Shim It Once and Done. SAVE

Shim It Once and Done. SAVE

Grove Products, Inc. has the perfect shim for every job every time.

Grove Products, Inc. has the perfect shim for all your shimming needs. With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help.

1-800-72-GROVE

Visit us online to see all of our available solid 3x4 Shims.

www.groveproductsinc.com

Free Samples are Available Upon Request.

Grove Products, Inc. is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

Knowing

Top Glass returns to the International Centre in Mississauga, Ont., on April 17 and you can check out our incredible lineup of educational speakers at topglasscanada.com. There’s something for architects, contractors and fabricators alike. All sessions qualify for OAA Structured

Producing spacer in-house can help you step into mass production.

The Ontario Glass and Metal Association is calling for nominations to its annual Awards for Excellence.

handling showcase

Lift it, tilt it and store is safely with these innovative handling solutions.

Glasstec is your chance to see new thin-glass technology

EDITORIAL

February 2018

We can only guess where new developments will take us.

I’m writing this at the start of the new year, which always seems like a good time to take the 30,000-foot view and try to get a sense of where things stand before we drive ahead. Just about everyone I talk to is busier than they want to be, which leaves the question of whether it’s time for investment in the business or to stuff money in the mattress for the inevitable rainy day. Oil prices are still low, so this little boom probably owes more to the surging American economy and its spillover effect on Canada. Change is often viewed with suspicion and fear, but the incredible pace of change these days seems to me to be creating conditions of great opportunity for companies that make the right moves going forward.

Volume 30 • Number 1

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

CIRCULATION MANAGER | Urszula GRZYB ugrzyb@annexbusinessmedia.com 416.442.5600 ext. 3537

MEDIA DESIGNER | Curtis MARTIN

DIRECTOR OF SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Ted MARKLE tmarkle@annexbusinessmedia.com

• Top Glass show issue

Looking through PwC Canada’s 2018 real estate forecast, some of the strongest statements are about the ongoing strength of the industrial market fueled by demand for logistics and warehousing, which is fueled by the steady increase in online shopping. Let’s put this trend together with some other trends. Condo developments in urban centres designed around a “live-work-play” lifestyle continue to lead all types of residential development in popularity. The mass baby boomer retirement is gaining speed, though many of them leave their day jobs to make as much or more freelancing in their old sector. Governments continue to be concerned about climate change and are throwing money at infrastructure with both hands.

• Booth previews

All signs point to steady urbanization and densification in our built environment. We’re transitioning to a different lifestyle where people do all of their living, working and playing on a smaller footprint, with less travelling around, and have stuff brought to them. I think we need to think less about single-family homes, malls, storefronts and office towers. We need to think more about mixed-use high-rises, train stations, warehouses, community centres and retirement homes. And the glass in all of them performing at the very highest levels of energy efficiency.

On the topic of change, we do have one important change in the magazine for 2018. After eight years of providing great insights and technical information on his Fenestration Forum page, we bid a fond farewell to Brian Burton as a columnist in this magazine. Burton started writing for Glass Canada in 2009, when he was working for Can-Best labs. He later moved on to Kleinfeldt Consultants then Exp, which positioned him to bring the latest in building envelope science to our pages. I want to thank Brian for all the thought and great writing he put into every column.

Burton can’t be replaced, so instead we have invited David Heska, a director with the southwestern Ontario building sciences team for WSP, to contribute a new column titled The Engineer. In this space, you’re going to find the very latest thinking in building science, including discussion of solutions to technical glazing problems, review of new standards and discussion of innovative design approaches. David is going to make a name for himself right off the bat with his first take in this magazine: a defence of reduced window/wall ratios to improve energy efficiency! Check it out on page 10. •

PRESIDENT & CEO | Mike FREDERICKS

Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

CIRCULATION email: asingh@annexbusinessmedia.com Tel: 416.510.5189

Fax: 416.510.6875 or 416.442.2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $36.50 (includes GST) ($39.55 includes HST/QST) U.S.A. - 1 Year $64.00 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

Vicwest has announced it has secured site plan approval with the town of Stratford, Ont., to expand its current manufacturing facilities, expected for completion in the second quarter of 2018. “The expansion of the Stratford manufacturing location allows Vicwest to amalgamate its Ontario-based operations into one centralized location,” said Bernard Lewis, senior vice-president of operations. “Currently, the industrial mills have been operating from our Oakville, Ont., location. This buildout will allow for the Oakville mills to be moved to the expanded Stratford facility. The Oakville offices will be moving to a new facility in Burlington, Ont., at the beginning of second quarter 2018.”

The move of the equipment from the Oakville facility to the expanded Stratford location is a strategic one, positioning Vicwest to continue to bring quality and innovative products to customers. Streamlining the

manufacturing to one central location will provide the opportunity for products to ship from one centralized location versus a second pick-up. The Stratford Centre of Excellence expansion is designed for maximum efficiency and output and will boast the following:

• Optimized floor space achieved through lean manufacturing principles.

• Increased mill operations speed as a result of variable frequency drives and servo controls.

• Lean principles applied to material flow from loading to shipping, enhancing overall efficiencies by reducing time and costs.

• Automated stackers at the end of mills.

• Automated wrapping of materials.

Vicwest has been in the building industry for 85 years and delivers manufactured building products across Canada.

Feb. 19 - 22

AAMA National Annual Conference Orlando, Fla. aamanet.org

Feb. 28

FenBC Technical Conference Surrey, B.C. fen-bc.org

March 1

FenCon18 Winnipeg, Man. fencon18.com

March 4 - 6

Building Envelope Conference Las Vegas, Nev. glasswebsite.com

March 21 - 24

Fensterbau Frontale Nuremburg, Germany frontale.de

April 17

Top Glass Mississauga, Ont. topglasscanada.com

April 23 - 28

GANA Annual Conference Napa, Calif. glasswebsite.com

June 11 - 14

AAMA National Summer Conference Olympic Valley, Calif. aamanet.org

June 21 - 23

AIA Conference New York, N.Y. conferenceonarchitecture.com

Aswe start a new year, the CGA board has decided it is time for a new mission and focus for the association. We are determined to deliver value for our members and do what we can as a national association to help the architectural glass industry across the country. The consistent challenge in every region is access to the skilled labour we need as an industry. This is not a local or even provincial phenomenon, but something that concerns fabricators and contractors in every part of Canada.Yet the response has been regional, with different approaches tried in different areas with little communication of success or failure and little sharing of knowledge when we find something that works. As a national organization, the CGA is in a unique position to knit together the various threads and create a cross-Canada strategy. This could include:

• Promotion of the glazing trades at the high school level

• Creation and promotion of college-level trade courses that meet requirements in any region

• Lobbying governments to invest in apprenticeship programs

• Hosting career fairs

• Populating a national online job board

• Promoting Red Seal certification among glaziers

As a first step, the CGA will be contacting our regional partners to collect information on what works, what doesn’t and what is needed in your area. We need your help! To offer your input, or volunteer your time, please email CGA president

David

Langton at

dlangton@compglass.com.

TheAGMCA is pleased to announce that Noel Marsella became the new executive director of the association at the start of 2018. Noel graciously accepted the position after making the difficult decision to close his glass business of the past 35 years. Having Noel at the helm

will provide valuable industry expertise to the many aspects of our association’s representation within the unionized sector of our industry. Noel has clearly demonstrated his dedication to our association over the past four years having served as a director of the AGMCA. Please join us in welcoming Noel onboard. We are confident Noel will guide our association, in the coming years, with enthusiasm, dedication and commitment.

Our last meeting was held Nov. 15 and we will have had another one by the time this goes to press. Minutes and reports from our last meeting

are on the PGAA’s website. Our Master Glazier program development continues. We remain underway on the development of both structural glazing and specialty glass, with a mandate to maintain efficiencies and to have both courses finished in the first quarter of 2018. This will leave us five courses to develop later in 2018 and beyond. However, the last courses offered up for the fall all had to be rescheduled for lack of participants and we have struggled to get subject matter experts. Just prior to Christmas, we sent out a survey to confirm continued support for the program with our members and we are awaiting responses. The upcoming year looks like another year of mixed blessings. Oil prices rising is a positive, met by the negatives of our NDP government’s changes to the Labour Act, the Workers Compensation Board and occupational health and safety regulations. These are not positive from a business perspective and now we face the spectre of a possible end to NAFTA. These are mixed signals and anything but a clear picture for our economic future.

The Ontario legislature held its third reading of Bill 142 –Construction Lien Amendment Act 2017 on Dec. 5. It was unanimously passed by a vote of 87 to zero and was granted royal assent on Dec. 12. For the whole story, take a look at Frank Fulton’s You Bet Your Glass column in this issue.

Welcome new members! We’re ecstatic to welcome these great companies who joined us in 2017: AKR Consulting Canada, Goldray Glass, INT machinery, Modular Window Systems, Noram Glass, Ten Plus Architectural Products, Tri-Temp Glass,Vicone High Performance Rubber, and Vision Aluminum.

Owner Alen Geronimo asked us to let you know that they have outgrown their downtown quarters and have moved to a larger and more accessible office in Mississauga. You can find out more by visiting gridlinedesigndrafting.com.

Do yourself a favour and come spend a few hours seeing everybody that’s anybody at Top Glass on Tuesday, April 17. Make sure to stop by OGMA’s table to say hello. If we have it in the budget, we’ll give you a candy.

Mark your calendar for Thursday, May 31, make your plans, arrange your group, and be at Pipers Heath Golf Club. Keep your eyes out for notices as the date approaches.

Mark your calendar for Thursday, September 20, make your plans, arrange your group and be at the Country Club in Woodbridge. Keep your eyes out for notices as the date approaches.

In case you missed it, companies had until the end of 2017 to put a new set of accessibility policies and procedures into place. To find out your legal obligations, go to ontario.ca/page/accessibility-laws.

The International Standards Organization (ISO) has published a new test standard: “Glass in building – electrochromic glazings – accelerated aging test and requirements.” This document is intended to provide a means for evaluating the durability of electrochromic glazings. The test procedures covered in this document include rapid but realistic cycling between high- and low-light transmission states and environmental parameters that are typically used in weatherability tests, such as simulated solar exposure and high temperature, which are realistic for the intended use of electrochromic glazings. The document specifies the accelerated aging test and requirements for electrochromic glazing. It is only applicable to chromogenic glazing that can be switched using an electrical stimulus from high to low transmission states and vice versa. This test method is not applicable to other chromogenic glazing, such as photochromic and thermochromic glazing, which do not

respond to electrical stimulus. The method is applicable to any electrochromic glazing fabricated for vision glass (including insulating glass units and laminated glass) for use in buildings such as doors, windows, skylights and exterior wall systems and glazing exposed to solar radiation. The layers used for constructing the EC glazing and for electrochromically changing the optical properties can be inorganic or organic materials.

AGC Asahi Glass and Kinestral Technologies, maker of Halio smart-tinting glass, have announced the creation of three joint-venture companies that will sell, distribute, and service Halio to the global market. Formed to accelerate the adoption of Halio, the new ventures – Halio North America, Halio International and Halio China – will be the exclusive sales and marketing agents for Halio smart-tinting glass in the commercial and residential housing industries. Halio China includes a third partner: G-Tech Optoelectronics Corp. (GTOC), a subsidiary of the Foxconn Technology Group. The three partners have been introducing Halio in their respective markets since the product was first unveiled in January at the BAU Trade Fair for Architecture, Materials and Systems in Munich, Germany. The joint ventures were formed to meet worldwide demand.

“Joining forces with AGC gives us access to a global sales and support infrastructure as well as decades of expertise in the use of glass in facades. GTOC meanwhile bolsters our manufacturing expertise and gives us access to China, one of the fastest growing markets for smart-tinting glass,” said S.B. Cha, CEO of Kinestral.

Halio technology enables glass to tint, reducing glare and blocking unwanted solar heat automatically or on command. Halio looks like ordinary clear glass until it tints, achieving its darkest shade in less than three minutes. Halio improves occupant comfort in smart homes and buildings while achieving the highest levels of energy efficiency. “We are convinced that Halio technology is poised to transform the glass industry,” said JeanFrancois Heris, senior executive officer of AGC and president of

ApexAluminum Extrusions has welcomed its newest team member, Ken Rowson, in the role of director of sales for their Apex facade systems division. He will be responsible for developing sales strategies, assisting in product design and leading all sales efforts for Apex’s architectural glazing system. “Ken brings more than 35 years’ experience in the aluminum and glazing industry to his position. We are very excited to have Ken join the Apex team and take the lead in introducing glaziers and architects to these new systems,” said Bill de Koning, vice-president of Apex.

With Ken’s assistance, Apex facade systems will be launching their high-performance vents and strip window system in 2018 to complement and expand upon their four current glazing systems, including Crest 175 standard entrance; Summit 200 thermal entrance; Meridian 450 storefront; Pinnacle 600 high-performance curtainwall and Keystone 500 high-performance slim curtainwall.

AGC Building and Industrial Glass Company. “Natural light is the number-one most desired feature in office designs, but conventional glass requires blinds, shades and awnings, or architectural elements that block heat and glare. Halio gives people the best of the outdoors while meeting increasingly stringent energy codes.” Jim Arnold, formerly senior vice-president of sales at Control4 and DirecTV, will head Halio North America. Alain Jardinet, a veteran executive of AGC Glass Europe, will lead Halio International, which will sell to all markets outside of North America and China. Halio China will be headed by Alex Jiang, an executive of GTOC.

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s Building Sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at david.heska@wsp.com

As we kick off the new year I’m excited to begin this column. The window industry is changing and we are seeing unprecedented pressure to manufacture better windows with lower U-values. However, along with this pressure there are many opportunities. At the WinDoor show held in November at the International Centre in Mississauga there were many great presentations regarding the trends in our industry. It’s no secret that there is pressure from government, engineers and architects to decrease the window-to-wall ratio of our buildings, but there were great counterpoints made regarding the benefits that increased interior daylight has on occupant comfort and overall well-being.

Eighty per cent of the annual available interior daylighting can be achieved with a windowto-wall ratio of 40 per cent. Interestingly, increasing the ratio beyond that has relatively little effect on the amount of daylighting achieved. Even at 100 per cent glass, the interior receives only 85 per cent of all the available light hitting the building. We hear a lot about how healthy and energy-efficient it is to allow lots of light in. What we hear less is that it is possible to achieve this without making the entire wall out of glass.

At the same time as we realize this, we see that design trends over the last 50 years don’t acknowledge this reality. Since 1974, ratios have climbed from about 30 per cent to an average today of close to 60. I don’t think we will ever go back to the 30 per cent window-to-wall ratio of the 1970s, but the trend to design buildings with a ratio greater than 60 per cent cannot continue.

The trend to design buildings with a ratio greater than 60 per cent cannot continue.

At a 50 per cent window-to-wall ratio, if the walls are R20 and the windows are R2 the effective R-value is only 3.6. If you take that same wall and increase the wall insulation to R40 (with R2 windows), your effective R-value only increases to 3.8. Now if you were to keep the walls at R20 and instead change the windows to R4 (U-value 0.25), your effective R-value jumps to 6.7. It’s very clear that installing higher-performing windows in our buildings will result in greater energy improvements. This needs to become the new standard and our industry needs to push the envelope by developing windows with U-values lower than 0.25. How low can we go? Will 0.20 become the new standard? Can we reach 0.15 or even 0.10? In the coming decade, triple-glazed windows will become increasingly popular, double thermal breaks will become standard and more composite materials will be used.

We will have the wait and see how the government of Ontario’s recent “GreenON” rebates will impact the residential market. Homeowners are now eligible for $500 per window (to a maximum of $5,000) if high-performance Energy Star windows are installed. I am seeing and hearing that manufacturers are showing an increased desire to achieve the Energy Star standard. In order to qualify the windows must have a U-factor at or below 0.25, but making homeowners aware of this rebate will be a challenge. Having only a small list of contractors qualified to installed these windows will likely result in the rebate not having the desired widereaching effect. What would happen if the rebate were given to the window manufacturers rather than the homeowners? Can the industry be trusted to use these rebates for research and development instead of boosting profits?

As we begin 2018 I challenge each reader to do their part in helping our industry build better buildings. That includes reasonable window-to-wall ratios (around 40 to 50 per cent). It includes windows with U-values less than 0.25 and it includes each of us doing our part to creatively develop products that are more energy efficient. •

by LINDSEY MCCAFFREY

Any workplace setting is bound to have at least one employee living with an injury or disability. But it doesn’t matter whether that employee’s injury or disability happened at work, at home, or somewhere in between. Employees do not have to be on worker’s compensation in order for employers to have a duty to accommodate disability. If an employee’s injury or disability completely or somewhat prevents them from doing their job, employers have a legal duty to “accommodate” them. To get the basics on employer and employee rights and responsibilities, Glass Canada spoke with the three experts in different parts of the country: Dan Soiseth, a human rights lawyer with the Community Legal Assistance Society in B.C.; Dianna St-Pierre, an Occupational Therapist and Disability Management Consultant with Occupational Concepts in New Brunswick; and Jennifer Threndyle, an AODA specialist with Workplace Safety and Prevention Services in Ontario.

While human rights are managed through each province and territory in Canada, each provincial human rights act is based on the Canadian Charter of Rights and Freedoms. So while there may be subtle differences from province to province, similar rules generally apply when it comes to accommodating employees with an injury or disability.

Generally speaking, an injury or disability could be any temporary or permanent condition that affects a worker, including something physical (a broken arm, slipped disk, sore back, heart attack, shoulder or knee injury), something mental or emotional (depression, bipolar disorder or anxiety) or substance addiction including drugs or alcohol. It does not matter where or when the injury or disability occurred, the employer is still legally accountable to accommodate the worker. It also doesn’t matter if the disability is the worker’s fault. Whether or not the injury occurred in the workplace and whether or not you were at fault is a question for labour authorities and worker’s compensation agencies. It has no relevance to your duty to accommodate the disabled worker

There are several ways an employer can temporarily or permanently accommodate workers who have been injured or have a disability.

Modifying the job requirements – In a manufacturing or construction environment, an employee with a strained back may not be able to lift heavy objects above a certain weight. Determining these limitations can be complicated and a matter for some discussion between medical professionals, the employee, the employer and any agencies involved but, once established, it is the employee’s legal right to be accommodated with work that does not violate those limitations.

Making changes to the work environment – Examples could include adjusting a work station, or installing a wheelchair ramp or lift.

Creating a new job – If the employee has a set of skills that could bring value to the company in some other role, the employer could create a new position for them. This is never mandated, however.

Addiction is considered a mental health issue and attracts just the same duty to accommodate as a physical injury. Simply firing employees who show up impaired will get you into trouble. You need to work out a plan to get them treatment.

Providing training or retraining – This can help the employee do a different job, or to help them stay in a modified version of their job.

Offering a more flexible work schedule – This can address problems where an employee can do a particular job, but perhaps not for an entire shift.

No threshold, but there are limits

Of course, some employees’ needs for accommodation are greater than others. That’s where the concept of “undue hardship” comes in. Generally speaking, “The employer must endure some hardship before they are legally entitled to give up on accommodating the employee,” says Soiseth. That said, “hardship” varies, often depending on the type and size of the business.

“The test for undue hardship is ‘would accommodating the employee put the company out of business, or impact the livelihood of others?,’” Threndyle explains.

Soiseth provides an example of an employee who receives a prognosis that they will be better in 18 months. “A small manufacturing shop may not be expected to hold their original job open for them, but a larger company would likely be required to give them their job back when they’re better,” he says. “This is because larger companies generally have more opportunities available to employees and can therefore be more flexible.”

Moreover, says St-Pierre, an employer does not have to create a new job for the worker if they can prove that job brings

no value to the company. The caveat is whether the worker has a set of skills that could help the business.

To justify not accommodating an injured or disabled employee, the employer must prove they could not accommodate without experiencing undue hardship. They may be required to demonstrate such things as the amount of effort they made to try to accommodate the worker, the options they explored to find a reasonable solution for the employee, and to provide reasons why further steps are not reasonable or practical.

“The employer will need to be able to back up what they did or didn’t do,” says St-Pierre. “It can’t just be ‘We didn’t have any jobs available for them to do.’”

Moreover, if an employee does not think their employer’s accommodation is good enough, they are entitled to decline that accommodation and file a human rights complaint through the tribunal or commission in their province.

That said, adds St-Pierre, “While the employer has an obligation to accommodate an employee by respecting their abilities and restrictions, the employee also has the obligation to accept reasonable accommodation when offered, even if it is not what the employee considers the preferred accommodation.”

Often, it doesn’t cost a lot to accommodate. There is no hardand-fast rule governing how much employers must pay to

accommodate employees. It depends on the individual situation. However, both Threndyle and St-Pierre say that the average cost of employers accommodating employees is less than $500 across all industries. “Often, all that accommodating employees requires is providing them with a larger monitor, or a sit-and-stand desk, or raising or lowering a manufacturing belt,” says Threndyle. “Most of these things are not that expensive.”

There are limits to accommodating employees when safety is involved. For example, there is a difference between accommodating a worker with an ongoing substance addiction and accommodating a worker who takes a substance on the job. “Ultimately, the employer needs to maintain a safe work environment for everybody,” says St-Pierre. “Whether somebody is taking a legal or illegal substance, safety is always the key thing. So accommodating someone with an addiction could mean providing a more flexible working schedule, but it doesn’t mean an employer is required to allow a drunk employee to operate heavy machinery.”

Threndyle agrees. “If a worker is a safety risk to themselves or others, they are not allowed to operate heavy equipment, work at heights or drive. Addiction is a mental health disability, but an employee cannot be under the influence and perform the duties of the job.”

What about employees who already have an injury or disability who may be applying for a physically demanding job like glass fabrication or installation? Legally, employees are not required to disclose to employers if they have a pre-existing condition, injury or disability, nor are employers allowed to ask. However, say Soiseth and St-Pierre, employers can still elicit information from applicants by focusing on job duties during the interview stage.

St-Pierre agrees, adding “In general, an employer is entitled to functional information: information about the person’s abilities and restrictions and safety concerns. And while you can’t ask about disabilities or diagnoses or medications, employees will often tell employers way more about themselves than is necessary. But that’s their choice.”

Threndyle recommends creating a robust job description with help from an ergonomist or other qualified professional, and asking the candidate to review, sign and date it. “Although this doesn’t secure 100 per cent protection for employers, they can put together a job description that details the physical demands of that job and have the candidate sign it, indicating they understand the terms. And if it turns out later that the candidate has misrepresented their abilities, they can be terminated. However, they may still have the right to go to their provincial human rights tribunal for discrimination based on disability,” she adds.

As for whether workers may use their

poses, Soiseth says employers should not generally worry. “Helping complainants with human rights cases is nearly 100 per cent of my job, and in my experience it is very, very rare for someone to get a job for the purpose of going on to workers compensation or trying to sue the employer,” says Soiseth. “That’s not to say it’s never happened, it’s just not something that employers should have on any short list of concerns when hiring.”

According to St-Pierre, it just makes good business sense for employers to accommodate their employees. “Think of it this way: you’re keeping an employee who has experience with the business,” she says. “If you have to replace that person completely, you’re losing everything they brought to your company in terms of experience and you’re going to have to reinvest in retraining and replacement of that employee. But ultimately, it’s just the right thing to do.”

Plus, she adds, “It has a positive effect on the overall morale of the company.” •

“It’s fair for an employer to describe the job duties and ask a job applicant if they can successfully handle the job,” says Soiseth. “Ask about training, qualifications, previous work and other experience. But keep the focus on the work to be done and the potential employee’s ability to do it, rather than on inherent disability.”

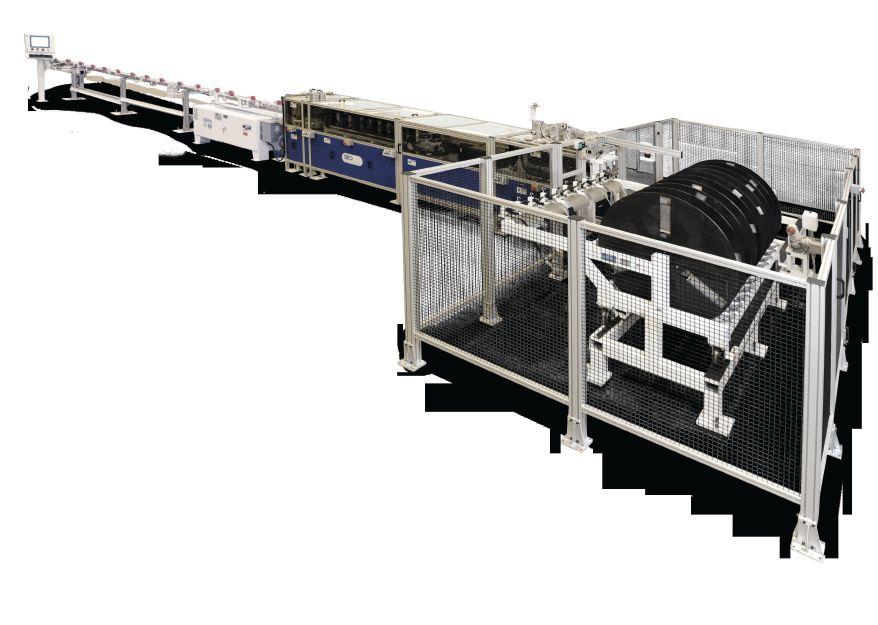

When it’s time to take IG production to the next level, fabricators can consider integrating automated spacer production into their process. It’s a big investment of money, space and training time, but a big payoff in reduced inventory, supply control and input costs.

Some insulating glass manufacturers are now making spacers in-house in order to achieve higher profit margins and achieve quicker response times.

The benefits of making your own IG units in the first place are obvious, according to Joe Shaheen, sales director at GED Integrated Solutions. “Making your own spacers and IG in house can save you up to 40 to 50 per cent of the cost of IG. That cost difference can be the difference between profitable window sales and break-even window sales,” Shaheen notes from his U.S. headquarters in Twinsburg, Ohio. “By producing IG in-house, you can react quicker to the unknowns that pop up, from breakage of the unit to simply losing track of the final product. When the truck is ready to go to a customer, the last thing needed is one or two missing window units. Making IG in-house allows for rush re-makes through the facility, thus allowing the truck to get on

the road.”

The cons, says Shaheen, are the same as those of any in-house production: the need for more space and staff. He puts the square footage required at roughly 10,000 for spacer and IG manufacture, but notes that this room is generally available with some reorganization of production lines and finished inventory. He adds that “robotics, automation and software also allows manufacturers to do more with the same or fewer people.”

Gerhard Reichert, president of Glasslam in Pompano Beach, Fla., also characterizes the biggest benefits of making spacers in-house as control and cost savings. “It puts everything to do with spacers in the glass fabricator’s hands,” he says, “and typically reduces inventory handling and costs associated with that. Just-in-time means you are not paying anyone else to make finished spacers. But, looking at scale, buying a machine and making spacers in-house is only worthwhile for larger firms. If a

company makes hundreds of IG units a day, it’s likely not worth it. But if it’s thousands a day, it’s definitely worth it.”

Like Shaheen, Reichert notes that a spacer-making machine purchase brings the need to train employees and requires enough space both for the production line and for storage of raw materials. On that front, he is excited to announce that Glasslam has just significantly shortened the space required for its WorldSpacer production line by 60 feet. “For the continuous spacer curing process, we now have an infrared-heated ZigZag conveyor module where the spacer goes back and forth five times in 20 feet, instead of continuing out in a 100-foot line,” he says. “This is one of the biggest updates we have made, and enables many more customers to make

spacers in-house because now they have the space to do so.”

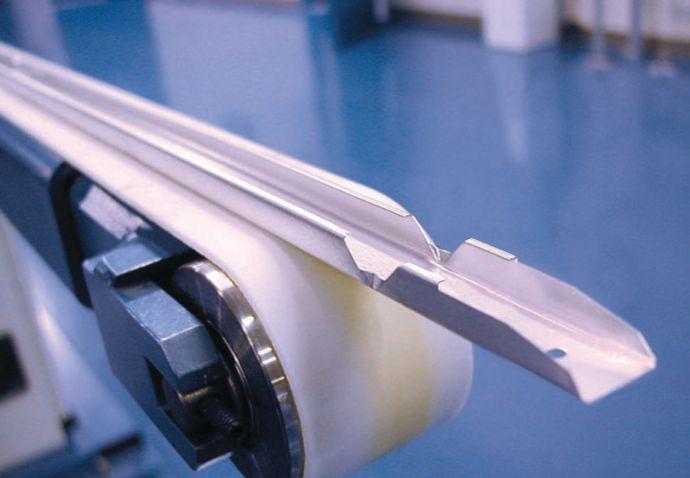

GED’s spacer machine is called the Intercept. It can produce spacers at up to 95 feet per minute. The process starts with flat coil as a raw material, fed through a punch/feeder press to punch out corners, tabs and grid locations. The coil is fed through a roll former in multiple passes, which forms the coil into the patented “U-Channel” configuration. The formed spacer now moves through a printer for adding labeling information and then is cut to length. Next on spacer’s journey is the extruder, which uses gear pump technology to apply a desiccated matrix into the channel and sealant to the sides and back

of the spacer. A worker now folds the spacer into the required shape and places it onto a conveyor where it moves to the assembly area.

Glasslam’s WorldSpacer process starts with a coil of 64 millimeter-wide corrugated stainless steel foil being fed through a forming module to create a 54-millimetre wide continuous stainless steel tray at a speed of 25 feet per minute for the entire flexible spacer-making process. A desiccant matrix material is cast extruded onto the moving stainless steel tray as a two-component liquid polyurethane resin, filling up the tray to a standard 4.8-millimetre spacer height level in a continuous fashion. The first conveyor section feeds in to an enclosed conveyor module providing infrared heat for the initial cure and five 20-foot levels of continuous cure time before exiting the conveyor module. The fully cured 54-millimetre-wide “web” then continues through a surfacebrushing module, a razor-blade-loaded multi-spacer cutting module (for up to four different-sized spacers at a time), a multi-spacer side-taping machine and finally on to a spacer reel coiling machine. From there, the loaded spacer reels are vacuum-sealed, double bagged and boxed.

Installation and training of a spacer manufacturing line generally takes a few weeks and Shaheen says the cost can vary from $1,000,000 to over $2,500,000. “For our system specifically (the Intercept), the range is more on the low end of the estimate,” he explains. “ROI is typically based on units

per man hour: total volume in how many hours with how many people. Some systems need fewer people to operate the line but are limited on the volume the system can produce per hour. The bottom line is that you have to look at the total cost and capability of the system you would want to implement, and not at any one aspect alone.” Raw materials can be ordered in parallel with the equipment and are usually available by the time the installation starts.

Reichert puts ROI on a million-dollar line and license at under two years for IG fabricators producing 2,000 or more units per day. “You can save $1 to $2 U.S. per average IG unit of 10 linear feet of spacer compared to ordering ready-made flexible spacers from an outside vendor,” he notes. “Each WorldSpacer line can produce 100 feet of 12-millimetre flexible stainless-steel spacer per minute, which is over 200,000 feet per week when running five eight-hour shifts. This is enough spacer capacity to feed three vertical automated IG lines running flexible spacer production robotically.”

Shaheen adds that any spacer machine manufacturer should provide customers with support during installation and training on both machine operation and maintenance, and that they should also provide evaluation of possible production bottlenecks. “Some systems can [allow customers to] produce a significant quantity of IG units: 2,400 in an eighthour shift,” he says. “This high volume may change your manufacturing structure.”

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass

• SentryGlas Lamination

Fax:

In terms of raw materials, Shaheen says any material can produce a durable, high-quality spacer. “The machine maintenance and attention to detail on the process have a lot to do with what you can expect,” he explains. “Having said that, speaking specifically about Intercept and our process, we have two different base materials and two colours of each: tin plate and stainless steel, both offered in black and grey, with a variety of extruded materials.” Shaheen says the tinplated spacer version offers the best price point, while still providing a warm-edge system compared to traditional box aluminum spacer. The stainless steel product, in his view, offers superior warm-edge performance and is priced out lower than other premium spacer systems. He believes the black colour provides a superior aesthetic perspective for a limited cost premium.

The spacer material of the WorldSpacer system is a two-component polyurethane resin which is mixed and extruded in a web matrix (with desiccant) onto 54-mm-wide corrugated stainless-steel foil, cured in under six minutes, then razor-cut to various spacer sizes. Reichert notes that in comparison, traditional manufacture of flexible silicone spacers is a very labour-intensive process requiring production in large batches, with industrial-sized energy-intensive

extruders, salt-curing baths, hot-water spacer washing, large batch ovens and so on. It is therefore not conducive to in-house spacer making. Reichert says that WorldSpacer has the unique ability to continuously make up to four different spacer sizes at the same time out of a standard spacer web. Standard colour is black and standard thickness is 4.8 mm, with custom colours white and light grey and custom thicknesses and web widths also available.

The production capabilities of modern spacer machinery are truly amazing. The Intercept system, for instance, can produce up to seven two-by-three-foot frames per minute and make frames as long as 28 feet or as small as six inches square. A single machine can achieve multiple metal and sealant options to produce single- or double-seal units. Dessicant is applied and gas holes punched automatically. Computerized production means changeovers and design updates can be accomplished quickly, sometimes even on the fly. There is no need to run huge batches of spacer and hold them on inventory because the automated process can produce only what you need, when you need it.

Installing automated spacer production doesn’t require a whole new shop. WorldSpacer lines, for instance, are configured in an 11-meter-long Ushape that is three metres wide, two meters high and weighs 7,500 pounds. No knocking out walls or special floors required. Electrical and air requirements are likewise not outside of the ordinary: 220-volt/15 kilowatt service and 0.82 KPA air supply.

GED Integrated Solutions has been in business since 1977. The company makes just about every type of glass and window fabrication equipment imaginable, including cutting, washing, material handling, welding and screen fabrication equipment – even software!

Glasslam has been providing solutions and materials for insulating glass, laminating, colouring and sealing for over 30 years. The WorldSpacer system was launched at GlassBuild in 2016.

The decision to purchase an in-house spacer system is a big one, but may be worth it for your company. If you have installed a spacer-making system in the last year or two, let us know how it went! •

by MARGARET WEBB

In our northern climates, where temperatures can plummet to -30 C and colder, consumers can see an increase in glass breakage in their windows. This year in the Ottawa area, an unprecedented number of glass breakages have been reported with temperatures in the -39 C range with intense sun for days on end. It’s a chilly time.

One of the common factors that can lead to breakage of annealed glass used in insulating glass units is thermal stress. How do you identify a thermal stress break from other types of glass breakage? Thermal stress breaks start at 90 degrees (perpendicular) to the glass edge. Depending on the degree of thermal stress, the crack may be a single break or a branch off in multiple directions. It all depends on how much stress needs to be relieved.

Breakage due to thermal stress involves the occurrence of a thermal gradient induced by uneven heating of glass by either solar irradiance or other heat sources. When sunlight impinges on a glass lite, some energy is reflected from the surface of the glass, some energy is absorbed by the glass and some energy is transmitted through the glass. Energy absorbed by the glass increases the temperature of the glass above the previously existing equilibrium condition. When glass is uniformly heated and if the support system can accommodate the thermally induced expansion of glass, no major stresses will be induced by the uniform temperature increase. However, the part of the glass surface that is shielded from direct sunlight by the edge supporting system or by shadow conditions will be heated unevenly. The uneven heating of glass will give rise to thermally induced in-plane tensile and compressive stresses. When the thermally induced tensile stresses become high enough and interact with certain

Thermally induced edge stress occurs when the centre of the glass is heated and the outer edges of the glass remain much cooler.

edge conditions, a thermal break can result. This can be especially true on these cold days with the sun beating down on windows.

In a thermal breakage situation, the edges of the glass are subjected to higher tensile stresses than the surface of the glass away from the edges. The thermally induced edge stress will be of a tensile condition, which occurs when the centre of the glass is heated substantially and the outer edges of the glass, protected by the glazing system, remain much cooler and create tension as the centre portion expands.

Because thermally induced stresses are membrane stresses, both the top and bottom surfaces of the glass are exposed to the same stress. Because of the orientation of the edge stress, breakage at the edge of a thermally loaded glass plate usually results in a crack normal to both vertical and horizontal projections of the edge.

Other factors that may increase the potential for thermal stress breakage are altitude (the greater the altitude, the higher the risk factor), building design (shadows created as a result of the design, such as overhangs and the colour of outdoor glazing stops), orientation (south- and southwest-facing windows are at increased risk), glass edge conditions (any imperfections at the glass edge), retrofit installation of films, the window frame (if the glass is embedded deep in the frame, dark coloured frames can be a risk factor), the kind and type of glass (fully tempered glass has a much lower risk factor for thermal stress breakage and dark tinted glass has an increased risk), the number of glazing lites (tripled-glazed units should be evaluated to determine if heat treating the middle lite will reduce the risk factor), solar absorption and radiation. There are other factors that can increase the risk of thermal stress breakage and a combination of any of these factors can greatly increase the risk of breakage.

So what can a manufacturer do? IG fabricators should advise their customers who can in turn advise consumers of the risk factors. An ounce of prevention is worth a pound of cure and will greatly reduce consumer dissatisfaction with their windows.

IGMA’s publication, TM-1500-14, Guidelines to Reduce Instances of Thermal Stress Breakage, includes detailed descriptions of each condition and recommendations on how to reduce risk factors for thermal stress breakage. Copies of this publication and others are available from the IGMA website at igmaonline.org. •

by ONTARIO GLASS AND METAL ASSOCIATION

TThe Ontario Glass and Metal Association has announced that nominations are now being received for the 2018 Awards for Excellence. There are two awards, one for Excellence in Architectural Glass and Metal Design and one for Excellence in Architectural Glass and Metal Execution.

The Awards for Excellence are annual awards that recognize excellence in the design and execution of a building that incorporates the use of architectural glass and metal. One award will be presented in each category.

The awards competition opens in January of each year. Any member of the OGMA in good standing may submit as many nominations as they wish. Projects nominated will be reviewed by a panel of judges consisting of one OGMA director and two practicing architects.

Submissions for nominations must include a minimum of 10 photographs of the nominated project and a comprehensive description of between 200 and 500 words. Submissions should be sent in digital format, accompanied by high resolution, print-quality photos.

The following criteria must be met in order for a project to be considered in either category:

• Nominations must be made on the official nomination form, which must be completely filled out.

• The project must be located within the province of Ontario.

ABOVE: It’s a chance to get recognized for the great work you and your team have done. Here, OGMA directors Steve Gusterson and Angelo Cairo present the award for design to Gary Watson of Diamond Schmitt Architects at Top Glass 2017.

• The project architect must be registered with the Ontario Association of Architects.

• The glazing contractor must be a member in good standing of the OGMA.

• The project must have been completed within the last five years.

• Nominations must be made by a member in good standing of the Ontario Glass and Metal Association, however, the architectural/design firm need not be.

• Members are not restricted in the number of nominations submitted.

• The project must incorporate glazing systems from North American manufacturers.

• Projects nominated need not be large – nominations can be made for portions of a project.

Nominations will be judged upon:

• Unique, pleasing or complex design or features.

• Level of difficulty in design.

• Level of difficulty in execution and the quality of fabrication and installation, as indicated in the photos provided.

• Incorporation of elements of sustainable design.

The architectural firm and glazing contractor selected to receive an award will be notified on March 30, 2018.

The awards will be presented at the Top Glass Conference on April 17, 2018. Award recipients are encouraged to attend the show to receive their award and to present the highlights of the winning nominations to show attendees.

The deadline for receipt of nominations for the 2018 awards is Friday, March 16.

For more information, contact Steve Gusterson of Alumicor at 416-456-1321 or s.gusterson@alumicor.com.

TAGG Industries – 2016 Excellence in Architectural Glass Execution for the Google headquarters in Kitchener, Ont.

Perkins Plus Will – 2016 Excellence in Architectural Glass Design for Mohawk College’s David Braley Athletic and Recreation Centre in Hamilton, Ont.

Noram Building Systems – 2017 Excellence in Architectural Glass Execution for the Vaughan Civic Centre Library in Vaughan, Ont.

Diamond Schmitt Architects – 2017 Excellence in Architectural Glass Design for Lazaridis Hall at Wilfrid Laurier University in Waterloo, Ont.•

To nominate a project you’re proud of, visit ogma.ca and download the nomination form.

ergo-robotic.com

The THOM 2200 telescopic handler outdoor manipulator is a fork-attached adapter to turn any telescopic handler into a remote controlled multi-axis glass manipulator.

The THOM 2200 has a 2,200-pound attachment capacity. Other sizes are available. Boom movements include 90 degrees up and 45 degrees down, in and out, tilt up and down, swivel left and right, and shift side to side. The THOM 2200 features Ergo’s EZ Pick feature and can rotate the workpiece. A double redundant vacuum system ensures safe handling. Especially useful for the rough terrain of job sites, the THOM is limited only by the height and capacity of the attached handler. The manipulator will grip any smooth material and operates independently of the handler by remote control.

glgcan.com

The GlassLift 680 mobile glass handler from GLG features unique handling safety and service characteristics. Three-dimensional manipulation of the glass is possible with the strong and precise head that allows for tilting in all directions. Users can approach the mounting area from any angle and adapt the load to fit. A powerful 335 ampere hour battery is standard with a lithium option that will fully charge in eight hours. the reliable hydrostatic drive with power steering makes the 680 very manoeuverable. Five-axis hydraulic operation means the load can be lifted straight up and down, rotated left and right, tilted forward and back, side loaded left and right or telescoped in and out. Load capacity is 1,499 pounds. The upper arm can mount objects up to 167 inches with precision and a bearing allows the arm to turn plus or minus 15 degrees. Twin front wheels and a hydraulic drive allow the 680 to operate in a wide variety of ground conditions.

erdmanautomation.com

Erdman tilt/tip equipment comes in handy if product requires a lift onto a work station or conveyor system.These machine create a safe, simple, and reliable way to transfer the largest, heaviest and most delicate workpieces. They are designed to fit into any line and will adapt to most conveyor systems.The specialty tilt/tip equipment eliminates lifting, significantly reducing the potential of back injuries and gently handles product. No dents, scratches or marks!

kearmfg.com

The window and glass manipulator from Kear Fabrication is the ideal solution to enable one employee to handle a job that would usually require two or more. Now glass fabricators can be assured that their investment is being handled quickly, efficiently and, most important, safely. Designed with the worker in mind, Kear manipulators can be fabricated to handle loads of more than 800 pounds and controls can be operated via radio or motion-activated. The head moves in a 340-degree circle with a brake that can only be released with the operator present. Swiftly move glass up, down, forward and reverse. It even has an option allowing the operator to pick partials up or lay them down horizontally.

wpg.com

Handling curved and bent glass has long been a challenge to manufacturers, fabricators and installers alike. Since 1964, Wood’s Powr-Grip has been making glass handling easier and less dangerous with handheld vacuum cups, below-thehook vacuum lifters and other high-quality products. A redline indicator or available audio alarm on WPG hand cups alerts the user of any significant vacuum loss. Vacuum gauges with coloured zones on Powr-Grip vacuum lifters clearly indicate whether the vacuum is sufficient for lifting. A dual vacuum system is available on many WPG vacuum lifters to reduce the risk of falling glass. Indicator lights and warning buzzers signal when a vacuum lifter is ready to move glass.

Whether you are loading curved glass onto processing machinery in the factory, handling bent panes in the shop for fabrication operations, or installing curved glass products on job sites, Wood’s Powr-Grip makes the right equipment for handling curved or bent glass more easily and safely.

crlaurence.com

The CRL 2402498 cutting table is constructed of heavy-gauge steel, electrically welded and painted. The table combines a popular counter-balanced tilt top mechanism with a 12-port air flotation system to provide easy loading and movement of glass sheets. Smaller than standard tables, this six-by-eight-foot table is easily portable and provides a very small footprint when standing upright. The 2402498 air float system runs off 110-volt, 60-hertz single phase power. The table is shipped with a full smooth 3/4-inch particle board top, carpet and adhesive. Assembly required.

by MESSE DUSSELDORF

Thin glass – as thin as a razor blade or a human hair –has new applications in protecting smartphone touchscreens, sensitive filters and sensors. Yet despite its extreme thinness, recent advances have rendered it also highly resilient and scratchproof. The flexibility and bending properties of the new thin-glass products may permit totally new applications in architecture, mobility and other industries. Thin glass is opening up new markets and turning visions into reality.

How this works can be seen at Glasstec 2018 in Düsseldorf.

Just as smartphones, tablets and e-book readers have changed the way we communicate and convey knowledge, scratch-proof touchscreens have produced totally new qualities in the manufacturing of glass, thus enhancing the performance of this material which has accompanied the history of mankind’s development since the first advanced civilizations. Ultrathin protective glass seems more like film than glass and is so bendable and flexible it can even be rolled up and transported to customers on rolls. Special manufacturing processes are now available, allowing for the production of ultra-thin glass films which – at 0.025 millimeters thick – are even thinner than a human hair or razor blade.

The starting material for production is molten glass which passes through rollers and is drawn upward or downward from a tank in what is known as an up-draw or down-draw process. It is then left to cool down on the production line as a film with the required thickness, ranging from 25 micrometers to 10 millimeters. Alongside these two methods – which, incidentally,

are older than float glass manufacturing – thin glass can also be produced with different specifications using overflow or microfloating processes. Whichever method a company chooses, the decisive element for the properties of thin glass is the formula of the molten glass, which differs from one manufacturer to another and is a well-guarded trade secret.

Thin glass is in demand for a wide range of products in numerous industries and can be classified quite differently, depending on its thickness. In construction and architecture, glass is considered to be thin if it is below three millimeters, with virtually no reasonable or practicable use for thicknesses below one millimeter. The needs are quite different elsewhere. In media technology, for instance, two-millimeter glass would be regarded as rather thick. This industry commonly measures thickness in micrometers and ultra-thin glass down to 20 micrometers tends to be treated as film and shipped on rolls. In the construction industry, thin glass can therefore be produced under a conventional floating process where minimal thicknesses are commonly around one millimeter.

The benefits of thin glass are its material and structural qualities on the one hand and its low weight on the other. There are potentials for this technology in combination with

ABOVE: Glass so thin and flexible it can be rolled up like paper – advances like these suggest incredible innovations on the horizon not only for electronics and automotive but also architecture and insulating glass.

other glasses, for instance in insulating glass units. The stability and resistance of thin glass can be further enhanced through chemical tempering – something which is particularly in demand for displays and protective covers on smartphones. Other applications are protective covers for microscopic instruments and near-infrared filters for smartphone cameras.

Thin glass in construction and architecture

The construction industry, too, uses thin glasses to cover a wide range of applications where polymer solutions have their limits (e.g. the coating on solar panels). Compared with a plastic film, glass is far more heat-resistant, keeps its shape, is gas-tight and has outstanding visual qualities.

Thin glass is being used more and more for the middle pane in triple glazing, where it allows a clear reduction of thickness and weight. One proposed pane structure comprises an outer float glass pane (four millimeters), a semi-tempered middle pane (two millimeters) and another float glass pane on the inside (three millimeters). Compared with conventional glazing, this combination reduces the weight from 30 to 22.5 kilograms per square meter. The benefits of light, thin glazing are particularly noticeable in refurbishment projects.

In architecture, thin glasses not only reduce weight but also excel with their combination of breakage resistance and high flexibility, allowing for more design freedom. They permit new and variable options in shape and design, as it is possible to add specially treated coats to thin glass through grinding or screen printing. However, such applications are still more a matter of vision than everyday use. Other forward-looking applications include integrated functional coats such as OPV (organic photovoltaics), where energy is harvested via windows and switchable PDLC (polymer dispersed liquid crystal) coatings. This technology permits the creation of cloudy, opaque viewing guards, which only become transparent under an electric current. One specialist in this type of technology is the Austrian company LiSEC whose vacuum coating process with diffusion-proof edge seals also protects functional coats from humidity and environmental impact. At Glasstec 2018, LiSEC will present, among other things, suitable machines for the treatment of thin glass.

Thanks to thin-glass technology, curved glasses may well become increasingly established in architecture. Tempered thin glass can be bent into the desired shape on site either through cold bending or installation bending and can then be used as single glass or as a coat. It is an inexpensive alternative to hot bending at the factory. Furthermore, cold-bent glass has excellent visual qualities, due to fewer distortions.

Thin glass in the micrometer range makes glass particularly flexible without compromising on stability and hardness. One company that specializes in the development and production of ultra-thin glass is Schott, which uses its own down-draw technology. Its project AS 87 Eco has led to what is currently the world’s thinnest glass, at only 25 micrometers, and is now massproduced for sensitive applications (e.g. fingerprints) and optical components (camera filters) in smartphones, where it offers reliable protection. The market for this type of glass is enormous. Furthermore, flexible thin glass is also opening up new innovative options in virtual, mixed and augmented reality (the computer-aided enhancement of our perception of reality). One vision for tomorrow’s electronics is to achieve a good level of bendability without compromising on the outstanding visual qualities, clarity and valuable tactile properties of glass. •

by FRANK FULTON

Being sophisticated and therefore a dedicated reader of You Bet Your Glass, you’re undoubtedly aware of what has been transpiring with the Construction Lien Act (CLA) in Ontario over the past four years through my updates, whining and rants on the subject. For those of you who are new, here’s a brief refresher.

Bill 69, the Prompt Payment Act 2014, was introduced into the Ontario Parliament in May, 2013, got as far as second reading, received insurmountable kickback from developers and municipalities and was canned in April, 2014.

In March, 2014, the Ministry of the Attorney General of Ontario (AGO) committed to conduct a thorough review of the CLA and in February, 2015, the AGO announced they had appointed Bruce Reynolds as counsel to conduct the review.

In April, 2016, following an unprecedented degree of review and consultation with stakeholders across the entire construction sector, Reynolds and Sharon Vogel presented the AGO with their report and recommendations entitled “Striking the Balance: Expert Review of Ontario’s Construction Lien Act.”

Based on those recommendations, in May, 2017, Bill 142 entitled the Construction Lien Amendment Act, 2017, received first reading in the Ontario parliament. Finally, following numerous debates and clause-by-clause dissection by the Standing Committee of the Legislative Assembly, in December 2017 the act received third reading and was carried by a unanimous 87 to zero vote, receiving royal assent a week later.

Hopefully the passing of Ontario’s legislation will serve as a guide and a catalyst to have fair payment terms established nationwide.

As a member of the architectural glass and glazing community in Canada, the passing of this Act should be viewed as a good start and lend encouragement that at a fair and equitable playing field will someday be achievable. We’re not there yet. There are a lot of devils in the details of this act that will have to play out before we can determine if meaningful prompt payment terms are achieved.

The Ontario Glass and Metal Association filed a brief with the Standing Committee recommending that they revise two of these devils, namely:

“6.2 (1) Proper invoices shall be given to an owner on a monthly basis, unless the contract provides otherwise.” Basically, this gives an owner or contractor the right to circumvent the prompt payment monthly requirement simply by writing their contract to include longer invoice submission schedules.

“13.19 (3) Subject to subsection (4), if an amount is not paid when it is due under this section, interest shall be paid on the oustanding balance at the prejudgment interest rate determined under subsection 127 (2) of the Courts of Justice Act …”. This prescribed rate is only 0.8 per cent. This clause will act as incentive for an owner or contractor to drag out their payments, pay you the puny interest and save having to use bank financing at around six per cent. You’ll be the party requiring high-cost financing.

Our petitions were not acted on and the Act was completed with the devilish details intact. We’ll raise them again when the Act comes up for review in five years, hopefully with the backing of Prompt Payment Ontario.

It’s encouraging that prompt payment is gaining traction across Canada. In May, 2017, the Senate of Canada passed Bill S-224, the Canada Prompt Payment Act, that applies to construction contracts involving government institutions. Payment terms have also been discussed in provincial parliaments throughout the country for a number of years now. Hopefully the passing of Ontario’s legislation will serve as a guide and a catalyst to have fair payment terms established nationwide. •

Explore the artistic possibilities of digital printing with a variety of opacities, multiple colors and custom designs – all created by digitally mixing six basic ceramic inks – black, white, green, blue, red and yellow – to create a durable, UV resistant, long lasting design. Start today with your own custom graphic or choose from one of Vitrum’s exclusive ready-to-print designs. For additional information visit vitrum.ca or call 1.888.391.1166.

There’s a reason why our GRS TAPER-LOC® Glass Railing System was the recipient of both the USGlass and Architectural Products Readers’ Choice Award—it expedites the installation process while ensuring compliance with the latest codes. The GRS TAPER-LOC® Glass Railing System features the first base shoe with ICC-ES approval. The base shoe has also been re-engineered to be 30% lighter. Patented, dry-glaze technology allows for up to 50% faster installations, and a new Safety Seal prevents reaching over the railing to install the drop-side gasket, reducing the risk of injury. Take advantage of the opportunity to specify and install with confidence.

• One-Person Installation

• Reduces Installation Time by 50%

• Precision Torque Tool Prevents Overtightening

E-mail: railings@crlaurence.com

Phone: (800) 421-6144 Ext. 7730

Web: crlaurence.ca/taper-loc

• ICC-ES Approval ESR-3269 (Monolithic)

• ICC-ES Approval ESR-3842 (Laminated)

• 2015 IBC Section 2407 Compliant