WINDOWS GO GLASSVENT

Kawneer Introduces GLASSvent™ UT Windows

Every so often it’s what you can’t see that makes the biggest impact. New GLASSvent™ UT (Ultra Thermal) Windows have a visually concealed vent designed for seamless integration with the framing system to create a complete, advanced, superior thermal solution for commercial construction. With best-in-class thermal performance, GLASSvent™ UT Windows are the ideal solution for architects and designers who want to provide fresh-air ventilation without decreasing the overall thermal rating of the façade. Never before has something so seamless offered such high thermal performance.

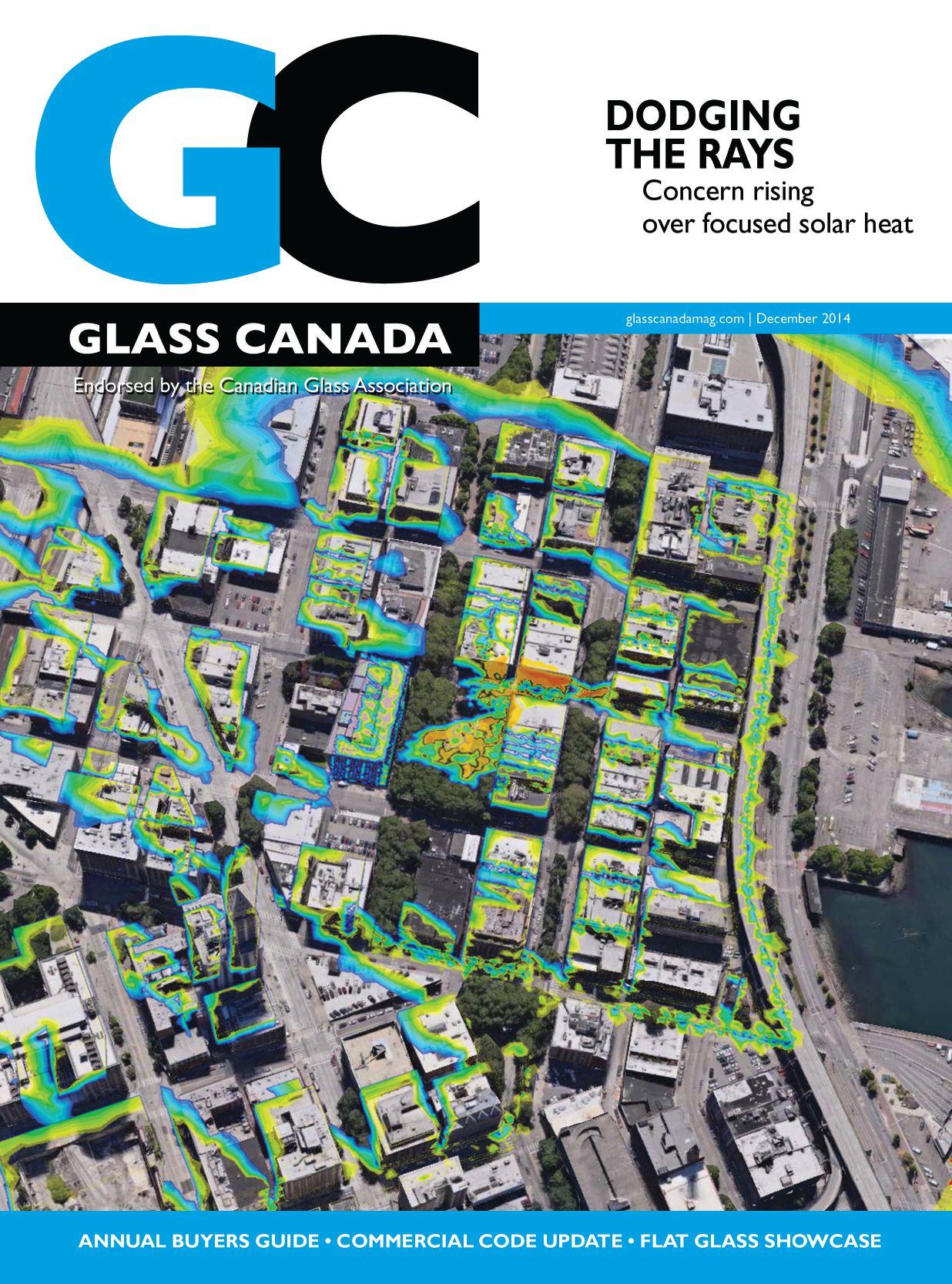

Focused reflected sunlight has caused some high-profile problems around major glazing projects. Time for an industry response, our expert says.

18 NAFS and you

What does the North American Fenestration Standard mean to ICI facades in Canada? RDH Group consultant Al Jaugelis has the answer.

22 Flat glass showcase

Everything starts with the glass. Find the latest innovations here.

25 Annual Buyers Guide

It’s like Santa’s sleigh full of top suppliers for all the good girls and boys in the Canadian glass industry.

isn’t like any other Twitter feed out there. It is the only one that sifts the online world for content relevant to Canadian glass construction and posts it in quick-hit headlines. Have a few minutes? Get out your phone and take a quick scroll.

Frank Fulton

A life’s learning

Industry legend Bob Maltby has shared his knowledge

in a new book

One of the many pleasures of the Glass Association of North America’s conference in Toronto last September was meeting Bob Maltby, 83, a veteran glass man who was instrumental in researching, developing and introducing to North America many of the techniques for making and processing flat glass that we take for granted today. Maltby has a PhD in physics and spent over 25 years at Libby Owens Ford and Glasstech before “retiring” in the early ‘80s into his own consulting business. During his tenure at LOF, Maltby seems to have had a really incredible amount of time and freedom to play with their sheet glass line and bending processes. This made him enough of an expert that he was heavily involved when PPG’s new float glass process was brought to the company. Think about all the changes and advances that have been made in glass technology since the Second World War: Maltby was there and was, in many cases, pioneering the new innovations on this continent. He holds a lot of patents.

NEXT ISSUE

• Top Glass preview

• Provincial Glass

The neat thing is, we can all now benefit from Maltby’s experience because he has written a book. It’s called simply Bob Maltby’s Glass Book – 50 Years in Lab & Factory. I confess I haven’t read it all yet, but it is here by my computer and I’m working my way through it while I wait for big files to upload. Considering the heavy technical information he is explaining, the book is actually quite engaging and not too difficult to read. And boy, is it informative. Have you been wondering what the secret is to getting the correct tension through the various glass layers in a tempering quench? How about the best way to minimize end kink? Do you wonder what bistable bow is and how it is caused? Well, wonder no more; Maltby has all the answers and he is good at putting them in plain English. He includes a ton of practical suggestions as well as explanations of the physical processes that are going on. It is not information you will use every day in your business, but I think just about everyone who gets this magazine would feel they had a better understanding of the material we use every day after reading it. To obtain a copy, email Maltby at maltbyjr@wcnet.org.

As this year comes to an end and we look ahead to 2015, there are some exciting developments on the horizon. Glass Canada’s commercial glazing conference, Top Glass, will return in April to the International Centre in Mississauga, Ont. Watch for some very special announcements concerning our speakers. We are hoping to bring you the launch of an important new standard that will be of critical interest to anyone building condos...’nuff said.

Hosting trade events like Top Glass can involve a delicate balancing act. When we seek feedback on the show, we often get conflicting answers. For instance, there is little agreement on whether the show should be held every year or every other year, or whether it should be held in downtown Toronto or at its present location in Mississauga. Please rest assured that your input is valued and respected, even if we have had to make alternate choices. •

@GlassCanadaMag

December 2014 Volume 26 • Number 6

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexweb.com 226.931.0545

SALES MANAGER | Danielle LABRIE dlabrie@annexweb.com 519.429.5187

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexweb.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

GROUP PUBLISHER | Martin MCANULTY mmcanulty@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@glasscanadamag.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0843-7041

CIRCULATION

e-mail: subscribe@glasscanadamag.com Tel: 866.790.6070 ext. 208 Fax: 877.624.1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Canada - 1 Year $36.75 (includes GST)

($39.55 includes HST/QST)

U.S.A. - 1 Year $50.00 (in US dollars)

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

www.glasscanadamag.com

INDUSTRY NEWS

Glass Canada at Fenestration West

British Columbia’s annual residential window and door event, Fenestration West, took place this past October at the Sheraton Guildford in Surrey. Eligible for three AIBC Core Learning Points, the one-day conference and table top show was sponsored by Intertek Testing and featured a variety of fenestration related presentations and networking opportunities. Akzo Nobel, Apex Aluminum Extrusions, BClear Benefits, Cascade AquaTech, ETS - Lindgren Guardian Industries, Leavitt Machinery Lenmak, Spectrum Skyworks and Tremco Sealants all exhibited. Glass Canada shared a table with the Canadian Glass Association.

Topics from the learning sessions included building code updates, aluminum extrusions as building materials, powder coating, energy code provisions and acoustic testing in the laboratory.

“The Association struggled this past year,” said outgoing Fen-BC president Terry

Adamson. “We wrestled on a number of levels with NAFS and the commercial glazier training school had some challenges. We had a hard time filling seats for all of the sessions so we’ve tried to bring in other training opportunities to keep the revenue coming in. We think we’re over the hump and that it was just bad timing.

“We have to get the commercial guys engaged,” added Adamson. “This year, the chairperson needs to come from the commercial sector so hopefully we can dedicate more effort to the concerns and challenges of the commercial side. To be fair and honest, the commercial glaziers and suppliers were quite neglected because as chair this past year and being from the residential side, I was completely and utterly devoted to NAFS and kind of forgot about the commercial guys. I apologize for that. Hopefully we get someone from the commercial side who is a real go-getter and we can bring everyone back in the fold.”

Feb. 3 - 7

IGMA Winter Conference Fort Lauderdale, Fla. igmaonline.org

Feb. 15 - 18

AAMA Annual Conference Fort Laudersale, Fla. aamanet.org

April 15

Top Glass Mississauga, Ont. topglasscanada.com

June 4 - 6

Fenestration Canada AGM Vancouver, B.C. fenestrationcanada.ca

March 5

No Frills Trade Show Toronto, Ont. toronto.csc-dcc.ca

March 8 - 10

GANA Building Envelope Conference Las Vegas, Nev. glasswebsite.com

May 13 - 14

PGAA Try-A-Trade Edmonton, Alta. pgaa.ca

June 3 - 4

Glass Connections Saskatoon, Sask. canadianglassassociation.com

August 13

PGAA Golf Red Deer, Alta. pgaa.ca

Sept. 17

OGMA Fall Golf location TBD ogma.ca

CGA Newsletter

CANADIAN GLASS ASSOCIATION

On the heels of a very successful Glass Connections event in Halifax, planning is already underway for the Canadian Glass Association’s Glass Connections 2015. The event will be held June 3 to 4, 2015, at the Sheraton Cavalier Saskatoon Hotel in Saskatoon, Sask. As in years past, the opening night will welcome attendees with a casual and fun reception, highlighting our host province. The following day will be filled with educational presentations, a keynote speaker, exhibitors and lots of networking time with your industry peers.

We are working to update the sponsorship opportunities and lay out the best exhibit space possible. If you are interested in receiving information about either, contact the CGA at info@canadianglassassociation.com.

Registration will open in 2015, but make sure to mark your calendar today to attend this great event.

ONTARIO

GLASS AND METAL ASSOCIATION

The OGMA held its fall seminar last week on Nov. 13 at Richmond Hill Golf Club in Richmond Hill, Ont. The session was well attended by 61 people.

The seminar included outgoing president, Steve Ringler’s, last presentation as president of the association. Ringler reminded attendees about upcoming OGMA events and initiatives and announced the associa-

Canadian Glass Association 619 Liverpool Road, Pickering, Ontario L1W 1R1 Tel: 604.855.0245 • Fax: 866.253.9979 canadianglassassociation.com

tion’s fall golf tournament raised $5,500 for Wounded Warriors of Canada. He thanked the board for its support and called the opportunity to serve an honour and a privilege. He welcomed incoming OGMA president, Angelo Cairo of Stouffville Glass, and praised his drive and enthusiasm. Cairo will take over in January, 2015. The OGMA thanks Steve for his dedicated service in bringing the new safety manual and the Workplace Safety and Prevention Services group to reality.

Charmaine Mitchell of Workplace Safety and Prevention Services introduced the OGMA Glass Shop Workplace Safety Manual. The document will be of particular importance to companies who do not have a formal safety policy in place and who do not have the time or resources to create a program on their own. The WSPS will work with your company to implement the safety program, will keep you updated on all changes to laws that you must be in compliance with, put you in a strong position to withstand a Workwell audit and help you to defend yourself with the Ministry of Labour in the event of a workplace accident. Your participation in this program is an absolute must for many obvious reasons.

Jennifer Threndyle, a WSPS subject matter expert for the Accessibility for Ontarians with Disabilities Act familiarized attendees with the legislation pertaining to disabilities and the effect new laws will have on glazing contractors and commercial entrance door builders. Threndyle’s entertaining talk was extremely eye-opening and informative, including solid tips to help glass shops avoid running afoul of the legislation.

David Thompson and John Hodder, building envelope

specialists with Entuitive, held an informative presentation and discussion on the topic of recent changes to building codes and gave an introduction to energy codes and how they affect the glazing industry. David looked at the evolution of products and materials and assessed where we currently stand, identifying the challenges our industry can expect to face in the future.

PROVINCIAL GLAZING ASSOCIATION OF ALBERTA

The PGAA in conjunction with the Southern Alberta Institute of Technology will be proceeding with our Master Glazier program. It has been a long road to this point but a cheque has been written and we are set to go with our foundation blueprint reading course. The additional eight courses will be on structural glazing, specialty glass, survey fieldwork, air seal barriers, project and site management, craftmanship, supervising and mentoring and doors and related hardware. The program will be open to all journeyman glaziers with five years’ field experience after obtaining journeyman certification. Successful completion of eight of the nine courses will earn a journeyman glazier Master Glazier certification from the PGAA. These courses will also be open to non-field employees who wish to upgrade their skills. Master Glazier certification will not be available to employees who do not meet the journeyman criteria. Watch this space for more updates on our progress.

After countless industry volunteer hours and support

from our SAIT partner, all four years of the Alberta Journeyman Glazier Program have been completely updated to reflect current glazing practices and materials. This update was daunting in its scope and a huge “thank you” is due the following contributors who made it happen: Blain Denholm of Alberta Glass, Richard Neal of Ferguson Glass, Brad Simpson of Cal-Tech Glass, Ron Walder of Glass Guild, Bob Stadnyk of Titan Glass, Mitch Huston of Alberta Glass, Steve Moore of Capilano Glass, Blake Simpson of Beacon Glass, Jim Brady of Desa Glass, Ed Dalzell of SAIT and Ken Nelson of Alberta Apprenticeship and Industry Training.

The Canadian General Standards Board is beginning the process of reviewing the 12 CGSB glass standards, many of which have not been updated for over 20 years. Brent Harder of Ferguson Glass in Calgary has been accepted as a voting member of the CGSB committee on glass. He will provide updates to the PGAA directors and may be asking various PGAA member companies for their input as standards are reviewed. We look forward to hearing from Brent on the committee’s progress.

Our annual PGAA golf tournament on August 14 at the Red Deer Riverbend golf course was sold out. Thank you from all the participants goes out to our volunteers, Ryan Ardiel of Tremco, Dan Rogers of PPG, Dwayne Stolz or Leydens Glass and John Reitmeir of Grant Metals.

The PGAA has many initiatives on the go. Go to our website, pgaa.ca, to learn more. Thank you to all those hardworking volunteers from the Glazing and Architectural Metals Association and the Glass Trades Association that make up our provincial association here in Alberta.

Azon to exit spacer business

Effective immediately, Azon will no longer produce the warm-edge spacer product Warm-Light for insulating glass. According to David Mills, Azon CEO, “Even though we believe the product to be the very best spacer for thermal and structural performance, we simply are not able to produce the material in our plant in a cost-efficient manner and we are unable to improve margins and still remain competitive in the

marketplace.” The Michigan-based company is appreciative of the many customers who chose the product for use in fabricating insulating glass over the past 20 years. Azon continues to be a leader in technology for the manufacture of thermal barrier aluminum fenestration, commonly referred to as the pour and de-bridge method with the growing network of aluminum extruders and window manufacturers worldwide.

Ontario report calls for sweeping changes

Paul Bélanger, Commissioner of the Elliot Lake Inquiry, recently released his final report in to the Algo Centre Mall parking deck roof collapse of June, 2012. The Inquiry Report makes 71 recommendations, many that would significantly strengthen the regulation of Ontario’s engineering profession. Significant new responsibilities for Ontario’s municipalities and chief building officials are also proposed.

“We are anticipating that Commissioner Bélanger’s report will have considerable impact on Ontario’s engineering profession”, said Barry Steinberg, CEO of Consulting Engineers of Ontario. “Ultimately, the significance of these recommendations hinge on what the government of Ontario chooses to adopt. Attorney General Meilleur has immediately committed to an advisory panel to consult with stakeholders on how to move forward on these proposals. CEO is looking forward to being intimately engaged in this process,” Steinberg said.

Of particular importance for engineers are the commission’s recommendations calling for an established system of continuing professional education for professional engineering

NanaWall educates

NanaWall held a lunch-and-learn at its Mississauga, Ont., showroom on Nov. 6, introducing about 25 attendees to its line of sliding and folding window wall systems for residential and commercial applications. Lunch was served while Ontario sales representative, Georges Lagasse, presented a detailed overview of the company’s products followed by a chance to try them out in NanaWall’s showroom in the International Centre’s SOFA area. NanaWall is a 25-year-old manufacturer headquartered in California, with some fabrication and assembly happening there.

NanaWall has been operating in Canada for about 15 years, with most of its initial business coming in more northern areas. NanaWall systems come in

license holders; developing a new performance standard for structural inspections of existing buildings; a requirement for a Structural Adequacy Report of existing buildings, prepared and sealed by a professional engineer certified as a structural engineering specialist; and providing additional information about professional engineering license holders that have been disciplined for professional misconduct.

“If enacted, these recommendations represent a net benefit for all concerned,” remarked Steinberg. “They will strengthen our profession’s fiduciary responsibility to serve and protect the public interest, as stipulated in the Professional Engineers Act. Going forward the real burden will be on the province and municipalities.

There are new responsibilities for chief building officials, and new requirements requiring changes to the Ontario Building Code impacting record keeping and reporting for the province and municipalities. Success will be defined by what effective enforcement looks like. It will be interesting to see to what recommendations are adopted.”

two main types: folding and sliding. The folding systems consist of aluminum or wood-frame glazed panels riding in top and bottom-mounted track systems. Flush and surface-mount sills are available, including a saddle sill for barrier-free applications. Systems incorporate a thermally broken structural strut, so installers can avoid pouring and de-bridging. Panels can swing in or out and can be stacked in a variety of configurations. With dual and triple glazing Lagasse said folding systems can achieve as low as 0.29 U-values and Energy Star ratings in southern Canadian zones. Panic hardware, concealed hardware and screened openings are all available. The sliding systems add the advantage of hiding the panels inside a wall pocket or in a remote location when the wall is opened – NanWall has even done systems where the panels are stored across a hall from the actual wall location. Sliding systems are supported from the top and are used with flush or low-profile sills. U-values drop as low as 0.26. The glazing is not involved in the structural integrity, so many decorative options are available in sliding systems. The systems can be rated for force-entry resistance and hurricane resistance. They can also meet AAMA standards for air/water ingress. Incorporating photo-chromatic glazing has been a challenge due to the wiring requirements.

Glasstec reports over 40,000 attendees

In late October, Glasstec 2014 saw rising numbers of exhibitors and trade visitors confirming positive market developments in the glass industry. About 1,300 exhibitors came from more than 50 countries and about 60 per cent of a total of 43,000 trade visitors arrived in Düsseldorf from all over the world. An majority of visitors gave Glasstec 2014 high marks and are planning to return in 2016. Glasstec 2014 attracted specialists from fields such as mechanical engineering, glass processing and finishing, crafts, architecture, construction, glazing and facade fabrication as well as the solar sector. The great majority of visitors came from middle and top management with specific intentions to invest.

Glass Technology Live, a specialty segment complementing Glasstec 2014, was extended this year. With the motto “Intelligent Glass,” glass products from the “nearer future” were presented to visitors. According to experts, display glass,

Dixen named CEO of A + W

Mark Thompson, CEO of the Friedman Operating Group, has announced that Peter Dixen has been named CEO of A+W Software. In this role he is succeeding Uwe Schmid, who has left to pursue other opportunities. A+W thanked Schmid for his role in strengthening the company’s product offering and market leadership. Dixen has assumed full responsibility for the worldwide operations of the A+W Software operating unit. He brings more than 20 years of glass and fenestration IT industry experience to his new role and is highly focused on customer satisfaction and long-lasting partnerships with A+W customers. His previous experience includes 13 years as IT application and internal software

Pleotint appoints Simkins VP

Pleotint has announced the appointment of Chad Simkins as its new vice president. In his new position, Simkins will lead domestic sales and marketing efforts for the company’s Suntuitive glass products and technology.

“This is an exciting day for our company,” said Harlan Byker, CEO. “As we continue to grow and refine Suntuitive glass, Chad’s background in material science and the glass industry brings a mix of experienced insight, creative thinking, and marketing expertise that will be valued additions to our existing team and culture.”

An 18-year glass industry veteran, Simkins has more than eight years of executive management experience with dynamic glass companies, serving most recently as

technical glass applications, glass printing and coating as well as thin glass will be the top themes for the coming three to five years. Eyecatchers such as display glass used in alternative areas of application and ultra-thin glass from the roll for electronic applications attracted the visitors’ attention. At the same time a top-notch specialist symposium offered a wide scope of daily changing presentations to an enthusiastic crowd. The three conferences - Solar meets Glass, Engineered Transparency and the Architecture Congress - were also a success and extremely well attended. For instance, about 200 participants from 23 countries discussed and shared knowledge on topics of engineered transparency and some 280 participants participated in the Architecture Congress on the last day of the show. The next Glasstec will be held in Düsseldorf in line with its two-year cycle from Sept. 20 to 23, 2016.

development director for an international glass company, A+W support manager focused on key accounts and, most recently, A+W vice-president of sales and marketing. Apart from his native language, Danish, Dixen speaks English, German, French and Japanese.

Based on his long-term experience in the glass industry, Dixen will focus on customer satisfaction as well as long-lasting partnerships and cooperation with all A+W customers. The requirements and expectations of customers will be the main goal for all sections of A+W, with a specific emphasis on strategic product development to meet the needs of A+W customers today and tomorrow.

senior sales executive for View. He is a recognized expert in new technology product commercialization, and has helped refine, develop and introduce new products for Sage Electrochromics, AGC, and PPG.

“I’m excited about the opportunity to help Pleotint’s management team guide the company into the future and to leverage the spirit of innovation they have worked so hard to cultivate,” Simkins said. “The dynamic glass industry is growing rapidly and Suntuitive glass is a differentiated product with unlimited potential for residential and commercial applications. It is well-positioned to capitalize on the increased demand for dynamic and adaptive glazings and I’m eager to use my experience to help make that happen.”

Dodging rays

rays

Pressure builds for action on focused solar reflection.

by VINCENTE MONTES AMOROS

Solar reflectivity has generated attention in the design world due to the appearance of “fryscrappers” or “death ray buildings,” as they have been referred to in public media. These creative nicknames come from accounts of the Siege of Syracuse in 214-212 B.C., when Archimedes supposedly used an array of mirrors to set an adversary’s warships on fire. Ancient scribes named these “death rays.” The principle is to concentrate reflected light on a small surface to increase its temperature, which should be familiar to anyone who played with a magnifying glass on a summer’s day.

The so-called death ray buildings (officially two have been registered to date) have several things in common. They both exhibit concave south-facing walls, which happen to be all glazed. The reflectance of the glass used is excess of 40 per cent. The focused reflections melted plastic and raised temperatures nearby. One of these buildings is located in Las Vegas, and it raised temperatures by 10 C, causing plastic bags and cups to melt. The second one is located in London, England’s Financial District and it raised ambient temperatures from 29 to 72 C. Surface temperatures of some materials nearby were recorded at 110 C. This building caused plastic components of a car parked nearby to melt. Other building materials such as TPO roofs and metal panels can produce a reflectivity effect similar to what happened in Los Angeles when the Walt Disney concert hall facade clad in stainless steel panels blasted condos across the street with blinding glare and heat.

Cases of melting gaskets in glazing systems, blistered paint, warping car consoles and tarps melted off buildings have all been reported in public media. However, not all cases make the news and not all cases get the coverage and exposure a very few have gotten. Solar reflectivity can indeed be a nuisance and also produce severe and hazardous conditions that can jeopardize public safety. If this issue has already been recognized and recorded, why is the industry still silent about the topic? Why are there no limits or a widely accepted performance criteria?

When trying to find the right measure or limit to effectively address solar reflectivity, several factors need to be considered. The first is discomfort to drivers. Drivers can be blasted by reflected light and get distracted with potentially dangerous consequences. Cities located 40 degrees or more from the equator represent a particular challenge because the sun’s natural position during the winter months is relatively low. At angles of less than 20 degrees, direct sunlight and reflections caused by sunlight can be within motorists’ cone of vision and produce glare.

Reflections from building facades can blind neighbours, ruin energy models and even damage buildings, cars and vegetation. Time for an industry response?

Nuisance to neighbours is another problem. A case in the Dallas Arts District was reported in 2012 where a residential high-rise building with highly reflective glass (in excess of 40 per cent reflectance co-efficient) casted reflections into a nearby museum. Reflections from the residential tower entered the museum’s galleries through a unique skylight design that was intended to allow only indirect sunlight from the north. The reflected light’s intensity increased not only the temperature on the museum’s garden but exceeded the acceptable light levels to safely display some works of art. At extreme thermal loads, the temperature increase can produce discomfort to pedestrians and at gathering places nearby.

Energy models can be invalidated by focused solar reflection. Depending on the project’s context and the intensity and duration of the reflected light, a building’s adjacent properties

could see an additional thermal load that was not considered in their energy modelling.

Solar reflectivity will intrinsically produce and increase heat in the surrounding environment. The intensity will depend on the material producing the reflection. Vegetation is adapted to a range of natural heal levels and it is possible that with a sudden increase in heat, it can start to decay and eventually die.

Light is comprised of different components: ultraviolet (UV), visible light and infrared. Human eyes can only see the visible light portion from the solar spectrum. To get the most benefit from natural daylighting without unnecessary heat gain, some glass coatings prevent the infrared portion from getting into the building. Whatever is not transmitted through the glass to the interior of the building is reflected and sent back to the environment, and that is not the visible light portion only. Reflected infrared light is essentially radiated heat that will raise the temperature of anything it hits. Reflected UV causes cell damage to living things and can break down certain materials, especially plastics.

To date, only Singapore and Sydney, Australia, have limits on the effects of solar reflectivity. The building code in both cities states that reflectance of construction materials is limited to 20 per cent and that a solar reflectivity assessment must be submitted for approval. The City of Dallas recently tried to modify its building code to address this phenomenon due to recent events in their Arts District. However, the proposal did not survive the public comment phase and the idea was abandoned.

Due to the lack of legislation or an industry standard, this phenomenon is generally not addressed during design and cannot be easily resolved after it happens. Because solar reflectivity can impact the visual and thermal aspect of a surrounding environment, different criteria and indices have been proposed but none is widely accepted or used. We have seen a handful of competing criteria with their own strengths and weaknesses. Four main ideas are out there.

The first criteria limits light brightness. Factors such as age, eye pigmentation and the pupil’s ability to rapidly adapt to contrast are just some of the variables that make tolerance to light brightness different for every person. Given these factors, limiting light brightness might not be the most objective criteria. Also, this limit does not address thermal load.

The second criteria found limits reflectance of construction materials. This limit is integrated to a couple of city building codes, as mentioned before, and can easily be met. However, complex building geometries can focus light which would produce solar reflectivity issues even with limits of this kind.

The third criteria limits thermal radiation. Although this limit can certainly be a more objective proposal because heat and its effects are measurable, one must be careful in selecting an appropriate threshold. Different levels of heat produce different effects. Some plastic materials have a melting point of less than 80 C and can be at jeopardy if a high threshold is selected. The surface temperature of materials like sealants or gaskets in glazing systems can rapidly increase when in contact with highly conductive metals in framing members.

The fourth criteria limits direct sunlight effect. By limiting the effect of reflectivity to no more than what direct sunlight produces could certainly result in conservative results. But plant species, materials and humans are accustomed to nominal sunlight conditions. In using this criteria we can be certain that the effects of solar reflectivity would be limited and controlled. This criteria

addresses the visual and thermal aspect of the phenomenon.

The study of solar reflectivity can benefit not only potential death-ray buildings but more normally shaped buildings too. Pedestrian comfort and vegetation sustainability can benefit from this type of analysis by making sure the proposed material or glazing is adequate for its surroundings. Some environmentally concerned designers, aware of the issue, have retained facade consultants to perform analysis on their proposed designs. They wanted to make sure their projects will not alter the surrounding areas and cause impact to neighbours.

Although the solar reflectivity phenomenon has always been part of glazed projects, it was only recently that designers and building owners started to become aware of the issue, in part due to projects that have gone wrong. Technology now exists to model and predict anything we can imagine. Technology and talent have demonstrated that any problem can be resolved.

Tall buildings are certainly an alternative in areas with limited space to build, and glass is a relatively cheap material that serves many functions in an already size-reduced building skin system. But the problem is not building height or the amount of area covered with exterior glass panelling. Although both factors carry their own weight, the real problem is us. The real problem is that in our contemporary designs we give little or no consideration to our environment and neighbours who are being affected by our lack of holistic building design. Surprisingly, the study of light and reflection is ancient, and although it is a very well documented and studied topic we have not extrapolated that knowledge to our industry.

The time is ripe for an industry standard that limits the amount and intensity of reflected light. Waiting for more death ray buildings to be built before reacting as an industry would not be proactive. Buildings rendering energy modelling of adjacent properties obsolete is a problem everyone should be concerned about even if you never plan to build a reflective facade. The industry needs to step in and propose limits to this nuisance. It has been almost 10 years since the first solar reflectivity case was reported from a stainless steel panel façade, more than four years since the first death ray building and over a year since the second death ray building came to light. Demand for solar reflectivity studies has increased during the past five years, which is just one indicator highlighting the need for industry-wide acceptance criteria for solar reflectivity.

Glazing options available today do not compromise energy performance with the use of less reflective glass. Contrary to common belief, buildings can still meet energy requirements with less reflective glass, as has been proven with recent designs across the globe. Since glazing products are not the limiting factor to mitigating this issue, the industry needs to react simply because architectural designs are becoming more complex in shape and geometry, which can aggravate this situation. •

About the author

Vincente Montes Amoros is a structural and facade engineer at CDC’s Virginia/Washington D.C. office. He has worked as a building envelope structural engineer and specialized in the design and engineering of natural stone, pre-cast concrete panels, composite panels and a variety of glazing systems. He has completed a Masters of Facade Engineering at the University of Bath in England. Montes Amoros started the solar reflectivity program at CDC and has continued to work on its development. He is published on a variety of building envelope topics in construction industry journals and magazines.

GLASSEVENT

SUMMER HOT AIR

by MARGARET WEBB

The Insulating Glass Manufacturers Association’s 2014 Summer Conference was held the first week of August in Quebec City. In addition to the technical meetings, highlights included a walking tour of the historic old city.

Since the last meeting, IGMA has published two new publications. The first is TB-1601-14, Guidelines for Use of Capillary Tubes. This document has been published jointly by IGMA and the Glass Association of North America. We have also released TB3001-14, A Brief Review of the Use of Setting Blocks for Insulating Glass Units. As with other IGMA publications, these documents are available for purchase through the new IGMA online store.

Emerging Technology and Innovation

The Emerging Technology and Innovation Committee met on the first day of the Quebec conference. The work of the Gas Permeability task group has been deferred while parameters are being estab-

IGMA drives industry standards in Quebec.

lished for a new field correlation study. The Advanced Testing Fenestration task group is working on three new test protocols designed to correlate to ASTM standards and provide faster means of testing IGUs for a number of qualities. Positive Negative Pressure Cycling (also called the Thumper) uses external pressure modulation of plus or minus one PSI to replicate the pressure changes witnessed within an IGU cavity. Variable Environmental Cycling (Oscar)

is a modified P1 chamber using full immersion UV at 100 per cent relative humidity and 60 C pressurized to five PSI. The Differential Thermal Cycling Unit (Big Hammer), developed by the National Renewable Energy Laboratory, uses rapid thermal cycling to replicate thermal cycles in ASTM E2188. The group is currently evaluating the fabrication of flawed test samples to determine equivalency to the ASTM standard. They are also working on how to correlate the NREL thermal chamber and

ABOVE: Gorgeous and historic Quebec City was the setting for the IGMA Summer Conference. Delegates enjoyed some great food and drink as well as a walking tour of the Old City. Next up, Fort Lauderdale, Fla.

the two other test methods with the ASTM E 2190 standard to ensure that the new test procedures will meet or exceed the objectives in the existing standard.

The Vacuum Insulating Glazing task group has completed the first draft of the technical bulletin, TB-2600, Vacuum Insulating Glazing. The first ballot has closed and the group will be reviewing the ballot comments. Most of the comments submitted were editorial. It is anticipated that this document may be published before the end of the year.

In addition to working on the Product Category Rule for fenestration products, the Life Cycle Assessment task group has solicited RFQ’s for the development of a processed glass PCR. The quotes have been received and the group will be meeting shortly to review the proposals and award the contract.

The Gas Content Field Correlation Study task group session is member-only due to the sensitivity of the subject. However, the task group is developing the parameters to commence a study of these units.

Technical Services

The Technical Services Committee met the second day with reports on task groups, codes and standards development in Canada and the U.S. and reports from our affiliated organizations. IGMA has created a new task group, Tolerances for IG Cavity Width, to address non-parallel glazing and the effect on thermal and long-term performance related to changes in the cavity width. The task group met early in October and established three work groups. The Manufacturing Tolerances working group will develop and establish manufacturing tolerances for allowable deflection. A number of certification agencies have added deflection inspection criteria to their programs, but have not established the values. The Thermal working group will contact the Lawrence Berkley National Laboratory and the University of Waterloo for further data on the impact of changes in IG cavity width on thermal performance and will make recommendations to the National Fenestration Rating Council for in-plant inspection requirements. The Impact of Reflectance working group will review existing available industry data on solar heat reflection from low-E coated glass. The scope and objectives of this group are under discussion. The three work groups will be meeting over the next month to develop their specific scopes and objectives. The entire task group will meet the end of November to review the scopes and deliverables and establish timelines for project completion.

Dimensional Tolerances

The task group that developed the technical manual on multiple cavity insulating glass units has now reconvened and will be undertaking a major revision of TR-1200, Dimensional Tolerances. This document will include multiple cavity IGUs but will primarily tighten up the tolerances included in the current document. This technical report has been withdrawn from circulation until it has been revised. Currently the group is soliciting manufacturer’s tolerances in order to revise the document.

TB-3001-14, A Brief Review of the Use of Setting Blocks for Insulating Glass Units is a companion piece to TM-300090(04), IGMA Glazing Guidelines for Insulating Glass Units for Commercial and Residential Use. It is intended to be distributed to window manufacturers to ensure the correct

size, strength and placement of setting blocks, particularly in multiple cavity IGU’s. This document has been published.

TM-3000-90(07), Section 5.0, Setting Blocks is a major revision to Section 5.0 of the IGMA glazing guidelines. It is being prepared for balloting to the IGMA board of directors. It is anticipated that this section will replace the existing Section 5.0 prior to the Summer Conference. Currently the diagrams are being updated to provide for future revision.

Canadian Standards Development

The Canadian General Standards Board has reconvened the CGSB Glass Committee. The first task that is being undertaken is a review of safety glazing. Currently, there are two Canadian standards which address safety glazing: CAN/CGSB 12.11, Wired Glass and CAN/CGSB 12.1, Tempered or Laminated Safety Glass.

These standards are now being reviewed in response to needs identified by manufacturers, glass users and regulators such as Health Canada and the National Research Council, which incorporate the standards by reference. The revisions will establish the performance requirements of glass to ensure it breaks in a safe manner. The current task is to update CGSB 12.1 and expand it to include other categories of safety glazing: organic coated and plastic. There are four task groups working on this update and progress is well under way with the hopes that the revised standard will be ready for public review in early 2015. There is also a strong commitment to review other safety glazing standards including ISO and the ANSI Z97.1 with a view to harmonizing where possible. The laminated section of the CGSB 12.1 standard is close to completion as well as the organic coated one.

All enquiries regarding the development of the CGSB glass standards should be forwarded to Jennifer Jimenez at CGSB. CGSB manages the standards development process using technical committees whose volunteer members represent a balance of interested parties, experts, general users and regulators.

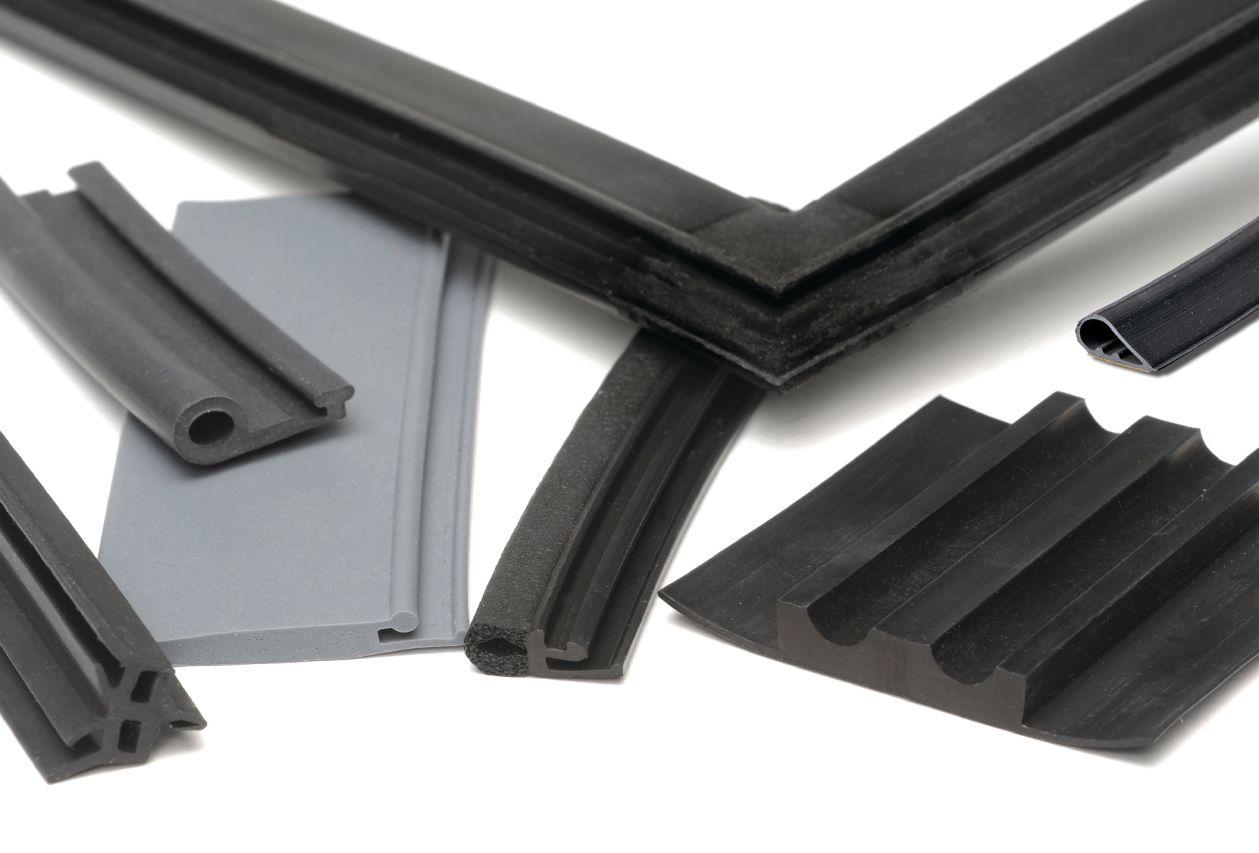

The Certification and Education Committee, specifically the Spacer and Integrated Spacer Systems Task Group, is looking at alternate ways to determine component equivalency. Currently the task group’s work has been placed on hold, pending work being done by the Sealant Adhesion to Spacer task group. The Sealant Adhesion to Spacer task group has developed a new test methodology based on a modification to the existing butterfly test. The group met at a manufacturing facility to validate the test and reported on the results at the Quebec City meetings. Based on feedback received, the work group will review the proposed test method.

The TM-4000, Quality Manufacturing task group is close to completing the first draft for the revised manual. This revision will include all clauses for accreditation to the ISO 9001:2008 standard specific to IG manufacturing. Additionally, each section includes a commentary on the purpose and objectives so that manufacturers can determine which sections are relevant to their manufacturing operations and those they are to be exempted from. The task group will be meeting to review the final draft and a ballot will be issued next month.

The IGMA 2015 Winter Conference will be held jointly with the Insulating Glass Certification Council in Fort Lauderdale, Feb. 3 to 8. Details on the meeting and networking sessions are under development. •

by LAURA WEIL

Laura Weil is chair of the Fenestration Canada

Membership

and Marketing Committee and sales and marketing manager for Euro Vinyl Windows of Woodbridge, Ont.

Step aboard

Whatever measure you use, the industry is experiencing a pace that hasn’t been felt in quite some time. It may be the result of the gradual American economic recovery making its way over the border. Perhaps the federal government incentive programs from 2010 have panned out. Could it be the long cold winter shook up consumers? Whatever brought recovery to our industry, it is welcome. Hard work and perseverance over the past few years is now showing promise and reward. New relationships and partnerships developed during the low times, and now the industry has opened up to a landscape which looks and feels stronger than it has in years. This is a good sign, as the next challenges of abundant business and greater expectations are being faced and there are some very well-equipped companies that are prepared to take advantage.

Creating efficiencies in the way we do business and having a solid understanding of what it is going to take to ensure that the ideal products are being applied is necessary to continued success. This is now the responsibility of every business related to the fenestration supply chain. Fenestration Canada proudly hosts venues to promote industry-specific collaboration and continued education. For instance, Windoor showcased the latest industry innovations from product offerings through to upcoming Passive House building trends that will soon become an influence in Canadian construction. Training and support from industry leaders is accessible to every participant. Should a trip to Toronto not be in the cards, then becoming a member of Fenestration Canada provides you with access to webinars pertaining to NAFS, code compliance, and the dreaded labelling

Collectively, we can become an accountable and responsible industry.

FENESTRATION

requirements and technical specifications for the consumer-driven Energy Star program.

Speaking of Windoor, the 20th edition of Canada’s window and door show went off in spectacular style. We weclomed over 2,300 fenestration professionals to downtown Toronto and ramped up the festivities with a rocking performance from the Blus Brothers band. This show was notable for some of the important industry meetings going on. Our Fabricator’s Council hosted a special session to review and discuss the results of its nationwide survey of test labs and certification authorities. This meeting went a long way toward clearing up some long-standing confusion around NAFS testing. Also, Al Jaugelis convened a meeting with the National Research Council to discuss the possibility of relaxing National Building Code restrictions on the use of PVC on high-rise building facades.

Fenestration Canada is growing a membership base across the country for these very reasons. This is allowing the organization to create a new website platform that will be the reliable and credible resource for all things fenestration-related in Canada. The vision is of an online go-to that will define who we are as an industry while providing the timely information required to succeed, packaged in a user friendly and stylish format which will be accessible from any device.

As powerful as an online webinar and resource-heavy website can be, nothing quite compares to an intensive three-day AGM with industry leaders. Fenestration Canada is hosting the 2015 AGM in beautiful and prosperous Vancouver, June 4 to 6. Following the success of Winnipeg’s AGM in June of 2014, there is much anticipation and encouragement for FenBC affiliates and industry fabricators from across the country to participate along with the existing favourable affiliate base. Time spent at the Faimont Hotel Vancouver will include technical sessions balanced with keynote speakers, the President’s Dinner and group outings. Coming together as an association and working together is powerful and enjoyable, as most companies are experiencing similar trials and tribulations of growth and improvement.

Collectively we can become an accountable and responsible industry – one dedicated to constant improvement in business, fabrication and service. Fenestration Canada continually holds open arms and minds to make this happen. •

COMMERCIAL NAFS

by AL JAUGELIS

While the National Building Code is clear that testing and labelling fenestration products to the North American Fenestration Standard (NAFS-08) and the Canadian Supplement is mandatory for Part 9 buildings, the application of these standards to commercial fenestration products, in both Part 3 and Part 9 buildings, is less straightforward.

The 2010 National Building Code and provincial codes based on it, such as the 2014 Ontario Building Code and the 2012 B.C. Building Code, all use very similar language with respect to the application of NAFS and the Canadian Supplement in both Part 9 and Part 5. The NBC is clear that our performance expectations for the wind and water resistance of fenestration products, called performance grades in the code, must be determined on a building-by-building basis, taking into account each building’s location, terrain, and the height of the fenestration product. For products within the scope of NAFS,

NAFS will not replace building engineering.

it directs us to use the Canadian Supplement to determine the appropriate design pressure, water penetration resistance, and snow load (for skylights), though it is entirely appropriate to use it for fenestration products outside the scope of NAFS as well. For products within the scope of the NAFS standard, these building-specific performance expectations are defined with respect to a property called “performance grade.” While performance grade ratings are denominated in IP (inch-pound unit)

design pressure increments of five pounds per square foot, ranging from PG15 to PG100, they also include successful testing to a range of specified tests in a prescribed order, starting with operating force (and force-to-latch for side-hinged door systems), air leakage, water penetration resistance, uniform load tests at both design pressure and structural test pressure (1.5 times design pressure), as well as forced-entry resistance. Successful testing to all these requirements is required to achieve a

ABOVE: Applying the North American Fenestration Standard in the commercial world of custom fabrication and site-glazed products is going to be tricky. Labelling will probably not be an option in most situations.

performance grade.

But NAFS testing does not end with the achievement of a performance grade. In addition to meeting the minimum test specimen size and performance grade requirements to qualify for one of the four performance classes (R, LC, CW and AW), there are additional auxiliary tests that evaluate product durability features.

While products can achieve a performance grade by testing to the minimum specified Canadian requirements in each of these test categories, manufacturers are well advised to test products to their maximum capabilities to ensure they have a larger market. After all, in Canada we have two levels of operable product air tightness, and depending on building location and height, products may require significantly higher water penetration resistance than the minimum test values required to achieve a performance grade. These higher-than-minimum air and water penetration resistance values are reported in the NAFS Secondary Designator.

From reading the code, one would never guess that “performance class” (which is different from performance grade) is the key concept at the heart of NAFS. The first of the general requirements in the standard is an introduction to the gateway performance requirements used to assign products to one of four performance classes, and these gateway requirements are summarized in Table 1 of NAFS-08. Eighty three pages later, the standard concludes with Table 27, also titled Gateway Performance Requirements, which expands Table 1 to seven pages of detailed testing requirements that exist for one purpose only: to classify each of the 30 product types in NAFS to one or more performance classes.

The code, however, says nothing at all about performance class, other than “the minimum level of performance required for windows, doors and skylights shall be that of the Performance Class R.” That is the lowest of the four classes.

It seems clear that while performance class distinguishes products on criteria that may be important to an architect or specifier, it is not a topic of interest to the code, which concerns itself primarily with performance grades.

NAFS in Part 9

In Part 9 we see a distinction between two types of fenestration products: “manufactured and preassembled” products whose performance is evaluated by testing to NAFS and the Canadian Supplement (Subsection 9.7.4), and “site-built” products whose performance is evaluated under Part 5 (Subsection 9.7.5).

The list of products the NAFS standard identifies as being outside its scope includes curtain wall and storefront, commercial entrance systems, revolving doors, commercial steel doors, and sloped glazing systems (other than unit skylights and roof windows). Window wall products, while not named in NAFS08, are defined in NAFS-11, where they are implicitly treated as mulled windows, and as such are legitimately within the scope of NAFS.

The use of the term site-built to refer to products outside the scope of NAFS is all the more striking given that there is no other meaning defined for this term in the code. These commercial glazing products are not actually built on-site—the frames are typically fabricated in an indoor manufacturing environment. It is possible that here the code is referring to site-glazed products, as the “manufacturing” of a fenestration product is not considered complete until the glass is installed. The distinction

between site-glazed and factory-glazed is an important one in the context of product labeling.

Subsection 9.7.5 makes it clear that under Part 9, the design and performance verification of commercial fenestration products that are outside the scope of NAFS is to be handled in the same way as in Part 3 buildings: with reference to Part 5 requirements for professional design and supervision.

NAFS in Part 5

Fenestration performance in Part 5 is addressed in Subsection 5.10.2. titled Windows, Doors and Skylights. Article 5.10.2.3. describes the structural, air leakage and water penetration design and performance requirements in this way:

5.10.2.3. Structural Loads, Air Leakage and Water Penetration 1) Windows, doors, skylights and their components shall be designed and constructed in accordance with a) Article 5.1.4.1., Section 5.4. and Section 5.6., or b) Article 5.10.2.2., where they are covered in the scope of the standards listed in Sentence 5.10.2.2.(1).

It is interesting that this article points to two ways of addressing air-water-structural performance: clause (1)(a), which refers to the specific Part 5 design and performance requirements, and clause (1)(b), which refers to NAFS and the Canadian Supplement but only for products within the scope of NAFS. The use of “or” at the end of clause (1)(a) suggests the NAFS compliance path in clause (1)(b) is an alternative to the Part 5 design parameters we used to design commercial glazing systems in previous editions of the code.

Designing fenestration systems to comply with the performance requirements in clause (1)(a) of article 5.10.2.3. is the domain of professional architects and engineers. But NAFS testing provides considerably less assurance about the real world performance of installed products than one might expect, and to my mind it is not a substitute for Part 5 design. Here are four reasons why.

First, for vertical fenestration, NAFS testing evaluates only wind-load resistance. But a fenestration product designed to Part 5 must also consider guard loads and human impact loads: important code requirements that affect windows with sills below guard height in most buildings.

Second, NAFS performance ratings are intended to validate the performance of the product only and not the installation method. So the NAFS-tested performance grade may give you a pretty reliable measure of the air and water tightness of the product to the edges of its frame. While this is useful information, a Part 5 designer is also interested in the performance of the interface between the fenestration product and the wall. Additional testing at the jobsite will be required to verify what NAFS cannot.

Third, NAFS testing for wind-load resistance is based on a fallacy: that one can separate the structural performance of a product from how it is anchored to a particular substrate. NAFS explicitly states that testing for performance grade is a test of the product and not the installation method. The test specimen installation language in the standard is so permissive that a large proportion of manufacturers anchor test specimens in ways that maximize performance grade ratings but could not responsibly be replicated in most buildings. In my view, this makes NAFStested performance ratings an unreliable indicator of real world structural performance. Because a product’s ability to resist imposed loads is critically dependent on anchoring, and anchoring methods must address particular substrate assemblies as well as

building movements due to wind and seismic events, understanding how a product is anchored is critically important to the structural designer. This information should be available in a NAFS test report, but in my experience test reports generally do not describe the test specimen installation in enough detail to determine their applicability to project conditions.

Fourth, there can be questions about the extent to which the NAFS-tested performance represents the work of the same party that will supply and install the product to a particular building. There are several things designers need to be aware of here. For one, there are certification programs that allow fenestration product manufacturers who have never tested the products they build to label those products with NAFS ratings based on testing performed by other parties such as the developer of the fenestration system. The rationale is that as long as the untested manufacturer uses the same components and follows the test documentation, the products should perform identically. This is, in my opinion, another fallacy. While this approach may be adequate to validate the performance of products such as fire doors, it is not robust enough to validate air or water performance which are affected by the most minute and subtle deviations in manufacturing processes and the tolerances of key components. Documentation is no substitute for testing of these properties.

The same concern applies to the advertised NAFS ratings from major fenestration system developers whose products come to market through fabricators and glazing contractors. If the party fabricating and glazing the product is not the party that tested the product, the work of the fabricator and glazier will need to be independently tested to learn if it has the performance attributes advertised by the system developer. NAFS performance ratings are generally reported on product labels, and some architects and building officials expect to see NAFS labels on all products, including site-glazed products, on Part 9 buildings. Unfortunately, this is generally not possible—or meaningful—for site-glazed products (one possible exception being site-glazing by the manufacturer who tested the product and uses the same materials and methods as when factory glazing).

All NAFS certification programs for fenestration products require labeling to take place at the manufacturing facility. Site labeling is not permitted except in extenuating circumstances and under special dispensation. The act of applying a label constitutes a declaration by the manufacturer that the product rating is valid because the rating is based on the testing of a production line sample that is identical in every significant way to the labeled product. It presupposes that the manufacturer has control over all the components, fabrication, assembly and glazing operations, and can assure the purchaser of the labelled quality. This is only possible for factory-glazed products.

In the case of site-glazed products, they are not usually glazed by the same party who built and tested the product line. What testing exists was likely performed by the system developer some time ago. The fabricator may or may not have access to the detailed test reports or to the detailed fabrication instructions that would be required for the fabricator to attempt to replicate the product as it was tested. The glazier may or may not have access to the same information, but is normally not under the supervision of a party that tested or regularly manufactures and glazes that product. When there is no single party in control of production, testing and labeling, there is no party with the authority or credibility to apply a label.

NAFS and commercial fenestration

The code is clear: many commercial fenestration products are outside the scope of the NAFS standard. The code refers to these products as “site-built” in Part 9. Regardless of whether these products are installed in Part 3 or Part 9 buildings, the code expects them to be designed to Part 5 as we have always done, and as if NAFS didn’t exist.

The code is also clear that for commercial fenestration products within the scope of NAFS, NAFS testing is permitted to demonstrate compliance with the air-water-structural requirements of the code in both Part 3 and Part 9 buildings. While the code permits this, designers need to be aware that NAFS testing is not intended to validate the installation method, and the unfortunate reality is that the standard permits manufacturers to anchor NAFS test specimens in a manner that differs from their usual or published installation practices. It would not be prudent to assume that tested performance grade ratings are valid when the test specimen’s installation method differs significantly from the installation method to be used at a particular building.

It is also worth considering whether NAFS wind-load resistance testing addresses all the Part 5 structural design and performance requirements applicable to fenestration products on a given building. For many buildings, there will be good reasons to not rely on NAFS testing alone but to supplement it or even replace it entirely with Part 5 design.

NAFS testing is not without value, however. Conducted properly, with products installed and anchored as they would be installed in the field, it can validate the performance of the product and the installation method, even if that is not the stated intent of NAFS. When products are tested to their limits and beyond, manufacturers can learn a lot about a product’s failure modes, and improve designs to make them more robust.

With respect to NAFS labeling, it is not possible to label site-glazed products with NAFS performance ratings unless the labeller is the entity that controls the entire manufacturing process, including glazing, and can vouch that the tested performance applies to the labeled production-line specimens. Even in this situation, site labelling would not be permitted by a third-party certifier. While NAFS testing and labeling provides the only practical method to demonstrate compliance with code requirements under Part 9, it is less useful under Part 3. When labeling is applicable, as for factory glazed products, it is not always desirable. On large buildings it is sometimes preferable to accept the manufacturer’s reporting of applicable NAFS ratings on the project shop drawings. These will be retained long after product labels are gone.

To my mind the chief value of NAFS testing and labeling is to verify that products comply with the requirements of a performance class, a property critically important to NAFS, but of little interest to the code. The ability to compare products on the basis of Performance Class is the chief innovation in the NAFS standard, one that gives designers a new tool to both prequalify products and evaluate proposed substitutions and claims of equivalency. This is a topic for another article. •

About the author

Al Jaugelis is a fenestration specialist at the RDH Group in Vancouver. He writes about the NAFS standard at the NAFS in Canada blog (rdh.com/nafs), on LinkedIn, and @Al_Jaugelis.

PRODUCTSHOWCASE

Everything starts with the glass. Here’s the latest from Canada’s top flat glass suppliers.

Clear, no green

ppgideascapes.com

The newest edition to PPG’s collection of performance tinted glasses, Optigray glass is an ultra-neutral, warm-light-grey glass designed to maximize light transmittance and clarity. By eliminating the green colour typically found in conventional clear glass formulations, Optigray glass produces a warm, ultra-neutral esthetic that brings crispness to vision glazing. To optimize performance, Optigray glass is designed to function as a substrate for solar control, low-e coatings such as those on Solarban 60, Solarban 70XL, Solarban 67 and Solarban R100 glasses. In a standard one-inch insulating glass unit, Solarban 60 Optigray glass has visible light transmittance of 50 per cent and a solar heat gain co-efficient of 0.30, which yields a light-to-solar-gain ratio of 1.67. With Solarban 70XL glass in the same configuration, Optigray glass generates an LSG ratio of 1.99 based on VLT of 47 per cent and a SHGC of 0.24. Optigray glass features an appearance that is significantly lighter and more subtle than Solargray and Graylite II glass by PPG. Optigray glass is certified at the silver level by the Cradle to Cradle Certified program.

Good enough for government

pilkington.com

Toronto City Hall consists of two curved towers overlooking a saucer-like chamber below. The east tower, which stands at 326 feet, and the west tower, standing at 260 feet, have both been re-glazed with an IGU combination of six mm Pilkington Eclipse Advantage Grey/air/ six mm Pilkington Optifloat Clear. These

energy-efficient choices combine lowemissivity with solar control for energy cost reductions compared to ordinary glass. They offer design flexibility through the ability to achieve natural colour with subtle reflectivity, high visible light transmittance and interior glare control. The products are durable and can be handled, cut, laminated, toughened, heat-strengthened, bent and made into IGUs using standard processing techniques. Advantage Grey and Optifloat Clear are available in a range of colours and are heat-treatable with colour stability. Beautifully

us.agc.com

Energy Select R42 is designed as beautifully reflective soft-coated low-emissivity glass suitable for high-rise residential and architectural facades. It provides moderate solar control and high levels of visible light transmittance. With its low solar heat gain co-efficient of 0.42 and high reflectivity, AGC’s Energy Select R42 is an outstanding choice for solar control.

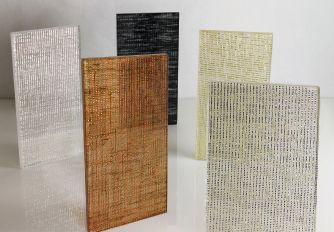

Glittering interiors

bendheimarchitectural.com

Bendheim has partnered with Bart Halpern to introduce a new exclusive collection of decorative architectural glass to the interior design market. Subtle at a distance, the Bendheim Hospitality Collection’s combination of natural colours and metallic hues is dazzling and bold up-close. The collection features five Glitterati textile colours – champagne, gold, copper, silver, and black – laminated in Bendheim low-iron glass. Additional Glitterati options are available on request. Installed in partitions, doors and windows, The glass can be supplied fully fabricated to specification in sizes up to 60 by 120 inches and approximate thicknesses ranging 5/16 inch to ¾ inch. Greater sizes are available on special order.

Cool grey ppgideascapes.com

Solarban Z75 glass is a solar control, low-e glass that features a cool-grey tint and offers architects and building owners an attractive combination of visible light transmittance, solar control and glare control. Because of its low exterior reflectance and neutral, cool-grey aesthetic, Solarban Z75 glass harmonizes

well with other building materials and low-e glasses such as Solarban Z50, Solarban 67 and Solarban R100 glasses by PPG. Interior reflectance values of less than 10 per cent allow Solarban Z75 glass to provide building occupants with clear, natural outdoor views. In a standard oneinch insulating glass unit, Solarban Z75 glass has visible light transmittance of 48 per cent and a solar heat gain co-efficient of 0.24, resulting in an exceptional lightto-solar-gain ratio of 2.00.

Alternative to soda lime

agcem.com

Launched in 2012 in Japan, AGC has started international marketing of Leoflex at Glasstec in October 2014. Leoflex is a very thin, chemically strengthened aluminosilicate glass, offering flexibility, weather ability and superior clarity as well as higher strength, impact resistance and scratch resistance compared to tempered soda lime. This results in new opportunities for manufacturers, product designers and architects to create lighter products with thinner, curved designs, while maintaining the beauty and durability of glass. The lightweight Leoflex allows the architect and designer to save weight and energy through this revolutionary green solution. With this new product, AGC aims at opening new markets for glass in the industrial and architectural fields, by replacing either soda lime, polycarbonate or plastic solutions. Whether it is to reduce the weight of your solar module cover glass or to get clearer and lighter curtain wall modules, Leoflex offers groundbreaking opportunities. Leoflex offers various processing options (e.g. cutting, lamination, printing, painting, cold bending) and is available in thicknesses ranging from 0.55 to two mm.

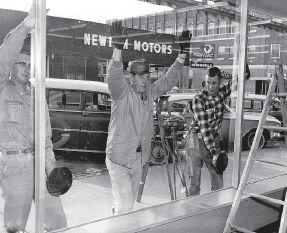

1964 Howard Wood’s vacuum cup revolutionized the Glass Industry. 2014 Wood’s Powr-Grip® vacuum cups and below-the-hook vacuum lifters can be found in nearly every country in the world!

Wood’s Powr-Grip offers a full line of products designed specifically for glass handling. To find more information or a distributor in your region, visit www.WPG.com or call

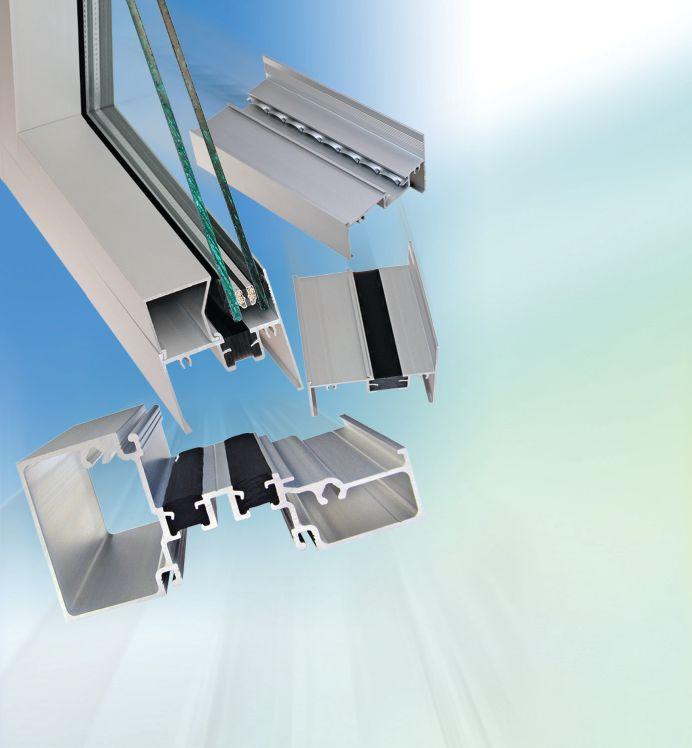

Daylighting systems produced with Azon structural thermal barrier technologies—the MLP™ or Dual Cavity—for aluminum windows along with high performance glazing components for insulating glass, will yield a fenestration system capable of upholding the highest efficiency and sustainability standards

by BRIAN BURTON

Brian is now involved with an innovative multidisciplinary firm that specializes in technical business writing: Award Bid Management Services http://award-bidmanagement-services. com/. The firm assists companies interested in selling goods and services to governments and institutions. He can be reached at Burton@award-bidmanagement.com

The price of progress

The federal government and, to a somewhat lesser degree, non-profit agencies have been actively stimulating research and development activities for many years using provisions within the Income Tax Act. In fact, since as far back as 1944, the federal government has enabled companies to deduct a reasonable proportion of expenditures related directly to research and development activities from their taxable business income, provided that the research meets certain specified conditions.

The government’s definition of scientific research refers to the acquisition of new knowledge or the development of new products or processes to develop new products, make improvements to existing products or processes, or to develop, test and evaluate prototypes. This definition includes work undertaken with respect to engineering, design, operations research, mathematical analysis, computer programming, data collection, testing and psychological research. The process of discovery must involve systematic investigation carried out by means of experimental work undertaken to advance scientific knowledge. This is further defined as work undertaken to achieve technological advancement for the purpose of creating new or improving existing materials, devices, products or processes. Critically, scientific research and development does not include market research, sales promotions or preparation of operational instructions for operation.

Three or four years ago, I submitted a paper to a conference on some of the factors that affect successful introduction of innovative new technologies for construction products. The paper did stimulate a certain amount of discussion with regard to the important factors that can influ-

The fact is that innovation in construction has proven to be relatively expensive.

FENESTRATION FORUM

ence or affect the successful introduction of new product innovations. Some of the key factors I discovered were the cost of adopting and using the innovation balanced against the time and discomfort the innovation saves. The perceived risk of functional consequences from adopting the innovation is another concern. The ease or difficulty with which the idea can be disseminated to others and the ease of implementing the innovation play into companys’ decisions. Compatibility of the innovation with existing products and processes is important, as is the ease of demonstrating the innovation’s application and its benefits.

These seven factors represent some of the reasons why research and development is often a challenge. It represents a business risk. Financial incentives delivered through income tax rebates mitigate at least some of this risk. Before embarking on a research and development project, you need to determine if a given innovation is cost-effective and functions adequately. In the case of construction, you also need to consider building code requirements including health and safety, fire ratings and in some cases the requirement for formal testing. Overall the construction sector has fared quite well with regard to development and introduction of innovations.

The construction industry has been studying its own process of innovation for over four decades. There are several elements to construction R&D that make it unique. The first element is immobility, meaning that buildings are not constructed on assembly lines (well, it has been tried, but has proven very difficult). This makes it hard to replicate building engineering innovations on different sites with different building processes. The second factor hindering innovation in construction is the high degree of complexity involved. Buildings work because the interaction of multiple systems. A radical change to one can have unintended consequences elsewhere. The requirement to meet existing building codes casts a chill on many innovative initiatives. Because building codes are concerned with occupant health and safety, they are necessarily written around what is known to work. An innovation, by definition, is unknown and will probably not meet code at first.

Finally, the fact is that innovation in construction has proven to be relatively expensive. Hence the need for tax credits. •

BUYERS GUIDE 2015

AA.W.T WORLD TRADE INC.

4321 North Knox Ave.

Chicago, IL 6064, USA

Tel: 773-777-7100

Fax: 773-777-0909

Email: sales@awt-gpi.com www.awt-gpi.com

ADELIO LATTUADA SRL

Via Abbondanza 11/13

Carbonate, 22070, Italy

Tel: +39 0331832713

Fax: +39 0331833886

Email: info@adeliolattuada.com www.adeliolattuada.com

ADVANCE DOOR SYSTEMS

P.O. Box 30028

Regina, SK S4N 4N0

Tel: 306-781-0207

Fax: 306-781-0231

Toll-Free: 1-877-781-0207

Email: advancedoor@sasktel.net www.advancedoor.com

AGC GLASS COMPANY NORTH AMERICA

11175 Cicero Drive, Suite 400 Alpharetta, GA 30022

Fax: 905-738-1177

Toll-Free: 1-800-251-0441

Email: info@us.agc.com www.us.agc.com

AGC Glass Company offers glazing products for Architectural, Interior, Residential and FireRated applications. AGC’s newest product introductions include Energy Select™ 28 high-performance low-e, and the Vision 120 System™ for fire-resistance.

AGNORA - ARCHITECTURAL GLASS NORTH AMERICA

200 Mountain Rd.

Collingwood, ON L9Y 4V5

Tel: 705-444-6654

Fax: 705-444-6657

Email: sales@agnora.com www.BIGASSGLASS.com

AKZONOBEL COATINGS INC

1313 Windsor Ave.

Columbus, OH 43211, USA

Fax: 614-421-4367

Toll-Free: 1-800-294-3361

Email: Extrusion.Coatings@akzonobel.com www.akzonobel.com/ccna

ALUMICOR LTD.

290 Humberline Dr. Toronto, ON M9W 5S2

Tel: 416-745-4222

Fax: 416-745-7759

Email: info@alumicor.com

www.alumicor.com

Alumicor champions LEED® with recycled aluminum architectural building envelope products, supporting green building projects. Alumicor serves North America through facilities in Winnipeg, Toronto, Montreal and Halifax. Contact information at www.alumicor.com.

AMERACAN EQUIPMENT LLC

8781 Sheridan Blvd. Westminster, CO 80003, USA

Tel: 303-669-9108

Fax: 888-210-9645

Toll-Free: 1-855-669-9108

Email: dave@ameracanequipment.com www.ameracanequipment.com

AMERI-CAN MACHINERY LTD.

2650 Meadowvale Blvd., Unit 5 Mississauga, ON L5N 6M5

Tel: 905-542-2055

Fax: 905-542-2261

Email: sales@ameri-can.ca www.ameri-can.ca

AMERICAN RENOLIT CORP.

403 Heron Dr., Suite C Swedesboro, NJ 08085, USA

Tel: 616-581-2156

Email: david.harris@renolit.com www.renolit.com

ARIBELL PRODUCTS LIMITED

71 Whitmore Rd., Units 1 & 2 Woodbridge, ON L4L 8G5

Tel: 905-669-5001

Fax: 905-669-5030

Email: brian@aribell.ca www.aribell.ca

ARROW SYSTEMS, INC.

2440 Jerauld Ave.

Niagara Falls, NY 14305, USA

Tel: 716-285-2749

Fax: 716-285-5087