Introducing OptiQ™ Ultra Thermal Windows – the smartest window you’ve ever met. The result of a pioneering partnership with the U.S. Department of Energy, OptiQ™ Windows reach a new level in thermal performance due to the groundbreaking features integrated into its design. OptiQ™ Windows are available in multiple configurations offering versatility and options for customization. The only thing smarter than the windows themselves is using them.

White knights Richard Wilson and Gord Tozer rode into Collingwood last May and bought the bankrupt Barber Glass facility only hours before it was to go to auction. Now they have their sights set on domination of the North American jumbo glass market.

16 Co-operating with competitors

Building envelope contractors hear calls for co-operation and increased standards at the BEC conference in Las Vegas.

18

Bouncing baby association

The Canadian Glass Association family grows with a new regional association in Atlantic Canada, the Atlantic Provincial Glazing Association.

22 Window and door hardware showcase Handle, hinges, locks and other things to make your glass move, or stay put.

Glass industry associations say they are ready for the changes to the laws that govern their not-for-profit status, but

some of the effects of the changes will be unpredictable.

New rules for not-for-profit corporations have passed into law, and your industry associations have until October 17, 2014, to comply with them or risk losing their statuses as not-for-profit organizations. They are all at different stages of preparation for the changes, but all are confident they will have everything in place in time. This is good news, since the changes could have serious impacts on how the associations are governed, how transparent their operations are and how much control members have over directors and executives.

The changes are contained in the Canada Not-for-profit Corporations Act, which replaces the old Canada Corporations Act, Part II. Given that the old Act has not had significant revision since its inception in 1917, it is probably fair to say that it was due for an update.

• Glassbuild preview

• sealants and adhesives showcase

Association members might want to get familiar with the new rules because there are some potentially big changes to how their organization is run. Members have expanded rights under the new Act to require directors to call meetings and submit meeting proposals. They can obtain court orders to stop so-called “oppressive” actions by associations that unfairly run against the interests of members. Directors must now disclose any material interests they may have in contracts or transactions with the corporation. They could even be held liable for certain financial liabilities of the not-for-profit corporation. Directors are not required to be residents of Canada, but their residency can have implications for the tax status of the corporation. Associations that take in more than $10,000 per year (that is, pretty much all the major ones) have additional rules. They must appoint an accountant, file public financial statements and may only donate to qualified organizations. The law firm Pallett Valo has a good overview of the new laws at www.pallettvalo.com.

Zana Gordon, executive director of the Canadian Glass Association, reports that the CGA completed all the necessary changes to its bylaws at the AGM on May 30. Members will notice one very big change in particular at the AGM in Montreal in 2013. Under the new rules, federally registered associations cannot have appointed directors; directors must be directly elected by the membership. This ends the CGA’s practice of automatically giving the president of each regional association a seat on the board. Any CGA member may now be nominated for a director’s seat, and members will have a chance to vote for their favourites in Montreal.

The consequences of this change promise to be very interesting. Will members elect a purely national board, with a pan-Canada perspective? Or will they focus on having their regions’ interests represented at the national level? It looks like the 2013 AGM is going to be a can’t-miss event. •

June 2012 Volume 24 • Number 3

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LAbrie dlabrie@annexweb.com 519-429-5187

SALES ASSISTANT | Tara JAcObs tjacobs@annexweb.com 519.429.5183 | 888.599.2228 ext. 219

MEDIA DESIGNER | Gerry WIEBE

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@glasscanada.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: subscribe@glasscanada.com

Tel: 866.790.6070 ext. 208

Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST)

($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

Industries has announced that the company’s EcoGuard solar boost mirrors are being installed at the Ivanpah solar Electric Generating system in California’s Mojave desert. the project, a partnership between NrG solar (a subsidiary of NrG Energy), Google and brightsource Energy, will nearly double the amount of solar thermal energy produced in the U.s. today.

Guardian started supplying the first of 160,000 of its EcoGuard solar boost mirrors to IsEGs in November 2011. “EcoGuard solar boost has been proven to withstand the extreme conditions found in the Mojave desert,” said Martin bracamonte, vice-president of science and technology at Guardian Flat Glass Group. “the technology used in manufacturing the glass gives it the extra edge in being a more durable and reliable resource to maximize capturing the sun’s energy for large-scale use.”

Guardian’s EcoGuard solar boost mirrors have an industry-leading reflectivity.

In 1978, Guardian Industries delivered one if its first sets of laminated flat mirrors to sandia National Laboratories, one of the first solar fields in the United states. today the manufacturer has four manufacturing lines specialized in solar mirrors throughout the world.

At the Ivanpah solar plant, thousands of software-controlled mirrors track the sun in two dimensions and reflect the sunlight to a boiler that sits atop a tower. When the concentrated sunlight strikes the boiler’s pipes, it heats the water to create superheated steam. this high-temperature steam is then piped from the boiler to a standard turbine where electricity is generated.

Located in Ivanpah, Calif., about five miles from the California/Nevada border, on federal land managed by the bureau of Land Management, Guardian EcoGuard solar boost mirrors will help deliver energy from the sun to more than 140,000 homes in California, during the peak hours of the day.

the cover of April Glass Canada has attracted a great deal of amused comment from the industry. It shows a student in a glazing apprenticeship program apparently installing a door closer on the wrong side of a mullion. the photo was a posed shot taken by a member of the school’s communications team and does not depict actual work in progress.

truth

hardware, an industry leader in the design and manufacture of quality operating hardware for the window and door industry, has announced the hiring of Jeff Graby as its new president and CEo. Graby brings more than 20 years experience as a senior executive in different industries.

Most recently Graby was executive vice-president and business unit leader at Interface solutions. Prior to that, Graby served in several senior executive roles including president of schneider Electric hVAC and Pumping solution Center and president and Coo of rAM Industries. A graduate of drexel University with a bachelor of science degree in mechanical engineering, Graby brings to truth hardware a wealth of knowledge and experience in business leadership and management of global companies while maintaining the ability to listen to the “voice of the customer” and provide solution selling.

our Fall Golf tournament is scheduled for thursday, september 13, 2012 at the Carrying Place Golf and Country Club. Make sure to join us for this fine day on a top quality course.

If you are conducting business in the glass industry in ontario, the oGMA is the voice that represents your interests at the provincial and federal level. Protect your business interests by becoming a member or as an associate member if you are a consultant to the industry. doug Morris is heading up membership for our association, so please contact him today at douglasmorris@ rogers.com, or visit the oGMA website.

the oGMA wants to notify all glass and glazing companies in the province that the ontario version of the Glazing systems specifications Manual of standards and Practices is now available for purchase. this all encompassing document is a “must have” reference tool for all companies in the industry. For more information and to order yours, visit our website at www.ogma.ca.

In last month’s CGA Members directory, the phone numbers listed for members of the Provincial Glaziers Association of Alberta were incorrect. Efforts to collect correct phone listings are ongoing. Glass Canada and the CGA regret the error.

CGA president, david Langton, attended the Alcoa retirement party for Keith Pynoo. Pynoo was one of the originating directors for the Canadian Glass Association and was also its first official president. Langton saluted Pynoo with a champagne toast. the CGA offers its congratulations to Keith on his many years of service to the industry. We wish him many years of restful retirement bliss and raise a glass to salute him. thanks, Keith.

the CGA Annual General Meeting took place on May 30. At this meeting, the board ratified a new set of bylaws as per the new Not For Profit Act. the most significant change to these bylaws is the way the

Canadian Glass Association P.O. Box 595 Abbotsford, B.C., V2T 6Z8 Tel: 604.855.0245 • Fax: 866.253.9979 www.canadianglassassociation.com

theGCAbC has a new location for its apprentice training program. the new facility is at 101 – 20351 duncan Way in Langley. the program has successfully completed two Level I classes and one Level II class. the training schedule is posted at www.gca-bc.org.

the GCAbC technical Committee is actively working on numerous projects under the chairmanship of harold Louwerse of Morrison hershfield. there is a Commercial Glazing task Group made up of various players - including the Ministry of Energy, the Association of Professional Engineers and Geoscientists of b.C., the Architecture Institute of b.C., to come up with a model specification for the Energy Efficiency Act so that all players understand what can and cannot be used. the committee is also starting to review the b.C. side of the glazing manual for updates.

board of directors is selected. Previously, the president or representatives of the provincial associations were automatically members of the Canadian Glass Association board. this has changed. All board positions will be nominated from the memberships of all the provincial associations. this is a large change to the possible configuration of the board of directors. Now members of the provincial associations do not have to be involved at the provincial level to participate at the national level. the first time this new set of bylaws and the new form of elections will take place will be at the AGM held in Montreal in May, 2013. More information will follow very soon.

A new b.C. building Code is due out mid-2012 and the GCAbC is making sure its standards and practices are consistent with the known changes.

the annual GCAbC golf tournament held May 17 at Northview Golf Course was another great success. With 150 golfers and a beautiful sunny day it could not go wrong. the top-tier sponsor Cardinal IG dazzled the golfing group again with an amazing set of golf clubs as the big prize of the evening. As a diamond Level sponsor, Vitrum Industries contributed small first aid kits that could fit in any golf bag or glove compartment of a car. the GCAbC would also like to thank its Platinum Level sponsors: hartung Canada, PFG Glass and starline Windows for the plasma tVs and the iPad. the Gold Level sponsors (dow Corning, Gienow Windows and doors, Guardian and tremco Canada) donated

chairperson Leonard Pianalto is a member of the steering committee to review the Energy rating system and the Energy Efficient Fenestration steering Committee. More information on these committees will be available soon.

the new Atlantic Provinces Glazing Association has been created. Congratulations to the new board of directors.

[More on the new association on page 18. Ed.]the Manitoba Association should be active very soon. stay tuned.

the CGA is researching costs for translating the Glazing systems specifications Manual into French. More to come soon.

two Xboxes and two Ps3s. the silver Level sponsors were a great support also: Alumicor, Cascade Aquatech, Flynn Canada and Veka.

the GCAbC had its first webinar on May 10. the topic was “structural detailing versus building Envelope.” our panelists were stéphane hoffman of Morrison hershfield and david Vadocz of berkeley Vadocz Engineering. the session was extremely well received and the attendees felt that the topic was interesting and timely. our webinars are recorded and available for two weeks to download.

the GCAbC technical Committee will be working in the next few weeks to set out the schedule of webinars for the next few months. Please watch the website for more information. the schedule for all meetings and topics is available on the GCAbC website at www.gca-bc.org.

AAMA502-12, “Voluntary specifica-

tion for Field testing of Newly Installed Fenestration Products,” has been published by the American Architectural Manufacturers Association.this updated specification establishes the requirements for field test specimens, apparatus, sampling, test procedures and test reports to be used in verifying the air infiltration resistance performance and water penetration resistance performance of newly installed fenestration products.

“the purpose of AAMA 502-12 is to provide a method which can be used to evaluate the installed performance of fenestration products for air leakage resistance and water penetration resistance under controllable, reproducible and appropriate conditions,” says Kim Flanary (Milgard), co-chair of the AAMA Field testing task Group.

In addition to editorial changes, revisions to AAMA 502-12 include the addition of the CW class and removal of C and hC classes as performance classes in examples of allowable air leakage rate, which is in keeping with the recently updated AAMA/WdMA/CsA 101/I.s.2/A440-11, North American Fenestration standard.

specifically, scott Warner of Architectural testing, co-chair of the AAMA Field testing task Group, says the specification was revised

to clarify language regarding field testing on project specific size windows that are smaller than the minimum gateway size identified in NAFs-11. “the acceptable air infiltration rate for these smaller sized products will be allowed to be increased at the discretion of the specifier and manufacturer,” he says.

Updated from the 2011 document, AAMA 502-12 references important industry standards which include AAMA/WdMA/CsA 101/I.s.2/ A440-11, “North American Fenestration standard/specification for windows, doors, and skylights;” AAMA 503-08, “Voluntary specification for Field testing of Newly Installed storefronts, Curtain Walls and sloped Glazing systems” and AstM E783-02 (2010), “standard test Method for Field Measurement of Air Leakage through Installed Exterior Windows and doors.” the specification is applicable during construction, prior to the issuance of the building occupancy permit but no later than six months after installation of the fenestration product.

AAMA 502-12, “Voluntary specification for Field testing of Newly Installed Fenestration Products” is available for AAMA members to download at a cost of $15. Non-members may purchase the document at a cost of $45 for download.the specification is also available for purchase on Cd and hardcopy. to order AAMA 502-12, visit AAMA’s publication store.

Aninternational executive with more than 40 years’ experience in the glass industry, Charles (Chuck) Croskey, has been named chairman of the board of directors for Guardian Industries.

A board member since 2010, Croskey has been with the company since 1970, most recently as group vice-president responsible for all of Guardian’s manufacturing, marketing and distribution operations throughout Asia, Africa and the Middle East. his depth of knowledge in glass and manufacturing as well as his critical leadership and management skills have resulted in the company’s strong growth in his regions of responsibility.

Croskey replaces outgoing chairman Peter Walters, who completed two terms as board chair. Walters remains a member of the board. “I look forward to a continuation of the

leadership Pete Walters has demonstrated to ensure Guardian’s leading position in its industries,” said Croskey. “My years with the company – ombined with our strength in manufacturing, technology and people – will help carry out Guardian’s strategy and vision.”

Croskey began his career at Guardian’s first float glass plant in Carleton, Mich. and went on to hold several posts at the company’s Kingsburg, Calif., float glass plant, ultimately responsible for the company’s West Coast operations, including float and fabrication facilities.

In 1988 he was named the company’s Employee of the year.

before joining Guardian, Croskey worked for General Motors Corporation.

Croskey received a bachelor of science in industrial engineering from General Motors Institute (now Kettering University) in Flint, Mich., and a juris doctorate from the University of detroit school of Law. he has been a member of the state bar of Michigan since 1978.

Kawneer Company has announced that bob Leyland, director of sales, has elected to retire on Aug. 3 after 37 years with the company. Colin brosmer, currently director of front-end services, will assume the role of director of sales effective July 27.

Leyland began his career with Kawneer in 1975 after graduating with a degree in marketing from Michigan state University. he started with the organization as a sales trainee in the Niles, Mich., headquarters and was quickly assigned to the Cincinnati, ohio, territory. bob returned to Niles in 1980, where he served as a national account manager and then as the product manager for storefront, entrances and framing.

Leyland moved to southern California in 1984, where he served as the district sales manager until 1994. he then moved to Norcross, Ga., to serve as the senior product manager for storefront, entrances and framing. he was named director of marketing in 1996, and then assumed executive leadership of the sales and marketing organizations in 1999. Leyland has continued to lead the North American sales organization since 2004.

by FrANK FULtoN

Frank Fulton is president of Fultech Fenestration Consulting. He has been in the industry for 30 years and can be reached via e-mail at fultech.fc@gmail.com.

If you live in a major centre in Canada, watch the TV news or read the papers, you are no doubt familiar with the urban panic and exaggerated media frenzy surrounding shattered glass falling from balcony railings onto the heads of unsuspecting pedestrians. Speculation and rumour have suggested the cause of the spontaneous breakage may be anything from faulty installations to railing fabrication errors, from flying stones from adjacent buildings to windblown balcony furniture, but the proven cause is the majority of instances is now known to be the presence of nickel sulphide inclusions within the glass.

So, what is a nickel sulphide inclusion?

In a batch of glass, contaminants such as stainless steel that contain nickel might be present, and these can combine with sulphur to form nickel sulphide inclusions. The process of tempering float glass can cause an inclusion to change from its normal low-temperature structure to a smaller high-temperature, crystalline structure. When the glass is cooled quickly, as part of the tempering process, the NiS particle is unable to change back to its original form. Over a period of time the NiS inclusion will slowly convert to its original low-temperature structure, increasing in size by two to four per cent. If the inclusion is located at a critical area within the glass, the growth can result in the shattering of the tempered pane for no apparent reason, hence spontaneous glass breakage. Interestingly, the presence of an NiS impurity does not necessarily mean that a lite will ultimately break spontaneously. This only happens when the NiS inclusion is located in a specific area within the lite.

What is certain is that the design of balcony guards has changed as a consequence.

yoU bEt yoUr GLAss

One of the people involved in determining the cause of the spontaneous breakage and playing a significant role in reaching a solution to minimize the potential for injury is Dave Prohaska of Prohaska Engineering. “While issues with spontaneous breakage have existed for several decades, the most publicized issue occurred with 12-millimetre tempered glass installed in the John Hancock Building in Boston. Glass manufacturers are hesitant to publish their research for fear of inciting the masses over an issue which is rare,” says Prohaska. What is known about NiS is that the concentration of the impurity is batch-related and therefore there is a higher probability of failure of tempered glass from a batch of primary glass with more impurities. According to Prohaska, “To date, the failure rate has been higher in eight-, 10- and 12-millimetre tempered glass than in six-millimetre. Much of the heavier glass has been imported from offshore, primarily Chinese, sources; however, some of the breaks have occurred in glass produced by North American suppliers of primary glass.”

Prohaska is unaware of the exact number of lites that have failed but estimates the number to be between 30 and 50 during the past year. “Statistically, this might represent one lite out of every thousand currently installed in balcony guards in the GTA.” Of note, this rate of failure is much lower than the eight-per-1,000 probability used in the design of glass for typical installations.

During the spring of 2012, to address the problem, the Ontario Ministry of Housing held four meetings, which included representation from many involved parties, to help identify issues and to provide recommendations that may provide the basis for changes to the Ontario Building Code. The process is ongoing, but what is certain is that the design of balcony guards has changed as a consequence of the spontaneous breakage experienced recently, and it is likely that more changes will be coming to the glass products permitted for use in balcony railings. In fact, the CSA is currently in the process of developing a new standard for balcony glass.•

All the machinery at Agnora is highly automated and oversized. This Bystronic laminating line features robotic alignment of the layers and can process sheets up to 130 by 275 inches.

Location: Collingwood

Some say value-added manufacturing cannot work in Canada. Our costs are too high, our domestic market too small and spread out. We are forever consigned to the role of hewer of wood and drawer of water. Others point to our educated population, sophisticated infrastructure, easy availability of capital and proximity to the biggest market in the world and wonder why we are not already on par with the likes of Japan and Germany when it comes to making and exporting advanced finished goods. The decline and fall of Barber Glass in late 2010 seemed to make the case for the naysayers. When John Barber risked $24 million to build the largest capacity architectural glass processing facility in North America, maybe he reached too high. From the failure of Avro to the recent declines of Nortel and RIM, maybe Barber was just another sad milestone on our nation’s meandering path through the wilderness of manufacturing obscurity. Not if Richard Wilson has anything to say about it. A Toronto-based developer and native of Collingwood, Ont., Wilson stepped up at the last minute on May 6, 2011, to forge a deal with Gord Tozer of

Caledon, Ont., to save the plant from auction and relaunch its operation as a fully functioning architectural glass provider under the name Agnora. In doing so, he saved about half the jobs at the Barber operation and kept the dream of world-class advanced glass production alive in Ontario and Canada.

Wilson is 50 years old and has two teenage boys. His wife, Laura, works with him at the plant. He grew up in Collingwood, the son of Rev. Douglas Wilson, a Presbyterian minister. He has been entrepreneurial and involved in construction since he was 14. He has kept a finger on the Collingwood business scene over the years, opening a bungee jumping attraction at Wasaga Beach and a local sporting goods store. But his main business was Wilson Project Management, a construction contracting and project management company specializing in custom builds and renovations for very high-end residences and commercial properties. Many of Wilson’s projects have had avant gard architectural designs demanding large and/or unusual window and window wall treatments. Thus his involvement with Barber and the specialty glass panels it was

Product: Jumbo architectural flat glass, laminated glass and insulating glass units.

Ownership: richard Wilson and Gordon tozer

Employees: 25

Plant size: 280,000 square feet

Capacity: 130 by 240 inches

Wilson and tozer bought the Collingwood assets of bankrupt barber Glass hours before they went to auction. the new company, Agnora, boasts some of the largest architectural glass processing equipment in North America.

able to provide. Wilson was a major customer of Barber prior to its collapse.

Agnora operates in 225,000 square feet of the 280,000-square-foot plant that Barber built in 2008. It is employing about 25 presently, though Wilson confidently predicts this number will rise. Agnora can automatically cut and seam sheets of flat glass up to 130 by 240 inches on its Lisec cutting and seaming lines. It can temper 130- by 280-inch panels in its Glaston

Agnora’s insulating glass line is the largest in North America, capable of aligning, inserting spacers and sealing panels up to 130 by 240 inches. The line also has the capability to produce offset units, including four-sided offsets.

tempering oven. Twin Intermac CNC routers can machine panels up to 130 by 240 inches each. The Adelio Lattuada single edger can process sheets up to 130 by 300 by two inches, with an even bigger one on the way. The Bystronic laminating line can automatically laminate sheets up to 130 by 240 inches, or manually laminate sheets up to 275 inches long. The Lisec IG line takes sheets of flat glass and creates insulated glass units up to 130 by 240 inches across with minimal handling by the operator. The line can apply the adhesive and seal around the outside of an eight-foot-square IG unit in 12 seconds. Agnora’s enormous ASC autoclave can bake laminated glass sheets up to 134 by 300 inches. The Giardina paint line can paint an 86- by 240-inch area. All of the equipment is less than four years old. Wilson gives Barber full credit for building one of the most advanced and largest-capacity glass production facilities in the world. As he tours the shop he says over and over, “I’m the luckiest guy in the world.”

Wilson’s purchase of the Barber plant was the stuff of high drama. Ever since Barber announced it was going into receivership, Collingwood’s economic development office had been in overdrive trying to find a buyer who would keep the glass production operations in town. When they contacted Wilson initially, he was only interested in a minor partnership because it looked like control of the operation would be diffused over many stakeholders and he is, by his own admission, “not a big partnership guy.” The Collingwood team managed to get a group of buyers in place, but one of the major investors dropped out literally the weekend before the sale was to take place. With the auction date looming, Barber’s operations manager, Jeff Wilkins, urged Wilson to step in. Finally, the day before the auction, Wilson called Gord Tozer, one of the major investors from the original group, as he was flying to Calgary. “I said, ‘Look, I think this is a good business,” Wilson remembers. “I have a strong background in the industry and I have already got pre-sold stuff to

buy. I want to make an offer. Will you go partners with me?’ And I didn’t even know the guy. I had met Gord twice but for about half an hour each time. But he is the type of guy who will do things on a handshake. And not knowing the guy, nothing in writing, he said, ‘Yes,’ so I gave them a million and a half, non-refundable.” Wilson says the partnership works well because Tozer has approached his stake in the company as an investment, while Wilson is more interested in marketing and companybuilding, leaving operations to his general manager, Wilkins. “I am the sales portion of it, Jeff is operations and Gord is the guy who keeps us grounded with financials,” he explains. “So between the three of us we are a fantastic team.”

“Everything I have done all my life, I want to build it to be the biggest and the best.” – Richard Wilson

This approach may sound rash, but Wilson had his reasons. “I was doing it because it is a good thing for Collingwood,” he explains. “And it is a good thing for my construction company because I always had problems sourcing good quality glass. I had to go to Europe. So I was being self-serving in a sense because I didn’t want [Barber] to go down because I put a lot of energy into helping develop this as well.” Wilson’s reasons aside, there was a more visceral urge behind his last-minute decision to grab the plant. “I like to win,” Wilson admits.

It is often said of entrepreneurs that where others see risks, they see opportunities. Wilson embodies this philosophy perfectly. “I was asked the question just a little while ago, ‘Don’t you see the risk in this?’” he says. “I said no. I don’t see risk, I see just the benefit of doing things. Things work out. If you work hard and there is a good business plan it works out. There is no risk. There is only risk if you are not willing to put the effort into it.”

Agnora’s business strategy is to be a high-end, automated, custom glass provider. Most of the equipment in the shop incorporates material handling cranes, vacuum lifters and robotic functions. In most cases, this is necessary simply because of the huge panels the equipment is designed to process. However, this level of automation leads most industry people to assume Agnora’s best strategy is to leverage its investment in automation into a low-cost, high-volume range of commodity products. Wilson will have none of it. He points to the fact that other large flat glass producers such as Guardian and Pilkington (Pilkington operates an automotive glass plant just on the other side of Collingwood) passed on buying the plant despite its bargain price. Some even expressed regret that they had to walk away from such an impressive facility. But their corporate strategy demands a certain market within easy geographical reach of an investment of that size, and central southern Ontario simply does not deliver. The big suppliers’ business model depends on shipping a certain volume of product, and beyond a certain range the shipping costs

eat too far into the margin. So Wilson understands he needs to take a different approach. He needs to use his automation and equipment capacity to take jobs no one else can do. He has to be willing to operate and deliver anywhere in North America, and to make his service levels so high that his customer will absorb the delivery costs. Wilson describes his target customer this way: “A customer who is installing a piece of glass in New York, who is shutting down a street, has a 200ton crane in there. He has police, he has everything and he has a $40,000 piece of glass. Well, the $40,000 piece of glass is the cheapest part. So he needs to know that when we supply something to him it is good and we have done all our due diligence and supplied him the best product we can that will meet his standards.”

Wilson and Wilkins feel the highmargin custom strategy will work because large architectural glass is one of the hottest trends in construction in North America right now. “The fastest-growing segment of the industry is the jumbo, no question,” Wilkins says. “Pilkington has said that for the last three years. So for us, little old Agnora, is there $60 or $70

million worth of high-end, high valueadded work? Absolutely. Is it growing? It is growing at double-digit rates. So, why not? Let’s focus there.”

Another advantage Wilson and Wilkins see in the custom market is the ability to protect margins against offshore competition. “It is a slippery slope, competing against the Chinese,” Wilkins says. “Is the price going to go up? No, it is not. So which way is the price going to go?” Wilson chimes in, “Why commoditize something like that? We have a company that can do something no one else in North America can.” Wilson says he is even willing to accept short periods of idle time and overstaffing in order to be readily able to meet customer demands. Labour costs constitute a relatively small part of the overhead in his highly automated shop, so he feels little pressure to wring every ounce of productivity out of his staff. “We are not going to chase bad work,” Wilson says. “That is what a lot of companies fall into, especially in a downturn. They chase bad work just to fill the void and to keep their people employed. They just get farther and farther in the hole and they do not realize that they are driving themselves into bankruptcy.” Wilson tells his staff they do not have to worry about such scenarios. “No one gets laid off, no matter what,” he says. “My staff is the least of my worries. My hydro bill every month is much more than all their wages.”

Wilson and Tozer’s rescue of architectural glass manufacturing in Collingwood has attracted national attention and the gratitude of various levels of government. FedDev Ontario, an agency of the federal government, made a $3.71 million grant to Agnora in March to help the company with its planned research and development initiatives. The company is planning to build an R&D lab with dedicated equipment for trying out new processes. Now, Agnora is using its regular production equipment to research new ideas, but this is not optimal because the research project has to wait for time on the production machine. Wilkins is thinking about researching some new performance interlayers to improve their laminated products, and he also plans to test a new soft coat from Saint-Gobain that may become the first-ever jumbosized soft-coat product in North America. But if Agnora’s plans are successful, it will achieve an even more important feat: giving support to the optimists about the future of the Canadian glass industry. •

by yVAN hoULE

Yvan Houle is president of Fenestration Canada. Fenestration Canada’s mission is to represent and support all aspects of the window and door manufacturing industry.

The Fenestration Canada Annual Meeting was held at the Fairmont Château Montebello, Que., from June 7 to 9. Attendees were able to take advantage of a very informative and exciting program. Delegates were updated on technical issues, trends and topical subjects. Ample networking opportunities and fun-filled activities were also scheduled in the beautiful resort setting.

The seemingly insatiable appetite and quest for information and updates on current issues and challenges facing the industry was addressed by the array of presentations on the program schedule.

Jeff Baker, Fenestration Canada’s technical consultant was on hand to go over the latest issues involving building and energy codes and standards. The presentation helped demystify the sometimes complicated technical language that accompanies published reference material. Delegates were able to get updated on the latest issues and trends in these areas.

J.F. Kogovsek of Maxam Marketing.com presented the highlights of Fenestration Canada’s strategy designed to inform building and code officials across Canada about practical issues stakeholders have in dealing with code sections that are key elements for those installing windows, doors and skylights. The training presentation also provided an overview of the North American Fenestration Standard and how performance requirements for fenestration products are determined.

Tracy Rogers, director of industry relations and advanced technology for Quanex Engineered Products Group, presented delegates with a comprehensive update on the latest trends, issues and challenges related to the “green agenda” for fenestration products. The implications of how this area can dramatically affect one’s business were of interest to all!

Attendees were able to take advantage of both educational and networking opportunities that benefited their businesses.

The Canadian Standards Association was also invited to update delegates on the most current developments regarding the Fenestration Installation Technician personnel certification program. Fenestration Canada and the Siding and Window Dealers Association of Canada are involved in determining the market need for a training program to prepare persons who will be required to obtain FIT certification.

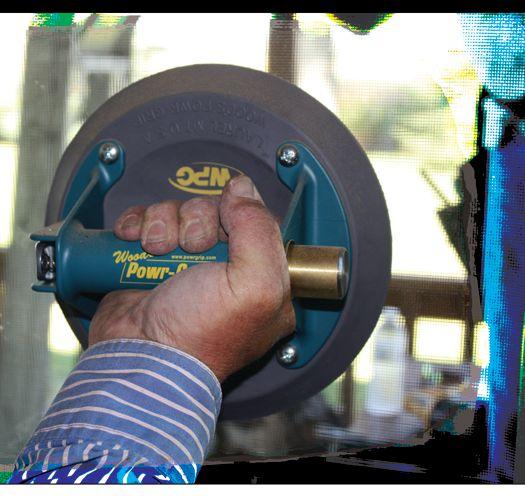

Mike Burk, product and sales specialist for Quanex Building Products, delivered a very informative presentation on the subject of preventing glass handling injuries. This was a topical subject area and drew interest from those concerned with safety issues when working with glass.

Joe Edl, president of TSI (Techcentiveservices Inc.), provided some good tips and information on leveraging grants and tax credits for your business, which caught the eyes and ears of all the businessfocused delegates. It seemed everyone was out to ensure they have a cost-effective and productive business.

The feature presentation was given by Scott Wilson, president of RankHigher.Ca, who brought delegates up to date with regard to doing business on the Internet and search engine optimization. The lack of an effective web marketing strategy by many Canadian companies has been cited as a problem that, unless reversed, will mean a widening gap in lost Internet sales in the years ahead. The captivating presentation was designed for decision makers, empowering them with the necessary knowledge to make the best Internet business decisions using proven strategies.

Fenestration Canada gratefully acknowledges the support it received from program sponsors and delegates who participated in the tranquil yet stunningly beautiful setting that Montebello has to offer. Attendees were able to take advantage of both educational and networking opportunities that benefited their businesses. •

by bILL LINGNELL

Bill Lingnell has over 46 years of experience in the technical field of glass and architectural products. He holds three Masters of Science degrees in engineering: civil, mechanical and engineering science. Lingnell is the technical consultant for the Insulating Glass Manufacturers Alliance.

Insulating glass standards have been developed over the years to assist insulating glass manufacturers, testing laboratories and certifying agencies in providing quality products and developing insulating glass units that will have long-term performance for the end user. The standards used in North America have been updated recently in the ASTM E 06 committee to accommodate some changes and additions to the newer standards, ASTM E 2188, 2189 and 2190, which have been commonly referred to as the HIGS standards (standing for Harmonization of Insulating Glass Standards). These three standards were a culmination of over six years of work to harmonize the former ASTM E 773, E 774 and E 1887 standards with the Canadian CGSB 12.8 standard. The three newer ASTM standards came into being in 2002. The previous E 773, E 774 and E 1887 standards have been discontinued as ASTM standards.

Currently, the laboratories testing insulating glass in the United States and Canada have the capabilities to test to the criteria referenced in the newer standards. The three ASTM standards are:

• ASTM E 2188-10 Standard Test Method for Insulating Glass Unit Performance

• ASTM E 2189-10 Standard Test Method for Testing Resistance to Fogging in Insulating Glass Units

• ASTM E 2190-10 Standard Specification for Insulating Glass Unit Performance and Evaluation

The standard specification E 2190 has recently added the testing protocol for argon-gas filled units. In it, argon concentration is measured by either ASTM Test Method E 2649 Test Method

The Canadian standard is basically used only in Canada and was last revised in 1997 to address argon gas filling of IGUs.

for Determining Argon Concentration in Sealed Insulating Units Using Spark Emission Spectroscopy or ASTM Test Method E 2269 Test Method for Determining Argon Concentration in Sealed Insulating Glass Units Using Gas Chromatography.

The E 2190 also outlines the qualifications for testing triple-glazed units. These have been added to the standard to accommodate the advancing use of triple-glazing in IGUs.

The Canadian standard CAN/CGSB-12.8-97 Insulating Glass Units is used in Canada for units that still require testing to this standard. It is basically used only in Canada and was last revised in 1997 to address argon gas filling of IGUs.

The ASTM standards are being updated and reviewed continuously at the semi-annual meetings of the ASTM E 06 Performance of Buildings committee that take place each April and October. The CGSB has not been active since 1997 relating to the Insulating Glass Standard.

The following chart is a brief comparison of the previously used standards to the presently used standards with regard to the high humidity tests, accelerated weathering tests, volatile fog testing, specimen requirements, and evaluation criterion.•

Organized by the Glass Association of North America, the Building Envelope Contractors Conference returned to the Paris Las Vegas Hotel and Casino this past March with speakers and sessions designed specifically for contract glaziers. In addition to educational and professional development opportunities offered, the conference included a meeting of the BEC Technical Committee as well as the very popular networking receptions and table top exhibits.

BEC division chair, Henry Taylor, who is the architectural services team manager for Kawneer, kicked off the event by telling the audience that the purpose of BEC is about sharing ideas. “BEC is about encouraging dialogue and conversation,” he said.

One of the highlights of the conference was the highly anticipated keynote presentation from Oldcastle BuildingEnvelope CEO Ted Hathaway, who described how technology is changing the glass business. “We need to think about the impact that the buildings we construct today have on the environment,” said Hathaway. “As an industry, how can we use new technology to build smarter building envelopes? Considering that in the United States, buildings consume over 49 per cent of the nation’s total energy, we need to re-examine past practices as the envelopes can no longer be passive or stupid. In fact, 50 per cent of the 8,603 buildings owned by the United States government were constructed between 1950 and 1995, and all of them are in need of upgrading.”

According to Hathaway, buildings currently account for 75 per cent of the carbon emissions on the planet, “So if we are serious about reducing greenhouse effects, we need to take a very

serious look at how we construct buildings in the future and how we retrofit the existing stock of buildings to achieve improved energy performance.”

Hathaway told the attendees that technology and collaboration are the two crucial elements that will make for smarter building envelopes. “The technology that is coming out of the manufacturing and software industries is what is driving the new design-build process,” he said. “Three dimensional modeling with BIM, Revit, Rhino, Grasshopper, Navisworks, Nitya, horizontal software and iPhone apps are revolutionizing the ways buildings are designed and creating an opportunity for tremendous collaboration in all stages of the design-build process.”

Above: Oldcastle BuildingEnvelope CEO Ted Hathaway addresses the conference. Hathaway sees opportunity in North America’s aging institutional infrastructure. Half of the U.S. government’s buildings were built between 1950 and 1995.

Hathaway stated that energy efficiency, sustainability and environmental stewardship are guiding the technology and, by default, building designs. “The idea is for the building to exist in its environment in the most efficient manner. All of these technologies facilitate the creation of smart building envelopes.”

Reinforcing the energy efficiency theme, Chris Dolan, director of commercial glass products for global glass manufacturer and BEC co-sponsor Guardian Industries introduced Guardian’s new SunGuard photovoltaic glass units which are being produced in partnership with San Mateo, Calif.-based Pythagoras. The companies announced that Guardian SunGuard PVGU is a BIPV solution that replaces standard vision and spandrel glass or skylights with a glass product that converts direct sunlight into energy.

According to Dolan, a recent report from industry analyst firm NanoMarkets estimates that the total market for BIPV glass will reach US$6.4 billion in revenues in 2016 compared to $1.5 billion in 2012. “SunGuard PVGU will help architects and building owners who are looking for solutions to achieve net-zero buildings,” said Dolan. “The product lets in diffused light, increases energy efficiency and generates electricity from the building facade, helping projects meet the new green energy codes. Additionally, BIPV projects may be eligible to earn substantial federal tax credits.”

Victor E. Corniellier, CEO of TSI/Exterior Wall Systems, provided a sobering yet inspirational seminar entitled “Leadership in your Contract Glazing Firm.” “I have a passion for this industry,” said Corniellier. “I have been in it my whole life. Today our industry is very, very pained. Take a look around. We see businesses that are collapsing and closing their doors while others are reorganizing. You can say, ‘Well, that’s one more competitor that I don’t have to worry about,’ but if you have that attitude, it is wrong. Because what is happening to our industry is the net result. We have all used this phrase: ‘How the hell did they do the job for that price?’ You hear it all over the country.”

Corniellier presented a slide listing the names of ten wellknown glass and aluminum companies that have recently gone out of business. “It is over for Trainor Glass, a pillar in the industry. Moving into the future, we want to be sure that we are not adding more company names to that list. If you talk to surety underwriters, they will tell you that contract glazing is one of the highest risk industries in the building trades nationwide.

There are national and regional companies in the glass industry that are not going to be here this time next year. My point of this doom and gloom, and I’m not a doom and gloom guy, is that you have to be a realist. We have to figure out how we’re going to get through this. We’re dealing with downward banking pressure on small business the likes of which we have never seen before.”

Corniellier provided several takeaways to help leaders better navigate the current environment, including recognizing the difference between process failure and people failure, emphasizing the importance of leading through tough times with relationships, improving internal and external communication and using basic tools such as mission statements and SWOT analysis. “Culture is not something that is simply written, it must be engrained in individuals,” he added. “Strategy must

Continued on page 21

www.glasstec.de www.solarpeq.de Oct O ber 23 – 26, 2012 Düssel D orf, Germany

s U mm IT for G lass Meeting point for the entire glass industry G lass I n all IT s fa C e T s Live presentation of the latest technology and innovations U n IQU e Val U e First-class ancillary program with accompanying congresses

CU s on solar P ro DUCTI on Parallel staging of solarpeq – the international trade event for solar production

by MIKE hIGGINs

Mike Higgins of Economy Glass in Moncton, N.B., is the new president of the Atlantic Provincial Glazing Association. He can be reached at 1-506-863-5335 or mike@ngg.ca.

Congratulations Atlantic Canada, you now have an association serving the glazing industry in our region! The directors of the new Atlantic Provincial Glazing Association are:

• Mike Higgins, Economy Glass - president/secretary

• Dan Parolin, Royal Door – vice-president/treasurer

• Allain Ouellette, City Glass - director

• Dan Everson, Economy Glass - director

• Tony Spurrell, Tremco - director

• Dave Boudreau, Alumicor - director

• Pramod Jolly, Alvin & Company – director

I would first like to thank Zana Gordon, executive director of the Canadian Glass Association, for her assistance and guidance through the initial set up. Her participation has been invaluable. I would also like to thank the board of directors who have graciously volunteered their time and enthusiasm toward this endeavor.

This association has been a long time coming, and with its inception the glazing industry is now represented from coast to coast for the first time. This is an important accomplishment given the desire of people from our industry to lobby governments and educational institutions to further develop training and certifications within our industry.

With the APGA’s inception the glazing industry is now represented from coast to coast for the first time.

Though you see certain names listed above as the current volunteer executive, multiple people in our industry have been promoting this idea for some time now. These people planted the seeds that allowed this important association to come together so easily this last time around. Their efforts are still clearly visible as I spend time talking to different glazing people within our region and I think the energy they put forward should be applauded. We would certainly welcome participation in any form from anyone who is interested in helping and promoting our agenda.

With the establishment of this Association, it is now time to turn our efforts towards the direction and purpose of our efforts. Things like training, certifications, working relationships and the overall promotion of our industry in Atlantic Canada, yes, including the great province of Newfoundland.

Things are rapidly changing in glazing and we have become very relevant. Things are becoming more and more complicated and the landscape is changing faster than it ever has. We have a lot of good people in this business, but we need new young blood to comein and dedicate themselves to the industry as a whole.

At our board meeting on April 12 in Moncton we discussed the direction and purpose of our organization at great length. There are key issues we feel are prominent and common for all active participants in our industry, items we can all take advantage of through participation in the association.

Once again, congratulations Atlantic Canada! We look forward to getting together soon.•

June 24 - 27

International Conference on Coatings on Glass and Plastics breda, Netherlands www.iccg9.eu

Sept. 12 - 14

Glassbuild America Las Vegas, Nev. www.glassbuildamerica.com

Sept. 13 - 14

Crane and rigging Conference Canada Edmonton, Alta. www.craneandriggingconference.com

Oct. 23 - 26

Glasstec/solarpeq dusseldorf, Germany www.glasstec-online.com

Nov. 6 - 8

Win-door toronto, ont. www.windoorshow.com

Nov. 14 - 16

Greenbuild san Francisco, Calif. www.greenbuildexpo.org

March 20 - 22

Glasspex India Mumbai, India www.mdna.com

May

Glass Connections and CGA AGM Montreal, Que. www.canadianglassassociation.com

June 20 - 22

AIA National Convention and design Expo denver, Colo. www.aia.org

by brIAN bUrtoN

Brian Burton is the author of Building Science Forum and is serving on CSA’s Fenestration Installation Technician Certification Committee. Brian is a research and development specialist for Exp (The new identity of Trow Associates). He can be reached at brian.burton@exp. com or through www. exp.com.

Virtually every component contained within modern building enclosures, including fenestration elements, is being revisited by manufacturers, designers and owners in ongoing efforts to reduce operating costs, increase energy efficiency and improve the level of occupant comfort. These efforts have been intensified over recent years partly as a result of the rapid increase in energy costs and the gradual recognition that the annual solar energy received on the building envelope surfaces is very close to being equal to the energy needed to operate the building. This is true in all four Canadian climate zones. In theory at least, with improved techniques and technologies used to capture and then use this energy, we should be able to design buildings that are energy self-sufficient. As a result, architects and building engineers are working hard to develop so-called “adaptive” or “responsive” building envelope systems.

These adaptive systems have the potential to use more of this available energy for heating, ventilation, cooling, lighting and electricity supply. One example of such an adaptive building envelope is a double facade that incorporates natural ventilation systems. The curtain wall system comprises an outer skin of glass and an inner wall constructed as a curtain wall that together provide a full-function wall. Prototypes of adaptive facade systems have been developed to act as modular systems that combine six primary principles applied in various combinations: decentralization of ventilation systems, incorporation of flushintegrated opening elements, automated daylighting control systems, high-performance UV protection, solar energy production using modern thin-film technology, and modular, or moveable, interior insulated panels to minimize heat loss or gain.

Currently there are three technologies that make the necessary high level of light control possible:

With improved techniques and technologies, we should be able to design buildings that are energy self-sufficient.

liquid crystal, electrochromic and suspended particle device. These smart glass technologies enable control of the light that is transmitted into the building from 100 per cent transmittance down to near zero. This has a direct bearing on the temperature and heat buildup inside the built environment and consequently on heating and cooling bills.

Adaptive systems are moving away from the centrally controlled HVAC systems we have been accustomed to installing in the past to create systems that are more localized. Instead of controlling heat loss and gain by moving warm air around the interior of the building using a central system, which is not really that efficient, the concept involves creating a system where at least some of these functions work together to adapt locally to exterior and interior environmental conditions. The concept actually involves giving each area of the building what amounts to its own independent HVAC system instead of a one-sizefits-all approach. The idea does present challenges not only because of the complexities involved but also because of the need to consider and balance moisture transport and movement within the system, which is considered one of the primary concerns in the industry. If these types of systems are effectively introduced and proven they could offer designers more flexibility and have considerable potential when it comes to reducing energy costs and improving building performance.

We also know that improving comfort levels and effectively controlling daylighting are important factors that affect occupant productivity in commercial buildings. Typically the financial impact regarding improved productivity is underestimated. In fact a one per cent improvement can offset a company’s entire energy costs. Occupants usually insist on some form of override for daylighting controls, and the numberone complaint regarding these systems involves the inability to modify daylighting controls to meet specific needs.

When it comes to assessing adaptive facades we still need to be able to reliably predict the thermal and optical performance of components and systems. We also have to consider the impact of increased cooling loads and cooling energy use for larger buildings and the potential for increased visual discomfort from sun penetration for people working at computer systems in daylighted offices. It is very likely we will continue to see innovations of this nature as building professionals continue their efforts to focus on sustainability. •

Continued from page 17

be communicated and shared with all levels of the company. It is not something that is shared in an executive meeting or board room.” Safety is paramount. Corniellier suggested having your employees adopt the buddy system: “I’ve got your back.”

Corniellier wrapped up his presentation saying glaziers should live by three four-letter words: cost, cash and risk. “None of us is too big to fail,” he said. “These three words are the vital signs of your business.”

Another well-attended, thought-provoking session was the roundtable panel entitled “How Contract Glaziers Can Assist in Building the Buildings of the Future” featuring the four stakeholders of a commercial contract: owner, architect, general contractor and sub-contractor. Each speaker discussed what his desired outcome was and what a well-executed contract looks like. “This session is designed for the glazing contractor to better understand the perspective and expectations of where these stakeholders are coming from,” said Taylor.

One of the high points of the panel discussion was the presentation by David Bellman, senior vice-president for Avalonbay Communities. “I figure if it has to do with glass and aluminum exterior wall, if the guys in this room can’t figure it out, it probably can’t be done,” said Bellman. “By definition, I’m the overall guy. I am not an external wall guy. From my budgetary standpoint, we are looking at the total package. We are looking at how

the systems work together. We cannot keep up with the high performance coatings. Getting those coatings tested and into the market and understanding how they perform is important to us. Combining storefronts with exterior walls would make my life easier. There are companies that are looking at do this and I think that would be a great idea moving into the future.”

According to Bellman, there is available capacity built into production schedules, however these are starting to be absorbed now and Bellman cautioned that perhaps with some of the projects moving forward there might be some production consideration in the pipeline. “From our perspective, the things that constitute a well-formed contract is for the specification in design and design execution to be met,” he said, adding that developers are looking for product manufacturing to be high quality and delivered on time. Bellman said that developers such as Avalonbay want a glazier that can follow the pace of the job, fulfill commitments related to installation, be punctilious and complete the job and close the building on time. “Watertight dates are among my key dates. I want to know when the envelope is watertight. It is a major milestone for developers.” •

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

Your New Design Solution—The Sentry™ Multi-Point Hinged Patio Door System.

You need the finest hardware to complete your door offering. Something customizable but simple. Strong but stylish. And above all, it needs to be designed for the North American market. Introducing, Truth’s new Sentry™ Multi-Point Hinged Patio Door System: an innovative solution packed with features that exceeds your expectations – and those of your customer.

Completely modular for custom design, this 300 series SST multi-point locking system easily fits in standard eurogrooves and offers superior strength and security with full 1" throw of dead bolts and shoot bolts.

The Sentry™ adjustable hinge exceeds ANSI grade 3 requirement by achieving 350,000 cycles on panels weighing up to 220 lbs and ANSI grade 1 impact specifications. Intuitive indicators allow for accurate vertical and horizontal adjustment.

Distinctive styling meets intuitive function. Truth offers multiple handle designs from traditional to contemporary, each with a North American designed 90 degree thumbturn located above the handle.

The Sentry™ Multi-Point Hinged Patio Door System – yet another engineered solution from the company you can trust – Truth Hardware.

For more information contact your Truth Representative or visit www.truth.com

www.truth.com

New energy specifications and requirements for increased window performance have created the need for sashes to contain triple-pane and/or laminated glass. this, combined with the move towards larger windows, has pushed the envelope on what standard duty, concealed casement hinges can handle. truth hardware has responded to this issue with its new high Performance hinge, which delivers impressive performance and weightcarrying capabilities, and allows window manufacturers to meet these demanding new requirements. truth’s high Performance hinge is capable of supporting a 140-pound sash, allowing manufacturers to use triple-pane and laminated glass packages in larger windows. this is made possible due to the innovative, patented, shoe design with a built-in roller to reduce friction during operation, thereby providing smoother travel even under maximum load.

www.stanleyblackanddecker.com

If you’re replacing the locksets in a home in 2012, break away from tradition with new contemporary and modern lockset designs from Weiser. Clean lines, smooth polished surfaces and just the right amount of enhancing detail are defining the new look for home security. “since trends and personal tastes are always changing, more people are choosing designs that are dynamic and will work with a range of home fashion styles,” said Mark Wallace, marketing manager from Weiser. “recently we have seen a mix of textures, colours and lines in contemporary home design that incorporate many styles and we have worked to include all of these trends in the new lockset designs.” In a recent brand study, Weiser found that 50 per cent of participants favour a transitional style for their home décor, demonstrating a growing trend toward incorporating both traditional and contemporary styles. Weiser derives its designs from trends in the architecture and fashion world, but does so without compromising function. smartKey technology is standard on all Weiser products, ensuring that one’s design choice is equipped with the best residential security. Weiser has introduced two new levers (Katara and Vedani), two new deadbolts (round and square) and a new handleset (tavaris). All these new modern locks are available at home improvement stores across Canada.

www.ashlandhardware.com

there is now a casement hardware system that can achieve water resistance that exceeds all code requirements. With its watertight, patented, o-ring seal technology integrated within the operator, consumers can appreciate added home protection from potential water and mould damage. the stainless steel construction incorporates a new, advanced composite assembly that thermally insulates the operator and significantly reduces transfer of heat and cold into the home. the tough, multi-point

lock offers a new progressive lock-up mechanism that delivers 30 per cent more vertical motion for maximum sash pull-in to close the window, and allows for easier consumer operation with its low-friction roller design. the operator passes AAMA Commercial Grade 901-96 cycle tests, and meets AAMA 101 hardware load ratings. the interlocking points will withstand 450 pounds of pulling force to pass AAMA dP 70, as well as dade County Impact and Cycle testing. Ashland’s visual design was preferred in consumer market research, and is offered in a choice of new, trend-setting finishes that include oil-rubbed bronze and satin nickel. the system includes detent lock and operator handles to indicate that the system is in open or closed positions, including a fold-away crank handle that blends into the operator cover to eliminate interference with window coverings. the operator is one of the easiest to operate, requiring less than one foot-pound of operating torque on a large, 113-pound window. Ashland’s hardware is also designed for easy integration into current window systems. the system makes for minimum changeovers in window manufacturing, providing the same route location for dual, dyad and straight-arm operator styles. the lock is designed to ease keeper location and maximize sash pull-in distance, while providing lock bar retainers that are selflocating to ensure proper positioning.

www.crlaurence.com

the CrL280 series top-hung sliding door system is one of the most versatile sliding door systems offered by CrL. there are six different configurations offering ceiling or glass-panel mounting. It also has no bottom track, so tripping hazards are eliminated. John o’brien, CrL architectural hardware brand manager, states, “the CrL280 series is not only stylish, versatile and safe, but we have designed this system to operate with a very smooth sliding action for finger-touch control.” the upper clamp and rolling assemblies feature fine-tuning adjustments, allowing the system to be adjusted for openings and floors that are not true and level. Each kit comes with concealed stops in the top track to hold the door open or closed. It is offered in a satin anodized finish or can be special ordered with stainless steel or brass cladding in polished or brushed finishes, or powder painted in a variety of standard or custom colours.

www.fenestration.net

Functional Fenestration Inc. introduces its stainless steel lift slide systems. FFI has provided lift slides to the North American market since 1992. FFI’s lift slide innovations – including stainless steel, integrated edge-pulls, half-gears, and taller locks – have attracted clients with quality and cost savings. Lift slides allow larger openings with fewer panels than standard sliders. Architects love the flexibility of design for window walls, pocket doors, curved walls and corner applications. Lift slides maximize views and bring the outdoors in for applications such as residential

and resort patios, balconies, restaurants and museums. Lift slides have lower air and water infiltration than other sliding door options and help manufacturers meet hurricane test standards. because the panels are lifted while they slide, the weather-seal does not wear out from friction. For access and ventilation, panels can lock open at any position. LEEd credits can be earned under Indoor Environmental Quality for natural ventilation, daylight and views. FFI has designed lift slide system improvements that are contract-manufactured exclusively for FFI and available nowhere else. the lift slides are made with stainless steel main moving parts, in a choice of two grades, 304 or 439. Pocket doors are easy; the FFI lock is prepped to accept FFI edge-pulls. the durable locks with sst drive rods and cases also have Kynar-coated faces. A taller, one-piece lock is available for up to eight-foot, eight-inch-tall doors. stronger extensions with a secure bolt-in rod are available for up to 14-foot-tall doors. FFI provides lower-cost half-gears and 10-pack gears that provide approximately 20 per cent savings over multi-panel systems. the higher-grade carriage offerings include 304-grade main parts and sst ball bearings. All lift slides include esthetic cover pieces to conceal gaps.

www.ferco.ca

G-U constant force coil springs are made with 304 stainless steel in weight ranges from three to eight pounds. Each coil is stamped with its weight category for easy identification. they can be used with monobloc cassettes or a standard spring support. three lengths are available: short tail (23 mm), medium tail (58 mm) and long tail (104 mm). Unit diameters range from 27.5 to 31.5 mm.

www.us.hoppe.com

Imagine being able to effortlessly combine interior living areas with the great outdoors. It is simple using hoppe’s new fold and slide hardware system. Ideal for openings up to 48 feet wide, this system

can use panels as large as three feet wide by 10 feet in height. the system is suitable for wood doors with a capacity of up to 165 pounds per panel. the hoppe fold and slide hardware system allows you to bring the outdoors in. It incorporates such features as precision bearings for a low rolling resistance, making even the heaviest of doors operate easily. the concealed bottom channel improves the threshold appearance and artfully blends with the exterior floor. Extensive use of stainless steel components offers high resistance to corrosion, even in coastal environments. A large range of handle designs and finishes is available. the various designs allow for matching hardware throughout the home with the same handle style and finish.

operation allows the homeowner to unlock and open the door in a single fluid motion. In reverse, the door closes and locks in the same single fluid motion. Using a modern design that eliminates the lever, the handle does not protrude into the glass area, enhancing the sightlines of any sliding door. the Intuition handle is designed for single and multi-panel applications. It fits the Interlock slim backset mortise locking system. Intuition handles are endurance tested to 20,000 cycles and the powder coat version is neutral salt-spray tested to a 1,000-hour minimum. the handles mount using the same route as Interlock’s current handles. Intuition handles are made with

Join a unique and growing company that is a leading manufacturer of innovative and sustainable engineered fabricated curtain wall, storefront, entrance and skylight systems. We have career opportunities, with room for advancement, in our Southwestern, Ontario location

We have career opportunities, with room for advancement, in our Southwestern, Ontario location.

Application Engineer/Design Architect

Application Engineer/Design Architect

Position includes leading a team of engineers, designers and drafters in the design of exciting and challenging projects. 7-10 years experience in architectural aluminum industry. Structural/mechanical engineering or architectural background with knowledge of building enclosure science, an asset.

Position includes leading a team of engineers, designers and drafters in the design of exciting and challenging projects. 7-10 years experience in architectural aluminum industry. Structural/mechanical engineering or architectural background with knowledge of building enclosure science, an asset.

Project Manager/Estimator

Project Manager/Estimator

Position requires a good understanding of building construction and a Bachelor degree/diploma in engineering or construction management. Experience in estimating or project management an asset.

Position requires a good understanding of building construction and a Bachelor degree/diploma in engineering or construction management. Experience in estimating or project management an asset.

We offer a relocation package, competitive wages and benefits which will commensurate with experience and skill level.

We offer a relocation package, competitive wages and benefits which will commensurate with experience and skill level.

Please send resume to: 477 Jutras Drive South, Lakeshore, ON N8N 5C4, hr@erieap.com www.erieap.com

Please send resume to: 477 Jutras Drive South, Lakeshore, ON N8N 5C4, hr@erieap.com www.erieap.com

by JohN roPEr

John Roper is the editor for The Installer, The Fabricator, The Conservatory Installer and Glass Works magazine published in the U.K.

So, let’s say you want to join an exclusive club, and let’s say the club would be happy to accept you. But first you have to provide the club with some personal details. “No problem,” you say. “What do you need to know?”

Well, here is a problem: the club is not allowed to tell you. Its own regulatory association –let’s call it UKLUB – says that it is the job of applicants to know what information they need to provide. Clubs are not allowed to tell them or to help them accumulate the necessary documents. Ridiculous? Of course. That is, until you factor in the British government and, more particularly, the British civil service.

In the U.K. we have government-regulated schemes which tradesmen are encouraged to join called “competent persons schemes.” The idea is that, whether you are an electrician, plumber or window fitter (or work in any other trade, for that matter), you are pre-approved by your scheme to self-approve your work and issue any necessary certificates. The competent persons scheme then spot-checks its members’ work. It all seemed to work well until the government decided to add another overseeing body to accredit the competent persons schemes that accredit the tradesmen. Meet UKAS: the United Kingdom Accreditation Service. Once it got its teeth into things, the situation began to resemble the one described above.

All we seem to see are more parasitic organisations overseeing more regulations.

It has a lot to do with the British government’s flagship energy-saving scheme, the Green Deal. For a company to be involved in the Green Deal, it will need to be a member of a competent persons scheme and that scheme will need to be approved by UKAS. But to join a competent persons scheme you have to fulfill certain criteria. Take a look at the top of the page to find out how this is handled.

EUroPEAN sCENE

Now, if I heard the recent Queen’s speech correctly, the government is talking about reducing red tape. Legislation will be introduced to reduce burdens on business by repealing unnecessary legislation and limiting state inspections. Of course the government has said this before but all we seem to see are more parasitic organisations overseeing more regulations. Who will keep an eye on UKAS? (How about BOR – British Overseers of Regulators?)

I happen to think that whoever came up with the Green Deal in the first place is barking mad. The idea is to improve the insulation in our leaky, drafty, old houses. Not a bad plan you might think; the U.K. has lots of those, indeed I have one myself. If my house were to be assessed by an accredited “assessor” to be suitable for the scheme then a “provider” would appoint an “installer” to carry out the work. There was even a suggestion that if, for instance, you asked a company to fit a new door and there was other insulation work needed to improve the property then you could not have the door unless all of the other work was carried out as well.

Under the Green Deal, financing for the work will be provided by approved finance companies at, apparently, a “low” rate of interest. The loan is credited to the house and paid for through an increased energy bill. Only someone as detached from the world as a politician or a senior civil servant could believe that someone would willingly buy a house with a built-in debt. There are many over here that think the Green Deal will give a huge boost to our industry. If it does produce more business that will be great, but it looks like the scheme will be tied up in red tape and could turn into a jobs-for-the-boys charter. The “installer” is appointed by the “provider” who in turn will be appointed by the “advisor” – it seems wide open to abuse. And the “installer” must be a member of a competent persons scheme . . . though no one is allowed to say what information he or she might have to provide in order to be so deemed.

It is a bloody mad world! •