Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

12 Canada’s great glazing

FEATURES

22 BEC sprint

Rich Porayko took a whirlwind tour of the National Glass Association’s Building Envelope Conference and sent this report on what he saw and heard.

26 Metalworking machiner y showcase

Glass isn’t much use without something to hold it. Here’s the latest in advanced metalworking equipment for aluminum and light steel fabrication.

ASSOCIATIONS

7 Canadian Glass Association

COLUMNISTS

10 The Engineer by David Heska

30 You Bet Your Glass By Frank Fulton

It’s our annual celebration of some of the outstanding glazing projects in Canada in the last year. Find inspiration in these beautiful and innovative achievements by your peers.

LETTERS TO THE EDITOR

Have your say

Got an opinion on something you’ve seen in the magazine? Have some information you’d like to share with the Canadian architectural glass industry? You can submit your letters and comments online by filling out our Letters to the Editor form at glasscanadamag.com.

Photo credit: Jess Redlarski

When a ban is not a ban

Tough talk about glass architecture could mean better business.

New York City mayor Bill de Blasio made quite a stir in late April when he seemed to announce New York would “ban” glass and steel skyscapers. Here’s his actual quote: “We’re going to introduce legislation to ban the glass and steel skyscrapers that have contributed so much to global warming. They have no place in our city or on our earth any more.”

The legislation he’s talking about is the so-called Dirty Buildings Bill, one of 10 bills passed by New York city council as part of its Climate Mobilization Act – a sweeping set of green initatives designed to bring New York in line with the Paris Climate Accords.

NEXT ISSUE

• AI fabrication

• SAIT training

Later in the announcement he goes on at some length about the evils of inefficient buildings, at one point bellowing that “our buildings must stop emitting so many dangerous pollutants.” I wasn’t aware that buildings actually emitted anything, but I suppose we can allow that he was taking a bit of an oratorical shortcut around saying “must stop contributing to the emission of so many dangerous pollutants by the energy sources that power them.” I admit his phrasing is definitely punchier and easier to understand. Though it does rather blur the point that if the buildings were powered by renewable energy sources or nuclear, they would not contribute to carbon emissions at all no matter how much power they drew.

• IGMA Summer Conference

Then things got weird. “If a company wants to build a big skyscraper they can use a lot of glass,” de Blasio went on, “if they do all the other things needed to reduce our emissions.”

Oh. So, far from the “ban” he mentions initially, we are talking about a tradeoff system to meet a whole-building efficiency standard.

So what is New York actually mandating? According to the Grist blog: “It requires around 50,000 of the city’s buildings to cut emissions by 40 per cent by 2030 and 80 per cent by 2050 by installing new windows, insulation and other retrofits to become more energy efficient.”

Given the age of most of New York’s buildings, renovations delivering 40 per cent improvements in energy efficiency are probably possible with off-the-shelf products that would have been due over the next 10 years anyway. So really the announcement is boringly similar to what has already been proposed or imposed in many jurisdictions across the continent. De Blasio’s fiery rhetoric about bans and dirty buildings should be seen in the context of a politician trying to look tough in the face of the powerful New York real estate lobby that has worked against tighter energy standards for years.

Do your best to act indignant in public about the insulting implication that architectural glass is a climate villain. Then smile to yourself as you cash your cheques for lucrative high-performance upgrades, paid for in part with the tax dollars of those slinging the slurs. •

June 2019

Volume 31 • Number 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR

| Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax)

U.S.A. - 1 Year $65.50 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

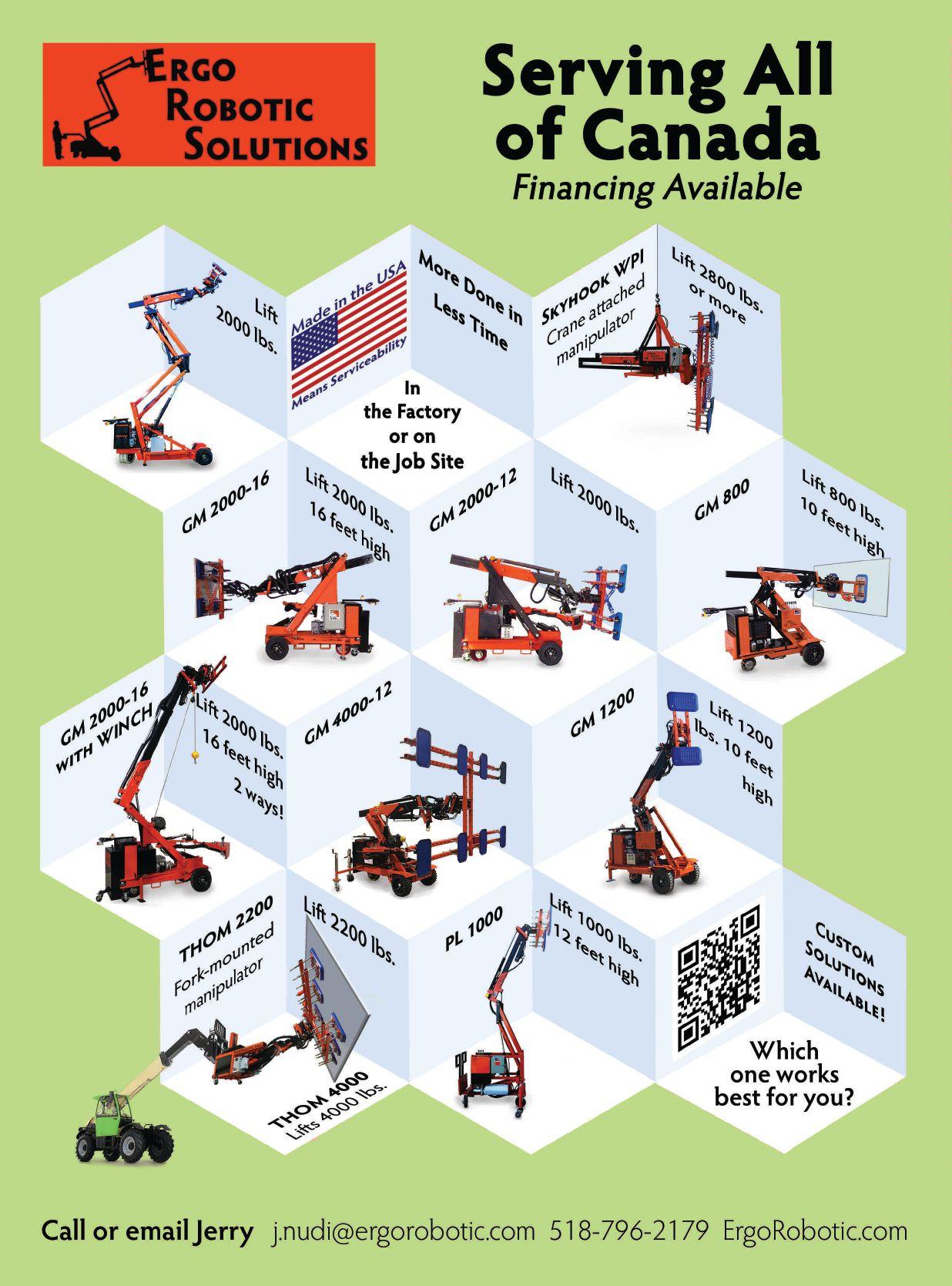

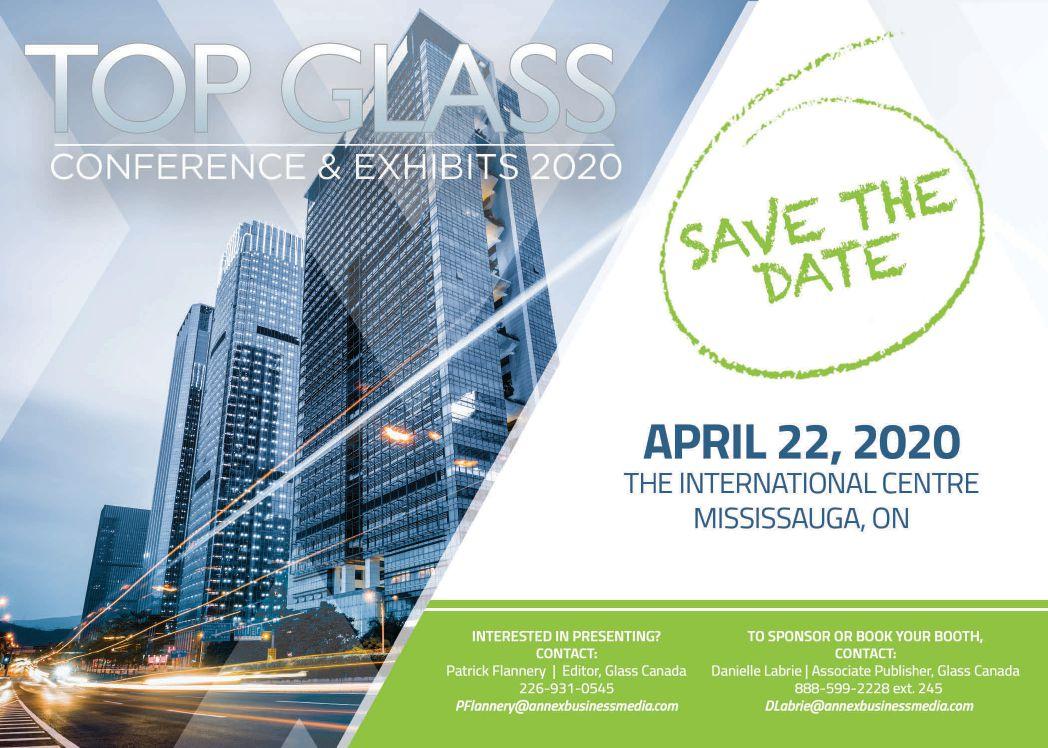

Top Glass crushes it

Top Glass 2019 surpassed all previous attendance records with over 300 glazing contractors, architectural glass fabricators, architects and other construction design professionals walking through the doors. They came to see 62 of Canada’s top suppliers of products for the commerical glass construction industry and to take in a sparkling education program addressing green building standards, bent IGU seal testing, contractor certification and anisotropy measurement science. But the numbers were not the real story. Most notable at Top Glass 2019 was the high quality of the attendees, with three out of four identifying as senior executives or owners of their organizations. Exhibitors reported solid business leads and even some deals being done right on the show floor. Energy was high and the strong traffic carried right through the day. Sessions were well-attended with a mix of architects, contractors and manufacturers asking many questions and even getting into some lively exchanges. Some attendees and exhibitors even took to Twitter to express their satisfaction with the day.

“What a day at Top Glass! Thanks to @GlassCanadaMag for putting on such an energetic conference!! “ - @GlasCurtain

“Happy to represent @ProvincialGlass at @GlassCanadaMag ‘s #TopGlassCanada A lot of smiles and laughs! “ - @BrettLucier

“All now set up and ready for visitors at the Top Glass Glass Canada conference and exhibition @GlassCanadaMag at the International Centre,Mississauga.” - @RegaLeadCanada

“Learning about green building standards and bldg envelope from Hamid Vossoughi P.Eng. @WSPCanada at #TopGlass @GlassCanadaMag” - @CdnConsultEng

“ The #TopGlassCanada Conference brings glazing contractors, curtain wall manufacturers, storefront fabricators, architects and building engineers together for a day of education, networking and review of the latest technology. - @halioglass

Top Glass returns to the International Centre April 22, 2020.

COMING EVENTS

June 6 - 8 AIA Conference Las Vegas, Nev. conferencearchitecture. com

June 16 - 28

Glass Performance Days Tampere, Finland gpd.fi

June 17 – 20

IGMA Summer Conference

Victoria, B.C. igmaonline.org

June 21

GAMA Golf Tournament Okotoks, Alta. pgaa.ca

Aug. 16

PGAA Golf Tournament Innisfail, Alta. pgaa.ca

Aug. 22

OGMA Fishing Derby Port Credit, Ont. ogma.ca

Sept. 17 – 19

GlassBuild America Atlanta, Ga. glassbuildamerica.com

Sept. 12

OGMA Fall Golf Woodbridge, Ont. ogma.ca

Oct. 23

FenBC Industry Conference Surrey, B.C. fen-bc.org

Nov. 12 – 14

IG Fabricator Workshop Plano, Texas igmaonline.org

CGA Newsletter

Canadian Glass Association

The Canadian Glass Association is considering organizing and funding industry support to update the withdrawn CAN/CGSB 12.20 standard for structural design of architectural glass. This standard has been allowed to lapse since the federal government stopped supporting standards development in 2002. Feedback we have received from around the industry indicates some interest in seeing this standard updated and referenced again rather than relying on U.S.dominated ASTM and ANSI standards in our codes.

As Canada’s only national organization for architectural glass contractors, the CGA is uniquely positioned to lead this effort. We’re inviting input from everyone in the industry as to whether you’d like to see us undertake this effort. We envision a fundraising drive would be necessary followed by formation of a technical committee to advise CGSB and work on the standards updates.

Please contact CGA president, David Langton of Competition Glass, (dlangton@compglass.com) to share your thoughts on this potential initiative.

Fenestration Association of B.C.

Thought leaders and fenestration gurus from Vancouver and beyond converged at Surrey’s Northview golf course on Feb. 28 for the Fenestration Association of BC’s annual Technical Conference and AGM. Back by popular demand, FenBC’s Code Talkers panel

Canadian Glass Association

3759 York Durham Line, Stouffville, Ont. L4A 7X4

Tel: 250.258.0578

canadianglassassociation.com

discussion returned to tackle the labyrinth of code interpretation and compliance issues facing western Canada’s building envelope industry. Moderated by Ply Gem’s Dave Goldsmith, the panel consisted of Al Jaugelis and David Vadocz of RDH Building Science; Centra Construction Group’s Anton Van Dyk; Gary Brown of SGB Services; Thomas Zaremba of Roetzel; and Vetrotech Saint Gobain’s Joseph Taylor. Arthur Huard of VIG Technologies provided an eye-opening presentation on vacuum insulated glazing sparking massive audience engagement that will be covered in further detail in a future update from FenBC.

RDH’s Graham Finch gave the keynote presentation “How the New BC Energy Step Code Will Impact Window Selection and Detailing” to provide more insight into where things are going in the window industry with a vision ahead for the next 10 or 15 years. According to Finch, triple glazing will occupy the greatest amount of space across the residential and commercial sectors.

Provincial Glass Association of Alberta

At the PGAA’s annual meeting on March 20, a new board was elected. The board was elected for a two year term, with exceptions as noted. Your new board is: Trevor Whyte of Griffin Glass, president; Jonathon Greenland of Alumicor, first vice-president; Keith Wallace of Metro Glass, second vice-president (returning); Gary Porter of Alberta Glass, past president; Mei Whyte of Metro Glass, treasurer; Taylor Wight of

Layton Consulting, secretary (returning); Dwayne Stolz of Leyden’s Glass & Mirror, director-at-large (returning); Ross Wady of All Glass Parts, director-at-large (returning); and Brad Simpson of Beacon Glass, director-at-large (returning). Congratulations to the new board.

Architectural Glass and Metal Contractors Association

It was great to see so many of our member glazing contractors at the Top Glass show in April. By all accounts, the show was a huge success and it was nice to have so many members of our industry drop by our booth to say hello. Top Glass provides an excellent forum to meet and greet our members and to talk about what is affecting them in the day-to-day running of their businesses. We look forward to participating once again at next year’s show!

As a reminder to our membership, be sure to check out our News section at agmca.ca for new and useful membership benefits. Some of these benefits include: membership with Two Grey Suits, a comprehensive online training course on employee engagement; an ever-expanding training library of e-learning webinars on critical HR topics; the HR Power Centre for dealing with the day-to-day people management issues that inevitably arise; and, when you need answers fast, you can talk to a senior HR Professional 24/7 through the TGS HR Hot Line.

Our members can also take advantage of AGMCA’s Commissioner for Taking Affidavits services (by appointment only).

Please contact our office for more information regarding Two Grey Suits, or to set up an appointment for Commissioner for Taking Affidavits services.

The AGMCA is continuously trying to improve and enhance services available to our membership.

Ontario Glass and Metal Association

OGMA President Andrew Dolphin and director Steve Gusterson had the honour of presenting the prestigious Awards of Excellence at the Top Glass show on April 17. The award for execution was presented to Angelo Cairo of Stouffville Glass for the Rob and Cheryl McEwen Graduate Study Building at the Schulich School of Business at York University, designed by Baird Sampson Neuert Architects and supplied by Oldcastle Building Envelope. The award for design was presented to Cannon Design for the York University Student Centre in Toronto installed by Applewood Glass & Mirror and supplied by Alumicor. The OGMA thanks the two architects who judged the project submissions: Adrian Phillips, senior project manager at the University of Toronto, and Paul Marcoccia, project architect with the City of Vaughan. LEE BAKER: At the spring golf tournament, Frank Fulton had the pleasure of presenting long-time OGMA director and friend Lee Baker with OGMA’s prestigious lifetime achievement award. Lee worked for many years in sales at Tremco and has also served as chairman of the Canada and Toronto Construction Associations. •

Duties on offshore curtainwall likely to remain

TheCanadian Border Services Agency has completed its review of Canada’s duties on imported Chinese curtainwall and told the Canadian International Trade Tribunal that dumping and subsidizing of Chinese products is likely to resume if the duties are removed. The report makes it likely that the CITT will leave the duties in place after it completes its investigation on July 3.

Since 2013, curtainwall imported by Jangho Curtain Wall has been subject to a 15.7 per cent anti-dumping duty and a 3.8 per cent countervailing duty. Yuanda’s imports have attracted duties of 49.3 per cent anti-dumping plus 5.3 per cent countervailing. All other imports of Chinese curtainwall have been hit with a 120 per cent anti-dumping duty and a 41.6 per cent countervailing duty. Jangho and Yuanda were assigned lower duties because they provided requested information to the CBSA in its initial investigation, while responses were absent or incomplete from other Chinese fabricators.

Countervailing duties of this kind are reviewed every five years. The CBSA began investigating the matter in the fall of 2018 to determine if the unfair Chinese practices were likely to resume if the duties were allowed to expire. It issued its report to the CITT in late January.

It found that “weakening [curtainwall] market conditions and the excess production capacity in China; the increasing export orientation of Chinese producers, the attractiveness of the Canadian market and its increased competition from domestic and foreign sources, along with the propensity of Chinese exporters to undercut Canadian prices” would likely cause Chinese exporters to resume dumping product in the event the duties were removed.

Schiavon leading Forel

Marco

Schiavon has been appointed CEO of Forel North America, a manufacturer of glass processing machinery. As CEO, Schiavon will oversee the operations at the St. Paul, Minn., and Toronto locations. Schiavon has been employeed at Forel for over 30 years and has gained extensive experience in the glass industry. During his career, Schiavon has held various positions of responsibility within the organization. Schiavon has extensive experience within the North American market, an area that has always been a strategic focus for Forel. With the aim to focus on further company development in North America and to offer customers in the U.S. and Canada an increasingly efficient customer service, both before the purchase and after installation, it was decided to entrust the management of the North American branch to Schiavon.

“Schiavon has a clear understanding of our customers’ needs,” said Riccardo Vianello, chaiman of the Forel board.

It also found that “the continued availability of subsidy programs for [curtainwall] exporters in China, the subsidizing of primary aluminum in China and other government intervention in the primary aluminum industry and the countervailing measures against Chinese aluminum products in Canada and in other jurisdictions” would likely lead to continued subsidization of Chinese curtainwall by the Chinese government if duties were removed.

Twelve Canadian glazing fabricators responded to the CBSA’s questionnaire as part of the review: BVGlazing Systems, Ferguson Neudorf Glass, Flynn Group, Contract Glaziers, Inland Glass & Aluminum, Integro Building Systems, Antamex (formerly Oldcastle), Quest Window Systems, Sotawall, Starline Windows, State Window and Toro Aluminum.

Chinese exporter Shenyang Yuanda also responded but “did not explicitly express an opinion with respect to the likelihood of continued or resumed dumping and/or subsidizing.” It did “contest some of the allegations made by the Canadian producers.” Specifically, it argued that the Chinese economy is experiencing slower growth rather than contraction and that demand for curtainwall in China will remain stable. It said lower project prices in China combined with higher project prices in North America did not add up to an incentive to dump product. No Canadian curtainwall importers responded to the questionnaire, and neither did the government of China.

The CITT’s investigation will focus on whether dumping and subsidizing by China presents a threat of “injury.” The report notes that the value of domestic sales of curtainwall in Canada increased by 8.9 per cent between 2015 and 2017 despite a 2.1 per cent reduction in volume.

AGMCC awarded U.S. non-profit status

The Architectural Glass and Metal Certification Council (AGMCC) – the governing council for both the North American Certification Council (NACC) and the Architectural Glass and Metal Technician Program (AGMT) – has received exempt status from federal income tax under Internal Revenue Code (IRC) Section 501(c)(3). To be considered tax-exempt under 501(c)(3), an organization must demonstrate organization and operation exclusively for an exempt purpose, more commonly referred to as charitable programs.

Marcy Rosen, AGMCC’s tax counsel at Schiff Hardin, explains that this recognition affirms the program’s mission. “501(c)(3) tax-exempt status is a reflection and recognition of the organization’s foundational principles and mission to benefit the public.” AGMCC can receive financial support to achieve these goals. but none of the organization’s earnings can be given to private shareholders or individuals.

David Bowles of Dermody, Burke, and Brown CPA’s states, “Under a tax-exempt status, businesses are able to function without the burden of tax consequences and focus on member services. As a 501(c)(3) the businesses can receive tax deductible contributions in addition to being exempt from income tax.”

Bernie Leaman, 1936 - 2019

Bernie Leaman, formerly of Commercial Aluminum, passed away at the age of 82 on May 12. Glass Canada columnist Frank Fulton remembered his friend and prominent leader in Canada’s architectural glass community.

It is with sadness that we share the news of the passing on May 12 of our friend and former royalty of the architectural metal industry in Canada. In our business, occasionally you will come across people who made a real impact on the industry. One of those people was Bernie Leaman of Commercial Aluminum. Bernie was that type of guy you were happy you had the opportunity of meeting. He always greeted people with a smile, was quick to laugh, personable, and fun to talk to – a very charismatic gentleman. Bernie Leaman started his working life as an office clerk in 1953 at the age of 17 and found his way into the glass and metal business with Millington Brothers Glass in 1955, doing the books, estimating, inside sales, and anything else that needed taking care of in the one-man office. That was his start to a long and rewarding career in our industry. Commercial Aluminum became part of the Indal group in 1965 and in 1969 Bernie was enticed to join the company and run the office for the princely wage of $55 per week. At the company Christmas party in 1976, Ian Moore announced that Bernie had been promoted to president of Commercial Aluminum. A few years later, Bernie opened a branch of Commercial Aluminum in Calgary.

Bernie always had a strong belief in people, their desire to succeed and a willingness to give them a break. Bernie gave many glaziers their start in business by extending them credit, while making it clear that his trust was not to be taken lightly. “You can’t be in business and stay in business if you are a dishonest person.”

Throughout his time in business, Bernie was a strong supporter of the Metro Toronto Glass Association, the predecessor to the OGMA, and served on its board for eight years as secretary, treasurer, and eventually president. To his final day, he has a plaque hanging in his home office dated June 22, 1977, honouring him as the MTGA Man of the Hour, beside the inaugural Lifetime Achievement Award bestowed upon him in 1998 by the OGMA.

When asked about the highlights of his career, Bernie cited all the marvelous relationships and friendships he cultivated with customers and suppliers during his career. “I have no negative memories whatsoever about my time in business … I loved every minute of it.” A few years ago, Bernie told me, “Everything I am today I owe to what I learned during my years spent at Commercial Aluminum”. We’re going to miss you, Bernie.

Greco buys Florida manufacturer

Windsor, Ont.,-based Greco Aluminum Railings has announced it has acquired Petersen Metals, a regional specialty manufacturer and installer of architectural metal products headquartered in Hudson, Fla. Petersen brings over 30 years of manufacturing experience in high-quality stainless steel, fabricated aluminum, mild steel railing assemblies and other custom architectural building components.

Dino Aleo, president of Greco, said, “Petersen Metals has an excellent track record of profitable growth over almost 30 years while maintaining its commitment to quality, service and technical proficiency. We believe this approach optimizes the company for long-term market leadership.”

With the acquisition, Greco expands its market focus from multifamily and commercial construction to now include educational, institutional, healthcare, retail, entertainment and hospitality projects. The addition of Petersen nearly doubles Greco’s manufacturing, sales, project management and installation services, thus strengthening the company’s national presence. Petersen’s added manufacturing capabilities include CNC milling and turning, press brake forming, coping, TIG welding and waterjet services, all which enable more efficient production across all product lines.

”Petersen brings complementary resources and talent to our team, and their line of architectural metal products expands our existing line of architectural railings,” says Jim Ellsworth, president of Greco’s U.S. operations. “The strategic integration of Petersen Metals will be implemented over the coming months and will be a critical part of our Greco growth strategy in the United States.”

UL shows off indoor test lab

ULopened the doors of its new building envelope test lab to members of the construction industry on April 11. Manufacturers, consultants, architects, owners and industry stakeholders attended the open house and were excited about the opportunity to install and test large envelope system mock-ups on a year-round basis at the largest indoor facility in Canada. Toronto deputy mayor and city councillor for Scarborough Centre, Michael Thompson, was in attendance for the ribbon-cutting ceremony and to recognize the Ferguson Neudorf team as the lab’s first customer. Located in Toronto, the new lab has been operational since November 2018 and serves the building envelope and building sciences market.The Toronto facility is one of the three UL Building Envelope test labs located in North America.

“We are excited to offer our testing services to one of the most active construction markets in the world,” said Joe Hosey, general manager for Canada at UL. “The expansion of our building envelope services in Toronto provides the construction industry throughout Ontario with access to an organization that is known worldwide for advancing building science.”

The Toronto testing facility can accommodate all forms of building envelope assemblies. The facility contains both a mock-up lab and a fenestration lab. The mock-up lab can test any fullscale wall assemblies, including window wall and curtain wall. It is located indoors in a 7,200-square-foot facility equipped with a 50-ton overhead crane and can test samples up to 37 feet in height, making it among the largest indoor facilities in Canada. The fenestration lab is equipped to test any sample size.

by DAVID HESKA

David Heska, P.Eng, is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows and residential buldings. He can be reached at David.Heska@wsp.com

Q&A on esthetics

Glass dominates the built environment and its quality and consistency can be an esthetic benefit or detriment. Building codes are stepping up the requirements for energy efficiency and for honest accounting of enclosure performance. This energy reckoning for assemblies often translates into designers squeezing every ounce of performance from glazed assemblies. In this article I’ve chosen to interview my colleague, Scott Armstrong, asking him a few questions on the visual characteristics of glass.

DH: In the past year you have been involved in numerous glazing projects. What are some of the experiences you’d like to share with our readers?

SA: Achieving a quality glazing product requires rigorous control through the entire fabrication and manufacturing cycle. An IGU must meet strict requirements for elements such as thickness, stress, bow, warp, roller wave, coating quality, seal consistency and sightline. Most manufacturers have extensive in-line quality assurance and quality control procedures to catch defects before they arrive at the fabrication plant or on site. Yet, we are regularly engaged to navigate late-stage discussions with owners and designers on quality and esthetics. Buildings with large glazed areas often rely on highly reflective low-E coatings to control solar heat gain and manage cooling energy intensity. Highly reflective coatings can exacerbate issues pertaining to esthetic quality since the exterior reflected image is pronounced. The reflected image in urban or clustered suburban environments often contains strong vertical and horizontal lines from adjacent

Glass flatness improves with thickness and better resists changes in flatness during heat strengthening or tempering.

THE ENGINEER

buildings. Coupled with the design trend toward sheer glass façades with narrow, flush joinery, distorted images become even more pronounced.

DH: What’s contributing to these esthetic issues?

SA: Heat treatment, especially tempering, can be a significant contributor to reflected image distortion since it can induce bow, warp, edge lift or roller wave to the finished product. Designers should consider whether the same durability and strength requirements can be achieved with heat strengthening rather than tempering to help mitigate potential distortion issues. Heat soaking can help reduce the risk of spontaneous breakage from nickel sulfide inclusions in tempered glass but using heat strengthened glass instead of tempered or heat-soaked tempered glass eliminates the risk altogether

Another trend is the use of thicker glass lites (eight- or 10-millimeter versus standard sixmillimeter) for the outer lite of an IGU. Glass flatness improves with thickness and better resists changes in flatness during heat strengthening or tempering. When coupling a thicker outer lite with a thinner inner lite, more of the cavity pressure will be distributed to the inner lite, reducing total distortion of the outer lite and exterior reflected image distortion.

DH: What can designers and owners learn from common complaints in the industry?

SA: Specifications should provide clear direction on which standards apply and what type of documentation is required to demonstrate compliance. Designers and owners should set reasonable expectations for optical flatness and should understand how some design decisions influence perceived quality of the finished product. In-line QA/QC procedures are the most reliable means for identifying non-conforming units and we advocate for third-party reviews of both production lines and QA/QC documentation. Setting expectations for quality early in the project provides the necessary benchmark against which future product can be evaluated. •

PAYING IT FORWARD

by JACK KOHANE

The new four-storey, multipurpose student centre at Canada’s third-largest university is designed to meet the changing needs of the institution’s diverse community, as well as for easily accessibility to the 55,000 undergraduate and graduate students. While most of the material palette is concrete, steel and glass, the 126,000 square-foot building’s interior includes an array of sustainable and user-led initiatives, including highperformance glazing/curtainwall and ample use of natural lighting. Daylight shines deep into the building through carefully placed skylights and numerous windows offer broad views of campus, while wide glass paneling encourages transparency to the landscaped outdoors.

The project’s Mississauga, Ont.,based glazing contractor, Applewood Glass, says the design process pushed many limits. As the curtainwall contractor, Applewood was responsible for the technical resolution, including engineering, of the structural supports, spandrels, seals and more. The process saw more than a few aspects of the original design adapt, but through close collaboration with all stakeholders, the student centre was completed in 18 months, instead of the projected two years.

Size proved one of the project’s major tests to pass. With some of the glass components, their sheer dimension proved daunting. Emanuel Santos, Applewood’s senior contracts manager, explains that to achieve the designer’s vision for the curtainwall, frames had to have the an appearance of floating off the building structure. “That required rethinking of traditional curtainwall fabrication and installation methodology,” he explains. Applewood used custom-fabricated stainless bottom edge support profiles which allowed the

edge of the glass along the bottom of the curtainwall frame installed on levels two to four to be projected beyond the physical limit of the supporting vertical curtainwall mullions. The IGUs required expanded copper mesh installed within to produce glazing units of the required sizes. This tested the extreme limitation of their fabrication capabilities. Special care when ordering had to be taken to ensure the orientation and pattern of the expanded mesh screen on the adjacent pieces matched to produce a uniform consistent appearance. To complete the fabrication of the larger-than-normal curtainwall framing panels, Applewood used overhead cranes and vacuum hoisting equipment which was purchased specifically for the job. Santos points out that the installation plan for the project was to keep stockpiling of frames on site to a minimum and to have the frames delivered to the site in a sequence that would permit immediate installation. •

AT A GLANCE –York University Student Centre

Architect: Cannon Design

Glazing contractor: Applewood Glass & Mirror

Mechanical/electrical engineering: MCW Consultants

Structural engineering: RJC Engineers

General contractor: EllisDon Corporation

Feature glass: Okalux Ornitech – triple-glazed units with copper mesh interlayer

Bird-friendly glass: Arnold Glas Ornilux Mikado

Standard vision glass: Viracon VRE1-59 insulating laminated

Oversized IGUs fabricated with bird-friendly UV-reflective coatings and expanded copper mesh were provided on a just-in-time basis to the job site.

COMMUNITY TOGETHERNESS

by ALAN DOWNWARD

Snohetta had one goal in mind for the new Calgary Central Library: create a strong visual identity for the Central Library that reflected its civic importance, one that referenced the ideas of community, togetherness and unity.

The Snohetta-Dialog collaboration reached completion in July 2018, and was embraced by the Calgary Public Library in September. The Calgary Central Librar y opened to the public on November 1, 2018.

As described by Snohetta, the aggregated variations on the hexagon form scatter across the building’s curved surface in alternating panels of fritted glass and occasional iridescent aluminum, portraying snowflake-like line work or interlocking houses. The pattern is contingent on all sides of the library. From an outside view, the Calgary Central Library has no distinguishable front because the exterior pattern stays consistent all the way around.

Dennis Rijkhoff, project architect at Snohetta, states the ideas of community, togetherness, and unity “led the team to create a bold pattern, composed of similar yet variable parts that work together to form a contiguous whole.”

In reference to the pattern and overlay of the glass, Rijkhoff said the hexagonal pattern “was designed to provide light and views, using a materiality that moves between transparent, fritted glass and opaque, iridescent metal panels.”

Due to Calgary’s cold but sunny climate, the facade was optimized to mitigate thermal, solar heat gain and glare conditions. Daylight exposure and views in each space were carefully studied for their effect on each interior space, as well as on the overall facade composition.

Many of the spaces along the facade are open and expansive. According to

Rijkoff,“The design process focused on providing a variety of conditions for people to enjoy in each space – the goal being that users can choose whether to sit in the sun or in the shade.”

Some areas of glass were also treated with a double-layered ceramic frit, white on the outward face to create a visual blend between glass and metal panel and dark grey on the inward face to reduce light diffusion and to preserve views to the exterior.

The facade is composed of 40 per cent glazing and 60 per cent insulated metal panels. The glazing is triple-pane low-iron, with argon-filled air gaps and two low-E coatings (#2 and #5 surfaces).

Snohetta is currently working on a number of projects internationally, including the Le Monde Headquarters in Paris and Temple University’s upcoming library. The Calgary Central Library is the third library Snohetta has complet-

AT A GLANCE –Calgary Central Library

Design architect: Snohetta

Executive architect: Dialog

Contractor: Stuart Olson

Glazing contractor: Ferguson

Client: Calgary Municipal Land Corporation

Size: 240,000 square feet

ed, in company with the Ryerson University Student Learning Centre in Toronto and the James B. Hunt Library at North Carolina State University. Stuart Olson is an Integrated construction and industrial solutions company. •

Ceramic frit was used on two surfaces to create the desired esthetics on the exterior while diffusing light on the interior.

A CROWN OF GLASS

by TREENA HEIN

Like any older hotel that’s aiming to thrive in today’s market, the Fairmont Queen Elizabeth in Montreal has again undergone renovations. Thanks to its updates, which include features like the stunning Espace C2 rooftop event facility designed by Sid Lee Architecture, the hotel remains of “one of the city’s top luxury and business destinations,” according to Azure magazine.

The Espace C2 pavilion has two levels: a lower level within the building and an upper space above the roofline that is totally enclosed with large panes of glass at angles that meet those of the spiky “butterfly” roof. Outside the space, the greater terrace of the rooftop is enclosed by glass railings which give visitors a feeling of seamlessly belonging to the city rather than any separation from it.

The interior of Espace C2 is designed, says the project’s architects at Sid Lee, to allow a wide variety of configurations so that it can be used in many different ways. Possibilities include a banquet hall, a cocktail dining room, a conference room and a unique workshopping space. The facility also includes a telescopic seating system installed below the mezzanine.

“Unfolded, the steps can accommodate spectators and it can even be converted into fun ball pits, providing an unconventional brainstorming experience,” the Sid Lee team explains.

To create an architecture that would be “invisible, with no barriers” and to create “an illusion of lightness,” for the pavilion, the threshold of the glass was encased in the pavement of the existing terrace rooftop.

The installation of a glass-enclosed pavilion on a hotel rooftop, as you can imagine, is quite challenging and this project involved a large amount of crane work. The crane had to be located be-

AT A GLANCE – Espace C2, Fairmont Queen Elizabeth

Architect: Sid Lee Architecture

Glazing contractor: Vitreco (Flynn Canada)

Glass fabricators: Prelco, Oldcastle

Vision glass: Energy Advantage tempered 6 mm exterior glass with black stainless steel framing, 6 mm airspace, and 8 mm clear low-E tempered interior glass

tween the Fairmont Queen Elizabeth and other buildings and therefore function within a narrow range of motion and at a significant height. “We had to get a lot of permits from the city and everything was done on weekends,” explains Vitreco project manager, Patrick Thibodeau, and service manager, Antoine Levasseur. “The pieces of glass were pretty large, so there

Glass railings: Double laminate 2-by10 mm tempered (interlayer instead of regular PVB so that if broken, nothing would fall down to the street)

Glass doors: Phantom doors (glass installed over the door instead of inside frame); Energy Advantage tempered glass of 76 mm thickness

was lots of coordination required.” The panes of the butterfly roof and the adjoining glass walls of the structure required careful placement at many different angles, but Levasseur notes that his firm has previously done similar projects and were well-prepared. “We always do weird and complicated projects,” he says. “It’s what we’re known for.”•

Creating wide vistas with the fewest possible separations required careful consideration of structural loads by engineers.

INTRODUCING THE COMMDOOR FOLDING DOOR SYSTEM

Designed for spectacular year-round enjoyment. Connect your outdoor oasis with the indoors: private residences, restaurants, cottages, patios, event centres, and entertainment complexes. Experience the full potential of your space today.

commdooraluminum.com

GREATGLAZING

JOINED IN LIGHT

by ROGER KNOX

From the glazing company to the architects to the construction firm, the same word was used in describing the rebuild of a popular B.C. spiritual and yoga retreat: renewal.

Blackcomb Glass, Patkau Architects and Alfred Horie Construction were all instrumental in the rebirth of the Yasodhara Ashram, or Temple of Light, a yoga retreat and study centre founded in 1963 by the late Swami Radha at Kootenay Bay, B.C., in the province’s southeast corner, on the east side of Kootenay Lake. The centre, which sits on a hilltop, was destroyed, save for the original foundation, in a June 2014 fire. Blackcomb Glass, Alfred Horie Construction and Patkau Architects collaborated throughout the redesign and rebuild phases to construct a new temple which was finished in 2017 and reopened in June 2018. The design fell to Patkau Architects, who were approached by the owners to renew the temple site by constructing a rarefied,

dome-like space on the original foundation. To flood that interior with light required the work of Blackcomb Glass of Whistler, B.C.

Blackcomb designer J.F. Robert called working on the Temple of Light “exceptional; one of our top-three projects. Collaboration was the key.” Design and 3-D modelling of the 2,250 square feet of glass required for the project was critical, especially having to deliver to a location 10 hours away from the shop on a remote hillside where you have to use a ferry to get to the centre. “The logistics were crazy and there were a lot of quirky things on the design,” Robert remembers.

The major challenge of the project was to execute the design’s evocative geometry on a tight budget. “The complex, cur vilinear geometry of this project was achieved with relatively modest means and conventional building materials by fabricating its sweeping petal-like forms utilizing principally straight engineered timber elements,” says Luke Stern of Patkau. “Each subpanel was manufac-

AT A GLANCE –Temple of Light

Architect: Patkau Architects

Glazing contractor: Blackcomb Glass

Glass fabricator: Garibaldi Glass

Structure: Raico SG2

Double IGU: 1/2-inch 6 x 6 mm Clear Temp with SN68 #2

Triple IGU: 1/2 x 1/2-inch 12 x 12 x 6 mm Clear Temp with SN68 #2

tured to a high degree of precision offsite using moder n digital manufacturing methods and custom, reusable jigs with knock-outs that allow the completed, convex frames to be released once assembled. Following manufacturing, the pre-clad subpanels were shipped to the site, efficiently assembled to enclose the domed primary worship space, and then glazed and sealed.” •

The site was a 10-hour drive from the contractor. 3D modelling was used to avoid site measurements.

Fit the bill—and the build.

Capture clarity with new Acuity™ Low-Iron Glass. Meet the aesthetic demands of architects and the performance demands of owners, all for a modest investment. Developed to withstand value-engineering, new Acuity ™ Glass by Vitro Architectural Glass (formerly PPG Glass) joins Starphire Ultra-Clear ® Glass in the Vitro family of low-iron brands. An affordable low-iron option available with Solarban ® solar control low-e coatings, Acuity™ glass offers vivid views with no green cast.

Request samples and learn more at vitroglazings.com/acuity

Low-Iron Glass ™

MOVEMENT AND LIGHT

by JESS REDLARSKI

The Springdale Library combines influence from both moder n visual elements and nature to create a marriage between movement, light and form which can be found around every turn of this truly unique building. Pushing beyond industry standards in complexity and oversized glass, the state-of-theart LEED Gold Springdale Librar y is a vision of glass and stainless steel that sings to the seamless illusion of dynamic movement, as the transparent building envelope flows in and out at incredibly dramatic vertical curves, all coming together to form a seamless triangular structure.

With oversized, curved glass printed with multicoloured digital frit pattern throughout both its interior and exterior, Springdale Library was a challenge in intricacy that required attention to detail and the highest quality; a challenge that Noram was ready to take on and deliver. Some of Springdale Library’s most complex exterior glazing components involved tight radiuses of as little as 1.5 meters on oversized IGU’s, with uniquely different digital printed patterns on each individual piece of glass. The Noram Wall 1100 unitized curtainwall system paired with these dramatically curved sections, consisting of glass stretching seamlessly from top to bottom, covering the entire frame with no single component exposed to echo the sense of flow and movement throughout the library’s exterior.

Alongside the curved glass corners of this unique building are sections of concave and convex stainless steel composite panels, reflecting the same stylized curvatures as the glass facade.

Within the interior of the library, an oversized circular glass skylight exceeding 4.2 meters in diameter with custom structural glass fin supports sits in the

centre of the main room with a sweeping ceiling leading up towards it. This beautifully seamless skylight reinforces the visual illusion of movement through dynamic shape that resonates throughout the entire libraries design.

All through the interior of the library, repetitions of the curved glass cor ners of the exterior are mimicked within alongside laminated glass partitions, each individual piece printed with a custom digital patter n. With key abstractions surrounding movement, light and form as inspiration, the Springdale Librar y is brought to fruition through the use of a state-of-the-art glass and metal facade for an incredibly unique and engaging library experience for the City of Brampton. Noram met all design intents head on, setting forth high quality standards by implementing sophisticated QA and QC programs into their operations from start to finish for the successful completion.•

AT A GLANCE –Springdale Library

Architect: RDHA

Glazing contractor: Noram Building Systems

General contractor: Aquicon

Curtainwall: Noram Wall 1100

IGU: North Glass

Glass: Multiple specs from multiple suppliers, including low-iron, double silver low-E, digital printed and laminated

For more great architectural glazing projects visit glasscanadamag.com > contractors > architectural design

Noram had to provide radii of as little as 1.5 meters on some of the exterior oversized IGUs.

THE BEC SPRINT

Report from the 2019 Building Envelope Conference

by RICH PORAYKO

From the minute one lands in Las Vegas for BEC, you are on. Presented by the National Glass Association now with GANA, it is an intense whirlwind of networking, seminars, meetings, and events until you fly back out. This past March, over 550 attendees attended the biggest BEC in a decade.

The rumor mill was unusually quiet, however there was a lot of chatter that companies are having difficulties keeping up with volume. Of course, talk of labour shortages came from across the board.

The lead BEC panel discussion, Cutting-Edge Facades, moderated by NGA energy code consultant, Tom Culp, dove into thermally efficient fenestration systems – where they are now and where they are headed. The panel explored ways to improve U-factors and condensation resistance through edgeof-glass and framing technologies. Culp told attendees that starting June 3 in Vancouver, all commercial and residential buildings seven storeys and higher will have to meet Vancouver’s zero-emissions building plan. “They are trying to really aggressively push to get there in a 2030 time frame. That’s not so far away,” said Culp. “In the last 20 years we’ve seen a sig-

nificant increase in the use of low-E glass. Market data is also showing a dramatic increase in thermally broken framing systems. The codes and markets are pushing that way. The trends are towards energy efficiency.”

“One of the key trends we’re seeing is the continued innovation of high-performance facades”, said Joe Erb, commercial sales specialist for Quanex Building Products. “There is a balanced approach on thermally broken framing materials, high performance glass and warm edge spacer technologies. All of this is driven to meet the more stringent energy codes that are coming out from ASHRAE.”

Erb explained how warm edge technology can contribute to achieve the challenges facing our exciting industry. “While the spacer may seem like a small component, it plays a critical and important role in overall performance in achieving thermal performance and condensation resistance.”

Technoform’s Helen Sanders explained that she uses the flow of a river as an analogy for flow of heat through a window. “If you want to block the flow of water in a river, it’s not much use putting a dam in the middle and forgetting about the edge. Water will flow freely around. It’s the same with a window. It’s no good making a great centre of glass and forgetting about the edge because the heat is just going to flow around the edge. It’s

ABOVE: Energy efficiency continued to be the hot topic at BEC in March. Attendees heard from experts that 2030 will come fast with aggressive targets for higher performance in many jurdisdictions around North America.

really important to think about the window more holistically so you are improving the thermal performance of the edges and the centre.”

“One statistic that blows me away is that commercial office buildings consume 40 per cent of the electricity generated in the United States annually,” said Cameron Scripture of Viracon. “That’s a lot of electricity. Lighting and air conditioning make up 50 per cent of the consumption of that energy. Things that we can impact the most with glass and glazing are the greatest users. Buildings are energy guzzlers. They are consuming energy at peak demand hours of the day. When electricity is most expensive is when these buildings are fully operating and consuming energy. We all have a great opportunity through our products and services to impact this.”

Conference in Las Vegas

One of the ways we have of improving the solar heat gain coefficient is by using double- or triple-silver low-E coatings,” said Scripture. “Tinting that exterior substrate is also another measure to dramatically enhance SHGC. By adding a ceramic frit pattern with 40-60 per cent coverage onto the second surface of your glass, you can enhance your SGHC performance by 40 to 80 per cent. These measures are widely used throughout our industry because of their esthetics, ability to save energy and to provide fast payback.”

Moderated by Max Perilstein, the panel discussion “To DIY or Not: Advancing and Improving Glazing Project Management” highlighted the labour crunch facing construction trades. Brian Filipiak of Alliance Glazing told the audience that some of Alliances’ brightest people don’t even have a degree related to construction. “We have a biology major and others with degrees in other areas. It’s about the right fit for the culture.”

University of Nevada – Las Vegas’ Neil Opfer stunned attendees telling them that he is seeing about 10 job offers for every graduate. “It’s absolutely insane,” said Opfer. “The market in Las Vegas is so hot that you see contractors stealing people from other contractors.”

Author and motivational speaker, Mary Kelly, provided a fast paced, funny

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards.

INDUSTRYEVENT

ABOVE: The Cutting Edge Facades panel included Cameron Scripture of Viracon, Helen Sanders of Technoform, Joe Erb of Quanex and Chris Giovannelli of Kawneer. Tom Culp of Birch Point Consulting moderated.

and informative keynote entitled “Change Management: Survive and Thrive in the New Economy.” “Our job as leaders is to see what’s coming. Our job is to forecast. Our whole purpose as leaders of our companies is to accurately predict what needs to happen next. Many of us look at past data but that doesn’t help at all moving forward.”

“Training your people is a huge issue,” said Kelly. After making a profit, Kelly explained that talent development and training is the number-one thing most CEOs have on their minds, and it’s where they are putting their dollars. “That’s it. You have to develop your people because that is going to move you forward.”

“Use the technology that is available to us,” said Kelly. “I often ask talent acquisition experts how many people do you have working from home? How many gig economy freelancers do you have? A lot say none and they are missing a huge, huge chunk. Many leaders say ‘I don’t know what they are doing all day if they are not here.’ I say, you don’t know what your own people are doing all day. You pay someone based on results, not for just showing up every day.”

FMI’s Cynthia Paul provided a sharp presentation and lively economic forecast in “Reading the Tea Leaves: Adjust, Adapt, Act.” Paul told attendees that Canada is recognized as the nicest country year-over-year. “They have their labour issues but they are going to continue to grow. Population growth in the U.S. is sitting at about 1.81 children for every woman of child bearing age. Canada is about 1.57 so they are growing through immigration and have grown more dramatically than the U.S. Oil prices are going up. Demand for housing is slowing. It’s a little bit different for mortgages. The Bank of Canada is much more conservative than the U.S. but they are going to continue to see some renovation work. The construction sector is being held hostage by talent shortages right now as the industry up there grows. One fifth of construction workers in Canada will retire in the next decade. That’s staggering. On average people leave the industry between 55 and 57. They are retiring at a rate of about 14 per cent and coming in at a rate of about 10 per cent. So anything around labour, talent, recruiting, development and technology will be the strategies at play.”

Paul explained that Canada has strong, diverse sectors and is going to continue to grow. “British Columbia is a very, very strong market led by Chinese investment. Saskatchewan has grown dramatically but is going to cool off a little bit. Canada has grown 1.7 million people in the last 18 months. Massive growth of people led through immigration.” •

Two-button safety

int-machinery.com

The Yilmaz ACK 550 up-cut saw is designed for straight- and miter-cutting large-size extrusions such as curtainwall profiles. The machine carries a 550-millimeter saw blade that is fed upwards by means of a hydropneumatic cylinder and driven by a powerful 5.5 horsepower motor. After the profile is clamped and the hood closed, the operator holds the two push buttons to raise the the blade up until the cut is completed. As soon as one or both buttons are released the blade returns back to its original position. The table can be rotated for mitre angles with pre-set location points at 75, 60, 45, 30, 22.5, 15 and zero degrees on both the left and right sides. It also has a pivoting range from minus 75 degrees left to plus 75 degrees right that

is infinitely adjustable and can be locked in position by a mechanical brake. The safety hood is operated pneumatically with a push button. The ACK 550 comes standard with a 550-millimeter saw blade and features an easy front access for blade replacement. Other standard items include a spray mist saw blade lubrication system; two vertical and one horizontal clamps; an air gun; adjustable saw blade feeding speed; and interior LED lighting. The Yilmaz ACK 550 is covered by a twoyear factory warranty.

Clean workspaces

int-machinery.com

The iVision iV2 3.5 horsepower industrial chip suction unit is the medium-sized single-port model of iVision industrial chip collectors and is recommended for use with single- or double-head saws generating a medium level of aluminum dust and chips. iV2 industrial vacuums are commonly used with cutting and fabrication equipment for residential or commercial windows, storefront and curtainwall. This unit features a structure made entirely of steel. The high-flow centrifugal fan features a flow rate up to 824 CFM. It includes a visual filling indicator, anti-scuff wheels with lock-in-place brakes, a quick-release container with a capacity of 26 gallons, a pneumatic shaker for easy filter cleaning and a silencer to reduce noise levels. An optional cleaning kit can be added to facilitate cleaning in and around the cutting machines for proper day-to day preventive maintenance.

Efficient processing

jsamachinerie.com

The Orion four-axis CNC machining centre from LGF Alu processes aluminum profiles at angles from zero to 180 degrees. It includes four controlled axes and four pneumatic standard clamps with automatic and controlled positioning. The 7.5 horsepower spindle has an ISO 30 cone and runs up to 12,000 RPM. Stroke is 4,000 by 1,000 by 500 millimeters, with an option for 7,000 millimeters on the X axis. Profiles longer than the machine may be worked. Speeds are up to 70 meters per minute. The Windows-based control runs proprietary LGF software. A five-position toolchanger is standard. Options include a bar code reader, an 18,000 RPM spindle, extra clamps, a UPS power supply and a 10-position toolchanger. Tolerances down to 0.2 millimeters may be achieved.

One or two work zones

mubeasystems.com

The Profile-Flex from Mubea Systems is a five-axis machine equipped with a highspeed spindle motor that can mill, drill, tap and saw tubes, profiles and extrusions in aluminium, steel, wood, vinyl and composites. The Profile-Flex is an ideal machine for finishing heavy aluminium and steel profiles nested over a full bar length. The Profile-Flex is a C-frame machining centre with a five-axis milling motor rated at 18 kilowatts with a tool turret with 36 places. It accepts a large profile section up to 550 millimeters by 370 millimeters high, with capability to measure, drill, tap, mill and saw. The result of the measuring probe is automatically compensated in the NC program. Clamps (eight or up to 16) are placed with the column of the machine or motorized by themselves. The Profile-Flex accepts workpieces up to 1,190 millime-

ters long. Motion is 80 meters per minute on the X axis and 60 meters per minute on the Y and Z axes. All models are delivered standard with safety fences on the left, right and back side of the machine. The front side is protected with a CEcertified LED safety curtain to protect the working area. As an option all models can be equipped as two working zones with a CE safety scanner. The great advantage of scanners is that there are no barriers in the middle of the machine, which makes loading and unloading a lot easier when switching from two zones to one large working area.

Find up-to-date product reviews of all the newest glass fabrication machinery online at glasscanadamag.com > technology > machinery

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass • SentryGlas Lamination

Opaci-Coat-300 Spandrel

METALWORKINGSHOWCASE

Powerful panel processing

axyz.com

The new PanelBuilder system from AXYZ is designed specifically for aluminum composite, metal composite, high-pressure laminate and fibre cement board. By combining an advanced, easy-to-use software solution with custom machine design, the PanelBuilder system makes it possible to process ACM materials faster, more consistently and at a lower cost. It incorporates a complete CAD/CAM solution with all the functionality needed for one-off or high-volume panel production. Alternatively, thanks to its open architecture design, it can be used in conjunction with existing CAD systems to provide powerful and

Slick interface

int-machinery.com

The Falcon is Mecal’s top of the line in its family of four-axis compact CNC working centres to machine aluminum extrusions. Its interface features an exceptionally user-friendly 3D graphics software that allows the operator to learn how to program and run the machine in just few hours. 3D design files such as IGES or STEP can also be imported by the optional CadLink software package that automatically recognizes machining, assigns tools and generates ready-togo programs. Falcon comes with five standard MMI clamps. Each clamp is equipped with its own motor and can simultaneously and autonomously position in a matter of few seconds. The MAM function allows the operator to change clamp orientation automatically during the machining cycle without an additional programming step or manual intervention. The 10-position standard tool magazine is expandable to 16 places that can hold angle heads and saw blades up to 200 millimeters in diameter. Falcon features a 150 metersper-minute X rapid speed that cuts down the cycle time. The servo-driven machine bed rotates plus.minus 125 degrees to allow working on the side faces of a profile. Choose between six-kilowatt ISO 30 and 8.5 kilowatt HSK 63F spindles, both available with an encoder for rigid tapping.

flexible nesting, automation and machine programming functionality. Users choose from manual, quick-release, high-power and highspeed spindles for optimum processing of rigid sheet materials. A rigid, welded steel frame, fitted with an aluminum deck, creates a strong structure to support the most demanding processes. Standard or helical racks are available for a choice of productivity and precision. All Z axes feature a precision ballscrew drive as standard. AXYZ machines have machined aluminum vacuum decks to maximize material hold-down for quality cutting and reduced waste. The vacuum zones can be switched with manual valves or automatically by the machine controller. The SmartConsole puts full machine control at the operator’s fingertips for fast and easy machine setup in an intuitive and compact package. An automatic tool length sensor ensures accurate and consistent cut depths. A range of high-power pumps or blowers is available to suit machine size and application requirements.

Ergonomic controls

u-r-b-a-n.com

The Onix 3300 3 Axis is a three-axis CNC machining centre specially designed for milling and drilling aluminium, PVC, light alloys in general and steel profiles up to three millimeters thick.

The machine has a 3,300-millimeter useful working capacity. It is provided with an automatic toolchanger and five-position tool rack with a position for one angle machining head for working on all three sides of profiles and a side-milling cutter for end-milling. The machine is fully enclosed. The steel head supports a four-kilowatt spindle running up to 18,000 RPM. The flexible and ergonomic operator console on the right side keeps the operator in control of the machine during setup.

Easy programming

windowmachinery.com

The C3S from Ameri-Can is a numerically controlled vertical router for aluminum, PVC, fiberglass and steel. Capable of working on three sides of the profile the pneumatic tilting working table orients at plus 90 degrees, zero degrees and minus 90 degrees. Intermediate angles are obtained by mechanical stops. Spindle speed adjustment from 3,000 to 15,000 RPM is controlled by a frequency inverter. X and Y axes are numerically controlled with all axes driven by brushless motors. The unit comes complete with four pnuematic double-acting clamps for material fixturing. The C3S includes software-compensated tool diameter correction and left and right profile zero stops. Milling capacity is 3,000 by 150 by 150 millimeters. Perimeter protection for safety is optional. The TS7005 touchscreen control allows for remote assistance and importation of DXF files for ease of programming. Options include two zero setting points pneumatic setting, a CNC-controlled automatic toolchanger system with six tools, full cabin guarding, Microsoft Windows-based interface and communication service for remote control by Ethernet or WiFi.

High

RPM

jrcmachinery.com

The Emmegi Comet T6 is a four-axis CNC machining centre that can machine five faces of aluminum or steel profiles using two bevel gears and a disk mill that can be part of the eight tools included in its inventory. It has two modes of operation. The single-part mode has a single machining area for bars up to 7.7 meters long. The pendulum mode has two autonomous machining zones in masked time. The machine comes standard with eight-vice automatic positioning with up to 12 vices optional. The fourth CNC axis allows the electrospindle to rotate from zero to 180 degrees continuously. The eight-place tool magazine is installed on the X-axis carriage. The control includes a 15-inch touch screen with USB connections. Travels are 7,700 by 470 by 420 millimeters. The eight-kilowatt spindle runs up to 24,000 RPM and uses an HSK 63F tooling cone. The Comet T6 includes a mobile table for easy loading and unloading of parts.

Cool crimping

int-machinery.com

Presta-Eisele’s Pressta 5000 is a flexible corner crimper for aluminum frames and windows. The process is purely a mechanical deformation principle: the aluminum extrusions are cut mitre and an aluminum corner cleat is entered at the end of both cut profiles. Due to the design of the corner cleat, the knives activated by the crimper deform in specific points the walls of the profiles, preventing the corner from re-opening. The flexibility of Pressta 5000 comes from its adjustable punching heads that are horizontally split. This helps offset the knives when the complexity of the window profile requires more than one corner cleat and the crimping points between the two cleats are not aligned together. Pressta 5000 is ideal when working with cleat grooves between 25 to 60 millimeters from the edge of the corner and a maximum profile height of 160 millimeters. The machine is equipped with a V-stop and pushing heads with a scale; a counter support with a 120 millimeter V-block in two independently adjustable blocks; two vertical pneumatic clamps; and eccentric discs for proper profile positioning. Cycle activation is by foot pedal control. To guarantee a synchronous motion of the punching heads, the Pressta 5000 uses hydropneumatic pressing operation.

by FRANK FULTON

Energy surcharges –the smoking gun

In the last edition we took an overview look at the business ethics of adding service fees and the energy surcharge (ESC) on glass products. We questioned why there is such a wide ranging discrepancy between the fees added by the glass producers and the fabricators and why the amount of the charges don’t appear to align with the input costs. In this edition we’re going to try to present enough information for you to determine if the ESC is justified, or otherwise.

The ESC was first introduced in the U.S. in 2002 as a temporary measure by the float glass manufacturers to offset the then-increasing cost of natural gas. Energy makes up 21 per cent of the cost of glass production. Shortly thereafter, the ESC was increased by including transportation costs, in part to offset rising diesel fuel costs. Freight makes up 11 per cent of the cost of glass production. Therefore, for the purpose of our assessment, 2000 to 2002, the three years leading up to the introduction of surcharges will be our starting benchmark point with costs compared to the end of 2018.

First, we note the discrepancy in the amount of the ESC between companies. A review of the 2019 first-quarter charges per manufacturer and how these translate to the selling price of six-millimeter clear annealed glass is revealing. AGC charges $72 U.S. per ton equal to $0.108 per square foot. Cardinal charges $538 U.S. per 44,000-pound truckload equal to $0.0367 per square foot. Guardian charges $0.0398 U.S. per pound equal to $0.1194 per square foot.

Surcharges are overstated and will, in all likelihood, continue to eternity.

Each supplier provides a different set of calculations to support their ESCs using values from a number of legitimate sources such as the New York Mercantile Exchange (NYMEX L3D) for natural gas costs; the U.S. Department of Energy Diesel Fuel Index; the Federal Reserve Economic Data (FRED) Producer Price Index: General Freight Trucking (PPI:GFT); and the Cass Truckload Linehaul Index. They put a combination of these values into formulas to arrive at a charge per pound, per ton, or per truckload of glass. It would take an actuarial scientist to make sense of the correlation between these index values and the ESC charges and to assess them for their validity. What I have found, though, is that the starting points or benchmarks of the costs are significantly less than what the actual costs were leading up to the introduction of energy surcharges. That suggests the surcharges are overstated and will, in all likelihood, continue to eternity.

Looking at the components that make up the total energy charge, the average cost of natural gas on the NYMEX L3D for the three-year period between 2000 and 2002 was $3.91 per million BTUs (MBTU). In 2018 it was $3.09, a drop of almost 21 per cent. In spite of this, all three suppliers we looked at are charging about $14 per ton on glass based on changes in natural gas costs. Guardian provides a chart to calculate the natural gas component charge per truckload based on a range of NYMEX values. Using a realistic starting benchmark value of $3.91 instead of the $2.50 starting point Guardian references, there should be an energy rebate of $100 per truckload!

Again, referring to charts provided by Guardian, the diesel component surcharge on glass kicks in when the cost of diesel fuel is more than $1.21 per gallon. The last time diesel was this low was in February, 2002. The three-year average prior to the introduction of surcharges was $1.40 so I believe this should be the starting point and would argue that the benchmark is set too low. Objectively, the average cost of diesel in 2018 increased to $3.18 which represents an increase of 127 per cent over 2000 to 2002 levels. This sounds like a lot until you consider a report from the U.S. Department of Transport stating that fuel costs comprise only 10.6 per cent of the cost of trucking. Furthermore, diesel costs make up only 1.2 per cent of the cost of glass production. I propose that the weight of diesel costs in ESC calculations is exaggerated, inflates the surcharge unrealistically, and is such a minor part of the mix it should be ignored.

I think we’ve found the smoking guns folks. It’s the starting benchmarks upon which all the surcharges are based. In the next edition we’ll complete the comparison of energy surcharges by the manufacturers and present what we calculate the surcharge should be. •

Frank Fulton is a former principal of Fulton Windows and a former president of the OGMA.

This is J consulta to overc both int makes t focus on the wor glass ma hav you can

This is Jeff. As an experienced, trusted architectural glass consultant, he understands the challenges you face and solutions to overcome them. For example, his extensive knowledge of both interior decorative glass and high-performance low-e glass makes the specification process quick and simple, letting you focus on your vision. And with Jeff, you take advantage of the world’s widest portfolio of products from the world’s largest glass manufacturer. All this comes with the confidence of knowing you have global resources at your fingertips, from a local pro you can trust.

Discove to

Discover AGC and meet your local go-to for architectural glass today. Visit AGCglass.com/MyGlassGoTo

de Waa Architectura AGC Glass

l al Glass Consultant

Jeff

GLASS THAT STANDS OUT

Making a statement in the Toronto skyline.

See what’s possible™ with Guardian SunGuard® Advanced Architectural Glass for your next project.

EY Tower

TORONTO, ONTARIO

with SunGuard® AG 50 and SunGuard® SuperNeutral® 68

© Edvard Mahnic Photography