PRODUCTS LIFT & SLIDE FOLDING ENTRANCE TILT & TURN CURTAIN WALL

PRODUCTS LIFT & SLIDE FOLDING ENTRANCE TILT & TURN CURTAIN WALL

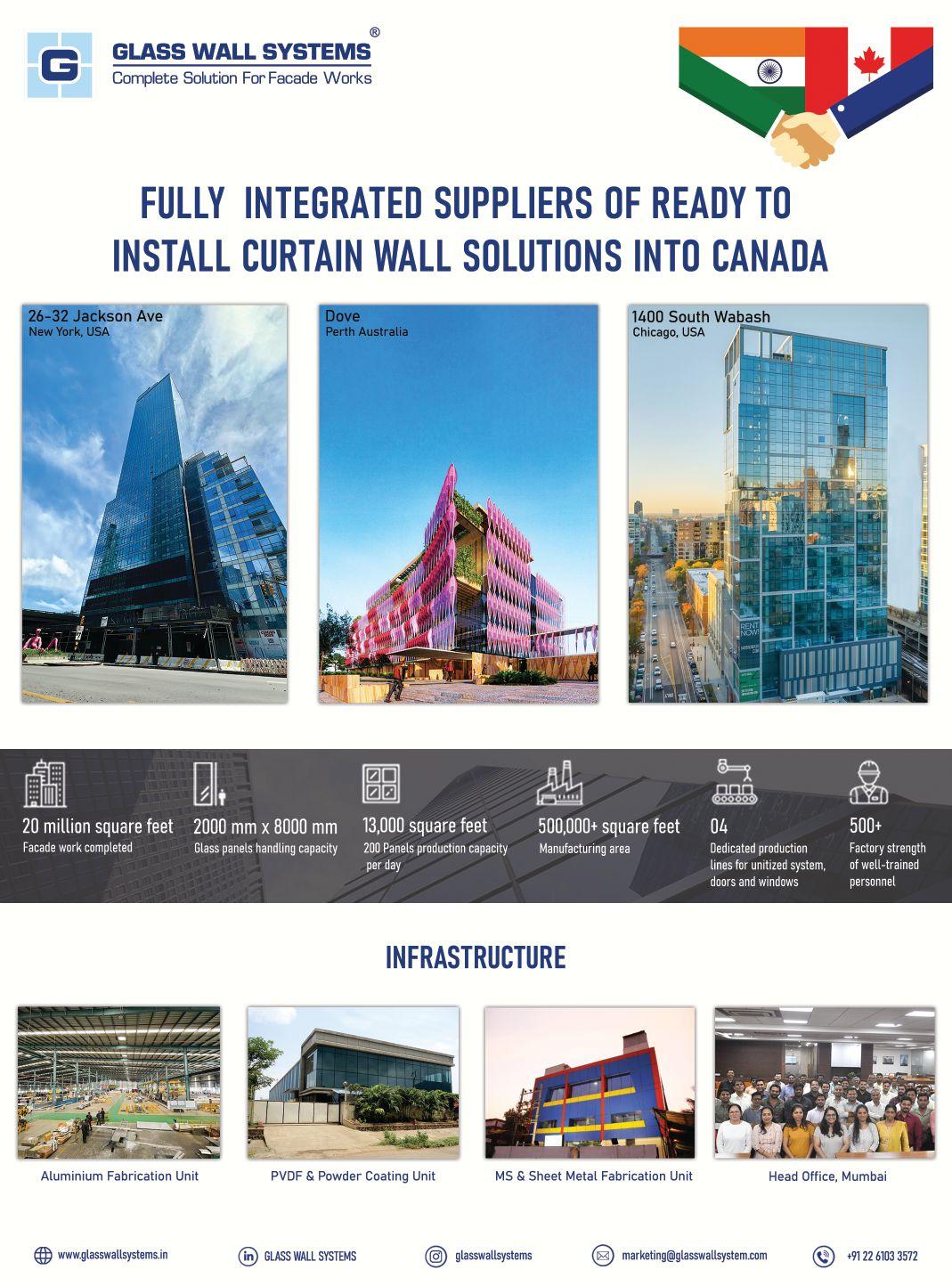

YOUR ONE STOP SHOP FOR ALL YOUR FENESTRATION NEEDS

Canada’s premier certified fabricator of Schuco and Reynaers products. All tested in North America to meet NFRC and North American fenestration standards. Uncompromised quality, service, and support for over 40 years.

Helen Sanders, general manager at Technoform and chair of the Fenestration and Glazing Industry Alliance Glass Products Research Committee, celebrates her 30th year in the industry by joining Glass Talk to talk about their work on the cutting edges of glass technology. The Committee is looking at new ways to confirm the amount of argon fill in IGUs; developing industry Product Category Rules for fabricated glass and load-testing vaccuum insulating glass, among other things. Sanders has the 411.

We’re bringing Canada’s architectural glass show

Since 2014, the Glass Canada B2B channel has hosted a one-day conference for the Canadian architectural glass industry in Mississauga, Ont., called Top Glass. We take four ballrooms at the International Centre right next to Pearson airport and fill them with around 40 exhibitors and a lecture hall where we present four education sessions through the day. Those sessions are laser-focused on the “commercial” side of the fenestration industry, addressing topics of interest to glass fabricators and glazing contractors involved in building and installing facades for Part 3 buildings and engineered custom homes. Because of the in-depth technical information on offer, Top Glass has become popular with architects and glazing specifiers as well. They can spend a day at the conference and pick up four Structured Learning Credits that most professional organizations will count against their total needed to maintain their certifications. Because of the support from our exhibitors and sponsors, we can offer free attendance. I’m truly proud of some of the tremendous content we’ve presented on the Top Glass stage.

Over the last 10 years, Top Glass has become something of a meeting place for the community, as well.

• Deki Home

• VIG myths

• Top

We’re proud to host the Ontario Glass and Metal Association’s Awards for Excellence at each show. It’s great to see the smiles on the faces of the honourees as the room applauds their amazing achievements. Canada’s other industry associations that are active in Ontario have piled in as well. At our last show, Fenestration Canada sponsored a large lounge area. Representatives from the Fenestration and Glazing Industry Alliance are always on hand and Amy Roberts delivered a terrific talk on bird-friendly glazing on its behalf. The Architectural Glass and Metal Contractors Association has a booth and we like to put them right next to their friends from the IUPAT union so they can get a jump on the next contract negotiations. There’s always a friendly and excited buzz on Association Row. With the PGAA and GAMA supporting and promoting Top Glass West, we’re sure this event will be no different.

Only one thing has been missing: our friends from western Canada. Some dedicated souls make their way from the Prairies and B.C. every year, but we realize it’s a long way to travel for a one-day event. So we’re bringing Top Glass to you. Calgary looks like the perfect location what with being relatively centrally located and a hotbed of stunning new architectural glass work in the last few years. Our goal is to put on such a compelling program that even people from Edmonton will be unable to resist coming. For details on what we have planned, please see page 28 then visit topglasswest.ca to register.

There’s a talented and dynamic architectural glass industry in Alberta and we hope you are as excited as we are to have Top Glass come to town. See you at Top Glass West!

August 2024

Volume 36 • Number 3

Annex Business Media P.O. Box 530, Simcoe, Ontario N3Y 4N5

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Rep.

Tel: 416.510.5113 Fax: 416.510.6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR/PUBLISHER | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

GROUP PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

ASSOCIATE EDITOR | Macenzie REBELO mrebelo@annexbusinessmedia.com 416.510.6851

BRAND SALES MANAGER | Leslie OSBORNE losborne@annexbusinessmedia.com 647.280.5885

ACCOUNT COORDINATOR | Barb COMER bcomer@annexbusinessmedia.com 519.429.5171

AUDIENCE DEVELOPMENT MANAGER | Shawn ARUL sarul@annexbusinessmedia.com 416.510.5181

MEDIA DESIGNER | Svetlana Avrutin

CEO | Scott JAMIESON sjamieson@annexbusinessmedia.com

SUBSCRIPTION RATES

Canada - 1 Year $37.74 (plus tax) U.S.A. - 1 Year $86.70 (in CDN dollars)

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

Occasionally, Glass Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

FGIA brings industry leaders together to improve home and building performance through better glass, window, door and skylight technologies and standards.

An FGIA membership gives you access to:

• Technical standards

• Market studies

• Professional development

• Certification discounts

• And an indispensable community of industry peers

Whether joining as an individual or business, FGIA will give you a leg up in an increasingly competitive industry. Join the alliance today at Join.FGIAonline.org

The Ontario Glass and Metal Association held its spring golf tournament June 12 with 120 golfers enjoying a beautiful sunsoaked day at Glen Eagle in Bolton, Ont. Golfers were helped on their way by OGMA executive director, Lori Brooks, and her helpers from Yarlmetal. Around 20 more joined the dinner afterwards. Conversations were so lively OGMA president, Steve Ringler (Alumicor), had some trouble settling everyone down for the speeches. Ringler introduced the 2024 board of directors: Blake Sanders (Spandreltech), Andrew Dolphin (BV Glazing), Keith Elmer, Greg Parkin (Brampton Glass and Mirror), Steve Peso (Tremco), John Rania

(Rimac), Robert Casinelli (Cadwin), Robert Maggiacomo (Universal Aluminum), Yoga Arulnamby (Yarlmetal) and Heather Sakai (Guardian). Sponsorship for the tournament was strong with 14 hole sponsors. The 2024 Glazing Apprentice Honour Student was announced: Joel Scott. Scott couldn’t attend so Architectural Glass and Metal Contractors Association executive director, Noel Marsella, accepted the award on his behalf. Scott will receive a $1,000 bursary toward his trades education at the Ontario Industrial and Finishing Skills Centre from OGMA and AGMCA. His instructors selected him for the award on the strength of his 92.83 grade average and his completion of the Architectural Glass and Metal Technician certification. The big moment was the presentation of the OGMA Lifetime Achievement Award to Bruce Cooke of Commdoor. Cooke started his career at Glaverbel Glass in 1975 at the age of 16. From there he worked for Armourguard Glass, AFG London, Oldcastle, Guardian, Saand and Glassopolis. Through it all his support for the association and many colleagues in the industry has been unwavering. Low score of 12 under went to Andrew Kennedy’s (Div8 Glazing Solutions) group. Frank Fulton took home the big raffle prize of a new barbeque. The OGMA fall golf tournament will be held Sept. 12 in Tottenham, Ont.

Sept. 16 - 19

FGIA Fall Conference Minneapolis, Minn. fgiaonline.org

Sept. 30 - Oct. 2

GlassBuild Dallas, Texas glassbuildamerica.com

Oct. 16 - 17

Top Glass West Calgary topglasswest.ca

Oct. 21 - 23

ASHRAE Decarbonization Conference

New York, N.Y. ashrae.org

Nov. 6

FenBC Regional Technical Summit Surrey, B.C. fgiaonline.org

2025

Feb. 17 - 19

FGIA Annual Conference Orlando, Fla. fgiaonline.org

April 30

Top Glass Mississauga, Ont. topglasscanada.com

June 16 - 18

FGIA Summer Conference Online fgiaonline.org

Sept. 19

AIA & Facades Philadelphia Philadelphia, Pa. aiaphiladelphia.org

The big family of the glazing and fenestration industry met at the AVFQ Annual Conference last April with 365 participants, a new record!

Conferences on current economic issues, artificial intelligence, automation and industry 5.0 particularly caught the attention of delegates. Gina Gaudreault, who has led the AVFQ for almost six years, will hand over the torch shortly. She is retiring from full-time professional life. Under her leadership, the AVFQ experienced strong expansion and raised the professionalism of the organization to a high level. The AVFQ is the industry’s leading organization for its 250 members!

It’s been an extremely active and exciting year so far with the Glass and Architectural Metals Association board spearheading a number of initiatives. Some of these include trade promotion at local high school fairs and Southern Alberta Institute of Technology glazier program practical project updates and enhancements by our associations and association members. GAMA and PGAA are also working closely with Glass Canada to help host the Top Glass trade conference and bringing it to Calgary in October, 2024. Alberta is still facing significant labour shortages in the trades. We as an association will continue our efforts in promoting and highlighting our unique trade

with continued support of our glazier program, which is offered through SAIT and the Northern Alberta Institute of Technology. With this being the 59th year of this amazing, dynamic and ever evolving association, GAMA is continuing to strive and grow on what seems to be a monthly basis. May’s association dinner meeting was held on May 9 where an impressive number of five new members were successfully voted into join GAMA, pushing our membership to over 50.

Manitoba has announced that Marcie Wilson will be stepping down as executive director in early June due to urgent family matters. For the last two years, Wilson served as a dedicated support to the board and members. She provided invaluable assistance and ensured a smooth operation of the organization. Fenestration Manitoba sincerely appreciates Wilson for her contributions and wish her and her family all the best during this challenging time. Nancy Zubriski has returned as executive director of the association.

Asan active member of the Council of Ontario Construction Associations, AGMCA is committed to promoting careers in the skilled trades to ensure that our members’ future labour requirements are fulfilled. The challenge is that even in slower periods such as we are currently experiencing, we need to focus on our longterm needs. A recent study in-

dicates the need to recruit over 100,000 new workers into the construction industry over the next 10 years in order to keep pace with retirements and new demand. The need to develop recruitment programs has never been greater. These programs must address the concerns not only of students, but also their parents, teachers and guidance counselors. We need to engage the Ministry of Education to promote a curriculum that prepares students for a high-paying career in construction, while highlighting the dynamic nature of our trade specifically. The current provincial government has heard from us and has responded with large financial commitments. Our glazier training centre partners at Finishing Trades Institute have applied for grants to keep up with the latest technology used in the glazing trade. The future is bright for construction in Ontario and our AGMCA member glazing contractors will be well prepared to handle the challenges of an ever-changing construction landscape.

Golf tournament The OGMA spring golf tournament was held on June 12 at the Glen Eagle Golf Club in Bolton, Ont. The weather could not have been better, and we had an excellent turnout for the tournament. Bruce Cooke was presented with the Lifetime Achievement Award – read more about it on page 6. We want to express our appreciation for all our tournament sponsors who helped us to make the event a success, with a special shoutout to the folks from Yarlmetal Fabrication for providing golf shirts, golf balls and tote bags to

attendees and for their help with set-up. Spring bursary Together with the AGMCA, we awarded our spring bursary to Joel Scott from CS Specialty Glazing Solutions. Joel receives a $1,000 bursary from the two associations. In the spring and fall of each year, a monetary award is provided to a student enrolled in the apprenticeship program of the Finishing Trades Institute in Vaughan, Ont. Recipients are selected by the instructing staff at the institute. Congratulations, Joel and well done! The next bursary award will be presented at the fall golf tournament in September. Board of directors update We’d like to extend a warm welcome to Yoga Arulnamby from Yarlmetal Fabrication and Robert Maggiacomo from Universal Aluminum who have joined the OGMA board of directors. We would also like to thank Eric Diotte and Robert Casinelli, who recently stepped down from the board, for all their efforts on behalf of our membership. We wish them both well in the future. As always, we encourage energetic industry participants to join the board and have a positive impact on the glass and metal industry. Please contact any current board member for further information or email info@ogma.ca. What’s next? OGMA is busy planning for events this fall, including a plant tour and an educational seminar, and we’re making ongoing updates to our website. Watch your inbox or visit ogma. ca to keep up to date on association happenings. And don’t forget to follow us on LinkedIn. If you have any ideas for educational sessions, networking opportunities, features you’d like to see on our website, or would like to arrange a plant tour that could be of benefit to our members, please reach out to info@omga.ca.

Pro-Line Automation Systems, a manufacturer of machinery and automated manufacturing systems for U-PVC, aluminum and fiberglass fenestration products, has welcomed Ellis L. Dillen to the Pro-Line management staff as vice-president and COO. Starting in the industry in 1987 as a machine builder on the shop floor, Dillen quickly moved through the ranks holding leadership positions in service, sales and eventually as president and CEO of a well-known supplier of machinery from Europe.

“I have met many great people along the way that have helped me get to where I am today and through it all my philosophy has been to treat our customers right through service

Aand support,” said Dillen. “A good salesperson can get the first order, but it’s the company’s dedication to servicing the customer that builds lasting relationships. I look forward to bringing this ideology to the new facility in Ohio.”

Vinode Ramnauth, president and CEO of Pro-Line, added, “I have known Ellis and his abilities for many years and I am happy that we were able to talk openly about our shared goals. In the end, I am extremely pleased that we were able to add Ellis to the team and I’m looking forward to supporting our U.S. customer base through our new US facility.”

Pro-Line Automation is headquartered in Woodbridge, Ont.

pogee Enterprises is marking its 75 anniversary with celebrations across its locations. Founded as the Harmon Glass Company in 1949, the company began with a single shop in Minneapolis, Minn. Today, Apogee has 4,400 employees, operating from 15 principal facilities in the U.S., Canada and Brazil. The company’s architectural products can be found on skyscrapers, medical clinics, schools and other buildings across the world. It also provides high-performance glass and acrylic products used in custom picture framing, museums and other applications.

“Seventy-five years is a remarkable milestone that few companies achieve and speaks to the resilience, ingenuity and innovation of the people that have built our company,” said Ty R. Silberhorn, CEO. “I’d like to extend my thanks to all of Apogee’s employees, past and present, who have contributed to our company’s success over the years.”

Initially, Harmon Glass replaced windshields for used car dealers and then began offering contract glass installation for buildings in 1955. Apogee Enterprises was formed in 1968 as the company expanded into multiple business lines. In 1971, Apogee became a publicly traded company, listing shares on the over-the-counter exchange and has continued to grow through acquisitions and organic growth investments, reaching $1.4 billion in sales in 2023. It now includes some of the largest brands in the North American architectural glass industry: Harmon (contract glazing); Viracon (glass fabrication); Alumicor, EFCO, Linetec and Tubelite (aluminum framing systems); and Tru Vue (optical coatings).

In other Apogee news, Jeffrey H. Appel has been promoted to director of sales for Apogee Enterprises and its architectural framing systems division, supporting Alumicor, EFCO and Tubelite brands, and the legacy Wausau Window products. He most recently served as northeast regional sales manager and brings 36 years’ experience in architectural sales serving the commercial building industry. Reporting directly to vice-president of sales, Jon Close, Appel is responsible for managing the regional sales managers and for their supervision of the local client development managers and independent sales representative agencies. Throughout his long career, Appel has earned the respect of customers, colleagues and building teams. For nearly 20 years, Appel has worked with EFCO products. He started as an estimator and project manager focusing on curtainwall before he joined the sales team’s south region. He then moved to the northeast region, where he also represented Wausau Windows. In addition, he has supported collaborative new product development across the EFCO and Tubelite brands. He taught strategic management for 10 years as an adjunct faculty member at James Madison University College of Business in Virginia. Appel graduated from JMU with a Bachelor of Business Administration and an M.B.A.

ASHRAE has issued a statement applauding the U.S. Department of Energy’s release of a standardized, verifiable basis for defining a zero emissions building. The “National Definition of a Zero Emissions Building: Part 1 Operating Emissions” is a comprehensive guideline aimed at providing a broadly accepted minimum standard for what constitutes a zero emissions building. ASHRAE says that by setting clear and measurable criteria, this definition offers a harmonized approach guiding both public and private entities in transitioning the building sector towards zero greenhouse gas emissions. To ensure compliance, the definition includes detailed methods of measurement and verification. For existing buildings, criteria such as Energy Star scores or measured whole-building energy use intensity are utilized, while new constructions must meet stringent energy efficiency and clean energy standards. While part one of the definition focuses on operational emissions, part two will address embodied carbon and refrigerant impacts. These elements are crucial in fully transitioning the building sector to zero emissions, ASHRAE says. The National Definition of a Zero Emissions Building will be embedded in nearly every green building certification, adopted by leading investors and utilized in federal programs.

The Fenestration and Glazing Industry Alli-

ance continued to show its commitment to Canada, hosting its big Summer Conference June 3 through 6 at the historic Le Westin Montreal. With the support of its Quebec partner, AVFQ, the FGIA offered an absolutely loaded schedule of meetings and educational presentations on everything from fenestration labelling to superficial cracking and beyond.

Of particular interest to architectural glaziers was Kayla Natividad’s presentation, “Embodied Carbon in Legislation, Regulation and Other Places.” The architectural technical services engineer for Pilkington reviewed the differences among flat glass, processed glass and fenestration assemblies’ Product Category Rules (PCR). Participants also learned the differences in key forms of embodied carbon policies like Buy Clean programs, climate action plans and zoning policies. Natividad described a PCR as “comparing apples to other apples,” Life Cycle Analyses (LCA) as “seeing what goes into baking an apple pie” and Environmental Product Declarations (EPD) as “making a nutrition label for that pie.”

Agency will standardize PCRs, and we know our processed glass PCR is about to expire. You can probably expect expansion of eligible materials, such as processed glass and full fenestration. There is a lot of work going on.”

“If we don’t understand something or don’t make it clear, [authorities] definitely won’t,” Natividad opined. “There are 76 regulatory policies worldwide and 58 of them are in Canada and the U.S. Most in North America are implemented at the local or city level. My crystal ball predicts the [U.S.] Environmental Protection

David Vadocz, principal at RDH Building Science, shared “How to Select Facade Systems for Iconic Building Architecture.” He illustrated his points about facade movement with several case studies, including an eye-opening reveal of the recently renovated University of British Columbia Museum of Anthropology building [see more on page 14]. Vadocz said selecting an appropriate facade system depends primarily on facade movement. “A major type is interstory drift, or its lateral movement relative to the floor above and below,” he said. “The facade goes along for the ride. The facade engineer needs to confirm what the interstory drift amounts are before the facade can be designed. Pay attention to both elastic or service interstory drift and inelastic interstory seismic drift.” The three types of facade movement are rotating, racking and translating. Typical interstory drift allows for movement of up to six inches, he said, although vertical movement is considered, too, and usually allows for up to 3/4 of an inch of movement. “Facades can have a combination of movements,” he said. “Don’t underestimate gravity and friction. This is where full-scale mockups can be important.”

BUSINESS PARTNERS AREA

Thickness - 3mm to 19mm Max. Long Polish 175” Max. Daigonal 160” Over the max size can be reviewed

Thickness - 4mm to 19mm

Over the max size can be reviewed Process meets ASTM C1048 and ANSI Z97.1

Rollcoat Spandrel (Opacicoat and Ceramic Frit)

and Digital Printer Ceramic Frit

CERTIFICATIONS/STANDARDS

LAMINATION 96 X 180

20 ROYAL GROUP CRESCENT, VAUGHAN, ON L4H 1X9 905-605-7040

TRULITE.COM

by AMY ROBERTS

Amy Roberts is FGIA’s Director of Canadian and Technical Glass Operations.

Thermal stress is one of the common factors leading to breakage of annealed glass used in insulating glass units. Uneven heating of glass by solar irradiance or other heat sources can induce a thermal gradient, thereby causing thermal stress resulting in breakage. IGMA TM1500, “Guidelines to Reduce Instances of Thermal Stress,” provides guidelines relating to thermal stress considerations for window glass products used in residential and commercial building envelope projects. It gives specific guidelines and design assistance for avoiding glass problems arising from breakage caused by thermal stress conditions. The Technical Bulletin provides crucial information that can be used to assess risk for thermal stress. For instance, it clarifies the effects of altitude from atmospheric pressure and solar irradiance. The least risk is when the building is under 3,000 feet above sea level. The solar intensity increases as altitude rises. Shadows from vertical mullions and horizontal frame overhangs cause temperature differences in heat-absorbing glass. If a vertical mullion is less than 20 inches deep, its shadow can be considered “mobile,” as it sweeps across the glass and does not remain still long enough to develop major temperature differences. Vertical mullions greater than 20 inches deep develop “static” shadows, which lead to higher glass stress. Mobile shadows typically develop 11 percent more stress than a “no shadow” situation. Static shadows develop about 35 percent more stress than a “no shadow” condition.

Winter temperatures influence the risk of breakage to the inner lite, while the risk of breakage to the outer lite stays consistent. Inner lites can have additional risks especially if the spacer is made from a highly conductive material and buried deep in the glazing cavity. Orientation also affects the risk of thermal breakage. North-facing buildings have the lowest risk, northeast and northwest are at medium risk of developing thermal stress and south, east-, and west-facing buildings are at the highest risk. Laser cut glass edges, with no damage, are at very low risk of thermal stress. However, cut edges with deep serration hackle and spalls are at high risk.

The Technical Bulletin also provides the risk levels of different framing options like structural silicone glazing, blinds, frames, gaskets and thermal barriers. It also shares the risk level of thermal stress for the different kinds of glass and type (heat strengthened or annealed, tinted, and coated). HVAC vents, shades and blinds also pose a certain risk. It’s important to review the risk level and design accordingly.

Thermal stress for multiple-cavity IGU lites must be evaluated to determine if the glass construction requires certain lites to be heat treated to prevent glass breakage. The amount of thermal stress induced in the glass lites is influenced by many factors, such as solar absorptance of the glass lites and their coatings; the spacer and sealant system; the framing system; and solar isolation provided by the perimeter glazing method. The solar absorptance (the amount of total solar radiation absorbed by the glass expressed as a percent) of the glass is one of the highest-ranking items when evaluating when annealed glass can be used or when heat treatment should be considered to resist thermal stress. Computer modelling programs like the LBNL WINDOW Program can help determine the integrated solar absorptance of glass lites. Solar irradiance is the basic load that will heat the glass, so it is key to the evaluation of thermal stress. It will vary based on the latitude, time of year, time of day and elevation.

Heat-treated glass is recommended for all spandrel conditions. For some extreme conditions heat-strengthened glass may not be sufficient and fully tempered glass may be required.

These guidelines aim to assist in identifying conditions that may increase the probability of thermal stress. Published in 2014, it is currently undergoing updates. Watch for the new edition coming soon! •

by RICH PORAYKO

Tesoro, situated in Southeast False Creek, graces Vancouver’s coveted waterfront as the final piece of Concert Properties’ newest master-planned community, The Creek. Spanning from its inception in January 2021 to its completion in April 2024, this 17-story building is a beacon of luxury living, featuring 92 residences that are two bedrooms or larger.

Crafted by Rafii and ZGF Architects, Tesoro is designed to achieve LEED Gold. Significant sustainability strategies were integrated in the project including strategic placement of operable windows to promote ventilation, utilization of highperformance glazing and building envelope, integration of solar shading devices including a lattice screen on the south- and west-facing facades to reduce mid-summer sun penetration while taking advantage of winter sun exposure at lower angles.

The structure is a striking example of contemporary west coast modernism. Its prime location near the waterfront and close to landmarks such as Science World necessitated a distinctive architectural design approach.

According to Jan Willemse, managing partner of the ZGF’s Vancouver office, the site for Tesoro was included in a rezoning application by Concert Properties in 2014 and granted permission on the condition that the building achieve “an exceptional design esthetic” and “notable and prominent landmark status.”

ABOVE: Tesoro is part of a large planned community on the Vancouver waterfront. It’s part of the city skyline now and had to hit a high bar for esthetic appeal.

Developer: Concert Properties

Architects: ZGF Architects and Rafii

Glazing contractor: Toro Aluminum

Curtainwall: Toro Aluminum

Glass type: Guardian SunGuard SN-54

Glass fabricator: ProTemp Glass

The broad, curved west facade is a visual anchor at the end of False Creek. The curved form echoes the sphere of Science World and arcing forms of the rail spurs and switch yards that once crisscrossed the site.

“The design met this high aspiration through a contextual design response that was informed by both a unique and highly visible waterfront site and the history of the Southeast False Creek neighborhood as a rail and shipyard,” said Willemse.

“The massing and exterior design was intended to provide a strong, cohesive and distinctive building silhouette, with an architectural concept connected to the site and its history, unified by a single design language and which stands out from the surroundings and background buildings.”

According to Willemse, the curved west facade also maximizes the number of units with waterfront views and creates a perspective effect from inside each unit, since the units are narrower at the interior and fan out towards the water. The effect draws the eye out, to the park, downtown skyline and mountains beyond.

“The form of the building with inset balconies and fixed exterior shading allows the glazing to be maximally transparent by reducing the pressure on the glazing to moderate solar heat gain,” adds Willemse. “Guardian SN 54 is an optimal balance between performance and light transmittance with a visually neutral appearance, allowing the view to predominate.”

“You can’t ignore this building as you’re passing by,” said Geoff Shellard, Pacific northwest architectural design manager for Guardian Glass. “Wood-toned soffits can sometimes contrast the glass to the point it can lend a green hue, accentuating the iron and third layer of silver in the low-E coating. SunGuard SN 54 is a highperformance dual-silver low-E coating designed to offer neutral tones, especially when paired with the black and grey tones of the window wall facade, spandrel and other structural elements in Tesoro.”

“SunGuard SN 54 is a dynamic coating, especially when coated on Ultraclear lowiron glass, which allows for enhanced visible light transmission and colour clarity, and accentuates the incredible Vancouver skyline with a level of reflectivity that plays with the ever-changing weather and built environment it’s situated in,” said Shellard.

“This means the building won’t necessarily look the same every single day. There is that dynamic component to it which has a ‘wow’ feature for a building located next to False Creek and Science World with great street level exposure and curb appeal.” •

Inset balconies and fixed exterior shading minimizes solar heat gain, allowing for very clear glass. Good for views, good for curb appeal.

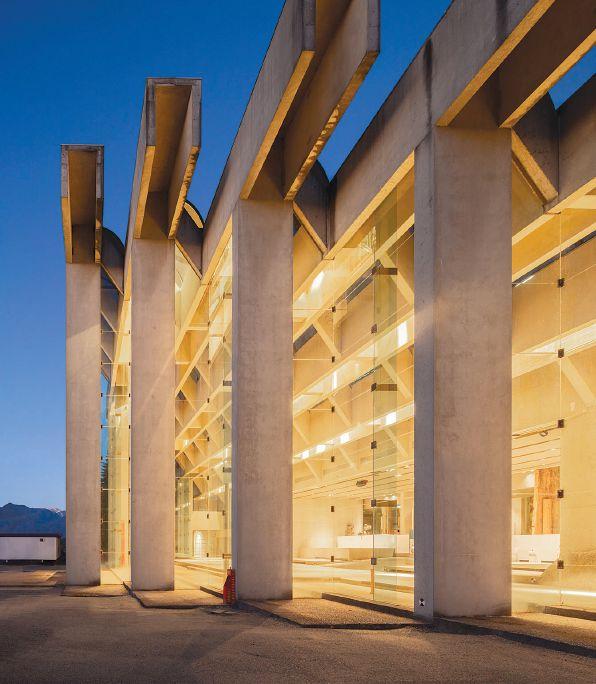

The beginnings of the University of British Columbia’s famous Museum of Anthropology (MOA) lie in the basement of the UBC Main Library with the university’s acquisition of the Frank Burnett Collection in 1927. The museum was officially established in 1947. In 1976, the new building, designed by renowned Canadian architect Arthur Erickson, opened to the public.

After graduating from UBC in 1968, Nick Mikovich, principal of Nick Mikovich Architects, joined the firm of Erickson/ Massey. He continued to work for Arthur Erickson Architects from its origins in 1972 and was a member of the design team for the award-winning museum.

“There were considerable artifacts from First Nations stored in the library’s basement,” Mikovich told attendees at Facades Plus Vancouver. “There was some funding from the federal government and Arthur was commissioned to design the building.”

The museum was built on the foundations of a World War II military base and, much like Erickson’s other projects, primarily uses concrete. “There is a lot of concrete,” explained Mikovich. “It would have almost cost more than the budget of the building to remove.” Erickson cleverly incorporated World War II gun emplacements in the design, featuring Bill Reid’s renowned Raven sculpture on a renovated gun battery.

“My relationship with this building started 30 years ago,” said Brian Hubbs, principal at RDH Building Science. “I moved to Vancouver from eastern Canada. I was a young principal at an engineering firm and I had quite a lot of experience fixing skylight systems and glazing systems that were leaking. I got a call from my boss at the time to go to UBC. I walked up and immediately fell in love with this building. It is a true relation-

Location: Vancouver

Architect: Nick Mikovich Architects

Glazing consultant: RDH Building Science

Skylight contractor: Blackcomb Glass

Facade contractor: Glastech

A lot of people in Vancouver are in love with this building. But after nearly 50 years it needed some TLC for its skylights and seismic upgrades for its massive vertical glass walls.

ship. This building has a soul. I love it. When you sit in there, you get emotional.”

“I tripped over something in the middle of the floor in the Great Hall,” recalled Hubbs. “I looked down and it was a row of bins collecting water. They had people there emptying bins on a regular basis when it was really raining.”

According to Hubbs, the rules of skylights are that they are neither a roof nor a wall. “They don’t work when you tilt them vertically, or if they don’t have a slope. Skylights have internal rafters, drainage and gutters that work when it’s sloped. If you want vertical glazing, use vertical glazing. If you want a roof, you put a roof membrane on it. The UBC skylight is a roof, a skylight and a wall, which I thought was impossible before I met the folks from Raico.”

“They are out of Europe and have this system which I had never seen before. I was a little suspect at first, but it had a continuous gasket which I thought could be interesting if we made it out of silicone. Durability is the big thing. We know that the weakest link in any of those glazing systems is the butyl seal. In a skylight that

expensive, it doesn’t make any sense to put the weakest link where you have to pull everything off to get to fix it. You want to put it somewhere that can be serviced. We went to Raico and met with their technical people. They said it makes a ton of sense. We know silicone lasts virtually forever, and then we know that when it’s welded together properly with silicone, it’s not a weak link anymore. The aluminum and the wood components and the stainless become weaker links than the seal.”

When the Museum of Anthropology Great Hall renewal project finally went ahead in 2020, Raico agreed to do the project.

The architect was fighting for esthetics. “We were fighting for durability, longevity and performance,” said Hubbs. “And then we got it installed. For the first time in a quarter century, that building doesn’t have any leaks.”

“The original Raven skylight had so many components to it,” shared David Vadocz, principal facade structural specialist with RDH Building Science. “It looked like this massive plastic UFO. And then you see what it looks like now. The structural sup-

ports are minimized and the skylight has a much greater vision area. You’re relying on your bigger glass for strength and stability incorporating it as a structural item itself, working with the thin members to hold it load conditions. It is really thinned out and it just came out beautiful.”

In addition to the skylight replacements, the MOA seismic renewal included replacing the structural glass facade of the famed Great Hall.

“The previous system wouldn’t have worked in an earthquake,” said Hubbs. “Anyone standing near that glass would have died. Our initial design had a lot more structural members. Felix came to the table and started looking at the load in a unique way and we were able to really reduce the number of fins to make it look much closer to the existing building. Normally there would be space between the columns and the glass, but we were able to hide it inside the columns. These are all little things that are quite complicated but nobody knows we were there. There used to be a fin or expansion joint and now there isn’t. That’s a good outcome. Less of less is more.” •

by TREENA HEIN

Sitting on the east bank of Lake Memphremagog, the Lakeside Gallery Residence is a glorious home that melds historic aspects of traditional rural Quebec barns with contemporary features, including the best possible use of glass.

This home has four inter-connected buildings (an outdoor summer home, an indoor winter home, living quarters and guest quarters) which all share traditional elements such as local stone and oversized cedar shingles, but also something revolutionary. It’s the stunning floor-to-ceiling glass wall which seamlessly blends inside and outside, enabling unmatched connection with the unique changes of light and landscape colour throughout each day and over each season.

The house was designed by Atelier Echelle, a Montreal-based studio founded by Veronica and Mathieu Lemieux-Blanchard. Of their approach, Mathieu notes “the owners wanted as much view as possible, and we were able to achieve that with the glass wall from Sky-Frame.” It has a total width of 55 feet wide and is 11 feet high. No frame is visible at ceiling or floor.

“Horizontally, this provides a panoramic view of the entire lake, with the mountain to the right and the curve of the lake of the left,” says Lemieux-Blanchard. “Vertically, the 11 feet of glass captures the horizon unimpaired, and the clients get to see the perfect sunsets.”

The Sky-Frame glass wall has seven triple-pane panels, each 7.5 feet across. Three can be moved with a motorized system controlled by a smartphone app or by switches on the wall.

Their installation was done by Solena of Montreal, which has done more than 60 Sky-Frame projects, all residential with

Location: Magog, Que.

Date completed: 2023

Architect: Atelier Echelle

Glazing contractors: Solena and MQ Windows

Glass wall fabricator: Sky-Frame, Switzerland

Glazier: Saint Gobain, Germany

Glass wall specs: PlaniTherm XN Diamant 4 mm/14 mm

90 percent argon fill with 0.76 mm PVB standard spacer/ Diamant 4 mm

one museum. “At the start, we had an architect approach us to install Sky-Frame for his project and since 2014, we are the Sky-Frame partner for eastern Canada,” says Solena president, Luc Bourgeois. “The installation must be done in an extremely precise manner. We go for training every year as the system is improved annually and the manual is updated.”

There are many steps before the glass pieces are installed into the recessed frame. “We have to make sure again and again that the frame is perfectly aligned and perfectly level,” Bourgeois explains. “To ensure the

bottom sill is perfectly level, Sky-Frame created its own tool. For the bottom weld, the general contractor installs plates in the concrete and we attach our plates to those. Once perfect alignment and level has been reached, the insulation and membrane are put in and then the glass pieces.” It took about three weeks to install the Sky-Frame glass wall at the Lakeside Gallery Residence.

Regarding the three moving panels, Bourgeois notes that their installation is quite a bit more complicated than that of sliding glass doors. “There’s a two-way track,” he explains, “and the electrician

does the wiring but we have to connect that to modules with Sky-Frame’s software. It is done at times where if we need technical support from Sky-Frame, which is based in Europe, we can access that.”

Lakeside Gallery Residence, which also has an in situ art gallery, is designed to appreciate the past and present human-made and natural beauty. The selected finishes of this home, such as water-struck clay bricks and local Cambrian granite, will age slowly and gracefully while offering timeless views of the lake and mountain, enabled by inventive use of glass. •

by TREENA HEIN

Not just useful and attractive, upon completion Concordia University of Edmonton’s new academic building will also have the distinction of extreme energy efficiency. It’s thought to be the first building in North America to have triple-glazed vacuum insulated glass units.

Designed by Reimagine Architects and Najfeldt Architect, this teaching facility includes 55 offices, 22 breakout rooms, 15 classrooms, three labs and two lecture halls, along with a spacious two-storey underground parkade.

Location: Edmonton

Date completed: construction ongoing

Architects: Reimagine Architects and Najfeldt Architect

Glazing contractor: GlasCurtain

VIG fabricator: LandVac

Glass specs: Triple-glazed VIG with low-E coating on surface #4

Make-up installed: 6 mm tempered plus 0.3 vacuum plus 6 mm tempered low-E double silver / 16 mm argon air space with black Technoform polypropylene composite spacer bar and black silicone / 6 mm tempered

U-value: 0.43

VT: 64 percent

SHGC: 0.38

Taking a closer look at the curtainwall, which combines a high-performance Thermaframe 8 fibreglass framing system from GlasCurtain with vacuum glass, Reimagine Architects has noted that it reduces heat loss by 30 percent beyond current industry best practices. “This system’s efficiency empowers the design team to deliver a facade of 50 percent glazing, which reduces the need for electric lighting, boosting the mental health of building occupants,” states the firm. “Compared to a typical triple-glazed envelope with aluminum frames, this innovation will save 155 tons of carbon emitted each year.”

But while the fabrication of the frames was quite straightforward, explains GlasCurtain managing director, Peter Dushenski, there were many challenges to the project, partly because it started during the peak of the pandemic. Due to several factors such as working from home, there were a few communication issues. Things like a couple of gaps in the architectural

drawings, “which can happen on any project and usually aren’t a huge deal,” Dushenski explains, “were tougher to correct.” In addition, the contractors and subcontractors (who’d committed to prices before inflation and labour pressures emerged) were feeling huge financial pressures.

There were also long lead times for the VIG units from Asia, up to 20 weeks. To deal with this, the general contractor (Chandos) elected to guarantee curtainwall opening site sizes, says Dushenski, so that GlasCurtain could begin fibreglass framing fabrication and order VIG units to meet the schedule. However, another aspect of the building – the concrete structure – did not perform correctly, and fixes to it delayed curtainwall installation.

The final finishing of Concordia University of Edmonton’s New Academic Building is going smoothly and it has an exciting future ahead. Data related to building efficiency will be tracked through a comprehensive set of modeling, monitoring and analysis tools, explains Reimagine Architects. “CUE will use this project and its results as a test-bed for future projects to cut energy consumption and improve building performance, and as a potential teaching tool.”

While there have been many exceptional challenges in its completion, the NAB’s ground-breaking energy efficiency is certain to inspire students and faculty for generations to come. •

To add to this, “Unfortunately there was also an error in the translation of the VIG purchase order to our supplier,” says Dushenski, “and we were delivered units with only one low-E coating when in fact we’d ordered units with two low-E coatings (surface #2 and #4).” Added to all these challenges were a handful of spontaneous VIG breakages shortly after installation but before the building was heated and conditioned. “Thankfully, we happened to have another VIG project already on order and were able to easily add to that shipment to expedite replacement units under warranty.”

by ANDREW SNOOK

Architect: Diamond Schmitt Architects

Glazing contractor: Tower Glazing Systems

Glass spec: Prelco double-glazed sealed unit 6mm clear with 272 low-E coating and bird-friendly frit on #2 Bird-friendly frit #2/warm edge spacer and argon fill/6mm clear glass

Total glass: 1,565 meters squared

General contractor: Harbridge Plus Cross

Completion date: March 2022

The University of Toronto is regularly ranked one of the top universities in the country and throughout the world. Students at home and abroad come to the post-secondary institution to study in droves and enjoy the busy nightlife that Canada’s most populated city offers. Like most post-secondary institutions, the school is always looking for ways improve the student experience on campus. For this reason, U of T recently undertook a major expansion of the Robarts Library with the Robarts Common project, a 45,000-squarefoot addition on to the back of Robarts Library.

“It’s Canada’s biggest research library, a gigantic building. It takes up a whole block,” says Aaron Costain, associate at Diamond Schmitt Architects and project architect for the Roberts Common project.

The Robarts Common project involved constructing a five-storey wing connected on floors two through five to the main Robarts Library building. The area is filled with natural light and offers 1,200 individual and group study spaces all equipped with nearby power outlets.

The research archives take up the floors above the fifth floor of the main library, and reading rooms took up most of the space of the library from the fifth floor down, which meant there were very few places for undergraduate students to sit down and study at the library, especially on the stack floors.

“There was nothing, a little bit here and there. Graduate students had these little cubicles on the stack floors, but for the undergrads there was just these crummy little dark areas with few windows,” Costain says.

In contrast, the Robarts Common building is filled with an abundance of natural light and a wide variety of seating options. “It’s a long, linear bar building, but we pushed and pulled the facade in unique ways in order to get some of that triangulation that the main building has,” Costain says.

The main building of the Robarts Library has very little natural light. Costain says his firm wanted to use glass as something that is the opposite of the main building itself. “The building looks like it’s completely glass, and it’s less than 40 percent glass in actual fact,” he says. “The back of it didn’t need any glass because it faced onto another building.”

The building’s unique triangular glass design came with its share of challenges. “The first challenge that we ran into was, how do we hold the glass out there? Ultimately, we went with outriggers at every structural bay and ring beams that ran around the building, with diagonal steel beams at every facet,” Costain explains. “This steel supports the windows up to two metres away from the slab, creating a slim interconnected space all along the west facade. This allows the building to have a three-dimensional quality similar to the existing library, and to provide a space for hot air and smoke exhaust to rise up and be extracted at the roof level.”

Another challenge was related to where the large triangular glass windows are tilting outwards. “If you use a traditional stick-built curtainwall system, it’s almost impossible to do a four-way capless system and apply the glass in place, and have it sit there long enough for the silicone to cure. So, when we had originally conceptualized this, we thought unitized curtainwall might be out of our price range, but maybe if we use a cassette system, this would be something that we could do where there’s just a piece of aluminum that fastens into the mullion so you can basically do a stick-built system that has this little semi-pre-glazed piece that easily clips in afterwards,” Costain explains. This method ended up being inefficient due to shop work and site work required and doubled the cost.

“Ultimately, Tower Glazing Systems proposed doing a unitized system, which really made the most sense,” Costain says. He adds that going with the unitized system had several efficiency advantages due to it being pre-glazed. “They were able to just go in and mount the brackets first, so the installer can just swing it into place, and it goes up very quickly. The other advantage is that there’s no waiting for curing time of silicone. The installation cost was substantially lower,” Costain says.

To go with the triangular design of the building, a custom birdfriendly frit was added to the glass. “They’re tiny triangles that picks up the triangulation of Robarts,” Costain says. “It’s spaced at

a certain spacing on the #2 surface so that birds don’t fly into it. We’ve got a low-E coating and the frit on the same surface, which is a little hard to do. Only a couple of companies can actually do that. In this case, it was Prelco.”

The five-year-long project ended up earning the 2024 OGMA Design Excellence Award. Costain says Tower Glazing’s solutions and installation was top notch. “They did a great job. It looks very tight. It’s almost like someone took a piece of Saran Wrap and just wrapped it over the structure. It has this very nice, clean, tight facade to it. I have to hand it to them, they knocked it out of the park.” •

by ANDREW SNOOK

When Applewood Glass was hired as the glazing contractor for a unique residential build overlooking the Niagara Escarpment, they knew there were going to be challenges. The project involved the construction of a massive modern glass house featuring approximately 4,000 square feet of glass on the main house and an additional 700 square feet of glass on the pond house.

“It’s fairly high up in elevation. Part of the reason for the design of the house and the massive windows that are facing south is so when you’re looking through those windows from the inside of the house, on a clear day, you can see the CN Tower. It’s pretty amazing,” says Anthony Menecola, president of Applewood Glass.

The project was well underway in 2018 when Applewood Glass got involved with the fully concrete construction.

“There wasn’t any wood on the house at all. It was all formed concrete, including the roof, including the walls. That took a considerable amount of time for them to engineer and to pour before they required finishes, so they contacted us when they were well into the project,” Menecola explains.

After being awarded the glazing contract, Applewood Glass started working on custom designs for the home, as the client wanted the window frames buried within the floors, walls and ceilings.

“They just wanted to see glass itself, so I came up with a design based on using some standard extrusions from local suppliers. In this case, we used Commdoor Aluminum, and I modified some of their sections to suit the details,” Menecola says.

The timing of the install for the project couldn’t have made things more difficult, as it landed in the middle of winter.

Project: Main house, 4,000 square feet; Pond House, 700 square feet

Glass spec: 6 mm low-iron annealed/1.52 mm clear PvB interlayer/6 mm low-iron Saint Gobain SKN 176 low-E annealed on #4 surface/15 mm black stainless steel spacer with argon/6 mm low-iron HS/15 mm black stainless steel spacer with argon/15 mm low-iron teempered

Glass: Tvitec

Curtain wall: Commdoor

Lift and slide doors/swing doors: Aluk

Pivot doors: Oikos

Silicone: Dow

Architect: Architects-Alliance

“It couldn’t have been a worse time, quite frankly, but we got through it. The contractor was very cooperative,” Menecola says.

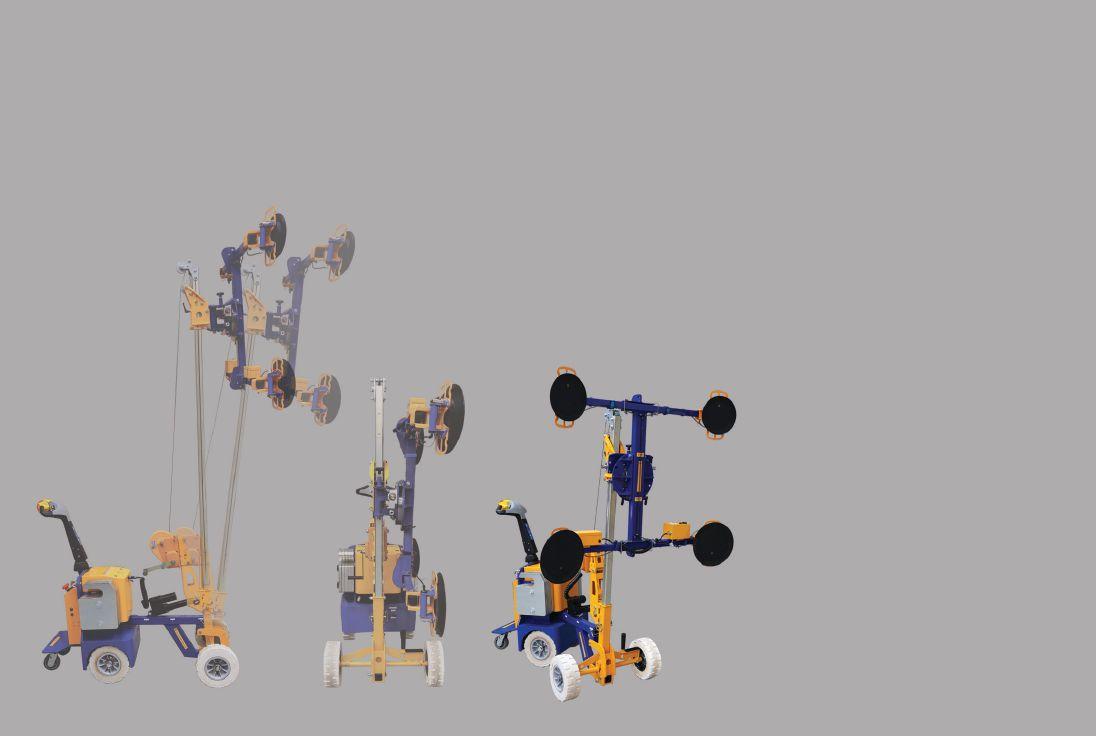

The largest pieces of glass weighed over 5,000 pounds and were 24 feet long by 10 feet high, and triple glazed. The smallest pieces of glass weighed approximately 3,500 pounds. There were about 25 pieces that needed to be installed. “They were all oversized,” Menecola says.

To perform the install, Applewood Glass borrowed a custom-built piece of lifting equipment from a glazing contractor in the U.S. “It’s basically an outrigger with a counterbalance weight. Because most of these big pieces went under a very large overhang, you couldn’t crane them in traditionally just by picking it up with a with a large suction cup,” Menecola explains. “It had to be offset to clear the overhang, so that part was extremely challenging. But without this piece of equipment, I don’t know how we would have done it because you couldn’t physically lift them.”

The glass had to come via container ship from Spain, which came with its own set of challenges.

“We had some issues with the glass because it came via container over the water and we had some breakage issues,” Menecola says. “The glass was so big it was sticking out of the top of the container. So, we had to go with an open-top container, and it took some abuse from ice, wind and snow. Some pieces came that were broken, unfortunately, so they had to be reordered.”

While Menecola was worried about breakage during the installation, no pieces were damaged during that phase of the project.

“The crew we had on site was fantastic. They did an excellent job and we came out with no breakage at all,” he says. “Being that they were so heavy, I had that concern in the back of my mind but at the end of the day, it all came out fine.”

The installation won Applewood Glass the OGMA Award for Execution. The judges noted, “This modern glass house, in using glass as a logical design response to its picturesque and rural setting responds to the contemporary reality of high energy costs and heightened environmen-

tal awareness. The solution – large, heavy, and fragile triple-glazed IGUs – opened the doors to other significant challenges, namely logistics and installation.”

“It was a highly custom design, both from an anchoring point of view and the fact that we modified some of the frame and buried it into the walls and floors to make it look seamless,” Menecola says. “We managed to use a curtainwall system, which usually is exposed, but we were able to bury it all. And, of course, we designed it in such a way that you can access it if there was ever an issue with servicing or replacing broken glass.”

The OGMA judges stated that, “The completed project is a clear demonstration of the uncompromised realization of the design while successfully overcoming the challenges of execution.”

“There were a lot of challenges on the project, but we managed to force through and get it all done. And at the end of the day, the project came out really nice and the owner was very happy,” Menecola says. “I’m very proud that we did it. It’s a really good project for us to showcase.” •

Fenestration Canada is proud to welcome Adrian Edge to its technical team as director of codes and regulatory affairs. Adrian will work under the guidance of Fenestration Canada’s technical director, Terry Adamson. When asked about his upcoming role, Adrian had the following to say: “To the members and community of Fenestration Canada, I am deeply humbled and excited to share my transition to the role of director of codes and regulatory affairs for Fenestration Canada. Over the last five years, I’ve enjoyed guiding our Pacific chapter, working with various task groups to develop the groundwork for a national certification system for window and door installers and participating in many other groups to help facilitate progress for our industry alongside our incredible members. In this role, I’m dedicated to three core goals in support of our industry. As a representative of our members, I am looking to build strong, long-lasting relationships with the various representatives involved in the codes and regulations that govern our industry and work toward a shared vision of how the future of fenestration could look. I will document, educate, and share to bring better clarity and transparency to the framework and decision-making about the codes and regulatory efforts that affect

Fenestration Canada plays a crucial role in this evolving landscape.

us. Last, I will act as your champion in the various arenas to advocate for language both simpler and more effective so we, as an industry, can regularly practice within the guidelines of the codes and ensure enforcement of those guidelines is practical. Excited to work for you all. Look forward to supporting you all very soon.” Adrian officially begins his role in September.

The Fenestration Canada Commercial Chapter was launched in spring 2023 and it has been a busy year. Brent Friesen of Acro Aluminum is our chair. Geoff Shellard of Guardian Glass is on the board of directors. We have dozens of new commercial members. Presentations from our monthly meetings have addressed the National Energy Codes, stick versus unitized curtainwall, glass coating protection and the Finishing Trades Institute. We launched the Canadian Glazing Conference that was held April 9 in Surrey. It was a huge success with over 160 attendees and 18 exhibitors. Terry Adamson is providing glass standards advocacy with the Canadian General Standards Board.

Fenestration Canada’s recruitment task group has been created to bring together members, government officials and educational providers with the common goal of promoting and educating others about fenestration. Paul Warltier from Competition Glass is our recruitment task group chair. We’ve met with Ontario’s Ministry of Education and showcased glazing at the Queen Elizabeth Secondary’s career fair as well as the New Generation Trades Expo. Some of the other task group initiatives include making social media videos and collaborating with North American Contractor Certification and the Finishing Trades Institute.

Our new job board is now live on the FenCan website. All FenCan members are encouraged to post job openings. We are also looking at creating a resume/job seeker board. More information can be found at fenestrationcanada.ca.

At the Facades Plus Conference held on May 21 in Vancouver, glass and aluminum were being presented as poor choices for building materials due to embodied carbon in favour of mass timber and terra cotta. In the words of Patrick Flannery, your products are the Devil. The battle for the wall is far from over. Fenestration Canada plays a crucial role in this evolving landscape, representing and advocating for the Canadian commercial glazing industry. FenCan stands at the forefront, ensuring that glazing businesses are well-represented and that their contributions to sustainable construction practices are recognized. Fenestration Canada’s commitment to advocacy is essential in navigating these changes and highlighting the benefits that glass and aluminum offer.

Join Fenestration Canada’s Commercial chapter to access unparalleled education, networking, technical support, advocacy, and skilled worker recruitment opportunities. For more information and to join, visit fenestrationcanada.ca or contact us at info@fenestrationcanada.ca.•

by CLAUDIO SACILOTTO

When we buy windows, how do we know how good they are? Nowadays, it’s easy to quantify a window’s performance by its test results and we can be more objective in determining how well it performs. It used to be that for the average homeowner, buying windows carried the same risk as the roulette wheel. It was hit and miss. Will these windows keep the house warm when it’s cold outside? Will they leak water when it’s raining? Will they keep the house occupants safe from burglars. Standardized testing was not commonplace. Without an objective test, it is difficult to know a window’s performance value, especially with respect to its geographical location and weather exposure.

Forty years ago, we saw the introduction of the CSA A440 windows performance standard into the Building Code. CSA A440 allowed us to rate windows based on certain key performance indices. Standard methods for testing air and water tightness and structural performance were available and we could compare products based on standard test results. CSA A440 also dictated minimum levels of performance. Forced to comply with certain minimum levels for performance, windows and doors evolved in their design.

We started seeing more innovative designs such as water drainage channels. Wood was gradually replaced with alternate materials such as vinyl which facilitated the drainage path. Properly sized weatherstrip and cam-lock hardware made windows tighter against air and water infiltration. Windows are typically more impervious today than they’ve ever been.

A multitude of test labs sprung up to satisfy this demand for testing. Right now, I’m imagining a collective grunt and eyerolls by manufacturers reading this as they’re thinking, “Government cash grab to require testing of all products (in all sorts of sizes) that need to be repeated every four or five years.” (BTW, every time someone says “cashgrab,” a window test engineer gets their wings.) Working 10 years in a test lab, I’ve heard my fair share. Test labs are not run by the government.

Every time someone says “cashgrab,” a window test engineer gets their wings.

However, what has really driven the design evolution in fenestration the last two decades is the expectation for thermal performance. Building codes, city bylaws, and Energy Star are all major drivers for this exponential improvement. We will never again see single pane glass windows, uncoated glass or aluminum extrusions that are not thermally broken being sold. I wouldn’t be surprised if in a few years the common themes around efficient fenestration will be electrochromic glass, VIGs and transparent wood. Yup, you can say you first heard it here in 2024 (although this has been talked about for years).

MURBs (multi-unit residential buildings) are becoming more prevalent, especially near transit hubs and architects now demand that windows and doors meet acoustical standards meant to mitigate the noise of adjacent highways and rail transit. Because densification squeezes more people in a smaller area, there is more demand for enhanced security standards as it relates to forced entry resistance. The reality of our times has homeowners and architects requesting resistance to extreme forced entry (think mad person with an axe or firearms). Currently these demands are not code driven (yet).

Extreme weather events have necessitated impact-resistant fenestration. This is not something new, but the markets for this requirement are not just in Miami. Local codes in coastal areas on both seaboards are seeing the benefit of impact resistant windows for products traditionally reserved for Florida. Insurance companies are driving this craze. Fenestration testing can get really complex and really expensive (cue the “cashgrab”).

Long gone are the days of a simple water test in order to populate the product brochure. Each manufactured window needs to undergo a comprehensive test plan. Depending on where it’s being used, the test plan may be quite complex. If you want to make the most of your testing dollars, talk to an engineer at the test lab or certification agency. They’re the best resources to ensure that you’re covered for the market you want to sell. •

Toronto has had all the fun long enough. For the first time, Canada’s favourite trade event for the architectural glass and glazing industry will take place Oct. 17 at the Best Western Premier Calgary Plaza Hotel and Conference Centre. Plus, on Oct. 16, Top Glass West will host tours of Oldcastle Building Envelope’s 72nd Ave SE fabrica-

• Windows, Doors & Curtain Walls

• Insulating Glass Units

• Fenestration Computer Simulation

• Safety Glazing

• EIFS

• Cladding & Building Systems

• Air Barriers

• Thermal Performance

• Condensation Resistance

• Instrumentation & Test Equipment

tion facility where attendees can see how architectural windows, curtainwall, entrances and storefront are made. Space is limited so register today!

Four education sessions will cover the hot industry topics of the day. Top Glass sessions are recognized by most professional organizations as eligible for structured learning credits, so architects and engineers can pick up the credits they need to maintain certification. Attendance certificates are provided.

Registration for Top Glass West is free courtesy of Canada’s top commercial glass and glazing suppliers. Visit over 20 exhibitors on our bustling show floor.

Top Glass West is proud of our support from Canada’s national and regional industry associations. Say hi to your friends from PGAA, GAMA, Fenestration Canada and FGIA at Top Glass West.

Let’s get together. See you at Top Glass!

October 16

Time: Ongoing throughout the day

Tour the Calgary location of one of the world’s largest architectural glazing fabricators, Oldcastle Building Envelope. Attendees will see architectural windows, curtainwall, entrances and storefront being manufactured and get all their questions answered by Oldcastle’s production experts. Space is limited so register today!

October 17

9:00 Show opens

10:00 Office to Residential Conversions: The challenge for glaziers

Presenter: PGAA

COVID has had at least one lasting effect on the architectural glass industry: a seemingly permanent reduction in demand for commercial real estate. Working from home is the new normal in dozens of industries that used to populate office towers, leaving building owners with vacancies that will take years of natural demand growth to fill. Rather than wait, some have decided to convert their commercial space into residential apartments and condominiums. Some of these don’t require changes to the facade but some do. In this presentation, hear from experts who have executed these projects and the special challenges and considerations they faced.

11:15 Emerging Technologies in Glass

Presenter: Amy Roberts, FGIA

Sometimes it feels like there’s nothing new under the sun when it comes to glass as a building material. But in fact, innovation is charging ahead in the architectural glass space creating exciting possibilities for the future – especially in the areas of thermal performance and embodied carbon. Amy Roberts, FGIA Director of Canadian and Technical Glass Operations, takes the stage at Top Glass West to tell us about vacuum insulating glass, photovoltaics, aerogel IG fill, dynamic glass, thin glass, composite panels, ransparent bamboo and concrete, smart glass and low carbon glass.

12:15 Lunch break

1:15 WHO PROFITS?: Lifting the burden of whole-building performance commissioning

Presenter: Anton Van Dyk, Layton Consulting

The world of low-carbon building construction is moving inexorably toward whole-building performance commissioning where projects will be evaluated and approved based on their overall carbon impact rather than the cobbled-together operational and embodied contributions of their individual parts. This means that, before they even generate a quote, glazing contractors have significant work to do to verify their products’ performance in a particular building detail. Worse, changes made to any other part of the building could send the glazier back to the drawing board to make upgrades or downgrades to their product in midstream. Anton Van Dyk of Layton Consulting has seen how this works to kick the can of performance verification down the chain to contractors and has some ideas for how this system could work better for all concerned.

2:30 Size Shouldn’t Matter, But It Does: New work to standardize thermal performance data for fenestration without defined assembly sizes

Presenter: Terry Adamson, Fenestration Canada

Establishing and certifying the thermal performance of a particular fenestration detail can be a thorn in the side of all concerned. Test data for units and mock-ups obtained at model size can be challenged when different sizes or designs are specified, necessitating new testing that adds cost and time to projects. Certified thermal results can be invalidated with size or design changes that can result in significantly different thermal performance. Industry stakeholders across the continent are looking at ways to model thermal performance across a range of detail sizes using software tools that can provide acceptable results for the specifiers. Fenestration Canada is part of those discussions and Terry Adamson, FenCan’s Technical Director, will give us the inside scoop.

4:00 Show ends

by RICH PORAYKO

Rich Porayko is business development director for Fenestration Canada Commercial

In his introductory remarks for the Facades Plus Vancouver conference held in May, Ryan Bragg, corporate and commercial principal at Perkins and Will, discussed the importance of considering not only operational carbon in building designs but also embodied carbon in specified materials. He particularly mentioned that glass and aluminum are materials that are quite high in embodied carbon. The operational carbon benefits of using triple glazing in southern B.C. may be offset by the embodied carbon incorporated in that extra lite of glass. During the panel on Indigenous Envelopes, architect Kate Gerson from Dialog addressed the new First Nations Health Authority office project. She stated, “Admittedly, the facade does include a lot of aluminum and glass, which, we’ve been reminded, are not ideal materials to use these days.”

When describing the early design stages of Winnipeg’s Fort Whyte Buffalo Crossing building, Stantec principal, Michael Banman, said, “At this point, most of the design was intuitive, based on first principles. We can’t have a lot of glazing and need to be really strategic where it is. We need a compact shape. We want to minimize the facade to the north. As architects, we understand these things and this was all largely intuitive.”

The project was analyzed by Stantec’s energy and environmental experts and they came back with a triangle-shaped building. According to Banman, their response was, “Don’t touch it, don’t move it, don’t do a thing. Don’t even move it 0.1 degree.”

“That was the exact right location in this world to maximize the buildings ability to balance energy in terms of the number of windows, type of windows, the location of the windows, the access to natural light and the exterior shading,” recalled Banman. “In the winter, we don’t just want the

Who knew there was such a big difference with spacers?

daylight in, so we specified a glazing that maximizes solar heat gain. We can’t afford the energy to pump that heat out of the building in the summer. We needed exterior solar shades. It’s not enough to let the heat in and then deal with it then. This is a mass timber building and has huge sliding screens attached to the very top of the parapet for exterior shading.”

Who knew there was such a big difference with spacers? Banman told attendees that there was a 65 per cent increase in energy from one spacer type alone. “That’s outrageous. If you’re dealing with a high-performance building, the spacer becomes incredibly important.”

Being a nature preserve, it’s not surprising there is bird-friendly glass. “This site has a lot of history of bringing waterfowl back to Winnipeg,” Banman said. “The unusual thing is the low-E coating is on the number three surface and you expect it to be on the number two. Many, many, many glaziers called to tell us that we have it wrong. We can assure you that we don’t have it wrong. It is correct. It’s just not what you are used to.”

J-F Robert, president of Blackcomb Facade Technology, shared insights from some notable projects his company has completed in the region. “You don’t need a Passive House-certified system to install a fenestration system in Passive House project but it’s a really good starting point,” he told attendees. The Raico system they use lends itself to complex shapes. “The steel system is rated for super-heavy glass loads up to a 3,300 pound IGU,” Roberts reported. “The timber system helps reduce the embodied carbon and has the least amount of aluminum because the timber is actually taking a big part of the wind load. The glazing pockets are shipped from Germany and the timber is local. Our preferred path to further reduce the carbon footprint is to source glass locally through Garibaldi Glass.”

“The Butterfly is a beautiful building in downtown Vancouver by Westbank,” said Robert. “Very fancy condos. They have a 50-meter-long pool where the glazing system is essentially a five-sided glass box. It is supported by GFRC ribs on the inside, which makes you feel like you’re on the inside a whale. We used silicone gaskets on this project to do all the joinery. RDH did a significant amount of testing and everything passed beautifully.” •

When it comes to thermal performance, U won’t believe how many choices Vitro Architectural Glass offers to improve both R- and U-values. Whether it’s pairing our Solarban® 70 low-e glass with new Sungate ThermL™ glass or using VacuMax™ Vacuum Insulating Glass, we can help you achieve better R- and U-values than ever before.

Ready to put more U in your specs? Let us show you how. vitroglazings.com/uvalue

Our family-owned company offers Corning® Med-X® Glass: high-quality transparent protective shielding against x-ray radiation:

• Extensive Radiation Shielding/ Leaded X-Ray Glass Stocked: Largest Available Sizes in the Industry, Biggest Inventory in North America

• Customizations & All Plate Sizes & Thicknesses Cut Specifically to Customer Requirements, Delivered Direct to Job Site

• Single Source Supplier (Including Fire-Rated Systems & Switchable Privacy Glass), In-house Lamination & Print/Film Division, +250,000 SF of Production Space

Contact your local account managers today: Chet Gillaspy Territory Manager, Performance Products Call: (856) 597-0803

Email: cgillaspy@mcgrory.com

Rocco Ficara, Français et Anglais Territory Manager, Performance Products Call: (856) 579-0307

Email: rficara@mcgrory.com Scan the code to visit our website, med.glass, for more information.