Labor-Saving

Shim It Once and Done. SAVE

Grove Shims™ has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Shims™ has the perfect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect alignment. No guesswork or realigning. Our shims save you time and money. Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com Free Samples are Available Upon Request.

Grove Shims™ is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

GLASS CANADA

The glass industry has come up with different approaches during the pandemic to train the next generation of talent entering the workspace.

High exposure and long life

There’s a couple new CSA standards in town – A440.6 and S478 – and David De Rose is the man with the information on both. A440.6 is a new standard for high-exposure fenestration that covers the right way to install and seal punched windows, continuous windows and window wall above four storeys. De Rose helped write both these standards, and he dishes on what’s in them and where they might be going in the future.

14 The condensation equation

Research shows how spacer technology affects condensation in the Canadian climate.

Safety helmets have been keeping the heads of construction workers safe for ages. Further advancements in design can now help prevent more injuries.

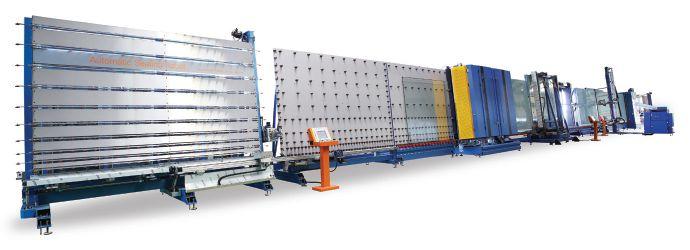

The things you need for great IG.

“All

Vectors of change

EDITORIAL

that is solid melts into air.” - Karl Marx

I don’t think I’m alone in feeling the ground shifting under my feet to a degree and in directions that I never thought possible. For most of my life, it has felt like change has come fairly gradually and in the form of incremental movements along previously established trends. 9/11 was an inflection point on that journey – a sudden event that shocked the world into sharp and long-lasting realignments of previously stable dynamics. The pandemic seems to be an event of comparable impact, and it’s happening in conjunction with political events that have people questioning the very viability of democracy as we’ve understood it for the last couple centuries. Simultaneously, and working to drive change and upheaval on both of the other two fronts, the influence of social media on the way we understand the world continues to accelerate. I wonder if this revolution in the way we communicate could have similar unintended consequences. Let’s bring these fuzzy musings about change around to what we are seeing in our industry right now.

NEXT ISSUE

• New CCDC

• Top Glass

• Xinyi glass plant

I do think the long-term future of the office tower and high-rise condominiums has been put into serious question by information technology, sharply accelerated by the pandemic. Most professionals don’t need to work out of an office any more and haven’t needed to for some time. But they continued to go in mostly out of inertia – the office was already there, it’s how the company had always operated and their bosses liked to see their smiling faces. Then the pandemic forced companies to make the change...and the results were not bad. Just about every company now knows that it can let its workers work from home and save money on office space. There are downsides in terms of company culture and teambuilding, for sure, but I find it hard to imagine they would overcome the hard dollars and cents associated with building leases, maintenance, office supplies and all the other expenses that come with maintaining a large facility.

If you don’t have to go into an office every day, why live in 500 square feet in a glass ant hill when you could move an hour out of the city and have a house, yard and no traffic for about the same price? Yes, I know the kids like the lifestyle. I also know most get tired of it within a few years.

I don’t predict complete abandonment of downtown cores or anything radical like that, but I do see the potential for a depressed market for new space going forward, and less maintenance and renovation work. Energy efficiency upgrades might mitigate some of that.

We talk about another, much more welcome change, on page 24. Glass Canada has joined with several other construction publications to participate in Women In Construction, a special channel dedicated to celebrating the achievements of women in Canada’s construction industries and promoting more inclusion. We’ve all watched as more and more women join our workforces and establish themselves in great careers. And we’ve all scratched our heads as to why there haven’t been even more and how we can get more young women to take a look at what we do. Here’s a chance to recognize a change that is already happening and to drive it forward, to everyone’s benefit.•

GLASS CANADA

February 2021

Volume 33 • Number 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquires or changes, please contact Shawn Arul, Audience Development Manager

Tel: 416.510.5181

Fax: 416.510.6875

Email: sarul@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE EDITOR | Sukanya RAY GHOSH srayghosh@annexbusinessmedia.com 647.203.7031

PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

NATIONAL ACCOUNT MANAGER | Amanda McCRACKEN AMcCracken@annexbusinessmedia.com 519.429.5234

ACCOUNT COORDINATOR | Barb Comer bcomer@annexbusinessmedia.com 519.429.5171

MEDIA DESIGNER | Alison KEBA

VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax) U.S.A. - 1 Year $85.00 (in CDN dollars)

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

ACCESS. SUPPORT. SAVINGS.

With the combined expert resources of AAMA and IGMA, the Fenestration and Glazing Industry Alliance (FGIA) brings industry leaders together to improve home and building performance through better glass, window, door and skylight technologies and standards.

Why join? An FGIA membership gives you access to an indispensable support network of peers as well as product certification from the industry leader in standards. Members also get access to FGIA’s full technical resource center and receive discounted rates on training, certification and professional development. Whether as an individual or business, joining FGIA will give you an advantage in an increasingly competitive industry.

Join the alliance today at Join.FGIAonline.org. FGIA gives your business a competitive advantage.

NEWS

Rhetoric heating up in battle over Xinyi float glass plant

Xinyi Canada’s proposal to build a $400 million float glass plant in Stratford, Ont., is on indefinite hold following delays by city council to vote on a cost-sharing agreement, according to reports from multiple news outlets. Stratford council claims the Ontario COVID lockdown is somehow interfering with its ability to make a decision. The proposal has met opposition from residents concerned about the plant’s environmental impact and the zoning process. A prominent musician is leading the charge against the proposal. This is Xinyi’s second attempt to make a deal with a southern Ontario municipality to locate 300 jobs in the province. Guelph, Ont., rejected Xinyi’s proposal in 2018 on the grounds the plant would use too much groundwater. Frank Fulton had some choice words about that one in his October 2018 column titled “And there they were...gone.” Fulton pointed out that the sole substantive objection to the plant locating in Guelph was over water use, but that the projected water use for the Xinyi plant was still below the threshold defined by the province as “dry in-

dustrial” and was less than other industries in the area use, such as Nestle Waters Canada. Fulton criticized Guelph council’s decision as a cave-in to NIMBYism. NIMBYism would appear to be back in the case of the Stratford proposal. Xinyi says its proposed plant meets all relevant environmental regulations. The proposal has even received a grant from Environment Canada to fund its energyefficient heat recycling system. Now, a CBC report by Colin Butler quotes Xinyi project manager, Chris Pidgeon, calling opposition groups looking to block the proposal “elitist” and “prejudiced,” suggesting anti-Chinese sentiment could be behind the continued opposition. He points to calls by Get Concerned Canada (a lobby group formed for the purpose of opposing the project) to have the area’s local Conservative MP question the Liberal government in Ottawa about Xinyi’s links to the Chinese government. GCC denied any bias and called Pidgeon’s comments “offensive” and “terrible.” Look for a full technical review of the Xinyi proposal in the April issue of Glass Canada. •

JOE SHAPIRO PASSES

On Dec. 22, 2020, industry veteran Joe Shapiro passed away at Sunnybrook Veteran’s Centre at the age of 97. Frank Fulton, president of Fultech Fenestration Consulting, notes, “Joe Shapiro was one of the pioneers – and one of the characters – in the glass business. He was a co-founder of Sealite Glass with Fred Fulton in the late 1950’s, one of the first independent small businesses manufacturing the new insulating glass units at the time. After Sealite Glass was sold to Glaverbel Glass, Joe started and operated Airlite Glass for many years.” Joe was the beloved husband of Shirley Shapiro; loving father and father-in-law of Neil and Dee and Michael and Debbie. Dear brother of Bernie and the late Freda Bernstein, Hilda Caplan, and Lou Shapiro. Devoted grandfather of Jared and Shelby, Lorraine and Jon, Daniel and Rachel, Zak, and Kyle. Devoted great-grandfather of Noah, and Benjamin. A graveside service was held on Dec. 23.

CANADA’S GLASS ASSOCIATIONS

FenBC

Weare all happy to see the end of 2020. This was a very hard year on all of us. FenBC would like to commend its membership on their leadership and commitment to a safe working environment for everyone. Also, a heartfelt thank you to the supportive community of construction associations here in B.C. FenBC held its Fall Webinar Series from October to December 2020. Over the three months we held 15 separate webinar sessions. Sessions included topics on the current state of the Red Seal Glazier apprentice training program, high performance windows, codes, laminated glass and aerogel, among other things. FenBC will be holding its Winter Webinar Series starting in January 2021. FenBC in partnership with BC Housing have completed and updated the guide Best Practices for Window and Door Replacement in Wood Framed Buildings. FenBC is accepting pre-orders for this important guide. The National Glazing Systems Specification manual is due to be completed in the beginning of the new year. The National Building Code cycle for 2020 is almost completed… almost. FenBC spent a lot of hours online with some of its fenestration colleagues. I would like to give a personal thank you to Jeff Baker from WestLab, Robert Jutras from AVFQ and Margaret Webb from FGIA for your knowledge of our national codes and the subsequent consequences of these code changes to our industry. Soon, here in B.C. we will be looking at our provincial codes. FenBC entered into a work-

ing partnership with FGIA this year. The two associations will be working on some projects together. At this time, we are not sure about our annual golf tournament in May 2021.

AGMCA

Following elections held at its recent Annual General Meeting, the AGMCA is pleased to present its board of directors for 2021: Tony Menecola, president (Applewood Glass and Mirror); John Bastedo, vicepresident (National Contract Glazing); Barrie Eon, treasurer (AGMCA); Kline Holland, director of labour relations (ret. AGC Glass); Joe Buck, director of training and apprenticeship (ret. Merit Glass); Bill Byers (Transit Glass and Aluminum); Angelo Cairo (Stouffville Glass); Tim Isaak (Peninsula Glass ); Noel Cunningham (Flynn Canada); and Noel Marsella, executive director of AGMCA. All board members can be reached by contacting info@agmca.ca On behalf of all of the unionized glazing contractors it represents, the AGMCA wishes to extend its deepest thanks to its volunteer board of directors for giving their time for the betterment of our industry, as we face another challenging year ahead.

AVFQ

The Quebec Government wants to make sure the economy does not go down. This is why it has just approved Bill 66 which will speed up 181 infrastructure projects. In addition, all these projects will be included in a pilot project currently in place, which aims to speed up payments to the

companies involved, as well as conciliation processes. Great news for our members in the commercial and institutional sectors! The Quebec government has set up a program aimed at retraining employees who are in areas that are very highly affected by COVID-19. The AVFQ works closely with governments and vocational training centers to implement quick and effective solutions. The AVFQ is adding more for its 2021 events in Quebec in the glass and fenestration industry. AVFQ’s annual conference will be held from Feb. 17 to 18 this year, in virtual mode. The theme of the conference is “Navigating a new sea.” Relevant conferences and innovative sponsors will provide an experience that should not be missed. Since training is an important mandate of the AVFQ, window installation training is being offered that leads to installer certification. A second hands-on training on the same subject is also available. The latter presents video clips demonstrating good practices. These six-hour webinar training sessions are available in French or English. For more information, contact info@avfq.ca. The AVFQ is closely involved in the Market Transformation Initiative of Natural Resources Canada. In addition to being represented on the advisory committee by its executive vice-president, Gina Gaudreault, the AVFQ also occupies three seats on the windows experts team. This work will have a significant impact on the future operations of our members. This is why our involvement is essential. The AVFQ would like to thank its members who collaborate, participate, and get involved.

PGAA

The PGAA has suspended most activities due to the pandemic. Our planned online directors meeting on Jan. 20 was postponed until our online Annual General Meeting planned for March. Keep your eye on pgaa.ca for details as they become available.

OGMA

Become

an OGMA member: If you are conducting business in the glass industry in Ontario, the OGMA is the voice that represents your interests at the provincial and federal level. Protect your business interests by becoming a member or as an associate member if you are a consultant to the industry. Please visit the OGMA website for more information. The year 2020 has been very difficult for many of us and it has been especially challenging for the OGMA. All of our events are geared towards physical attendance which we were not able to do. Because of this the OGMA will not be charging any dues in 2021 to companies that had paid their 2020 invoice. With the release of multiple vaccines there is light at the end of the tunnel and we plan to resume events next year as soon as it is safe and practical to do so. We hope to see all of you in person in 2021 and resume our role as the networking facilitator of our industry. The OGMA plans to assist members in the meantime by rolling out technical white papers prepared by our knowledgeable members. Stay tuned. •

The

AODA

deadline is here already

EEffective Jan. 1, the Access for Ontarians with Disabilities Act requires websites for non-profit, public and private companies with over 50 employees to meet a wide-ranging set of requirements for accessibility or face fines of up to $100,000 per day for corporations and $50,000 per day for directors and owners. The requirements are extensive and there are very few websites in this industry that would comply. Text needs to be convertible to large print, braille, speech, symbols or simpler language. Video and audio must have captions available. Simplified layouts must be offered. All functions must be accessible with a keyboard only without use of a mouse. These are just a few of the requirements. By law, new and significantly refreshed public websites must be made accessible if you are a private or non-profit organization with 50+ employees; or a public sector organization. The organization that controls the website must meet the accessibility requirements. Complete details of the requirements and penalties are available on the Government of Ontario website.

Quebec streamlines infrastructure projects to boost post-COVID activity

The Quebec National Assembly has passed Bill 66, which removes or eases several regulations for 181 large infrastructure projects. Most of the projects are transportation-related, but there are several hospital and long-term-care home projects in there as well. Regulations for land expropriation, environmental review, zoning and awarding contracts have been altered. A good explanation of the changes has been posted by the law firm Osler on its website at osler.com.

StatsCan building permits: November 2020 Serious Labs, GPRC announce partnership

Serious Labs and Grande Prairie Regional College have signed a memorandum of understanding to bring innovative lift-equipment training solutions to the students of GPRC. Together they will implement Serious Labs’ current VR training solutions as well as collaborate on and pilot new learning solutions to achieve an expanded vision and scope for technical training in northwestern Alberta.

“We are excited to be a part of GPRC’s learning initiative right here in Alberta that recognizes the importance of advancements in training and technology in a shifting world,” said Jim Colvin, president and CEO of Serious Labs. “This partnership is synergistic with our own goal of increasing learning engagement and collapsing the gap between vocational training and jobsite readiness, particularly during the added challenge of the COVID-19 pandemic.”

As a first step of this initiative, GPRC and Serious Labs will introduce Serious Labs’ award-winning mobile elevated work platform operator training simulator into a pilot program with the intent of developing a series of micro-credentials to ensure that GPRC apprentices are jobsite ready. Existing skilled tradespeople will also have the ability to augment their jobsite readiness. The initiative will create an added benefit to employers and site owners who will be able to reduce the time and expense of providing additional training to employees.

“GPRC’s administrative strategy, 5GPRC, prioritizes innovation, partnership and the commitment to how our college will provide modern and innovative learning experiences for students in our region,” said Robert Murray, president and CEO of GPRC. “GPRC is well-known for its innovative approach to post-secondary education, particularly in the skilled trades and apprenticeships. Their intention to utilize training tools such as VR simulators demonstrates their next-generation thinking,” said Colvin.

The total value of building permits rose 12.9 percent to $9.4 billion in November, the third highest value on record – with the highest value having been reached in April 2019. Much of this growth was led by large permits for multi-family dwellings in British Columbia and Ontario, and an office building in the city of Toronto. The value of residential permits rose to new heights in November, increasing 10 percent to $6.4 billion and breaking the previous record set in September 2020. Multi-family dwellings rose 14.8 percent to $3.5 billion. A $376 million permit issued for Sugar Wharf Condominiums in the city of Toronto contributed to the record high reported in Ontario ($1.6 billion). Non-residential permits rose by almost one-fifth (19.5 percent) to $3 billion in November, mainly due to a $507 million building permit for the new Cadillac Fairview office building in downtown Toronto. Excluding this permit, the non-residential sector would have shown a slight decline nationally. The value of commercial permits rose by almost one-third (31.2 percent) to $1.6 billion, based on the strength of the Cadillac Fairview office building. Consequently, Ontario (94 percent) reached its second highest level on record. The total value of institutional permits rose by nearly one-quarter (23.2 percent) to $900 million in November, with gains in seven provinces. Newfoundland and Labrador reported the largest increase, mainly due to a $57 million permit for continued repairs to Western Health’s long-term palliative care home in Corner Brook. British Columbia (44.2 percent) had the second highest gain as a result of a permit issued for a new secondary school in the city of Burnaby, as well as two permits issued for new nursing homes in Vancouver and Victoria. Industrial permits fell for the fifth time in six months, declining 9.3 percent to $537 million in November. Five provinces posted a decrease in this component, with Ontario (11 percent) and British Columbia (44.1 percent) registering the most significant drops.

Ontario MOL moves to cap WSIB premiums, recognize N.L. working-at-heights training

In a call with Glass Canada, Ontario Minister of Labour, Training and Skills Development, Monte McNaughton, laid out the ministry’s plans to cap Workplace Safety and Insurance Board premium hikes and to recognize working at heights training certificates held by workers from Newfoundland and Labrador. According to McNaughton, the ministry will move to cap 2021 WSIB premium increases on Ontario businesses at two percent. The action is necessary, he said, in order to offset a statistical rise in the average price of labour in Ontario due to the pandemic. COVID-19 has caused lower-wage workers to be laid off in higher numbers than higher earners. The combination of fewer workers at higher wages would have driven a WSIB premium increase of nine percent without intervention. Benefit payments for workers will not be affected, McNaughton says. The cap applies to the 2021 calendar year.

“We listened to small business owners, many of them contractors with six to eight employees, who told us they might

have to mortgage their houses if rates go up,” McNaughton said. “We’re going to save small businesses $40 to $50 million with this.” McNaughton said the rates will “self-adjust” back to normal when pandemic measures are lifted and workers get back on the job.

The other measure McNaughton announced was an amendment to Ontario’s Occupational Health and Safety Training law to automatically recognize working-at-heights training received and certified in Newfoundland and Labrador. McNaughton referenced especially a “huge” shortage of boilermakers, saying he was responding to requests from automotive manufacturers, nuclear plants and Sarnia’s petrochemical industry to enable 750 boilermakers from Newfoundland and Labrador to work immediately upon arriving in the province.

“We are knocking down barriers to increase labour mobility,” McNaughton said.

Fronsoe joins Vitro Architectural Glass as national architectural manager

Vitro Architectural Glass (formerly PPG Glass) has announced that Chris Fronsoe has been appointed national architectural manager for the Northwest region. In this role, Fronsoe will provide sales and service support to architects, specification writers, glazing contractors, façade consultants and Vitro certified fabricators for the commercial construction market in Washington, Oregon and Idaho in the U.S. and British Columbia and Alberta in Canada.

Fronsoe has years of experience working with glass industry professionals, most recently on both vertical and sloped glazing projects.

“Chris has a strong background as a salesman in a wide range of commercial markets, but he also has an extensive

knowledge of the glass and glazing industries,” said Glenn Davis, vice-president of international sales at Vitro Architectural Glass. “His experience working with fabricators worldwide to set up multinational distribution networks makes him perfectly suited for working with our customers in the northwestern U.S. and Canada.”

Fronsoe holds a bachelor of arts degree in business management and Organizational Leadership from George Fox College in Newberg, Ore. He has served on technical committees with the National Glass Association and has also been a featured speaker at multiple glass industry events, including Glass Performance Days, GlassCon Global, Facade Tectonics and Top Glass.

Construction alliance calls for funds commitment

The Residential and Civil Construction Alliance of Ontario has released a video that calls on the federal and provincial governments to take urgent action and commit more funds to municipalities so that state-of-good-repair projects can be tendered in 2021. The video is based on a report by Prism Economics and Analysis, called “Averting a Crisis: The need to protect Ontario’s infrastructure investments,” which indicates that Ontario is headed for heavy job losses in construction and related industries and a worsening economic crisis if infrastructure investments dry up. The report was commissioned by RCCAO to gauge the impact of possible cancellations of construction maintenance and repair projects by municipalities, universities and colleges, school boards and hospitals. It indicates 41,000 construction-

related jobs are at risk if building permits continue to decline. Overall, 117,000 direct construction, supply chain and broader economy jobs are under threat due to cancellations. Ontario contractors report that project tenders are already down, and hundreds of construction workers have already been laid off.

“They must now follow through on the next phase of funding so that municipalities can give the green light to muchneeded state-of-good-repair projects for 2021,” says Nadia Todorova, interim executive director of RCCAO.

Cities are facing increased costs due to the COVID-19 pandemic. A Safe Restart Agreement 2.0 would provide municipalities with financial certainty so they can proceed with necessary state-of-good repair projects. •

Training at

a distance

Glass industry training and certification during – and after – a pandemic.

by TREENA HEIN

Among the vast number of things that COVID-19 has affected this year are education and industry certification in the glass industry and other sectors. To see how industry members have kept it rolling during the pandemic, we’ve checked in with organizations across Canada and beyond. We wanted to know, how is in-person and online learning working out? And will any uptick in online training and testing stay in place because it’s more appealing to a younger generation of glaziers?

Let’s start with the Finishing Trades Institute of B.C., where glazier apprenticeship training is normally offered in class sizes of 16. Three six-week sessions of classroom and shop learning are provided over four years, with each block (Level 1, 2 and 3) followed by time apprenticing on the job with a union or non-union glazing contractor. FTIBC is currently the only facility in B.C. that trains glaziers to the Red Seal standard.

Online learning was never a serious consideration for the FITBC in response to the pandemic. Director Patrick Byrne explains that the construction trades are so hands-on that online learning is neither practical nor wanted by the students. He adds that “apprentices need to understand in the training that the trades are hands-on physical work that often involves team work. You have to be a self-starter who is strong both physically and mentally in order to succeed. I meet regularly with other building trades directors of training, and they all agree that online trade instruction is very limited in what can be taught effectively.”

Right before the lockdown this spring in mid-March, FITBC was lucky in terms of timing because a Level 2 glazier class had just finished. Byrne and his colleagues shut down all of the apprenticeship programs (glazier, painting, wall and ceiling installer and drywall finishing) and came up with a plan for when the government saw fit to loosen some of the restrictions. That came in mid-June, and they were ready.

Since that time, using various protocols, the FITBC ran four glazing classes, two level 1s, a level 2 and a level 3. There has been no COVID-19 transmission. “Our protocols are working,” says Byrne. “We reduced class size to eight and reconfigured some of the mock-ups so that they could be used individually. We have careful oversight by our instructor, Mark Longmore, we have hand sanitizer stations and do a lot of hand washing. We did constant cleaning at the start of the pandemic but as we’ve learned about this virus, it’s more about mask wearing and social distancing than anything else. Mark has found training to be challenging in this new environment but has found ways around that.”

According to Longmore, the most difficult part of training during this pandemic is the fact that students now must work on projects as individuals, whereas normally they would team up with partners on some of the more complex tasks. “The protocols that we currently have in place don’t allow for the collaborative problem solving that used to take place between the apprentices during the course of the day and that’s unfortunate,” Longmore says. “However, on the upside, working individually can expose weaknesses that may have not have come to light as readily as when you have a partner there to point those out. This allows me to focus more on those areas of concern.”

The FITBC apprenticeship programs are also now segregated so that each trade is isolated from the others. Normally, there are important and necessary interactions between the students in each

trade, like on a job site, but now, each trade has its own shop, classroom, lunchroom and washrooms. “We shut down the free coffee and vending machines and now everyone brings their own lunch and coffee,” says Byrne. “We will continue with this until the provincial health office gives us the green light on returning to normal. We’ve consistently had a 90 to 95 percent pass rate and despite COVID-19, that’s continuing.”

Online and in person

However, at FTI Ontario in Toronto, online learning has been used significantly since the pandemic began in March. “At that point, we were in the third week of a Level 3 eight-week class that had started out with 16 people,” explains glazier apprentice, and health and safety instructor, Steve Laird. “We then started up online modules to cover another three weeks of class. These are the IFTI Learning Management System online courses that have been around for ten years and they are free to use. But then we had six students decide they didn’t want to continue with the online learning. We had a lot of discussion with them, and we told them they wouldn’t be able to come back for a while and they were fine with that. They are all now slotted in for January’s Level 3 class.”

The remaining 10 students were allowed to return to the building in mid-August to finish the practical part of Level 3. Laird explains that physical distancing is indeed an issue in Level 3 when the students work in pairs or groups of four, but in Level 1 and 2 the students pretty much work on individual projects. “It was actually good that the six didn’t come back because with physical distancing, it would have been difficult to accommodate 16, but 10 was okay,” Laird says. “We were pretty keen to get this group in because every student had all their apprenticeship hours and just needed to finish the practical Level 3 and write the exam. But at this point (early December), they still haven’t been able to write their exam.”

FTI Ontario also does certification courses for WHMIS, elevated work platforms, swing stages, forklift operation, hoisting and rigging, eight-ton and

Pre-pandemic, hands-on training involved a lot of group projects. This has now changed to individual work only.

In-person courses are being offered with reduced capacity of students and with mask and distancing protocols in place.

smaller cranes and so on, but they’re on hiatus and Laird says it’s not cost effective to create online versions. “United Rentals has online courses for forklift and scissor lift, with simulators in some places, and then you take the practical exam with them or one of their partners in more remote locations,” he observes. “Use of this may expand in future and it’s great but expensive.”

This fall, FTI classes for each level

have been kept to ten. The theory part of each level is proceeding online and for the practical part of each level, FTI is alternating two different levels between two parts of the building. Staff brought in a washroom trailer so that each group has its own as well as another fridge and coffee machine.

Laird believes the online courses are working well in that students can do them at the speed they want and keep

the course material for reference. “They get to see the theory in action when they come in for the practical, and it’s working OK,” he says. “I get a lot of questions by email and we work through them. But you don’t have the discussion you have in person. When we are in the same space for the practical, there isn’t as much discussion either because it’s not worth the bother with a mask and it’s tough enough to ask questions. It’ll be great to be back to normal. Our classes are filling faster because they are smaller and waiting list is growing.”

“Apprentices need to understand in the training that the trades are handson physical work that often involves team work.”

– Patrick Byrne, director of FITBC.

Online goes in-person

The story of how the pandemic has shaped online and inperson learning is quite a different one for Administrative Management Systems. This U.S.-based company administers the North American Contractor Certification program for glazing contractors in Canada and the U.S., and in 2019 started the Architectural Glass and Metal Technician certification program for individual glaziers.

To understand this, we need to know how certification went before COVID-19’s arrival. At that time, there were only a few support materials available to contractors in terms of learning about the program’s quality management requirements and their benefits. “Very few companies used them,” says AMS’s Ben Beeler. “Due to the pandemic we had excess time on our hands and we realized we could create resources to bridge the disconnect between how contractors currently addressed quality in their business and how they could be benefiting from implementing the program requirements for certification. So, we developed a free, online workshop and started offering it to individual contractors, an introduction to quality management processes and their benefits. One, two or three people from the contractor company sit down with us virtually, and it’s a great way to answer all their questions and explain everything.”

Pretty soon, however, companies were asking for further workshops to delve into the various aspects of the quality management requirements. AMS then developed five more, four on specific elements of quality and one on safety. “We had no idea how popular it would be,” says Beeler. “We thought we’d have to talk people into having the initial workshop. And while most of the workshops are done with companies going through the initial certification process, we’ve been shocked that companies already certified wanted to have workshops, to further improve their quality management and ask questions. During the workshops they’re presented with lots of examples of how quality management processes and procedures might be put in place in their business, which is the biggest part of certification.”

These workshops, says Beeler, have cut the certification timeline for participating companies roughly in half. “If we had known this before, we’d have put the workshops in place long ago,” he says. Indeed, the existence of these online workshops has caused AMS to think about offering them in person as well, in various cities after the pandemic is over, to a large group of representatives from different companies. [Glass Canada readers will have a chance to take part in one of these workshops for free at Top Glass on April 21. - ed.]

AMS rolled out AGMT certification for individual glaziers in 2019 and had planned its first in-person testing session in Canada in spring 2020. The certification test involves a written test to assess a glazier’s knowledge as well as a lengthy physical test to assess their abilities. Beeler explains that normally, the written test is done on a laptop with a proctor present in a group setting. But since the pandemic, AMS has offered the test to individuals in Canada and the U.S. through a service that administers the proctoring remotely. That is, to take the test, the glazier sets up his/her computer’s webcam before logging into the test and also sets up a second camera (generally on the applicant’s cell phone) that allows a proctor to view the student from the side. Beeler says however that classroom testing will likely resume after the pandemic as it’s easier and more comfortable for the applicants. •

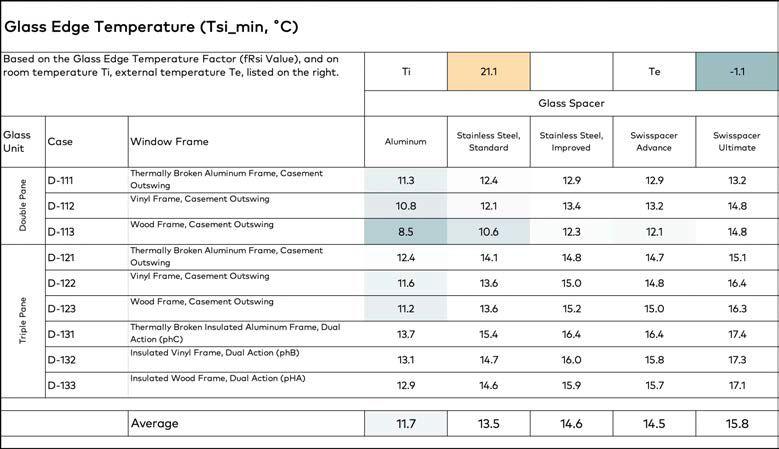

The condensation equation

A new study takes a look at the effects of spacers on condensation in Canadian climate conditions.

If there’s going to be a condensation problem in a building interior, it will show up at the glass edge first. Ironically, today’s airtight builds can make the problem worse.

The thermal quality of glass spacers dramatically affect the physical properties of one of the most critical areas of the entire building thermal envelope – the interface between window frame and glass unit. The spacers influence the heat flow, resulting in higher heat losses and consequently lower localized temperatures along the glass edge.

The glass edge is one of the places condensation occurs sooner than anywhere else in a building. Since its 2012 update, the International Energy Conservation Code (IECC) has been pushing buildings to be increasingly more airtight across America. This is great news for overall building durability through avoidance of exfiltration and associated moisture-driven damages. Increased building air tightness also leads to significant improvements in energy efficiency, thanks to the reduction in heating and cooling. However, a more airtight building envelope leads to higher relative humidity inside buildings as uncontrolled air leaks

contribute to removing moisture water vapour from inside buildings. According to ASHRAE Standard 160, a family of four produces 2.5 gallons of water vapour every single day. This means that regardless of how humid or dry a climate may be, moisture comes from within the building.

Proper moisture management in buildings has evolved into an interdisciplinary field, bridging architectural detailing, window specifications and structural and mechanical engineering. The more buildings become airtight and insulated, the more they behave as one physical object where all parts are interrelated. Today, the selection of a window product (including glass spacers) has consequences on the mechanical system in the effort to avoid mould/ condensation, and vice versa.

Unfortunately, the evolution of building standards (until the 2018 IECC update, at least) has still failed to mandate this interdisciplinary approach, resulting in manufacturers and professionals being incrementally more exposed to liability.

This table shows the minimum temperature factors (fRsi_min) necessary to avoid condensation at different combinations of internal relative humidity (RHi), and external temperature (Te) - room temperature Ti is assumed to be 21°C.

Even the condensation resistance method established by the National Fenestration Rating Council does not provide a conclusive method to prevent condensation in fenestration products.

Given these circumstances, the impact of different glass spacers on the performance of window products is assessed both in terms of heat flow (U-factors), as well as of surface temperatures to avoid condensation.

The study conducted by Swisspacer was executed by creating combinations of five glass spacer products and nine window frame profiles. The 45 resulting combinations were evaluated in terms of localized heat flow (frame and edgeof-glass U-factors), whole-window heat losses (total U-factor) and glass edge temperatures.

The condensation resistance (CR) method defined by NFRC assigns a score to the fenestration product. This is executed by averaging internal surface temperatures resulting from three separate simulations (that is, at 30, 50 and 70 percent relative humidity).

The purpose of the CR score is to allow different products to be compared to one another, not to assess the actual risk of condensation on one specific product as part of the design process.

Due to its mathematical nature, the CR score does not represent a tool to be

used in professional practice, in combination with other design parameters.

For this reason, for the purpose of calculating localized internal temperatures on the glass edge with the goal to avoid condensation, this report refers to the temperature factor’ method (fRsi value) as described in ISO 13788.

fRsi = ( Tsi_min - Te ) / ( Ti - Te )

• fRsi: temperature factor

• Ti: room temperature

• Te: external temperature

• Tsi: minimum localized lowest temperature on the model considered

Once the fRsi value is calculated with the finite element method, the localized lowest temperature on the internal surface can be calculated by reversing the above formula as: Tsi_min = Te + fRsi * ( Ti - Te )

Nine different window frame profiles were selected as part of this study, with the intention to cover a range of frame types, materials, operation, glass units, and overall energy performance. While the list of frames included does not cover all options available on the Canadian market, it can be considered to be significantly representative for the scope of this report. Five types of glass spacers were used in the modeling, in order to provide a wide enough range of performance for the analysis. For greater accuracy, the spacers were modeled according to their actual materials and geometry rather than

using the two-box model. Two types of insulated glass units were considered for the modeling. All glass units were modeled sealed with hot melt butyl.

Risk of condensation

Condensation occurs as a combination of localized low temperatures (Tsi_min), and relative humidity inside the building (RHi). NFRC condensation resistance is purely an averaged score over multiple data points, and it is designed to allow comparisons between different window products. However, it is not of use when trying to assess the risk of condensation on one specific product.

The ISO 13788 temperature factor method is designed specifically to estimate the risk of condensation on the internal surface of building components, including fenestration products. The localized lowest localized temperature (Tsi_min) on the internal surface of the combination of window frame/glass unit/ glass spacer is calculated with formula 04, based on the fRsi value, and the internal/external temperatures Ti, Te.

The temperature factor described in ISO 13788 is the same as illustrated in CSA A440.2, with the only difference being that the CSA method relies on testing on a physical specimen instead of FEM modeling.

INNOVATIONS

This table shows the lowest temperature on the glass edge (Tsi_min), resulting from the combination of the temperature factors, room temperature (Ti = 21°C), and external temperature (-1.1°C).

Conclusions

The Canadian construction industry is undergoing significant changes in terms of how quality is measured in buildings, and the expectations and liability that come with it.

Energy codes now require buildings to be airtight, yet they still fail in thoroughly addressing the consequences associated with this practice in terms of building science and proper moisture management. Design teams often still limit their work to traditional siloed scopes, without realizing how interrelated different portions of the building have become. For example, specifying a traditional aluminum glass spacer now has consequences on the building moisture management, and impacts other scopes of the design (e.g. the mechanical system). This increase in risk of moisture-driven damages is still largely unknown to many Canadian architectural glass professionals.

The purpose of this report was to assess the impact of different glass spacers on the performance of Canadian fenestration products. The evaluation covered

“Energy codes now require buildings to be airtight, yet they fail in addressing the consequences associated with this practice.”

both energy performance, and avoidance of moisture-driven damages.

Improvements were noted on the whole-window U-factors provided by using better glass spacers. Compared to the baseline of aluminum spacers, the use of warm edge spacers such as Swisspacer Ultimate allows reductions in heat losses by up to over 22 percent and about 16 percent in average across all window products considered. Improvement of the window energy rating was also evident for residential use, depending on the type of glass spacer used.

However, the critical advantage of using warm edge glass spacers lay in the higher glass edge temperatures resulting from the heat loss reduction. Warm edge spacers provided considerably higher

glass edge temperatures compared to the aluminum spacer baseline: from 4.1C temperature difference at -1.1C external temperature, to 8.7C temperature difference at -26.1C external temperature. With buildings becoming more airtight and closer to zero energy consumption, accurate detailing and selection of climatesuitable components become critical steps towards ensuring project success. The results of the analysis summarized in this report clearly show how much of a difference warm edge glass spacers can make both in terms of energy efficiency, and prevention of condensation. •

This paper was prepared by Emu Systems for Swisspacer. A section of the paper has been reprinted here with permission from Swisspacer.

by KAYDEEN LAIRD

FGIA Education Manager

Pivoting to online education

As we have slowly eased into the new year, there is more hope that most things will get back to normal in the coming months. But no matter what, 2020’s impact will remain in some ways – including the development and expansion of remote training. While some of our educational content was already remote-friendly, a lot of work went into pivoting those that were not to an online platform. FGIA’s education team has been working around the clock to deliver the valuable professional development that our members have come to appreciate and expect. Here is a rundown of what changed in 2020 as we all learned to adapt.

InstallationMasters: The pandemic made homeowners more interested in home improvement and the benefits of daylighting and fresh air, which can both be met with properly installed windows and doors. As a result, FGIA is now offering a virtual option to qualified, currently accredited InstallationMasters instructors so they can train installers to be ready when homeowners begin to seek fenestration-related improvements.This interim virtual training option is only available for a limited time, and the expiration for virtual classes will be communicated as the situation with the pandemic continues to develop.

IG Fabricators Workshop: Ever since its launch in 2016, this popular training event has hosted more than 300 industry professionals, leading them through the most important aspects of fabricating and testing IG units. Because it is such a hands-on, participatory event where indi-

FGIA’s education team has been working round the clock to deliver valuable professional development that our members have come to appreciate and expect.

viduals must be in close proximity to get the full experience, it was not feasible to host in 2020. However, FGIA is committed to bringing it back as an in-person training opportunity in 2021. In the meantime, an FGIA task group has explored extending the reach of this event by addressing the topics covered in the annual workshop through a new online video series, which is targeted to be available on an on-going basis later in 2021.

FenestrationMasters: The FGIA education team further demonstrated its industry commitment by launching FenestrationMasters 2.0 in its entirety last fall, which includes updated content reflecting current technical documents and standards, as well as code requirements in a redesigned, more interactive platform.

FGIA Webinars: The FGIA webinar program was already a great remote training opportunity. FGIA hosts a webinar each month, except for months featuring FGIA conferences. This program provides a convenient vehicle for communicating important FGIA and industry messages to members and non-members, covering issues including U.S. and Canadian codes and regulations, trade tariffs, product performance under hurricane conditions, market size analysis and sustainability.

In response to the pandemic, the organization issued a member feedback survey. Results were taken into account when planning webinar topics and speakers. This has continued in the planning for 2021’s slate of webinars as well.

Despite the challenges and with the support of our members, FGIA was able to adapt to a new way of life and doing business in 2020 by converting traditionally in-person trainings to an online format. The organization still values advanced education and doing its part to ensure a skilled labour force in the industry. We welcome your ideas as we move forward. Meanwhile, we hope to get to see folks in the industry in-person soon. •

FGIA

Go bird-friendly What you need to know about bird-friendly glass

Ongoing research as shown that a visual cue must be used on surface one in order for birds to avoid the glass surface. But this creates some challenges for glass fabricators.

Bird-friendly. It seems like we hear it all the time, but what do we need to know in order to best satisfy our clients’ needs, budget and building aesthetic?

Building designs, facade materials and green initiatives continue to evolve and interplay as urban areas move into an ecoconscious era. From the growing use of electric cars, to energy-saving devices, to thermostats and smart HVAC systems, the green evolution is becoming ubiquitous. Glass in and of itself is a recyclable material, and coating innovations improve overall building efficiency. So glass figures to be a material of choice in green design.

As an industry, our goal has been to establish buildings that are habitable and healthy for humans. The use of low-E coatings, insulated glass units, interlayers and glazing all play a part into how large a glass system can be while maintaining a comfortable living and working space. From an environmental standpoint, these same technologies play a pivotal roll in a building’s thermal insulation, solar heat gain characteristics and overall energy conservation.

Many of these innovations have been inward to best serve both human and energy conservation requirements, but now

the evolution of exterior architectural glass is underway, generating a fully realized, green, eco-conscious product from the inside out.

The issue

Up to one billion bird strikes are estimated in the U.S. and up to 25 million strikes are estimated in Canada every year. This staggering number of bird fatalities typically occurs from low-rise and residential buildings.

To put this figure into perspective, one of the worst environmental disasters in history, the Exxon Valdez, killed an estimated 250,000 birds. Thus, the toll windows have on the wild bird population is the equivalent of up to 4,100 Exxon Valdez spills every year.

A leading figure in the study of bird strikes is Dan Klem, Jr. who has been studying bird collisions since 1974. According to Klem and his sizeable body of research, birds simply can’t see glass. More specifically, window reflection is the leading cause of daytime bird strikes, while lights left on after sundown are the leading cause of nighttime strikes.

The answer to the nighttime issue is evident: turn off building lights. The American Bird Conservancy’s Lights Out

ETCHED GLASS

Pros

• A number of style options

• Medium-sized application up to 96 inches by 130 inches

• Low-E coating option

• Economical cost

• Highly durable marker on surface one with a 10-year warranty

Cons

• Size limitations. Typically, these products range in the “medium” sized glass and may be difficult to implement for oversized applications.

• Pattern visible to the naked eye

• Alignment and design consideration to produce the best building esthetic can be challenging.

• May require frequent cleaning in dense urban areas.

recommendations are focused on educating building operators on this phenomenon and taking corrective action. However, daytime strikes are not so clear-cut. Due to reflection a visual cue must be used on surface one to assist birds in seeing the glass object.

Lastly, a majority of bird strikes fall below a 16-foot height due to the fact this is a common measure of trees and objects necessary to land, nest and rest.

From a legislative standpoint, federal, provincial and municipal requirements surrounding bird-friendly design are coming to fruition. Toronto led the way in specific municipal mandates regarding bird-friendly building conformance. Since 2010, the city has required new developments to adhere to the Toronto Green Standard, which contains birdfriendly mandates.

For example, on new buildings that require bird-friendly glass, visual markers can be no smaller than five millimetres and no greater than 100 millimetres apart. Dependent on the building type and location, 85 percent of the lower level (below 16 to 18 feet) must contain bird-friendly glass. The mandate also contains all variants one may face including buildings on grades, glass balconies, fly-through conditions, parallel glass surfaces and rooftop vegetation.

In Toronto, all new building designs

UV COATED

Pros

• This product is incredibly effective against bird strikes, while being all but clear to the human eye. Extremely durable.

• Low-E coating option

Cons

• Size limitations. Typically, these products range in the “medium” sized glass and may be difficult to implement for oversized applications.

• May require lamination

• A UV coating may require the same type of glass (and size) to be used throughout the entire project for consistency.

• Can be very expensive

CUSTOM-PRINTED FRIT

Pros

• Printed frit allows for the use of oversized glass, up to approximately 130 inches by 300 inches for oversized application.

• Design of the dots and dot pattern can be unique, and even branded.

• An efficient square-foot cost on par with etched glass

• Various glass types and suppliers can be used.

• Can be laminated with any coated glass.

Cons

• Dot pattern visible to the naked eye

• Alignment and design consideration to produce the best building esthetic can be challenging.

• May require frequent cleaning in dense urban areas.

“From a legislative standpoint, federal, provincial and municipal requirements surrounding bird-friendly design are coming to fruition. Toronto led the way in specific municipal mandates regarding birdfriendly building conformance. Since 2010, new developments are required to adhere to these mandates.”

must comply with the Toronto Green Standard, which are then approved through the planning approval process.

It’s not a matter of if you need to know bird-friendly glass as a glazing professional – the requirements are already here. The following is what you need to know to best satisfy a client’s specifications.

Know your standards

In 2019, the Canadian Standards Association released their first document to solidify the practice of bird-friendly building design. The standard, CSA A460:19 takes a prescriptive approach to bird-friendly design and construction, taking into consideration an enormous body of resources, including opacity and geometry of facade materials, in order to best mitigate fatalities.

For architectural glass, the two-by-four inches rule is the gold standard deterrent.

What is the two-by-four inches rule? It is a guideline that states horizontal lines or patterns must not be more than two inches apart, while vertical lines or patterns can be no more than four inches apart. Keep this in mind as a rule of thumb when considering which bird options will perform the best.

Surface one – It’s your time to not shine

“Because daytime strikes are often attributed to exterior reflection, it is necessary for visuals to be on surface one for best effectiveness,” says Marc Deschamps, director of products and business development at Walker Glass Company.

Bird-friendly glass comes in a variety of options, all of which have benefits and drawbacks. As a glazier, here is a running list of what you should know.

#1 Etched glass

As the name suggests, acid etch glass specific to bird-friendly applications. The etch must be on surface one. First are the size considerations: etched birdfriendly glass is available in 96-by-130 inches maximum. Next, thickness considerations. Thicknesses range from three to 12 millimeters. Available makeups include clear, low iron or tinted glass substrates with or without low E on the second surface. Eteched designs include lines or dots two inches by two inches to four inches by four inches and can feature organic patterns as well. The design will only be effective if it follows the two inches by four inches rule. An example of an etched bird-friendly product is Walker Glass’ AviProtek E Pattern 215.

#2 UV Coated

The UV coated option appears transparent to humans, but completely visible to birds in the 300-400 nanometre spectrum. It’s available up to 102 by 144 inches from Guardian BirdFirst or 96 by 130 inches from Walker AviProtek T. Thicknesses are six millimetres with special considerations. Aviprotek T offers a UV marker on surface 1 on clear or low iron glass; SN 62/27, SN 68, and NU 78/65 from Guardian BirdFirst also has the technology. The designs are two-inch bars, lines, patterns or dots, two inches by four inches

Walker Glass’s AviProtek T is an example of the UV-Coated variety of bird-friendly glass.

#3 Custom-printed frit

Printed frit is a dot pattern that allows for oversized glass dimensions and creative branding solutions. This option is the most versatile with the ability deliver on varying thicknesses and glass types. It is scalable from one to hundreds of custom dimensions. At Agnora, we can do 130 by 300 inches on our DipTech printer. Sixto 19-millimetre thicknesses are possible. Because it’s a custom item, the makeup of bird-friendly fritted glass can be specified at the time of order. Designs can include lines, patterns, dots or a custom design. An example of a custom frit bird-friendly product is Pilkington OptiWhite with a two inches by two inches custom shape or oversized.

Use case as a glazier

In the previous section we described the attributes of materials. In this section we will explore the pros and cons of each type to help you ask right questions and select the correct architectural glass product.

To create oversized printed frit, Agnora employs the Dip-Tech NEraD Series ceramic printer and its unique ability to print oversized architectural glass. This $3 million investment in print technology allows for any design to be applied to the glass substrate and projects often extend in scope beyond traditional bird frit. “We see a huge number of specialized projects,” says Joe LindseAgnora’s digital print specialist. “The Dip-Tech is a phenomenol tool and it allows us to

use a great range of colour, opacity and custom mixtures to create unique results such as art prints, custom edge frit or bird frit.”

Other considerations, specifically for bird-friendly glass includes dot alignment between units and limits on the final glass sizing. “Bird-friendly glass is still in its infancy,” says Lindsey. “We see people just asking for bird-friendly, without detailing the type of pattern, opacity, spacing and even alignment between lites or IGU’s that they want. These are all things that need to be considered. These are all things that are important to the look of the final installation. It’s better to get it correct from the beginning.”

Each of the above scenarios should be considered when either designing for a bird-friendly application, adhering to a specification or selecting replacement lites for a project. These important considerations should also be accounted for when choosing to align yourself with a birdfriendly product and fabricator.

In closing, do not think of bird-friendly as a product that is just a “check box,” but rather an opportunity to help define an esthetic for a building and helping to achieve an architectural vision while conforming to requirements and eco-conscious design. As requirements for birdfriendly glazing become more common in Toronto and beyond, we will all have to use our creativity to continue to produce great facades that also protect our feathered friends.•

Dots on the glass surface act help birds avoid fatal collisions.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows. He can be reached at David. Heska@wsp.com.

Case solved

Happy New Year to all of our Glass Canada readers! I hope you had a restful and enjoyable time off and that you were able to be active outside during the holiday season. Everyone in my family was up bright and early on Christmas Day and the fresh snow allowed us to put our new toboggan and GT Snowracer to immediate use. A few days later I picked up a fictional mystery novel and was able to quickly read through it. Everyone loves a mystery case solved, right?

In my December column I presented a recent project case study example that I have been working on for a two-storey warehouse and office building constructed 40 years ago. The client knew that their aging windows needed to be replaced and hired us to complete an evaluation. We presented them with three options. Option one: refinish the frames and install new double glazed IGUs. Option two: replace the entire window system with a new double-glazed system. Option three: replace the entire window system with a new triple -lazed system.

I have received many emails and comments related to this example. One person suggested “Start with a high-performance frame. Some double-glazed windows perform better than tripleglazed”. Another person stated “What is the capital outlay for each option? What is the difference in the insulating values? What is the life cycle of each?” These are all great points. It is true

I think we need to be taking the ROI question a few steps further and consider not only the financial return on investment but also the social and environmental factors.

THE ENGINEER

that there are some double-glazed windows that are better than triple-glazed, and answering the return on investment question is always valid. I think we need to be taking the ROI question a few steps further and consider not only the financial return on investment but also the social and environmental factors. For example, what is the embodied and operational carbon comparison for the three options outlined above? Which is the most sustainable and durable?

In the end the client decided to proceed with the second option: to replace the entire window system with a new double-glazed system. This option was chosen in part because the majority of the building enclosure is the roof. In fact, the roof represents 85 percent of the enclosure area. Fourteen percent of the building enclosure is brick wall and less than one percent is windows. Using simplified modelling, we determined that the existing enclosure had an insulating value of approximately R13. (Please note this insulating R-value is well below current code requirements, but small-scale retrofits typically do not have to comply with current code). We presented the client the modelling results that showed by upgrading to a triple-glazed system we would only be able to achieve an improvement to R14.

If the windows represented more than just one percent of the building enclosure, or if the client wanted to consider a complete enclosure renewal, our recommendation would likely have been different. But in this case the double-glazed option was selected. Our design specified a high performance five-inch frame, new double-glazed windows with argon glass fill, a low E coating on surface #2 and a thin-wall stainless steel spacer. The specified frame options allow for triple-glazed IGUs if at some point in the future the client wants to upgrade. The building permit is currently being obtained and construction will begin in April. •

KEEPING YOUR HEAD

Why aren’t construction workers wearing safer helmets?

by PETER HALLDIN

Construction can be a dangerous industry. Across North America, construction professionals – whether ironworkers, sandhogs, electricians or plumbers – build the tallest buildings, the longest highways and the most awe-inspiring infrastructure that has forever been the foundation of moving a national economy forward. They do so knowing the risks inherent in achieving big things – and knowing that things can sometimes take a bad turn, with one in every 10 construction workers being injured every year and companies bearing the financial brunt of those injuries in both workers’ compensation costs and lost time on jobs.

When jobsite incidents occur, it’s a worker’s safety equipment that can often mean the difference between going home, going to the hospital or going to the morgue.

Safety helmets are the most ubiquitous piece of equipment found on any job site. They are the extension of a worker’s personality, often meticulously decorated with stickers from past jobs, union affiliations or favorite bands and beverages.

But many of those helmets are missing something: a piece of technology that can reduce the risk of a traumatic brain injury.

Construction companies outside the U.S. utilize MIPS technology (Multi-directional Impact Protection System) inside the helmet, which is an insert that reduces the risk for rotational motion injuries. When something falls from height or impacts from the side and strikes a worker on a job site, it never hits straight on. There is almost always an angled force that comes to bear, rotating the head inside the helmet and causing trauma to the brain. MIPS technology allows the helmet to rotate, reducing the rotational motion that may cause stress on the brain.

The MIPS brain protection system is designed to add protection against rotational motion transferred to the brain. Rotational motion affects the brain and increases the

helmets?

risk for minor and severe brain injuries. When implemented in a helmet, MIPS can reduce rotational motion by redirecting energies and forces otherwise transferred to the brain. The core of MIPS is a low-friction layer that allows the head to move 10-15 millimetres relative to the helmet in all directions, reducing rotational motion to the brain. MIPS makes the helmet safer and adds protection.

Rotational motion from an angled impact can cause strain in the brain that can lead to tearing in the brain tissue. This information is based on data gathered using sensors inside crash test dummy heads. The dummy head, wearing a helmet, was subjected to an angled impact in a test rig at the MIPS lab in Sweden. The test showed the strain in the brain from an angled impact when the dummy head was wearing the same type of helmet, with and without MIPS.

Statistics show that many brain injuries occur due to angled impacts to the head. However, in standard helmet tests the helmet is dropped vertically onto a flat surface and this does not create an angled impact. These results are helpful for measuring precise vertical impacts, but inferior for measuring a more realistic scenario of an angled impact.

The MIPS test rig is developed for testing angled impacts to simulate a fall during a crash. Depending on what type of helmet is tested, the helmet is dropped from 2.2 to 3.1 metres onto a 45-degree impact angle covered with grinding paper.

MAIN: The MIPS brain protection system is designed to add protection against rotational motion transferred to the brain.

ABOVE: The dummy head, wearing a helmet, was subjected to an angled impact in a test rig at the MIPS lab in Sweden.

Three different types of impact points are tested and all helmets are tested in all sizes.

Data is gathered using nine accelerometers inside a Hybrid III crash test dummy head and analyzed using finite element models. The same helmet model is compared with and without MIPS to make sure the helmet passes the strain reduction criteria MIPS have on all approved helmets.

More than 27,000 tests have been conducted at the global test centre in Stockholm, Sweden. In addition to that, a number of third-party tests have also been made supporting MIPS safety claims.

Many sport helmet brands offer bicycle, ski, hockey, motorcycle, and other helmets with MIPS technology. Yet a survey shows that most North American construction helmets lack the inclusion of MIPS technology. Construction workers deserve the same protection.

In an industry where safety is universally touted as “a top priority” or “job number one,” we think putting safer technology into the hands – and on the heads – of every North American construction worker is an absolute necessity. •

Peter Halldin is CSO and co-founder of MIPS, and a researcher at the Swedish Royal Institute of Technology. Together with Hans von Holst, a Swedish neurosurgeon, they founded MIPS, a brain protection system – engineered to add protection to helmets.

Photo

Credit:

MIPS

This one’s for the ladies

Women In Construction will promote women in the construction trades March 8

You’ve heard this one before: an estimated 257,100 workers across Canada will retire in the next decade, roughly 22 percent of the country’s 2019 construction labour force, while only 227,600 workers will enter the workforce during that same period, according to BuildForce Canada. That’s a shortfall of nearly 30,000 workers across the country just to maintain the current pool of workers, not including any additional workers needed to support growth. Where can we look for the workers we will need going forward? It’s a question with a few potential answers, but in 2019 there were 182,000 women in the construction sector out of a total work construction sector workforce of 1.463 million, according to the Daily Commercial News. Given women make up about half the population, that number is about a third of what you would expect it to be. Getting more women involved in the trades and construction has been a dream in the industry for a long time. A combination of factors continues to both create barriers to women who might be interested in the trades, and to depress interest in the trades among women.

Glass Canada, in conjunction with seven other Canadian construction trade publications, has joined in an initiative to try to tackle these issues from both ends. Introducing Women In Construction, a special online channel dedicated to celebrating the achievements of Canadian women in construction trades and business. Anchored at the women-inconstruction.ca website, Women In Construction compiles profiles, news stories, videos, podcasts, feature articles and images to show the world – and women considering a career in the industry – what prominent women are doing in Canadian construction. The first week of March will see exclusive rollouts of new content on the website and the social channels of the eight collaborating magazines, culminating in a special live online event March 8, International Women’s Day. The March 8 event will include two interactive panel discussions: Driving Change in the Construction Industry, which will celebrate top women leaders in the field, and Solving Challenges Women Continue to Face in Construction, which will bring together women who are fighting to increase inclusivity for some brainstorming and problem-solving.

Event date: March 8

Time: 2:00 EST

To register: Follow link on the glasscanadamag.com homepage

MARCH 8 AGENDA

Keynote – Building a better Canada: The power of diversity and inclusion in the construction industry

Mary Van Buren, president, Canadian Construction Association

The future growth of the construction industry will depend on its ability to attract, develop and retain women and other under-represented groups. Mary Van Buren will speak about the importance of inspiring the next generation of workers to join the multi-faceted field of construction. She will discuss what needs to happen to foster an inclusive construction industry and initiatives CCA has spearheaded to actively champion diversity.

Mary Van Buren is the president of the Canadian Construction Association

(CCA). Mary is a proven leader with an exceptional track record in advancing member interests by introducing innovative world-class member services, promoting the value of the profession and advocating adoption of technology and standards to improve professionalism. She excels at creating and communicating a compelling vision combined with focusing on developing and empowering people to generate positive outcomes for members. An expert in marketing, communications, strategy and digital, she has worked in the private, public and not-for-profit sectors and has held executive roles at leading associations and not-for-profits, including the Canadian Medical Association’s subsidiary, MD Financial Management, and Export Development Canada.In her previous role as vice-presidentof marketing and IT at the Canadian Real Estate Association, Maryled a team of 60 to grow its premier services, Realtor.ca and WebForms into the double digits.

Panel: Driving Change in the Construction Industry

Marg Latham, P.Eng., CMC

Marg Latham is a professional engineer and certified management consultant. She is president of Aqua Libra Consulting, a management consulting firm. Since starting her business in 2010, she has helped public and private engineering organizations improve professional practice and quality management. From 2000 to 2009, Latham was a vice-president with consulting firms, UMA and AECOM where she implemented management systems to improve client delivery. She spent the first 20 years of her career managing institutional, residential and infrastructure projects in Toronto, Winnipeg and Vancouver. In 2001, Marg was named ‘Outstanding Woman in Construction,’ an award co-presented by the Vancouver Regional Construction Association and Canadian Construction Women. In 2017, Marg was shortlisted for the Women in Infrastructure national award for ‘Outstanding Leader.’ In June 2019, she became chair of the Board of the Canadian Centre for

Women in Science, Engineering, Trades and Technology (WinSETT) and actively volunteers her time to increase the number of women in science, engineering, trades and technology.

Stephanie Rota, CEO, Carmelin

Design Build

Obtaining her MBA from the Schulich School of Business, Rota leans on this education in running the business today. Her experience working for a real estate developer gave first-hand exposure to all aspects of a build. With a focus on customer experience, Rota ensures clients are informed and consulted on every aspect of the project. In the industry, Rota is a contributing columnist for Canadian Contractor magazine and will be serving on the BILD Renovator Executive Council for 2021.

Panel: Solving Challenges

Women Continue to Face in Construction

Jennifer Green, Skills Ontario