Rich Porayko reports on acoustical glazing from last October’s FenWest conference in B.C.

Everything you need to get your glass in gear.

Canadian methods travel well for Border Glass.

Clean process water impacts your bottom line.

Rich Porayko reports on acoustical glazing from last October’s FenWest conference in B.C.

Everything you need to get your glass in gear.

Canadian methods travel well for Border Glass.

Clean process water impacts your bottom line.

Here’s a line I hear from companies in this industry sometimes:

“We like to keep a low profile.”

• top projects

What? This bizarre sentiment flies in the face of every known principle of business. If the goal of a company is to grow (as it has to be, or face dissolution) then it has to be familiar to as many potential customers as possible. Since there are new players entering the market all the time, and new people coming into control of old players, it is simply impossible for a business owner to be sure he is making direct contact with everyone important. It is therefore critical that a business have a prominent public profile, at least within the market it serves. And there is no such thing as too high a profile. Yes, some drawbacks come with being widely known. Your staff might have to field some time-wasting calls from suppliers who don’t have anything you want or customers who can’t pay for what you have. Rivals might try to poach good employees. Charities might target you for donations. Competitors might target your customers. But chances are, in a market as small as the Canadian glazing industry, these things are happening to your company already. These challenges need to be set against the undeniable benefit of being well known and well understood in your market: increased sales and business opportunities. Isn’t that why we all go to work every day?

• Government concierge

• IG products

One objection I have heard to having a higher profile is that company owners want competitors to have the least possible amount of information about their companies. A good principle but, like anything, it can be taken too far. There is a lot of information companies can share without giving away critical secrets. Look at public companies that have to publish all their financial information. Somehow they manage to maintain their competitive edge even with a very high degree of transparency.

“Word-of-mouth” seems to be the most popular method of branding and marketing in the glazing industry. It does have the advantage of being cheap. But if it is really so effective, I have to wonder why the most successful companies do not rely on it more. Instead, you see the largest and wealthiest companies with the most brand recognition consistently spending the most on advertising and publicity. If a high profile goes with high revenues, what does a low profile go with?

I think one reason why some companies avoid even friendly publicity is because they are afraid they will mess it up. While the old adage that there is no such thing as bad publicity is not entirely true (just ask Rob Ford), companies in this business tend to worry too much about looking bad and not enough about being invisible. Remember, PR help is available. Maybe you can’t afford a professional PR agency, but you probably know a sharp young person in your organization who can rattle on with the best of them. Why not empower him or her to deliver some talking points when necessary? •

February 2014 Volume 26 • Number 1

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: subscribe@glasscanadamag.com Tel: 866.790.6070 ext. 208 Fax: 877.624.1940 Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST) ($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

KevinBaird has been named president of the Global Flat Glass Group for Guardian Industries Corp., and will assume full P&L responsibility of this business. Baird replaces scott thomsen, who has resigned for health reasons. Most recently, Baird has been president and CEo of sRG Global, a Guardian company. sRG Global is one of the world’s largest manufacturers of chrome plated plastic parts for the automotive, commercial truck and household appliance industries. since joining the company in 2008, Baird created a world-class leadership team and strengthened and expanded sRG Global’s manufacturing position in major world markets including North America, Western and Central Europe and China. “this will be a seamless transition for our customers and Guardian,” said Ron Vaupel, CEo of Guardian Industries. “Kevin brings to our Flat Glass Group a proven record that parallels our objective to create long-term value with a strong focus on innovation. he will be supported by a seasoned global leadership team ready to reinforce this vision. our customers can be assured of Guardian’s continued commitment to their success.”

dave Prater, sRG vice-president of engineering, commercial and program management, will move into the position of president and CEo of sRG Global.

thomsen joined Guardian at its science and technology Center in 1999 and was responsible for directing research and development initiatives while playing a vital role in bringing innovative products to market. Before being named Global Flat Glass president in 2011, he was group vice-president of North American Flat Glass operations, and chief technology officer. “scott’s vision, leadership and boundless energy have helped transform Guardian into an industry leader in product research and innovation,” said Vaupel. “he was instrumental in the development of our science and technology Center and went on to lead North America and then Global Flat Glass with an unrivaled passion and dedication to our customers, this company and its people.” According to Vaupel, thomsen continues to work with Guardian on critical initiatives on a consultancy basis, adding, “We all stand behind scott’s decision and are excited that he will support Guardian moving forward.”

tyman, the parent company of both Amesbury and truth hardware, has announced senior management changes as part of the integration of the businesses after the acquisition of truth in July 2013. Jeff Graby, currently president of truth hardware has assumed the role of president and CEo for the combined Amesbury and truth organizations. Graby joined truth in 2012 and oversaw the divestment of the business from Melrose to tyman. Prior to that he held a number of senior management positions within Interface solutions, RAM Industries and FEs systems. Jonathan Petromelis, currently CEo of Amesbury, has made the decision to further his career outside of the tyman Group. Following a period of handover he will advise on integration initiatives before leaving the business. In addition, Mike McCann has joined the company to oversee sales activity across both brands as senior vice-president of sales. McCann brings sales and marketing experience from senior roles, most recently with Guardian Industries were he was VP Global sales.

the CGA regrets to announce that Fenestration B.C. has left the association. Its board expressed the view that the CGA was not providing sufficient value to its members now that the Glazing Contractors Association of B.C. has merged with the Window and door Manufacturers Association of B.C. to form the new association. We respectfully disagree, but wish FenBC well in its future endeavors.

save the date! the Canadian Glass Association’s Glass Connections Conference is set for thursday, June 5, in halifax, with an informal meetand-greet set for June 4. the meet-and-greet will be hosted by the Atlantic Glass Association complete with Nova scotia-style hospitality. the venue will be the holiday Inn harbourview hotel at 101 Wyse Road, dartmouth, N.s. – Guest speakers for the conference are still to be determined, as well as the registration fee. stay tuned for more updates. We are thrilled to announce our first sponsor for the event; dow Corning has committed to a Platinum sponsorship!

the PGAA is considering creating new awards for top glazing projects, one in northern Alberta and one in southern Alberta. We will again be registering for a try-A-trade in the provincial skills Competition,

which is set for Edmonton in May this year.

the Golf tournament will be held at the River Bend Golf Course in Red deer this year where they have air-conditioned meeting facilities and fairwayroaming carts. the tentative date is for August 21, which is a thursday.

the Master Glazier Program course development has been cancelled by the southern Alberta Institute of technology. the PGAA will now consider its options on how and where to get these courses developed, as we still feel the MGP is a worthwhile endeavor.

Finally, the PGAA’s AGM will be held in Red deer on March 12, when elections will be held. For more information, visit pgaa.ca.

It is with profound regret to report the passing of hugh duke on dec. 27, 2013. hugh was president of Inkan. he was a true leader in every sense of the word; a man well recognized and respected throughout the industry and a long time member and supporter of the oGMA. hugh will be sadly missed by his many friends in the business.

Workplace safety and Prevention services held its fourth meeting at tremco on Jan. 21, dealing with violence and harassment in the workplace. these meetings are of great value and benefit to glazing contractors and glass shops and cover many topics that have a significant impact on your business. If you are interested in attending a future meeting or joining the group, contact steve

Ringler. steve.ogm@bellnet.ca. the Ministry of Labour announced Nov. 15 that all workplaces governed by the occupational health and safety Act must provide training for supervisors and workers by July 1, 2014, and that the training must meet the specific equirements set out in the regulation. the training must include instruction in seven key areas for workers and six key areas for supervisors. It is imperative that your company satisfies these requirements, as penalties will be imposed on those that have not complied. You can find more about the new regulations and access the e-learning modules at labour. gov.on.ca.

In January, the oGMA reached agreement with Workplace safety and Prevention services, formerly the IAPA, to proceed on the creation of a manual geared specifically for small and midsized glazing contractors and glass shops. the manual will be made available to all oGMA member companies and will be of particular importance to companies who do not have a formal documented safety policy in place and who do not have the time or resources to create a program on their own. the WsPs will work with your company to implement the safety program, keep you updated on all changes to laws, put you in a strong position to withstand a Workwell audit, and help you to defend yourself with the Ministry of Labour in the event of a workplace accident. Your participation in this program is an absolute must for many obvious reasons. Contact an oGMA director for more information.

We will once again be holding our annual race night at the Woodbine Racetrack in

April. Flyers will be sent shortly with dates and details. If you haven’t been before, come give it a try. the races are fun to watch, the company is of the highest caliber, and the prime rib outstanding.

We are excited to be moving to a fabulous new venue for our spring golf this year. Join us at Pipers heath GC on thursday, May 29. We’re holding the tournament this year to coincide with the exciting new top Glass Conference and Exhibits show being held at the International Centre in Mississauga on May 28. Participants coming to town for the show are welcome to stay an extra day and join us at our golf event. In addition to a great golf day and steak dinner, the oGMA is pleased to announce here that we will also be presenting the Lifetime Achievement Award to a longtime glass industry icon, the well-deserving doug hotham.

If you are conducting business in the glass industry in ontario, the oGMA is the voice that represents your interests at the provincial and federal level. Protect your business interests by becoming a member or as an associate member if you are a consultant to the industry. doug Morris is heading up membership for our association, so please contact him today at douglasmorris@rogers.com or visit the oGMA website.

the oGMA wants to notify all glass and glazing companies in the province that the ontario version of the Glazing systems specifications Manual of standards and Practices is now available for purchase. this all-encompassing document is a must-have reference tool for all companies in the industry. For more information and to order yours, visit our website at ogma.ca.

PPG Industries will sponsor the 61st annual Progressive Architecture Awards (P/A Awards) ceremony, Feb. 20 at the Modern at the Museum of Modern Art in New York. the P/A Awards, initiated in 1954 by the editors of Progressive Architecture magazine and now sponsored by hanley-Wood, publishers of ARCHITECT magazine, are among the industry’s most prestigious juried awards. their purpose is to recognize building projects that challenge the boundaries of convention and promote overall design excellence and innovation. Last year, 10 projects earned P/A Awards, including five in the U.s. and one each in Canada, France, Germany, Mexico and the Netherlands.

As part of the event, PPG will recognize the 65th anniversary of Philip Johnson’s iconic Glass house in New Canaan, Conn., which was constructed in 1949 with ultra-clear, low-iron glass by PPG and later refurbished with starphire ultra-clear glass by PPG. Johnson and his partner, John Burgee, were the architects of record for PPG Place, a six-building complex in Pittsburgh that includes one PPG Place, the 40-story, neogothic, glass-spired tower that houses PPG’s global headquarters.

Juha Liettyä, member of Glaston’s executive management group, has been appointed senior vice-president of its Machines division. Juha Liettyä is currently head for the Machines division’s heat treatment product line. Juha Liettyä joined Glaston in 1986 and has been a member of the executive management group since 2007. t he appointment is part of the streamlining of decision making in the Machines division and a new senior vicepresident for the heat treatment product line will not be appointed. s enior vice-president of pre-processing and tools, Roberto Quintero, returns from Italy to Finland for personal reasons at the end of 2013. Glaston has transfered the sales and manufacturing of tools from the

Machines segment to the s ervices segment, feeling the transfer enables more efficient customer service as the customer’s contact persons and logistic network are the same. t he first interim report of 2014 will be prepared in accordance with the new business structure. t he Machines segment is divided into two product lines: heat treatment, which comprises manufacturing and sale of glass tempering, bending and laminating machines, and pre-processing, which now comprises manufacturing and sale of glass preprocessing machines. t he s ervices segment now includes maintenance and service of glass processing machines and the sale of spare parts and upgrades as well as the sale and manufacturing of tools.

Intertek Group has acquired Architectural testing Inc., one of the largest building products testing and certification companies in North America. Intertek purchased the company from private equity firm Wafra Partners and the management shareholders for a total cash consideration of Us$95 million. headquartered in York, Penn., AtI was set up in 1975 to verify the performance of residential window systems, but has since expanded into related residential and commercial markets including exterior wall systems and interior finish systems. the company employs 293 highly specialized technicians and engineers across 28 locations in the U.s. AtI says its investment in proprietary equipment and testing methodologies, its strong reputation with the regulatory bodies and manufacturers, combined with the improvement in the construction market in the U.s. provides Intertek with a strong platform for continued growth both domestically and internationally. Where Intertek has

already been successful in using its global network to expand its building products offering to new fast-growth overseas markets, it plans to develop AtI’s specialized offering in the same way to manufacturers internationally. Advances in high performance materials used for windows and walls particularly in response to reducing energy use and environmental damage are potential structural growth drivers for this business globally. Intertek also plans to provide its wide range of product testing expertise and comprehensive suite of certification marks to AtI’s established customer base. Wolfhart hauser, CEo of Intertek said “the industry, our customers and our stakeholders will all benefit from the combination of AtI and Intertek. this is a long term strategic opportunity which allows us to better serve our customers while enabling us to further expand our building products locations outside the U.s. and penetrate high growth areas around the globe.”

Kuraray and duPont have announced a definitive agreement for duPont to sell Glass Laminating solutions/Vinyls (GLs/Vinyls), a part of duPont Packaging and Industrial Polymers, to Kuraray for Us$543 million, plus the value of the inventories. the sale is expected to close during the first half of 2014 pending customary regulatory approvals. GLs/Vinyls is a leading supplier of polyvinyl butyral and ionomer sheets for safety glass, and vinyl acetate monomer and polyvinyl alcohol (PVA) products used in a variety of architectural, automotive and industrial applications. GLs/Vinyls delivered full-year 2012 net sales of more than Us$500 million. It has about 600 employees with six manufacturing sites in the U.s., Europe and Asia that serve more than 350 customers worldwide. Keiji Murakami, president of Kuraray’s Vinyl Acetate Company said, “Kuraray was one of the first to successfully industrialize and globally market PVA. As a pioneer of vinyl acetate-related business, Kuraray has a global presence in the business area of PVA resin, PVB resin and film, PVA film that is used for LCd and detergent unit packing, EVoh (ethylene vinyl alcohol) resin (trademarked as EVAL) used for food packaging and gasoline tanks, and PVA fiber (vinylon) that is used for a substitute of asbestos and a reinforcing material of cement. We will benefit from duPont’s talented global GLs/Vinyls team and their technology, R&d, manufacturing and sales network that

Wood’s Powr-Grip has announced the addition of a new technical sales representative in its Laurel, Mont., home office. Amy Jeffery comes to Powr-Grip with a strong background in sales and customer service. A Montana native, Amy grew up at the foot of the Absaroka-Beartooth Mountains

has supported it over the years. I am convinced these areas of expertise will allow us to continue to expand our vinyl acetate business going forward,” said Murakami.

“GLs/Vinyls will have a good home with Kuraray. that company’s focus on PVA as a central part of its core vinyl acetate business, its strong global market position and its capacity to invest in GLs/Vinyls all make this a good fit,” said William J. harvey, president of duPont Packaging and Industrial Polymers.

Kuraray was established in 1926. In 1950, the company achieved a corporate milestone as one of the first in the world to bring polyvinyl alcohol synthetic fiber to market. In subsequent years, Kuraray used its proprietary technology in the area of polymer chemistry and synthetic chemistry to develop resins, chemicals, fibers and textiles and others. Kuraray has overseas subsidiaries in 19 countries and regions outside Japan, as a global specialty chemical company. duPont has been bringing world-class science and engineering to the global marketplace in the form of innovative products, materials, and services since 1802. the company believes that by collaborating with customers, governments, NGos, and thought leaders, it can help find solutions to such global challenges as providing enough healthy food for people everywhere, decreasing dependence on fossil fuels, and protecting life and the environment.

and graduated from Montana state University–Billings with a degree in math and elementary education. Most recently, Amy was employed in sales management, where she directed the efforts of nearly 700 workers in Eastern Montana and Northeast Wyoming.

by CollEEn CroSS

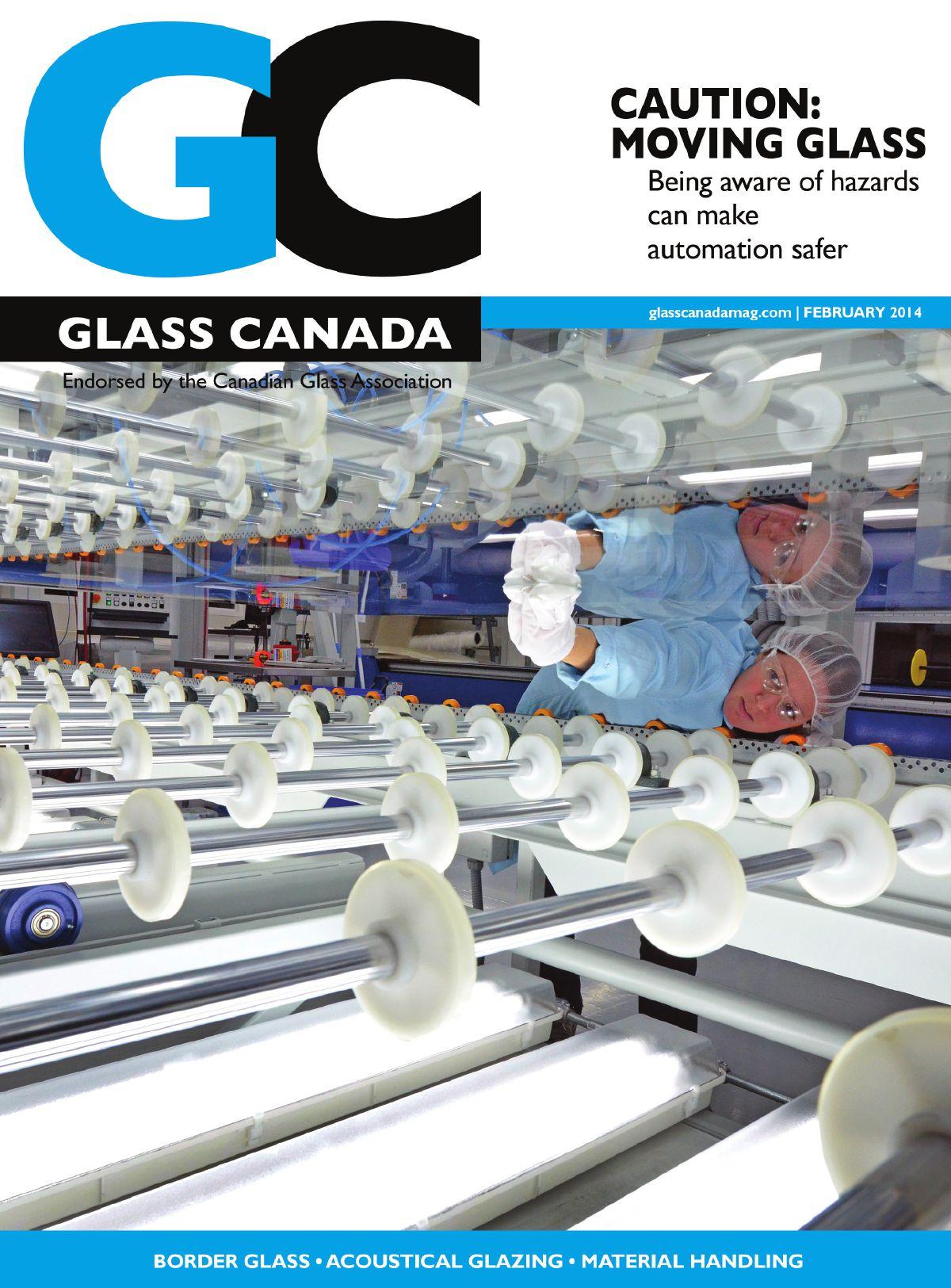

Moving glass has greater potential than stationary to injure or kill those handling it. Whether flat glass is being moved by forklift, suctioned lift, L-cart or automated system, it presents laceration, amputation and crushing hazards that may not be immediately apparent. Glass workers need to be educated on these hazards and taught procedures and habits that reduce the risk of injury on the job.

A key factor in crush incidents is something called “stored energy,” which contributes to crush injuries.

“Once it starts to go, glass is hard to stop,” says Mike Burk, product sales specialist for Quanex Building Products of Ohio and chairman of the Insulating Glass Manufacturers Alliance’s Glass Safety Awareness Council.

“Moving glass has momentum. The forces of gravity are against us,” says Burk. “Glass is silent and deadly.”

When materials such as glass or machinery are moving, especially in large amounts, their stored energy increases, he says.

“Stored” or “potential” energy is defined by the Safety Engineering Network as that “type of stored energy related to the sheer weight of things in the workplace, such as loaded pallets, heavy equipment, and bulk material.”

Overall, Burk says, he sees the most dangerous aspect of glass operations as handling and cutting large loads of glass. “You can wear all kinds of PPE to stop you from getting cut, but there’s not too much to stop you from being crushed.”

He says he doesn’t see as many deaths from lacerations as he used to “because people have gotten pretty good at protecting themselves from that.” However, the crushing incidents – people being crushed by large loads of lite – seem to be up based on anecdotal evidence.

We need to be observant and aware of the sheer weight of materials and the

hazard this energy creates, says Burk, who regularly gives seminars on glass safety throughout North America but says he is “not a trained safety guy, just passionate about safety and tired of seeing people get hurt.”

For example, in October 2011, the Occupational Health and Safety Insider reported that two workers in Kingston, Ont., were unpacking a crate of sheets of tempered arena glass when they removed the front panels. One of the workers left while the other cut the straps securing the glass in the crate. The glass fell onto the worker, injuring his leg.

Workers are at greater risk of laceration and amputation injuries when dealing with the complexity of machine elements and types of mechanical motion found in automated systems. Such systems bring workers in contact with elastic potential energy (as found in cables and ropes) and mechanical or electric potential energy (as found in motors, control panels, conveyors and hydraulic systems).

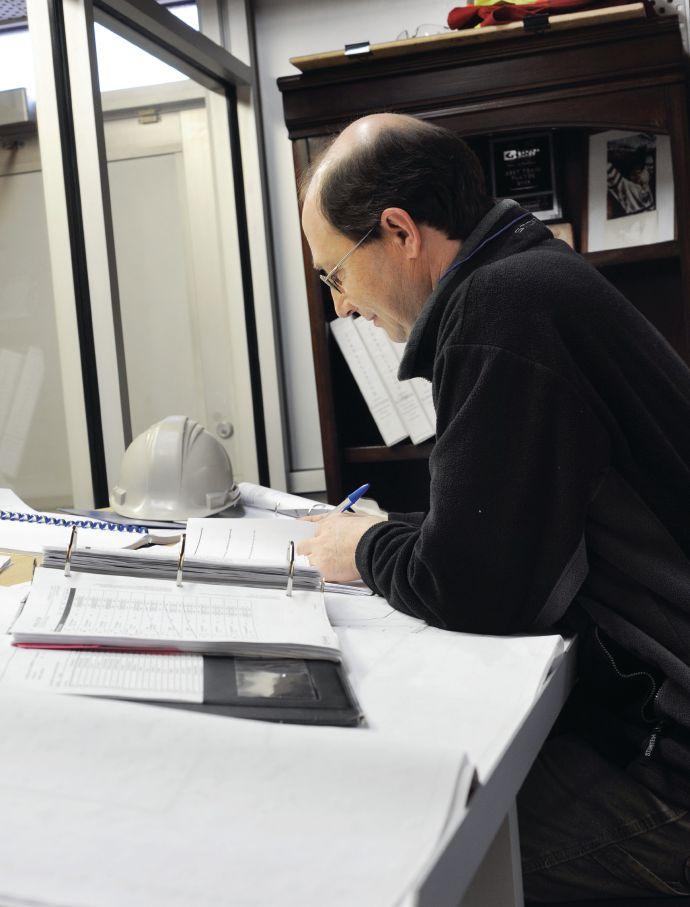

According to an Occupational Safety and Health Administration (OSHA) “Amputations” fact sheet, “pinch points” occur “when two parts move together and at least one moves in a rotary or circular motion that gears, motors, belt drives and pulleys generate.” Pinch points present hazards, as do several other machine components present hazards: point of operation; power-transmission apparatuses such as flywheels,

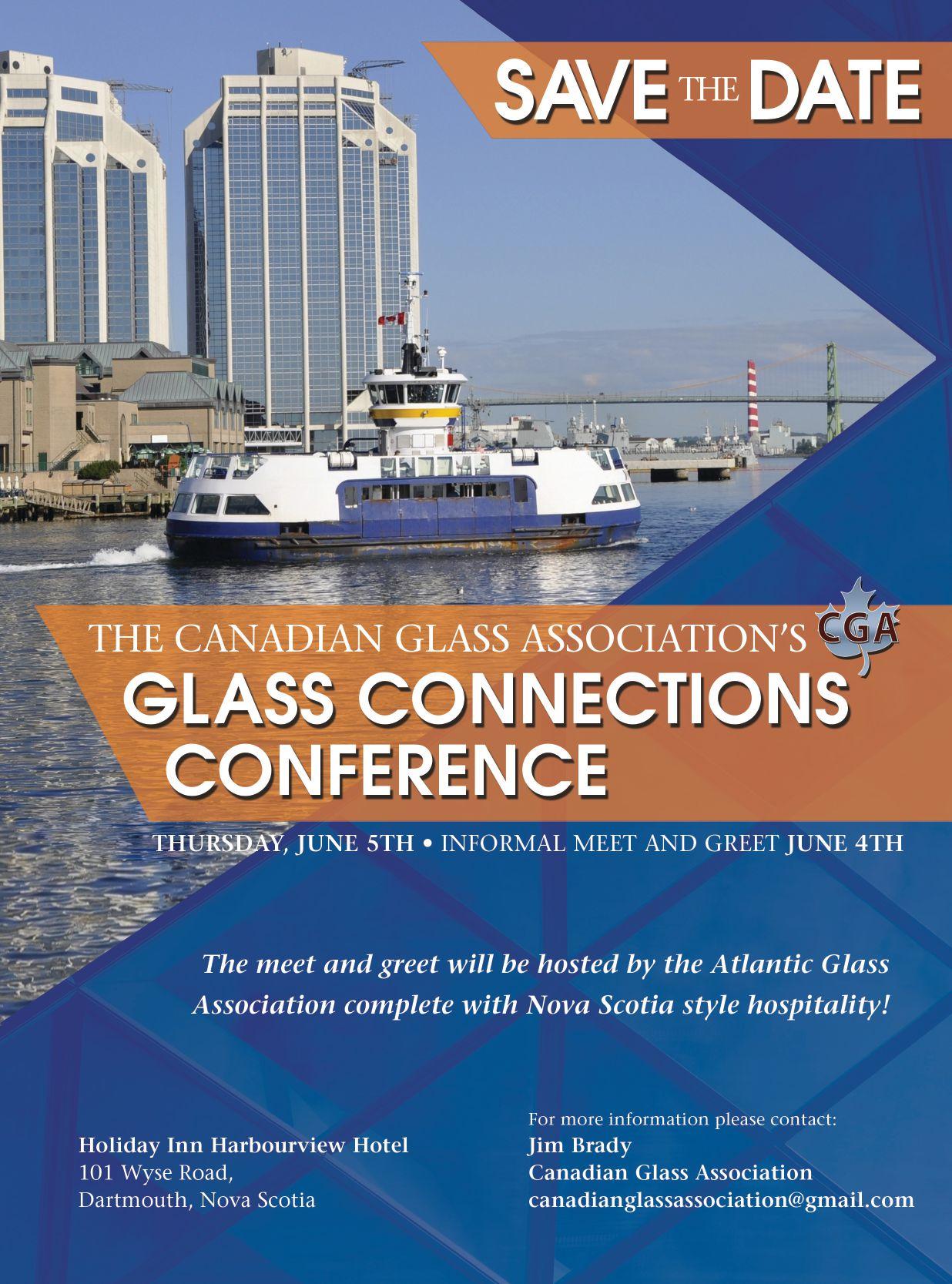

Dangers from automated equipment include pinch points, impacts from moving parts and electrocution. Simply making workers aware of what dangers a particular piece of equipment poses goes a long way toward making the workplace safer, safety experts say.

Photo credit: Agnora

pulleys, belts, chains and gears; and other moving parts.

Mechanical motion such as rotating, reciprocating, transversing, cutting, punching, shearing and bending introduces special dangers within a plant.

Toni Volpato, a consultant with Workplace Safety and Prevention Services (WSPS), highlights another related issue facing fabricators and glaziers working with automated systems: ergonomics.

The use of robotics to eliminate manual material handling is helping in prevention of ergonomic injuries, says Volpato. Robotics has reduced ergonomic stresses and severe laceration injuries that have been associated with material handling in the production workforce. However, increased use of robotics and process automation introduces moving machinery and electrical power hazards. That means a whole new set of hazards and risk being transferred from production workers to maintenance workers.

Burk says combatting these dangers requires awareness of these and other potential hazards, and solid procedures.

It’s important workers know their risks and have clear instructions on procedures. In the above case of the crush injury, a lapse in training resulted not only in an injured worker but also in fines for the company. According to a government news release, “an MOL investigation found that the

Safety regulations vary from province to province across Canada, but a general duty for employers to take reasonable steps to ensure safety is common everywhere. Organizations like the OGMA are trying to make it easier for companies to find the safety information they need.

worker hadn’t been advised that it was a safety hazard to unpack glass without assistance. The company pleaded guilty to failing to acquaint the worker with this hazard and was fined $55,000.”

Burk says there are some obvious steps operators can take to heighten awareness of risk. For example, he wonders why we don’t see more safety signs in glass departments, a relatively simple practice that would provide an immediate visual warning. “ ‘Warning: moving glass,’ they might say. I’ve never seen one,” he says. “You see hard hats and you see safety glasses and things like that, but just a big old label that says ‘caution: moving glass’ – that says a lot.”

Lockout/tag out procedures: “Be diligent in lockout/tag out procedures,” he says. “Lock out or tag out every bit you are responsible for. This step is especially important with machinery.”

The Canadian Centre for Occupational Health and Safety provides guidelines for lockout/tag out (LOTO) procedures on its website at www. ccohs.ca.

Stops and guards: Regular testing and maintenance of equipment is another crucial factor in plant safety. This includes inspection of emergency stops and conveyor belt guards.

Burk says some companies test emergency stops, or e-stops, daily; others test at the beginning of every shift. It’s important to be aware of what happens when you carry out an e-stop so that there are no surprises: most e-stops involve a hard, or immediate, stop, which brings with it another set of dangers in addition to their implications for productivity.

Burk stresses the importance of using proper guards and gates. The CSA Group standard, CAN/CSA-Z142-10: Code for Power Press Operation: Health, Safety, and Guarding Requirements, provides a good basis for evaluation of your company’s safeguarding procedures.

Controlling access: When transporting glass on carts, he says, safety means “avoiding tight spaces, uneven surfaces and surfaces not in good repair.” Burk urges management to control access to the glass department and other areas workers use, such as aisles and pathways, to keep people from walking into dangerous areas.

He cites a positive example of management taking the lead to control access at a plant he visits: when a truck occasionally blocks a major aisle, forcing workers to walk around it, the company has taken the step of requiring all

movement to stop while the truck is in the way.

“Everything stops,” he says. “Nobody walks around the truck or through the truck.

“Does it impact their business? Yes, it does. They’ve either had to rearrange everything . . . or come up with this policy. There are things that have to wait 20 minutes, but that’s better for this company than having people walk around the truck.”

Although provinces and territories fall under individual legislation, the CSA Group sets complementary safety standards that are voluntary and represent best practices. CSA standards may be enforced by law when referenced in provincial, territorial or federal legislation or regulations. Volpato says, “Many regulations made under Ontario’s Occupational Health and Safety Act require compliance with standards published by the CSA Group.

She adds that a recent development should make it easier for companies to access CSA standards: “Ontario – together with the other provinces and territories – is currently working with the CSA Group to make it easier for employers and workers to comply

with occupational health and safety requirements. Thanks to a pilot project funded in part by the government of Ontario, you can now read the relevant CSA standards before you buy. CSA standards are available online for many sectors, including industry, health care, mining, manufacturing, agriculture and construction.”

Looking from the outside in Burk says his group of companies relies heavily on third-party inspection, believing that “a fresh pair of eyes” often sees what they cannot. When you do the same thing every day, he says, you just don’t see the potential hazards or weaknesses in a system. He says positive changes may be slow, but over time you see massive changes when you have someone helping who knows a lot about the concerns and regulations.

An example of outside evaluation has been happening in Ontario throughout 2013 and continues in 2014. Ontario Glass & Metal Association (OGMA) president Steven Ringler has been working with Volpato and Workplace Safety and Prevention Services offering half-day information sessions to OGMA members to discuss health and safety topics of interest to the group.

“The WSPS offers expertise on the topic and the members have the opportunity to share ideas and best practices with each other during the meetings. Topics of interest to date have been H&S policy development, accident investigation, workplace inspections, guarding of machinery and violence and harassment.”

WSPS advises on the critical areas of occupational hygiene, ergonomics, safeguarding and warehouse safety. Volpato says the organization also will work with Ringler and the OGMA on the development of a health and safety manual customized to the needs of each employer.

Mike Burk points out something else companies can do to improve safety immediately and at low cost. “Form a safety committee and get people from different departments on that committee.” Employees from shipping or “the other side of the wall” such as front office staff – even vendors – will be more likely to ask why you do something until they get at the root of the problem, he says.

Asking “the five whys” is a tenet

of the kaizen philosophy. Kaizen, Japanese for “improvement” or “change for the best,” refers to philosophy or practices that focus upon continuous improvement of processes in manufacturing, engineering, and business management.

“Say you wanted to improve the production of a line. You would look at exactly how everything moves and

do spaghetti diagrams that show how everything moves product-wise.”

New workers often get training from shadowing more senior workers, Burk says, which has both good and bad sides – it often teaches good habits. “But you’ve got a few out there who won’t wear PPE and say things like ‘I’ve been doing this for 30 years and I haven’t got caught yet.’ ” •

CSA group

www.csagroup.org/ca/en/services/ codes-and-standards

Association of Workers’ Compensation Boards of Canada www.awcbc.org/en/safetyassociations. asp

Legislation that applies across Canada (not specific to glass industry)

www.awcbc.org/en/occupationalhealth andsafetyactsandregulations.asp

Workplace Safety Prevention Services

www.healthandsafetyontario.ca/wsps/ home.aspx 1-877-494-WsPs, ext. 977, or 905-614-1400

Canadian Centre for Occupational Health and Safety www.ccohs.ca 1-800-668-4284 or 905-572-2981

1964 Howard Wood’s vacuum cup revolutionized the Glass Industry. 2014 Wood’s Powr-Grip® vacuum cups and below-the-hook vacuum lifters can be found in nearly every country in the world!

1964

2014

Wood’s Powr-Grip offers a full line of products designed specifically for glass handling. To find more information or a distributor in your region, visit www.WPG.com or call 800.548.7341.

by MARGAREt WEBB

Margaret Webb is the executive director of the Insulating Glass Manufacturers Association.

The use of setting blocks in an insulating glass unit addresses many important issues and adds features that enhance the overall performance of the IGU as well as the entire fenestration system. The use of setting blocks is vital to successfully support IGUs and enhance their long-term performance. Compatibility, size, placement, hardness, profile, thickness, and material are all issues that should be carefully considered when using setting blocks.

Setting blocks serve many purposes. They cushion the bottom edge of the IGU and distribute the weight of the unit to the support frame or structure that holds the unit. Specific guidelines are given by IGMA regarding the placement of the setting blocks along with their size, material and hardness required to properly support the dead weight of the IGU.

Setting blocks also provide an exit path for any water that may infiltrate the glazing system by leading it via the sill member to the weep system or designed water drainage method. They provide uniform support to each lite of the IGU and assist in minimizing the potential for point pressures on the bottom edge of the glass that can lead to glass fracture or edge chipping. For multiple-cavity IGUs, the placement of the setting blocks must support each lite of glass.

Setting blocks is a critical element of the fenestration system’s water management system. Properly placed and sized correctly, they impede the capillary action of liquids (namely water) between surface finishes and IGU sealants. The thickness of the setting block should be considered for the prevention of trapped liquids. It is important to maintain a distance greater that that known to cause the capillary conditions between materials.

Incompatibility of setting block materials may lead to deterioration and collapse of this crucial element.

Compatibility is very important in the selection of the setting block material and ensures that the setting blocks will perform over the lifetime of the fenestration product. Incompatibility may lead to deterioration of the materials resulting in collapse of this crucial element of the weep system allowing water to become trapped in the glazing channel.

Adhering to the specific IGMA setting block guidelines will result in properly supported IGU and is an important element to successfully glazing the unit and ensuring long-term performance. IGMA recommends that all fenestration manufacturers consult with their IG fabricator to ensure that the setting blocks are sized correctly, are appropriately placed and that the setting block material used will be compatible both with the IG and glazing sealants.

Further information on setting blocks and other glazing recommendations may be found in IGMA’s TM-4000-90(07), North American Glazing Guidelines for Sealed Insulating Glass Units for Commercial and Residential Use. Please contact the IGMA office for further information on this and other industry publications.

Your input is important to the continuing evolution of IGMA guidelines like these. One great way to get involved is to attend our conferences, held twice each year in different locations in the U.S. and Canada. Our Annual Conference takes place March 4 through 7 in San Francisco, where attendees will hear from all our technical committees, attend the IGMA Education Seminar and have a chance to chime in with their opinions and feedback. But the conference is not all dry tech-talk. This year’s conference will include a night tour of Alcatraz’s famous island prison and a ‘60s-themed dinner where guests are invited to dress up in their best hippie or mod gear. If you cannot make it to our Annual Conference, never fear, we will hold another Technical Conference this August in Quebec City, date to be announced.•

by sKIP MACLEAN

Skip Maclean is president of Fenestration Canada. He is business development manager for Tru-Tech Doors and has over 40 years’ experience in the window and door industry.

The 2013 Win-Door North America show held Nov. 12 through 14 at the Metro Toronto Convention Centre demonstrated continued industry strength with exhibitor floor space sales up and registrations on par with previous shows. A strong educational program attracted many visitors looking for the latest updates on important topics dealing with code changes, new technologies and research to guide future business planning. The Canadian window and door manufacturing industry continues to move through an important developmental period and Fenestration Canada is in a solid position to serve its members in a number of critical areas. The association’s office is now a focal point for cost-effective management of priorities identified by members ranging from expanding membership recruitment strategies, creating suitable programming for events and fostering ever-important interaction and engagement with industry stakeholders.

A strategic objective for 2014 is to foster a greater level of accountability at the committee level thereby ensuring that the industry is well served across a broad spectrum of initiatives. This will necessitate a re-vitalization of our committee structures so that they become more responsive to membership requirements for products and services that are relevant to challenges facing the sector. One such initiative was the creation of a Fabricators’ Council in direct response to member fabricators who wanted a specific forum and the opportunity to have a say and potentially make a difference in the future of this industry. The association also plans to continue developing and offering information seminars and webinars designed to

A strategic objective for 2014 is to foster a greater level of accountability at the committee level.

keep members current on regulations and compliance requirements.

Speaking of regulations, check out our Building Code Fenestration Performance Calculator, which is now live on our website. This free tool gives you the critical design specifications your windows and doors will have to meet under the Canadian supplement to NAFS-08, including minimum performance grade, minimum positive design pressure, minimum negative design pressure, minimum water penetration resistance test pressure and the minimum Canadian rating for air infiltration/exfiltration. Just plug in your region, the height above ground you product is to be installed and the type of surrounding terrain and the calculator fills in the numbers. Please keep in mind that these numbers are for general guidance only and not legally binding. Always consult your test lab and local building code officials to find out if a particular product is compliant in your area.

Looking further ahead, the annual meeting will be held this June in Winnipeg. The conference is a highly rewarding event where some very close bonds are developed among a wide range of industry members from all facets of the industry. Those who participate realize how rewarding it is to be able to combine prized networking opportunities with topical seminars and presentations dealing with the pulse of challenges and issues facing the fenestration sector. If you are involved in any aspect of the fenestration industry, we invite you to mark your calendars and plan on attending the 2014 AGM being held in Winnipeg at the Hotel Fort Garry, June 12 to 14.

Finally, Fenestration Canada wishes to extend its congratulations to our technical consultant, Jeff Baker, who recently became the first-ever Canadian elected chairman of the National Fenestration Research Council.

As always, members and potential members alike are encouraged to visit our website regularly for important updates on activities and resource materials. The link is www.fenestrationcanada.ca •

Alex Gluskin programs the automated CNC multi-tool workstation. Border Glass has invested in staying on pace with the much larger competitors.

Photo credit: Anna Borys

Celebrating 47 years of in the glass industry, Border Glass is proud to be a successful, thirdgeneration family-owned business. Correction, a successful, thirdgeneration, professionally managed family-owned business.

Originally founded in 1967 in Selkirk, Man., by Don Borys, a longrespected member of the Manitoba glass and aluminum community, Border Glass is now owned by Don’s sons David and Paul, who have relocated and expanded operations with offices and manufacturing facilities in Winnipeg and Phoenix, Ariz.

“We’re a professionally managed, family owned business,” says Paul Borys, president, CEO and co-owner of Border Glass. “Ten years ago, as we were looking to a young third generation coming on board, we felt the need to bring on a group of skilled management professionals and I believe we have succeeded in building a very solid team. They are virtually running the company now, and that’s very gratifying considering how much we’ve invested into our people.”

“We have approximately 75

employees,” says co-owner and director of sales David Borys. “Our biggest and most important asset are our people. The culture of family permeates everything we do. I do not get tired of saying that, because it’s a fact. We have second- and some third-generation employees. We often have employees bringing their kids and/or nephews here because it’s a great place to work. That’s what we’re all about.”

“All three of my kids, and two of Paul’s kids work for Border Glass in very responsible roles,” says David. “Our brother Tim is Border’s director of production. We have a lot of excellent people here that do a very good job for us.”

Border Glass serves low- to medium-rise curtain wall customers across western Canada but primarily in Manitoba and Alberta. The company boasts a long list of flagship projects including malls, office buildings, arenas and airports. Some of the projects Border Glass has completed include MTS Centre (home of the Winnipeg Jets), the Manitoba Remand Centre, the Winnipeg Police Services building, the University College of

Year established: 1967

Number of employees: 80

Location: Winnipeg, Man., and Phoenix, Ariz.

Facility: 37,000 square feet

Products: Installed curtain wall and commercial storefront

Main markets: Manitoba, saskatchewan, Alberta and Arizona

the North (UCN) located in northern Manitoba and the interior portion of the “double skin envelope” of the Manitoba Hydro Building. Border is wrapping up the interior portion of the Canadian Museum of Human Rights and is currently working on Heritage Landing on the Assiniboine river which is a 28-storey, $70,000,000 tower. The company is also installing the curtain wall for the podium at the mixed-use, 200,000-square-foot Centrepoint in downtown Winnipeg which includes residences, a boutique hotel, two restaurants and offices.

“For a big project, we might

Some examples of Border Glass’ work. Top right is the Optical Science Building at the University of Arizona and bottom is the MTS Centre in Winnipeg, home of the Winnipeg Jets. Border Glass has found its familiarity with high thermal specifications has given it an advantage in the southern U.S. Photo credits: Anna Borys

see competition from Toronto and Vancouver,” says David, “but Winnipeg is, relatively speaking, not that big of a city. It’s not that attractive a market for them. The true high rise towers don’t exist here. The tallest are typically 30 floors and we’ve been in Manitoba for 47 years which makes it a challenge for out-of-town competitors to compete for the bigger jobs.”

According to David, Border Glass has grown where it can easily handle anything in Winnipeg, however they also reach out into Saskatchewan, Alberta and even south of the border as well.

“We’ve been in the United States for 12 years now, primarily in Arizona, however we’ve completed projects in Washington and North Dakota as well,” says Paul, who lives and works out of the company’s Phoenix location. Paul frequently travels to Canada fulfilling his role on both sides of the border.

“We were met with open arms in Arizona,” says Paul. “Contractors and developers saw how we performed in the first few years and our reputation and business grew by word of mouth from there. In Canada, the building codes are based mainly on thermal performance, debatably more so than air and water, and we brought that standard of performance to the southern U.S. Heating isn’t much of a concern in the Phoenix area but energy costs for cooling are an issue so the thermal performance of our walls in the U.S. is an important consideration.”

“Our approach is to focus on quality but at the same time get jobs closed in as quickly as possible. Much of our product is installed outside and for half the year our northern crews work in a very harsh climate. For that reason alone it seems we were geared for a better timeline on large projects than our local competitors in the U.S.”

“The trend is very much towards energy efficiency,” says David. “We often help out at the design stage of projects, which includes performance reviews, cost budgeting, and providing

advice for systems or details. We make ourselves available to owners, architects, and engineers to provide this service.”

David continues, “The need is usually made up of three components: performance, price and delivery. We tailor-make our product and service to fit the job. If we only have three months to install it, we need to look at the supplier and the system. If there is a need for high performance, for instance a swimming pool or a tightly controlled environment, then we work with the designers to make sure the system is appropriate. If there are significant budget concerns, we can look at considering alternative suppliers.”

“We know most of the architects

“We are like a breath of fresh air in the Phoenix market.” – Paul Borys

very well,” says David. “They will call us in and might have a partial idea of a glazing system, but a clear vision of what they are looking for and we’ll say ‘tell us what you want to do.’ We will work with whatever product and/ or supplier necessary to get the right solution. If necessary, we’ll cut our own dies and do what we have to do.”

There has always been a demand in Canada and the U.S. for security glazing in institutions such as penitentiaries, courthouses and detention centres which have high-end requirements on the interior. “We are very fortunate to have projects such as the Winnipeg Remand Centre and Sherriff Joe Arpaio’s new home in Arizona as a significant part of our portfolio,” shares Paul. “When we perform on the building envelope of a jail or a courthouse, we generally do all of the security glazing within. On the U.S. side, Homeland Security since 9-11 has imposed demanding design requirements on our industry, such as blast mitigation. There are some good specialty glazing opportunities available for glazing contractors in Canada and

Ryan Trombo, Border Glass production manager, reviews drawings for a current project.

the U.S. who want to expand outside the building envelope.”

Five years ago the economy crashed and the American division of Border Glass went into survival mode to pull through the tough times. “Several of our competitors are gone now and we are perfectly positioned to take advantage of the sleeping giant awakening,” says Paul. “And not just Arizona; we see signs of the entire U.S. coming back to life. We have invested a lot in maintaining a presence as well as staying on pace with the much larger competitors. We’re looking to expand our market size and volume in the U.S. in the next several years.”

“Border Glass as a whole has thrived in the last six or eight years largely due to the high standard and work ethic of our people” states Paul. “We’ve created a culture and working environment that good people want to be a part of. If you talk to the CEO of any successful company, they are going to tell you that a key to successful growth is to get the right people in the right seats. My job for the last eight years has been largely focused on accomplishing that. We have very little turnover in our company. There must be something about the way we treat our employees right from the day they arrive and lately we don’t spend a lot of money on help wanted ads.”

“We’re like a breath of fresh air when it comes to employers in the Phoenix market,” says Paul. “We don’t lay off very easily. If we find good people, we try to keep them busy. We paid for everyone to stay at home over Christmas. You have to spend money to make money and we’ve found that ‘our people’ is a very good place to invest. That’s been a win-win for many years now. We’re happy with the profitability and David and I hear from folks on a regular basis that Border Glass is a great place to work. That to me, is a big part of being successful in business.” •

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

Canada’s new event for the commercial glazing industry, top Glass, has announced its lineup of AIA- and oAA-accredited learning sessions, available free to attendees on May 28 at the International Centre in Mississauga, o nt. t hree technical sessions will take place over the course of the day-long event, plus a keynote address that will start the day. t he top Glass keynote speaker will be announced at a later date.

Kicking off the technical sessions will be Paul Chackery of Fenzi North America with is AIA-accredited talk, “ trends in adhesives and sealants.” t he session will provide an overview of the characteristics insulating glass sealants must provide to ensure longterm thermal performance, structural durability and longevity in insulating glass units. Learning outcomes include identifying the components of an IG unit and discussing how they contribute to the function of the unit as a whole in energy performance and safety glazing applications; identifying

and comparing IG sealant types and determining key differences between primary and secondary seals, and assessing the durability and mechanical properties of an IG sealant and selecting an appropriate product for specific applications to ensure thermal performance does not diminish over the life-span of the building.

Next up will be “ d aylighting and thermal controls for the green building specialist,” by John Carpenter, president of Clearstream Architectural Products. Carpenter will discuss architectural glass techniques available to reduce illuminating, heating and cooling costs, referencing case studies illustrating the new h VAC advancements including a look at View’s h umber h ospital project, the largest dynamic glass installation in North America. Carpenter will also discuss programable electrochromic glas, including glass with dynamic and static visible light control and advanced glass façade developments with media glass. and programmable applications.

Finally, Richard Brightling of s tella

Architectural h ardware will wrap up the day’s sessions with “Beyond the hardware: Counting the whole cost of point-supported building envelope design.” In his role as a sales representative architects often ask Brightling about the cost of pointsupported hardware. As it turns out, they are not really interested in the cost of hardware, but rather the cost of the overall job. t his includes four key aspects including hardware, glass engineering, primary glass and installation labour. Brightling will provide pricing guidelines for the various types of structural glazing projects which people not familiar with this niche market find useful. h e will illustrate the five primary ways to build a structural glass wall and the attendant ballpark costs associated with the various methodologies. top Glass is made possible by Gold s ponsor tremco, s ilver s ponsor Alumicor and association partners, the Canadian Glass Association and the o ntario Glass and Metal Association.

by rICH PorAYko

Eastern Canada’s flagship fenestration event, Fenestration West, returned to the Delta Burnaby this past October. The event was created by the Fenestration Association of British Columbia (FEN-BC) following a merger of the non-profit Glazing Contractors Association of B.C. (GCABC) and the Window and Door Manufacturers Association of B.C. (WDMABC). Eligible for AIBC Core Learning Units, Fenestration West 2013 was sponsored by Apex Aluminum Extrusions.

Topics from the sessions included dynamic eletrochromic programmable glass,

specifying the energy performance of glazing products in B.C., thermal bridging for building assemblies and building a watertight door.

One of the standout presentations had to be “Acoustic Performance of Windows” presented by Briét (Brizi) Coetzer, from North Vancouver’s BKL Consultants. According to Coetzer, urban planners in most Metro Vancouver municipalities have requirements in place to ensure that new residential projects proposed for high noise environments will be designed to achieve acceptable interior noise levels. Although exterior walls, roofs, doors and ventilation will sometimes require upgrading, it isn’t a surprise, as Coetzer explained to the attendees, that windows are the controlling factor with respect to the interior noise levels.

Even where there are no specific requirements imposed by municipalities, designers are paying careful attention to the acoustic performance of windows where noise-sensitive buildings such as residences, hotels, churches, schools and hospitals are involved. Speaking on a very timely, technical topic, Coetzer provided an excellent introduction and clearly explained the basics of sound, magnitude, frequencies, decibels, noise types and how humans hear all of the above.

“Single number ratings such as Sound Transmission Class (STC) and Outside to Inside Transmission Class (OITC) are

both a weighted average of the performance of a product which can assist designers in evaluating the acoustic performance of two similar products to determine which one is better,” said Coetzer. “A single number rating is a single number that represents a whole range of frequencies. Can you really rely on one number to give you an accurate performance of the window? I would suggest not. It is helpful to make initial decisions; however, there is a lot of detail which gets lost in coming up with this single number. These numbers perform adequately over a range of generalized cases but perform extremely well in almost none.”

“OITC is more suited for applications where you are dealing with outdoor to indoor noise transmission whereas STC is more suited for indoor room to room noise transmission.” The STC classification system is based on the amount of attenuation required to reduce a standard household noise spectrum to be subjectively quiet. Noise sources used in generating this standard household spectrum consisted of loud speech, radio, television, vacuum cleaner noise and air conditioner noise. “So if that is the kind of noise that you want to mitigate, then STC is the appropriate choice,” said Coetzer.

Building envelope companies deal with outdoor to indoor sound transmission of traffic noise, for example. “That is a different frequency spectrum completely which has a much

ABOVE: Leonard Pianalto of RJC brought attendees up to speed on how to specify the energy performance of glazing components in B.C.’s new, more complicated regime under the Energy Efficiency Act. Photo credit: Rich Porayko

bigger low-frequency component that isn’t easy to mitigate with windows,” stated Coetzer. “So the STC rating is not going to give you an accurate indication of relative acoustic performance if you are trying to mitigate low frequency noise because the STC classification system is, by nature, principally controlled by midto high-frequency noise.

“The OITC test method came about during the late 1980s in response to a perceived need for a more robust rating system that performed adequately for low-frequency incident sounds,” said Coetzer. “The OITC classification system performs well in situations where the incident sound is broadband in nature and is dominated by low-frequency sound such as typical vehicle, aircraft and railway traffic noise. This is more representative of the real situation in which designers would be trying to choose appropriate exterior fenestration products,” said Coetzer.

According to Coetzer, the rule of thumb for glass thickness is the mass law, which says “for fixed incident frequency, the transmission loss across a barrier can be increased by approximately six decibels by doubling the mass per unit area.” So if you replace three-millimetre lites with six-millimetre lites, for example, you could increase transmission loss by six decibels, which is the equivalent of allowing only one quarter of the noise energy incident on the glass to pass through to the indoor space.

However, this is complicated by the “co-incidence effect” and “mass-air-mass resonance.” It is always a good idea to call in the acoustical experts to evaluate the performance of an assembly in the context of the proposed construction.

Airspace is also important. Coetzer explained to attendees that if you double the airspace, you could get an additional three-decibel increase in sound transmission loss. This rule of thumb seems to work well for STC ratings on assemblies with air spaces over 19 millimetres but is less correlated with OITC ratings.

Another key takeaway from Coetzer’s presentation was that laminated glass has constrained layer damping that significantly improves the transmission loss. “If you think of a sound wave moving through the glass, once it hits that constrained layer, there is a lot of energy that gets absorbed (transferred to heat). Laminated glass definitely helps. The

use of laminated glass with appropriate interlayer increases transmission loss by approximately five decibels.”

Interestingly enough, if you add a gas such as argon to an insulated glass unit, it does change the shape of the transmission loss curve but usually does not result in any significant change to the OITC or STC rating.

Coetzer also explained that edge damping improves transmission loss; however, it’s marginal and is really only in the lower and upper frequencies. Most of the transmission loss that is of benefit to human hearing is in the middle frequency range, which is not improved by edge damping. Triple glazing also performs no better than double glazing with the same total glass weight and the same overall section depth.

In order to improve acoustical performance, you want to focus foremost on glass thickness and airspace size, with consideration given to panel size, use of laminated glass and airtight installation.

“If you have a large panel of glass, it is more flexible and is able to vibrate more when exposed to a noise source. A more rigid, smaller panel of glass will improve

the transmission loss because the glass stiffness reduces the ability of the glass to vibrate. So it’s better to have a smaller panel size if acoustics are a concern but it’s very important to look at the TL data from the lab and know what panel size was used in the test which produced the STC/OITC rating,” explained Coetzer. Air leakage is another acoustic degrading factor that is most apparent at high frequencies. “Gaskets must seal positively when the window is closed,” said Coetzer. “If you have air leakage around the edge of a panel, the high frequency performance is significantly degraded. If the window isn’t sealed airtight, all of the efforts of extra glass thickness, laminated glass and increased airspace can be wasted. Double gaskets should be employed to provide sealing redundancy.” •

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

Bohle likes the flexibility of decentralized water-cleaning systems that can be easily moved, integrated into larger systems or reconfigured as processes and machinery change. Bottom line: the operator is more likely to use and take care of the machine if it is easy to do so and accessible.

When processing glass with machinery (drilling, grinding, polishing), glass particles are removed from the glass surface by an abrasive force. In most cases, the working area is cooled with water which prevents heat cracks at the glass edges and at the same time flushes the glass particles away. As long as this process is effectively cooling the cutting area, few operators give much thought to the cleanliness of the water, or the benefits of using cleaner water in the process.

Normally, the dirty cooling water is drained into a collecting tank where only coarse particles can settle and thus be filtered. The the water is then circulated back into the cutting machine. As a result, the water gets more and more contaminated the longer the machine is in use. Because of this, it has to be exchanged at regular intervals. With a volume of 400 liters (typical for a straight line edger with eight to 11 spindles) and only a weekly cleaning cycle in a one-shift operation, this not only results in a yearly water consumption of approximately 20,000 liters, but also implies further, significant cost

for the disposal of the waste water, depending on regulations in your area.

Clean cooling water further considerable advantages. In combination with coolant, it provides a continuously high grinding and polishing quality and increases the performance of the machine by up to 20 per cent, the service life of the tools by up to 30 per cent, and reliably prevents the cooling water from becoming alkaline. Of course, you can also add coolant to uncleaned water, however, when the water needs to be exchanged, the coolant is discarded at the same time. This can put you afoul of further environmental regulations and incur costs for disposal and replacement coolant.

The ambition to make industrial processes environmentally friendly and reduce costs at the same time leads increasingly to the installation of water cleaning systems. These cannot only be installed in large plants or when new glass processing machines are purchased but can be connected to existing machines without any problem.

In the glass industry, centrifuges or central cleaning stations based on

sedimentation are the most commonly used systems to clean the cooling water. The disadvantage of a centrifuge is the high operating cost of electricity, the comparatively high susceptibility to faults, the high maintenance cost and, most importantly, the fact that centrifuges cannot filter glass particles smaller than five microns. In contrast, water cleaning systems based on the principle of sedimentation can filter even the smallest glass particles almost entirely. By adding the correct amount of flocculant, nearly clear water is gained. Even oily residues are removed almost entirely.

Centralized water cleaning systems can be complex to set up and operate. Modern sedimentors, including Bohle’s, have been designed to work in a decentralized configuration at the individual glass processing machine and are therefore more economic to both purchase and operate, less error-prone, more compact and more user-friendly.

In Bohle-style sedimentors, flocculant is added to the grinding water to bind fine glass particles which can then settle to the bottom and be discharged. The glass sludge can usually be disposed of

as normal residual waste. Flocculants are available that react exclusively within the sedimentor tank, making the waste water safe for disposal.

Bohle feels cleaning water using the bypass principle is superior to other methods. With this principle, part of the water is taken out of the water circuit, cleaned and fed back into the machine. Bypass cleaning systems can very easily be integrated with already existing glass processing machinery. Also, when planning new glass processing lines, bypass systems require relatively less space and low investment costs. Flocculant does not enter into the machinery circuit and soapy buildup on the tools is practically eliminated.

In in-line cleaning systems, all the cooling water is cleaned as it is circulated. This approach has benefits for some applications, which is why Bohle offers both. Apart from the larger space and investment requirements, the correct dosing of the flocculant in in-line systems is very complex. In-line sedimentation systems can achieve an even lower content of solids in the water, however this is normally not required.

Look for a water cleaning system manufacturer that offers systems for different sizes of glass processing machinery, from basic machines all the way up to crosslinked, double-sided, straight line edgers. Every plant and every project is different, so you need a company that can customize its system for your shop and grow as you grow.

To justify a water cleaning system, look at cost savings on fresh water use, disposal of waste water, cleaning labour and machine idle time. If you can, also consider the impact of better machine performance and longer tool life. A sedimentary water cleaning system should pay for itself in less than a year.

Bohle Sedimentor technology is in successful operation in many mediumsized glass processing companies but also in large enterprises such as Pilkington, Auer Lighting, Velux, Saint-Gobain, and Salgglas Automotive. •

July 7-10, 2014

Philadelphia Convention Center Philadelphia, PA, USA

GlassCon Global is the first event of its kind in North America. It brings together global innovations in glass technology from Europe and North America to further the development of the glass industry.

You don’t want to miss this dynamic, educational forum. Register now!

cynergyergonomics.com

handling vertical lifts, manual ergonomic pick and place systems and workstation improvements for manufacturing, assembly, production and distribution centers that currently use human power for material handling as well as providing automated material handling solutions.

eight-inch casters.

“ o ur rolling work benches are found on commercial jobsites everywhere because of their durability, versatility, and security features,” says Jim s carlata, director of marketing operations for Knaack.

Knaack s toragemaster rolling work benches are available through a large network of construction equipment dealers and distributors.

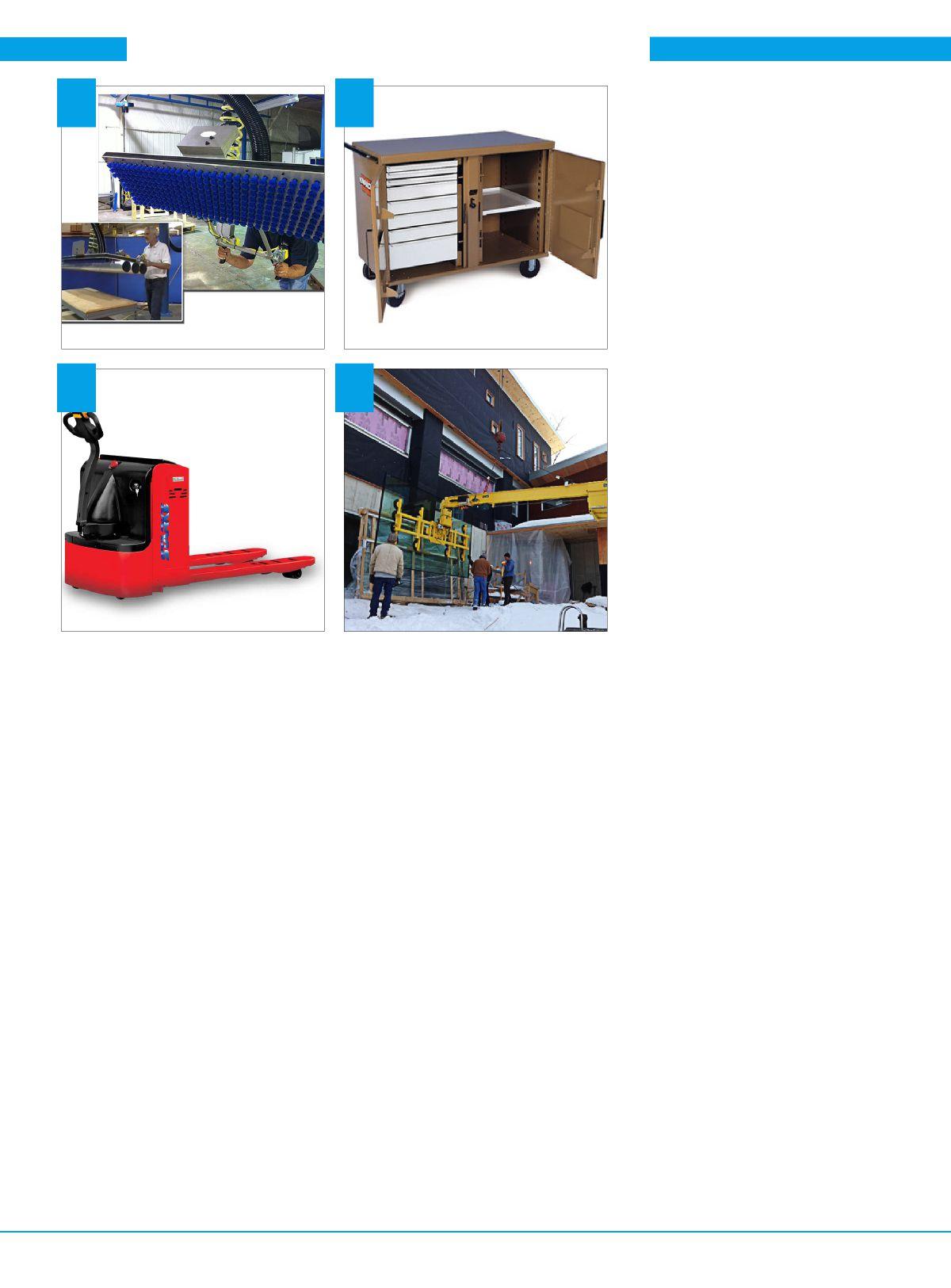

starkecanada.com

t he New s tarke LiftMaxx P t 45WAXB t AC electric walk-behind pallet truck provides more than just an average material handling solution for your business. t he truck features a riser axle that is located at the highest point of the forks, which protects the riser axles from uneven floors. s pring-loaded castors improve lateral stability and enhance truck performance and service life. t he efficient AC motor is mounted parallel with the wheel in an upright position allowing for a tight turning radius and ease of maintenance. t he advanced Curtis control system allows for full program ability to preference. t he New P t 45WAX is now available at your authorized s tarke dealers throughout the U s A and Canada.

knaack.ca

Meet the challenge of installing windows, Plexiglas and other materials under overhangs or into other hard-to-reach places with the CB3 d C s CounterBalancer. When combined with PowrGrip’s MR1611L d C Vacuum Lifter, this equipment extends the load forward from the crane’s cable through the use of a remote controlled, power counterweight, making otherwise difficult or dangerous installations possible. Measuring 18-1/2 feet long and capable of lifting a massive 2800 pounds, the CB3 features a maximum reach of nearly seven feet, making short work of the most troublesome overhangs or obstacles. Powr-Grip’s CB3 Counter-Balancer comes standard with a rigid mount for our MR1611L d C Vacuum Lifter. An integrated mounting platform allows the counterbalance beam to rest at a 1 3 4 2

Cynergy Ergonomics has recently developed a universal lifting system to lift and manipulate materials with vastly different geometries with a single vacuum lifter. With capacities of over 1,000 pounds and the ability to handle virtually any shape or geometry, this vacuum gripper is suitable for job shops, custom manufacturers and shipping/ receiving areas that are tasked with handling a wide range of products. t he smart design maintains vacuum only on the cups which have contacted the lifting surface allowing it to handle cylindrical products such as pipe, flat items such as board or panels and varied geometries such as turbine blades, pallets, curved shapes and more. Cynergy Ergonomics specializes in ergonomic workstations and material handling equipment such as lifts, articulating arm manipulators, sheet, panel and roll lifters, vacuum tube lifting, roll manipulators and material handling equipment. It specializes in lifting device design, lift assist system designs, material

Knaack s toragemaster rolling work benches are super heavy-duty, professional-grade storage, coupled with convenient work surfaces for jobsites that require mobility. t he work benches are offered in a complete range of sizes and load capacities, with eight models to choose from. Models 45, 47, 49 and 63 (the mechanic’s tool chest) have six-inch casters and 1,000-pound load capacities. Model 47 can also be customized with your choice of shelving and drawers. h eavy-duty rolling work benches (models 58 and 59) take up to 2,650 pounds while providing almost 10 square feet of work space. t he Knaack War Wagon rolling work bench (model 62) accommodates over 2.5 tons of payload with a generous 13 square feet of work surface, sitting on

powrgrip.com

convenient elevation for attaching the MR16, dispensing with the need for two separate cranes or elaborate assembly procedures. Although the MR16 Vacuum Lifter is the standard attachment, the CB3 Counter-Balancer can easily be adapted to connect another vacuum lifter, when a different one is required.

vi-cas.com

Vi-Cas Manufacturing offers a wide range of vacuum cups for ergonomic lifters of all types and sizes. Round, rectangular or oval cups are available from stock for immediate shipment for a variety of lift manufacturers including Cynergy Ergonomics, Indutrol and others. s izes and types of cups to fit virtually any type of vacuum equipment used for lifting, manipulating, or pickand-place applications. Accessories such as vacuum valves, swivel joints and level compensators can increase the productivity and energy efficiency of lifting systems. Materials are available to suit most any application including food handling, high-temperature materials, anti-static for handling electronic components, and more. An extensive online catalog – searchable by cup attributes such as diameter, height, width, and more – can be viewed on the website. Vi-Cas can quote custom designs from customer-supplied drawings, or reverse-engineer from customer-supplied cups. Vi-Cas has been manufacturing vacuum cups in various shapes, sizes and materials sine 1970. It provides short or long manufacturing runs, with short turnaround times. o n-demand delivery is also available. In addition to large vacuum cups, Vi-Cas offers micro-cups and bellows, soap cups, grabbers, suction cups, tightening discs, and grippers, as well as accessories including level compensators, swivel joints, vacuum valves and fittings and adaptors to suit any application.

bystronic-glass.com

Bystronic glass handling systems are designed to ensure easy and safe transport. t hey allow a flexible and economic use in every flat glass and plate-processing branch of industry. t he

5 7 8 6

remarkable features of Bystronic’s tried, proven and innovative technology are not only reliable and of the highest quality, but also have the following clear advantages: careful handling of load, minimized effort, timesaving operation and cost reduction. Bystronic X-Y craneways feature lightweight construction and are available in individual, customized solutions. t hey are free-moving with large traversing ranges.

d ifferent suspension possibilities are available, including from existing ceiling beams, hall supporting pillars, jib constructions or on separate pillars. Even attachments to jib constructions or other steel sub-structures are possible. At heavier weights Bystronic X-Y craneways are designed with two different kinds of friction wheel drive.

crlaurence.ca

Glass fabricators can easily eliminate edge corrosion on soft-coat insulated glass units using the CRL low-E edge deletion table from C.R. Laurence. A certified h EPA-filtered air vacuum system is included. two-inch, non-marking

roller balls allow glass to move easily. t he operator moves one edge of the coated glass under the abrasive wheel, then turns the glass to run the remaining edges through the wheel, before passing the finished sheet onto the next step. t he edge deletion motor is one horsepower, 3,450 RPM. A 1/2-inch coating removal wheel is included.

abacomachines.com

t he AGL-28 glass lifter from Abaco features fully automated clamping jaws with four lower wheels to protect your glass. Four upper wheels create pressure on the glass and serve as guides. An additional layer of vulcanized rubber allows for added grip. t he light and compact design is easy for operators to handle. t he AGL-28 grips from 1/8 to 1 1/8-inch glass sheets. •

by BRIAN BURtoN

Brian Burton is a business development consultant and is serving on the Personnel Committee for the CSA’s Certification Program for Fenestration Installation Technicians. You can contact him at brianburton@live.ca or visit his new website at http://burtons-pen.com

Engineers Canada has established a committee to examine the vulnerability of buildings to global climate change, defining it as any systematic change in long-term statistics of climate elements sustained over several decades or longer. Building envelopes have become thinner and lighter with evolving construction materials and systems and are especially susceptible to even minor changes in weather patterns.

Cities, with their high density of buildings, are particularly vulnerable to extreme weather events and premature deterioration of building enclosure systems. The foremost concern involves the health, safety and well-being of occupants. Canadians spend over 90 per cent of their time indoors. In addition to temperature extremes, occupants can be adversely affected by changes in humidity levels and by the presence of chemicals, pollutants and/or mould. Building enclosure systems are also in direct contact with the elements. As such, the envelope serves an important function as an environmental separator between the outside elements and interior conditions.

For existing buildings, the age and condition of the structure, the materials used in its construction and the type of building envelope system can influence its ability to resist the forces of climate change. For example, a 50-year-old masonry building constructed using a face-sealed cladding system will have very little capacity to resist the impact of climate change because the shell of the building is directly exposed to the ever-changing and increasingly hostile exterior environmental conditions. In buildings that incorporate pressure-equalized rainscreen walls, the primary environmental separators are concealed and less exposed to the elements.

Climate change creates uncertainty that may undermine the meterorological data we use to design buildings.

Several climate change factors may have a direct impact on the building envelope. Higher solar intensity causes higher exterior and interior surface temperatures.

Some areas may see shifts the in the form and intensity of precipitation, including an increase in instances of melting permafrost, freezing rain and rain on snow. Shifts in the peaks and frequency of high humidity levels can be harmful, as can changes in the seasonal range of temperatures combined with increased frequency and longevity of heat waves or cold snaps. These changes in temperature and the forms of precipitation acting on the enclosure systems can lead to dimensional changes of materials which in turn can lead to cracking and fissuring in polymer-based materials such as vinyl cladding, window frames, sealants and gaskets.

Other environmental factors that may be indirectly exacerbated by climate change include increases in dust and other airborne particulate matter, acid rain, UV radiation, wind-driven dust mixed with rain, and rain.