Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Grove Shims™ has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Presenting our annual focus on amazing Canadian creations in architectural glass.

24 Top Glass, top results

Top Glass 2021 kept the audience engaged and interested throughout the day.

26 Under the Glass

The owners of Griffin Glass are not afraid to make changes and try new things to drive the company’s growth.

7 Canada’s Glass Associations 11 Fenestration and Glazing Industry Alliance

10 The Engineer By David Heska

30 That’s Rich By Rich Porayko

Black Canadians have been part of our construction industry for as long as there’s been one, including many Black-owned contracting businesses. Now, a new organization known as the Afro-Canadian Contractors Association has come along. Association president, Sephton Spence, joins GlassTalk to tell us all about it.

By the time you read this, my whole household will have received our first shots of a COVID vaccine. It’s a tremendous relief and we’re all very much looking forward to a more normal summer of hanging out with family and friends in the back yard and at the cottage.

I hope my optimism isn’t misplaced. Here in Ontario, my daughter’s high school has already announced a reduced daily schedule of only two classes per day when school re-opens in September. September! Just about everyone in the province ought to be vaccinated by then, and many of us will have had our second shots. Continuing to restrict school activities at that point seems to me to be an excess of caution.

• Machining

• COR

• Float glass

But excessive caution appears to be going around. The closure of outdoor activities such as golf, tennis and parks doesn’t make any sense from the perspective of preventing people from actually catching the virus. It is very difficult to catch outdoors. I get that this is part of a general effort to keep people from moving around but it sure looks like overreach, especially when you consider how badly people need some opportunity to do something outside the house. Then there’s the continuing recommendations for businesses to wipe all their surfaces down all the time. We’ve known for a while now that this is not how the virus spreads. This goes for the federal guidelines, too, which continue to recommend no alteration in social distancing, gathering and mask-wearing for people who have been vaccinated. Yes, vaccinated people still have some small chance of getting and spreading the disease, but eliminating all instances of infection was never the goal – it’s likely COVID-19 or its variants will become a permanent seasonal epidemic similar to influenza. The goal was to prevent uncontrolled spread leading to so many infections at once that health care systems become overwhelmed. With a critical mass of the population vaccinated, that risk largely goes away.

Don’t get me wrong, I’m proud of the efforts we’ve made in Canada to save as many lives as possible and grateful to the health experts who have worked so hard to tell us how to stay safe and delivered the miraculous vaccines. I still urge everyone to follow the guidelines and rules our public health authorities put forward. They certainly know more about this stuff than I do. But I would hope there is no “mission creep” in the health community that leads to people not being able to experience the relief and return to normal we have earned over the last year.

For one thing, the economy needs it. The last Ontario Construction Secretariat bulletin showed a five percent decline in ICI building permit values in Q1 2021 versus Q1 2020, led by a 17 percent reduction in commercial permits. I’ve spoken here before about the potential for a long-term depression in commercial real estate coming out of weak demand for office space. I hope I’m wrong. The federal budget disappointed somewhat in not promising a big infrastructure package targeted at the ICI sector – most of the proposed spending is aimed at residential homeowners. I’m not sure much stimulus is needed and it may even be inflationary if taken too far. All we really need in this country is to be allowed to reap the crop we’ve sown with our discipline and good behaviour and return to normal as soon as possible. •

June 2021

Volume 33 • Number 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquiries or changes, please contact

Shawn Arul, Audience Development Manager

Tel: 416.510.5181

Fax: 416.510.6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE EDITOR | Sukanya RAY GHOSH srayghosh@annexbusinessmedia.com 647.203.7031

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

NATIONAL ACCOUNT MANAGER | Amanda McCRACKEN AMcCracken@annexbusinessmedia.com 519.429.5234

ACCOUNT COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Curtis MARTIN

VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $85.00 (in CDN dollars)

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

To celebrate International Women’s Day, eight of Canada’s leading construction media brands teamed up to deliver an exclusive virtual event. You can view the content ondemand, and stay on top of news throughout the year, at women-in-construction.ca.

SPONSOR

GOLD SPONSORS

SPONSORS

SPONSOR

PRESENTED BY

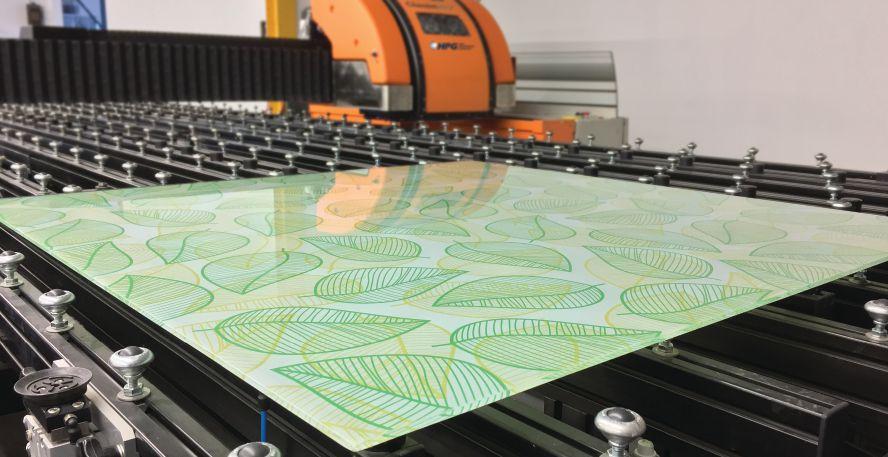

Canadian Premium Sand has announced a shift in the direction of the company’s business strategy to focus on developing its Wanipigow silica sand deposit into a sustainable float glass manufacturing and coating facility. This facility would be designed to utilize the best available technology with a focus on sustainability initiatives such as waste heat recovery and optimizing use of Manitoba’s abundant and inexpensive renewable electricity to set a new standard for low-carbon-footprint glass manufacturing. The greater Winnipeg area presents an opportunity for significant long-term manufacturing cost and logistics advantages for a float glass facility focused on energy efficient architectural glass or solar glass. The shift in business strategy is the result of an internal review of the various applications for the company’s silica sand deposit, which identified float glass manufacturing as a high potential application for which the company’s silica sand is ideally suited. Float glass manufacturing has shown better overall project economics and market stability compared to Wanipigow proppant production for fracking. This internal review is supported by an independent business study commissioned by the company and conducted by an independent international glass-markets-focused consulting group, GlassGlobal Consulting.

“Today, there is not a single float glass manufacturing facility in Canada”, stated Glenn Leroux, president and CEO of CPS. “Every pane of glass utilized in this country is imported. Based on the business study and market projections completed by GlassGlobal, current dynamics in North America show a manufacturing supply deficit demonstrating the requirement for up to four additional float glass facilities by 2025 in order for North America to be self-sufficient. Establishing a float glass facility in Canada using responsibly sourced local raw materials and responsibly produced Canadian energy creates a unique opportunity to provide much-needed sustainably manufactured float glass to Canadian, North American and international markets in an environmentally responsible manner.”

Preliminary test work shows that the Wanipigow Lower Black Island Formation sand at the test site has potential for use in the manufacture of ultra-clear, energyefficient architectural float glass as well as solar glass for use in solar panels. The testing of a small subset of the company’s silica sand was conducted by an independent ISO/IEC 17025:2018-accredited laboratory specializing in glass and raw materials analysis. Three individual samples were collected from archived drill cores for test work.

June 17

AIA Conference –Firm Resilience Online conferenceonarchitecture.com

June 22

FGIA Virtual Summer Conference Online fgiaonline.org

July 8

AIA Conference –Sustainable Practice Online conferenceonarchitecture.com

July 29

AIA Conference –Community Engagement Online conferenceonarchitecture.com

August 19

AVFQ Open Blainville, Que. avfq.ca

August 19

AIA Conference – Building Efficiencies Online conferenceonarchitecture.com

Sept. 13 - 15

GlassBuild America Atlanta, Ga. glassbuildamerica.com

Sept. 23

Wagdy Anis Symposium on Building Science Boston, Mass. architects.org

Oct. 18

FGIA Fall Conference Phoenix, Ariz. fgiaonline.org

Oct. 20 - 22

GPD Finland Tampere, Finland gpd.fi

Incollaboration with the Fenestration and Glazing Industry Alliance and the Fenestration Association of British Columbia, AVFQ invited associations related to our industry to develop an educational piece on the two compliance thermal performance pathways for fenestration products in Canada. The target audiences for this publication are homeowners; builders; architects and other specifying authorities; building code officials; and even the fenestration industry itself. The AVFQ asked UL experts to prepare specific training to help AVFQ members prepare for the new regulations in Chapter 1.1 Quebec Building Efficiency of the Quebec Building Code. Nearly 100 people have followed the training so far. The regulations have been in effect since June 27, 2020. Our industry must comply by Dec. 27 and the changes are significant. With training being one of AVFQ’s important services, a webinar on changes to CSA A440.6: 20 was presented exclusively to 100 members, all in collaboration with UL. Offered since November, 2019, FIT window installers training has reached nearly 400 participants so far. Recently, the Quebec Association of Building Inspectors entrusted the AVFQ with training its members on FIT. About a hundred building inspectors have taken this training, which will allow monitoring of good installation practices on construction sites in Quebec. AVFQ is currently collaborating with Quebec Energy Transition as part of the re-evaluation of the Novoclimat program. This program encourages the construction of new homes with high energy performance,

according to specific construction requirements. An important achievement is the Curtain Wall Guide, which is aimed at architects and other construction professionals. Released in 2018, the Curtain Wall Guide is under review and a new updated version offering better visuals and ease of navigation will be available shortly.

The Ontario Glass and Metal Association is excited to announce the addition of two new members to its board of directors: Blake Sanders and Steve Peso. Blake Sanders heads the contract administration department, joint health and safety committee and often assists in managing the overall operations of Spandrel Tech. Having grown up working in the fabrication plant, gaining years of experience and knowledge of product data, application and construction, Blake moved up within the company to one of the top management roles. While some may say they have a “lifetime of experience,” being the third generation in the family business Blake goes even beyond that. Steve Peso is a technical sales representative with the Tremco Construction Products Group with over 12 years of sales and management experience in the coatings and building envelope industry. Steve started his career at Sherwin Williams Paint Company and moved through various positions and progressive levels of responsibility. Ready to expand his knowledge into the broader coatings and construction business, Steve was drawn to the enthusiasm and camaraderie at Tremco.

The unionized glazing contractors in Ontario represented by the Architectural Glass and Metal Contractors Association have a proven track record and a higher level of safety on their jobsites and in their shops. A recent analysis performed by the Ontario Construction Secretariat found that unionized contractors are 31 percent safer than their non-unionized counterparts. This means that the training programs we have invested significantly in are working, and that our member firms take safety seriously. Throughout the pandemic, our industry has stepped up and outperformed to combat the spread of COVID-19 on our jobsites and in our shops. AGMCA member contractors quickly adapted to the new health and safety protocols, which contributed to some impressive numbers for the construction industry overall.

As of April 16, the WSIB reported 21,133 approved claims relating to workplace transmissions of COVID-19, of which only 289, or 1.37 percent, were from the construction industry. The AGMCA is part of a larger group of construction associations that are currently lobbying government to keep our industry open and functioning. We need our glazing contractors to be financially viable and healthy as we get called upon to build new manufacturing and warehouse facilities, as well as the infrastructure that will be needed to lead us all out of the pandemic.

The Fenestration Association of BC met with Independent Contractors and Business Associations to discuss the possibility of partnering to develop a glazier apprentice training program after one of our mutual members asked both of our associations to research the possibilities. As ICBA is the largest sponsor of apprentices in B.C., the partnership made sense. FenBC and ICBA held a joint membership meeting with glazing industry stakeholders to understand the current challenges glazing contractors are facing in terms of recruitment, training and the potential implementation of compulsory trades in B.C. After several rounds of consultation, we concluded that the most suitable solution to address these challenges is through the development of a Red Seal challenge program for glaziers in B.C. Working with ICBA we have come up with a proposal to develop an online support program to assist those apprentices who are ready to challenge the Red Seal exam and be on the way to becoming a Red Seal journeyperson. As you all know, this program cannot be successful without support, both financial and in participation, from all of the B.C. glazing industry. If you have any questions you can reach out to Zana Gordon (zgordon@ fen-bc.org) or Nicola Blockley (nicola@icba.ca).

The federal government released its 2021 budget on April 19. Here are some highlights of special interest to the architectural glass industry. Budget 2021 proposes to extend the wage subsidy until Sept. 25. It also proposes to gradually decrease the subsidy rate, beginning July 4, in order to ensure an orderly phase-out of the program as vaccinations are completed and the economy reopens. It proposes to extend the rent subsidy and Lockdown Support until Sept. 25. It also proposes to gradually decrease the rate of the rent subsidy, beginning July 4. The government recently extended the application deadline for Canada Emergency Business Account to June 30. The government proposes to provide up to 12 additional weeks of Canada Recovery Benefit to a maximum of 50 weeks. Budget 2021 proposes to introduce the new Canada Recovery Hiring Program for eligible employers that continue to experience qualifying declines in revenues relative to before the pandemic. The budget also proposes many long-term changes to EI. Budget 2021 proposes to provide $46.9 million over two years to support additional research partnerships between colleges, CEGEPs, polytechnics, and businesses through the Natural Sciences and Engineering Research Council’s College and Community Innovation Program. Budget 2021 proposes to invest $5.7 million over two years to provide more businesses with access to the National Research Council’s Industrial Research Assistance Program’s interactive visits, where firms can access equipment, facilities, and expertise at collegeaffiliated Technology Access Centres. Budget 2021 proposes to provide $500 million over five years, starting in 2021-22, and $100 million per year ongoing, to expand the Industrial Research Assistance Program to support up to 2,500 additional innovative small and medium-sized firms. The budget also commits $5 billion over seven years to increase funding for the Strategic Innovation Fund’s Net Zero Accelerator. Through the Net Zero Accelerator the fund would scale up its support for projects that will help decarbonize heavy industry, support clean technologies and help meaningfully accelerate domestic greenhouse gas emissions reductions by 2030. In order to demonstrate to Canada’s trading partners the importance of

M arch 2021 marked the third consecutive month of record-setting numbers as building permits rose 5.7 percent to $10.9 billion, reflecting a booming residential sector. Constant dollar estimates are available, for the first time, for the building-permit series dating back to 2011. On a constant dollar basis using 2012 dollars, building permits increased by four percent to $8.1 billion, a number only surpassed by the April 2019 value of $8.2 billion. The residential sector climbed 15.9 percent, clearing the $8 billion mark for the first time in March. Multi-family dwellings jumped 24.5 percent compared with February to an unprecedented $4.3 billion. This gain resulted largely from permits being issued for residential towers in the cities of Toronto, Burlington, and Vaughan. Single-family homes also reached new heights, increasing 7.6 percent to $3.8

balanced procurement opportunities, the government will pursue reciprocal procurement policies to ensure that goods and services are only procured from countries that grant Canadian businesses a similar level of market access. Budget 2021 proposes to allocate $21 million over three years to work with provincial and territorial partners to enhance the capacity of the Internal Trade Secretariat that supports the Canadian Free Trade Agreement in order to accelerate the reduction of trade barriers within Canada. Budget 2021 proposes to provide $22.6 million over four years to Infrastructure Canada to conduct Canada’s first-ever National Infrastructure Assessment. The assessment would help identify needs and priorities for Canada’s built environment. Budget 2021 proposes to provide up to $101.4 million over five years to Innovation, Science and Economic Development Canada for the Small Business and Entrepreneurship Development Program. It proposes to provide $960 million over three years to Employment and Social Development Canada for a new Sectoral Workforce Solutions Program. The government also said it will engage with stakeholders to examine what barriers exist to the creation of employee ownership trusts in Canada, and how workers and owners of private businesses in Canada could benefit from the use of employee ownership trusts.

billion. The census metropolitan area of Oshawa was responsible for just over one-third of this growth. Following a month in which several major permits were issued for care facilities, institutional permits fell 33.5 percent to $732.1 million. Eight provinces posted a decline in this component, with Quebec (54.5 percent decrease) recording the most significant drop. Commercial permits decreased 14.6 percent to $1.5 billion, about 25 percent lower than the average monthly value reported in 2019. After declining slightly in the first two months of 2020, commercial permits took a large hit at the start of the pandemic and have since averaged around the $1.5 billion mark observed in March. Industrial permits, the only component to report a gain in the non-residential sector, rose 16.4 percent to $650.5 million. Several major permits were issued, including a new relay control centre for railroads in the city of Montreal and the Rutherford Station of the Go Transit system in the city of Vaughan. Overall, the non-residential sector fell 15.6 percent to $2.8 billion.

Glasswerks has acquired the glass manufacturing assets of Columbia Commercial Building Products and J.E. Berkowitz. Both companies were previously part of Consolidated Glass Holdings. This acquisition marks the latest investment as Glasswerks solidifies its national presence. Through this purchase, Glasswerks has added multiple tempering lines, insulating glass lines, a laminating line and substantial supporting assets to its current production. Continued expansion and investments have effectively made Glasswerks one of the largest privately-owned custom glass fabricators west of the Mississippi. Glasswerks currently operates in over 700,000 square feet of fabrication space across locations in Southgate, Temecula, and Carson, Calif.

The Ontario Construction Secretariat hosted its online State of the Industry and Outlook Conference on March 4. The OCS presented a very informative and comprehensive overview of the Ontario construction environment. The event featured an economic update from CIBC deputy chief economist, Benjamin Tal, OCS director of research Katherine Jacobs’ report on her survey of contractor attitudes, a panel discussion on health and safety on jobsites and a presentation and question-and-answer session with senior editor of The Atlantic , David Frum. Tal’s presentation outlined a recession that was unlike any ever seen before in history. He described the road forward as one of “normalizing the abnormal.” Both Tal and Frum noted that American trade policy was unlikely to change much under the Biden administration. On the overall effects of the pandemic, Tal was relatively upbeat. He described the recession as deep, but very narrow. It has been unlike any other recession in that service industries have been hit far worse than goods providers. Tal mentioned that the pandemic may have spurred the long-awaited productivity improvements in Canadian manufacturing and construction as companies were forced to take risks. He predicted a stronger recovery in the second half than the Bank of Canada’s forecast. Tal pointed to the disproportionate impact

on the service sector, which has more flexibility to bounce back faster than manufacturing. Canadian incomes actually rose during the pandemic, which has never happened in a recession before. Jobs losses were restricted to lowincome earners – higher paying jobs gained 350,000 positions last year. Yet the spending decline was all at the upper income levels. Another fascinating prediction from Tal was that the pandemic has created the conditions for a permanent increase in government spending. Public spending in Canada was around 15 percent of GDP before the pandemic and has now jumped up to 35 percent. Tal thinks spending may drop back to around 17 percent and stabilize there. Tal called this the “most housing-friendly recession in history.” Tal pointed to the asymmetrical nature of this recession, with the brunt of the impact falling on low-income workers who were renters anyway and higher-income people often being better off. The housing market has acted the opposite of how it normally does in a recession in other ways, too, with demand exceeding supply and price inflation going faster outside big urban areas than inside them. He views the work-from-home phenomenon as not likely to put a long-term dent in demand for office space, saying it’s temporary and people will want to return to offices when they can.

billion

The Financial Accountability Office of Ontario has released its review of the Government of Ontario’s new program to lower electricity costs for industrial and large commercial ratepayers. Announced in the 2020 Ontario Budget, the province will reduce electricity prices for industrial and large commercial ratepayers by subsidizing the cost of 33,000 green energy contracts with wind, solar and bioenergy generators. The program, which began Jan. 1, will shift nearly 85 percent of the cost of electricity generated under these contracts from ratepayers to the province until the last contract expires around 2040. Over the life of the program, from 2020-21 to 2039-40, the total estimated net cost to the province is $15.2 billion. In just the first three years, the FAO estimates that the program will cost the province $2.8 billion. The FAO’s three-year cost estimate is significantly higher than the province’s $1.3 billion cost estimate reported in the 2020 Ontario budget, as the government’s three-year estimate included additional cost forecast changes for the Ontario Electricity Rebate that were unrelated to the new program. In 2021-22, the FAO estimates that approximately 1,400 industrial ratepayers will receive an average 17 percent reduction in the price of electricity and a 14 percent reduction in their electricity bills. Large commercial ratepayers will see an average 19 percent reduction in the price of electricity and a 16 percent reduction in their electricity bills. After accounting for the impact of the subsidy in 2021-22, the FAO projects that electricity prices for large commercial ratepayers in Ontario will remain among the highest in Canada, while Ontario industrial ratepayers will see electricity prices drop below the Canadian average and below most nearby competing US jurisdictions.

For more news, podcasts and other great content from the architectural glass industry, please visit glasscanadamag.com.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows. He can be reached at David. Heska@wsp.com.

If you’re like me, the stay-at-home measures have allowed for additional time to kick back and enjoy Netflix or Disney Plus. Recently, I was watching Lord of the Rings and Bilbo’s speech to his party guests made me pause and reflect. He says, “I don’t know half of you half as well as I should like, and I like less than half of you half as well as you deserve.” I’ll leave the interpretation of that statement to the philosophers, but I would like to take this column to explore the importance of knowing people.

For our regular Glass Canada readers you are already somewhat familiar with one of the window replacement projects I’m currently working on where new double-glazed windows are being installed at a large single-storey facility. The drama opens with a cast of five characters: the client, the engineer, the general contractor, the glazing contractor and the window manufacturer. In this production, I’ll be acting as the engineer. The design is complete and three different but similar glazing systems have been specified. Through a public procurement process the low-bid contractor was selected and the contract awarded. The general contractor is a middle-income man with a button-up shirt. The glazing contractor has ripped jeans and a rusty truck. The actress, representing the window manufacturer, is a well-known professional, highly respected in the industry. So how will this play out?

Act three begins with the engineer, client, general contractor and glazing contractor getting to know one another at the pre-construction meeting. They have never worked together

“I don’t know half of you half as well as I should like, and I like less than half of you half as well as you deserve.”

and the general contractor indicates that the shop drawings will be submitted in one week and mobilization will occur in early June. Notably absent from the scene is the window manufacturer.

Shop drawings are prepared by the glazing contractor and the engineer returns comments that many items are not in accordance with the contract specifications. Anchor and fastener information is missing, penetrations through the sill membrane are shown where they are not permitted and interior air seals are discontinuous. A second set of shop drawings are produced with most of the comments unaddressed. The spotlight then turns to the engineer who is on the phone with the well-known window manufacturer. They are discussing a different project where shop drawings have just been approved with very similar changes.

Act four begins with a conference call between the engineer, general contractor and glazing contractor. The mood is tense and the contractors indicate that the window manufacturer has told them that the requested changes cannot be made. Then a long, drawn-out silence. How does the engineer respond? He knows that the changes can, should and will occur. He has completed numerous past projects with these revisions. But both contractors are unaware of the relationship between the engineer and the window manufacturer.

At this point, you can probably guess which half of the room was liked less than half as well as it deserved.

I’m happy to report that the story ends well, shop drawings are now approved and production is underway. May this be a little reminder for us all that honesty and relationships matter. It’s all who you know. •

by AMY ROBERTS

There are two pathways to calculate fenestration thermal performance in Canada: the U-factor pathway and the Energy Rating pathway. U-factor is a physical measurement of the amount of heat energy transferred across a unit area of wall over a given time span per degree of indoor-outdoor temperature difference. ER is a dimensionless rating number arrived at by calculation and computer modeling that combines and demonstrates the balance among solar heat gain, U-factor and air infiltration. The higher the number, the more efficient the product. For most Energy Star-approved windows, ER ranges between 25 and 35 points. Note that fixed windows will naturally have a higher ER number than operable windows and only like operator types can be meaningfully compared using ER ratings. The two indices cannot be directly translated from one to the other.

There is some confusion in the Canadian marketplace as to when to use one or the other of these two compliance pathways to demonstrate energy efficiency – not just for architects, specifiers, building officials and homeowners, but also within the fenestration industry itself. This has been an ongoing issue for well over 10 years and was recently a subject of discussion at the Natural Resources Canada Market Transformation Roadmap meetings.

The time has come to provide clarification to the Canadian market as to what these two values mean, the appropriate use of either of these values and which jurisdictions accept them. To bring this about, the Canadian fenestration industry, as represented by FGIA, the AVFQ, the Fenestration Association of BC, Fenestration Canada, and Fenestration Manitoba, have launched a

“Industry associations are collaborating on a white paper on thermal performance compliance pathways in fenestration.”

collaborative effort to develop a substantive white paper document for end-users that provides a clear understanding of the two compliance pathways for thermal performance of fenestration for both residential and commercial buildings in Canada. Provisionally titled Thermal Performance Compliance for Fenestration in Canada, it will provide information on fenestration product compliance for thermal performance in Canada for architects, homeowners, building code officials and other interested stakeholders.

To be presented in a neutral and non-preferential format, the finished document will be comprised of historical background information, details about the two different U-factor and Energy Rating calculation variables and what they represent, examples of the appropriate application and the rationale behind each thermal performance rating pathway, and it will define the considerations for using each. It will additionally include an interpretation of the associated product labels, information on which jurisdictions accept one or both thermal performance compliance pathways as prescriptive and/or performance-based approaches and supply a list of resources and references for further information.

The committee preparing this document includes coast-to-coast representation from top experts in the field. For example, in order to ensure consistency with the CSA A440.2 technical specification, the chair and co-chair of the CSA A440.2 committee are at the table. Also, the committee includes participation from NRCan and a representative building inspector from the township of Rothesay, N.B. Others could contribute as the project progresses. The first meeting of the group took place on April 8 with a detailed examination of the document’s outline and content.

It is important that all industry organizations and representation from across Canada come together to develop this much-needed education piece, which everyone will be able to post to their website as a complimentary download. All collaborating parties will be equally acknowledged for their contribution. •

by TREENA HEIN

The city of Richmond, B.C., is a busy place, just across the river from Vancouver, and when its firehall needed an upgrade city leaders decided it best to create a new combined emergency services centre. “It’s the first combined fire and ambulance station in the province,” notes Jon Fearn, business development manager at Flynn Canada’s Surrey office, the glazing firm.

To reflect the two emergency services housed inside, the three-storey building sports a distinct dual-folding roofline. However, the design also throws back to the historic roots of firehalls, with its bright red cladding on the upper level. It’s LEED Gold-certified and complies with BCBC 2012, ensuring it can act as a department operations centre where

staff can provide response following a seismic event. In addition to having an earthquake-resistant structure, there are tie-ins for concrete aprons at the front of the building and an on-site emergency generator. The building received a notable mention in the Mixed-Use Facilities category in the 2019 Firehouse Magazine Station Awards.

Within the building, there are six bays, two for fire rescue vehicles, two for emergency vehicle service and two for ambulances. The building also has sleeping dorms, offices, an exercise space and a quiet room that helps paramedics decompress after responding to calls. There is also an outdoor patio and, adjoining it, are the offices, kitchen and dining room, oriented to maximize incoming natural light to provide a soothing and connect-

Architect: DGBK Architects (with limited non-design consulting from S2 Architecture)

Contractor: Stuart Olson

Installer: CPA Flynn Group of Companies

Insulating glass units

CAN/CGSB-12.8

Double unit, 25 mm overall thickness

Argon fill

Six mm clear tempered inner and outer lite

Low-E Solarban 70XL coating on #2

U-value: overall maximum 2.3

Safety glass

CAN/CGSB-12.1

Tempered: type 2, Class B clear float

Laminated: type 1, class B clear float, Interlayer: minimum 0.76 mm PVB

Laminated glass guardrail

HS with diffuse ionoplast interlayer

Thickness, panel size and attachment to suit loading

Total building footprint

25,995 square feet

Completed 2018

ing effect. Further natural light is used extensively in the training classrooms, where occupants can view both the site training area below and neighbouring green spaces.

The north stair tower, with its Guardian 275 translucent wall panel system, has been described as “a beacon for the neighbourhood.” Soft light fills the stairwell and produces a lantern effect from a distance. Architect Ralf Janus, principal at DGBK Architects, explains that glass features were chosen on the basis of providing

Natural light is used to create a soothing environment for first-responders in living quarters, eating areas and the quiet room.

transparency to the area, with the entire building serving at nighttime as a “neighbourhood symbol and presence.” Janus adds that this was achieved through “more glass [being included] than is typically used in a firehall or emergency response building,” and that “much design effort went into the light effects achieved in the evenings and through the night to create a soft but constant community presence.”

He adds, “as the building was going to have a large presence on the street, we tried to break down the mass by ‘eroding’ some of the corners with transparent elements, namely the glazing. This design also allowed the interior to feel somewhat less ‘bounded’ at the corners and thereby extends the interior space.”

There were structural challenges using glass in these locations, says Janus, but, “excellent engineering gave us the desired solutions. The glass and fibreglass were used firstly for the usual reason of providing light to the interior, but also to create a feeling of openness from the interior by virtue of its placement at

Glass was used to enhance the building’s transparency so its mass doesn’t loom over the street and create hard boundaries.

corners and edges.” Fearn notes that installation of the glass with the fibreglass panels is no different than other types of glass installation.

In the glazing, Flynn used products from U.S. Aluminum’s 2200 Series cur

tainwall, 550T Series doors, 7200 series casement windows and 3000 Series slid-

by ADAM MITCHELL

Unique, innovative, custom facades are the hallmark of Audi dealerships across the world.

Their design ethos centres around the creation of a unique brand experience that is both iconic and unmistakable in any environment. Just like Audi’s vehicles, nothing short of extraordinary performance and beautiful esthetics will suffice.

Challenges present themselves in any construction. When the new Audi dealership in St.Catharines, Ont., was built, the distinctive building design required a unique glazing solution for a prominent corner of the building. A steel beam impeded the installation of traditional insulated glass units, resulting in the need for a specialized solution. Agnora’s Vision90 IGU was the perfect product to meet these uncommon circumstances for Fairview Glass and Mirror, the glazier responsible for the challenging installation.

The Vision90 is a proprietary insulated glass unit designed

Fabricators: Agnora

Glazing contractor: Fairview Glass and Mirror

Glass: Corner insulated glass unit: 10mm tempered SGG

Cool-Lite Xtreme 70/33 II Diamant

and fabricated by Agnora. Traditional IGU’s meet at a corner, leading to an overlap creating an unsightly join. The Vision90 eliminates this look by marrying four mitered pieces of glass, a spacer and a proprietary sealant to create a glass corner yielding perfect visibility.

“Fairview had a condition that was hard to glaze in a traditional sense. A post in the corner of the building was so close to the glass that it would not allow Fairview to properly seal two traditional IGU’s at the corner,” explains James

Cole, senior project manager at Agnora. “Fairview asked if we could make our Vision90 corner unit for this installation, since the corner comes as a singleglazed product.”

Traditionally, Agnora fabricates all Vision90’s with a 90-degree angle as standard. However, a bespoke, 76-degree angle was needed to align with the building’s layout.

“This type of IGU is serving a purpose that is different from to the market we originally designed it for,” Cole says. “We envisioned this beautiful glass for homes and galleries and here it is making it easier for the glazier to install around a site condition.”

Getting jiggy with it

“I’d seen some prototypes of the specialty IGU on Instagram, so I reached out and asked, ‘Do you think you could do a more acute version of that?’ Agnora isn’t one to step away from a challenge,” says David Roberts, operations manager at Fairview.

Agnora designed and fabricated two custom Vision90’s for the project. The resulting glass was a fully sealed IGU, joined at a 76-degree miter using Agnora’s proprietary bonding, resulting in a seamless corner. The inner and outer lites consisted of 10-mm tempered SGG Cool-Lite Xtreme 70/33 II Diamant with a 12-mm spacer running the perimeter.

One of the challenges in manufacturing this uniquely angled glass was that Agnora did not have any jigs inhouse that could be used for the project.

“All of our jigs were designed for 90 degrees, so we didn’t have anything in house for that specific dimension,” Cole says. “It being a sharper angle added to the complexity of the actual fabrication process.”

Louis Moreau, head of innovation and technology at Agnora, created an entirely new jig and alignment method to satisfy the highly specific angle.

“We had to reassemble and create a new jig, and we succeeded,” he says. “Since the Vision90 is a fully sealedcorner IGU, alignment of the bonded surfaces is paramount.”

To ensure a successful installation, Fairview carefully laser measured all the dimensions for the pieces and sent them to Agnora prior to fabrication.

“Everything fit like a glove: the corners, the angles. We didn’t lose a piece of glass on that job,” Roberts says.

“The Vision90 IGU has the unique benefit of being just like any other window. It is a complete unit. There are not two IGU’s you need to align, use foam spacers, and seal. You just get the unit and pop it in,” says Cole. “It’s a

simplified installation process.”

Bigger is better

Roberts says that newly designed dealerships like the Audi in St.Catharines are requiring bigger and bigger pieces of glass. “On the Audi project, and the other newly designed dealerships, it’s glass everything and it’s getting bigger,” Roberts says. “The only place we could source the glass from locally was Agnora. They had no problem making the glass; they’re not going to let you down.” •

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

Due to its strong focus on the sectors of health and technology, Surrey, B.C., is the fastest-growing city in British Columbia. To serve the companies and agencies in these sectors, a number of new buildings have been constructed downtown, including City Centre 3. Close to all of downtown’s popular amenities, the 10-storey building is designed to achieve LEED Gold certification and has 9,000 square feet of retail space on the main floor. Construction began in 2018.

CC3 is steps from the Expo Line, the future light rail train to South Surrey and Langley City Centre, and blocks from the King George SkyTrain station. The eighth floor in particular provides broad views into the nearby valley. Over the entrance, the curtainwall is designed in a striking triangular shape, with the long tip of the triangle reaching upwards to the sky.

The construction firm, Lark Group, explains that in nearby City Centre 1 and 2, there are numerous health, education and technology-based organizations and professionals focused on innovation and B.C.’s emerging technology economy. Indeed, the

Glazing contractor: DESA Glass

Architectural firm:

WA Architects

Contractor: Lark Group

Curtainwall: Desa 2500 High

Performance Curtain Wall System (ground floor) and unitized curtainwall (level two through 10)

Vision sealed units

One foot overall 6mm Guardian

SN68 Crystal Blue tempered with low-E – warm edge spacer and argon – 6mm clear tempered

Spandrel sealed units - podium and unitized curtainwall

One foot overall 6mm clear HS with Harmony Blue on surface #2 –spacer – 6mm clear tempered

Spandrel sealed units

outward leaning wall

One foot overall 6mm clear HS –spacer – 6mm clear HS with Warm Grey on surface #4

Glass ceiling (in continuation of outward leaning wall at L2) 21mm overall laminated glass, 10mm clear tempered – .060 Warm Grey interlayer – 10 mm clear tempered

Total building footprint 133,500 square feet

Completed 2020

entire high-profile Health and Technology District in Surrey is home to a network of academics, entrepreneurs, multinational and start-up companies, along with some of the most advanced digital health, wellness, technology and clinical service organizations. Amenities of City Centre 1, 2 and 3 include state-of-the-art fitness facilities, secure underground parking, retail outlets and restaurants, and a common rooftop terrace. CC3 is the latest in a

The entrance of the building features a frosted glass canopy that is integrated with the angled soffit.

series of eight more buildings planned for the district. Vancouver-based virtual/augmented reality company Stambol Studios has created a 360-degree virtual rendering of what the district will look like in future, and this firm (fittingly) already has an office there.

Architect Joel Smith is the designer of CC3 and principal at WA Architects of Vancouver and Victoria B.C., a firm over four decades old. In terms of how glass fits into the overall purpose and design, Smith says, “the primary expression of CC3 is its glazed curtainwall, which envelopes the majority of the building and is highlighted with a dynamic angled truncation at the southwest corner. The truncated glazed geometry at this corner and the sloped soffit below was challenging to detail, but the result is exciting and dynamic.”

Since CC3 is a health and technology-

focused project, Smith and his colleagues chose blue-tinted vision glazing and dark blue spandrel glass, evoking reliability and competence. “The glass canopy on the south side is glazed with frosted glass,” adds Smith, “which provides weather protection and filters light to the pedestrian realm below.”

Glazing fabrication and installation was handled by Desa Glass, located east of Calgary, Alta. Founded in 1988, the company fabricates and installs a wide variety of aluminum performance systems from its 68,000 square-foot new state-of-the-art facility. Over 90 percent of its aluminum profiles and gaskets are produced in Canada.

President Dan Barker notes that while the CC3 project was quite straightforward, the Desa 2500 high-performance curtainwall system used from level 2 to 10 had an angled truncation in one cor-

ner, which provided a few small challenges. “The biggest of these was to re-design the custom entrance soffit,” he explains. “The initial design wasn’t going to work structurally, so we had to design a new ceiling that would be structurally sound and also look good in terms of complimenting the other building elements. It turned out very well.”

At the entrance, there was also a frosted glass canopy that had to be integrated with the angled soffit. “It was the first time we installed this sort of sloped canopy and since then we’ve done a few similar canopies,” Barker notes.

Since that curtainwall system was installed, Desa has created products that are higher performance through its inhouse design and engineering team to meet the Net Zero Ready 2030 national building code. •

Variant, developed by SolidCAD, is a web-based configurator that is built on the Autodesk Forge platform and was developed for manufacturing customers that want to streamline their quotation and design-to-manufacturing processes.

Variant goes well beyond Configure, Price, Quote (CPQ), where a user (whether it is a manufacturers internal sales team, a prospective customer or dealer) can make product selections almost anywhere with an intuitive web interface. The results include a 3D viewable model, associated bill of material and professional quotation. Key Features

or give us a call at 1-877-438-2231

by ANDREW SNOOK

The look of downtown Winnipeg has been changing significantly over the past few years. Unlike many other major cities across Canada, towering office buildings have not been a significant part of Winnipeg’s downtown core. That is starting to change. One reason is the ongoing construction of True North Square.

Once construction is complete, True North Square will feature four office towers with more than one million square feet of combined office space, retail space, public space and a hotel (Sutton Place Hotel and Residences).

The first two towers have been constructed with the remaining tower projects and hotel construction currently underway.

Construction of the first tower, a 17-storey Class A office and retail building located at 242 Hargrave Avenue, was completed in June 2018. This milestone marked the first privately developed office building to be built in almost 30 years in Winnipeg.

The general contractor on the first two towers (and an additional tower currently under construction) was PCL Constructors. Chris Erbus, envelope superintendent on the project for PCL, said accuracy during the construction of the structures of the buildings was extremely important because of the curtainwall system that was used.

“The building was 3D-modelled and we utilized Total stations and engineers to do layout of the embedded anchor pockets provided by Gamma [PCL’s curtainwall subcontrac -

Architect: Perkins and Will, Architecture49

Envelope consultant: BVDA Group, Crosier Kilgour and Partners

Glazing contractor: Border Glass

Glass: 1,400 double and triple IG prefabricated glazing panels

Projection completion: Tower 1 2018 and 2019

General contractor: PCL

tor]. They provided the pockets and those were cast in place. They were laid out according to Gamma’s requirements for their curtainwall system. That was the main focus during the construction of the structure itself,” Erbus says. “There were some other aspects that had to be taken into account as well, like our man and material hoists required tie-backs for the building, and we had to make sure it wouldn’t interfere with the installation of the curtainwall. The crane tie-backs were strategically placed so we could optimize the installation around those required components. After that it was managing the installation of the different types of curtainwall that we had on the project.”

The first four floors of the 242 Hargrave Tower had a

The five-sided building design created some challenges for the curtainwall fastening system.

unique design that needed to be taken into consideration during its construction.

“The first four floors are a mix of stick frame curtainwall with one floor of a unitized system that goes between two structural floors,” Erbus explains. “Then above the fourth floor, that’s where it’s four-sided structural sealed unitized curtainwall.”

One interesting aspect of the design of the first tower is that it has five sides.

“It’s kind of like a pie shape with a north, east, south, west, but then a face that has a slight curve to it, which faces the northwest that oscillates. This is one of the defining features of this building. One side of the building – on the north side of that northwest face – it steps outward, so each level kind of comes out more. Then on the south end of that curved face, it steps in,” Erbus explains.

“From level four to level 17, it steps out about 15 feet on one end and then on the other end it goes in about 15 feet. The floor plate changes and the curtainwall does an interesting twist. That was a real big challenge in terms of getting the structure right, but also, it wasn’t a flat wall of curtainwall. You have a unitized system that locks together. Each unit along that system has a different connection at the top and the bottom. So that was probably the most interesting and challenging part of the curtainwall system on that tower.”

The majority of the glass for both towers was unitized, foursided structural sealant glazing system produced at Gamma’s plant in Quebec City.

“The glazing system was a triple-glazed system. They utilized the triple-glazed system for an increase in thermal performance, so we didn’t need perimeter heating systems around the building,” Erbus says.

Sheldon Howden, field manager for Border Glass, the installer that worked on the first and second floors and the podium of the Hargrave Tower glass installation, and all of the installation for the second tower, says that getting the heavy glass units to where they needed to glaze it was challenging at times during the first tower’s construction.

“The first and second floors were all triple-glazed big units –heavy glass. For the second floor, we actually had a spider crane set up with a manipulator to angle the glass out of the openings and then flop it back upright to actually glaze into the exterior of the curtainwall, just because we had no access to the outside,” he says. “You’ve got 700- and 800-pound units and you’ve got a few inches either way to get them through.”

For the podium, they used all Alumicor products.

“It was 2600 four-sided SSG,” Howden says.

On the second tower – a 25-storey residential rental building equipped with office and retail spaces – Border Glass installed all the glass for the bridge, podium and tower using a unitized curtainwall system between March 2018 and August 2019.

The first floor was all triple-glazed IGUs with duals installed for the rest of the way up the tower with the exception of the penthouse, where some triples were used.

The two towers are built in compliance with the National Energy Code using the performance method. •

by SUKANYA RAY

At the eastern edge of downtown Toronto, a residential community is being built since 2009 that is breaking new ground with every phase of the construction process. Nearing the completion of its fourth phase, the River City Development consists primarily of condominiums and townhouses. Of this, the design of River City 3 has managed to capture the attention of the construction community specifically after accolades for its design.

Saucier and Perotte Architects and Zas Architects came together to design the entire River City project, including River City 3. The idea was to create a livable, sustainable neighbourhood in the area, according to Paul Stevens, senior principal at Zas Architects. “Architecturally, we wanted to develop a community that looked quite different from other multi-residential projects in Toronto. We joked that there were too many buildings with green and blue glass everywhere. We wanted to create something visually appealing on the skyline.”

Stevens notes that, typically, glass is one of the weaker envelope components in terms of energy, heat gain and loss in a building. However, it was also very important to use glass as people want bright units with great views. Therefore, the team of architects wanted to use glass in a way that would contribute to the sustainability requirements of a LEED Gold project.

Architect: Saucier and Perotte; Zas Architects

Glazing Contractor: Quest Window Systems

Structural: Read Jones Christoffersen

LEED Consultant: WSP

IGU: Pilkington grey-tinted solar and Cardinal low-E 272

Fenestration: Ecowall window system, Italian lift and glide sliding patio doors

Completed in: 2019

“We wanted to use glass in a way which was meaningful, that was sustainable. Glass is typically one of the more expensive components in a building, so we wanted to be able to work with a budget for glass that may include different types of glass or different patterns of glass that would improve architectural expression of the building,” explains Stevens.

The River City 3 building has about 40 to 45 percent glass, in terms of overall building envelope. The team specified low-E products. Double-glazed units were used as triple-glazed prod-

ucts were out of budget. For the purpose of energy efficiency, the team wanted to minimize heat loss through frames of the curtainwall and window wall systems. Therefore, the largest possible glass panels were created.

Stevens notes that to get as much visibility as possible, the architectural team pushed very hard to use as much curtainwall in the project as possible, especially in the retail spaces around the base of the building. Window wall systems were used in areas that have large balconies.

He adds that a range of glass products were used in neutral colours.

“We used black smoked glass that had a lot to do with how we would like to transition between metal panels to glass panels. We also used patterned glass. This was not only just overall patterned panels but also panels that fade as you move across horizontally. It goes whiter and whiter untill the glass is 50 percent translucent. In other places, the

DEMO DAYS is a new manufacturers video portal which will help you learn about new products and services from Canada’s leading manufacturers.

DEMO DAYS features dozens of video demonstrations in a variety of categories: Additive Manufacturing, Automation, Cleantech, Cyber Security, Electronics and Electrical, Maintenance, Manufacturing/Production, Material Handling, Packaging and Software.

panels go from 50 percent translucent to 100 percent opaque.”

To meet the city’s design guidelines, bird-friendly glass was used throughout the base of the building. For the glass balcony panels in the building, tempered glass has been used. Stevens explains that if anything were to happen, the tempered glass would shatter into tiny pieces instead of large ones.

Quest Window Systems was tasked with adding the glazing and fenestration elements to the building to complete the vision. Martin Cash, CEO of Quest Windows, notes that a variety of materials were used in the project. “We used our own Ecowall window system, which was the primary framing system for the residential component. It was enhanced with our own proprietary awning windows with European multipoint hardware and our Italian lift-and-glide sliding patio doors.”

For the glazing, the architects speci-

fied a combination of Pilkington greytinted solar glass and Cardinal low-E 272 in the insulated glass unit. Additionally, Quest Windows manufactured its own proprietary curtainwall system, which was a four-sided silicone SSG system. It was glazed with a similar combination of glass, but the inboard light was laminated to meet the STC ratings that were required and specified on the project. Cash further adds that the ground floor areas were done with a proprietary stick-built curtainwall system. And that was done with four sided SSG glazing as well. “We used a Phantom-designed commercial door, which is, in effect, a front-glazed style of Phantom commercial door and entry system,” says Cash.

Cash explains that to install the glass and fenestration systems all tools known to the industry were used, including scaffolding, swing stages, spider cranes and tower cranes, to achieve the astounding end result. •

by SUKANYA RAY GHOSH

Glass Canada hosted its second virtual Top Glass Conference and Exhibits on April 21. The constant challenges thrown by COVID-19 have ensured that people around the world keep learning to adapt, evolve and make the best out of the situation. The first virtual Top Glass event hosted in 2020 offered an excellent learning opportunity. The result was that this year, though virtual, the event

had more to offer and had excellent engagement throughout.

To kick-off the day, Gary Watson, senior associate at Diamond Schmitt Architects, discussed how the last year has impacted and changed everyone. He noted that the Zoom icon represented one of the greatest shifts of everyone’s lives. In his office, the internet system has become the cornerstone of culture and communication. Watson discussed how the virtual lifestyle has removed geographical borders. Residential real estate transactions are hitting new records. Construction companies have quickly embraced technology to adapt to the changes. Evolution of 3D printing technology is making a significant impact in the industry and setting the course for the future. He also observed that architects are shifting towards “less-glass” buildings in an attempt to be more environment conscious, but there are glass technologies that can offset solar heat gain or increase it during winters that can help save energy. He ended by saying that the pandemic has taught us the value of our environment and encouraged everyone to find a way to build better buildings.

Mark Jacobson from Kuraray America gave an update on glass lamination technology. During the presentation, Jacobson discussed the types of interlayers used in laminated glass; the added benefits of each interlayer; architectural uses of laminated glass; testing and standards; and compatibility issues. He focussed on two types of laminated glass, those made with polyvinyl butyral

and those made with ionoplast. He ended the presentation with the following conclusions: both PVB and ionoplast laminates break safely; both PVB and ionoplast interlayers glass offer safety and versatility; laminated glass complies with building code requirements for safety and impact resistance; and laminated glass provides impact resistance to windborne debris in hurricanes and bomb blasts.

For the third session of the day, Will Nash from WSP talked about low carbon building materials specifically for the glazing industry. Nash noted that we have a clear consumption problem as our annual consumption is roughly 1.75 times what the Earth can sustain. Nash explained that to produce a life cycle assessment of buildings, it is a necessity to get Environmental Product Declarations of the different components going into the building. The EPDs point out the global warming potential of the materials. An international standard called PAS 2080 provides a framework for carbon management in infrastructure. Alternative materials were also discussed.

The last session of the day on swing stage technology and safety was presented by Rik Vandelinde from Winsafe. During the presentation, Vandelinde talked about the types of suspended/ swing stages; the access challenges to consider when designing buildings; regulations; and the types of temporary access systems.

The audience stayed alert and interested throughout, with questions pouring in during each of the sessions. •

GOODBYE VIRTUAL SHOWS, HELLO REAL PRODUCTS, REAL PEOPLE AND REAL BUSINESS OPPORTUNITIES.

THE LARGEST GLASS, GLAZING, WINDOW AND DOOR EVENT IN THE WESTERN HEMISPHERE RETURNS FOR BUYING AND BUSINESS BUILDING THAT ONLY AN IN-PERSON TRADE SHOW CAN DELIVER. BACK TO BUSINESS. BACK TO GLASSBUILD. SEPTEMBER 13-15, ATLANTA

The owners of Griffin Glass are “not scared to try anything.”

The owners of Griffin Glass have aggressively grown their business with a “young mentality.” That’s enabled them to land some high-profile projects, like this one in Calgary’s University District

While Trevor Whyte may have had his start in the glazing world at the family business as a teenager, he’s gone on to co-own his own booming business, which he and his business partner, Travis Ward, have grown significantly in both size and capabilities. Griffin Glass, first started in 1960, now provides a full range of glass and architectural metals for industrial, institutional and commercial construction projects. It was one of Alberta’s first construction companies to acquire a certificate of recognition for safety.

Whyte was only 14 years old when he started working at his father’s glass company in Calgary: Metro Glass Products, a firm started by his grandfather. As many young family members do, he began by sweeping floors. Eventually, he was moved into fabrication, but Metro Glass was more of a supply than a fabrication business. And because Whyte found he liked the challenges of fabrication, he branched out to become a certified glazier.

His apprenticeship began at some

smaller local glazing firms, but when approached by Griffin leadership to come and work there, Whyte decided to take the offer. “I made the jump in 2000 and slowly worked up the chain from there,” he says. “I obtained my ticket in 2005 and Travis also earned his journeyman ticket at Griffin around that time. I offered to purchase shares in 2009, and then the previous owners announced that they wanted to transition out. A few years later, Travis and I were the sole owners.”

So, what were a couple of smart young men with a passion for glazing to do with a company that, while well-established, was small in terms of projects (in both size and dollar value) and workforce? Grow it, of course, by updating the firm and implementing fresh ideas.

“To give an idea of what things were like, our receptionist was still using a typewriter prior to us obtaining full ownership of the company,” Whyte explains. “I think the previous ownership group were hesitant in welcoming changes and adapting to the ever-chang-

Location: Calgary No. of Staff: 30

Founded: 1960 Facility: 5,000 sq/ft

Griffin Glass provides aluminum entrances, storefront, windows, glass and glazing, skylights, curtainwall and automatic operators in Calgary and southern Alberta. Notable projects include Block 23 and Central Park, 4th Street Underpass and the Calgary Stampede Agriculture Building.

ing construction world. The mentality was to stick to the basics, standard curtainwall, straightforward glazing projects, nothing out of the ordinary. But we have a different mentality. We’re not scared to try anything.”

Learning by doing

However, the road to success is seldom smooth and Whyte and Ward obviously had challenges to contend with. “I would have to say the biggest chal-

them to glaze a complex connecting structure called “The Jewel.”

lenge in the early years of ownership would be not having any mentorship during the transition from employee to ownership roles,” says Whyte. “At that particular time, we had a lot of work on the books and in full swing but, looking back, I wouldn’t change a thing. It essentially forced the two of us to grow up quickly, getting thrown to the wolves the way we did. We learned a lot in a very short period of time.”

When they caught their breath, Ward and Whyte began investing significantly in company growth, from investing in enterprise resource planning software to purchasing new heavy equipment (they now have three boom lifts and a scissor lift, for example). They also expanded their fabrication facility by adding another bay and have also now acquired the building where their business is situated.

“We grew the business by putting back into it,” says Whyte. “Staffing in the early days was also a bit difficult in terms of recruiting qualified and trustworthy individuals. This type of glazier was hard to find. They are assets that other firms hold onto by treating them well. We have done the same. Over the years we have built a family-type mentality in the office and in the field that I am extremely proud of. This is an environment that I believe attracts qualified glaziers as it seems we do not have to actively pursue these individuals anymore. They want to work here based on the reputation we have created.”

Whyte enjoys coming to work and its important to him that everyone else at Griffin Glass does too. “We have a great comradery throughout the business, and we all have our own jobs

SOME SEE A CURTAIN WALL

WE SEE AN OPEN OPPORTUNITY TO COLLABORATE

High-Performance Curtain Wall at York University’s Schulich School of Business

Visit obe.com/case-studies to see how our team of technical experts partnered with the glazing contractor to take this project from vision to reality. Let’s solve your next project, together.

we need to perform to ensure the company is profitable but we have fun doing it,” he says. “I also feel amazing that with my contribution to this company and my ownership role that I have earned, I can provide jobs for others, especially in these trying times.”

As they grew in size and capability, Griffin Glass took on greater and greater

challenges. Among the projects that they have successfully completed that Whyte describes as, “let’s say, very interesting,” is the glass canopy at the NE Shaw facility located in North Calgary. (It’s actually the first picture that appears when one visits the Griffin website.) This project consisted of a full-day 3D scan and 150 pieces of opaque laminated glazing, not one alike.

Whyte adds, “one project that has

Inside the facility of Griffin Glass.

tested our skills to a level not seen before is on our University Block 23 project.” Known more broadly as Block 23 and Central Park in Calgary’s University District, the project is a combination of a large central park space (green space, four-season public use areas such as a skating rink, water fountain, a staging area for concerts, a picnic area complete with tables and barbecue pits), coupled with a retail development (Staples, Cineplex, daycare, restaurants) on an adjacent parcel to the north. Structurally, explains Whyte, the project “consists of two four-story buildings, a parkade that connects the two buildings and a ‘feature’ pedestrian access structure called the ‘Jewel’ [that features custom-fritted glass]. In all my years, I have never seen anything like this, a structure that lives up to its name.”

Another interesting Griffin project is the 4th Street Underpass in Calgary, part of an upgrade of several of the city’s downtown CP railway underpasses because they were dark,

MATERIALS

Galvanized/Mild Steel 26ga to 1/4”

Painted and Anodized Aluminum 0.032” to 1/4”

Pre-painted Steels

Stainless Steel/Brass/Copper/Zinc

SERVICES

Shearing/Punching/Notching/Routering/Bending

Stud & Spot Welding

Assembly/Prototypes

Backpan Fabrication

unpleasant and even considered unsafe, so used only out of necessity. The 4th Street Underpass is the main gateway and key corridor for pedestrians and vehicles moving between the Beltline and downtown core, and each day over 8,000 pedestrians pass through it. Along with re-vamping and updating the corridor structurally, the project also includes a large-scale electronic artwork project. As described by Skyrise Calgary: “Aside from offering a brighter, cleaner atmosphere, the artwork’s animated light and colour responds to the flow of people through the space, making it a dynamic piece.” Whyte explains that it required 200 laminated glass panels, every one a different size. “It’s the neatest thing,” he says, “and we as Griffin Glass are proud to be a part of this City of Calgary enhancement feature.” (Video is available on YouTube.)

Some of many other Griffin projects include the Calgary Stampede Agricultural Building, the University of Calgary downtown campus, the Canalta Centre in Medicine Hat and the Inglewood Bird Sanctuary and Nature Centre. Located just five kilometres east of downtown on the Bow River, the Sanctuary’s Nature Centre looks out on 36 hectares and includes an exhibit hall and meeting space. It is currently being expanded due to increasing demand for outdoor education.

Right now, Whyte is “truly proud” of where the company is in terms of its present success and also “extremely excited” for the years to come. “We’ve shaped our firm in a way that we can compete on projects that range from simple storefront repairs to multi-million-dollar buildings,” he explains. “This not only gives us the advantage when the economy is prospering and construction is booming as we can choose the projects that best suit our company, but when construction is slow, we’re not governed by a small niche or subject to a certain defined range of projects that we can pursue. I don’t know what the future holds as the construction industry is a rollercoaster at the best of times, but our vision is to keep growing the business on all fronts.” While he builds his business, Whyte maintains a strong focus on building the industry and the trade as well. He is president of the Provincial Glazing Association of Alberta, an umbrella association encompassing both the Glass and Architectural Metals Association (GAMA) and the Glass Trades Association (GTA). He’s past president of GAMA and a presiding officer for his local apprenticeship committee and and sits on the Provincial Apprenticeship Committee board. This keeps him plugged in to Alberta’s system for regulating the trades and developing training and labour policies. Just because he co-owns the business now doesn’t mean Whyte has forgotten his roots as an apprentice working his way up.

Whyte says he owes everything that he is, personally and financially, to his business and to the glazing trade. “I’ve met so many great people and made great friends, some I even consider family,” he says. “Most importantly, I’ve been able to provide for my two children and give them a life that in their eyes makes them proud of their father for creating.”

by RICH PORAYKO

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company. richp@constructioncreativecom

Unprecedented times. It’s my daily mantra. Everyone is saying the same thing: it’s a mess. COVID continues to wreak havoc. Lead times are way out. There are glass shortages everywhere. Primaries are rationing allocations. Logistics is a nightmare.

On the bright side (I hope), there have been two price increases in six months. Considering that lumber has nearly tripled since falling off a cliff last March, this increase should probably stick for a while.

Labour continues to be a major pain point. It’s deja vu all over again with companies poaching workers on job sites with cash bonuses. How and where the industry looks to recruit people has changed. Chances are that you are old and reading this in a magazine or on a desktop computer. That’s okay, I’m old, too. I also know the importance of understanding the market I want to reach. In this case, 15 to 25-year-olds who think and behave very differently than myself and my peers.

At the recent BC American Marketing Association (re)Vision Virtual Conference, Phil Hsia, business solutions manager with Snapchat, had a fireside chat with Arak Bhokanandh, vice-president of digital for Clearly on marketing to Millennials and Gen Z.

“Gen Z now makes up 30 percent of the global population and will start to represent the lion’s share of commercial activity,” said Bhokanandh. “They are growing up in this internet and socially connected age. We look at their journeys and meet them where they are at.” (Please stop and read that one more time).

“The best way to reach someone who is Gen Z or a millennial is on their mobile devices. Specifically, on social apps.”

“At Snapchat, we understand the value of Gen Z and millennials,” said Hsia. “This platform reaches two out of three Canadians between the ages of 13 to 34. We do internal research to understand our audience and it always comes as a surprise how much they are involved in the current social situation. They have really leaned in. They want to make a difference. Gen Z and millennials are trying to change the world for the better.”

“This generation are truth-seekers,” agreed Bhokanandh. “They listen and care about social issues. They are holistic.” He said that this age group cares if a company embeds its values. “This generation has been even more selective in the brands and products they engage with. They care about social justice issues. They care and lean far more in. They want products with longevity that don’t have a harmful impact on the world.”

Bhokanandh told attendees that this generation is far more mobile. “Their device usage is more mobile. However, they are also mobile in their workplace and the way they go about their business. With the rise of the gig economy, they have a freedom of choice on how they earn their value.”

This changes how we communicate with them. “The reality is they want to get stuff done really quickly,” said Bhokanandh. “Their attention span, with all of the noise out there, is really short so any conversations or interactions with them has to be meaningful and direct.”