14 The Smallest Room

The latest and greatest in shower and bath enclosure products.

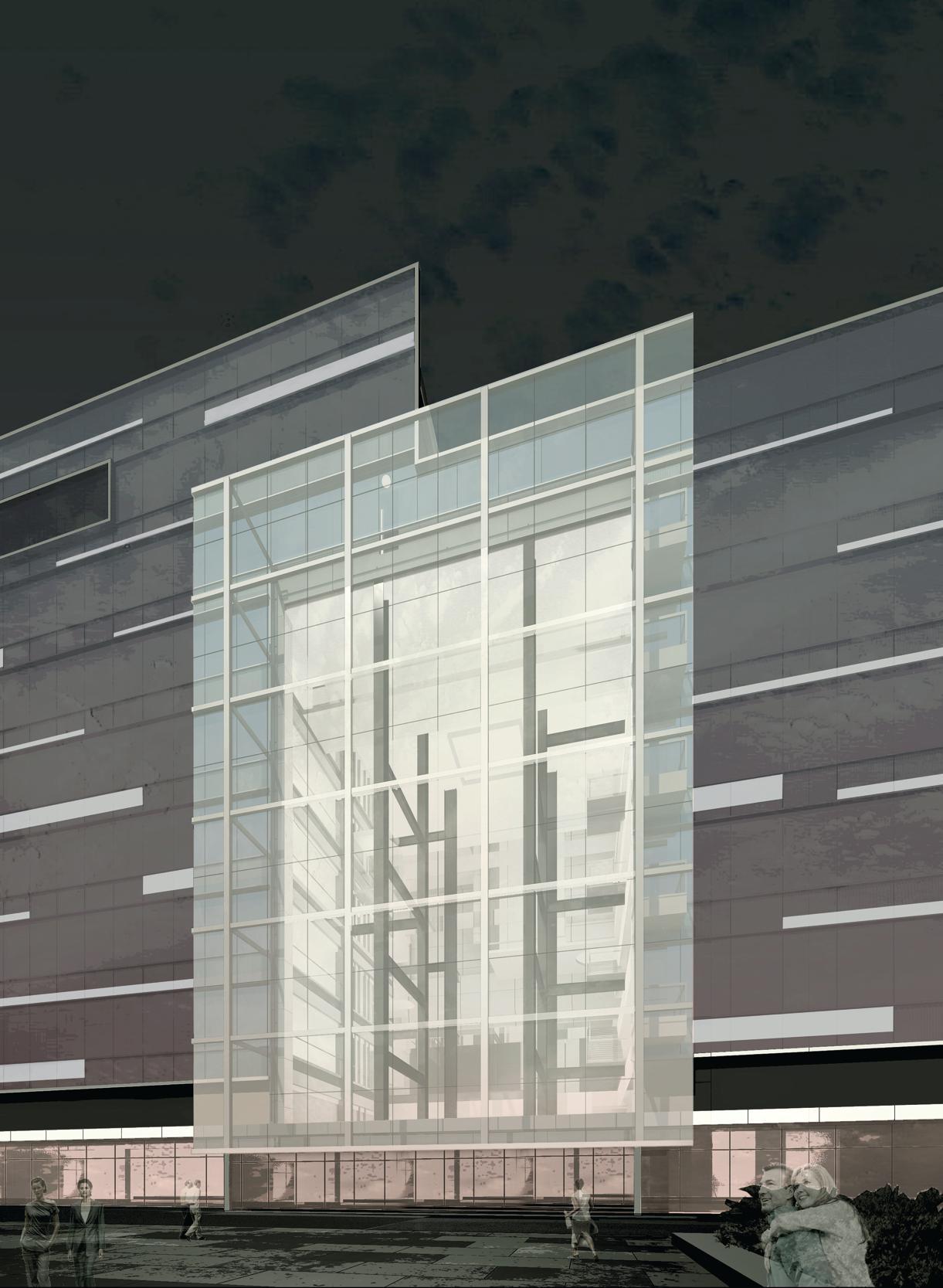

18 Curtain Walls

A special feature on the constant innovation of curtain walls and envelopes.

22 CWDMA Update

The latest scoop on the Canadian Window and Door Manufacturers Association.

24 Glass Connections Preview

What’s in store at the Canadian Glass Association’s premiere event in Toronto.

5 Editorial Build relationships

6 Industry news

New people, current events, and much more… 27 New Products

New gear from a variety of manufacturers.

16 You Bet Your Glass

Frank Fulton

John Roper

Brian Burton

Stay

January/February 2011 Volume 23 • Number 1

Annex Publishing & Printing Inc.

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Mike DAVEY mdavey@annexweb.com 519.428.3471 ext. 241

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5188

SALES DIRECTOR | Martin MCANULTY mmcanulty@annexweb.com 519.429.5178

SALES ASSISTANT | Sandy MELS smels@annexweb.com 519.429.5183 | 888.599.2228 ext. 219

PRODUCTION ARTIST | Kelli KRAMER

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN

ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: ncuerrier@annexweb.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: ncuerrier@annexweb.com

Tel: 866.790.6070 ext. 208

Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST)

($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

It’s amazing how much a shift in perspective can change everything. Changing how you view your business can have positive effects throughout the entire organization, as long as you take the time to communicate that shift to your colleagues.

There are a lot of people who view business as a sort of battlefield. Markets and potential customers are viewed as territory to be conquered (or lost). Managers build armies of employees, and duke it out both within the company and outside of it. Competitors are seen as the enemy, even when they’re not, and the soldiers wait around for orders, even when they know exactly what to do and how to do it.

There are likely some advantages to be had by looking at business as a war. One word of caution, though: don’t let your customers know that you think of them as being conquered. You might find that the military occupation wasn’t very thorough, and that they’ve suddenly gone over to “the enemy.”

There’s at least one other way to view business. Instead of seeing it as a battlefield, try to look at the industry as a community. True, some members of the community may have interests that are diametrically opposed to your own. But that’s probably true only some of the time. At other times, you might find that you have a lot in common, and can work together to reach your goals.

• Hot Glass

• Cold Glass

• Best Business Practices Sealants and adhesives Window and door hardware

• Glass testing

Business can be viewed as a series of relationships, just like those found in any community. Building strong relationships among all parts of the community means a stronger community overall. A strong tide raises all boats.

Don’t get me wrong. I’m not saying you should invite all of your competitors into the office and let them start pawing through your records. That would be stupid. However, maybe it’s time to stop thinking of them as the enemy, and start thinking of them as potential friends.

When your company and the competition are vying for a big contract, it may be tempting to talk of winning and losing. But those terms really aren’t appropriate. If you don’t get the contract, you haven’t lost anything that you had to begin with. If you do get the contract, you haven’t won, because it’s not a game that can be won. Chances are that you got the contract because you offered something the other guy didn’t.

In a lot of cases, what the “winner” offered was a real relationship. We would all rather do business with someone we know. Low bids and/or high-quality work will only take you so far. People want to know you.

If you decide to change your attitude, you’ve got to make sure to let your staff know too. If you’re trying to build relationships, and they’re trying to fight a war, you might end up with some problems on your hands. •

The Canadian Window and Door Manufacturer Association (CWDMA) has announced that it will hold its 2011 Annual General Meeting in Banff, Alta.

The beautiful Fairmont Banff Springs Hotel will be the setting for the CWDMA AGM on May 26, 27 and 28. The association reports that an informative seminar package will be offered in addition to a variety of networking and social activities set in the spectacular Rocky Mountains.

Last year’s annual general meeting took place at the Pillar and Post in Niagara-on-theLake. A lot of ground was covered over three days, including a wealth of technical information. Steve Hopgood presented updates to the Energy Star program.

The Technical & Issues Session kicked off with “The Power of Branding” presented by Phil Otto of REVOLVE branding agency. This was immediately followed by Steve Hopwood update on the Energy Star program. Hopwood is the Energy Star account manager for Natural Resources Canada’s Office of Energy Efficiency. Following the Energy Star update, Miles Murphy of the Canadian Standards Association (CSA) gave a presentation on the Fenestration Installation Technician (FIT) Personnel Certification Program.

Murphy discussed what the proposed program would do, and how it is being developed. He also discussed possible future development of FIT levels 2 and 3, following the successful deployment of FIT level 1. Level 2 would deal residential installation over three stories, and Level 3 would concentrate on commercial installations.

Technical sessions continued with a presentation on national building code changes and how windows and doors are affected. The presentation was conducted CWDMA technical consultant Jeff Baker of WestLab.

Also on the slate for informative presentations at the last annual general meeting was a session dedicated to lean manufacturing for window and door producers. The session was presented by Sepp Gmeiner of Lignum Consulting. In brief, lean manufacturing is an approach to eliminating waste, enabling continuous improvement and ensuring that every single business operation serves the customer.

Extended stay packages will be offered at the Fairmont Banff Springs Hotel. Further meeting and registration details will be posted as plans are finalized. For more information, please visit www.cwdma.ca.

ABOVE: The beautiful Fairmont Banff Springs Hotel will host the next annual general meeting for the Canadian Window and Door Manufacturer Association.

The Sommer & Maca Machinery Division of C.R. Laurence (CRL) has recently doubled the duration of warranties on the company’s new glass machinery. Lloyd Talbert, president of CRL, comments, “This new longer warranty is evidence of the value commitment we make to every customer. It also reflects our honest confidence in our glass machinery. Since C.R. Laurence acquired Sommer & Maca nearly three years ago, we have completely modernized the production facility, and also upgraded much of our glass machinery product line. We are proud of the quality products this division consistently manufactures. Our Sommer & Maca machines are built to exact specifications and tested by machinery experts, then crated and shipped for use throughout the world. An extensive inventory of service parts is maintained, and trained technicians can provide installation and service assistance for the entire line.” For additional information and assistance, interested parties can contact CRL at 1-866-583-1377 or visit www.somaca.com.

Canadian Glass Association P.O. Box 213, 10688 King George Highway, Surrey, B.C. V3T 4W8 Tel.: 778.837.2913 • Fax: 866.253.9979 www.canadianglassassocition.com

The Vancouver iteration of Glass Connections also included a tabletop tradeshow with a number of different exhibitors, including DSG Custom Glass, represented at the Vancouver show by sales manager Colin Thom.

Glass Connections

Toronto 2011 will be a highly focused educational and networking event for glaziers, architects, engineers, designers, spec writers, commercial construction contractors and building owners.

In addition, the conference will host a tabletop trade show to give manufacturers and suppliers the opportunity to showcase their products, services and upcoming technologies.

This one-day event, presenting the latest technologies for the glass and metal industry used to improve the productivity of glazing building envelopes, will be held May 3, 2011, in downtown Toronto.

Speakers and topics include:

1. Raise Your Window Performance to Meet Tomorrow’s New Levels

Speaker: Christopher Barry – Director Technical Services, Pilkington NA Inc.

2. Harvesting Sunlight – Using Photovoltaics and Advanced Thermal Glazing Units to

meet new Federal, Provincial and Municipal GREEN sustainable design initiatives*

Speakers: John Carpenter –President, Clearstream International Products, and Schott Okalux Architectural Glass

3. Silicone Sealants in Construction*

Speaker: Scott Waechter, Dow Corning

4. Glacier Discovery Walk

Speaker: Brock Schroeder, Read Jones Christoffersen

5. Canada’s Two Defining Influences over the next Decade – Commodities and Construction

Speaker: Alex Carrick, Chief Economist, Reed Construction Data

*Continuing education credits available: The presentations by John Carpenter of Schott Okalux Architectural Glass and Scott Waechter of Dow Corning qualify for one hour AIBC core continuing education credits.

A copy of the complete schedule, and more preview information on Glass Connections 2011, can be found on page 24 of this issue.

Advance registration is required for Glass Connections 2011. Registration forms are

available for download at www. canadianglassassociation.com.

For more information, please contact Fred Fulton, second vicepresident of the Canadian Glass Association at 416-768-6873 or via email to FultonF1@gmail.com.

Sponsorships for the meeting are still available. For sponsorship information, please contact Zana Gordon at zgordon@ canadianglassassociation.com.

The OGMA board of directors and association membership would like to extend its gratitude to Ennio Rea for his leadership as president of the association for the past five years. Rea puts his heart into the job and has always been totally dedicated to the industry.

Frank Fulton is proud to take the reins for the next two years, with Steve Ringler serving as vice-president, Brian Wiles as treasurer, and Angelo Cairo as secretary. Any input about the direction of the association is certainly welcomed.

The OGMA wants to notify all glass and glazing companies in the province that the Ontario version of the Glazing Systems Specifications Manual of Standards and Practices is now available for purchase. The association says this all-encompassing document is a “must-have” reference tool for all companies in the industry. For more information and to order yours, visit the website at www.ogma.ca.

The OGMA is holding it’s race night at Woodbine Race Track on Monday, May 2, 2011. It is a little unusual to hold an event on a Monday, but the OGMA is co-ordinating with the CGA Conference and Trade Show taking place at the Delta Chelsea Hotel in Toronto on Tuesday, May 3. Delegates attending the show are invited to join OGMA for an evening at the racetrack, drop some coin on the ponies, swap stories with your contemporaries, and have a great prime rib buffet dinner.

The OGMA has also announced that it will be holding its Spring Golf Tournament this year on Thursday May 26, 2011, at the Glen Eagle Golf Club near Bolton. Notices will be sent to members and posted on the website as the event date approaches.

The OGMA would like to extend its gratitude to Peter Wong for his fine presentation on LEED, and to Tremco for graciously allowing the association to use its facilities for the fall seminar on Thursday, November 18. The event was reasonably well attended, and the price was right, being free to all members. The OGMA will be putting on a few seminars in the coming year, and encourages all companies to send their employees to learn what’s going on in the industry.

If you are conducting business in the glass industry in Ontario, the OGMA wants you as a member or as an associate member if you are a consultant to the industry. Doug Morris is heading up membership for the association, so please contact him at douglasmorris@rogers.com.

Mervin Lichty, with his wife and partner Tillie Lichty by his side, has announced that he will take on a new role as the chief strategic officer and chairman of the company.

Established in 1984, MDL Doors is now one of the largest pre-hanging facilities in Canada, supplying retail lumberyards and window and door specialists throughout Ontario. Seen in the photo above is the Brussels, Ont., branch of MDL Doors.

Addressing the entire staff and management of MDL Doors during a meeting held at the company’s facility in Brussels, Ont., Lichty advised that over the next six months he will transition the day-to-day responsibilities of

running the company from himself, as the current president/general manager, to the management team. He will continue to be instrumental in key strategic roles.

The key priorities of the company are continued growth and providing quality doors and service to its loyal customers. Lichty stated, “For the company to continue to grow and succeed we need to make changes, and this change will create an opportunity for MDL Doors to move to the next level.The management team in place is perfectly positioned to move the company forward and facilitate the changes that will help create a sustainable company for its current and future customers in addition to the community, employees and their families.”

MDL Doors supplies exterior steel and fibreglass door systems to more than 750 dealers across Ontario, including Home Hardware, Rona,Tim-Br Mart, Castle and a variety of independent dealers.

For more information, please visit www.mdldoors.com.

TRON: Legacy hit theatres on Dec. 17.The much-anticipated remake of the original 1982 Disney science fiction film stars Jeff Bridges and

features plenty of CGI. However, much of the tone and atmosphere is created by the generous use of decorative and structural glass.

Many of the explosive and pyrotechnic special effects are enhanced with flying tempered glass and a recurring set features a one-inch tempered .030 diffused white laminated glass floor (shown above), as laminated by Metro Vancouver-based Lami Glass, a division of Hartung Glass Industries, and installed by 24 Hour Glass.

Diamon-Fusion International has announced that it has promoted Russell C. Slaybaugh to vice-president and general manager of Diamon-Fusion International. Slaybaugh has been with the company in an executive role for the past five years, during which DFI has achieved a compound annual growth rate in sales of more than 16 per cent. Since joining DFI, he has been responsible for DFI operations and domestic sales efforts, successfully restructuring the sales and support team and redesigning operations to improve process quality, efficiency and scalability. Despite the tough

global economic conditions, DFI continues to experience sustained growth, both domestically and internationally, due in large part to the successful management by the entire DFI executive team, which includes Slaybaugh.

Slaybaugh received his MBA with emphases in entrepreneurship and strategic management and consulting from the University of Southern California’s Marshall School of Business. His undergraduate degree in managerial economics was received from the University of California at Davis. He also holds a Certificate of Supply Chain Management from the University of California at Irvine.

Diamond Sea-Glaze Manufacturing Ltd. (DSG) and Research Frontiers Inc. jointly announced to the yacht industry that DSG has become licensed to make SPDSmart marine windows and other products worldwide. When Research Frontiers’ patented SPD-Smart lightcontrol technology is used in yacht windows and other products, users can instantly and precisely control and “tune” the amount of light, glare and heat coming through their windows, while preserving their view.

The non-exclusive worldwide licence provides for a 15 per cent royalty to Research Frontiers on sales of licensed products, including windows, hatches, doors and partitions. The minimum annual royalties and other licence terms were not disclosed.

“Diamond Sea Glaze’s marine glazings are used throughout the world on boats ranging from government and commercial vessels, to pleasure boats and yachts,” said Dave Bockhold, CEO of DSG. “Many of our customers are now asking for products that provide advanced light control, and we have been working with a major yacht manufacturer as our first launch customer for SPD-Smart windows. Our evaluation indicates that SPD-Smart technology can exceed the demanding needs of our customers due

to its extraordinary ability to quickly adjust its tint to any desired level, including very dark states that can exceed 99.5 per cent light blockage. We anticipate that marketing activities with this new product will begin early in the second quarter of 2011 with integration into our launch customer’s megayacht product line later in the year.”

Joseph M. Harary, president and CEO of Research Frontiers Inc., noted: “DSG is a world leader in the manufacturing of marine closures and glass products, and we are very pleased they now will offer the world’s highest-performing dynamic glazing technology to their customers. SPD-Smart technology is very well-suited for the marine environment. A typical yacht can use as many as five different types of fixed-tint glass to achieve privacy in the staterooms, preserving views in the living and dining rooms, and heat blockage in the pilot rooms and other areas. Right now, naval architects and yacht designers must compromise performance in each area through use of conventional glass. However, with the introduction of SPD-SmartGlass technology, performance and esthetics can be maximized.”

Additional information about SPD-Smart windows and other products can be found at www.SmartGlass.com.

A

plant becomes a thing of strength and beauty.

by MIKE DAVEY

There’s no question that buildings can inspire us, with both their interior and the face they present to the outside world. There are few people who could enter, say, the Sistine Chapel and remain unmoved. However, when it comes to inspirational interiors, there are probably very few decommissioned power plants that would make the list. There is at least one, though; the Water Street Coal Fired Generating Station in Halifax. By April of 2011, it will become the new headquarters for Nova Scotia Power Inc. (NSPI).

The Water Street Coal Fired Generating Station began its life with the installation of its first generator in 1911. Construction of the current building took place progressively with a series of modules, beginning with the northernmost one in 1944 and finishing at the south end of the site in 1959. The plant operated from 1944 to 1986 and was finally decommissioned in 1999.

The original building was composed of a concrete clad steel structure that encloses several high-volume spaces that originally housed equipment for generating electricity.

The new building was designed by WZMH Architects, a firm with projects in Canada, the United States, Europe, Asia, and the Middle East. The original site itself has inspired the design for its new life as the headquarters of NSPI.

Early visits to the site were inspirational for the design team. The soaring interior spaces with an exposed latticework of steel framework were reminiscent of the imagery of Russian deconstructivism design. The design retains a memory of, and celebrates, the original structure.

The project is located on a five-acre site at the southern end of the Halifax downtown waterfront with access from Lower Water Street. The site steps down approximately 7.5 metres from Lower Water Street to the harbour, east of the site. To the south there has been significant redevelopment of some of existing harbour buildings, including the NASCAT and Pier 21. To the north and west, vacant lots exist that will be subject to future development.

The free-standing structure in the Atrium frames interesting views to the waterfront. Transparent stairs and bridges that thread their way through the structure provide connectivity within the building. The memory of the chimneys is recalled in the Galleria, with their bases becoming skylights. The interior finishes recall an industrial esthetic, from the polished concrete floor in the atrium to the expanded metal mesh on the balustrades.

In addition to a lot of interior work, the entire building is receiving a new skin. Formerly clad in concrete, as befits a heavy-use industrial building, the new envelope is constructed of low-iron glass, floating out from the original volume.

WZMH Architects’ design for the NSPI headquarters was a finalist for the Zerofootprint ReSkinning Award in 2010.

The project retains and adapts the original concrete-clad steel structure by reskinning it in a tight building envelope to minimize energy loss. Existing piping from the Halifax harbour will carry seawater for cooling. The building will exemplify the first major use of “chilled beam” technology in Canada. Additional energy-saving strategies include the provision of heat recovery from HVAC systems, daylight and occupancy sensors for lighting, and solar panels for water heating and supplementary building heating. The building is a LEED Platinum Level candidate.

An artist’s rendering of how the building may look at night after the renovation and reskinning work is completed. Even at night, it is easy to see how the redesigned edifice will connect downtown Halifax with the historic harbour.

When it’s completed, the facility will house more than 500 staff and provide onsite parking for 150 cars.

Paul Currie is the senior project manager for NSPI. He says there were a number of reasons NSPI chose this building, and chose to reskin it in glass.

“The existing building was a barrier to the waterfront,” says Currie. “It’s over 36 metres high, and it was basically this big mass of concrete with no openings. That’s changing. The atrium will form the main entrance on Lower Water Street, and as it’s a large, transparent volume right through the centre of the building, it will provide a visual link through the building. The water on the other side will be visible from the street.”

It’s true that the building and site design reinforce the visual and pedestrian connections from city streets to the water in a very dramatic way. A portion of the existing structure at the north was demolished to allow a connection from Morris Street to the harbour. On the south, the beginning of the

LEFT: A view of the Atrium, the core of NSPI’s new headquarters. It will become the focus of activity within the building, and will provide a place for NSPI’s staff to eat lunch and socialize, especially during the winter months.

INSET: A snail’s eye view of the Atrium.

boardwalk is reinforced at the termination of a view and pedestrian corridor from Perimeter Road.

The use of this building isn’t just about making Halifax a more picturesque city. Make no mistake, NSPI is a power company, and understands the importance of environmental factors.

“We wanted to demonstrate environmental responsibility and show leadership in energy conservation,” says Currie. “The unique adaptive reuse of the building will be a visible statement of the corporation’s commitment to sustainability. The stated objective for the project is to achieve Gold Level LEED certification as a minimum, with a target of Platinum Level certification, subject to a detailed analysis of cost and feasibility.

Although the building’s new skin will certainly contribute LEED points, it is the heating and cooling system that is truly innovative. Seawater cooling (and heating) is being provided utilizing existing piping from the Halifax harbour originally used to cool power-generating turbines. The building will represent the first major use of “chilled beam” technology in Canada. Although it is widely used in parts of Europe, and has seen use in parts of the United States, the new NSPI headquarters is believed to be the first large-scale use of this technology in the country. The system, which is located within the ceiling space, utilizes low-energy seawater rather than air to transport cooling, thereby lowering energy consumption.

Additional energy-saving strategies include the provision of heat recovery on HVAC, and daylight and occupancy sensors for lighting and supplemental heating for both the building and hot water with the use of solar thermal panels.

RIGHT: A lot of demolition work had to be done to the decommissioned power plant before the building phase could begin.

BOTTOM RIGHT: A view of the building before renovations began. A lot has changed, and much more will change by the time work is completed around April of this year.

The “reskinning” of the existing building shell will result in an energy-efficient tight building envelope that will minimize energy loss/gain at the building perimeter.

Most of the demolition residue will be reused: steel will be recycled off site, and the rubble from concrete that is saw cut to make window openings will be used as fill to adjust site grades west of the building.

In addition to the environmental factors, Currie says another objective of NSPI led to the use of glass as reskinning material.

“We want to show the community we serve that we’re an accessible organization,” he says. “Transparent entries on both the boardwalk and Lower Water Street will invite the public into the facility and gives us the opportunity to showcase our environmental stewardship.”

This sense of openness is reinforced by the views between floors from either the Atrium or the Galleria. Glass elevators located on the edge of the Atrium, and adjacent “oasis” areas on each floor, make this central space into the true heart of the facility, and the focus of activity within the building. If the Atrium will be the heart of NSPI’s new headquarters, then it is the

Galleria that will function as its central nervous system, serving as the main artery of internal horizontal travel.

Whether or not the completed building attains the LEED Platinum status

being sought, at least one of the organization’s goals will be realized. The new headquarters of NSPI puts forward a sense of openness and connects downtown Halifax with its historic harbour. •

by MIKE DAVEY

There was a time when merely having hot water and a chance to bathe regularly was considered the height of decadence, something available only to the wealthy. Luckily for us and for our neighbours’ noses, times have changed.

However, there is still luxury to be found in what is sometimes euphemistically called “the smallest room.” Over the next two pages we present some of the most upto-date glass products for the modern bathroom.

Robert A.M. Stern Collection | Bendheim www.bendheim.com Bendheim has collaborated with Robert A.M. Stern Architects and OmniDécor of Italy, to create a new collection of glasses for the international design/build market. The new collection was designed for installation in partition walls, doors and windows, shower enclosures, building facades, and decorative features.

The Robert A.M. Stern Collection for Bendheim includes four etched pattern glasses offering varying levels of obscuration. Intricate designs on both sides of the glass lend a strong sense of dimensionality and movement, allowing the glass to dynamically interact with light and surrounding design elements. The permanently etched glass surfaces are non-coated and naturally resistant to fingerprints and staining over the lifetime of the product.

The collection is produced on ultra-clear low-iron float

glass, utilizing sophisticated production methods, with particular attention to the strictest environmental protection standards. The collection can contribute points to LEED v.3: EA Credit 1 “Optimize Energy Performance” and IEQ Credits 8.1 and 8.2 “Daylight & Views.”

The glass is available in three standard thicknesses: 1/4-inch (six-millimetre), 3/8-inch (10-millimetre) and 1/2-inch

ABOVE: CRL Hydroslide Kits come in four finishes: chrome fittings with a brite anodized sliding track, polished brass with a brite gold anodized sliding track, brushed nickel with brushed nickel anodized sliding track, and oil rubbed bronze anodized sliding track. Each kit comes with complete fabrication and installation instructions.

RIGHT: Merletto, part of the Robert A.M. Stern collection from Bendheim, draws inspiration from some of nature’s most dramatic forms – electrical pulses and biomorphic forms – as well as the modern visual arts. Its distinctive, fine linear design gracefully adds sparkle and punch to interior spaces. BOTTOM

RIGHT: The Revolution from Groupe VFG is a panel concept made entirely of glass. The product uses no hinges and features ultra-silent handling, easy maintenance and high durability.

(12-millimetre) and in sheets up to 88.5 inches by 126 inches (225 centimetres by 320 centimetres). Additional thicknesses and colours, including bronze, amber, blue and green, can be custom ordered.

Hydroslide Sliding Shower Door Kits | C.R. Laurence

www.crlaurence.com

C.R. Laurence says the Hydroslide Sliding Shower Door Kits were designed for full standing showers or above bathtubs. The Hydroslide System can accommodate a wide range of shower designs with fixed glass panels on either end, or at both sides at 90 or 180 degrees. The Hydroslide System also accommodates the option of floor-to-near-ceiling glass panels with a sliding door.

Kits are available in either 60- or 84-inch (1,524- or 2,134-millimetre) widths. Installers can cut the width to size, and height is optional as long as the sliding door glass weighs less than 88 pounds (40 kilograms). The 180-degree wall-towall installation requires only the 180 Degree Standard Kit for the installation. Individual or replacement parts can also be ordered. Bottom glass attachments, thresholds, and handles or knobs must be ordered separately.

CRL Hydroslide Kits come in four finishes: chrome fittings with a brite anodized sliding track, polished brass with a brite gold anodized sliding track, brushed nickel with brushed nickel anodized sliding track, and oil rubbed bronze anodized sliding track. Each kit comes with complete fabrication and installation instructions.

Roda by Basco | Basco Shower Enclosures

www.rodabybasco.com

Basco Shower Enclosures has recently launched Roda by Basco, a collection of luxury shower enclosures. The company says the Roda brand was designed to not only meet the needs of consumers looking to create their own personal haven, but also to make the experience of purchasing a shower door intuitive and easy. Every Roda enclosure is backed by Basco’s lifetime warranty.

The eight collections of Roda offer a number of different styles, configurations and accessory options:

• Geolux: Unique, striking geometric profile and solid hardware

• Vonse: Luxurious motion and ingenious, wave-like beauty

• Rolaire: Architectural elegance and high-tech functionality

• Evo: Industrial perfection with urban sophistication

• Celesta: Streamlined and unencumbered elegance

• Dresden: Harmony between function and minimalist design

• Tresor: Timeless traditional design with rich, enhanced accents

• Preceria: Elliptical elegance combined with solid, curvilinear hardware

Revolution | Groupe VFG

www.vfg.ca/en

According to Groupe VFG, the Revolution is an innovative panel concept made entirely of glass. The product uses no hinges and features ultra silent handling, easy maintenance and high durability.

The Revolution is the result of extensive research by Quebecbased Groupe VFG. The company says this product is ideal as a shower door, a bath enclosure or an interior partition. In fact, it can even be used to replace traditional French doors. The panels can be customized to customer requirements.

Groupe VFG is a Quebec-based family business that also offers the Leclerc line of glass shower doors. •

by FRANK FULTON

Frank Fulton is president of Fultech Fenestration Consulting. He has been in the industry for 30 years and can be reached via e-mail at fultech.fc@gmail.com.

So we’ve put another year behind us and by now are digging into what we want to get done in 2011. The past year wrapped up with a number of interesting things going on in the industry. In our little corner of the country, Ennio Rea stepped down as president of the Ontario Glass and Metal Association (OGMA), after serving six years of a two-year term of office (no, that’s not a typo). Ennio has been involved on and off in our association for the better part of the past 30 years. You would be hard pressed to find anyone in our industry who has given so much of his time and heart to the cause, and I’d like to offer my personal acknowledgement of his contributions. Of course, getting rid of him completely won’t happen immediately. We’re happy to have him continue on the OGMA board as past president, and you’re still bound to see him with the microphone in his hand at our golf tournaments.

The OGMA wrapped up our year with a seminar on LEED presented by Peter Wong, one of a handful of LEED Accredited Professionals in North America. I attended the presentation with the intention of learning enough on the subject to enlighten you in this column. Instead, I’m going to do you a favour by just hitting what struck me as most useful, because, quite frankly, to elaborate on the details of this program would bore you to death, or at a minimum cause you to turn the page. It’s a difficult and complicated subject that Peter handled well.

• LEED stands for “Leadership in Energy and Environmental Design.”

The new North American Fenestration Standard (NAFS-08) is the active standard for window products in Canada, effective January 2011.

• It’s a certification program for the design, construction and operation of green buildings.

• LEED is a point system that deals with five key areas: sustainable site development, water and energy efficiency, materials selection, and indoor environmental quality.

• Doing a LEED project is going to cost you. As a contractor or material supplier working on a LEED project, you’re going to spend a lot of time and money in submissions, documentation and consultants, so don’t get caught short.

• Get an expert like Peter Wong involved to guide you through the confusing maze of requirements.

The Canadian Standards Association A-440 Windows technical committee convened towards the end of last year as well. In addition to the usual maintenance and housekeeping issues associated with the standard, the committee voted to allow the A-440-00 version to expire at the end of 2010.

What this means is that the new North American Fenestration Standard (NAFS-08) is the active standard for window products in Canada, effective January 2011. This is actually quite a big deal because the rating systems of product performance are very different from previous versions and may likely require retesting of many windows and doors on the market.

It also means that the 2011 version of the National Building Code of Canada will be referencing the NAFS-08 standard. If you manufacture windows or doors, it would be in your best interest to get up to speed on the new standard if you haven’t done so already.

Lastly, to wrap up on last year, it was my honour to succeed Ennio Rea and take the reins of the OGMA for the next two years. One of my first duties was to attend a directors meeting of the Canadian Glass Association (CGA) as a guest, where I caught up with CGA president Richard Verdon.

On the heels of a very successful program held in British Columbia last year, the national group will host Glass Connections 2011 at the Delta Chelsea Hotel in Toronto on May 3. Visit www.glasscanadamag.com for updates and previews as the day draws closer. The OGMA is going to hold its race night at Woodbine Racetrack on May 2 to support the event.•

by JOHN ROPER

John Roper is the editor for The Installer, The Fabricator, The Conservatory Installer and Glass Works magazine published in the U.K.

Windows that have not been formally energy rated under the Window Energy Rating scheme (WERs), or have not received a formal U-value, can still comply with the building regulations that came into effect on Oct. 1.

In a letter sent to its members before the switch, Fensa offered two ways that fabricators could prove that their products achieve a U-value of 1.6 W/m 2 K, which do not require costly formal processes.

In the lead-up to Oct. 1, when the new regulations were due to come into force, the British Fenestration Rating Council (BFRC), the U.K.’s national system for rating energy efficient windows, had been promoting the Window Energy Rating scheme (WERs) as the preferred method of proving compliance with the building regulations – the government announced that windows with a WER of at least a C (up to a possible A) will comply. The alternative U-value method, which has received far less publicity, has been touted as being far more onerous. In both cases, expensive formal testing, calculations and registration are required.

However, fabricators were told that Fensa inspectors would require no formal evidence of compliance if their timber (70-millimetre depth minimum) or PVC windows were constructed using soft coat low-e glass, warm edge spacer (16-millimetre minimum), and 90 per cent argon gas, “i.e., there will be no need to provide

Fensa offered two ways that fabricators could prove that their products achieve a U-value of 1.6 W/m2K, which do not require costly formal processes.

further evidence to the consumer or to the Fensa inspector, providing there is no evidence to suggest that our assumption is incorrect.”

The letter also gave details of an online U-value calculator that can determine the whole window U-value. Available from mid-September 2011, the calculator will store the details on a database alongside results from other authorized calculators. “These details will be passed to our inspectors when you, at the point of registration, indicate that the installation conforms to a particular calculation held in our database,” the letter explained. It will cost C$318 (£199) a year to use, for an unlimited number of calculations.

Giles Willson, a director of the BFRC, told The Glazine : “The standard unit as per the press release two weeks ago installed in timber and five-chamber PVC-U systems will achieve a 1.6 U-value. This is not the only solution to achieve compliance – i.e., I know some three-chamber systems will achieve the 1.6 with this spec unit, and other systems will achieve 1.6 without soft coat or gas or warm edge spacer bars.

“This is a spec which will work and is proven in making life for compliance easier for large sectors of the market. The fact a more cost-effective solution may be available by using WER or U-value calculation is down to the manufacturer.” •

For more information on the European Scene, including regulations, new technology, new products and marketing trends, see more of John’s columns at www. glasscanadamag.com

According to Steve Gusterson of Alumicor, thermally broken curtain wall systems are going to be frequently used when the owner is concerned about longevity and operating costs. Such is the case of the Edmonton Clinic, currently under construction by PCL Construction Management. The building uses Alumicor’s Thermawall system.

The glass and glazing industry in Canada is rapidly changing. Decorative effects using fritted and laminated products are being used to add colour and enhance the facade more than ever. Acoustical insulation is starting to be discussed during the design phase now instead of as an afterthought. Architects and designers are taking advantage of products such as glasscladpolycarbonates for bold new designs such as Point Supported Structural Walls with increased security, safety and flexibility. BIPV still has obstacles; however, it is well on its way.

Improving the overall building performance still trumps all of the other trends. As of Jan. 1, 2011, the Government of British Columbia has legislated that every new glazing system installed in the province must have a U-value below 2.85. There are exceptions; however, for the most part it is technically illegal to do otherwise. The B.C. Energy Efficiency Act places the burden of responsibility for testing and compliance on the manufacturer, which in this case is the glazing contractor.

The Energy Efficient Buildings Strategy is part of the B.C. government’s goal to reduce greenhouse gas emissions by 66 per cent.

“The rest of the country is going to be watching B.C. to see what they are doing and how successful it is, and will eventually follow in one way or another,” says Steve Gusterson, pre-construction design services manager for Canadian architectural aluminum building products manufacturer Alumicor. “I really believe that B.C. is going to be setting a trend here.”

Even in parts of the country where energy regulations are less strict, there has been a real emphasis on improving the curtain wall system, “Thermal improvements are really being embraced by architects and developers,” says Gusterson. “They see the value in building better performing buildings.”

The days of screws penetrating thermal breaks are going by the wayside. Gusterson explains, “As long as the code allows it, there is always going to

be a market for the lower-end, single-storey storefront applications, but any building of significance, where the owner is concerned about longevity and operating costs, is going to be using thermally broken curtain wall systems instead of the thermally improved systems that have been used forever.”

“Last year Alumicor introduced a truly thermally broken design called Thermawall,” says Gusterson. “It is a stick built system that incorporates a structural polyamide thermal break. For triple-sealed units, it has two thermal breaks. It is one of the few purposely designed, thermally broken triple curtain walls on the market. There has been a lot of interest in triple units in places such as Fort St. John in northern B.C. We are currently supplying the retrofit at the Edmonton Federal Building. Community and recreation centres are also popular applications because we can seamlessly transition from standard curtain wall in the facade to thermally broken curtain walls in areas with high humidity such as pools.”

“We’re also seeing owners now willing to pay a little extra for better performing windows with rainscreen designs and drain systems,” points out Gusterson. “They are getting away from the prime seal systems that can leak if they are not fabricated or installed properly.”

Building information modelling

“In Ontario, you can go from –55 F tonight to 55 F tomorrow morning,” says Wesley Sanders, president of Spandreltech, manufacturer of aluminum building envelope products such as Galvaspan galvanized steel back panels. “That’s a 100-degree temperature change in one day. That’s why the Canadian curtain wall industry can go anywhere in the world.”

For Sanders, the most significant innovation, not only for curtain wall, but for the whole building has been in 3-D rendering software and Building Information Modeling (BIM). Projects in the United States are already mandating that all sub-trades be running BIM software in order to even qualify to submit a tender.

“We’ve solved a ton of problems by using the 3-D rendering to prove to an architect or client that the design won’t work,” explains Sanders. “We can show them the whole panel system; we can open and close panels so we can see how it locks and hooks. And they see where the design fails. Solving those problems in advance saves money and time, which is why we are hiring two architectural technologists to further develop that service.”

Curtain wall and window wall improvements

“We know what the glass can do. There is always room for improvement in the frames surrounding the glass,” says Arthur Chan, vice-president of design and engineering for Burnaby, B.C.-based Advanced Glazing Systems. “Window wall has come a long way. The latest designs have a higher performance thermal break. They replaced the old PVC, pour and debridge type of resin based material with a high-end ISO bar polyamide based thermal break material.” However, the air/vapour barrier is generally designed and located at the back of the framing system.

The problem with conventional window wall is that it allows cold air under wind pressure to migrate into the hollow space of the frame. Chan explains, “If you have interior warm moist air in contact with a cold metal surface, you are going to have condensation. In a worst case scenario in cold climates such as Edmonton, you might have ice building up on the window sill if there is a lack of interior air circulation.”

According to Chan, in theory, a window system with inclusion of a good thermal break and glazing gaskets works fine. When drain holes are introduced, the cavity in frame tubes, deflection header and sill runner are pressure equalized, thus allowing outside air into the frame cavity. The separation between the air in the cavity and the interior air is only the metal wall. You have the thermal break up front; however, you allow cool air to migrate in under exterior air movement. Ideally, there has to be some kind of foam block or insulation inside to block off the cold air coming in or warm air escape by conduction.

For some, such as Wesley Sanders, president of Spandreltech, the rise of Building Information Modeling (BIM) software has been the most important innovation not just in curtain walls, but for the whole building.

Sanders says BIM software has helped point out flaws in building design. Solving these problems in advance saves time and money.

Chan continues, “Curtain wall in Canada generally has an air and vapour seal immediately behind the interior face of the glass, whether it is a stick built or unitized system. Anything behind the glass to the inside, including the tubular member of the curtain wall, is on the warm side of the building. Heat will conduct from the inside, through the

At 62 storeys, Living ShangriLa is the tallest building in Vancouver. It uses three glazing systems – capped, 2SSG and 4SSG. A special feature are the 1340 luminescent panels known as “buttons.” Measuring 24-inches square, they were developed by Garibaldi Glass and laminated by Lami Glass Products. The buttons conceal exhaust vents and change colour during the day depending on the light source and viewing angle.

frame members and thermal break. The frame is still cool to the touch but there won’t be condensation or ice inside if the framing system is designed adequately.”

Air also circulates in the glazing pocket around the perimeter of the glass unit in a window or curtain wall. This air is in contact with the metal behind the thermal break. To enhance the thermal resistance, one may consider inserting a baffle or foam blocks into the pocket and also keeping the baffle in line with the exterior face of the glass. However, you risk blocking the water drain, which is used for ventilation and keeping the perimeter of the sealed unit dry.

Many of the glazing systems with the inadequate thermal breaks that have been around for the last 20 or 30 years are becoming obsolete. Some of the breaks are 1/8-inch-thick PVC material, which is simply not thick enough to reduce heat conduction.

“They also have a lot of large screws

through the pressure plate that conduct heat,” says Chan. “The only thing you can do to enhance such a framing system is to use an IGU with the low-e glass and argon gas fill airspace to bring the U-value down.”

Having two thermal breaks, one in the front of the screw stem and one from the back of the stem to the frame tube reduce the thermal transfer. The outer thermal break also serves as a seal against water and behind the pressure plate and snap cap.

“It helps tremendously and a lot of people are doing it that way now,” points out Chan. “The screw from the pressure plate to the aluminum screw stem still conducts some heat. In our analysis, it’s very minor but we still consider it. You have to combine an enhanced thermally broken frame with high performance low-e glass and gas-fill air space in order to get it to where you need it under the B.C. Energy Efficiency Code.”

Technology has improved with a

better quality polyamide thermal break, which can be as wide as 35 millimetres, depending on the design.

“The wider the bar, the better it is because it has a greater separation between the exterior aluminum and the interior frame tube. Polyamide is very stable and resilient. It is also protected from UV and stays dry housed in the glazing system. The strength of the thermal break is typically around 80 per cent of the aluminum. A double ‘dog-bone’ configuration design has been around for a long time. One thermal break is under tension and the other is under compression, so they work off each other like a bridge.”

There are additional costs associated with upgrading to this type of design. Thermal breaks and their insertion into the aluminum extrusions are not cheap. Without them, however, some glazing systems may not meet the spec.

Four-sided structural glazing

“There are advantages to the capless 4SSG system in terms of thermal resistance,” says Chan. “With the capless system; one commonly has rubber or silicone sealant with foam backing, flush with the face of the glass. The entire face of the 4SSG system is the rainscreen and a thermal barrier. The gasket or silicone inline with the face of the glass acts as a thermal break. In order to meet the energy requirements, low-e glass and high-performance spacer bar are still required and gas filled air space may also be a consideration.”

When you upgrade to a 4SSG system, you have to balance out the cost, design and aesthetics. The capped system is simply using pressure to keep the glass in place and to maintain air/water tightness. 4SSG needs structural sealant and sometimes mechanical method to hold the glass in place. Most 4SSG systems have to be factory glazed for quality control reasons.

“In B.C., our specifications are more stringent than other provinces.” Chan continues, “The B.C. government is taking the lead and other provinces are looking to see what is happening and eventually the rest of the country will probably follow. The B.C. Energy Efficiency Act has been implemented for some time. Glazing contractors that design, manufacture and install their proprietary curtain wall and are responsible to meet the specification mostly on a project basis and have some flexibility to get their glazing system to meet the energy requirement.”

There is scrambling between some glazing contractors and products distributors on some existing glazing systems. Some parties are pointing fingers, claiming “it’s not my job, it’s your job” to arrive at manufactured products to meet the code.

“Some contractors may still try to sneak in a non-compliant frame here or there,” says Chan. “However if they are caught, I’m sure there will be consequences. On the other hand, you have to consider evaluating the thermal performance on a selected glazing system and glass before you can even bid on projects.”

This will be life in the Canadian glass industry for the short term. There will be confusion and frustration and if we follow our neighbours to the south, likely even legal action. Lean margins will become leaner. A changeover of this scope is always painful and costly but most agree that the industry will improve and emerge stronger than ever. •

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, B.C. richp@constructioncreative.com

by KEVIN PELLEY

Kevin Pelley, president of the Canadian Window and Door Manufacturer Association (CWDMA), and Mike Nolan, president of the EMS Chiefs of Canada, officially opened Win-Door 2010 on Nov. 16. Retiring CWDMA Directors were also recognized on Nov. 17. Scott Target of Global Windows and Doors and Martin Tremblay of Servitek Fenestration Inc. received Service Awards in recognition of their hard work.

The CWDMA and WinDoor would like to thank the following sponsors for their generous support of WinDoor 2010:

• Livingston International –EMS

• Novatech Group Inc. –Parking

• Richersons Enterprise Limited – Parking

• Royal Group/Thermoplast –Lunches/beer cups

• Truth Hardware – Badge lanyards/pillar wraps/EMS

• Trimlite – Registration desk

• Cardinal IG – Codes & Standards Update – by Jeff Baker, CWDMA Technical Consultant

• Screenco Manufacturing – Strategic Planning for Your Closely Held Business by Bob Langdon

• UltraFab – Economic Forecast by Peter Norman of Altus Group

The CWDMA fall meeting was held on Tuesday, Nov. 16, a change from its traditional Thursday morning time slot. The CWDMA board members and committee chairs presented an overview of their activities from the past year and highlighted upcoming activities and initiatives.

As always, the educational sessions were well attended. On

Wednesday, Nov. 17, Jeff Baker, CWDMA Technical Consultant, presented an informative update on codes and standards. The focus was on NAFS testing requirements for doors and upcoming changes in the building code and NAFS that window manufacturers will need to implement to achieve compliance with the new building code.

Returning speaker Bob Langdon offered two seminars, the first of which was Strategic Planning for Your Business. In this program, Langdon illustrated how to differentiate products and services in the marketplace, thus enabling a higher gross margin. Langdon’s second seminar, Maximizing Profitability in a Recovering

ABOVE: Morgan Hanam of Enermodal Engineering at the CWDMA 2010 Annual General Meeting in Niagaraon-the-Lake at the Pillar and Post. The association’s 2011 Annual General Meeting will take place in Banff, Alta.

Economy, highlighted how to increase one’s understanding of the Profit and Loss statement, thus enabling preparation of a viable financial business forecast.

Thursday, Nov. 18 featured three wellattended sessions:

• Peter Norman, general manager of Altus Group Economics, presented an informative financial forecast. Norman is a specialist in economic and demographic analysis, construction economics, building products, technology studies and forecasting services. A welcome addition to the Win-Door program, Norman has a well-rounded background in the real estate and construction industries.

• Steve Hopwood from Natural Resources Canada covered new developments in the October 2010 ENERGY STAR specifications. He also provided tips on how to label for ENERGY STAR, discussed some of the do’s and don’ts of submitting model information and outlined possible future changes.

• Miles Murphy, product manager for the Canadian Standards Association (CSA), reviewed the development of the first Canadian program to certify installers of windows, doors and skylights. This national initiative, known as the F.I.T. Personal Certification Program, has been developed to support the need for quality installations that meet industry standards and best practices, while promoting energy efficiency and consumer confidence. Murphy provided a progress report to date that included timely information on the scope of the program, subject matter being developed for certification, knowledge and practice domains, and more.

The prestigious CP Loewen Award was also presented on Nov. 17. The award, which recognizes outstanding dedication, commitment and accomplishment in the window and door industry, was presented to this year’s deserving recipient, Clare Knechtel of KML Windows and Doors. CWDMA recognized a career dedicated to improving our industry, with generosity of spirit and respect for all involved.

An active participant in the CWDMA, Knechtel was involved in resolving technical issues involved with codes. He was a contributor to the development of the technical standards for testing sashless windows. He regularly attended and was a vocal participant in the CWDMA’s meetings, while always remaining dedicated to

“getting the work done.” He also served on the WDMA Board - the CWDMA’s U.S. counterpart - where he continually looked out for Canadian interests and worked to strengthen relations between the two associations. He was also actively involved in AAMA, regularly attending meetings.

In 1964, Clare Knechtel left Time Glass in Sarnia to join the Robert Hunt Corporation in London, Ont. Here he introduced Pella Wood Windows to the market. In 1982, Knechtel left Robert Hunt Corporation and formed Knechtel Millwork in London with his wife Carole and children. Manufacturing custom architectural windows and doors, he grew the business dramatically with regular trucking runs into the U.S. market.

Over the next 20 years, the company grew to employ 325 people. KML’s quality and service as a manufacturer of “oneof-a-kind” windows and doors caught the attention of Andersen Windows, and in 2001 Andersen bought KML. Visit www.cwdma.ca to read more about our recipient.

Congratulations to the 2010 WinDoor award winners! The James Parker Booth Awards presentations took place on Wednesday, Nov. 17. Congratulations to Edgetech IG, who took first place overall for the second year in a row. Trimlite was awarded second place in the large booth category and Apricot

Coating Systems took the award for best small booth. Well done and congratulations to all the winners!

Mark your calendar now for the 2011 CWDMA Annual General Meeting! The beautiful Fairmont Banff Springs Hotel in Banff, Alta., will be the setting for the CWDMA AGM on May 26-28.

As always, an informative seminar package will be offered in addition to a variety of networking and social activities set in the spectacular Rocky Mountains. Extended stay packages will be offered at the Fairmont Banff Springs Hotel. Further meeting and registration details will be posted as plans are finalized.

Members are encouraged to review their membership directory listing regularly at www.cwdma.ca. Each member is listed on the website and the listing is linked to your one-page membership directory listing, and to your website, if you wish. The online directory is organized by membership category. E-mail or fax the CWDMA office if your listing requires any adjustments we can either make the required revisions for you or send a username and password so you can make the corrections. There is always good traffic to our site, so please ensure your information is current. •

by MIKE DAVEY

Just as the Vancouver event did, the Toronto Glass Connections will feature a tabletop trade show. Shown here are Ed Lemire, Mike Taylor and Chris Combs of Cascade Aqua Tech, one of the exhibiting companies at the Vancouver event.

Glass Connections, the premier event of the Canadian Glass Association (CGA), is coming to Toronto in May 2011. Although this will be the first event to take place in Ontario, Glass Connections already has an excellent track record. The content of the first event, which took place in Vancouver in September 2010, was so informative that, in the words of one attendee, “It challenged many seasoned glass professionals in attendance to question what they thought they knew about architectural glass.”

The goal was to make Glass Connections a cost-effective and highly focused one-day conference that combines several elements traditionally found on longer programs, and to present a valuable educational forum designed to maximize your investment in time.

As Zana Gordon, executive director of the CGA, notes, Glass Connections

is more than just an industry event.

“Glass Connections . . . represents a promise that we made at the beginning of the year to reach out to glass professionals across the country, solidify our status as a national association for glaziers, and provide tangible resources to help the industry,” said Gordon.

Glass Connections 2011 will take place May 3 at the Delta Chelsea Hotel in Toronto, Ont. Advance registration is required. Registration forms can be downloaded at www.canadianglassassociation.com.

In this special preview of Glass Connections 2011, we’ll be digging deeper into what attendees can expect from the presentations and other education opportunities.

Presenters and topics

• Raise Your Window Performance to Meet Tomorrow’s New Levels.

Presented by: Christopher Barry, Director

Technical Services, Pilkington NA

• Minimum performance levels in building codes; ER, NFRC, ASHRAE and LEED rating levels; and consumer performance preferences are all being raised to new levels.

This presentation will demonstrate how adding a low-emissivity coat, or coatings, always helps window thermal performance, making it more energy efficient.

Also covered will be how centre of glass thermal performance can now be so much better than the edge that attention must be paid to edge-of-glass spacers and window frame thermal properties to achieve desired improvements to the complete window.

Solar control requires evaluation to see if free, passive solar heat gain should be admitted or rejected. As the thermal and solar control properties of a window are improved, it becomes more important to check that the resulting thermal stresses are properly evaluated, using currently available tools, and that appropriate measures are taken to prevent glass breakage.

• Harvesting Sunlight – Using Photovoltaics and Advanced Thermal Glazing Units to Meet New Federal, Provincial and Municipal GREEN Sustainable Design Initiatives. Presented by: John Carpenter, president, Clearstream International Products and Schott Okalux Architectural Glass

This presentation qualifies for AIA credits. Topics include:

• BIPV Glass Units – Building integrated photovoltaics and taking advantage of provincial net metering opportunities

• Advanced thermal glazing units –Cooling, heating and illumination controls for occupant comfort and reduced energy loads

• Sophisticated light directed glazing units – Glass units built according to the building’s latitude and longitude co-ordinates

• Forward-thinking digitized glazing

– Precise image transfer over large glass surfaces, without silkscreening

• New developments – Switchable glass: Opaque to clear/clear to opaque for privacy controls, invisible ultraviolet pattern glass to reduce or eliminate bird collisions.

• Silicone sealants in construction.

Presented by: Scott Waechter, Dow Corning

This course qualifies for AIA credits. Learn about the differences in sealant technologies available in the market and why the trend over the past decade is toward the use of more use of silicone sealants. Waechter will also speak about proper building joint design details as well as the proper procedures for installing building joint sealants. Additional topics to be covered include sealants and LEEDs, sealant staining, sealant compatibility, low dirt pick-up sealants.

• Glacier discovery walk.

Presented by: Brock Shroeder, Read Jones Christoffersen

This presentation will inform attendees on the design and detailing of an exterior structural glass floor and balustrade for a tourist attraction in a northern climate.

• Canada’s two defining influences over the next decade – Commodities and construction.

Presented by: Alex Carrick, Chief Economist, Reed Construction Data

6:30 – 8 a.m.

Registration – buffet breakfast – networking –trade booths 8 – 8:15 a.m.

Welcome and opening remarks by Richard Verdon, president, CGA

8:15 – 8:45 a.m.

Introductions and agenda 8:45 – 9:45 a.m.

Raise your window performance to meet tomorrow’s new levels 9:45 – 10:45 a.m.

Harvesting sunlight 10:45 – 11 a.m.

Health and refreshment break 11 a.m. – 12 p.m.

Silicone sealants in construction 12 – 1:30 p.m.

Commodities play a huge role in the construction industry. First, as the base material for all building products, they determine costs. Second, the demand for and price of commodities drive resource project investment plans. This is where emerging economies come in. It’s hard to believe, but total Canadian employment in construction is gradually catching up with employment in manufacturing. This has implications for Ontario’s industrial structure. It also helps to explains why growth prospects in Western Canada and portions of Eastern Canada are considered better than for central Canada.

Buffet lunch and trade show

1:30 – 2:30 p.m.

Glacier discovery walk

2:30 – 3:30 p.m.

Canada’s two defining influences over the next decade

3:30 – 4 p.m.

Trade show and networking 4 – 4:30 p.m.

Wrap-up – what have we learned?

For more information on Glass Connections 2011, please visit www.canadianglassassociation.com.•

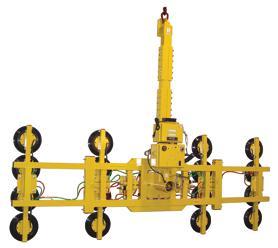

The MR1611LDC below-the-hook vacuum lifter was developed by Wood’s Powr-Grip to meet the challenge of constructing curtain walls and handling other architectural components.

This lifter features a multivariable pad frame for lifting and manoeuvring a variety of sizes of curtain wall materials and other nonporous loads. The lift bar can be assembled in two different lengths, providing the ability to install material under overhangs.

The variable length and width of the pad spread allows configurations ranging from 53-1/4 inches long by 12 inches wide (1,353 millimetres by 305 millimetres) to a remarkable 169 inches long by 49 inches wide (4,293 millimetres by 1,245 millimetres).

Capable of handling loads ranging from 700 to 2800 pounds (320 to 1270 kilograms), the MR1611LDC features a DC power source for maximum portability and continuous 360-degree rotation to facilitate proper load positioning.

For more information, please visit www.powrgrip.com or call 1-800-548-7341.

CRL’s new Tube Style Standoff System comes as a complete unit,which the company says is simple to install.

Bob Carlson, who heads up CRL’s Display Hardware Technical Sales Team, states, “The fact that these standoffs come as a complete unit is unique to the industry. In the past, the base and cap were sold separately, and installation required a hanger bolt or threaded rod, plus separate Allen screws, nuts, and washers. With our new system, the standoff comes complete with a base and threaded insert, cap with welded stud, clear washers and macaroni. To install the standoff the threaded inserts are simply attached to the substrate with a screw. The standoff base is then screwed on to the mounted insert. The

Bystronic has introduced a high-speed sealing machine for insulating glass units in the form of the speed’sealer. According to Bystronic, the new machine seals windows and facade elements at a maximum flow rate, while at the same time, offering the highest application speed.

According to the company, this means it is now possible, even with different production conditions, to actively and consistently mix the two sealant material components, thanks to a dynamic mixer.

The speed-sealer was presented for the very first time at a top secret area of the Bystronic glass stand at glasstec 2010 in Düsseldorf, Germany. In a small production run, invited guests were able to see the sealing of double insulating glass units and triple insulating glass units with two different spacer widths, facade elements with 20-millimetre by 20-millimetre sealant joints as well as forming glass without any tool changing whatsoever.

Bystronic says the speed’sealer operates both quickly and extremely precisely. According to the company, the machine seals double and triple insulating glass units at high speed with a consistently convincing quality, and this is achieved regardless of the sealing material selected, variations in material quality or temperature, or even straight after production commences. The constant mixing ratio of the two adhesive components is monitored electronically. In addition, the self-cleaning dynamic mixer prevents any clogging of the mixing section eliminating the need to clean the external rinsing cabinet. The high-precision dosing technology ensures a highly accurate, volume-controlled application of the sealing material together with immediate adjustments in volumes where the joint depths vary.

cap assembly is later installed through the panel.”

CRL’s Tube Style Standoff Systems are available in two sizes: 5/8-inch (15.9-millimetre) and one-inch (25.4-millimetre). Finish choices are chrome and satin chrome. The maximum recommended panel thickness is 3/8 inches (9.5 millimetres).

Carlson concludes, “The fact that these standoffs are sold as a system makes them cost-effective as well. They are ideal for the installation of vertical panels or displays, exhibits, and signage. They can also be used in horizontal applications such as elevating a glass top on a table or desk.”

For more information, please visit www.crlaurence.com.

By using a dynamic mixer, the speed’sealer operates with a very low material pressure; this ensures minimal wear and tear on the dosing system. The flexible sealing of triple insulating glass units that have varying gap sizes between panes is produced in a double-circulation process without having to change the nozzles or encounter machine downtime. With this, the middle pane of a triple insulating glass unit can be secured via an adjustable motor. Alternatively, the speed’sealer can be equipped with an automatic change-over system, which, within two minutes, allows for an unmanned change of materials.

Maeda USA will display five fully compliant mini-cranes with new attachments at ConExpo. Models range from 3,800- to 10,800-pound capacity with lift heights to 68 feet.

Maeda says its mini-cranes are being used in many non-traditional roles, including curtain wall and glass handling for commercial construction, steel erection, lifting inside highrise structures and virtually any lifting role where space is limited. All Maeda mini-cranes meet ASME and EPA requirements for North America.

“This is the first time fully compliant Maeda mini-cranes have been displayed at ConExpo, “explains Tony Inman, president of Maeda USA, western hemisphere distributor for Maeda Japan. “The minicrane method of material handling has been successfully proven in our territory and the market is finding many applications for smaller cranes,” according to Inman. Maeda cranes can fit through openings as small as 24 inches wide.

The company will also display new attachments that expand the utilization of their mini-crane line including a man-basket, jib attachments, a glass manipulator, and a searcher hook, which is a boom tip extension arm for lifts where there are overhead restrictions. A new accessory transformer package will also be shown, which converts the power supply when operating electrically.

Maeda will be exhibiting at booth 440 in the Gold Lot at ConExpo, taking place March 22 to 26 at the Las Vegas Convention Centre in Las Vegas, Nev.The line can also be previewed by visiting www.maedausa.com.

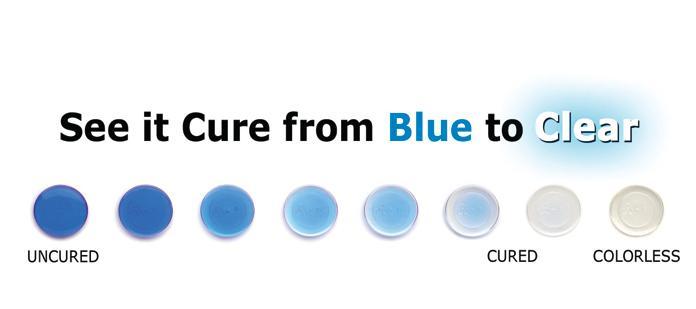

DYMAX Corporation has released a new adhesive featuring a built-in cure indicator. 3225-T-SC is a versatile, plastic-bonding adhesive formulated with DYMAX’s patented See-Cure technology.This material is designed for rapid bonding, laminating, and sealing of most plastics such as PMMA (acrylic), PC, PVC, ABS, PA, PU, SAN,TPU, and aluminum. It can also be considered for bonding glass, stainless steel, and brass substrates in combination with plastic substrates.

3225-T-SC is formulated to cure with DYMAX broad-spectrum curing equipment such as the BlueWave 200 Spot Lamps, 5000-EC Flood Lamp(s)/UVCS Conveyor Systems, and the narrow-spectrum BlueWave LED Prime UVA Spot Lamp.

3225-T-SC is coloured bright blue in the uncured state.The adhesive’s high visibility enables automated vision systems to confirm adhesive placement prior to the cure. During the curing process, the blue colour of the adhesive transitions to clear, and provides an obvious, visual confirmation that a full cure has been achieved. 3225-T-SC is designed to cure tack free and clear in appearance after exposure to DYMAX broadspectrum curing equipment in less than four seconds at 200 mW/cm2 at 385 nm and in less than three seconds with the DYMAX BlueWave LED Prime UVA system.

For more information, please visit www.dymax.com.

by BRIAN BURTON

Brian Burton is a Business Development Consultant for Kleinfeldt Consultants. He can be reached at bburton@ kcl.ca.

Now that the updated model energy code (NECB 2011) has been formally released, several apparent limitations regarding the actual application of the code have been raised by various stakeholders in the industry. If you study the code documents it’s quite obvious that this is a very complex undertaking.

In large part, this is a result of the wide range of climactic conditions across the country as well as the large number of different housing and building types. In addition, construction technology in general and fenestration elements in particular are becoming more and more complex. It shouldn’t come as a surprise that the code documents appear to require some “fine-tuning.”

Prior to the release of the model energy code, most of the attention was focused on the costs it might impose on the industry and the limitations it could place on designers. There is also an ongoing debate about using the “simple payback method” as opposed to “total life cycle cost analysis” to calculate life-cycle costing.

When it came to the new model energy code, the intended mandate was to improve energy efficiency in buildings by 25 per cent. Part of the development of this standard involved attempting to match the existing ASHRAE Standard 90.1, which describes the minimum required prescriptive R-values for roof and wall insulation levels for various climate zones in the United States.

Normally energy codes provide several different means for the designer to comply with the

Prior to the release of the model energy code, most of the attention was focused on costs it might impose and the limitations it could place on designers.

FENESTRATION FORUM

code. The first is termed “prescriptive,” which basically defines minimum energy requirements for all components. The second involves allowing “trade-offs” between the various building components in their energy use – as long as the total energy savings do not differ significantly from those that would have been achieved by a prescriptive path.

Several technical challenges were identified when industry experts applied the formula to some building designs and found that using the new code presented difficulties when attempting to achieve the energy efficiency targets for some specific building types. There were also other limitations pointed out that occur when attempting to apply the “fenestration to wall ratio” in colder climates zones using standard building practices. As a result, recommendations have been made to the Executive of the Canadian Commission on Building and Fire Codes regarding certain alterations that could be applied that could improve the new code.

Feedback received from the industry suggests that effectively applying the new code will be a challenge for certain types of buildings; namely, semi-heated warehouses, hospitals, hotels and strip malls. In simple terms, this means it will be very difficult to achieve a 25 per cent improvement in energy efficiency for these types of buildings.

Recommendations about how to make the necessary adjustments in the code have been put forward and are being considered by the various government standing committees that are involved, including the Executive of the Canadian Commission on Building and Fire Codes.

I suspect these modifications can be made without too much difficulty and, in my view, Canada has once again demonstrated its expertise in the field of building science and construction.

The code outlines several elements regarding general improvements in energy efficiency, including air leakage, assembly construction, baseline construction, control devices for lighting, costing, fenestration to wall ratio, and heat recovery.

For more details, please visit www.glasscanadamag.com.•

Structural