Labor-Saving

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Products, Inc. has the per fect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for per fect allignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims. www.groveproductsinc.com Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions

GLASS CANADA

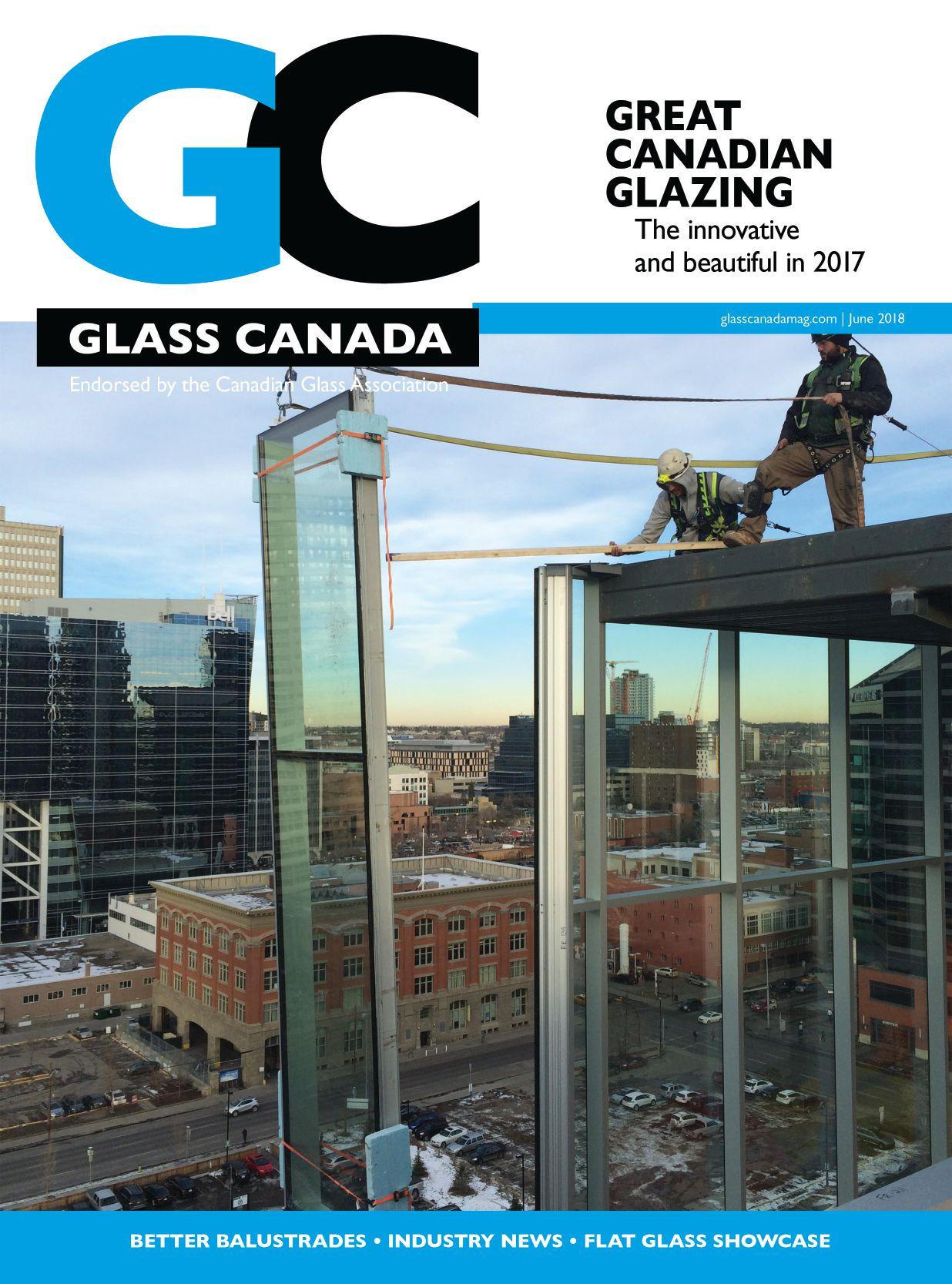

12 Canada’s Great Glazing

Canadian glass and metal contractors continue to achieve the most advanced and attractive projects in the world. Here’s our look at a few of them.

Top suppliers listed

All Canada’s top suppliers to the glass and glazing industry are at your fingertips in the online Glass Canada Buyers Guide at glasscanadamag.com. Searchable and organized into convenient categories, the Buyers Guide is a great resource whether you are looking for a specific company or browsing for a new supplier.

22 Better balustrades

Our experts discuss new two-part polyurethane grouts and the possibilities they create for meeting balcony standards while retaining great esthetics.

26 Flat glass showcase

The latest and greatest in innovative and high-performing glass products.

7 Canadian Glass Association

10 The Engineer by David Heska

30 You Bet Your Glass by Frank Fulton

Beware IT disease

EDITORIAL

A creeping corporate mould from the black depths of Silicone Valley.

I feel I can get away with throwing some shade at an entire profession as I was once employed on the outskirts of it myself. Many years ago when I was between jobs I worked in a call centre for a big American telecommunications provider doing tech support for their web portal. Our explicit instructions were to get the customer off the phone as fast as possible. Indeed, our entire job performance metric depended on it. We were told to look first and foremost for evidence that the customer’s problem was arising from something that wasn’t the contractor’s fault (for instance, a problem with Windows, or the hardware, or Internet Explorer) and to direct them to seek support from one of those providers. We were strongly discouraged from offering any help with these sorts of issues, even if we knew how to fix the problem and could do so fairly quickly.

Of course, not viewing my job there as a career option, I went ahead and gave each caller all the help I could. Which, ironically, led me to have one of the highest performance ratings in the company. It’s funny how just changing a few security settings takes less time than persuading a customer to go away and make another call after they’ve already been on hold for half an hour.

NEXT ISSUE

• Bass Installations

• Fabrication Equipment

You see, I’m not a fan of the effect information technology has had on customer service. I still remember my shock in 1992 when, having bought my first PC and failed in my attempts to decipher the Bible-sized DOS manual that came with it, I found that there was simply no in-person help available. When I called the store I bought it from, I was told they only handle hardware issues and couldn’t help me with anything software-related. I was directed to a phone number.

We’ve gotten so used to this most of you won’t see the problem. But at the time it was a major paradigm shift. I’d just bought an expensive item from a local retailer. Up until that point, it was assumed that a retailer had to stand behind what they sold and make some attempt to ensure customer satisfaction. But instead, this company felt free to pawn me off on its supplier on the other side of the continent. For some reason I have never been able to discover, this was OK because the product was software. Since it was a new thing to buy, new rules applied.

Once other sectors saw what the software industry was getting away with, it didn’t take them long to seize the opportunity to withdraw their investments in customer service. It’s commonplace now to be unable to get service or support from a retailer on anything from power tools to TVs.

My curse is to look for root causes in everything and the cause I see here is something I’ll call IT disease. It comes from the dislike engineers have for dealing with humans and all their ignorance and messy unpredictability. This translates into a certain workplace culture where human problems are deflected or ignored, often with an attitude of arrogant impatience. As corporate diseases go, it’s one of the worst as it leads to resentment, backbiting and, ultimately, nothing getting done.

How do you prevent IT disease in your organization? •

GLASS CANADA

June 2018

Volume 30 • Number 3

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Emily SUN

DIRECTOR OF SALES/GROUP

PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Ted MARKLE tmarkle@annexbusinessmedia.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars) Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

NEWS

Glittering glass days

Glass Day, presented by Burnaby B.C.’s Garibaldi Glass, welcomed over 400 glazing contractors, architects, designers and glass professionals from across Canada, the U.S. and even Europe on May 4. Attendees were treated to a fabulous Cinco De Mayo lunch complete with icy cold Coronas in between plant tours, networking and a variety of rotating AIA/AIBC accredited seminars that were being held in Garibaldi’s top-notch conference rooms, training room and fullsize theatre.

“This is our eighth annual Glass Day, however it’s not just about glass,” said Carey Mobius, CEO of Garibaldi. “It’s about the entire building envelope. The jewellry on the buildings. The eyebrows. The size of the podium products. Stone being incorporated. The purpose of what we do for Glass Day is really to help educate people on what’s going on out in the marketplace. Every year we bring speakers in and this year we had some absolutely phenomenal, world-class speakers with us. There was a lot of education with a fantastic turnout of people.”

This year’s event wasn’t only exceptional for Garibaldi because the attendance was

the highest it has ever been. This year, Carey, Chris and Craig (the three brothers who run the company) got to show off their new toy, a brand new 130-by-258-inch oversize tempering furnace from renowned Finish glass machinery manufacturer, Taifin. Several seminars included various components of oversize. The seminar on handling big glass by Bryan Strobel and Daniel Meuchel of Wood’s Powr-Grip was very popular. Glass rookies (there were a lot), got the basics from Russ Rozanskas’ “Glass 101” presentation. The veterans literally lined up for “Designing with Structural Glass Interlayers” presented by Mark Jacobson of Kuraray America and “When to Use Storefront on Curtainwall Construction” hosted by Chris Lambart of Kawneer. The keynote seminar with something for everyone was the “Design Challenges and Trends” panel discussion. Moderated by Carey Mobius, the panel included James Cheng, principal of James KM Cheng Architects, Doug Walker, technical director for Permasteelisa, Larry Carbary, industry scientist for Dow Corning USA and Steve Thomas, regional technical advisor for Guardian Glass.

COMING EVENTS

June 11 - 14 AAMA National Summer Conference Olympic Valley, Calif. aamanet.org

June 15

AVFQ Golf

Quebec City, Que. avfq.ca

June 21 - 23

AIA Conference New York, N.Y. conferenceonarchitecture.com

July 28 - Aug. 1

IGMA Summer Technical Conference Vancouver, B.C. igmaonline.org

Aug. 23

PGAA Golf Lacombe, Alta. pgaa.ca

Sept. 12 - 14

GlassBuild America Las Vegas, Nev. glassbuildamerica.com

Sept. 20

OGMA Fall Golf Woodbridge, Ont. ogma.ca

Oct. 24

FenBC Industry Conference Surrey, B.C. fen-bc.org

2019 April 17

Top Glass Mississauga, Ont. topglasscanada.com

CGA Newsletter

CANADIAN GLASS ASSOCIATION

National CGA activities are presently on hiatus while the association maps a new mission and vision. To help plan the future direction of your glass association, please contact David Langton at dlangton@ compglass.com.

FENESTRATION ASSOCIATION OF B.C.

FenBC held its Annual General Meeting on Feb 24. Please welcome our new board:

• James Bates (JTB Installations)

• Mark Frampton (Excalabor Glass and Aluminum)

• Murray Frank (Constructive Home Solutions)

• David Goldsmith (Plygem)

• Frank Hua (Frank Hua Engineering)

• Peter Kuschnir (Starline Windows)

• David Langton (Competition Glass)

• Cam Leslie (All West Glass)

• Jason Loutet (Intertek)

• Cal Marshall (Retro Teck Windows)

• Carlos Mueller (Atlas Meridian Glass Works)

• JF Robert (Blackcomb Glass)

• Amy Roberts (PFG Glass) David Langton of Competition Glass has agreed to continue as our chairperson. Thank you to our board members who have stepped down: Tara Brummet (Vitrum Industries), Riccardo DeSantis (Intertek), Debra Dotschkat (GC Glass Canada), Phil Chilibeck (All West Glass), and Kevin Saito (Exp Services).

Our February 2018 conference was a great success. After lunch we held a round table open discussion on how the association can improve its services to the membership. The discussion generated some ideas that the association will be building on over the next few months. Most of the discussion was around training and education. FenBC’s technical committee and education committee will be working some of the ideas discussed.

FenBC is working with Morrison Hershfield to update our Glazing Systems

Canadian Glass Association 619 Liverpool Road, Pickering, Ontario L1W 1R1 Tel: 604.855.0245 • Fax: 866.253.9979 canadianglassassociation.com

Specifications Manual to meet the current National Building Code.

PROVINCIAL GLAZIERS ASSOCIATION OF ALBERTA

At

our March Annual General Meeting, held March 21 in Red Deer, Alta., our election of officers was held. Our 2018 executive includes:

• President: Gary Porter, staying on for one additional year

• First vice-president: Rick Makepeace (Capital City Fabrication), staying in the seat for one additional year

• Second vice-president: Keith Wallace (Metro Glass), two-year term

• Treasurer: Mei Whyte, one year left on her two-year term

• Secretary: Taylor Wight (Layton Consulting), two-year term

• Director-at-large: Dwayne Stolz (Leyden’s Glass), two-year term

2018 will be a busy year as we continue the development of our Master Glazier Program, where our third and fourth courses will be released (Structural Glazing and Specialty Glass) and should bring us to a bit of a tipping point in terms of having a more comprehensive offering. That said, we need to re-work our marketing efforts to get the MGP out to all glaziers and glass shops in the province. With our new secretary onboard, we hope to have the Glass and Architectural Metals Association data (meeting minutes, etc.) available on pgaa.ca and our membership files updated in the very near future. Additionally, we are looking at exploring the idea of hiring an executive assistant (money allowing) and getting more involved with social media. .

ARCHITECTURAL GLASS AND METAL CONTRACTORS ASSOCIATION

The AGMCA continues to play an active role in representing our member

contractors on numerous issues that affect the day-to-day operations of their businesses. Of recent concern, for instance, is the implementation of Bill 148 by the Ontario government, which adversely affects our member companies, especially as it relates to emergency paid days off as well as new shift-scheduling burdens. Our association also has had a long-standing interest in skills training. Our volunteer board of directors continues to serve the membership by constantly monitoring the progress of apprentices. To that end ,the AGMCA was recently represented at the Future Building show, held at the International Centre in Mississauga, Ont. Over 7,000 high school students, together with their teachers and guidance counselors, attended and were hopefully influenced by the impressive booth put together by our training centre partners at the Finishing Trades Institute. To learn more about the AGMCA, we can be contacted through our website at agmca.ca.

ONTARIO GLASS AND METAL ASSOCIATION

GORDON SOUTHWORTH: It is with sadness that we relay the news of Gord losing his battle with cancer in July, 2017. We only learned of this regrettable news recently. I knew Gord quite well through our many years in business and through our kids playing hockey in the same league in Streetsville. Gord participated in many OGMA events over the years and was a long time employee at Embury Company.

DENIS LAVOIE: I regret to inform members of the passing on April 23 of my long-time employee and friend. Denis came to Fulton Windows from Canadian Glass in the late ‘90s and eventually managed operations, project services and production. He was a dedicated, low-key, nose-to-the-grindstone type of person with a subtle sense of humour. We worked closely for many years and I am truly going to miss him. Denis later worked at Sherwood Windows before suddenly and unexpectedly ending his working career at Oldcastle in December 2017 due to his illness.

Float glass production to return to Canada

Xinyi Canada, a Hong Kong-based glass manufacturer, has announced plans to open a new float glass plant in Guelph, Ont. The company is presently seeking bylaw amendments from Guelph city council in order to proceed. According to the company website: “The Xinyi glass plant in Guelph will be a modern manufacturing facility with a total floor area of 2 million square feet. The facility will provide enclosed structures for glass manufacturing, corporate offices, a warehouse and loading bays. All manufacturing operations will be carried out within enclosed buildings. Loading goods and finished glass products will be done in the loading bay area of the warehouse section in the enclosed factory buildings. Float glass manufacturing is a dry production operation, and the production areas need to be maintained in a clean environment to avoid adhesion of dust onto the glass surface that can affect the quality of the glass stock sheet. Appropriate measures have been incorporated into facility design, orientation of production lines and operational arrangements to effectively minimize noise and dust impact on the neighbourhood. The new glass facility will adopt an innovative high-capacity furnace design and have advanced operational controls with on-line monitoring and

interactive feedback mechanisms to achieve energy savings and high production yields. The production line is highly automated with an advanced optical scanning system to ensure glass quality. Any defective product is screened out, shattered and recycled back to raw material batching system. A fully automatic stacking system will be used, avoiding direct manual handling of glass and enhancing the quiet and safety of operations. This project will be the first new float glass plant in Canada since 2008, when Canada’s last float glass plant in Owen Sound, Ont., closed. It represents a new beginning and the rebirth of the glass industry in Canada. The facility will also be the first new float glass line to be built in North America since 2006, reflecting the competitive strength of Ontario in attracting advanced manufacturing investment to Canada. The new float glass plant has incorporated breakthrough innovative features in furnace and production line design. The float glass line will have a capacity 50 per cent more than the largest float glass line currently in production in North America. It will be the most competitive float glass production facility in North America. The facility will recover waste heat from furnace outlet for power generation, for heating and for hot water supply for plant use.”

Goldray sells fabricating plant to BG Glass

Goldray Industries has announced the sale of its glass fabricating plant located in Barrie, Ont., to BG Glass Technologies. This facility has highly specialized heat treatment equipment, focusing on tempering, heat soaking, fabrication and back painting.

“We are delighted to have BG Glass Technologies as the purchaser for our factory in Barrie. Goldray is very supportive of this venture and we have no doubt that BGGT will continue to serve our Ontario customer base. This sale will allow us to focus on our innovative new products and systems that we are producing in our Calgary headquarters” said Goldray Industries CEO and president, Cathie Saroka. “We are excited to be developing new glass technologies to better serve our customers across North America.”

John Barber, president of BGGT, said, “We are extremely excited to have acquired this prime glass fabrication facility and its strong customer base. With our experience in glass fabrication and our strong relationships with architects, designers, and the OEM market, we see many expansion opportunities for this new venture. This acquisition provides vertical integration to the Barber group of companies’ existing operations. We will utilize our partnerships with global suppliers to identify new technologies and provide unique quality products to support our customers’ architectural designs.”

Top Glass tops out

It was a great day of spirited conversations among all levels of the Canadian architectural glass industry at Top Glass on April 17 in Mississauga, Ont. Despite the truly unbelievable bad weather in southern Ontario, 315 attendees managed to get to the International Centre, tour 61 exhibitors and sit in four cutting-edge educational sessions. Attendees were about evenly split between architects/specifiers and glazing contractors. Highlights of the show floor included the launch of a new product for Sunview Patio Doors, the massive Leggera door system that uses magnetic levitation to enable effortless sliding of the huge panels. Sunview went all-out with a big video wall behind its doors, aptly demonstrating the kinds of views users would experience. The seminar sessions were full with around 100 architects in the seats collecting their OAA learning credits. There were nice moments of industry recognition as the Ontario Glass and Metal Association presented its Awards of Excellence to two worthy members. Moriyama and Teshima Architects won the award for design with their work on the Humber College Student Welcome and Resource Centre. Bass Installations won for execution for the UTSC Environmental Science and Chemistry Building.

Owners of Arlington Equipment indicted

New York state authorities have announced an indictment charging Robert Mirel and Debra Burnett, the owners and operators of Arlington Equipment Corp. , with defrauding companies and business owners throughout North America by pretending to sell glass installation equipment and laundering hundreds of thousands of dollars in criminal proceeds through shell and shelf companies. The indictment alleges that over at least five years, Mirel and Burnett stole over $1.2 million from over 40 customers, the New York Department of Labor, The New York Department of Tax and Finance and several employees who were not fairly compensated. Both defendants were arrested on a 29-count indictment including charges of grand larceny in the second and third degrees and money laundering in the second

degree. Mirel, 71, and Burnett, 65, were arraigned in Warren County Court. Mirel remains in custody on a $500,000 cash bail or a $1 million bond. Burnett remains in custody on a $100,000 cash bail or $300,000 bond. If convicted of all counts, Mirel and Burnett face between five to 15 years in state prison. According to the indictment, customers purchasing glass manipulators from Arlington Equipment Corp. provided a down payment of at least 50 per cent but allegedly never received a finished product. By April, 2013, Arlington had terminated almost all of their employees. Nevertheless, Arlington continued to take dozens of orders for manipulators through at least 2016. Allegedly, in many instances, Mirel and/or Burnett would inform customers that the manipulators were complete and ready to ship, but they required custom-

ers to pay the balance of the order prior to shipment; however, after receiving the balance, Arlington never sent the manipulator to the customer. In addition to these allegations, Mirel and Burnett are charged with taking manipulators from victims for repairs and then either repairing and selling them to other customers, or dismantling them to use their parts in new and refurbished products without the permission of the original owners.

Big day for Provincial Glass Personnel moves at Walker

Provincial

Glass and Mirror in London, Ont., opened its doors to the media and city dignitaries for a tour and ribbon-cutting ceremony at its new Horton Street location. The 34-year-old company has relocated from its prior facility on York Street and approximately doubled the space it has to operate in with the acquisition of the former Canada Computers space. The move included putting on a snazzy new facade and completely renovating the office space and fabrication shop. All-told, Provincial now has 12,000 square feet to play in. Lucier is blown away by the determination and resourcefulness of his staff, who kept business going while working out of construction trailers and a makeshift fabrication shop in a rented storage facility.

“My staff are absolute rockstars,” Lucier enthuses. “It’s unbelievable what they went through. In our temporary facility we basically had dial-up internet. My staff has been unbelievable and now we’re seeing the fruits of the labour.”

Lucier’s decision to remain downtown was an unusual one for a manufacturer in London. The area he is in had a sketchy reputation, but is undergoing a renaissance with significant investments in a skills training school, a large Goodwill community centre and a newer Boys and Girls Club nearby. London mayor Matt Brown, who was on hand to cut the ribbon, was appreciative of Provincial’s vote of faith in the neighbourhood. “This is perfect example of what drives our economy in London,” Brown said. “It’s a confidence boost. This is a long-standing London company that is effectively doubling in size and staying in the downtown core. This is a company that is committed to its community, and I’m so thankful for that.”

Walker Glass has announced the appointment of Charles Alexander as its business development manager. Alexander will replace Marc Deschamps, who recently retired from Walker. Alexander will be responsible for leading the company’s marketing and business development functions, including the architectural services group, as well as leading various strategic growth projects for the company. Prior to joining the company, Alexander’s experience came from the industrial products and construction/green building industry sectors where he held senior management positions in sales, marketing, business development and operations for companies including the Canam Group. Alexander holds an undergraduate degree in civil engineering and he completed his MBA at McGill University.

Walker has also announced the promotion of Danik Dancause to the position of manager of marketing operations. Dancause has been with Walker since 2002 and has held various positions within the company in a business development and marketing capacity. In 2011, he assumed the architectural representation responsibilities for eastern Canada. He will now be responsible for establishing Walker’s marketing vision as well as managing the day-to-day marketing operations.

Robert Mirel

Debra Burnett

Charles Alexander

Danik Dancause

by David Heska

David Heska, P.Eng. is a director with WSP’s Building Sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David. Heska@wsp.com

All spacers not created equal

Iwas born and raised here in Canada and there are many things about our country that I’m extremely proud of. But I must admit whenever I hear someone refer to the United States’ Declaration of Independence, part of me wishes that this document was in our history and not theirs. Namely the second paragraph, which states, “We hold these truths to be self-evident, that all men are created equal, that they are endowed by their Creator with certain unalienable rights, that among these are life, liberty and the pursuit of happiness.” Men and women are created equal, regardless of our race, ethnic origin, religion or status. While this is true, there are many examples of manufactured products where this is not true. Specifically, in the glass industry, it is becoming more and more apparent that spacers are not created equal.

An insulating glass spacer is placed within the unit to hold the glass panes at a fixed distance from each other, establishing the size of the interpane space. Typical spacers are four to eight millimeters wide and 12 to 14 millimeters thick. Traditional aluminum spacers are roll formed, inexpensive, highly conductive, and can create stress on the primary seals due to their expansion and contraction. As aluminum spacers decrease in popularity, three other types of spacers have become more common: stainless steel spacers, hybrid spacers, and flexible spacers. But which type of spacer is the best?

To answer this question there are a number of factors that must be considered and in this short article there is only room to briefly scratch the surface. Items to consider include strength, durability, conductivity, and price. There is a lot of information published by manufacturers and

Don’t let anyone fool you when they claim there is no difference between one product and another.

THE ENGINEER

researchers comparing these factors and sometimes the information is inconsistent. One manufacturer claims that their spacer “is stronger and more esthetically pleasing” and that their spacer “reduces the stress on the primary and secondary seals.” The next manufacturer claims that their spacer “keeps the argon gas in place longer.” Then there are others who claim that the conductivity of their stainless steel spacer is the same as other flexible foam spacers.

Fortunately, the National Fenestration Rating Council publishes its Procedure for Determining Thermophysical Properties of Materials. Appendix C of this document (NFRC 101-2017 [E2A6]) is updated three to six times a year creating an industry-approved baseline for spacer density and conductivity values. Here are the published conductivity values for a few commonly used spacers (units in W/m∙K). The Cardinal stainless steel spacer has a conductivity of 14.187. The TGI NA stainless steel M-Spacer is 14.0. The Intercept Ultra stainless steel spacer is 13.63. The Quanex Spacer S2 Premium is 0.125. The Tremco EnerEdge silicone warm-edge spacer is 0.118. It should be noted that these values represent the spacer only and do not include the surrounding primary or secondary seals.

Over the past 20 years our company has developed an extensive electronic library of over 500 spacers that are used in computer thermal models. We recently completed a report for a client comparing 28 spacers. When modelling a simple 1.2-by-1.5-meter double-glazed IGU (without framing elements; three-millimeter glass with a low-E coating on surface 2 and 90 per cent argon fill) we determined that the U-value of the window ranged from 1.68 to 1.46 W/m2∙K and the condensation resistance ranged from 19 to 53. For a simple triple-glazed IGU with a variety of spacers, the U-values ranged from 0.89 to 0.64 W/m2∙K. This report is now a valuable tool for our team that we have been able to reference as we advise window manufacturers which spacers provide better thermally modelled test results.

Conductivity is only one of the factors that should be considered when determining which spacer to specify or install, but don’t let anyone fool you when they claim there is no difference between one product and another. There are differences and they matter and, unlike people, spacers are not created equal. •

A FEELING OF LIGHTNESS GREATGLAZING

by LINDSEY MCCAFFERY

Practically anywhere you walk within the 4,500-square foot Slender House, you can see the property’s breathtaking waterfront thanks to a plethora of custom-made glass. Finished in July 2017, the residence is located in Ogden, Que., nestled near the U.S. border and solidly anchored into the rock on the steep shores of Lake Memphremagog.

MU Architecture’s client requested that the house be exposed to the waterfront as much as possible. Vast and bright, the residence’s floor-to-ceiling glass (via large bay windows, patio

“We are always stretching the limit of performance and size.”

doors and a skylight) literally light up the place while offering views of the lake, no matter the room. Several of the openings were extremely large for a residence. For example, the opening for the patio door is approximately 11 feet tall, and openings for windows run as large as six-by-10-feet-high. As such, MU Architecture selected Alumilex, a specialist in high-end and high-performing projects, to supply and install all the aluminum windows and doors.

The products used came from Alumilex’s 2060 series and 120 series, specifically, tilt-and-turn windows and lift-and-slide doors that are highly energy-efficient and easy to use.

“We are always stretching the limit of performance and sizes of windows and doors, and so for this project we decided to go to the extreme with our fabrication and solution and sizes,” says Tony Benzo of Alumilex.

To reduce thermal transmission, Alumilex ensured every sash and frame member consists of heavy aluminum extrusions assembled into a single member with two fiberglass-reinforced continuous polyamide thermal breaks. Crimping the polyamide bars in the internal and external sections provides rigidity; and since both aluminum and polyamide have similar expansion and contraction properties, the structural integrity remains constant

AT A GLANCE – Slender House

Architects/designers: MU Architecture

Team: Charles Côté, Jean-Sébastien Herr, Magda Telenga, Rosalie Trépanier-Blais, Steeve Galté, Camille Mollaret, PierrePaul Guillemette

Cabinet maker: Illo, Maël Le Bars

Structural engineer: GenieX

Contractor: Denis Legault Construction

Project Completion: July 2017

under all weather conditions. Moreover, all joinery is executed using right-angle die-cast cleats for faithful geometry. The critical task of sealing the mobile sash to the fixed frame was achieved by using EPDM prime seals and a secondary rebate gasket that prevents any residual infiltration. The glazing unit is also sealed with double EPDM continuous compression seals for maximum air- and water-tightness. •

ABOVE: The scenic location of the Slender House demanded designers push the envelope on big glass windows.

INNOVATION FOR WHAT’S INSIDE.

Inspiring façade solutions in education. Buildings that maximize natural light, enhance security, promote air ventilation and regulate temperature create a learning environment that keeps students engaged, encourages teacher passion and promotes an improved educational experience. Better schools build better communities.

kawneer.com

THE BIG ONE GREATGLAZING

by RICH PORAYKO

Brookfield Place challenges with oversized elements.

Afull-block development consisting of office towers, retail space and an outdoor plaza, Calgary’s Brookfield Place steps up as one of western Canada’s tallest buildings.

A collaboration between SKA Architecture and Dialog, the base of Brookfield Place is a three-storey podium, standalone pavilion and two floor-to-ceiling glazed skywalk bridges, part of Calgary’s Plus 15 network.

Calgary’s Evolution Glass partnered with German-based Seele who designed and engineered the system in their head office near Munich. The steel was fabricated in the Czech Republic while the glass was predominately fabricated in China with the complicated corner units manufactured in Portugal. Everything was shipped to Calgary where Evolution assembled and ultimately installed the complete system.

Brookfield Place’s glazing includes massive (approximately 10- by 20-foottall) sealed units with 12mm/12mm lowiron tempered laminated glass on the inboard and outboard lites.

“They are gigantic windows,” says Richard Munro, senior projects manager for Evolution Glass. “The lobby is four

lites of 12-millimeter low-iron tempered and laminated.”

“I’ve been told that it’s never been done before anywhere in the world,” says Munro. “The pavilion is an all-glass structure. Not only are the walls glass but so is the roof. The giant skylight on the roof and the vertical walls curve at the top slope into the roof and connect into the skylight via a giant gutter system.”

There is the oversize factor, but to make things really interesting, all of the corner windows are bent. The building also gets progressively larger as you get higher so the bottom of the lobby is smaller than it is at the top. On the top corners of the pavilion, which are also curved, there is actually a double bend happening. “The top piece is shaped like a J but also rounds out around the corner. It was definitely something different.”

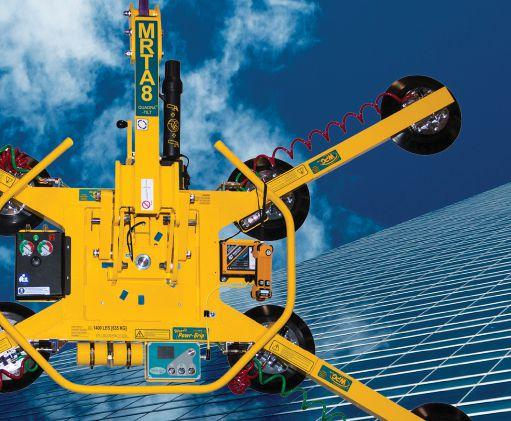

When Evolution Glass was awarded the podium and pavilion project, they set out to purchase a custom vacuum glass lifter. “We obviously wanted something that could handle the weight,” says Munro. “But we also needed versatility and to be able to accommodate the various shapes of the job. We designed a set of custom cups

that would take the weight and then we engineered custom attachments that could be added on to accommodate the shapes.”

Evolution introduced a bar feature with tilting cups that allowed them to attach to either side of the J-shaped panels. “We also built an L-shaped version with custom cups so we could attach to the Lshaped glass in the right fulcrum points,” shares Munro. “They had to go in perfectly level and flat. It was a bit of an undertaking to get that to lift properly. We had an idea how to do that but needed to actually set it up and test our idea offsite with some trial and error in practicum so when we got on site everything went in nice and smooth.”

Evolution had different mobile cranes on site for the duration of the project, however the average weight of each skylight unit was 600 pounds and the company needed a larger crane with a different set of glazing cups to reach over the pavilion walls from the streets. “There were a lot of logistical challenges that had to be overcome. Lots of stakeholders. We were working for Seele and Seele was working for ElisDon and ElisDon was working for Brookfield. Plus coordinating with the other trades on the site.”

It is the biggest job that Evolution Glass has ever undertaken. As an installation-only contractor for this project, Munro says it was a large contract for labour-only, equipment and access.

ABOVE: Globally sourced, Brookfield Place rises as Calgary’s tallest building. It houses 2.4 million square feet of office space with retail space on the ground.

“To install the pavilion structure, you have a three-storey, freestanding building with a floating skywalk that wraps around the perimeter of the building,” says Munro. “For access, we had to build a custom threestorey scaffolding on the inside to do all of our anchoring connections on the steel as well as to do all of the interior finishing details. Up on the inside of the pavilion, especially around the gutters, there were all sorts of custom cladding so we had this huge scaffolding set up for several months. According to Munro, the scaffolding actually acted as a temporary support for the

pavilion steel. “There was a lot of engineering involved in making sure the scaffolding was capable of supporting the structure.”

On the backs of the curtainwall steel sections, there are chases to accommodate electrical conduit and fire sprinklers. “It is a unique aspect of this curtainwall to have the chases built right into the framing system,” says Munro. “In a normal curtainwall, you’d probably have some kind of steel skeleton structure and in this case we didn’t have that so the curtainwall was the skeleton structure.” Munro describes the system as basically large pieces of steel

AT A GLANCE – Brookfield Place

Glazing contractor (Podium/Pavilion): Evolution Glass

Glazing contractor (Tower): Oldcastle BuildingEnvelope

Curtainwall glazing: Seele

Lobby glass makeup: 12mm low iron tempered /clear PVB interlayer/12mm low iron tempered /clear PVB interlayer /12mm low iron tempered /clear PVB interlayer/12mm low iron tempered

Podium Glass Makeup: 12mm low iron tempered /clear PVB interlayer/12mm low iron tempered / air space / 12mm low iron tempered /clear PVB interlayer/12mm low iron tempered

Architect: SKA Architecture Ltd. and Dialog collaboration

designed to support itself as well as the giant glass panels while hiding all the electrical and sprinklers. “We had custom covers that went over top all of that after the fact so there was a lot of coordination with different trades.”

Evolution also custom-built over 70 10-foot by 20-foot shadow boxes that, according to Munro, were basically oversized, insulated backpans with textured stainless steel face panels. Each shadow box has a lite of glass with ceramic frit installed on the front of it.

To protect the pocket in front of the shadow box and the glass from condensation, everything is tied into a manufactured air system. “We plumbed in warmed, compressed air that is continuously pumped into every single shadowbox cavity,” says Munro. “Each one is individually connected with a compressed airline running back to a machine that constantly monitors key metrics including the humidity, air pressure and temperatures of every single piece. On top of being glaziers, we basically figured out how to be plumbers, HVAC, electricians and glaziers. It was pretty wild.” •

What is GlassCon Global?

GlassCon Global is an industry event created to drive innovation in glass technology and has earned a reputation for being an event that impacts the architectural glass & glazing industry. Focusing on technical presentations and networking, GlassCon features some of the brightest minds in architectural glass & glazing from all corners of the world.

GlassCon Global

is being held in Chicago at the Holiday Inn Mart Plaza from Sept. 5-7.

Anirban

Chairman and CEO of the Sage Policy Consulting Group, presenting “Brown Sugar: Rockin’the Economic Data”

Doug Noble, the Director of the Graduate Building Science and Ph.D. Programs at USC Architecture, presenting “Glass Week Curriculum”

Anirban Basu

Basu,

Doug Noble

GREATGLAZING

MODERN TRADITION

by STEVE MORREN

The Humber College Lakeshore campus has opened the doors to a brand new building. Their challenge? Find a somewhat modern glazing respecting Toronto`s city standards for a unique college campus that dates back to the 1880s and needs to be restored.

The firm of Moriyama and Teshima Architects brought an impressive resume into this project and a massive amount of familiarity with the Humber College campus thanks to designing several other projects there.

With the challenges noted above, this project needed concentration in the significant area of glazing and according to Adrienne Tam of Moriyama and Teshima the design plans for the glass featured a specific focus.

“The study hall for the Humber College for Entrepreneurship was created to be a vibrant hub that cultivates collaborative relationships between students and industry professionals. We wanted to select a glazing that would complement this use and provide natural daylighting for the study hall. The three different types of glass patterns create a variety of muted textured shadows that enhance the light

AT A GLANCE – Humber College

Glazing contractor: Redspire

Architect: Moriyama and Teshima

Architects

Outboard lites: Walker Textures

AviProtek 211(#1) with Vitro Solarban

70 XL (#2), ½-inch air space

Inboard lite: 6mm clear

Inboard lite: Walker Textures

AviProtek 211(#4)

quality in the room.”

So how does the firm find those right products and which ones would they choose and why?

“The intent was to create a clean modern volume that engages the heritage façade with minimal impact while also providing maximum exposure of the historical building. To take advantage of the interplay of light and shadows within the space, we incorporated three types of glazing units: a clear unit, a unit with single layer of ‘random’ vertical stripes and a unit with two layers of random vertically striped glass on surfaces 1 and 4. By doubling up the vertically etched glass with the distance of the unit between them, a sense of depth and movement is introduced along the building face as one moves through the space.”

The key mention here was the vertically etched glass. Where did that come from and how did it come about? Tam explains.

“There are a number of fritted products available on the market but we were

on a quest for a bird-friendly glass treatment that would allow the low-E coating to be applied to surface 2. An acid-etched pattern by Walker Textures on the exterior surface meant the application was integral to the glass and unlike other products, not a separate material bound to the glass that is then exposed to the environment.”

The Walker Textures bird-friendly products used on this iconic project were combined with the high performance low-E manufactured by Vitro to complete the insulating glass makeups.

This project brought together many factors that are constant considerations in the design world. Items such as making a building fit into the design landscape, having sufficient daylighting for occupant comfort, energy performance, or codes and environmental responsibilities (bird friendly glazing) are becoming common. The new structure at Humber College met and exceeded the challenges of all of these items thanks to fantastic design and innovative product solutions. •

ABOVE: The challenge: merge a modern space into the existing 19th-century architecture of a downtown Toronto college without creating an eyesore. Careful design and innovative glass products produced a result that exceeded all expectations.

no substitutes.

See the beauty — not the glass — only with Starphire® glass

Don’t accept imitations. Only Starphire Ultra-Clear® Glass by Vitro

Architectural Glass (formerly PPG Glass) allows views so brilliant, you’ll forget the glass is even there. For interiors, exteriors as well as heavy and safety glass applications in thicknesses up to ¾ inch, no low-iron glass consistently maintains its transparency, color fidelity, vivid beauty and distinctive blue edge like Starphire® glass.

Request samples at www.starphireglass.com

Starphire Ultra-Clear® Glass

Conventional Clear Glass

GREATGLAZING

TOGETHERNESS SPACE

by JORDAN WHITEHOUSE

When Lemay’s architects set out to design a new office building for construction firm Pomerleau in Lévis, Que., in 2016, they knew they wanted to do two things: bring the outdoors inside and promote a sense of collaboration and connection between employees.

Now that it’s done, it’s clear they’ve accomplished those goals with a lot of help from the Multiver glass that Lévis-based contractor Vitrerie Univerre used.

The two-storey building contains fully glazed office spaces and conference rooms shared among three wings. Each of those wings frames floor-to-ceiling views of the neighbouring forest and gravitates around a central courtyard. All four sides of the building are abundantly fenestrated, particularly on the southern, eastern and northern facades, filling the open-concept space with tons of natural light. The facades that face the highway feature judiciously punched windows to control bright rays of sunshine and surrounding noise. The facades on the inner courtyard are entirely made of windows over two levels. This was done to reinforce the relationship with the existing natural forest and to unify the building’s three wings around it, says Lemay architect, Denis Tessier. “As a result, building occupants enjoy views of the courtyard forming the heart of the project, as well as activity elsewhere in the building. This accentuates a sense of fellowship and collaboration.”

For the most part, Vitrerie Univerre used a sealed unit, 25.4-millimetre-thick product made of six-millimetre clear tempered glass with low-E select 40 on face 2 and argon-enhanced black Technoform spacers. This is a high-performance composition and is not so grey or green-tinted as to negatively affect user comfort. For the spandrel sections, they followed a shadowbox principle with a sealed unit of ultra-clear, 22.2-millimetre glass made of clear six-millimetre exterior glass, black argon-enhanced Technoform

AT A GLANCE

Architect: Lemay

Contractor: Vitrerie Univerre

Glass Supplier: Multiver

Glass: 25.4mm sealed unit – 6mm clear tempered with low-E select 40 on surface 2 and argon-enhanced black Technoform spacers

Spandrel: 22.2mm sealed unit – ultra-clear 6mm exterior glass with black argon-enhanced Technoform spacers and Optiwhite 6mm tempered with white Cerafrit coating #208101 on face 4

and Optiwhite six-millimetre tempered glass with white Cerafrit coating #20-8101 on face 4. They used ultra-clear glass so that they could preserve the white appearance of the Cerafrit, which otherwise would have taken on a greenish hue from the glass’s natural tint.

Overall, it was a relatively smooth install for Vitrerie Univerre, but there were a few challenges. First, because there were interior alignments to be respected, the angled sections of the south facades and those facing the inner courtyard took extra care. Second, the positioning and precision of the west facade’s punched windows were somewhat demanding since everything needed to align with the metallic facing on the upper level. The glass joints between facades were also a challenge because the angles were often non-standard and needed to be made of structural silicone joints. Vitrerie Univerre was well aware of these challenges ahead of time, though, which made overcoming them much smoother, says Denis Tessier. “All of them were discussed beforehand at the kick-off meeting so that the sub-contractor would be advised of all the particularities. Details were then reworked to facilitate and better control installation and outcome.”

The result is a stunning, light-filled building that’s not just getting praises from Pomerleau employees. Late last year, it earned Lemay an Excellence Award from the Ordre du Architects du Quebec and an American Architecture Prize.

About the contractor

Vitrerie Univerre was founded in 1987 and is located in Levis, Que., on the south shore of the St. Lawrence River, opposite Quebec City. It specializes in the manufacture and installation of aluminum doors, frames, windows and curtainwall. •

ABOVE: Unusual angles created some challenges for the glaziers. Careful planning and proactive discussion made it all come together.

PHOTO CREDIT: JONATHAN ROBERT

GREATGLAZING

DANCING IN THE STREET

by TREENA HEIN

Any new dance studio created in this day and age has to have lots of light and lots of modern energy – and that means lots of glass. In the case of the new space for Decidedly Jazz Danceworks (DJD), a Calgary professional dance company and recreational dance school, “the studios benefit from a vast amount of vision glass, 32 feet of it,” notes site manager Colin Swirles at glazing contractor, Flynn Canada.

The new studio space is located on five floors of an 11-storey expansion of the unique Kahanoff Centre for Charitable Activities in the heart of downtown Calgary. The project aimed to connect the dancers practicing in the studios, people using the public function rooms and even performers in the 200-seat theatre with people on sidewalks down below. A chain-mail curtain can be drawn for privacy within the theater and for projection and other special effects. Each separate fully glazed studio offers multiple and varied views so that dance activity is fully showcased simultaneously from the street.

In terms of unique glass aspects of the structure, the back of the theatre stage consists of a fully glazed, acoustically separated, two-storey structured glass wall that not only allows the street direct visibility to the performances, but a skyline backdrop for the set design when desired. Design challenges with regard to the glass included “acoustic privacy.” Each of the seven studios were designed to achieve stringent acoustic separation so that music and footfalls generated in one space aren’t heard in others. “We used isolation pads from anchor to substrate,” says Swirles, “to minimize vibration and noise.”

AT A GLANCE

Architectural firm: Dialog (Janice Liebe, design architect; Matthew Horch, senior architect Nancy Logan, interior design)

Glazing contractor: Flynn Canada

Glass fabricators: Flynn Canada

Curtainwall glass specification: 32,000 square feet of Flynnwall 6450 unitized curtainwall; four-sided silicone, lower panels 32 feet in height

Vision glass: 25mm double-glazed units - Solarban 60

Exterior - 6mm low-E heat strengthened with PPG; 12.7mm argon-filled air space with stainless steel spacer

Interior - 6mm clear tempered

Spandrels: Monolithic, Vista Cool Solargray

Other: Glass railings: 12mm clear tempered glass, CRLBSG top gasket and CRL-B5S 10D base shoe; clear anodized cladding bonded to rail with VHB tape and silicone, CRL-TL5X

Taper-LOC for 12 mm glass and CRL-SHCS 12X1 cap screw

Glass entrances/doors feature unitized curtainwalls above

“We used two rigging systems, transferring in mid-air.”

In terms of glass installation, Swirles says the biggest challenge was the enormity of the unitized panels. “The lower panels L-2 to 5 were about 32 feet high, half of which we had to deal with using a concrete floor slab that created a soffit,” he explains. “To install them, we used two rigging systems, transferring the glass pieces from one to another in mid-air. We used a traditional coffin hoist off a donkey rig, then cored holes in the slab and used a tifor to make the switch.” •

ABOVE: Installing the large curtainwall sections required something of a high-wire act, transferring the panels from one rig to another part way up the building.

Photo: Pino & Nicola Dell’Aquila

Better balustrades

Polyurethane grouts can create new possibilities.

New grouts can make new designs possible by allowing glass to be embedded in the substrate without visible mechanical fastenings. In this subway station, the glass comes straight out of the floor, creating a seamless view.

Light-flooded spaces and a general airiness in buildings are no longer just a trend in the architectural world, but are increasingly state-of-theart. This general airiness achieved through the use of transparent materials does not end with the balcony. Total vision glazing and glass balustrades can offer continuity to wide open spaces, if they are not interrupted by framing or other mechanical fixations. When it comes to connecting glass to frame materials, new solutions are coming to market every day.

For total vision glazing and glass balustrades, the attachment of the glass panes to the floor ideally is concealed, leaving a barely visible, uninterrupted wall of glass. Glass grouting with cementitious grout has become a widespread, economic technology for balcony glazing, but many cases of breakage have been reported because of its hardness and rigidity.

Furthermore, in the past few years, glazing regulations for balustrades have changed significantly. The 2018 version of the international building code is now out. Codes require that a top rail or handrail be attached to guards with structural glass panels, unless the baluster panels are laminated with two or more glass plies

of equal thickness and of the same flat glass type. Furthermore the panels shall be tested to remain in place as a barrier following impact or glass breakage in accordance with ASTM E2353. Similarly CSA A500 is increasing the requirements on the glass thickness and strength. The end result is use of laminated glass and other thick configurations. In all three conditions noted in CSA A500, standard laminated glass is being specified.

Laminated safety glass has replaced single monolithic glass with significant consequences for glass grouting. Cementitious grout is very aggressive against the interlayers for laminated glass, causing discolouration and milky areas and even delamination and glass breakage. It is no longer a durable solution for glass grouting. This has created a need that structural sealant providers have met by developing a compatible solution with self-levelling two-part polyurethane (PU) grouts.

Glass embedding

For example, with the SikaGlaze GG-735 system, the bottom glass edge is embedded in a U-shaped profile. The loads are securely transferred through the glass elements, resulting in uniform stress distribution. The

23–26 OCTOBER 2018 DÜSSELDORF, GERMANY

THINK TANK

Experience the future of glass live. Enter into a dialogue with the leading experts in the world of glass. Discover the latest trends, products, developments and innovations.

Nowhere else, only here at the world’s leading trade fair glasstec. Be part of it!

Find out more: glasstec.de/thinktank

One new system allows the glass to be bonded to a metal panel that adheres to the substrate.When the adhesive is hidden with a print, only the glass surface is seen.

grout creates a strong but flexible fastening solution, capable of withstanding high static and impact loads. It is ideal for glass-wall grouting jobs.

The mechanics and workability of self-levelling two-part PU grouts can be excellent. The better ones offer just enough flexibility to take up some stress created by impact or thermal expansion while remaining rigid enough to prevent sway in the balustrade.

Before specifying a self-levelling two-part PU grout, ensure the product has been rigorously tested for your application. SikaGlaze GG-735 was tested and certified at the Laboratory for Steel and Light Metal Construction in Munich, Germany, for accident proofing, based on technical regulations for the use of accident-proof glazing. Products tested this way are supported by a German general building authority test report. The test comprised two 10-millimeter tempered or heat-strengthened safetyglass panes with a 1.52 millimeter PVB interlayer. The clamping depth of the glass pane was 100 millimeters. The U-channel was made of 10 millimeter steel and was very rigid in order to test the worst-case scenario. Impact tests were carried out with a pendulum, according to DIN EN 12600, with a dropping height of 700 millimeters. Further testing to the Florida building code allows systems of this kind to be compliant as a GMP-Postless Glass Railing System, which requires systems to pass windload tests, concentrated pull tests of 292 pounds with a safety factor of two, and large missile impact tests.

The installation of the glass panes in two-part PU grout systems is simple and economical. They are easily mixed on-site with a butterfly mixer or a two-component pump with a static mixer attached to the nozzle. The long open time of the product offers the applicator two methods of installation. In the first method, the PU grout is filled to a calculated level into the channel. Then the glass glides into its final position. A spacer tape at the bottom and at the edge of the glass maintains the distance between the glass and the support frame. In the second method, glass is first positioned and fixed in the channel, ideally

with wedges and setting blocks made of the PU grout for an optimal stress distribution. Then the PU grout is poured into the channel. When employing this method, make sure you select a product with low viscosity. With the second method, a clearance of 10 millimeters between glass and channel is recommended, resulting in a grout volume of only 2.5 liters per meter. With the first method, this volume can be further reduced, but the clearance on each side should not be less than six millimeters. This low volume, together with easy applicability, makes the method a very competitive glass fixation technology, overall. In exterior applications, the PU grout is normally protected against UV radiation and weathering with a bead of silicone sealant.

In the case of glass breakage, the panes can easily be replaced for repair work. The broken glass is first removed. After the glass pane is demolished with a hammer, the lamination interlayer is cut through with a knife. The embedding material and the glass is destroyed with a demolition hammer and lifted out with a crowbar. Finally, the support frame is cleaned thoroughly to remove dust, glass debris and embedding material. Alternatively, the use of a release agent on the channel and the glass before applying the grout makes it possible to remove the un-demolished glass with the help of a crane.

Optimal Optical Appearance

Other new solutions are emerging to improve the balustrade system even further. What if the architect wants to showcase the immaculate optical appearance of the glass and hide the floor slab? Products like Sikasil SG-500 for structural glass bonding can help. A perforated metal sheet, made of aluminum or steel, is bonded to the glass pane. The perforation in the metal profile allows the adhesive to through-cure whatever size bonding area is required. The glass pane may optionally have a screen print on the bonding area to hide the adhesive, as well as the metal profile. Sika also tested this innovative technology at the Laboratory for Steel and Light Metal Construction and at Bucharest University for accident proofing, based on German technical regulations for the use of accident-proof glazing.

In this era of great concern over the safety of balustrades combined with an esthetic desire for unimpeded views, PU grout suppliers are stepping up with new solutions that can satisfy every requirement. •

Azon Saves Energy

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

FLATGLASSSHOWCASE

Diffuse illumination

okaluxna.com

Okalux insulating glass with capillary slabs diffuses daylight into the depths of the interior while providing excellent solar heat protection, glare protection and privacy. The light transmission and solar heat gain coefficient values of the glass can be individually adjusted to suit the requirements of any building ranging from gymnasiums and museums to this exclusive Hudson Guesthouse designed by Janson Goldstein Architecture. Notice how elegantly the glass wall maximizes the building’s transparency and views. Whether for use in residential, commercial or institutional buildings, Okalux is a sustainable daylighting solution that adds user comfort and an attractive appearance to any design. A mix of Okalux light-diffusing glass and ordinary clear glass provides the home owner with both privacy and open views, as seen in this meadow-surrounded guesthouse.

Blocks entry

security-glazing.com

As school officials across the country look for ways to improve safety and security in their facilities, glass fabricator Global Security Glazing is working to educate them on the capabilities of specialized glazing solutions, such as Childguard security glazing. Since 2013, there have been more than 300 school shootings in the U.S., according to data from Everytown for Gun Safety. In 2018 alone, there has been one school shooting per week on average, as recently reported by CNN. Short-term

Shines throughout

bendheim.com

A wall of 22.5-foot-tall channel glass by Bendheim Wall Systems greets visitors to the new Museum of the Bible in Washington, D.C. The brilliant, towering channel glass wall cladding defines the museum’s entrance and arcade. It conveys a crystalline appearance, symbolic of the original building’s function as a cold storage warehouse. In other areas throughout the museum, translucent channel glass façade elements bring daylight in, while establishing a sense of privacy. Bendheim’s channel glass is designed with unique structural and esthetic qualities. Its ability to span great heights was essential to achieving a monolithic, continuous look for the grand, 40-foot-tall main entrance. Channel glass creates virtually uninterrupted walls of glass, limitless in length and up to 23 feet tall, with little or no need for intermediate framing. The U-shape of the glass enhances its structural properties, allowing it to achieve far greater spans than flat glass of the same thickness. The entrance and arcade of the Museum of the Bible are clad in Bendheim’s low-iron Clarissimo channel glass, featuring a translucent white ceramic frit. Many of the channels are selectively fritted, providing a seamless transition from opacity to transparency. Light radiating from the highly polished Clarissimo glass surfaces bounces off the 140-foot-long image-projecting ceiling. The reflected light, working in tandem with the LED screen technology, helps transform the character of the space and creates an immersive experience. Bendheim’s 504 Rough Cast channel glass, installed in the company’s SF-60 frame system, enhances the exterior of the building. The light-diffusing textured glass channels create a contrast with adjacent clear insulated glass units.

measures are focusing on how to prohibit attackers from gaining entry into schools and other facilities. As a result, entry points such as glass windows and doors are being examined. Many older schools across the country were constructed with tempered glass, which shatters into blunt pellets immediately upon impact. Surface-applied safety films are available for glass that offers varied levels of resistance to forced-entry, but they must be anchored to the window framing and can be broken through with minimal effort. Bullet-resistant glass, while highly effective, is costly and requires window and door framing that can support the glass’ additional weight and thickness. Manufactured by Global Security Glazing, Childguard glazing is a laminated security glass construction that’s specially designed for use in school and educational facilities to withstand forced-entry scenarios. Available for both new and retrofit applications, Childguard glazing can be used in insulating glass units and paired with high-performance, tinted, and other glass options to meet safety, energy, and other design goals.

Inviting the public in

guardianglass.com

Diamond Schmitt Architects has designed new public spaces and a new entry that, for the first time, connects the National Arts Centre to the community. Guardian SunGuard SuperNeutral 70/41 coating on jumbo, low-iron glass, provides the transparency and beauty that invites patrons in. The spaces are constructed of exposed wood and framed on a custom-designed glass curtain wall system that pushes the limits of glass innovation. The introduction of 23,000 square feet of Guardian

FLATGLASSSHOWCASE

SunGuard SuperNeutral 70/41 coating on jumbo, low-iron glass brings value to the setting by giving patrons and visitors openness and warmth for events from day to evening. Fabricated by Carey Glass and installed by Verval, the glass curtain wall, which includes insulating glass units up to 95 by 228 feet, is a counterpoint to all the enclosed concrete that previously shaped the NAC. Jumbo insulating glass units deliver uninterrupted views in and out, opening the NAC to the city, and the use of the high performance, low-E SunGuard coating on low-iron glass ensures those views have striking clarity. SunGuard SuperNeutral 70/41 coated glass brings in abundant natural light, while also contributing to energy management while controlling solar heat gain so those open spaces don’t overheat.

For the birds

walkerglass.com

Bird collisions with building glass facades have been thoroughly documented with hundreds of millions of birds dying every year in North America. Clear glass represents a major threat to birds. However, im-

collisions. For instance, visual markers on windows reduce collisions and are most effective on the outside surface of the glass as they can be seen from all angles. Also, visual markers need to respect the two-by-four rule, meaning markers spaced at two inches or less of horizontal space or four inches or less of vertical space. It is also known that birds perceive UV signals at a different wavelength than humans, meaning that markers made with UV coatings respecting the above-mentioned rules are hardly seen by humans but seen by birds. Pilkington North America and Walker Glass have developed AviProtek T, glass solution using Pilkington pyrolytic coated glass.

Innovative coating

vitroglazings.com

Vitro Glass’s innovative quad-silver coating technology, Solarban 90 solar control low-E glass continues a rich tradition of “ahead of its time” products within the Solarban glass family. Introduced for commercial construction in 2015 and residential applications in 2017, the quad-silver coating devised for Solarban 90 glass gives Vitro Glass an entirely new platform for product innovation, including the potential for new glass appearance and performance combinations. Developed with architects to meet architectural glass that delivers enhanced solar control, Solarban 90 enables architects

to specify larger expanses without sacrificing energy performance. Versatile and functional, Solarban 90 glass can be combined with any Vitro performance-tinted glass to unite colour with the coating’s heat-blocking capability. In a standard one-inch insulating glass unit with clear glass, Solarban 90 glass has a solar-heat-gain coefficient of 0.23, a 15 per cent improvement over Solarban 70XL glass. When coated on performance-tinted glasses such as Pacifica glass or Solargray glass, Solarban 90 glass can achieve SHGCs of as low as 0.17 in a one-inch IGU. Solarban 90 glass also features a VLT of 51 per cent and a light-to-solar gain (LSG) ratio of 2.22.

Dampens key wavelengths

hartung-glass.com

Urban planners in many Canadian municipalities are now requiring that new residential projects proposed for high noise environments will be designed to achieve acceptable interior noise levels. Although exterior walls, roofs, doors and ventilation will sometimes require upgrading, windows are the controlling factor with respect to interior noise levels. Architects are paying careful attention to the acoustic performance of windows where noise sensitive buildings such as residences, hotels, churches, schools and hospitals are involved. Hartung Glass Canada provides a sound solution for dealing with noise pollution through acoustic PVB laminated interlayers. Hartung’s sound-dampening laminated safety glass provides proven ambient noise reduction to architects and designers for projects in urban corridors near highways, railroads and airports. This advanced, three-layer-system decouples and disseminates sound waves for superior sound dampening performance and reduces perceived loudness by up to 50 per cent, decreasing transmitted sound up to 10 decibels versus non-laminated glass. The patented technology is compatible with other security and decorative PVB interlayers and targets sounds in the 1,000 to 4,000 Hertz range, which is the most sensitive range of human hearing.

Colour-changing smart glass

nodiscorp.com

Nodis, a provider of technology to transform glass into electrically switchable smart glass and displays, has announced availability of its TruTint smart glass technology. TruTint transforms windows, giving people the ability to change the tint, colour and temperature characteristics of windows instantly. TruTint uses colour-coated nanoparticles that are oriented when a voltage is applied and act as small light shutters. This allows the setting of any level of tint from clear to opaque. With multiple colours, one can switch to any colour for the glass (opaque, transparent or any tint colour in between). Nodis smart glass technology is designed to make glass beautiful, responsive and energy-saving with real-time changing colour, tint, infrared heating control and glare reduction.

RESOURCEDIRECTORY

by FRANK FULTON

The next thing?

Since the accidental invention of glass by Phoenician sailors 7,000 years ago, technological advances over the centuries have resulted in the development of broad sheet glass followed by crown glass, cast glass, drawn sheet glass and finally float glass. The next advancement in glass could soon be upon us in the form of nanotechnology.

The science now exists to practically eliminate surface reflections from glass, creating “invisible” glass. Watching television, working at a computer screen, taking photographs, or using a smart phone outdoors can all be negatively affected by glare created by the reflection of light. Not only will this technology improve the user experience for consumer electronic displays, it can also enhance the energy-conversion efficiency of solar cells by minimizing the amount of sunlight, and therefore energy, lost to reflection. When developed into a viable commercial process, reflection-free glass will certainly allow for some very creative architectural building designs while providing crystal-clear views at night from inside a lit room. When combined with low-E coatings, because light will not be reflected, the energy performance qualities of the coating will be maximized.

The next advancement in glass could be upon us in the form of nanotechnology.

The scientists at the Center for Functional Nanomaterials (CFN) at the Brookhaven National Laboratory in Upton, N.Y., have developed the means to alter the surface properties of glass by adding a nanoscale-thick layer of cones or spikes that render it reflection-free and thereby nearly invisible.Nanotechnology and nanoscience are the study and application of extremely small things and can be used across all the other science fields such as chemistry, biology, physics, materials science and engineering. This science works in scales called nanometres. So, you ask, what is a nanometre? Well, it’s smaller than miniscule. One nanometre is one billionth of a metre. There are 25.4 million nanometres in a linear inch, and for comparative reference, a layer of 0.0007-inch anodized coating on aluminum is over 17 thousand nanometres thick. According to Chuck Black, the director of CFN and renowned as the expert scientist in his field, “your fingernails grow at a rate of one nanometre per second.”

YOU BET YOUR GLASS

Next you might ask why glass reflection happens in the first place. Consider that light travels through air at around 300,000 kilometres per second but when it gets to a piece of glass it can suddenly move at only 200,000 kilometres per second. This results in a photonic traffic jam of light at the glass surface creating a reflection. Each piece of clear glass reflects eight per cent of light. But the addition of a nanosized layer on the surface acts as a buffer between the air and glass, changing the speed of the light gradually instead of suddenly, allowing all of the light to transfer through the glass and thereby virtually eliminating a reflection.

How is the non-reflective nanolayer produced? Black states that “nanotextured glass is created by first coating the glass surface with a polystyrene (Styrofoam) / polymethylmethacrylate (Plexiglass) copolymer, heating it, then hardening it by infusing aluminum oxide. Once hardened, plasma etching is applied that removes the initial coating materials, leaving a uniform pattern of aluminum oxide particles behind. The etch eats away the glass surface around, but not beneath, the aluminum particles creating microscopic valleys and leaving behind miniature 170 nanometre tall peaks or spikes. A two-inch piece of glass has 900 billion spikes on its surface!”

Although there are applied coatings in the market that address glare on picture glass and specific colours seen through eye glasses, these treatments deal with only one wavelength of light whereas the nanotextured layer developed by Black and his team transmits the full spectrum of visible wavelengths. Their revolutionary process doesn’t add a coating that could be scratched or damaged but actually changes the physical properties of the glass. Additionally, not only does this treatment make the glass invisible and eliminate glare, it also makes it water-repellent, self-cleaning, and anti-fogging. Just imagine driving your car with this glass in your windshield! •

PRINTED DESIGNS

IN SIZES UP TO 110" X 200"

PROJECT: 450 Alaskan - Seattle, WA

ARCHITECT: NBBJ

CERTIFICATION TARGET: LEED® Gold

SPECIFICATION: Entice® Thermal Entrance U.S. Patent 9,074,413

For the first time, all-glass aesthetics and full-frame thermal performance in one entrance system. Entice® meets stringent energy codes and looks great doing it, satisfying the most discerning designers, owners, and code officials.

• Ultra-Narrow 1-1/8" Vertical Stiles

• Thermally Broken with U-Factors as Low as 0.33

• NFRC Rated and Satisfies ASHRAE 90.1-2016 Air Infiltration Criteria

“Best in Category - Openings” —

“Best Product for Retail”

“The cleanliness in lines is equaled by the sophistication of the hardware and performance.” — Product Innovation Awards Judge