Shim It Once and Done. SAVE

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time.

Grove Products, Inc. has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help.

1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims.

www.groveproductsinc.com

Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

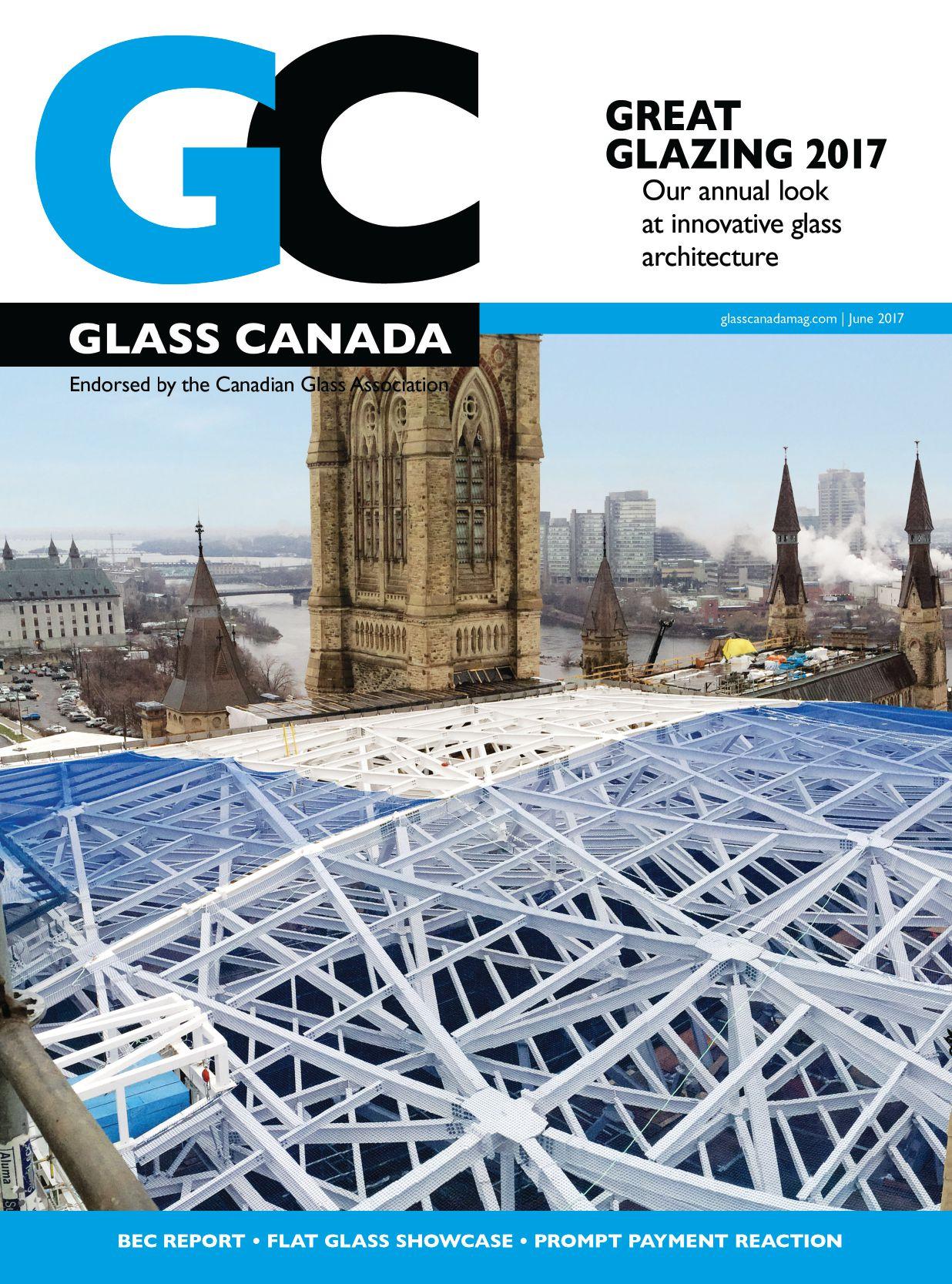

Our annual look at great glazing projects across Canada includes eco-factories, colour-shifting libraries and the most famous buildings in Canada.

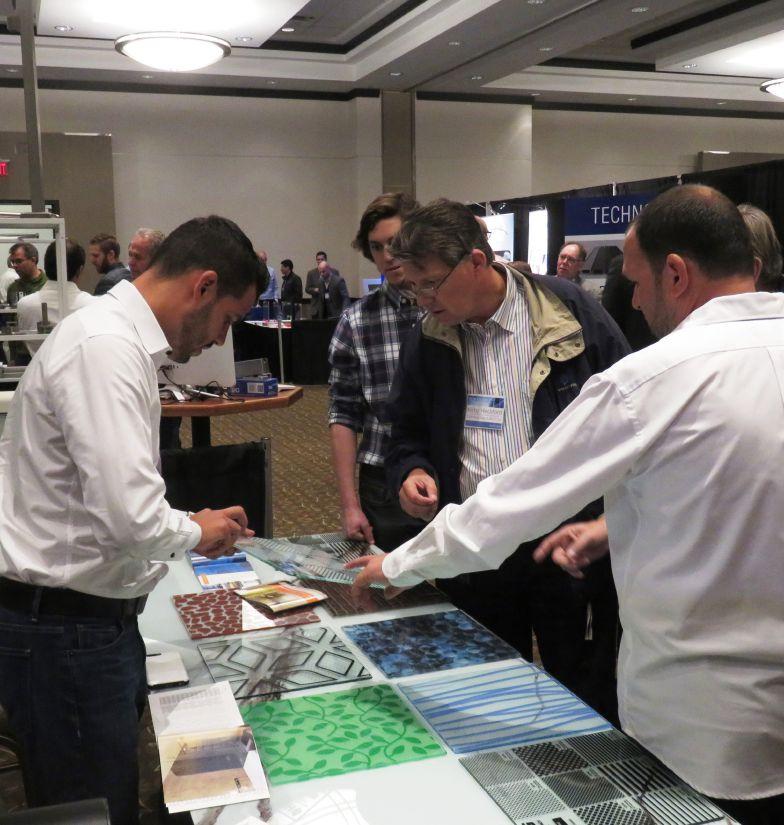

Glass Canada staff take a lot of photos at industry events – too many to put in the magazine. Don’t worry, your 15 minutes of fame are still available in our Facebook photo albums. Have a look, Like a friend and leave your comments!

Canada’s commercial glazing show draws rave reviews from exhibitors and attendees.

The Building Envelope Conference provides a comprehensive look at the industry from some of its top minds.

Flat glass showcase

New and amazing innovations in glass technology to fire your creativity.

EDITORIAL

Still lots of expert talk about millennials. No seminar program at a large event is complete without sessions telling us how to motivate them, how to retain them, how to find them and how to sell to them. What do they want? What do they like? One pictures a curious crowd of baby boomers peering through glass at a captive millennial, wondering what it eats.

I don’t think the habits of millennials can be all that exotic since they are, at the end of the day, simply young people. You know, like we all were at some point in the distant past. Many of the complaints and observations I’ve read about millennials are simply reruns of the same comments every generation has made about the one following. Compared to us, the young people are always lazy, irresponsible, intellectually shallow and focused on all the wrong things. Some of this is accurate, as young people are young people and by definition still have much to learn. And some of it is unfair and, dare I say, motivated by jealousy.

• Fabricating machinery

• Insulating window wall

My observation of young people coming up in the workforce today is that they are superior to us in almost every respect. Smart, good-looking and remarkably healthy emotionally. Fewer problems with law-breaking, violence and substance abuse. Better educated. They lack only experience. Yes, the period of adolescence has been extended in this age of plenty and few millennials are as committed to mortgages, careers and families as we were at the same age. Is this a sign of weak character or greater intelligence? People today can expect to live almost 10 years longer than they could when I was in my 20s. It sure makes more sense to me to use that time to extend your period of freedom and fun when you are young than to extend your time in the retirement home at the other end.

So I think that rather than being different from us, millennials are presented with a different set of circumstances. Frank Martin, University of South Carolina head basketball coach, says, “You know what makes me sick to my stomach? When I hear grown people say that kids have changed. Kids haven’t changed. Kids don’t know anything about anything. We’ve changed as adults. We demand less of kids. We expect less of kids. We make their lives easier instead of preparing them for what life is truly about. We’re the ones that have changed.”

I think that’s pretty much dead on. So if kids haven’t changed, why are business owners having such a struggle reaching them? It’s because the kids’ circumstances have changed and they are, as I opined above, smarter, better balanced and possessing a clearer sense of their own self-interest. They are not going to accept unpleasant working conditions because of some hard-work ethic designed to benefit the employer and not the employee. They are not going to sacrifice their experience today in order to get ahead at a company because they have no illusions about loyalty. They don’t trust employers to reward loyalty with loyalty and know they will change jobs many times before settling down.

Bottom line: they value their time highly and won’t be taken advantage of. The millennials are the same as we are and want all the same things. They are just a heck of a lot better at getting them. •

June 2017 Volume 29 • Number 3

Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Emily SUN

DIRECTOR OF SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexweb.com

COO | Ted MARKLE tmarkle@annexweb.com

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbizmedia.com

Tel: 416-510-5189

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbizmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

UL, a global safety science certifier, has expanded its service offerings further into the building envelope and building sciences market with the acquisition of CLEB, a leading Canadian building science and building envelope service provider. CLEB, a Montreal-based company, is a privately owned business. CLEB provides a wide range of building science services, including building envelope testing services, building forensic services and field testing and building system commissioning services for architects, building owners, manufacturers and others in the building construction markets across North America. CLEB’s unique laboratory facilities are among the largest in Canada and are accredited by the major North American accreditation organizations. Over the last thirty years, CLEB has contributed to many highcaliber projects throughout Eastern Canada and the northeastern United States, as well as projects beyond North America.

“UL and CLEB have a shared mission and complementary businesses. We are relied upon by building construction communities for the services and knowledge that they need to enhance public safety, meet regulatory demands, protect brand value and successfully access global markets,” said vice-

president and general manager of UL building and life safety technologies division, Chris Hasbrook. “Working as one, UL and CLEB will continue to grow the vision that has brought us together, and grow our position as the global leader in the field of building science.’’

CLEB’s employees will join and strengthen UL’s industry professionals and recently inaugurated building envelope testing facility located in Northbrook, Ill. Effective immediately, the company will operate as CLEB, a UL Company. The group’s building science thought leadership and global centers of excellence will be based out of the Montreal and Northbrook headquarters.

“We are excited by this opportunity to join forces with UL and provide best-in-class services to the building envelope community,” said Mario Gonçalves, former president of CLEB and new principal and global business leader for building science technologies for CLEB. “Our group’s shared reputation for delivering industry-leading services and in-depth industry knowledge will continue to strengthen our position as leaders in the field of building science services and building envelope testing and certification. Combining with UL will allow us to significantly accelerate our access to global markets.”

June 7 - 8

Glass Connections Burnaby, B.C. canadianglassassociation.com

July 31 - Aug. 3

IGMA Summer Conference Montreal, Que. igmaonline.org

August 24

CSC Golf

Richmond Hill, Ont. toronto.csc-dcc.ca

Sept. 12 - 14

GlassBuild Atlanta, Ga. glassbuildamerica.com

Sept. 21

OGMA Fall Golf Woodbridge, Ont. ogma.ca

2018

Jan. 29 - Feb. 2

IGMA Winter Conference Tucson, Ariz. igmaonline.org

March 21 - 24

Fensterbau Frontale Nuremburg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

June 21 - 23

AIA Conference New York, N.Y. conferenceonarchitecture.com

Connections is not just our name, it’s our game! Don’t miss the opportunity to join your peers in the industry on June 7 and 8 at the Delta Hotels Burnaby Conference Center in Vancouver, B.C. The Conference features a tabletop session that also includes billing as a Bronze sponsor. Greater sponsorship levels are also available and can be viewed on our website. Please contact executive director Sara Neiswanger (sara@glasswebsite.com) to find out more.

Highlights of the program include presentations on glazing restorations, passive house window certification, bird friendly glazing, and more. Visit CGA’s website for updates and to register (canadianglassassociation.com).

The CGA is pleased to welcome the Fenestration Association of B.C. provincial association and its members as a valued member and partner of the organization. FenBC was established through the merger of the Glazing Contractors Association of B.C. (GCABC) and the Window and Door Manufacturers Association of BC (WDMA-BC). FenBC represents all parties engaged in the commercial and residential sectors of the fenestration industry. Zana Gordon, FenBC’s executive director, and David Langton of Competition Glass will be representing the association on the CGA board of directors.

Membership in CGA is available through a provincial association or as an individual company membership. Contact Sara Neiswanger for more information at sara@glasswebsite.com.

Did you know the CGA has

Canadian Glass Association 619 Liverpool Road, Pickering, Ontario L1W 1R1 Tel: 604.855.0245 • Fax: 866.253.9979 canadianglassassociation.com

an online bookstore? Manuals may be purchased online and will be shipped directly to your door. Visit CGA’s library today at canadianglassassociation. com/store/.

TheAGMCA is in search of an individual with demonstrated leadership and administrative skills who can work effectively with the association’s board of directors and various industry-related committees. The successful candidate will have a good understanding of the collective bargaining process. The new executive director will take office ASAP. Applications may be directed in confidence to the address shown below. Candidates selected for an interview will be contacted.

Chairman

AGMCA Search Committee 619 Liverpool Road Pickering, Ont. L1W 1R1 info@agmca.ca

TheOGMA is sad to inform members about the passing of our long time industry colleague, Dennis Haatvedt, on March 23 at the far too early age of 58. Dennis was diagnosed with brain cancer just about a year ago. Dennis was a longterm director with the Architectural Glass and Metal Contractors Association and for the last year of his working life he

served as their executive director. Prior to that, he spent about 35 years with AGC Glass, many of those as head of their glass shop division. Dennis was one of the good guys in our industry and he will be truly missed.

The wife of Al Jones for the past 66 years and mother of Steven Jones of Parkway Glass, Barbara Jones, left us on April 10. Al worked for Sealite Glass back in the late ’50s and early ’60s, and both Mr. and Mrs. Jones have been close to many in the industry for more than a half century.

Sergei Mihhailenko, P.Eng and Les Szcepanski, P.Eng. presented an excellent, informative and entertaining presentation on the application of the new CSA A500-16 Building Guards standard that will soon be adopted into building codes across Canada governing the use of glass in railings and balustrades on April 12 at the Richmond Hill Golf Club. The OGMA extends its appreciation to our co-sponsors for this event: Trulite Glass and Aluminum Solutions and Kuraray America. Over 100 people from across Ontario attended.

The OGMA greeted members and visitors to this year’s Top Glass event held on April 20. The show was the largest to date, was excellently run with a ton of informative presentations and a lot of enthusiastic traffic. Everybody who’s anybody was there including many glass industry dignitaries. OGMA president Angelo Cairo and director Steve Gusterson presented the OGMA Awards of Excellence. This years recipients were Diamond Schmitt Architects for the Wilfred Laurier University Lazaridis Hall (Award for Design) and Noram Building Systems for the Vaughan Civic Centre Public Resource Library (Award for Execution).

Back by popular demand,

plan on attending on August 10. Mark your calendar now, considering booking a boat for your company and a group of good customers and watch your mail for details.

The OGMA will once again hold our fall golf tournament at the prestigious Country Club in Woodbridge on Sept. 21. Mark your calendar now. Details will follow as the date approaches.

In case you missed it, companies had until the end of 2016 to put accessibility policies and procedures in place for the communication of all of your information and your employment practices to conform with the Accessibility for Ontarians with Disabilities Act (AODA). To find out your legal obligations, go to ontario.ca/page/accessibility-laws, then contact Workplace Safety and Prevention Services to help you put it in place.

If your company isn’t managing your workplace safety policies, if you have any injured employees on Workplace Safety and Insurance Board (WSIB) benefits (40 per cent penalty per dollar of wages), or if you are found liable for a workplace accident (average penalty between $60,000 and $120,000), we have developed a program to assist you. For the past four years, the OGMA has worked with WSPS to create a health and safety plan designed specifically for glass shops and glazing contractors. They are offering their plan to OGMA members for about half what they usually charge for similar plans, and the companies who have signed on so far have had nothing but great reviews for the program. If you haven’t had any accidents or fines, congratulations, but it’s really a matter of when, not if. Being proactive, being up to date, being compliant to all the workplace legislation is a job you don’t have time to do.

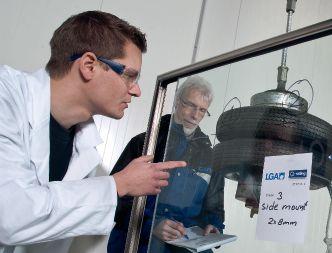

TheAmerican Architectural Manufacturers Association (AAMA) recently released a new document providing a standard laboratory procedure for exterior shading devices and the project-specific evaluation of downward static ice and snow loads, and impacts on them from falling ice or snow. AAMA 514-16, “Standard Test Method of Static Loading and Impact on Exterior Shading Devices,” uses sandbags to simulate downward loads from ice and snow to test shading devices.

“Exterior sun shades are used to reduce solar heat gain and glare and redirect natural daylight,” said Steve Fronek of Wausau Window and Wall Systems), co-chair of the shading device task Group. “AAMA 514 was created to provide design professionals with a consistent, repeatable, test method to help in assessing the effects of snow build-up and ice impact on exterior shading devices. Accretion and release of a certain amount of ice and snow should be considered inevitable in most U.S. climates.”

While sun shades and other exterior projections are both sources and targets of falling ice and snow, they should not be considered protection from them, noted Fronek.

TheNational Glass Association (NGA) and Window and Door Dealers Alliance (WDDA) have just announced author and generational expert Cam Marston will return to GlassBuild America as keynote speaker at the Opening Session. Marston’s presentation resonated deeply at GlassBuild America 2015 and he is back by popular demand to present “The Multi-Generation Workplace – Do You Know How to Manage It?” He will share how understanding the differences of each generation, from baby boomers to millennials, can help attract and retain a new generation of employees. Attendees will walk away with actionable ideas to help them effectively manage across the generations.

“We still hear positive comments about Cam Marston from GlassBuild attendees who saw his presentation in 2015,” said Nicole Harris, NGA\WDDA president and CEO. “With such enduring interest, we invited him back to give us his updated perspective on a topic that so many of our members, attendees and exhibitors face in their own workplaces.”

The GlassBuild America Opening Session will be held Sept. 12 from 8:30 to 10:00 a.m. and is open to all attendees and exhibitors at no additional cost. A continental breakfast will be served. Taking place Sept. 12 to 14 in Atlanta, GlassBuild America 2017 will also feature Express Learning, the 12th annual Glazing Executives Forum, the third annual Window and Door Dealer Days and The Dream Showroom. More than 400 exhibiting companies are expected to showcase their most innovative architectural glass, metals and residential window and door products and services.

Registration for GlassBuild America is open, with discounted earlybird registration prices in effect through mid-June. NGA and WDDA members receive special member rates.

“AAMA 514 simulates the accumulation of snow and ice loads by the application of sandbags while monitoring deflections to ensure the product remains within acceptable visual limitations,” said Greg McKenna of Kawneer, also co-chair of the group. “A safety factor is also included in an overload test. In addition to testing full-size mock-up assemblies for static and impact loads, guidance is given on conducting component tests on the individual structural elements of the sun shade.”

Apogee Enterprises has announced that it has entered into an agreement to acquire 100 per cent of the stock of privately held EFCO Corporation from Pella Corporation for approximately $195 million. EFCO is a leading U.S. manufacturer of architectural aluminum window, curtainwall, storefront and entrance systems for commercial construction projects. Apogee, which provides distinctive value-added glass and metal solutions for the architectural and picture framing industries, expects to close on the purchase of EFCO in the first half of fiscal 2018, pending regulatory approval.

“Our acquisition of EFCO will accelerate our growth strategies and expand our presence in mid-size commercial buildings and broaden our product offerings,” said Joseph F. Puishys, Apogee CEO. “EFCO operates in a space we know and structurally has similar operations to those across the Apogee businesses. In addition, with its broad range of high-performance window, curtainwall and storefront products, it rounds out the Apogee product offering. We also see significant margin enhancement opportunities as we leverage Apogee’s scale, operational excellence expertise and supply chain synergies that build on initiatives already being implemented by EFCO’s strong management team. EFCO is a growing and profitable company, with annual revenues of more than $250 million that are largely generated from less cyclical mid-size and small commercial projects, a target Apogee growth sector,” he said.

EFCO’s management team will continue to lead the business following the acquisition close. “Apogee is an ideal parent company for EFCO,” said Cameron McGinley, EFCO president. “We are pleased to be joining the Apogee family and look forward to working with Apogee to capitalize on product, market and operational opportunities.”

Mario Savoie has joined Alumicor in the position of vice-president and regional general manager for the company’s eastern region. Savoie brings over 30 years of industry experience, direct and indirect with his work as sales and estimation manager for Groupe Bussieres, general manager at Vitererie Laberge and Montreal service centre manager for Kawneer. He will be responsible for all aspects of the eastern region.

In other Alumicor news, Mario Lemay came

Along- awaited certification program for architectural glass and metal technicians is now one step closer to a reality. Administrative Management Systems (AMS) is beginning the task of developing a third -party, personnel certification program for architectural glass and metal technicians with the intent of gaining ANSI accreditation in accordance with ISO/IEC 17024. Following an open forum summit of industry leaders, stakeholders, and interested parties held in Las Vegas at the end of the BEC Conference in February that confirmed the need for, and potential model of, the program , AMS was invited to submit a proposal to the Finishing Trades Institute for the development of a personnel certification program. AMS has since been granted approval to begin the first phase of what is estimated in total to be an 18- to 24- month project. The first phase will include defining the competency and practical requirements for an architectural glass and metal technician with direction and input from committees of industry experts and stakeholders. An open process to identify industry participants for inclusion on the steering committees will begin immediately.

“The best opportunity for success of the program rests with steering committees and eventually a certification board that evenly represent the three primary stakeholder segments of the industry,” said Ben Beeler, the program ’s co-designer and operations manager. “The glazing technician population, glazing contractors, and the user community must work in balanced concert to achieve a program that meets all the industry’s requirements. We are looking far and wide for as much assistance with this endeavor as possible.”

Glass has announced that Darijo Babic has been named director of key commercial projects for North America. Babic will work with Guardian’s channel partners, fabricators, project glaziers and architects to grow Guardian SunGuard architectural glass business on commercial building projects.

“Darijo is well-known and respected in our industry and having him on our team will help boost Guardian SunGuard sales to the next level,” said Andy Russo, director of sales for the U.S. and Canada. “The commercial segment is extremely important to Guardian and with our commitment to innovation, including our upcoming jumbo coater. We look forward to Darijo developing and executing a strategy to pursue and win key projects in close collaboration with our North America sales team and channel partners.”

Babic comes to Guardian from the prominent glazing contractor, Enclos Corp., where he was pre-construction manager for the eastern U.S. Prior to that, he held a variety of roles with PPG Industries, including national manager of the construction market team for the U.S., Canada and Mexico.

full circle as he returned to the field in March as regional sales manager for the northern shore of Montreal up to Abitibi, serving architects and dealers. He started with Alumicor sales in 1994, serving the architectural and glazing contractor community for 12 years. He took his direct experience inside when he was eventually promoted to senior operations manager for Quebec and then later on to eastern Canada senior operations manager.

Vitro has acquired Pittsburgh Glass Works’ (PGW) automotive glass business from LKQ Corporation. The acquisition completes the agreement announced last December for US$310 million. Headquartered in Pittsburgh, PGW operates seven manufacturing plants, two satellite facilities and two float glass furnaces in the U.S. It also has one manufacturing plant in Poland and owns an equity participation in two joint ventures, one each in Mexico and China. The acquisition, combined with the purchase of PPG’s former flat glass business completed last October, expands Vitro’s float glass manufacturing and fabrication facilities.

Adrian Sada Cueva, CEO of Vitro, said the addition of PGW’s original equipment business will enable the company to serve a greater number of customers in the automotive glass business and increase its global coverage. “The experience and state-of-the-art technology PGW brings to our business will enhance our technical, research and development capabilities,” he explained. “It will further strengthen our company and create a business staffed by talented employees and strategically positioned for growth.”

Joe Stas, CEO of PGW, said the transaction represents the beginning of an exciting new era for PGW associates and stakeholders.

“Vitro has a sterling reputation throughout the industry as a highly competent and capable glass manufacturer, based on more than a century of glass-making experience across the automotive, architectural and glass container industries. By harnessing the strength of a newly expanded workforce and their technical capabilities, Vitro is committed to creating a next-generation auto glass company.”

The combined automotive glass business will unite its research and development capabilities with those of Vitro Architectural Glass, PPG’s former flat glass business unit.

by MARGARET WEBB

Let’s take a look at the recent great work by our Technical Services Committee, chaired by Jeff Haberer of Trulite Glass and Aluminum Solutions. The committee currently has one ballot under consideration, “Voluntary Guidelines for IGU Manufacturing Tolerances.” The ballot closes at the end of May and the task group will review the ballot comments. If the ballot is successful, the document will be balloted to the IGMA Technical Policy Committee for the next level of approval per IGMA’s document development procedures.

The Glazing Guidelines task group, chaired by Tracy Rogers of Keystone Certifications, is working jointly with the GANA Insulating Division to develop a technical bulletin (identified as TB-1800-XX) on IGU’s with unsupported edges. The bulletin addresses concerns regarding the structural and durability performance of unsupported IGU edges subject to uniform load including glass stresses, practical glass deflections, sealant strength capabilities, spacer stress and deformation limits, load durations, dead load support and setting block location plus other variables that influence the unsupported edge condition for IGUs. All sections of the draft document have been written and the task group is reviewing the sections. Once this review has been completed, the document will be balloted to the Technical Services Committee and GANA’s Insulating Division.

The joint IGMA-AAMA task group, Edge Pressure on Insulating Glass Units, co-chaired by Helen Sanders of Technoform Glass Insulation and Paul Bush of Vitro Architectural, will be meeting in June to review the two proposals that have been received to develop a test fixture to

The Technical Services Committee develops best practices guidelines for our industry.

measure edge seal pressure. The task group will be finalizing the remainder of the test parameters at their next conference call.

The IG Cavity Compensation task group, chaired by Aaron Ryan of Pella Corporation was initiated in mid-December, has been meeting monthly and has established a document outline and populated several sections of the document. Cavity compensation methods that are included in the manual are capillary tubes (both on-site sealing and leave-open), breather tubes, valves (also known as the burping method), desiccant adsorption/desorption, pre-inflating/pre-deflating the unit, temperature manipulation at the manufacturing environment and bladders (for on-site sealing). The task group is following the same template as TB-1601, Guidelines for Use of Capillary Tubes.

The IG Cavity Width task group, chaired by Dan Braun of Intertek/Architectural Testing, has finalized the TM-4400, Voluntary Guidelines for IGU Manufacturing Tolerances and has forwarded the document for balloting to the IGMA Technical Services Committee.

The Thermal Stress task group, chaired by Jeff Haberer has been reconvened to consider adding a section on ceramic frit to TM-1500, Guidelines to Reduce Instances of Thermal Stress.

In other IGMA news, the IG Fabricator Workshop, professionally moderated by Oak Moser of Oak Hill Consulting, held the most recent workshop at the Exova facilities in Mississauga, Ont. In addition to the workstations for frost point, glass cleaning and cutting, desiccant/desiccated matrix, gas measurement, volatile fog and sealant, two sessions were added as a result of past participant feedback: a spacer workstation and a session on how to conduct a forensic investigation (with real case studies as examples). The committee is considering holding one face-to-face workshop annually and offering online video sessions for the remainder of the year at a reduced rate. The task group responsible for the workshop is looking at how to best deliver the online sessions. This workshop would not be possible without the support of our volunteer workstation moderators. Thank you to Bill Briese of GED Integrated Solutions, Mike Burk of GED Integrated Solutions, David Cooper of Guardian Industries, Randi Ernst of FDR Design, Jeff Haberer of Trulite Glass and Aluminum Solutions, Bill Lingnell our IGMA Technical Consultant, Shulin Cui of SilicaStar, Richard Warren of Tremco and Brian White of H.B. Fuller. •

QRAILING IS PROUD TO ANNOUNCE THE INTENSIFICATION OF ITS SALES NETWORK IN CANADA. THROUGH PARTNERSHIPS WITH WELLESTABLISHED CANADIAN ARCHITECTURAL PROJECT AND HARDWARE SPECIALISTS, THE COMPANY NOW OFFERS A GLOBAL BRAND WITH LOCAL EXPERTISE.

“Partnering up with Canadian companies was a logical step for Q-railing. Although Q-railing is a global brand, we strive to meet the demands of our local customer, within their specific market,” says Thomas Sixt, Sales Director of Q-railing North America. “With our network of trusted, wellestablished Canadian suppliers of architectural hardware and project services, we offer superior local service for our international brand of designer railing systems. Like us, our partners strive for the best quality solutions in the building industry. After successfully working with these firms for many years we are excited to appoint them as exclusive distributors of Q-railing products.”

Distributor partners

Q-railing’s exclusive Canadian partners include three architectural hardware distribution specialists - Bezdan, Cascade Aqua-Tech and All Glass Parts. Bezdan is a well-respected architectural railing solutions specialist. Cascade Aqua-Tech is a leading provider of building envelope solutions and architectural hardware in the Western part of Canada. All Glass Parts is dedicated to serving the window, door and glass industry across Canada and the U.S. All three have a core competence in metal and glass, as well as extensive warehousing facilities to ensure products are available for quick delivery.

For large construction projects in North America, Q-railing works exclusively with Glasscan. Having a great reputation with architects and contractors, Glasscan represents top tier industry leaders who produce products that meet the highest quality standards. A leading example of one of Glasscan’s recent Q-railing projects is the Bank of Canada renovation.

Since 2004, architects, designers and contractors around the world have relied on Q-railing as their source for railing systems and glass balustrades. Its products offer form, function and safety, and are known among glaziers and metal workers for their easy and straightforward installation methods. “Because a railing system needs to do more than look good, all Q-railing systems are designed to exceed the highest industry safety standards,” states Sixt. “Through extensive testing, institutions and internationally-leading enforcing authorities have certified the safety of our products and systems. Railing systems are there to protect people from falling and at Q-railing we take this very seriously.”

by TREENA HEIN

As part of the current Parliament Buildings rehabilitation being performed by PCL Constructors Canada, work on the pre-Confederation West Block began in 2011. By the fall of 2018, its permanent courtyard infill will serve as a temporary House of Commons Chamber during the upcoming rehab of the Centre Block over the following 10 years.

It’s estimated that the infill will increase useable space of the historic building by about 50 per cent. Following the return of the House of Commons to the finished Centre Block, the West Block will house Parliamentary office suites and the infill will be converted into committee rooms.

The star of the interim House of Commons Chamber is the triple-glazed infill roof, with its stunning diamond and triangle-shaped panes. Georges Drolet at Fournier Gersovitz Moss Drolet Architects (in joint venture with Arcop on this project) is the partner in charge of courtyard design. He says it was very important that the infill, once covered, kept

its original exterior character. “A glass roof was the best way to allow a maximum of natural light into the space,” he notes, “and keep the exterior facades visible.”

Drolet reports that over the past two decades there have been a number of significant projects around the world incorporating

glass-covered courtyards within historic buildings, such as the National Portrait Gallery in Washington and the British Museum in London. “These, however, are neo-classical buildings with a regular edge condition,” he notes. “The West Block is the first in a picturesque Gothic Revival building with an irregular perimeter

Above: Since it’s the Parliament Buildings, the West Block renovation has attracted attention from all across the country. CBC’s Rick Mercer visited the site and shot a segment for his show where he “helped” Seele install one of the skylight panels.

of chimneys, turrets, towers and varied rooflines. It’s a very complex challenge.”

The existing building could not carry the weight of the new roof, so an independent grid structure was built of all-Canadian steel (a total of seven kilometres all lined up) held together with over 30,000 bolts. “In addition, in order to provide the most appropriate environment for the Chamber space, a variety of conditions needed to be met,” Drolet explains, “such as acoustic characteristics responsive to debating and exterior noise mitigation, especially at times when TV broadcasting will be in progress. Light control is important

Joint architects: Arcop and Fournier Gersovitz Moss Drolet

Architects

Facade Contractor: Seele

Canada Inc./Seele GmbH Germany Glass Suppliers: Shenzhen Shennanyi Glass Product Co – inner roof laylight glazing and spandrel glass at pavilions

BGT (Bischoff Glastechnik) – outer roof glazing, vertical clerestory façade with doors and outer glazing at southwest skylight Glass specification:

Outer roof glazing – low-E coated triple-glazed insulated units in five single panes as step-glazing with flush cover plates and three layers of defense with both triangular and diamond-shaped pieces

Inner overhead glazing – triple-laminated glazing units in triangular shape with white ceramic diamond-shaped frit and pyrolytic low-E coating, partially with clear interlayer, partially with milky interlayer

Vertical clerestory façade access door –Pilkington Opti-white heat-strengthened and three lites of Guardian ultra-clear heat-strengthened with No. 4 Guardian Sunguard low-E coating, SGP Ionoplast interlayer foils and stainless steel edge spacers with black silicone edge bonding

for TV camera operation, with blocking all direct sunlight being the main goal.”

The team accomplished discrete integration of all elements through a layered roof assembly, which contains a triple-glazed outer envelope, mechanized sun louvers, a light transmission maintenance platform, and the lower laylight, which acts as a ceiling to the interim Chamber and incorporates acoustic absorption panels, ventilation and fire suppression.

Project manager Sebastian Keller of Seele Canada/Germany says the installation of the glass roof was challenging for several reasons. “There were deflections and movements between new structure and the existing building, two completely independent systems,” he says. “We used an innovative new European netting system to provide easier access for installation, without the need to wear harness and lanyard.”

Installation of the stunning glass roof was also challenging because it mostly took place during the winter of 20162017. This meant conducting pre-assembly in heated enclosures, lifting of preassembled framing to the roof top, sealing

gasket joints in heated enclosures on the roof, and glazing in both snow and wind – a collective feat that speaks to the nature of Canada and seems fitting for a Parliament Building retrofit.

Seele Canada is based in Toronto. It is the Canadian branch of an owner-managed multinational with operations in 12 locations, including Germany (the company’s origin location in 1984), Austria, Czech Republic, U.K, France, the U.S., China, Singapore and the United Arab Emirates. Seele employs over 1,000 worldwide. Canadian operations are led by Andres Hafner, president, Michael Steinhulb, vice-president, and Adam Barrie, sales manager. According to the company website, the organization’s strengths are providing the whole range of construction competencies for building facade, drawing on the depth of expertise available in the company’s huge global network. The main focus for Seele Canada is steel and glass facades and other noteworthy projects include the TEC Bridge in Toronto and Brookfield Place in Calgary. •

by JACK KOHANE

The newest landmark building on the campus of Wilfrid Laurier University in Waterloo, Ont., is the 220,000-square-foot, four-storey Lazaridis Hall, named after BlackBerry cofounder and philanthropist, Mike Lazaridis. Crowning the structure’s central atrium, now the main gathering place for students, faculty and visitors, is the 130-foot-long glass skylight, the stunning signature feature of the $70 million building that houses the University’s School of Business and Economics, along with the dean office, grad student space, computer labs, 300and 150-person lecture halls, learning space, a broadcast facility, a two-level 1,000-seat auditorium for convocation, seven lecture halls, cafes, computer and math labs. The skylight represents not just the project’s structural tour de force, but also a case study in innovative design and installation.

“With our free-form nodal system, the skylight steel members could be shipped to site with a factory finish already applied because the skylight would be assembled with bolted connections between skylight members and nodes,” explains J.B. Howell, senior regional sales manager for Novum Structures from his Sarasota, Fla., office, the glazing skylight contractor for the Lazaridis Hall project. “Installation was able to occur quickly and safely on the ground with Novum’s FF-System and the skylight

was stick built, one piece at a time.” Large segments were put into their final location as the skylight was completed. Once all of the steel was in place, the glass was carefully placed onto the skylight steel structure. The glass was attached using the Novum’s versatile edge clamp glazing support system. The flexibility of the Novum ECG attachments allowed the planar glass to segment the free form curves desired. “Lifting and installation of individual lites of glass 60 feet in the air was a challenge, but

ABOVE: The breathtaking central atrium of Lazaridis Hall has space for a four-storey-tall bamboo grove. Features like that combined with natural daylight pouring in the the huge skylight give a true feeling of being outdoors to students, faculty and visitors.

overcome with careful planning and execution of the work,” he adds.

Novum began its involvement with Lazaridis Hall in 2013, during the project’s early design stages, completing its portion of the structural construction in mid-2016. The Hall was officially opened by university and local dignitaries this May. Novum, together with Westmount Storefront Systems in Kitchener, Ont., (the vertical glaziers), teamed with Toronto-based Diamond Schmitt Architects in the design and construction of the atrium’s skylight. An eye-riveting, eco-coup of the LEED Gold-certified structure is a towering bamboo grove that rises through all four storeys, reaching to the glass arc of the roof.

“The entire building has been designed to ‘live right’ on the street, deliberately pushed forward to encourage easy interaction between Laurier students and the community,” notes Gary Watson, the

Joint architects: Arcop and Fournier Gersovitz Moss Drolet

Architects

Facade Contractor: Seele

Canada Inc./Seele Architect: Diamond Schmitt Architects

Glazing contractor: Novum

Structures/Westmount Storefront Systems

Curtain wall mullions: Alumicor

2500 series

Glass: Vitro Solarban 70XL, with custom bird-friendly fit at ground floor

Spandrel: Solarban 70XL with custom colour Opacicoat 300 on surface #4

Doors: Phantom doors by Alumicor – aluminum with double-glazed unit mounted to the exterior surface

Glass units and custom fritting: Trulite

Novum supplied the incredible 130-foot-long skylight that acts as the focal point for the central atrium of Lazaridis Hall at Laurier University. Westmount Storefront Systems installed it. Lifting the lites 60 feet into position was described as “a challenge.”

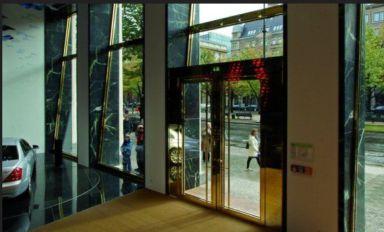

project architect and an associate with Diamond Schmitt Architects. He points out that the sidewalk and glazed entrance areas seem to blend together. As visitors step into the main entrance, they have a clear line of vision through the threestory curtain wall to the glass exit doors at the back of the building. “Glass is the critical component of the project’s cohesive design, helping to increase the sense of seamless transition from inside to out,” he says.

Diamond Schmitt Architects took home the Ontario Glass and Metal Association’s 2017 Award of Excellence for Design for the project. The award was presented at Top Glass in April.

Westmount Storefront Systems was founded in Kitchener, Ont., in 1993 by Tim Mitchell. According to the company website, its strengths include advanced curtainwall systems for custom office towers and complex commercial store-

fronts. Dedicated, long-term employees deliver exceptional customer service and on-time, on-budget work. Westmount is particulary proud of its stateof-the-art fabricating facility using CNC machinery and the latest 3D modelling software. They work constantly to update and upgrade processes and equipment to stay at the forefront of facade fabrication technology. Areas of expertise include both split mullion and standard curtainwall; interior flushline systems; arched curtainwall frames; door systems from Alumicor and Commdoor; aluminum sunshades, vents, and entrances; and aluminum panels and column covers, both anodized and painted. Offering a full spectrum of colour options is another strength for Westmount.

Westmount operates across Ontario and has recently taken on some work in Edmonton. The company employs about 50, with three permanent subcontractors. The impressive client list includes Loblaws, Canadian Tire and Future Shop. •

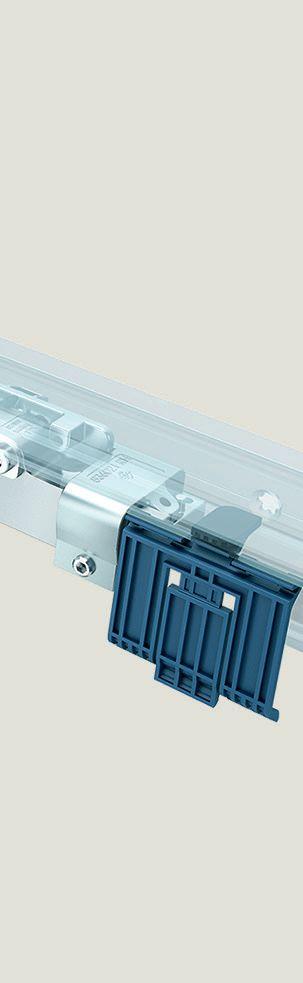

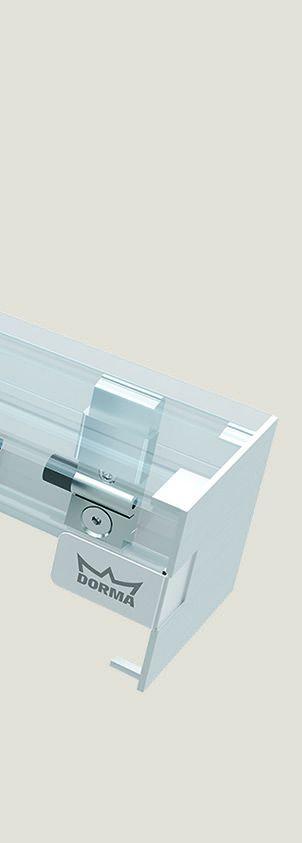

01 DORMOTION

No cutouts required in glass. The damping mechanism simply mounts on the door panel and clamps tight. 03 Anti-jump mechanism Simple activation of anti-jump mechanism.

DORMOTION start/stop Mounts on track rail, secured by a clamping screw.

Height adjustment Door panel height adjustment available any time.

MUTO Comfort — our manual sliding door system — is so easy to install, you’ll think we’re hiding something. We are! The compact header conceals multiple options and adjustable controls to enhance convenience and operation.Plus, glass cutting or drilling is not required — making MUTO the new standard for quick, precise and hassle-free installation. Versatile, convenient, compact and easy to install — MUTO is one smooth operator.

Call 1-800-387-4938 for more MUTO information. DORMA and KABA are now dormakaba. Visit dormakaba.ca

mounting To fit cover, simply twist clip-on mounting into track rail, then clip on profile from below. 06 End stops

Clamp fit enables end stops to be installed, adjusted with ease.

by RICH PORAYKO

BC Passive House (BCPH) Factory is an “all-wood construction” demonstration project, co-owned and built by Whistler-based general contractor Durfeld Constructors and Vancouver’s Equilibrium Consulting Inc., an engineering firm that focuses on heavy wood construction. BCPH mandated that the design and construction of their new facility must exemplify their investment in wood construction, prefabrication, energy efficiency, and sustainable design practice.

According BC Passive House Factory architect, John Hemsworth of Hemsworth Architecture, the main inspiration for the design came from the belief that the industrial, everyday buildings that make up a vast amount of our built environment can be just as important, and well considered,

as our public buildings.

BC Passive House Factory was conceived as a simple, light filled, 1,500-square-metre wooden box used for the manufacturing of prefabricated Passive House panels. “Durfeld regularly receives panel packages from BC Passive House for building high-performance homes throughout the Whistler area,” says Kyle Moen, a building technologist with Durfeld Constructors. BCPH will also supply high-performance panel packages to private projects in British Columbia, with the intent that the building is finished on site by local tradesmen.

“The shop windows are a 360-degree curtain wall system

that brings a lot of natural daylighting into the area so we have limited lighting requirements,” says Moen. According to Hemsworth, the effect of the daylighting, with views to the surrounding mountains and exposed wood finishes within the workspace, is a warm, comfortable and inviting space to work in.

Heating for the shop space is provided by a biomass boiler that burns the wood waste from the manufacturing process and distributes heat through a radiant-heat flooring system. “The shop itself is a working area that we keep around 10 degrees Celsius so we didn’t build it to Passive House standards. We have in-floor heating in this area so any wood offcuts produced, can

ABOVE: Innovative, custom-fabricated curtainwall and windows constitute an integral part of an overall building system designed for maximum energy efficiency and minimal environmental impact.

is perfect for contemporary structures that are big on light, smart on energy. Our clients prefer its light blue color, and CrystalBlue pairs perfectly with the SunGuard® coatings we specify.”

Paulo Perkins, GraceHebert Architects New Guardian CrystalBlue™

Spandrel HT

be rounded up and put into a boiler. We are heating the shop with our own manufacturing waste,” says Moen.

“The building’s main glazing is within the Passive House conference area which is under a fairly substantial overhang facing south towards Mount Curry,” says Moen. “That area could heat up quickly so we targeted the overhang to keep the majority of the summer sun out of the conference area and maximize usable heat gain in the winter.” This lower-level glazing is all floor-toceiling Passive House windows from Optiwin, a passive house window manufacturer based out of Austria. Durfeld is the Canadian representative for Optiwin windows including the Resista wood-framed, aluminum-clad, triple IGU, SwissSpacer warm edge spacer window system.

“They are manufactured in Europe and sent over in a shipping container. We’re comfortable with the Optiwin product. We’ve been bringing these in for the last four or five years. The team knows all of the details and installation requirements.” According to Moen, the Optiwin system boasts an impressive Rvalue of nine, glazing U-value of 0.5, solar gain heat coefficient of 0.53, frame U-value of 0.81 and sill U-value of 0.76.

The office and meeting spaces were designed to meet the rigorous Passive House standard. “With Passive House you can run into challenges with mechanical engineering. For a project of this scale, you are required to have a mechanical engineer sign off on all the systems. Unfortunately, they are legally bound to work with their own energy modelling systems such as ASHRAE. These modelling systems are not really intended for minimum heating and cooling designs so they wind up over-specifying equipment needs. We got into a bit of a battle with them, but in the end we conceded, there are a number of baseboard heaters in the office that have never been turned on,” says Moen.

The envelope was optimized to dramatically reduce the energy required for heating and cooling. The efficiency of the envelope enables the solar gain through the windows and the heat from the occupants to provide the majority of heating required for the office and meeting rooms. A high-efficiency heat recovery ventilation unit provides a constant supply of fresh filtered air to the office, making for a healthy, oxygenated work environment.

“With Passive House, the interior temperature never tends to drop below around 16 degrees Celsius no matter the season, however some supplemental heating is provided with a mini split heat pump which can supply minimal amounts of heat and cooling if we need them,” says Moen. The upstairs area with the offices generally has around five people that work there. There is no exterior glazing so it is very well thermally protected and the primary heat gain is from people and equipment so they don’t

Contractor: Durfeld Constructors

Architect: Hemsworth Architecture

Consultant: Equilibrium Consulting

Glass: Guardian SunGuard SN68

Fabricator: Optiwin

IGU: Resista wood-framed, aluminum-clad triple IGU with SwissSpacer warm edge

360-degree clerestory windows with Guardian SunGuard SN68 fabricated by Garibaldi Glass Industries provide natural daylight and views to the surrounding mountains.

really require any added heat at all. They have a vent window for fresh air and will tap into the cooling provision on the heat pump if they need to.”

The main structure of the building is Douglas Fir glulam post and beam, with solid wood cross laminated timber panel walls, all manufactured in British Columba. The roof assembly consists of prefabricated two- by 12-foot panels that assisted the erection by offering permanent bracing for the columns and beams during assembly. Using this prefabricated format, the building’s superstructure went up in just eight days.

The exterior of the building was finished with untreated fir and larch two-by-fours, preassembled with wood screens. The wood utilized for the screens was left untreated to age with each passing season, providing a natural, no-maintenance siding solution. The screen design also incorporated a varied density with openness of the slats over the clerestories to provide greater solar shading on the south and west facades, while maintaining the stunning views to the surrounding mountains. The result is a simple, cost-effective façade that carefully and subtly responds to and embraces its unique and beautiful surroundings.

The facility is the first of its kind in North America and will increase awareness of the Passive House standard and sustainable, energy efficient, wood based construction. •

Pilkington OptiView™ is ideal for museums and displays, but is also a practical choice for retail storefronts, showrooms, and a host of applications where an anti-reflective glass can improve views. By minimizing visible light reflectance to less than 2 percent, Pilkington OptiView™ provides a superior viewing experience without the glare of clear float glass.

l Blocks more than 99 percent of transmitted UV light

l Transmits more than 90 percent visible light

l Superior safety, security, and acoustic performance

l Low-e properties and thermal insulation when installed in an insulating glass unit

l Durable pyrolytic coating and virtually unlimited shelf-life 1.800.221.0444

by JACK KOHANE

The Vaughan Civic Centre Resource Library is a shining example of one of the most challenging glazing jobs in the Greater Toronto Area to date,” says Ted Redlarski, president of Noram Building Systems, glass fabricators and installers of the new $15 million library sited on Toronto’s northern outskirts. “Certain elevations of the building proved the most tricky,” he continues. “Glass is used to build a wall of sweeping curves tilting sideways 15 degrees and leaning forwards from zero to 15 degrees, substantially twisting the infill glass and aluminum panels, creating an extraordinary illusion appearing to defy the laws of physics.”

Speaking from his company’s 150,000 square-foot facility located in Mississauga, Ont., Redlarski is referring to the City of Vaughan’s gleaming 35,500 square foot stand-alone building that’s the latest addition to the sprawling administrative campus, the Vaughan Civic Centre. With its ethereal façade and shifting translucent form, the library is called a beacon of the community, one that makes a cool and clear statement that this is a meeting place tailored for the future of the city. Opened to the public in May 2016, the library encompasses a media lab (with a recording studio), collaboration spaces, meeting rooms, a teen-only lounge, public-access computers, a study hall, and a multi-storey marketplace that includes retailers and a café.

“This is a very important facility for the City of Vaughan,” says Paul Stevens, principal at Toronto-based ZAS Architects, who spearheaded the library’s unconventional, whimsical design that over the course of the day appears to dissolve from transparent to solid, its geometric form constantly shifting and changing with the daylight. “The exterior’s signature feature is achieved through a collection of concave semi-mirrored surfaces,” he explains. Reflecting its surroundings and patrons, the façade reveals a layered set of interior spaces with a tiered courtyard at its centre. The inspiration for the playful form and roofline are inspired by the curved elements of a roller coaster track at nearby Canada’s Wonderland theme park, Stevens explains with a smile.

In order to craft such a sophisticated shape, the design had to be first produced in a complex 3D model. Notes Redlarski, “From this model, we extracted and refined the exact sizes and angles to achieve each infill panel and frame components’ unique and perfect fit.” Throughout the installation process, further intricate steps were taken to ensure its success. The installation of the anchor points required complex laser triangulation in order to place the anchors in their precise positions. Due to the twisted shape of the frame, multiple pieces of glass and panels were subject to substantial cold bending during installation. With the masterful relationships between glass and aluminum, and the visual relationship of pushing the boundaries of physics in architecture, the gradient frit pattern creates a seamless transition from vision glass to solid panel that Redlarski believes adds more depth and artistry to the look of the library. “Our entire team is proud to be part of this great accomplishment,” he affirms.

Noram won the Ontario Glass and Metal Association’s 2017 Award of Excellence for Execution for this project. Redlarski accepted the award at Top Glass in April. In presenting the award, the OGMA judges said: “The curvilinear form of the building’s plan coupled with the vertical cant in two axis of the curtainwall system requires significant design detailing and coordination, and generates construction challenges which are all successfully met. This building is a dynamic and excellent example of the application of standard curtainwall technology to create a very visually distinct façade.”

Complex tilted panels create an illusion of movement as the sun hits the Vaughan Civic Centre library from different angles through the day. The design was inspired by the curves of a nearby roller coaster at Canada’s Wonderland.

Glazing contractor: Noram Building Systems

Architect: ZAS Architects

Curtainwall: Custom modified 2600 by Alumicor

Vision glass: Guardian low-iron SNX 62/27

Fabricator: Trulite Industries

Windows: Alumicor

Noram Building Systems is part of the Noram Group based in Mississauga, Ont., that has been in business for about 20 years. Design-assist is a major part of Noram’s value proposition, allowing the company to integrate a viable plan for the building facade right from the earliest stages of project planning. Noram also provides fully in-house fabrication and installation, retaining quality and logistics control over every aspect of the facade project out of its 150,000-square-foot production facility. Noram proudly advertises its affiliation with the Canada Green Building Council. •

by TREENA HEIN

Melding stunning historic elements with safety and high environmental standards are the hallmarks of the recent renovation of the Wellington Building in Ottawa. Located across from Parliament Hill, it was constructed in 1927 for the Metropolitan Insurance Company, underwent a substantial enlargement in 1959 and was acquired by the Crown in 1973. A major renovation, started in 2008 under primary architect NORR Limited, has prepared the Wellington to house the offices for 70 members of Parliament and much more.

As the project’s heritage conservation architect, EVOQ Architecture was responsible for tasks such as the copper roof replacement and restoration of the existing masonry envelope. Inside, the mosaic-vaulted vestibule, marble-clad lobbies and historic stairs were brought back to their former glory to the fullest extent possible.

Restoring the distinctive historical glazing features, notes EVOQ architect Eric

Stein, involved integrating heritage conservation with both building security and energy performance. “All the building’s 428 exterior windows were replaced with thermally-broken aluminum units, custom-designed to replicate as closely as possible the exterior appearance of the original steel units,” he explains. “As these profiles are much narrower than typical aluminum extrusions. We consulted with several window fabricators to ensure that replication of the original muntins and frames was possible

without sacrificing performance and structural stiffness.” In the end, all windows (except the exterior punched ones) along with many other glass features were installed by National Contract Glaziers with contractor Amor Construction. A low-reflectivity film was used to better simulate the original transparent look and the frame bite on the sealed units was tailored to respond to the high winds possible near Parliament Hill.

The distinctive glass canopy is a close replica of the original

ABOVE: Replicating the original look of the steel windows while upgrading to energy-efficient, thermally broken frames required some special, narrower-than-usual systems. A large skylight and entrance canopy let light into the 90-year-old building.

cast iron feature that originally adorned the main Wellington Street entrance. Stein says laminated and tempered glass was selected to address the large spans and ensure proper resistance to snow loads.

Inside the building, new bronze doors, transoms and screens were re-created to match the surviving units, with the inconspicuous integration of modern electrified hardware. “As bronze reinforced framing units are not commercially available,” says Stein, “a close collaboration with fabricators Insulgard and Soheil Mosun allowed the integration of a custom-fabricated bronze ‘skin’ that emulated the appearance of the original screens.”

The spacious multi-level atrium houses the entrance lobby, a resource library and committee rooms, with a large 5,000-square-foot skylight filling the space with natural light. According to construction firm EllisDon, the skylight is set into extruded aluminum purlins and rafters, supported by a structural steel grid. The 152 triple-laminated units are made up of 17 different sizes and shapes, each with an average weight of 450 pounds.

“All the skylight glazing was installed with structural silicone, capless other than for the ridge members which also provided a home for the lightning protection rods,” explains NORR architect Paul Dolan. “Clear vision sealed units were installed in the interior with a scrim-coated perimeter. The flush eaves incorporated concealed heat trace guttering.” Below the skylight is a secondary framework grid incorporating a light-diffusing stretched film and lighting. This frame also supports rails for a travelling gantry for maintenance and re-lamping.

NGC’s Ron Coppens lists a primary challenge of the glazing installation to be the large pieces of glass at entrances – some almost 18 feet long but only four inches in width. “In many cases,” he says, “custom hoisting equipment and apparatuses were required on site.”

National Contract Glazing is an Ottawabased arcbitectural glazing contractor led by John Bastedo and Jean-Guy Tremblay. Established in 2000, the company employs about 50 and operates out of an 8,000-square-foot plant. The main focus

is design, fabrication and installation of aluminum curtain wall, storefront, windows, skylights and glazing. Primary market area is eastern Ontario. Notable other projects include MacOdrum Library at Carleton University (high-performance, structurally glazed curtainwall, windows, doors, all-glass doors and skylights); St. Francis Xavier high school in Ottawa (curtainwall, skylights, windows and doors); the Genivar Building (segmented curtainwall, windows, doors and all-glass doors); and the Irving Greenberg Cancer Centre (high-performance, triple-glazed curtainwall, door, all-glass doors and screens). The company is comfortable with both small and large, complex projects, priding itself on a process allowing it to effectively track completion and deliver results on time. Multiphase public projects like the Parliament Hill renovations are not a problem for National Contract Glazing.

NCG uses unionized glaziers. The company website lists safety as a main concern, boasting a permanent joint health and safety committee, trained site supervisors and participation in the Workplace Safety and Insurance Board’s Safety Groups program.

Architects: Primary – NORR Limited

Heritage conservation – EVOQ Architecture

Contractor: EllisDon/Amor Construction

Glazing contractor: National Contract Glazing

Fabricators: Insulgard and Soheil Mosun, IBG, Custom Window, Oldcastle

Vision glass:

Exterior heritage windows – 32 mm insulating glass with outboard nine-millimeter clear tempered and clear heat-strengthened Solarban 60 #2, 13 mm dark bronze low profile air space with 25 mm integral grid finish; inboard fivemillimeter clear heat-strengthened or threemillimeter clear tempered with .030 clear PVB

Skylight – silicone sealed, six-millimeter

Solarban 60 VT clear tempered (low-E on surface #2); 13 mm air space with black stainless steel spacer; six-millimeter clear tempered with .060 PVB; argon filled

Glass railings: stainless steel posts and fittings with 13 mm tempered/laminated

Store front: Alumicor 3400 series thermallybroken entrance framing and sealed unit glazing with custom grills

Canopy framing and glazing: Kawneer 1600 framing and ¾-inch tempered/laminated Glass entrances: 5/8- and ¾-inch clear tempered with custom stainless steel fittings

National Contract Glazing was the subject of Glass Canada’s Under the Glass feature in June 2016, which chronicled the development of the company from a tiny startup in an industrial unit so small Bastedo and Tremblay couldn’t turn around a 24-foot extrusion. The story covers the roles of other key players in the company, including office manager Kathy Knox, chief estimator Michel St. Denis and business manager Keith Cowan. Coppens, who was interviewed for this article, is a senior project manager who took the lead on Wellington Hall. He works with Jason Georganas and Alex Wertwyn to provide expert project management services to NCG clients. •

by PATRICK FLANNERY

The reviews are in for last week’s Top Glass conference and the response is very positive. Over 80 per cent of respondents to the post-show survey rated the seminars and award presentation good or excellent. On the show floor, 93 per cent gave top marks. In the comments, attendees noted the growth in the size of the show (58 exhibitors, up from 30 in Top Glass’ first year) and the quality of the networking opportunities.

Attendance broke down as follows:

• 222 total attendees

• 35 architects and engineers

• 31 fabricators

• 38 glaziers

• 15 consultants

• 3 construction specification

• 8 educational institution

• 8 “other”

“Our pre-registrations for

the show were exactly the same as in 2016,” said Danielle Labrie, show manager, “but we had fewer attendees show up on the day. It was raining, so the driving was poor, and some of our architects might have been less motivated to come because their OAA [Ontario Association of Architects] credits don’t come due until next year.” Despite a slow end to the day, most exhibitors expressed satisfaction with the high quality of the attendees they

encountered. Alumicor has already renewed as Gold Sponsor for the 2018 event.

The continuing success of the show has organizers planning for yet more expansion in 2018. Top Glass will return to the In ternational Centre April 17, 2018, with an expanded show floor. Organizers are now accepting proposals for speaker sessions –learn more at topglasscanada.com.

ABOVE: With almost 60 exhibitors on the show floor, glazing contractors, glass fabricators and archi tects alike were able to find interesting products for their businesses in one convenient visit.

by RICH PORAYKO

If the National Glass Association’s GlassBuild America could be described as the best buffet in Vegas, a smorgasbord of delights for every glass nerd in the industry, the Glass Association of North America’s Building Enclosure Contractors (BEC) Conference is more like the Foundation Room on the 63rd floor of Mandalay Bay: an intimate, information-intensive experience for 403 of the biggest names in the business.

The 2.5-day event kicked off at Caesar’s Palace with GANA president Stanley Yee announcing that GANA and the NGA had together appointed a joint task force to explore a combination of the two organizations; “This is going to be a very short-lived and focused task force” said Yee. “It’s our association. It’s our glass and glazing industry. We’re thinking big picture for the whole industry. More importantly, it’s your glass and glazing industry. It will take you and us to grow this and develop it into what we want it to be.”

Julia Schimmelpenningh, global applications manager for Eastman Chemical Company, past GANA president and renowned expert in laminated glass delivered a superb and hugely optimistic state-of-the-glass-industry address. According to Schimmelpenningh, in 2016 most segments in commercial and residential were strong. “Sometimes in double digit growth and essentially it was a very good year. Glass prices are very, very steady. We have not had the change over the years that the other construction materials have.”

Taking a look forward into 2017, Schimmelpenningh told the packed audience that global construction is expected to grow by 85 per cent to $15.5 trillion. “The impetus is expected to be from the U.S., India and China which is a very good thing. There is going to be a tremendous amount of growth. Strong growth in the commercial sectors but slower overall versus 2016.”

Treading lightly, Schimmelpenningh addressed the topic on everyone’s mind. “I don’t know if anyone was aware but we have a new administration. And that new administration is doing stuff. We have activities going on. What we need to watch as an industry are the reforms going on from a finance and tax standpoint. We need to look at policy changes and see how that effects anything we do from a labour, immigration and trade side. Regulatory reduction may actually help the industry depending on what may be happening in that area. It may make our industry a little freer. On the other hand, it may make it a little messier.”

“Infrastructure spending is the big silver lining of the new administration,” said Schimmelpenningh. “They have been saying all along than they are going to spend on infrastructure. The question is, where are they going to spend it? Are they going to spend it on roadways or institutional buildings? Chances are that with the state of our roads and bridges in this country right now, a good portion of the spending will be there. With that being the

case, we are going to need buildings and structures to accommodate those things.”

Labour has been a recurring theme for over a decade. The reality is, labour from a design and engineering standpoint can now be done on a global basis. “There are plenty of people to do that,” said Schimmelpenningh. “You can be sitting in California and have someone in Germany doing your structural engineering and design. You do not need to have somebody in place. Where it becomes an issue is skilled labour with glazing contractors. You need to understand you have a wealth of people available. You need to make the trade attractive. We need to make sure they are trained and love what they are doing.”

Part of the labour equation is a generational issue. Family businesses are not finding successors because the kids are going off

to other areas. “There is a well-known saying that once you’re in the glass industry for five years, you cannot get out,” joked Schimmelpenningh. “Whether you want to or not, you are sucked into that vortex for life. Well guess what? Millennials, the new workforce, do not subscribe to that. They essentially say, ‘Uh-huh, I’ll be out of here in three years.’”

You take the time, energy and training to get them certified and they leave. “How we prepare ourselves for that is the establishment of training mechanisms to bring these people on board into our industry faster,” Schimmelpenningh said.

“If we look at the markets, our prediction is much more glass,” said Schimmelpenningh. “Larger lites, daylighting applications, structural and podiums. We’re going to see all of that evolving. We’re going to see neutrality in colour continue. Low-iron glasses are going to continue to be used. That doesn’t mean there isn’t going to be any colour, it’s just going to be neutral and pure.”

According to Schimmelpenningh, people are getting uncomfortable with glare but are looking for modest reflectance because they want privacy. “We also see a lot of glass being used in interior design for daylight depth to bring natural light deep inside the building as well as colours, graphics and printing. There is a preference to have glass in hospitals because of the cleanliness.” Glass is much easier to clean versus wall systems.

“Oversized is going to appear over and over again. We’re going big. We need to prepare ourselves to go bigger. We’re also seeing the glass go thicker and thicker. How do you get these huge pieces of glass into the inner cities? How do you store them? How do you get them put up onto the building? How do you replace them? All of that needs to be considered. The simplicity of the glazing is not going to be the same.”

Schimmelpenningh told the audience that the changes for railings are going to affect the glass market as well. Schools will be using more security glazing especially entryways and visual points so staff can see what is coming and can protect students. Stadiums and amusement zones are also using a lot of glass for visibility and safety.

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows and curtain wall, along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

Anderson President, Anderson Glass, LLC Waco, Texas

Elevate yourself. “As a pilot, one of the things that I was told was that you want to go the highest altitude possible,” said Schimmelpenningh. “Because when something happens, when a bad time comes, you have a lot further to come

down and land safely from a higher height than just skimming the ground. Let yourself soar. Let yourself put in those complex, very high value-added pieces of glass. Put in those huge sizes. Do the stuff you need to do now because we are on an economic wave that is very, very attractive. Make the most of it right now.”

The Contractor Glazier Challenges panel moderated by glass expert Max Perilstein fired on all cylinders. The last presentation of the conference and part of the Contract Glazier Deep Dive, the discussion acted as an anchor and drew an impressive crowd considering for many it was day three or more in Vegas. Featuring glazing contractor panelists from across the U.S., the statements echoed many of the messages from throughout the conference.

Joe Clabbers, president of National Glass and Metal Co., opened up about challenges his Philadelphia-based glazing contract firm has to deal with. “Having the right people and developing talent is a big challenge. We try to stay active in our local labour market. We’re a union contractor so we’re involved in apprentice training. We try to homegrow our people. They are hard to find so you have to make them.”

According to Clabbers, a Philadelphia training centre became accredited with the Department of Education so now when an apprentice finishes their four-year apprenticeship, they earn an associate’s degree as well. “That helps to combat Mom and Dad saying ‘You want to go to college. You don’t want to work with your hands your whole life.’ So that has been a good recruiting tool.”

“I was going to come up and say ‘Labour, labour, labour’ and then sit down,” agreed Ted Derby of LCG Facades. “It is always a big, big issue. We have an in-house training program that we

instituted about two years ago. We are in a non-union area and we felt like we needed to do something to stabilize our workforce and bring the level up. Architects and engineers are challenging us with every new project that they are developing. We really need to be able to respond to those challenges with expert, quality people in the field and it’s challenging to get those people to be able to stay with you. We provide a stable environment for them where they can raise their family and be a part of the glazing community.”

“We are on an economic wave that is very attractive.”

- Julia Schimmelpenningh

Bill Sullivan, president of Brin Glass Company told the audience that the architectural community and general contractors are also struggling with staffing. “What we are seeing on projects more and more which concerns us is incomplete plans and specifications,” said Sullivan. “Incomplete or inaccurate details. Greater emphasis and reliance on the glazing contractor to assist with drawings, design and development – including structural requirements. Thermal requirements that are often not compatible with the project.”

According to Sullivan, the general contractors are also dealing with inexperienced field superintendents, project managers and project engineers. “We find that they lack the experience to recognize incomplete details on the drawings and perceive the problems that they are going to cause on the job. Improper sequencing of trade schedules. They wanted us on site a few weeks ago. Unfortunately there wasn’t any sheathing on the building. The brick wasn’t there but the field superintendent wanted us there for some reason. Lack of knowledge of the scope of work for each trade. We see that as being a problem. When we are dealing with people that are not as experienced as we would like them to be, they lack the capacity to make those decisions to effect that project.”

“One of the other challenges that we’ve had some success with is where we are insisting on being paid for design assist,” said Derby. “For many years I remember providing design assist without any type of compensation. Buildings are so technical and the interfaces are so important, you really need to have a collaborative effort between the architect, the contractor and the installing façade contractors in order to have a really successful building. Qualified staff or the lack thereof can strongly effect the success of failure of any given job.”

Derby shared with the audience members what a rolling schedule is. “It is a schedule modified by the general contractor to roll the current schedule likely forward from what was originally established in order to pick up speed on the job. It reduces our durations and puts more pressure on us. One of their other favourite things is to schedule landscaping right underneath us.”