Labor-Saving

Grove Shims has the perfect shim for every job every time. Our 3”x 4” Horseshoe Shims are available in 9 thicknesses.

Looking for the right shim?

Grove Shims has the per fect shim for all your shimming needs.

With color-coded shims and solid thicknesses, the right shim can be easily applied for perfect allignment. No guesswork or realigning. Our shims save you time and money.

Need help? Just ask! We’re here to help. 978-534-5188

Visit us online to see all of our available solid 3x4 Shims. www.groveshims.com

Free Samples are Available Upon Request.

Grove Shims is the leading producer of plastic structural shims. We have been in business since 1962, making shims since 1975, our family-owned business provides prompt, personalized attention to each order. In addition to our large line of in-stock shims, we will custom fabricate parts to meet your unique requirements. Unlike many competitors, our shims are solid and do not have hollow voids, so you can depend on them in crucial, load-bearing conditions.

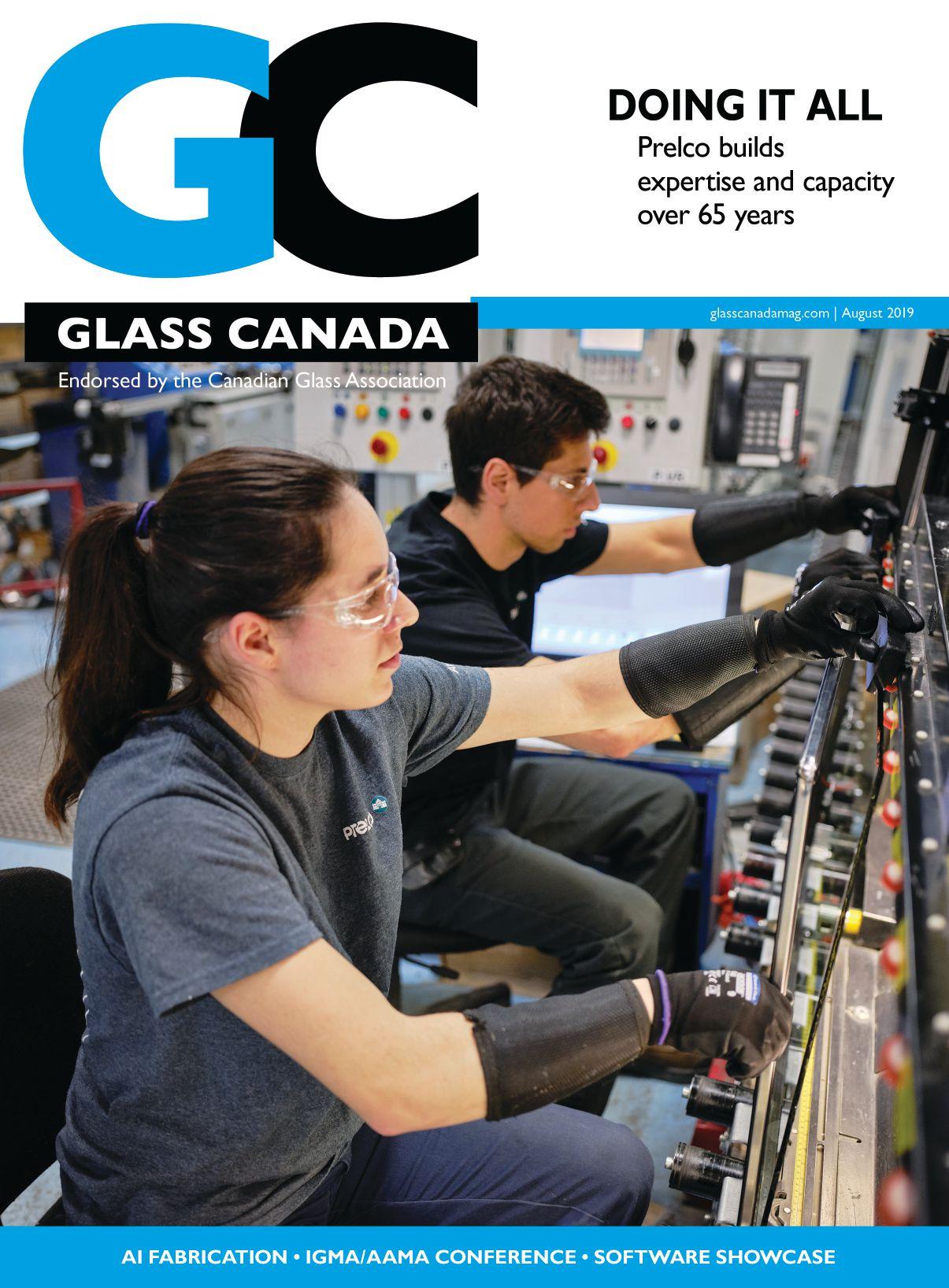

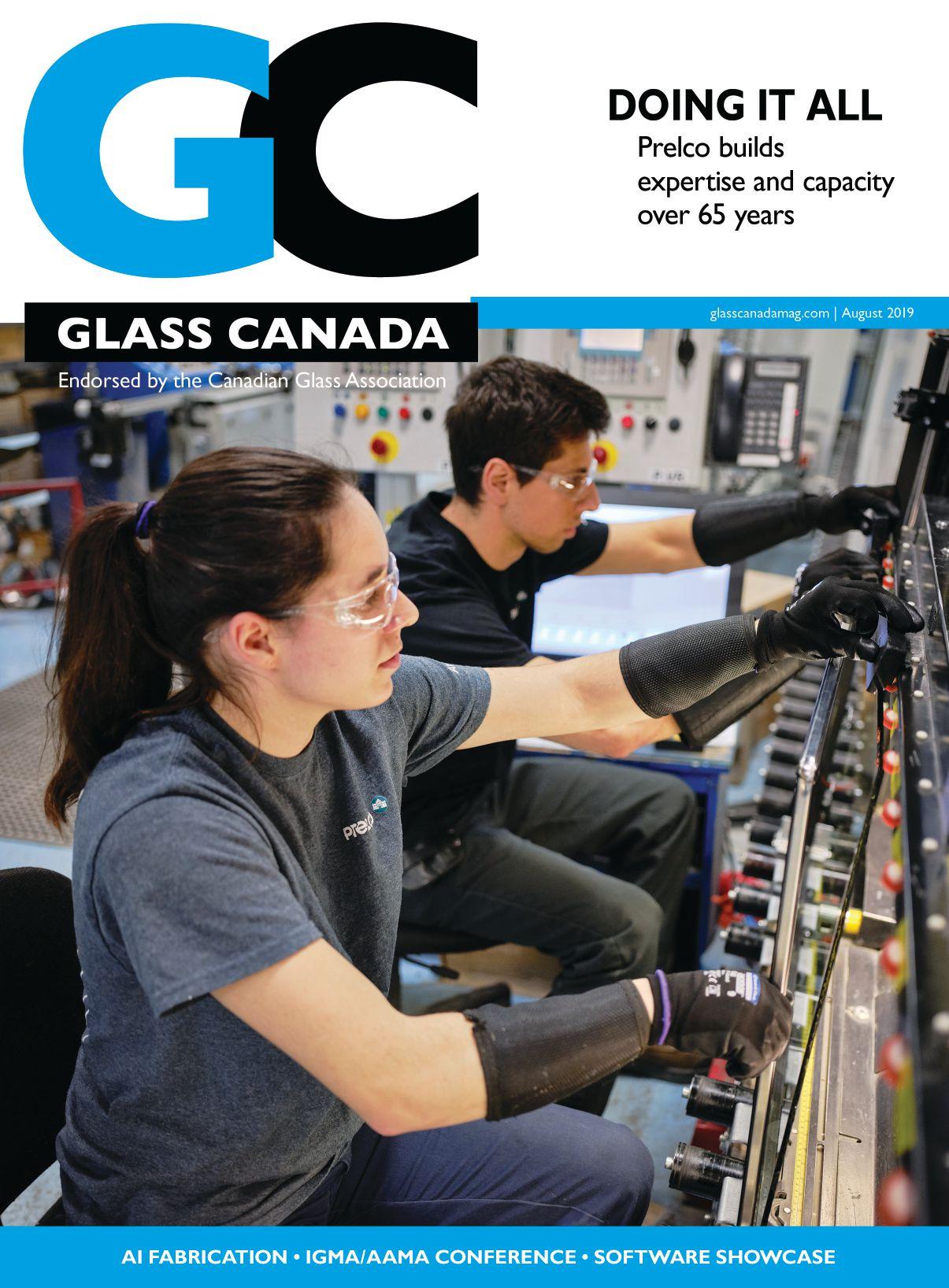

Prelco has steadily increased and expanded its capabilities since it’s origins in 1954, but cherishes its roots in Riviere-du-Loup, Que.

Curated content

18 Operation optimization

The promise of artificial intelligence in manufacturing lies less in automation of processes and more in effective collection and use of data.

22 Software showcase

Check out these new products for BIM modelling and managing your business. 24 Better together

Our report from the AAMA/IGMA joint conference in Victoria.

You’ll find everything in the print edition of Glass Canada magazine and more online. Articles are organized into categories for your convenience. Whether you are a contractor, a fabricator, looking for the latest updates to codes and standards or just browsing for the latest news, there’s a section with the information you need right at your fingertips.

Give them control

EDITORIAL

People work better when they own their jobs.

I’m reading a book called Lost Connections by Johann Hari. It’s about depression and anxiety and explores some reasons why these problems are growing so fast in recent decades, especially in developed countries. Hari discusses a number of inter-related possibilities, but one part in particular caught my eye as being relevant to employers everywhere.

Hari references a study done of British civil servants in the 1970s. The researcher, Michael Marmot, wanted to find out who was more at risk of stressrelated heart attacks: the bosses at the top, or the lower-ranking workers. The assumption going in was that the bosses would be most at risk because of the higher levels of responsibility they had.

GLASS CANADA

August 2019

Volume 31 • Number 4

Annex Business Media

P.O. Box 530, Simcoe, Ontario N3Y 4N5

EDITOR | Patrick FLANNERY pflannery@annexbusinessmedia.com 226.931.0545

ASSOCIATE PUBLISHER | Danielle LABRIE dlabrie@annexbusinessmedia.com 519.429.5187

NEXT ISSUE

Marmot’s study found the opposite. The lower the bureaucrats were on the 19-layer totem pole, the higher their levels of stress. Through interviews, Marmot was able to narrow this down to a more specific source. He found that those with more control over their jobs had less stress. The workload, the pay, the level of responsibility and the difficulty and complexity of their tasks seemed to matter much less than whether they had decision-making power and the freedom to structure their work and solve problems as they saw fit. Despite the fact that everyone from bosses down to typists essentially had desk jobs that involved pushing paper all day, the bosses were happier because they got to decide what they were doing and how to do it from hour to hour.

• Quality

• Furnaces

• Carey Glass

This clicked with me because so many of the labour management trends I’ve watched over the last 30 years seem to be going in exactly the opposite direction. “Lean” processes are an example. Every Lean workshop I’ve sat in calls on companies to break down their processes to essential tasks and create hyper-analyzed plans to maximize the efficiency of literally every step an employee takes throughout the day. Now, there are ways to implement this with employee input so they retain a degree of control over the process. But the end result seems to me to be a work day where the person spends most of their time robotically carrying out the same sequence of tasks. Maybe some of that is unavoidable in manufacturing operations, but I’ve seen the same thinking brought to service and office jobs. In an effort to boost efficiency, employers strip even complex government jobs down to their basic elements, distribute each element to a different worker and automate as much as they can.

My instinct runs completely counter to this and I think Hari’s insights back me up. I’m a fan of hiring competent people and holding them accountable for results. How they get those results is a lot less important. Attach incentives for contributing to higher-level goals that match your own. Give them broad powers to get involved in whatever parts of the business they need to in order to reach those goals. Maybe employees will find new ways to do their jobs, or even invent new jobs, that take your company to places you didn’t even imagine. And along the way, I bet they will be happier, more productive and stay with you longer. Giving people responsibility. Call it a new management fad. •

ACCOUNT COORDINATOR | Stephanie DeFIELDS sdefields@annexbusinessmedia.com 519.429.5196 | 888.599.2228 ext. 257

MEDIA DESIGNER | Alison KEBA

VP SALES/GROUP PUBLISHER | Martin McANULTY mmcanulty@annexbusinessmedia.com

COO | Scott JAMIESON

Publication Mail Agreement #40065710

Printed in Canada ISSN 0843-7041

CIRCULATION

email: asingh@annexbusinessmedia.com

Tel: 416-510-5189

Fax: 416-510-6875 (main) 416-510-5133

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

SUBSCRIPTION RATES

Canada - 1 Year $37.00 (plus tax)

U.S.A. - 1 Year $65.50 (in US dollars)

Occasionally, Glass Canada will mail informationon behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com

Tel: 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.glasscanadamag.com

NEWS

GPD goes to next level

The opening ceremony of the Glass Performance Days 2019 conference took place in Tampere, Finland, on June 26. The event got off to a great start with an impressive number of 750 international glass specialists gathered together in the TahtiAreena exhibition and sports centre, which combined music and lights, and above all, a place to share knowledge. With the theme of “All eyes on smarter glass,” a global lineup of speakers gave their views on the glass business and the importance of embracing and implementing new technologies.

The opening words of the GPD event were given by Jorma Vitkala, chairman of the Organizing Committee. “This year, the focus is very much on the future. Smart cities, smart buildings and smart glazing are our future. Changes are happening faster than ever before. But we need to continue being the catalysts for ideas and innovation. Since 1992 when the very first GPD took place, more than 14,000 delegates have participated, over 3,500 presentations have been given and some 11,000 pages of technical documents have been written,” he shared. “GPD has truly become a unique platform for trustworthy information.” It was Vitkala’s last time leading the event, as he has retired as chairperson.

A star-studded lineup of speakers followed, including Arto Metsanen, CEO and president of Glaston; executive director of the city of Tampere, Teppo Rantanen; Stefan Blach of Studio Libeskind; Mike Pilliod, director of manufacturing innovation at Tesla; and Sener Oktik, CTO of Sisecam.

Metsanan strongly emphasized the importance of collaboration in the industry. “The global need for environmental energy and sustainability is reshaping the nature of glass. Energy efficiency has always been a challenge. As a material, though, glass is very competitive in terms of CO2 reduction. It provides a unique opportunity for the sustainable development of the world. But we can only succeed if we work together. No company or individual can do this alone. That’s why we introduced Step Change.”

At the end of the opening ceremony, James O’Callaghan from Eckersley O’Callaghan was announced as the recipient of the Jorma Vitkala Award 2019 in recognition of all the great job he has been doing throughout his life to the development of structural glass designs, sharing his knowledge around the world and being a true contributor for the entire glass industry.

McKenna named marketing manager for Vitro

Nathan McKenna has been named marketing manager for Vitro Architectural Glass. In his new post, McKenna will provide marketing support for Vitro Glass’s residential, commercial and specialty divisions. He also will oversee the company’s marketing plans and support its architectural teams throughout the United States and Canada. McKenna joined Vitro Glass in 2015 as a national architectural manager. He had previously worked at Columbia Commercial Building Products in Dallas,Texas, where he served as glass division manager.

“Nathan brings more than a decade of experience in glass fabrication and architectural sales to his new position,” said Patrick J. Kenny, vice-president of marketing. “He is a proven problem-solver and understands the performance demands architects, specifiers, fabricators and contractors face.”

CGA Newsletter

CGA

Weare trying to “activate” the Canadian Glass Association with certain issues as our driving force. One idea is to build interest within the national glazing community to work with the Canadian General Standards Board and re-write the CAN/CGSB 12.20 structural standards for architectural glass. We’ve heard from some members that there is renewed interest from the industry (in Alberta and B.C., especially) to update the standard. CGSB officials tell us the main obstacle to proceeding is funding from the glazing industry. This could be a job suited for the CGA as the CAN/CGSB standards are of national interest. With the Canadian Glass Association leading a combined effort of the provincial glass associations, we could try to raise the necessary funds and contribute technical input to the update. We need feedback from our provincial member associations to gauge interest in embarking on this long-term mission. Please email David Langton (dlangton@

Canadian Glass Association PO Box 36117, Surrey, BC V3S 7Y5 Tel: 778.571.0245 fen-bc.org > Canadian Glass Association

compglass.com) or Zana Gordon (zgordon@fen-bc.org) with your feedback, suggestions or other ideas.

FenBC

FenBC is very active at this time. Save the date for the FenBC Industry Conference on Oct. 23 at Northview Golf Course in Surrey. We are in the process of confirming a few of the speakers. We will be sending out notices soon. The program will include eight sessions –four for commercial contractors and four for manufacturers. We will be bringing back the popular keynote breakfast panel “The Code Talkers.” Our keynote lunch speaker is to be determined.

The FenBC Annual Golf Tournament was another success. Great weather, good friends, superior course and good food. Thank you to our sponsors, Cascade Aquatech, PFG Glass and Competition Glass. Watch for further announcements on the FenBC Annual Golf Tournament coming in May 2020.

FenBC is working with the Canadian Glass Association to re-establish it as the national entity for the commercial glazier industry in Canada.

The glazier apprentice Red Seal training program is up for review. FenBC will be working to support the process of reviewing the Red Seal Occupational Standards for glazier training.

PGAA

TheProvincial Glaziers Association of Alberta is in full swing with its new executive which was elected in March 2019. The annual golf tournament is scheduled for Aug. 15 in Innisfail.

Earlier in the year at a Glass and Metal Association dinner meeting it was announced that the Edmonton glazier training campus was being closed indefinitely, which caused extensive anxiousness especially with northern Alberta glazing firms. Just recently, the Northern Alberta Institute of Technology has announced that they will be offering the program in Edmonton, which was comforting news. Calgary and Edmonton glazier programs are running strong with substantial continued commitment from the industry. Calgary glazier program instructors are currently updating course handouts to reflect the recently updated program, which was completely rehauled by the provincial apprenticeship committee (PAC) over a five-year span (2012 – 2017). They are almost done with the update. Edmonton handouts are up-to-date. A PAC meeting was held in late June where course content was reviewed and will be continually enhanced over future PAC board member engagements.

AGMCA

All

member companies of AGMCA support the Finishing Trades Institute, with training centres located in Toronto, Ottawa and Hamilton, Ont. FTI is the officially designated training delivery agent in Ontario for in-school classes of the apprenticeship program for our very specialized trade, architectural glass and metal technician.

FTI apprentices are trained using the latest equipment and techniques. We oversee training and student progress through the system, together with our union counterparts, via the Ontario Glaziers Apprenticeship Training Committee, or

OGATC, of which three directors of AGMCA are volunteer members.

To that end, at a recent visit to our training centre, Ontario premier Doug Ford was pressed by AGMCA to keep government support for our apprenticeship programs flowing, as we are all well aware of the oncoming shortage of skilled trade workers. Further exposure to trades is also required at the high school level and students need to be informed about the highly skilled and well-paying careers available to them through our trade.

OGMA

ENERGY SURCHARGES:

Please read Frank Fulton’s You Bet Your Glass column on the back page then do your part by calling your glass supplier to lobby them to do the right thing by dropping their ESC. Send your feedback to Frank at fultech.fc@gmail.com.

FISH ON: Be ready to get on a boat bright an early in Port Credit on Thursday, August 22, for what is always a fabulous day on the water hunting salmon with your friends and colleagues. Flyers are out and all you have to do is sign up and get up early.

FALL GOLF: Plan now on being at The Country Club in Woodbridge on Thursday, September 12. Members will be seeing a flyer in their inbox any day now.

JOINT OGMA/CSC

SEMINAR DAY: The OGMA are teaming up with the Toronto chapter of Construction Specifications Canada to put on a spectacular program of informative and interesting topics. The event will be held on Thursday, Nov. 14, at the Richmond Hill Country Club. Details to follow.

Ontario premier Doug Ford (centre) visited the Toronto Finishing Trades Institute training facility in June. With him is Angelo Cairo of Stouffville Glass (left) and Noel Marsella, AGMCA executive director.

Salem buys HHH Tempering

Salem Distributing of Winston-Salem, N.C., has announced its acquisition of HHH Tempering Resources, a fabrication machinery provider. With this move, Salem aims to substantially increase its foothold in the flat glass industry it serves as Salem Flat Glass and Mirror. The acquisition is described as a strategic move in Salem’s greater vision of providing the glass industry with innovative solutions and unmatched service.

CEO and owner of Salem, Mike Willard, stated, “Our core focus is to grow and enrich the quality of our employeeowners’ lives while delivering success to our customers. The acquisition of HHH will expand these efforts and help us achieve our goals of growing our company while staying customer-focused, accountable and solution-oriented. We believe the great reputation for quality products and technical service that HHH has built is a fit for the Salem family.”

HHH will continue providing glass tempering machinery

and technical service. Mike Synon, HHH president and CEO, as well as the rest of the HHH technical and leadership teams, will stay in place. Synon said, “We’re excited to join forces and become part of the Salem family. The entire HHH team looks forward to continuing to serve the needs of North American fabricators.” HHH headquarters will relocate to WinstonSalem following the acquisition.

Schmidt to lead sales for Glaston

The Glaston Group has appointed Michael Schmidt vice-president of sales and marketing for North America. He will be responsible for the integration, organization and oversight of the sales team in North America for both the Glaston and Bystronic glass portfolios. Schmidt is a 20-year veteran of the glass industry with extensive knowledge of glass fabrication processes and solutions throughout the commercial and window and door industries.

Johnson elected IGCC president

The Insulating Glass Certification Council (IGCC) recently completed its 2019 annual meeting in Tampa, Fla. In recognition of his many years of dedicated service to the organization, public interest board member Dennis Johnson of Raths, Raths & Johnson of Willowbrook, Ill., was elected president of the organization.

“Dennis’s dedication to the principles and initiatives of IGCC has been significant over the years. He has a particular ability to apply his keen technical background to the discussions of the organization while always keeping the IGCC mission of assurance to the public of product quality and performance forefront,” says John Kent, IGCC administrative manager.

The meeting agenda was full, as usual, with numerous initiatives moved forward. The IGCC renewed support of the Rapid Assessment Chamber effort to develop a test method that can evaluate IG unit performance in a shorter time than the current ASTM E2190 standard. Further data is expected this fall with a correlation study anticipated in early 2020. With the recent release of the 2019 versions of ASTM E2188, E2189 and E2190, the IGCC will review the implementation of these standards revisions as they apply to IGCC-approved testing laboratories and the IGCC/IGMA certification program. Specific direction will be provided to all IGCC/IGMA participants. There remains interest in bringing the IG certification process for both the U.S. and Canada closer together. Differences in the IGCC/IGMA ASTM E2190 program and the IGMAC CAN/CGSB 12.8 programs were compared and best practices identified. IGCC approved moving forward with this effort through continued dialogue with IGMA/IGMAC.

Final approval was established for insulating glass component codes. More than just a way to identify components, these codes serve as the definition of generic equivalency between products and affect the required IG testing. This project has been a thorny issue for many years as it will influence alternate sources of supply for fabricators. However, the guidance established should put to rest discrepancies between how this matter was handled in the U.S. and Canada, furthering North American harmonization.

COMING EVENTS

Aug. 15

PGAA Golf Tournament Innisfail, Alta. pgaa.ca

Aug. 22

OGMA Fishing Derby Mississauga, Ont. ogma.ca

Sept. 12

OGMA Fall Golf Toronto, Ont. ogma.ca

Sept. 17

GlassBuild Atlanta, Ga. glassbuildamerica.com

Oct. 11

Facades Plus Toronto, Ont. facadesplus.com

Oct. 23

FenBC Industry Conference Surrey, B.C. fen-bc.org

Nov. 12

IG Fabricator Workshop Plano, Texas igmaonline.org

by DAVID HESKA

David Heska, P.Eng. is a director with WSP’s building sciences team in southwestern Ontario. He oversees the operation of the Hamilton, Kitchener and Windsor offices. David has been involved on window simulation projects as well as the design and replacement of windows in commercial and residential buildings. He can be reached at David.Heska@wsp.com

The writing on the (glass) wall

When the mayor of New York City commemorated Earth Day in April stating that he would “introduce legislation to ban the glass and steel skyscrapers that have contributed so much to global warming,” many in our industry took note. Did the mayor actually mean that he would ban glass or was this another classic example of hyperbole? Three months later we are all still here, buildings continue to be constructed in New York City with glass, and the sky has not fallen. However, the intention of the mayor’s statement is clear: we need to build better buildings.

Closer to home our provincial governments have been taking steps to improve our building stock. B.C. seems to always be a few steps ahead with Ontario typically following along after. Some of our readers may be aware that the July 1 deadline for buildings in Ontario to report on their 2018 energy use has come and gone. All commercial, industrial and multi-unit residential building owners are now required to report the equivalent electricity and natural gas usage of their buildings per gross floor area. For this year’s deadline, any building greater than 100,000 square feet was required to submit, but next year the threshold drops to any building greater than 50,000 square feet. So what does this have to do with the glass industry? This background information goes to show that the push for better-performing window wall and curtainwall systems with lower U-values is not going away. It is going to increase.

To be honest, I’m happy we are getting serious about improving the performance of our buildings. In 2009. Natural Resources Canada released a report outlining the energy use intensity

The push for better-performing systems with lower U-values is not going away

THE ENGINEER

of Canadian buildings. Those constructed between 1920 and 1999 generally had an energy use intensity of around 300 equivalent kilowatt hours per meter squared. But after the year 2000, guess what happened? The energy use intensity of buildings jumped to over 350 ekWh/m2. I won’t join the New York mayor in blaming the glass and steel industries (since we were simply responding to the market trends). If clients and architects are asking for more glass, then we can give them more glass. But the question now becomes what will be done going forward. The IGMA Emerging Technologies Committee provided a good report at the recent conference in British Columbia highlighting some trends. The solution will not be easy. It will require innovation and investments, and mistakes will be made along the way. But we need to figure out how to reduce air leakage through our window wall and curtainwall assemblies. We need to continue to improve the thermal performance of these systems at the mullions and at the centre of glass. Partnerships and collaborative testing between companies needs to increase along with engagement with our post-secondary institutions.

The next-wave energy use intensity data should made public in the next few months. But until then let’s roll up our sleeves, innovate and improve our built environment with glass that’s durable and efficient! •

Over 55 years’ expertise in engineering and manufacturing vacuum lifting equipment.

Our engineers follow the high standards set by the American Society of Mechanical Engineers (ASME) to design the safest possible equipment.

WE TEST EVERY SINGLE PRODUCT

While many companies only test random samples, at Wood’s Powr-Grip, we test each and every product to ensure consistently high quality.

CUTTING-EDGE TECHNOLOGY

Exclusively from WPG, Intelli-Grip® Technology monitors vacuum and power systems to maximize safety and efficiency while simplifying maintenance and repairs—and so much more!

The (almost) everything glass company

Prelco supplies glass for multiple applications.

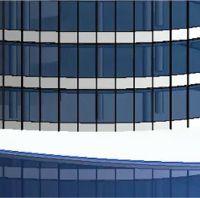

Silkscreened insulating glass, low-E 366 and low-E 272, on the Wilder Building at Espace Danse, Montreal. Prelco starts with the architect’s vision and works from there.

AT A GLANCE | Prelco

Group

From its beginnings in 1954 cutting mirrors, replacing window screens and broken windows, the company now known as the Prelco Group is a vertically integrated supplier of value-added glass products to architectural, transportation and defense clients.

Dominic Lavoie has been the CEO of Prelco since just June, 2018, but like many people found running familyowned businesses, he has been with the company all his young life, since 2006. Coincidentally, his father worked as an engineer with the company for nearly the same number of years (he joined the company in 1973) before purchasing it in 1987. Vitrerie Générale created Prelco in 1973 and the two companies merged to become Prelco Inc. in 1988.

That the company headquarters and main 200,000-square-foot plant remain in Rivière-du-Loup, hundreds of kilometres from the nearest large city (but only a short distance from the Trans-Canada

Highway), and never “upped sticks” to, say, an urban industrial park, is a family point of pride, Lavoie says. “This was something my father wanted. He is not from Rivière-du-Loup but when he moved here, he fell in love with the place and decided he wanted the headquarters to be here. Only during the past 19 years did we expand to other cities.”

Like other small towns (Rivière-duLoup has around 20,000 souls) that have large, good businesses, it sounds as though Prelco’s employees value not having to “move to the big city” to find quality work. “On average, our employees have been with the company for more than 15 years, although recent hires have pushed that [average age] down somewhat. Generally, when they start at Prelco, they end their careers here. I inherited that from my father. I’m really proud of that.”

Vitrerie Générale began with five employees. But a dozen or so expansions later, Prelco now employs 350 in Rivière-

Founded: 1954

Owner: Family owned

Headquarters: Riviere-du -Loup, Que.

Employees: 650

Facilities: Six factories in eastern North America

Serves: Mainly Canada and U.S., with customers globally

du-Loup and around 650 across its six production plants.

When Prelco decided to expand out of town, it proceeded rapidly, mainly by buying client companies that, for the most part, were its own customers: A new production site in Saint-Jacques, N.B., came first in 2000. Then, in quick succession, Prelco purchased Montrealbased Industries Thermalite in 2002; Belleville, Ont.,-based Beclawat Manufacturing in 2005, and Princeville, Que.,-based Veralex in 2006.

Prelco MTL (previously Thermalite) specialises in high-performance insulated

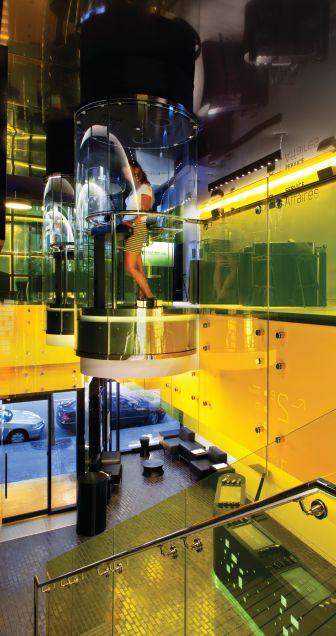

This gorgeous project, created with Vancera laminated glass and tempered glass, is in Videotron’s Montreal store. Supplying colour is a point of pride for Prelco.

glass units. Beclawat serves the marine, rail, transit and defence industries. Veralex specialises in marine pleasure craft. “Veralex and Beclawat were customers of ours. We decided to integrate them. They make frames. It was for us something that made sense,” Lavoie says.

Prelco’s foray into the United States came in the form of setting up a plant in Rouses Point, N.Y., in 2016 to facilitate penetrating the U.S. market. While Prelco’s largest market is Canada and the U.S., it has some customers in Europe and sells glass sometimes to China. “We have glass that goes to Australia too,” Lavoie says.

As a result of its growth and acquisitions, Prelco’s products now range from insulating, spandrel, structural and heattreated glass (with their many subtypes), for buildings; safety glass and frame systems for transportation (locomotives, Montreal’s Metro trains, the Vancouver SkyTrain); and glass for ground and marine defense applications such as ballistic, electromagnetically shielded and blast-resistant glass. Prelco’s marine clients include the Coast Guard, Seaspan Shipyard and the Offshore Fisheries science vessels it has built.

While the acquisitions unquestionably added expertise and verticality to the company, it is Prelco’s homegrown drive for technical superiority that distinguishes it from its main competitors, Lavoie says. “I don’t think there is another glass company in Canada with as much technical knowledge. Almost all our technical people are engineers. The knowledge we have is huge.” Specialist trades also include computer programmers, chemists and mould-making experts. “Our key assets are our technical people. Our continuous improvement team is the way we evolve,” Lavoie explains.

Among other things, the company offers turnkey solutions for framed and unframed window solutions, full engineering services, including CAD two- and three-dimensional modelling and in-house testing facilities. It possesses a range of certifications, including NIJ Standard-0101.06, EN1063 and STANAG 4569 standards, and NAVSEA.

Prelco is also Lloyd’s Registry Typeapproved.

Prelco does not make any primary glass. It buys glass stock and adds value to it – a critical point in understanding what the company does. “There is no more glass manufacturing in Canada. We purchase raw glass sheets called float glass. Our typical raw material is 130 by 204 inches. We transform the raw product to finished products.

“We see ourselves not anymore as a glass fabricator, but as experts in glass solutions. We develop them with architects, engineers and designers. We work with our customers to develop the best products. That makes us the largest glass company in Canada and one of the top 10 in North America,” Lavoie says, referring to a 2019 U.S. article that ranked

It is Prelco’s homegrown drive for technical superiority that distinguishes it from its main competitors.

top glass fabricators.

While Prelco is not particularly transparent about how it does this and that (my question about how glass that provides electromagnetic shielding is made yielded a diplomatic, “That is the secret of the recipe.”) there is plenty to say about what it does. Does a client want to block UV rays? Build curtainwall that automatically darkens as the day gets brighter (Prelco recently supplied just this kind of glass – a thermochromic glass, trade named Prel-Shade – to the CN Tower restaurant)? Keep hurricanelaunched objects from coming through its windows? Keep out bullets (Prelco has its own shooting room for ballistic glass)? Provide fire resistance? Or perhaps keep demanding air traffic controllers happy? “We do four to five air traffic control towers a year. The glass quality is really special. The glass needs to be perfect. This quality of glass is never found in commercial products,” Lavoie says.

Buying from Prelco is not like walking into a store and picking out a window. “Never,” Lavoie says. “For example, at Veralex we always sit with

Photo credit: Stéphane Brugger

the boatbuilding designer. We start with a blank page and design the most beautiful windshield we can imagine. It is the same with trains. We design the best windows for their business. Architecture...the best product that suits their needs. The architect’s name will be on

the building. He wants it perfect.”

A nice example of helping fulfill architects’ visions are buildings with silkscreened glass or digital in-glass printing. A digital printer will apply one or more layers of liquid ceramic on the surface of the glass. Images can be repeated on

several glass panels or enlarged and split between a number of panels, all in high definition. Or, a ceramic frit coating may be applied and fused with a heat treatment to the glass. Of the application of these two techniques, Lavoie says, “The main ones that put Prelco on the map are Ryerson University in Toronto and the École de technologie supérieure in Montreal. We are doing Phase II now –all jet printed.”

Prelco moves with the times. Take insulating glass, a good-sounding choice as the global warming crisis demands the development of more energy-efficient solutions. “Coatings improve the typical insulated glass. It was a niche market 10-15 years ago. Architects want to mix energy performance with esthetics, [like using] different colours,” Lavoie says.

The increase in the frequency of hurricanes is driving changes in standards too. “On the U.S. east coast, there are new tendencies toward hurricane glass –laminated so no objects can get through the glass. It is becoming a norm. The standards are changing,” Lavoie says.

Prelco is still growing. It recently doubled the capacity of its Prelco MTL plant to 100,000 square feet and is building a brand new plant for Veralex in Princeville, Que.

Is there any chance Prelco has hit a glass ceiling, so to speak, in serving new markets? Pulling a couple of my amateur notions of exotic applications out of my hat, I ask Lavoie if Prelco has supplied glass for spaceships or subsea vessels

Prelco takes pride in the fact that, on average, its employees have been with the company 15 years. They say they appreciate the opportunity to work without having to move to the “big city.”

such as bathyscaphes. “Not yet.” He chuckles quietly and adds, “I think we will get there.”

Prelco has collaborated on several projects that have attracted national attention. For instance, it supplied vision glass for the Espace C2 event facility on the roof of the Fairmont Queen Elizabeth hotel in downtown Montreal – a project recognized as one of Canada’s top glazing projects in June Glass Canada. The project required oversized Energy Advantage tempered six-millimeter exterior glass panels with black stainless steel framing, and eight-millimeter clear low-E tempered on the interior.

Prelco also got involved with a very high-profile project in the renovations to the Wilder Espace Danse building in Montreal Place des Arts. The 1918 building got a completely new facade in 2017, including silkscreened and low-E insulating glass supplied by Prelco. The building now houses the Grands Ballet Canadiens as well as three other dance organizations.

But possibly the highest profile project – both in terms of notoriety and actual height – was Prelco’s work on the CN Tower. Anyone who had been up the tower before 2017 can attest to the scorching rays that came through the clear glass on the observation deck on a sunny day. Working with Suntuitive and Pleotint, Prelco fabricated new dynamic glass panels that adapt to solar conditions without electronics or human control.

With clients like these and a growing portfolio of nationally recognized work, it is becomiing clear that there’s nothing Prelco can’t do. •

by MARGARET WEBB

Training on demand

What is an insulating glass failure? IGMA defines it as fogged units with or without sealant adhesive loss; cracked glass; damaged coatings; displaced spacer; contaminants inside the unit, loss of inert gas fill and non-flat glass which may result in a visual or thermal issue.

Two of IGMA’s main areas of focus are developing technical manuals to support the quality manufacturing of insulating glass units for long-term performance and education. Since its formation, the IGMA has offered technical seminars based on providing information on the basic components used in the fabrication of insulating glass units.

Fast forward a few years and the focus of the seminars changed with the development of TM-4100, Preventing IG Failures, a manual developed on how to handle and integrate the IG components into a successful insulating glass unit. Targeted to the manufacturing floor, TM-4100 is a dos and don’ts approach to components and quality management. Each page in the manual is designed to be posted in the corresponding area of the plant as a quick reference. The new face-to-face seminar launched in 2006 with this new focus and has expanded over the years to include how to select glass for a specific function, how to avoid common glazing errors to preserve long-term performance and how to investigate failures if and when they do occur.

Education programs are very different today than even five years ago, especially for Millennials. “Death by PowerPoint” is a thing of the past, so IGMA developed the IG Fabricator Workshop, which provides hands-on experience for participants. It also led to the development of the Preventing IG

Preventing IG Failures and the IG Fabricators Workshop is a complete training program for the novice and experienced plant worker. IGMA

Failures online program, a 12-month subscription provided directly to the employee and available at their convenience. Still based on PowerPoint, it also includes video to engage the individual.

The Preventing IG Failures online education seminar includes 10 hours of training material – available at any time, for a 12-month period – given by subject-matter-expert instructors. The program is available as a complete package or a la carte if there is a specific topic of interest. Each session is an hour long and the topics include glass receiving; cutting and washing; spacers; internal components and connectors; desiccants and desiccated matrix; sealants; gas filling; glass and glass breakage; glazing guidelines; handling glass safely; selecting glass for optimum performance; and how to investigate insulating glass failures using tried and true forensic examination techniques.

Preventing the above list of failures is what Preventing IG Failures is all about as well as determining if these failures are due to components, workmanship, glazing, installation or the environment. The seminar provides guidelines for the testing, fabrication, packaging, shipment and glassing of IG units to assist in achieving long-term performance by minimizing seal failures using existing technology for edge seal design along with the selection of sealants, desiccants, spacers, gases, glass and other components used for the manufacture of quality insulating glass units.

The combination of the online Preventing IG Failures and the IG Fabricators Workshop is a complete training program for the novice and experienced plant worker. The workshop provides hands-on experience, instantly transferable to the work environment, and access to equipment that most plant personnel may never touch but that has a direct impact on their work environment and the produced product. Preventing IG Failures provides the in-depth background to the manufacturing process to allow employees to understand the complete process; how other stages in the fabrication process affect each step in the process; and how a failure at one stage can lead to overall failure in field performance.

For further information on the program, please visit the IGMA website (igmaonline.org), call the IGMA office or visit us at GlassBuild 2019 in Atlanta. We will have the entire program available for preview. •

Operation optimization

The state of artificial intelligence

Industrial AI is still in its infancy, but future applications may include deep process optimization, improved control of robotics and safety enhancement.

If you were to ask the leaders within the fabricating and manufacturing sectors how important artificial intelligence is for the future success of their companies, most of them will tell you it’s a critical component. That said, just how far along are we in the evolution of A.I. in these sectors?

“I work with at a lot of different plants in manufacturing, as well as fabrication companies, and a lot of them are actually trying to figure out exactly where A.I. falls into place,” says Alexander Wong, associate professor at the University of Waterloo and Canada research chair in artificial intelligence. “There are some very interesting places where it can really help be a game changer in improving efficiency and quality, as well as just managing logistics.”

Wong says that many of the most recent advances in A.I. have been related to machine learning. He says companies are taking advantage of vast amounts of collected data that they’ve acquired from their manufacturing and fabricating operations and are using it to make better decisions.

“By feeding this mass wealth of data,

and instructing the machine learning algorithms to make predictions based on the data, you’re able to greater improve the efficiency and quality of the products that get manufactured,” he says.

Craig Resnick, a vice-president within the ARC advisory group (a technology consultancy), says that A.I. grows as part of an evolution, not a revolution, within the manufacturing and fabricating sectors, and that companies that are getting to the stage where they want to deploy any sort of A.I. solutions need to look to their historical data.

“You combine that with some of the analytic tools that are available today from analytics software providers and that at least gives you the foundation for pattern recognition and the ability to kind of help make decisions based on historical outcomes,” Resnick explains. “What we’re really seeing at this point is it’s not so much that all these processes are now running all by themselves because of the history, but what we see is the ability to integrate some of the historical information, and use it with tools such as augmented reality and mixed reality. So it’s providing data to

the operators and maintenance people to help them make better decisions. But also comparing what they’ve seen in the real world, and helping them make decisions based on what’s happened in the past.”

No data? Then start collecting

If a company doesn’t have a vast amount of historical data to draw from, this doesn’t mean it still can’t embrace the use of artificial intelligence for its operations.

“The main thing we would do is recommend – before they go A.I. – to focus on the biggest business problem they have,” Resnick says.

In glass manufacturing, as with other manufacturing industries, the No. 1 issue for most companies is unscheduled downtime.

“They’ll say, ‘We can’t make glass because a motor has failed or a conveyor has failed.’ So what we will suggest is to invest in some low-cost sensors that you can install on some of their rotating equipment, such as the gearbox of a motor that might drive a conveyor,” Resnick adds. “So if we can now figure out when those bearings are running too hot, or when the gearbox oil is running too hot, or has lost its viscosity, or there are filings in the oil bath, then the company can go ahead and have a scheduled downtime to replace the problem rather than wait until a failure – where now you’re in a crisis mode to try to get a repairperson or a maintenance person and replacement parts.”

Once a company starts to collect this type of data through its automation systems, it can then invest in a software package that analyzes the data to help with future decisions. As a company collects these vast amounts of data, the next step is to find an artificial intelligence solution that can mine that data and help the company’s manufacturing operation make better decisions based on factors like raw materials, time of day, and the temperature and humidity of its plant.

“That way, when there is a problem that causes downtime, you can now almost take a snapshot as to what happened at that time and say, ‘Maybe we need to run the plant a little bit warmer or a little bit cooler,’” Resnick explains. “That is the kind of thing you can learn through artificial intelligence.”

In some cases, artificial intelligence has found that a manufacturing operation running too fast is the root of its problems.

“Sometimes plants actually slow down their production because what they find is when they start producing at higher rates their overall equipment effectiveness may begin to fall,” Resnick says. “So then they find that if they scale back and slow the manufacturing process down, they’re actually more profitable. Even though they’re producing a little slower, what they’re producing is going to be more first-run quality.”

Having this kind of information at one’s fingertips can help a plant manager understand it is not always desirable to run equipment at its full capacity, 24/7, which is a natural instinct for most companies looking to get as quick a return on their investment in equipment as possible.

“Sometimes with artificial intelligence you’ll find out these problems. And by having all this data, you may get information that says if we run at 95 per cent capacity rather than 100 per cent capacity it turns out we have better first-run quality,” Resnick says. “It may also take into account energy prices and give the feedback that you need to do more of that heavy energy consumption manufacturing certain times of the day because the electric rate is less. It really is a great tool to learn your business, but if you don’t have the history it’s really difficult to make the best decisions.”

Connecting the supply chain

Another reason manufacturers leverage A.I. is to connect their supply chains from the raw materials being supplied and the transportation of those raw materials all the way through the process to the expected demands of customers.

“You certainly don’t want to be building up any inventory and having most of those costs on the books. You want to be as close as possible to just-in-time manufacturing, but at the same time finding that balance between what is your customer demand and availability of material and the transportation aspects of the raw material,” Resnick says. “That’s really where it helps, because by accumulating that data, you might know the certain materials that are used in the manufacturing of your product, based on the vendor,

based on the time of day, based on the time of year… and that might affect how to set up some of the parameters of your manufacturing.”

Robots and A.I.

When it comes to robotics in the factories, the number of errors they commit tends to stem from a combination of the amount of historical data they have access to and how well equipped the robots are with the appropriate sensing technologies.

“You can’t make all your decisions based on history. At the same time, you can’t make all your decisions based on what the robot sees in front of it,” Resnick says.

To solve this problem, the best solution is often collaborative robotics, where a robot works alongside an employee.

“We find that does a better job of training the robot,” Resnick says. “If the robot is learning on the job based on different scenarios and the worker is kind of helping it do the right thing, that really helps to make sure that the best data for

AI can help a plant manager understand that it is not always desirable to run equipment at its full capacity.

future use is being stored and helping the robots on their job history.”

The human working alongside the robot is also more likely to detect unique one-off type of scenarios that the robot was not programmed to deal with.

“That’s really where the collaborative robot has the opportunity to learn,” Resnick says. “So we find that it’s better in collaborative robotics that are really highly instrumented with sensors to at the same time have the ability to take real-time input from the operator that’s working alongside it. That is where we tend to be very enthusiastic.”

Safer operations

Another other area where people have been using artificial intelligence to optimize aspects of their operations is safety.

Wong says that companies are using A.I. as a surveillance tool in their plants.

“Plants are leveraging machine learning and computer vision to kind of survey the area using cameras to make sure everyone has their safety equipment, that certain equipment is working as it should be, and that there are not any hazardous scenarios happening,” he says.

These days, it seems the most hazardous scenario a fabricator can be involved in is failing to embrace A.I. as a key part of its future planning. •

Improving safety is another potential use of A.I. Cameras can be connected to intelligent systems that identify when workers are not wearing PPE, for instance.

INDUSTRYEVENT

BETTER TOGETHER

by PATRICK FLANNERY

Margaret Webb and Janice Yglesias, executive directors of the Insulating Glass Manufacturers Alliance and the American Architectual Manufacturers Association, respectively, opened the first day of official business at the joint AAMA/IGMA Summer Conference in Victoria, B.C., in June swith a report to membership. Most of the discussion addressed progress and plans for the merger of the two associations, which members will vote on in July. If approved, the new merged organization will be called the Fenestration Glazing Industry Alliance.

The AAMA and IGMA try out a joint event.

Mike DeSoto of MI Windows and Doors in Gratz, Penn.; Mark Hutchinson of of Intigral; and Donnie Hunter of Kawneer took the podium to urge members to vote in favour of the merger. DeSoto pointed to the expanded influence on standards for residential fenestration that the merged association would have, and commented that it would be nice to only have to attend half as many meetings. Hutchinson said he’d found participation in AAMA useful even though he only makes IG because of the insight into residential building he gets. Hunter felt that commerical and residential glazing are fundamentally similar enough to co-exist in one association and that the two sides getting together was a signal of strength for the industry.

Yglesias and Webb outlined the voting procedures and urged members to read the unification prospectus available on the association websites. Pending a successful vote, the associations will begin strategic meetings in the fall to finalize details of the new organization. Part of that effort will be a new name and

branding for the association, though the old names will likely be retained for use on familiar products and documents to maintain brand consistency.

Yglesias mentioned the AAMA’s upcoming National Fall Conference in Austin, Texas, Sept. 30 to Oct. 3 and GlassBuild in Atlanta Sept. 17 to 19, which both AAMA and IGMA support. She also said the first event for the merged association, provided the vote passes, would likely be the Annual Conference in Fort Lauderdale, Fla., in Feb. 2020.

Yglesias also welcomed Sam Leeke as the AAMA’s new certification coordinator, acting as members’ main point of contact for all its certification programs. Tamara Baskin has moved to become technical services coordinator, herding the cats of industry knowledge as they work on new codes and standards.

ABOVE: The conference gave AAMA and IGMA members the chance to get to know each other with some fun events. Above, Eric Vanderpool of Performance Additives has a moment of deep thought on the scavenger hunt.

Attendees then got a dose of adrenaline from the keynote speaker, Patrick Moore. Moore, a co-founder of Greenpeace who left the organization over its opposition to plastics and now works with the Vinyl Institute, delivered a provocative talk challenging a swath of environmentalist shibboleths, including dismissal of climate change as an urgent problem.

The reality of climate change and the urgency to address it has been accepted science in Canada for some time, to the extent that governments are pushing hard for major and expensive upgrades to fenestration energy efficiency over the next decades. According to Moore, they are wasting their time. In his view, it’s doubtful whether human-caused carbon dioxide emissions have any important impact on climate at all, saying average temperature fluctuations correlate more closely with changes in solar activity. He called carbon dioxide a benefit as it stimulates plant growth. He pointed out that carbon dioxide levels were much higher in Earth’s ancient history and that tropical conditions persisted in the Arctic, but life flourished. Human emissions of carbon diox-

ide, Moore claimed, are only restoring to the atmosphere what living things have been taking out for eons and perhaps rescuing us from a condition where carbon dioxide levels would drop low enough to restrict plant growth. No mention of the possible negative effects of this happening far faster under human influence than the millions of years it took for the carbon dioxide to be taken out in the first place, and since the talk ran long there was not time for questions. Wildfires and extreme weather events, he said, probably have nothing to do with climate change and are not actually happening any more frequently than they always have.

The hair-raising claims did not stop there. Moore included a spirited defence of logging, describing clear-cuts as “temporary meadows” and claiming they provide a more diverse environment supporting more species. Our discomfort with them, he said, is a matter of esthetics rather than any real ecological concern. No species has ever been rendered extinct by habitat destruction from forestry, he claimed. He really got into his wheelhouse on plastics. The huge “garbage patch” of discarded

plastics in the Pacific Ocean does not exist, he says. He pointed to a number of photoshopped and dishonestly represented internet postings from green activists as evidence that there is a a great deal of misinformation circulating about plastics. They are inert and harmless to wildlife, he claimed, saying animals that ingest them will simply pass them out again without harm. A celebrated meme of a bird feeding plastic shards to its chick is actually evidence of plastic’s benefit, as the shards are likely to act the same way as stones do in a bird’s gizzard. Investment in wind and solar energy sources is also overemphasized, Moore claimed, saying it is impossible to build enough of this infrastructure to meet needs. He recommends nuclear and hydroelectricity instead. Oil production and use will remain necessary for the foreseeable future, and investment in the Alberta oil sands and pipelines should proceed apace. He blamed opposition to the oilsands on lobbying from the U.S. Rockefeller Foundation.

Agree or disagree, it was hard to imagine a more conversation-provoking presentation. •

SOFTWARESOLUTIONS

All aspects covered

smart-builder.com

SmartGlass from Smart Builder includes a dedicated dashboard that allows teams to customize their widgets to monitor key metrics relating to their role. For example, an accountant may have “jobs ready to invoice’ at the top of their dashboard, whereas the business owner has “bids won” and “bids lost” for the month. Users can see at a glance KPIs to keep a pulse on the company; quotes, orders and invoices, which are conveniently grouped as draft, ready, complete, overdue and paid; and site photos, means anyone in the company can see what is going on with jobs. Using the job diary, users can pin important notes to the top of the job diary to ensure they don’t get missed; upload photos and documents from the office and from jobsites; review the full history of job status changes in chronological order; and search the diary to quickly find important details. The scheduling screen allows anyone on the team to see what is going on and to easily communicate changes with installers and customers. Supervisors can manage staff, vehicles or workshop stations; assign multiple staff to a job; easily email customers to

confirm and change appointments; see when materials for installation have been received; and report on time quoted vs time spent. Integration with Google Calendar and Office 365 means users can update the schedule with the click of a button and installers can see where they need to be right on their phones. Smart-Toolbox can quote any glass or glazing job, including showers, shopfronts, railings, mirrors and window replacements. Time-saving features include a built-in glass designer that autocalculates prices as the designer draws. The toolbox can set up standard jobs and templates and quote revisions and options. Users can add colour pictures to quotes and email them directly to customers. Smart-Glass can be used to to draw up panels for quotes and orders. Whether it’s glass for mirrors, showers, partitions, railings, table tops or windows, the software is fast and easy to use

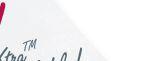

Streamlines accounting

glassfabricationsoftware.com

Tri-Temp Glass has manufactured tempered glass for showers, railings, entrance systems, interior partitions and architectural glass applications since 2007.

• Tempered up to 96 x 144

• Custom Laminated up to 86 x 144

• Bent Tempered Laminated to 66 x 96

• Back Painted Glass

• SentryGlas Lamination

• Opaci-Coat-300 Spandrel

Fax: 416-285-9468

Email: cs@tritempglass.com

GlassTrax is designed to be complete and affordable glass software. Complete sales orders can be filled out quickly with added notes and comments. Users can add processes and fabrication work to give a complete price to customers. They can select shapes from the optimization software’s library of shapes then send the order directly out to optimization software. GlassTrax can add attachments to orders and specific lines then email, fax, or print the sales order, confirmation and invoice directly to the customer. GlassTrax can track how much glass has been processed in a day, week, month, or year. Users get real-time updates on order status to find out where bottlenecks occur. Efficiency is improved by setting capacity thresholds to create production schedules. Plant mangers can find out the value of the scrap and get detailed reports on recuts. GlassTrax has the ability to import customer orders from a variety of formats. Importing orders eliminates double entry and cuts down on miscommunication between customers and order entry personnel. Importing orders from customers streamlines operations, saves time and allows for better customer service. Purchase orders are created in just seconds. Users can keep track of inventory that arrives in a damaged condition. Email, fax, print, or upload purchase orders to send them directly to vendors. GlassTrax allows users to create purchase orders directly from the sales order screen when they need to buy out an item they do not carry in stock for a customer, eliminating double-entry. Inventory control and sales order processing is simplified with GlassTrax. Pricing can be set by specific customer, customer type, product type, category type and more. GlassTrax can help accurately manage inventory in real time with automated reminders to purchase more inventory when specific inventory items are running low. All accounting can be managed right from GlassTrax. The software was written by an accountant who understands how to make bookkeeping clean and simple. Users can create invoices and credits in a few simple steps; review customer accounts; pay bills and print checks with just a couple of clicks.

Full visibility

glassmanager.ca

GlassManager allows glass professionals to prepare accurate estimate templates. Descriptions of materials and services can be saved and repeatedly used to create consistency among staff from one quote to the next. GlassManager can schedule tasks each day and assign them to staff. Calendar views allow managers to easily see jobs being worked on and to see upcoming jobs to prepare material orders and schedule staff who handle fabrication. The GlassManager team works with users to import details and pricing information for materials. These details are included in all documents produced by the software including estimates, invoices and PO’s.

Users can set up details for all vendors and easily create and issue purchase orders. Purchase orders can be assigned to jobs to easily match costs against every project. Field staff can log time against jobs on their computer or mobile device while on site. Hours captured on billable projects are instantly calculated for future invoices. By tracking time against jobs, managers andity on every job. GlassManager provides a consolidated view onibility on the business. Users can see project status, who’s been assigned, hours tracked and all documents associated with each job. Standardized material descriptions and hourly staff costs are automatically captured for invoicing so any employee can prepare professional invoices quickly so there aren’t payment delays. Owners can have completely visibility into the business with a real-time dashboard and easy-to-produce reports that

Revit building design software from Autodesck can be used for every phase of projects from concept to visualization. It incorporates BIM tools, captureand-communicate concepts and precise design intent. Users can place intelligent elements like walls,tions, schedules, 3D views and renderings. Users can optimize building performance early in the design process, run cost estimates and monitor performance changes over the project’s and building’s lifetime. Revit generates photorealistic renderings. Users can create documentation with cut-aways and 3D views and stereo panoramas to extend designs to virtual reality. Since Revit is a multidiscipline BIM platform, users can share model data with engineers and contractors within Revit, reducing coordination tasks. Designers can insert a PDF into Revit from any source and snap to the PDF to model new elements based on the 2D data.

RESOURCEDIRECTORY

by FRANK FULTON

Frank Fulton is a former principal of Fulton Windows and former president of the OGMA.

The last word on ESCs

In the last edition we found that starting benchmark values used by glass manufacturers to calculate energy surcharges were far lower than what the actual costs were at the beginning of the surcharge program in 2002, meaning that surcharges can be vastly overstated and will likely run into eternity.

Since the beginning of the year, as of the end of May, 2019, the cost of natural gas has plummeted 33 per cent to levels not seen since mid-2012. Referencing the realistic starting benchmark cost we determined in our last column using the information provided by the glass manufacturers that there should now realistically be an energy rebate of $200 per truckload on the natural gas portion of their total ESC. I haven’t seen any rebates from any of the manufacturers but there have been modest decreases in the amount charged.

Assessing the ESC freight component charges gets a bit complicated. Guardian’s first quarter 2019 diesel charge works out to $8.40 per ton and AGC’s, $21 per ton, however, based on production numbers from Pilkington and diesel usage as a percentage of total freight costs from the U.S. Department of Transportation, the total diesel cost per ton of glass is $5.85, considerably less than both surcharges. Per truckload, total freight charges by ACG are $1,267; by Guardian, $1,443; and by Cardinal, $238. One would expect these to be the same from company to company. These significant discrepancies raise suspicion about the validity of the charges.

As referenced above, according to a study presented by Pilkington Glass in 2010, the transportation component of the total cost of glass production is 11 per cent. The FRED Producer

The nicest word I can come up with is “unconscionable.”

YOU BET YOUR GLASS

Price Index: General Freight Trucking shows that between December 2003 and December 2018 the cost of trucking increased 42 per cent, similar to general inflation over the same period. This calculates to only a 4.6 per cent escalation in the overall cost of producing glass due to freight costs over a 15-year period.

A 22-ton truckload of six millimeter clear glass selling for US$0.75 per square foot would be worth $11,000. Based on the realistic cost increase of 4.6 per cent of the total price of glass based on freight, one can calculate that the increase in the freight component since 2003 should be $508 per truckload or $23.10 per ton, significantly less than the $58 per ton being charged by AGC or the $65.50 being charged by Guardian.

In summary, when legitimately determined input costs provided by the U.S. government are evaluated during the period of 2002 to 2018, the true total of incremental energy expenses amounts to $23.10 per ton for freight minus $9.09 per ton of cost reductions for natural gas for what amounts to only $14.01 per ton of glass or about two cents per square foot. Over this period, the Producers Price Index shows that the base selling price of raw flat glass has increased by about 10 cents per square foot.

The nicest word I can come up with for what the glass fabricators are doing with the energy “sucker-charge” is “unconscionable.” As a buyer of glass products, you are all too aware that fabricators charge a straight percentage ESC add-on, not only on the glass portion of their sale but on every component that makes up the sale, such as hole-drilling and shower door hardware – an egregious cash grab. In my brief time as an employee of a large glass fabricator, coincidentally at the time the ESC was introduced to the glass buying market, the then-president was overheard saying that the ESC was the greatest thing to happen to the company in their history as every dime went straight to the bottom line. Fabricator acquaintances have confided, off the record, that the ESC they charge is a blatant scam but they get away with it. Sometimes I think we should have usury or anti-gouging laws in this country.

Going forward, all costs should be included in the product price and manufacturers, as they currently do, can continue to manage the risk of cost fluctuations through the futures market. •

Fit the bill—and the build.

Capture clarity with new Acuity ™ Low-Iron Glass. Meet the aesthetic demands of architects and the performance demands of owners, all for a modest investment. Developed to withstand value-engineering, new Acuity ™ Glass by Vitro Architectural Glass (formerly PPG Glass) joins Starphire Ultra-Clear ® Glass in the Vitro family of low-iron brands. An affordable low-iron option available with Solarban® solar control low-e coatings, Acuity™ glass offers vivid views with no green cast.

Request samples and learn more at vitroglazings.com/acuity

™

Low-Iron Glass

GLASS FOR NEW HEIGHTS

Marking a destination in Metro D.C.

Central Place

ARLINGTON, VIRGINIA

with SunGuard® AG 43, SuperNeutral ® 68 and SNX 62/27 on clear

Guardian SunGuard® Architectural Glass helps set projects apart with bold performance and style.

©2019 Guardian Glass, LLC | GuardianGlass.com/CentralPlace

Joseph Romeo Photography