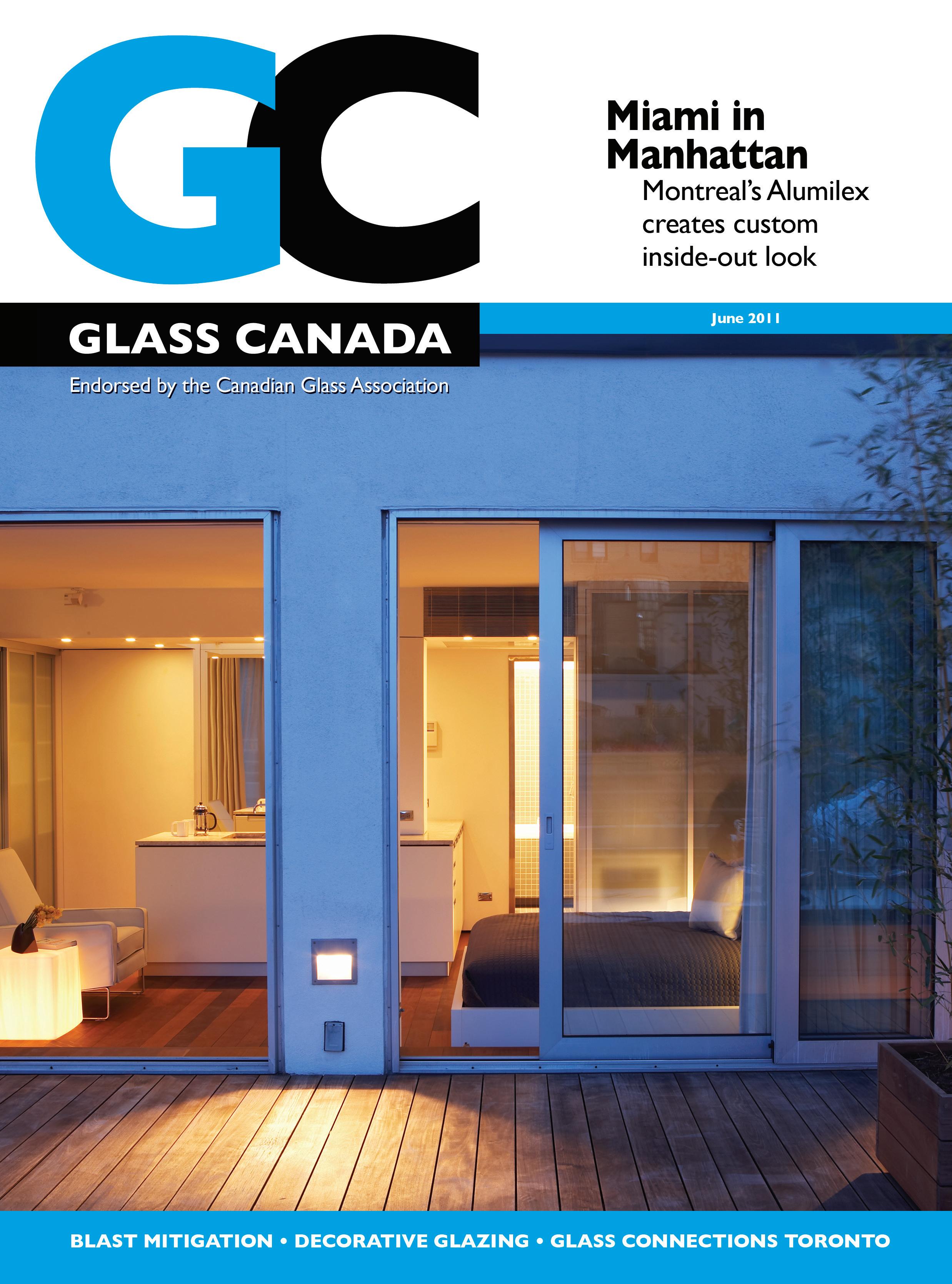

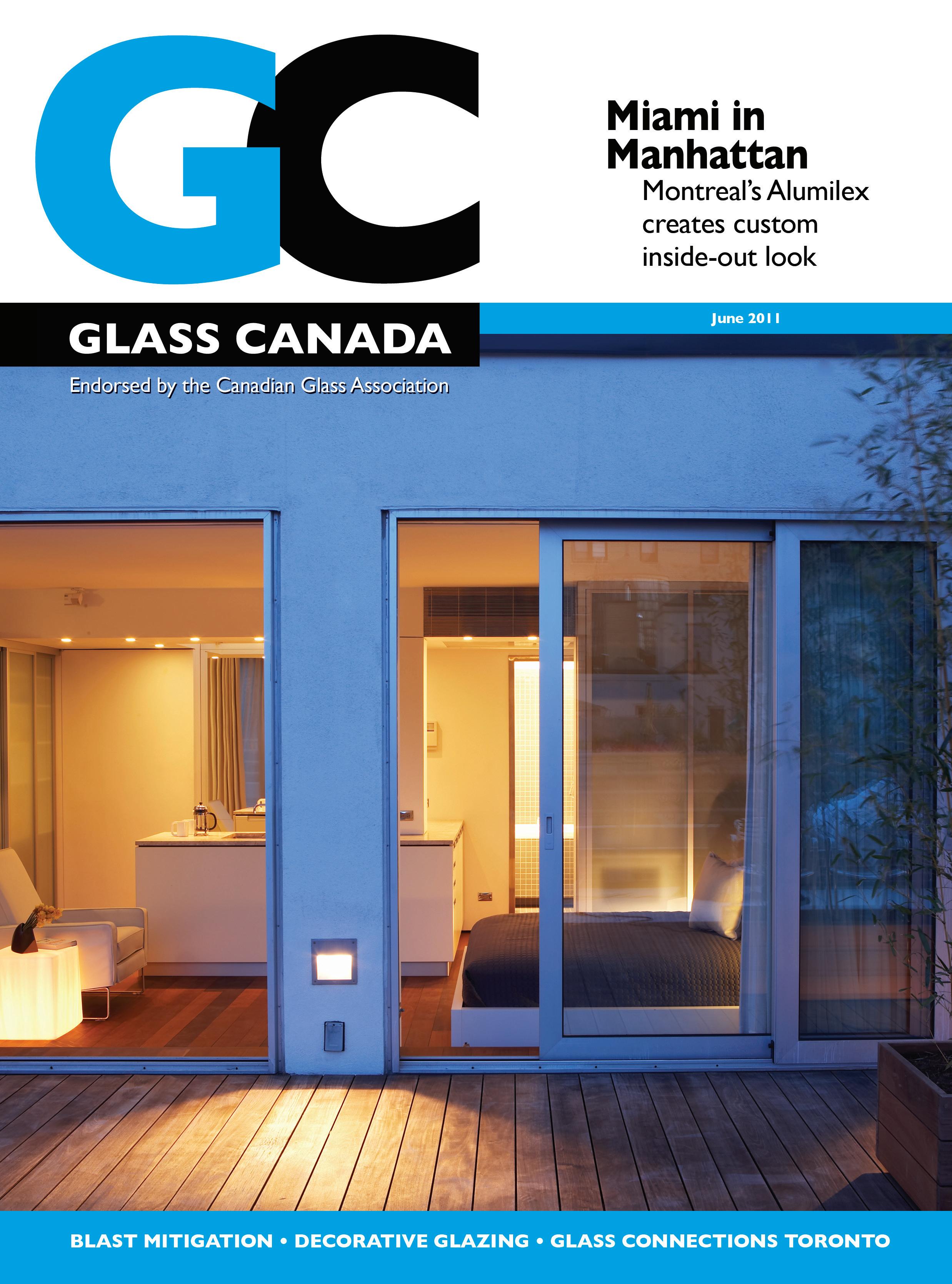

A New York designer looks to Montreal’s Alumilex to create a seamless inside-out transition.

12 Glass Connections Toronto

The CGA brings its popular educational series downtown with an idea-packed program and a phalanx of top suppliers.

16 The business of decorative glass

Glaziers can land lucrative contracts with some expertise in providing eye-catching solutions. But don’t stand still.

22 BEC Las Vegas

Building envelope contractors gathered to look for ways to weather the ongoing hard times in the U.S. construction market.

14 CWDMA Update

Here’s a chance to get FIT for less.

18 Innovations

Important concepts in blast mitigation, with a showcase of top products.

24 New Products

Automated IG fabricating line, hardware for tempered glass doors, tool tethers and more.

Edgetech I.G. has once again been recognized for its ongoing commitment to the health and safety of employees by the Guernsey-Noble Safety Council. The company was presented with the Group Award and the Special Award at the council’s awards luncheon in April.

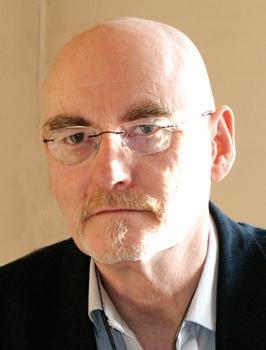

EDITORIAL

Look at the photo from OGMA’s Race Nite on page 7. People are enjoying themselves. Whatever else was accomplished that night, it made people smile.

People are fascinated with people. When I was starting out in magazines, my editor gave me a simple tip for taking a photo: always have a person in it. He illustrated his point by asking me to imagine a beautiful landscape shot of a mountain. Lovely, certainly, and worthy of a look. Then he asked me to imagine there is a tiny person way down in one corner of the picture. Instantly, the viewer’s attention is riveted to the solitary person, despite him being only a minor detail in a huge shot full of detail. Who is he? What is he doing there? Is he climbing the mountain? Is he lost? In my subsequent career I have found this principle to be correct over and over again. People just naturally focus on other people.

And why not? We are social creatures. People in groups are relatively happy and productive. People alone tend to be miserable and desperate. Our brains have parts dedicated only to recognizing faces. All this suggests we not only prefer to associate with others, but we actually need to.

• Equipment for your shop

• Laminated glass

I think this bigger point has a more specific application in the case of trade associations. There are a lot of good, practical business reasons for supporting industry associations and remaining active in them. Frank Fulton hits on one in his regular column on page 26, and delivers a sharp kick in the glass to apathetic glaziers at the same time. So I want to talk about the less-discussed reason for participating in an industry association: the fun and satisfaction of interacting with your peers.

You probably don’t need an association event to get together and have some laughs with friends, but then again maybe you do. It can be lonely at the top of a company when you are The Boss to everyone around you. Few of us have much spare time for social activity after hours. Association events are a chance to meet and interact with other people who are in exactly the same circumstances as you, with all the same joys and frustrations. Sometimes it just does the heart good to shoot the breeze with someone who gets it. Is there ever such a thing as having too many friends?

There are the reasons for doing things that people talk about, then there are the real reasons they do them, and sometimes the two are not the same. My experience has been that, apart from all the good, logical reasons for supporting an association, people do it because they like it, and because they meet their friends there. •

June 2011 Volume 23 • Number 3

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Kory PEARN kpearn@annexweb.com 519.902.8574

SALES DIRECTOR | Martin MCANULTY mmcanulty@annexweb.com 519.429.5178

SALES ASSISTANT | Pauline O’NEILL poneill@annexweb.com 519.429.5183 | 888.599.2228 ext. 219

PRODUCTION ARTIST | Kelli KRAMER

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: ncuerrier@annexweb.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: ncuerrier@annexweb.com Tel: 866.790.6070 ext. 208 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) $39.55 includes HST/QST

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

Edgetech I.G. celebrated the official opening of its Heinsberg, Germany, manufacturing plant on May 19 with more than 150 guests, including local dignitaries, media, customers, suppliers and other industry representatives from around the globe. Among the attendees were David Petratis, chairman and CEO of Quanex (Edgetech’s parent company), and Mike Hovan, senior vice-president, sales and marketing, of Quanex’s Engineered Products group.

“The much-anticipated Heinsberg grand opening was an incredible success,” Petratis said. “To walk among industry leaders from around the world and to see firsthand the excitement surrounding the new facility was inspiring. I look forward to watching the operation flourish and grow in the coming years.”

Hovan, who served as Edgetech’s president for 11 years, commented, “Super Spacer and warm edge technology in general has been embraced by the increasingly energy-conscious marketplace in Europe.The Heinsberg manufacturing plant comes at the perfect time when Edgetech anticipates 80 per cent growth in the

region this year alone. I would like to personally thank those who were able to help us mark this memorable occasion – the support we received from the industry and local community was overwhelming.”

At the grand opening, Edgetech officials provided tours of the facility and unveiled plans for further expansion. According to Andy Jones, Edgetech’s European managing director, the company will add two more extrusion lines by 2012 to accommodate the expected sales growth.

“Continental Europe is a strategically important market for Edgetech and investing in Heinsberg, our third manufacturing facility, shows our commitment to achieving market leadership,” Jones said.

Edgetech I.G. is well known in the window industry for its flagship product, Super Spacer, which has contributed to the energy efficiency and sustainability of residential and commercial buildings worldwide for more than 20 years. To support sales in more than 80 countries, Edgetech has manufacturing facilities in the United States, United Kingdom and Germany.

ABOVE: Left to right: David Petratis, chairman and CEO, Quanex Building Products; Stephan Pusch, district administrator; Andy Jones, managing director, Edgetech Europe; Wolfgang Dieder, mayor of Heinsberg; Mike Hovan, senior vice-president of sales and marketing, Quanex; Petra Wassner, CEO, NRW Invest; Joachim Steiner, County of Heinsberg.

Basco Shower Enclosures, in conjunction with the Interior Design Continuing Education Council (IDCEC), has introduced a newly formed continuing education course called Demystifying Shower Door Selection. The IDCEC Continuing Education System, a consortium of professional organizations in the United States and Canada that co-ordinates continuing education approval activities, has approved the course for continuing education credits.

“Designers are doing many more heavy glass shower projects and there is an intimidating fear factor in selling these doors,” notes Don Gamble, executive vice-president of sales and marketing for Basco Shower Enclosures. “The course takes designers step by step through the selection process, sharing with designers how to identify the space and the options available for different applications.”

The course reinforces design concepts and the benefits of shower doors, identifies common configurations and considerations for sliding and swing enclosures, provides characteristics of framed, frameless and heavy glass enclosures, and recognizes and applies steps for selecting a successful shower enclosure solution.

The free, 60-minute course provides10 CEU credits. It can be delivered in person by a trained Basco CE facilitator. Contact marketing @bascoshowerdoor.com or 1-800-543-1938 to inquire about a course provider in your area.

Building on the success of the last two conferences (Glass Connections Vancouver 2010 and Glass Connections Toronto 2011) the Canadian Glass Association is holding the next conference, Glass Connections Edmonton 2011, at the Delta Edmonton South on Oct. 27, 2011. A call for papers has been issued and the program will be defined after the technical committee has reviewed all the submissions. The deadline for submissions is July 15. The call for papers has indicated that topics relevant to a cold climate are preferred. This event offers sponsorship opportunities at all levels. For more information you can go to our website at www. canadianglassassociation.com.

TheOGMA held our Race Nite at Woodbine Racetrack on May 2 with 57 of our finest members who know

a good time when they see one. The buffet served up was exceptional and some lucky participants even managed to take home a few more bucks than they came with.

The OGMA was a proud co-host of the CGA Glass Connections Conference held at the Delta Chelsea Hotel in Toronto on Tuesday, May 3. The presentations by the five speakers blew the crowd of just over 100 away with a ton of new and fascinating information and facts. The venue was top drawer, and the day definitely exceeded expectations.

Fast approaching is our Spring Golf Tournament on May 26 at the Glen Eagle Golf Club near Bolton, Ont. Spaces are filling up fast, so go to the OGMA website and get signed up. It is not too late to sponsor a hole or a prize. Make sure to come out and support your industry.

If you are conducting business in the glass industry in Ontario, the OGMA is the voice that represents your interests at the provincial and federal level. Protect your business interests by becoming a member or associate member. Doug Morris is heading up

membership for our association, so please contact him today at douglasmorris@rogers.com, or visit the OGMA website.

The OGMA wants to notify all glass and glazing companies in the province that the Ontario version of the Glazing Systems Specifications Manual of Standards and Practices is now available for purchase. This all-encompassing document is a must-have reference tool for all companies in the industry. For more information, and to order yours, visit our website at www.ogma.ca.

Our Fall Golf Tournament is set for Sept. 22 at the Carrying Place Golf Club. Details will be forthcoming as the date approaches, but go ahead and mark your calendar today.

The GCABC and Window and Door Manufacturers Association of B.C. (WDMA) held its 20th annual golf tournament

May 19 at the two Arnold Palmer-designed courses featured at Surrey, B.C.’s Northview Golf

and Country Club.

The GCABC/WDMA Golf committee consists of: Seth Maretz of National Glass, co-chair, Devin Pickles of Starline Windors, co-chair, Rich Porayko of Construction Creative and Ivo Tanner of the Quality Auditing Institute.

Over 187 glazing contractors, suppliers, consultants and window and door manufacturers attended the hugely successful event where sponsors CP Distributors, Vitrum Industries, PFG Glass, Quanex Building Products, Starline Windows, Finishing Trades Institutes of B.C., Flynn Canada, Gienow Windows and Doors, Guardian Industries, Oasis Windows, Tremco and over 30 hole sponsors donated two 50-inch plasma TVs, an iPad 2, two Wii consoles, two Xboxes, two PS3s and 187 prepaid Visa cards. Platinum sponsor Cardinal IG also presented the grand prize of a set of premium Callaway golf clubs to Seth Maretz, sales manager of National Glass.

Feedback from the membership and sponsors was very positive. The GCABC/ WDMA board members wish to congratulate all the winners and thank all of the volunteers, participants, sponsors and supporters of the event.

The Barrie Examiner has reported that Richard Wilson, a Toronto construction contractor, and Gord Tozer, an investor from

Chronoglass, a division of Vitre-Art, can now offer digital ceramic printing on glass from its Montreal plant. The investment is expected to create 15 jobs in the short term, and possibly more down the road. Chronoglass says it is the only company in eastern and central Canada to offer this sixcolour digital printing process.

Digital printing with ceramic inks

Ireceive your magazine and read it from cover to cover each month.

I am the Energy Efficiency Compliance Coordinator on contract to the B.C. Ministry of Energy and Mines.

I am writing to inform your readers that the correction on page 9 of the April issue gives an incomplete and possibly misleading description of the requirements of the B.C. Energy Efficiency Act. The correction states that “Metal framed curtain wall, window wall and storefront products must have a

Caledon, Ont., have purchased all the assets of the Collingwood, Ont., plant of the former Barber Glass and plan to reopen the plant as an architectural glass manufacturing operation. Between 40 and 50 workers will be hired for the new company. The deal was closed just before the plant’s equipment was to be auctioned off under the terms of a receivership filing last November. Wilson, a native of Collingwood, was a customer of Barber’s and cited his ties to the community as a factor in his decision to step in. The plant is one of only two facilities in North America capable of producing 10- by 20-foot glass panels.

June 20 - 22, 2011

WDMA Technical Conference

Grand Rapids, Mich.

September 12 - 14, 2011

GlassBuild America Atlanta, Ga.

October 10 - 11, 2011

permanently and unalterably applies motifs, photographs, text, colours or textures on all types of glass with resolutions and hue complexities never before achieved.The process could be a valuable technical tool for architects, designers and decorators who want to produce creative, high-tech solutions. Potential institutional, corporate and residential applications include curtain walls, doors and windows, storefronts, display windows, signs, partitions, furniture, shower doors and floors.

Chronoglass has collaborated with the Menkès Shooner Dagenais Le Tourneux and Provencher Roy Plus Associés architects consortium in the production of the Montreal Casino’s new glass stairway.

Chronoglass can also fabricate laminated glass by inserting different materials between two layers, such as transparent or translucent coloured film, metallic mesh or fabric.

RCI Building Envelope Technology Symposium Charlotte, N.C.

October 27, 2011

Glass Connections

Edmonton Edmonton, Alta.

November 15 - 17, 2011

Win-Door Toronto, Ont.

November 24 - 25, 2011

AIPVFQ Annual Meeting Quebec City, Que.

November 20December 2, 2011

Construct Canada Toronto, Ont.

March 18 - 20, 2012

maximum U-value of 2.57.” This is the case for buildings over 600 square metres floor area and residential buildings five storeys and higher (with some exemptions).

However, the same products, when installed in a building of 600 square metres or less, and residential buildings up to four storeys, must have a maximum U-value of 2.0 (with some exemptions).

-David Bruce P.Eng. Energy Efficiency Compliance Coordinator contracted to B.C. Ministry of Energy and Mines

The CGA Member’s Directory published in April Glass Canada included an incorrect

web address for Calgary’s Griffin Glass.The company’s correct address is www.griffinglass.ca.

BEC Conference

Las Vegas, Nev.

March 21 - 24, 2012

Fensterbau Frontale Nuremberg, Germany

May 17 - 19, 2012

AIA National Convention Washington, D.C.

June 7 - 9, 2012

Fenestration Canada Annual Meeting Montebello, Que.

by PaTrick Flannery

Designers want to turn the things they see in their heads into real objects. Darryl Hudak, 52, is a designer. He studied industrial design at school, and worked through the ’80s and ’90s designing retail products, graphics and furniture, including work on the launch of the Gap’s Old Navy stores. When Hudak looked at an abandoned penthouse storeroom at the top of a classic, pre-war apartment building on Manhattan’s upper west side, he saw a 1,400-square-foot rooftop terrace that was level with the floor in the penthouse space. A vision came into his mind of a beach house in Miami, of moving seamlessly from a relaxed and minimalist interior space out into the wide outdoors: a home without walls.

“I saw an opportunity to marry the interior and the exterior,” Hudak explains. “The elevation of the floor and the terrace were at such a point that it enabled me to envision stepping out of the penthouse to the terrace with only one step.” Built in 1910, at a time when penthouses were not seen as desirable living spaces, Hudak guesses the room was initially a superintendent’s apartment, later used as a storeroom. No one had lived in it for 30 years. But the terrace made it a very rare and valuable find in downtown New York, and Hudak knew he could turn it into something special if he spared no expense on the renovation.

To create the most perfect inside-out feeling, Hudak knew he wanted nothing but glass with as few partitions and seams as possible. However, there are reasons huge glass walls of this kind are more common in Florida beach houses than in penthouses atop New York highrises. Hudak knew he would need a special kind of company to fabricate the window wall of his imagination.

He searched the Internet and found Montreal-based Alumilex. “They were that much more enticing because they are in Canada,” Hudak says. “I thought, ‘If they are in Canada and they are making eight-by-eight spans of glass, they must

Darryl Hudak’s vision was to marry the interior to the 1,400-square-foot rooftop terrace, creating a seamless transition between the indoors and outdoors. Alumilex supplied four eight-foot-square glass panels and an innovative lift and slide system.

know what they are doing.’ You can buy these systems in the southwest and southeast Florida; you can do anything you want with windows there. But on the top of a penthouse in a pre-war building in Manhattan? You have to be careful. This winter we had four feet of snow up against them.”

The window wall was such a key part of Hudak’s design he actually drove to the factory in Montreal to talk the project over with Tony Benzo. “I wanted to see the showroom, so I could feel and touch and get to a comfort level,” Hudak remembers. Hudak was impressed with the courtesy he was shown at Alumilex, which is usually involved in much larger projects. “They treated me extremely well, even though I wasn’t the head of some big real estate developer. They gave me respect and did not look down on my job. That is not common.”

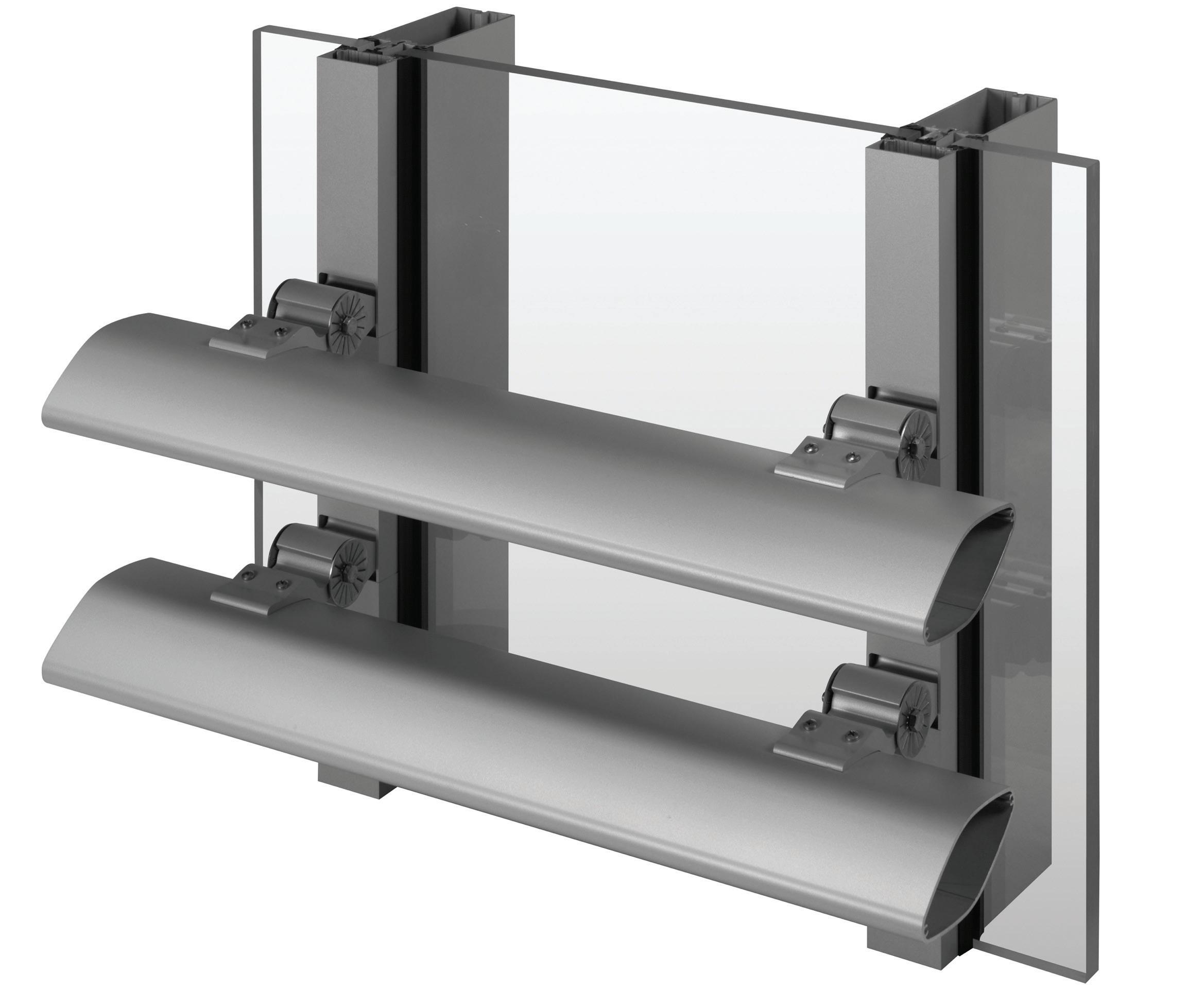

The solution Alumilex was able to offer Hudak was four eight-foot by eight-foot glass panels with an advanced sliding and locking system that allows each panel to be unlocked, lifted slightly and pushed to one side. “I believe we are one of the few manufacturers in North America with these lift and slide doors,” Benzo says. Hudak agrees. “Esthetically, this job could not have been done by any other fabricator.”

Alumilex used SN-68 SunGuard glass from Guardian tempered in and out with argon and a low-conductive spacer. “We had to look at heat gain,” Benzo says. “He

wanted heat gain and SN-68 was one of the best performing low-Es for view values and shading.” Benzo had to take special care with the door design, as well. “It is a patio door that slides and when it gets into locking position, it comes down to lock itself properly. But you basically have to lift the whole panel to slide it. We use very expensive hardware so we can build big, big doors. We did a bi-part and left the two centre panels open in case you want to interlock. So we did a lot of design work and design-build type work.”

One of the great challenges of the project was transporting the huge panels and lifting them into place in the busy confines of the Manhattan streets. “The actual delivery took place about 3 a.m.,” Hudak remembers. “The trucks are so massive and have to be secured so a crane can lift the windows.”

As for the final result, Hudak could not be happier. “I was able to use the same flooring material inside and out: ipe wood,” he says. “It creates a nice visual continuity between the interior and the exterior. The penthouse is only about 450 square feet, but it has all the amenities of an entire apartment. I put floor-to-ceiling drapes on so I have the ability to open everything up. When you walk in, you feel like you are on the beach. All you see is this marriage of the interior and the sky. At night you see a lot of twinkling lights from the city, and I have a sliver view of Central Park.” •

by PaTrick Flannery

Glass Connections provided a chance for over 100 attendees from all walks of the glass industry to come together on May 3 to learn and network at the Delta Chelsea hotel in downtown Toronto. The Canadian Glass Association event was structured around four educational presentations with tabletop displays and a buffet breakfast and lunch.

CGA president Richard Verdon opened the session with a review of the association’s recent initiatives, of which Glass Connections was one. The Toronto session was only the second edition of the new program, following the inaugural session in Vancouver last fall. Verdon said the CGA has been working hard to develop new, CGA-affiliated member associations in parts of the country that do not have them, and he hopes to be able to announce new groups in Manitoba and the Maritimes soon. Verdon also thanked the 14 sponsors who made the event possible.

CGA Technical Committee

chair Leonard Pianalto acted as MC, introducing and thanking speakers.

Chris Barry of Pilkington Glass explained the behaviour of light passing through glass and how it generates different colours. He discussed the best ways to judge the colour of a piece of glass and to avoid common errors in colour matching.

He also discussed heat transmission through glass, and dispelled some common misconceptions about insulating glass and how it works best. It seemed like Barry had a startling and/or useful fact on every slide. He also commented that the glass industry is in fact well ahead of the regulations governments are contemplating for energy efficiency, and that present technology can

ABOVE: CGA president Richard Verdon reviewed association business with about 112 attendees. There were 14 tabletop displays and six sponsors including the platinum sponsor, Dow Corning. Topics included the behaviour of electromagnetic radiation in glass, high-tech glass applications, advances in adhesives and sealants, novel glass designs and a general economic overview.

achieve the highest standards likely to be introduced.

Next up was John Carpenter from Clearstream International. Carpenter presented a number of amazing, high-tech glass applications including super-insulating glass for use in Antarctica, solar panels for the Hubble telescope, bricks for the Madrid train bombing memorial that cause lines of poetry to become visible when lit, and solar power generators so powerful they have the potential to meet the entire world’s power needs using an area equal to four per cent of the Sahara desert. He went on to discuss using daylight in buildings to provide high levels of lighting without heat or glare, showing how advanced glass technology could diffuse light and remove harsh shadows and dark areas. Imaginations were whirring by the end of his inspiring presentation.

Scott Waechter of Dow Corning commented that it seemed unfortunate to follow the previous two presentations with a discussion of goo; nevertheless, he delivered a highly practical look at the differences between organic and silicone sealants and a veritable flood of tips for how to effectively deploy sealants and adhesives in curtain wall applications. “Test, test, test,” was his mantra, saying there are simply too many unique variables in every construction project to take anything for granted.

John Kooymans of Read Jones Christoffersen dazzled the group next with his breathtaking architectural glass creations. Glass staircases, bridges, observation boxes at the top of the Sears tower and enormous skylights opening entire malls to the sky – Kooymans is apparently prepared to build absolutely anything out of glass. Kooymans’ colleague then attracted the most discussion of the day with his presentation of a 300-metre glass pedestrian observation bridge mounted on a semicircular cantilevered suspension bridge that projects from the side of a mountain overlooking a glacier. It was hard for many in attendance to see how it could work, but the photos were right there for all to see.

Finally, Alex Carrick, chief economist of CanData’s economic forecasting group, riveted everyone with a penetrating analysis of the world political and economic scene, culminating in a detailed discussion of the U.S. and Canadian housing markets that supported a number of important forecasts for the next year. This wasn’t a view from 30,000 feet: it was a view from orbit from one of the guys behind the numbers we all read about in the paper. And he was funny. Carrick covered a dizzying array of issues and trends, but his presentation boiled down to set of predictions for the construction industry over the next decade. He saw a long term decline in manufacturing employment for North America, but strong growth for the construction sector. He predicts that China’s growth will slow due to a combination of bad government, labour unrest and a shortage of young workers. Domestic construction will grow for three reasons. First, Canada’s housing market remains strong and growing. Second, government stimulus programs continue to boost building.

And finally, high commodity prices will fuel mega-projects similar to the tar sands that spin off benefits for every other sector in the region. Carrick noted that 200 of the 240 biggest projects in Canada now are institutional, a trend he expects to continue as the Baby Boomers retire and need medical facilities.

The atmosphere was very convivial, with animated discussions going on between speakers and crowds around the tabletop displays. It was clear that the attendees welcomed and enjoyed the opportunity to spend some unstructured time together, and one got the sense that perhaps there had not been enough such opportunities in the recent past. The discussions were so engrossing that Pinalto frequently had trouble calming the room down enough to introduce the next speaker.

Dow Corning, Commdoor Aluminum, Alumicor, CRL Laurence, GTS, Ray-Bar Engineering and Saftifirst sponsored the event.

The next Glass Connections event will take place Oct. 27 at the Delta South hotel in Edmonton. Sponsorships and tabletop exhibition spots are still open. Attendees can download registration forms at www.canadianglassassociation.com, or obtain them by contacting Zana Gordon at 1-604-855-0245 or zgordon@ canadianglassassociation.com. •

The CWDMA has a lot going on right now. Here’s code changes, and the CSA’s new Fenestration Installation

by kevin Pelley

Our Win-Door North America Show, scheduled for Nov. 15,16 and 17 in Toronto, has announced the presentation of important seminars on Canadian building codes as they apply to windows and doors, with special highlights for door manufacturers. To get the word out on codes, the show will offer attendees seminars on the Wednesday and Thursday of the show, led by the CWDMA’s technical advisor, Jeff Baker. As an engineer and renowned expert in fenestration rating, Baker is a respected industry source for factual information on code compliance and such other programs as Energy Star. His two seminars will cover highlights of the new codes as well as special break-out information that relates specifically to windows and doors.

The latest codes in effect – NBC 2010 – will begin rolling out across the country in late 2011 and early 2012, starting in Ontario and Quebec. They will require manufacturers, dealers and installers to meet a host of requirements in such areas as labelling of products for air, water, structural and U-Values. The codes also affect the installation of windows, doors and skylights, and carry sections dealing with sealants, trim and flashing.

It is our understanding that these new codes will be strictly enforced, which means that code officials will be scrutinizing product closely for labelling to ensure it complies with the code, and that it has undergone stringent testing at certified test agencies for a broad range of requirements. It also means installers, building inspectors and new home warranty inspectors will need to be well informed and in the habit of checking work very closely to avoid problems later. In a regulatory environment that is changing, new windows, patio doors,

Here’s a look

The CSA is beta-testing its online exam for its Fenestration Installation Technician certification, which is launching later this year. you can get in early at a discount price by going to www.cwdma.ca and following the links to the test. you only pay if you pass the test and want the certification.

skylights and doors will have to meet a challenging array of requirements comprising air infiltration/exfiltration, wind resistance, water leakage and heat transfer, as well as requirements in the areas of egress, resistance to forced entry, spread of fire, minimum size, overall performance rating, and more. Doors, windows and skylights will be subject to standards based on January design temperature and 1/50 wind pressure ratings by region across the country.

Doors have been an integral part of the national building code for many years; however the new code signals a renewed scrutiny. Products will now require temporary and permanent labels. Entrance doors must have a door viewer or transparent glazing in the door or sidelite. Exterior doors will be given a class (minimum R), assigned a performance grade and tested for size, positive/ negative design pressure (DP), air infiltration/exfiltration and cycles. Exterior doors will have to meet new energy standards and resist forced entry, all the while operating with ease.

Window and door installation certification program

CWDMA is pleased to distribute a questionnaire to assist SAWDAC (the Siding and Window Dealers Association of Canada) in determining the market need for a training program to prepare persons who will be required to obtain

Fenestration Installation Technician (FIT) certification, which is currently in draft form through the Canadian Standards Association (CSA) with support from CWDMA and government. The CSA FIT certification process involves taking an examination with over 100 questions to test and confirm the knowledge of people involved in the installation and servicing of windows, patio doors, doors and skylights. CSA will administer the FIT certification program but does not intend to offer preparation training for the FIT examination. Visit our website at www.cwdma. ca to access the questionnaire – your input would be appreciated.

CSA Standards is launching the FIT certification program this summer or fall. Before the certification exam can be offered, it must be beta-tested to provide valuable feedback to assist in establishing the final exam questions and the pass/fail score for certification. If you are up for the challenge of beta-testing this brand new certification, sign up now. Exams will be deployed at testing centres throughout Canada starting in June 2011. Applications must be submitted by June 1. There is a special, discounted beta tester price of $250. Payment will be collected only if you pass the test and would like to obtain the certification. The beta test will take four hours. Be one of the first to earn certification as a FIT-Level 1. More details are available at the CWDMA website. •

by rich Porayko

The specialty market has rebounded faster than other segments of the glass industry with such projects as airports, hotels, office buildings, labs, recreational facilities, schools and hospitals. Applications for decorative product are all over the map, while exciting new products are launched, including digitally printed product, glass that replicates stone and wood, and lamination featuring innovative fabrics and other materials. Esthetics aside, the common thread across the continent continues to be privacy, colour and daylighting.

Reinvention

“Daylighting is important,” says Joel Berman, president of Joel Berman Glass Studios (JBGS).

“Light transmission is a big deal.” Well known as cast glass innovators for over 25 years, JBGS are designers and manufacturers of architectural glass art in contemporary styles, with decorative products including direct-printed graphics, and back painted, recycled and laminated glass products featuring veneers and wire meshes. “Our products range from production

‘New’

to one-of-a-kind public art,” explains Berman. “For example, we are currently working on a glass iceberg that will be hung from the ceiling of the Winnipeg airport. We are also supplying an airport in Qatar which includes six water walls and various partitioning.”

According to Berman, many of the traditional applications for decorative glass are still strong. Hospitality applications tend to be shower doors or privacy partitions for restaurants and suites. Health-care facilities use partitions for privacy that are passive in

design so they help people feel relaxed. Commercial projects typically include boardroom walls and sidelites. Airports often feature glass sculptures as public art.

Public art is an area of interest that is growing. “We just completed a whole city block of glass in a public park in New York from 29th to 30th street,” says Berman.

Berman says in the last few years there has also been a growing demand for decorative glass in horizontal surfaces, including back

ABOVE: St. Joseph’s Oratory in Montreal, using Starphire Satin 1 Face, tempered and laminated with coated interlayers. An acid etch removed the glare, providing full-colour rendering. Walker can provide acid-etch finishes on clear glass up to 100 by 144 inches. Photo courtesy of Walker Glass.

painted countertops, tables, canopies, floors and stairs, and that JBGS recently completed a glass sidewalk in New York. “As long as we are producing new and different designs, architects and designers gravitate to them.”

“Coloured glass is in high demand. The ability to apply colour to glass is what designers dream about,” says Marc Deschamps, business development manager for Montreal-based acid etch glass and mirror manufacturer Walker Glass. “When acid etch is used on the first surface, it removes the glare and you can really get the full impact of any colour on subsequent surfaces.”

“Architects are also trying to balance daylighting and glare,” says Deschamps. In addition to such applications as wall cladding, acid etch glass is often used in partitions, office enclosures, doors, conference rooms “or anywhere someone would want daylighting to blend with total, or partial, privacy.”

According to Deschamps, the product can be used in vision and non-vision spandrel areas for enhanced colour rendering due to the glare reduction. “Demand for acid etch in such exterior applications as the first surface of an insulated glass unit has been growing stronger,” he says. “An IG unit featuring acid etch on the first surface combined with a high performance softcoat low-e on the third surface offers great performance.”

It is also possible to laminate a highperformance lite with acid etch on the first surface and the low-e coating on the interior number 4 surface. This would allow another coating on surface 5. Deschamps says, “Some of the avant garde architects out there will use a partial acid pattern to create such patterns as stripes and bands on the exterior surface of the curtain wall.”

Deschamps says acid etch is weather resistant because there is nothing else but glass. “We are simply polishing the glass surface and not adding any outside elements to the process,” he says. “We have also launched etched PPG Clarvista shower glass very recently. The product allows for privacy via the acid etch on the outside of the shower and corrosion resistance from the PPG Clarivista low-maintenance coating

on the inside of the shower. Our customers have been telling us it is a winning combination.”

“As architects and designers become aware that it is possible to print almost any type of image or illustration on the surface of glass, demand for digitally printed glass on the exterior has been increasing,” says Colin Thom, director of sales for Langley, B.C.based DSG Custom Glass. DSG is a supplier of digitally printed glass products that feature photorealistic images the company claims will never fade, peel or crack. “Our product mix is mostly interior; however, exterior is growing,” says Thom. “The blend at this point is around 60 per cent interior and 40 per cent exterior.”

“DSG recently supplied a fitness and wellness centre in Montreal where the entire front facade is using direct-printed glass in the IG units,” says Thom. “Using frit in the exterior has a double benefit, because not only does frit provide a decorative element, it also reduces solar heat gain.”

According to Thom, tiling is also becoming increasingly popular in both interior and exterior applications. This is the process of creating a large image or series of images by printing a number of smaller individual lites to generate the overall vision.

“As the industry changes, on the positive side, there is more drive and need for specialty product,” says Bernard Lax, CEO of Los Angeles-based decorative glass pioneer Pulp Studio. “On the negative side, a lot of suppliers that have ventured into the business may not be prepared for some of the challenges specialty products bring in terms of understanding delivery, quality standards, pricing, sampling challenges and the conceptual element of working with a designer from the beginning. Many manufacturers spend more time trying to capitalize on the back end, picking up a job based on price with no investment in the design process.”

Lax continues, “What is really evolving in the industry is, there are many specialty products that are becoming commoditybased, such as back painted glass. These Continued on page 28

Contractor

Blast mitigation technology has progressed to the point where even such buildings as the National Gallery of Canada, seen here, can be made safer. 3M upgraded the gallery’s windows in 2000. Building an understanding of blast mitigation standards and practices could land you some nice contracts in the ballooning institutional construction market.

As the trend continues to expand the use of glass in building envelopes to create innovative architectural designs, the challenge of perimeter security from a blast mitigation or crime perspective remains a daunting task, to say the least. Security consultants or specialists must take a number of factors into consideration that may include several restrictions to making changes to existing structures.

Once the threats have been revealed via TRA (Threat Risk Assessment), the design process of incorporating multiple layers of security begins. In terms of blast mitigation, increasing the stand-off distance is typically the first objective to minimize the blast pressure if at all possible.

The next step involves strengthening the building envelope to meet the required level of protection as per the TRA, and windows are generally considered to be the weakest link. While the interface between window frames and the structure of existing buildings can be strengthened, interior esthet-

ics and costs typically direct the focus elsewhere. Securing the glass will be the focus of this article. Since glass replacement to mitigate an explosive event (whether intentional or accidental) is expensive, retrofitting or upgrading the existing glass has been the most popular and proven method to improve life safety in existing buildings. This also meets sustainability objectives by reusing existing materials. Containing glass fragments during a blast is critical to protect people and property due to the high velocity of flying shards of glass.

In response to the heightened concern about terrorism, test methods were developed to mitigate hazards to people within buildings posed by glass shards propelled by the forces of an explosive event. The most recognized test method in North America remains the openarena GSA (General Services Administration) test method that lists criteria of performance against a real blast event. This standard test method uses

various blasts (using the equivalent of 200 to 500 pounds of TNT) and stand-off distances (ranging from 120 to 190 feet) to produce specific blast pressures on four-foot by 5 ½-foot windows equating to a four to five psi blast load.

Performance Condition 2 essentially means the glass breaks but is held in place. It is important to note that no security film on standard commercial IG units has met Performance Condition 1 in which the glass does not break. It is also important to note that the GSA is a minimum standard and four to five psi is a low blast load. In reality, a blast is likely to be bigger, closer and hitting larger windows than those specified in the GSA test. Therefore, higher blast load resistance (i.e., 14 psi) is desirable to provide maximum life safety protection.

The most popular method of upgrading existing glass is to retrofit applied, optically clear, security window film (also known as window laminate) since it holds the broken pieces together and greatly reduces glass fragmentation into the building. There are two types of security film that are polyester-based with a pressure-sensitive adhesive: basic layered (typically one to three layers from seven to 14 millimetres thick), and micro-layered (typically 28 and 42 layers from four to six millimetres thick).

Although basic polyester films can meet the lower blast loads, the specialized blast mitigation micro-layer films are more commonly selected on projects in Canada and throughout the world. This is due to the significant tear-resistance properties that 28- and 42-layered constructed films provide (more than four times the tear resistance of similar thicknesses of basic layered films).

It is well understood that tear resistance and elasticity of a security film are critical factors in creating a flexible membrane to help capture the energy from a blast regardless of attachment methods. Since micro-layer films are thinner than the basic polyester films, they are able to expand and absorb more energy without tearing, thus reducing stress on the frames. Once the micro-layer film has been penetrated by glass shards, it is able to withstand the positive/negative pressures of the blast combined with the sheer weight of the glass that can easily tear basic polyester, defeating the purpose.

film is key

While attachment of the security film is optional on commercial IG units using

micro-layered technology, it is best to attach the film to the frame to enhance the overall performance of life safety protection. Methods of attachment range from mechanical systems involving screws and metal materials to specialized wet glazing using a bead of structural adhesive. Typically the wet glaze method of attachment is favoured due to the elasticity of the bead and the lower installed cost. Different levels of performance are achieved depending on which specialized wet glaze system is used. Although there are other methods to attach or capture glass fragments, such as catch-bar or cable systems and blast curtains, they are not normally used in Canada due to poor esthetics and higher costs.

Performance-based specifications combined with installation requirements are becoming the most popular method to help ensure the best security film system is selected for the project. As with most quality manufactured products, the quality of workmanship required to install the system must be well understood before the tender is awarded to eliminate problems and project delays. This is especially true with optically clear security window film technologies that upgrade existing glass, since such installation imperfections as dust particles are noticeable and tend to be rejected.

Blast mitigation is rated according to how far glass fragments project into the space beyond the window when subjected to a standard explosive force. The American General Service Administration recognizes six levels (“Performance Conditions”) of blast protection.

Performance Condition

1. Glass does not break.

2. Glazing cracks but is retained by the frame. Dusting or very small fragments near sill or on floor acceptable.

3. Glazing cracks. Fragments enter space and land on floor no further than 3.3 feet from the window.

4. Glazing cracks. Fragments enter space and land on floor no further than 10 feet from the window.

5. Glazing cracks. Fragments enter space and land on floor and impact a vertical witness panel at a distance of no more than 10 feet from the window at a height no greater than 2 feet above the floor.

6. Glazing cracks and window system fails catastrophically. Fragments enter space impacting a vertical witness panel at a distance of no more than 10 feet from the window at a height greater than 2 feet above the floor.

There are also combined energy saving and security window films available that may be of value depending on the application and sun exposure of the existing glass. This can be determined through a site inspection by a specialist who is familiar with this form of technology and has the capability to conduct an energy audit.

Quality manufactured window security films also have a proprietary, scratch-resistant coating that allows the use of ammoniabased window cleaners with soft cloths, which will help to maintain your investment year after year. •

Profilon ER-1 was developed in Germany and is said to be the thickest and toughest retrofit film product available tested to the European ER-1 standards. ER-1-EN 13541 (NS) is a standard requiring the glazing system to be able to withstand a blast over-pressure of in excess of 7.2 psi with a duration of greater than 128 milliseconds.

What does this mean in laymen’s terms?

Profilon ER-1 has been actually tested under both U.S. and European test criteria and has proven itself effective at almost double the current U.S. standards. Profilon ER-1 has exceeded the GSA Class 2 standard tests of the U.S. government.

Why does this matter?

Protection from explosive blasts is not something that happens in a military range or a laboratory. Most acts of terrorism occur in urban settings where buildings and traffic preclude creating large standoff distances from a targeted building or place. The ability of Profilon ER-1 to work effectively relatively close to an explosion means that a higher level of protection can be achieved without the need for expensive re-glazing of a building. This has proven cost effective for many facilities worldwide where access to the building is public and the perimeter cannot be secured sufficiently to set back a threat far enough to prevent catastrophic damage. Thinner films available on the market may fail in this respect, regardless of frame attachment used.

Profilon ER-1 is used in conjunction with Profilon AXA1 - UL/ULC listed security film to provide the most effective protection of a building while keeping an eye on the budget.

Profilon has been a popular choice for blast mitigation for embassies, government buildings, commercial facilities and the oil and petrochemical industries worldwide for over 25 years. Profilon is also used extensively in Canada by facility managers for physical protection of glass against vandalism and break-and-enter and is virtually undetectable on glass with over 90 per cent visual light transmission.

Dymond protective window films were recently used in a 300,000-pound contract at the St. Enoch shopping centre in Glasgow, Scotland, to protect shoppers from the risk of falling glass from the roof.

Despite modern manufacturing methods that make the condition very rare, the risk of nickel sulphide in toughened glass presents an ongoing headache for facilities management companies. Nickel sulphide crystals can cause toughened glass to shatter spontaneously and without warning. If that toughened glass forms part of a large glass roof in a shopping centre, then you can run the risk of killing someone.

Glasgow’s St. Enoch shopping centre is famed for its glass roof, so when the centre was refurbished recently, facilities management company, Ivanhoe Cambridge, wanted a solution to prevent the glass from shattering and risking shoppers’ wellbeing.

Therefore, Deans Ltd., the specialist contractor for the project, installed Dymond Defender two-ply anti-shatter film – an adhesive-backed polymeric film – on the glass units in the roof of St Enoch shopping centre, which will keep them intact should the units unexpectedly shatter.

“Glass panels, like the ones at the St. Enoch Shopping Centre, can weigh up to 30 kilograms, so it is vital that technically advanced systems are used to maintain their integrity,” Ken Amos, Dymond Products managing director, said.

The decision to install Dymond Products’ anti-shatter film was a wise one because one of the glass units did subsequently shatter unexpectedly. However, it was held in place by the film and retention system. The glass was then replaced safely and discreetly out of hours, so that the shopping centre could open as usual without any disruption to business.

Commenting on the suitability of the film on such a project, Ken said: “We are particularly proud that Dymond Defender anti-shatter films have been specified by the U.K. Home Office

Scientific Development Branch for Blast Mitigation for windows in buildings, and the film has recently become one of the first products to pass a new international safety glazing standard: ISO draft 16933 Glass in Building Explosion Resistant Security Glazing.”

Dymond Defender has also been certified to BS EN 12600 Class 1B, BS 6206 1981 Class A and

ANSI Z97.1 Class A. The Dymond Platinum Edge Retention system is certified to ISO 16933, TN47 and GGF 5.18.5.

Dymond products are unlike any other product on the market, primarily because they are supplied by Garware, an integrated film manufacturer.

Cascade Coil Drapery and its recently formed affiliated company, Cascade Coil Defense Systems, has introduced a new blast-mitigation fabric, GuardianCoil.

The patent-pending GuardianCoil works by stopping and/or entrapping flying objects – glass shards and other materials – resulting from external primary or secondary bomb blasts or explosions. GuardianCoil’s interwoven (metal) coils stretch to absorb the flying glass splinters and other objects. GuardianCoil features a special retainment system that works like a glove to catch and deposit glass onto the floor below a protected window.

In multiple tests, GuardianCoil achieved high levels of government safety compliance based on multiple General Services Administration (GSA) government standards for blast mitigation. The company received its GSA government contract in September, 2010; GuardianCoil is offered under two categories, Blast Mitigation and Architectural Drapery.

Cascade Coil president Ron Schoenheit foresees many uses for GuardianCoil in embassies and consulates, airports, military bases, government office buildings and hotels and other private businesses. Hotels in particular are vulnerable targets for terrorists. According to Peter Greenberg, in a CBS Evening News report, “Americanbranded hotels are the choice for terrorists.” The NCTC reports that, worldwide, 60 hotels have been attacked since Jan. 1, 2009.

GuardianCoil is available in four major weaves, ranging from 3/32-inch to 1/4-inch. The

blast-mitigation fabric is produced in regular carbon steel or stainless steel in several gauges. A green product, GuardianCoil is easy-to-clean, cost-effective and even comes in any colour, thus avoiding the prisonlike, negative psychological feel associated with many blast-mitigating products. Over the years, Cascade Coil architectural drapery has filled the need for window opacity, allowing natural light and unobstructed views, and indeed is one of the product’s distinctions.

People like to look outside their windows. This fact of life gives GuardianCoil a major advantage over other blast-mitigation fabrics, which can obscure windows. In more than one instance, Schoenheit learned that workers regularly push back existing blast-mitigating fabrics so they can see outside, thereby negating any blast-protection value.

GuardianCoil is not only translucent so people can see out, it also can be configured to fit any size window. For additional protection inside potentially vulnerable spaces, GuardianCoil can be used as decorative interior partitions or room dividers.

Life safety protection is the key objective when defending against a blast – whether intentional or accidental – to minimize your risk and liabilities. Upgrading existing glass with film has been proven to save lives by keeping glass shards together. 3M invented micro-layer film technology to do just that.

Micro-layers are more flexible and tear resistant than basic layered window film products. The 28 and 42 micro-layer films absorb more blast energy and deter crime to provide a higher level of life safety protection for people and property. Windows are the weakest link in perimeter security. Retrofit your windows by upgrading the glass and strengthen the weakest link in your security system.

by rich Porayko

The 2011 Building Envelope Contractors (BEC) conference was held in Las Vegas at the fantastic Paris Hotel from March 26 to 29. Presented by the Glass Association of North America (GANA), the sessions and networking at BEC were phenomenal. The Glass Week/BEC joint conference was very well attended and was the big highlight of the entire conference. GANA reports 350 attendees including a mixture of fabricators and glazing contractors. The program focused on the economy and the near future of the glazing market.

Diana Perreiah of Kawneer opened the learning sessions with a presentation on the state of the aluminum industry, describing the world megatrends of population growth, urbanization and climate change. Perreiah said U.S. architectural billings are growing, and the worst of the recession is behind us.

Viracon’s Don McCann

provided a very informative presentation called “Glass: If some is good, is more better?” McCann described how the last version of ASHRAE mandated the use of substantially less glass in new buildings. Because of such organized industry associations as GANA, the industry was able to lobby to have the specs changed. McCann also appealed to

the industry to educate architects, developers and specifiers, specifically on window-to-wall ratio and the effective aperture of glass.

AGC’s Serge Martin presented on the state of the glass industry, saying that over the course of the global recession, worldwide demand for glass has dropped 60 to 70

ABOVE: The BEC conference was held at the Paris Las Vegas Resort. It is an annual educational event for glazing contractors and glass company executives. The BEC is timed to coincide with Glass Week, GANA’s larger event that brings together its seven divisions for a number of conferences and meetings. IGMA’s annual conference is in the mix, as well.

per cent. According to Martin, there has been a decrease in North America; however, there has been an increase in South America and China. Martin stressed that North America is not a leading market in glass technology and that glass consumption is 40 per cent higher in Europe than on this side of the Atlantic. In fact, the price for glass has actually decreased over the last 20 years whereas other building products have all increased significantly.

Martin said glass companies need to diversify into BIPV, solar, switchable glass and transportation. He said that from float tank to installation our industry loses 50 per cent of all flat glass through breakage and waste. In order to improve, the glass business needs to reduce waste, increase efficiency and increase value.

A common thread at BEC was making sure the rate of innovation inside your firm outpaces the rate of improvement outside your company. John Rovi of CDC provided a thoughtprovoking presentation called Spring Training: Why it is critical in the Major Leagues (and major contract glazing firms). He highlighted self-training through conferences, classes, reading and volunteering. GANA hosts the BEC conference as part of Glass Week, its novel approach to bringing together the diverse groups that make up its membership. Glass Week is made up of three main events: Glass Week, the BEC conference and the Insulating Glass Manufacturers Association annual conference. Glass Week includes meetings of GANA’s seven divisions: Marketing, Technical, Decorative, Energy, Mirror, Protective and Laminating. The IGMA conference includes board meetings, educational seminars and meetings of the various committees.

At the time of the event, the sad news of western Canada’s Advanced Glazing Systems bankruptcy was breaking with the Barber Glass auction still fresh on everyone’s mind. Over the course of

the next few weeks, Vitro America and UGC were sold off to private investment firms and US Aluminum shut its doors. No doubt, there will be more shockwaves before this is over. All this emphasizes the need to keep yourself sharp through continuous education as

you never know what is going to happen next. •

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@ constructioncreative.com.

Kawneer has introduced Versoleil SunShades: the next generation of Kawneer’s sunshade platform. Versoleil offers a broad range of versatile products to suit almost any project under the sun. Pre-engineered for multiple curtain wall systems, the common component design offers versatility in both form and function. Versoleil SunShades are designed to provide you with the design flexibility to incorporate sunshades easily into any building envelope to help create your vision. The product includes highly configurable blade options for maximum shading and energy saving potential. For more information, visit www.kawneer.com.

With the Sashline, Bystronic glass offers an opportunity to inexpensively manufacture PVC windows. The production line for direct glazing integrates the manufacture of insulating glass units into the production process of the window sashes. A separate insulating glass production is eliminated – this saves time and reduces costs.

Glass plates are directly bonded to the corresponding window sashes and gas-filled on the automatic, vertical production line. This makes it possible to process different glass sizes in a variable sequence, as well as diverse window profiles. “Our customers save up to 20 per cent in production costs compared to the conventional glazing of window sashes with insulating glass,” explains Klaus Puschmann, product manager at the Bystronic glass technology centre, Bystronic Lenhardt, which developed the Sashline. “As a result, the investment in the line can pay for itself in less than a year.”

Bystronic glass presented the first Sash Line for integrated window production at the GlassBuild America 2009 Exhibition. The window manufacturer Northeast Building Products based in Philadelphia, Pa., purchased the first line and is still extremely satisfied with it today. “On average, we can produce up to 720 integrated

sash profiles in mixed sequence per shift on the Sashline. Previously we were only able to produce about half this amount. Even the previously extremely laborious inert gas filling is now completely automated. Thanks to the higher output, we can save one shift in production and can now guarantee our customers significantly lower delivery times,” explains Alan Levin, CEO and president of Northeast Building Products. In addition to the productivity, Northeast Building Products is still particularly impressed by the consistent quality of the end products: “Our previous production that was primarily collaborative was defined by separate processing procedures and no continuous work sequence. Now, we place glass and window sash on the production line in a parallel manner and a staff member is able to remove the completely glazed window sash at the end of the processing procedure. No further user intervention is required during the production.”

For more information, visit www.bystronicglass.com.

Gear Keeper tool and instrument tethers are built for heavyduty industrial use with maximum breakage strength and durability. Designed to survive severe conditions such as extended salt water and chlorine exposure, Gear Keeper retractable tethers are virtually jam-free with a patented flushing system that self clears debris from the retractor mechanism. Long lasting and tough, with millions of systems in use, Gear Keeper tethers have a failure rate of less than .001 per cent. The full line of Gear Keeper instrument tethers and accessories are available on the company’s website at www.gearkeeper.com.

General Glass International has launched the Kaleidoscope Collection using Alice direct-toglass printing. This assortment of seven patterns allows for kaleidoscopic versatility for interior and exterior applications. Inspired by the geometries of fractals, Whisper, Shard, Lucent, Orbit, Stria, Tangent and Coppice are customizable by colour and scale, allowing each pattern to reveal a new context.

Designed for cross-market appeal, GGI

features the Kaleidoscope Collection in six customizable colourways per pattern to inspire and expand your design offering. Applications include wall cladding, entranceways, interior partitions, signage and furniture.

The Kaleidoscope Collection is printed on low iron and low iron satin etch glass, in sizes up to 84 by 168 inches and thicknesses from 5/32 – ¾ inch.

For details, visit www.generalglass.com.

PPG Industries has introduced Solarphire PV glass, a product designed to maximize solar energy transmission for photovoltaic modules.

Because of its exceptional clarity, Solarphire PV glass delivers enhanced transmittance in the ultraviolet/visible portion of the solar spectrum, between 350 and 1100 nanometers, where crystalline photovoltaic cells are most responsive to the sun’s energy. This clarity is the result of a proprietary glass formulation that allows Solarphire PV glass to transmit more solar energy than leading competitive products, which increases the energy efficiency of solar cells.

Victoria M. Holt, PPG senior vice-president, glass and fibreglass, said Solarphire PV glass exemplifies industry initiatives that protect the environment and promote alternative forms of energy. “By creating products that help to keep homes cooler and to improve the energy efficiency of commercial buildings, PPG is committed to making glass an integral part of America’s ongoing sustainability efforts,” she said.

“Solarphire PV glass represents another major advance because it makes the collection of solar energy more efficient, thereby reducing the cost of solar power and making solar technology more attractive to power companies, investors, government entities and other stakeholders.”

Solarphire PV glass is the cornerstone of a series of photovoltaic glass products PPG will be introducing to the solar power industry. To complement Solarphire PV glass, PPG will continue to offer Solarphire glass in its original cerium-inclusive formulation, which maximizes

the service life of solar components by reducing UV light transmission.

For more about Solarphire PV glass visit www.ppgsolarphire.com.

Advanced design and technology support extreme reliability in the new Center Lock and Strike Housing from Dorma Glas. Featuring the technology of Dorma’s ML9071 heavy-duty Grade 1 mortise lockset, the Center Lock incorporates high-strength springs and a positive stop that eliminates lever sagging.

The footprint of the new unit measures a sleek five inches by nine inches. Features include a core changeable cylinder and a latch bolt operated by a lever on either side.

The Center Lock permits exit from the inside even when locked. Special keying is available direct from Dorma or from local locksmiths. Standard finishes for the Center Lock and Strike Housing are satin stainless steel and clear anodized aluminum. Additional finish options are available on request. For further information, contact Dorma Glas at 1-800-451-0649.

by FRANK FULTON

Frank Fulton is president of Fultech Fenestration Consulting. He has been in the industry for 30 years and can be reached via e-mail at fultech.fc@gmail.com.

In my last column we looked at how the passing of legislation in certain jurisdictions in the U.S. has led to the opening of litigation floodgates, washing away legions of window and glazing companies. It got me wondering why nobody seemed to see this coming or take any action to head it off.

Let’s face it, the glass and glazing contracting industries in the U.S. and Canada are not much more than a disjointed rag-tag collection of individual companies. There is no strong collective voice standing up to protect the rights and interests of companies in the industry. Unlike the electrical and mechanical trades, our industry commands nowhere near the amount of respect it should, considering the level of expertise and skill that goes into our trade.

Because of the way bureaucracies, governments and standard-writing organizations function in Canada, our industry could be at risk of legislation similar to that recently enacted in the U.S. In Canada’s industry, the organization does not exist with the strength, the industry backing and sufficient resources to protect our interests.

So, who is to blame for allowing your business to be in such a tenuous situation, just one faceless committee vote away from introducing crippling legislation or building code changes? It is you, the person who does not support your association, who contributes to the overall apathetic nature of our industry and puts us all at risk.

Sure, we have the Canadian Glass Association, made up of glass associations in British Columbia, Alberta, Saskatchewan and Ontario. Glass companies in Manitoba and all points east of

It is you, the person who does not support your association, who contributes to the overall apathetic nature of our industry and puts us all at risk.

Ontario have no representation whatsoever. The thing that disturbs me most is that there are at least 1,500 companies in Ontario in the glass, metal, and related products industries, and only about six per cent of those are members of the two associations that are trying to represent them, the Ontario Glass and Metal Association and the Architectural Glass and Metal Contractors Association.

The glass associations in Canada do the best they can with dedicated volunteers from the industry, but for the most part the money, resources and wherewithal necessary to safeguard our industry and your business at the jurisdictional level are just not there. Our industry can only be as strong as you are willing to make it through membership in your local association and participation in its boards, committees and events. All things considered, membership is pretty cheap insurance.

This all brings me around to the recent Glass Connections 2011 conference in Toronto in May put on by the Canadian Glass Association with the OGMA and AGMCA as host associations.

I had the pleasure of attending the event in Toronto and I must say that it exceeded my expectations by leaps and bounds. All five presenters were knowledgeable and articulate and their topics were very interesting and informative, at some points spellbinding, at others funny, but always entertaining. Although it was a very full day, it never seemed to drag, and some of the presentations seemed to come to an end before you had heard enough. It really was that good, and a refreshing change from the daily grind.

The only thing missing from this great event was representation from our industry in Ontario, the very people it was meant to promote. Just over 100 people signed up to attend, and of those maybe 20 were glazing contractors, maybe less. Quite frankly, the lack of participation was a huge disappointment.

Participation in our industry associations makes us all stronger. The only way they will be there for you in the future when you need them is if you support them now. •

by BRIAN BURTON

Brian Burton is a Business Development Consultant for Kleinfeldt Consultants. He can be reached at bburton@ kcl.ca.

Alittle over a year ago, the federal government pulled the plug on the EcoEnergy Retrofit Homes Program, which was designed to provide grants to homeowners with up to $5,000 for pre-retrofit assessments and energy retrofits.

When they suspended the extremely popular program they gave the public and the businesses involved approximately 24 hours’ notice.

The suspension came as a major surprise and there were several formal petitions to Parliament. According to NDP Member of Parliament Olivia Chow, “The program had proven economic benefits and realized significant reductions in greenhouse gas emissions.” The petition also mentioned that the cancellation threatened an entire industry of professional renovation contractors across Canada.

Having worked extensively in the insulation industry for most of my career, I knew immediately that there was a lot more going on here than the general public would ever know about.

The Conservatives were spending something like $150 million per year on the program. They topped the fund off with another $80 million in the budget that brought down the government and triggered the recent election.

The Conservatives, Liberals and New Democrats all promised to reinstate the program because in theory energy efficiency measures help create economic activity. They also have the added benefit of saving homeowners more money on energy bills. This money can then be spent on other goods and services, providing another boost to the economy.

Unfortunately, this is a significant oversimplification of the issues relating to energy efficiency in residential

typical

structures, reduction of carbon emissions and predictions regarding consumer spending habits.

All of these government programs have serious limitations because close to half of the money is spent on government administration and conducting the actual energy audits rather than specific improvements or upgrades.

The C.D. Howe Institute went so far as to suggest we were literally “burning cash to warm our homes” in a recent report. In the report the Institute cited studies that show nearly half the people who receive grants for retrofitting would have completed the upgrades regardless of government incentives.

Although these programs are generally viewed in a positive light by the window, glass and fenestration industries, the plain fact of the matter is that undertaking a residential energy audit and accomplishing upgrades is much more complicated than it first appears.

In Canada a typical home contains over 100,000 individual building components and functions as an integrated system in which alterations made to one element will affect the other components.

Effective evaluation of energy performance requires consideration of the elements that affect heat, air and water vapour flow while at the same time recognizing environmental factors, including weather, humidity, solar radiation, air quality, durability and the safety of the occupants.

In most cases the greatest improvements are typically obtained by simultaneously reducing unwanted air leakage, improving thermal characteristics of the building enclosure and using techniques to recover energy, while at the same time replacing and/or modifying any environmental control systems that consume energy.

Effective energy audits should also include recommendations with regard to moisture control, ventilation and reducing demand by improving the occupant’s knowledge of the factors that affect energy consumption.

In my view, before reinstating the program, we would be well advised to lobby the Canadian Construction Materials Centre to put out an open RFP tender to study the entire issue to ensure the program functions efficiently. •

products, which have a big product range on the market, used to be mainly ceramic frit or silicone. Now we have back painted products that are more environmentally friendly, water-based coatings that are more open to customization and wider variety of colour.”

According to Lax, the biggest dilemma in the industry is that there are a lot of people who still don’t understand the dynamic differences between these coatings, and the challenges or benefits between one type of product and another. “What is lacking in the industry is the educational aspect of the business. The contract glaziers aren’t out there trying to understand the differences and nuances of the different products and the industry is doing nothing to educate them.”

To the detriment of everyone in the business, decorative products, which are among the most expensive products in the glass industry, have typically been purchased from the lowest bidder. Lax says, “It amazes me that companies still buy based on a promise and not based on research or fact. You end up with a company buying tens or hundreds of thousands of dollars worth of glass from resources that may or may not be viable vendors and not knowing some of the basic differences.”

“I rarely have any glass company ask me about the warranty,” says Lax. “People are always in a hurry to bid a job so they go with the lowest number and it doesn’t always pan out to be a successful project. There are jobs out there with the wrong product installed that have poor performance, which has an impact on the entire product range. It comes down to buying the right product. And that lack of education in the industry is the basis of people making good or bad decisions. Whether it is graphic, laminated or back

painted product, it comes down to the decision maker who is buying the glass and what that person knows about the product and the selection of the vendor.”

It is obvious that graphic imaging is becoming more popular and with it comes the issue of colour sustainability on the exterior. “There are people that don’t understand what the sustainability issues are. The first questions they should be asking before anything else are not about the price but about sunlight testing and warranty information on the colours. Yet there are many installers that are buying product and never asking about warranty or sustainability. It is happening slowly. As the industry becomes more aware, we are seeing more and more educated buyers asking questions.”

Architects and developers are always looking to gain energy benefits, however they ultimately want a building that also looks good. “Some of the biggest decorative trends we’ve been following are for products outside the building that offer solar benefits such as shading coefficient and still have decorative elements such as sunshades,” Lax explains.

Pulp has recently launched a new product Lax describes as including different decorative elements suspended inside an insulated glass unit that minimizes the need for having high-maintenance sunscreens on the exterior of a building. “If you are a true decorative glass producer, every week is a different product. The key to being successful is to be able to make any product in any given week and carry the inventory of the components you need to do so,” says Lax. “There are opportunistic companies that jump in the market for certain job specific products that they don’t stock all the time. The true producers of these products are usually carrying inventories and can deliver a certain amount of that product any given week.” •

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

by JOHN ROPER

John

Roper is the editor for The Installer, The Fabricator, The Conservatory Installer and Glass Works magazine published in the U.K.