Glassopolis proudly supports the Canadian glass industry. We manufacture in Canada, employing Canadians, to serve Canadian customers and partners with the best fire-rated and specialty glass products. We have been here for 113 years.

■ A family business for four generations.

■ Founded in 1912 in Canada.

■ Manufacturing facility in Toronto.

■ Nation-wide distribution.

■ Local pickup.

Schott Pyran® Platinum

Schott Pyran® IGU

Protect-FE Forced Entry

Schott Pyran® Platinum

Safety Glass

Schott Robax® Fireplace

Protect-BR3 Bullet Resistant

Protect-WS Windstorm Protect-X Radiation Shielding

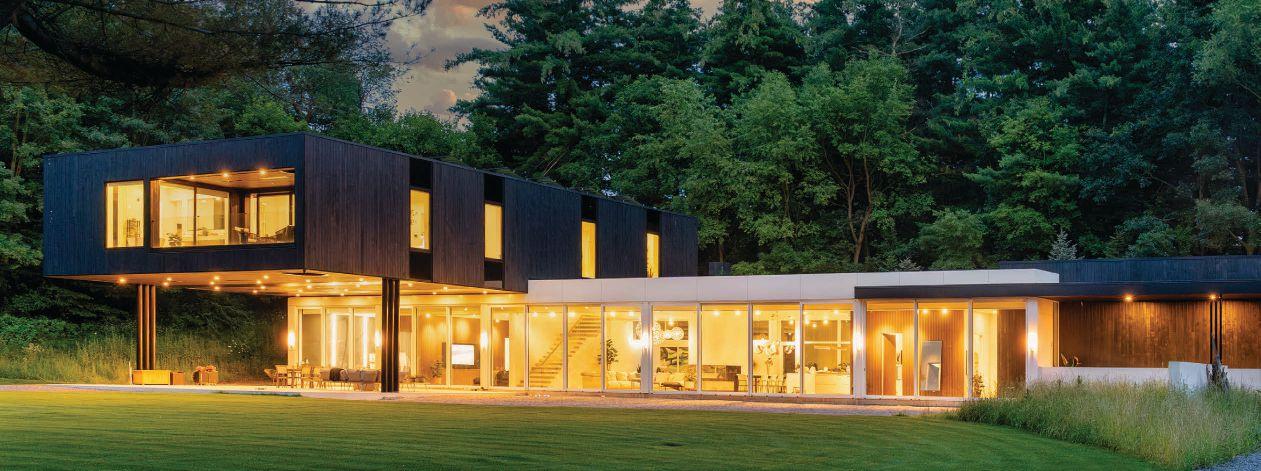

year we celebrate some of the incredible achievements in architectural glass that were completed across the country. And 2024 was spectacular.

Tsawwassen Elders Centre, Tsawwassen, B.C.

CIBC Square II, Toronto

Ontario Secondary School Teachers Federation Headquarters, Toronto

How would it be if all the databases and charts and spreadsheets and regulations and tiers defining whether our products comply with sustainable building laws just…went away? Replaced by one number: – the only number that matters – the amount of carbon dioxide emitted over a building’s lifetime as a result of its manufacture, construction, use and disposal. Partner at Layton Consulting, Jonathon “JoMo” Layton joins the podcast to chew over this radical idea and lend his expertise to the question of whether it could work and how it would affect us all.

Rocket scientists figured out early last century that you could make a rocket go higher and farther by lifting off using one set of engines, jettisoning them to save weight, then firing a second stage to boost the payload to yet higher speeds. That’s the approach that put the Apollo astronauts on the Moon. These days, it feels like we might be getting close to a kind of second stage ignition in fenestration and glass technology that could take us to heights no one ever imagined before.

The first stage that we have been burning for about 40 years is coated glass and thermally broken window frames. Since their inception, we’ve gotten better and better at making them, innovating with materials and extrusion technology to discover the most insulating ways to fill holes in buildings while letting light in. But this century, it started to look like we’d gone as far as we could with those technologies. Major advances in energy efficiency were getting hard to come by, but there was still some distance to go to meet the kind of reductions in energy use that climate science told us were necessary. As recently as 10 years ago, it looked like the first stage’s fuel had run out and no one was sure what if anything would power a second stage.

• Inside Luxwall

• Smart facades

• Carbon calculations

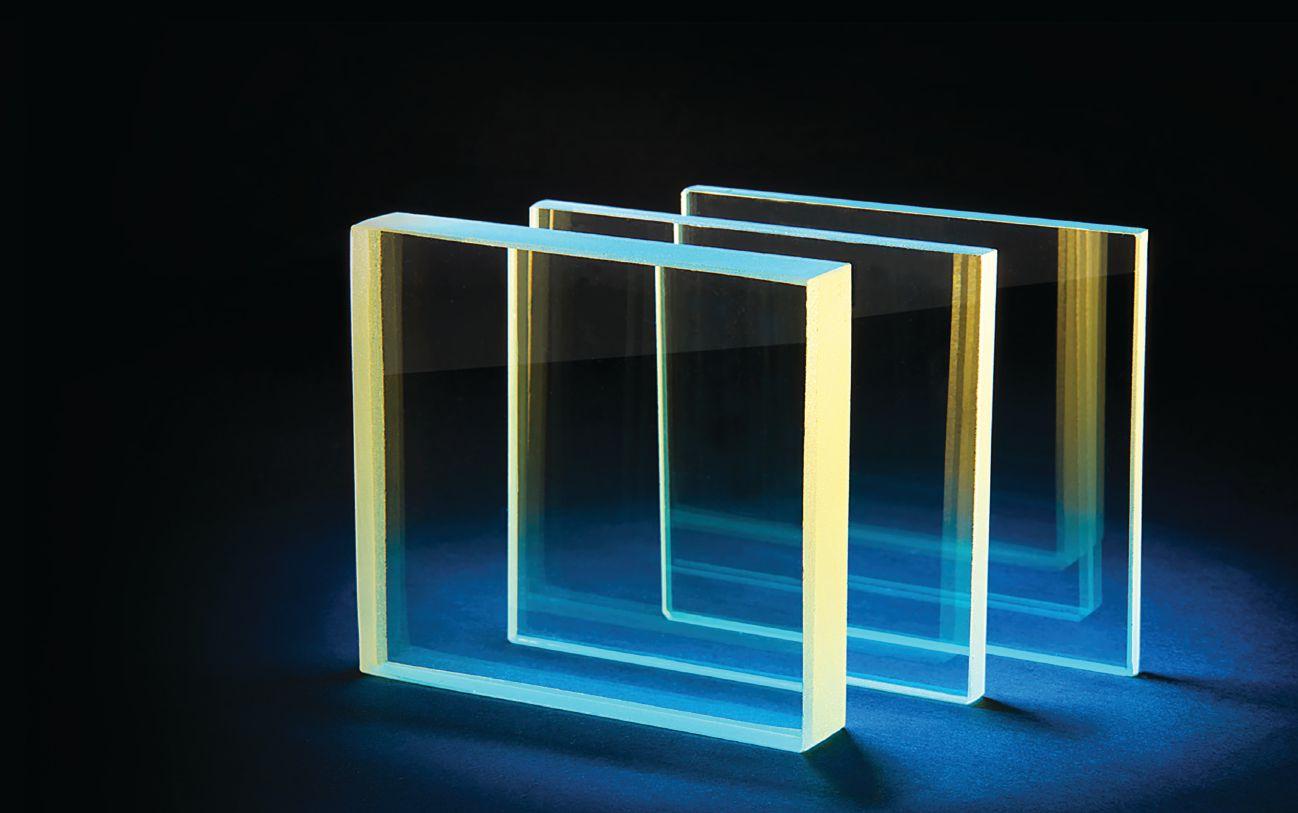

It looks like we may have found some new potential sources of rocket fuel. Last month, I was invited to tour LuxWall’s incredible vacuum insulating glass manufacturing facility in Litchfield, Mi. Scott Thomsen is the CEO there and he was very generous with his time in taking me through the whole operation. There were things happening with glass fabrication there that I have no seen in any other plant. Correction: most of the things happening there were things I have not seen in any other plant. Automated cutting, marking and edge conditioning lines that automatically retool to produce and handle various glass sizes with the click of a mouse. “Hypertempering” that leaves the glass flat to within 400 microns. Robots that place internal IG supports the size of a grain of sand without tipping them over on their sides.

Steel clamps that look like something made by a blacksmith, yet apply very precise clamping forces and are applied and removed by other robots. Ultra-precise primer and sealant application. All resulting in VIG units that cost about three times per square foot what high-end double-silver IG would cost, but insulate four times as well.

Recently, Sydney, N.S.,’s own Advanced Glazings launched a version of its Solera product for the residential market. These translucent glass panels are filled with aerogel – the lowest-density solid known to science. A block of it can float on the flame of a Bunsen burner. When used as fill in an IG unit, it achieves an R25 insulating rating with anything from zero- to 65-percent light transmittance . Perfect for letting lots of light into interiors without blowing up the wall’s energy performance.

Finally, you’ll notice in our Great Glazing items several mass timber facades. Now, there’s nothing new about wood and glulam. But what is new is the building science –and code officials’ acceptance of it – that allows builders to construct larger and taller structures with it than ever before. Wood is actually a carbon-negative material in that the tree soaks up CO2 from the atmosphere throughout its life and locks it into its cells, only to be released if it is burned. So using lumber for building then growing more to replace it actually removes CO2 from the atmosphere. Mass timber building could therefore be seen as another part of the second-stage engineering advance that could take us to the sustainability stars. •

August 2025

Volume 37 • Number 3 Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep. Tel: 416.510.5113 Fax: 416.510.6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR/PUBLISHER | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

GROUP PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

BRAND SALES MANAGER | Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT COORDINATOR | Emily GUIMARÃES eguimaraes@annexbusinessmedia.com 416.510.5118

AUDIENCE DEVELOPMENT MANAGER | Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

MEDIA DESIGNER | Brooke SHAW

CEO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.74 (plus tax) U.S.A. - 1 Year $86.70 (in CDN dollars) Publication Mail Agreement #40065710 Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

Grey Goat Hardware has officially expanded to Calgary — a major step forward in the company’s national growth strategy. With the launch of its large new distribution center in Alberta, Grey Goat Hardware is bringing faster service, better stock availability, and local support to glazing professionals across Western Canada.

Since its founding, Grey Goat Hardware has grown into a trusted name in glazing hardware distribution, with strategically located facilities in Toronto, Montreal, and Calgary. GGH supplies over 5,000 SKUs across frameless showers, glass railings, architectural hardware, and commercial entrance systems — supporting customers from coast to coast.

But GGH’s reputation has always been about more than just inventory. “Our customers are under pressure to deliver — and we understand that,” says Michael Flear, CEO of GGH. “Every member of our team is aligned around one goal: making sure our customers get what they need, when they need it, with real support behind it. That’s how we’ve built trust, and that’s how we plan to grow.”

That philosophy extends into product development. GGH works directly with engineers, glaziers, and installation professionals to ensure its products are not only code-compliant but practical and efficient. “We design based on feedback from the field,” says Ron Rehel, VP of Product. “That means fewer delays, faster installs, and smarter solutions for our customers.”

The new Calgary distribution center is already helping cus -

CONTACT US!

We’re Happy to Service You!

< Learn more or open an account

TORONTO (HEAD OFFICE)

606 Rivermede Rd., Unit 1-2, Concord, ON L4K 2H6

Contact: 905-264-1600

cs.toronto@ggshardware.com

tomers across Alberta, British Columbia, Saskatchewan, and beyond access the stock and service they need with shorter lead times. “Our presence in Calgary reinforces our commitment to the West,” says Levi Coultier, Calgary Warehouse Manager. “It’s more than a logistics hub — it’s a way for us to stand behind our customers with the same reliability we’ve built in the East.”

As GGH continues to grow, its core values remain unchanged: dependable service, engineered product innovation, and a genuine commitment to the glazing professionals who rely on them every day. With a larger footprint and a stronger supply network, GGH is positioned to serve the industry like never before — one project at a time.

MONTREAL

8145 Ave Marco-Polo, Montreal, QC H1E 5Y8

514-547-3422

cs.montreal@ggshardware.com

CALGARY OFFICE

Unit #248, 2880 45 Ave SE, Calgary, AB T2B 3M1 905-264-1600

cs.calgary@ggshardware.com

The Ontario Glass and Metal Association is protesting the Ontario government’s award of a major facade contract to an American glazier. From the release:

On June 13 we submitted a formal letter to Premier Doug Ford and the Kinga Surma, Minister of Infrastructure, raising serious concerns about the awarding of a $140 million facade contract at the new Trillium Health Partners “M” Hospital project to Permasteelisa/Benson – a U.S.-owned firm reportedly planning to manufac-

ture the facade in Mexico.

As of today, we have not received any response from the Ontario government. We believe this issue is of significant public interest and importance, given the use of taxpayer dollars, the implications for Ontario jobs, and the broader economic impact of awarding such large infrastructure contracts to foreign-owned companies.

Ontario companies are fully capable of delivering this project to world-class standards. Yet, under the current arrangement, the economic benefits – including skilled jobs and local manufacturing – will be lost to jurisdictions outside Canada.

We are urging the government of Ontario to:

• Reassess the contract award and initiate a fair, competitive procurement process prioritizing Ontario-based contractors.

• Rescind invitations to foreign firms for similar upcoming public infrastructure projects, such as the Ottawa Civic Hospital project, to ensure alignment with Ontario’s economic and employment goals.

The full text of the association’s letter is online at glasscanadamag.com.

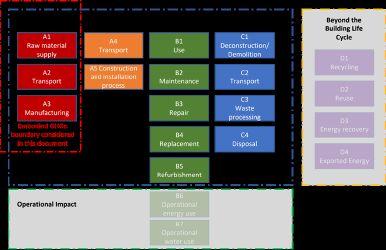

TheCanadian Board for Harmonized Construction Codes has released a draft position paper outlining proposed goals for future National Building Code requirements around embodied carbon. Ottawa has targeted the 2030 code update to add embodied carbon provisions to the NBC. The CBHCC collected public input on the paper in July. Main takeaways from the paper:

• Restrictions would follow a tiered format similar to what has been implemented for energy efficiency requirements;

• Initially only lifecycle stages A1 through A3 (raw material supply, transport and manufacturing of components) would be considered;

• Performance metrics would be based on percent-improvement over a reference model, with “ongoing policy discussions” about adding intensity metrics such as emissions per square foot and absolute emissions;

• A prescriptive compliance path for Part 9 buildings to be included;

• “Flexibility” for rural and remote locations to allow for their greater carbon costs of transportation and construction.

Last April, we held our Annual Conference with a record of more than 400 participants. We are now focusing on our Omnium that will be on August 27 at Golf de Lachute in the Montreal area. We are proud to say that our 288 tee times were sold in less than four hours. This will be another great event where all the members of our industry will have the opportunity to network.

We just launched 10 short training clips on the following topics: linear economy, BIM and robotization. These are offered free of charge to our members. Our training program also still offers the FIT Window Installers Training which presents good practices with regard to the CSA A440.4:19 standard. The training is available in English and French. It allows you to acquire the knowledge to take the Installer Certification Program exam. It is however important to note that this fall we will launch a revamped and up-todate version of this training. So stay tuned!

Aswe enter into our 46th year of serving unionized glazing and door contractors across the province, the board of directors of the AGMCA is pleased to launch our new logo and refreshed website and branding.

The new logo takes inspiration from point-supported glazing systems and the mounts and

fittings used to hold multiple pieces of glass together. This serves as a metaphor for our association that strives to reach out and support various parts of the glazing community in the province of Ontario.

From time to time the Architectural Glass and Metal Contractors Association uses this space to highlight its volunteer directors or its member companies. This month, we salute our newest director, Steve LeBlanc of Contract Glaziers (CGI ) based out of Windsor, Ont.

CGI is a leader in building envelope solutions with widely recognized expertise in modern curtainwall design, fabrication and installation. Steve broke into our industry in 1984, when he joined the contract division of Canadian Glass. Since that time Steve has worked at several well-known outfits, and many of our members will know him from his time spent over the years at Indal Glass, Commdoor Aluminum, Alumicor, Oldcastle or Trulite. In 2010, Steve moved on to Contract Glaziers/Ennova Facades, and is now their director of business development.

Steve is also a Certified Technical Representative with Construction Specifications Canada, giving him unique insight and knowledge of the construction process. Steve assists CGI clients with skilled interpretation of project specific requirements and is also able to provide them with insight in the preparation of product specifications.

Steve was elected to our board of directors at our most recent AGM and his knowledge of our industry is surpassed only by his positive attitude and warm personality. Steve is a welcome addition to our team. He can be reached at sleblanc@ contractglaziers.com

For more information on the AGMCA, please visit agmca. ca or reach out to us at info@ agmca.ca.

Members of the Glass and Architectural Metal Association of Alberta are enjoying a quiet summer and focusing on our businesses. We are looking forward to seeing the entire Alberta glass industry at Top Glass West on Oct. 21, where we will present our annual apprenticeship awards.

TheOGMA Spring Golf Tournament took place on May 29 at TPC Toronto at Osprey Valley in Bolton, Ont. – its first time at this prestigious venue. Despite less-than-ideal weather, the event was a great success thanks to the excellent course conditions and the venue’s preparations for the RBC Canadian Open. OGMA extends sincere thanks to all sponsors, including Architectural Glass and Metal Contractors Association (AGMCA), Alcurv Canada, Alumicor, Bothwell-Accurate, CS2, Commdoor Aluminum, Glassopolis, Grey Goat Hardware, Gridline Drafting, Imagic Glass, Pecora Corporation, Rimac Fabricators, SBMS, Spandreltech (sponsor of the mojito bar!), Tremco, Trulite, and Yarlmetal Fabrications. The next tournament is scheduled for Sept. 18 at Woodington Lake Golf Club in Tottenham, Ont. –stay tuned for registration and sponsorship details.

The OGMA Lifetime Achievement Award was presented to Steve Gusterson from Alumicor at the spring golf tournament. Read all about it in

the news section on page 8. Joseph Le of Fairview Glass and Mirror has been awarded the $1,000 spring bursary from the OGMA and AGMCA. Chosen by his instructors at the Finishing Trades Institute of Ontario, Joseph stood out for his strong commitment to learning, mentorship of fellow apprentices and an outstanding 90.96 percent average in the advanced class. The next bursary will be awarded at the fall golf tournament in September.

One of our most popular events, Race Nite, made its longawaited comeback! On July 17, OGMA members gathered at Woodbine Racetrack for an afternoon of great food, drink and exciting thoroughbred racing.

After a hiatus due to COVID, the return of this much-loved event was met with enthusiasm by all attendance. Members enjoyed reconnecting with colleagues in a relaxed setting, making the day both a professional and social success. It was a fantastic reminder of the value of in-person networking and a welcome return to tradition.

We hope you will join us for our annual OGMA fishing derby in late August. Watch your inbox for details. Space will be limited for this event. Visit ogma.ca for more information.

We are thrilled to announce the launch of the newly redesigned OGMA website, just in time for our 35th anniversary! The revamped site offers a fresh look, improved navigation and enhanced functionality, including mobile-friendly access and dedicated member profile pages. What’s next? OGMA is busy planning even more events this fall, including our fall golf tournament at Woodington Lake Golf Club, a plant tour on Oct. 24, and a potential educational seminar.

The Finishing Trades Institute of Ontario has announced its first annual Glazier Expo, taking place on Oct. 24 at its Toronto training centre located at 130 Toro Road. Held in partnership with the Architectural Glass and Metal Contractors Association, the event will welcome glazing contractors, general contractors, architects, union representatives, government officials and skilled trades workers for a full day of networking, education, and demonstrations under the theme “Innovation, Education, Certification.” Registration for the event is online at ftiontario.com.

“As the director of the Finishing Trades Institute of Ontario, I am proud to be hosting our first annual Glazier Expo,” Antonella Di Caro comments. “This event reflects our ongoing commitment to innovation, education, and certification – key pillars in preparing our apprentices to strengthen and advance the skilled trades workforce.”

“We are excited to welcome our member glazing contractors to the first annual Glazier Expo,” said Noel Marsella, AGMCA executive directior. “There will be several demonstra-

tions during the day including a pre-glazed curtainwall installation under job site conditions on the newly completed exterior steel structure. We are thankful to our industry partners at Alumicor for their contribution and commitment to this important upgrade in skills training.“

Guests will have the opportunity to:

• Tour FTI’s newly expanded Toronto facility;

• Learn about cutting-edge glazing training programs;

• Witness live glazing demonstrations, including a showcase of the AGMT (Architectural Glass and Metal Technician) test;

• Explore exhibits from select vendors, each offering industry swag and product insight;

• Have breakfast provided by the International Union of Painters and Allied Trades and lunch sponsored by AGMCA.

SteveGusterson was given the Ontario Glass and Metal Association’s 2025 Lifetime Achievement Award at its golf tournament on May 29. Gusterson has had a remarkable five-decadelong career in the glass and metal industry. His journey began in 1974 with a summer job at Alumicor and evolved through hands-on roles at various glass shops across Canada, eventually leading to senior positions, including vice-president of sales for Ontario at Alumicor. Beyond his professional achievements, Gusterson has been a passionate contributor to the industry through education, mentorship and leadership roles in organizations like the OGMA and Construction Specifications Canada (CSC). He played key roles in initiatives such as the OGMA website, the Awards of Excellence program and the Ontario Glazing Systems Manual. His dedication has earned him multiple honours, including appointment to CSC’s College of Fellows and Life Membership. Now semi-retired, Steve continues to work with the design community while planning to enjoy more time with his wife, Lori, and pursue his interest in antique military artifacts.

Agnora and West Coast Insu-

lated Glass have announced the appointment of Pamela Murphy as vice-president of sales and marketing. Murphy brings over 20 years of experience in the building materials industry, most recently serving as general manager for Marvin Windows Canada. Murphy has led major brand transformations, grown considerable market share in the premium residential segment and was a driving force in strengthening distributor and architectural relationships nationwide. Her experience aligns closely with Agnora and WCG’s focus on delivering precision-crafted architectural glass solutions for luxury retail, residential and commercial applications.

“Pamela’s strategic mindset, customer-first philosophy, and deep understanding of the high-performance window and facade market make her an exceptional fit with our team,” says Corey Boland, CEO of Agnora and WCG. “Her leadership will be instrumental as we continue to expand our services and capabilities and deliver the highest level of technical support to our partners across North America.

In her role, Murphy will oversee sales strategy, client engagement and business development efforts, further enhancing Agnora and WCG’s position as a leading supplier of premium architectural glass solutions.

“Joining this team is an exciting opportunity to help shape the future of architectural glass, working alongside passionate professionals who care deeply about quality and collaboration,” said Murphy.

Vicone High Performance Rubber has announced the sale of its extrusion manufacturing division to Pro-Flex Rubber, a longestablished extrusion rubber manufacturer based in Granby, Que. The transaction officially closed on June 9. This transition marks a strategic realignment for Vicone, which has operated its own extrusion facility for over a decade and has served clients across multiple industries since its founding in 2004. Moving forward, Vicone will focus exclusively on the value-added reselling of custom moulded rubber parts, supporting specialized markets including medical, recreational, food and beverage and others.

“This is an exciting new chapter for both our team and our customers,” said Eric Leclair, president of Vicone. “Pro-Flex has a long-standing reputation for quality and precision in rubber manufacturing, and we’re confident they will continue to deliver the level of service and reliability our extrusion clients expect.”

Pro-Flex Rubber, founded in 1989, will now take over all extrusion-related operations and customer support, particularly in key sectors like architectural glass and glazing. Key Vicone personnel, including technical and product development experts, have transitioned to Pro-Flex to ensure operational continuity and smooth client experience.

Jerome Fortin, general manager of Pro-Flex, added: “This acquisi tion is an exciting step forward for Pro-Flex. It adds new extrusion capacity to our operations and brings with it a strong roster of customers in the architectural glass and glazing industry. We look

forward to supporting these clients with the same attention to quality and service that has defined both our companies.”

Transition overview:

• Pro-Flex has assumed full responsibility for extrusion operations, production, customer service and billing;

by RICH PORAYKO

Vancouver’s skyline is set to welcome a groundbreaking addition with 2150 Keith Drive, affectionately known as “The Hive.” This 10-story mass-timber marvel, designed by Dialog, is not just an architectural feat but a testament to sustainable design and urban revitalization. Once completed, the Hive will be the tallest bracedframe mass timber project in North America.

The Hive’s honeycomb-inspired facade is more than an esthetic choice. It integrates gardens and outdoor spaces on every level, embodying the project’s organic ethos. “‘What is an organic building? And what does it mean to design an organic building?’ This is a question we were tasked with exploring at the outset of our project,” explained project architect, Lindsay Duthie, to attendees at the Vancouver Facades Plus conference in May. “Sustainability runs deep in the owner’s veins and in their company, so our design mandate was to design an office headquarters building that embodies these values.”

The Hive is a trailblazer. Its nine-story mass timber structure, free of concrete cores, significantly reduces embodied carbon emissions. “Given the sustainability mandate, we knew early on the structure would be mass timber,” Duthie noted. “We started looking at traditional post-and-beam scenarios, but we also wanted to explore what structural innovations would be possible.”

Working closely with structural engineers Fast Plus Epp, the team moved seismic-resisting elements to the building’s perimeter in the form of braced frames. “This did a number of things. It opened up the floor plate to make it more open and flexible for office use and it also allowed us to approach the core design differently. This

project does not have concrete cores, which further drives down our embodied carbon emissions.”

Situated near the False Creek Flats, the site presented unique challenges, including proximity to a Skytrain station and an old sewer line. “We’re right up against a Skytrain station with a TransLink right of way to the north and then the Central Valley Greenway setback to the south,” said Duthie. “Finally, there’s a decades-old sewer line that couldn’t take any load. These constraints are what shaped the footprint of the building.”

Despite these challenges, the site offered incredible advantages, including views of the North Shore mountains, excellent solar orientation, and transit and cycling access. “The honeycomb expression you see today was developed to incorporate a series of balconies on the exterior, providing outdoor space on every level. Ultimately, what we designed is a facade

expression that follows the structural forces in the building.”

One of the most significant technical hurdles was the unitized glazing system, which lacked built-in tolerance for in-out anchoring – a critical aspect for alignment and structural flexibility. To solve this, glazing contractor Bothwell-Accurate developed a custom anchoring solution using ledger angles and cross-laminated timber.

“Securing approval from the system manufacturer was a challenge in itself, but we succeeded after multiple iterations and technical reviews,” shared Steve McLean, vice-president of glazing for Bothwell-Accurate.

Achieving the desired thermal and condensation performance required several rounds of redesign, coordination and value engi-

neering. This involved fine-tuning system assemblies while maintaining the architectural intent and energy efficiency goals.

The installation sequence posed another major challenge, as the facade panels had to be installed simultaneously with mass timber construction. “We addressed this by bringing in a custom spider crane to manoeuver panels without overloading the timber floors or risking surface damage,” explained McLean.

An additional coordination challenge involved the pre-installation of cladding panels within the glazing units since they were adjacent to other panels. “To achieve the seamless architectural vision with minimal visible joints, we fully prefabricated each panel system and installed them prior to final hanging,” said McLean.

“The honeycomb expression you see today evolved from those very challenges,” adds McLean. “It integrates balconies at every level and reflects the structural forces within the building. What emerged is not just a facade, but a unified architectural and structural expression.”

The Hive’s striking façade owes much of its brilliance to the innovative glasswork provided by Garibaldi Glass Industries. The project includes approximately 70,000 square feet of triple-insulated glass units, featuring two different low-E coatings for optimal energy performance. Alex Han, project manager at Garibaldi, highlights the unique challenges and triumphs of the project, “With its honeycomb design, nearly every IGU had a unique shape.”

“We used Guardian SunGuard SNX 62/27 on surface two and SunGuard SN 60 on surface four,” Han explains. “This combination not only enhances energy efficiency but also complements the building’s esthetic.”

To meet the project’s demands, Garibaldi implemented a staggered production schedule. “The glass sizes were so similar that we had to carefully plan production to avoid mix-ups,” Han notes. “It was a logistical challenge, but one we were excited to tackle.”

“I toured The Hive during the RAIC Spring Conference back in 2024 before a stitch of glass was installed,” says Geoff

Shellard, Pacific Northwest regional architectural manager for Guardian Glass. “The Hive is one of those projects that turns heads and gathers a lot of attention.”

Shellard goes on to say, “The work done by our partners, Garibaldi Glass and Bothwell-Accurate, not only showcase the quality of their craftsmanship, it also highlights the value of using triple-silver solar-selective low-E coatings, even more so when paired with another low-E coting in a triple IGU configuration. Occupant wellbeing through lower solar heat gain on the south and west facades will help to keep the oven in the kitchen where it belongs.”

Set to complete in 2025, The Hive is targeting LEED Gold certification and aims for net-zero energy readiness. Its all-electric design, triple-glazed curtainwall and exposed mass timber structure exemplify cuttingedge green building practices.

As The Hive takes shape, it stands as a buzzing beacon of innovation, sustainability and community – a true testament to what’s possible when design and purpose align. •

by MARION PYNN

The building envelope of the Intermunicipal Police Headquarters in Terrebonne, Que., features a sophisticated, multi-functional layered glazing system. Designed to meet LEED Gold standards, the 13,000-square-meter, four-storey facility serves the communities of Terrebonne, Sainte-Anne-des-Plaines and Bois-des-Filion. Walker Textures Satinlite acid-etched glass in its cladding contributes toward environmental performance, visual integration with the landscape and functional requirements tied to the building’s use as a secure police facility.

Carl-Antonyn Default of Sid Lee Architecture, the firm that led execution and construction supervision for the project, describes the building’s two main elements: “a light, striated longitudinal bar

evoking the trunks of forest trees, set atop a more massive base that reflects the surrounding natural landscape.” The podium is clad in six-millimeter clear glass with a full-surface Satinlite etch on surface #1, laminated to another six-millimeter lite with a reflective coating on surface #3 and black ceramic paint on surface #4. The result is a visually darkened facade with low reflectance and a matte finish.

This assembly was fabricated by Prelco, then installed by Groupe Brosseau Vitrerie using ultra-thin silicone joints and a minimal rear support to maintain uninterrupted visual surfaces. The multilayered assembly gave the fabrication and installation teams a chance to show their skills.

As Jonathan Brosseau of Groupe Brosseau Vitrerie explained, “A project like this takes solid coordination from everyone

Location: Terrebonne, Que.

Architects: Lemay Architecture et

Design and Sid Lee Architecture

Glass: Walker Textures Satinlite

Glass fabrication: Prelco

Glazing: Groupe Brosseau Vitrerie

involved. With the different types of glass and the scale of the facade, careful planning was essential, and it shows in the final result.” Sylvain Maillet, Prelco’s architectural technical advice director, added, “Prelco is proud to have contributed to the Terrebonne Police Headquarters proj-

ect by supplying high-quality glass panels. Thanks to proven expertise and rigorous coordination, production went smoothly.”

Lemay, the firm responsible for the project’s conceptual design and construction documents, selected the glass configuration to meet both esthetic and technical goals. “Taking into account the programmatic needs of the project, including the fact that a police station requires a degree of enclosure and introversion, we opted for acid-etched glass with slight reflectivity,” said Lemay architect, Ramzi Bosha. This reflectivity allowed the base volume to blend into the landscape while meeting privacy and performance needs.

Default elaborated, “For reasons of privacy and security, most ground-floor spaces did not require openings. The challenge was to conceal a few windows within an otherwise monolithic block.” To that end, the architectural team developed a strategy that places windows behind the laminated glass and uses both etching and ceramic paint to control visibility. “The etched glass lets daylight in without creating direct views in or out,” said Default. “Meanwhile, the ceramic paint enabled us to achieve the desired transition in opacity at window areas. From the outside, the facade reads as one large unified surface with no visible windows.”

In addition to visual control, the fullsurface etch plays an ecological role by diffusing reflections and enhancing bird

safety, an especially important consideration given the site’s forested surroundings. To the human eye, however, the glass treatment helps integrate the building with its surroundings. “Laminating the etched glass with a reflective lite was consistent with our intention not to produce imposing mirrors, but to help the building volumes dissolve into the environment,” said Bosha. “The reflective glass, with its ability to play with light and shadow, further enriches the facade by adding visual depth and a dynamic quality that evolves throughout the day.”

The Terrebonne Intermunicipal Police Headquarters shows how multi-layered glazing systems combining acid-etched,

reflective, and ceramic-painted components can meet complex demands for durability, privacy, daylighting, and visual integration. The result is a technically sound, high-performance envelope that balances design intent with site-specific performance. •

ISO 17025 SCC & AAMA accredited

Building Envelope Laboratories Cost

by RICH PORAYKO

The scenic shores of Tsawwassen First Nation recently welcomed the Tsawwassen Elders Centre. Dekor Glass played a pivotal role in bringing its bold design to life.

A complex challenge, boldly taken.

From the outset, the Tsawwassen Elders Centre posed a unique challenge. “This was a complicated project,” explains Dann Jenn, co-owner of Dekor Glass. High-level architectural drawings painted a vision of vast expanses of glass: the kind that seemed to float midair. “A lot of it – brackets, structural support, engineering design – was up to us. We made it happen,” Jenn revealed.

The glazing package in the Tsawwassen Elders Centre is not only functional but meticulously customized. For the ground-level storefront system, Kawneer 451UT ultra-thermal aluminum storefront was paired with Kawneer Insulclad doors to deliver maximum efficiency. The second level features a high-span Kawneer 1600UT System1 curtainwall, providing ultra-thermal performance and a striking visual impact.

A standout feature of the project was the bird-safe fritted glass, specifically engineered for both environmental responsibility and esthetic cohesion. Violet Lang, project manager at Garibaldi Glass, describes the glass makeup: “We had a four-by-four, quarter-inch dot frit patten on the exterior first surface with Guardian SunGuard SNX 62/27 low-E coating on surface #3. We fabricated 4,000 square feet with zero rejects, 100 percent on-time delivery and no issues.” This flawless execution was a direct result of seamless collaboration between Garibaldi and Dekor Glass. “We have a strong partnership with Dekor. They are great at submitting orders on time while providing all of the information that we need to be able to produce them. We always have multiple ongoing projects with them,” says Lang.

“The alignment of the dots was key,” notes Jenn. “All the horizontal and vertical patterns had to line up perfectly across several panels. Garibaldi’s expertise was invaluable here. They dialed everything in, even managing to get glass orders filled within a couple of weeks despite the complexity.”

“I have family ties to the Tsawwassen First Nation,” says Geoff Shellard, Pacific Northwest regional architectural manager for Guardian Glass. “There’s a lot of pride that comes with seeing projects like the Elders Centre become a focal point to celebrate. Iredale Architecture has taken great care to design something for the community, while understanding the significance of the building’s location along the Pacific Flyway. Any use of bird-friendly glass that makes its way from design to specification to installation, rather than being a post-applied afterthought to mitigate bird strikes after completion, is a significant achievement.”

Beyond esthetics, functionality played a major role in the design. The Tsawwassen Elders Centre was engineered for post-disaster performance, ensuring resilience for the community in the event of an earthquake or other natural disasters.

The roofing system is supported by glulam beams designed to move independently under seismic strain. To match this innovative structure, the glazing system needed adaptability. “There’s a massive, raked wall with uniquely shaped glass panes, multiple structural braces and shock absorbers built into the framework,” says Jenn enthusiastically. One glass section prominently showcases the seismic isolator. These engineering accomplishments required meticulous off-site fabrication and on-site coordination.

While the technical innovation is impressive, the essence of the Tsawwassen Elders Centre lies in its deep connection to community and land. Peter Hildebrand – a principal at Iredale Architecture and the creative mind behind the design – describes his inspiration for the structure. “It’s a beautiful location. The intent behind the design was to make the roof really float,” he explains. “To do that, you almost have to separate it from the cladding. We wanted just this transparent layer where the walls meet the roof, so you can truly see the roof floating above the building.” This design choice not only maximized the mesmerizing ocean views but also created a space where the community feels immersed in their natural surroundings.

Hildebrand goes on to share how the Elders Centre’s form was influenced by its location within a key bird sanctuary along the Pacific Flyway migration route. “If you see it from the oceanside, it almost looks like a bird ready to take flight over the water,” he says. This connection to the wildlife echoes throughout the project, including the bird-friendly fritted glass and the unique motifs created by artists within the Tsawwassen First Nation. “In the whole lobby area, we used designs by one of their community artists –very subtle graphics of different bird species as panels, almost like a grid, embedded right in the glass,” Hildebrand notes.

The design, however, goes beyond esthetics. “Within the building, you’ll notice all these dampers to resist seismic activity. It’s a new technology that’s not even in the building code yet. It was developed in New Zealand after the earthquakes,” he explains. “It’s a series of spring-loaded dampers that allow movement during an earthquake but pull the structure back into place afterward.” This cutting-edge feature, coupled with a light steel structure and glulam beams, allowed the striking roof to “touch down very lightly,” as Hildebrand puts it – achieving both resilience and visual elegance.

Working with Indigenous communities, Hildebrand emphasizes, means designing with narrative and respect for tradition. “First Nations communities are often looking for a narrative rooted in nature or in their history and especially in the land. These projects are about resonating with history, people, language and the landscape.” Each building, he adds, should “provide something inspirational and influential so the kids can look at it and go, ‘Holy smokes, this

is for us.’” This approach leads to designs that are uniquely meaningful for each community.

Ultimately, the Tsawwassen Elders Centre is not just a sanctuary for elders, but an enduring symbol for future generations. “If we can create a building the community truly values, it’s more likely to be cared for and to stand for decades – one of the most sustainable things an architect can do,” says Hildebrand.

Reflecting on the project’s cultural resonance, Jenn shares, “Being on their land, it’s a different feel altogether. It’s humbling to contribute to a space meant to serve the community for generations.” •

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass

• SentryGlas Lamination

• Opaci-Coat-300 Spandrel

Phone: 416-285-1890

Toll Free: 1-855-757-8367

Fax: 416-285-9468

Email: cs@tritempglass.com

An innovative diamond facade completes a striking new park complex landmark in Canada’s largest city.

by TREENA HEIN

Described as “setting a new standard for community,” the CIBC Square complex consists of residences, workspaces, a one-acre elevated park and other places to socialize and celebrate culture and cuisine. All three buildings, spanning three million square feet, connect to nearby transit hubs such as Union Station. Because of the proximity to an active rail corridor, much of the construction had to be done at night when no trains were running. Indeed, construction was complex and presented risks, with Canam Group and EllisDon fabricating and installing 18,000 metric tons of structural steel, including 12 massive mega-nodes weighing between 18 to 40 tons each.

CIBC Square is designed to attain LEED Platinum certification. Each level offers an abundance of natural sunlight, with occupancy and daylight sensors throughout to minimize lighting use. The front entrance, completed by Novum, showcases a point-supported glazing system elegantly suspended from a tensioned cable wall. Senior building envelope specialist, Victor Diec at Entuitive, explains: “This design enhances the building’s grand entrance with a seamless, modern esthetic. With this type of system, there are significant engineering challenges to analyze the stress around the point and cable supports.”

Location: Toronto

To be completed: 2025

Design: Wilkinson Eyre Architects

Architect of record: Adamson

Associates Architects

Transportation contractor: Entuitive

Podium contractor: Novum

Curtainwall contractor: Harmon

Glass fabricator: Viracon (USA), Finnglass (Finland)

The facade, with its striking diamondshaped panels, was constructed by Harmon. As Diec explains, its multifaceted angles converging at precision-engineered nodes demanded meticulous attention to detail in glass cutting, sizing and fabrication. “Seamlessly integrated with the curtainwall system, each panel ensures geometric consistency of the envelope. There are also strategically placed lighting fixtures that highlight the facade’s sculptural depth.”

Boris Friedman, senior project manager at Harmon, agrees that the geometry of the building was the main challenge in this project. “Due to the complexity, the design of our curtainwall had to be fully modeled in 3D,” he notes. “While a typical square building would have four to five frame types per floor, on 141 Bay just the corner frames count six different types. Some frames are flat, some are at

a tilted plane and the corners are L-shaped. The frames that make up the diamond perimeter have a diagonal mullion with two pieces of glass (one from either side of the diagonal) installed at different angles creating the diamond shape going in and out.”

All these frame types required specific assembly procedures and tools. Custom frame beds were made for the non-flat frames to hold them in place on the assembly lines. “Then you have the non-typical-height floors to maintain the diamond-shape geometry,” Friedman explains. “These frames required welded mullions and horizontals to have the diagonals pass in the correct locations, instead of corner-to-corner like a typical floor.”

Friedman adds that the install subcontractor, Building Envelope Systems Installation (BESI), “did great job working out the kinks of installing the different frame types and was able to reach an install duration of three days per floor at our peak.” The top of the building is being completed now (summer 2025) and includes four skylights. •

by MARION PYNN

The new Ontario Secondary School Teachers’ Federation headquarters, designed by Moriyama Teshima Architects (MTA), is the firm’s first completed mass timber project and a milestone for sustainable development in Toronto. Officially known as the OSSTF new Headquarters and Multi-Tenant Commercial Building, the project includes 124,000 square feet of mixed-use floor space. Design goals included carbon reduction, ecological protection, occupant wellbeing and LEED

Platinum certification. Materials like laminated mass timber and AviProtek E energy-efficient bird-friendly glass helped MTA design a building to meet these goals.

MTA partner Philip Silverstein described the client’s request: “The mandate from the client was a low-carbon building, meaning a mass timber, futureproofed, net zero operating energy building meeting Toronto Green Standard Tier 4, which no other building in the city had met. To meet that, we couldn’t leave anything on the table.”

While the OSSTF headquarters is no-

With the lowest U-factors available, window systems with Azon will meet thermal regulations for years to come.

table for its structural use of mass timber, the building envelope does its share of heavy lifting as well. To support the goal of net-zero operational carbon, MTA selected AviProtek E glass with a Solarban 90 low-E coating from Vitro Architectural Glass on surface #2. Since the bird-friendly markers on this glass are placed on the first surface, they allow second-surface application of the low-E coating to optimize energy performance. This gave MTA the freedom to increase window space for improved daylight harvesting.

As Silverstein explained, “The heating and cooling were the largest energy loads, but what surprised us were the high lighting loads, which we had to find a way to reduce. We solved this by utilizing daylight harvesting techniques. We designed the head of the windows to be as high as possible, fine-tuned the window-to-wall ratio – in our case it was 60:40 – and placed the lighting on daylight dimming controls. These measures brought the energy required to run the lighting down by 60 percent. This builds in lifetime cost savings using passive solutions. The highperformance building envelope allowed us to slightly increase the window area without impacting solar heat gain.”

The choice of bird-friendly glass was also key. With such large windows overlooking the Don Valley Ravine, an important habitat along the Atlantic and Mississippi flyways, bird strikes were a concern. To mitigate this risk, MTA used AviProtek E pattern 215, with five-millimeter dots spaced two-by-two inches apart. This closely spaced pattern meets both the Toronto Green Standard and CSA A460:19 for bird-friendly building design. The first-surface etching ensures visibility in all lighting conditions, regardless of reflection, while its monolithic acid-etched

Location: Toronto

Architect: Moriyama Teshima

Architects

Glass: Walker AviProtek E with Vitro

Solarban low-E

IG fabrication: Trulite

Glazing: Gage Aluminum

treatment withstands weathering and wear without the need for any special maintenance.

The glass selection also enhances occupant comfort. Increasing the window-towall ratio allowed for increases in natural light and scenic views of the ravine. This biophilic approach supports well-being, improves productivity, and helps regulate

circadian rhythms for occupants. With a subtle bird-friendly pattern that does not affect sightlines or daylight, the windows provide a balanced solution for sustainability, comfort and wildlife protection.

The new OSSTF headquarters pushes the limits of sustainable development through its forward-thinking design and MTA’s commitment to meet the demanding criteria of LEED Platinum and the Toronto Green Standard. It wasn’t a simple project, but the team’s extensive planning paid off. According to Chris Priolo of Gage Aluminum and Glass, who installed the glass in this project, “Everything went in smoothly. The specs were clear, the units were consistent and the site was well organized. It was one of those installs where things just came together.” It’s proof that with careful planning and teamwork, even the most ambitious projects can come together seamlessly.

The project has already been recognized for a number of awards, including a Rethinking the Future Award; two LOOP Design Awards; and two Architecture Press Release (APR) Global Future Design Awards. •

by TREENA HEIN

Vaughan, the community north of Toronto that’s perhaps best known for being home to Canada’s Wonderland theme park, has recently reinvented itself, in part due to striking new landmarks such as Festival Condominiums.

The four towers, ranging from 41 to 59 storeys, feature distinctive sculptured white balconies and concrete construction. The tallest of the four (190.5 meters) is the tallest building in all of what’s now known as VMC, or Vaughn Metropolitan Centre. Together, the four buildings will house 5,000 people.

Indeed, Festival is just one part of a 75-acre community called Assembly Park. The central plaza will feature boutique shops, cafes, restaurants, a fitness facility and a grocery store, encircled by arts and entertainment venues, including a new community centre, school, 45 acres of parkland and 17 kilometers of trails and bike lanes.

In terms of indoor amenities, Festival has ample open public spaces with a covered pedestrian mews that will connect residents and visitors to future phases of the project. “Festival is like no other project in the GTA – it’s an ambitious, allencompassing community that sets a new industry standard in Vaughan,” Jared Menkes, Menkes executive vice-president of high rise residential, has stated.

Last year, the next phase of the project began south of Festival with the construction of a threetower community called Bravo. The architectural firm, Arcadis, notes that the downtown core of the entire community will feature a central public spaced called Revel Park, with all areas being able to hold stormwater as required. The ‘sunken plaza’ of the park will be able to hold up to 3.5 meters of water following extreme storms, and can serve as a skating rink in the winter.

Aluminum Window Designs completed the installation of the windows and segmented glass railings, and states that all went well. The windows are basically standard in terms of angles and shape and installation challenges were minimal. •

Location: Vaughan, Ont.

Owner: Menkes Developments and QuadReal Property Group

Date completed (four buildings): 2022-2025

Architect: Arcadis

Glazing contractor: Aluminum Window Design

Glass fabricator: Saint-Gobain

We are North America’s premier fabricator of award winning windows and doors. Our products are made to stand up to extreme weather conditions, giving you maximum comfort and performance all year round. Built to meet NFRC standards, Passive House, and Net Zero requirements.

Bigfoot Windows and Doors are tested and approved.

Intertek: Certifi cation that proves your credibility in the market.

NFAS: Tests and evaluates performance of fenestration product for Canadian and US Markets.

Fenestration Canada: Installer certifi cation programs assure the credibility of the installer.

NAMI: Certifi cation, inspection, and quality assurance provided to the building industry in accordance with international guidelines.

NFRC: Proves that the products energy effi ciency performance has been tested, providing consumers assurance and reliability.

As we conclude yet another productive quarter at Fenestration Canada, we’re thrilled to share key updates and developments that have taken place over the past few months.

We’re excited to announce the 2025 Fenestration Canada Manitoba Golf Tournament! Scheduled for Aug. 20, this exciting event offers an incredible opportunity to connect, compete and support Canada’s fenestration community. There’s no better way to build relationships than over a round of golf, and the historic St. Boniface Golf Club is the perfect backdrop. Built in 1931, this picturesque course features tree-lined fairways, challenging greens, and strategically placed water hazards and bunkers – all designed to provide an exceptional experience for golfers of every skill level. Beyond the game, your participation directly supports Fenestration Canada’s regional events and programs, which are vital to strengthening and growing the window, door and commercial glazing industry. Take advantage of our special rates to make the day even better. Rally your team and make it a group outing to remember. Mark your calendars – it’s shaping up to be one of the highlights of the year.

Investing in the future of the fenestration industry remains a cornerstone of our work at Fenestration Canada, which is why we’re thrilled to announce that applications are now open for the 2025 Fenestration Canada Scholarship Program. The Fenestration Canada Scholarship is awarded to a motivated and passionate individual who is connected to the fenestration industry. The ideal candidate exhibits a commitment to their studies, combined with a clear vision of how their studies will positively impact the community. The candidate is not only focused on personal success but also on

LEFT: At the Halifax Spring Conference, Jennifer Small (Screenco) and Fenestration Canada president, Ron Edger (Centennial Windows), presented the President’s Award for outstanding volunteer participation to Jayme Tilley of Screenco… over the phone. Tilley was unable to make it to the conference in person.

RIGHT: As outgoing FenCan president, Cam Drew hands off the ceremonial pepper grinder to Edger.

the broader impact they can make. The candidate’s commitment to academic and professional growth aligns with the aims and goals of the scholarship. We believe that by empowering young talent, we not only support these individuals but also ensure the long-term growth and strength of our industry. This program represents an incredible opportunity for students to take the next step in their educational journey while connecting with an industry that values their contributions and ideas. We request students, educators, and industry members to spread the word about this initiative. Applications are open until Sept. 12 so don’t wait – submit yours today!

The 2025 Fenestration Canada Spring Conference, held May 27 through 30 at the historic Lord Nelson Hotel in Halifax, was a huge success, blending industry innovation, collaboration and a touch of East Coast hospitality. FenCan member services director, Cam Drew, urged attendees to rethink processes with tools like Value Stream Mapping, Spaghetti Diagrams, 5S and Gemba Walks to minimize waste and boost productivity. His emphasis on communication was a recurring theme throughout the conference. Guardian’s Geoff Shellard, the original “glasshole,” took home the 2025 Most Valuable Volunteer award in a lighthearted karaoke face-off. His contributions to Fenestration Canada and the window, door and commercial glazing community were enthusiastically celebrated! The success of FenCan’s 2025 Spring Conference wouldn’t have been possible without our passionate volunteers; insightful speakers and knowledgeable panelists; generous sponsors and supportive partners; and the warm, maritime hospitality of the Atlantic Chapter team.

Our industry is constantly evolving, and so is Fenestration Canada. From delivering high-value networking events to advocating for positive change and nurturing future leaders, we remain dedicated to serving our members and advancing the fenestration sector. Mark your calendar for Sept. 11 as Fenestration Canada brings together professionals across the industry and beyond for its highly anticipated Online Training Showcase Event. This two-hour virtual gathering is set to deliver unparalleled insights, top-tier training and invaluable networking opportunities, all from the convenience of your home or office. Whether you’re an experienced fenestration professional or just beginning your career, this event is tailored to empower you with the skills and knowledge needed to thrive in an evolving industry.

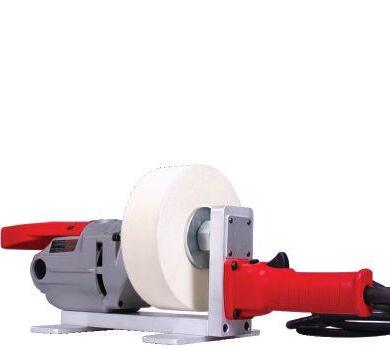

Consolidate machines, reallocate labor, improve ergonomics, lower costs and enhance part quality

Save at least $800,000/year in material costs with our Zero Scrap Saw and lineal optimization software

“Catalog-only” doesn’t cut it

Your specs are our marching orders — customizing controls, outfeeds and tooling is just part of the job

Unthinkable throughput targets

Need two complex parts completely cut, fabricated and ready for the next step in under 60 seconds? No problem

We encourage all members to stay connected and actively engaged in our initiatives. Sessions are available on Fenestration Canada’s YouTube channel. Watch for important takeaways and announcements as we gear up for WinDoor 2025 in Toronto this October. Follow us on social media, visit our website for the latest news, and join us at upcoming events to stay informed and involved. Your participation and support are vital to shaping the dialogue around the challenges and opportunities that lie ahead for our industry. For more details about the highlighted events and programs, visit fenestrationcanada.ca or email us at info@ fenestrationcanada.ca. • josephmachine.com sales@josephmachine.com

by CLAUDIO SACILOTTO

Pick up any trade magazine these days, and it’s nearly impossible to avoid the topic of artificial intelligence. Whether I’m browsing online or listening to industry podcasts on my commute, AI seems to affect everything. And it’s not just a passing trend. What surprises me most is how quietly AI has become part of our everyday work in the fenestration and glass industry. It’s been integrating into our systems and processes gradually, often without us even noticing. From production planning to customer engagement and quality control, AI is making its mark.

Of course, we’ve all heard the fear-driven narratives: that AI will replace people, take over jobs or even run the world. It sounds like something out of a sci-fi film, but there’s genuine concern. And yes, AI will undoubtedly change the nature of work. But it doesn’t mean humans won’t be needed. If anything, AI is pushing us to refocus on the creative, strategic and interpersonal parts of our roles...the things machines can’t replicate. AI is here to stay. With rapidly growing computing power, it will only continue to influence how we live and work. The challenge and the opportunity is learning how to work with it, not against it.

Many companies have already started using AI in customer-facing areas. Think of chatbots on websites. A few years ago, they were clunky and frustrating. Today, they’re far better at understanding and responding to customer needs. And because AI learns with every interaction, these tools continue to improve over time.

AI is also driving major improvements behind the scenes. In operations and resource planning, companies are now using AI-powered ERP systems that analyze vast amounts of data in real time. These systems can forecast demand, schedule production and manage materials more efficiently than traditional software ever could. They help reduce waste, minimize delays and keep operations running smoothly. Salesforce and other CRM platforms have also embraced AI, using tools like Einstein AI to enhance forecasting, target marketing efforts and automate workflows. The goal isn’t to replace human decision-making – it’s to support it with faster, more accurate insights.

AI is not a threat to be feared, it’s a tool to be leveraged.

Where I’ve seen AI really shine in our industry is in quality management. Glass is meant to be looked through, not at. If you’re noticing the glass, chances are there’s a defect. Traditionally, identifying scratches, chips or coating flaws relied on human inspection. Now, AI-powered visual systems, trained with deep learning algorithms, can detect even microscopic imperfections. These systems reduce downtime, improve consistency and help keep product quality high without slowing down production.

Another exciting area of innovation is the use of AI in smart glass technologies. While photochromic or electrochromic glass that responds to light and temperature has been around for some time, the integration of AI is what truly makes it “intelligent.” These AI-enhanced glass systems gather data from environmental sensors (like sun angle, temperature, and cloud cover) and internal building sensors (like occupancy and usage patterns). AI algorithms then analyze this data to dynamically adjust the glass’s tint or transparency. The result? Improved occupant comfort, reduced HVAC loads and energy savings. When integrated with building management systems, these windows can work in harmony with lighting, shading and climate control to maximize overall building performance. This level of automation is helping architects and engineers design smarter, greener buildings, reshaping our expectations of what windows can do.

My personal experience with AI started during the pandemic. Like many, I turned to tools like ChatGPT to help generate content, summarize data and brainstorm ideas. The results weren’t always perfect, but they sparked new ways of working. What stood out was how quickly the technology improved.

Today, I rely on Microsoft Copilot as a digital assistant. It sorts through spreadsheets, identifies patterns, and even helps draft articles like this one. It’s not just a convenience – it’s become a productivity tool of great value.

AI is not a threat to be feared, it’s a tool to be leveraged. It’s transforming our industry in powerful ways: improving manufacturing, enhancing design, reducing waste and delivering smarter buildings. The future belongs to those who embrace this change. AI isn’t going away. It’s evolving and so must we. •

by AMY ROBERTS

Amy Roberts is FGIA’s Director of Canadian and Technical Glass Operations.

New accessibility rules came into effect in British Columbia in March 2025. British Columbia Building Code 2024 (BCBC 2024) now requires that at least one for every five units (20 percent) be designed as an adaptable dwelling unit. Under the new code, halls and corridors, bedrooms, bathrooms, kitchens, outlets, switches and doors must be adaptable. All large new condominium and apartment buildings must have adaptable suites. First-floor suites in smaller apartment buildings and condominiums must be easily adapted so that anyone with a disability can live in them. The BCBC defines an adaptable dwelling unit as “a dwelling unit designed and constructed with some accessible features, and which accommodates the future modification to provide more accessible features.”

Adaptable dwelling unit requirements can be found in subsection 3.8.5. of Division B. Under the new rules, buildings must have accessible clearances through doorways and along paths of travel to living space; accessible space in one bedroom, bathroom, and kitchen; switches and other controls at accessible heights; and reinforcement of bathroom walls to allow future installation of grab bars. The adaptable dwelling unit provisions in BCBC 2024 apply to single-storey units that are served by a common accessible interior corridor. However, per Article 3.8.5.1. of Division B, adaptable dwelling unit provisions do not apply when the dwelling unit is more than two stories; has its own separate entry/exit to the exterior; or is not served by an interior corridor that is required to be accessible. For buildings following Part 3 of Division B, first-storey dwelling units must be adaptable, but second-

The cost to build one unit could increase by $40- to $100,000.

storey units may not be unless an elevator provides access to that storey. An elevator is required in three-storey buildings.

For buildings following Part 9 of Division B, first-storey dwelling units must be adaptable, but second- and third-storey units are not required to be adaptable unless an elevator provides access to those floors. An elevator is not required in buildings following Part 9 of Division B, if the second- and third-stories contain only dwellings. Nevertheless, for buildings following Part 3 or Part 9, an elevator is required to connect accessible common areas such as recreation areas, garbage and recycling rooms, and rooftop occupancies. It’s important to note that only one bedroom and one bathroom in an adaptable dwelling unit need to be adaptable. The designated adaptable bedroom and bathroom must be connected with a path of travel that meets minimum clear width requirements. Additionally, the path of travel must be connected to the unit’s entry/exit door, a living space, and an adaptable kitchen.

The transition period for adaptable dwellings has been extended for in-stream projects with substantial design work completed in accordance with BCBC 2018. Projects with building permits applied for before March 8, 2027, will be exempt from the new adaptable dwelling unit requirements. Projects that do not meet the criteria for an exemption and for which a building permit is applied on or after March 10, 2025, must comply with BCBC 2024.

With bigger rooms, wider halls, lower outlets, wider doors and various changes to washrooms, the cost to build one unit could increase by approximately $40- to $100,000. Due to the cost increase, the new requirements would either reduce the number of units available or make them more expensive. Developers have shared their concerns that changes to BCBC to build more adaptable dwellings will increase expenses for both builders and buyers. B.C.’s Housing Minister, Ravi Kahlon, acknowledged that the cost for retrofitting a unit is more expensive than initial builds, but stressed the changes are not as expensive as previously suspected, and that the government is working with developers to address their concerns.

BC’s Building and Safety Standards Branch has released three information bulletins to help stakeholders understand the new changes. One addresses the application, one addresses FAQs, while the other explains the transition timing in detail. As with all such developments, FGIA will continue to monitor this matter. •

by DOUG MILBURN

Dr. Doug Milburn is chairman of Advanced Glazings, makers of Solera and Aerogel window products. He is proudly based in Cape Breton, N.S.

We’ve been falling for plastic promises. For years, architects, designers, builders and building owners have been misled. The translucent glazing category is riddled with bold claims, glossy brochures and far too many projects quietly yellowing in the sun. It’s time to challenge the status quo and to call time on the long-standing deception that’s crept into our industry.

The culprits? “Plastics” and “polycarbonate.” You’ve seen them. You’ve used them. And if you’ve been in the built environment long enough, you’ve probably seen them fail.

These materials, still widely marketed as durable and sustainable, are in reality just highly engineered iterations of the same short-lived plastics we’re eliminating from other parts of our lives. In essence, they are single-use plastics for buildings – prone to discoloration, degradation and premature failure that necessitates regular maintenance or complete replacement.

Let’s be clear: fibre-reinforced plastics and polycarbonate systems do not last. They stain. They yellow. They leak. And when fibre bloom sets in, the strong unpleasant odor is unmistakable. These materials break down even faster in high-sunlight environments, precisely where light matters most. Their aged, nicotine-stained appearance isn’t just an eyesore, it’s a visual indictment of poor material choice.

It’s time to stop choosing the wrong translucents.

Don’t just take my word for it. Entire sub-industries have sprung up to deal with the aftermath: repair kits, patching solutions, coatings and stopgaps for a failure cycle we’ve normalized. Imagine if roofing materials failed this often. Imagine if windows required recoating every few years. We’d call them defective. Yet, somehow, we’ve allowed this to persist in translucent glazing. That has to stop.

The architectural community deserves better. More importantly, the buildings we design – schools, hospitals, research labs, museums – deserve materials that stand the test of time, not those that quietly compromise on performance and integrity. We need solutions that don’t degrade in quality with every passing year or season. We need daylighting materials that are stable, clean and reliable for decades, not just for the warranty period.

There’s also the myth of “value.” Low-cost translucent plastics are often marketed as budgetfriendly solutions, but any perceived savings vanish when you factor in maintenance, cleaning, energy inefficiencies and eventual replacement. Lifecycle costs – not sticker prices – should guide our choices in critical infrastructure. Too many design decisions are made at the specification stage with short-term budgets in mind and long-term consequences ignored.

So why are we still installing the same yellowing plastic in our schools? In our hospitals? In our cultural institutions? Quite simply, we shouldn’t be, and many in the industry already know this. Builders know. Engineers know. Facility managers tasked with cleaning up the mess a few years down the road definitely know. But the players pushing plastic with their marketing machines and industry influence have managed to rebrand obsolescence as innovation. They’ve disguised plastic as permanence. They’ve sold short-term material life as long-term value. And they’ve exploited the silence of a professional community too hesitant to say, “enough.”

Well, enough is enough.

This is a call to action. A call to rethink what we’re tolerating, what we’re specifying and what we’re accepting in the name of “good enough.” Once you know the truth about these materials, you can’t unknow it. Let’s stop settling. Let’s stop selling yellowing plastic. Let’s stop designing for obsolescence and start building like the future deserves it. •

Canada's celebration of the architectural glass industry returns to Calgary for a second year

&

Best Western Premier Calgary Plaza Hotel & Conference Centre This year’s content

TEST ONCE AND SCALE

Explore a new world of performance validation with Fenestration Canada’s online thermal performance calculator.

INSIDE LUXWALL

See how cuttingedge vacuum insulating glass is made.

GAMA AWARDS

Celebrate Alberta’s next generation of glaziers with the GAMA Apprenticeship Awards.

FIREPROOF FENESTRATION

Lessons from Canada’s most expensive wildfire resilience test.

THE ONE NUMBER PANEL

Experts discuss a new approach to sustainable building regulation.

by RICH PORAYKO

Rich Porayko is a professional writer and founding partner of Construction Creative, a marketing and communications company located in Metro Vancouver, BC. richp@ constructioncreative.com

Canada finds itself in a peculiar economic moment where the traditional metrics seem misaligned with public sentiment. On paper, parts of the economy are thriving, but the experiences of workers, businesses and investors tell a more complicated story, particularly in Division 8 construction.

Statistics Canada’s numbers suggest strength in the commercial construction sector, with nonresidential investment rising 3.1 percent year-over-year in May. This growth might seem to contradict the waves of uncertainty felt by many glass industry players, as anecdotal reports paint a picture of instability. While some commercial glaziers hold backlogs spanning years, others are shuttering operations, laying off employees or cutting back to three-day work weeks. This unevenness makes it clear that not everyone is benefiting from these gains.

Interestingly, multi-unit residential construction saw a marked decline, dropping by $295.2 million to $8.5 billion in May. Ontario and Quebec led these losses, contributing $166.4 million and $159.0 million to the downturn, respectively. Meanwhile, Alberta and Saskatchewan bucked the trend, posting gains of $50.4 million and $20.2 million. The divergence between regions reflects varying provincial priorities tied to resource markets and shifting demographics, but it does little to alleviate the broader perception of turmoil.

Growth seems to contradict the waves of uncertainty felt by many glass industry players.

THAT’S RICH

The BC Construction Association adds another layer to the conversation with concerns about payment certainty. A staggering 91 percent of employers have reportedly faced late payments for completed work within the past year, and 69 percent say they went unpaid at least once altogether. Despite $158 billion in ongoing construction projects and 400 tower cranes gracing B.C.’s skyline, issues like late payments and stalled workflows contribute significantly to perceptions of instability. The numbers show activity is happening, but it feels less like growth and more like survival for many businesses navigating fierce competition and tightening margins.

While on paper, commercial construction appears to be expanding, residential real estate is facing an ongoing, pronounced slowdown. Single-family home starts have plummeted, and the once-lucrative condo market has stagnated. Real estate speculation – a significant driver of past booms – has fizzled out. Landlords, once heralded as entrepreneurial investors, now grapple with surging costs, stricter regulatory environments and dwindling public goodwill. AirBnB properties that were once a staple of short-term rental income strategies are increasingly fading into memory.

The challenges plaguing residential investment ripple beyond developers. Public confidence in real estate has eroded, with mortgage defaults and project delays garnering attention across social media. Current market conditions have dampened the traditional appeal of owning rental property. Even when the business calculations suggest profitability, the risks and responsibilities tied to being a landlord often outweigh the potential rewards.

Given these struggles, the apparent growth in commercial construction warrants closer scrutiny. StatsCan points to investment in transportation and utility projects, trade and service facilities, recreational spaces, hotels, educational institutions and even religious and welfare buildings. While these developments provide an explanation for the rise in non-residential investment, they also hint at a shift in economic priorities. Infrastructure that supports transportation, education and community well-being tends to be backed by government spending or long-term institutional investment, areas somewhat shielded from the volatility of private-sector dynamics.

Yet even within office construction – a traditional growth engine for commercial real estate – the outlook is murky. The hybrid work revolution and reduced demand for new office space have put downward pressure on this segment. What once symbolized economic optimism now faces declining relevance in a world recalibrated by the pandemic. It’s hard to look at the short-term future of office towers in Canada and feel bullish. •

Now, you can do it in one fell swoop.

Introducing BirdSmart™ Bird Safe Glass by Vitro Architectural Glass, a first-surface laser-etched glass with a Solarban® low-e coating produced at one central location.

Now you can order all your glass — including bird safe glass — from the name you know and trust. vitroglazings.com/birdsmart

Our family-owned company of over 40 years offers Corning® Med-X® Glass: high-quality transparent protective shielding against x-ray radiation.

• Extensive Radiation Shielding/ Leaded X-Ray Glass Stocked: Largest Available Sizes in the Industry (54" x 108"), Biggest Inventory in North America

• Customizations & All Plate Sizes & Thicknesses Cut Specifically to Customer Requirements, Delivered Direct to Job Site

• Single Source Supplier (Including Fire-Rated Systems & Switchable Privacy Glass), In-house Lamination & Print/Film Division, +250,000 SF of Production Space