show floor. Sponsors Flexijet, CRL, Damac Glass, Screenco, Kuraray, Novatech and Mappi affirmed their commitment to Canada’s glaziers and glass fabricators with generous support.

The lecture hall saw about 100 attendees taking in exclusive presentations on wood glazed facade design, glass characteristics and appearance, embodied carbon and the Eaton Centre skylight refurbishment. Presenters poured their all into the content and the quality of the information. Discussions during and after the presentations were lively. Luc Paquet of Unicel Architectural, Heather Sakai of Guardian Glass, Andrew Crosby of RJC, Matthew Firestone of Zeidler Architecture and Claudio Sacilotto of Novatech really delivered some top-notch expertise.

Top Glass 2024 will take place April 17. See you at Top Glass!

TheFenestration and Glazing Industry Alliance has updated a document providing a standard laboratory procedure for evaluation of thermal cycling effects on large exterior fenestration components and cladding by an AAMA Accredited Independent Laboratory. AAMA 501.5-23 “Test Method for Serviceability of Exterior Fenestration After Thermal Cycling,” is now available for purchase in the FGIA online store. In this update, the thermal cycling test method was aligned with the recently published AAMA 501.9 surface temperature assessment for condensation evaluation. The update also includes: a more repeatable and more representative cycling protocol; testing for glass breakage and noise associated with wall systems’ expansion and contraction; and permanent damage caused by thermal cycling. FGIA has also updated a technical information report determining design wind loads on exterior fenestration and cladding systems using national standards ASCE/SEI 7-16 and ASCE/ SEI 7-22, “Minimum Design Loads and Associated Criteria for Buildings and Other Structures.” AAMA TIRA15-23 “Overview of Design Wind Load Determination for Fenestration Systems” provides details for exterior fenestration and cladding systems and covers boundary layer wind tunnel testing and its use.

Post-COVID, the Provincial Glaziers Association of Alberta has turned to addressing the very difficult labour market conditions that threaten our industry in Alberta. The Calgarybased local, the Glass and Architectural Metals Association, has returned to bi-monthly dinner meetings and has presented some highly ranked speakers and some very active meetings over the past few months. The Edmonton-based local, the Glass Trades Association has recently, with some assistance from GAMA had a Try-A-Trade booth at the Skills Canada Alberta event. The PGAA offered a firstyear bursary of $500 to help year-one students bridge the gap between work and employment insurance to help boost enrollment at both SAIT (Calgary) and NAIT (Edmonton). These were delivered in January and March respectively. The PGAA participated in an Alberta government industry round table in April. Many important and contentious issues were discussed. [Find the PGAA’s full report on the round table and its positions on the issues at glasscanadamag.com/community/association news - ed.]

Pictured above is Tracey Oliveira, membership services coordinator, and Noel Marsella , executive director, at the AGMCA booth at Top Glass.

It was great to see many of our member glazing contractors stop by our booth at Top Glass this year. We had some lively discussions with our members, bringing them up to date on items such as the available apprenticeship grants and the women in the skilled trades program. The Architectural Glass and Metal Contractors Association was established in 1979 to provide a strong voice for unionized glazing contractors in the province of Ontario.The AGMCA is the designated employer bargaining agency for all glazing contractors signatory to collective agreements between AGMCA and the International Union of Painters amd Allied Trades.

TheAVFQ held its 2023 Annual Conference at the beautiful Fairmont Manoir Richelieu in the Charlevoix region from April 26 to 28. Again this year, there was a record number of participants with 355 people. The Annual Conference focused on the digital transformation of equipment but also on human resources and how to support them well through these changes. An exhibition of member suppliers made it possible to present the new products as well as the Gala des Prix Lumieres aimed at rewarding projects in seven categories. This major industry gathering is also an opportunity to hold the Annual General Meeting. Frederic Grondin from Robover continues his mandate as president of the AVFQ. Two new directors are joining the board of directors: Nathalie Thibault from Lepage Millwork and Marie-Loup Lalonge from Vitrerie Lalonge. The AVFQ board of directors is therefore

equal in terms of women and men! The scarcity of labour is of course affecting window and door manufacturers and glaziers. The AVFQ has developed a video presenting the profession and thus attracting new people. It was also presented for the first time to the participants of the annual conference.

Spring is typically a busy time for the Ontario Glass and Metal Association and, with COVID restrictions well behind us, we are pleased to be able to get back to our usual program of events. Thank you to our directors, Steve Ringler, Steve Gusterson, April Donvito, Steven Peso, Eric Diotte and Robert Casellini for representing the OGMA at the Top Glass conference in April. During the show, Steve Gusterson, awards director, presented the prestigious OGMA Awards for Excellence in Glass and Metal Design and Execution. Congratulations to Perkins Plus Will for their design work on the York University School of Continuing Studies in Toronto. Congratulations also to Antamex Industries for execution on the new Toronto Courthouse. OGMA presented its first seminar of the year, which focused on the hot topic of first-surface birdfriendly requirements as per Toronto Green Standard, Version 4 on May 18 at the Richmond Hill Country Club. Michael Mesure, executive director of the Fatal Light Awareness Program, and Mauro Carreno, associate andsenior architect at BDP Quadrangle, gave presentations that were enlightening and informative. OGMA is pleased to announce that we have a launched a new OGMA

company page on LinkedIn. Connect with us today to keep up to date on association news, events and announcements. What’s next? We are working on revamping our website and expanding our social media presence. We have several social events planned for the coming months. Watch your inbox or visit ogma.ca to keep up to date on association happenings. If you have any ideas for seminars, educational sessions or networking opportunities, or would like to arrange a plant tour that could be of benefit to our members, please reach out to info@omga.ca. We’d love to hear from you!

May 8, Fenestration Manitoba hosted Robert Jutras from UL Laboratory to give us a presentation on codes. With the information Robert presented, many appreciated the work they completed in their products and just as many were concerned about the need of their organizations to make sure the work for the accreditation of their products was acceptable. Robert’s presentation shared the information in an understandable form so we can continue to comprehend these codes and new ones on the horizon. Fenestration Manitoba continues to inform their membership with knowledge that can be gathered and driven forward through ideas and actions to make the manufacturing of windows and doors more efficient. We make some of the best glazed products in North America. Customers in extreme weather conditions have the products in a climate to prove it.

SteveGusterson, vice-president of Alumicor’s pre-construction design in Canada, was honoured by Construction Specifications Canada with its Life Membership Award. The Life Membership Award is the highest accolade that CSC can bestow on an individual. It is presented in recognition of outstanding service, dedication, support and commitment to the association and the design and construction community. CSC lists only 55 members as having received the Life Membership Award since its inception in 1975. CSC’s executive council and board of directors made the announcement on March 20. The award was presented during CSC Conference 2023, held in Calgary, May 24 through 28, where Gusterson was honoured by his colleagues from Alumicor, CSC and across the industry.

Avi Bar, Alumicor’s vice-president of sales, said, “We join with CSC in congratulating Steve on his Life Membership Award in a career filled with so many achievements. We applaud his exceptional commitment to the educational advancement of the industry. Alumicor and our customers are fortunate to benefit from Steve’s leadership, experience and in-depth knowledge.”

For more than 40 years, architects, contractors and installers have turned to Gusterson for support with their architectural

Sikahas completed the acquisition of MBCC Group. With the transaction, Sika says it has strengthened its footprint across all regions, reinforced its range of products and services across the entire construction life cycle and driven the sustainable transformation of the construction industry further and faster. MBCC Group, headquartered in Mannheim, Germany, and formerly owned by an affiliate of Lone Star Funds, is active in the field of construction systems and admixture systems. To close the transaction and to comply with regulatory requirements, Sika sold MBCC Group’s chemical admixtures assets in the U.K., the U.S.A., Canada, Europe, Australia and New Zealand to the international private equity firm Cinven. The business now acquired by Sika generated sales of over $3 billion in 2022, employs 6,200 people and operates in over 60 countries and 95 production facilities.

“Today is a historic day for Sika,” said Thomas Hasler, CEO. “We are delighted to welcome the MBCC employees to the Sika family. We embark on our exciting journey and will continue to drive Sika’s growth story. ”

Sika will offer a wide and comprehensive range of solutions to enable the sustainable transformation of the construction industry and help customers reduce their carbon footprint. With this transaction, Sika strengthens its growth platform by broadening its product and solution offerings in four of five core technologies and seven of eight Sika target markets. Customers will benefit from an enhanced and more efficient distribution network across all construction markets. The combined group is set to reach sales in excess of $18 billion in 2023. MBCC’s strong main brands Master Builders Solutions, PCI, Thermotek, Wolman, Fire Protectors, Colorbiotics, Watson Bowman Acme, TPH, and Nautec are well established in the marketplace.

aluminum product selections and specifications. He has held numerous roles in his many years with Alumicor. Based in Toronto, he works most closely with design teams and customers located in Ontario, helping them with their commercial building projects. Throughout his career, Gusterson has remained an active member of CSC for more than 20 years and firmly believes in giving back to the design and construction industry. Honouring his “significant and conspicuous contribution to CSC,” Gusterson was inducted into the prestigious CSC College of Fellows in 2021. Nominations for fellowship are received by at least seven people, including a minimum of three Fellows and representatives of three or more chapters. Gusterson’s nomination exceeded all requirements. Gusterson has volunteered on numerous CSC committees and has served as the Toronto Chapter’s chair and director. A Certified Technical Representative (CTR) since 2000, he also has served as an instructor of the CTR coursework for the Toronto Chapter and a member of CSC’s Technical Representative Program since 2012. CSC twice recognized Gusterson’s leadership in Toronto with a Chapter Award of Merit (2009, 2013) and twice presented him with a Programme Director’s Award (2014, 2022) for his contributions to the education program.

Karl Lenhardt, founder and managing director of the former Lenhardt Maschinenbau (now Glaston Germany) in Neuhausen-Hamburg has passed away at the age of 82.

“Glaston Corporation and employees mourn the loss of a down-toearth, conscientious, responsible and visionary entrepreneur,” says Anders Dahlblom, CEO and president of Glaston Corporation.

Dietmar Walz, senior vice-president of Glaston’s Insulating Glass business unit, adds, “With Karl Lenhardt, we are losing a personality for whom people were always at the centre of his thoughts and actions. For him, the company’s success was based not only on his inventive thinking but predominantly on the personal commitment and expertise of his loyal, long-standing employees.”

Lenhardt went into business in 1966 at the age of 27. Thirty-six years later, on the occasion of his retirement in 2002, he would hand over a medium-sized mechanical engineering company with 300 employees at the time, which is still considered one of the world market leaders in the field of glass processing. He is considered one of the pioneers in glass processing today. The current process for manufacturing insulating glass for windows and facades was developed by him. More than 150 patents were based on his inventive genius, including the TPS technology he introduced to the market in 1995.

TheOntario government is preparing young people for in-demand and well-paying careers by allowing students in grade 11 to transition to a full-time, skilled trades apprenticeship program. Upon receiving their Certificate of Apprenticeship, these young workers can apply for their Ontario Secondary School Diploma as mature students. At a time when the province continues to face historic labour shortages, this change means that more students will be able to enter the trades faster than ever before to help build Ontario.

“These changes provide students with exciting pathways to goodpaying jobs and rewarding careers and support our government’s ongoing work to attract more young people into the skilled trades,” said premier Doug Ford. “Whether it’s enhancing trades education in our schools, breaking down barriers for newcomers or upskilling workers, we’re leaving no stone unturned to train the skilled workforce that will build Ontario.”

In the construction sector alone, 72,000 new workers are needed by 2027 to fill open positions because of retirements and expected job growth. To help deliver the province’s infrastructure plans, including building 1.5 million homes by 2031, more people are needed in the skilled trades.

“For far too long, parents and students have been told the only path to succeed in life is by going to university, which is simply not true,” said Monte McNaughton, minister of labour, immigration, training and skills development. “When you have a career in the skilled trades, you have a career for life. Our government will continue to provide students with the tools they need to land well-paying and life-long careers.”

Additionally, the government will begin consultations in fall 2023 with employers, unions, education stakeholders, trainers, parents and others about ways to make it even easier for young people to enter a career in the trades. This includes the potential of lowering entry requirements for some of the 106 skilled trades that currently require a grade 12-level education.

“To ensure all students can get ahead in this province, we are accelerating pathways from high school to apprenticeship learning and ultimately, a career in the skilled trades,” said Stephen Lecce, minister of education. “Our government’s mission is to fill the skills gap by better connecting Ontario students to these good-paying jobs, helping many students who may not have graduated now gain a credential that leads them to meaningful employment.”

“Skills Ontario applauds the government for its continued investment in building Ontario’s workforce of the future.,” said Ian Howcroft, CEO of Skills Ontario. “This latest initiative will support and help young people after grade 10 to better enter an apprenticeship to start their career. With enormous and growing skills shortages, it is imperative that we continue to introduce innovative solutions and pathways that will assist young people who are interested in careers in the skilled trades.”

“This is an exciting announcement,” commented Ian Cunningham, president of the Council of Ontario Construction Associations. “I look forward to the consultation scheduled for the fall of 2023 that will consider lowering the grade 12 requirement for some trades. It’s an important consideration especially as it applies to older apprenticeship applicants with the life experience and aptitudes for the trades but who lack high school graduation.”

In March, British Columbia’s zero-carbon buildings community recognized a group of properties that have demonstrated leadership in producing minimal carbon pollution from their component materials and during their construction. The inaugural BC Embodied Carbon Awards, hosted by the Carbon Leadership Forum British Columbia took place on March 30. CLF British Columbia, a program area of the Zero Emissions Building Exchange (ZEBx) and part of the Metro Vancouver Zero Emissions Innovation Centre (ZEIC), is B.C.’s centre of excellence in low-carbon building design. A capacity crowd, in excess of 100, packed into the events lounge of Steamworks Brewpub on Water Street in Vancouver. The awards were introduced by Peter Robinson, chair of Metro Vancouver ZEIC, alongside city of Vancouver councillor, Adriane Carr, also a ZEIC board member. The awards were presented by George Heyman, minister of environment and climate change strategy and Caroline Butchart, CLF British Columbia program manager for ZEBx. More than 25 organizations sent in entries with the awards split into five categories, each with buildings located in Vancouver and in the wider province.

Winners

Small Buildings – Vancouver Third Space Commons, Third Quadrant Design

This project at UBC’s campus, with input from a student design team, is a first, using an existing single-family home that will be deconstructed and the materials and systems re-used from the original building.

Small Buildings – British Columbia Inlet View, Carbonwise

This is a single-family home where the client went beyond regular construction standards.

Large Buildings – Vancouver 365 Railway, Perkins Plus Will

This is a mass timber addition of four storeys to an existing two-storey concrete building originally built in 1949.

Large Buildings – British Columbia Discover Montessori, Checkwitch Poiron Architects

This is a project to build a school located in Nanaimo, B.C.

Commitment to Change – Public, not for profit organizations

City of Nelson

Commitment to Change – Private organizations

EllisDon

by TREENA HEIN

As most of those in the glass and general construction sectors are aware, embodied carbon restrictions for buildings are coming down the pipe. These are restrictions on the carbon dioxide emissions produced in making various building components, as well as emissions involved at end-of-life for disposal (or perhaps recycling or reuse). Generating those limits, staying within them, designing for them and achieving certifications related to them – all of this requires what’s known as a life cycle analysis of building components and even entire buildings. LCAs trace the entire picture, from beginning to end, in an attempt to create a holistic picture of a product’s contribution to climate change.

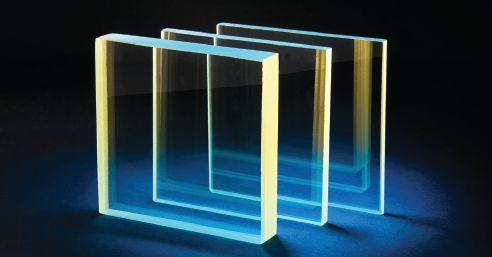

To do any analysis requires data and the more detailed and comprehensive the data, the better the analysis will be. With facade-building LCAs,

glazing firms will be required to provide all the data they currently have on hand. But for complete traceability, they also may be required to integrate data-collection into their manufacturing and perhaps installation processes – and maybe even into facade systems themselves.

Matteo Giovanardi at the Polytechnic University of Turin in Italy, with colleagues at Delft University of Technology in the Netherlands, recently published a study on gathering facade traceability data. As they explain in their paper, traceability data

is useful for carbon analysis and the related circular economy: where components or materials that have reached end-of-life are re-used or recycled, where possible, in a circular continual fashion. This matters in terms of embodied carbon restrictions because carbon emissions are reduced in circular economy frameworks compared to conventional frameworks that involve continual use of virgin materials. A circular economy framework can only be effectively applied to facades when we know where and how the aluminum frame, glass panel and insulation materi-

ABOVE: Italy’s Permasteelisa used RFID tracking in the production and delivery of components for the Elba Philharmonic in Hamburg, Germany. The company says it is now attaching sensors to all its components in all its projects and looking at expanding how it uses integrated wireless communications for a variety of purposes.

als were made, where they were used, and how they got where they are. Giovanardi and his colleagues note that, in general, availability of this data right now in the facade sector is poor and siloed and that over 90 percent of it is simply stored and not used.

The question of why there just isn’t much effective sharing of information is one that Giovanardi and his colleagues put to their industry focus group. Giovanardi reports that all those people interviewed within the group expressed no interest in sharing information. He notes also that “information is often confidential and bound by commercial agreements” and that industry members “provide data only for regulatory compliance.”

New sensor systems can help in data gathering. Various sensor systems across many industries are enabling gains in process efficiencies, better decisions, improvements in product development and much more. The facade industry need not be an exception.

Much data about the building envelope

can be gathered using Internet of Things (IoT) wireless sensor technologies. In their study, Giovanardi and his colleagues clarified the value of traceability data for facades. It identified 12 types of information crucial for facade traceability and analyzed five main opportunities to use IoT to get that information and mapped traceability data flows.

Beyond traceability (gathering and keeping information for compliance, certification and more), IoT can also serve a monitoring function in terms of facade components or entire facade performance. IoT systems can also engage with building users, he says, offering them the possibility to connect with the facade for security or other purposes.

In the context of gathering, storing and sharing facade traceability information, Giovanardi and his team concluded RFID sensors and tags can be useful. “In the facade sector, RFID could be used as ‘smart tags’ for supporting logistic activities and maintenance,” he says.

RFID tags, whether passive (no battery)

or active (battery-powered), require the use of a reader (a device that activates the tag and reads the data on the tag) that must be within about 40 feet. RFID is widely used in shipping to track movement of goods or to activate processes. For example, fob RFID keys, when brought near a door or machine, automatically trigger or enable the lock to open or the machine to start.

In a shipping context, with façade components for example, a skid’s RFID tag is read by the nearby reader and the associated software pulls up where it originated, where it has travelled and on what dates. Information can be added to the tag file continually.

Giovanardi notes that Permasteelisa tested RFID tag use in creating the stunning facade of the Elba Philharmonic upper building located at the waterfront in Hamburg, Germany, built atop a very large and plain brick factory. This facade, which includes hundreds of curved glass panels, has been described as “a gigantic, iridescent crystal, whose appearance keeps

12 ways enhanced tracking helps

Whether using RFID or other wireless communications technology, there are at least 12 ways that integrated sensors and data transmission in building facades might help both contractors and building owners.

1. Asset contract

Imagine being able to ask a broken component when it was purchased and for how much; what its product name is; who sold it; and what the warranty and serial number are – and do it right there on site with a tap on your phone.

2. Service contract

Substantial losses in both performance and money happen every year because facade components are not properly maintained or replaced at the end of their useful lives. Tracing technology can deliver a maintance schedule for components and alerts for service staff, then log the work done. Then the longevity of the component can be assessed to help determine its value. Don’t just say you deliver well-built, long-lasting glazing...be able to prove it with data.

3. Technical features

Facade typology, dimensions, weight, frame materials, glass spec – all these can be attached to readable technology or at least stored in a local database for easy recovery. Having the information on hand makes life a lot easier when it comes time to design renovations or upgrades.

4. Guides and instructions

Installers don’t always read the instructions anyway, but at least they can be readily available if a chip on the part can send it to their phone. With the proliferation of mechanical features on advanced facades, easy access to operation, maintenance and installation instructions can be crucial.

5. Performance declaration

What’s the U-value of that IGU? Embedded technology can record testing and performance data that can be used to analyze building performance and design renovations and upgrades. With a better database, data from individual components can be drawn together to get a picture of the whole envelope performance.

6. Certifications

Building inspectors need quick access to labels certifying component compliance. Tracing data systems can provide that and prevent commissioning headaches.

7. Supply chain

In the coming age of embodied carbon measurement, where a product comes from and what went into making it will be critical information. Information stored and transmitted from tracing technology can give the whole picture from where the product originated up to the present.

8. Logistics and construction

Accurately tracking product through production to the jobsite is a challenge. Chipping and coding product is a solution. Then the data can be used afterwards to improve processes and remove bottlenecks.

9. Operational and management

Facades that collect data about use and occupation can inform property owners as to which parts of their building are performing better or worse and guide maintenance

and upgrade decisions. For instance, sensors might detect rooms that are being heated unnecessarily without the lights on, indicating energy wasted on unoccupied space.

Longevity, disassembly instructions and disposal are not just going to be the waste disposal contractor’s concern in the years ahead. When a product is judged on its complete life cycle from cradle to grave, information on how to destroy, recycle or re-use it will be needed and could be provided by attached tracing technology.

More and more, facades are being asked to do more for the occupants. Architects are looking for systems that can deliver a specific

All components eventually wear out and tracking their lifespans, disposal and replacement carbon costs will be demanded by property owners in the future.

experience tailored to the building use. This requires integrated control of light and daylighting, shading, ventilation, HVAC, humidity and more. Facades that can collect and transmit data are critical to achieving these spaces.

Improvement is a process of looking at what has been done and seeing how it could be done better or differently. Collecting data on the performance of any system is a necessary step.

As mentioned, the study lists a dozen areas where collecting more traceability information would help with facade LCA. In terms of what a facade provider might do or have to do in the future to collect this information, Giovanardi and his colleagues point to a “facade passport” as a possibility.

This would be similar to a material passport, defined by Giovanardi as “a data set describing the characteristics of materials and components in products and systems.” They are being considered as a key strategy in European policies for promoting the reuse and recycling of building products. This is aimed at tracking material sources, recording their manufacturing processes and preserving this information over time, enabling a greater value for complex and long-lasting building components such as building facades. Giovanardi adds, “this would be a unique information framework where whole life cycle information can collected and make it available to different stakeholders. The main issue is to organize different data to be able to exploit useful information from it.”

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass

• SentryGlas Lamination

• Opaci-Coat-300 Spandrel

However, at this point, Giovanardi says using facade life-cycle traceability information and employing a circular economy for facades “is possible but still a long way off.” One challenge is technological, in that facade components are not generally designed for disassembly. That is, they are not designed so that the components at the end of facade life can be taken apart efficiently for re-use or recycle. It’s also costly to deal with facade components at the end of life. Giovanardi adds, bluntly, “facade producers today have no interest in managing facade end-of-life.”

All these issues lead him to conclude that new business models must be developed to support the transition to circular thinking. “For example,” he says, “a ‘facade as a service’ concept.” In this approach, the facade would be provided by the manufacturer to the building for its lifetime but remains technically owned by the facade manufacturer and is reclaimed once a building has reached end-of-life.

However it is achieved, Giovanardi and his colleagues believe that storing facade information in a common, life-cycle oriented framework accessible to multiple actors is important going forward – and they assert that “facade manufacturers, being the central players in the system, have the task of driving this transition.” They conclude that “greater and more detailed knowledge of the materials in use could facilitate the creation of circular systems and the definition of government guidelines and incentives tailored to the real demand of the existing building stock. Advances in IoT and lessons learned from other industries in the use of RFID technologies to manage large data sets with limited cost and time allow us to imagine future scenarios.” •

by CLAUDIO SACILOTTO

Building design is about to go through a revolution. Construction methods and materials are being looked at differently than in the past. Improvements in operational efficiencies have been performed for many years but now their strategies will go beyond efficiency and take a more holistic approach to climate-friendly construction.

As a society, we’ve acknowledged the issue of climate change and have done much on improving energy efficiency in our daily lives with the intention that there will be less carbon dioxide emissions. Our building codes require us to design ever-more insulating envelopes. But is this enough? Have we reached a plateau where the law of diminishing returns reveals that we’ve done the most that we can? Perhaps we need to rethink everything and get back to understanding what the real issue is. We need to prevent accelerated global warming due to the accumulation of various greenhouse gases (most notably carbon dioxide) in our atmosphere. So the real issue is carbon release, wherever it comes from, not necessarily just from energy production.

Processes or materials that do not use fossil fuels do not significantly add to the carbon dioxide content in the atmosphere. This means that energy production through hydroelectric generation, solar power, wind power or even nuclear power does not add carbon dioxide to the atmosphere. Note, we’re not talking here about whether the energy source is overall “green,” but strictly about its carbon emissions. To beat this thing, the ultimate goal is to become carbon efficient.

What is becoming more concerning is the carbon footprint of the materials being used to construct buildings.

Structures are now being built with a “net-zero” approach in mind. However, as we’ve made buildings and their components more energy-efficient, what is becoming more concerning is the carbon footprint of the materials being used to construct those buildings, which can include concrete, steel, glass, and insulation. The carbon footprint associated with the mining, processing and transportation of raw materials; the manufacturing of the product; the transfer to the jobsite; and the construction process, all combined, is commonly known as embodied carbon. All these materials and processes are ringing up a large carbon footprint even before the building has completed its construction. It has been calculated that, worldwide, embodied carbon accounts for 11 percent of the world’s carbon emissions. Until we address embodied carbon in a significant way, we really cannot “net-zero energy” our way out of the climate crisis. What does that mean for the construction industry?

Architects and designers are now considering embodied carbon in their designs. There is increased scrutiny of the source of materials used. For example, off-shore aluminum is calculated to have a higher carbon footprint than Canadian-produced aluminum, where smelters use hydroelectric power to make aluminum billets. Environmental product declarations for project materials are increasingly being requested from suppliers to account for carbon footprints for environmental certifications. Additionally, traditional building materials are being supplanted in favour of more climate-friendly alternative materials. For example, there is accelerated growth in mass timber construction in North America and Europe, much of it being used to replace concrete and steel for structure construction. Even construction techniques are evolving, as many construction projects are monitoring the carbon footprint of the construction process. Specific measures can include reducing the amount of transportation that is needed to get materials to the project site, using green fuels and taking steps to improve the fuel efficiency of equipment on the site.

It feels like these changes are being rushed, but to fix this climate issue before it’s too late desperate changes are needed. The revolution is here. •

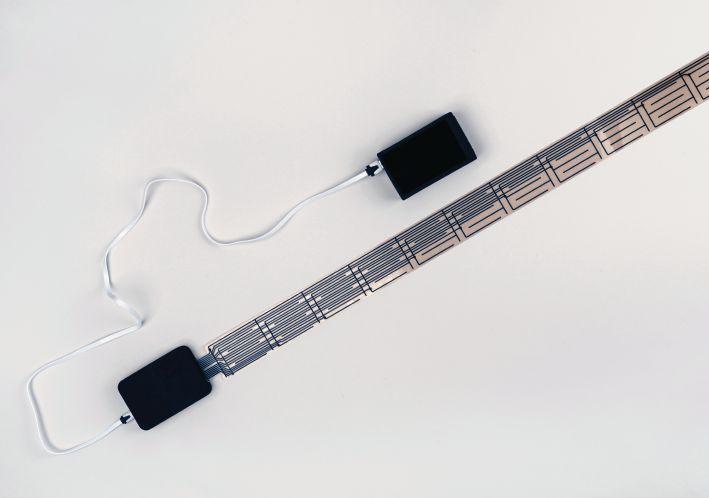

Microtransmitter technology has reached the point where sensors that communicate wirelessly can be installed almost anywhere without wiring or difficult power hookups. Here’s a water-sensing “smart tape” from Laiier.

Internet of Things (IoT) technology to monitor things like appliances in the home and pumps in manufacturing plants is now well established. Without further ado, let’s take a look at IoT developments in facades and other building components.

The potential exists for wireless sensor systems to be installed in the building facade, monitoring conditions like air pressure, electrical resistance, moisture and temperature and reporting leaks to maintenance teams as needed. Research models have been created exploring the many applications. At least one major European glazier is already using sensors to detect the rate of heat loss in different areas. Future installations could compare the performance of two different types of facades or glass in different buildings in terms of heat or acoustics.

Let’s first look at “Comparative Analysis of Technologies Used in Responsive Building Facades,” published by a team including Negar Heidari Matin, director and founder of the new Oklahoma University High Performance Interior Architecture

Laboratory (an interdisciplinary research team spanning interior architecture, building science and advanced building technology). In the analysis, scientists note that facade sensor setups could have central or decentralized sensors and could also include material sensors. When asked for an example, Matin notes that some types of smart glass “can detect moisture and unacceptable temperature changes.” Also known as switchable glass, dynamic glass and smart-tinting glass, smart glass is able to change its reflective properties to darken and prevent sunlight and heat from entering a building and also provide privacy. Active smart glass technologies include electrochromic, liquid crystal and suspended particle. Passive versions include thermochromic and photochromic technologies.

In a study from Italy called “A SubZonal PMV-Based HVAC and Facade Control System for Curtain Wall Buildings,” the team created an experimental test room in a building with curtainwall where infra-red sensors were used to measure and separately control different sub-zones

of a room to regulate the heating, cooling and light level. A new facade module was developed to integrate sensors and actuators, with dedicated housing for hardware and cabling. The modules were composed of double pane windows and aluminum frame with thermal break. The overall control system included a distributed sensors and actuators network, also embedded into the facade modules, to measure indoor and outdoor parameters and to regulate fan-coils, windows opening and shadings with a subzonal approach.

Last year, a group of scientists in China published a study where optical fiber sensors were used successfully to monitor and analyze curtainwall deformation that can occur over time due to aging materials, corrosion and loosening of fasteners. Sensors based on fiber optics provide excellent sensing performance and can function in remote and harsh environments. They are also cost-effective, very small (the size of a human hair), lightweight and immune to electromagnetic interference.

Jerry Kestenbaum, founder and CEO of New York-based Aware Buildings, provides his thoughts about how sensors could be placed inside facades. Aware Buildings employs mostly water leak but also other types of IoT sensors (temperature, humidity, air quality, acoustic) to alert building managers so they can act quickly to deal with issues.

Kestenbaum first notes that today’s sensors can be programmed to take readings and report in a wide variety of ways. “They can do whatever you like,” he says. “They can detect and report on a full range of data or just specific data at chosen intervals. They can take readings and relay them all or only relay when the reading is outside of range, known as anomaly reporting.

To confirm that it’s a real and significant anomaly and not just

Leak-detection technology has become incredibly sensitive and convenient thanks to sensors like this that communicate with smart phone apps, probably saving millions in damage in commercial buildings every year. But sensors can grab lots of other data too on things like temperature, frame deflection and humidity.

a momentary fluctuation of site conditions, the sensor can be set to do edge detection algorithms, such as gathering an average of several readings over a short interval and acting on the resulting average anomaly. There is skill in designing sensors that do edge computing and alerting, though. Kestenbaum adds that if you only have the system set for anomaly readings, you also need the sensor to regularly relay a proof-of-life: a heartbeat reading, as it’s called, to show it’s still working and still connected to your systems.

Looking at how wireless sensors would function in facades, Kestenbaum notes that they would need to relay signals over distances but also may have to penetrate through various building materials, which means the signal must be stronger while at the same time not drawing excess battery energy. ”We watch new developments closely in terms of power and range and redundancy, and there has been great progress,” he says. “There’s a range of technologies that have been tried. In terms of distance, with the right ones you can now achieve distances from a hub to wireless sensors of hundreds of feet and often across several vertical floors, especially in open spaces like a floor in a commercial building.”

Advances have also been made in batteries and power con-

We are pleased to announce Mr. Colin

With a combined 30 years of manufacturing, commercial and fenestration industry experience, Ms. Lakevold and Mr. Wiebe have worked collaboratively in senior level positions at All Weather Windows for the past 10 years.

As Co-CEO’s, Mr. Wiebe and Ms. Lakevold’ s complementary skill set will help forge the future of All Weather Windows. Through a collaborative leadership approach, they will drive the organizations strategic vision forward delivering exceptional value to customers and stakeholders.

Power supply is one concern when it comes to integrating sensors into facades. Designing with access to batteries in mind may be necessary.

sumption. “We use specialized long-life batteries that last over 10 years,” says Kestenbaum. “Sensor components can be selected that use very little power, such as those that measure for temperature and humidity. And the technology has become very smart about sleep cycles that can be engineered into the sensor firmware, which means they only use power when programmed to wake up and take a reading.”

However, at some point, any sensor attached to or within a facade could require servicing or fresh batteries. Because the sensor could be installed out of arm reach, you’d need a way to take the sensor out of its bracket, bring it to the maintenance person for a battery change and place it back. “I think the best approach would be to outfit the sensor with a magnet and use a magnetic snaking tool for remote grabbing,” Kestenbaum says. “If needed, you’d include a very inexpensive scoping camera on a wire with a light to the end of the grabber in order to see what you are doing.”

Kestenbaum also notes that power-over-ethernet (PoE) could be used to power facade sensors instead of batteries. It’s a method of providing both power and networking to a device via data network cabling, and very suited to powering low- to medium-power devices that can make use of both power and connectivity in a single cable. PoE can power sensors even 1,000 feet away.

Wireless printed sensors and sensor cables could be used in facades to detect moisture at the seams and are indeed designed to detect very, very small amounts of moisture. For example, Laiier offers its Severn sensor array printed using Henkel conductive ink that can detect as little as two drops of water. These types of sensors are also made by companies such as Alliot, AKCP and Alta. As stated in a Laiier company blog entry, “sensors like this cover a specific area where leaking might occur. This might include roofs, flooring and in and around the pipe infrastructure of your building. Printed sensors have a thin, flexible form factor, often using adhesives so they can be easily installed in any size or shape. Sensor cables achieve a similar goal, albeit with less flexibility. As the name suggests, they enable you to install different sensors in hard-to-reach places by cable.”

In December, Laiier announced a partnership with Henkel to develop more novel printed electronics and enable more use of Laiier´s Severn water leak detector in commercial and industrial buildings. Henkel’s range of Loctite inks for printing electronics include silver, carbon, dielectric and other non-conductive inks, as well as silver/silver chloride inks. Beyond water detection sensors, the company’s inks are also suitable for a wide variety of sensor technologies, including self-regulating heating, pressure sensing or printed antennas. The Severn water leak detector is the world’s first smart tape and combines printed carbon and dielectric inks from Henkel with electronic hardware and digital services. It’s thin, conformable, self-adherent and designed to work throughout the building envelope. The tape is easy to install by an untrained professional, applicable to various surfaces and highly sensitive with a large coverage area. The sensors are split into multiple sensing zones in order to identify the precise location of a leak.

In the coming world of increased demand for data acquisition from building facades, glass and metal fabricators will need to become familiar with integrating sensor technology into their designs. Italian fabricator Permasteelia now uses RFID transmitters in all its installations. •

Patrick Flannery

Fenestration Canada debuted its new commercial division with a panel discussion titled Commercial Pain Points at its Spring Conference in Kelowna, B.C., on May 24. The discussion focussed on several topics of particular interest to architectural glazing contractors and glass fabricators and represented a departure from FenCan’s usual fare aimed at residential window and door manufacturers. Many interesting points and insights were raised and one left with the impression the conversation could have gone on for much longer...as no doubt it will at future events.

On stage were Jonathan Adams, COO and partner at Layton Consulting in Surrey, B.C.; Brent Friesen, president of Baywest Glazing in Langley, B.C., and chair of FenCan Commercial; Jeff Makimoto, Fen Can’s commercial technical director; and Rich Porayko, commercial business devel opment director for the association.

Adams set the table with a presenta tion explaining structural glass standards covering balustrades, building guards and safety glass and pointing to several mis conceptions and misuses of them. The standards under discussion were CAN CGSP 12.1; CAN CGSP 12.20 M89, ASTM E1300 and CSA A500. Adams’ big point was that there’s a lot more to safety glazing than is covered in the standards.

“The safety glazing standard is fo cused on one key part of safety and one part only,” he explained. “That is reducing the likelihood of injury to a person when when they’re interacting with glass. The standard also does not address strength, or durability, or fire-rated things.”

Another part of Adams’ presentation that was of particular interest to glazing contrrac tors was his discussion of the roles of the Registered Professional of Record and Sup porting Registered Professional on a project. Briefly, the RPR is the architect or lead en gineer with final responsibility for certifying construction as complete and to plan, and SRPs are one or more professionals to whom

the RPR might delegate authority for checking aspects of the project and reporting on their readiness. It’s a fairly simple system in concept, but Adams addressed the many issues that arise in practice.

“Some of the things that we often come across are the subcontractor maybe doesn’t know who the RPR is,” Adams said. “The RPR doesn’t know who the SRP is or the subcontractor. This is what we commonly see, this is just the way it has been in many cases. The subcontractor doesn’t notify the SRP of the installation progress until the installation becomes complete. And then the RPR asks for the documents. Well, a field review has to be done. And if we can’t go on site to see things like

fasteners because they’ll cover it up with with trim and things like that, then how can we provide these documents? So it’s really in the glaziers best interest to, early on, make sure that you know if an SRP is required, who the RPR is, and to make sure that that the SRP is getting on site to review your proof for your project so that you don’t have to start tearing stuff out after the fact. I think my advice would be just press whoever is hiring you to figure out who those individuals are so that we can at least ensure that somebody is taking responsibility, right? The architect may say, ‘I don’t need supporting professionals,’ but it’s up to him to make that call, not the contractor.”

by AMY ROBERTS

Because the Fenestration and Glazing Industry Alliance is committed to addressing issues within B.C. that are of high importance to commercial glazing contractors and residential window manufacturers in addition to glass fabricators, specifiers and engineers, speakers at the April 12 FenBC Region 2023 Industry Summit featured content for both of those sectors. Sessions covered topics specific to British Columbia including how to manage price escalation in the commercial contracting sector; an overview of available rebate programs for residential window replacement; and insight into the work being done by WorkSafeBC. The popular Code Talkers panel discussion and an introduction to devices for window fall prevention also generated engaging questions and commentary from participants. Plus, we were very pleased to have proudly honoured Zana Gordon, former FenBC executive director, who retired from the industry in 2022. Overall, the virtual event was a success for the region.During the commercial track session, Tyler Galbraith of Jenkins Marzban Logan presented “Managing Price Escalation and Other Contract Considerations” and gave general legal suggestions for managing expectations, understanding contracts and the importance of documentation on a project. “Since the pandemic, price escalation has been significant when it comes to the cost of construction and related materials. In B.C., the court isn’t going to help you out of a bad deal,” he noted. Galbraith talked about two common types of escalation clauses: delay or event-based, and threshold or percentage-based. In any event, he stressed the importance of keeping the counter party appraised of any issues so they may help mitigate them. Give written notice, he said, not just verbal.

The FenBC Region Industry Summit featured content for both residental and commercial audiences.

Those with more residential interests learned about leveraging B.C. window replacement rebates within the sales process and the Home Performance Stakeholder Council contractor network qualification for their installer teams. This was led by co-presenters Grant Moonie of the B.C. Ministry of Energy, Mines and Low Carbon Innovation and Greg Bloom of the Home Performance Stakeholder Council. “CleanBC Better Homes and the Home Renovation Rebate Program is an integrated offer of financial rebates for residential customers looking to make energy efficient upgrades to their homes. The program’s goals are to help people conserve energy and make their buildings healthier and more comfortable and to accelerate retrofits that help households reduce greenhouse gas emissions and energy use,” explained Moonie. One important requirement for this program is that the installer needs to be part of the Home Performance Contractor Network, which is a database of retrofit contractors in B.C. that meet specified trade designation and training qualifications and are subject to ongoing review and quality assurance checks. Companies registered in the HPCN are required to submit business documentation, submit references, agree to a code of conduct and complete industry best practice training.

The Code Talkers panel discussion addressed changes within the Part 9 residential building code requirements and Part 3 commercial building code requirements. Another session featured a panel of industry experts who discussed window fall prevention as well as the requirements for window-opening control devices and challenges and considerations for balancing fall prevention with emergency escape and rescue in B.C. and national codes.

During the opening remarks of the summit, FGIA FenBC Region leaders commended the career of Zana Gordon, who was presented with an award, a bouquet of flowers and a tribute video from her colleagues and peers.

Two more FenBC-related events will be happening in 2023, including a FenBC-sponsored session at the FGIA Summer Conference this June as well as the in-person FenBC Region Technical Summit in Surry, B.C. on Oct. 18. •

by RICH PORAYKO

Rich

Porayko is business development manager, commercial, for Fenestration Canada

We’re halfway through 2023 and FenCan’s Commercial Chapter is growing rapidly. As our membership continues to rise, Fenestration Canada’s commitment to developing innovative and impactful value remains strong. We are excited to announce Isabelle Clewley has joined our team as Member Services Advisor. Isabelle’s enthusiasm and expertise will be an incredible asset to our members and association. Isabelle’s experience in customer service and people skills will provide our members with exceptional support. Whether it’s a new membership, technical question, billing question, or a general inquiry, Isabelle and the rest of FenCan’s team is always ready to help.

The Fenestration Canada Commercial Chapter is thrilled to announce that Brent Friesen, owner of Langley, B.C.-based Baywest Glazing Systems, has been appointed as the new chair of our chapter. We couldn’t be more delighted to have Brent leading the team. Brent has owned Baywest (formerly Clearbrook Glass) since 2015. He is passionate about building a great glazing business through innovation and hard work. Brent earned a CPA accounting designation in 2010 and has served on boards for other not-for-profit organizations. “As chair of the FenCan Commercial Chapter, I am committed to working with our members and stakeholders to create a vibrant, productive and successful organization,” said Friesen. “My goal is to ensure that we are operating at an optimal level so that our members can take advantage of the resources available to them. I plan to foster collaboration among all involved in order to create a unified and effective working environment.” Brent is married with two little boys. When not at work he enjoys music, history, and bouldering.

We are thrilled to announce that Brent Friesen has been appointed the new chair.

As chair, Brent will bring his extensive experience and knowledge in leadership and glazing to help the FenCan Commercial Chapter to reach our goals and create a positive impact in the commercial glazing community. We know that with his guidance, our chapter will be able to grow and succeed in all of its endeavors.

We are very pleased to let our members know that we have been advised work will begin soon on updates to three Canadian glass standards. Funding has been secured from the Standards Council of Canada to update CAN/CGSB-12.20 “Structural Design of Glass for Buildings” (currently withdrawn), CAN/CGSB-12.1 “Safety Glazing” and CAN/CGSB-12.8 “Insulating Glass Units.” The CGSB Technical Committee on Glass has been tasked to take on this somewhat monumental task. Considering 12.20 was last updated in 1989 there will be plenty to update. Terry Adamson, Fenestration Canada’s technical director, holds a seat on this committee and has advised me to reach out to our commercial membership and ask if there are members wishing to participate in this work. If interested you can reach out to Terry (terry@fenestrationcanada.ca using the subject CGSB) and he will forward your request to the CGSB staff for consideration. We are eager to support and participate in this project and to see this work finally begin. It is expected the process may take up to three years to complete.

The Commercial Chapter membership drive was an outstanding success, with dozens of companies joining the new chapter. The drive achieved its goals of early adoption, engagement and participation, setting a solid foundation for future growth. We are incredibly grateful to all those who helped make this initiative such a success and we look forward to further strengthening our membership in the coming months.

We are excited to continue building on this successful foundation and start developing new initiatives to provide members with value. These projects and programs will continue to make FenCan the premier organization for glazing contractors, glass fabricators, facade consultants and suppliers. Together, we can achieve great things! •

by BARB HOOLEY AND MICHELLE THROSSELL

Canada is a wellrecognized leader of Public Private Partnerships (P3s) and continues to successfully deliver significant and complex P3s when used on the right projects. The P3 model typically shoulders most of the design and delivery risk onto the supply chain, and recent changes in the market have led to an increase in alternative procurement models being used to distribute this risk more evenly and gain other advantages to enable successful project outcomes.

In recent years, projects have become increasingly larger and more complex, leading to increased delivery challenges. These challenges, when combined with material and labour shortages and the rising cost of goods, have led to

alternative contracting models such as Alliancing and Progressive Design and Build gaining popularity in the market. These more collaborative contracts are focused first on building a relationship between the owner and the delivery team. They involve a collaborative “one team” culture, shared risk profile, open book policy and data transparency, all of which lay the foundation for securing mutually beneficial outcomes.

Alliance and Progressive Design Build models have their roots in the U.K. and Australian infrastructure markets where market condi-

tions drove a move towards a more balanced and collaborative approach. Projects like the Thames Tideway Tunnel and High Speed 2 (HS2) are examples of mega-programs utilizing these evolving contracts to build market interest and encourage more successful delivery outcomes. Turner and Townsend have been HS2’s procurement delivery partner since 2021 and have supported the development and implementation of a procurement approach which includes many of the new approaches discussed here, including the requirements of contractors for project management information.

ABOVE: New approaches to contracting may drive a greater need for data collection and sharing. Are you ready?

These alternative contract models require a shift in data management requirements to effectively support the development and execution of the contract. Significantly more data points will become available that need to be identified, tracked and collated in a meaningful way to effectively support status reporting and decision making through the life of the contract.

Crucial to the successful management of this data and overall implementation of this newer, more progressive way of contracting is to have an integrated project controls function to provide a single source of truth and heartbeat for the project.

The integrated project controls function continually measures, monitors and interprets inter-disciplinary data to meet the requirements of the stakeholders. By establishing an integrated project controls function from the outset, information can be organized and understood to better guide the project strategy, to define the delivery plan and ultimately inform the owner’s decision on how to proceed with the project through its lifecycle.

Due to the more collaborative and “open book” approach in these contracts as well as the shared risk and reward, more data is collected, available and used by all parties to make best decisions for the project overall. Subcontractors like glaziers or fabricators will likely need to contribute to this data collection if they are providing significant materials or services over a time frame where progress measurement becomes relevant.

Although this type of project controls data collection and analysis can benefit subcontractors doing smaller scale work, involvement in mega-projects makes it more necessary. An ability to provide a wide range of data to contractors would be of benefit. Examples of data that could be required include quantities, milestones and percentage-complete for the schedule progress; budget, cost-incurred and forecast-to-go for the cost progress; top risks, P50/P80 and contingency forecasts for risk; and overall performance against agreed KPI’s.

When an Alliance or Progressive Design Build contract type is selected, the chosen delivery team will often be entering into a contract with an immature design, high-level budget and limited understanding of the delivery risk. The first task involves working with the owner to develop the design, schedule and cost, typically on an open-book, cost-reimbursable basis.

During the development phase, the owner will have better line of sight and access to more performance and cost data than would normally be the case under a P3/fixed-price arrangement. To leverage the power of this information, an integrated project controls function can efficiently capture and analyse the available data to support the owner’s role as contract administrator. The project controls team plays an important role as the design is developed and the parties work together to collectively establish the scope, cost, and delivery schedule by providing benchmarked data, data analysis and helping to plan the project in the most efficient way.

Another fundamental role fulfilled by project controls is to develop and analyze the project risk profile, first identifying and assessing the risks and undertaking statistical analysis to determine

the potential cost and schedule impact, which then informs the contingency budget and allocation of responsibilities between the parties. Taking the time to properly understand and assess risk is crucial in a contracting arrangement which shares risk between the owner and delivery team and in some cases rewards the contractor for effectively managing their risk within budget.

Given the nature of these contracting methods, a high volume of change is expected, especially in the early stages, as the project develops. An integrated project controls approach is required to ensure these changes are accurately identified, quantified, reviewed and implemented to maintain a current and accurate position in terms of scope, cost, and schedule.

This shift in contracting approach is an exciting development for Canada. It presents an opportunity to bring the best elements, and the learnings, from the early adopters of the strategy in the United Kingdom, Australia and elsewhere in the world. Although success with collaborative contracts has been demonstrated in these markets, there are fundamental building blocks required to support that success, and a holistic, detailed and integrated project controls approach goes to the heart of the model and its success.

Barb Hooley is communications manager for Canada at Turner and Townsend. Michelle Throssell is a director at Turner and Townsend’s Toronto office. turnerandtownsend.com

MATERIALS

Galvanized/Mild Steel 26ga to 1/4”

Painted and Anodized Aluminum 0.032” to 1/4”

Pre-painted Steels

Stainless Steel/Brass/Copper/Zinc

SERVICES

Shearing/Punching/Notching/Routering/Bending

Stud & Spot Welding

Assembly/Prototypes

Backpan Fabrication

• Established in 1980

• COR Certified

• ISO 9001:2015 Certified

• CNC Press Brakes - 8’, 12’ & 14’

• CNC Router Table/Punch Center

• One piece to 10,000+ pieces

291210 Wagon Wheel Road

Rocky View, Alberta T4A 0E2 grantmetal.com

Toll Free: 800-672-6088

Phone: 403-590-8000

info@grantmetal.com

Smart-Toolbox is a glazing job management system designed specifically for the glass industry. By streamlining the quoting, scheduling, ordering and invoicing processes for the entire team, Smart-Toolbox removes bottlenecks and boosts efficiency. The intuitive glass job statuses and user-friendly dashboard enable users to identify and address potential mistakes before they become problems. Interactive online quotes empower customers to visualize their glass or shower, accept the quote and make online payments, eliminating the need to chase payments or disrupt teammates. Glaziers can say goodbye to the hassle of chasing paper, hunting for job folders and interrupting colleagues every time a customer calls by working smarter, not harder, with Smart-Toolbox. The team at SmartBuilder have been developing glass software exclusively for glaziers and glass fabricators for more than two decades. By working closely with clients to enhance tools continually, Smart-Builder drives a more efficient and streamlined glass business.

Flexijet has released FlexiCAD 3.3, the latest software accompanying the Flexijet 3D digital measurement system. This release includes Flexijet Livestream, a live camera view of the points being measured, adding even more flexibility when measuring outdoors or in bright light situations. With Flexijet 3D and FlexiCAD, measurement drawings are created in real time on the jobsite, allowing for the immediate verification of as-built measurements and eliminating the need to return to site after drafting for verification. Flexijet can move to aim its laser back at points, allowing users to mark out mounting and drill points and visually verify measurements. Adjustments are made in real time while on-site, reducing the risk of later human and drafting errors and streamlining the measurement verification process. Flexijet 3D is helping the glass industry transition from traditional manual measuring methods to accurate digital measurements. Flexijet 3D’s Next Generation laser technology allows it to capture sub-millimeter-accurate 2D and 3D measurements of actual site conditions. This accuracy helps to reduces errors and end the need for costly reworks or adjustments, resulting in substantial cost savings for glass fabricators. The measurement drawings created with FlexiCAD are detailed and accurate, providing a digital representation of the site conditions and outages as well as final designs. Digital measurement drawings also facilitate effective communication between the fabricators and other stakeholders, such as architects, contractors, and clients. And digital measurement files can be shared directly with suppliers to eliminate the chance of human error or miscommunication. By replacing manual methods with digital measurement technology, Flexijet 3D improves efficiency, enhances accuracy and enables the seamless transfer of measurements. With its CAD-centered editing power, the FlexiCAD software empowers glass fabricators to deliver perfect installations, reduce costs and stay at the forefront of innovation in the glass industry.

fhc-usa.com

Frameless Hardware Company has launched its new design, quoting and ordering online configurator. This new program is designed to expedite and improve the quoting and ordering process for all-glass entrances and storefronts comprising Herc-Door entrances, Steincraft panic devices and all combinations of headers, sidelites, transoms and related hardware packages. Ease of use and accessibility were primary drivers for incorporating monthly membership packages available without license fees. Cloud-based server integration and the Instaquote platform ensures peace-of-mind by eliminating the human-error factor with robust, intelligent built-in safety backstops to guarantee the opening meets applicable specifications, codes and standards. Additionally, users can easily export entire bid packages complete with 3D renderings to give their customers a comprehensive understanding of the design, components, cost and esthetics. The program integrates the latest available technology to provide customers with a handy, foolproof dashboard for seamless estimation. The new FHC Instaquote online design, quote and order system is live and available now.

sigfoxcanada.com

Sigfox is service provider for Internet of Things, specializing in connecting simple, low powered, low-cost devices to the internet while consuming as little energy as possible. It offers an endto-end packaged solution for glass and window rack tracking. Benefits of implementing the solution include reduced loss ratios; improved cycle times; increased operational efficiencies; improved service delivery and customer relations. Users can immediately locate lost and vacant racks while reducing loss rates by 50 to 90 percent. Empty racks can be collected quicker to reduce cycle times and improve rack fleet utilization, scaling faster. The technology reduces manual handling and saves time planning tasks with automated recurring inventory. The software suite produces updated and accurate data for each delivery to improve product visibility and quickly resolve customer issues. Bill Gioskos of Sigfox Canada has partnered with HeronTrack to offer the Smart Glass rack tracking solution to keep track of glass stillages. The cost-effective proven solution combines tracking devices and a dashboard specifically designed for supply chain optimization to locate glass racks when they move out of supply, chain journeys, improve customer experience and save money.

openjanela.com

OpenJanela software for glass fabricators adapts to the individual user’s way of doing business while bringing experience and knowledge gained from dealing with hundreds of glass fabricators.